Patents

Literature

284 results about "Decene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Decene /dɛkɛn/ is an alkene with the formula C₁₀H₂₀. Decene contains a chain of ten carbon atoms with one double bond. There are many isomers of decene depending on the position and geometry of the double bond. Dec-1-ene is the only isomer of industrial importance. As an alpha olefin, it is used as a monomer in copolymers and is an intermediate in the production of epoxides, amines, oxo alcohols, synthetic lubricants, synthetic fatty acids and alkylated aromatics.

Process for producing liquid polyalphaolefin polymer, metallocene catalyst therefor, the resulting polymer and lubricant containing same

InactiveUS6858767B1Eliminate needHydrocarbons from unsaturated hydrocarbon additionHydrocarbonsPolymer scienceHydrogen

A liquid polyalphaolefin homo- or copolymer, preferably 1-decene, which is substantially amorphous is obtained by a polymerization process employing hydrogen and a particular type of metallocene catalyst. Additionally, liquid polyalphaolefin homo- or copolymer containing from 2 to about 12 carbon atoms possess a unique combination of properties, i.e., low molecular weight (Mw), low polydispersity index (Mw / Mn controllable kinematic viscosity (Kv100), low Iodine Number (I2) and low glass transition temperature (Tg) and are substantially amorphous. The liquid polyalphaolefin homo- or copolymers provided herein are useful for manufacturing a variety of products including lubricating oils in which the polyalphaolefin functions as a viscosity modifier.

Owner:DEUT BANK AG NEW YORK BRANCH

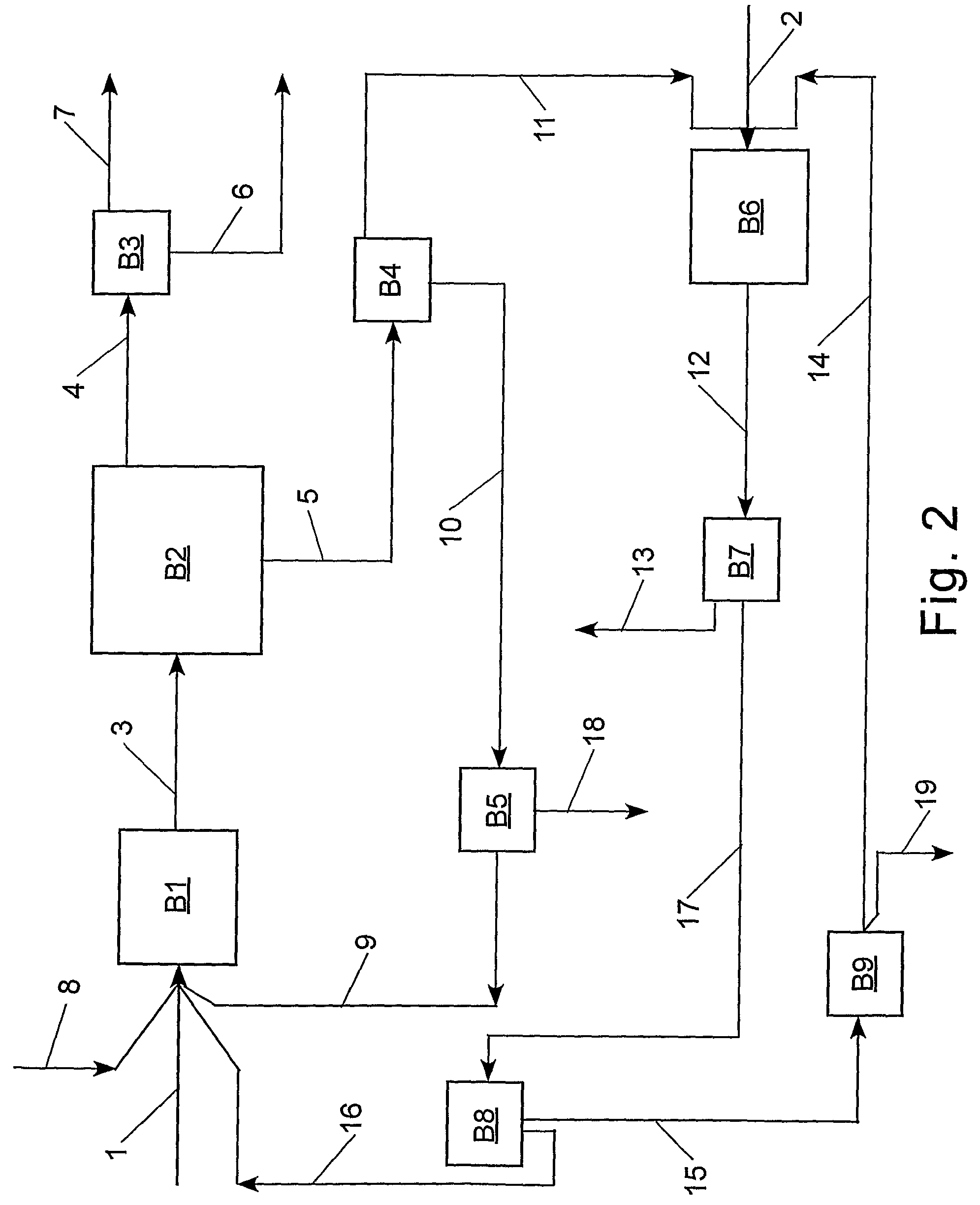

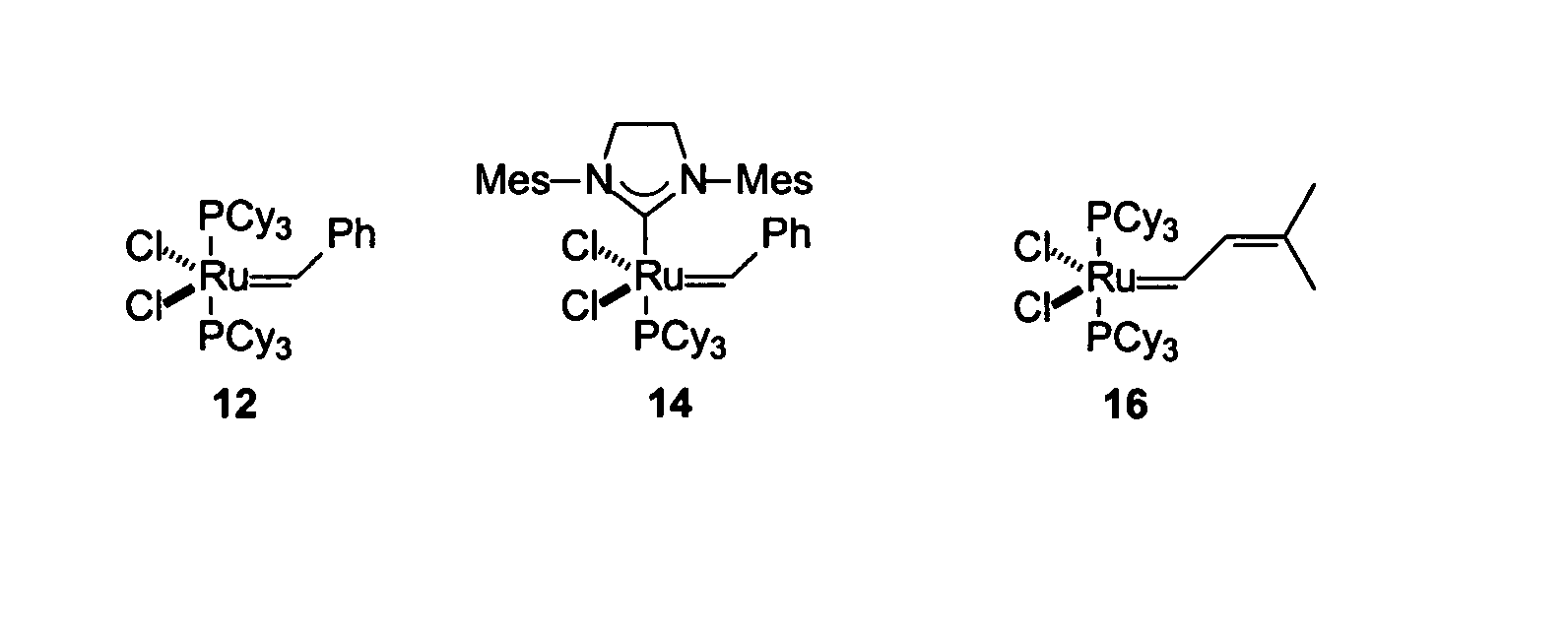

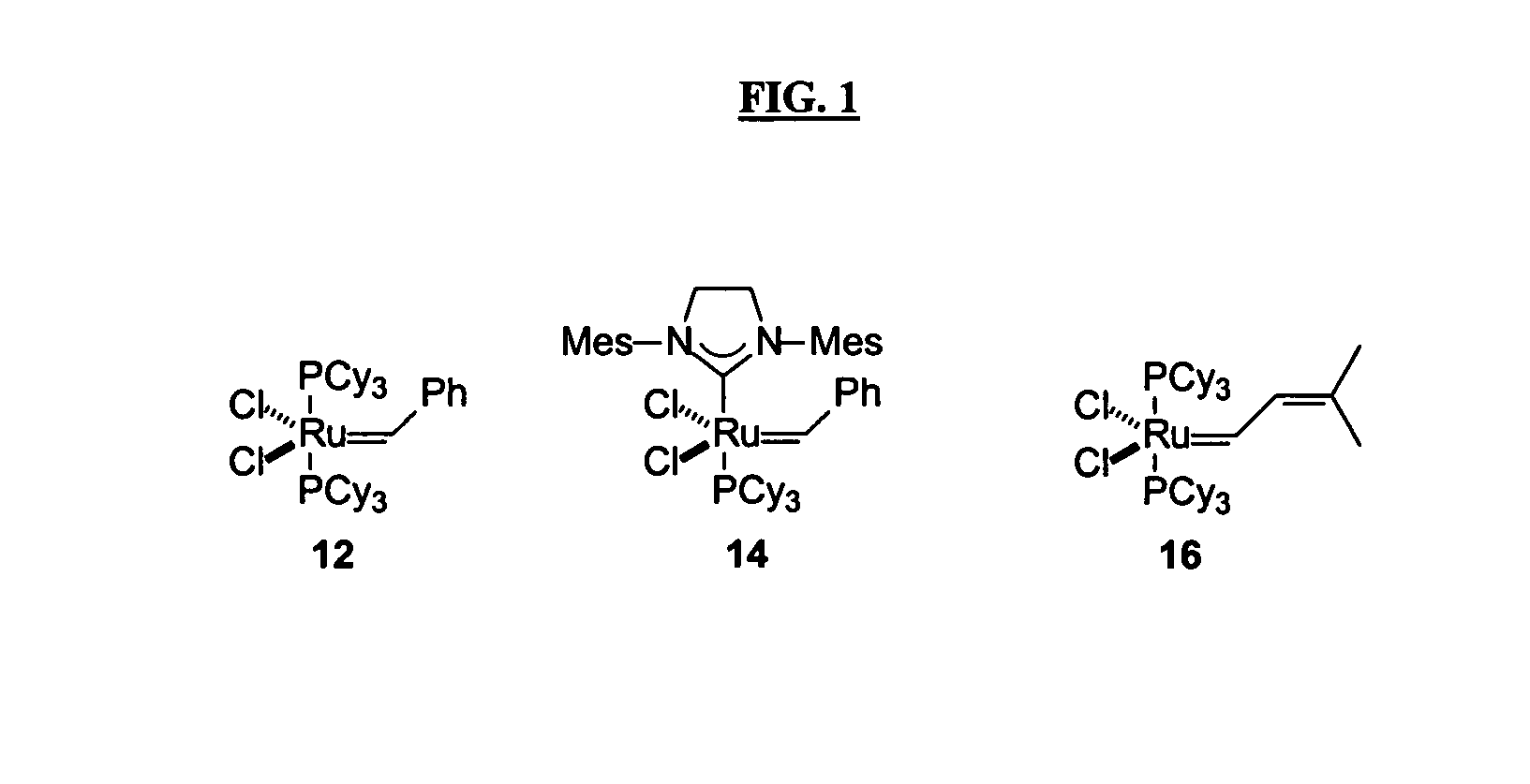

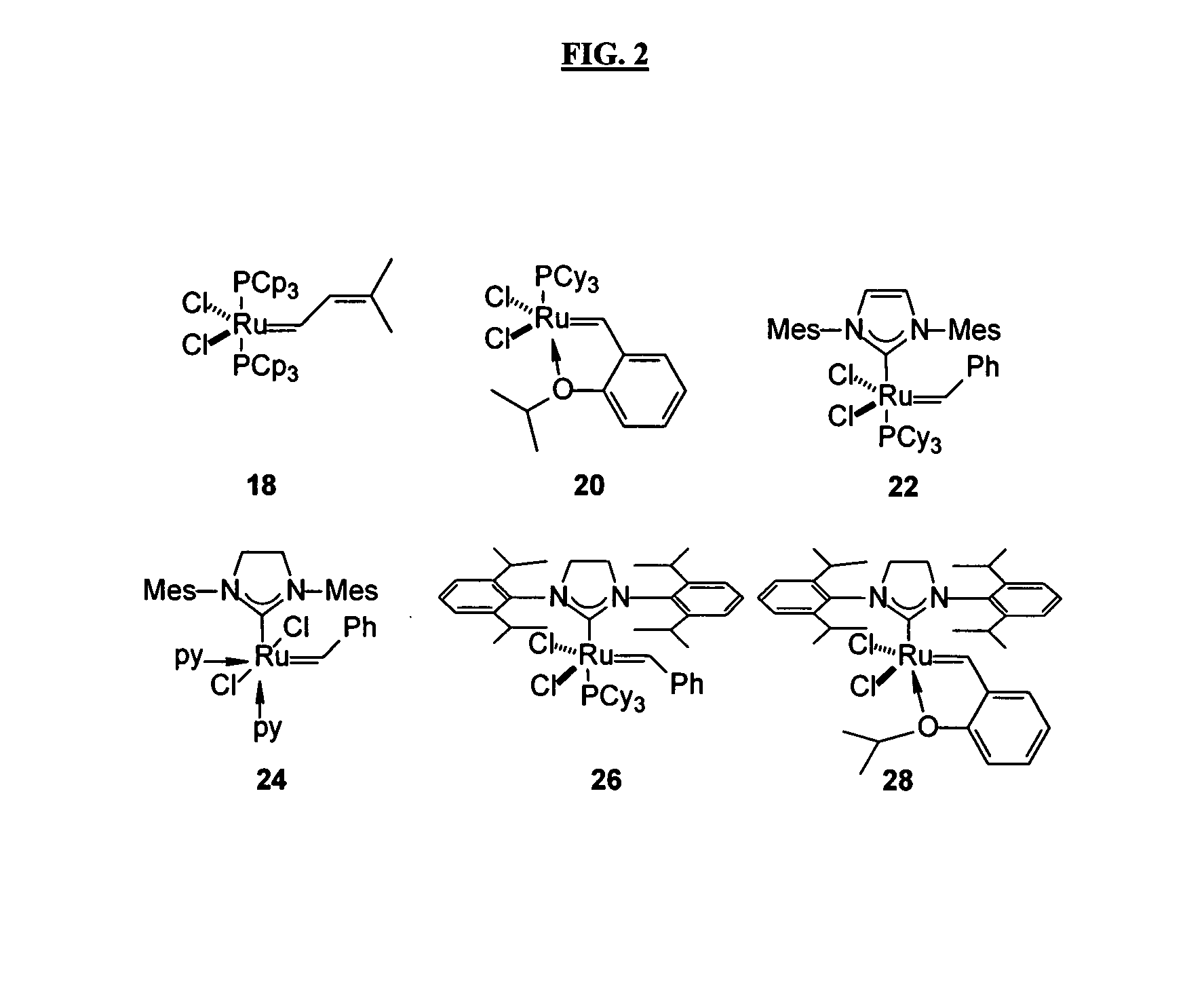

Metathesis of unsaturated fatty acid esters or unsaturated fatty acids with lower olefins

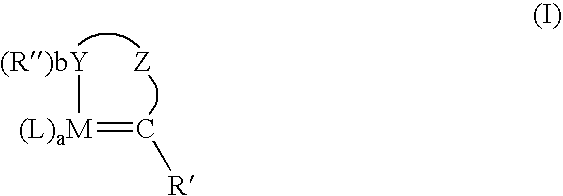

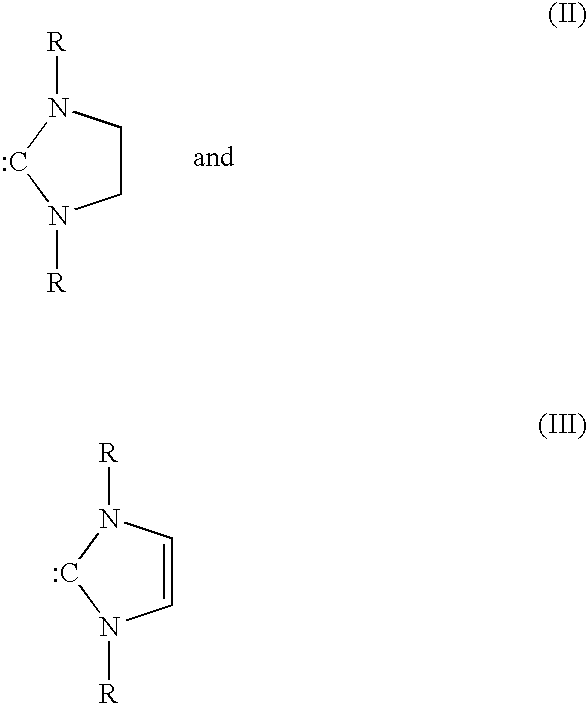

ActiveUS20050070750A1Excellent activityGood activity and efficiencyFatty acid chemical modificationFatty acids production/refiningOleic Acid TriglycerideOlefin metathesis

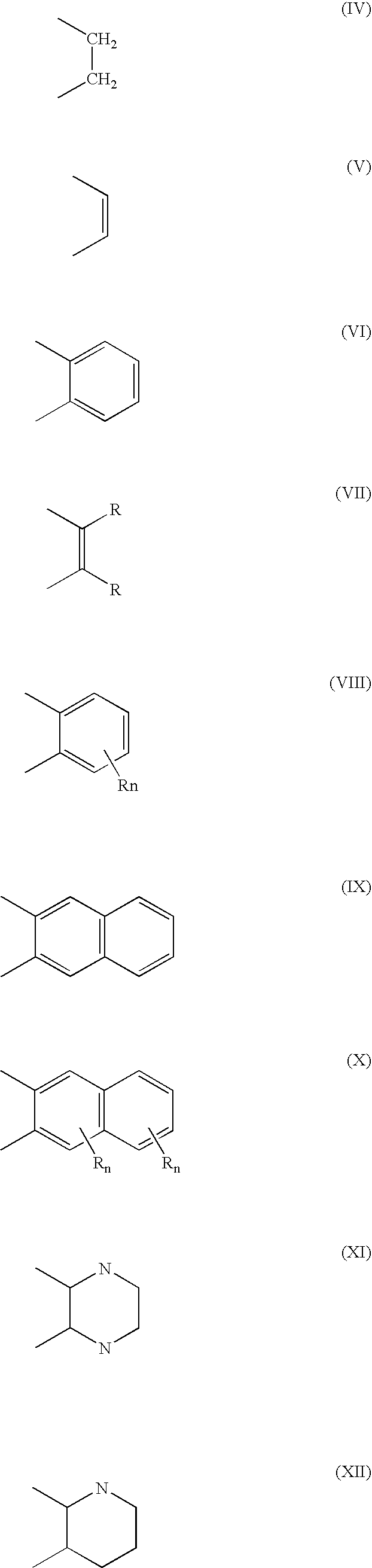

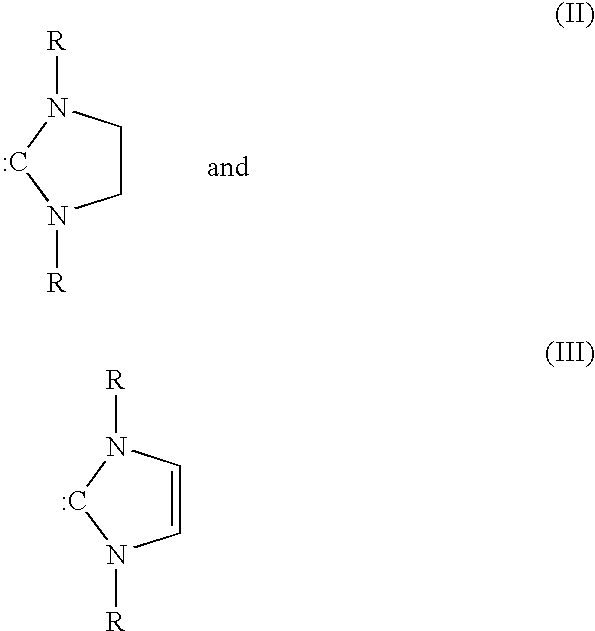

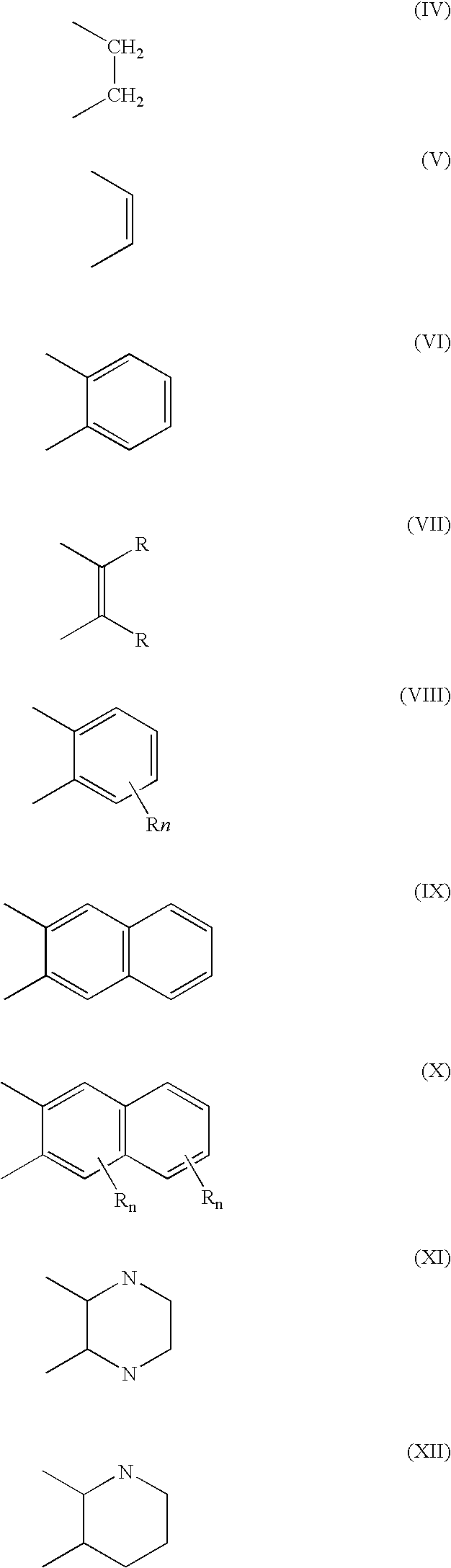

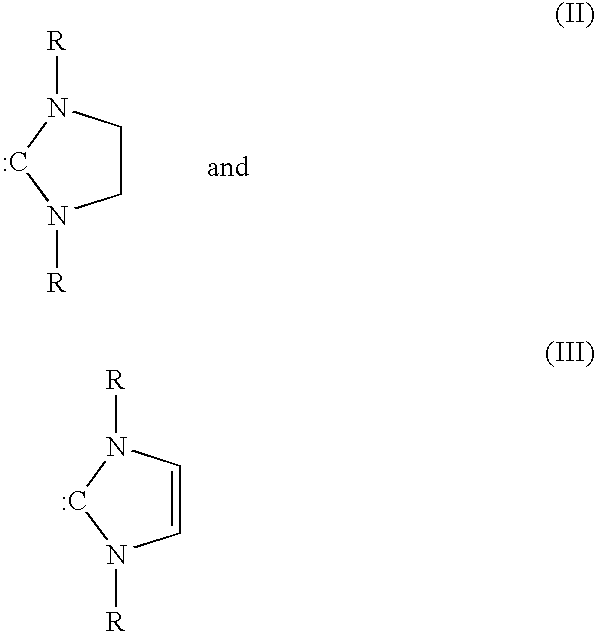

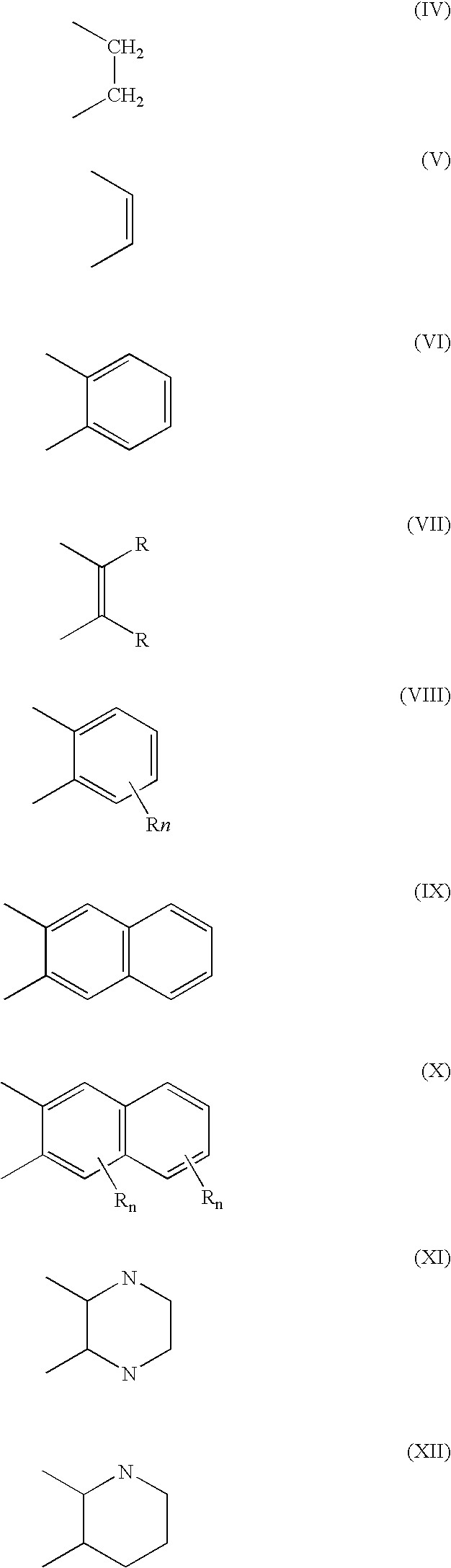

An olefin metathesis process involving contacting an unsaturated fatty acid ester or unsaturated fatty acid, such as methyloleate or oleic acid, with a lower olefin, preferably ethylene, in the presence of a metathesis catalyst so as to prepare a first product olefin, preferably, a reduced chain α-olefin, such as methyl-9-decenoate or 9-decenoic acid, respectively. The metathesis catalyst contains ruthenium or osmium and a chelating ligand, preferably, a chelating ligand containing a carbene moiety and a second donor moiety of a Group 15 or 16 element Optionally, the catalyst can be supported on a catalyst support, such as, a cross-linked polymeric resin.

Owner:DOW GLOBAL TECH LLC

Low viscosity PAO based on 1-tetradecene

ActiveUS7544850B2Liquid hydrocarbon mixtures productionHydrocarbons from unsaturated hydrocarbon additionAlcohol1-Hexene

Disclosed herein is a method of making a PAO using tetradecene and particularly mixtures comprising 1-hexene, 1-decene, 1-dodecene, and 1-tetradecene, characterized by a low viscosity and excellent cold temperature properties, using a promoter system comprising an alcohol and an ester. In embodiments, the product has properties similar to those obtainable using a feed of solely 1-decene.

Owner:EXXONMOBIL CHEM PAT INC

Process for the synthesis of unsaturated alcohols

ActiveUS7176336B2Increase the number ofIncrease productionOxygen-containing compound preparationOrganic compound preparationPolymer scienceDecene

A process of preparing an unsaturated alcohol (olefin alcohol), such as, a homo-allylic mono-alcohol or homo-allylic polyol, involving protecting a hydroxy-substituted unsaturated fatty acid or fatty acid ester, such as methyl ricinoleate, derived from a seed oil, to form a hydroxy-protected unsaturated fatty acid or fatty acid ester; homo-metathesizing or cross-metathesizing the hydroxy-protected unsaturated fatty acid or fatty acid ester to produce a product mixture containing a hydroxy-protected unsaturated metathesis product; and deprotecting the hydroxy-protected unsaturated metathesis product under conditions sufficient to prepare the unsaturated alcohol. Preferably, methyl ricinoleate is converted by cross-metathesis or homo-metathesis into the homo-allylic mono-alcohol 1-decene-4-ol or the homo-allylic polyol 9-octadecene-7,12-diol, respectively.

Owner:DOW GLOBAL TECH LLC

High viscosity polyalphaolefins based on 1-hexene, 1-dodecene and 1-tetradecene

ActiveUS7547811B2Liquid hydrocarbon mixtures productionHydrocarbons from unsaturated hydrocarbon addition1-OcteneOctene

This invention relates to the use of olefin mixtures containing 1-hexene / 1-decene / 1-dodecene and, additionally, 1-octene or 1-decene to produce high viscosity polyalphaolefins (PAOs) having a viscosity of from about 40 cSt to about 100 cSt at 100° C. (ASTM D-445) and a number average molecular weight of between about 1200 to about 4000, particularly useful as lubricant base stocks.

Owner:EXXONMOBIL CHEM PAT INC

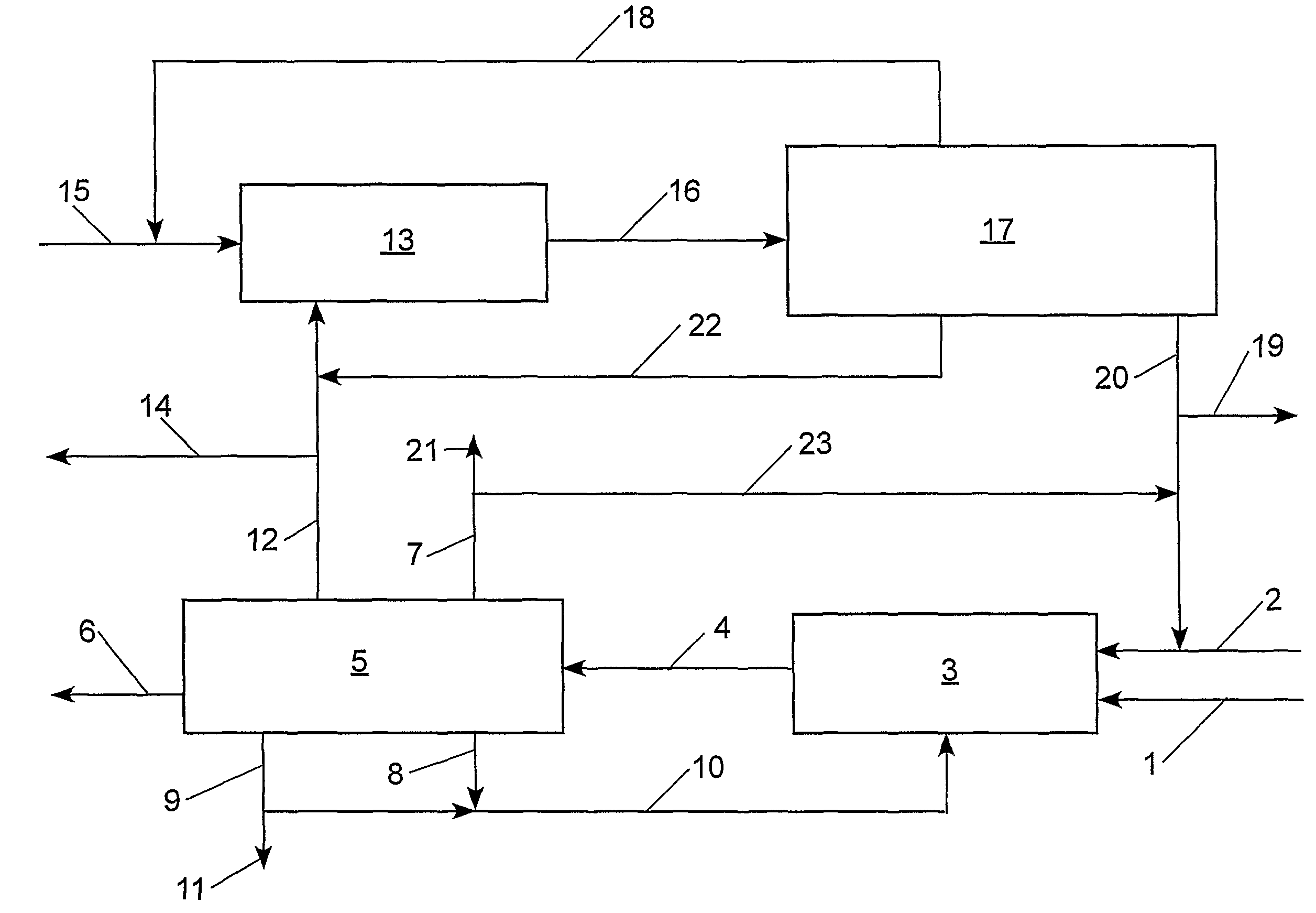

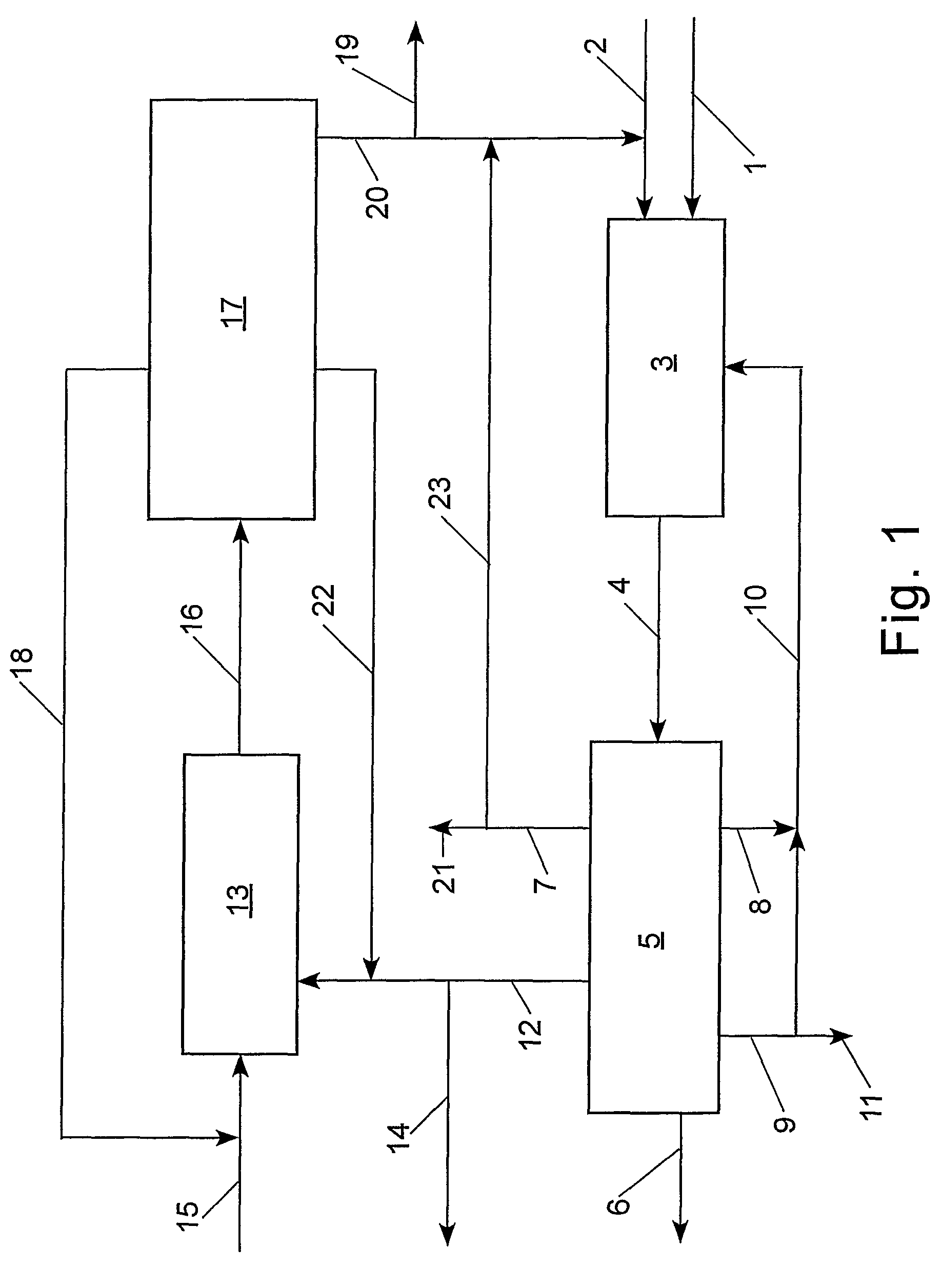

Metathesis process for preparing an alpha, omega-functionalized olefin

InactiveUS7812185B2Shorten the lengthImprove turnover rateOrganic compound preparationCarboxylic acid esters preparationReaction zoneAlpha-olefin

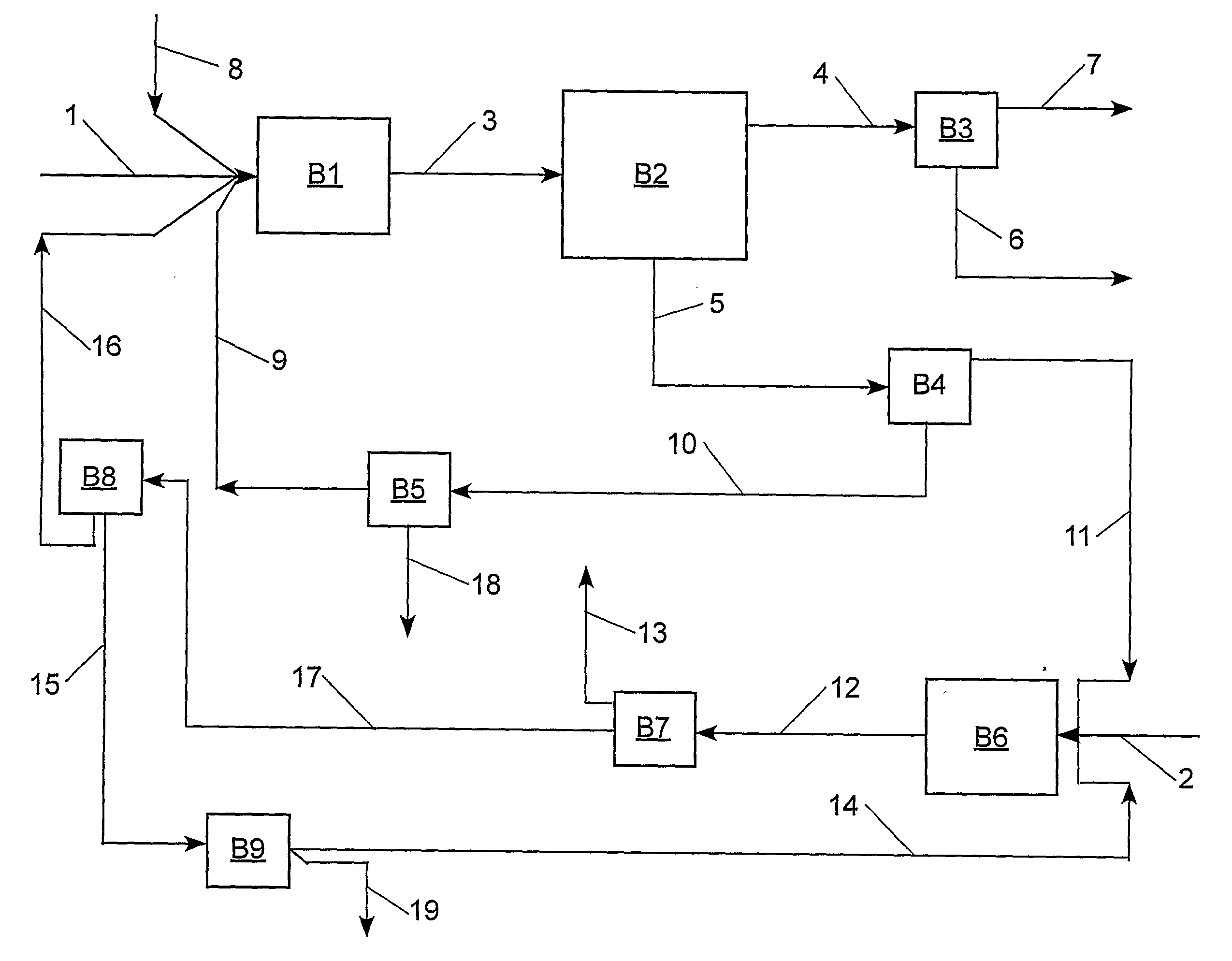

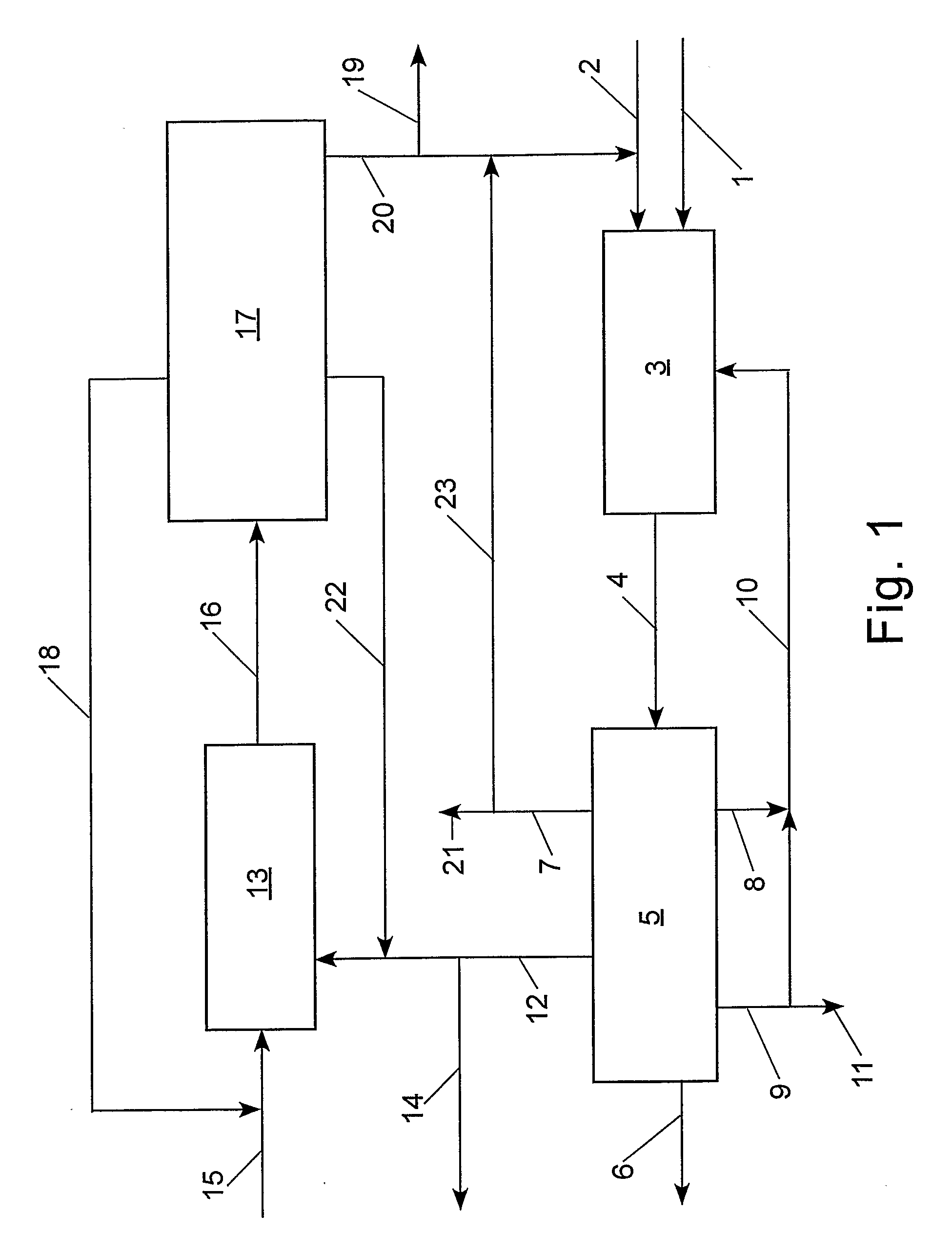

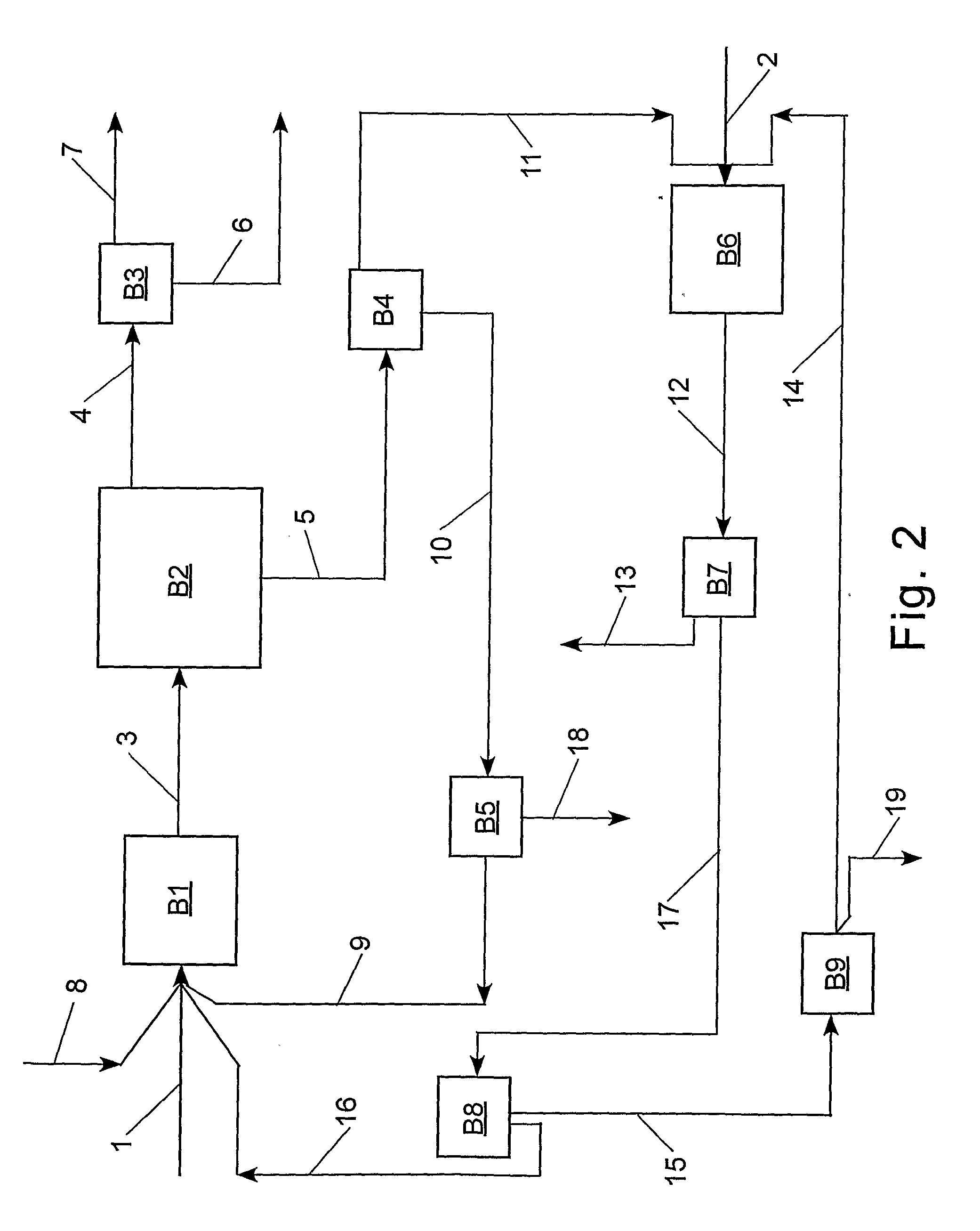

A cross-metathesis process for preparing an α,ω-functionalized olefin, such as methyl 9-decenoate, and an α-olefin having three or more carbon atoms, such as 1-decene. The process involves contacting in a first reaction zone an α-functionalized internal olefin, such as methyl oleate, and an α-olefinic monomer having three or more carbon atoms, such as 1-decene, with a first metathesis catalyst to prepare an effluent stream containing the α,ω-functionalized olefin, such as methyl 9-decenoate, an unfunctionalized internal olefin, such as 9-octadecene, unconverted reactant olefins, and optionally, an α,ω-difunctionalized internal olefinic dimer, such as dimethyl 9-octadecen-1,18-dioate; separating said effluent streams; then contacting in a second reaction zone the unfunctionalized internal olefin with ethylene in the presence of a second metathesis catalyst to obtain a second product effluent containing the α-olefinic monomer having three or more carbon atoms; and cycling a portion of the α-olefinic monomer stream(s) to the first zone.

Owner:DOW GLOBAL TECH LLC

Low viscosity polyalphapolefin based on 1-decene and 1-dodecene

ActiveUS7592497B2Liquid hydrocarbon mixtures productionHydrocarbons from unsaturated hydrocarbon additionAlcoholAlpha-olefin

The invention relates to a method of making a PAO from mixtures comprising 1-decene and 1-dodecene, characterized by a low viscosity and excellent cold temperature properties, using a promoter system comprising an alcohol. In embodiments, the product has properties similar to those obtainable using a feed of solely 1-decene.

Owner:EXXONMOBIL CHEM PAT INC

Co-oligomerization of 1-dodecene and 1-decene

InactiveUS6646174B2Quantity minimizationOrganic chemistry methodsLiquid hydrocarbon mixtures productionViscosity indexAlpha-olefin

A process for the co-oligomerization of 1-dodecene and 1-decene to produce a polyalphaolefin having a kinetic viscosity of 4 to 6 cSt at 100° C., a Noack weight loss of 4 to 9%, a viscosity index of 130 to 145, and a pour point of -60° C. to -50° C.

Owner:INEOS USA LLC

Antimicrobial compositions, methods and systems

InactiveUS20080033026A1Broad antimicrobial activity spectrumEfficacious activityBiocideDead animal preservationDecenoic AcidPHENOL LIQUID

The invention provides methods for treating a surface, the method including steps of applying a surface treatment composition to a surface, wherein the surface treatment composition includes a substantially phenol-free cleansing agent and an antimicrobial agent, the antimicrobial agent comprising 9-decenoic acid, a salt of 9-decenoic acid, an ester of 9-decenoic acid, or a combination thereof, wherein the antimicrobial agent is present in an amount sufficient to control microbial growth. Also described are methods for treating a surface that include the step of applying a surface treatment composition having a pH in the range of 4.1 to 8.5 to a surface, wherein the surface treatment composition includes a cleansing agent and an antimicrobial agent, the antimicrobial agent comprising 9-decenoic acid, a salt of 9-decenoic acid, an ester of 9-decenoic acid, or a combination thereof, wherein the antimicrobial agent is present in an amount sufficient to control microbial growth. Also described are surface treatment compositions including the antimicrobial agents.

Owner:ELEVANCE RENEWABLE SCIENCES INC

Metathesis Process For Preparing An Alpha, Omega-Functionalized Olefin

InactiveUS20080228017A1Shorten the lengthImprove turnover rateOrganic compound preparationCarboxylic acid esters preparationReaction zoneAlpha-olefin

A cross-metathesis process for preparing an α,ω-functionalized olefin, such as methyl 9-decenoate, and an α-olefin having three or more carbon atoms, such as 1-decene. The process involves contacting in a first reaction zone an α-functionalized internal olefin, such as methyl oleate, and an α-olefinic monomer having three or more carbon atoms, such as 1-decene, with a first metathesis catalyst to prepare an effluent stream containing the α,ω-functionalized olefin, such as methyl 9-decenoate, an unfunctionalized internal olefin, such as 9-octadecene, unconverted reactant olefins, and optionally, an α,ω-difunctionalized internal olefinic dimer, such as dimethyl 9-octadecen-1,18-dioate; separating said effluent streams; then contacting in a second reaction zone the unfunctionalized internal olefin with ethylene in the presence of a second metathesis catalyst to obtain a second product effluent containing the α-olefinic monomer having three or more carbon atoms; and cycling a portion of the α-olefinic monomer stream(s) to the first zone.

Owner:DOW GLOBAL TECH LLC

Process for the synthesis of unsaturated alcohols

ActiveUS20050080301A1Increase the number of turnoversIncrease productionOxygen-containing compound preparationOrganic compound preparationMethyl ricinoleatePolyol

A process of preparing an unsaturated alcohol (olefin alcohol), such as, a homo-allylic mono-alcohol or homo-allylic polyol, involving protecting a hydroxy-substituted unsaturated fatty acid or fatty acid ester, such as methyl ricinoleate, derived from a seed oil, to form a hydroxy-protected unsaturated fatty acid or fatty acid ester; homo-metathesizing or cross-metathesizing the hydroxy-protected unsaturated fatty acid or fatty acid ester to produce a product mixture containing a hydroxy-protected unsaturated metathesis product; and deprotecting the hydroxy-protected unsaturated metathesis product under conditions sufficient to prepare the unsaturated alcohol. Preferably, methyl ricinoleate is converted by cross-metathesis or homo-metathesis into the homo-allylic mono-alcohol 1-decene-4-ol or the homo-allylic polyol 9-octadecene-7,12-diol, respectively.

Owner:DOW GLOBAL TECH LLC

Controlling branch level and viscosity of polyalphaolefins with propene addition

InactiveUS20090198089A1High VIHigh thickening efficiencyHydrocarbons from unsaturated hydrocarbon additionHydrocarbonsAlpha-olefinAlkene

The invention relates to a polyalphaolefin formed from a decene and propene and having a branch level greater than 19% and to a process for forming such polyalphaolefins. The invention also relates to a process for forming a polyalphaolefin from at least two monomers, the two monomers comprising a decene and propene, the process comprising the steps of, inter alia, providing a correlation between the total amount of propene used to form the polyalphaolefin and at least one of branch level or viscosity of the polyalphaolefin to make polyalphaolefins comprising decene and propene with predictable branch levels and viscosities.

Owner:LANXESS SOLUTIONS US INC

Irradiated biaxially oriented film

Owner:BEMIS COMPANY INC

High viscosity polyalphaolefins based on 1-hexene, 1-dodecene and 1-tetradecene

ActiveUS20070225533A1Improve low temperature performanceHigh viscosityLiquid hydrocarbon mixtures productionHydrocarbons from unsaturated hydrocarbon addition1-OcteneOctene

This invention relates to the use of olefin mixtures containing 1-hexene / 1-decene / 1-dodecene and, additionally, 1-octene or 1-decene to produce high viscosity polyalphaolefins (PAOs) having a viscosity of from about 40 cSt to about 100 cSt at 100° C. (ASTM D-445) and a number average molecular weight of between about 1200 to about 4000, particularly useful as lubricant base stocks.

Owner:EXXONMOBIL CHEM PAT INC

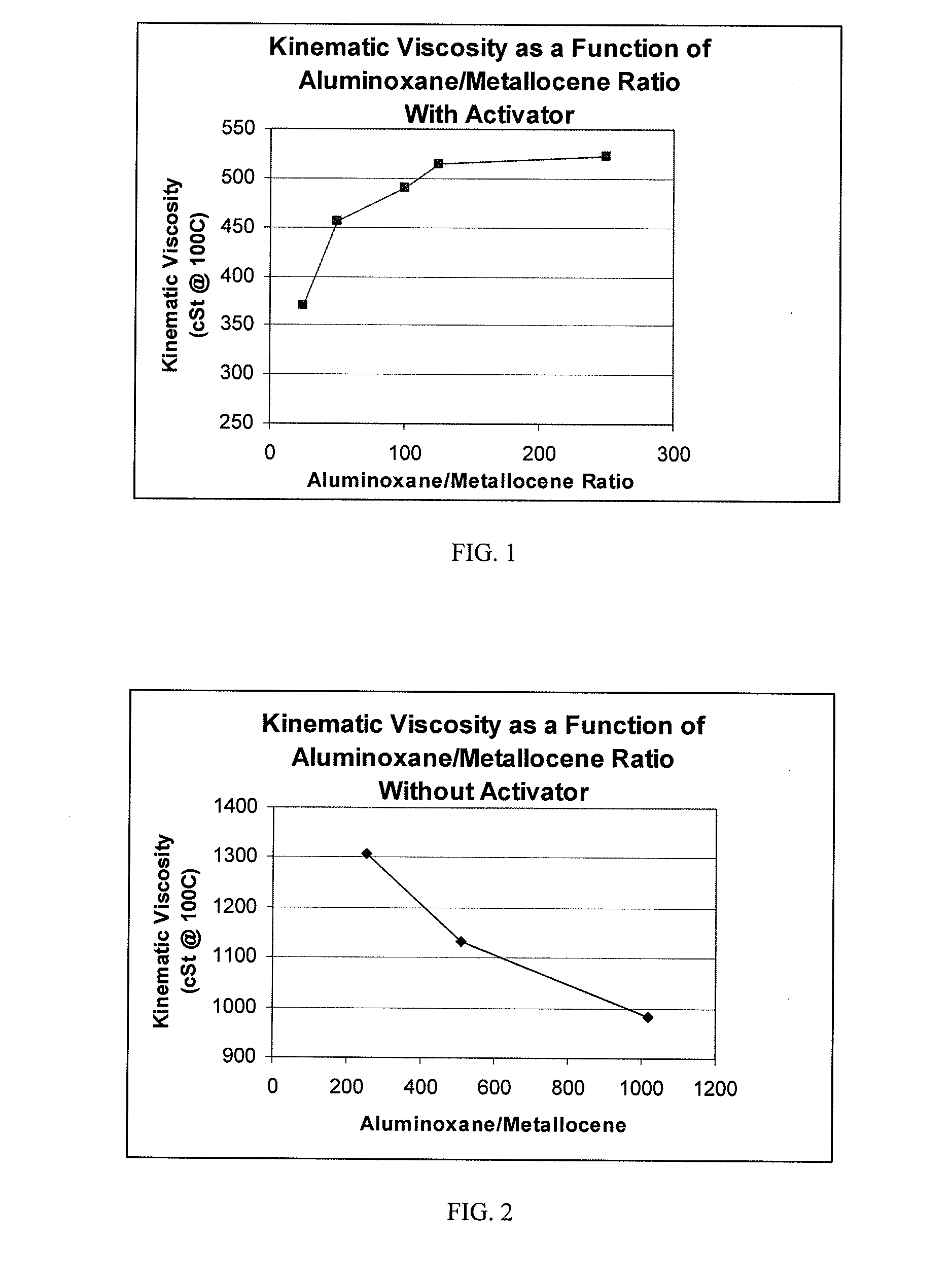

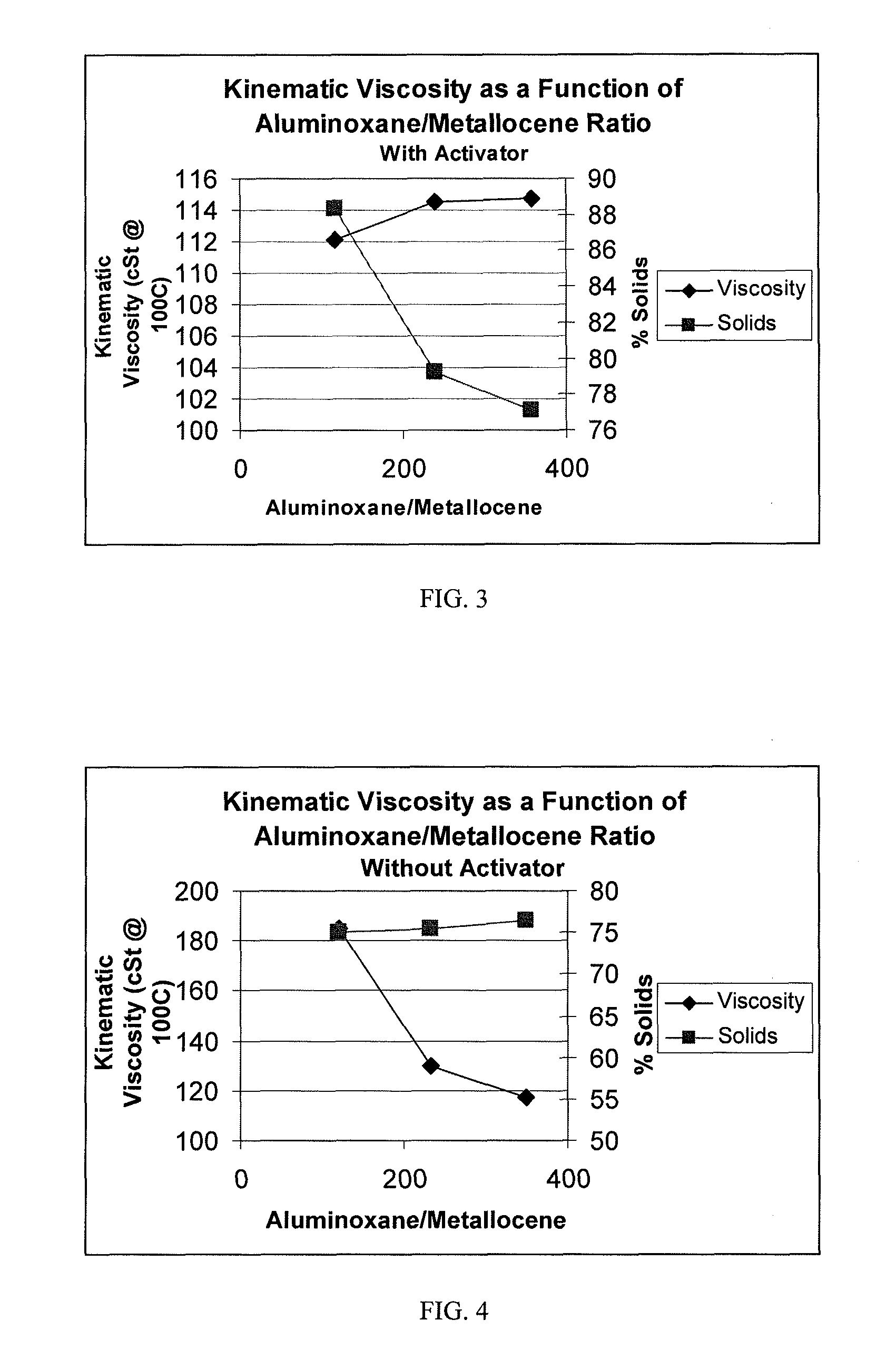

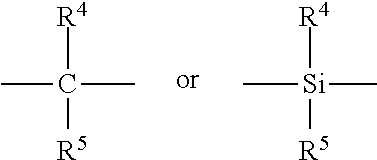

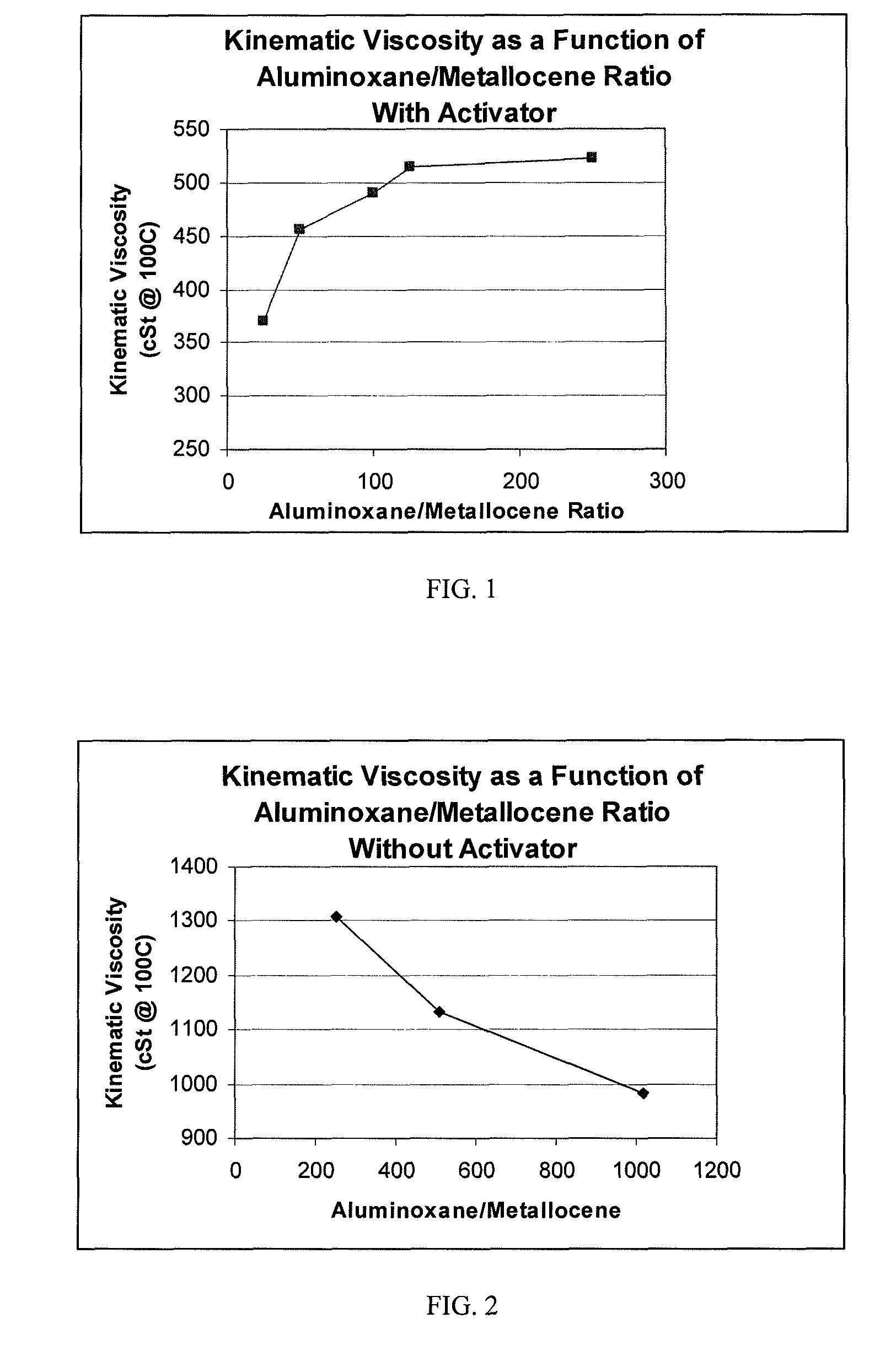

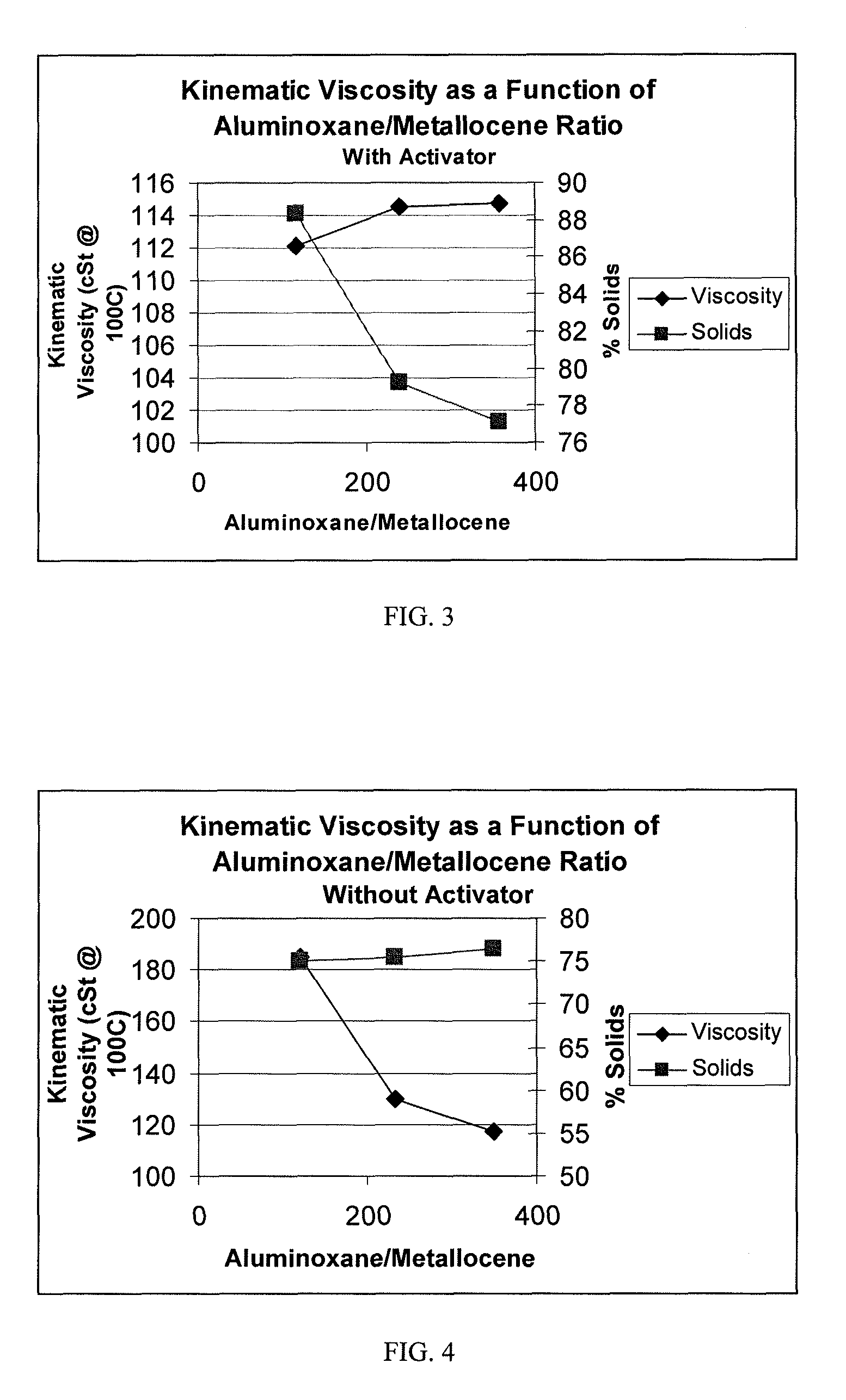

Processes for Controlling the Viscosity of Polyalphaolefins

ActiveUS20110040052A1Molar ratio can not be raisedMaintain good propertiesHydrocarbons from unsaturated hydrocarbon additionHydrocarbonsAluminoxaneOrganoboron compounds

The invention relates to a process for forming a polyalphaolefin, the process comprising the step of polymerizing at least one C8-C12 monomer, preferably a decene such as 1-decene, in the presence of an aluminoxane, an activator and a metallocene to form the polyalphaolefin, wherein the molar ratio of the aluminoxane to the metallocene is less than 250:1. The invention also relates to a process for forming a polyalphaolefin having a desired kinematic viscosity from at least one monomer in the presence of an aluminoxane, an organoboron compound and a metallocene. The process comprises the steps of, inter alia, providing a correlation between (i) the molar ratio of the aluminoxane to at least one of the organoboron compound and the metallocene, and (ii) the kinematic viscosity of the polyalphaolefin to form polyalphaolefins having predictable viscosities.

Owner:LANXESS SOLUTIONS US INC

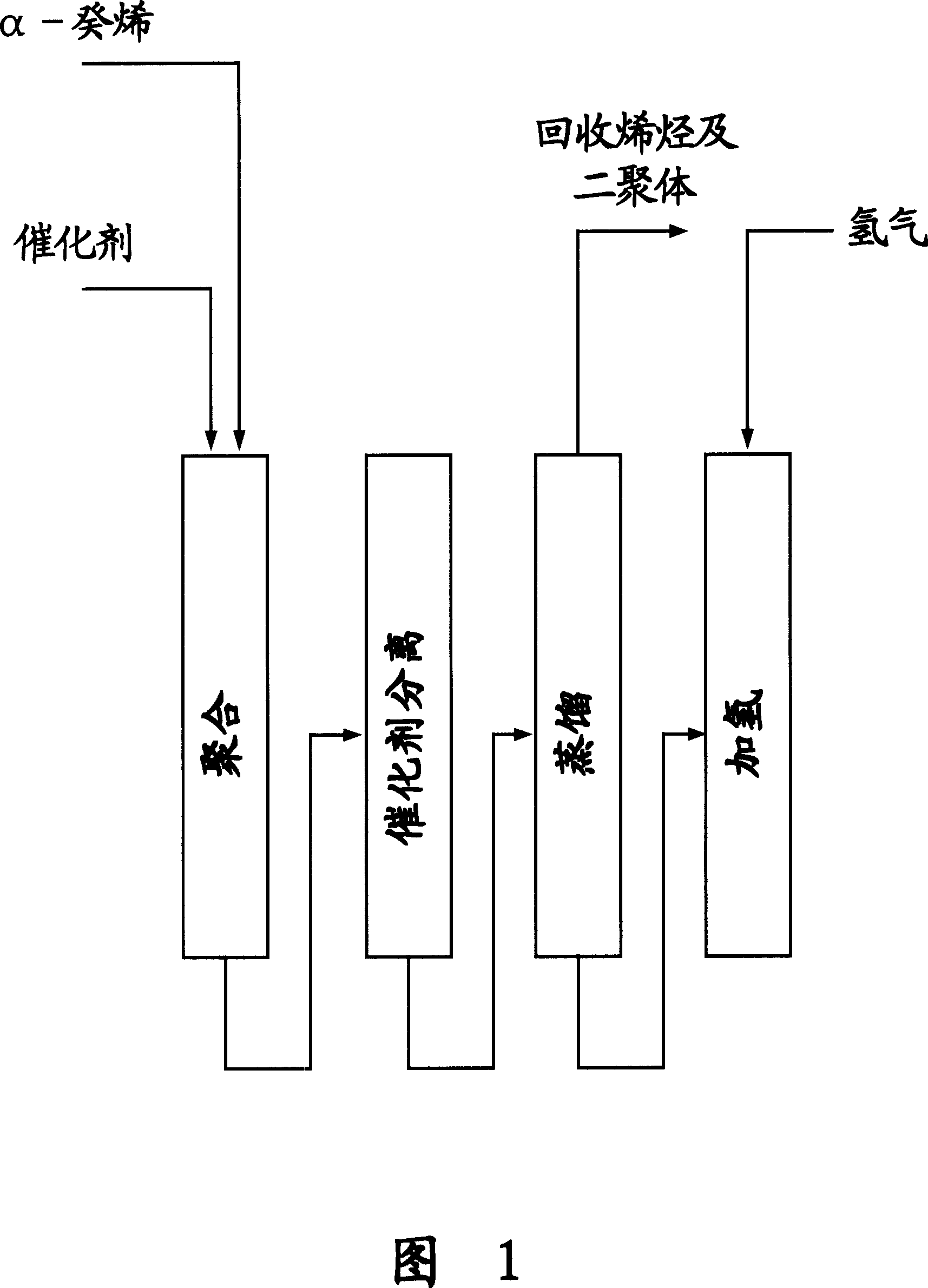

Preparation method of medium-viscosity poly alpha-olefin base oil

ActiveCN103666552AEasy to separateReduce pollutionTreatment with polymerisationOligomerDistilled water

The invention relates to a preparation method of medium-viscosity poly alpha-olefin base oil. The preparation method comprises the following steps: under conditions with a temperature of 20 DEG C-120 DEG C, reaction pressure of 0.1 MPa-1.4 MPa and a volume ratio of alpha-olefin / a solvent of (1:0)-(1:3), catalyzing 1-decene or 1-decene and alpha-olefin of C8-C12 for oligomerization for 2 hours-12 hours by using an alkaline-modified AlCl3 / Al2O3 immobilized catalyst; and filtering the catalyst after stopping reaction, washing by distilled water, distilling under the normal pressure to remove the solvent, distilling under reduced pressure to remove un-reacted alpha-olefin to obtain alpha-olefin oligomer base oil, wherein the yield of the poly alpha-olefin is greater than 60 omega%, the movement viscosity of the oligomer at 100 DEG C is 10.0mm<2> / s-25.0mm<2> / s, and the chlorine content of the oligomer is less than 2.0 omega%.

Owner:PETROCHINA CO LTD +1

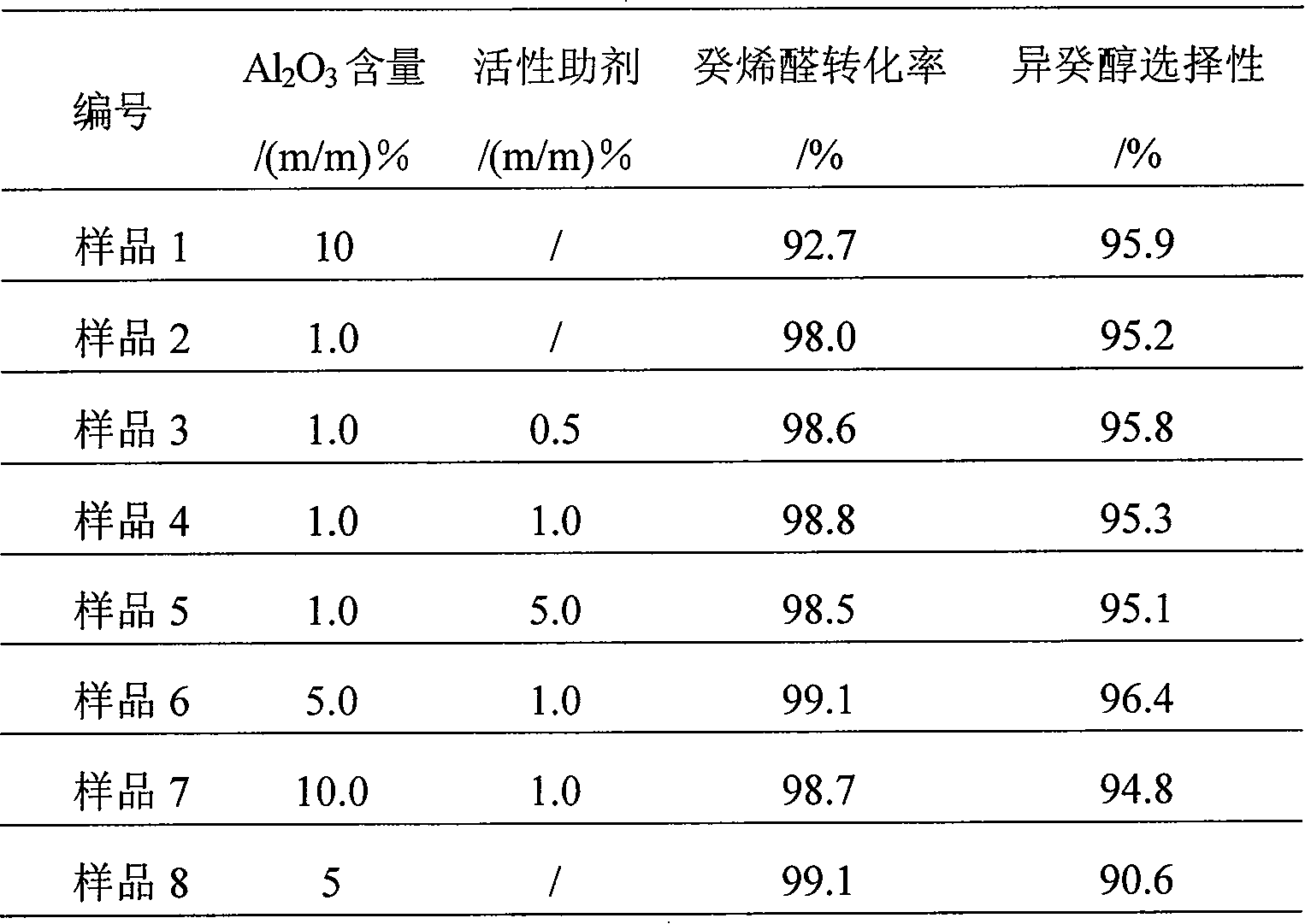

Catalyst for preparation of decyl alcohols by gas-phase hydrogenation of decylenaldehydes and preparation method thereof

InactiveCN101185893AIncrease the outer surface areaReduce resistanceMetal/metal-oxides/metal-hydroxide catalystsGas phaseCopper oxide

A catalyst used for making isodecyl alcohol with decene aldehyde gas phase hydrogenation and a preparation method belong to the technical field of catalyst. The catalyst uses coprecipitation to prepare, and mainly comprises copper oxide, zinc oxide, alumina, the content of which is respectively 20%-70%, 28%-70%, and 1%-10%. The active assistant has the content of 0.1%-2.0% (m / m). The catalyst is used for making isodecyl alcohol with decene aldehyde gas phase hydrogenation, with higher decene aldehyde conversion rate (more than or equal to 99.1%) and isodecyl alcohol selectivity (more than or equal to 96.4%).

Owner:SINOPEC NANJING RES INST OF CHEM IND CO LTD

Low viscosity PAO based on 1-tetradecene

ActiveUS20070225534A1Low viscosityLiquid hydrocarbon mixtures productionHydrocarbons from unsaturated hydrocarbon additionAlcohol1-Hexene

Disclosed herein is a method of making a PAO using tetradecene and particularly mixtures comprising 1-hexene, 1-decene, 1-dodecene, and 1-tetradecene, characterized by a low viscosity and excellent cold temperature properties, using a promoter system comprising an alcohol and an ester. In embodiments, the product has properties similar to those obtainable using a feed of solely 1-decene.

Owner:EXXONMOBIL CHEM PAT INC

Preparation method of high viscosity index poly alpha olefine synthetic oil

InactiveCN1948243AStable in natureHigh yieldHydrocarbon purification/separationHydrocarbons from unsaturated hydrocarbon additionReaction temperatureViscosity index

The present invention relates to a preparation method of poly-alpha-olefin synthetic oil with high viscosity index. Said method includes the following steps: in a still-type reactor making alpha-decene raw material be contacted with active chrome catalyst, under the condition of 0.1-20 MPa and 100-250 deg.C making reaction for 2-20 h, separating catalyst, reaction product and unreacted alpha-decene, making the described reaction product undergo the process of hydrogenation treatment so as to obtain the invented product poly-alpha-olefin synthetic oil.

Owner:PLA AIR FORCE OIL MATERIAL RES INST

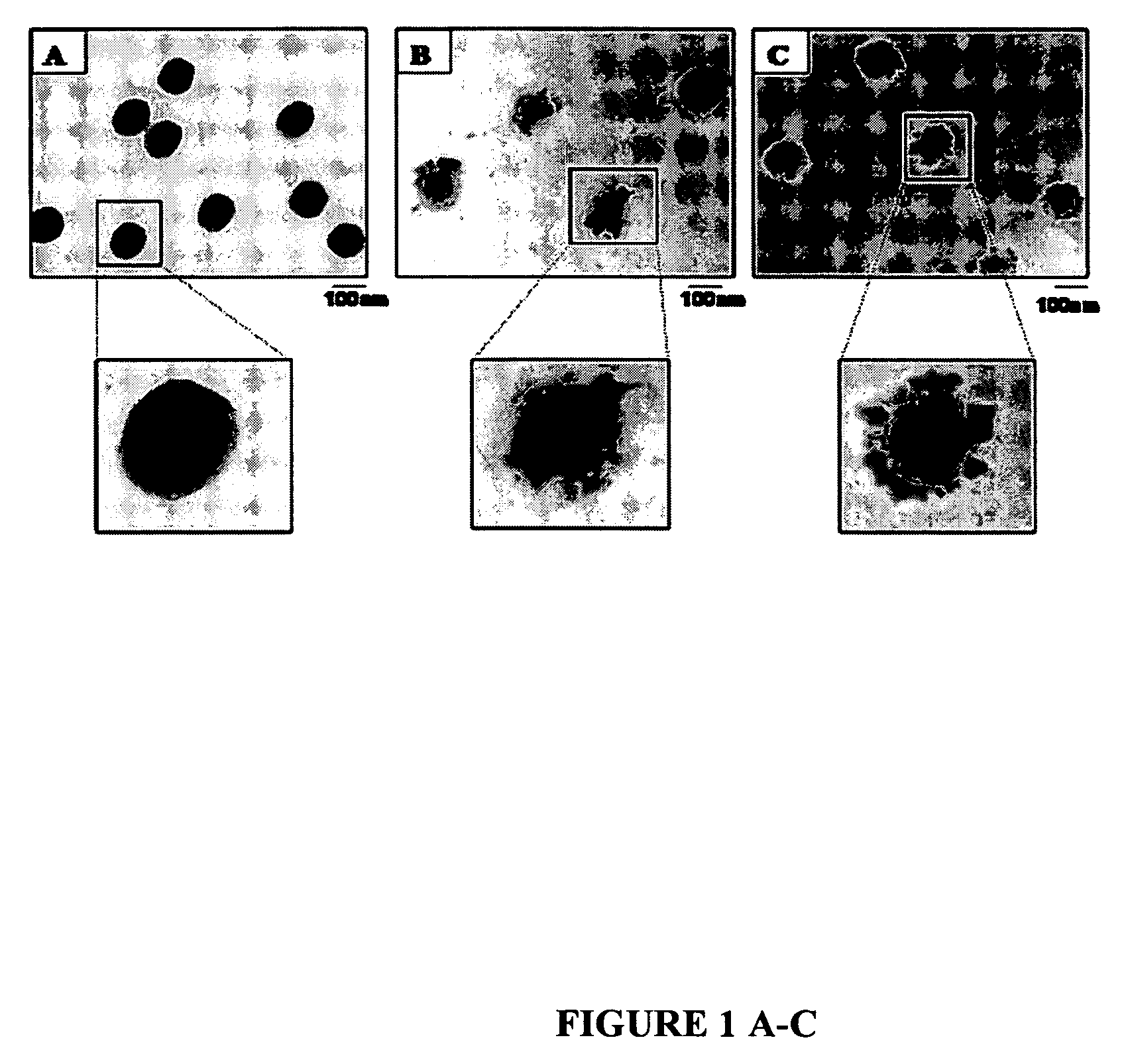

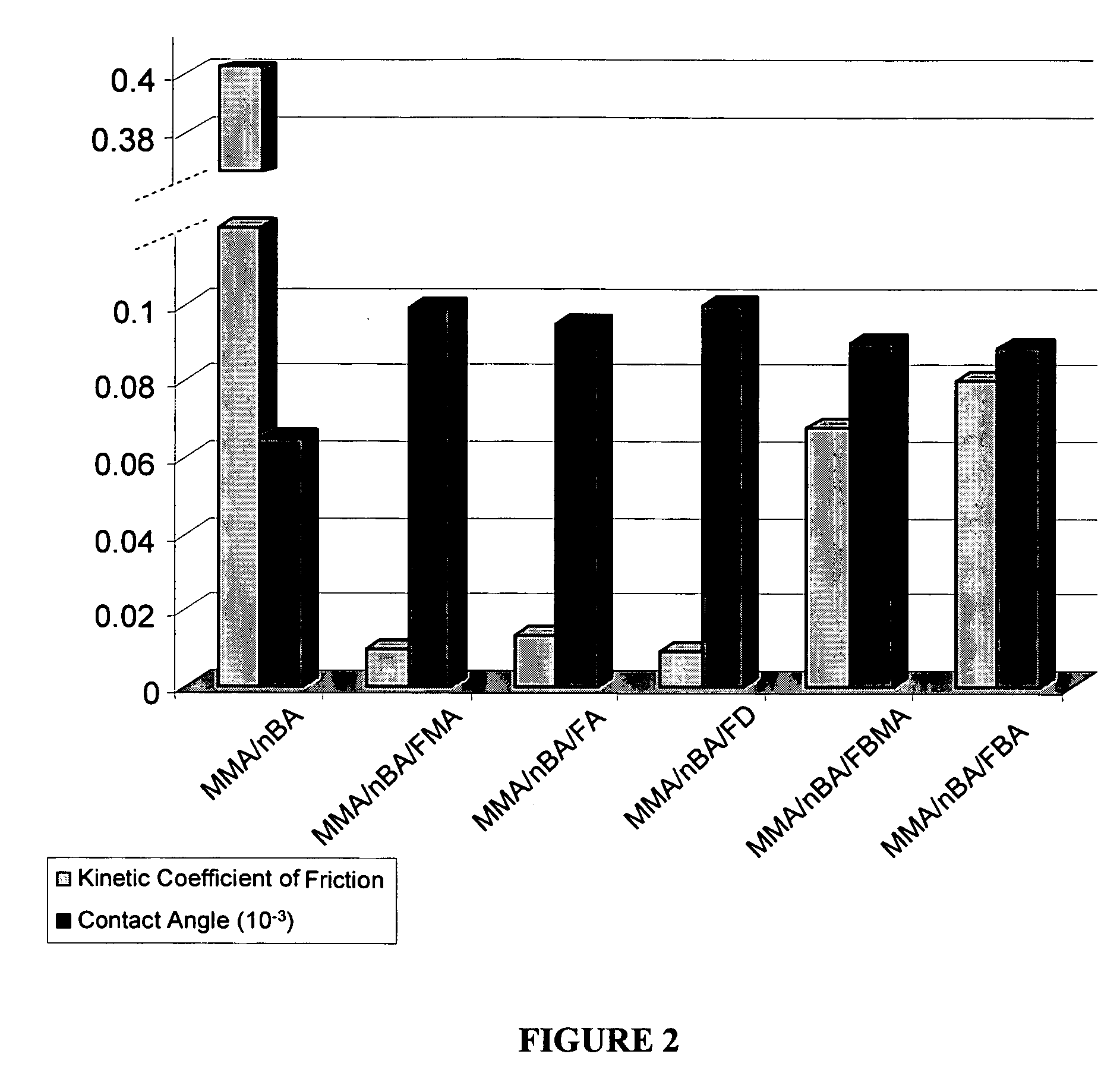

Method for producing stable fluorine-containing water-dispersible latexes

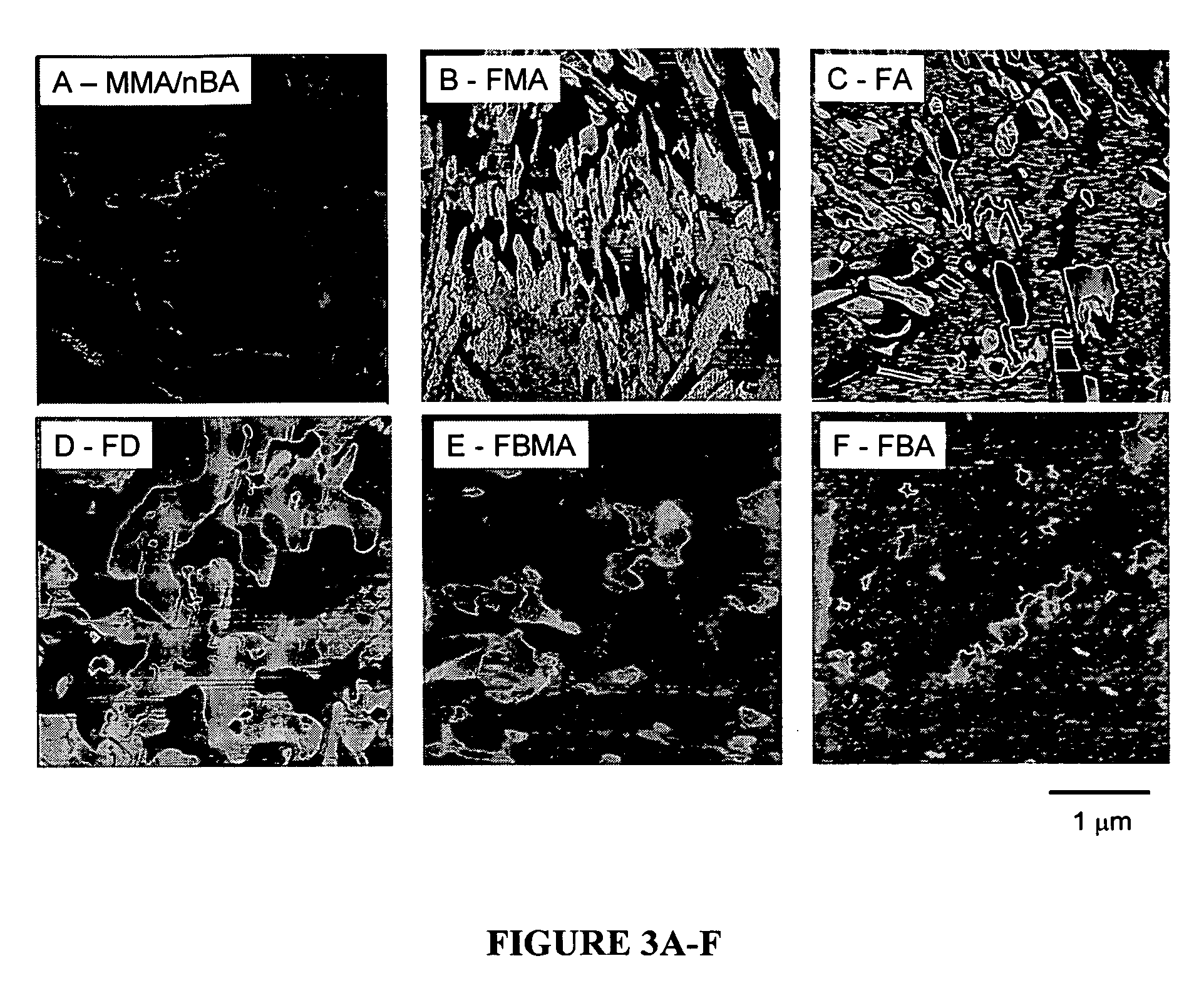

InactiveUS20060229398A1Improve the environmentFibre treatmentEmulsion paintsPhosphoric Acid EstersMethacrylate

A process is disclosed for making stable colloidal dispersions (latexes) that form polymeric films containing fluoro-monomers such as heptadecafluorodecyl methacrylate (FMA), heptadecafluorodecyl acrylate (FA), heptadecafluoro-1-decene (FD), heptafluorobutyl acrylate (FBA), and heptafluorobutyl methacrylate (FBMA). The process involves use of a surfactant system containing a fluorocarbon-containing phosphoric acid ester salt such as phosphoric acid bis(tridecafluorooctyl) ester ammonium salt and an anionic alkyl sulfate such as sodium dodecyl sulfate. The combination of polymerization conditions and surfactant system facilitates a suitable environment for the aqueous copolymerization of the fluoro-monomer with one or more co-monomers in the acrylate and / or methacrylate families, such as n-butyl acrylate and methyl methacrylate.

Owner:UNIVERSITY OF SOUTHERN MISSISSIPPI

Natural antibacterial pearl wool

InactiveCN103333392AAvoid safety hazardsOvercome the disadvantages of prone to static electricityDecenoic AcidPolymer science

The invention relates to natural antibacterial pearl wool and belongs to the field of macromolecular materials. The pearl wool is characterized by comprising the following raw materials in parts by weight: 90 to 110 parts of low-density polyethylene (LDPE) resin particles, 1 to 2 parts of antistatic agent, 0.1 to 0.5 part of foaming agent, 0.001 to 0.005 part of color master batch, 0.3 to 0.6 part of monoglyceride, 0.5 to 1 part of calcium carbonate, 0.5 to 1 part of talc powder, 0.01 to 0.05 part of 10-hydroxy-2-decenoic acid, and 0.5 to 2 parts of melamine phosphate. By adopting the safe and non-flammable foaming agent, the antistatic agent and the flame retardant, the pearl wool has high safety factor; and by adding the natural antibacterial agent, the pearl wool has an antibacterial function.

Owner:SUZHOU NEW DISTRICT JIAHE PLASTIC

High viscosity PAOs based on 1-decene/1-dodecene

ActiveUS7550640B2Liquid hydrocarbon mixtures productionHydrocarbons from unsaturated hydrocarbon additionAlpha-olefinViscosity

This invention relates to the use of 1-decene / 1-dodecene olefin mixture to produce high viscosity polyalphaolefins (PAOs) having a viscosity of from about 40 cSt to about 100 cSt at 100° C. (ASTM D-445) and a number average molecular weight of between about 1200 to about 4000, particularly useful as lubricant base stocks.

Owner:EXXONMOBIL CHEM PAT INC

Supported catalyst for alpha-olefin oligomerization, and preparation and application thereof

ActiveCN102240563AReduce pollutionReduce chlorine contentPhysical/chemical process catalystsHydrocarbons1-OcteneAlpha-olefin

The invention relates to a supported catalyst for alpha-olefin oligomerization, and preparation and application thereof. The catalyst takes gamma-aluminium oxide as a carrier, which is loaded with aluminium trichloride and a VIII group transition metal salt; the catalyst comprises the following components according to weight percentage: 2.5-6.0% of aluminium, 6.0-12.0% of chlorine, 0.5-5.0% of VIII group transition metal salt, and rest being the gamma-aluminium oxide besides SO42- and / or NO3-; and the VIII group transition metal is iron, cobalt, nickel or copper. The supported catalyst exhibits high activity and high stability in catalyzing the oligomerization reaction of 1-decene or 1-octene, overcomes the strong corrosivity of the aluminium trichloride catalyst, and is easy to be separated from the product, and also avoids the problems of a large quantity of sewage and environmental pollution produced by the aluminium trichloride catalyst.

Owner:PETROCHINA CO LTD +1

Composition for hard article surface cleaning liquid

InactiveUS7030070B2Organic detergent compounding agentsEssential-oils/perfumesSurface cleaningDamascone

A fragrant compound or fragrant composition stable for a long period of time in an acidic hard article surface cleaning liquid adjusted so as to be acidic, particularly to pH 2.0 to 3.0 with an organic acid. One or more of fragrant compounds selected from the group consisting of 2,6-dimethyl-2-heptanol, 3,3-dimethylcyclohexyl methyl ketone, o-tert-butylcyclohexanol, α-amylcinnamic aldehyde, α-damascone, γ-octalactone, γ-nonalactone, γ-decalactone, anethole, ethyl benzoate, ethyl 2,2,6-trimethylcyclohexanecarboxylate, 2,2,6-trimethyl-1-crotonylcyclohexane, 6-acetyl-1,1,2,4,4,7-hexamethyltetrahydronaphthalene, isoamyl phenylethyl ether, methyl octin carbonate, 6,7-dihydro-1,1,2,3,3-pentamethyl-4(5H)-indanone, tricyclodecenyl acetate, undecyl aldehyde, fenchyl acetate, dihydrojasmone, cedryl methyl ether, p-cresol, hexyl aldehyde, and rosephenone are stable.

Owner:TAKASAGO INTERNATIONAL CORPORATION

Low viscosity polyalphapolefin based on 1-decene and 1-dodecene

ActiveUS20070225535A1Liquid hydrocarbon mixtures productionHydrocarbons from unsaturated hydrocarbon additionAlcoholDecene

The invention relates to a method of making a PAO from mixtures comprising 1-decene and 1-dodecene, characterized by a low viscosity and excellent cold temperature properties, using a promoter system comprising an alcohol. In embodiments, the product has properties similar to those obtainable using a feed of solely 1-decene.

Owner:EXXONMOBIL CHEM PAT INC

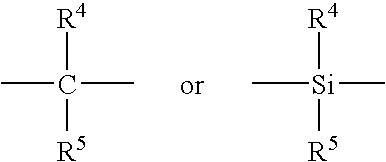

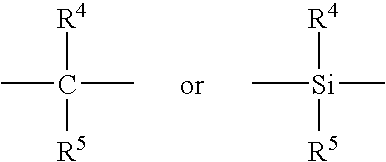

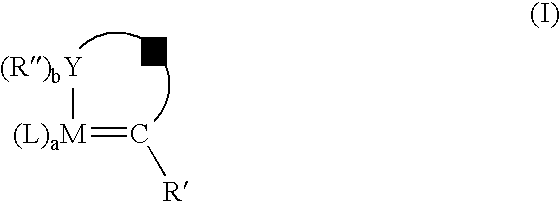

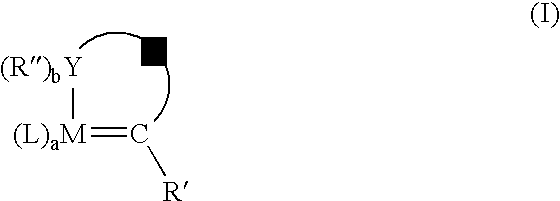

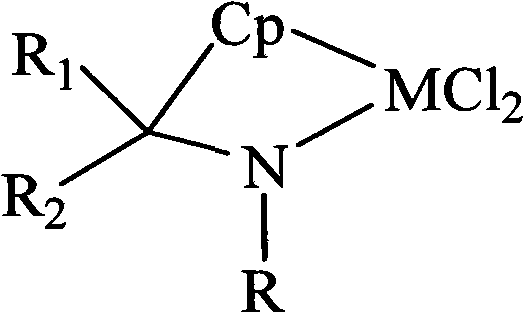

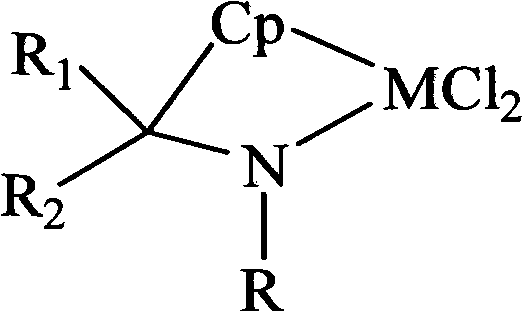

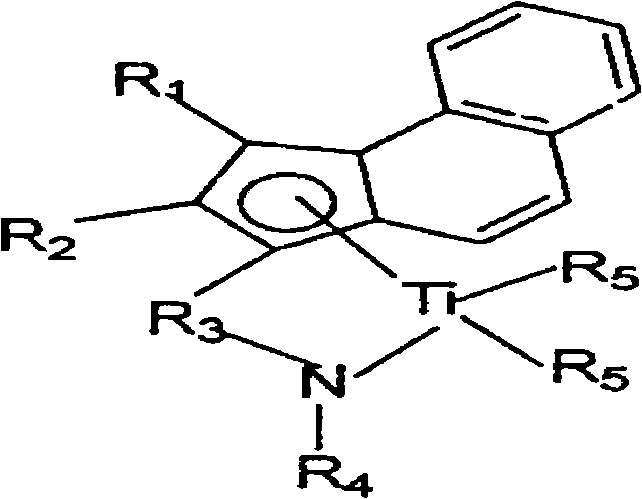

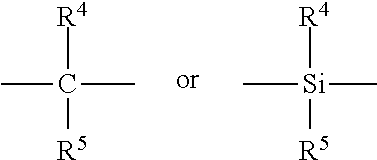

Copolymerization method of ethane/alpha-alkene

The invention relates to a copolymerization method of ethane / alpha-alkene, which is characterized in that: a mixture of constrained geometry carbon-bridged single metallocene is used as catalyst to catalyze ethane / alpha-alkene copolymerization; constrained geometry carbon-bridged single metallocene catalyst comprises a constrained geometry carbon-bridged single metallocene compound which is represented by the following structural general formula (I): R represents H or tertiary butyl or allyl containing 1-10 carbon atoms; R1, R2 respectively represents H or alkyl or aromatic base containing 1-10 carbon atoms; M represents Ti or Zr; Cp represents cyclopentadienyl, substituted cyclopentadienyl, indenyl or substituted indenyl; the molo ratio of the constrained geometry carbon-bridged single metallocene compound to the other compounds is 5-7:1; fulvene and amido are subject to a lithium reaction and then followed by a complexation with metal, thereby that the mixture of constrained geometry carbon-bridged single metallocene containing different substituents is obtained. The method disclosed in the invention can be used in the copolymerization of ethane / 1-hexane, ethane / 1-octene and ethane / 1-decene, and the insertion rate of long-chain alpha-alkene is high.

Owner:PETROCHINA CO LTD +1

Absorbent article comprising complexed or encapsulated reactive compounds

ActiveUS20140377207A1Effective in counteracting malodourReduce odorCapsule deliveryMedical waste disposalAnimal fecesAcetaldehyde

Absorbent articles comprising one or more complexed or encapsulated compounds compounds selected from: melonal, adoxal, trans-2-hexenal, ligustral, Floral Super, Florhydral, 5-methyl-2-thiophene-carboxaldehyde, hydratropic aldehyde, undecenal, 9-undecenal, 10-undecenal, trans-4-decenal, cis-6-nonenal, isocyclocitral, precyclemone b, (E)-2,(z)-6-nonadienal, undecyl aldehyde, methyl-octyl-acetaldehyde, Lauric aldehyde, silvial, vanillin, floralozone; are particularly effective in reducing malodors coming from degradation of proteinaceous materials such as food, menses or feces.

Owner:THE PROCTER & GAMBLE COMPANY

Decene Oligomers

ActiveUS20180016204A1Hydrocarbons from unsaturated hydrocarbon additionCatalystsOligomerMethyl group

A composition comprising olefin oligomers of one or more olefin monomers, the olefin monomers comprising a branched C10 olefin monomer comprising i) 3-propyl-1-heptene, ii) 4-ethyl-1-octene, iii) 5-methyl-1-nonene, or iv) any combination thereof. A composition comprising substantially hydrogenated olefin oligomers, wherein the olefin oligomers are oligomers of one or more olefin monomers, the olefin monomers comprising a branched C10 olefin monomer comprising i) 3-propyl-1-heptene, ii) 4-ethyl-1-octene, iii) 5-methyl-1-nonene, or iv) any combination thereof. A process comprising a) contacting 1) a catalyst system and 2) a monomer feedstock comprising a branched C10 olefin monomer comprising i) 3-propyl-1-heptene, ii) 4-ethyl-1-octene, iii) 5-methyl-1-nonene, or iv) any combination thereof in a reaction zone; and b) forming olefin oligomers.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Processes for controlling the viscosity of polyalphaolefins

ActiveUS8067652B2Maintain good propertiesProperty is limitedHydrocarbons from unsaturated hydrocarbon additionHydrocarbonsAluminoxaneOrganoboron compounds

Owner:LANXESS SOLUTIONS US INC

Co-oligomerization of 1-dodecene and 1-decene

InactiveUS20030166986A1Overcome problemsQuantity minimizationOrganic chemistry methodsLiquid hydrocarbon mixtures productionViscosity indexAlpha-olefin

A process for the co-oligomerization of 1-dodecene and 1-decene to produce a polyalphaolefin having a kinetic viscosity of 4 to 6 cSt at 100° C., a Noack weight loss of 4 to 9%, a viscosity index of 130 to 145, and a pour point of -60° C. to -50° C.

Owner:INEOS USA LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com