Patents

Literature

55results about How to "Extend online time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

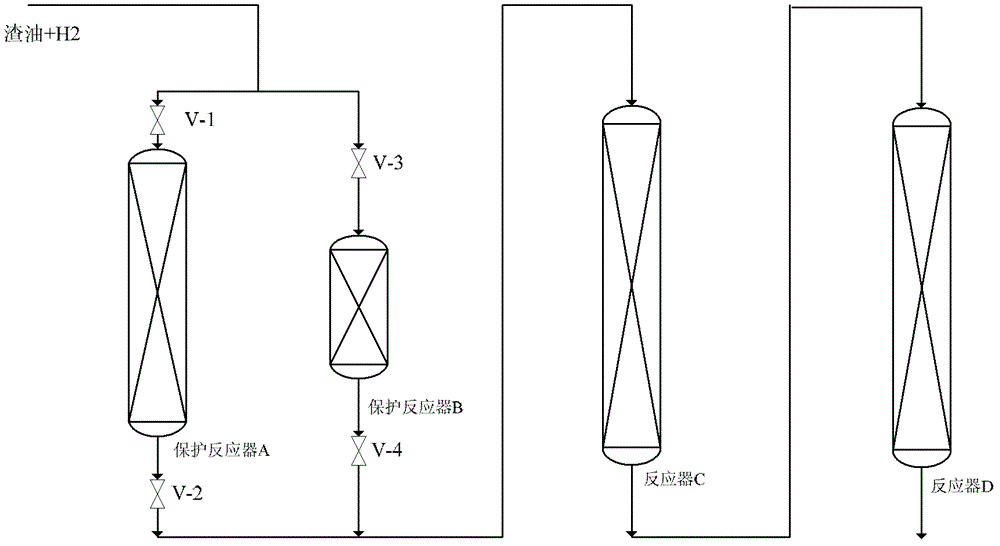

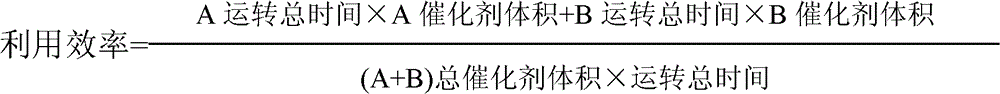

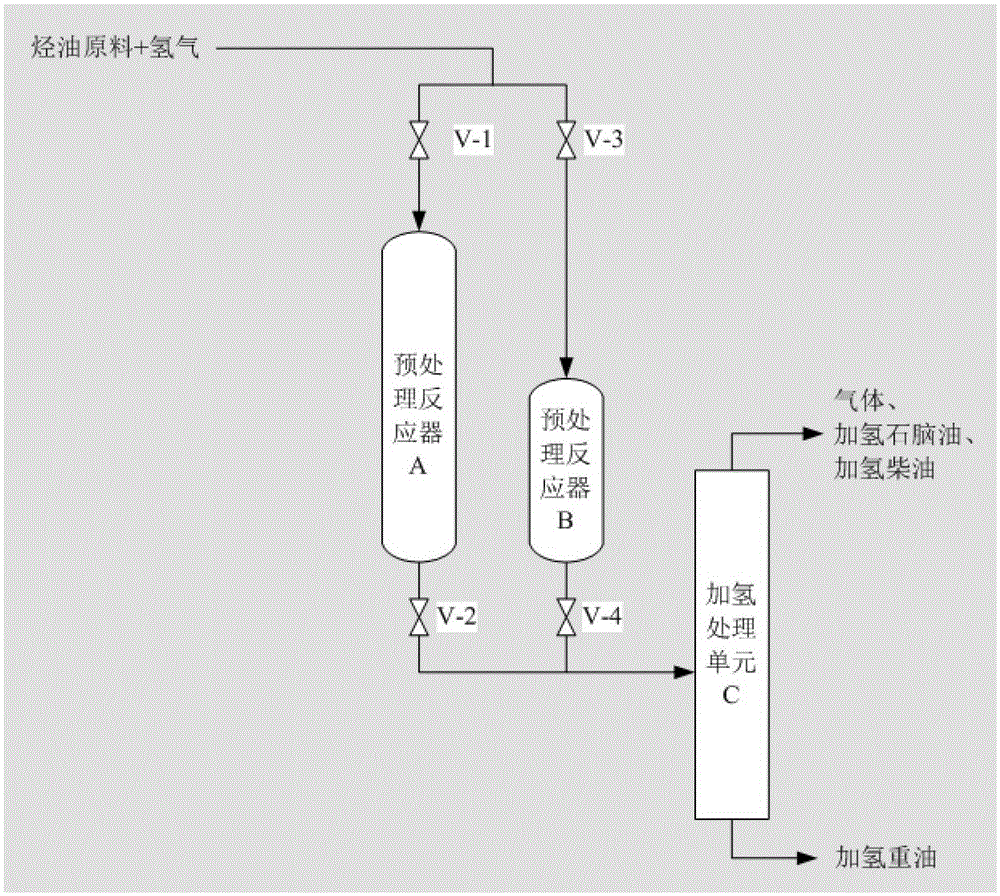

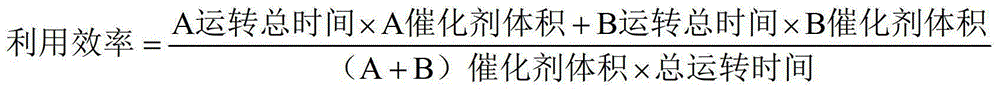

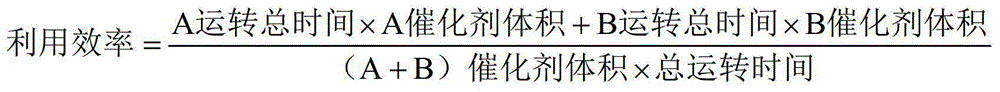

Hydrotreating device and application thereof as well as residual oil hydrotreating method

ActiveCN103059928AExtend online timeShort online timeTreatment with hydrotreatment processesHydrogenProcess engineering

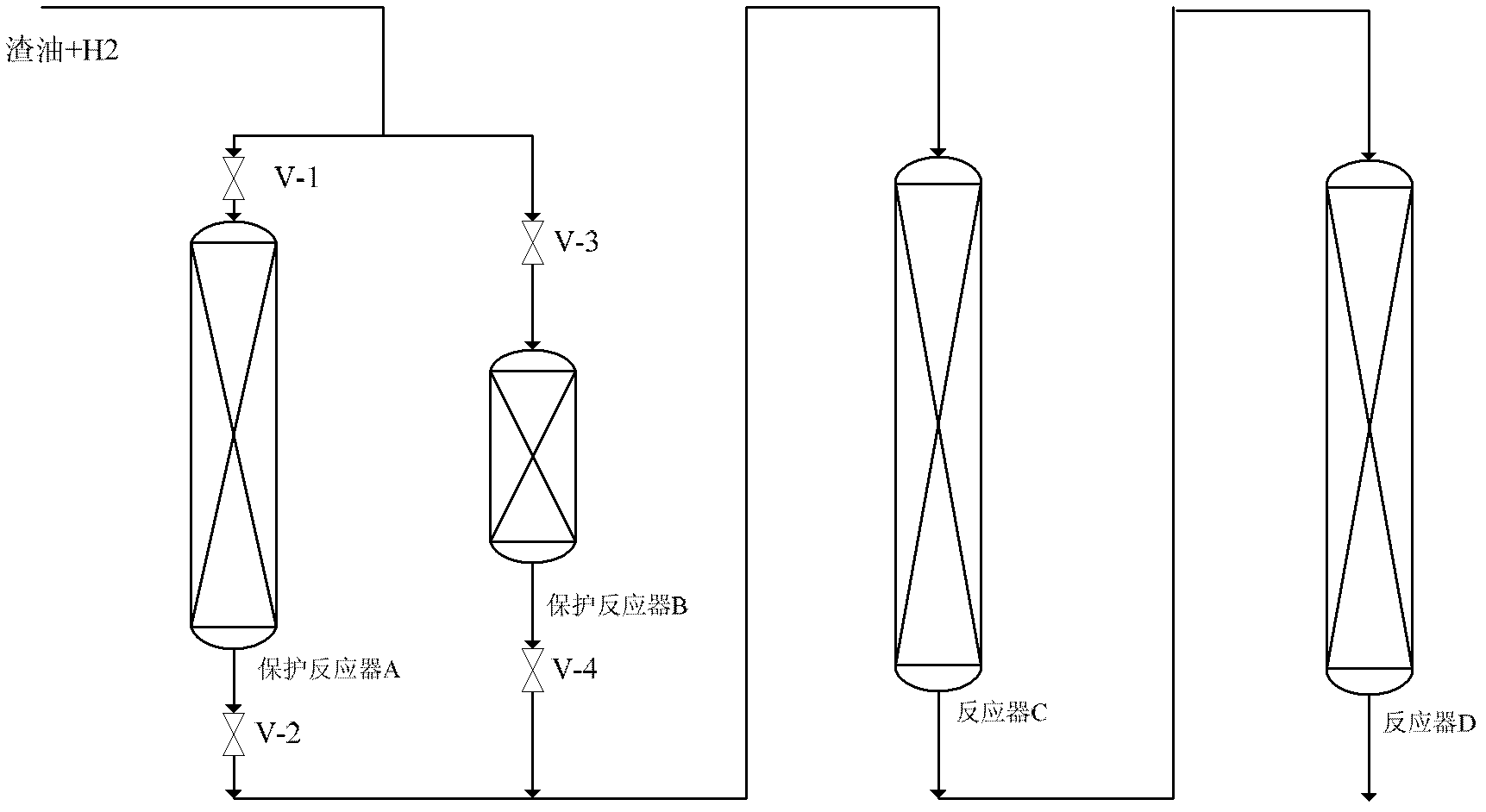

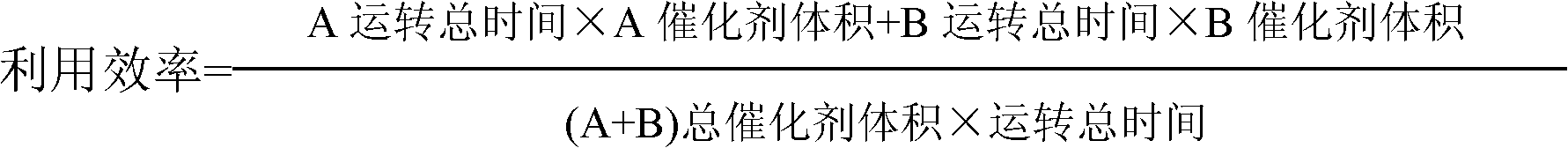

The invention provides a hydrotreating device which comprises a hydrotreating protection unit and a main hydrotreating unit, which are connected with each other in series, wherein the hydrotreating protection unit comprises a main hydrotreating protection reactor and a spare hydrotreating protection reactor, which are connected with each other in parallel, and the volume of the main hydrotreating protection reactor is larger than that of the spare hydrotreating protection reactor. The invention further provides the application of the hydrotreating device and a residual oil hydrotreating method. The method comprises the following steps of: introducing the residual oil and the hydrogen into the hydrotreating device, and alternately using the main hydrotreating protection reactor and the spare hydrotreating protection reactor in the process of hydrotreating, wherein the online time of the main hydrotreating protection reactor is longer than that of the spare hydrotreating protection reactor. The method provided by the invention is particularly suitable for machining the high-carbon content residual oil and the high-metal content residual oil. Furthermore, the bigger hydrotreating protection reactor is longer in online time, so that the invention is higher in reactor use ratio.

Owner:CHINA PETROLEUM & CHEM CORP +1

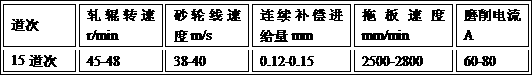

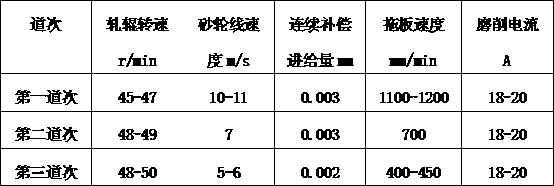

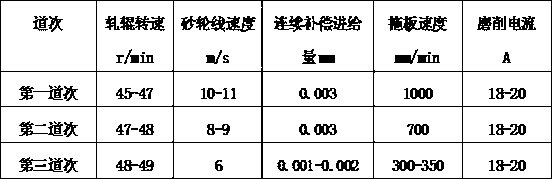

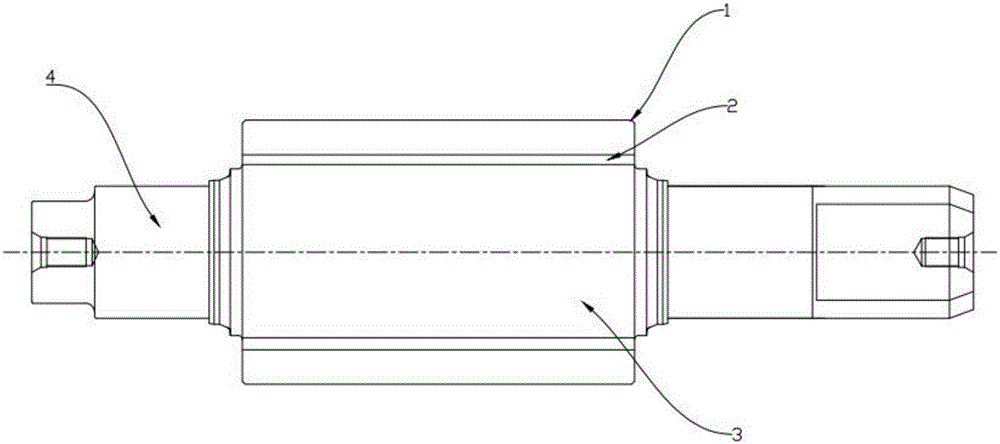

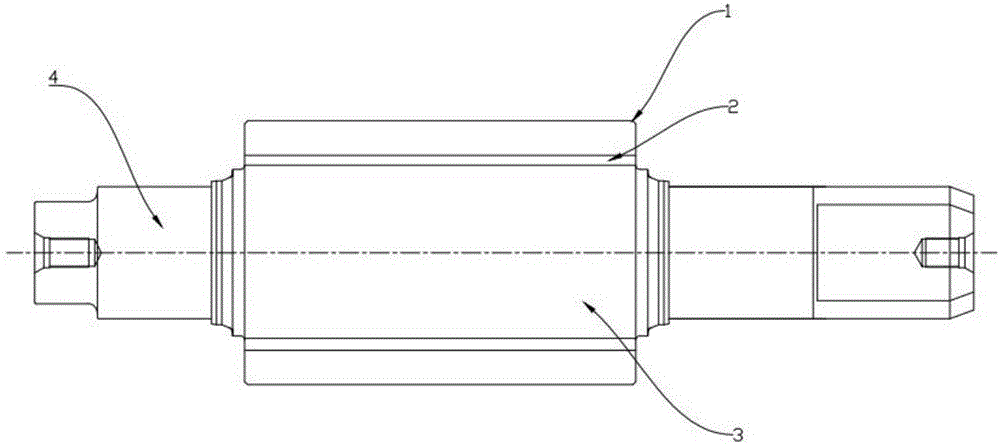

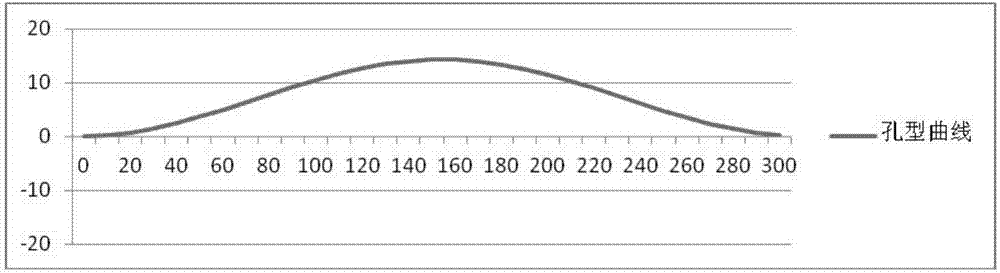

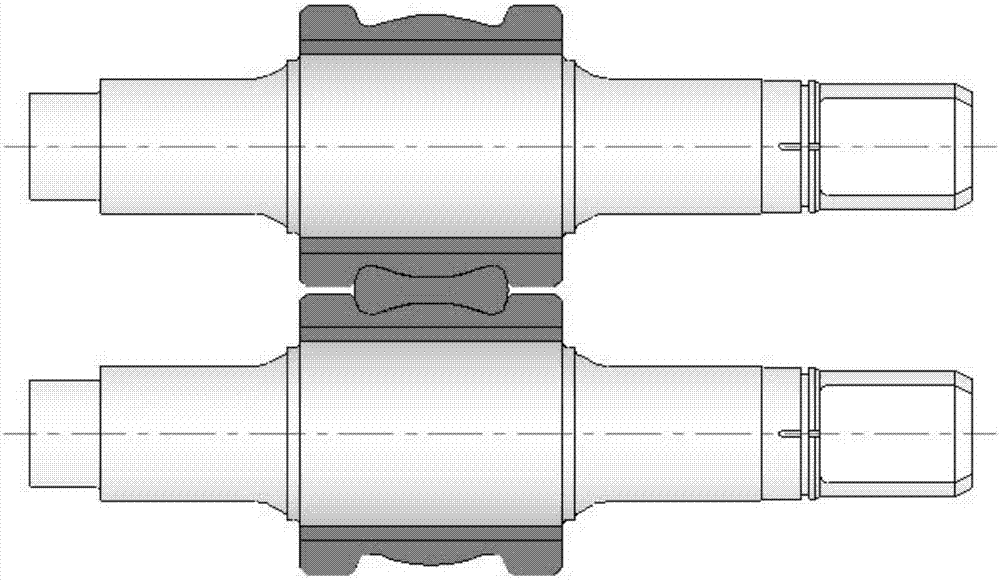

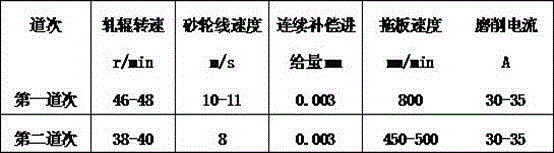

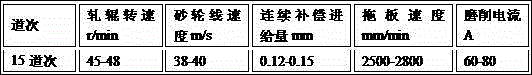

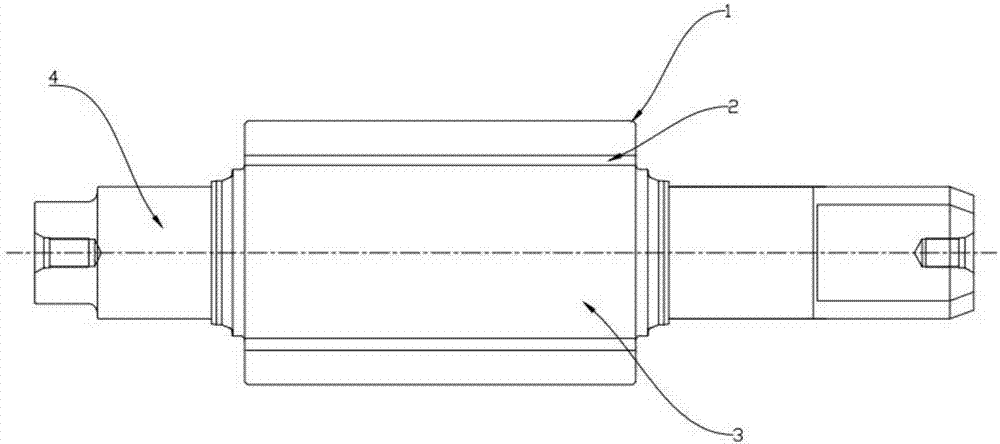

Grinding method for controlling roughness of surfaces of different rollers

ActiveCN103231289AReduce the frequency of roll changesExtend online timeRevolution surface grinding machinesNumerical controlSurface roughness

The invention relates to a roller grinding processing method, in particular to a grinding method for controlling the roughness of the surfaces of different rollers through sand wheels of the same type used on a numerical control roller grinding machine. The method comprises the following steps of: trimming the sand wheels to guarantee the balance of the sand wheels and the flatness and fineness of the working surfaces of the sand wheels; and after the sand wheels are trimmed, performing roller precision grinding in three steps, namely rough grinding, mediate grinding and fine grinding, wherein the grinding precision and the cylindricity of the rollers are smaller than 0.005mm, and the coaxiality is smaller than 0.005mm; and setting required grinding parameters according to different roughness requirement values, and carrying out grinding according to the roughness requirement values in three passes in a non-spark state. The method is simple and is easy to operate; the working efficiency of a machine tool and the working efficiency of a rolling machine can be improved; the roller replacement frequency of the rollers is reduced; the on-line time of the rollers is prolonged; the plate shape and the surface quality are improved; and therefore, the cost is reduced and the benefit is improved.

Owner:唐山瑞丰钢铁(集团)有限公司

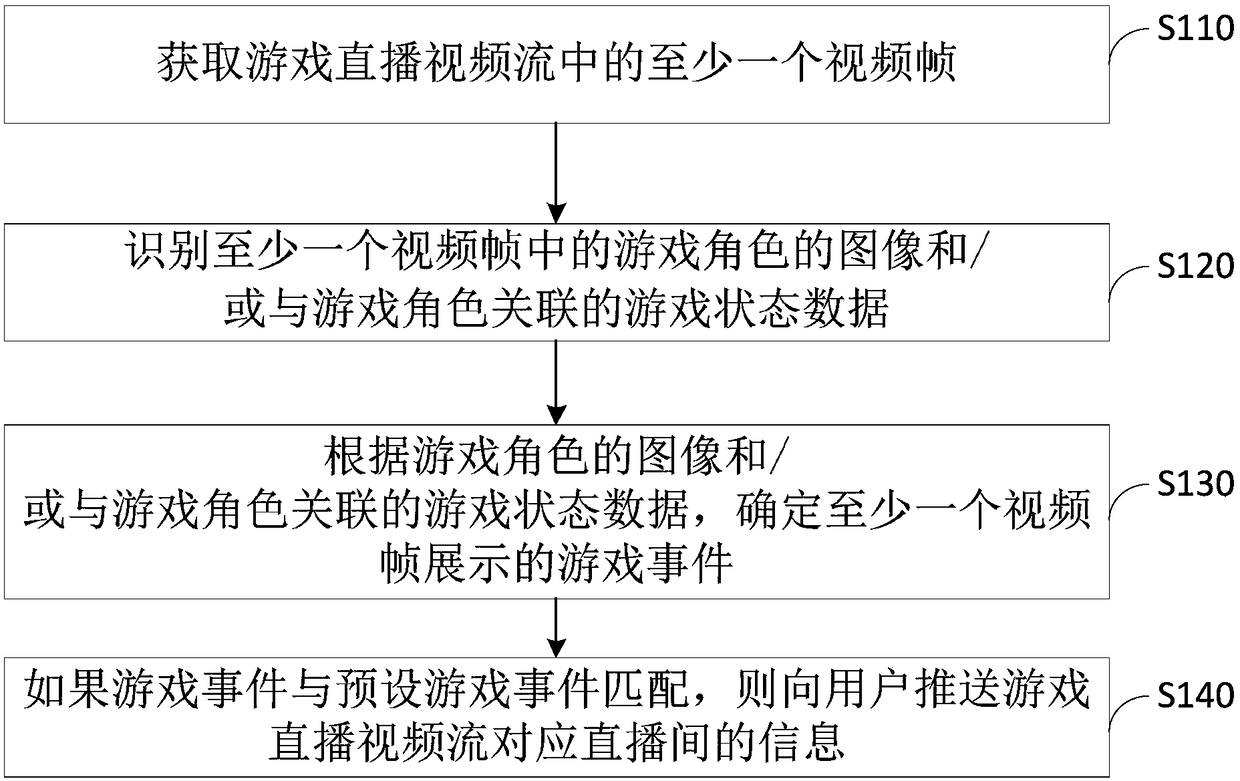

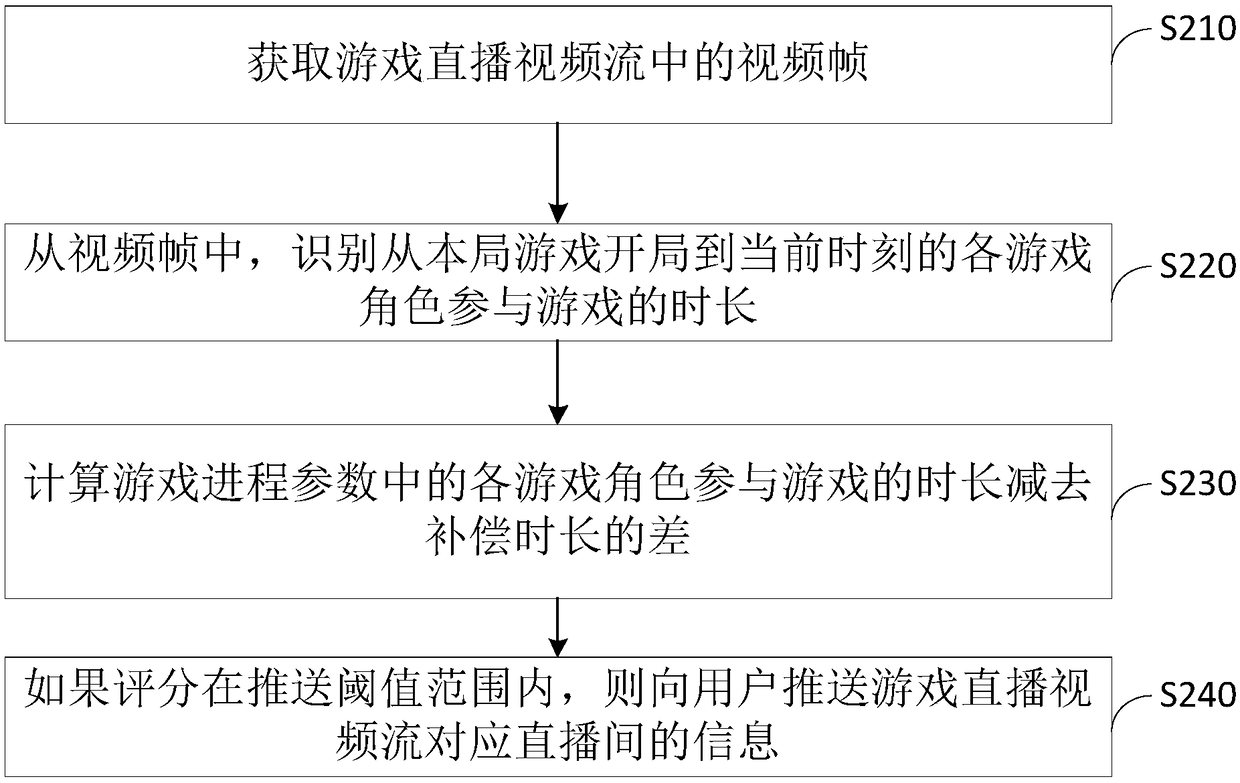

Live broadcast room information pushing method and device, server and medium

ActiveCN108833936AEasy accessImprove content distribution efficiencySelective content distributionMultimedia

The embodiment of the invention discloses a live broadcast room information pushing method and device, a server and a medium. The method comprises a step of obtaining at least one video frame in a game live broadcast video stream, a step of identifying an image of a game character in the at least one video frame and / or a game state data associated with the game character, a step of determining a game event displayed by the at least one video frame according to the image of the game character and / or the game state data associated with the game character, and a step of pushing the information ofa live broadcast room corresponding to the game live broadcast video stream to a user if the game event is matched with a preset game event. In this embodiment, the push of a high-quality live broadcast room can be achieved according to the game event displayed in the game live broadcast video stream.

Owner:GUANGZHOU HUYA INFORMATION TECH CO LTD

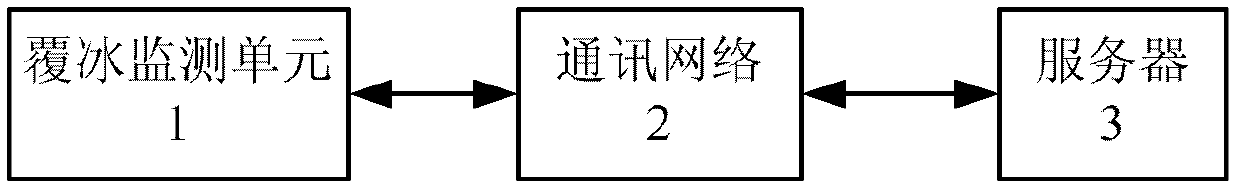

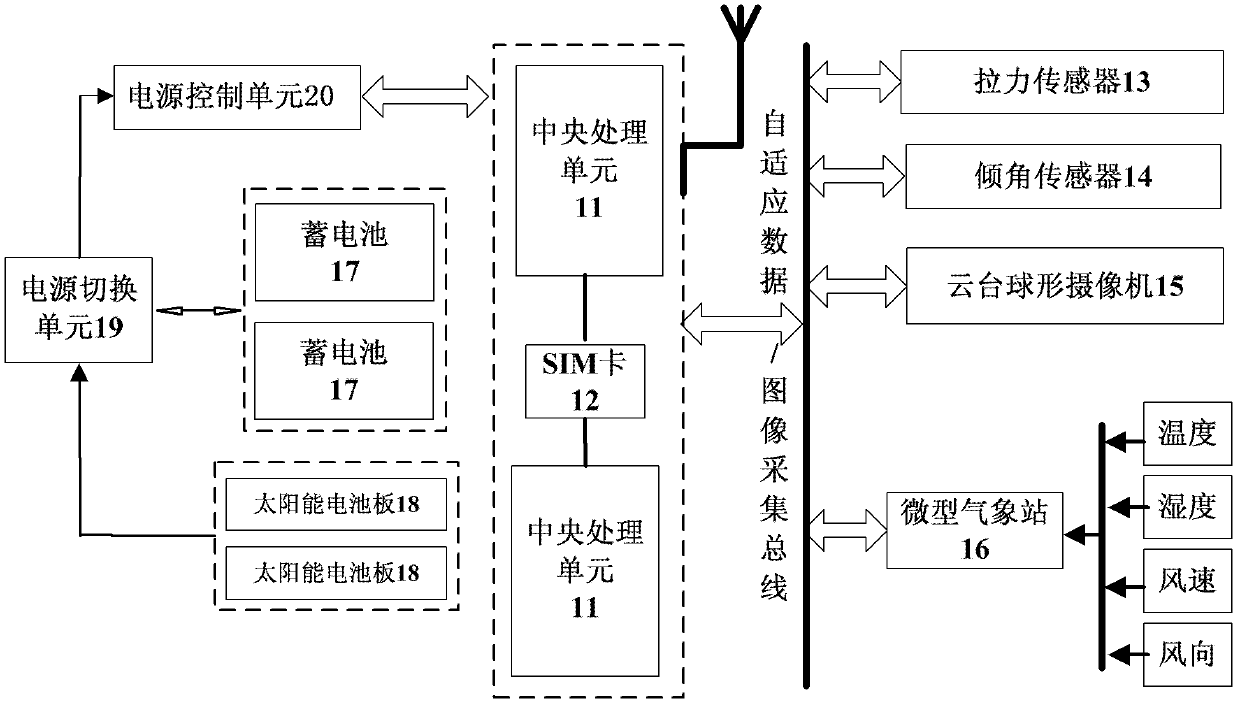

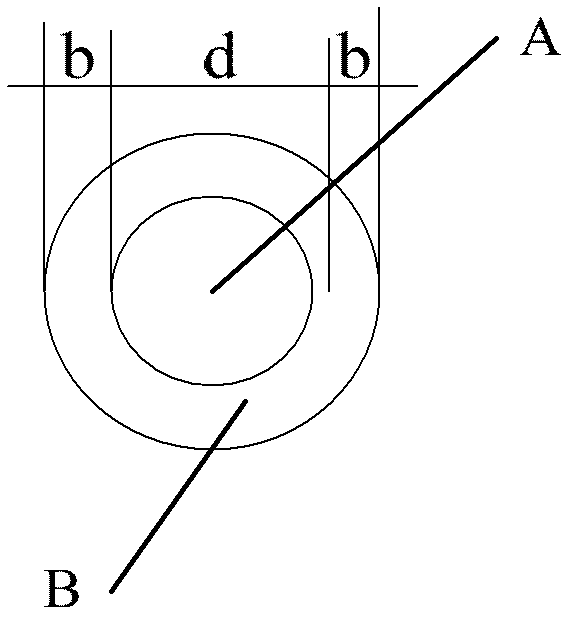

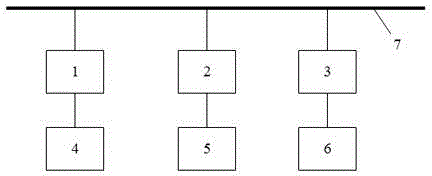

Power transmission line icing intelligent on-line monitoring system

InactiveCN103376083ALow operating failure rateHighly integratedMeasurement devicesMathematical modelMonitoring system

The invention relates to a power transmission line icing intelligent on-line monitoring system which comprises an icing monitoring unit, a communication network and a server. The icing monitoring unit is connected with the server through the communication network and collects state information of a power transmission line, icing thickness information is figured out through an icing thickness mathematical model, the state information and the icing thickness information are transmitted to the server through the communication network in real time, and icing thickness changing trend information of the power transmission line is calculated through the server according to the state information and the icing thickness information. If the icing thickness exceeds a setting threshold value, an alarm is timely given, so real-time monitoring for the power transmission line is achieved. Compared with the prior art, the power transmission line icing intelligent on-line monitoring system has the advantages of being high in integration and reliability and low in power consumption.

Owner:ELECTRIC POWER SCI RES INST OF GUIZHOU POWER GRID CO LTD +1

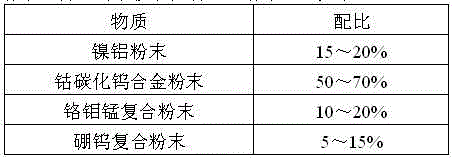

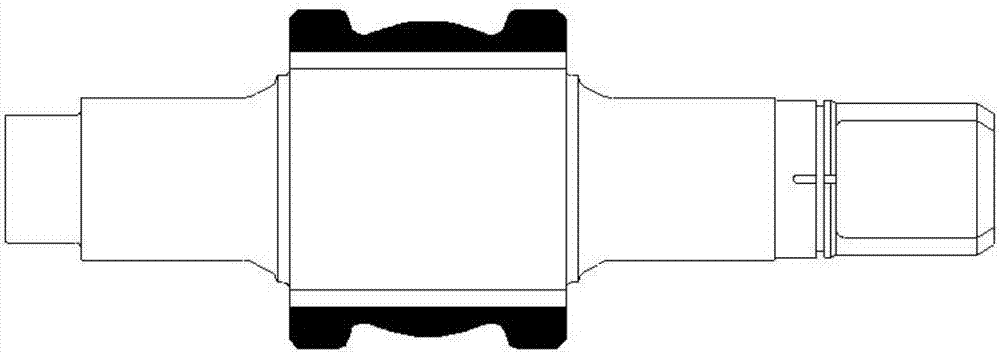

Alloy ultrasonic-spraying strengthening method for roll pass surface of finishing roll of section steel and spraying material

ActiveCN104611664ASimple and efficient operationEasy to operateMolten spray coatingTungstenAluminium

The invention discloses an alloy ultrasonic-spraying strengthening method for a roll pass surface of a finishing roll of section steel and a spraying material, and belongs to the technical field of material surface strengthening. Nano-scaled carbide alloy powder is selected and used in the method and includes 15-20% of nickel-aluminum powder, 50-70% of cobalt-tungsten carbide alloy powder, 10-20% of chrome-molybdenum-manganese composite powder and 5-15% of boron-tungsten composite powder. The method comprises the following steps: firstly, priming on the finishing roll of the section steel with the nickel-aluminum powder by 0.02 mm; secondly, fusing the cobalt-tungsten carbide alloy powder, the chrome-molybdenum-manganese composite powder and the boron-tungsten composite powder, and uniformly spraying a fused material to the surface of the roll, wherein the thickness of a spraying layer is 0.15-0.20 mm, a distance between a spray gun and a sprayed surface is 160-180 mm, and an included angle between the spray gun and the sprayed surface is not more than 90 degrees. The method adopts an alloy ultrasonic-spraying strengthening mode, so that the high-temperature resistance and the wear resistance of the roll pass surface are improved, the online time of the roll is prolonged, the total amount of steel is increased by more than one time, and the service life of the roll is prolonged by more than two times.

Owner:ANHUI HENGYI HARD FACE ENG CO LTD

A kind of hydrotreating method of hydrocarbon oil

ActiveCN104119952BReduce temperature riseEasy hydrogenation reactionTreatment with hydrotreatment processesHydrogenReaction temperature

Owner:CHINA PETROLEUM & CHEM CORP +1

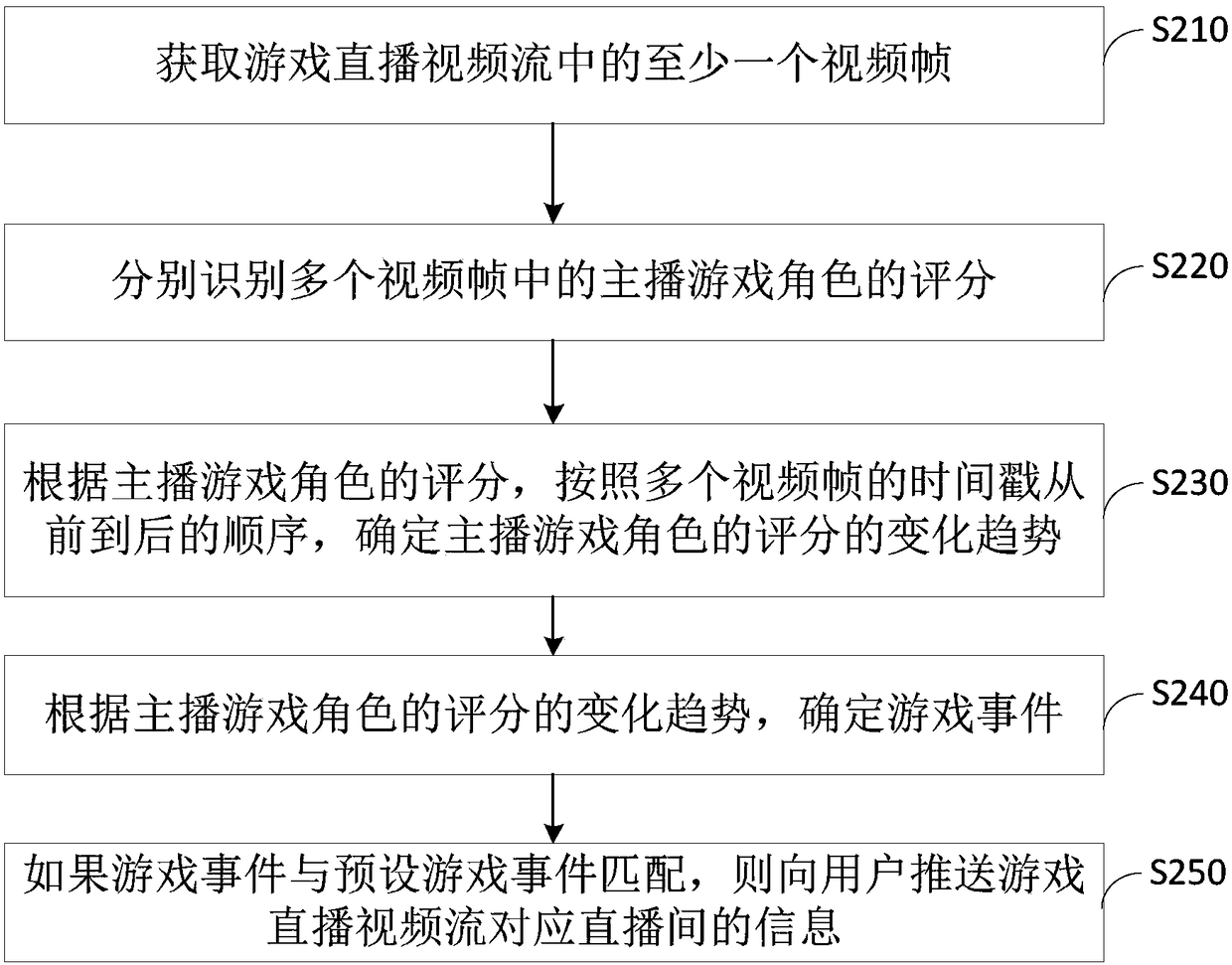

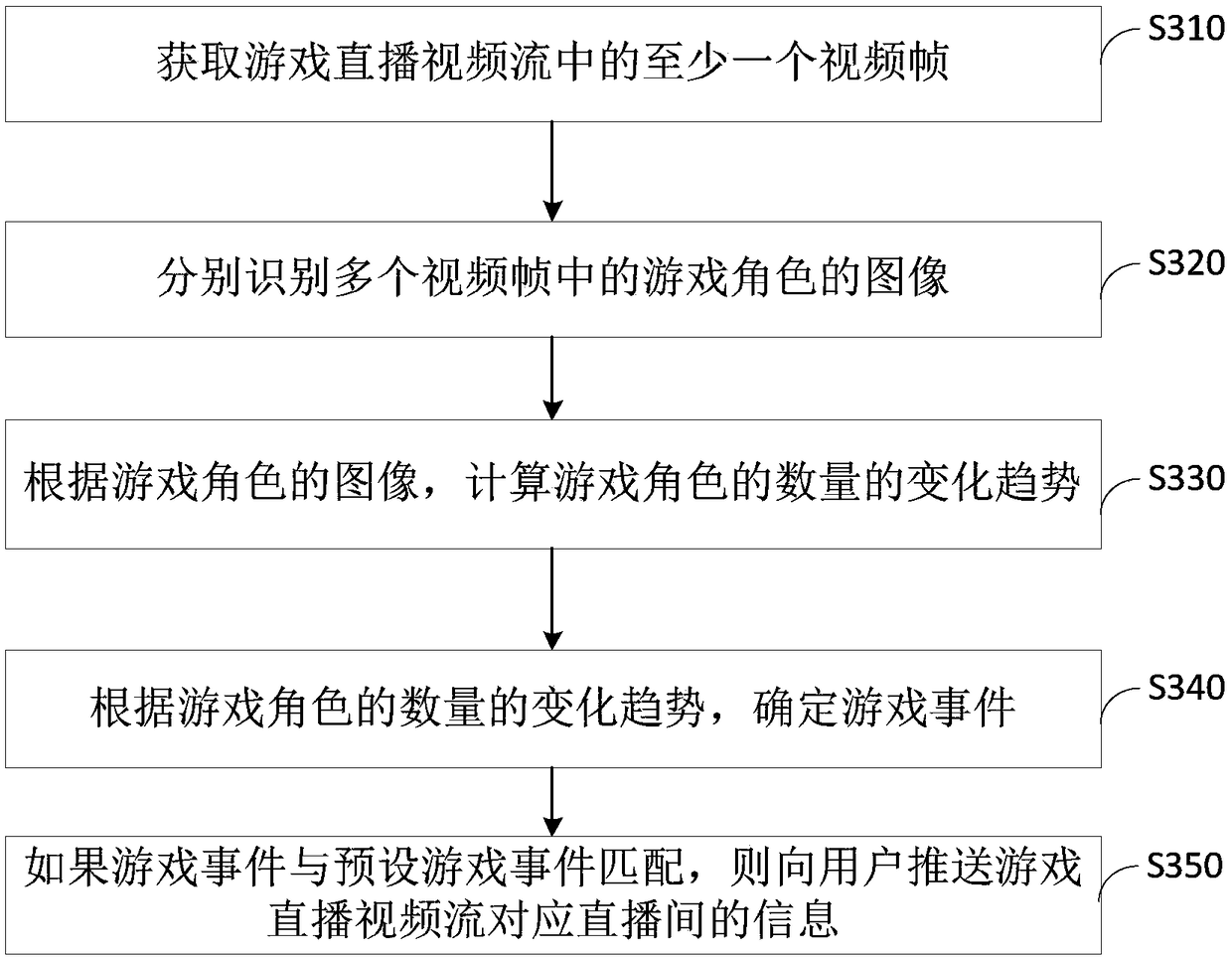

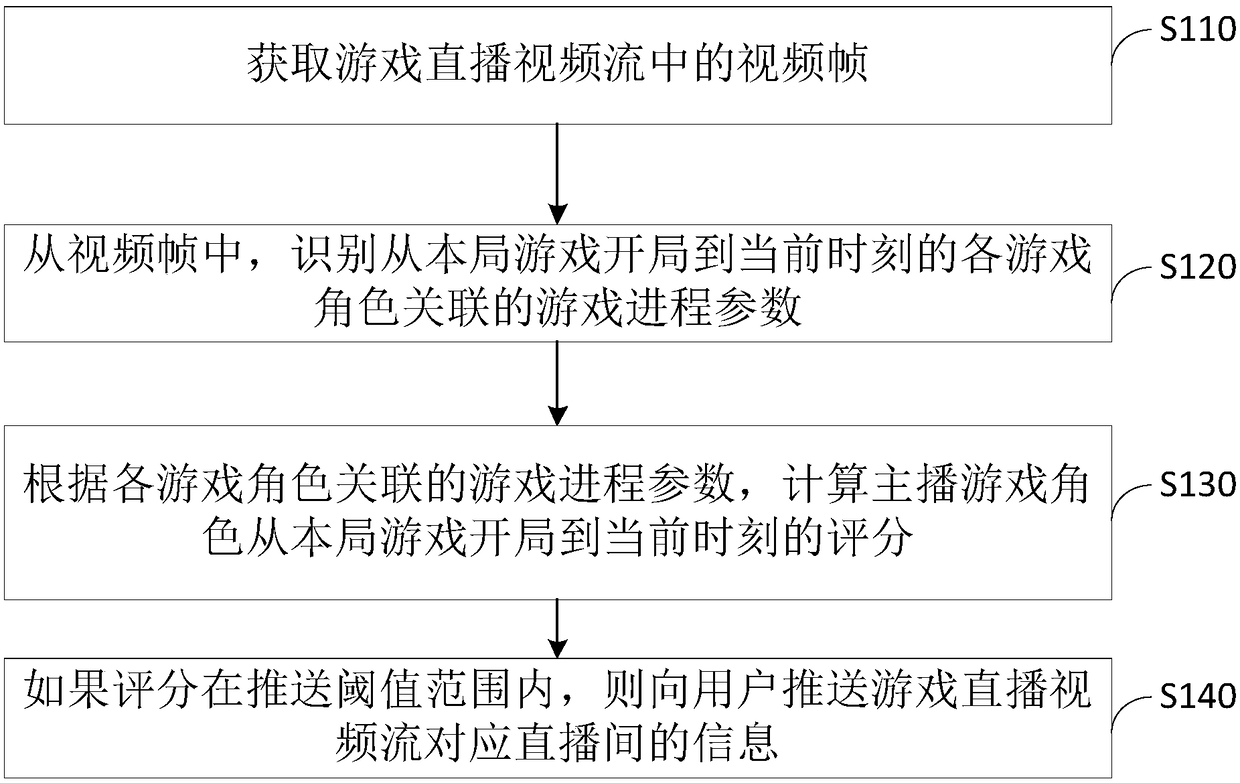

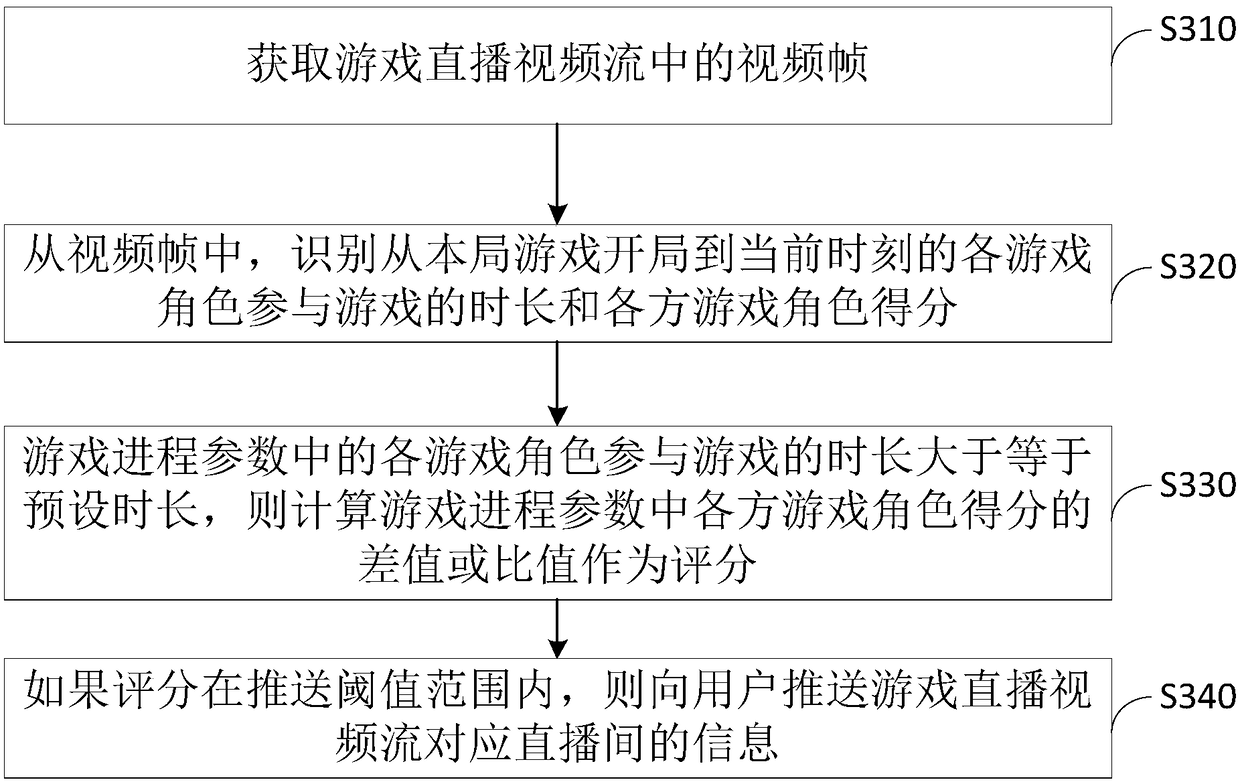

Live broadcast room information push method and device, equipment and medium

ActiveCN108881949AEasy accessConducive to content distribution efficiencySelective content distributionMultimedia

The embodiment of the invention discloses a live broadcast room information push method and device, equipment and a medium. The method includes the following steps: obtaining a video frame in a game live broadcast video stream; identifying game process parameters associated with each game character from the start of the current round of the game to the current moment from the video frame; calculating a score of an anchor game character from the start of the current round of the game to the current moment according to the game process parameters associated with each game character; and if the score reaches a push threshold, pushing information of a live broadcast room corresponding to the game live broadcast video stream to users. According to the embodiment, high-quality game live broadcast rooms can be recommended to the users according to the score of the anchor game character from the start of the current round of the game to the current moment.

Owner:GUANGZHOU HUYA INFORMATION TECH CO LTD

Quenching boiler provided with enhanced heat transfer member

ActiveCN101893396AReduce cokingExtend online timeThermal non-catalytic crackingStationary tubular conduit assembliesEnhanced heat transferVapor phase

The invention discloses a quenching boiler provided with an enhanced heat transfer member. The quenching boiler comprises a heat exchange pipe and a shell layer. The enhanced heat transfer member is arranged in the heat exchange pipe of the quenching boiler and is arranged at a position where a vapor phase in shell-side fluid of the quenching boiler accounts for less than 5 volume percent of the fluid or at a position where the temperature of the shell-side fluid of the quenching boiler is higher than 520 DEG C. The quenching boiler is applied to an ethylene cracking device, can enhance the heat transfer effect of the quenching boiler, and delays the coking of the quenching boiler so as to prolong the online time of the quenching boiler.

Owner:CHINA PETROLEUM & CHEM CORP +1

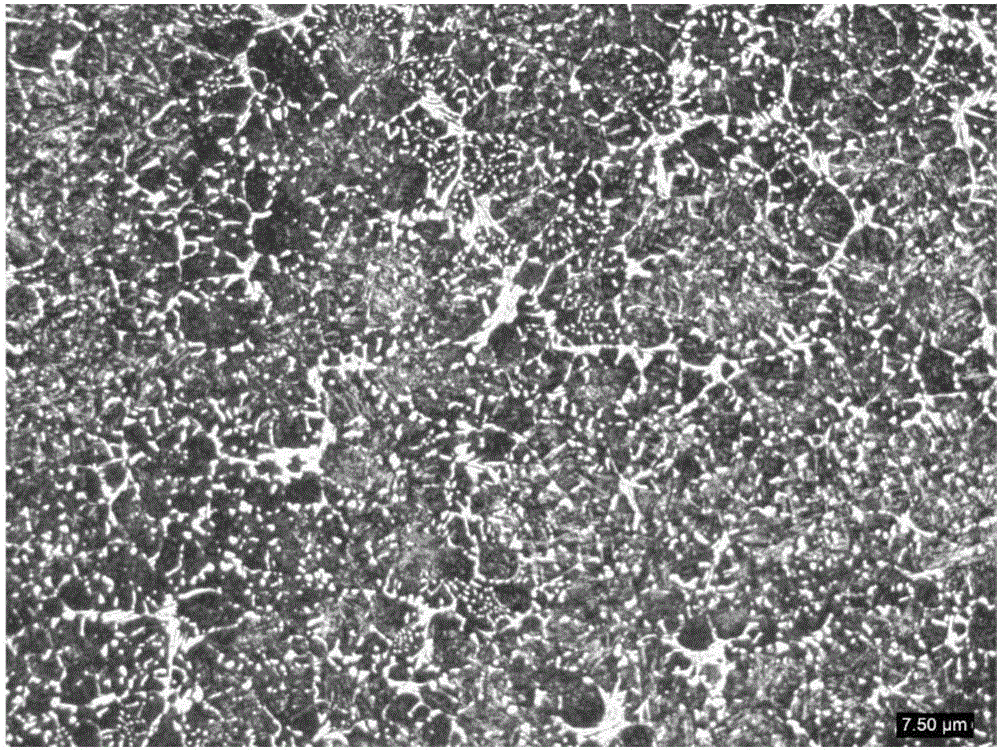

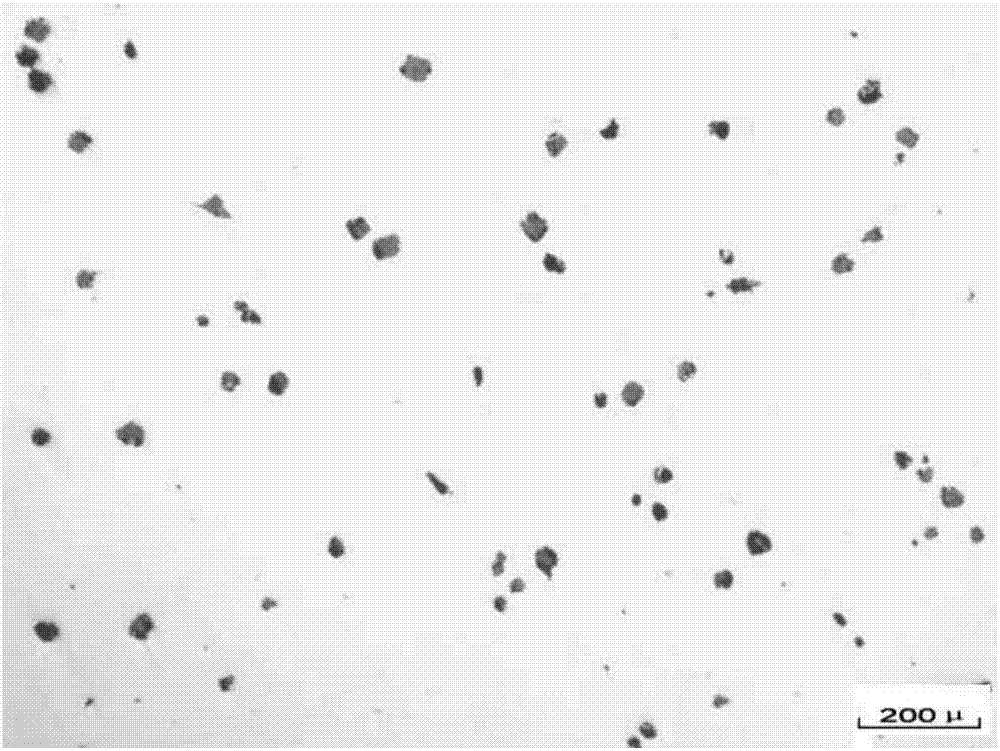

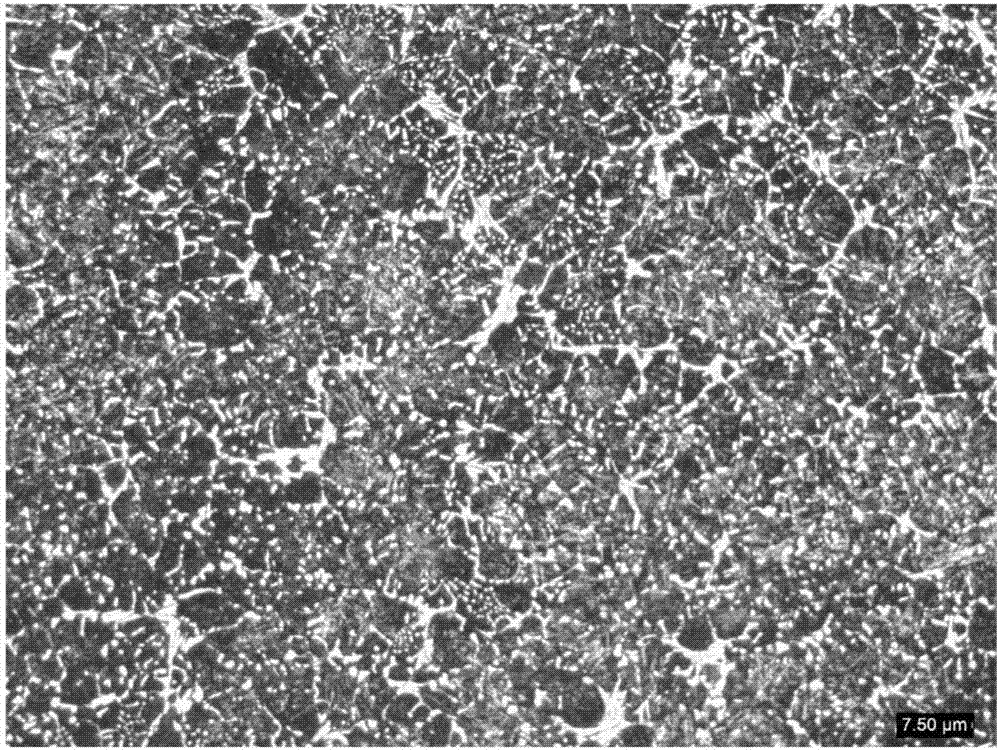

Graphite-containing high-speed steel roller

ActiveCN106086705AAnti-accident propertiesHas high wear resistanceRollsMetal rolling arrangementsBorideSurface brightness

The invention discloses a graphite-containing high-speed steel roller and belongs to the field of mechanical casting. B and N chemical elements are introduced into traditional high-speed steel components; MC-type and / or M<2>C-type, and dot-shaped and / or blocky highly-hard alloy carbides, nitrides and borides with the total area percentage being 20-35% are dispersed and distributed in a matrix structure of a working layer; the two steps that firstly, carbide, nitride and boride modification treatment is performed, and then graphite modification inoculation treatment is performed are adopted, graphite is separated out of an original structure, therefore, the high-speed steel roller maintains the unique advantage of high temperature abrasion resistance of traditional high-speed steel, meanwhile, the problem of a large friction coefficient of original traditional high-speed steel rollers is solved, the abrasion resistance of high-speed steel is fully achieved, the lubrication effect between the roller and a workpiece during rolling is achieved, and therefore, occurrence of the steel-adhesion phenomenon is prevented; and besides, by means of heat-conducting property and lubricating property of graphite, the defects of thermal impact, hot cracking sensitivity, steel adhesion tendency and surface texturing tendency of the high-speed steel rollers can be overcome, and especially during usage for a finished product rack, the surface brightness of rolled products is improved remarkably.

Owner:SANXIN HEAVY IND MACHINERY

Manufacturing method of graphite-contained high-speed steel centrifugal composite steel core roller

ActiveCN106282821AAnti-accident propertiesHas high wear resistanceRollsMetal rolling arrangementsBorideFully developed

The invention discloses a manufacturing method of a graphite-contained high-speed steel centrifugal composite steel core roller, and belongs to the field of mechanical casting. Chemical elements of B and N are introduced in a traditional high-speed steel component, MC type and / or M2C type dotted and / or blocky high-hard alloy carbides, nitrides and borides with the total area percentage of 20% to 35% are dispersed and distributed in a work layer base body structure; through carbide, nitride and boride modification, graphite is subject to two-step treatment of modification and inoculation, graphite is precipitated in an original structure, and therefore the high-speed steel roller has the advantages of the specific high-temperature wear resisting of traditional high-speed steel and meanwhile the problem that an original traditional high-speed steel roller is large in friction coefficient is solved; wear-resisting performance of the high-speed steel is fully developed, the lubricating effect between the roller and a workpiece in the rolling process is achieved, and happening of the steel bonding phenomenon is avoided; due to the heat conduction performance and the lubricating characteristic of graphite, the defects that the high-speed steel roller is sensitive to hot impact and hot-cracking susceptibility, steel bonding is prone to happening, and surface roughing is prone to happening can be overcome, and particularly when a finished product rack is used, the surface bright degree of a rolled material is obviously improved.

Owner:SANXIN HEAVY IND MACHINERY

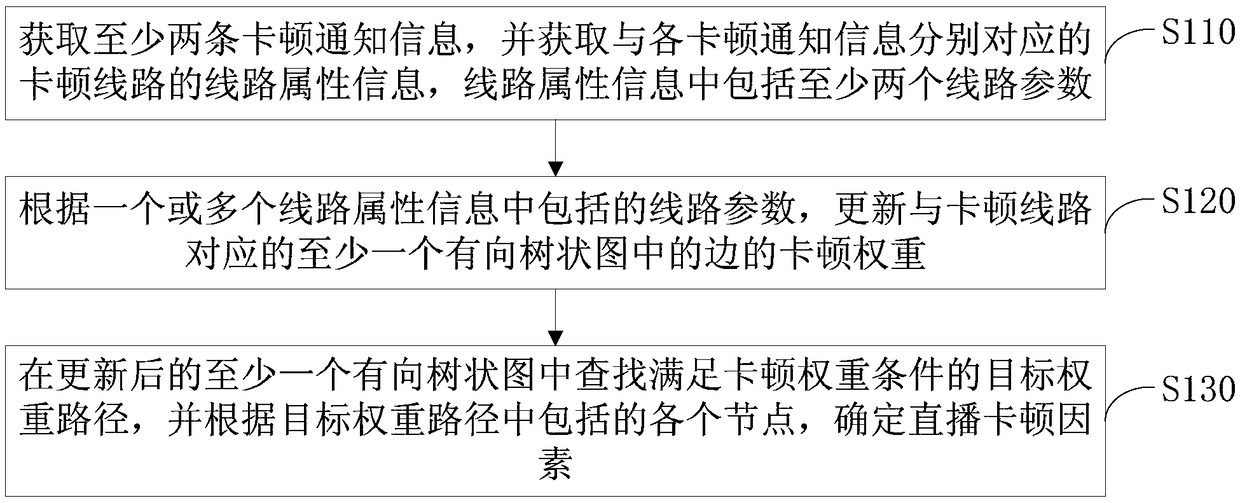

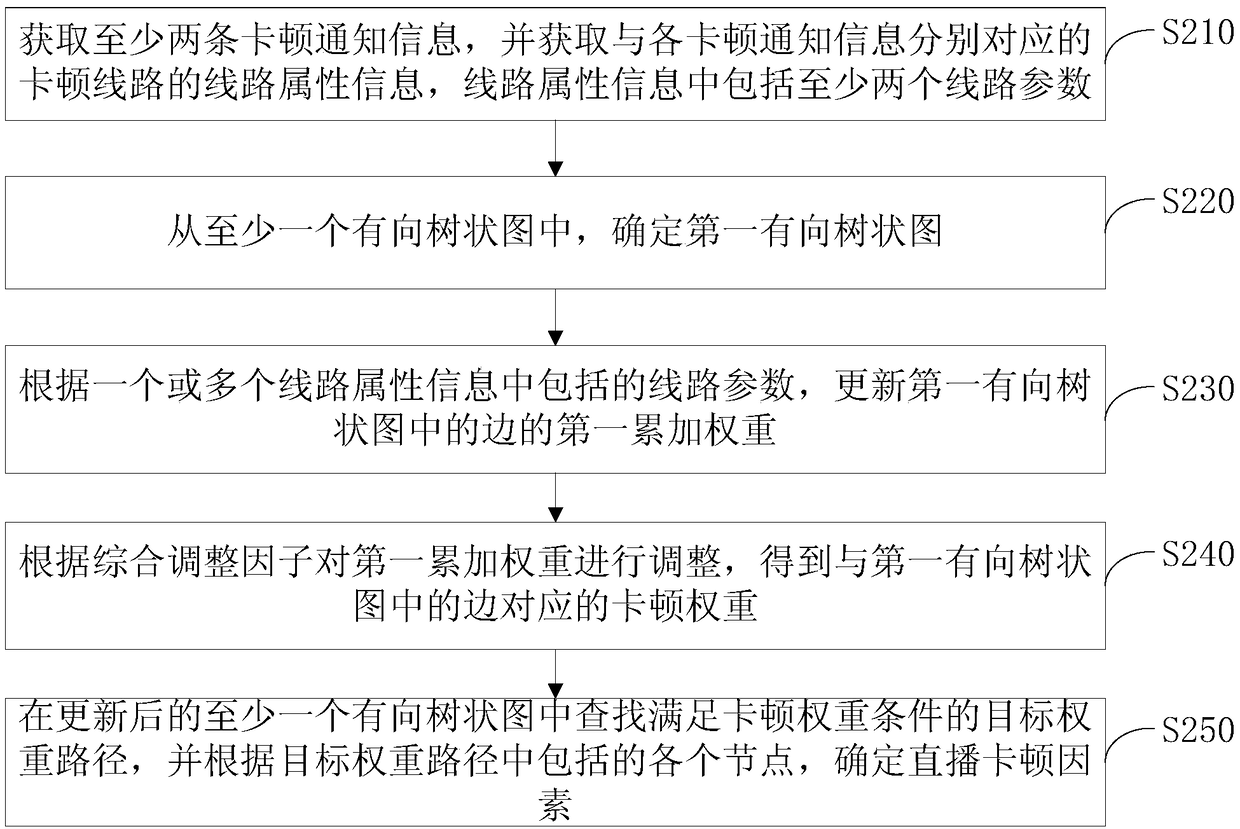

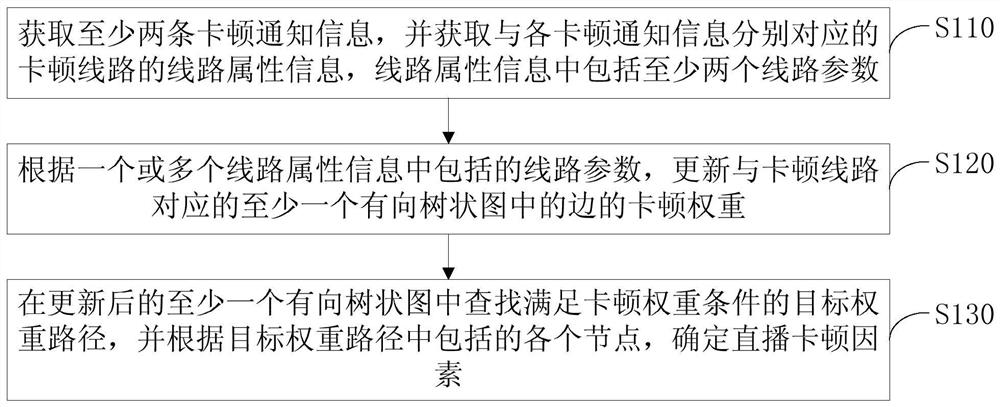

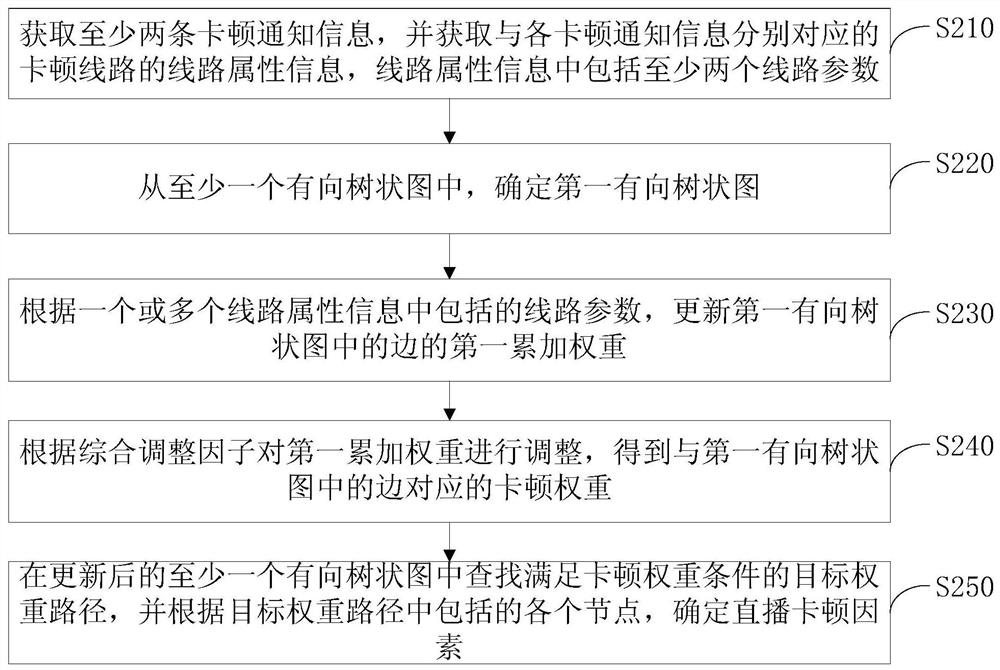

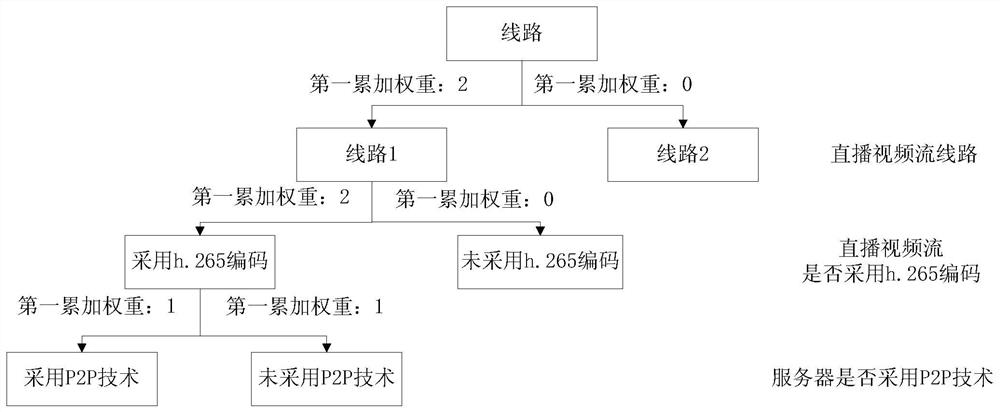

Method and device for determining factors for live streaming stagnation, server and storage medium

The embodiment of the invention discloses a method and a device for determining factors for live streaming stagnation, a server and a storage medium. The method includes the steps of acquiring two ormore pieces of stagnation notice information, and acquiring circuit attribute information of stagnated circuits corresponding to the stagnation notice information, wherein each circuit attribute information includes two or more circuit parameters; updating stagnation weights of edges in one or more directed tree map corresponding to the stagnated circuits according to the circuit parameters in oneor more pieces of circuit attribute information, wherein nodes in the directed tree maps correspond to the circuit parameters in the stagnated circuits; looking up target weights paths meeting the stagnation weight conditions in the updated directed tree maps, and determining the factors for live streaming stagnation according to the nodes in the target weight paths. By the method, the device, the server and the storage medium, the factors for live streaming stagnation can be located quickly and accurately.

Owner:GUANGZHOU HUYA INFORMATION TECH CO LTD

Wear-resistant type strong-widening roller for strip steel

ActiveCN107511398AHigh anti-wear propertiesSolve the problem of not easy to bite steelRollsMetal rolling arrangementsWear resistantStrip steel

The invention discloses a wear-resistant type strong-widening roller for strip steel and belongs to the field of narrow strip steel production equipment. A roller work layer adopts a high-chrome-molybdenum-vanadium-series alloy material which comprises 2.0-3.0% of C, 0.4-1.0% of Si, 0.6-1.0% of Mn, 8-32% of Cr, 0.8-1.8% of Ni, 0.8-2.0% of Mo and 0.2-1.2% of V; and the roller shape adopts a sine curve. The roller is used for a narrow strip steel rough rolling rack and has the effects of being high in strip steel blank forced widening efficiency and capable of eliminating loosening of steel blank centers and improving the plate quality; the roller has super-strong wear resistance, and thus the online time is 2-3 times that of a traditional NiCrMo roller; the roller has good characteristics of the hot cracking resistance and the fatigue weight losing resistance, the dismounted reconditioning restoration quantity of the roller is reduced by 40% compared with a traditional NiCrMo roller, and the plate face quality is obviously improved; and the comprehensive service life is prolonged to be three times or more that of the traditional roller, and the comprehensive ton-of-steel cost is reduced by 30%.

Owner:SANXIN HEAVY IND MACHINERY

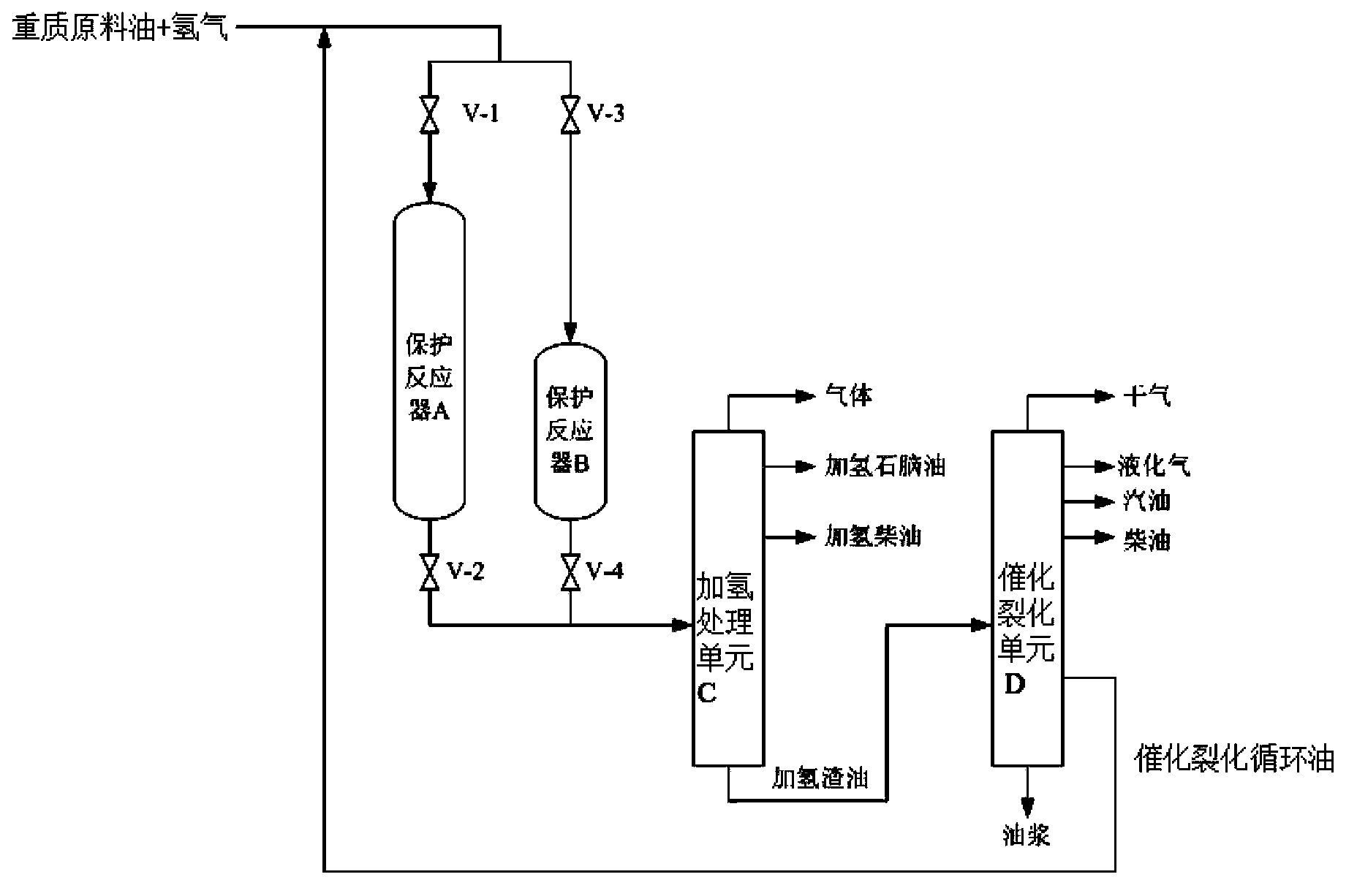

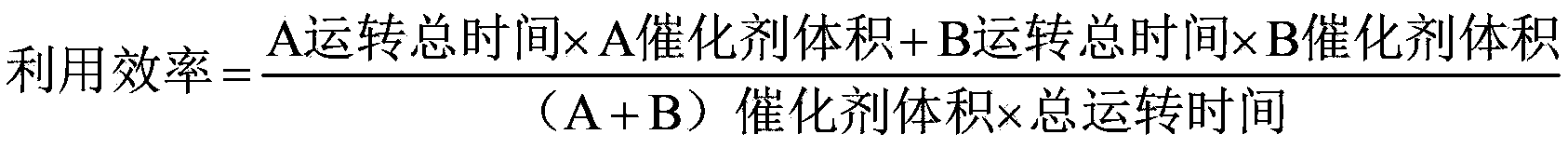

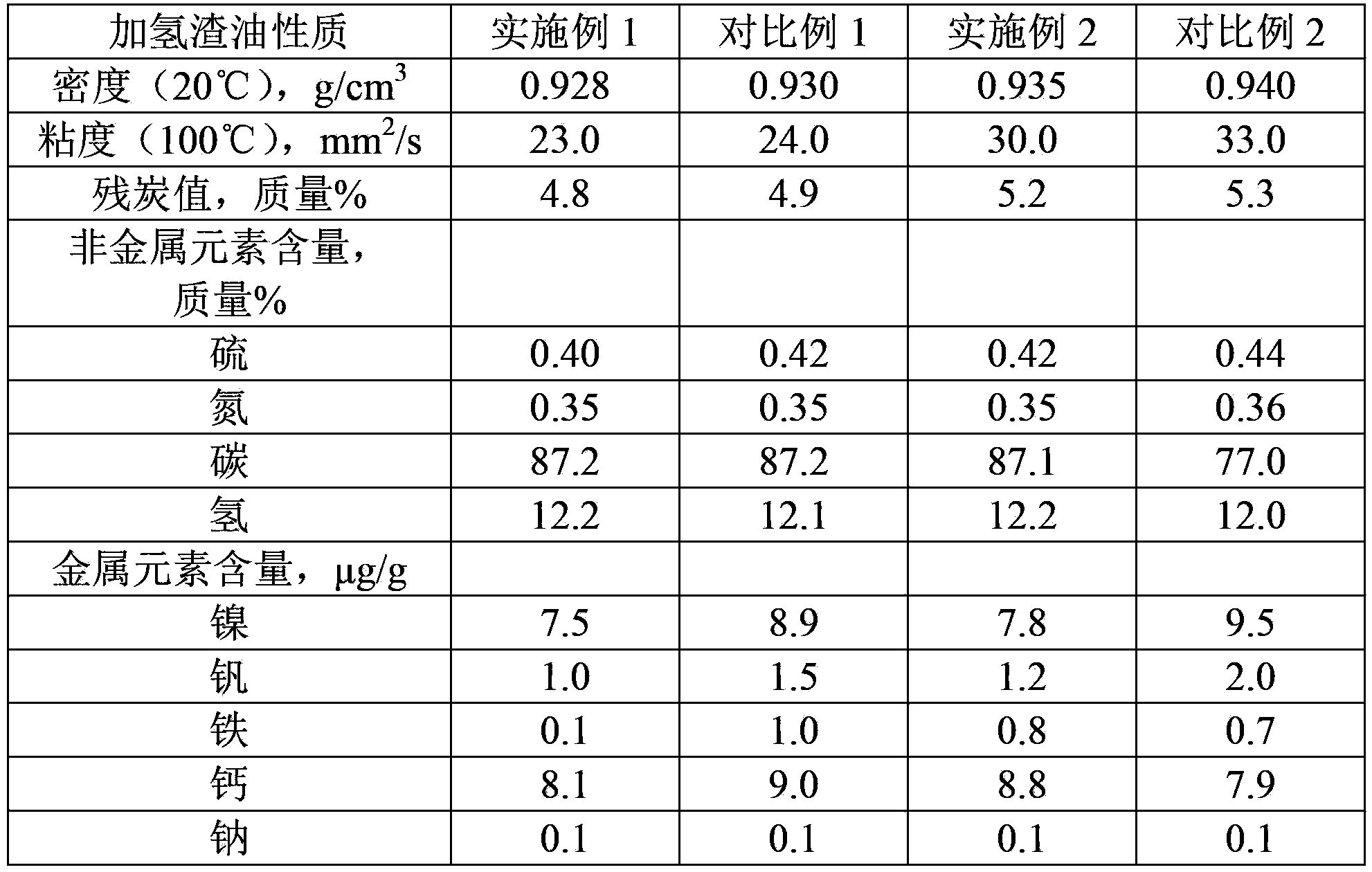

Heavy raw oil treatment apparatus, its application, and heavy raw oil treatment method

ActiveCN104119955AExtend online timeShort online timeTreatment with hydrotreatment processesEconomic benefitsUtilization rate

The invention provides a heavy raw oil treatment apparatus. The treatment apparatus comprises a hydrogenation protection unit, a hydrotreatment unit and a catalytic cracking unit which are connected in series, wherein the hydrogenation protection unit comprises a main hydrogenation protection reactor and a standby hydrogenation protection reactor which are connected in parallel, and the volume of the main hydrogenation protection reactor is greater than the volume of the standby hydrogenation protection reactor. The invention also provides an application of the heavy raw oil treatment apparatus in the treatment of many oil products, and a method for treating the heavy raw oil by using the heavy raw oil treatment apparatus. Compared with apparatuses in the prior art, the heavy raw oil treatment apparatus adopting the asymmetric switchable protection reactors substantially improves the space utilization rate of the reactors and realizes an obvious economic benefit due to the online time of the larger protection reactor is long and the online time of the smaller protection reactor is short.

Owner:CHINA PETROLEUM & CHEM CORP +1

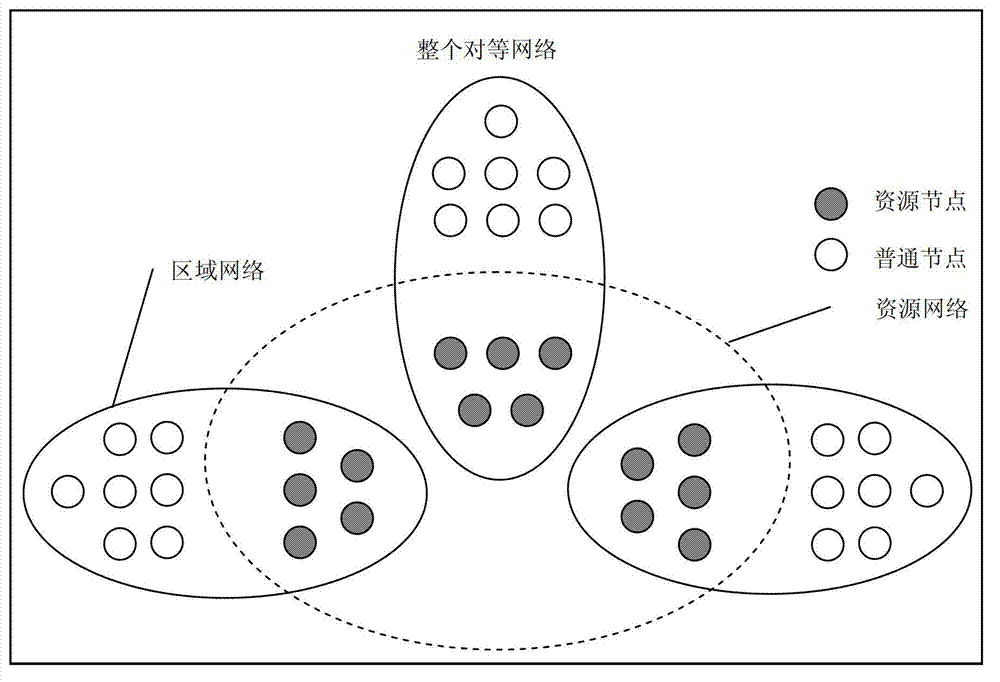

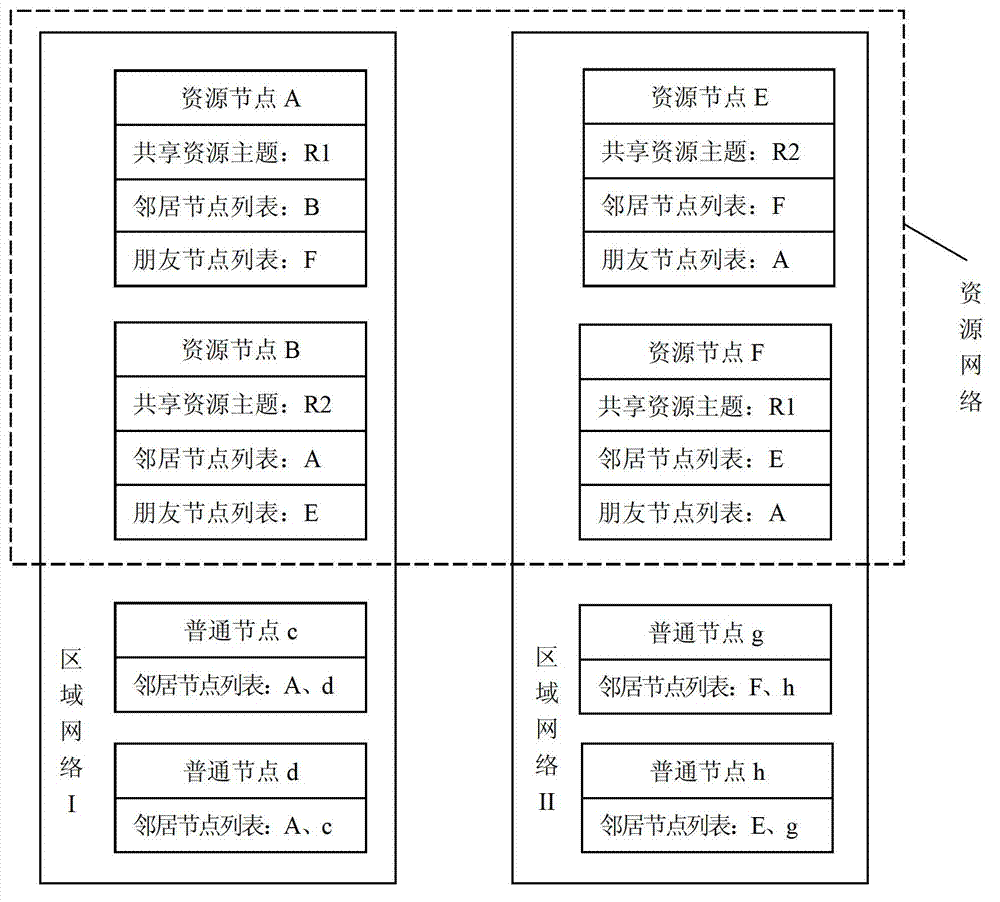

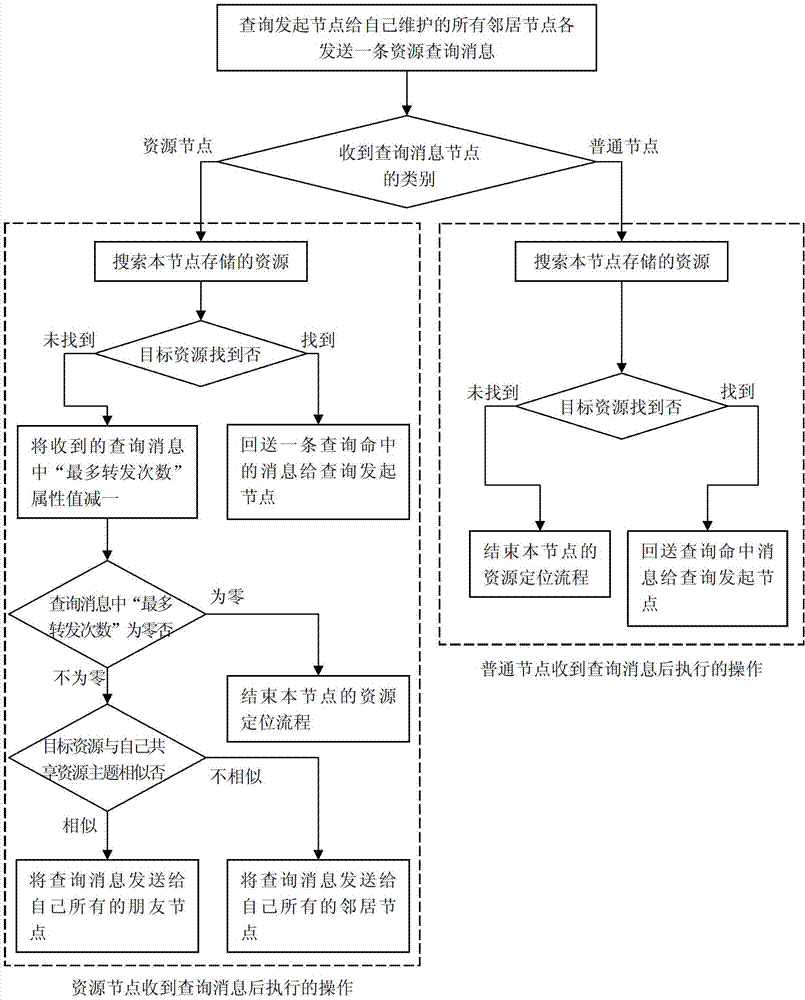

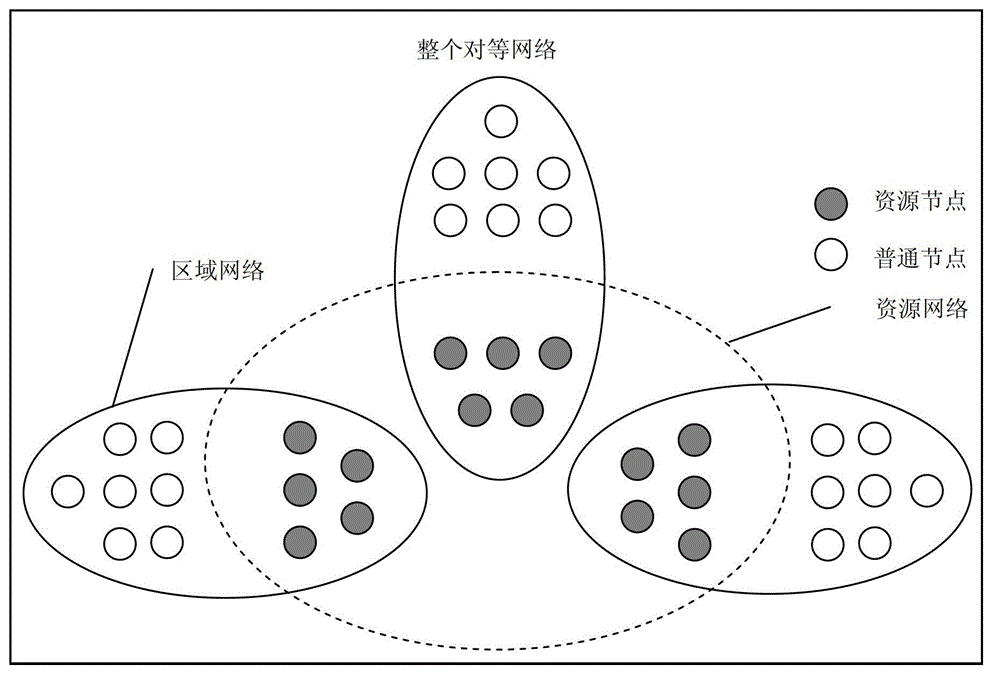

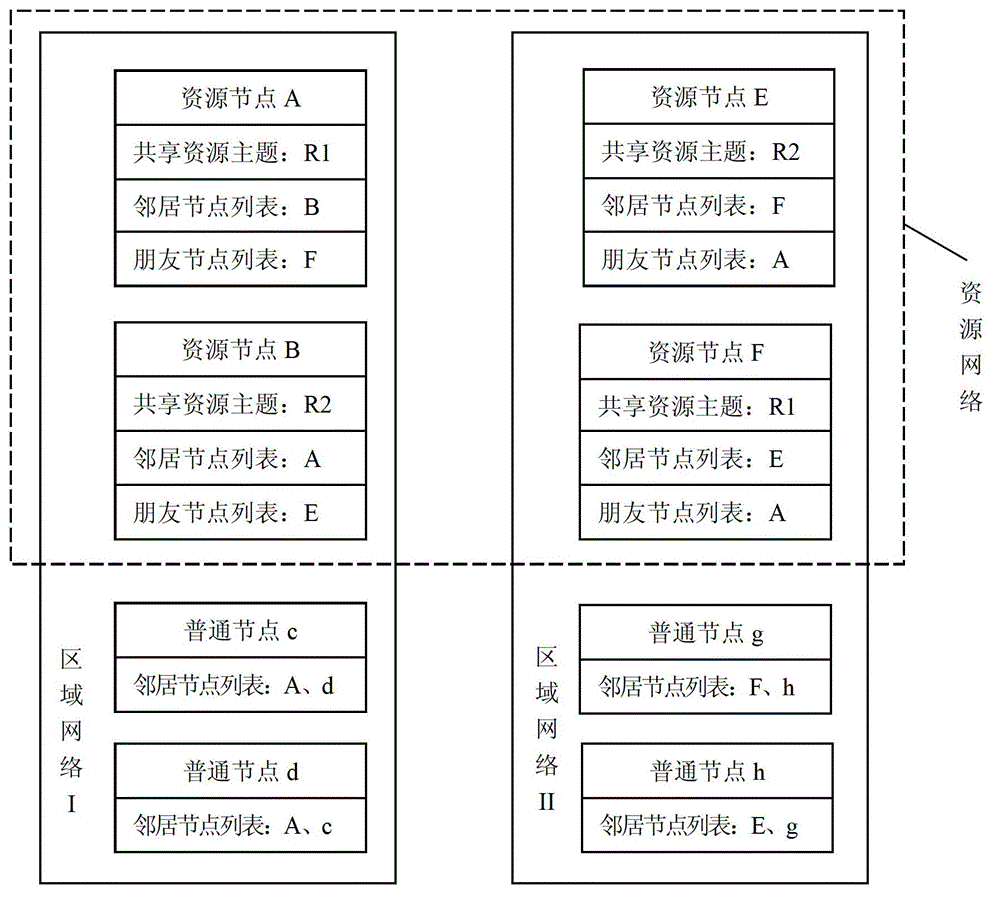

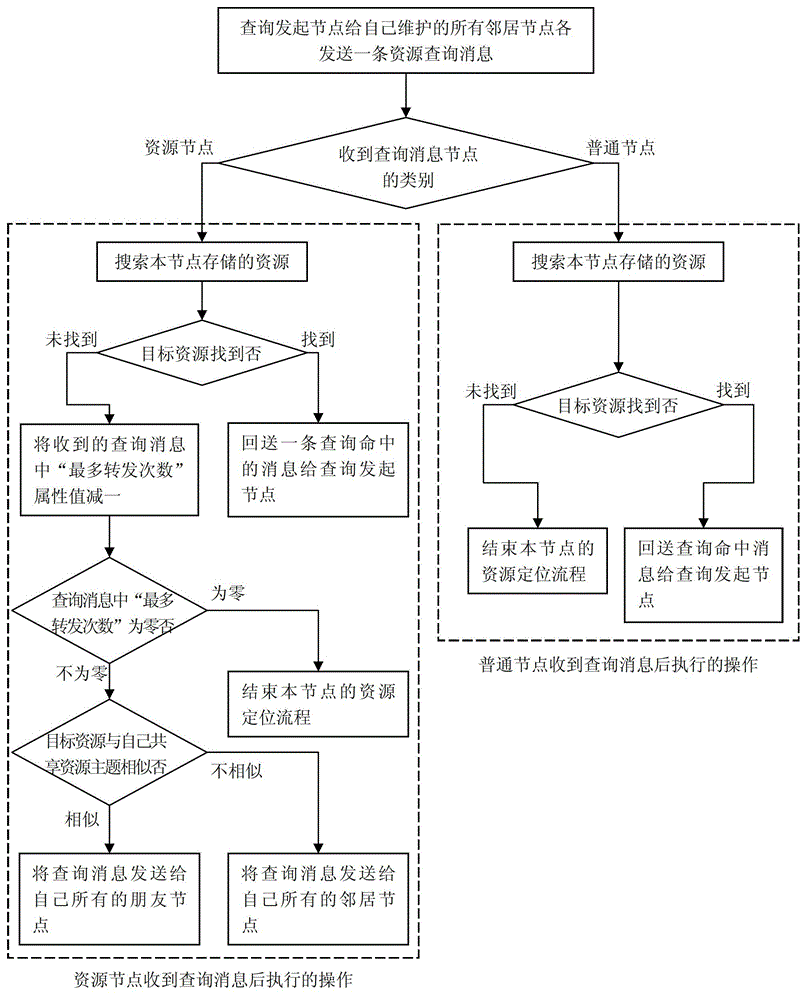

Peer-to-peer network and network resource location method thereof

ActiveCN103118113AGuaranteed normal transmissionExtend online timeTransmissionGeolocationResource network

The invention discloses a peer-to-peer network. The peer-to-peer network comprises local area networks and resource networks, wherein the local area networks are composed of resource nodes and common nodes and are partitioned according to locations of the resource nodes and the common nodes, and the resource networks are composed of all resource nodes in the network and can assist the nodes of the peer-to-peer network in evaluating relative distance with other nodes. The resource networks are composed of all resource nodes in the peer-to-peer network and integrate resources of the resource nodes in the peer-to-peer network. The invention further discloses a network resource location method based on node heterogeneity in the peer-to-peer network. By the peer-to-peer network and the network resource location method thereof, quick location can be realized, target resources can be acquired nearby, and higher network transmission performance can be realized.

Owner:CCCC FOURTH HARBOR ENG INST +2

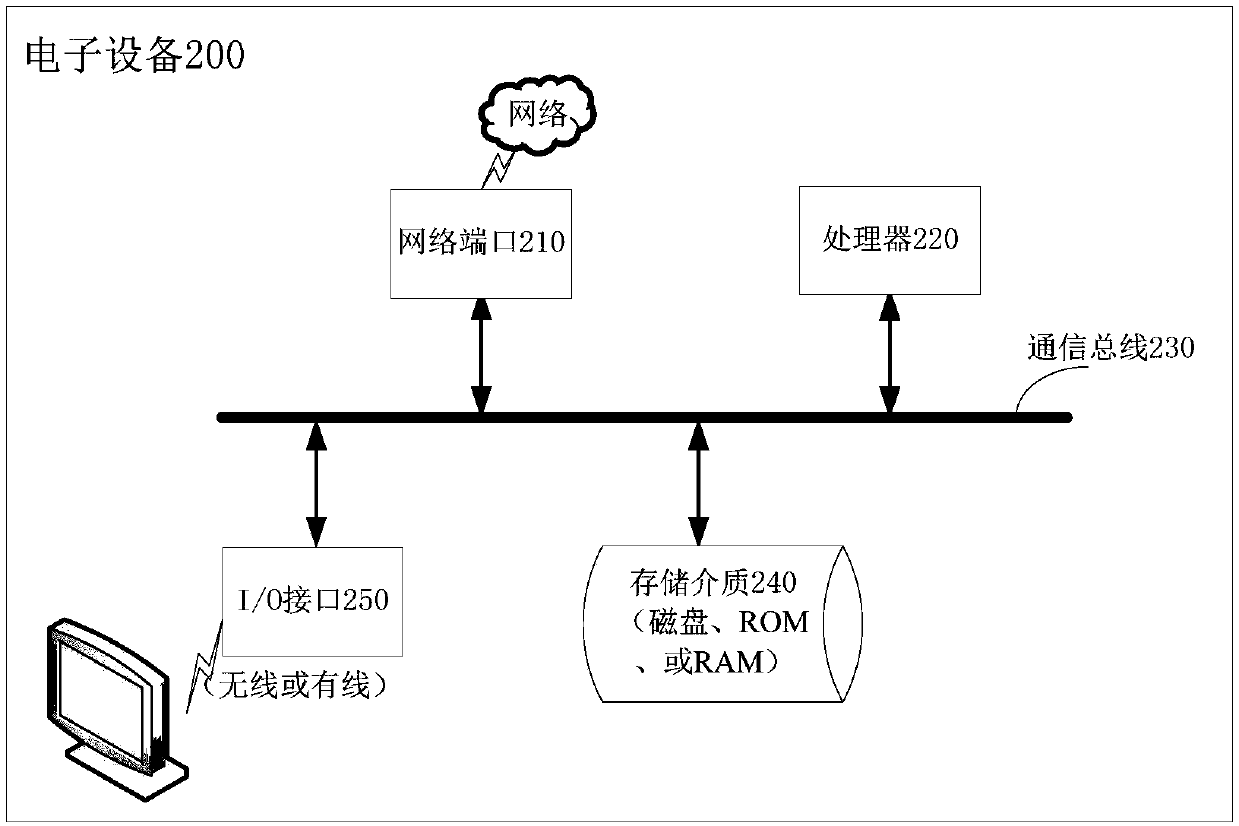

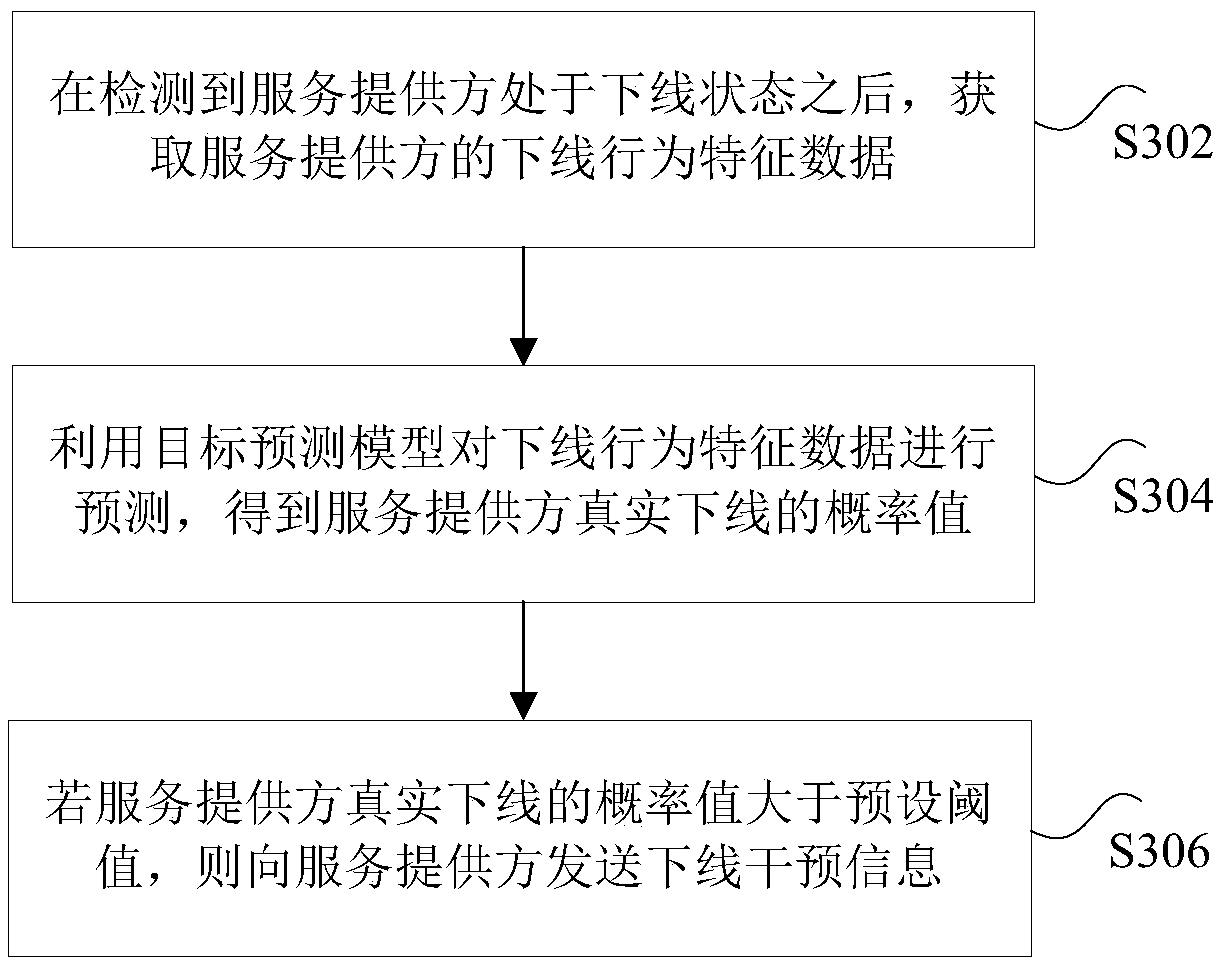

Driver offline intervention method and device, electronic equipment and computer storage medium

InactiveCN111340265AExtend online timeImprove capacity schedulingForecastingFeature dataDistributed computing

The invention provides a driver offline intervention method and device, electronic equipment and a computer storage medium, and the method comprises the steps: obtaining offline behavior feature dataof a service provider after the service provider is detected to be in an offline state; predicting the offline behavior characteristic data by using the target prediction model to obtain a real offline probability value of the service provider; and if the probability value of the real offline of the service provider is greater than the preset threshold, sending offline intervention information tothe service provider, the offline intervention information being used for reminding the service provider to prolong the offline time. According to the invention, the authenticity of the current offline of the service provider is predicted by using the machine learning model, and the offline intervention information is used to intervene the car receiving behavior of the service provider, so that the online duration of the service provider is improved, and the effect of improving the transport capacity scheduling is achieved.

Owner:BEIJING DIDI INFINITY TECH & DEV

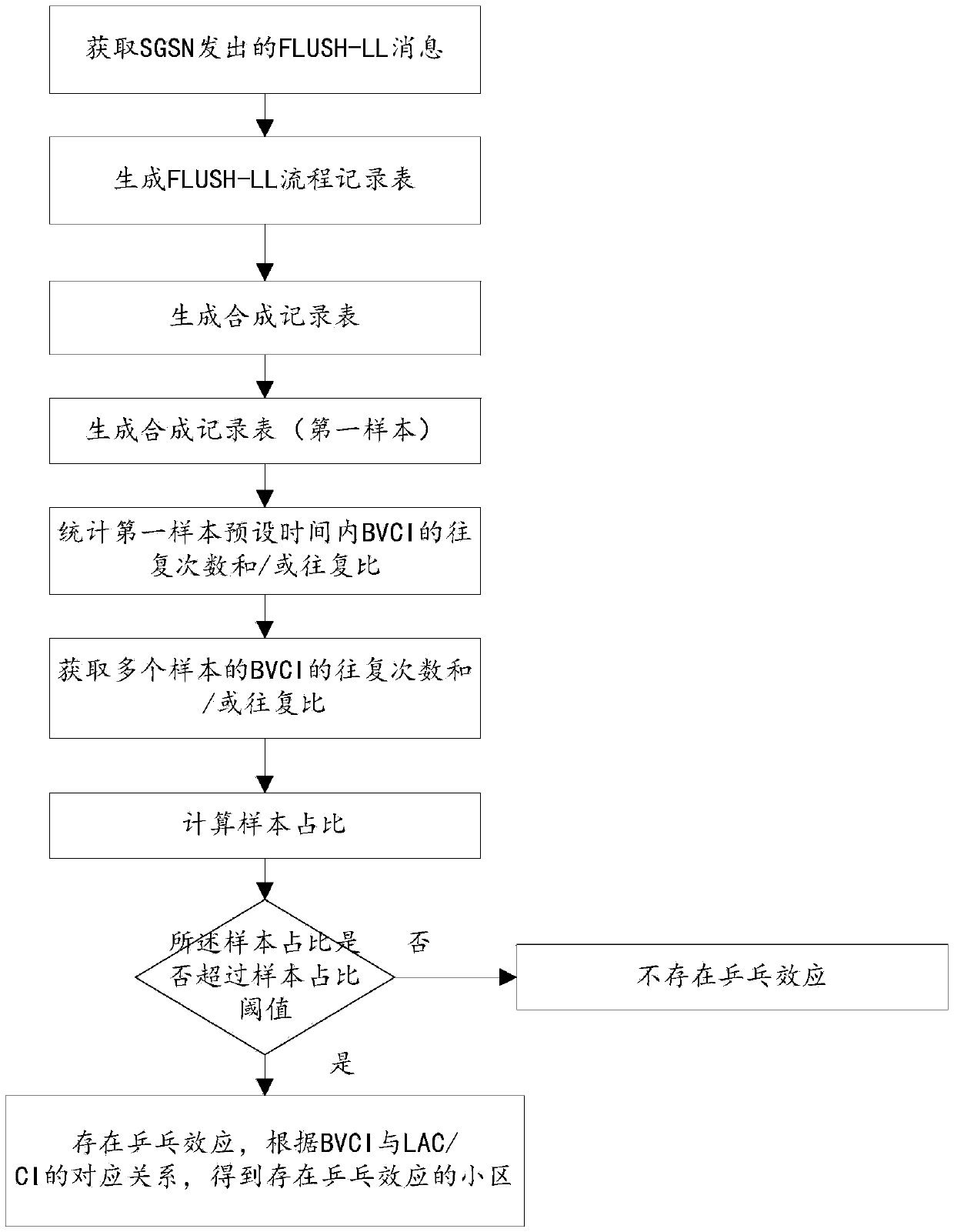

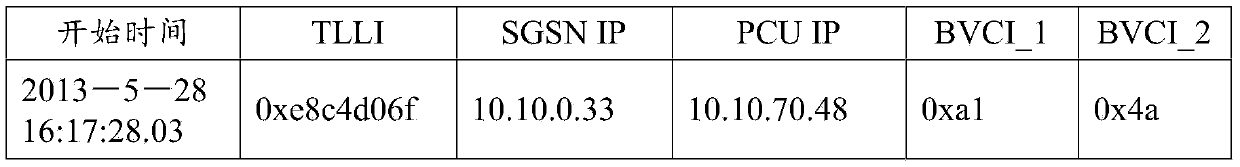

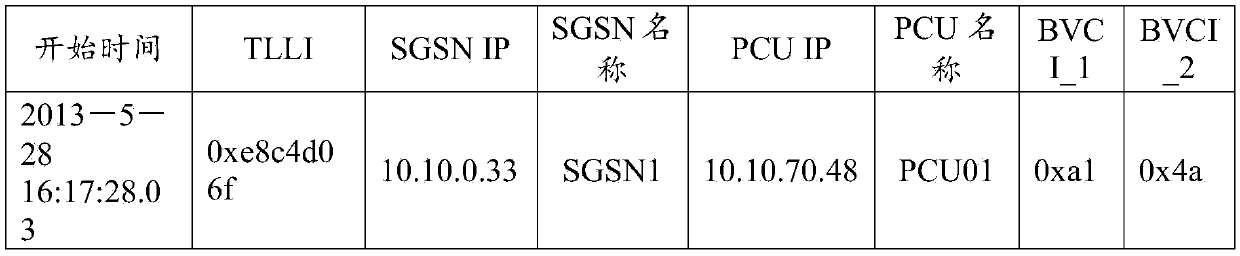

Method for positioning ping-pong effect cell by means of Gb interface signaling analysis

InactiveCN105376759AReduce overheadReduce the difficulty of implementationWireless communicationComputer scienceProtocol stack

The invention relates to a method for positioning a ping-pong effect cell by means of Gb interface signaling analysis. Packet domain core network Gb interface signaling is analyzed, and an algorithm for judging a ping-pong effect is designed, and the ping-pong effect cell is directly obtained. According to the invention, an active discovering mechanism is adopted, the ping-pong effect cell analysis based on FLUSH-LL signaling is realized, and the method for positioning the ping-pong effect cell by means of Gb interface signaling analysis has the advantages that the protocol stack is simple, the realization difficulty is low, the hardware cost is low, the accuracy of ping-pong effect cell analysis is high, etc.

Owner:BEIJING ZHONGCHUANG TELECOM TEST

A peer-to-peer network and its network resource location method

ActiveCN103118113BGuaranteed normal transmissionExtend online timeTransmissionGeolocationResource network

The invention discloses a peer-to-peer network. The peer-to-peer network comprises local area networks and resource networks, wherein the local area networks are composed of resource nodes and common nodes and are partitioned according to locations of the resource nodes and the common nodes, and the resource networks are composed of all resource nodes in the network and can assist the nodes of the peer-to-peer network in evaluating relative distance with other nodes. The resource networks are composed of all resource nodes in the peer-to-peer network and integrate resources of the resource nodes in the peer-to-peer network. The invention further discloses a network resource location method based on node heterogeneity in the peer-to-peer network. By the peer-to-peer network and the network resource location method thereof, quick location can be realized, target resources can be acquired nearby, and higher network transmission performance can be realized.

Owner:CCCC FOURTH HARBOR ENG INST +2

Hydrotreating device and application thereof as well as residual oil hydrotreating method

ActiveCN103059928BExtend online timeShort online timeTreatment with hydrotreatment processesProcess engineeringResidual oil

The invention provides a hydrotreating device which comprises a hydrotreating protection unit and a main hydrotreating unit, which are connected with each other in series, wherein the hydrotreating protection unit comprises a main hydrotreating protection reactor and a spare hydrotreating protection reactor, which are connected with each other in parallel, and the volume of the main hydrotreating protection reactor is larger than that of the spare hydrotreating protection reactor. The invention further provides the application of the hydrotreating device and a residual oil hydrotreating method. The method comprises the following steps of: introducing the residual oil and the hydrogen into the hydrotreating device, and alternately using the main hydrotreating protection reactor and the spare hydrotreating protection reactor in the process of hydrotreating, wherein the online time of the main hydrotreating protection reactor is longer than that of the spare hydrotreating protection reactor. The method provided by the invention is particularly suitable for machining the high-carbon content residual oil and the high-metal content residual oil. Furthermore, the bigger hydrotreating protection reactor is longer in online time, so that the invention is higher in reactor use ratio.

Owner:CHINA PETROLEUM & CHEM CORP +1

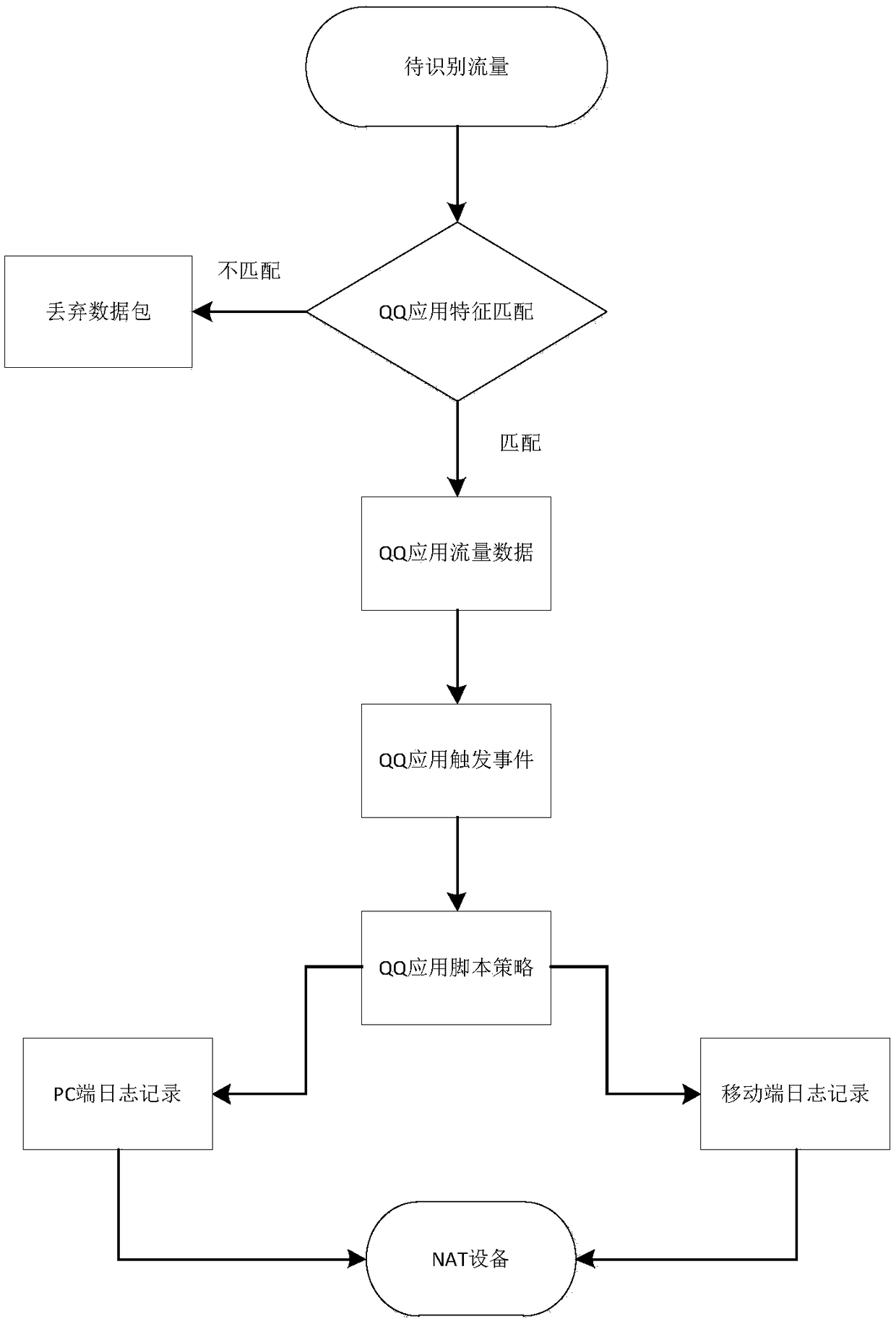

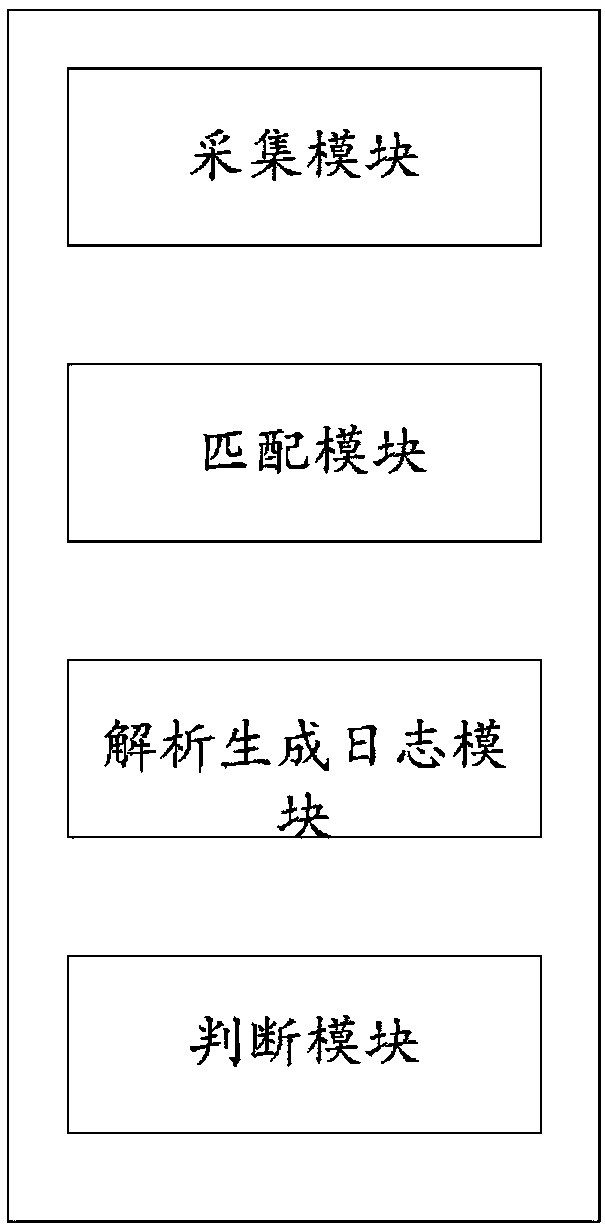

NAT (Network Address Translation) detection method and system based on instant messaging application

InactiveCN108092876AIncrease the number of usersExtend online timeData switching networksReal-time dataOperational system

The invention relates to an NAT (Network Address Translation) detection method and system based on an instant messaging application. Real-time data collection, QQ application identification and QQ application analysis are carried out. For the same IP, if QQ log records of a PC side and a mobile side coexist within a time interval, a device can be accurately judged as an NAT device. The method is independent of certain specific operating system. A coverage range is wide. The identification rate is high. The operation is simple and convenient.

Owner:HUBEI UNIV

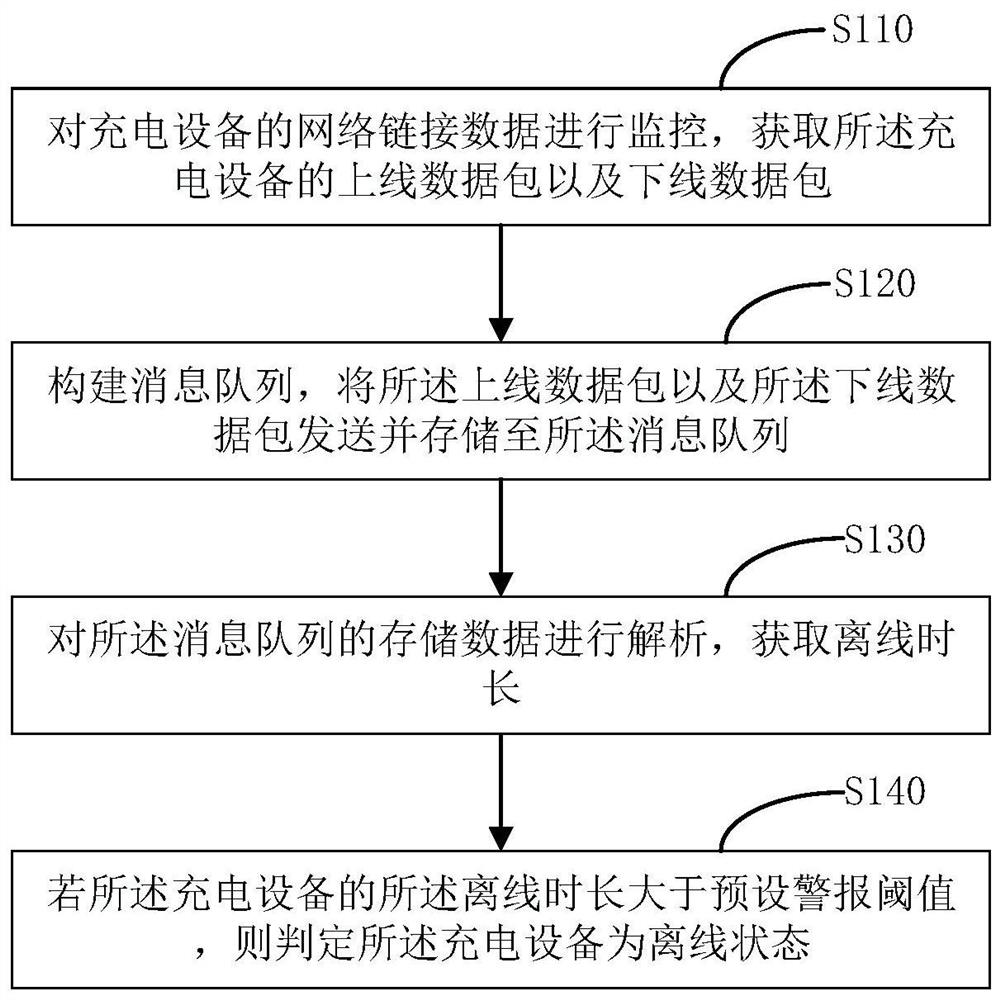

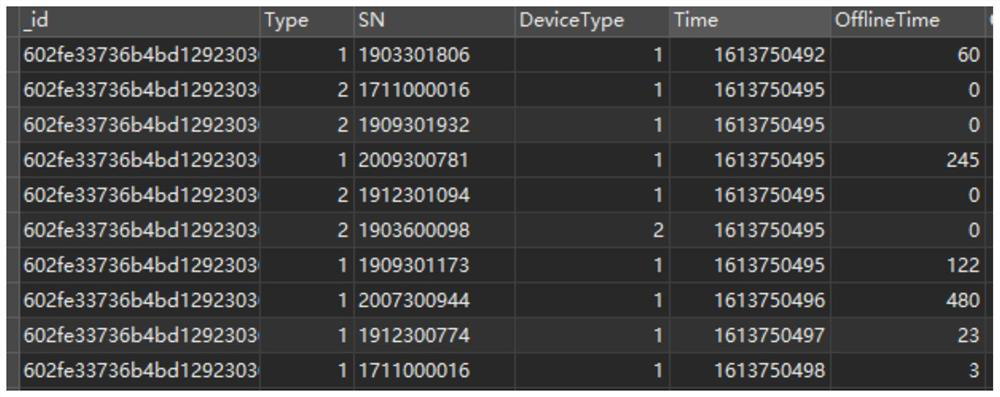

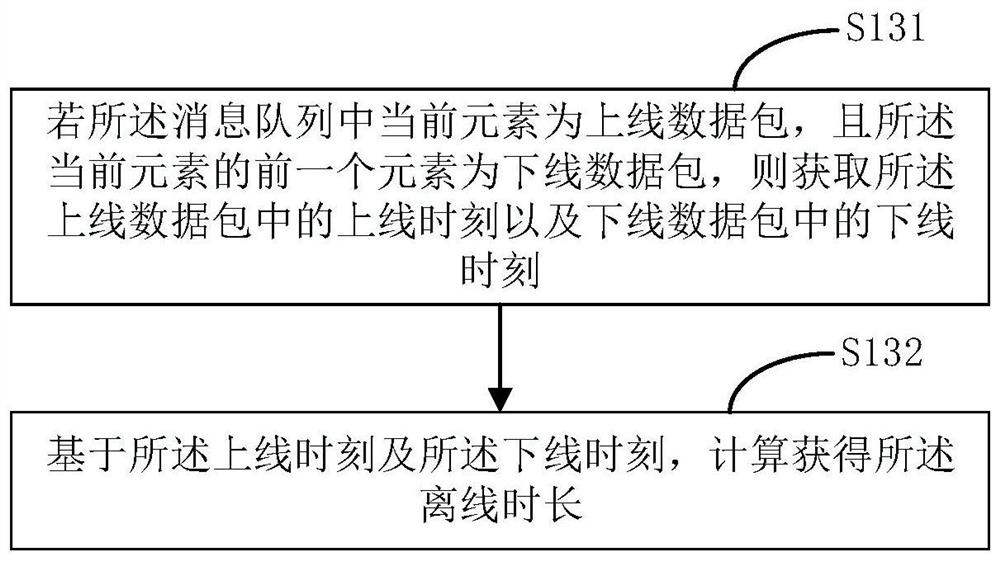

Offline judgment method and system of charging equipment, equipment and computer storage medium

PendingCN113079063AMake sure to get it rightImprove accuracyData switching networksMessage queueData pack

The invention discloses an offline judgment method and system of charging equipment, equipment and a computer storage medium. The method comprises the following steps: monitoring network link data of the charging equipment, and obtaining an online data packet and an offline data packet of the charging equipment; constructing a message queue, and sending and storing the online data packet and the offline data packet to the message queue; analyzing the storage data of the message queue to obtain an offline time length; and if the offline duration of the charging equipment is greater than a preset alarm threshold value, judging that the charging equipment is in an offline state. The problem of real-time judgment of the offline state of the charging equipment is solved, the manual offline inspection cost is greatly saved, the online duration of the charging equipment is prolonged, and the operation income is increased.

Owner:深圳市小兔充充科技有限公司

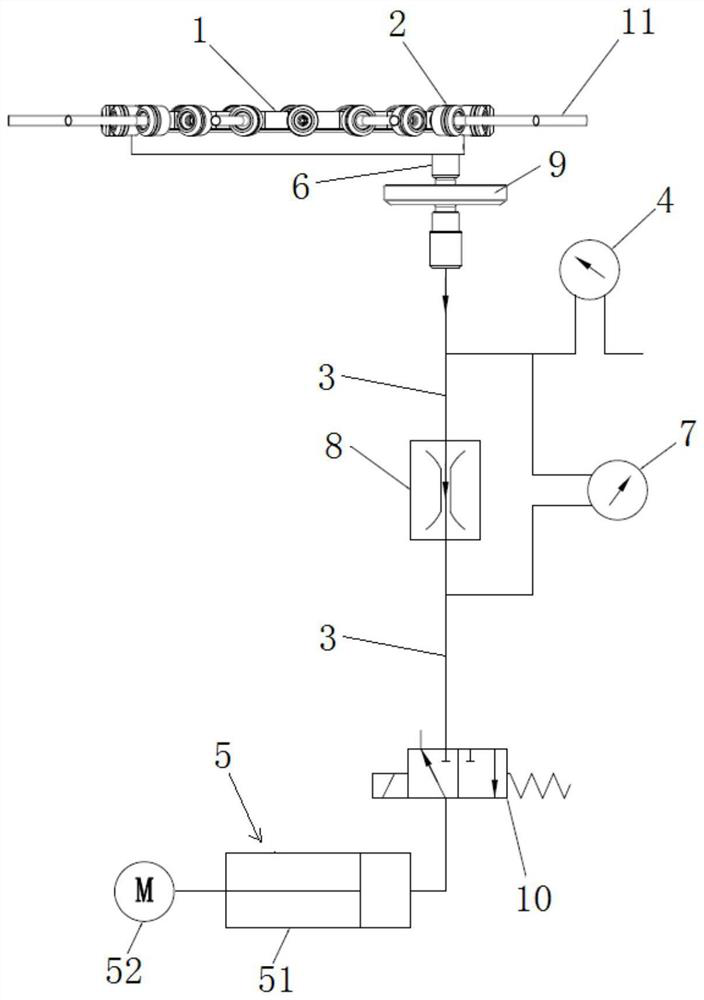

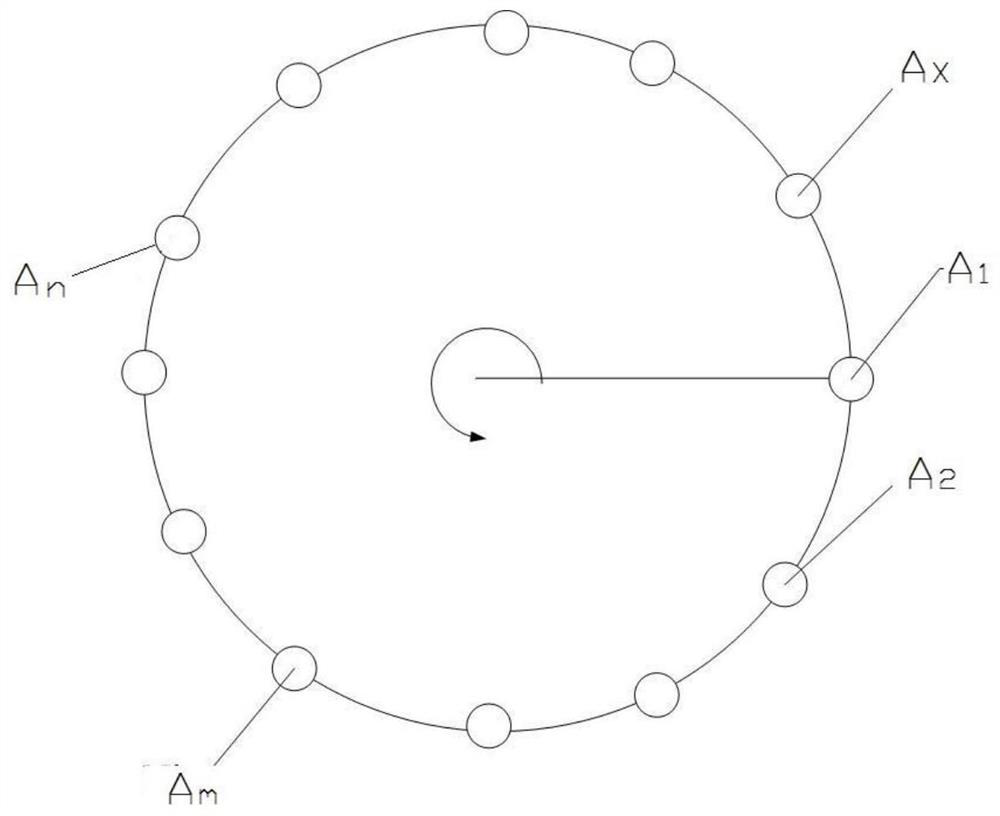

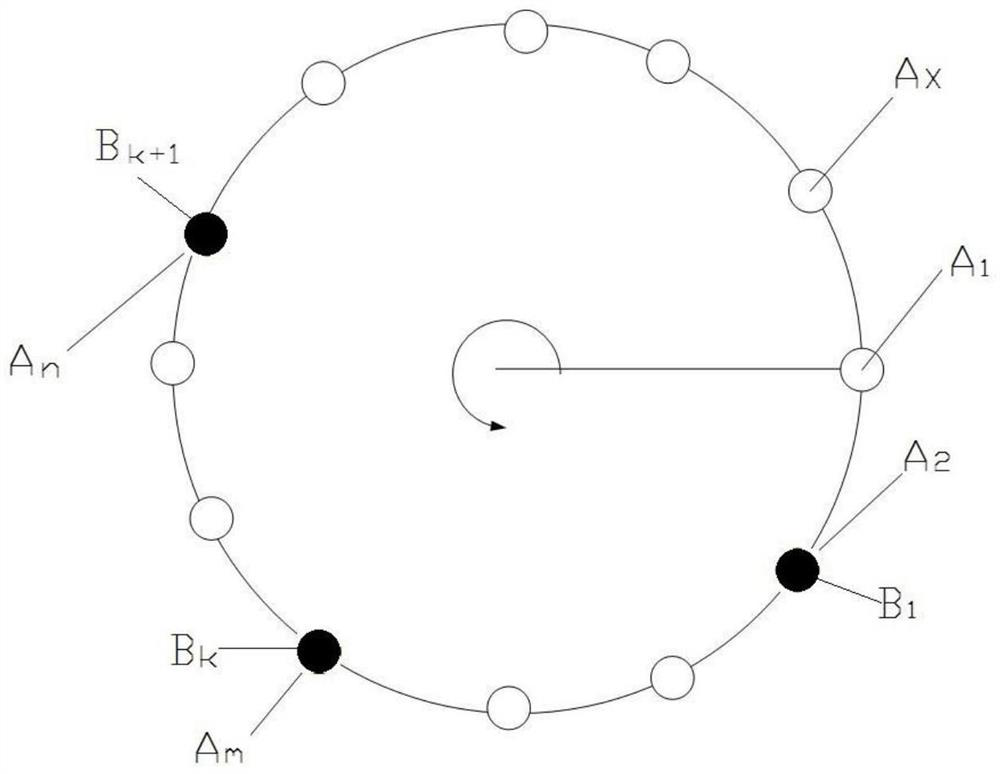

Cigarette dynamic suction resistance detection instrument and method thereof

ActiveCN112304803ASpeed up the testing processExtend online timeMaterial analysisEngineeringAnnular array

The invention relates to a cigarette dynamic suction resistance detection instrument and a method thereof, the cigarette dynamic suction resistance detection instrument comprises a turntable, a smokecirculating pipe, a first differential pressure sensor, a suction mechanism and a control processing system, the turntable is internally provided with X independent air passages, X is greater than orequal to 2, and the X independent air passages are arranged in an annular array along the circumferential direction of the turntable, one end opening of the air channel is a cigarette receiving opening used for being connected with a cigarette, the other end opening of the air channel is a butt joint opening formed in the lower end face of the rotary disc, the butt joint opening is used for beingin butt joint communication with the front end opening of the smoke circulation pipe, the front end opening of the smoke circulation pipe is provided with a sealing assembly in sealing contact with the lower end face of the rotary disc, the rear end of the flue gas circulation pipe is connected with the suction mechanism, and the first differential pressure sensor is used for detecting the differential pressure between the interior of the flue gas circulation pipe and the atmospheric pressure in real time; and the first differential pressure sensor and the suction mechanism are connected withthe control processing system. The cigarette dynamic suction resistance detection instrument can simultaneously detect the dynamic suction resistance of a plurality of cigarettes, and greatly accelerates the dynamic suction resistance detection process.

Owner:SHANGHAI TOBACCO GRP CO LTD

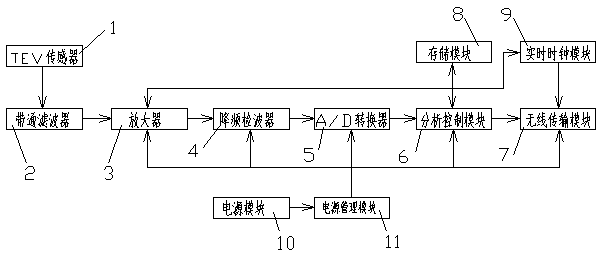

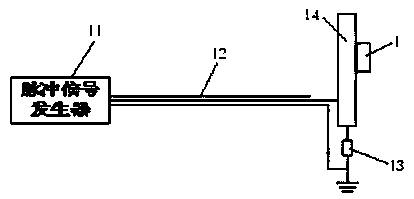

Ad-hoc network sensing device for earth wave of switch cabinet

PendingCN109884489AOvercoming the defects of discharge detectionExtend online timeTesting circuitsBand-pass filterMaterial resources

The invention discloses an ad-hoc network sensing device for an earth wave of a switch cabinet. The device comprises a transient earth voltage sensor, a band-pass filter, an amplifier, a down-frequency detector, an A / D converter, an analysis control module, a storage module, a wireless transmission module and a real-time clock module; the transient earth voltage sensor is used for detecting a partial discharge signal of the earth wave and outputting the partial discharge signal to the band-pass filter; the band-pass filter, the amplifier, the down-frequency detector and the A / D converter are connected in sequence and are used for transmitting a digital signal to the analysis control module, the analysis control module is used for extracting characteristic information of the partial discharge signal and preliminarily evaluating the insulation state of the switch cabinet, the storage module is used for storing the detection data, the wireless transmission module is used for transmittingthe detection data and receiving a control instruction issued by a monitoring terminal, and the real-time clock module is used for regularly starting the wireless transmission module to send the detection data. According to the device, the insulation state of the switch cabinet is preliminarily evaluated, manpower and material resources are saved, the detection efficiency is improved, and the subjectivity of manual detection is avoided.

Owner:SHANGHAI JINYI INSPECTION TECH

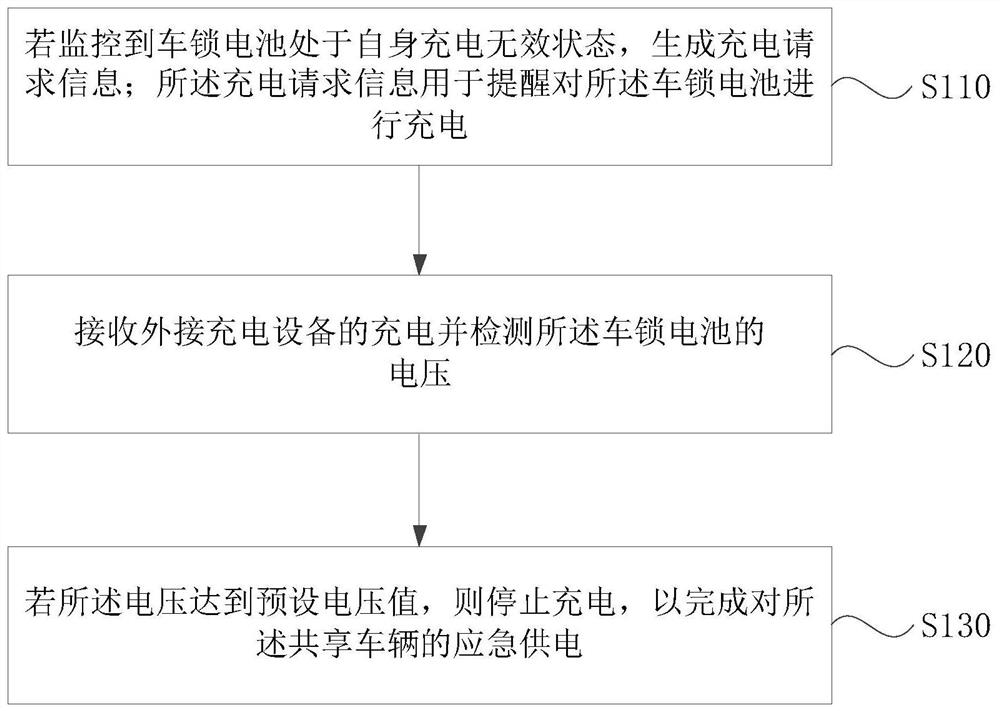

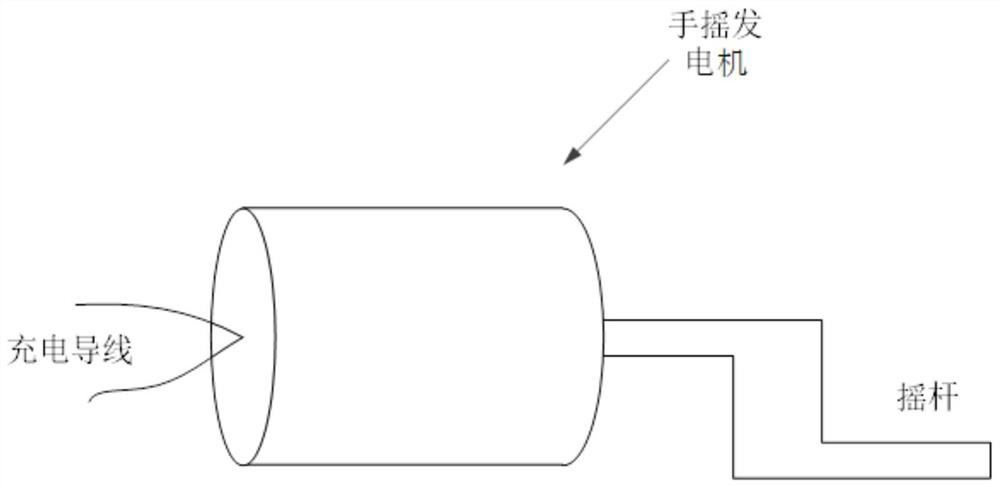

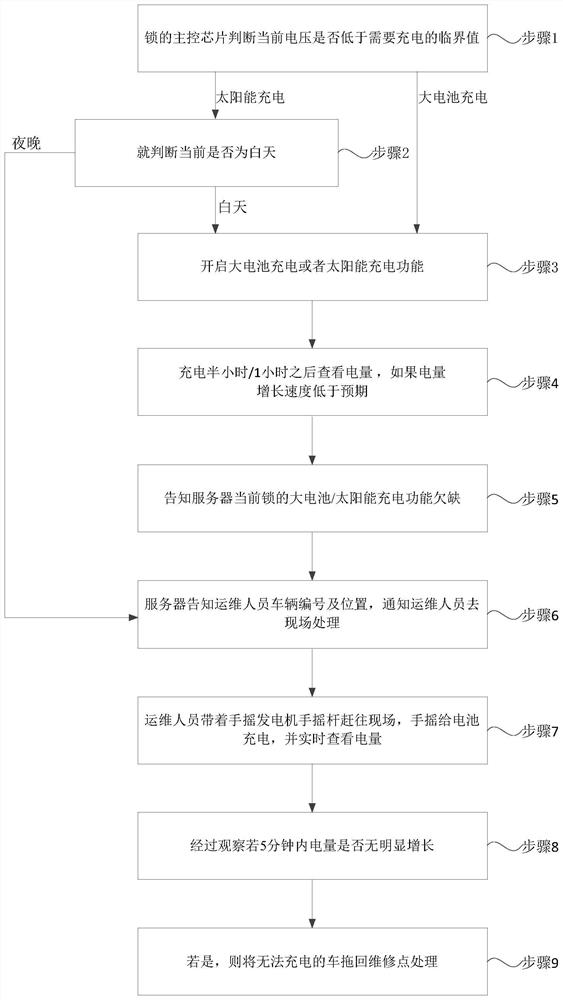

Emergency power supply method and device for shared vehicle, medium and electronic equipment

PendingCN111953045AExtend online timeShorten the timeCircuit monitoring/indicationDifferent batteries chargingEmbedded systemAutomotive engineering

The invention discloses an emergency power supply method and device for a shared vehicle, a medium and electronic equipment. The method comprises the steps: if it is monitored that a bicycle lock battery is in a self-charging invalid state, generating charging request information, wherein the charging request information is used for reminding a user to charge the bicycle lock battery; receiving the charging of external charging equipment, and detecting the voltage of the bicycle lock battery; if the voltage reaches a preset voltage value, stopping the charging, so as to complete the emergencypower supply for the shared vehicle. By adopting the scheme, operation and maintenance personnel can quickly charge the vehicle lock battery through the external charging equipment under the conditionthat the vehicle is out of power and is out of contact, so the vehicle can be registered and put into operation on the Internet as soon as possible, the time from the out-of-contact state to the put-into-operation state of the vehicle is greatly shortened, the online time of the vehicle is prolonged, and the income is increased.

Owner:SHANGHAI JUNZHENG NETWORK TECH CO LTD

Grinding method for controlling surface roughness of different rolls

ActiveCN103231289BReduce the frequency of roll changesExtend online timeRevolution surface grinding machinesNumerical controlSurface roughness

Owner:唐山瑞丰钢铁(集团)有限公司

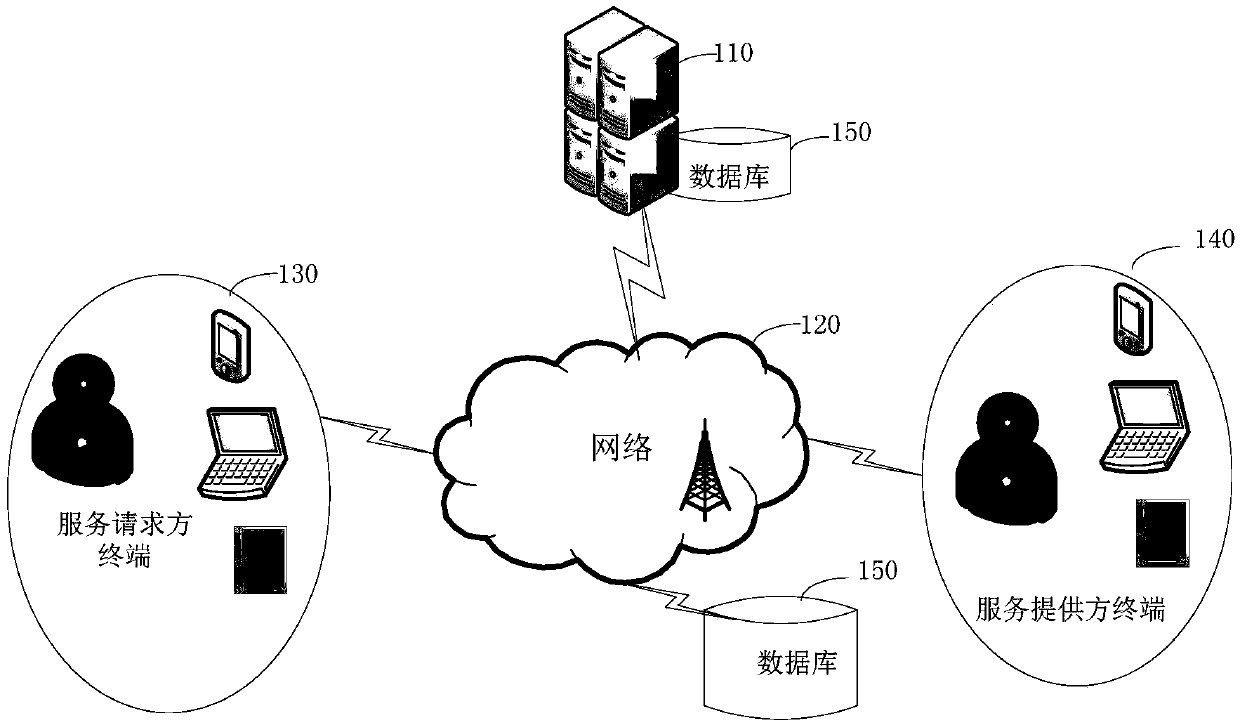

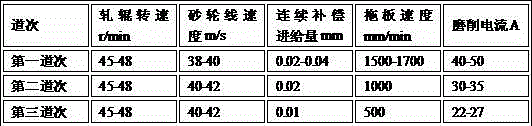

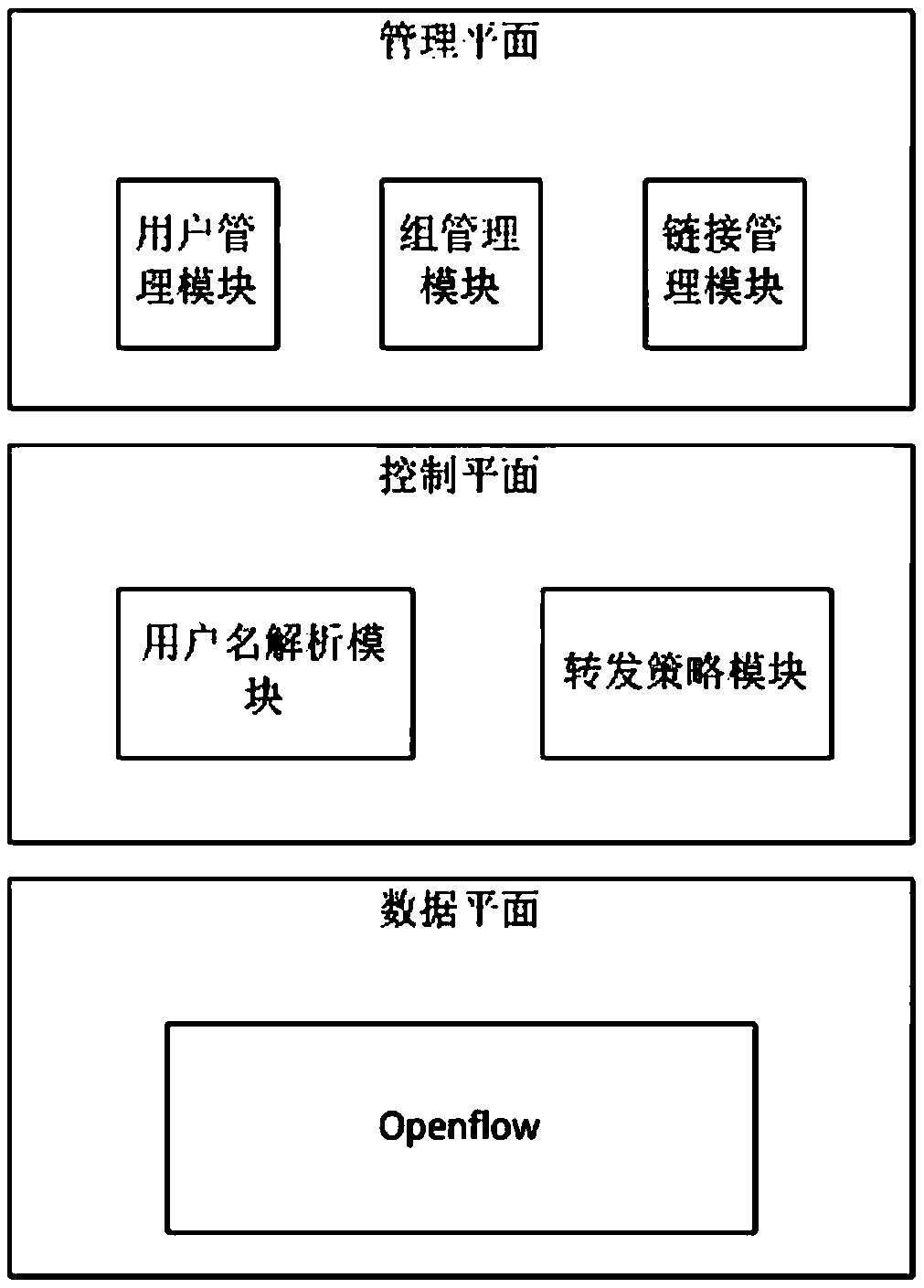

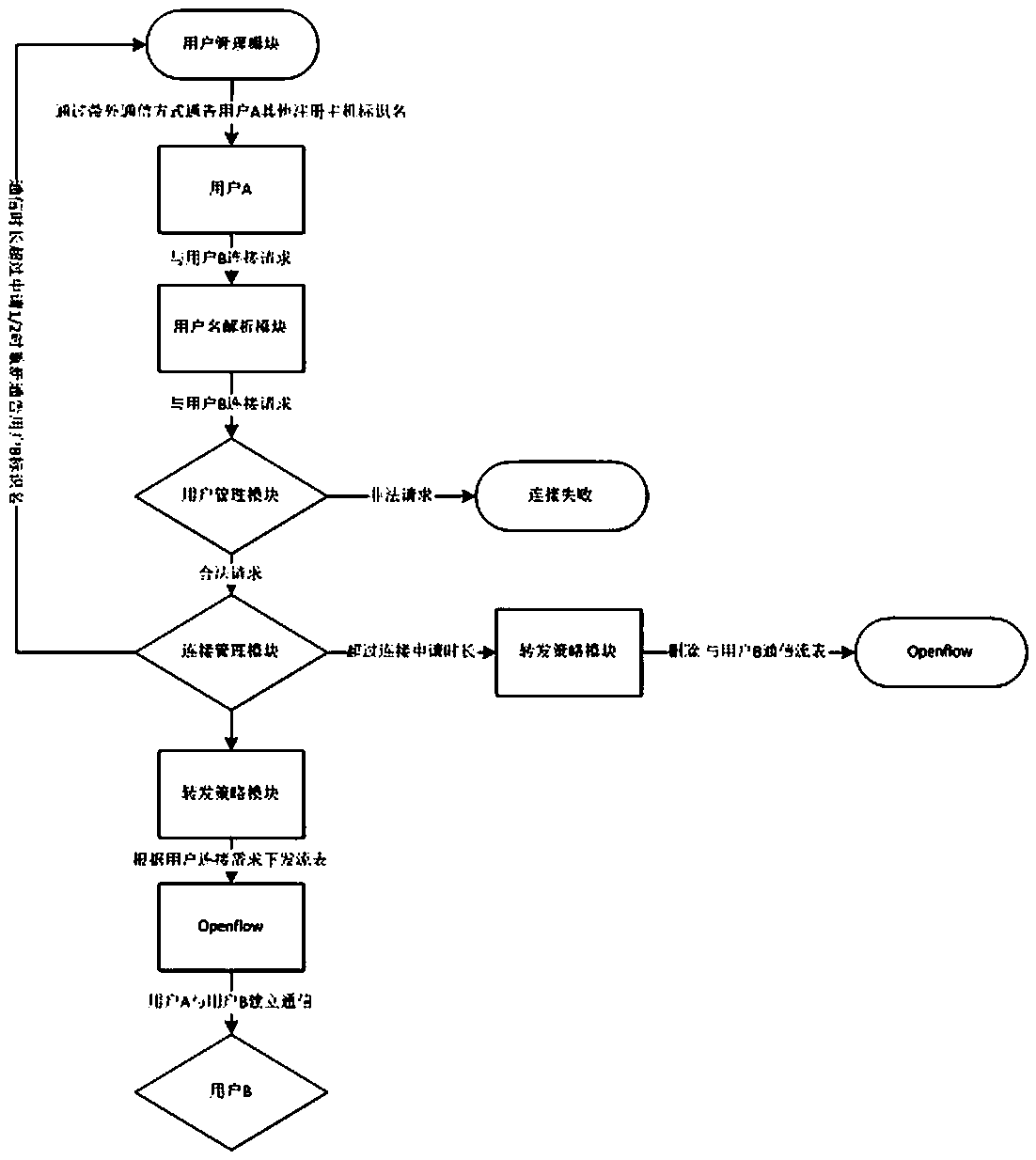

System and method for on-demand dynamic authentication and connection of users in local area network

The present invention relates to the field of computer networks, in particular to a system and method for dynamic authentication and connection of users in a local area network on demand, which consists of three planes, which are respectively a data plane, a control plane and a management plane, and the connection between the data plane and the control plane Through Openflow protocol communication, the control plane and management plane run in the operating system and interact through inter-process communication. Among them: the data plane includes an Openflow switch, which is responsible for data interaction with the control plane, according to the flow issued by the forwarding policy module The table performs data forwarding; the control plane includes a user name resolution module and a forwarding policy module; the management plane includes a user management module, a group management module and a connection management module. The invention solves the risk problem that the user host in the ordinary local area network is online for a long time and the network topology is basically unchanged, and an attacker can use this condition to attack and steal information.

Owner:ZHUHAI GAOLING INFORMATION TECH COLTD +1

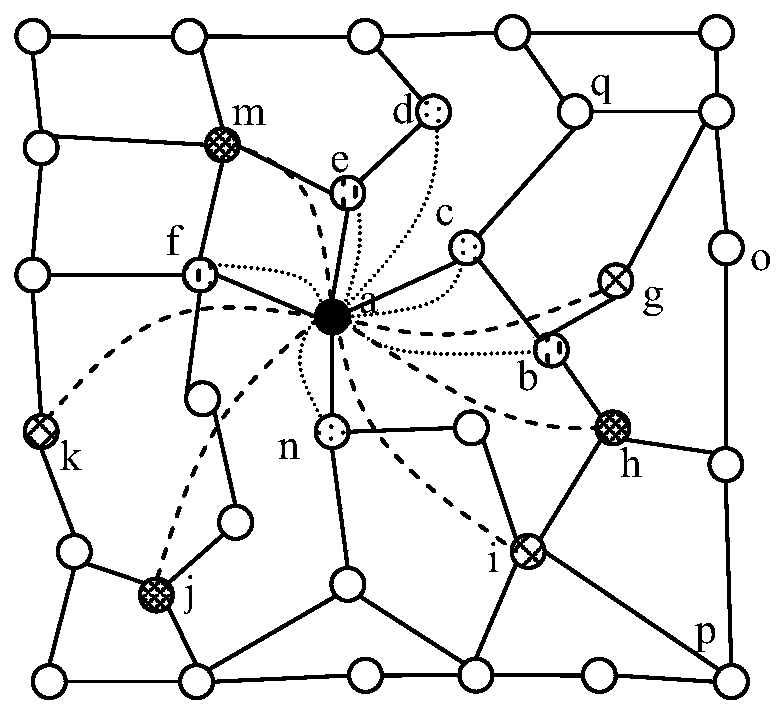

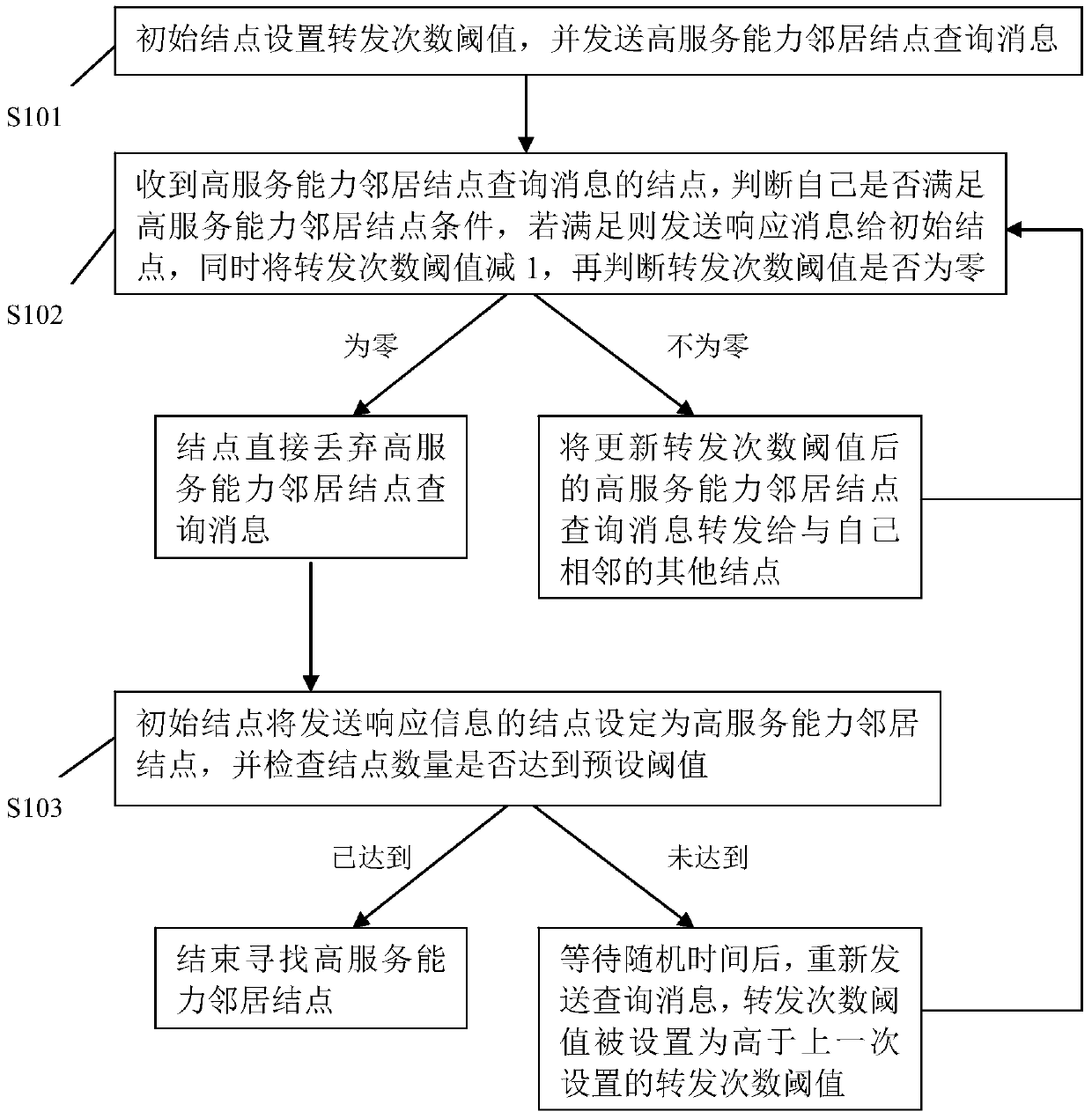

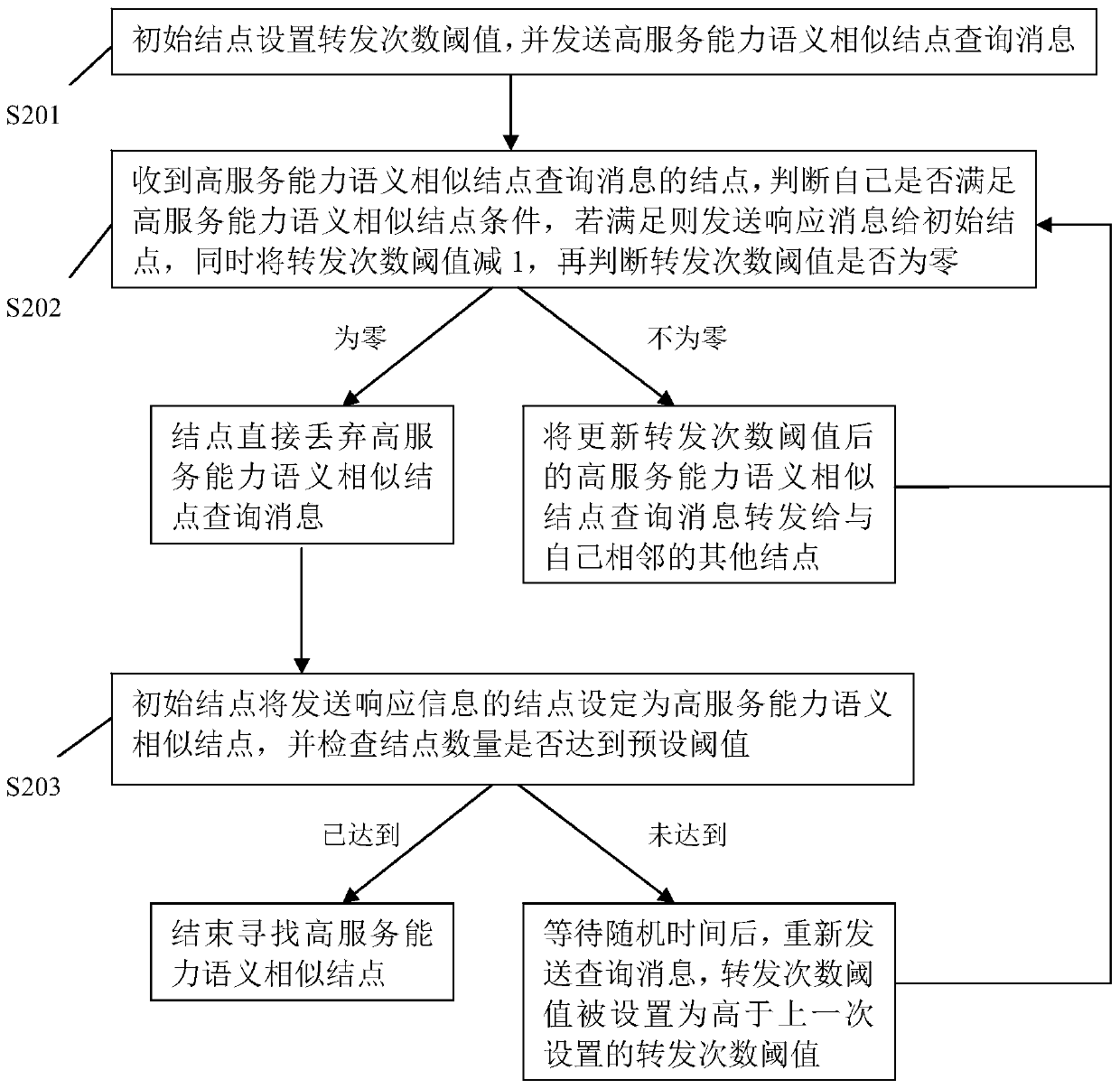

Peer-to-peer network based on differentiated service and resource positioning method

ActiveCN110149381AEfficient and convenient positioningClear topologyNetwork topologiesTransmissionBroadbandDifferentiated service

The invention discloses a peer-to-peer network based on differentiated services. According to different characteristics of parameters such as broadband speed, resource quantity, network distance, semantic similarity and online time length of nodes in the network, nodes in the peer-to-peer network form a high-quality node topological structure and a common node topological structure for maintenance; the service performance of the node is distinguished. When the method is applied to a huge and complex P2P peer-to-peer network, the technology can effectively integrate nodes in the network, so that the node topological structure in the network is clearer. The invention further discloses a resource positioning method based on the peer-to-peer network. Resource positioning services with different characteristics are provided for users according to different resource positioning requirements of the users, resource positioning is more efficient and convenient, and the resource positioning efficiency in the peer-to-peer network is greatly improved.

Owner:肇庆市华盈体育科技有限公司

A manufacturing method of graphite-containing high-speed steel centrifugal composite steel core roll

ActiveCN106282821BAnti-accident propertiesHas high wear resistanceRollsMetal rolling arrangementsBorideFully developed

The invention discloses a manufacturing method of a graphite-contained high-speed steel centrifugal composite steel core roller, and belongs to the field of mechanical casting. Chemical elements of B and N are introduced in a traditional high-speed steel component, MC type and / or M2C type dotted and / or blocky high-hard alloy carbides, nitrides and borides with the total area percentage of 20% to 35% are dispersed and distributed in a work layer base body structure; through carbide, nitride and boride modification, graphite is subject to two-step treatment of modification and inoculation, graphite is precipitated in an original structure, and therefore the high-speed steel roller has the advantages of the specific high-temperature wear resisting of traditional high-speed steel and meanwhile the problem that an original traditional high-speed steel roller is large in friction coefficient is solved; wear-resisting performance of the high-speed steel is fully developed, the lubricating effect between the roller and a workpiece in the rolling process is achieved, and happening of the steel bonding phenomenon is avoided; due to the heat conduction performance and the lubricating characteristic of graphite, the defects that the high-speed steel roller is sensitive to hot impact and hot-cracking susceptibility, steel bonding is prone to happening, and surface roughing is prone to happening can be overcome, and particularly when a finished product rack is used, the surface bright degree of a rolled material is obviously improved.

Owner:SANXIN HEAVY IND MACHINERY

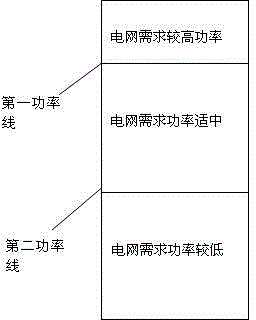

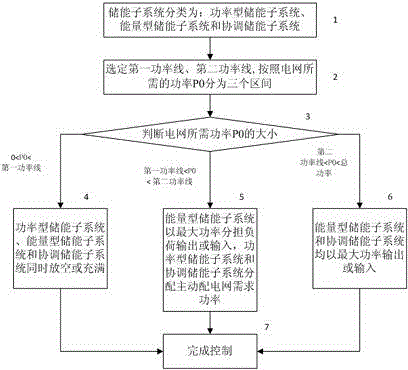

Battery energy storage system and control method taking into account both energy type and power type

ActiveCN103580291BLess investmentEasy to implementElectrical storage systemFlexible AC transmissionBattery storage power stationPower station

The invention discloses a battery energy storage system integrating energy type and power type. The system comprises a power grid bus, as well as a coordination type energy storage subsystem, a power type energy storage subsystem and an energy type energy storage subsystem which are connected with a power grid bus in parallel, wherein the coordination type energy storage subsystem, the power type energy storage subsystem and the energy type energy storage subsystem are respectively connected with bidirectional inverters in series and respectively connected with the power grid bus through the circuits of the bidirectional inverters. The system manages proportions of complex energy storage allocated by the power interval of a power grid, is classified into the power type, the coordination type and energy type energy storage subsystems, realizes that a whole energy storage power station meets the requirement of the power grid through power allocation when the power requirement change of the power grid is met within a large range, respectively gives the advantages of power type batteries, coordination type batteries and energy type batteries into full play and complements the disadvantages of the batteries, realizes the performance optimization, is simple and flexible, and easy to realize, reduces the equipment investment, improves the equipment utilization ratio, and has good economic benefits.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

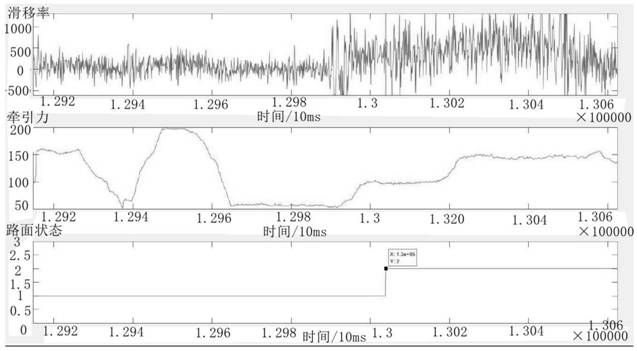

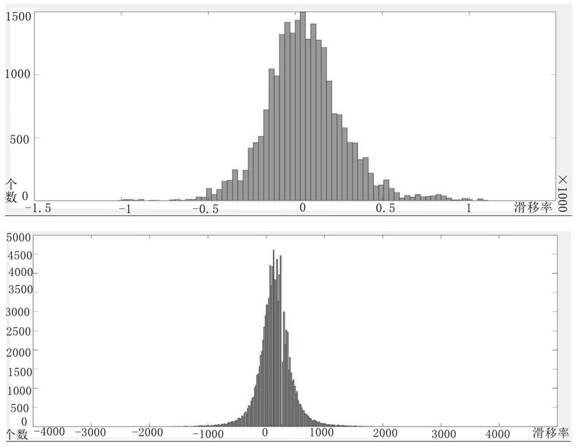

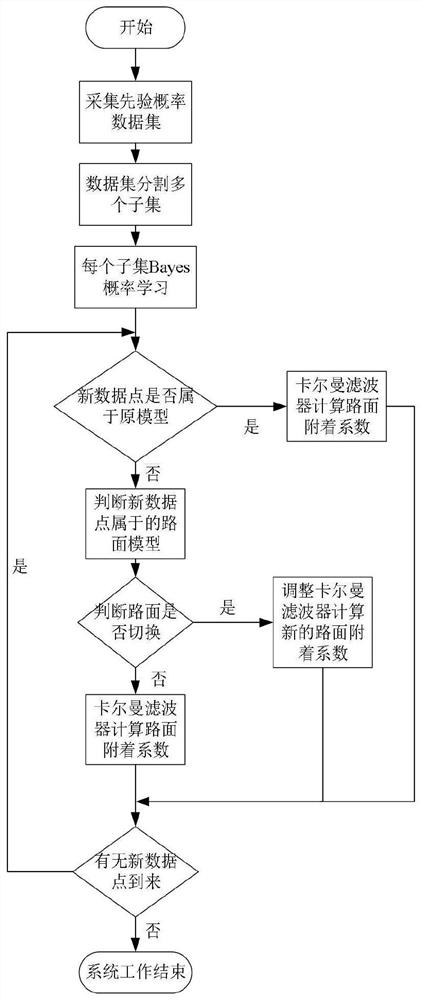

Pavement adhesion coefficient estimation method based on Bayes classifier

ActiveCN113619587ADistributed focusIncrease credibilityCharacter and pattern recognitionEngineeringRoad surface

The invention discloses a pavement adhesion coefficient estimation method based on a Bayes classifier, and the method is based on the theory of the Bayes classifier and comprises the steps of determining the attribution of a road model through a data point set of the traction force of a certain side and the slip rate of an automobile during the driving of the automobile, dividing the collected overall data point set into a plurality of data subsets according to the traction force range, analyzing the newly collected data points, obtaining the prior probability of the data points, calculating the posterior probability of the data points, determining the attribution of the road model, and accurately calculating the adhesion coefficient of the road model according to the new road model. Through the above mode, by learning the prior probability of the Bayes subset, when a real-time data point arrives, the posterior probability of each traction subset interval is calculated, the road surface switching time can be calculated through the method, and the point set affiliation result after road surface switching can be obtained, so that the affiliation of the road model is determined; and the adhesion coefficient of the pavement model is obtained.

Owner:赵超超

Method, device, server and storage medium for determining live freeze factors

The embodiment of the invention discloses a method, a device, a server and a storage medium for determining live freeze factors. Wherein, the method includes: obtaining at least two stall notification information, and obtaining line attribute information of the stall line respectively corresponding to each of the stall notification information, and the line attribute information includes at least two line parameters; according to a or a plurality of line parameters included in the line attribute information, update the stuck weight of at least one edge in the directed dendrogram corresponding to the stuck line, wherein each node in the directed dendrogram is related to the stuck line Corresponding to each line parameter in the line; in the updated at least one directed dendrogram, search for a target weight path that satisfies the freeze weight condition, and determine the live freeze according to each node included in the target weight path factor. The embodiment of the present invention can quickly and accurately locate the factors that cause live broadcast stuttering.

Owner:GUANGZHOU HUYA INFORMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com