A transport and distribution system for starch

A conveying system and starch technology, applied in conveyors, transportation and packaging, loading/unloading, etc., can solve the problems of short storage time, large starch loss, damaged packaging bags, etc., and achieve short transportation distance and less starch material loss. , the effect of timely supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

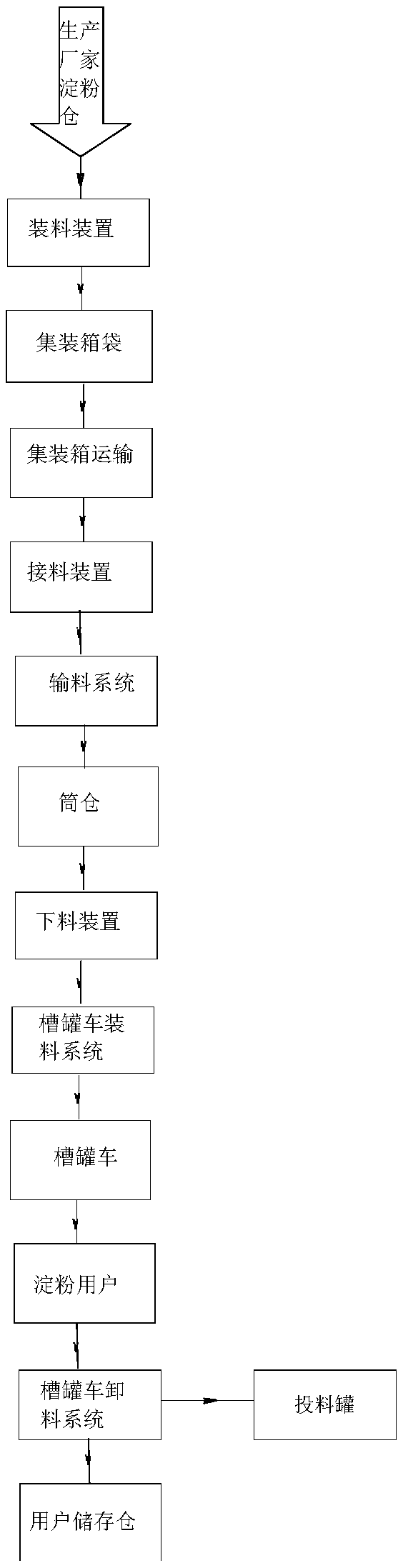

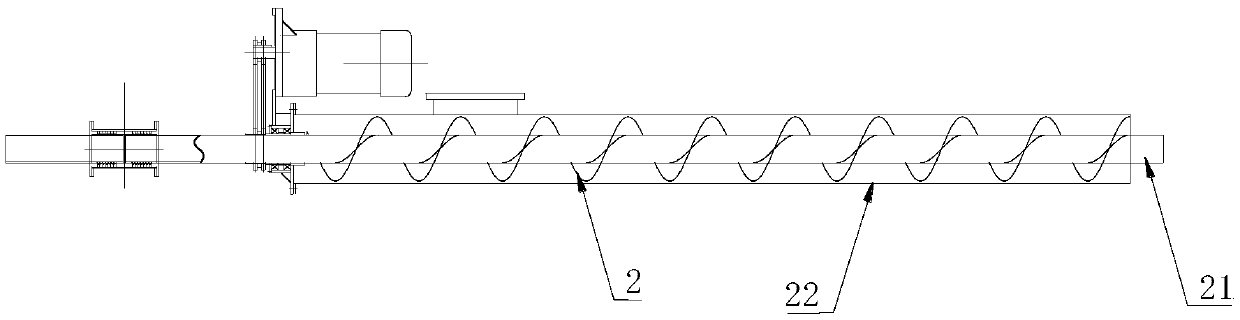

[0041] This embodiment provides a transportation and distribution system for starch, such as Figure 1 to Figure 5 As shown, it includes: several containers 1, loading device 2, receiving device 3, feeding system 4, silo 5, unloading device (not shown in the figure), tank car loading system (not shown in the figure) out), tank trucks (not shown in the figure), starch users (not shown in the figure).

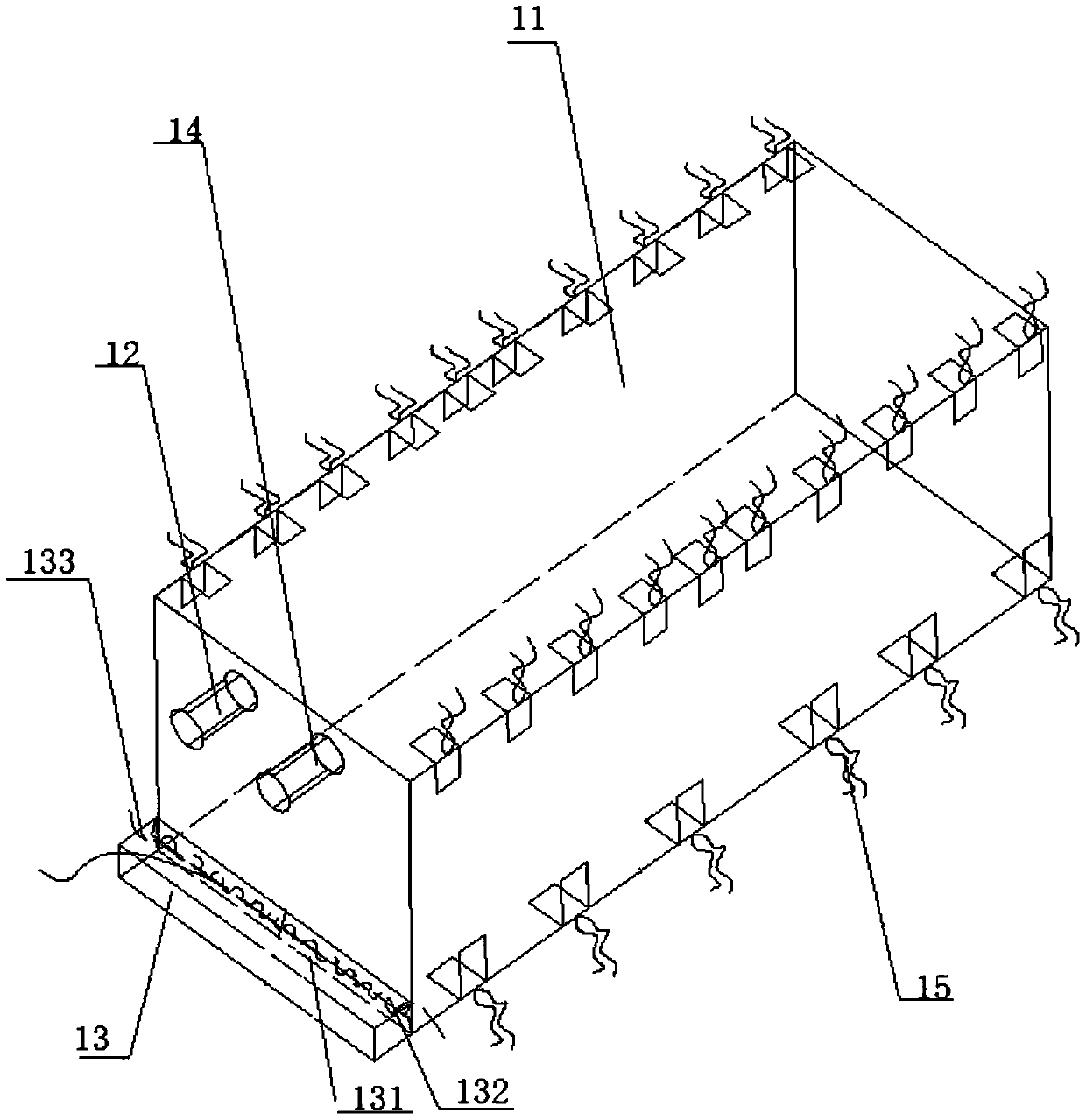

[0042] The container 1 is provided with a cabinet bag 11, such as figure 2 As shown, the cabinet bag 11 is provided with a feed port 12 and a discharge port 13. By directly packing the starch in the cabinet bag 11, the container 1 is transported, avoiding the use of a large number of small packaging bags for independent packaging, and then manual handling and loading. A lot of small bags are saved, which is convenient for the automation of loading and unloading. The cabinet bag 11 is provided with a hook 15, and the cabinet bag 11 is a cube compatible with the container 1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com