Method for preparing epoxidized methyl acetorieinoleate

A technology for epoxy acetyl ricinole and methyl ricinoleate, which is applied in the field of preparing epoxy acetyl ricinoleate methyl ester, can solve problems such as reducing acetic anhydride and catalyst separation measures, and achieves short reaction time, little equipment corrosion, Easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

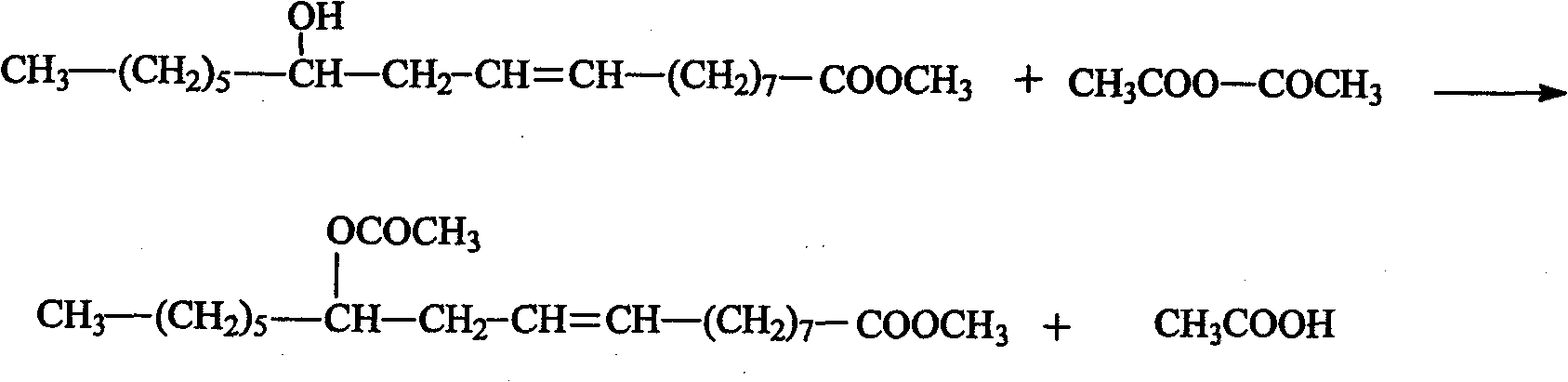

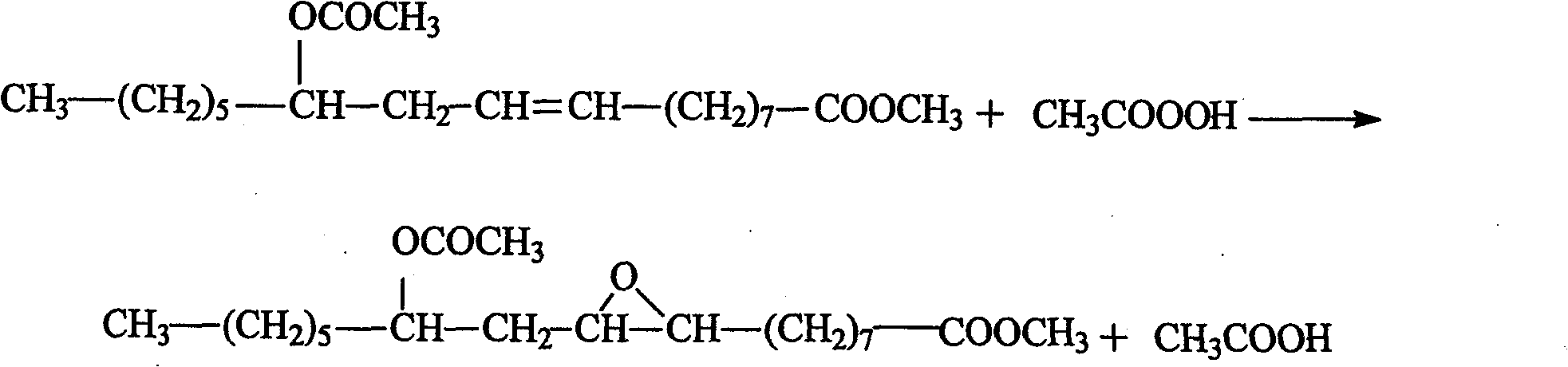

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: In 0.25L reactor, add ricinoleic acid methyl ester and acetic anhydride (molar mass ratio 1: 2), catalyst solid acid NaHSO 4 The addition amount is 1.5%, react at 70°C for 1 hour, and the conversion rate reaches 93.37%; the addition amount of hydrogen peroxide is 30%, the reaction temperature is 60°C, add hydrogen peroxide dropwise for 0.5 hour, and then react for 2.5 hours, the epoxy value of the product is 4.8.

Embodiment 2

[0025] Embodiment 2: In 0.25L reactor, add ricinoleic acid methyl ester and acetic anhydride (molar mass ratio 1: 2), catalyst solid acid NaHSO 4 The addition amount is 0.5%, reacted at 80°C for 2 hours, and the conversion rate reached 96.21%; the addition amount of hydrogen peroxide was 40%, the reaction temperature was 60°C, the hydrogen peroxide was added dropwise for 0.5 hour, and then reacted for 3 hours, the epoxy value of the product was 4.9.

Embodiment 3

[0026] Embodiment 3: in 0.25L reactor, add ricinoleic acid methyl ester and acetic anhydride (molar mass ratio 1: 2), catalyst solid acid NaHSO 4 The addition amount is 1%, react at 60°C for 3 hours, and the conversion rate reaches 90.36%; the addition amount of hydrogen peroxide is 40%, the reaction temperature is 70°C, add hydrogen peroxide dropwise for 0.5 hour, and react for another 2 hours, the epoxy value of the product is 5.0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com