Preparation method of soft acrylic resin leather retanning agent

A technology of acrylic resin and retanning agent, applied in small raw hide/large raw hide/leather/fur treatment, small raw hide/large raw hide/leather hide/fur chemical treatment, animal husbandry, etc., can solve the problem of leather fatliquoring and retanning agent Rare and other problems, to achieve the effect of simplifying the production route, good permeability, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

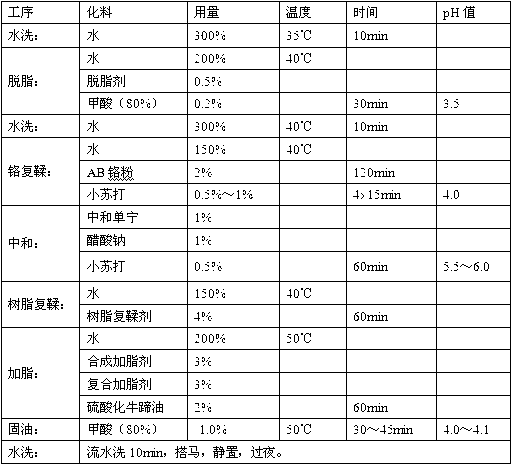

Method used

Image

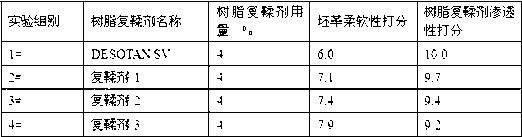

Examples

Embodiment 1

[0029] 1) Add 15.0 grams of acrylic acid and 17.9 grams of methacrylic acid into a three-necked flask, slowly add 55.6 grams of 30% sodium hydroxide aqueous solution at 20-30°C, and react for 30 minutes to obtain monomer aqueous solution A1; Acrylamide, 3.0 grams of isopropanol and 40 grams of deionized water were mixed to obtain monomer aqueous solution B1; 3.6 grams of ammonium persulfate was used to prepare initiator aqueous solution C1 with a mass concentration of 5%; set aside.

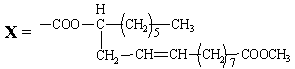

[0030] 2) Add 31.2 grams of ricinoleic acid methyl ester and 10.3 grams of maleic anhydride to a three-necked flask equipped with a stirrer and a reflux condenser, raise the temperature to 90°C, and react for 4 hours to obtain ricinoleic acid methyl ester maleic acid monoester ;

[0031] 3) Add 4.3 grams of ricinoleic acid methyl ester maleic acid monoester to a four-necked flask equipped with a stirrer, stir, add 1.8 grams of 30% sodium hydroxide aqueous solution dropwise and react at 20-30°C fo...

Embodiment 2

[0033] 1) Add 15.0 grams of acrylic acid and 17.9 grams of methacrylic acid into a three-necked flask, slowly add 55.6 grams of 30% sodium hydroxide aqueous solution at 20-30 °C, and react for 30 minutes to obtain monomer aqueous solution A2; Acrylamide, 6.0 grams of 1,2-propanediol and 40 grams of deionized water were mixed to obtain monomer aqueous solution B2; 2.4 grams of ammonium persulfate was used to prepare initiator aqueous solution C2 with a mass concentration of 5%; standby;

[0034] 2) Add 31.2 grams of ricinoleic acid methyl ester and 10.3 grams of maleic anhydride to a three-necked flask equipped with a stirrer and a reflux condenser, raise the temperature to 110°C, and react for 2.5 hours to obtain ricinoleic acid methyl ester maleic acid monoester ;

[0035] 3) Add 8.7 grams of ricinoleic acid methyl ester maleic acid monoester to a four-neck flask equipped with a stirrer, stir, add 3.7 grams of 30% sodium hydroxide aqueous solution dropwise and react at 20-30°...

Embodiment 3

[0037] 1) Add 8.6 grams of acrylic acid and 10.2 grams of methacrylic acid into a three-necked flask, slowly add 31.9 grams of 30% sodium hydroxide aqueous solution at 20-30°C, and react for 30 minutes to obtain monomer aqueous solution A3; Acrylamide, 3.0 grams of isopropanol and 40 grams of deionized water are mixed to obtain monomer aqueous solution B3; 1.2 grams of ammonium persulfate are used to make the initiator aqueous solution C3 of mass concentration 5%; standby;

[0038] 2) Add 31.2 grams of ricinoleic acid methyl ester and 10.3 grams of maleic anhydride to a three-necked flask equipped with a stirrer and a reflux condenser, raise the temperature to 120°C, and react for 2 hours to obtain ricinoleic acid methyl ester maleic acid monoester ;

[0039] 3) Add 13.0 grams of ricinoleic acid methyl ester maleic acid monoester to a four-neck flask equipped with a stirrer, stir, add 5.5 grams of 30% sodium hydroxide aqueous solution dropwise, and react at 20-30°C for 30 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com