Patents

Literature

69 results about "Methyl ricinoleate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for the synthesis of unsaturated alcohols

ActiveUS7176336B2Increase the number ofIncrease productionOxygen-containing compound preparationOrganic compound preparationPolymer scienceDecene

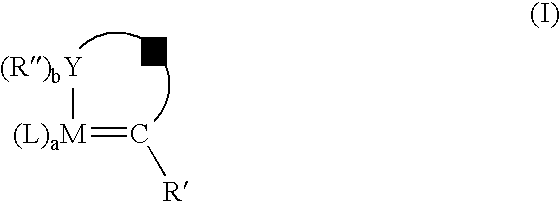

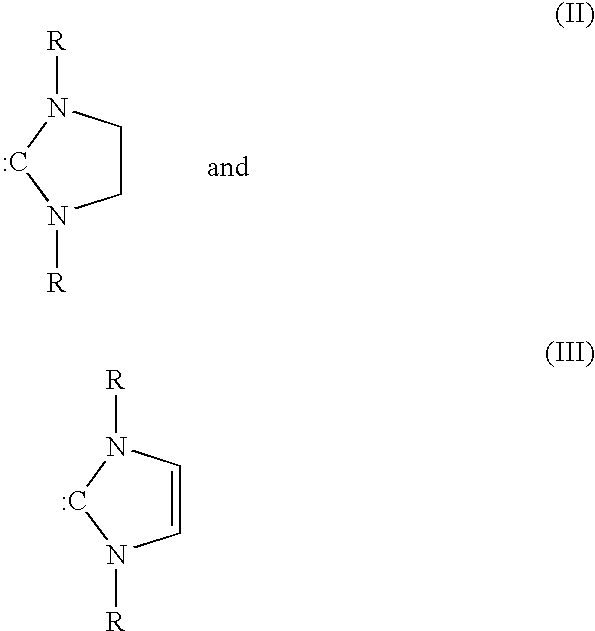

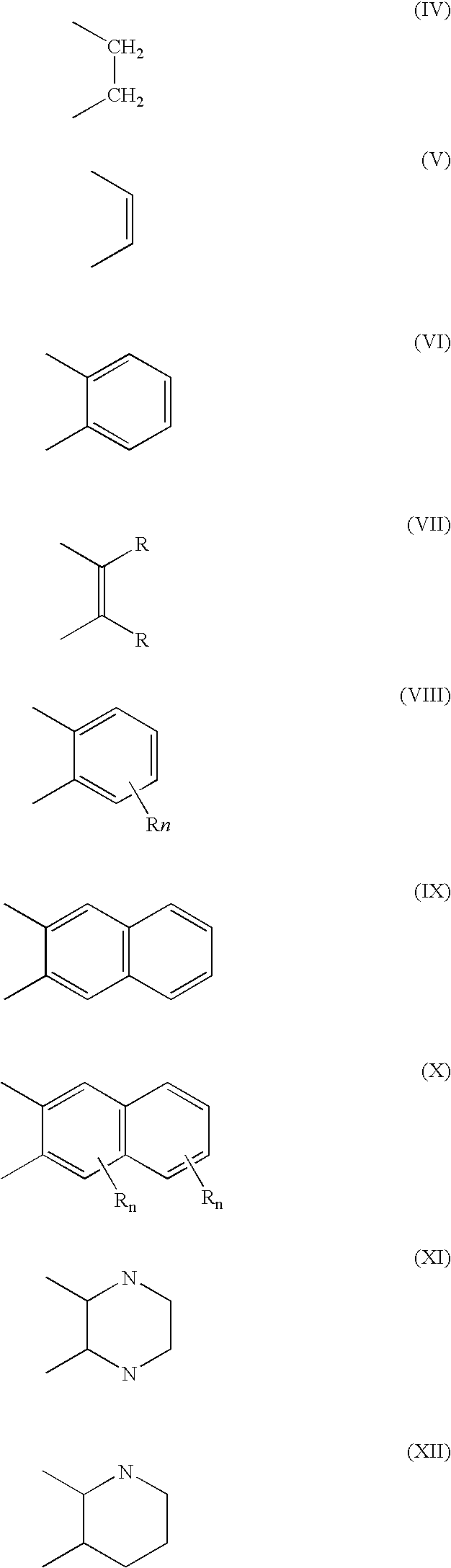

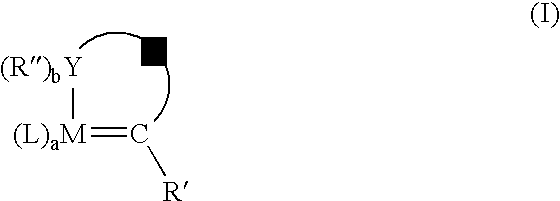

A process of preparing an unsaturated alcohol (olefin alcohol), such as, a homo-allylic mono-alcohol or homo-allylic polyol, involving protecting a hydroxy-substituted unsaturated fatty acid or fatty acid ester, such as methyl ricinoleate, derived from a seed oil, to form a hydroxy-protected unsaturated fatty acid or fatty acid ester; homo-metathesizing or cross-metathesizing the hydroxy-protected unsaturated fatty acid or fatty acid ester to produce a product mixture containing a hydroxy-protected unsaturated metathesis product; and deprotecting the hydroxy-protected unsaturated metathesis product under conditions sufficient to prepare the unsaturated alcohol. Preferably, methyl ricinoleate is converted by cross-metathesis or homo-metathesis into the homo-allylic mono-alcohol 1-decene-4-ol or the homo-allylic polyol 9-octadecene-7,12-diol, respectively.

Owner:DOW GLOBAL TECH LLC

Process for the synthesis of unsaturated alcohols

ActiveUS20050080301A1Increase the number of turnoversIncrease productionOxygen-containing compound preparationOrganic compound preparationMethyl ricinoleatePolyol

A process of preparing an unsaturated alcohol (olefin alcohol), such as, a homo-allylic mono-alcohol or homo-allylic polyol, involving protecting a hydroxy-substituted unsaturated fatty acid or fatty acid ester, such as methyl ricinoleate, derived from a seed oil, to form a hydroxy-protected unsaturated fatty acid or fatty acid ester; homo-metathesizing or cross-metathesizing the hydroxy-protected unsaturated fatty acid or fatty acid ester to produce a product mixture containing a hydroxy-protected unsaturated metathesis product; and deprotecting the hydroxy-protected unsaturated metathesis product under conditions sufficient to prepare the unsaturated alcohol. Preferably, methyl ricinoleate is converted by cross-metathesis or homo-metathesis into the homo-allylic mono-alcohol 1-decene-4-ol or the homo-allylic polyol 9-octadecene-7,12-diol, respectively.

Owner:DOW GLOBAL TECH LLC

Suppression of carcinoma using high purity conjugated linoleic acid (CLA)

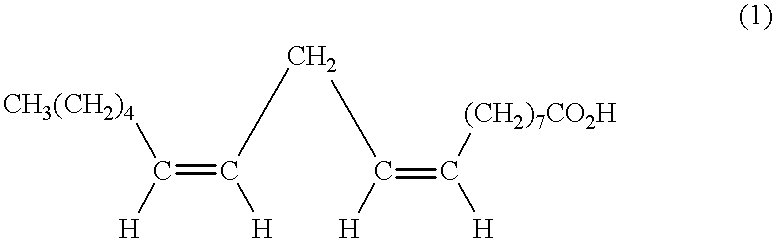

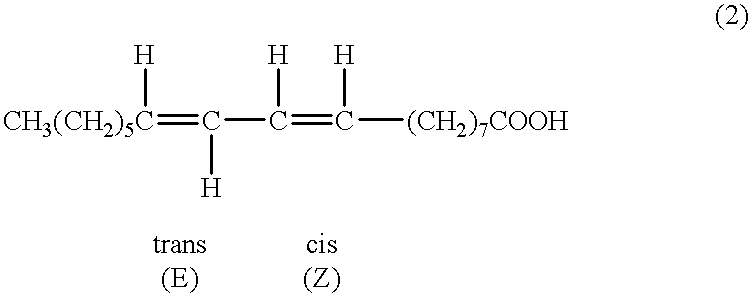

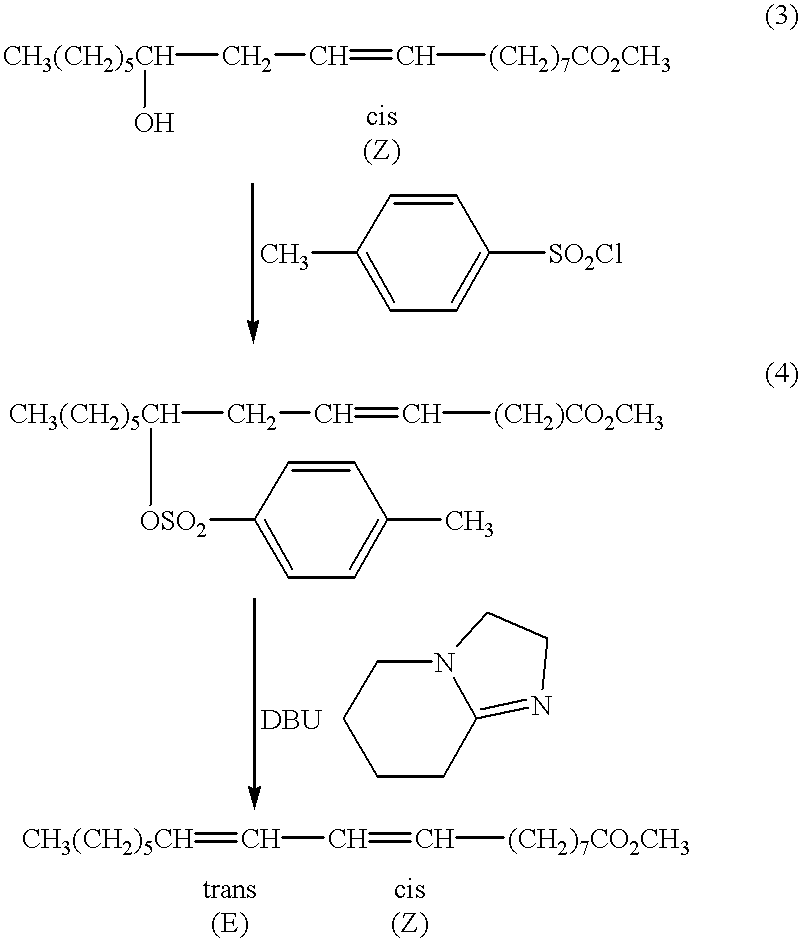

A method for the treatment of carcinoma in a human is disclosed, including administering to a human a therapeutically effective amount of 9-cis, 11-trans octadecadienoic acid formed by reacting an ester of ricinoleic acid with a tosyl chloride or a mesyl chloride to form a tosylate or mesylate of an ester of ricinoleic acid, and reacting the tosylate or mesylate of an ester of ricinoleic acid with diazabicyclo-undecene. The method includes administering to a human a purified conjugated linoleic acid (CLA) produced by a novel synthesis process for producing 9-cis, 11-trans octadecadienoic acid at room temperature in high yield including providing a tosylate or mesylate of a methyl ester of ricinoleic acid and providing a purified 9-cis, 11-trans octadecadienoic acid formed when the tosylate or mesylate reacts with diazabicyclo-undecene.

Owner:MATREYA

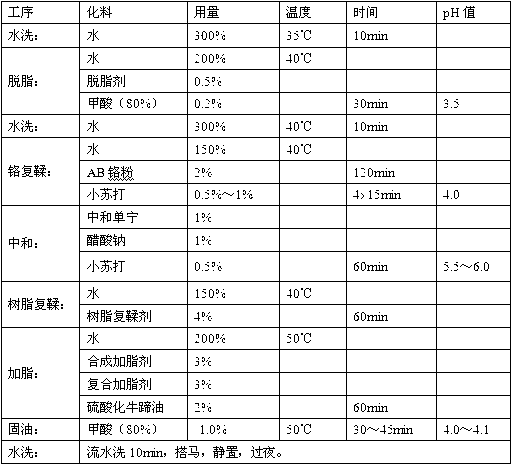

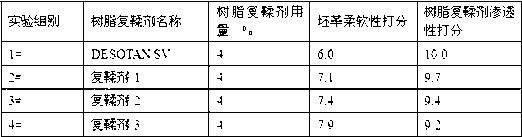

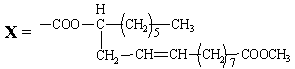

Preparation method of soft acrylic resin leather retanning agent

ActiveCN103255243AImprove permeabilitySimple production routeTanning treatmentFiberMethyl ricinoleate

The invention discloses a soft acrylic resin leather retanning agent and a preparation method thereof. The preparation method comprises the following steps of: firstly performing an esterification reaction based on methyl ricinoleate and maleic anhydride to generate maleic monoester of methyl ricinoleate, and neutralizing with sodium hydroxide to obtain a methyl ricinoleate maleic monoester sodium salt monomer; and then performing free radical polymerization of the methyl ricinoleate maleic monoester sodium salt monomer with a vinyl monomer in a waterborne system to obtain an acrylic resin retanning agent of which the side chain contains the methyl ricinoleate-structure long-chain lipophilic group. The retanning agent disclosed by the invention can be used for filling and retanning crust leather and also can be used for perfectly softening crust leather fiber, is a fat-liquoring type acrylic resin leather retanning agent, and realizes a certain waterproof effect on the chrome tanning crust leather.

Owner:四川德赛尔新材料科技有限公司

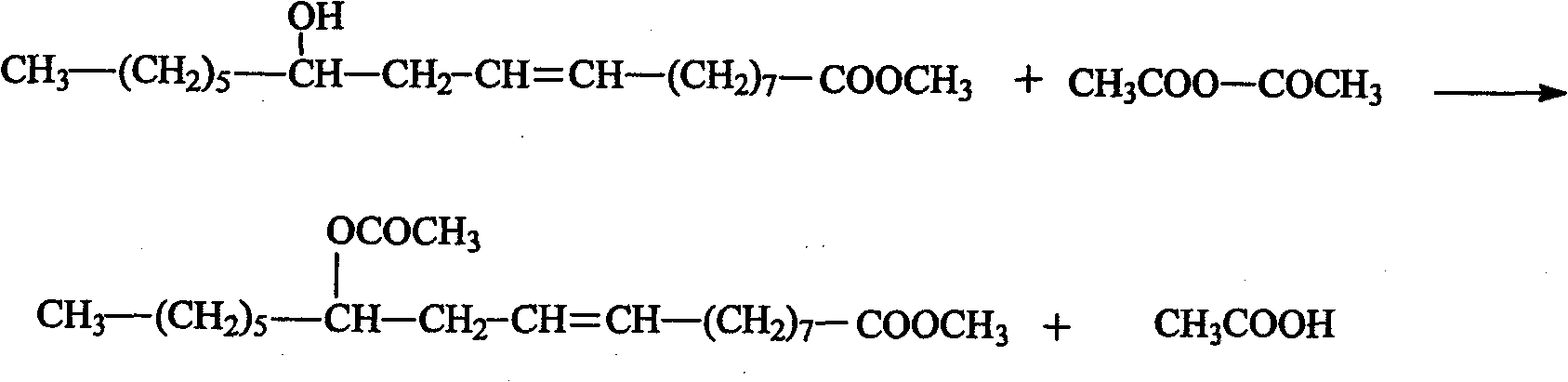

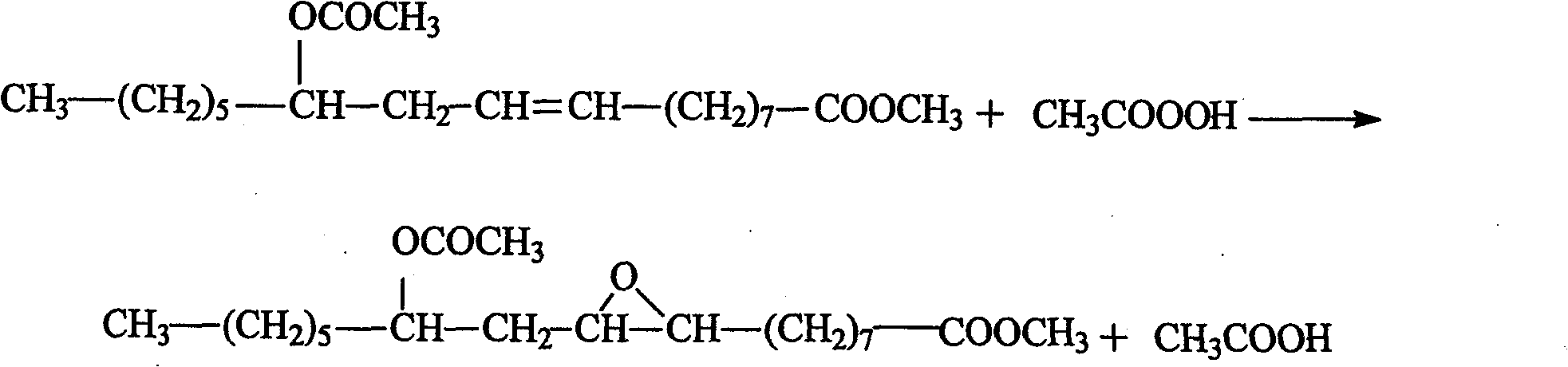

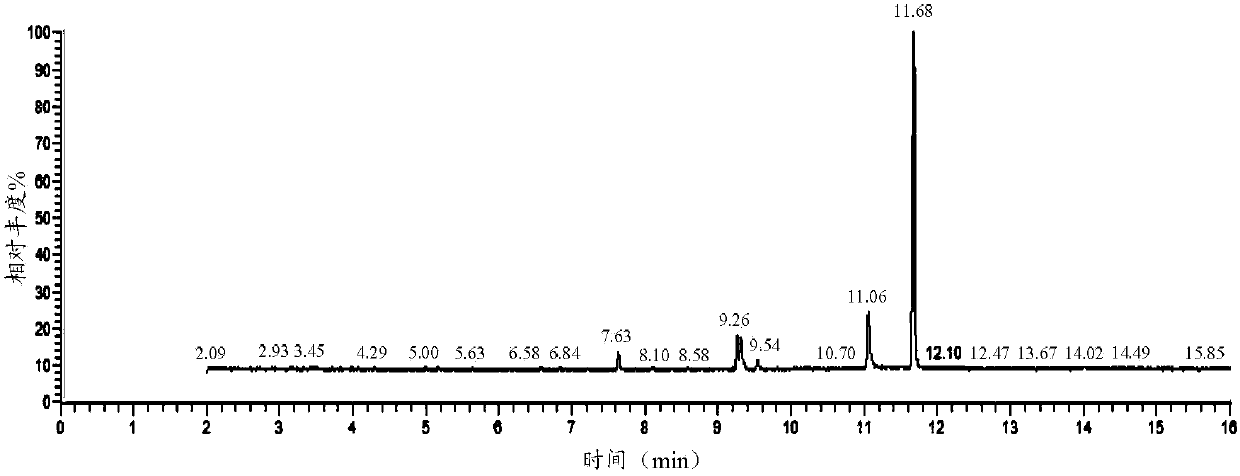

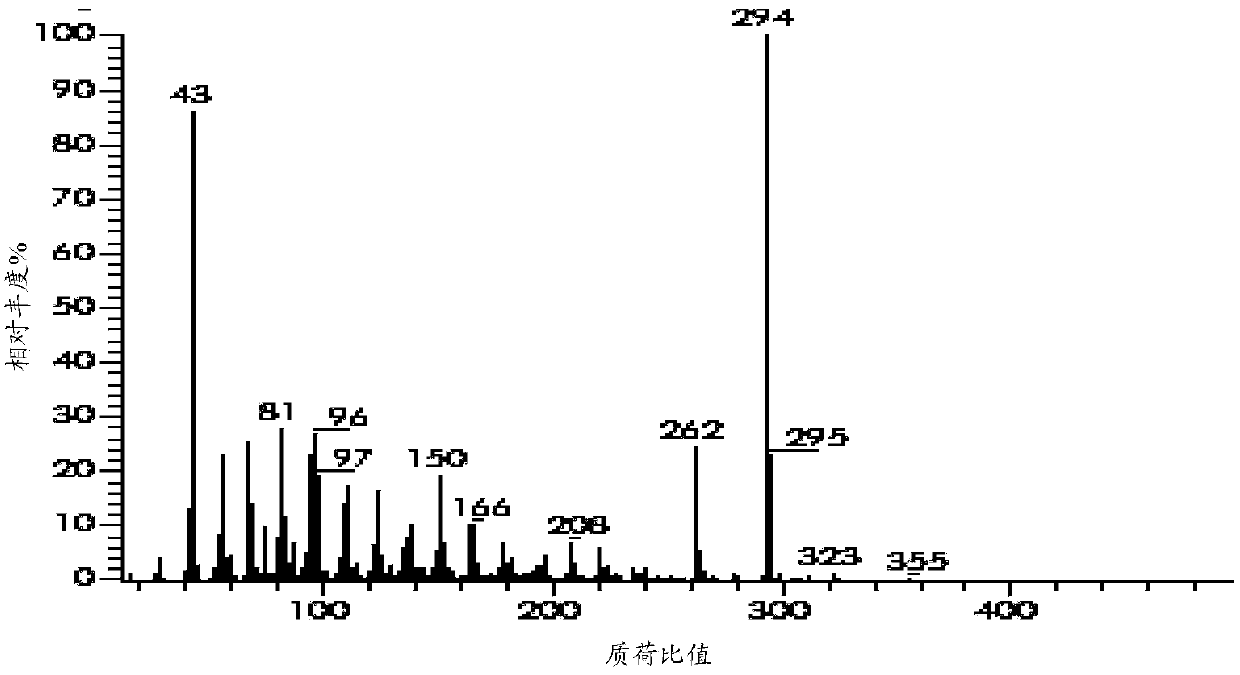

Method for preparing epoxidized methyl acetorieinoleate

InactiveCN101774985AFully contactedAvoid alkoxylationOrganic chemistryMethyl ricinoleateAcetic anhydride

The invention relates to a method for preparing epoxidized methyl acetorieinoleate, which is processed by the following steps: (1) under the condition that the reaction pressure is the normal pressure and the reaction temperature is between the room temperature and 140 DEG C, adding a solid acid NaHSO4 catalyst into a mixed liquor of methyl ricinoleate and acetic anhydride, stirring the mixture, wherein the usage amount of the solid acid NaHSO4 catalyst occupies more than or equal to 0.1 percent of methyl ricinoleate by mass, the mole ratio of the methyl ricinoleate to the acetic anhydride is 1:1.5-2.5 and the reaction time is between 0.1 and 10 hours; (2) directly making the reaction liquid in the step (1) carry out epoxidation with aqueous solution of H2O2, wherein the mole ratio of methyl acetylricinolate to H2O2 is 1:1-2, the reaction temperature is between the room temperature and 100 DEG C, the reaction time is between 1 and 10 hours and the reaction pressure is the normal pressure; and (3) after washing the crude epoxidized methyl acetorieinoleate until the epoxidized methyl acetorieinoleate is neutral, dehydrating to obtain the refined epoxidized methyl acetorieinoleate. The method reduces the acetylation reaction temperature from 140 DEG C to between 60 and 80 DEG C and catalyzes the epoxidation of the acetylated product so as to improve the epoxide number of the epoxidation product.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

Preparation method of metal drawing lubricant

InactiveCN106675738AImprove adsorption capacityGood film formingLubricant compositionPolyvinyl alcoholCarbon nanotube

The invention discloses a preparation method of a metal drawing lubricant, and belongs to the technical field of lubricant preparation. The method comprises the steps of preparing lubricating oil base oil from ricinic acid methyl ester as a raw material, stripping molybdenum disulfide crystal through an ultrasonic assisted stripping method to prepare graphene structure-like molybdenum disulfide; compounding with a carbon nanotube dispersion liquid, doping carbon nanotubes into the graphene structure-like molybdenum disulfide to prepare the dispersion liquid which is high in stability, high in radiating capability and good in dispersibility; and finally stirring the lubricating oil base oil, polyvinyl alcohol and deionized water and mixing the mixture with the carbon-doped graphene structure-like molybdenum disulfide to obtain the metal drawing lubricant. A low-shear stress film is formed on the surface of a friction pair by using the prepared graphene structure-like molybdenum disulfide, so that the friction coefficient is reduced and the low-shear stress film plays filling and repairing roles on the friction surface, meanwhile, the conditions of breakage of a metal wire and generation of an offensive odor are not easily generated in the using process, and the low-shear stress film is free of a harm to the environment and a human body and has a wide application prospect.

Owner:唐林元

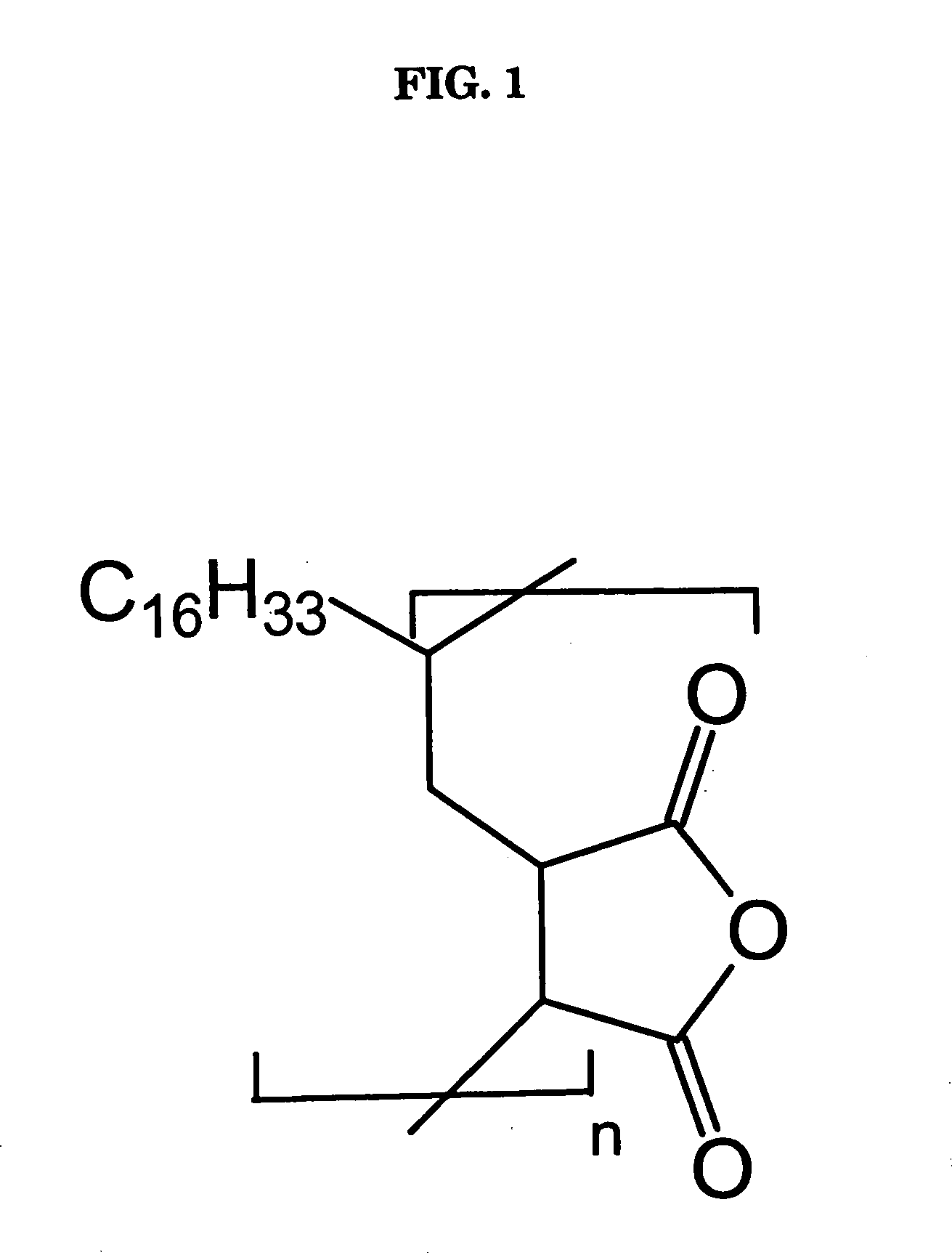

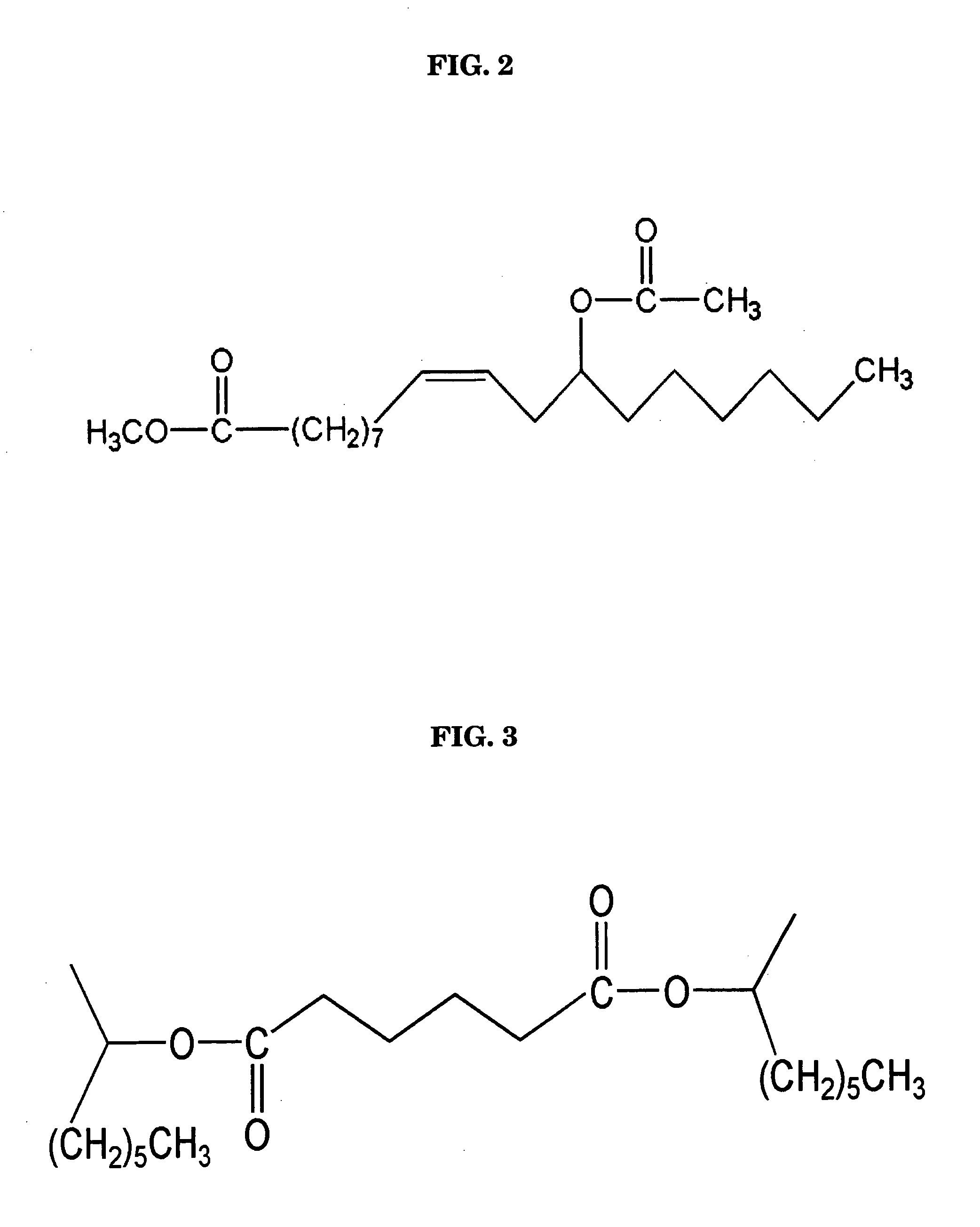

Delivery system for film-forming polymer

A film-forming composition formed by solubilizing higher concentrations of polyanhydride resins using a mixture of a fatty acid triglyceride derivative and a diester of 2-Octanol and Adipic Acid. In one embodiment, a composition in accordance with the invention comprises between about 1% and 55% by weight of Furandione (2,5)-Polymer with 1-Octadecene; between about 10% and 35% by weight of Dicapryl Adipate; and between about 10% and 35% by weight of Methyl Acetyl Ricinoleate. Such a composition may impart a water resistant property to oil-in-water and water-in-oil emulsions, and to anhydrous solid and semi-solid preparations, while remaining solubilized, stable and pourable at 25° C.

Owner:VERTELLUS PERFORMANCE MATERIALS

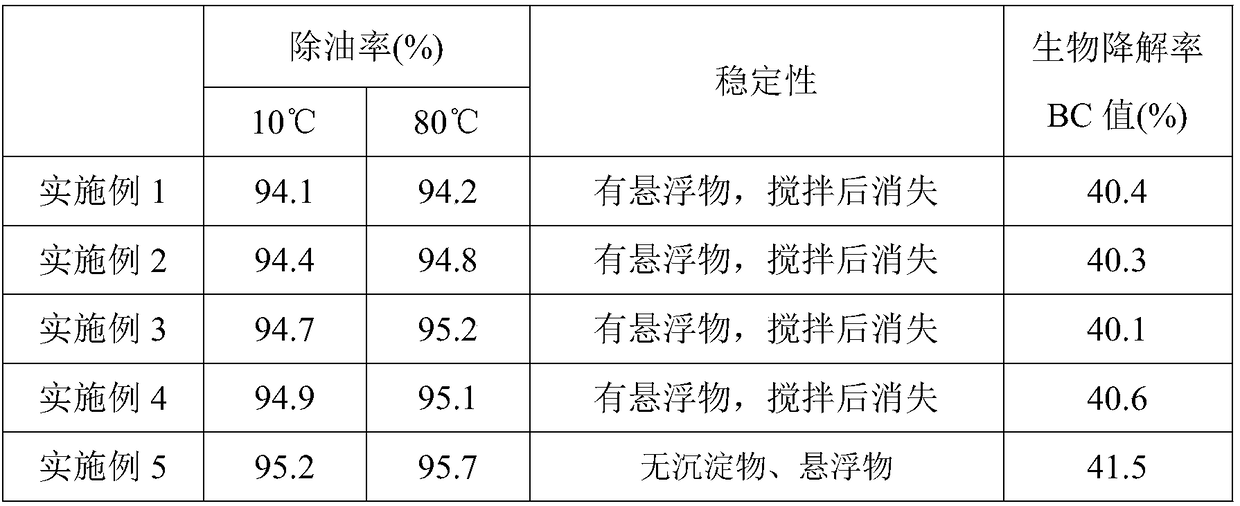

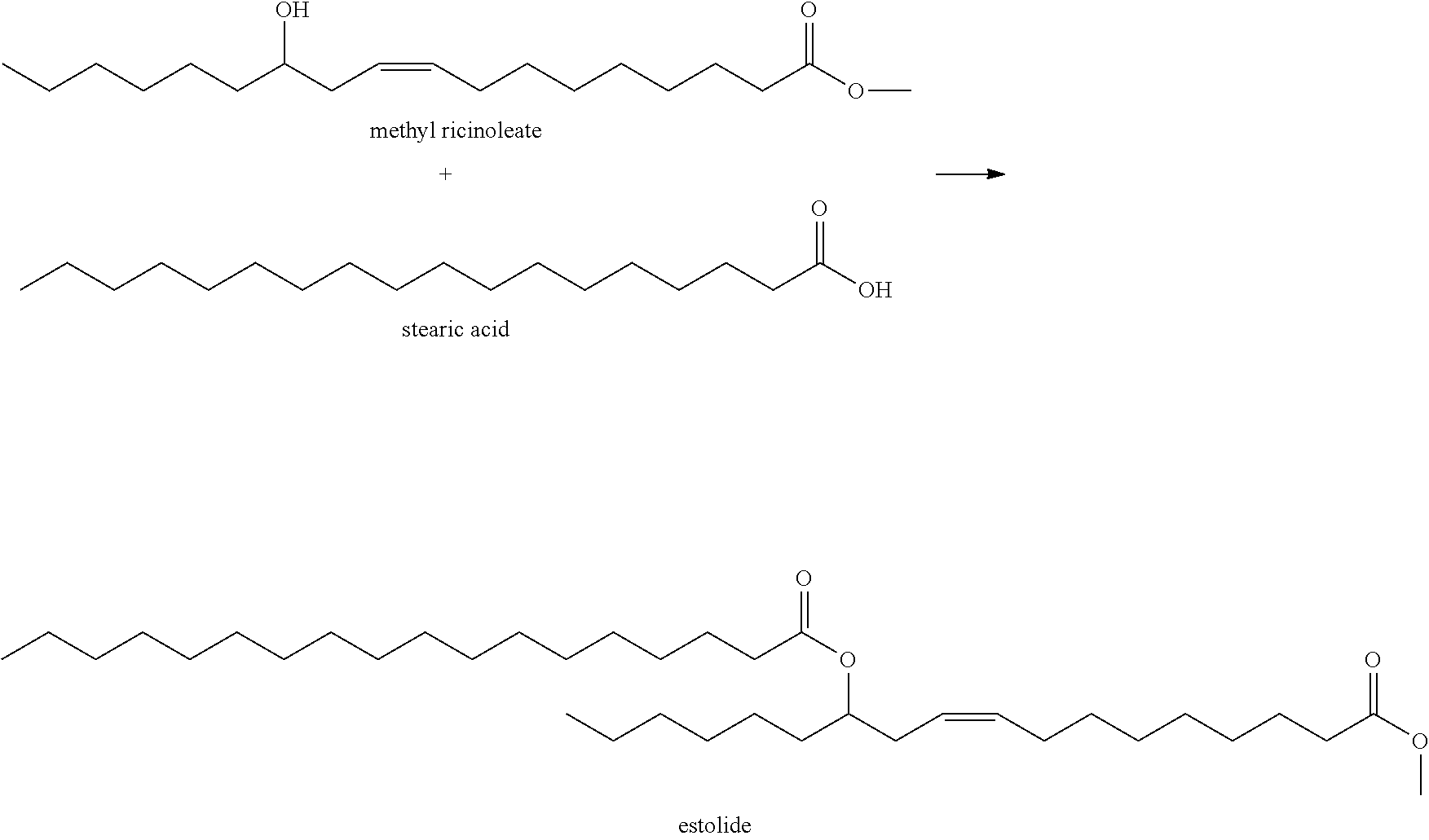

Environment-friendly oil removal agent

The invention relates to the field of oil removal agents, in particular to an environment-friendly oil removal agent. The environment-friendly oil removal agent at least comprises the following components of, by weight, 5-13 parts of alcohol alkoxylate sodium sulfate, 3-12 parts of ricinoleic acid methyl ester ethoxylates, 2-5 parts of coco fatty acid diethanol amide, 1-4 parts of 12 dodecyl dimethyl benzyl ammonium chloride, 2-3 parts of dodecyl dimethyl betaine, 5-12 parts of succinic acid, 3-7 parts of citric acid, 1-3 parts of hydrochloric acid, 1-2 parts of hydrofluoric acid and 65-85 parts of deionized water.

Owner:中山市浩科化工科技有限公司

Method for ozonization preparation of 2-nonenyl aldehyde

InactiveCN101508634ANo pollution in the processImprove reducibilityOrganic compound preparationPreparation by hydrogenolysisReductive decomposition2-Nonenal

The invention relates to a method for preparing 2-nonenal by ozonization with castor methyl oleate as the raw material, ethanol and n-hexane as the solvent, comprising performing ozonization by ventilating O3 / O2 gas mixture after uniformly mixing the raw material and the solvent at the low temperature, slowly dropping aqueous solution of NaHSO3 in ozonides, raising temperature for reductive decomposition, regulating the pH to 9-11 by sodium hydroxide solution, setting the mixture aside for layering, removing the water layer, rinsing the organic phase to neutrality by de-ionized water, adding dilute sulphuric acid for reflux, and recovering solution through reduced pressure distillation, and obtaining the target product, 2-nonenal, through the molecular distillation of the reaction mixture. In the method, no high pressure is needed during the reaction; the solvent of n-hexane can be recovered for repeated use; the mixed solvent system solves the serious corrosion to the devices by using acetic acid as solvent; the method has clean process, environmental protection, safe execution, simple operation and convenient mass production. The separation and purification of the products are simple.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

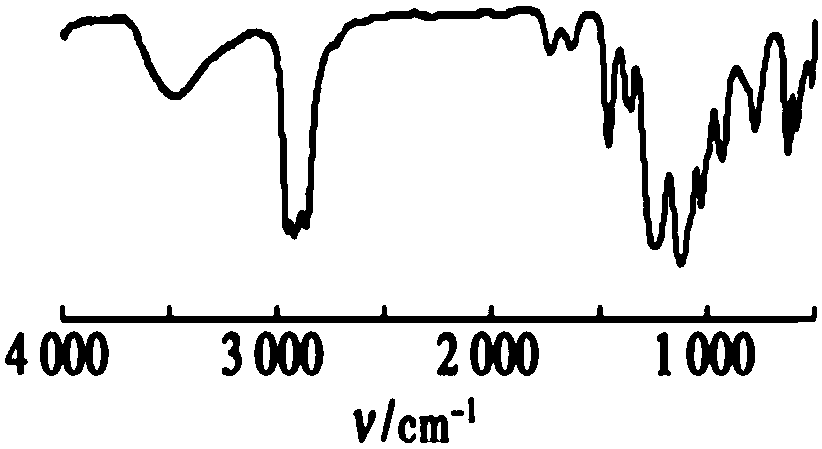

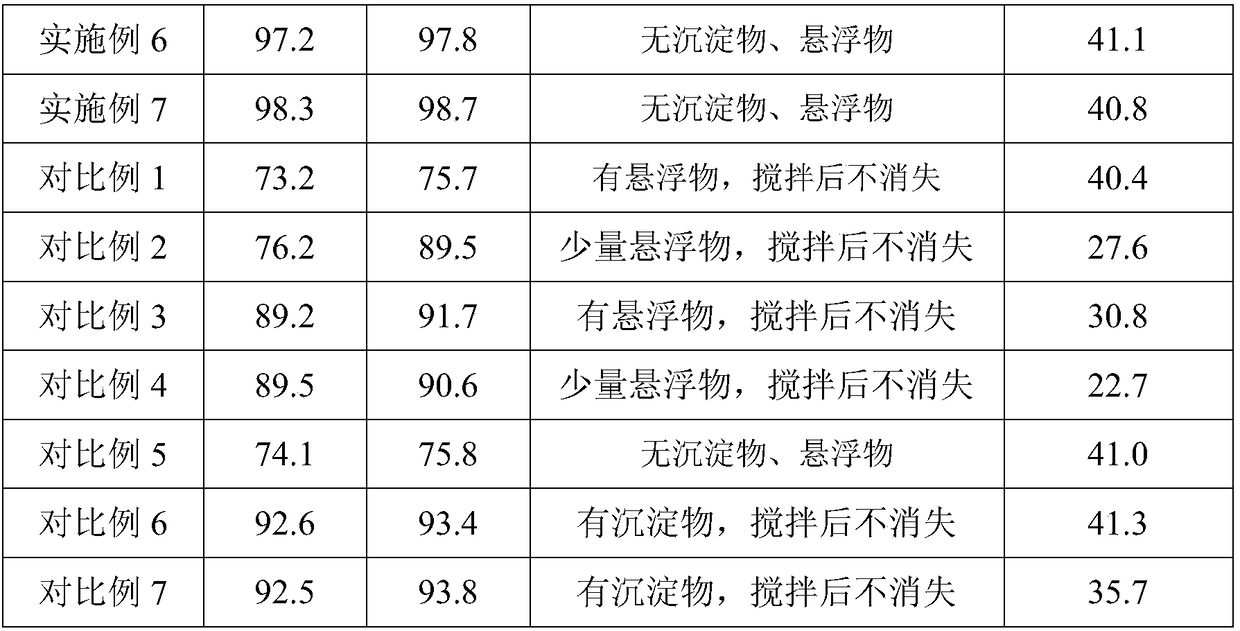

Enzymatic process for synthesizing estolides

This invention is a process for enzymatic synthesis of estolides through the reaction between stearic acid and methyl ricinoleate, using an immobilized lipase as the catalyst, in a solvent-free medium. This process prevents degradation of the product, reduces the formation of secondary products that generate color and odor in the lubricant, and allows recovery of the lipase and its subsequent reuse.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

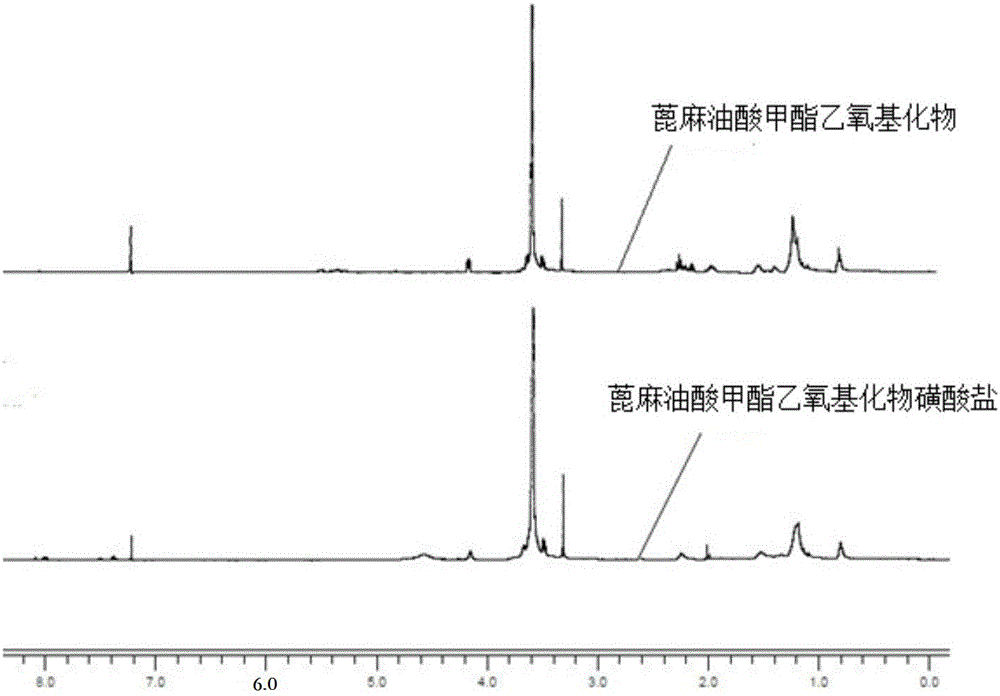

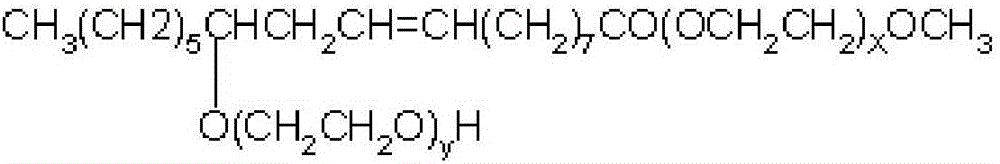

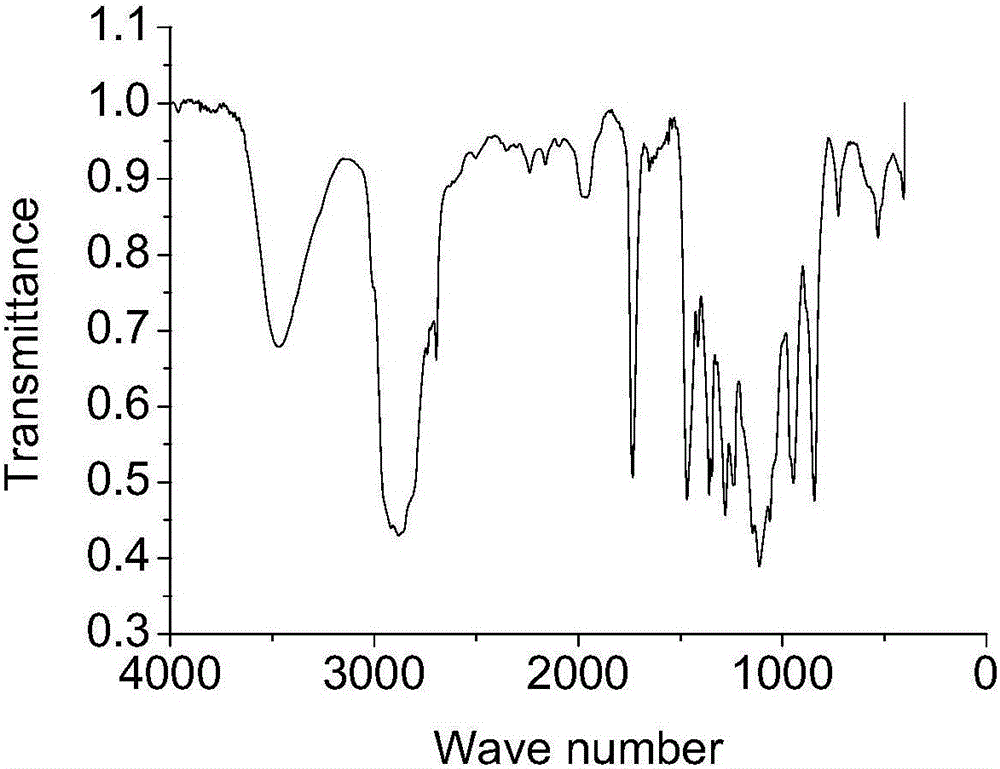

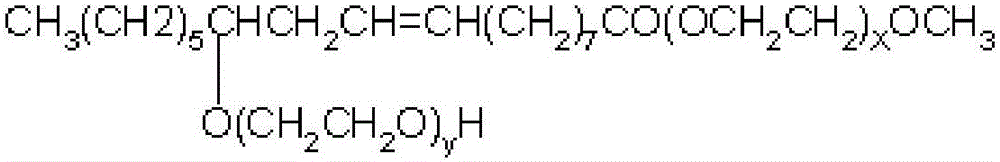

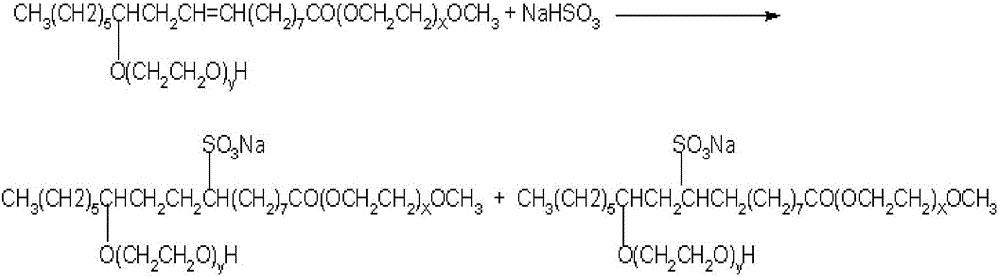

Method for synthesizing methyl ricinoleate ethoxylate sulfonate

ActiveCN106588707ALow reaction temperatureImprove conversion rateTransportation and packagingSulfonic acids salts preparationMethyl ricinoleateDistillation

A method for synthesizing methyl ricinoleate ethoxylate sulfonate comprises the steps that methyl ricinoleate ethoxylate, sodium bisulfite, a catalyst, deionized water and higher alcohol are added to a reactor, stirred vigorously and subjected to a reaction at 30-55 DEG C for 2-3 h, wherein the mole ratio of the methyl ricinoleate ethoxylate to the sodium bisulfite is 1:(1-3.5), the use quantity of the catalyst is 4.5%-6.5% of the mass of the methyl ricinoleate ethoxylate, and the mass ratio of the higher alcohol, the deionized water and the methyl ricinoleate ethoxylate is (1-3.5):(1-3.5):1; after the reaction, water and the higher alcohol are removed through reduced-pressure distillation, obtained solids are dissolved with excessive absolute ethyl alcohol, salts in the solution are removed through hot filtration, ethyl alcohol is removed through reduced-pressure distillation, and a product is obtained. The method has the advantages of low reaction temperature, short reaction time and high conversion rate.

Owner:CHINA RES INST OF DAILY CHEM IND

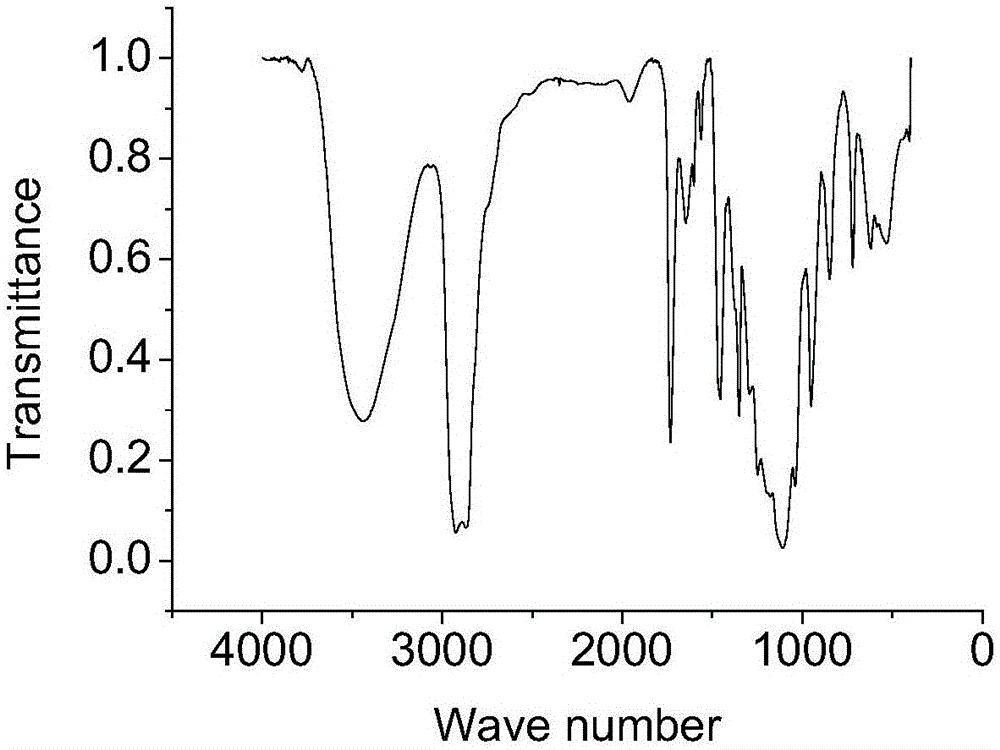

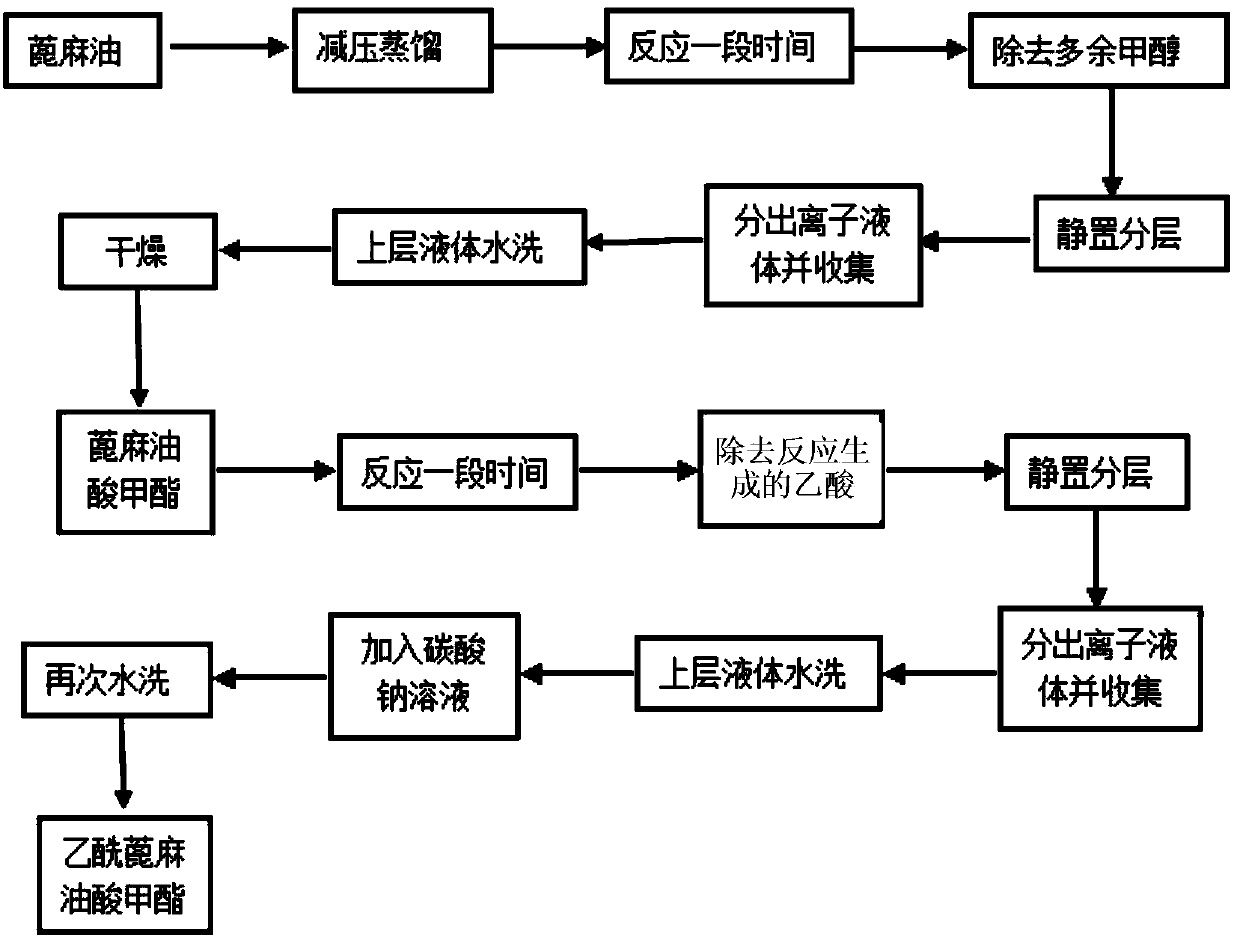

Preparation method of methyl acetylricinolate

ActiveCN103992223ARealize industrialized mass productionHigh yieldOrganic compound preparationCarboxylic acid esters preparationMethyl ricinoleateAcetylation

The invention provides a preparation method of methyl acetylricinolate, the preparation method comprises the following steps: step a, using ionic liquid catalyst (Hmim) HSO4 for methyl esterification of castor oil to obtain methyl ricinoleate; and step b: using the ionic liquid catalyst (Hmim) HSO4 for acetylization of the methyl ricinoleate to obtain the methyl acetylricinolate. According to the preparation method, the (Hmim) HSO4 ionic liquid catalyst is used for methyl esterification and acetylation of the castor oil to obtain the methyl acetylricinolate, and the method has the advantages of simple production process, low cost and high product yield, and is conducive to the realization of the industrialized mass production of the methyl acetylricinolate.

Owner:YANCHENG INST OF TECH

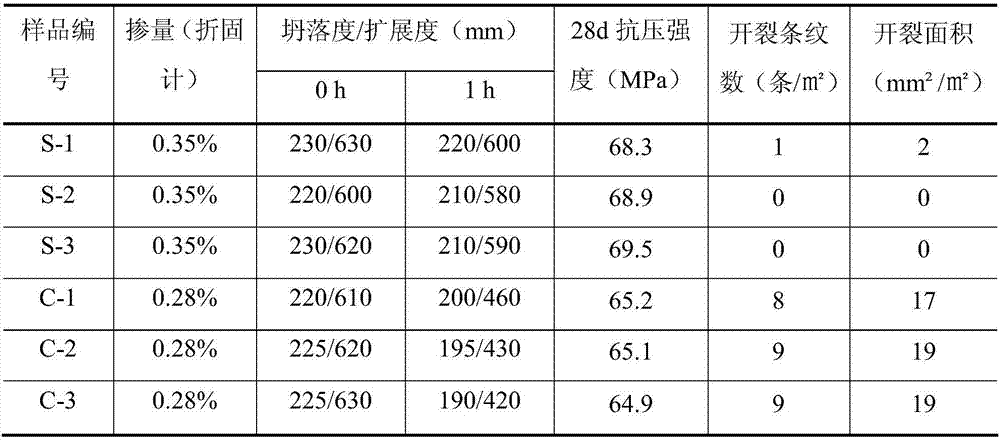

Self-curing polycarboxylic type water reducer and preparation method thereof

The invention belongs to the technical field of concrete additives and particularly relates to a self-curing polycarboxylic type water reducer and a preparation method thereof. The self-curing polycarboxylic type water reducer is prepared from a polyether macromonomer, a polyether micromonomer, a regulation monomer-methyl ricinoleate, a grafting monomer-sodium hydroxyethyl methyl cellulose, a cross-linking agent-ethylene glycol dimethacrylate, a chain transfer agent, an initiator and deionized water. The self-curing polycarboxylic type water reducer has the advantages that after the sodium hydroxyethyl methyl cellulose is introduced into a molecular structure and the cross-linking agent-the ethylene glycol dimethacrylate is used for proper cross-linking, the self-curing polycarboxylic type water reducer can achieve solvent swelling and is capable of retaining internal water required by cement hydration, thereby having a self-curing function.

Owner:山东华伟银凯建材科技股份有限公司

Low temperature resistant PVC water supply pipe used in severe cold region and preparation method thereof

The invention discloses a low temperature resistant PVC (polyvinyl chloride) water supply pipe used in severe cold region and a preparation method thereof. The low temperature resistant PVC water supply pipe used in the severe cold region is prepared from the following raw materials in parts by weight: 42-56 parts of PVC resin SG-7, 34-48 parts of polyethylene terephthalate, 10-15 parts of tetrafluoroethylene-perfluoroalkyl vinyl ether copolymer, 11-19 parts of triethylene glycol di-2-ethylhexoate(triglycol dioctate), 10-15 epoxidation acetyl ricinolic acid methyl ester, 9-18 parts of oil shale ash, 14-22 parts of white mud, 10-15 parts of lithium soap powder, 4-7 parts of low molecular weight polypropylene, 3-6 parts of erucicamide, 1-2 parts of calcium stearate, 1-2 parts of zinc stearate, 2-4 parts of pentaerythritol adipate ester, 1.5-2.5 parts of uracil, 2-3 parts of aniline methyltriethoxysilane, 22-26 parts of filled masterbatch, 1-2 parts of salicylic acid-tert-butyl-phenyl ester and 0.5-1.5 parts of 3-(3,5-di-tert-butyl-4-hydroxyl phenyl) methyl propionate. The PVC pipe provided by the invention is good in the comprehensive performance and simultaneously has the characteristics of low temperature resistance, high strength, high impact resistance and high toughness; the PVC pipe can meet requirements for utilization in the severe cold region at temperature below minus 40 DEG C and is not prone to crack; the service life is long; the market competiveness is high.

Owner:ANHUI DINGYUAN ZHENYUN PLASTIC

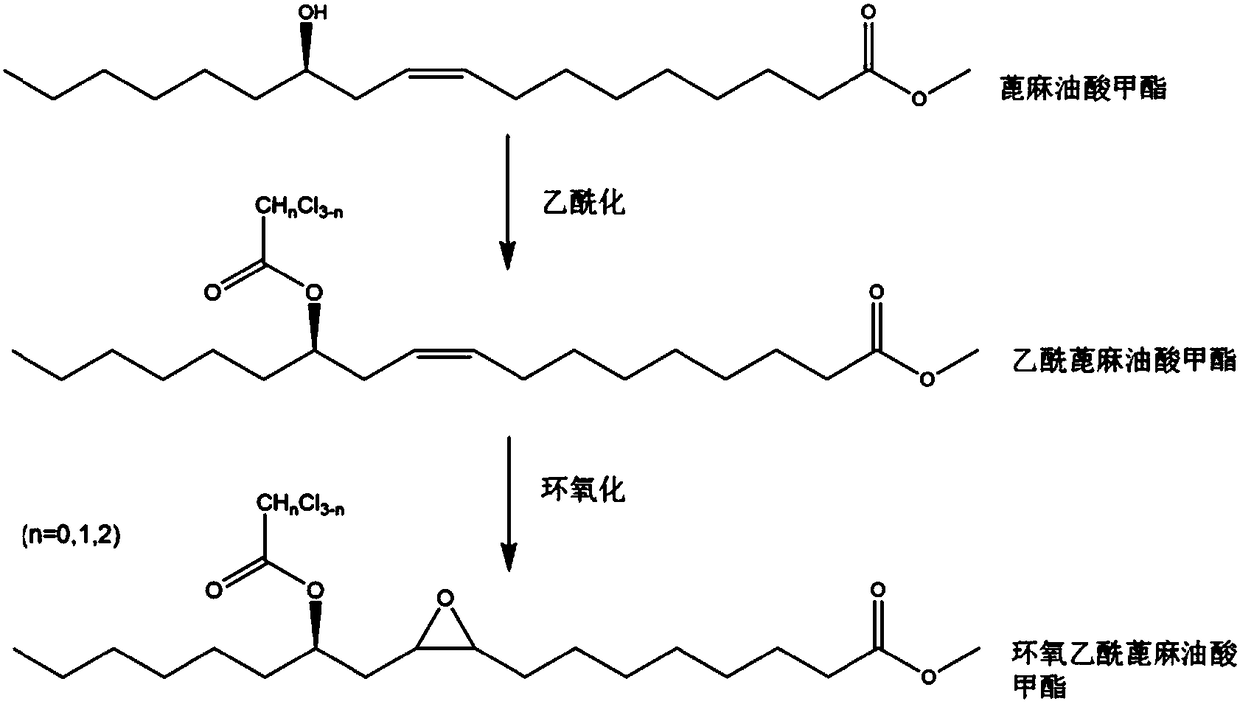

Method for improving compatibility of epoxidized methyl acetylricinolate plasticizer and PVC (Polyvinyl Chloride) resin

The invention discloses a method for improving the compatibility of an epoxidized methyl acetylricinolate plasticizer and PVC (Polyvinyl Chloride) resin. The method is characterized in that a utilizedacetylation reagent contains chlorine atoms with a certain quantity; the compatibility of the epoxidized methyl acetylricinolate plasticizer and the chlorine-containing PVC resin can be remarkably improved, so that the transferring resistance of the plasticizer is improved, and the flexibility and durability of a PVC product are improved. The plasticizer prepared by the method disclosed by the invention has no toxin and is environmentally friendly, can be used for replacing or partially replacing a phthalate plasticizer to produce products including polyvinyl chloride artificial leather, foodpackages, medical devices and the like, and has a wide application prospect.

Owner:SICHUAN UNIV

Polyurethane foam insulation material and preparation method thereof

The invention discloses a polyurethane foam insulation material, which is composed of the following ingredients (by weight): 80-100 parts of a polyurethane prepolymer, 100-120 parts of isocyanate, 15-20 parts of spirulina small molecule peptide, 5-10 parts of a microencapsulated phase change material, 15-30 parts of deionized water, 5-8 parts of stearic acid modified perlite, and 3-5 parts of epoxidized methyl acetoricinoleate. The polyurethane foam insulation material has good mechanical properties and heatproof heat-retaining property, water resistance and yellowing resistance, and overcomesthe insufficiencies of all-water foaming rigid polyurethane foam plastic, such as crispy foams and large heat conductivity coefficient.

Owner:广西南宁桂尔创环保科技有限公司

Flame-retardant polyurethane flexible foam and preparation method thereof

The invention provides a flame-retardant polyurethane flexible foam and a preparation method thereof. The flame-retardant polyurethane flexible foam comprises a component A and a component B, wherein the component A is composed of sucrose polyether, water, dimorpholinodiethylether, ammonium methyl ricinolcic acid sulfate, butanediol, and a flame retardant, and the component B is composed of toluene diisocyanate and polypropylene oxide glycol. The flame-retardant polyurethane flexible foam not only has various excellent properties such as high resilience and the like of polyurethane flexible foams, but also has a good flame retardant performance.

Owner:应急管理部四川消防研究所

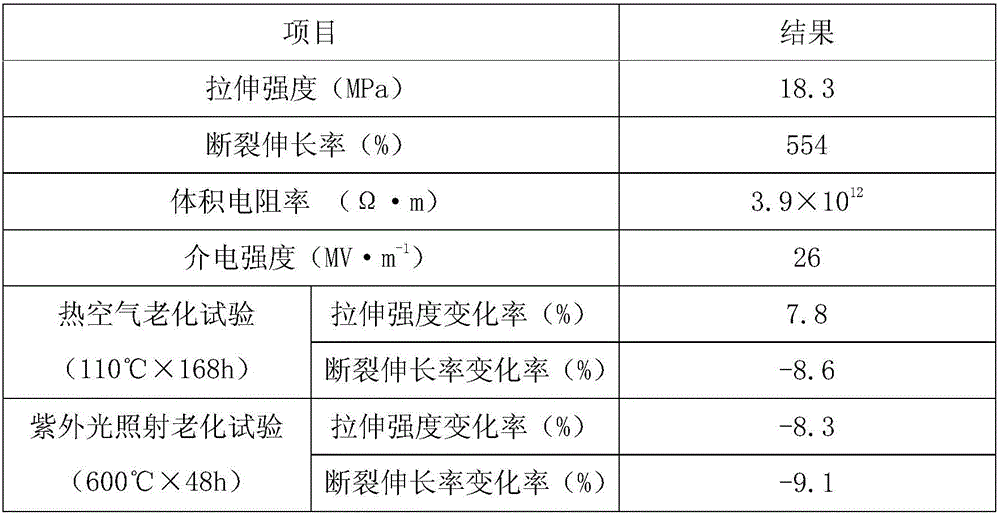

High-strength cable material used for railway vehicle, and preparation method thereof

ActiveCN104017365AHigh mechanical strengthImprove thermal stabilityPlastic/resin/waxes insulatorsGlycidyl methacrylatePhosphine oxide

The invention discloses a high-strength cable material used for a railway vehicle, and a preparation method thereof. The high-strength cable material is prepared from the following raw materials by weight: 85-105 parts of polyphenylene sulfide, 40-60 parts of aromatic polycarbonate, 25-35 parts of ethylene-methyl acrylate-glycidyl methacrylate terpolymer, 4-8 parts of diphenyl-methane-diisocyanate, 12-16 parts of bis(4-carboxyphenyl)phenyl-phosphine oxide, 10-15 parts of zinc aluminate, 20-30 parts of magnesium hydroxide,8-12 parts of basalt short fibers, 2-3 parts of methacryloyloxy propyltrimethoxysilane, 3-5 parts of tri-(stearic mercaptoacetate)antimonium, 2-3 parts of calcium stearate, 1.5-2.5 parts of barium stearate, 4-8 parts of erucyl amide, 3-6 parts of polyethylene wax, 15-20 parts of calcined clay, 10-15 parts of basic magnesium chloride whiskers, 20-30 parts of precipitated white carbon black, 14-18 parts of modified stone powder, 10-15 parts of epoxidized methyl acetorieinoleate and 2-3 parts of an antioxidant 1222. The cable material provided by the invention has the advantages of high mechanical strength, high flame retardance, fire resistance, good thermal stability, excellent electrical insulation property, wide usage temperature range, etc.

Owner:ANHUI KANGLIYA CO LTD

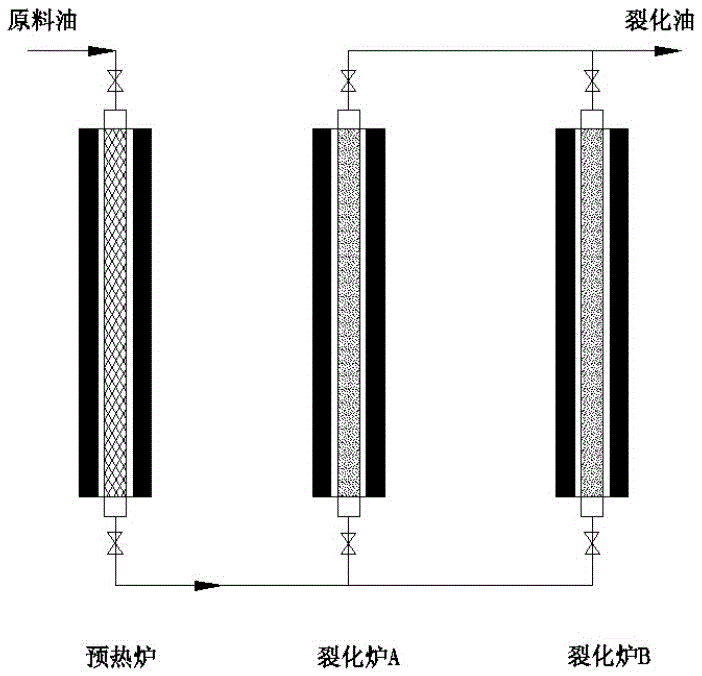

Method for preparing 10-undecylenic acid and heptanal by catalytic cracking

ActiveCN103819330BReduce aggregationReduced responsePreparation from carboxylic acid saltsMolecular sieve catalystsMethyl ricinoleateIsomerization

The invention relates to a process for producing polyundecancylamide resin through castor oil and particularly relates to a method for preparing 10-undecenoic acid and heptanal through the castor oil in the process. The method comprises the following steps: ester interchange is performed on the castor oil and methyl alcohol to generate ricinic acid methyl ester; catalytic cracking is performed on the ricinic acid methyl ester to generate10-undecenoic acid methyl ester and heptanal; pressure-reduction rectification separation is performed on the 10-undecenoic acid methyl ester and heptana; saponification and acidification are performed on the 10-undecenoic acid methyl ester and heptana, so that 10-undecylenic acid is obtained; the ricinic acid methyl ester is mixed with water (or water vapor) according to the mass ratio of 1:(0.5-2), the mixture is preheated to 200-400 DEG C, and then is loaded into a cracking still filled with a catalyst, and cracking is performed at the temperature of 400-500 DEG C, so that the 10-undecenoic acid and heptanal are generated. According to the invention, due to catalytic action, the cracking temperature is reduced greatly, so that side reactions such as polymerization and isomerization of the double bond, the secondary cracking of a product and coking are reduced, and the yield of the 10-undecenoic acid and heptanal is improved greatly.

Owner:江苏东鼎化学科技有限公司

Pre-dispersing masterbatch for rubber accelerator ETU (N,N-ethylene thiourea) and preparation method of pre-dispersing masterbatch

The invention discloses pre-dispersing masterbatch for an rubber accelerator ETU (N,N-ethylene thiourea) and a preparation method of the pre-dispersing masterbatch. The pre-dispersing masterbatch comprises components in parts by weight as follows: 72-82 parts of ETU, 8-16 parts of rubber carriers, 2-4 parts of EVA (ethylene vinyl acetate copolymer) resin, 1-3 parts of epoxidized methyl acetorieinoleate, 2-4 parts of saturated fatty acid zinc, 1-8 parts of naphthenic oil and 1-3 parts of color masterbatch. The pre-dispersing masterbatch for the rubber accelerator ETU is convenient to store, transport and weigh, the preparation method of the pre-dispersing masterbatch is simple and high in operability, original activity of ETU can be guaranteed, the problems that ETU is prone to agglomeration and is non-uniform in dispersion when directly put into rubber for mixing are solved, the problem of ETU dust pollution can be solved, and the health problem of an operator caused by inhalation of ETU dust is solved; besides, the masterbatch is colored, so that material identification and management are facilitated, mistaken charging caused by the operator during feeding for follow-up rubber product mixing is avoided, and the application of the color masterbatch has no influence on colors of follow-up prepared rubber products.

Owner:NINGBO ACTMIX POLYMER

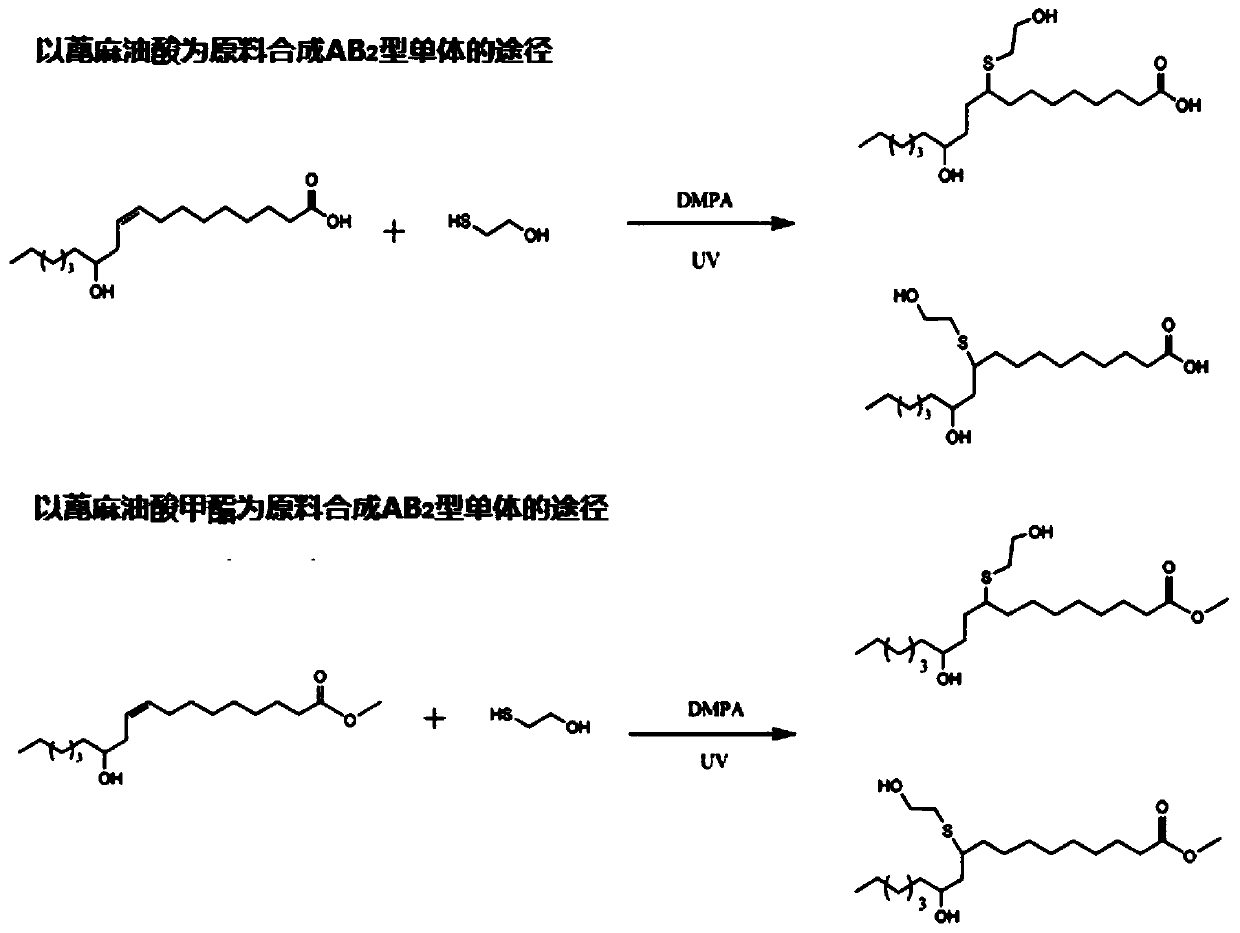

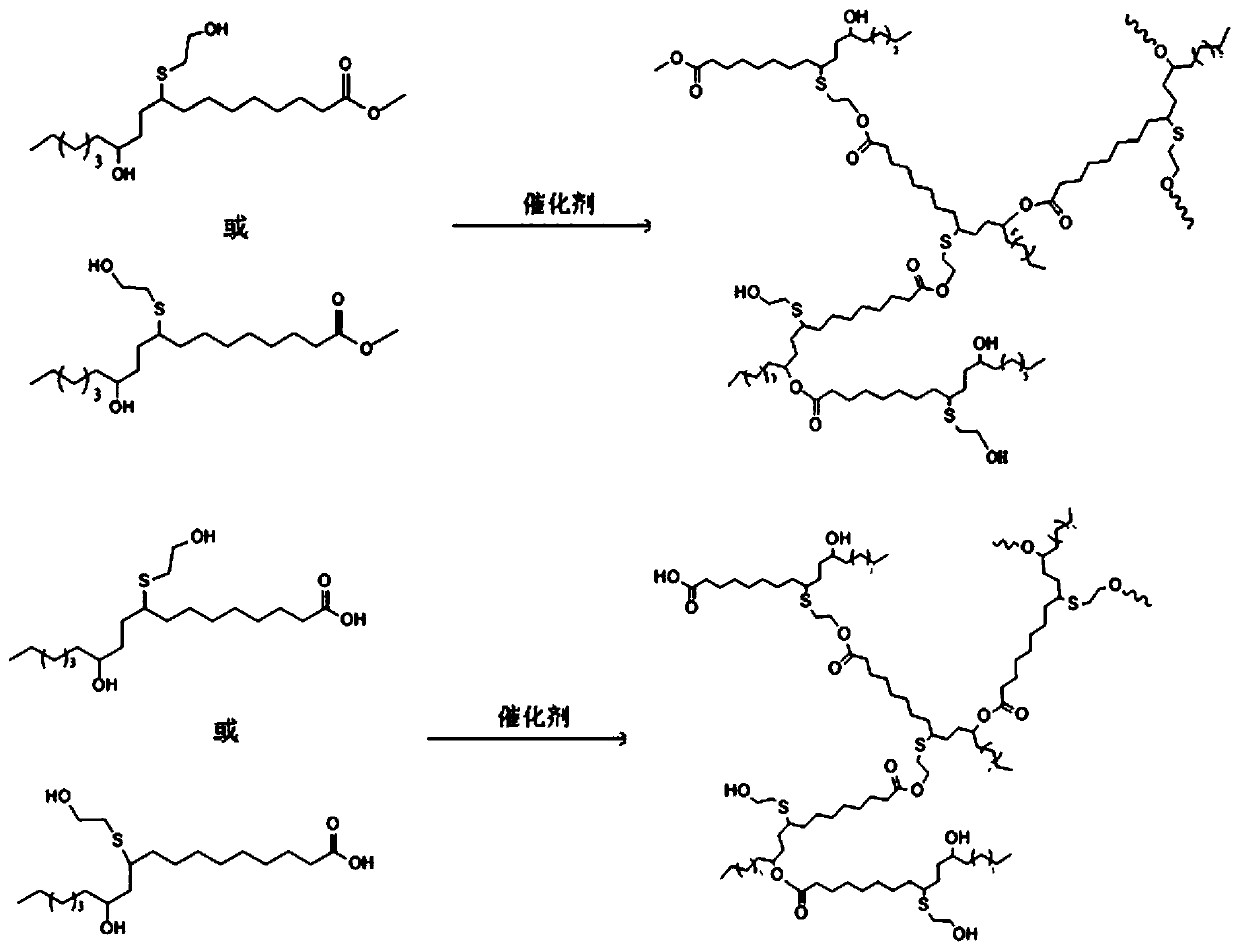

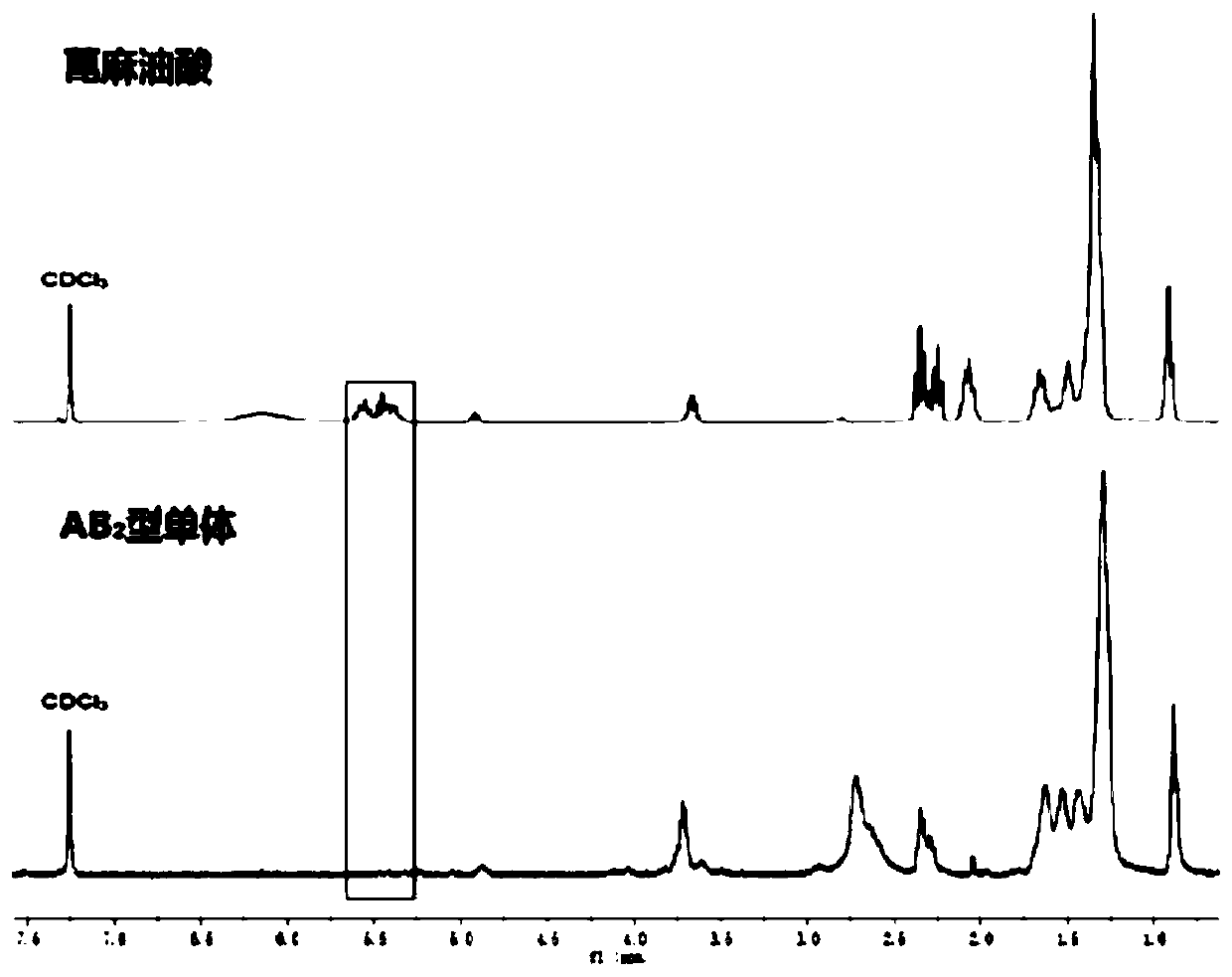

Synthetic method of castor oil derivative based long-chain HBP (hyperbranched polyester) with low viscosity and good chain segment flexibility

The invention discloses a synthetic method of castor oil derivative based long-chain HBP (hyperbranched polyester) with low viscosity and good chain segment flexibility. Biodegradable ricinoleic acidor methyl ricinoleate which is sourced from natural renewable resources is used as a starting material instead of a non-biodegradable petroleum based chemical, an ABn self-polycondensation monomer issynthesized conveniently and efficiently by an environment-friendly solvent-free thiol-ene photo-click reaction, and novel bio-based HBP is obtained finally in a staged polymerization manner. Comparedwith the conventional petroleum based HBP, synthesized bio-based HBP not only has highly-branched molecular structure of general HBP, but also has the advantages of low glass transition temperature,good fluidity and the like due to the specific structural characteristics that a main chain of HBP has longer soft segments and contains a large quantity of C6 aliphatic alkyl hanging side chains.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Wool spinning oiling agent with high performance

The invention discloses a wool spinning oiling agent with high performance which is composed of spindle oil, oleic acid polyethylene glycol ester, oleic acid polyoxyethylene (14) ester, oleyl alcohol and castor methyl oleate. The wool spinning oiling agent with high performance has the advantages of reasonable formula, good usage effect and low production cost.

Owner:宋建英

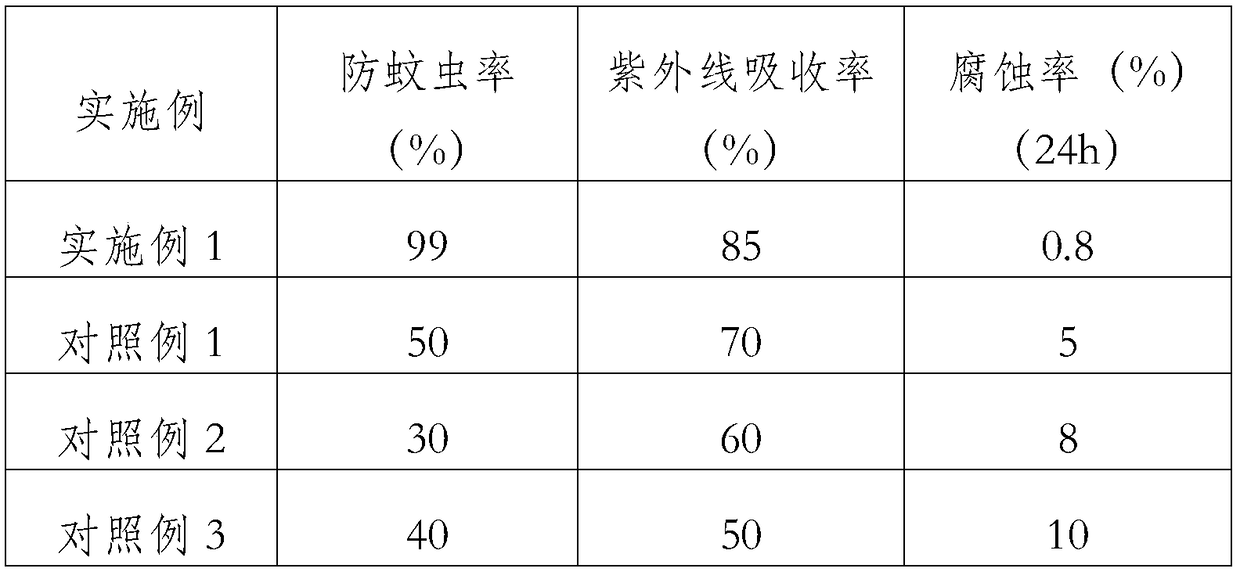

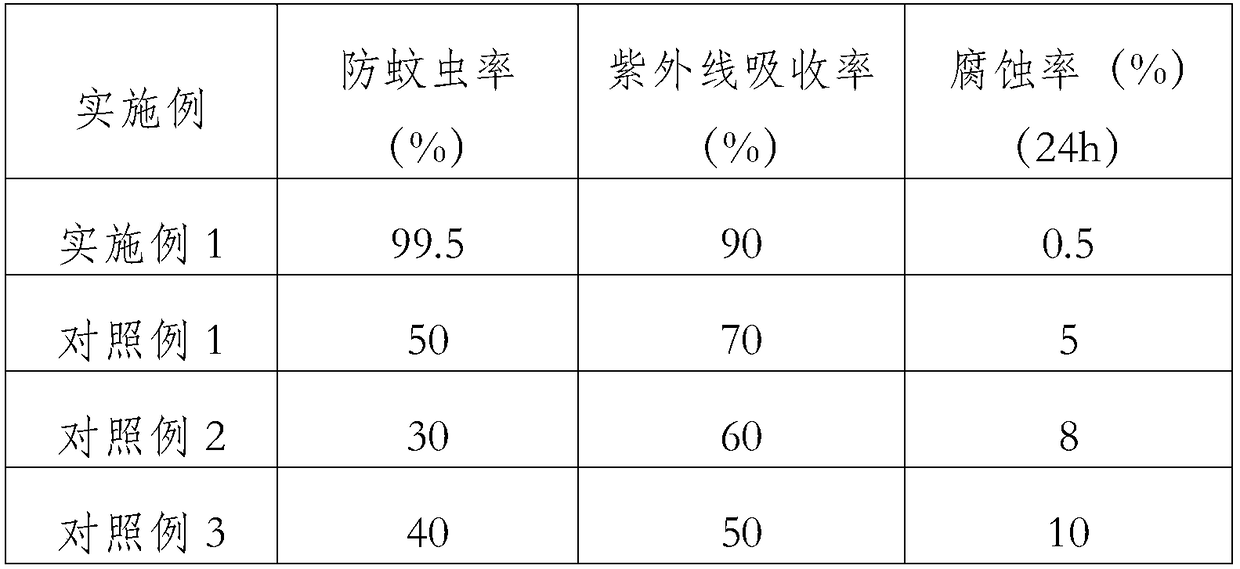

An automobile windshield washer fluid for use in summer and a preparation method thereof

PendingCN108774592AImprove mosquito repellent effectGuaranteed claritySurface-active detergent compositionsDetergent perfumesWater basedUltraviolet

An automobile windshield washer fluid for use in summer and a preparation method thereof are disclosed. The windshield washer fluid includes lauric acid, coconut oil acid diethanolamide, ethoxylated methyl ricinoleate, ethanol, essence, an aqueous ultraviolet ray absorbent PR020, chrysanthemum flower essential oil, water-based lanolin, and water. The windshield washer fluid has good mosquito repellent effect, can greatly reduce stay of mosquitoes on glass, can maintain glass clarity well and has good cleaning effect. The windshield washer fluid can effectively resist ultraviolet rays, preventsultraviolet rays from entering an automobile through glass, and under the premise of not damaging metal or rubber, can effectively protect the metal and rubber from being corroded by other substances. A manufacturing process is simple and easy to operate, and raw materials are cheap, easily available, nontoxic, harmless, nonirritant to human body and low in volatility. The method is simplified inprocess, safe and simple in operation and prone to industrial production. Good economic benefit can be obtained through use of the windshield washer fluid.

Owner:江苏今日卫生用品有限公司

Method for ozonization preparation of 2-nonenyl aldehyde

InactiveCN101508634BNo pollution in the processImprove reducibilityOrganic compound preparationPreparation by hydrogenolysisReductive decomposition2-Nonenal

The invention relates to a method for preparing 2-nonenal by ozonization with castor methyl oleate as the raw material, ethanol and n-hexane as the solvent, comprising performing ozonization by ventilating O3 / O2 gas mixture after uniformly mixing the raw material and the solvent at the low temperature, slowly dropping aqueous solution of NaHSO3 in ozonides, raising temperature for reductive decomposition, regulating the pH to 9-11 by sodium hydroxide solution, setting the mixture aside for layering, removing the water layer, rinsing the organic phase to neutrality by de-ionized water, adding dilute sulphuric acid for reflux, and recovering solution through reduced pressure distillation, and obtaining the target product, 2-nonenal, through the molecular distillation of the reaction mixture. In the method, no high pressure is needed during the reaction; the solvent of n-hexane can be recovered for repeated use; the mixed solvent system solves the serious corrosion to the devices by using acetic acid as solvent; the method has clean process, environmental protection, safe execution, simple operation and convenient mass production. The separation and purification of the products are simple.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

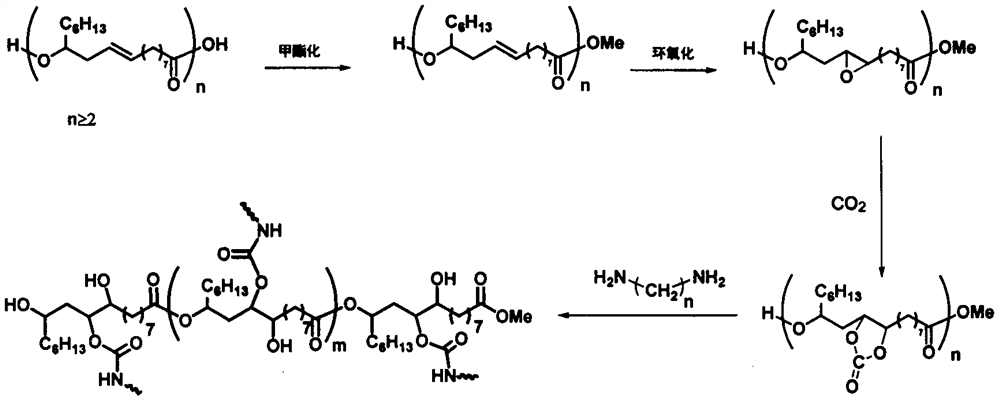

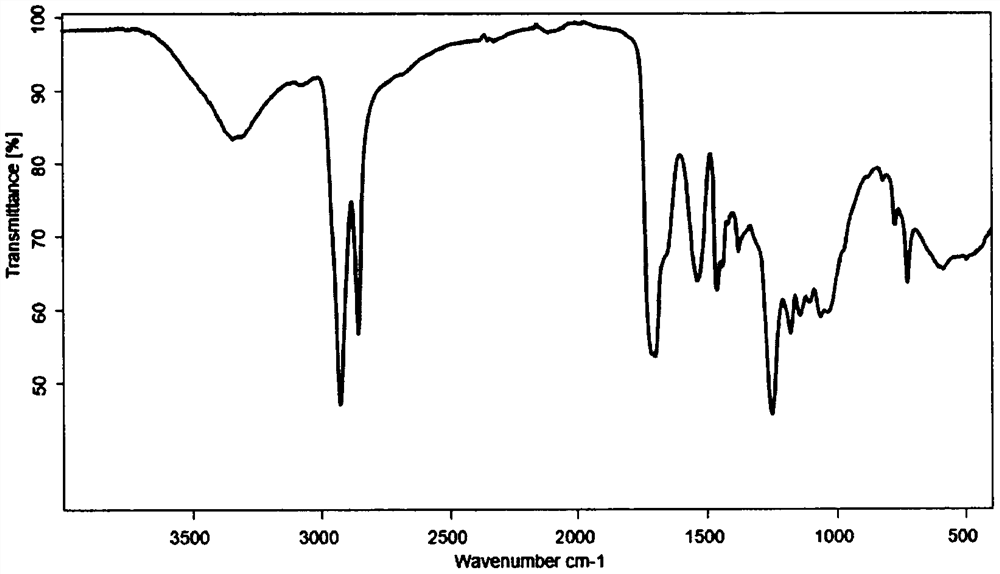

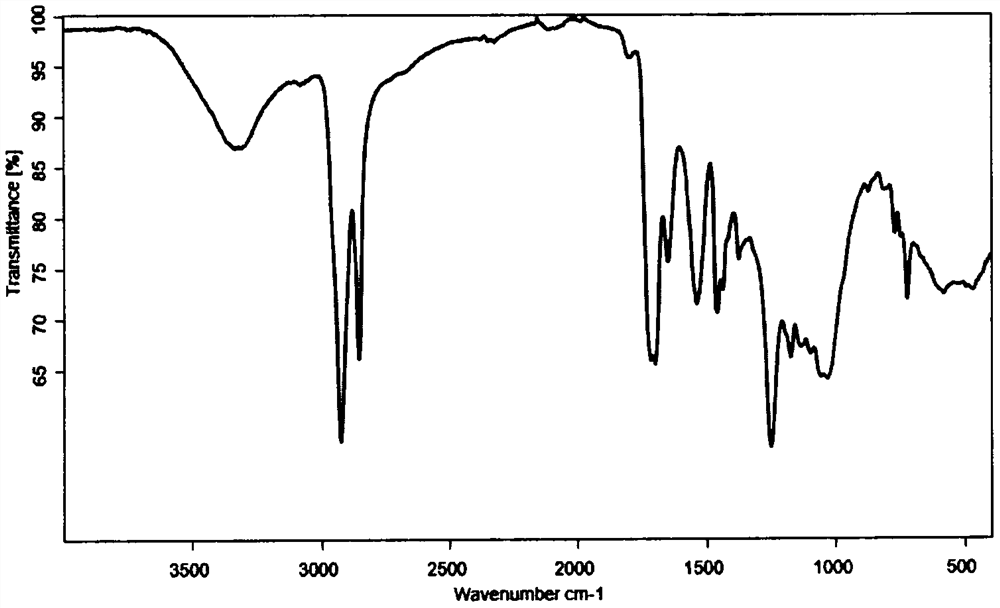

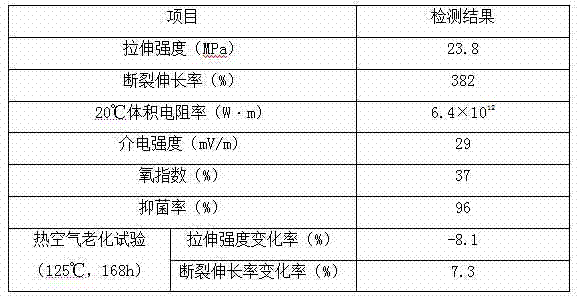

Novel castor-based polyurethane coating material and preparation method thereof

PendingCN114591674AEasy to store and transportIn line with the development concept of not competing with others for foodFireproof paintsPolyurea/polyurethane coatingsMethyl ricinoleatePolymer science

The invention relates to a novel castor-based polyurethane coating material and a preparation method thereof.The preparation method comprises the steps that oligomeric ricinoleic acid with different acid values serves as a raw material, carboxyl in the oligomeric ricinoleic acid is subjected to methyl esterification, and polyricinoleic acid methyl ester is formed; then, double bonds in polyricinoleic acid methyl ester molecules are subjected to epoxidation; and further performing cycloaddition reaction on the obtained epoxidized methyl polyricinoleate and carbon dioxide to prepare the polycyclic carbonate methyl ricinoleate containing 3-8 cyclic carbonate structural units as a polyurethane precursor. The polyurethane precursor reacts with polyamine, and obtained polyurethane has water resistance and acid and alkali resistance, is stable at the temperature of 200 DEG C and can be used as a coating material. The process is clean and pollution-free, non-edible oil castor oil is used as a raw material, and the development concept that biomass does not comply with people for grains is met.

Owner:NANKAI UNIV +1

Mouldproof special material for communication optical fiber cable jacket and preparation method thereof

InactiveCN104327483AGood mold resistanceImprove water resistanceTemperature resistanceDiazolidinyl urea

The invention discloses a mouldproof special material for a communication optical fiber cable jacket and a preparation method thereof. The mouldproof special material is prepared from the following raw materials in parts by weight: 42-64 parts of polyphenyl ether, 28-44 parts of a styrene-butadiene-styrene triblock copolymer, 4-7 parts of diazolidinyl urea, 3-5 parts of para-hydroxybenzoate chitosan ester, 2-4 parts of o-phenylphenol, 10-15 parts of light roasting powder, 8-14 parts of epoxidized methyl acetorieinoleate, 10-15 parts of sienna stone powder, 1-2 parts of allylthiourea, 4-6 parts of alurninium hydroxydistearate, 5-10 parts of dioctyl isophthalate, 12-16 parts of cryolite powder, 4-8 parts of butyl epoxystearate, 5-10 parts of liquid paraffin, 6-12 parts of magnesium hydroxide, 4-8 parts of zinc borate, 1-2 parts of nickel dibutyl dithiocarbamate, 2-3 parts of propyl gallate and 3-5 parts of auxiliaries. The special material for the jacket disclosed by the invention is good in mouldproof property, wear resistance and corrosion resistance, can be used for a long time in a humid environment, can be used for effectively inhibiting propagation of moulds and has excellent dimensional stability, remarkable propagate, relatively high tensile strength and relatively good creep resistance, wear resistance and temperature resistance.

Owner:安徽电信器材贸易工业有限责任公司

Method for synthesizing methyl ricinoleate ethoxylate sulfonate

ActiveCN106588706AThe synthesis process is simple and safeLow foamingTransportation and packagingSulfonic acids salts preparationAnhydrous ethanolMethyl ricinoleate

The invention relates to a method for synthesizing methyl ricinoleate ethoxylate sulfonate. The method comprises the steps of adding methyl ricinoleate ethoxylate, sodium bisulfite, a catalyst, deionized water and low carbon alcohol into a reactor, carrying out a reaction with violent stirring, carrying out distilling at reduced pressure after the reaction ends so as to remove water and the low carbon alcohol, carrying out dissolving by using excessive anhydrous ethanol so as to remove unreacted sodium bisulfite and produced sodium sulfite, and carrying out distilling at reduced pressure to remove ethanol, thereby obtaining the product, wherein the mole ratio of methyl ricinoleate ethoxylate to sodium bisulfite is 1: (1.5 to 2.5), the use level of the catalyst is 1.5% to 2.5% the mass of methyl ricinoleate ethoxylate, and the mass ratio of the low carbon alcohol to the deionized water to methyl ricinoleate ethoxylate is (0.9 to 3): (0.9 to 3): 1. The method has the advantages that the synthesis process is simple and safe, and waste acids and waste alkalis cannot be generated.

Owner:CHINA RES INST OF DAILY CHEM IND

Polyvinyl chloride cable material with good light and heat stability and preparation method thereof

InactiveCN106065141AExtended service lifeGood light stabilityPlastic/resin/waxes insulatorsApatitePolyvinyl chloride

The invention discloses a polyvinyl chloride cable material with good light and heat stability and a preparation method thereof. The polyvinyl chloride cable material is prepared from 79-92 parts by weight of polyvinyl chloride, 36-48 parts by weight of polyvinylpyridine, 15-20 parts by weight of resorcinol monobenzoate, 18-24 parts by weight of pandermite, 20-30 parts by weight of a copolymer of vinyl chloride and vinyl isobutyl ether, 22-34 parts by weight of picrite, 8-13 parts by weight of triglycidyl isocyanurate, 6-7 parts by weight of a di-n-octyltin moleate polymer, 8-10 parts by weight of butyl stearate, 14-22 parts by weight of titanium dioxide and 13-21 parts by weight of apatite. Through polyvinyl chloride cable material formula improvement such as use of polyvinylpyridine, the copolymer of vinyl chloride and vinyl isobutyl ether, aromatic hydrocarbon-modified terpene resin, pine soot, epoxidized methyl acetoricinoleate and titanium dioxide, the prepared cable material has good light stability, good heat stability and good weatherability, greatly reduces polyvinyl chloride cable material light and heat aging rates and prolongs a service life of the polyvinyl chloride cable material.

Owner:ANHUI SAIHUA CABLE

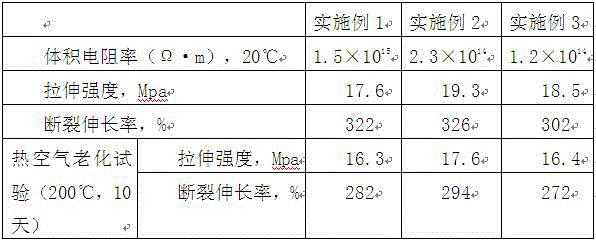

Modified pseudo-boehmite butadiene-acrylonitrile rubber compound cable material and preparation method thereof

InactiveCN106589494AHigh volume resistivityGood compatibilityRubber insulatorsRubber materialPolymer science

The invention discloses a modified pseudo-boehmite butadiene-acrylonitrile rubber compound cable material and a preparation method thereof. The modified pseudo-boehmite butadiene-acrylonitrile rubber compound cable material is prepared from the following raw materials in parts by weight: 50 to 60 parts of acrylonitrile rubber, 30 to 35 parts of pseudo-boehmite, 20 to 30 parts of thermoplastic polyurethane elastomer, 30 to 40 parts of poly(isobutylene-co-p-methyl-styrene-co-p-bromomethylstyrene), 10 to 12 parts of neopentyl glycol dibenzoate, 6 to 8 parts of calcium stearate, 30 to 40 parts of 2-ethylhexyl diphenyl phosphate, 3 to 5 parts of zinc oxide, 6 to 8 parts of chloropropyl triethoxy silane, 4 to 6 parts of polyterpene phenolic resin, and the like. According to the modified pseudo-boehmite butadiene-acrylonitrile rubber compound cable material and the preparation method thereof provided by the invention, the modified pseudo-boehmite butadiene-acrylonitrile rubber is used, so that the volume resistivity of the acrylonitrile rubber is increased, and an electrical insulation property of the acrylonitrile rubber is improved; and the pseudo-boehmite treated by the chloropropyl triethoxy silane, the epoxidized methyl acetorieinoleate and the 2-ethylhexyl diphenyl phosphate is used as a filler, so that a mechanical property of the product is improved, the surface states of pseudo-boehmite particles can be well improved, the compatibility of the pseudo-boehmite particles and the acrylonitrile rubber is improved, and the ageing resistance of the acrylonitrile rubber material can be remarkably improved.

Owner:盛天洋

Automobile glass water used in summer and preparation method of automobile glass water

PendingCN109181891AReduce exposureReduce surface tensionNon-ionic surface-active compoundsDetergent perfumesWater useLight energy

The invention discloses automobile glass water used in summer and a preparation method of the automobile glass water. The automobile glass water used in summer comprises lauric acid, coconut diethanolamide, castor oil acid methyl ester ethoxylate, ethanol, essence, an ultraviolet light absorber uv-p, lavender essential oil, sorbic acid and water. Due to the addition of the ultraviolet light absorber, the absorbed light energy is converted into heat energy by virtue of the conversion from a keto molecular structure to an enol molecular structure, so that the irradiation of ultraviolet light toa substrate is reduced, and the substrate is better protected; the surface of the substrate is firmly coated with an effective substance by virtue of sorbic acid serving as a corrosion inhibitor, so that the service life of the substrate is prolonged, and rusting can also be avoided. A surfactant prepared by compounding lauric acid, coconut diethanolamide and ethoxylate can be used for remarkablyreducing the tension on the surface of the substrate and improving the cleaning effect of the solution, meanwhile, the surfactant interacts with the ultraviolet light absorber and the corrosion inhibitor, and therefore, the ultraviolet light absorption effect and the anti-corrosion effect are obviously improved.

Owner:江苏今日卫生用品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com