Hydrogenation method for producing aromatics extraction raw material

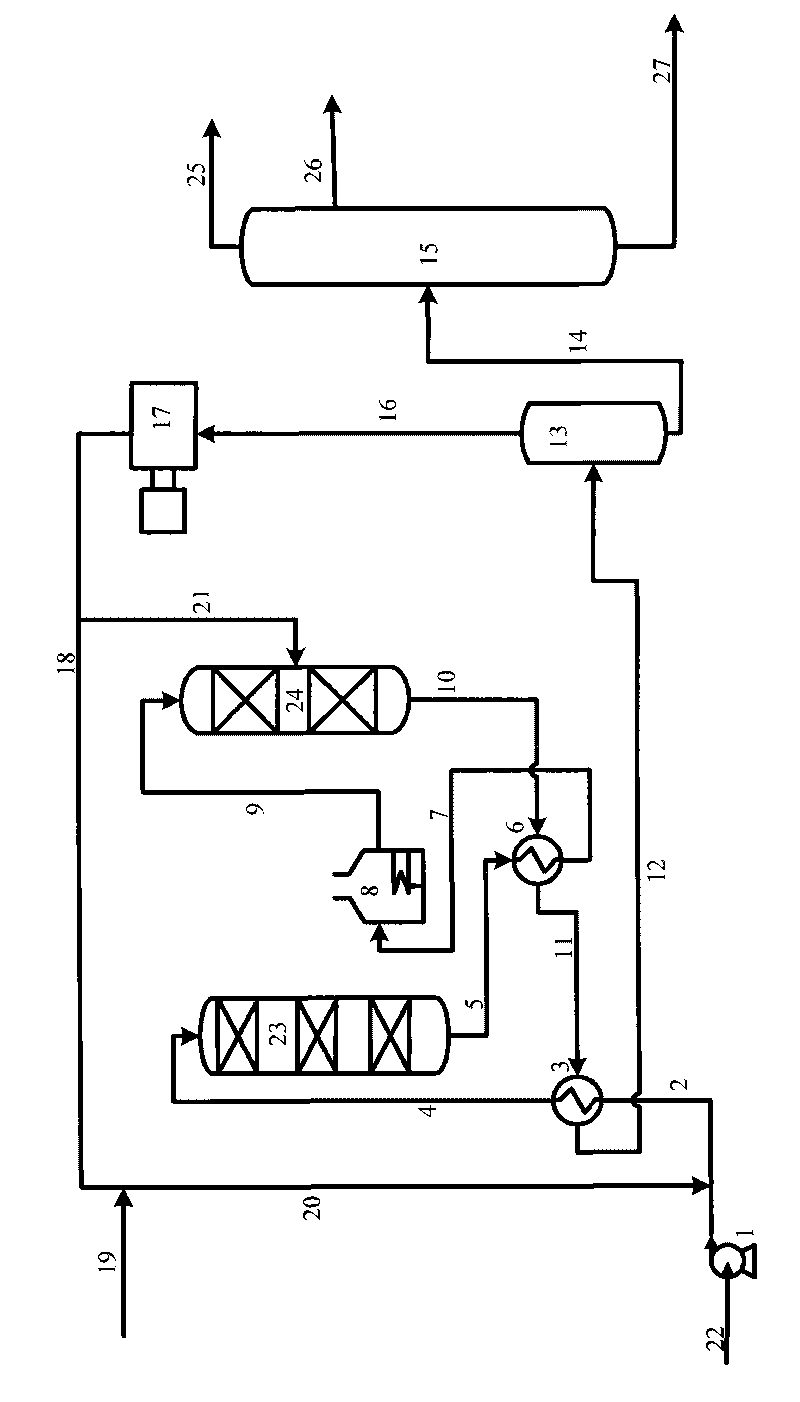

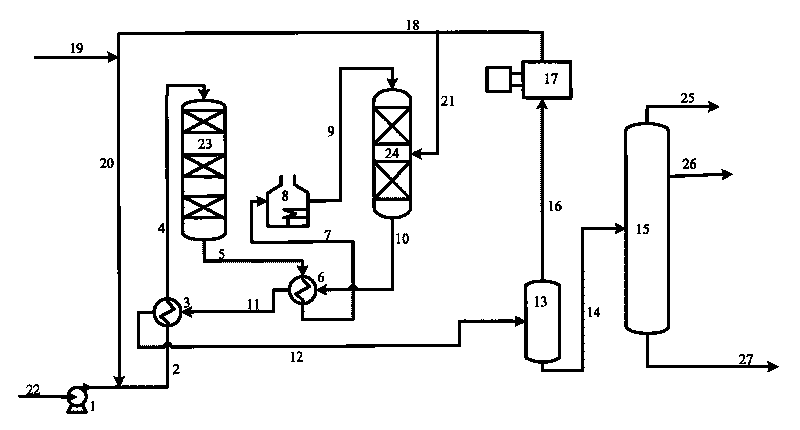

A technology for aromatics extraction and raw materials, which is applied in the field of hydrogenation for processing high-diene gasoline fractions. It can solve the problems of gasoline fraction instability, reactor pressure drop rise, and high sulfur and nitrogen content, and achieve stable long-term operation and delay the top Effects of coking and prolonging the operating cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A catalytic cracking gasoline is used as raw material A, and the properties are shown in Table 1. Feed oil A and hydrogen into the first reactor (one reverse) and sequentially contact with the hydrogenation protection agents A, B, and C to remove diolefins at 180°C, and the reaction effluent is in the second reactor (two reverse) After contacting with the hydrofining preparation RS-1, the hydrofining reaction is carried out at 300°C. The reaction effluent is cooled and separated and then enters the stabilization tower, and the final liquid phase product is obtained from the stabilization tower bottom. Based on the overall catalyst of the first reactor, the filling volume percentages of the hydrogenation protection agent A, the hydrogenation protection agent B and the hydrogenation protection agent C are 20 volume %, 40 volume% and 40 volume% respectively. The hydrogenation process conditions and product properties are shown in Table 2.

[0040] It can be seen from Table 2...

Embodiment 2

[0042] Using a catalytic cracking gasoline as raw material B, the properties are shown in Table 1. Feed oil A and hydrogen into the first reactor (one reverse) and sequentially contact with the hydrogenation protective agents A, B, and C to remove diolefins at 160°C, and the reaction effluent is in the second reactor (two reverse) After contacting with the hydrofining preparation RS-1, the hydrofining reaction is carried out at 310°C. The reaction effluent enters the stabilization tower after cooling and separation, and the final liquid phase product is obtained from the stabilization tower bottom. Based on the overall catalyst of the first reactor, the filling volume percentages of the hydrogenation protection agent A, the hydrogenation protection agent B, and the hydrogenation protection agent C are 18 vol%, 36 vol% and 46 vol%, respectively. The hydrogenation process conditions and product properties are shown in Table 2.

[0043] The hydrogenation process conditions and prod...

Embodiment 3

[0047] The raw materials are the same as those used in Example 1, and the properties are shown in Table 1. The process flow and process conditions are the same as in Example 1. The device has been operated for a long time, and the stability of the device has been investigated. The results are shown in Table 3. It can be seen from Table 3 that the laboratory device still has no pressure difference after 1500h of stable operation, indicating that the method provided by this patent can process high diene worth gasoline raw materials and still ensure the long-term stable operation of the device.

[0048] Table 1

[0049] raw material name

[0050] Table 2

[0051] Process conditions

[0052] Process conditions

[0053] table 3

[0054] Process conditions

[0055] Process conditions

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com