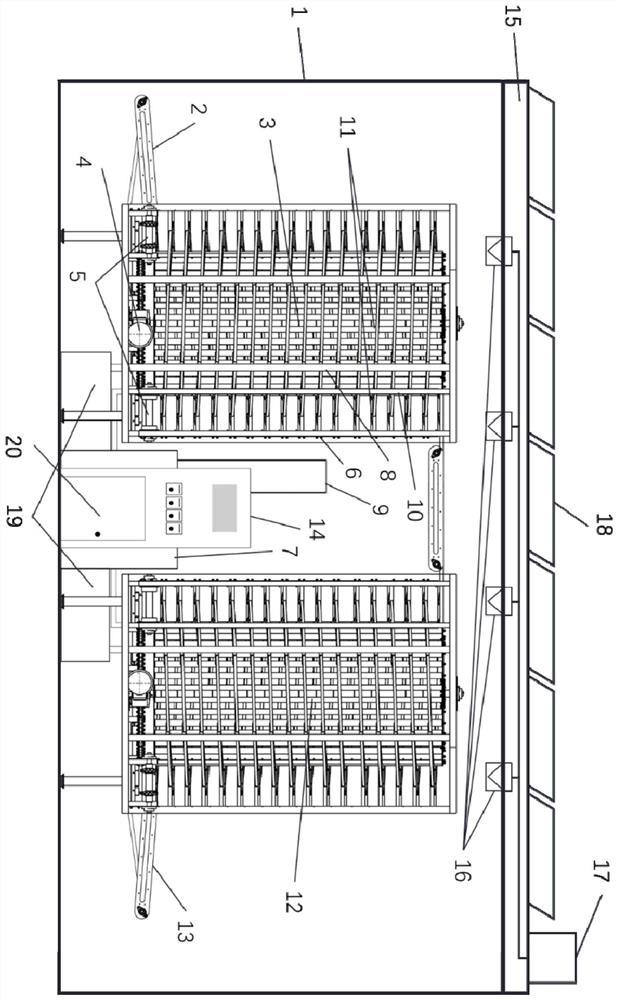

Plant hydroponic production system

A production system and plant water technology, applied in the field of plant cultivation equipment, can solve the problems of large floor space and low space utilization rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

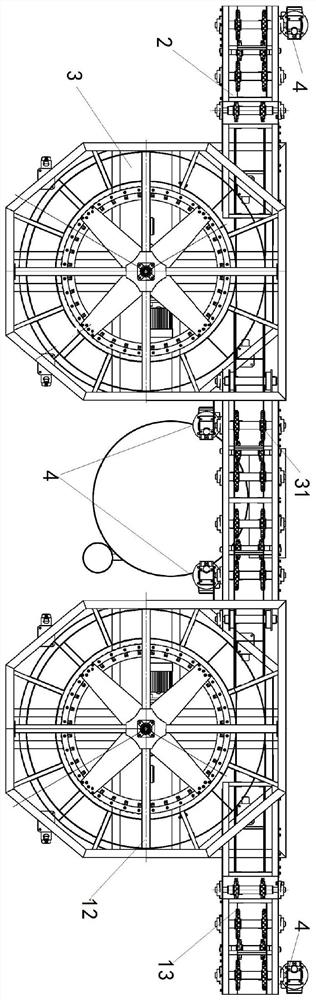

Embodiment 1

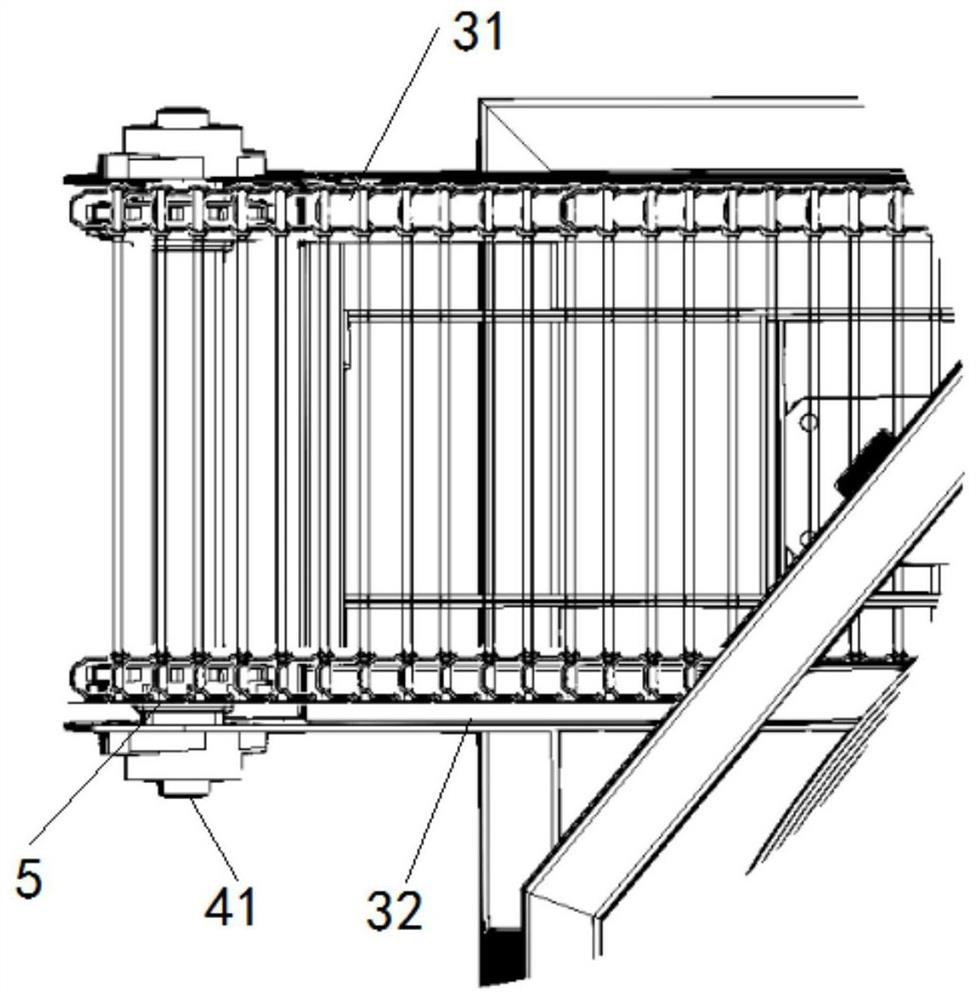

[0063] see Figure 5 and Figure 6 As shown, in the present embodiment, the quantity of the water outlet holes 821 on the water supply pipe 82 positioned at the downstream of the conveyer belt 31 is greater than the quantity of the water outlet holes 821 on the water supply pipe 82 located at its upstream, and there is a gap between the total water supply pipe 81 and the water storage tank 7. The main control valve, the controller is electrically connected with the main control valve, and is used to control the on-off of the main control valve. The controller realizes the delivery of water in the water storage tank 7 by regulating the on-off of the main control valve. Due to the longer growth time of the culture trays located in the lower part of the production tower main body, more irrigation is required, therefore, see Figure 6 As shown, in the first tower main body 3, the quantity of water outlet holes 821 on the lower floor water supply pipe 82 is less than the quantity...

Embodiment 2

[0065] The difference between this embodiment and the above-mentioned embodiment is that, see Figure 7 and Figure 8 As shown, the number of water outlet holes 821 on each layer of bearing part 32 is the same, and there is a sub-control valve 83 between each water supply pipe 82 and the main water supply pipe 81, and the sub-control valve 83 can be a solenoid valve in the prior art. The controller is electrically connected with all sub-control valves 83 to control the on-off time of each sub-control valve 83 to adjust the water volume.

[0066] All sub-control valves 83 are electrically connected to the output ends of the controller, and the on-off time of each sub-control valve 83 is controlled by the controller to realize that the water in the water storage tank 7 enters into different amounts in each water supply pipe 82, and then Adjust the amount of water. Specifically, the opening time of the control valve on the water supply pipe 82 located downstream of the conveyor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com