Quenching boiler provided with enhanced heat transfer member

A quenching boiler and enhanced heat transfer technology, applied in heat transfer modification, non-catalytic thermal cracking, cracking, etc., can solve the problems of difficult processing and manufacturing, high cost and other problems, and achieve the extension of online time, improve life, and extend online time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment is to use the same bathtub type quenching boiler as Comparative Example 1, and a cracking furnace with an ethylene production capacity of 100,000 tons / year is equipped with the quenching boiler of the present invention. Its dimensions and parameters are shown in Table 1, and the process parameters are shown in Table 1. Table 2. The raw material of cracking furnace is HVGO.

[0048] Table 2 Process Parameters of Quenching Boiler

[0049]

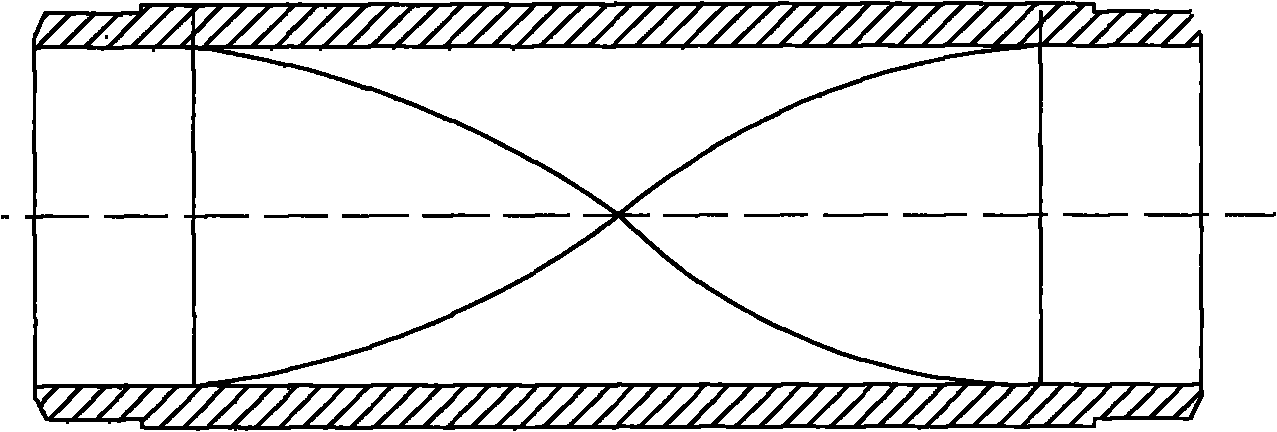

[0050] according to Figure 4 The temperature change curve of the bathtub-type quenching boiler shown in , and the tube-side pyrolysis gas flow, pressure and temperature are calculated to obtain the temperature value when the shell-side high-pressure water vaporizes at 5%, and the tube-side cracking gas flow corresponding to this temperature is calculated in the tube of the quenching boiler. According to the cracking gas flow rate, pressure and temperature, the linear velocity of the cracking gas flow can be obtaine...

Embodiment 2

[0059] The present embodiment is a cracking furnace with an ethylene production capacity of 100,000 tons / year, equipped with a bathtub-type quenching boiler of the present invention, its dimensions and parameters are shown in Table 3, and its process parameters are shown in Table 4. The raw material of cracking furnace is NAP.

[0060] according to Figure 4 The temperature change curve shown in , and the tube-side gas flow, pressure and temperature can be calculated to obtain the temperature value when the shell-side high-pressure water is vaporized at 5%, and the residence time of the tube-side cracking gas flow in the tube-side of the quenching boiler is calculated at this temperature, Therefore, it can be calculated according to the linear velocity of the airflow that the vaporization rate of the shell-side high-pressure water is 5% at a distance of about 90D from the tube-side inlet. Considering the reasons of coke cleaning and easy operation, the twisted sheet tube is set...

Embodiment 3

[0066] This embodiment is a cracking furnace with an ethylene production capacity of 100,000 tons / year, and the bath-type quenching boiler it is equipped with is the quenching boiler of the present invention, its dimensions and parameters are shown in Table 5, and its process parameters are shown in Table 6. The raw material of cracking furnace is NAP.

[0067] according to Figure 4 The temperature change curve of the bathtub-type quenching boiler shown in can obtain the residence time of the tube-side airflow in the tube-side of the quenching boiler at 520°C, so that the position can be calculated according to the linear velocity of the tube-side airflow. It can be seen that the fluid temperature in the tube is about 520°C at a distance of about 115D from the entrance of the tube, and the twisted sheet tube is set at a distance of 1600mm from the entrance of the tube in consideration of coke cleaning and convenient operation.

[0068] Compared with Comparative Example 2, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com