Patents

Literature

52 results about "Bromine number" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

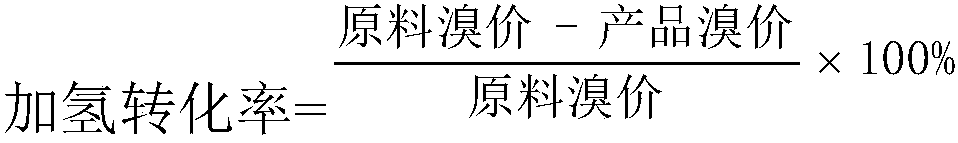

Bromine number is the amount of bromine in grams absorbed by 100 grams (3.5 oz) of a sample. The number indicates the degree of unsaturation. The Bromine Number is useful as a measure of aliphatic unsaturation in gasoline samples. The California ARB, in its Motor Vehicle Fuels Compliance Assistance Program, indicated that every unit of Bromine Number is equivalent to twice the percentage point of olefin content in gasoline. So, a gasoline with Bromine Number 30 would have an olefin content of not more than 15 vol%. One refinery compiled a year's worth of data on Bromine Number and the corresponding olefin content of gasoline. The data showed that the Bromine Number of gasoline is about 2.4 times the olefin content. A gasoline with Bromine Number of 30 would then have an olefin content of about 12.5 percent by volume, which is slightly lower than ARB's assumption, but still is higher than the CaRFG maximum limit of 10 percent by volume.

Polyalpha-Olefin Compositions and Processes to Produce the Same

ActiveUS20090005279A1Hydrocarbon by hydrogenationHydrocarbons from unsaturated hydrocarbon additionBromine numberPolymer science

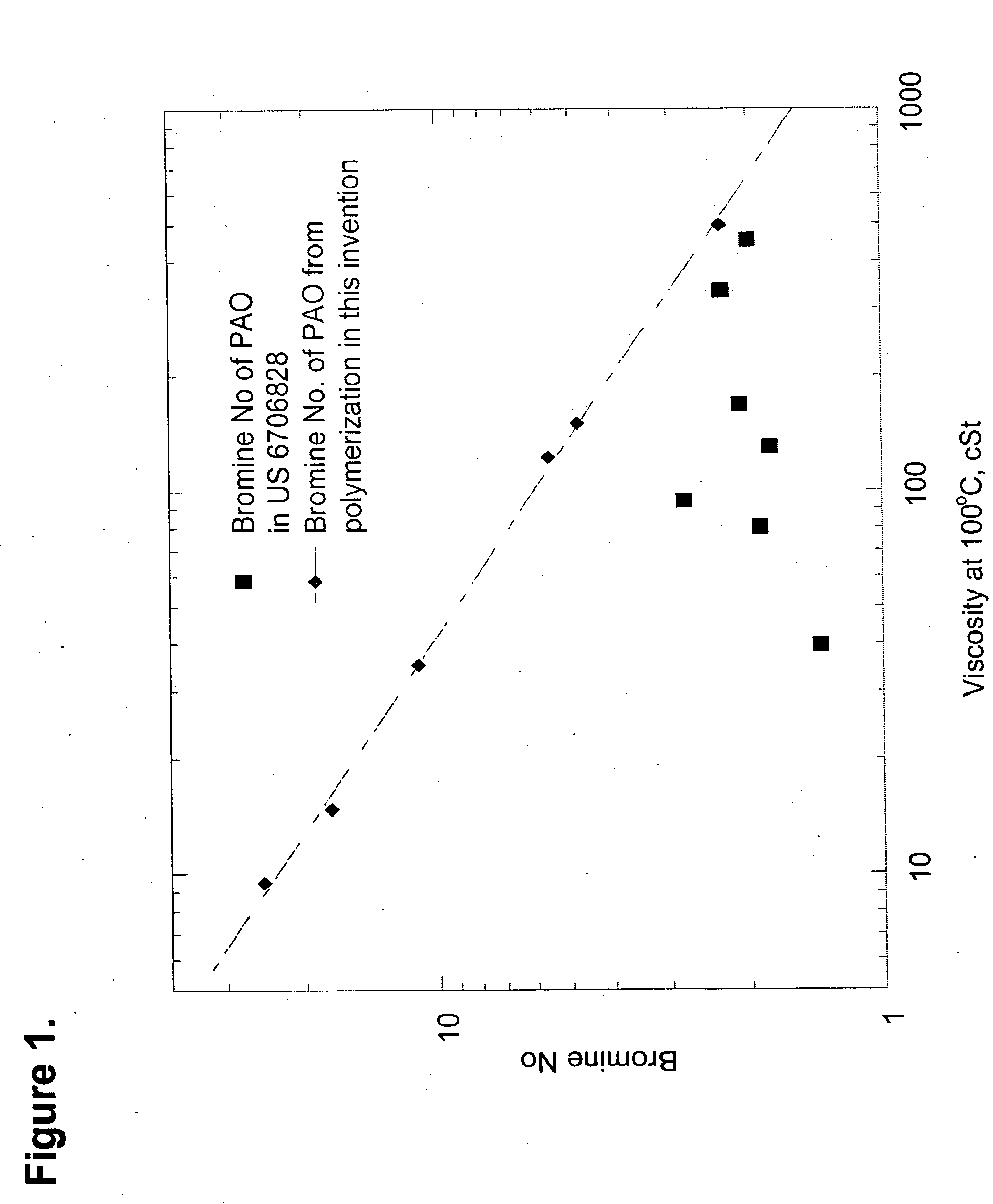

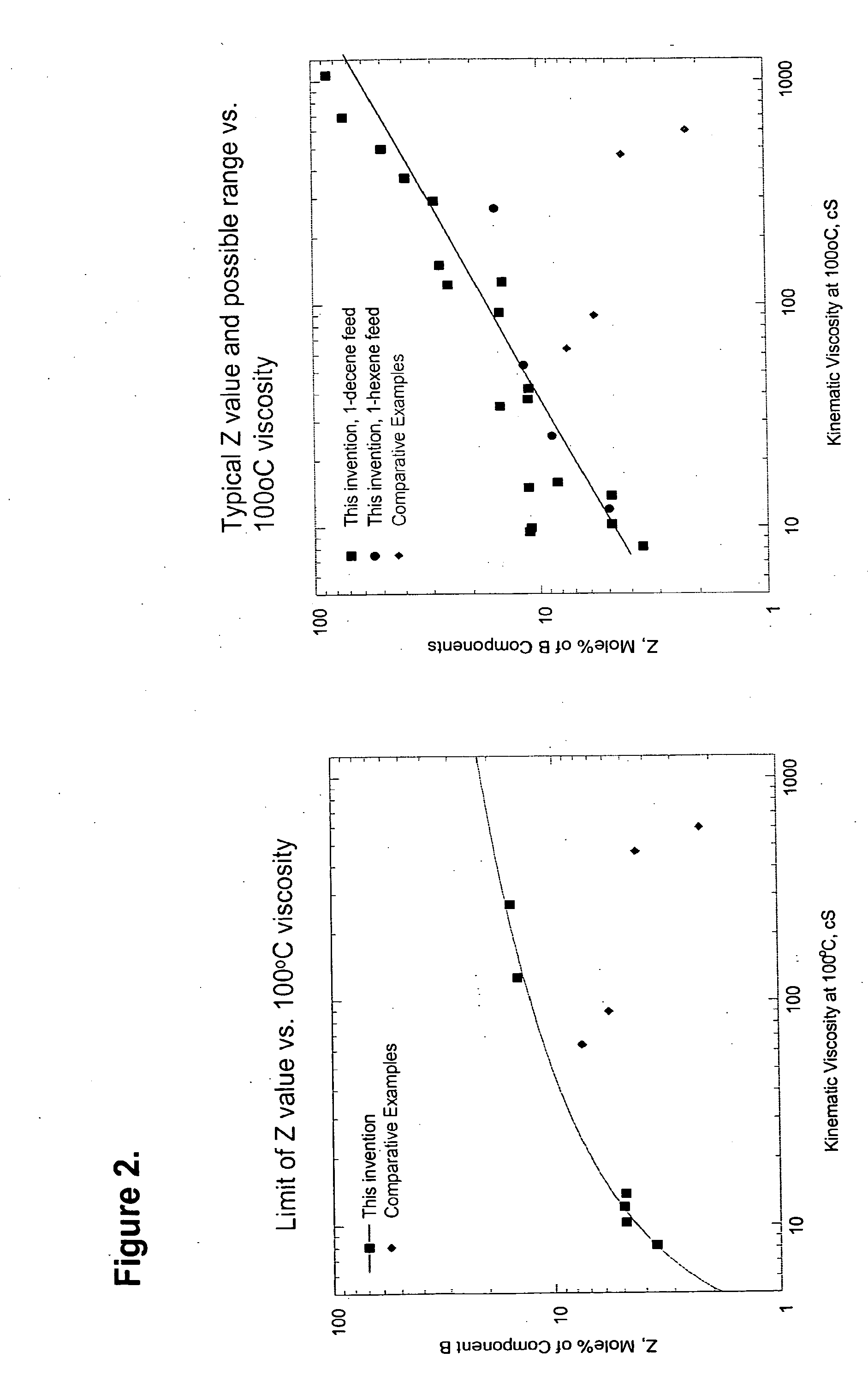

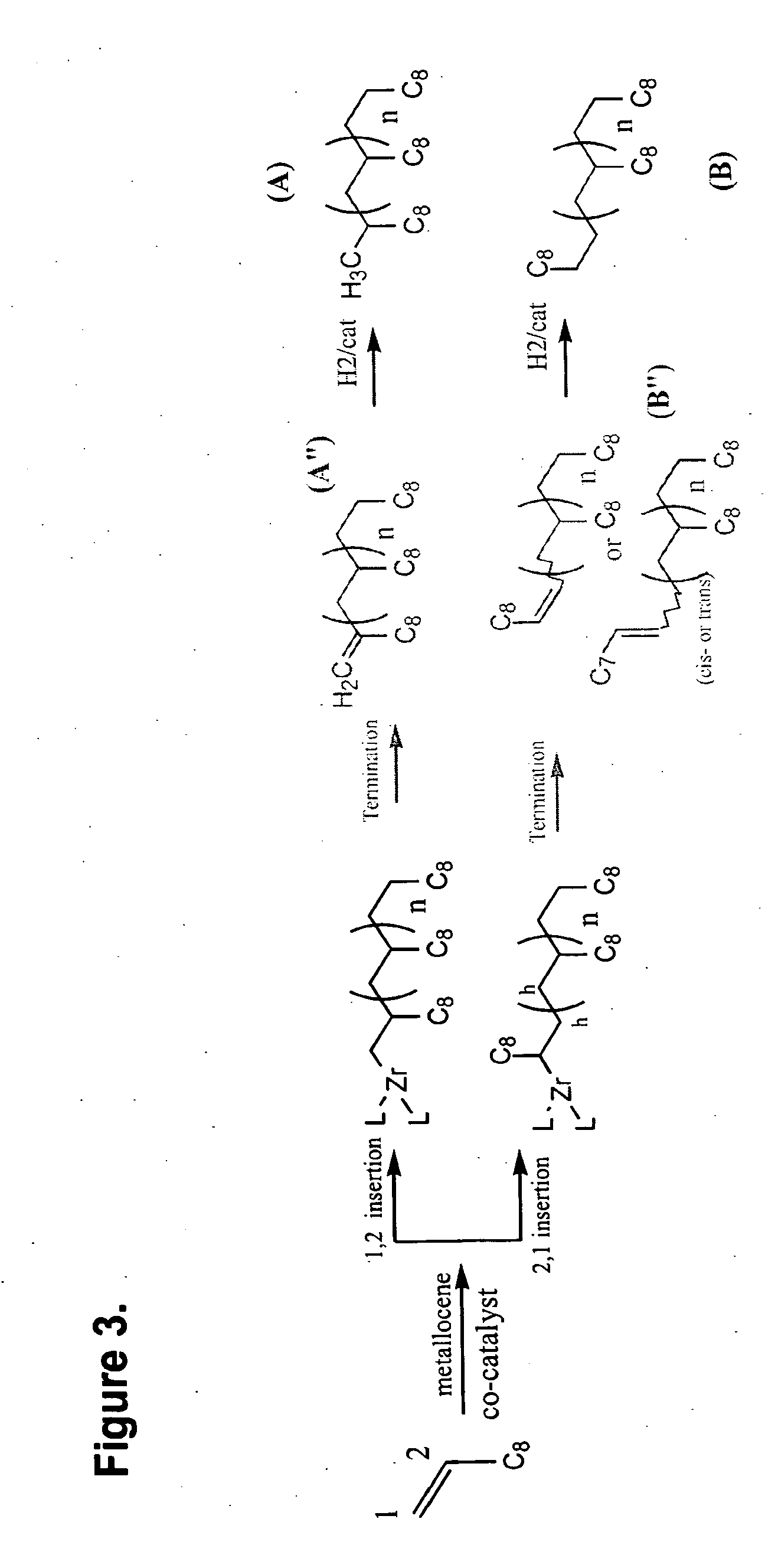

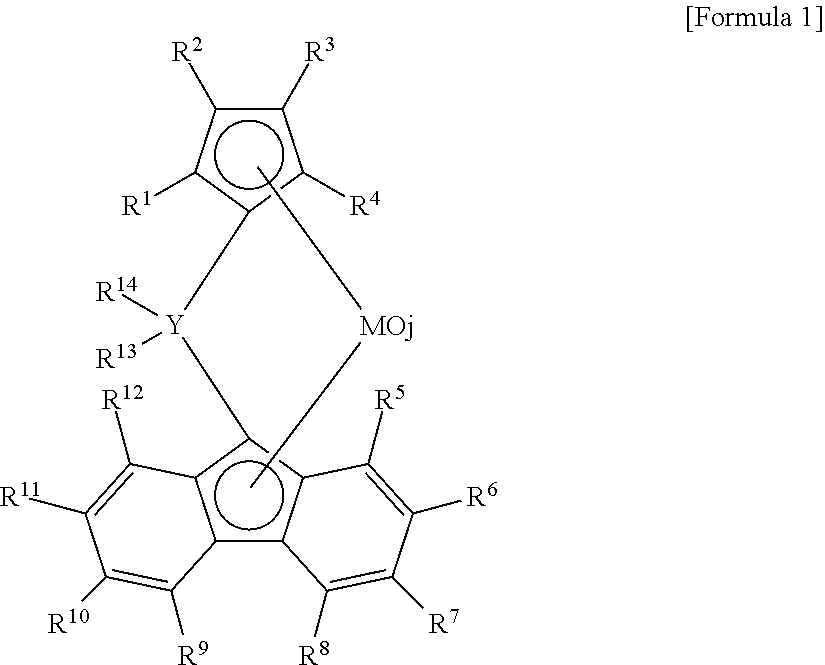

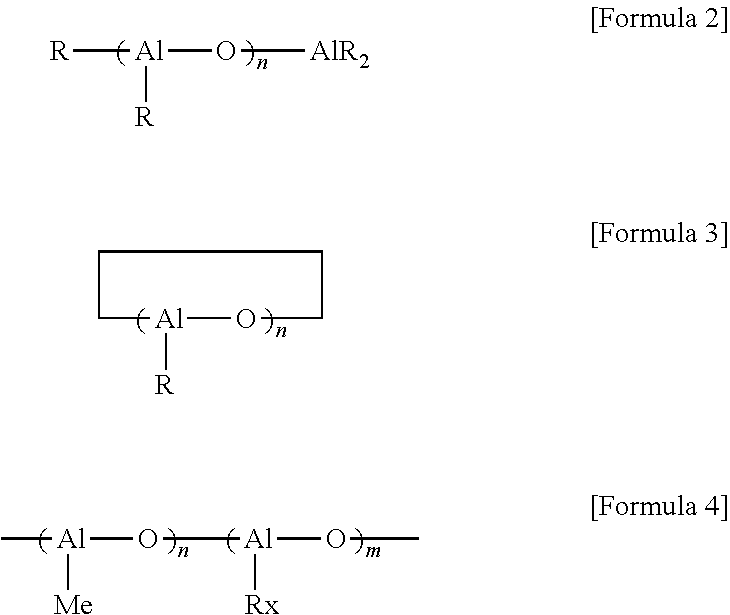

This invention relates to a polyalpha-olefin (and hydrogenated analogs thereof) comprising more than 50 mole % of one or more C5 to C24 alpha-olefin monomers where the polyalpha-olefin has: a) 40 mole % or more of mm triads, b) a Bromine number of Y or greater, where Y is equal to 89.92*(V)′°5863, where V is the Kinematic Viscosity of the polyalpha-olefin measured at 100° C. in cSt, and c) 1,2 disubstituted olefins present at 7 mole % or more, preferably having Z mole % or more of units represented by the formula: where j, k and m are each, independently, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21, or 22, n is an integer from 1 to 350, and where Z=8.420*Log(V)−4.048, where V is the kinematic viscosity of the polyalpha-olefin measured at 1000 C in cSt This invention also relates to process to produce such polyalpha-olefins.

Owner:EXXONMOBIL CHEM PAT INC

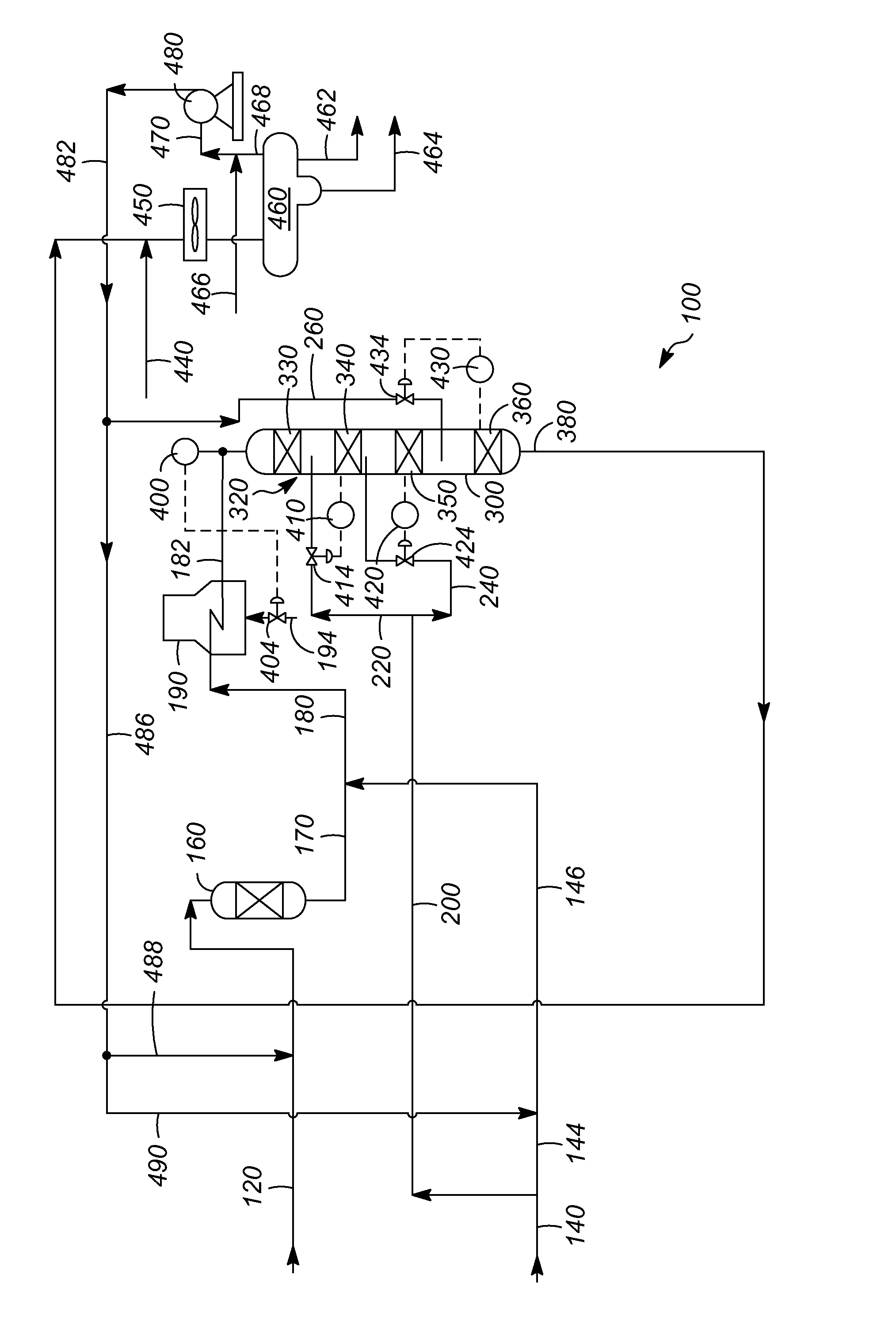

Hydrotreating process and controlling a temperature thereof

ActiveUS20120273394A1Reduce the amount requiredTreatment with hydrotreatment processesRefining by selective hydrogenationBromine numberNaphtha

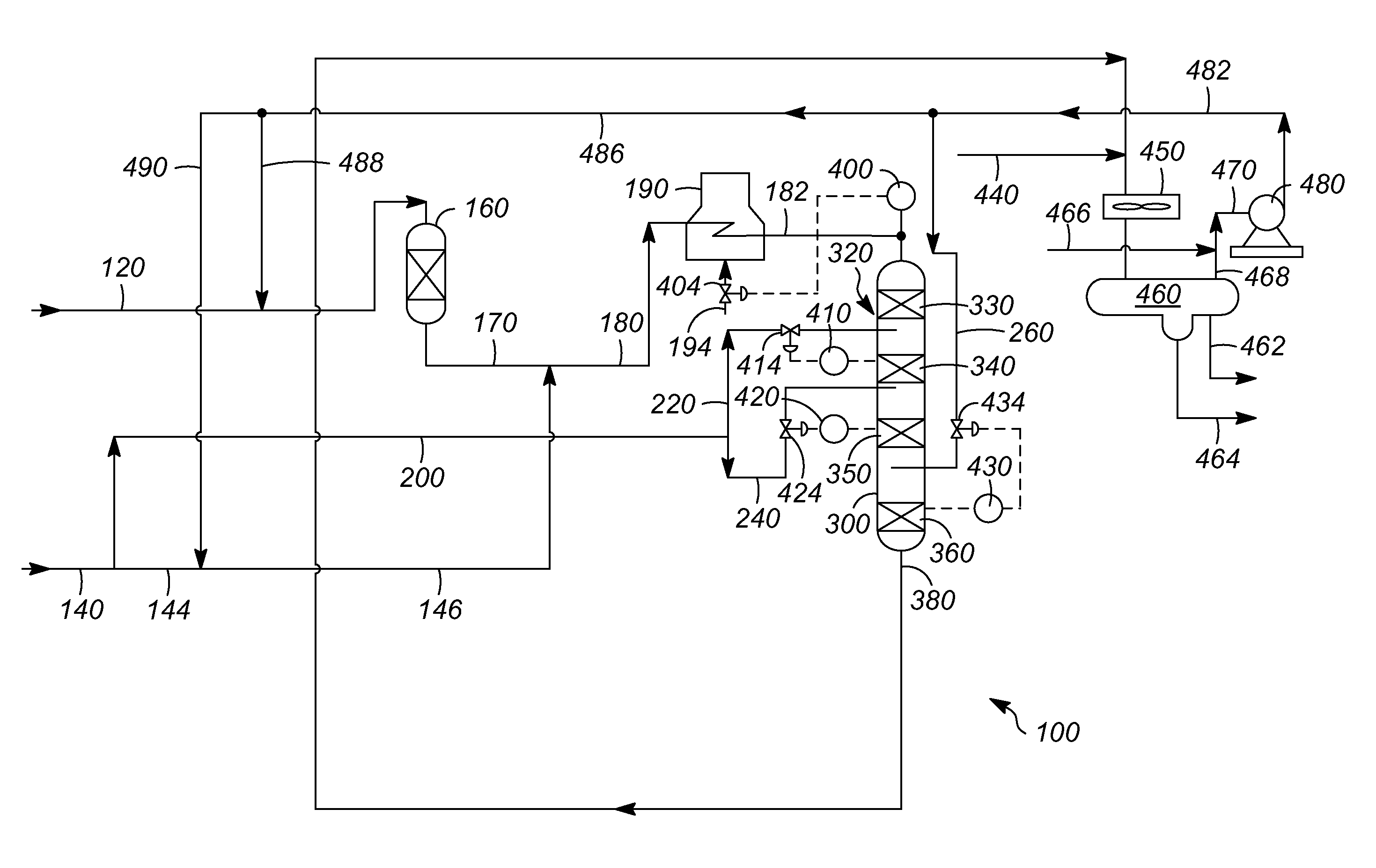

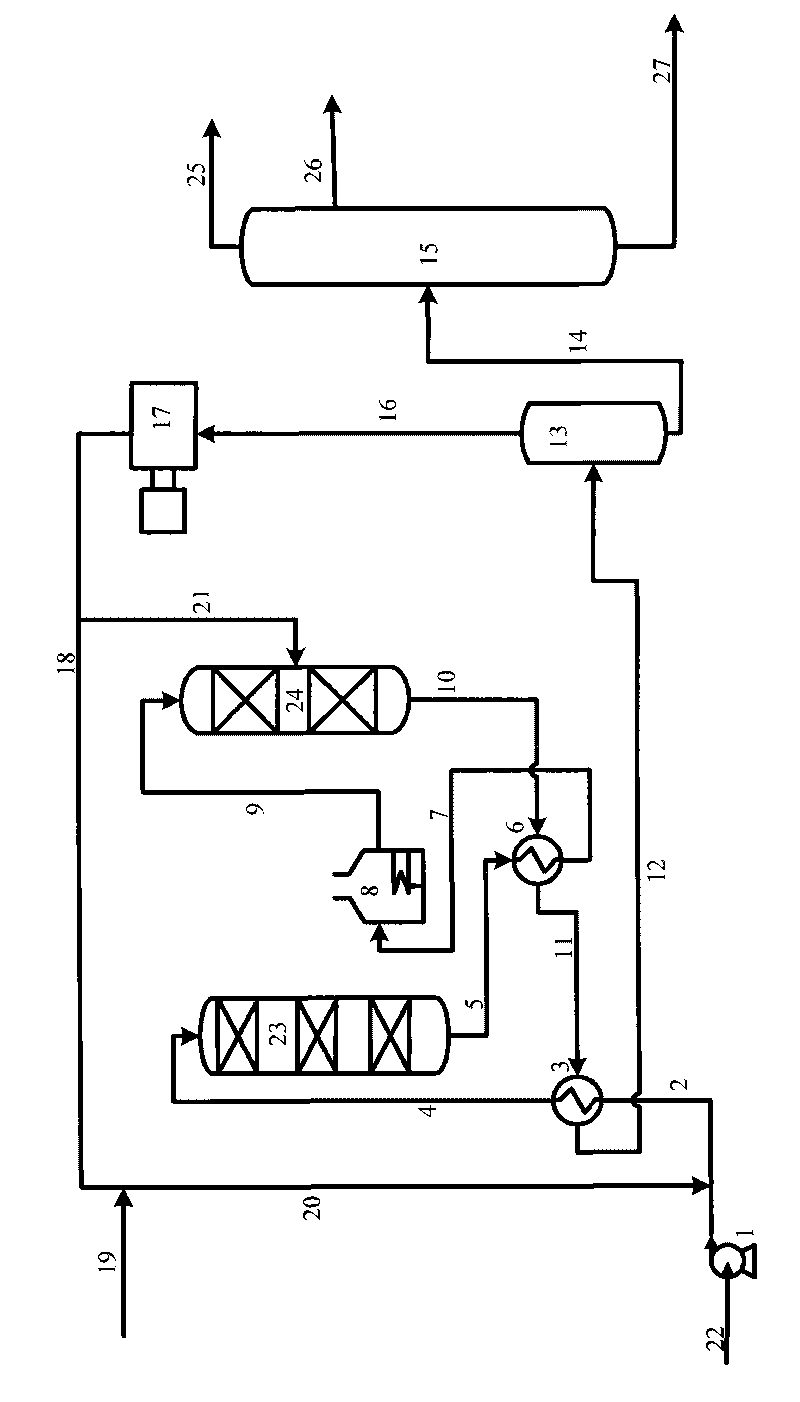

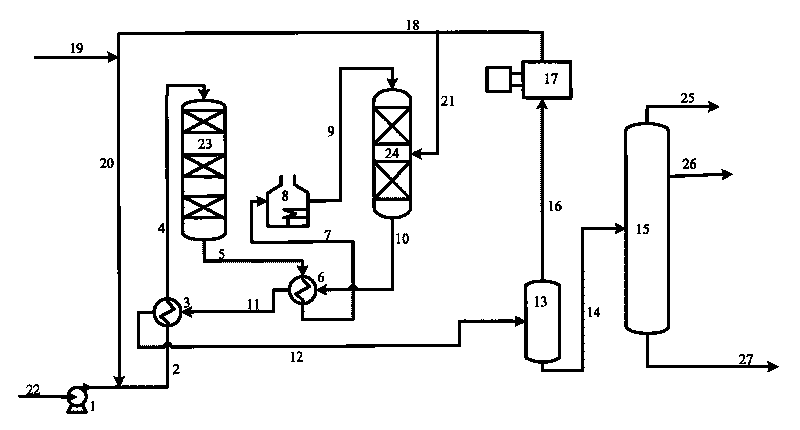

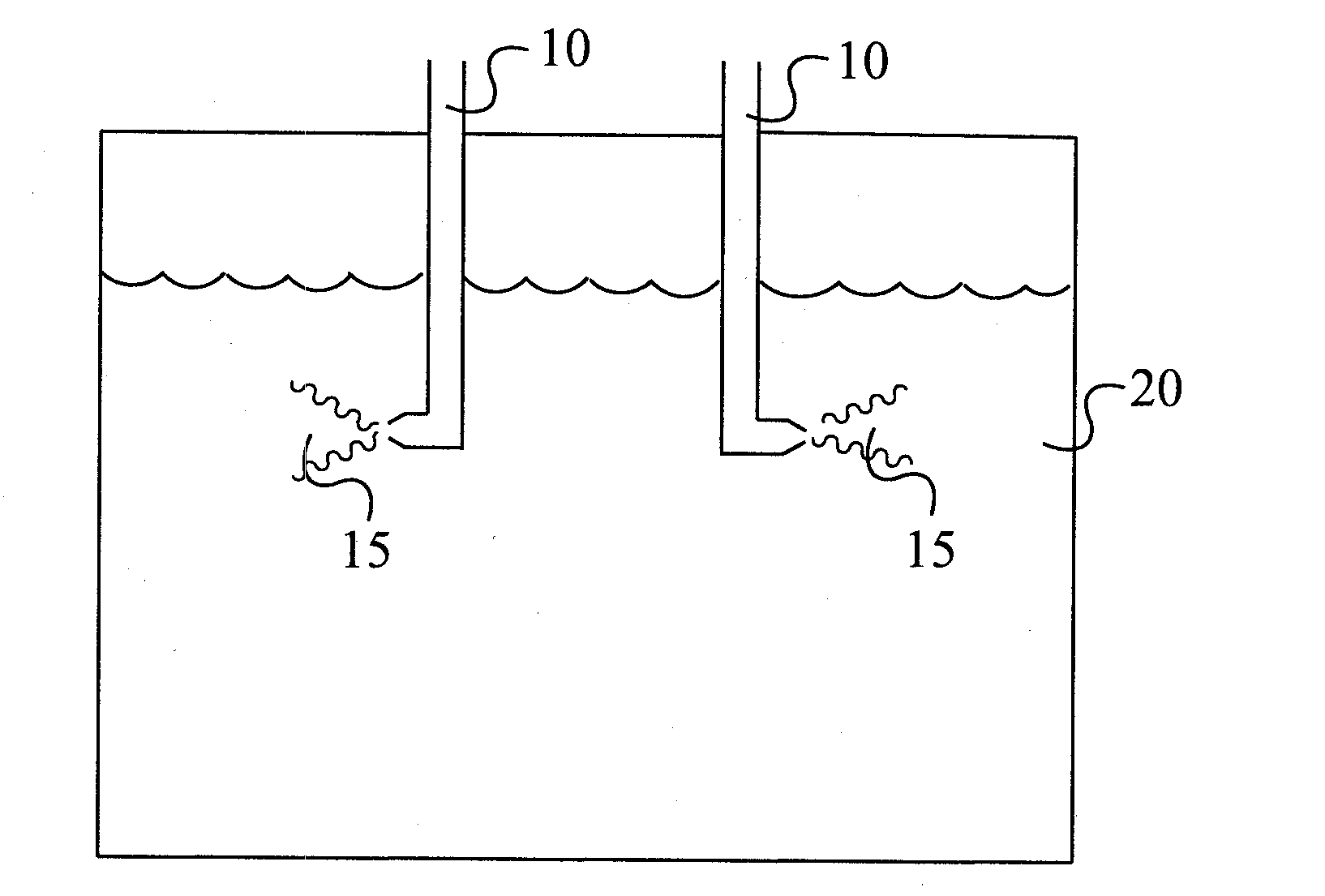

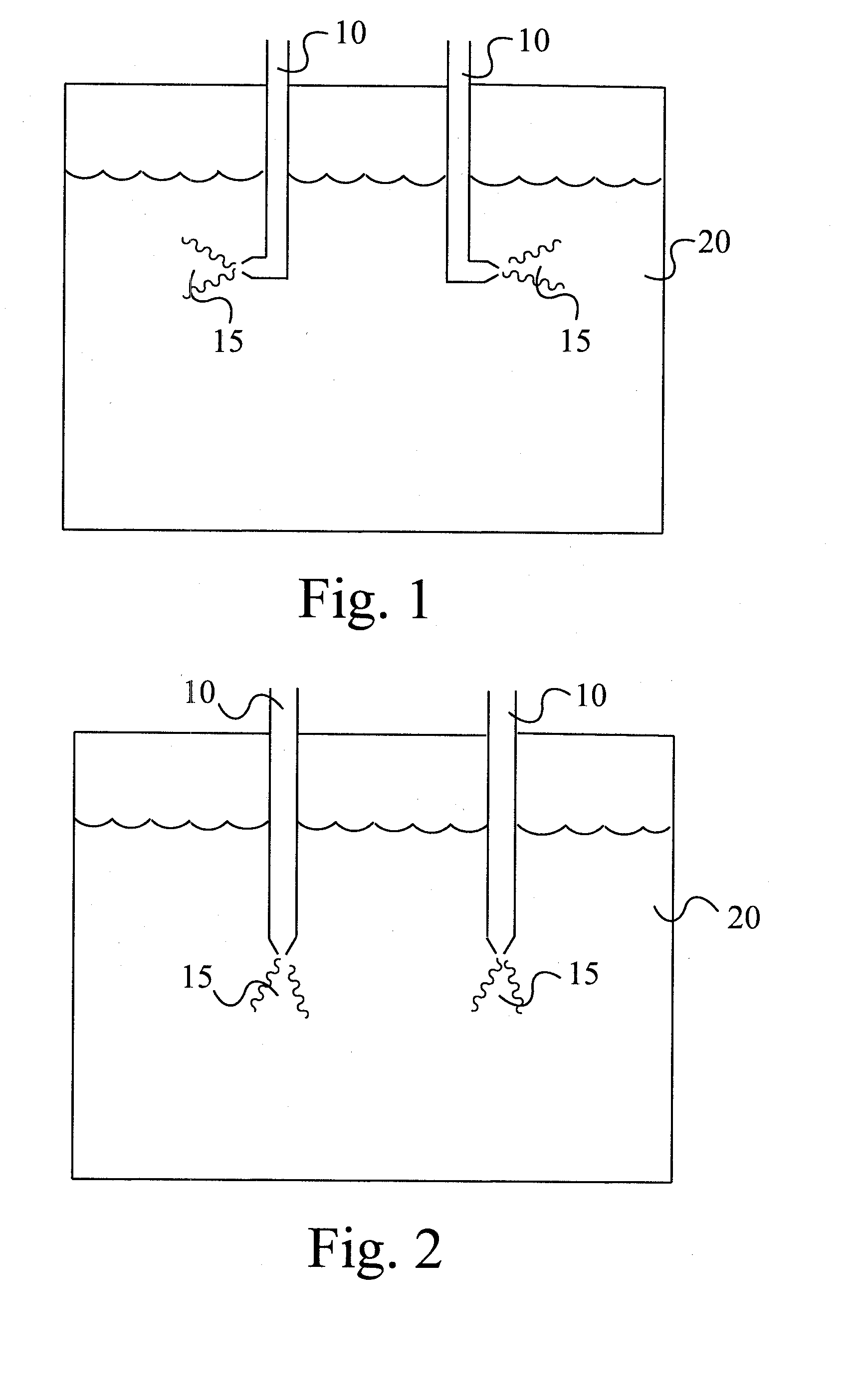

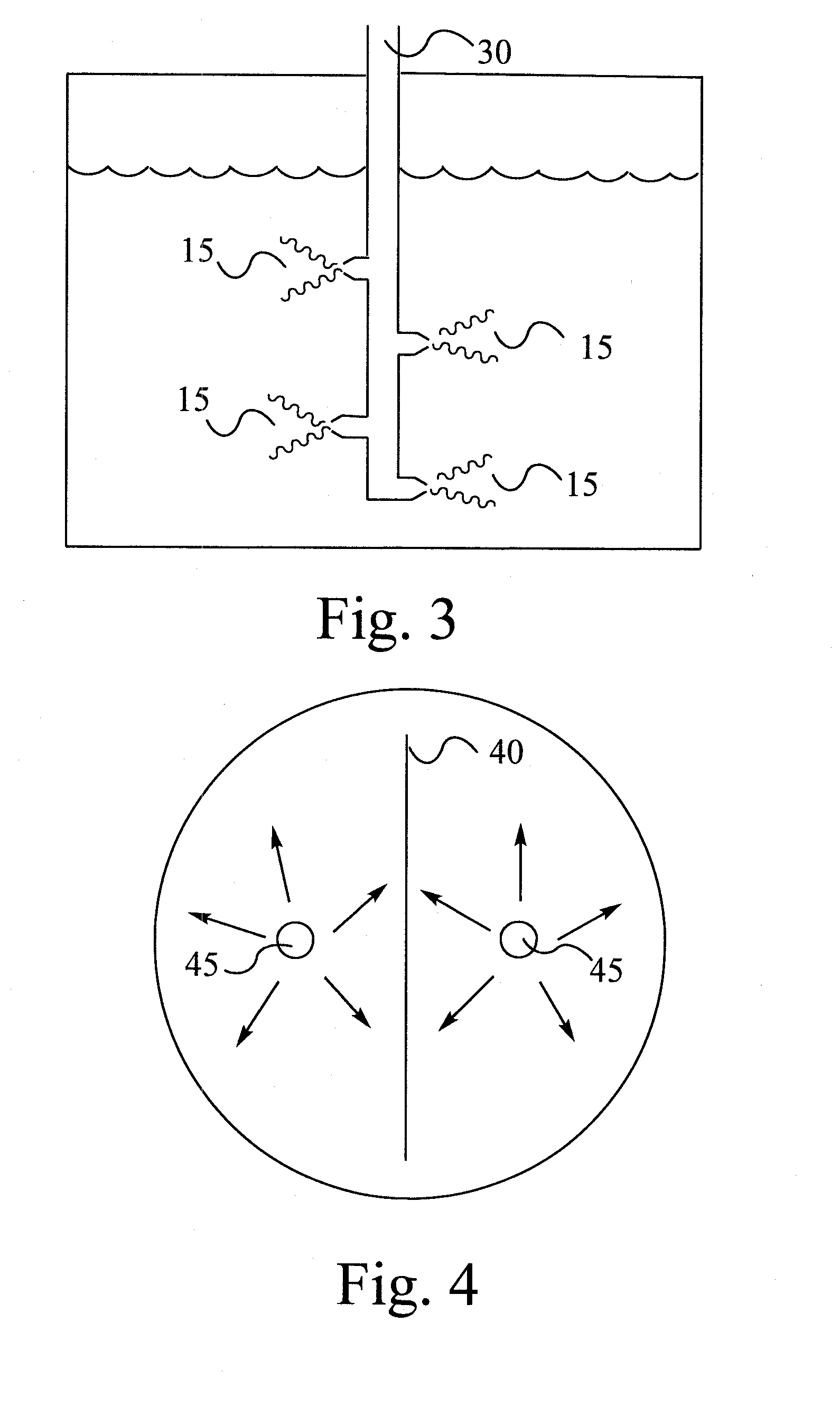

One exemplary embodiment can be a hydrotreating process. The hydrotreating process can include providing a first feed stream having a coker naphtha with a bromine number of about 10-about 120, combining the first feed stream with a second feed stream having a straight run naphtha with a bromine number of less than about 10 to create a combined feed, providing the combined feed to a hydrotreating reactor having at least one catalyst bed, and separating a quench stream from the second feed stream and providing the quench stream after the at least one catalyst bed.

Owner:UOP LLC

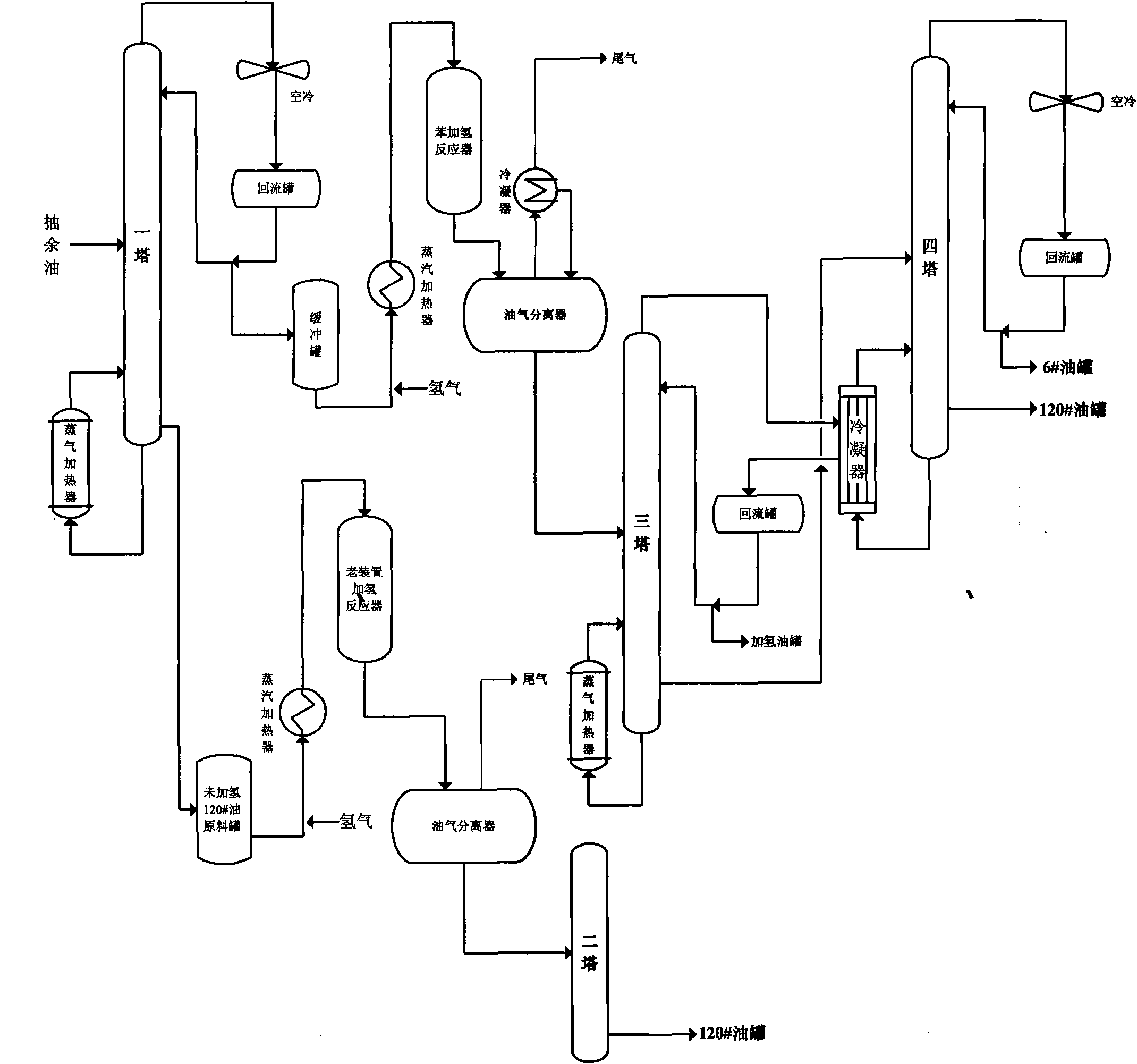

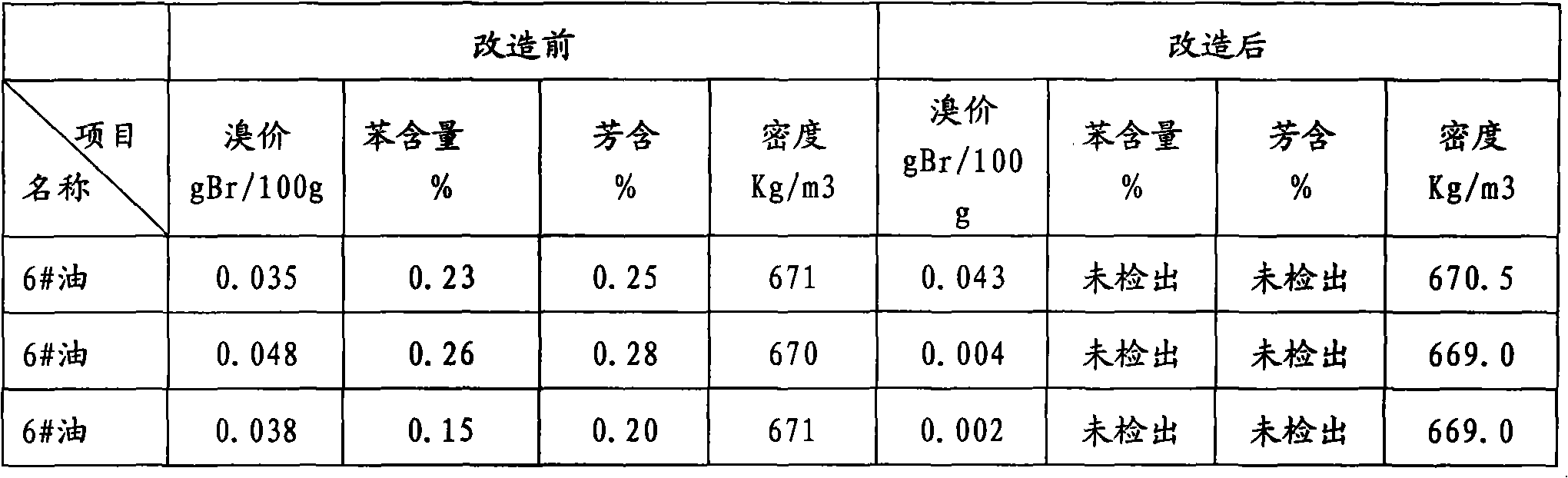

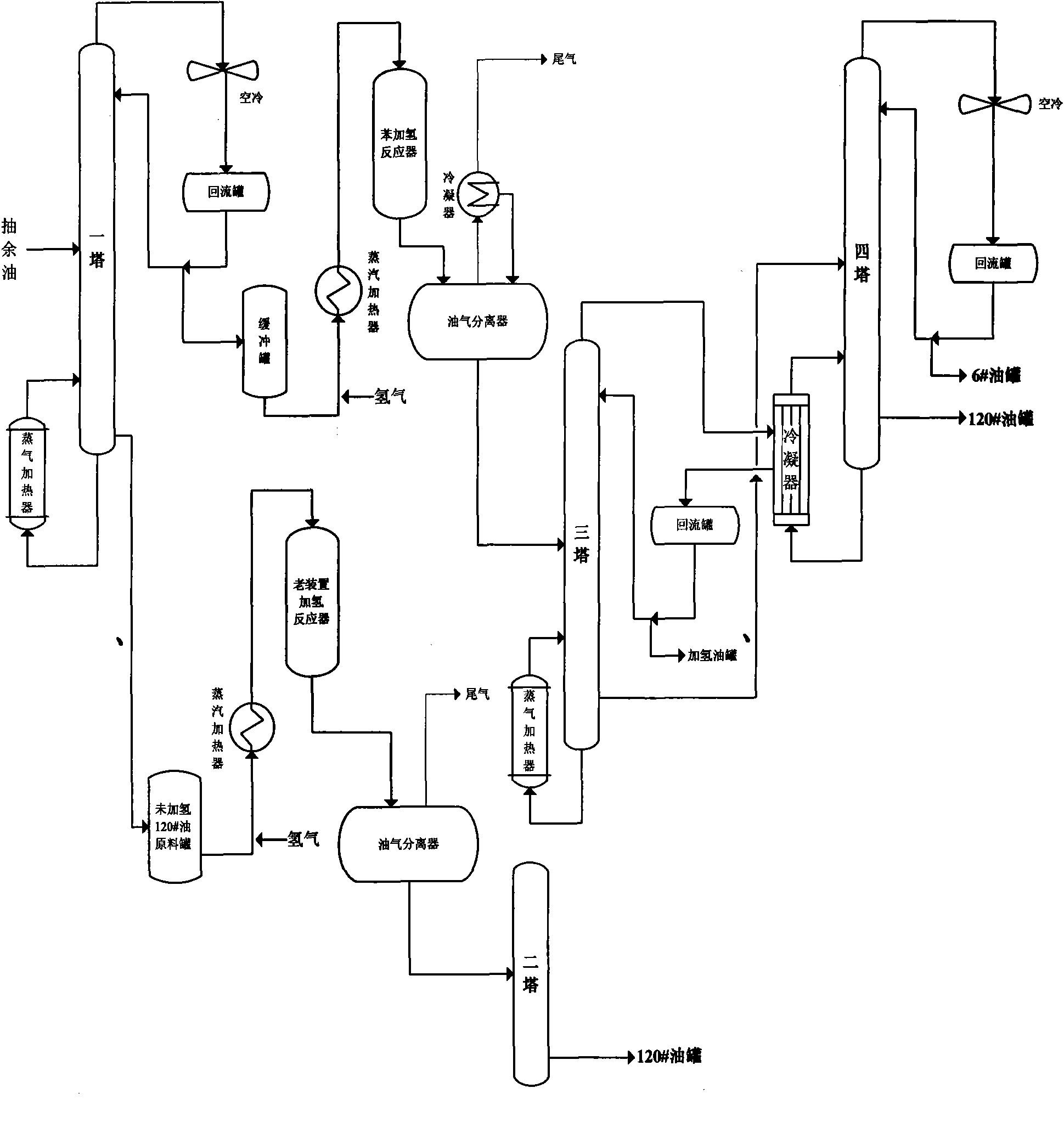

Process for producing solvent oil by removing aromatic hydrocarbon from raffinate oil

ActiveCN101974347ANot easy to cokeHigh activityTreatment with hydrotreatment processesBromine numberSulfolane

The invention discloses a process for producing solvent oil by removing aromatic hydrocarbon from raffinate oil, which comprises the following steps of: (1) rectifying raffinate oil, and removing sulfolane, water and colloid substances from the raffinate oil; (2) completely hydrogenating the raffinate oil obtained in the step (1) under the action of a benzene hydrogenation catalyst; and (3) removing excessive hydrogen from the product of the step (2) by separating, rectifying and collecting the product at the top of a rectifying tower to obtain solvent oil No.6 or normal hexane. In the method, all the raw materials are cleaned, hydrogenated and separated, reformed circulating hydrogen can be used, and the distillation range of the product is controllable. The content of aromatic hydrocarbon in the obtained product is trace, and the bromine number is lower than 100 mgBr / 100g.

Owner:TIANJIN JINGHUA PETROCHEM

Copolymer, hydrogenated product thereof, and process for producing the same

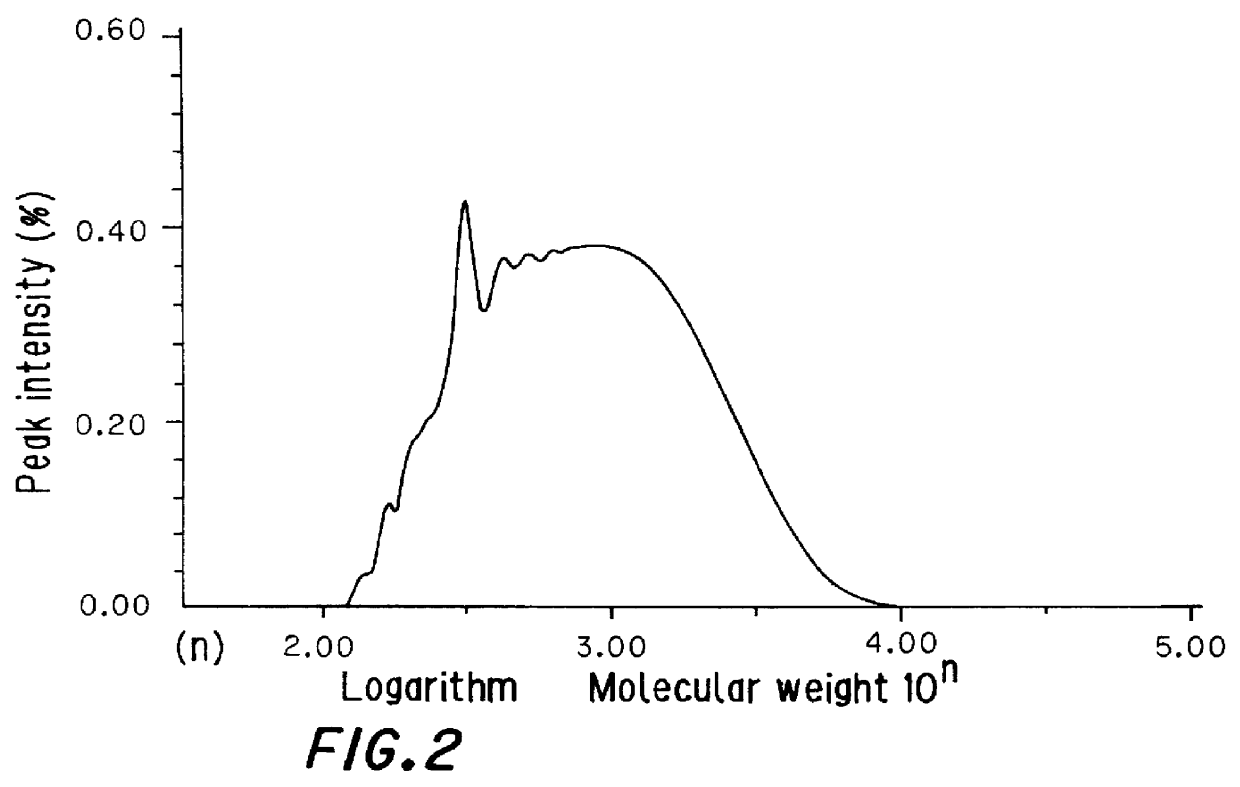

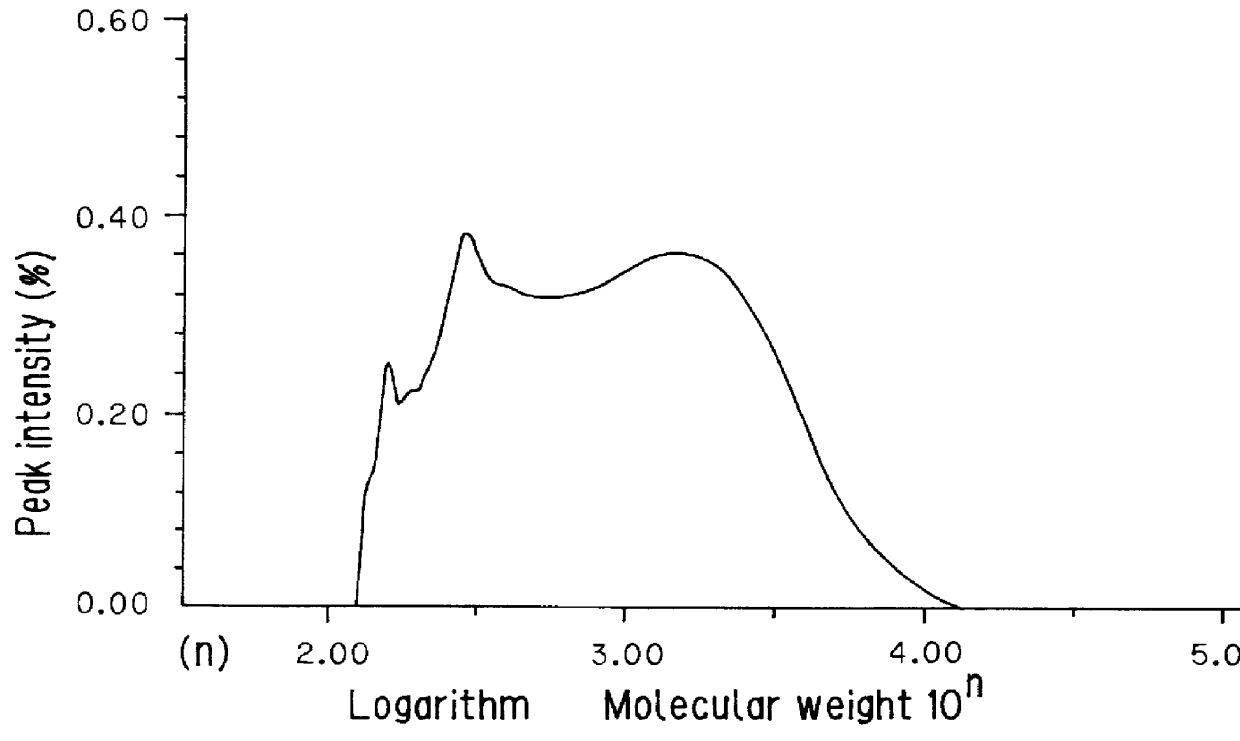

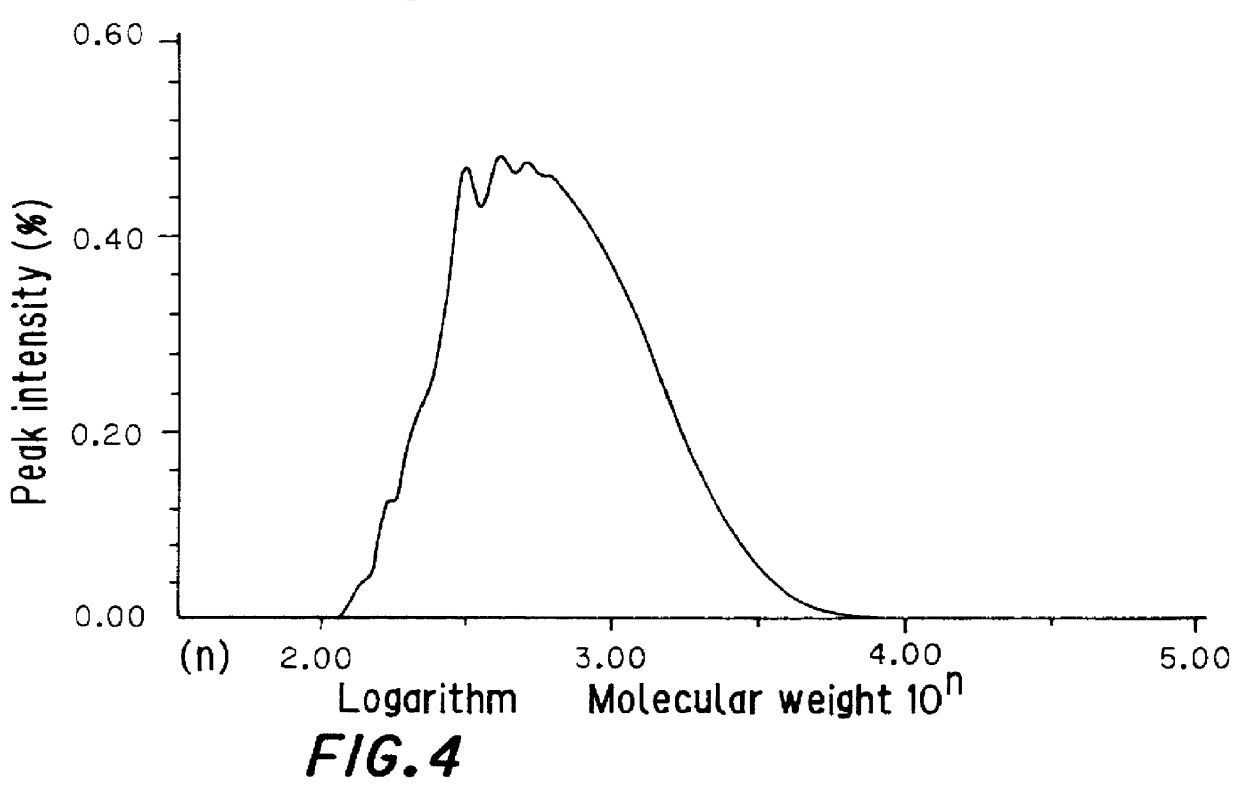

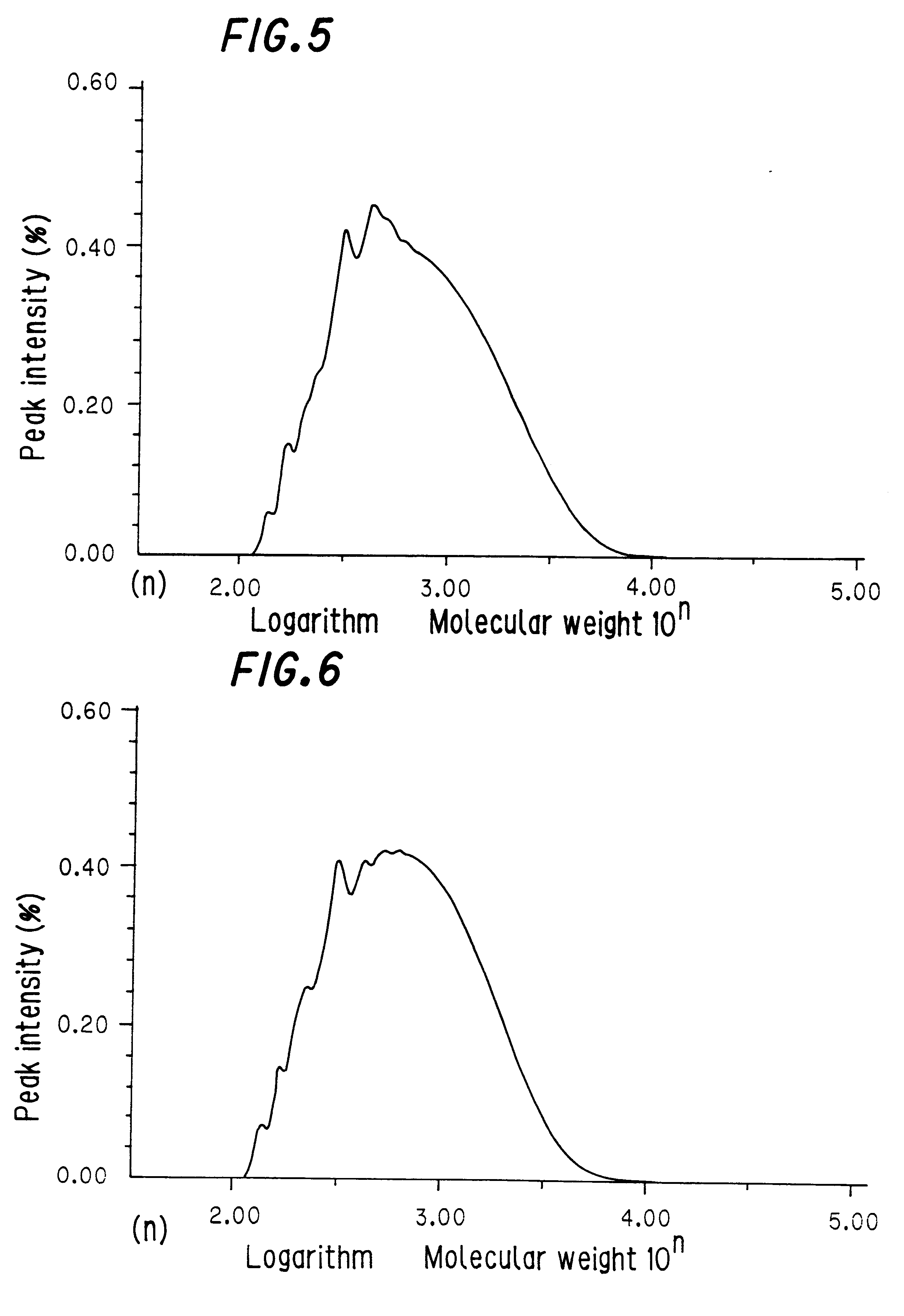

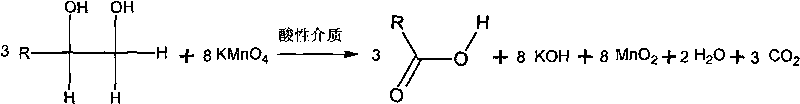

A hydrogenated product of a copolymer of cyclopentadiene and / or dicyclopentadiene and a vinyl-substituted aromatic compound. The copolymer has a softening point of from 60 to 130 DEG C., a vinyl-substituted aromatic compound content of from 30 to 90% by weight, a bromine number of from 30 to 90 g / 100 g, a number average molecular weight of from 400 to 1,000, and a weight average molecular weight / number average molecular weight (Mw / Mn) ratio of 2.5 or less. The hydrogenated product has a softening point of 60 to 130 DEG C., a vinyl-substituted aromatic compound content of 0 to 35% by weight, a bromine number of 0 to 300 g / 100 g, a number average molecular weight of 400 to 1,000 and a weight average molecular weight / number average molecular weight ratio of 2.5 or less. The hydrogenated product is useful as a substrate in the production of a tackifier and an adhesive.

Owner:IDEMITSU KOSAN CO LTD

Copolymer of ethylene and alpha-olefin, and method for preparing same

A liquid random copolymer of ethylene and alpha-olefin prepared by using specific metallocene catalyst and ionic compound and a method for preparing the same are disclosed. The liquid random copolymer has high viscosity index and shear stability so that it is useful as synthetic lubricants. The liquid random copolymer of ethylene and alpha-olefin (1) comprises 60 to 40 mol % of ethylene units and 40 to 60 mol % of alpha-olefin unit having 3 to 20 carbon atoms, (2) has number average molecular weight (Mn) of 500 to 10,000 and a molecular weight distribution (Mw / Mn, Mw is the weight average molecular weight) of 3 or less measured by Gel Permeation Chromatography (GPC) (3) has Kinematic Viscosity at 100° C. of 30 to 5,000, (4) has pour point of 30 to −45° C., and (5) has Bromine Number of 0.1 or less.

Owner:DL CHEM CO LTD

Hydrogenation method for producing aromatics extraction raw material

ActiveCN101724456AMeet the requirements of the feedReduce cokingTreatment with hydrotreatment processesSulfurGasoline

The invention relates to a hydrogenation method for producing an aromatics extraction raw material. The method adopts two hydrogenation units and performs different reactions at different temperatures, wherein the first hydrogenation unit is filled with protective agents with different specifications in a graded loading mode; the protective agents are mainly used for removing diene, delaying the coking of the top part of a catalyst bed layer and prolonging the running period of a device at a low temperature; the second hydrogenation unit is filled with a hydrorefining catalyst for desulfurization, denitrification and alkene saturation at a high temperature and alkene saturation as little as possible. The hydrogenation method broadens the source of the aromatics extraction raw material; through the method provided by the invention, gasoline fractions with high diene value content and high impurity content can be converted; and the obtained product has the nitrogen content and the sulphur content of less than 1 mu g / g, and the bromine value of less than 0.5 gBr / 100g so as to meet the requirement of an aromatics extraction device on feeding.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composition of a superior lubricant or lubricant blendstock

ActiveUS20090050521A1Low costCatalystsHydrocarbon preparation catalystsBromine numberPolymer science

A composition of a superior lubricant or lubricant component having a very high VI, a low cloud point, a difference between the T90 and T10 boiling points of at least 250° F. by SIMDIST, and a very low Bromine Number.

Owner:CHEVROU USA INC

Method for preparing dicyclopentadiene hydrogenated petroleum resin

ActiveCN102558444AGood dispersionLarge specific surface areaCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsBromine numberHydrogen

The invention relates to a method for preparing dicyclopentadiene hydrogenated petroleum resin. Dicyclopentadiene petroleum resin is used as a raw material and hydrogenated under the action of a catalyst to prepare the dicyclopentadiene hydrogenated petroleum resin, wherein the weight ratio of the dicyclopentadiene petroleum resin to the catalyst is 100: (3-6), the hydrogenating temperature is 170 to 215 DEG C, the pressure of the reaction hydrogen is 3.0 to 5.5MPa, and the reaction time is 4 to 8 hours; a silicon-aluminum composite oxide is used as a carrier in the catalyst, the active ingredient of the catalyst is Pd, the weight of the Pd is 0.1 to 1.0 percent of the weight of the catalyst, the specific surface of the catalyst is 350 to 420 m<2> / g, and the pore volume is 0.6 to 0.7ml / g;and according to the dicyclopentadiene hydrogenated petroleum resin product prepared by the method, the bromine number is less than or equal to 2.0gBr / 100g, the chromaticity (Gardner) is less than orequal to 1, and the softening point is 110 to 120 DEG C.

Owner:PETROCHINA CO LTD

Preparation method of polymaleic acid

The invention discloses a preparation method of polymaleic acid, belonging to the field of chemical technology and aiming at providing a preparation method of polymaleic acid with high product yield, low bromine number and stable quality, and meanwhile, the polymaleic acid average molecular weight of which is more than 5500 is suitable for commercial process. The preparation method has the technical key points that 1 part by weight of maleic anhydride, 1.2 to 1.4 parts by weight of distilled water and 0.015 to 0.02 parts by weight of mixture of transition metal ion M compound and ammonium salt are put into a reaction kettle once to be heated from 40 to 60 DEG C to be totally dissolved; then perhydrol is slowly added to polymerize under the condition of continuous stirring, polymerization reaction temperature is controlled to be 90 to 100 DEG C, and heat preservation reaction time is 1 to 2 hours, so that the polymaleic acid whose average molecular weight is bigger than 5500 can be obtained. The yield can be more than 99.0% (counted by maleic anhydride), bromine number is smaller than 30mg / g, and products have stable quality. The preparation method for polymaleic acid has environmentally-friendly and clean technology, produces no three wastes and has the advantages of convenient operation and low production cost, thus the preparation method of polymaleic acid is suitable for large-scale industrial production.

Owner:安徽海瀚水处理科技有限公司

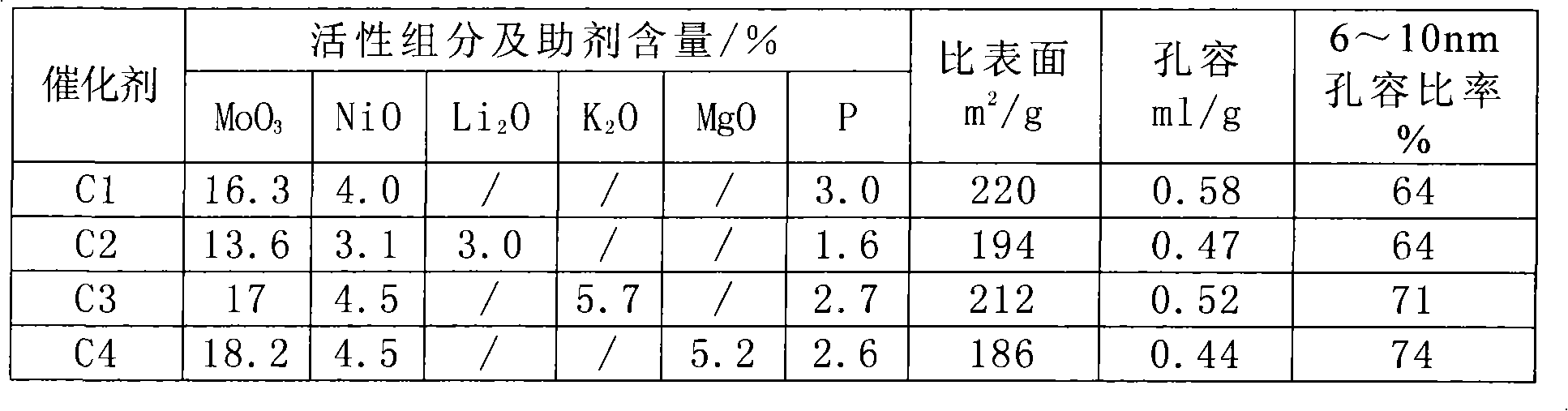

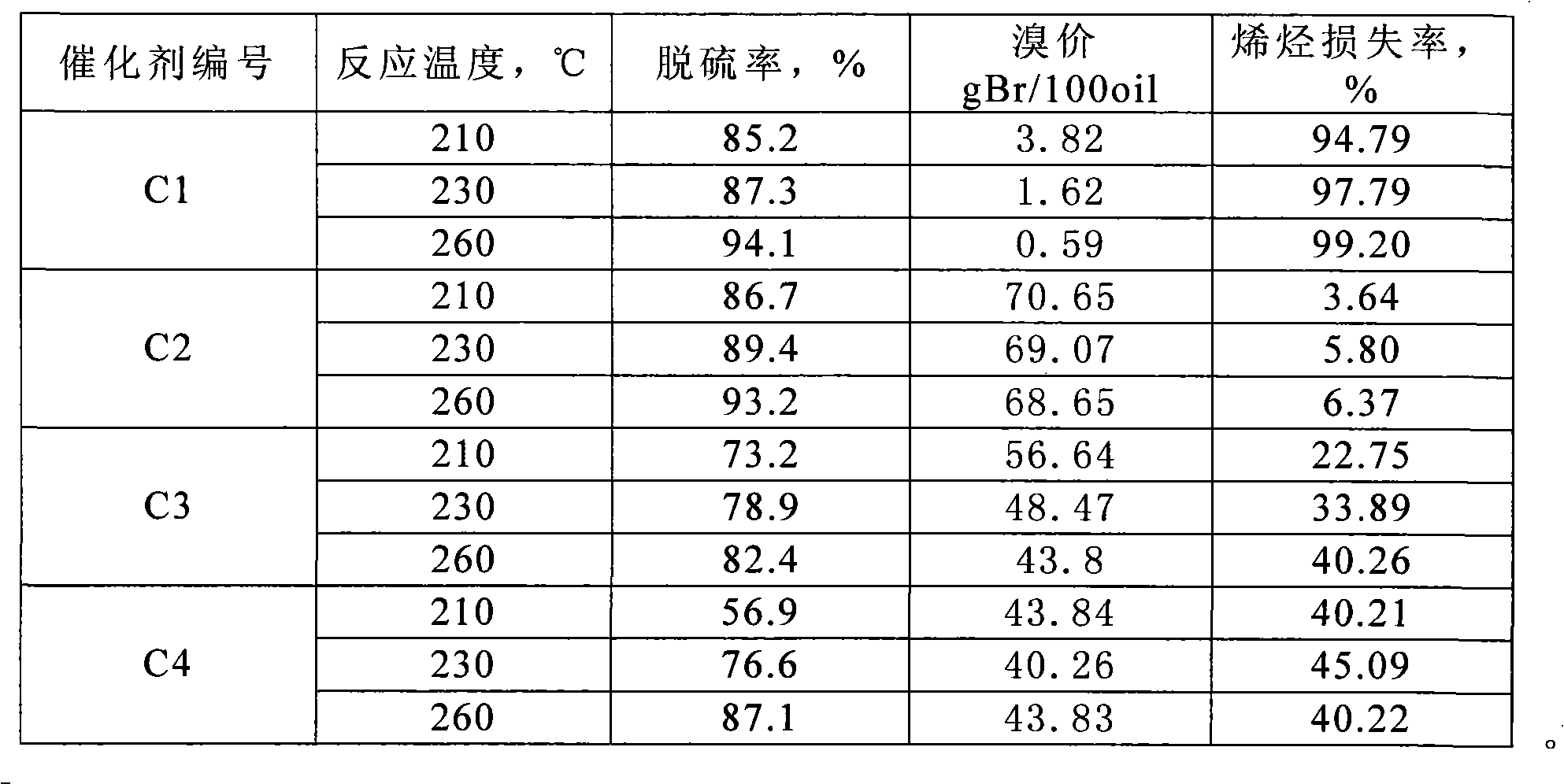

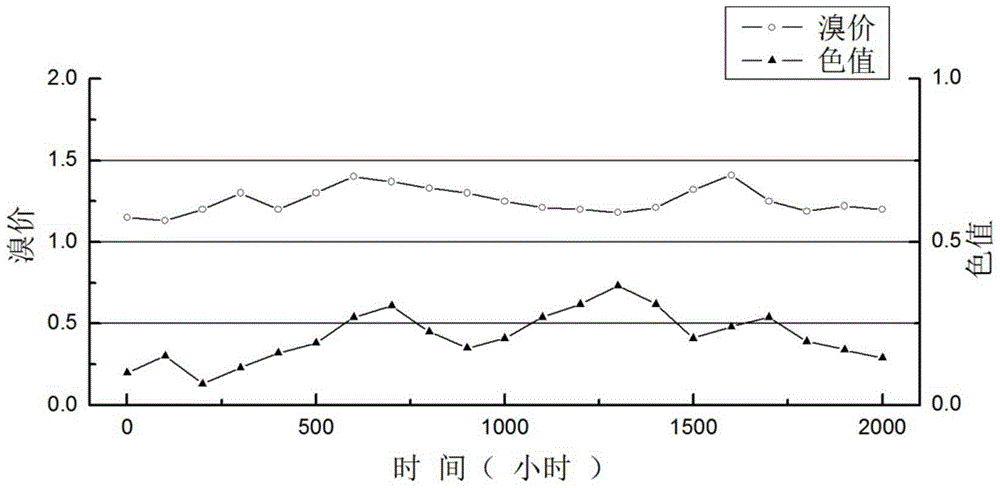

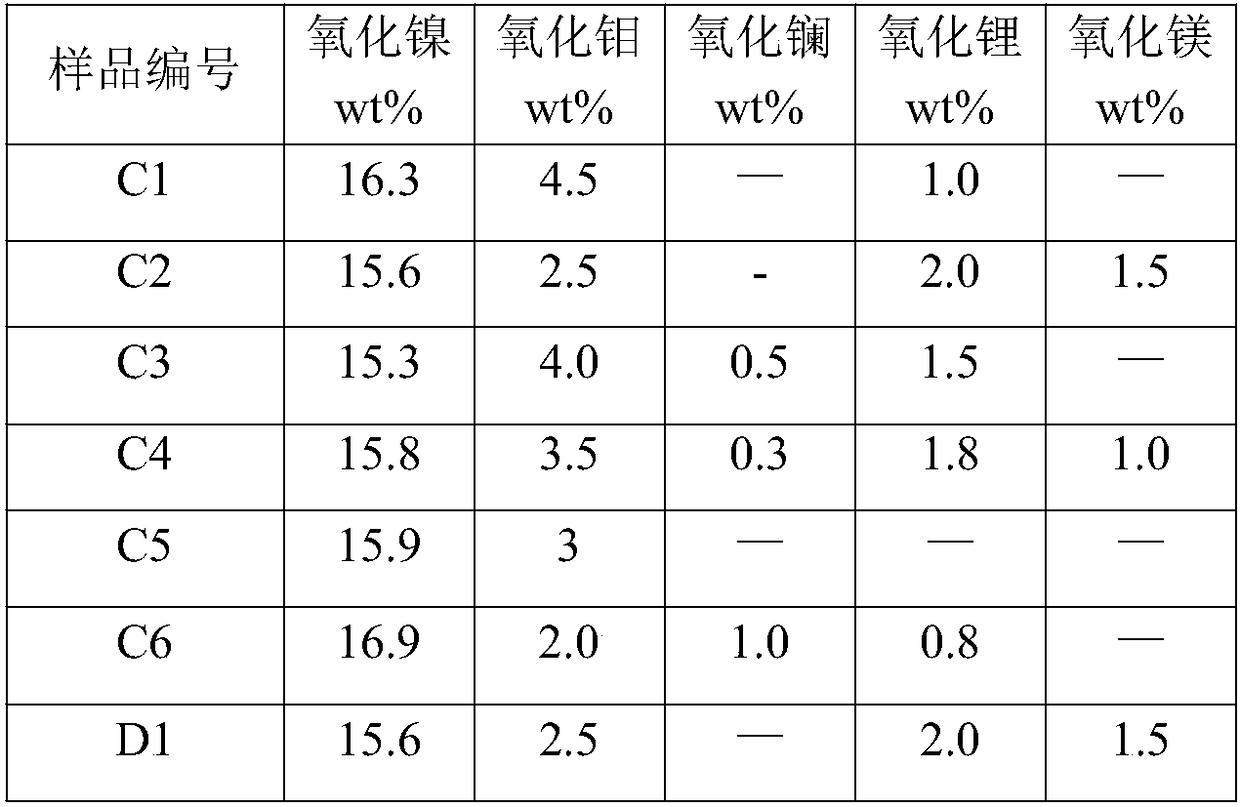

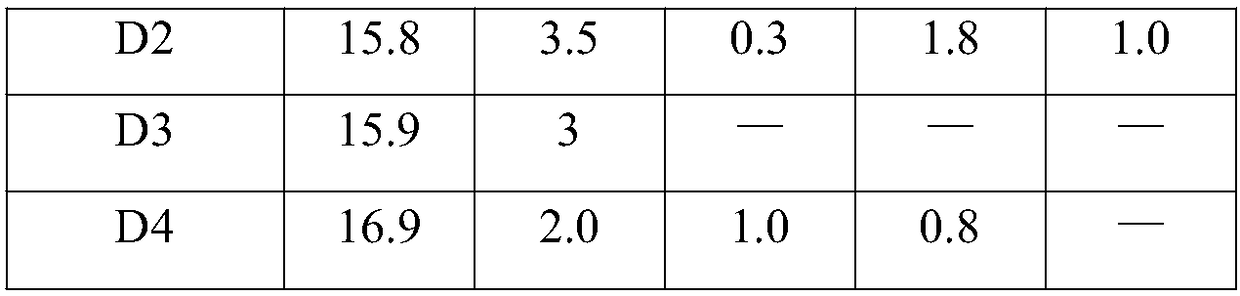

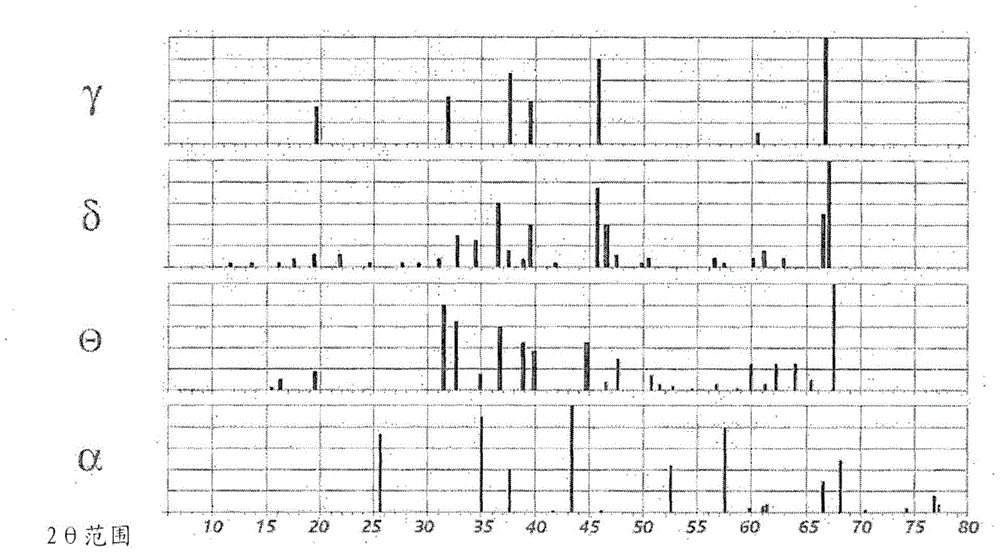

Distillate oil hydrogen refining catalyst

ActiveCN101811060AHigh desulfurization rateHigh selectivityPhysical/chemical process catalystsRefining to eliminate hetero atomsBromine numberAlkaline earth metal

The invention relates to a distillate oil hydrogen refining catalyst. In the catalyst, theta alumina is used as a vector, Mo and Ni are used as active components, and alkali metal or alkali-earth and P are used as auxiliary agents. The catalyst comprises the following components in percentage by mass: 2 to 8 percent of the alkali metal or alkali-earth metal, 10 to 19 percent of MoO3, 4.5 to 7 percent of NiO, 1.5 to 4 percent of P, and the balance of the alumina vector. The catalyst is used as the catalyst of light distillate oil hydrogen process with boiling range less than 220 DEG C, so that monoolefine in the distillate oil can be furthest maintained while sulfur in the distillate oil is removed. V to V is equal to 3 (catalytic gasoline) to 1 (coker gasoline) by evaluating raw oil, wherein the sulfur content is 520 mu g.g-1, and bromine number is 73.32g Br / 100g Oil; and the reaction condition is that the temperature is between 200 and 260 DEG C, the pressure is 4.0MPa, the liquid space velocity is 2.5h-1, the volume ratio of hydrogen to oil is 250 to 1, the highest desulfurization rate is 93.2 percent, and the olefin loss rate is no more than 10 percent.

Owner:PETROCHINA CO LTD

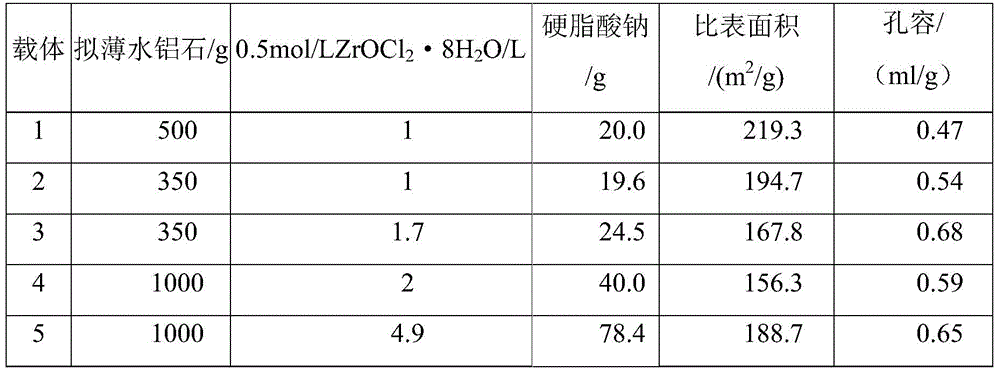

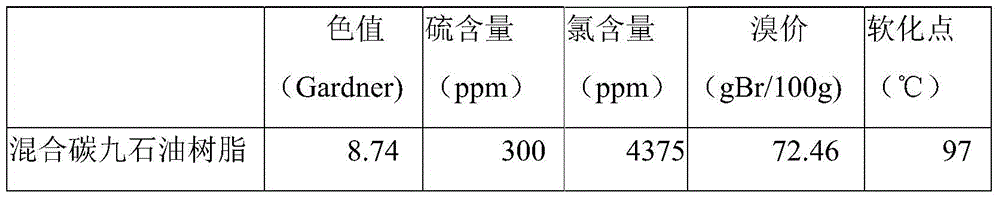

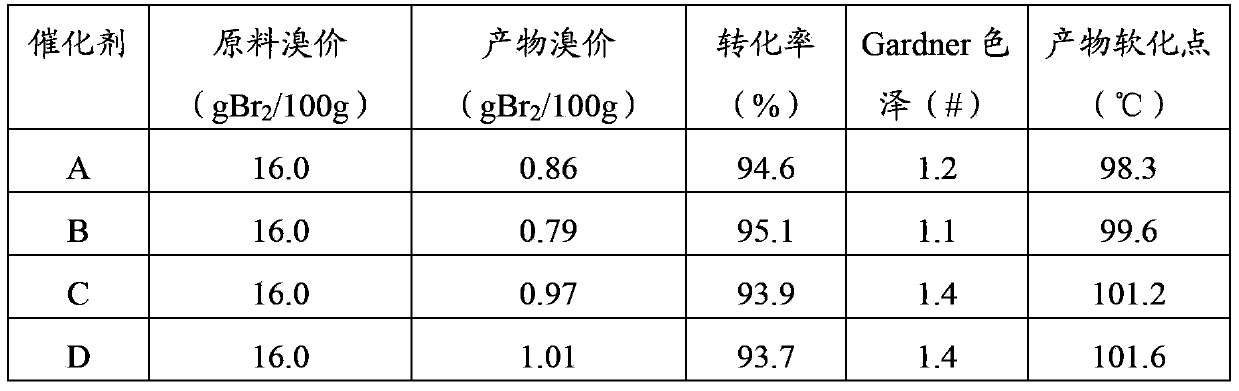

Catalyst for C9 petroleum resin hydrogenation reaction and preparation method thereof

ActiveCN105664968AImprove anti-sintering performanceSolution to short lifeMetal/metal-oxides/metal-hydroxide catalystsBromine numberBromine

The invention discloses a catalyst for a C9 petroleum resin hydrogenation reaction and a preparation method thereof and aims to provide a catalyst which not only has excellent hydrogenation catalytic activity but also has impurity resistant stability, can maintain a stable activity even under a high sulfur and chlorine condition, is prolonged in service life and develops the adaptability on the raw material resin. The catalyst can be used for preparing hydrogenated C9 petroleum resin being high in bromine number, light in color and high in softening point. The catalyst includes, by weight, 100 parts of a composite zirconium oxide / alumina carrier, 8-20 parts of Ni and 0.3-2.0 parts of Pt. The invention belongs to the technical field of catalyst.

Owner:GUANGDONG UNIV OF TECH

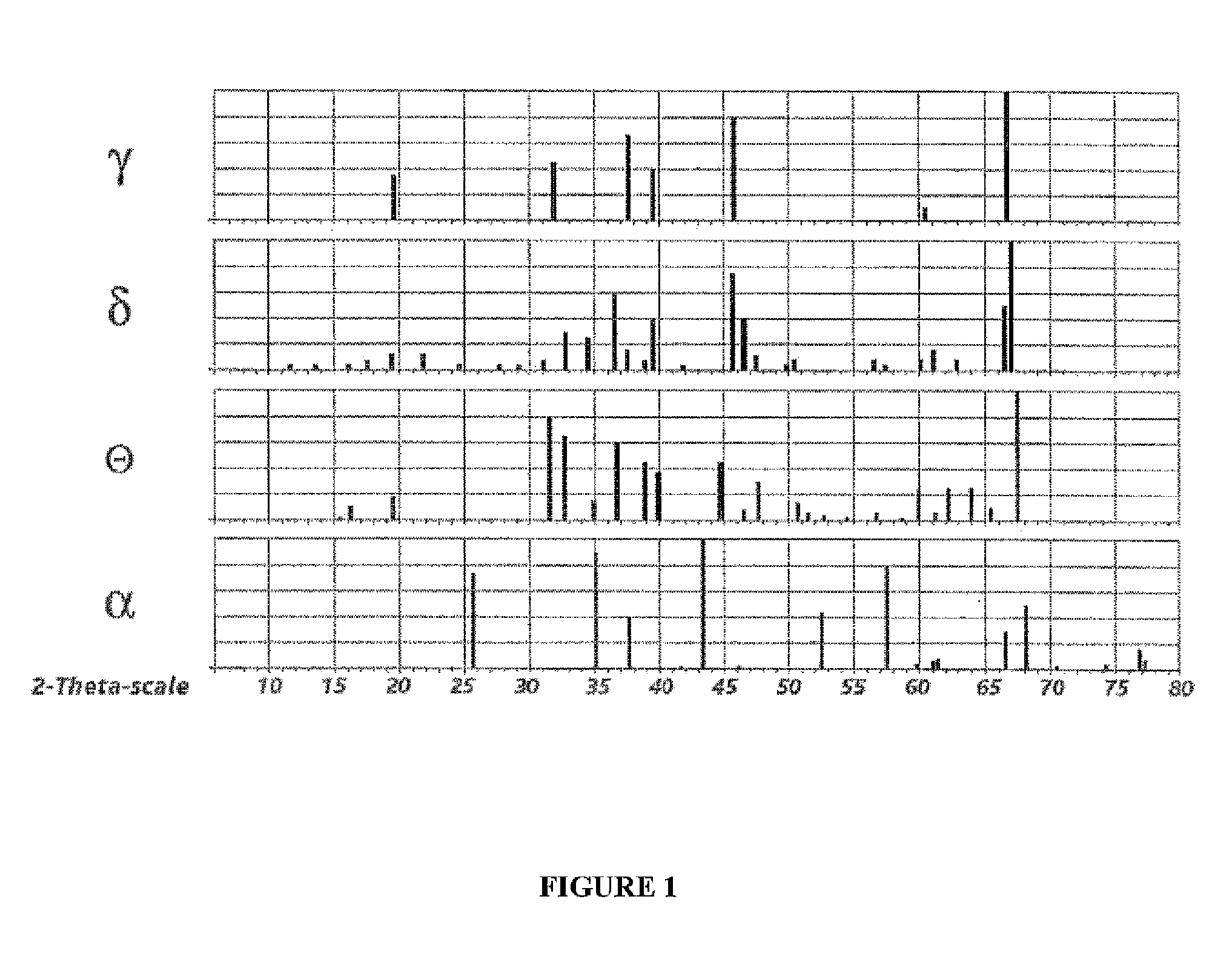

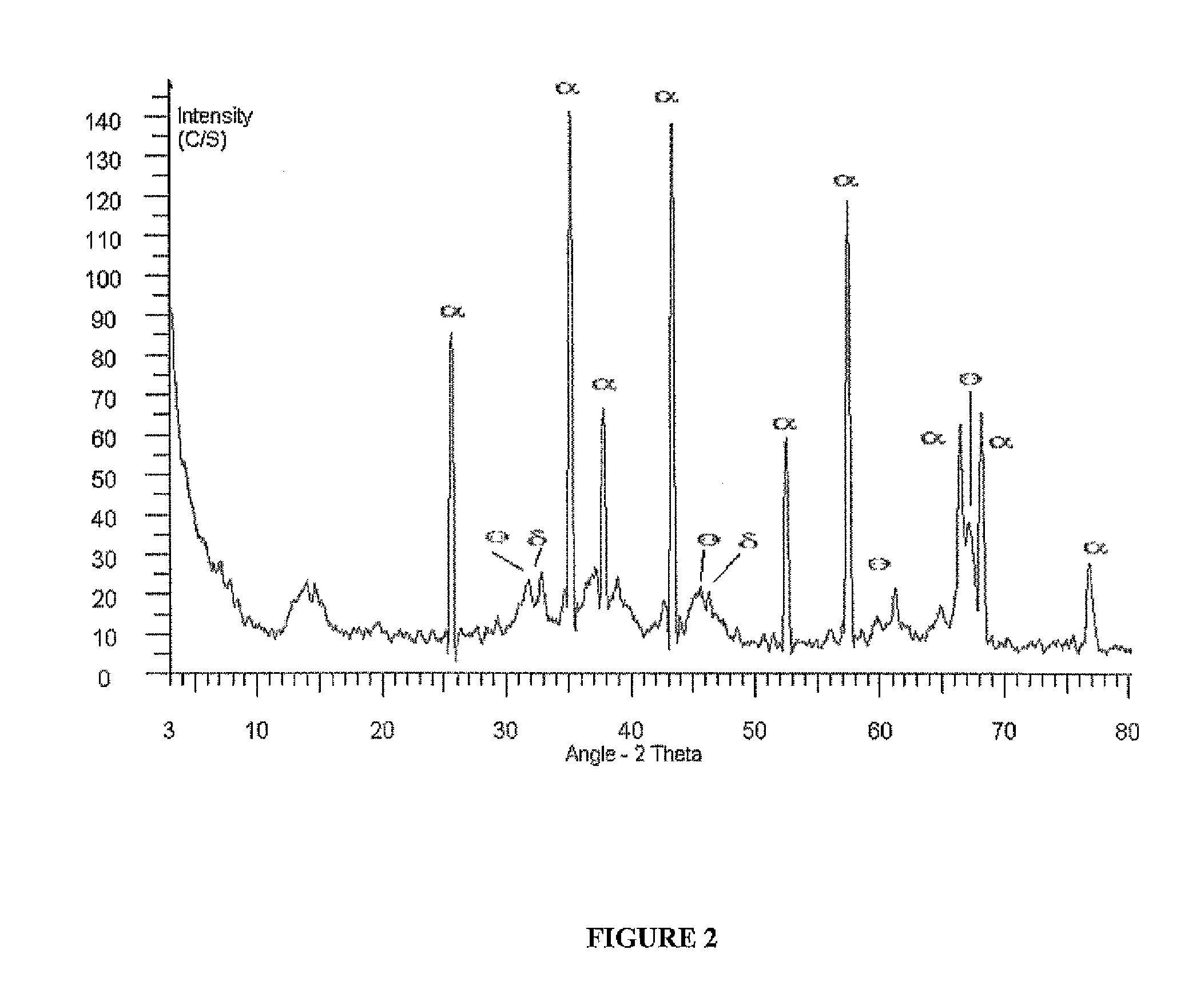

Catalyst composite for dehydrogenation of hydrocarbons and method of preparation thereof

InactiveUS20140323785A1Minimal dehydrationSpeed up the conversion processHydrocarbon by dehydrogenationOrganic-compounds/hydrides/coordination-complexes catalystsBromine numberHalogen

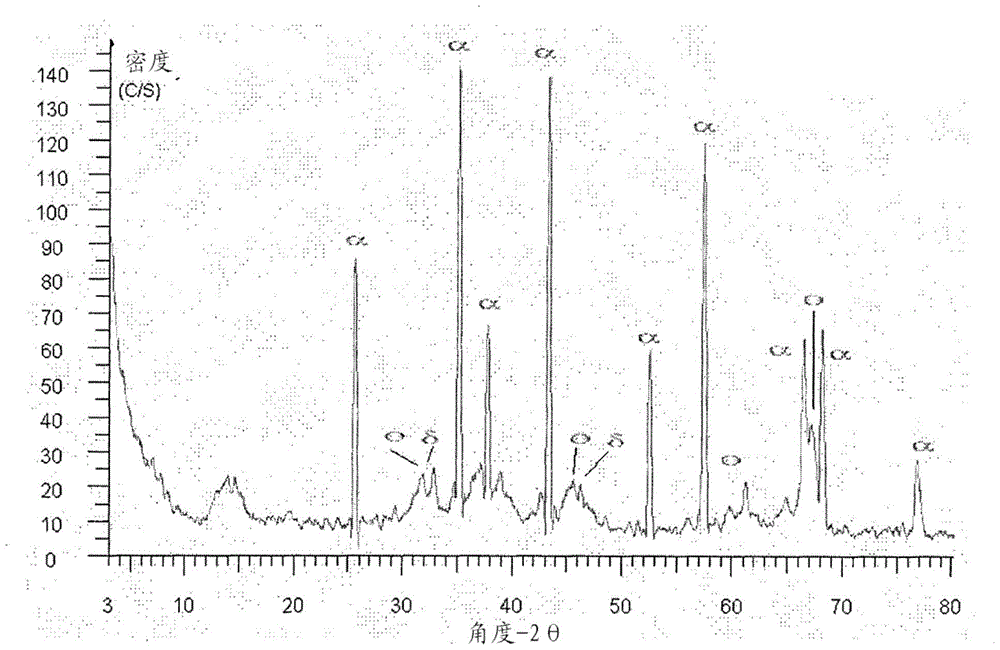

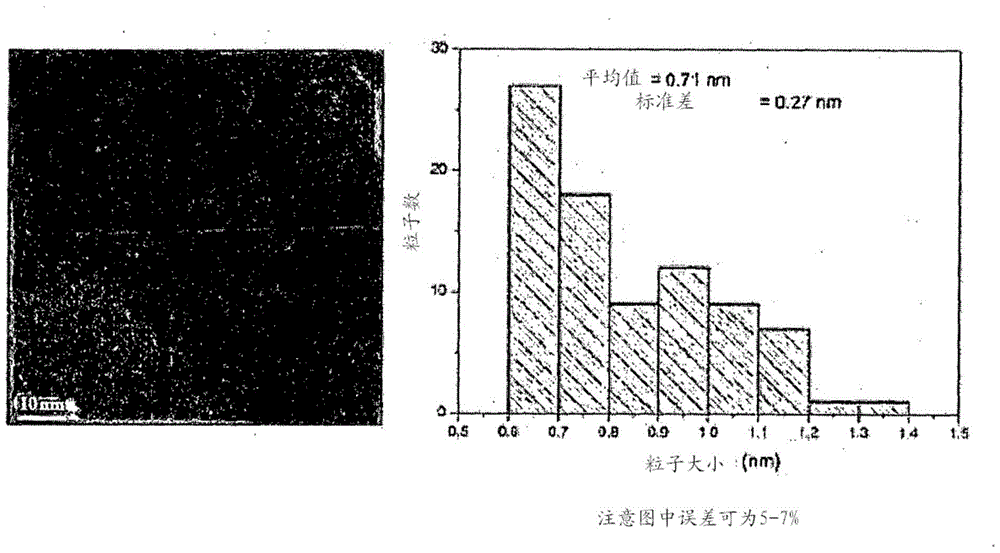

The present invention provides a dehydrogenation catalyst composite that is capable of providing a dehydrogenated hydrocarbon product characterized by a bromine number of at least 19. for hydrocarbons. The dehydrogenation catalyst of the present invention comprises a nano-sized complex containing a Group VIII component; a group IVA component and a sulfur containing capping agent; an alkali component; a halogen component; and a support with an inner core of alpha alumina and an outer layer comprising a mixture of gamma alumina and delta alumina.

Owner:RELIANCE INDUSTRIES LIMITED

Catalytic system for preparation of high branched alkane from olefins

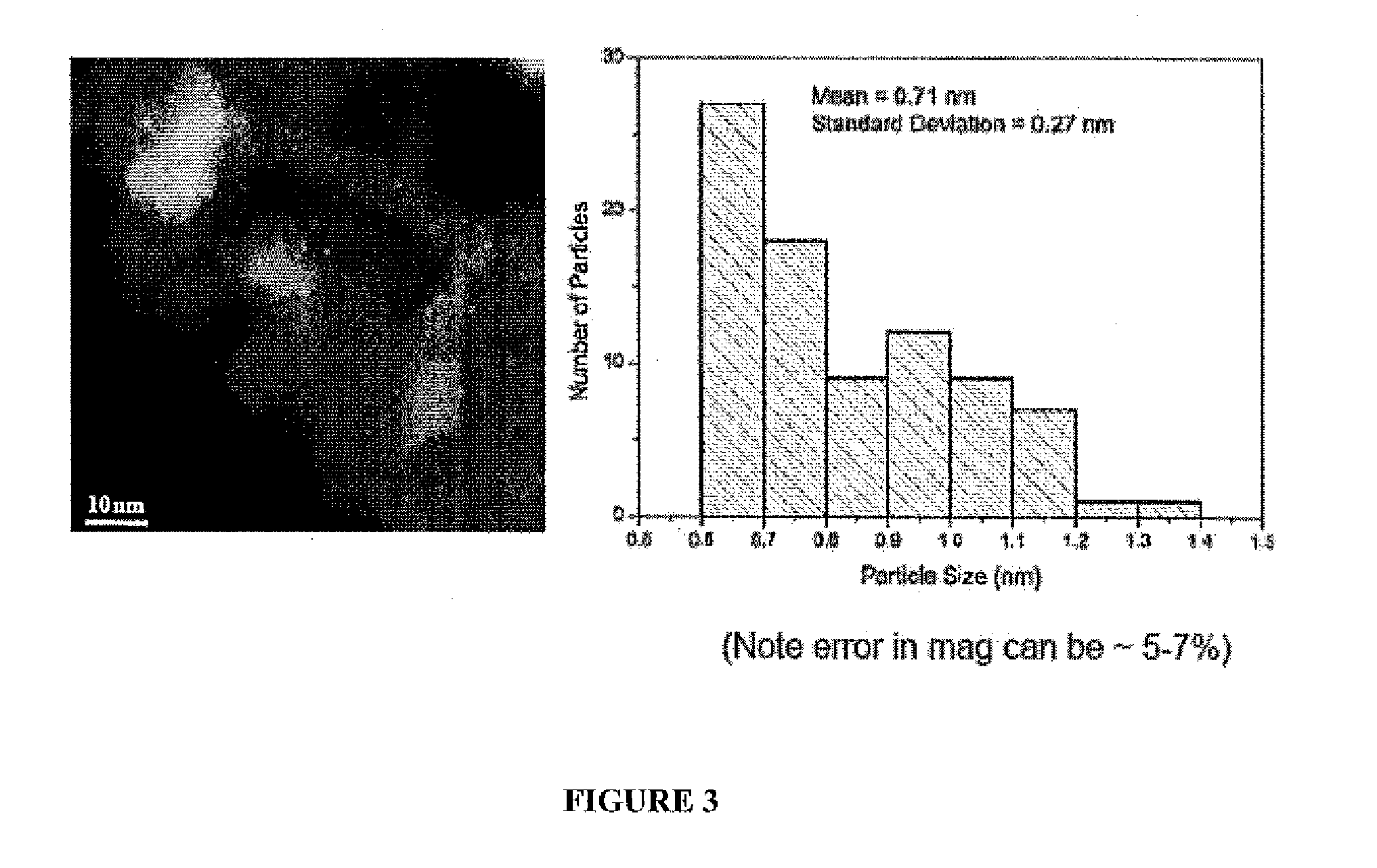

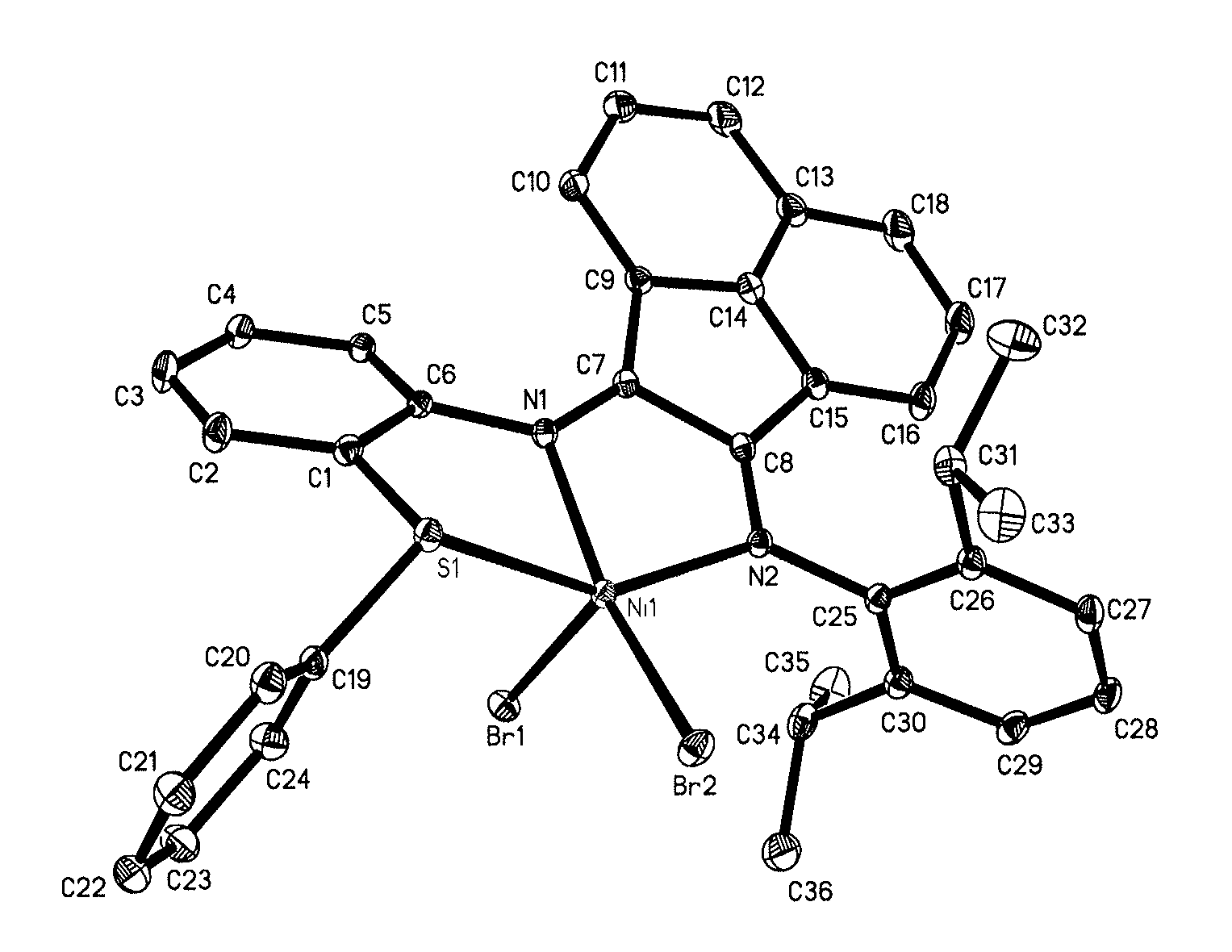

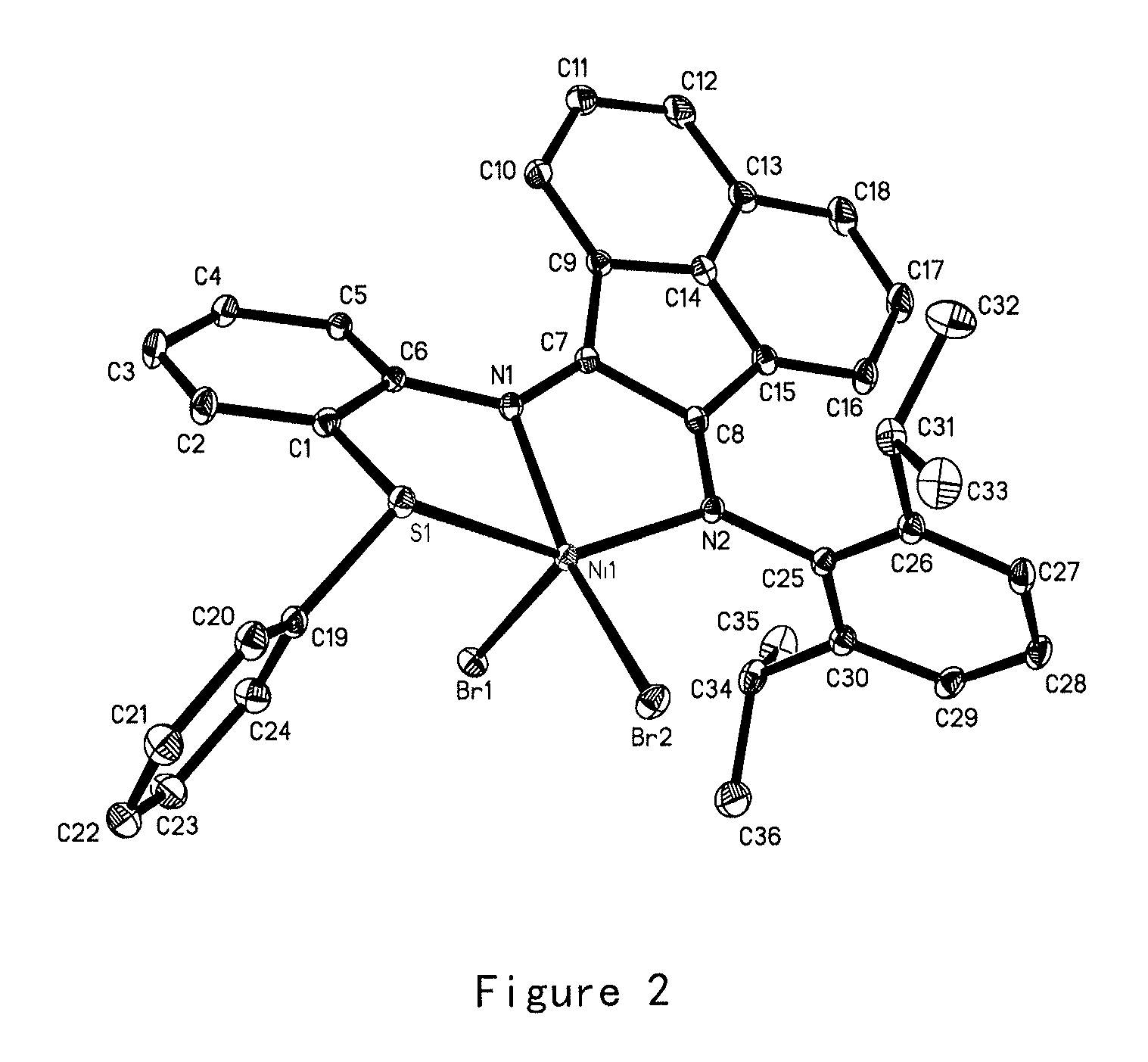

ActiveUS20140088319A1Hydrocarbon purification/separationNickel organic compoundsBromine numberBase oil

Owner:NANJING CHEMRUN CO LTD

C5 petroleum resin hydrogenation method

ActiveCN108264586AAppropriate pore size distributionImprove hydrogenation activityHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsDistillationFixed bed

The invention provides a C5 petroleum resin hydrogenation method. The method includes: dissolving C5 petroleum resin into an organic solvent in a mixer, preheating, adding into a fixed bed hydrogenation reactor filled with a nickel-molybdenum hydrogenation catalyst, sending hydrogenated materials into a steam stripping tower, recycling the organic solvent extracted from the upper portion after refining the organic solvent through a distillation column, and obtaining C5 petroleum resin at the bottom of the steam stripping tower. By adoption of the catalyst prepared from a nickel-containing carrier in a specific crystal form, reactive metal utilization rate can be greatly improved, and catalyst preparation difficulty is lowered; in addition, due to adding of a selected active component, a synergistic effect is achieved, and C5 petroleum resin low in bromine number and high in chromaticity and stability can be obtained.

Owner:PETROCHINA CO LTD

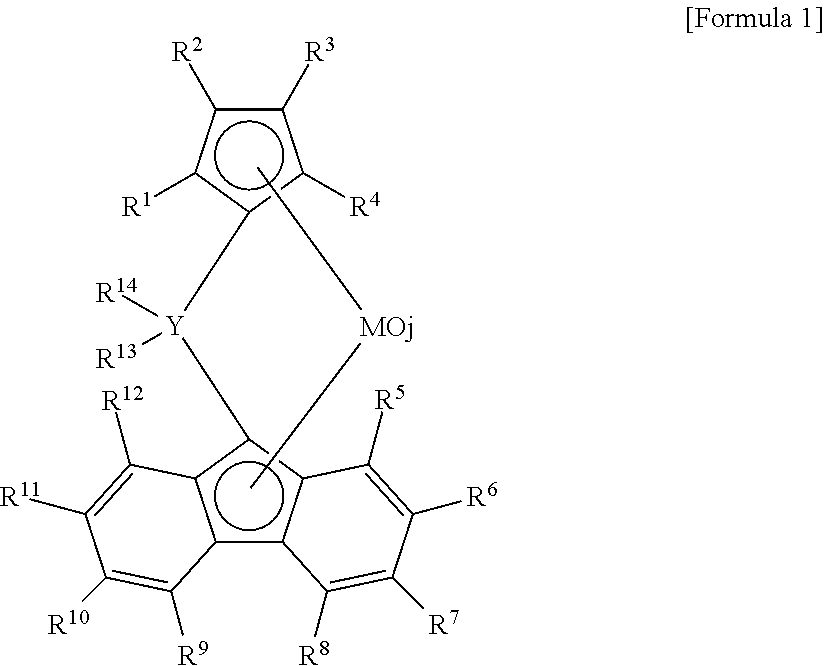

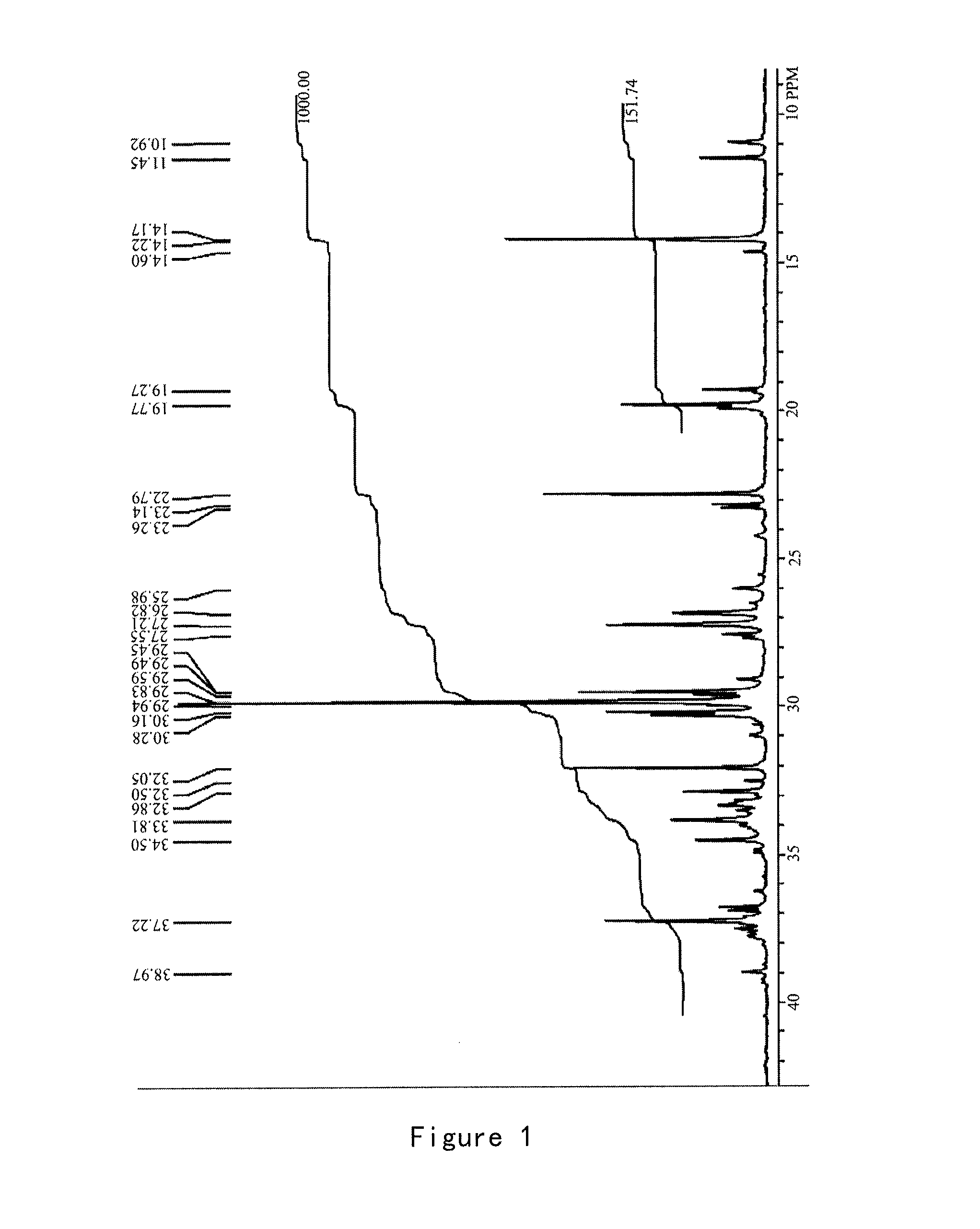

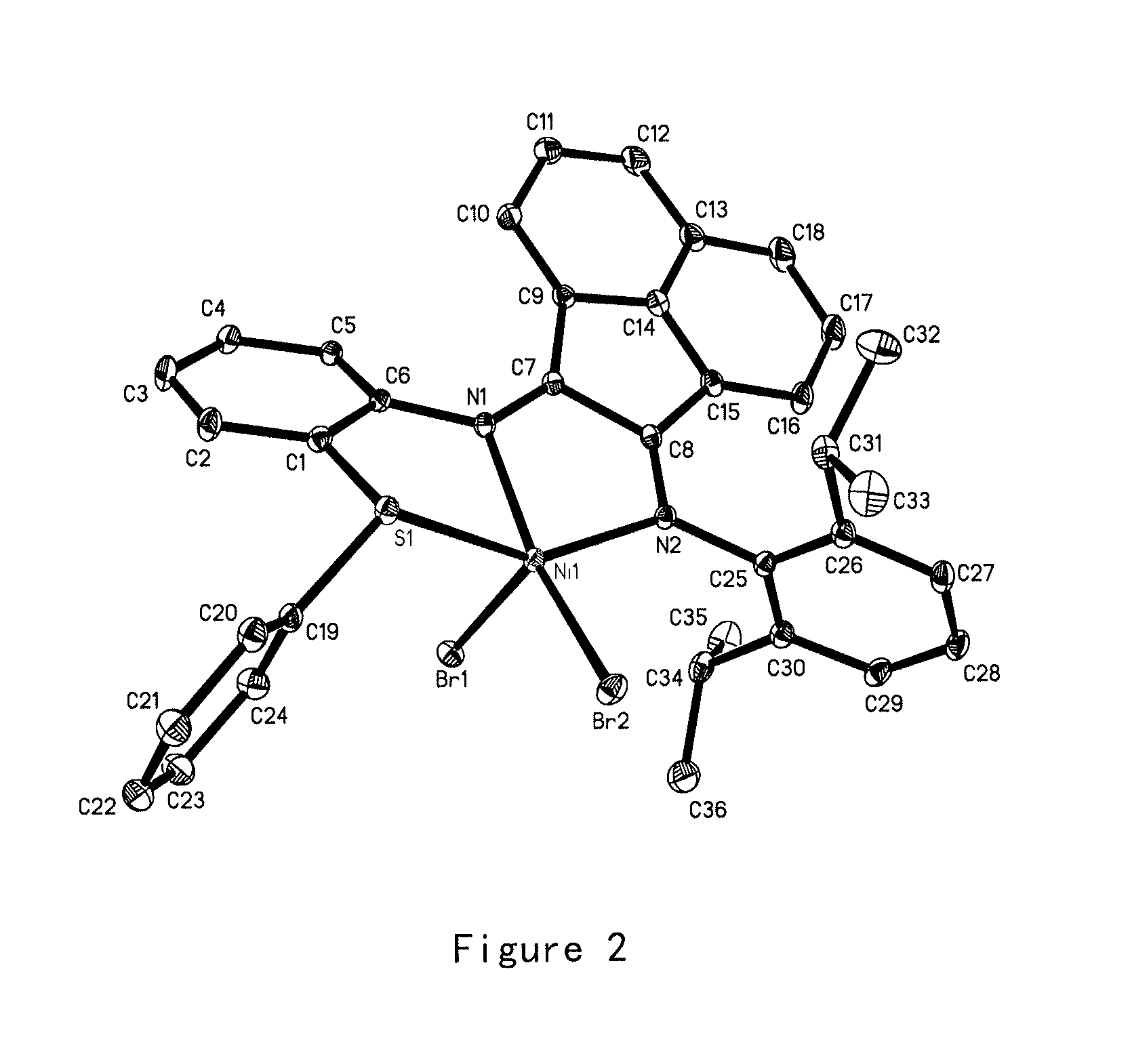

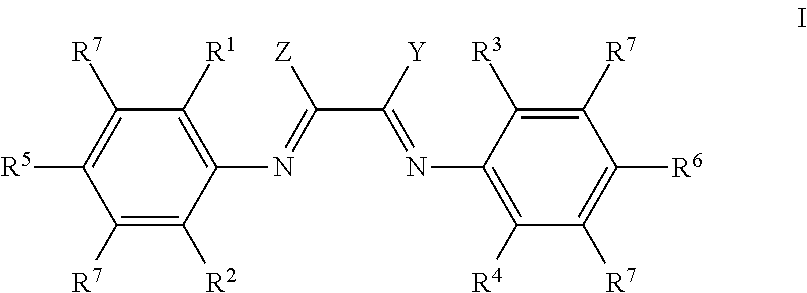

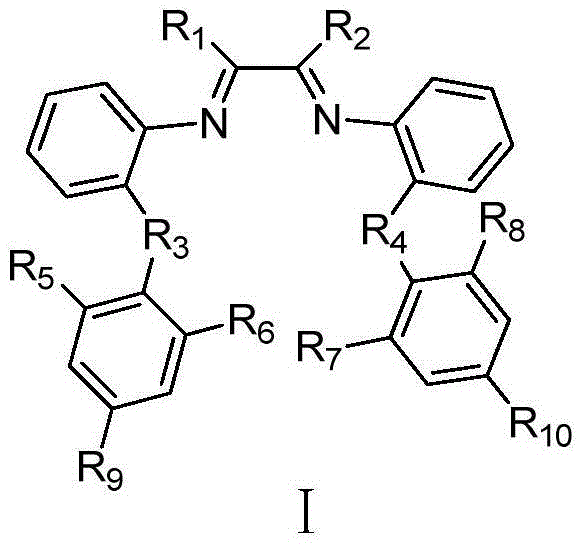

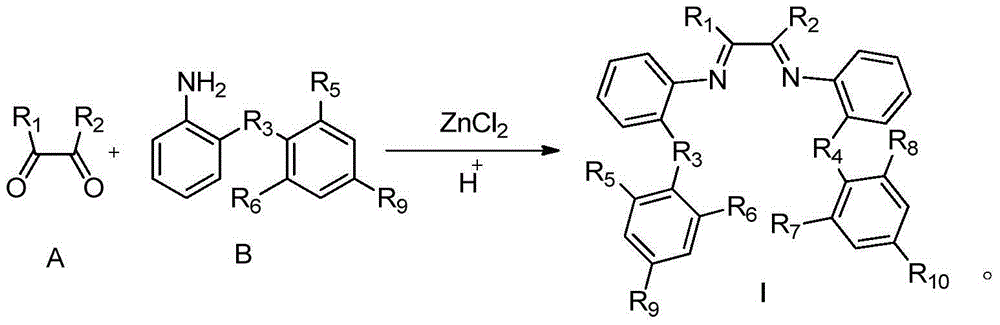

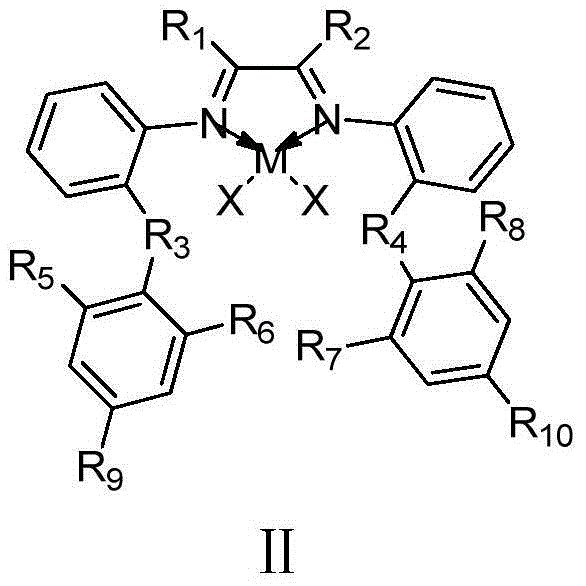

Catalyst ligand for direct synthesis of lubricant base oil by ethylene, complex of catalyst ligand as well as preparation method and application

The invention belongs to the field of preparation of lubricating oil and provides a catalyst ligand for direct synthesis of lubricant base oil by ethylene. The ligand is a ligand which adopts a symmetrical structure and is shown in the following formula I (shown in the description), wherein R1 and R2 are hydrogen atoms or C1-C4 alkyl groups, or R1, R2 and adjacent carbon atoms form one of the following substituted or non-substituted groups: acenaphthenyl, phenanthryl and C5-C8 naphthenic base, and R1 and R2 are the same; R3 and R4 are sulphur atoms, carbonyl, sulfuryl, carbon atoms or CHOH, and R3 and R4 are the same; R5-R8 are H, C1-C4 alkyl groups and halogen, R5(R6)=R7(R8); R9 and R10 are H, C1-C4 alkyl groups and halogen and the R9 and R10 are the same. The ligand provided by the invention has the symmetrical structure, and is synthesized through one step, easy to control and high in yield. Since a metal complex is adopted, catalytic efficiency is high, catalytic activity is high and the bromine number of oily polyethylene obtained through preparation is lower.

Owner:CHANGZHOU UNIV

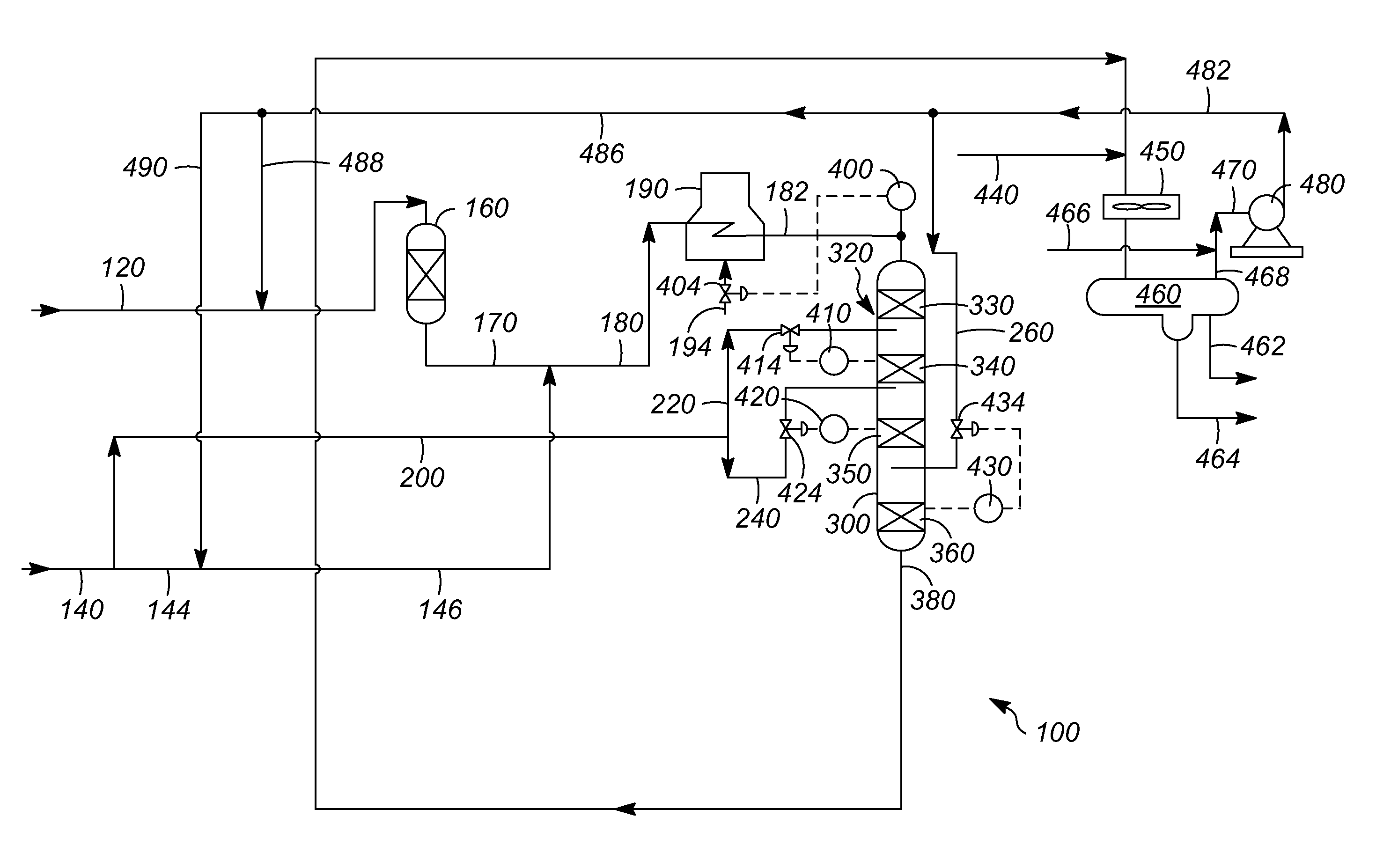

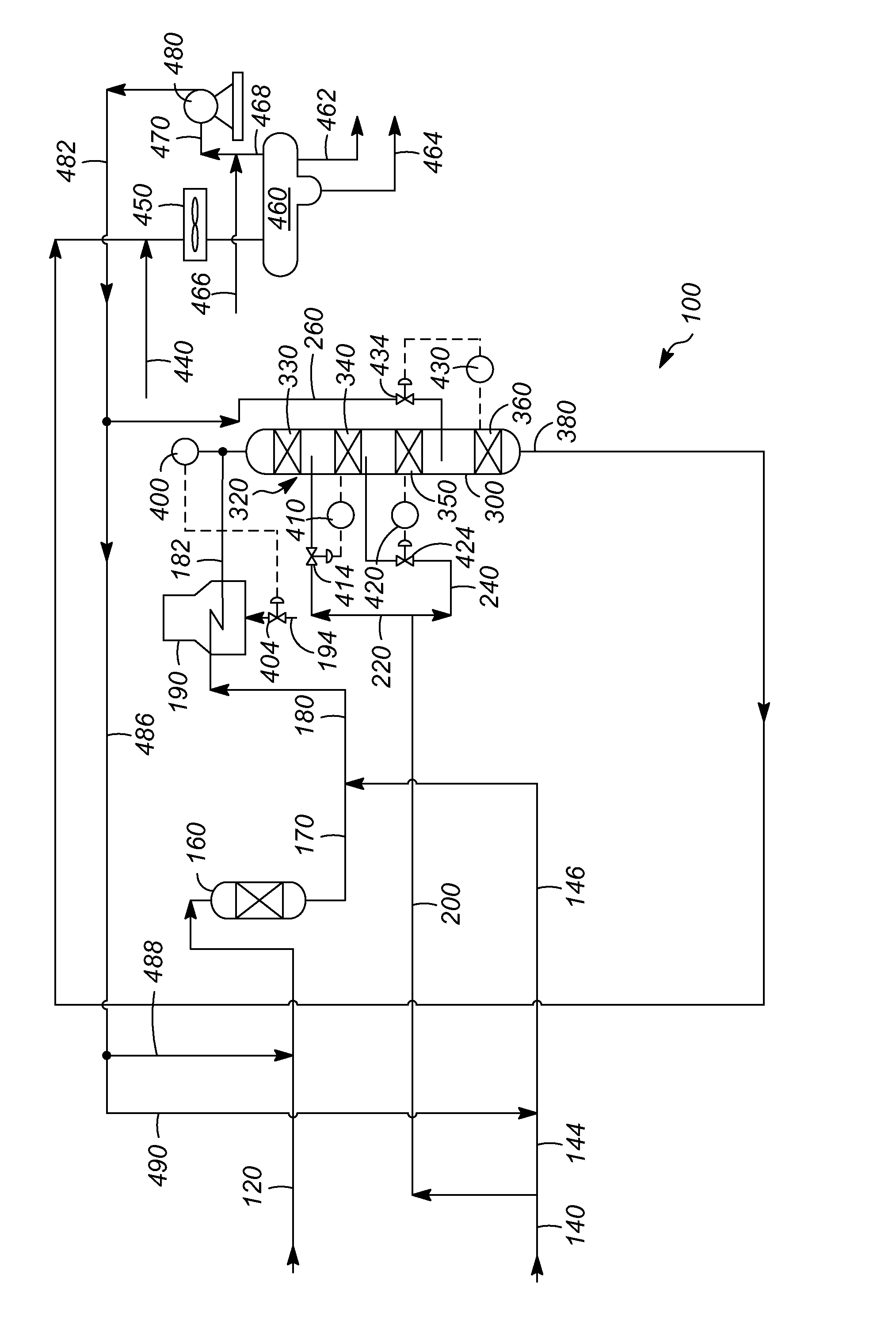

Hydrotreating process and controlling a temperature thereof

ActiveUS8911616B2Reduce the amount requiredTreatment with plural parallel cracking stages onlyTreatment with plural parallel stages onlyBromine numberNaphtha

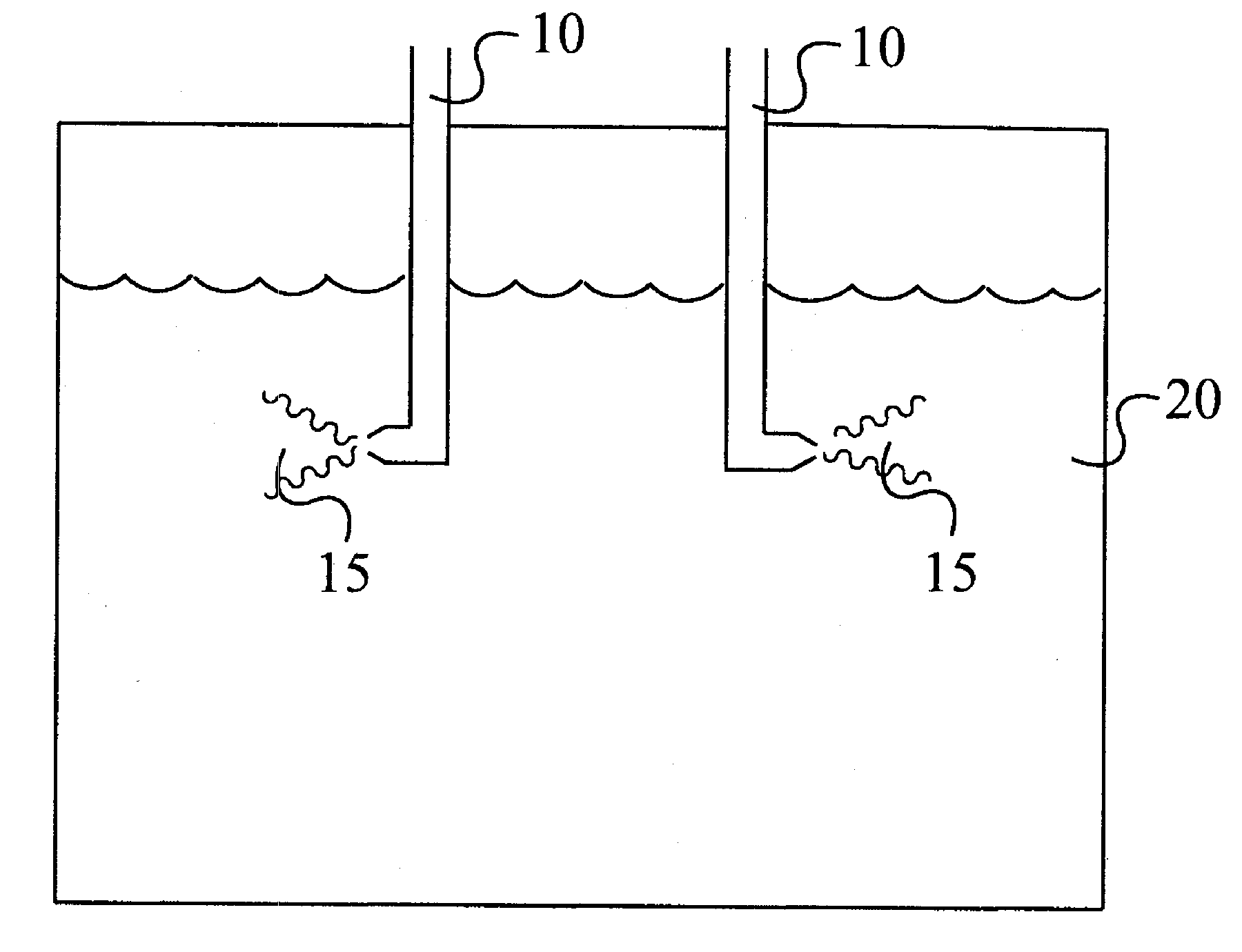

One exemplary embodiment can be a hydrotreating process. The hydrotreating process can include providing a first feed stream having a coker naphtha with a bromine number of about 10-about 120, combining the first feed stream with a second feed stream having a straight run naphtha with a bromine number of less than about 10 to create a combined feed, providing the combined feed to a hydrotreating reactor having at least one catalyst bed, and separating a quench stream from the second feed stream and providing the quench stream after the at least one catalyst bed.

Owner:UOP LLC

Catalyst for non-hydrogenating olefin removal of aromatic hydrocarbon and preparation method for catalyst

InactiveCN103041841AEliminate pollutionHigh deolefin catalytic performanceMolecular sieve catalystsChemical modification purification/separationBromine numberBromine

The invention aims to prepare a catalyst for non-hydrogenating olefin removal of aromatic hydrocarbon by using waste catalytic cracking catalyst. The catalyst for non-hydrogenating olefin removal of the aromatic hydrocarbon is prepared by the following steps: mixing the waste catalytic cracking catalyst with the metal content less than 5,000 ug / g and aluminum oxide dry glue powder; extruding into strips and forming; and roasting at the temperature of 540 DEG C for 4 hours to obtain the catalyst for non-hydrogenating olefin removal of the aromatic hydrocarbon, wherein the mass content of the waste catalytic cracking catalyst is 60 to 80 percent; the aluminum oxide content is 20 to 40 percent; and the acid content of the catalyst is 0.3 to 0.5 mmol / g, the specific surface area of the catalyst is 290 to 320 m<2> / g and the average aperture of the catalyst is 8.5 to 10 nm. When the catalyst is used for catalyzing the non-hydrogenating olefin removal of the aromatic hydrocarbon, the bromine number can be reduced from 3,000 mg / 100 g to below 20 mg / 100 g commonly and the aromatic hydrocarbon loss is less than 0.01 percent.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY +1

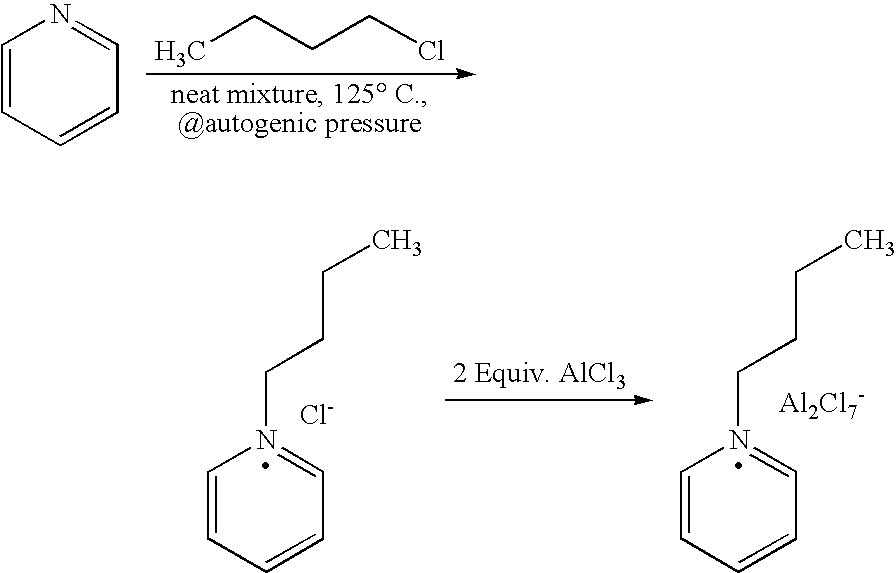

Preparation and provision of high assay decabromodiphenylethane

ActiveUS20080227903A1Extended reaction timeDecrease productivityMolecular sieve catalystCatalystsBromine numberLiquid state

High assay, reaction-derived decabromodiphenylethane product is prepared by feeding (i) diphenylethane or (ii) partially brominated diphenylethane having an average bromine number less than about two, or (iii) both of (i) and (ii), into the liquid confines of a reaction mixture. Such reaction mixture is (a) formed from components comprised of excess liquid bromine and aluminum-based Lewis acid bromination catalyst, and (b) maintained at one or more elevated reaction temperatures of from about 45°-90° C., and at least when elevated pressure is needed to keep a liquid state in the reaction mixture at the temperature(s) used, the reaction mixture is at such an elevated pressure, whereby ar-bromination occurs. The feeding is conducted at a rate slow enough to form high assay reaction-derived decabromodiphenylethane product, which is an effective flame retardant.

Owner:ALBEMARLE CORP

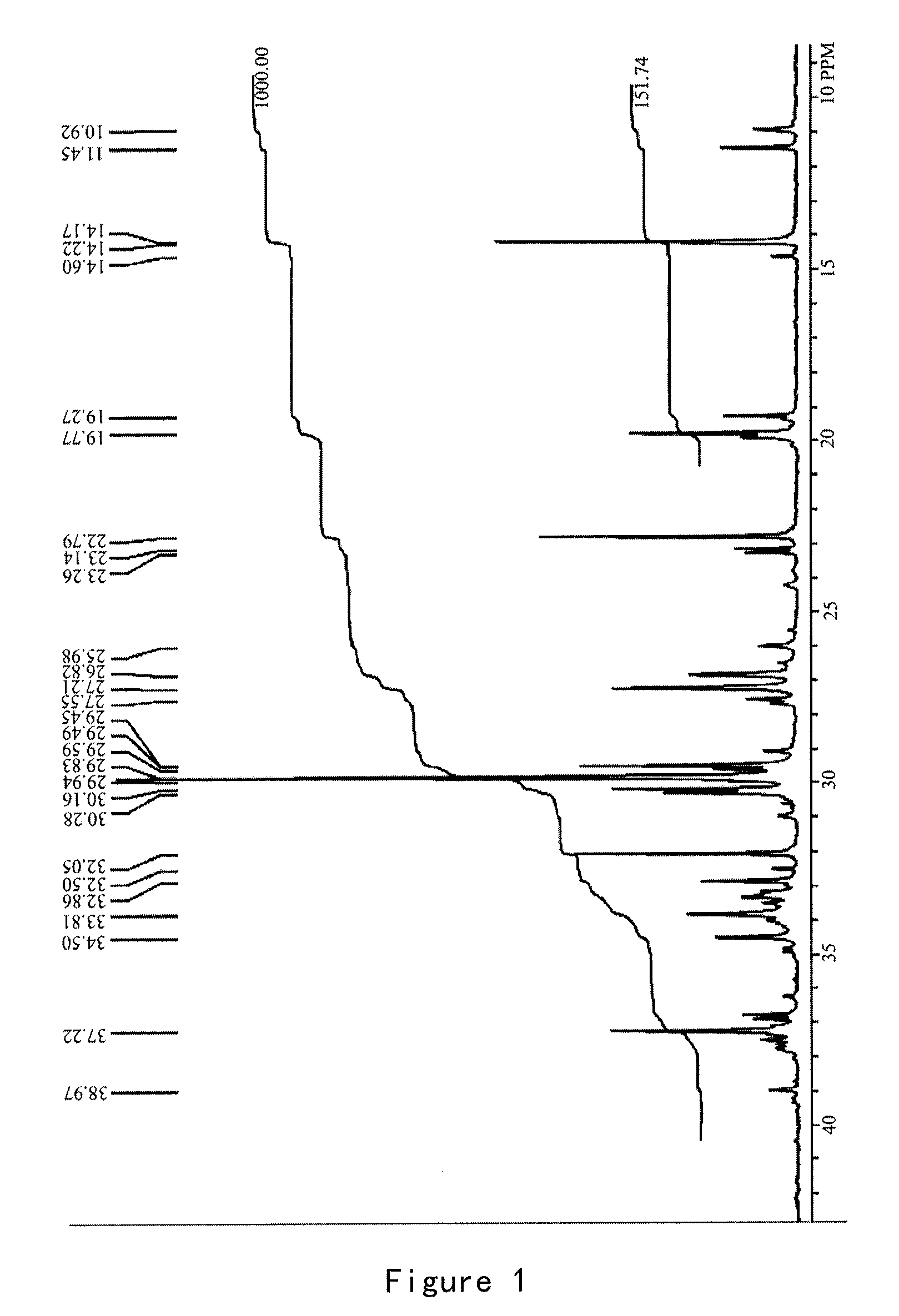

Low-cost poly-alpha-olefin base oil and preparation method thereof

InactiveCN103374433AEasy to makeImmobilized reaction efficiency is highTreatment with hydrotreatment processesBase-materialsAlpha-olefinTert butyl

The invention discloses a low-cost PAO (poly-alpha-olefin) base oil and a preparation method thereof. The preparation method comprises the following steps: carrying out oligomerization reaction on raw materials isobutylene and C8-C12 alpha-olefins at 50-80 DEG C under the hydrogen partial pressure of 0.25-0.4 MPa and the reaction pressure of 0.5-1.0 MPa by using gamma-aluminum oxide (gamma-Al2O3)-supported nickel (II)-organic aluminum as a catalyst and tert-butyl chlorine as a cocatalyst, and carrying out after-treatment to obtain oligomers; and hydrogenizing the oligomers to obtain the PAO base oil. The C8-C12 alpha-olefin content in the obtained PAO base oil is 60-81 omega%, the number-average molecular weight of the base oil is less than 550, the molecular weight distribution is less than 15, the 100 DEG C kinematic viscosity is 8.8-28.0 mm<2> / s, the viscosity index is 121-147, the pour point is -38 to -52 DEG C, and the bromine number is less than 0.050 bromine g / 100g PAO.

Owner:上海泰强粘合剂有限公司 +1

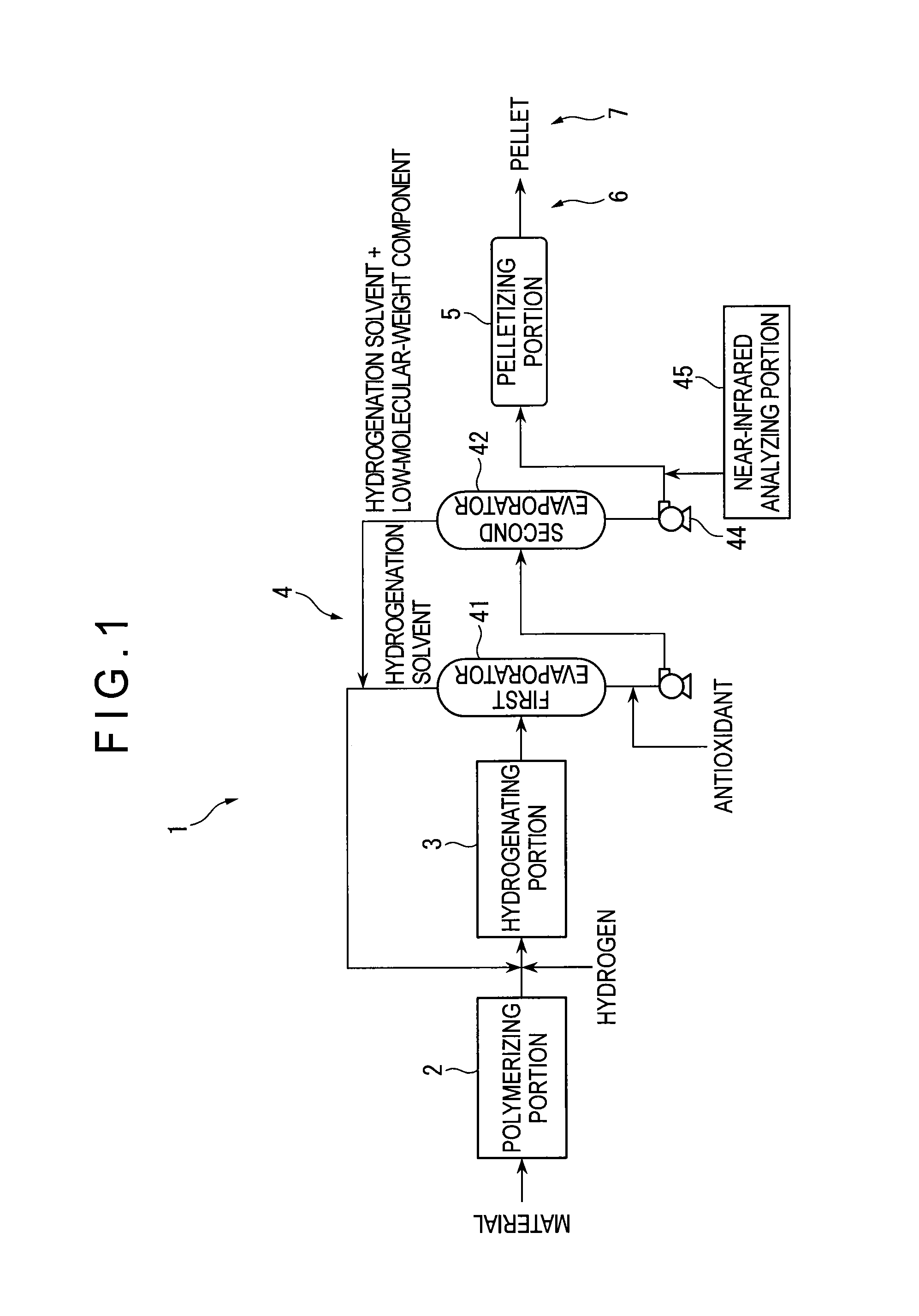

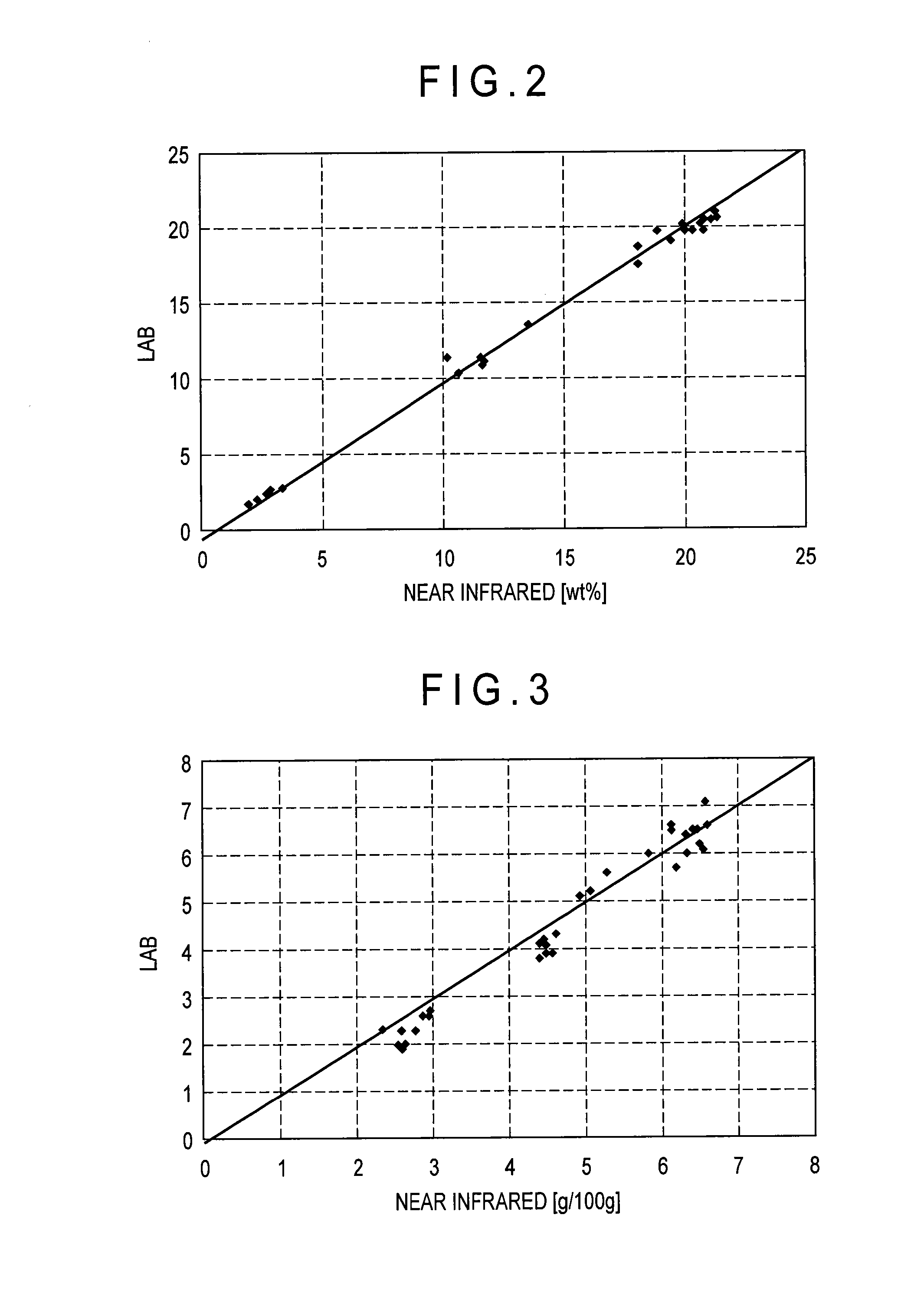

Process for producing hydrogenated petroleum resin

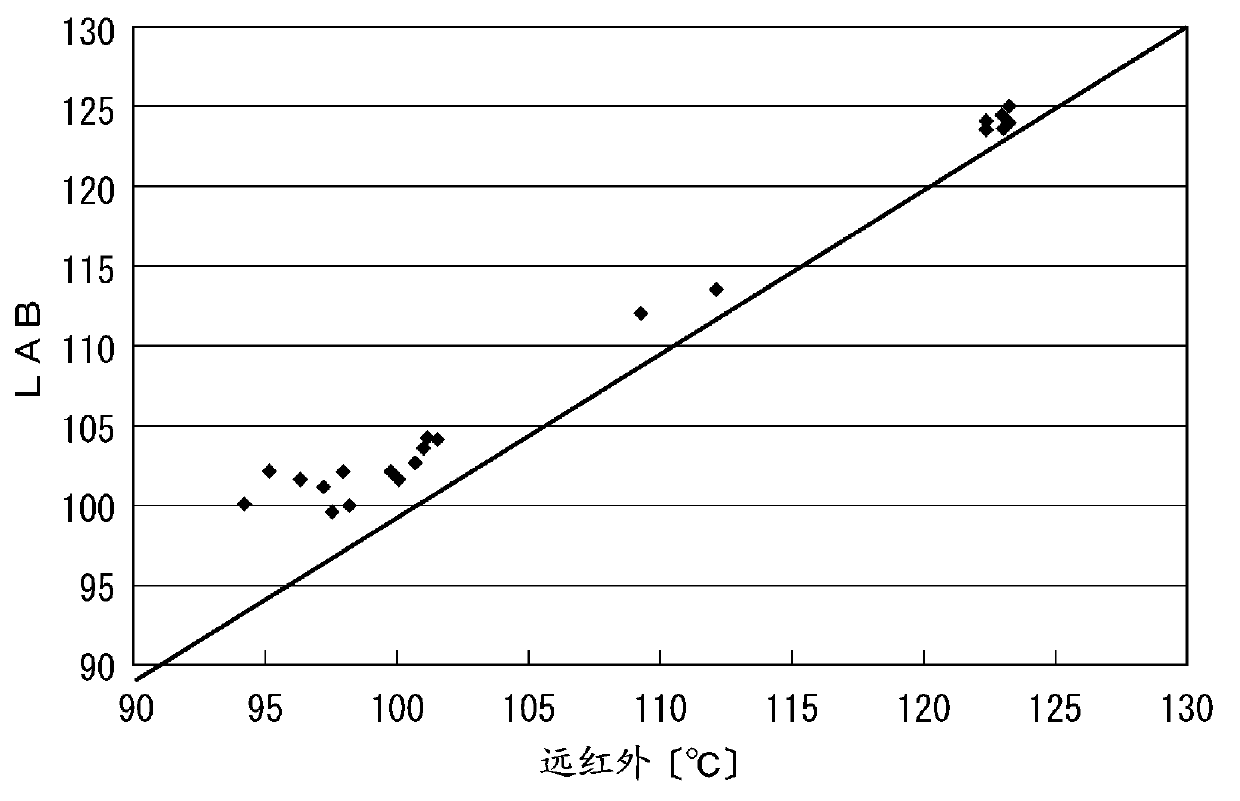

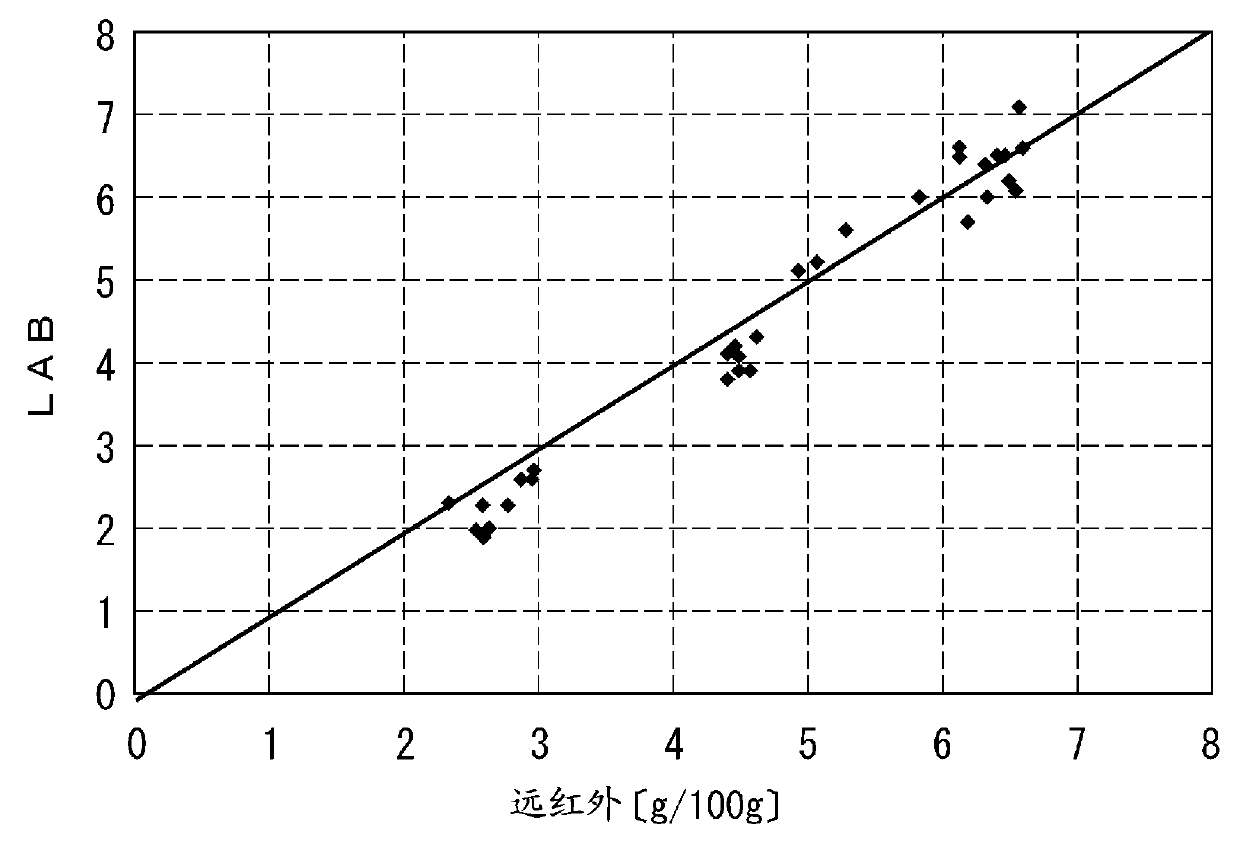

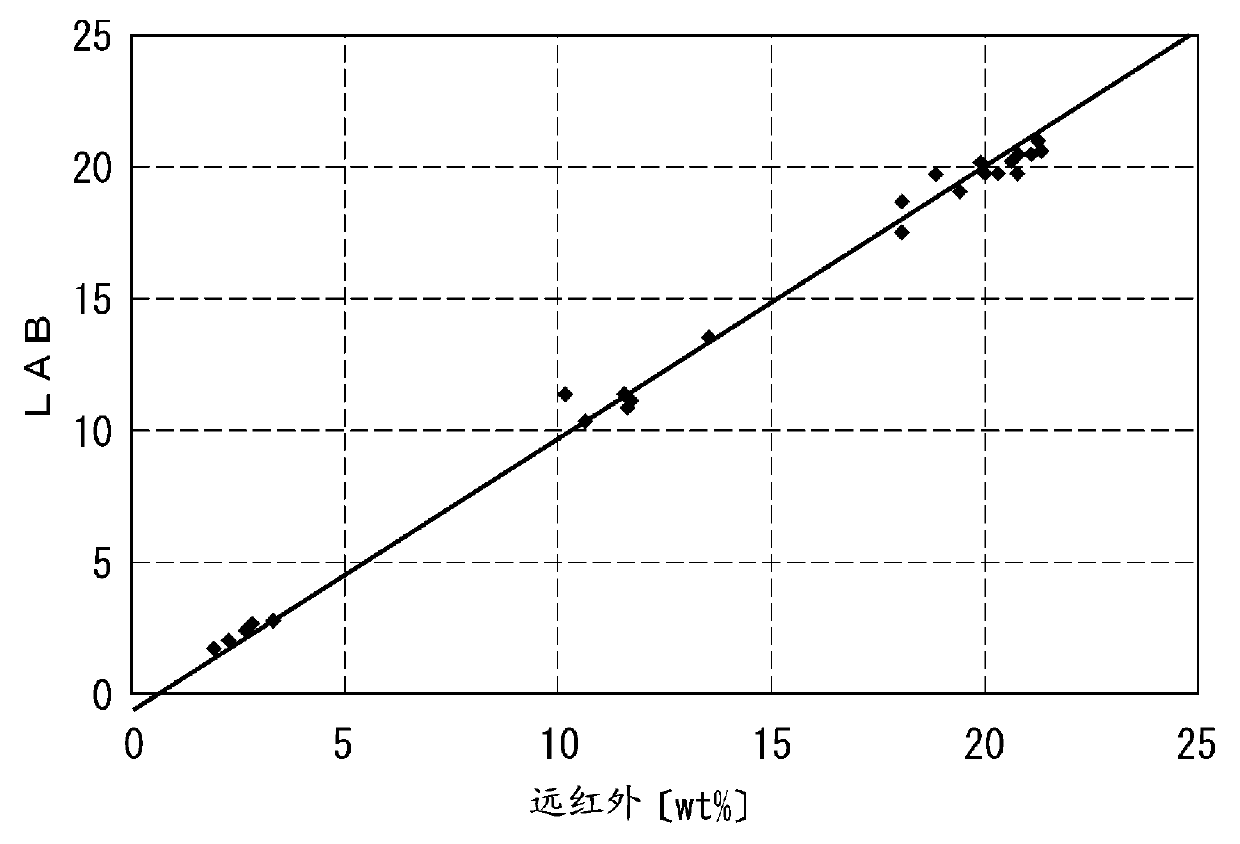

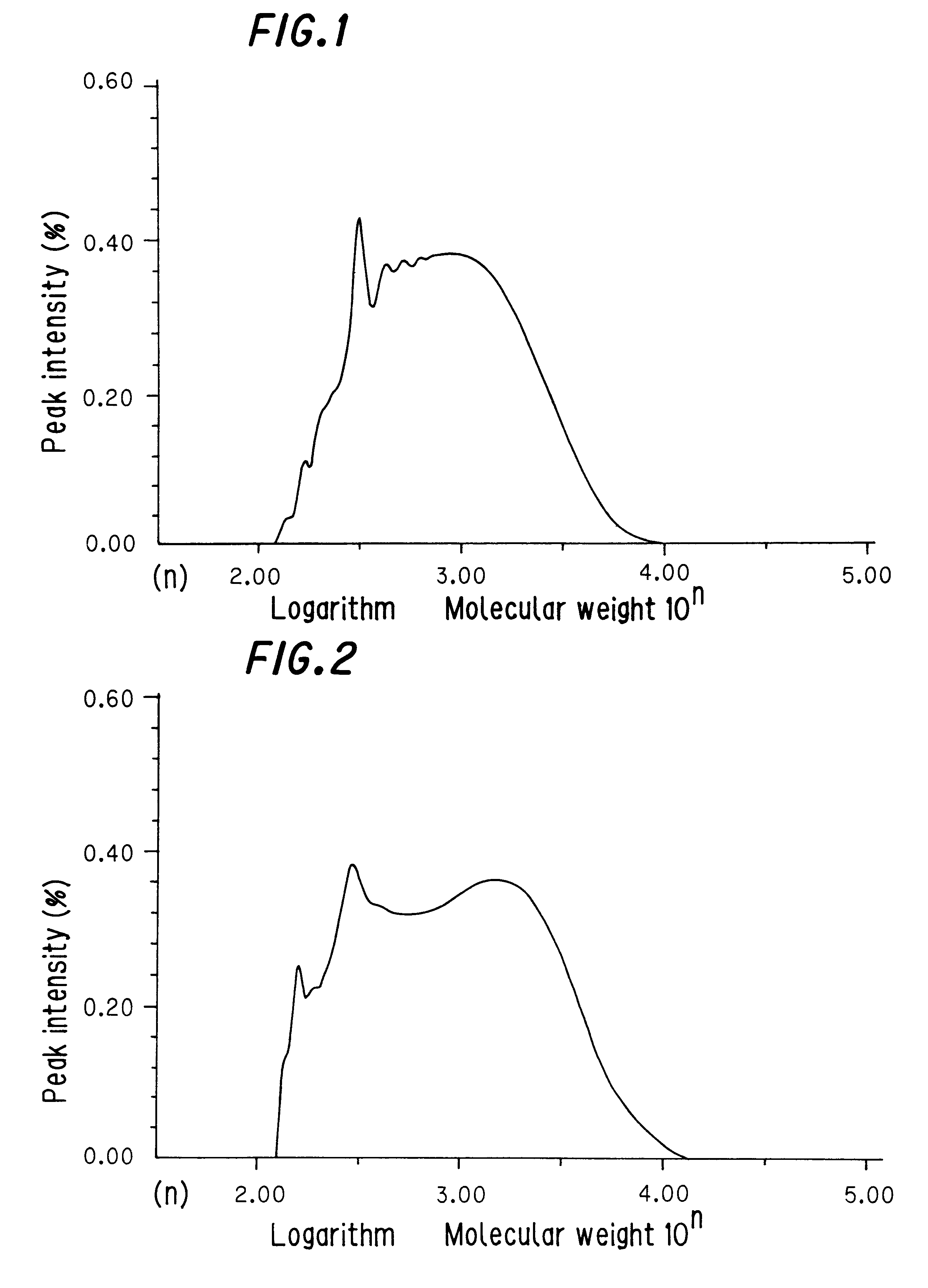

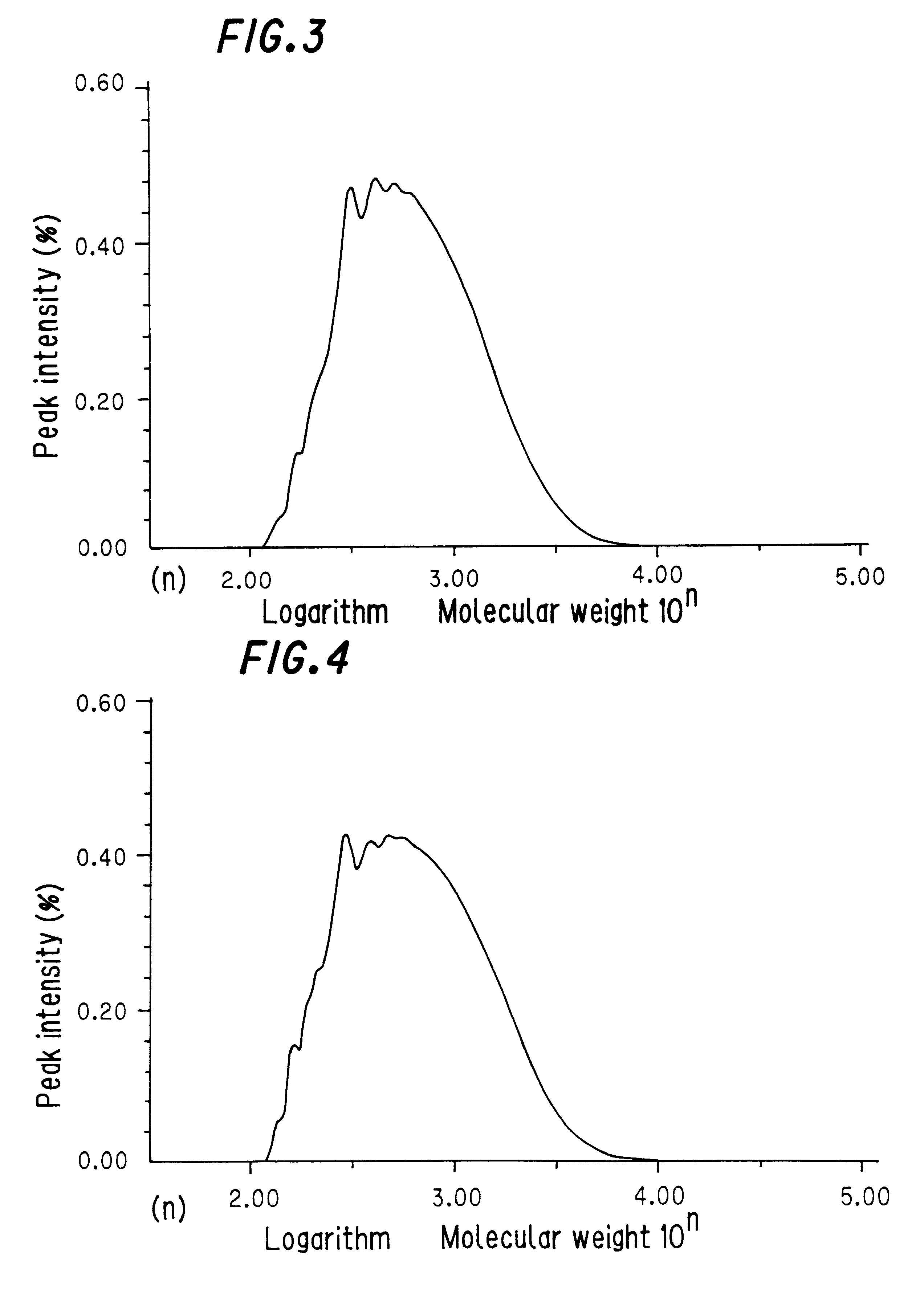

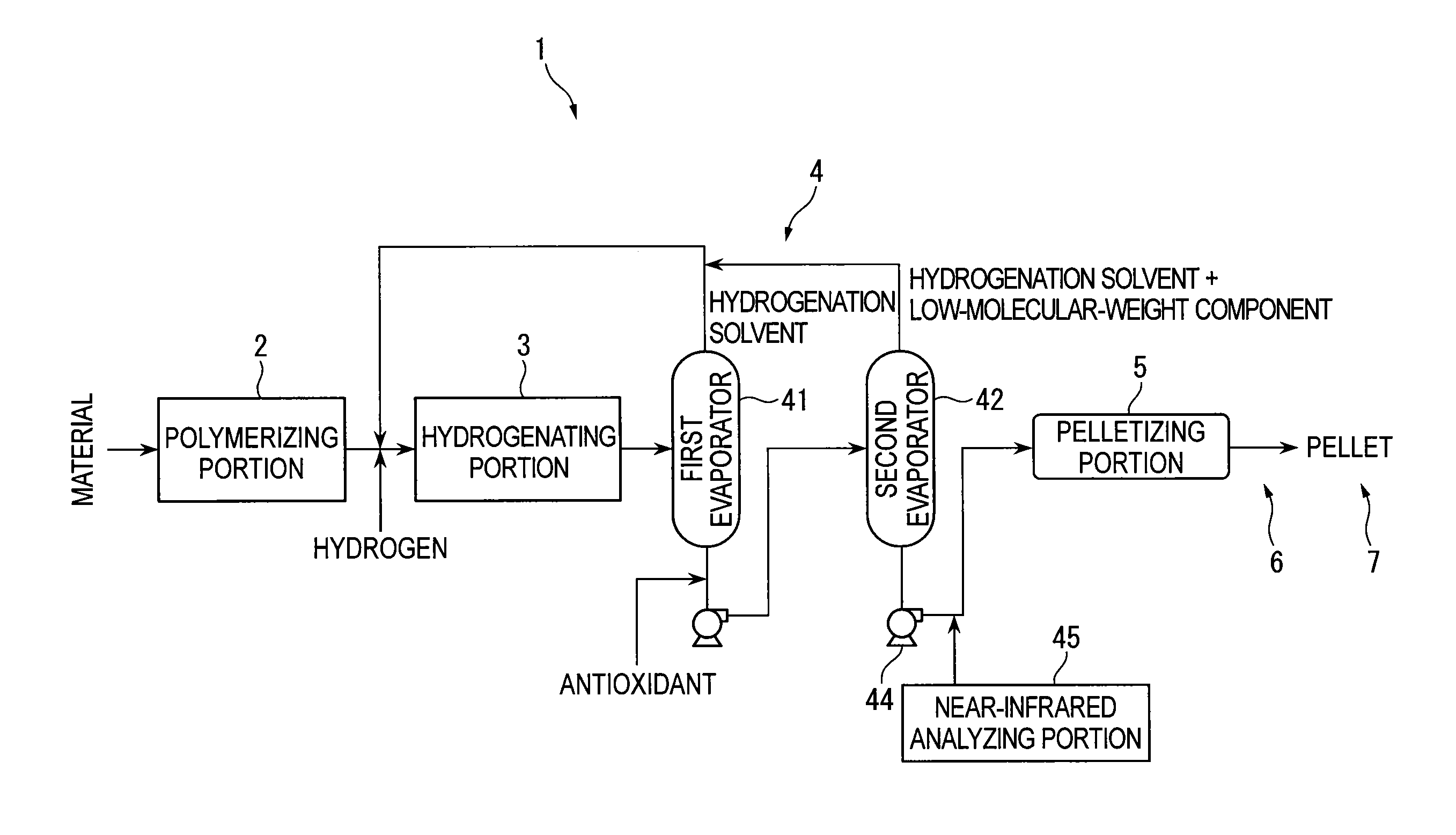

A hydrogenated compound (hydrogenated petroleum resin) which is a molten resin from which a hydrogenation solvent has been separated in a hydrogenation-solvent removal step is examined for a near-infrared absorption spectrum, and the aromatic content, bromine number, and softening point which are the values of properties of the hydrogenated compound are calculated on the basis of calibration curve data. Operation conditions concerning at least one of the temperature, pressure, reaction time, and hydrogen amount within a hydrogenation reaction part (3) are controlled so as to reduce both the difference between the aromatic content determined by the near-infrared analysis and the aromatic content of hydrogenated-petroleum-resin pellets to be produced and the difference between the bromine number determined by the analysis and the bromine number of the pellets. At least the temperature or the pressure of a thin-film evaporator (42) is controlled so as to reduce the difference between the softening point determined by the near-infrared analysis and the softening point of the hydrogenated-petroleum-resin pellets to be produced.

Owner:IDEMITSU KOSAN CO LTD

Copolymer and process for producing the same

Owner:IDEMITSU KOSAN CO LTD

Method for preparing dicyclopentadiene hydrogenated petroleum resin

ActiveCN102558444BGood dispersionLarge specific surface areaCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsBromine numberHydrogen

The invention relates to a method for preparing dicyclopentadiene hydrogenated petroleum resin. Dicyclopentadiene petroleum resin is used as a raw material and hydrogenated under the action of a catalyst to prepare the dicyclopentadiene hydrogenated petroleum resin, wherein the weight ratio of the dicyclopentadiene petroleum resin to the catalyst is 100: (3-6), the hydrogenating temperature is 170 to 215 DEG C, the pressure of the reaction hydrogen is 3.0 to 5.5MPa, and the reaction time is 4 to 8 hours; a silicon-aluminum composite oxide is used as a carrier in the catalyst, the active ingredient of the catalyst is Pd, the weight of the Pd is 0.1 to 1.0 percent of the weight of the catalyst, the specific surface of the catalyst is 350 to 420 m<2> / g, and the pore volume is 0.6 to 0.7ml / g;and according to the dicyclopentadiene hydrogenated petroleum resin product prepared by the method, the bromine number is less than or equal to 2.0gBr / 100g, the chromaticity (Gardner) is less than orequal to 1, and the softening point is 110 to 120 DEG C.

Owner:PETROCHINA CO LTD

Method for removing unsaturated hydrocarbon and thiophene from coking benzene

InactiveCN101691321AHarm reductionSimple and ReactiveChemical modification purification/separationBenzeneBromine number

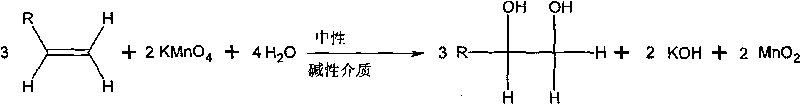

The invention relates to a method for removing unsaturated hydrocarbon and thiophene from coking benzene, which comprises the following steps: stirring potassium permanganate, a metal chloride water solution and coking benzene in a container for reaction; converting the unsaturated hydrocarbon and the thiophene in the coking benzene into substances capable of dissolving in water easily, and separating and washing the substances; and then refining to obtain the coking benzene. The method is suitable for coking benzene, coking crude benzene, petroleum benzene, methylbenzene, reagent benzene and the like, and ensures that the acid washing color index is not deeper than 0.1g / l, the bromine number is not higher than 0.03g / 100ml, the total sulfur content is not higher than 1mg / kg, and the quality index reaches the quality level of the superior product of the coking benzene in China standard.

Owner:TAIYUAN UNIV OF TECH +1

Process for producing hydrogenated petroleum resin

A near-infrared absorption spectrum of a hydrogenated compound (hydrogenated petroleum resin) in a form of a molten resin from which a hydrogenation solvent is separated in a hydrogenation solvent removing step is measured to calculate an aromatic content ratio and a softening point as physical property values of the hydrogenated compound based on analytical curve data. At least one of a temperature, pressure, reaction time and hydrogen content in a hydrogenating portion is controlled such that a difference between the aromatic content ratio and the bromine number measured in the near-infrared spectrometry and an aromatic content ratio and bromine number of a target hydrogenated petroleum resin pellet becomes small. At least one of a temperature and pressure in a thin-film evaporator is controlled such that a difference between a softening point measured in the near-infrared spectrometry and a softening point of the target hydrogenated petroleum resin pellet becomes small.

Owner:IDEMITSU KOSAN CO LTD

Petroleum resin hydrogenation catalyst and preparation and application methods thereof

InactiveCN104174410ALarge hole volumeEasy to prepareMetal/metal-oxides/metal-hydroxide catalystsBromine numberHydrogenation reaction

The invention provides a petroleum resin hydrogenation catalyst. The catalyst comprises a titanium oxide-aluminum oxide composite oxide carrier, Ni, an IB-group element and a VIB-group element, wherein the Ni, the IB-group element and the VIB-group element are supported by the carrier. Under catalysis of the catalyst, a petroleum resin hydrogenation reaction has high selectivity and a high conversion rate, and hydrogenated petroleum resin with high color purity, low bromine number and good thermal stability can be prepared. In addition, a preparing method of the catalyst is simple and low in cost and is suitable for industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst composite for dehydrogenation of hydrocarbons and its preparation method

InactiveCN104105546BOrganic-compounds/hydrides/coordination-complexes catalystsCatalystsBromine numberHalogen

Owner:RELIANCE INDUSTRIES LIMITED

Preparation and provision of high assay decabromodiphenylethane

ActiveUS7994373B2Extended reaction timeDecrease productivityMolecular sieve catalystCatalystsBromine numberBromine

High assay, reaction-derived decabromodiphenylethane product is prepared by feeding (i) diphenylethane or (ii) partially brominated diphenylethane having an average bromine number less than about two, or (iii) both of (i) and (ii), into the liquid confines of a reaction mixture. Such reaction mixture is (a) formed from components comprised of excess liquid bromine and aluminum-based Lewis acid bromination catalyst, and (b) maintained at one or more elevated reaction temperatures of from about 45°-90° C., and at least when elevated pressure is needed to keep a liquid state in the reaction mixture at the temperature(s) used, the reaction mixture is at such an elevated pressure, whereby ar-bromination occurs. The feeding is conducted at a rate slow enough to form high assay reaction-derived decabromodiphenylethane product, which is an effective flame retardant.

Owner:ALBEMARLE CORP

Petroleum resin hydrogenation catalyst and preparation method and application thereof

ActiveCN105749972AImprove sulfur resistanceExtended service lifeOrganic-compounds/hydrides/coordination-complexes catalystsHeteropoly acidPetroleum

The present invention relates to a petroleum resin hydrogenation catalyst which is a heteropolyacid-salt-modified skeletal nickel catalyst, the catalyst comprises Ni-Al-M, a component M is one or two or more of Fe, Co, Mn and Zn, or one or two or more of phosphorus molybdenum heteropoly acid salts or phosphorus tungsten heteropoly acid salts, the weight percentages of solid powder Ni, Al and M are as follows: Ni is 30-90%, Al is 5-60 %, and M is 0.1-15%, and the sum of the weight percentage of the Ni, Al and M is 100%. An added cocatalyst can increase the skeletal nickel catalyst sulfur resistant properties, and can effectively increase the service life of the catalyst. The petroleum resin hydrogenation catalyst is used for petroleum resin hydrogenation, reaction conditions are mild, thermal stability of obtained hydrogenation resin is improved, and bromine number and Gardner chromaticity are decreased obviously.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Aqueous electrodeposition paints and the production and use thereof

Aqueous electrophoretic lacquer capable of being deposited cataphoretically, containingA) an aqueous dispersion of cationically modified polyurethane (meth)acrylates (a1) with terminal, ethylenically unsaturated (meth)acrylic double bonds, and reactive thinner (a2) with at least two ethylenically unsaturated (meth)acrylic double bonds, the (meth)acrylic double bonds of the mixture of (a1) and (a2) corresponding to a bromine number of 20 to 150 g bromine / 100 g solids, andB) photoinitiators and optionally free-radical initiators capable of thermal activation,the terminal, ethylenically unsaturated (meth)acrylic double bonds of the polyurethane (meth)acrylates being bonded with the anionically modified polyurethane prepolymer via urethane, urea, amide or ester groups,and optionally conventional auxiliary substances and additives, pigments and / or fillers.

Owner:EI DU PONT DE NEMOURS & CO

Catalytic system for preparation of high branched alkane from olefins

ActiveUS9315755B2Organic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsBromine numberOlefin polymerization

The present invention discloses a catalytic system for preparing highly branched alkane from olefin, which contains novel nickel or palladium complexes. In the presence of the catalytic system, highly branched oily alkane mixture can be efficiently obtained from olefins (such as ethylene) under mild conditions. The alkane mixture has a low bromine number, and can be used as a processing aid(s) and lubricant base oil with high-performance. Provides also was a method for preparing the catalyst and a method for preparing an oily olefin polymer.

Owner:NANJING CHEMRUN CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com