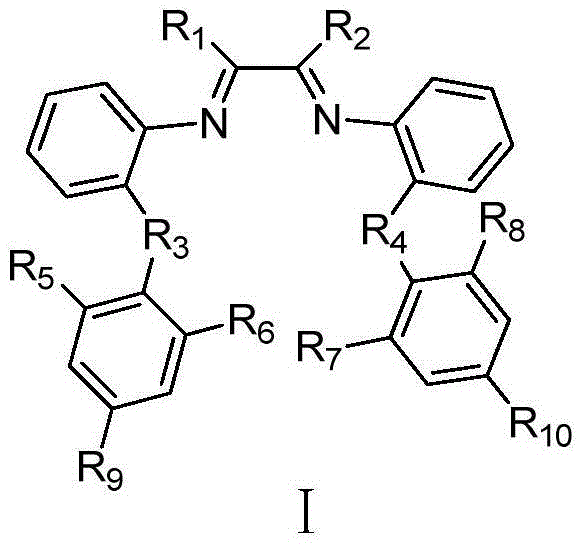

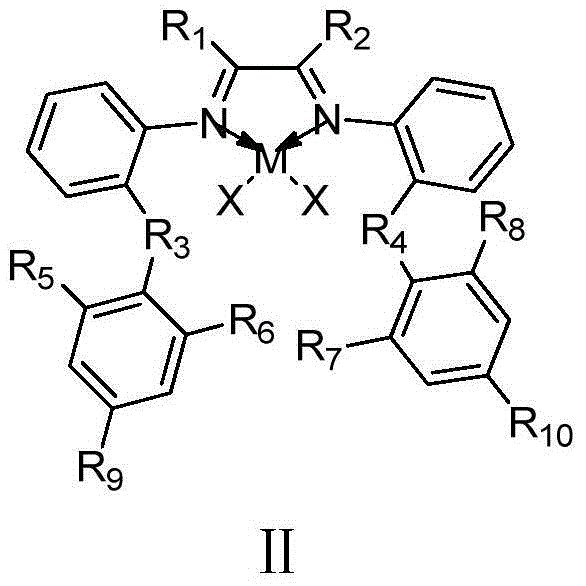

Catalyst ligand for direct synthesis of lubricant base oil by ethylene, complex of catalyst ligand as well as preparation method and application

A technology for synthesizing lubricating oil and base oil, which is applied to the preparation of organic compounds, lubricating compositions, iron-organic compounds, etc. It can solve the problems of high purity of 1-decene, high bromine value of oily polyethylene, and difficult control, and achieve Good catalytic activity, high catalytic efficiency and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

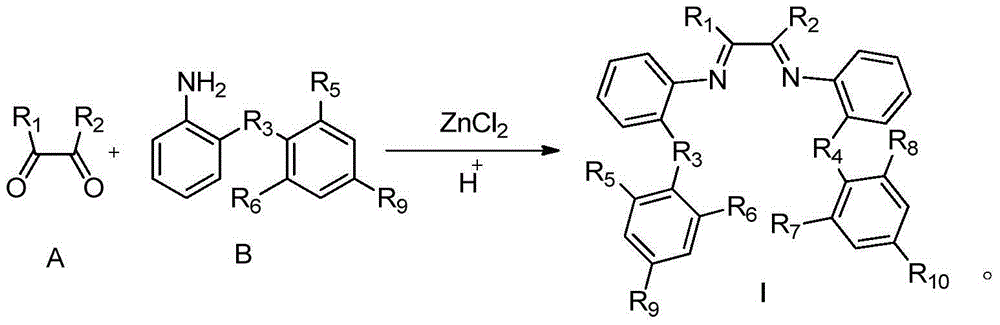

Method used

Image

Examples

Embodiment 1

[0045] Synthesis of ligand IA

[0046] Add 0.73g acenaphthenquinone (2mmol), 0.68g zinc chloride, and 10ml acetic acid to a 100ml round bottom flask, and heat to 60℃; add 2.01g (10mmol) of 2-aminodiphenyl sulfide, heat up to reaction temperature of 120℃, and react under reflux After 0.5h, filter while hot, and wash the filter residue with hot acetic acid, and then repeatedly wash with ether to remove acetic acid. A red solid powder is obtained, which is pure compound IA after being drained. The yield was 92%. 1 HNMR(400MHZ,CDCl 3 ): δ=7.19-8.32 (24H, m); Anal.Calcd.For C 36 H 24 N 2 S 2 : C, 78.80; H, 4.41. Found: C, 79.01; H, 4.39.

Embodiment 2

[0048] Synthesis of ligand IB

[0049] Add 0.73g acenaphthoquinone (2mmol), 0.68g zinc chloride and 12ml acetic acid to a 100ml round bottom flask, and heat to 60℃; add 2.33g (10mmol) of 2-aminodiphenylsulfone, heat up to reaction temperature of 120℃, reflux reaction 0.5 After h, filter while hot, and wash the filter residue with hot acetic acid, and then repeatedly wash with ether to remove acetic acid. A red solid powder is obtained, which is pure compound IB after being sucked dry. The yield was 81%. 1 HNMR(400MHZ,CDCl 3 ): δ=7.40-8.22 (24H, m); Anal.Calcd.For C 36 H 24 N 2 O 4 S 2 : C, 70.57; H, 3.95. Found: C, 71.01; H, 3.68.

Embodiment 3

[0051] Synthesis of Ligand IC

[0052] Add 0.09g (1mmol) diacetyl, 1.01g (5mmol) 2-aminodiphenyl sulfide and 86ml methanol to a 100ml round bottom flask. After stirring, add 0.15ml of formic acid and raise the temperature to 40℃. TLC monitors the reaction, 12h Then stop the reaction. After filtering, washing with methanol, the filtrate was spin-dried to obtain a yellow viscous substance, and methanol was added to ultrasound to obtain a pale yellow solid product with a yield of 58%. 1 HNMR(400MHZ,CDCl 3 ): δ=7.28-7.56 (18H, m), 2.15 (6H, s); Anal.Calcd.For C 28 H 24 N 2 S 2 : C, 74.30; H, 5.34. Found: C, 74.00; H, 4.98.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com