Mouldproof special material for communication optical fiber cable jacket and preparation method thereof

A technology for communication optical cables and sheath tubes, which is applied in the field of special materials for anti-mold communication optical cable sheath tubes and its preparation. It can solve the problems affecting the normal transportation of optical cables, easy to breed mold, and corrode the sheath tubes. It achieves excellent dimensional stability, Inhibits the growth of mold and has good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

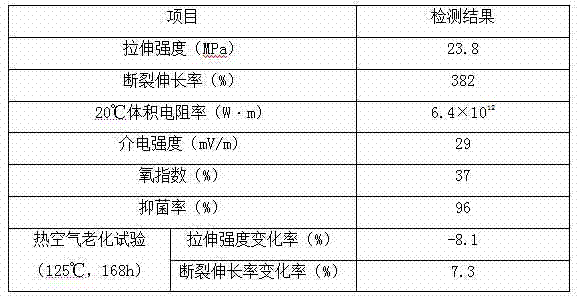

Examples

Embodiment

[0012] A special material for anti-mold communication optical cable sheath tube, made of the following raw materials in weight (kg): polyphenylene ether 56, styrene-butadiene-styrene triblock copolymer 36, diazolidinyl urea 5 , Chitosan p-hydroxybenzoate 4, o-phenylphenol 3, lightly burned powder 12, epoxyacetyl ricinoleic acid methyl ester 12, loess stone powder 13, allyl thiourea 1.5, aluminum distearate 5 , Dioctyl isophthalate 8, cryolite powder 14, epoxy butyl stearate 6, liquid paraffin 8, magnesium hydroxide 9, zinc borate 6, nickel dibutyl dithiocarbamate 1.5, propyl gallate Ester 2.5, Auxiliary 4;

[0013] The preparation method of the auxiliary agent is as follows: a. Take the following raw materials by weight (kg): calcium zirconate 12, methylene bis(2,4-di-tert-butylphenoxy)aluminum phosphate 4, titanium oxalate 3.5, Tourite 10, 3,5-di-tert-butyl-4-hydroxybenzoic acid methyl ester 2.3, dodecyl glucoside 1.2, N-aminoethylpiperazine 1, diisobutyl fumarate 8, suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com