Patents

Literature

45 results about "ALUMINUM DISTEARATE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Product Details & Information Aluminum Distearate, also referred to as Aluminum Soap, has a variety of applications and uses, primarily as a thickener and a hydrophobic agent. See below for more details on the use of this product in different applications, which can include plastics, oil and gas additives, food and beverage, and various others.

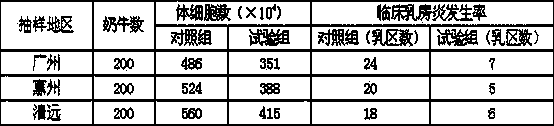

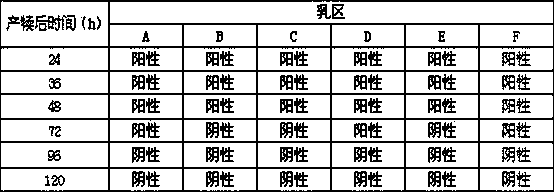

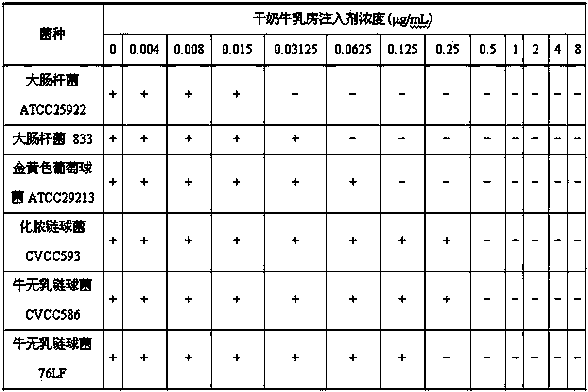

Breast injectant used for preventing and treating dry-milk-period dairy cow mastitis and preparation method thereof

InactiveCN103479574AReduce somatic cell countReduce incidenceAntibacterial agentsOrganic active ingredientsBiotechnologyMilk cow's

The invention relates to a novel veterinary drug, in particular to a breast injectant used for preventing and treating dairy cow dry-milk-period mastitis, dairy cow postpartum recessive mastitis and dairy cow subclicnical type mastitis and a preparation method of the breast injectant. The breast injectant comprises the components of cephalosporin, aluminum distearate and liquid paraffin. Compared with the prior art, the breast injectant has the advantages of being long in effect time, stable, broad in spectrum, remarkable in effect, free of toxic and side effects, low in price and free of influences on normal gestation and safety of milk quality.

Owner:SOUTH CHINA AGRI UNIV

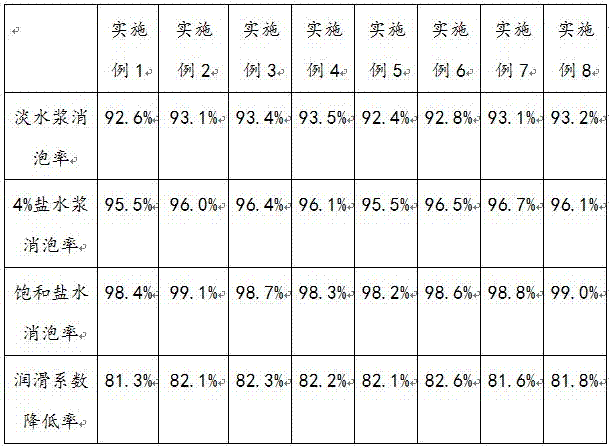

Defoaming agent for water-based drilling fluid and preparation method thereof

The invention relates to a defoaming agent for a water-based drilling fluid and a preparation method thereof. Selected solvent oil, stearic acid, oleic acid, isooctyl alcohol and tributyl phosphate are compounded. The solvent oil is heated to swell aluminum distearate, so as to facilitate compound with other components to play synergistic effect. The method for producing the defoaming agent has simple preparation process; the defoaming agent displays excellent defoaming effect with a small amount; and the product has lubrication action.

Owner:SICHUAN RENZHI PETROCHEMICAL TECHNOLOGY CO LTD

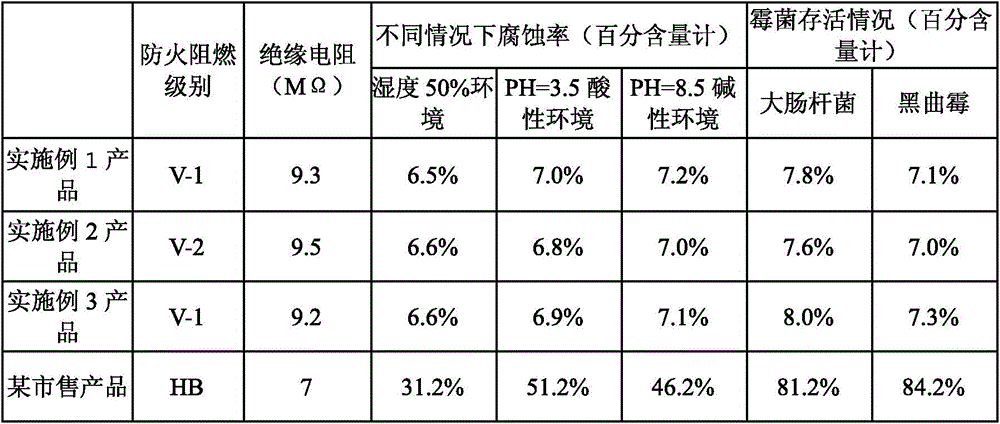

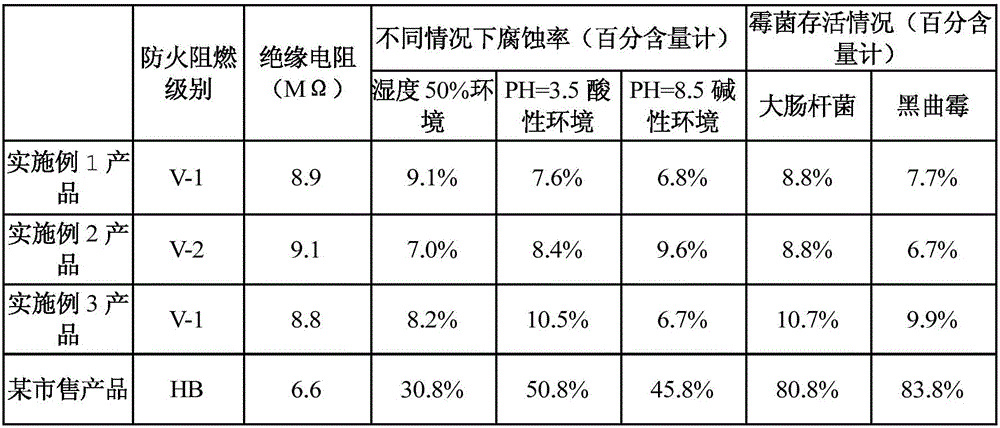

Anticorrosive multifunctional cable for civil building construction

InactiveCN105924912ASoft textureExcellent flame retardantPlastic/resin/waxes insulatorsInsulated cablesPhosphateCobalt

The invention relates to an anticorrosive multifunctional cable for civil building construction. The cable comprises a plurality of copper alloy leads and lags, the copper alloy leads are arranged in parallel, every copper alloy lead is coated with one lag, and the lag comprises poly(butylene succinate), polyketone resin, bimaleimide resin, dimethyl formamide, cottonseed oil, phosphate ester, phenylmethyl silicone oil, 2-mercaptobenzothiazole, benzalkonium chloride, dodecyl dimethyl benzyl ammonium chloride, didecyldimethylammonium chloride, phenyltriethoxysilane, lithium phosphate powder, zeolite powder, barium sulfate powder, molybdenum disulfide powder, fly ash, antimony oxide powder, dolomite powder, nanometer zinc oxide, trichloroethyl phosphate, polybenzimidazole imide, nanometer magnesium hydroxide, alkyl glycoside, ethylene glycol dimethacrylate, aluminum distearate, alkyl benzene sulfonic acid, sodium lauryl sulfate, petroleum sulfonate and cobalt isooctoate. The use performances of the cable are improved in the invention.

Owner:虞永华

Environment-friendly type drilling fluid anti-wear agent with high temperature resistance and preparation method of environment-friendly type drilling fluid anti-wear agent

InactiveCN105505338AHigh temperature resistanceLow biological toxicityDrilling compositionZinc compoundsPhosphorus pentasulfide

The invention relates to the technical field of drilling fluid auxiliaries, and provides an environment-friendly type drilling fluid anti-wear agent with high temperature resistance and a preparation method of the environment-friendly type drilling fluid anti-wear agent. The environment-friendly type drilling fluid anti-wear agent with the high temperature resistance comprises raw materials as follows: phosphorus pentasulfide, isooctyl alcohol, oleic acid, diethyl ammonium phosphate, potassium hydroxide, a molybdenum di-zinc compound, dimethyl silicon oil, zinc carbonate, aluminum distearate and water. The environment-friendly type drilling fluid anti-wear agent with the high temperature resistance is prepared from a natural polymer material, biomass oil and lipid through modified synthesis and esterification reaction, is not only an environment-friendly type drilling fluid auxiliary, but also can reduce wear, decrease frictional resistance and torque, increase the drilling rate and reduce drilling cost effectively and has higher tolerable temperature and higher salt intrusion resistance, thereby having more popularization value and further having better rock fragment hydrated dispersion inhibition capacity and better shale expansion inhibition function, and accordingly, the environment-friendly type drilling fluid anti-wear agent with the high temperature resistance is the environment-friendly drilling fluid auxiliary with the high temperature resistance and has the characteristics of advancement, maturity and economic efficiency.

Owner:XINJIANG DEBANG PETROLEUM TECH CO LTD

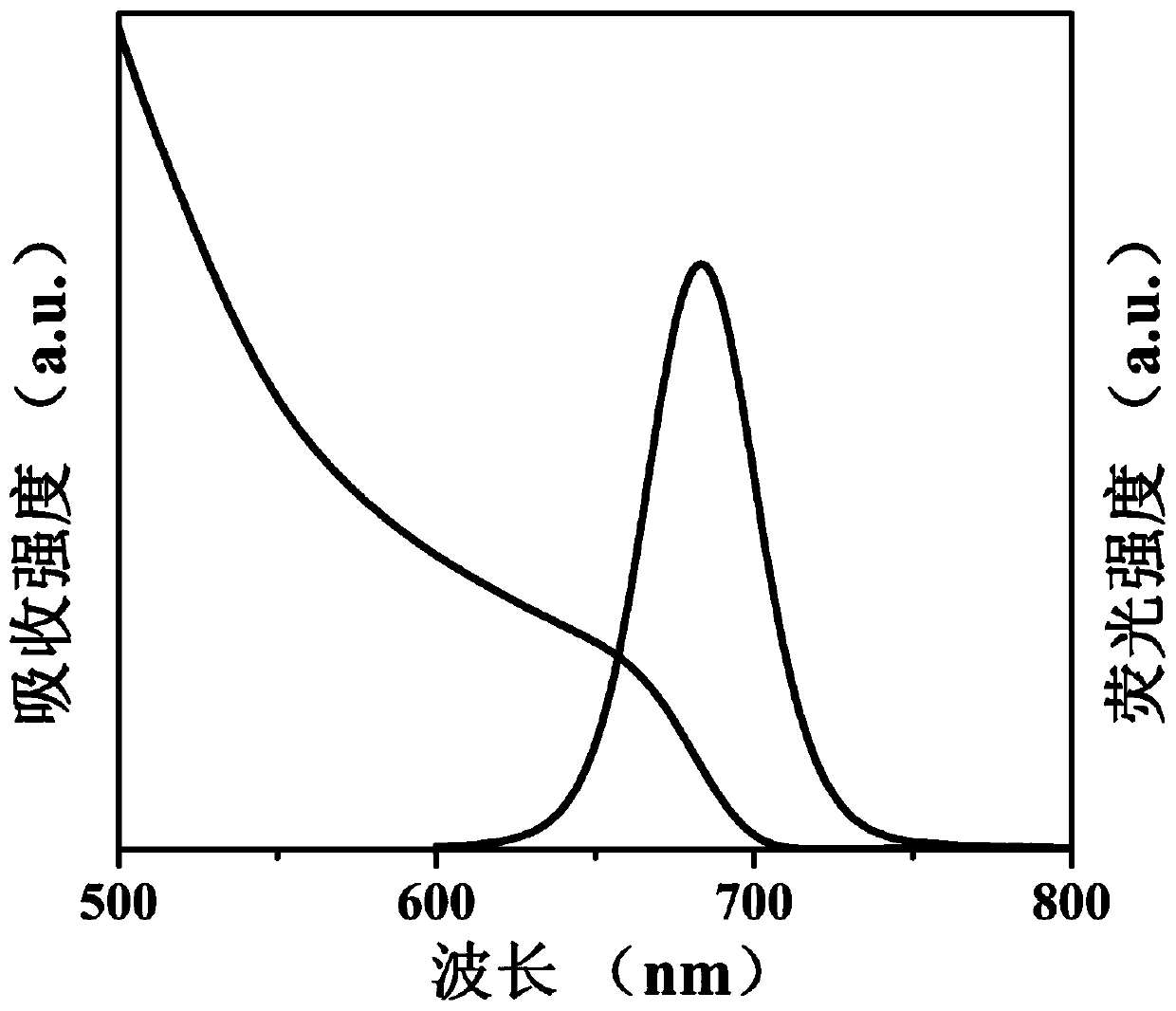

Aluminum distearate coating method for improving stability of perovskite quantum dots

The invention discloses an aluminum distearate coating method for improving the stability of perovskite quantum dots. The method includes the steps of: adding lead halide and aluminum distearate in amolar ratio of 1:(0.2-2) into a mixed solution of oleylamine, oleic acid and 1-octadecene in a volume ratio of 0.7:0.7:5, conducting heating stirring under a vacuum condition to obtain a lead halide precursor solution, heating the lead halide precursor solution under the protection of nitrogen, injecting a cesium source solution, carrying out reaction, then performing cooling to room temperature to obtain a crude product aluminum distearate coated colloidal perovskite quantum dot dispersion liquid, and performing purification to obtain an aluminum distearate coated colloidal perovskite quantumdot dispersion liquid. The stearic acid in the aluminum distearate adopted by the invention can be combined with metal ions on the surfaces of the perovskite quantum dots to effectively passivate thesurface defects of the quantum dots, thus increasing the fluorescence quantum yield, and improving the chemical and optical stability of the quantum dots under illumination, high temperature and polar environments.

Owner:EAST CHINA UNIV OF SCI & TECH

Soft pottery clay and manufacturing method thereof

InactiveCN102503240ABeautiful colorTo achieve the effect of long-term placementWhite powderPolyvinyl chloride

The invention relates to soft pottery clay and a manufacturing method thereof. The soft pottery clay comprises the following components which are mixed together: polyvinyl chloride paste resin, aluminum distearate, zinc stearate, calcium stearate, dioctylphthalate, titanium white powder, mixed resins and silicon dioxide. The manufacturing method of the soft pottery clay comprises the following steps: 1) supplying polyvinyl chloride paste resin, aluminum distearate, zinc stearate, calcium stearate, dioctylphthalate, titanium white powder, mixed resins and silicon dioxide, mixing and stirring, and then standing by and cooling; 2) after cooling, placing into a stirrer for stirring, and then taking out and naturally cooling; 3) after cooling, placing into the stirrer for stirring again, and then taking out and naturally cooling; and 4) after cooling, mixing with white powder and uniformly stirring, and cooling, thereby obtaining an end product. The soft pottery clay can be processed into various patterns through a handicraft and the patterns can be attached to the surface and the interior of an object. If the soft pottery clay is not processed at high temperature, the soft pottery clay is reusable and is ultrahigh in plasticity and viscidity.

Owner:丁森

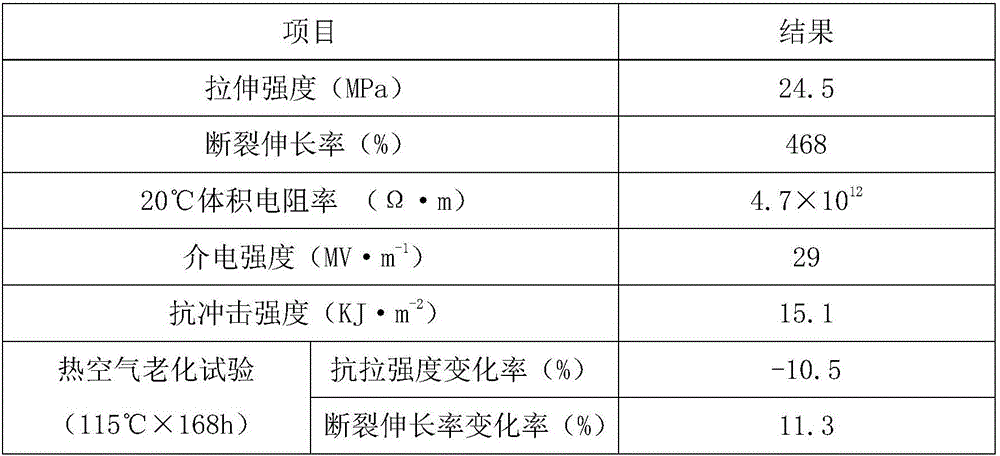

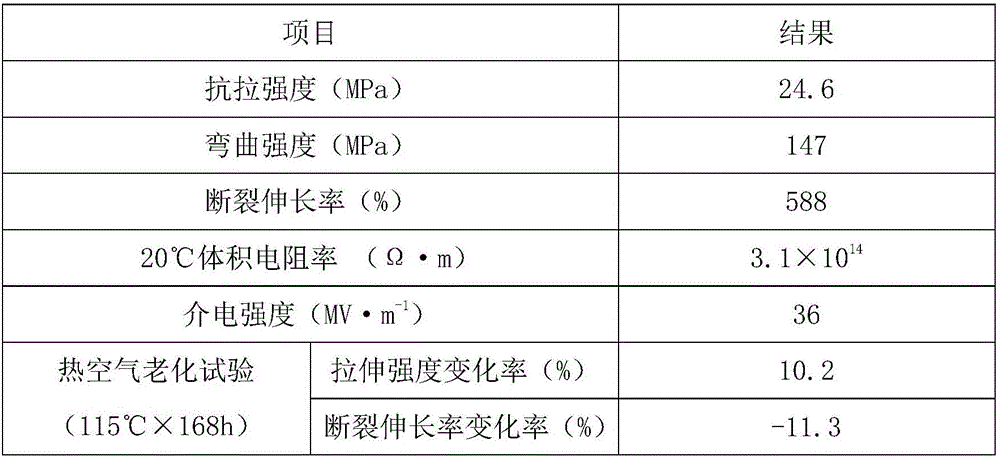

High-elasticity high-toughness polypropylene cable material for communication and preparation method thereof

InactiveCN106317622AImprove toughnessIncrease elasticityPlastic/resin/waxes insulatorsInsulated cablesPolypropyleneVolcanic ash

The invention discloses a high-elasticity high-toughness polypropylene cable material for communication and a preparation method thereof. The high-elasticity high-toughness polypropylene cable material for communication is prepared from the following raw materials in parts by weight: 70-90 parts of atactic polypropylene, 25-35 parts of thermoplastic elastomer SEEPS, 14-26 parts of butanediol cycloterephthalate, 15-25 parts of nano cellulose whisker, 12-20 parts of coumarone indene resin, 6-12 parts of hydroxyl aluminum distearate, 20-30 parts of siliceous shale, 16-24 parts of diisodecyl phthalate, 18-32 parts of asbestos tailing, 2-4 parts of cadmium stearate, 10-15 parts of flocking powder, 9-16 parts of basic magnesium sulfate whisker and 15-25 parts of volcanic ash. The toughness and elasticity of the material are improved; by adding the nano cellulose whisker, flocking powder, basic magnesium sulfate whisker and other raw materials into the system, the tensile strength and elongation at break of the material are enhanced; and the heat resistance, wear resistance and corrosion resistance of the material can also be improved.

Owner:ANHUI CHUNHUI INSTR CABLE GROUP

High temperature resistant antioxidant long-acting antirust grease and preparation method thereof

InactiveCN104312674AImprove rust resistanceImprove high temperature stabilityAdditivesParaffin waxZno nanoparticles

The invention discloses a high temperature resistant antioxidant long-acting antirust grease. The high temperature resistant antioxidant long-acting antirust grease is characterized in that the antirust grease is prepared from the following raw materials in parts by weight: 12-14 parts of high viscosity mineral oil, 15-28 parts of coal oil, 5-7 parts of 200-mesh amorphous graphite, 3-5 parts of nano zinc oxide, 1-2 parts of OP-8 emulsifier, 2-3 parts of aluminum distearate, 43-47 parts of solid paraffin, 12-15 parts of Vaseline, 1-2 parts of calcium hydroxide, 1-2 parts of zinc butyl octyl dithiophosphate, 6-8 parts of barium dinonyl naphthalene sulfonate and 2.5-4 parts of protective agent. The high temperature resistant components such as amorphous graphite and nano zinc oxide are added into the antirust grease through grinding, so that the high temperature resistance and heat stability are enhanced; the protective agent is added, so that the antirust grease has good waterproof lubrication effect, a firm hydrophobic membrane can be formed on the surface of metal, and rusting caused by corrosion of water and oxygen is avoided; the antirust grease is resistant to high temperature and oxidation, the product is not evaporated all the year round, the effect is lasting, and the antirust performance is excellent.

Owner:ANHUI WEISA HEAVY MACHINERY

Glass-fiber-added composite absorbing material and preparation method thereof

InactiveCN106380693AHigh oil absorptionImprove mechanical propertiesBenzoic acidPotassium persulfate

The invention discloses a glass-fiber-added composite absorbing material and a preparation method thereof. The composite absorbing material is mainly prepared from polypropylene, trioctyl metabenzene tricarboxylate and butyl acrylate by adding sodium carboxymethyl cellulose, polyoxyethylene laurate, polybenzimidazole imide, 2-hydroxy-6-methyl benzoic acid, diphenyl silanediol, potassium persulfate, diatomite, alkali-free glass fiber, hydroxy aluminum distearate, nano zinc oxide, andalusite powder, potassium salicylate, a surface treating agent and a foaming agent. The preparation method comprises the following steps: grinding, sintering, ultrasonic treatment, polymerization, acid pickling, dry treatment, extrusion, foaming, granulation and the like. The glass-fiber-added composite absorbing material has the advantages of excellent oil absorbing effect for crude oil, excellent mechanical oil holding effect, favorable oil retaining effect and high absorption rate, can satisfy the requirements of industry, and has favorable application prospects.

Owner:苏州佰思科节能环保科技有限公司

Environmentally friendly galvanized metal repair agent and preparation method thereof

InactiveCN106700671AGood dispersionImprove corrosion resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsThionylMaterials science

The invention provides an environmentally friendly galvanized metal repair agent and a preparation method thereof. The environmentally friendly galvanized metal repair agent is prepared from, by mass, 15-20 parts of attapulgite, 20-30 parts of amino clay, 1-7 parts of aluminum distearate, 4-8 parts of ceramic ultrafine powder, 4-15 parts of composite nano-powder, 3-6 parts of sodium potassium silicate, 3-5 parts of gamma-thionyl trimethoxysilane, 2-6 parts of gamma-aminopropyl triethoxysilane, 12-18 parts of waterborne polyurethane, and 3-5 parts of poly trimethoxysilane. The preparation method of the environmentally friendly galvanized metal repair agent comprises the steps of mixing, heating, kneading, grinding and the like, the prepared environmentally friendly galvanized metal repair agent has the advantages of being good in abrasive resistance, anti-corrosion and lubricating, high in metal bonding strength, and long in service life.

Owner:吴中区穹窿山天仲高分子材料技术研究所

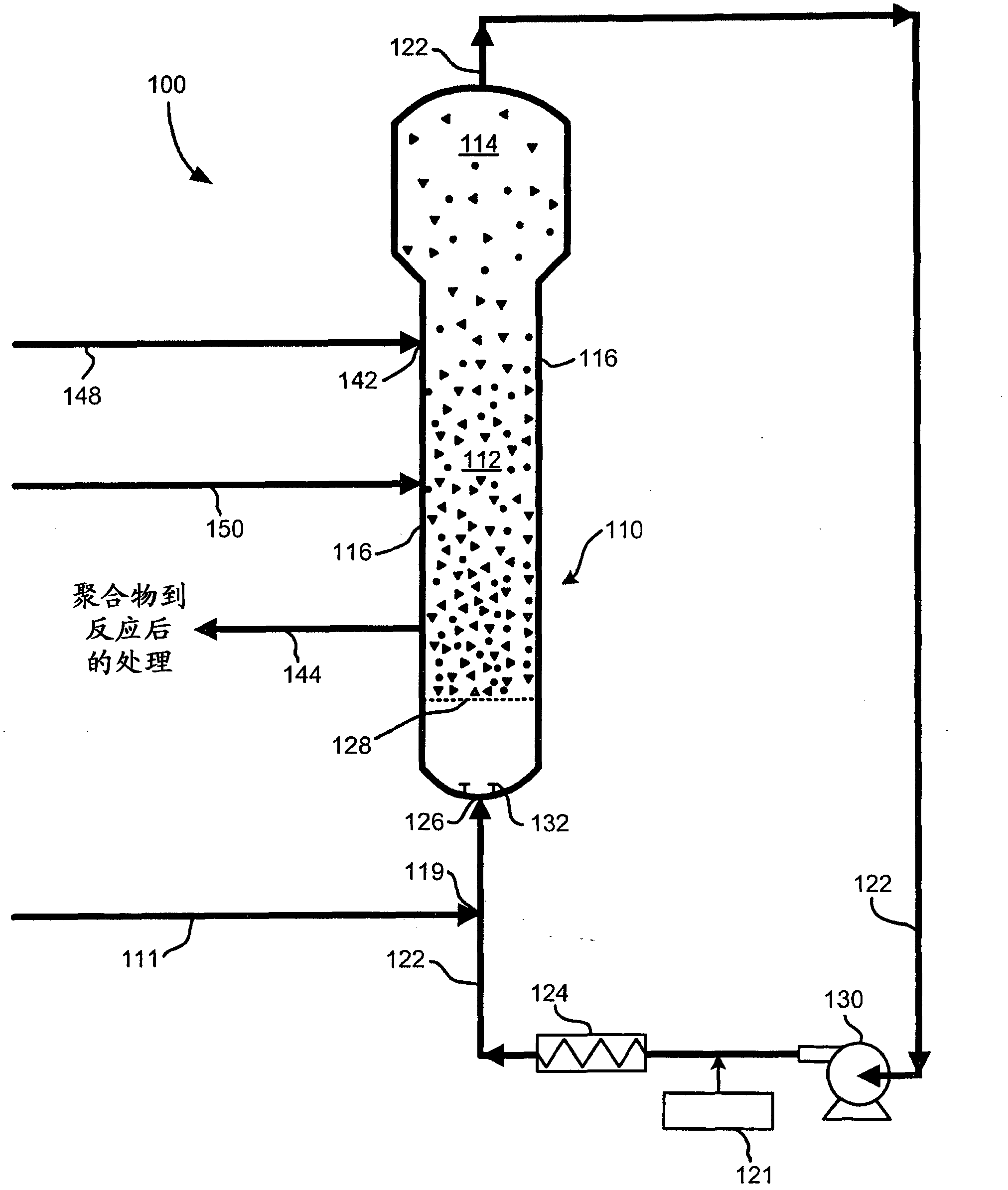

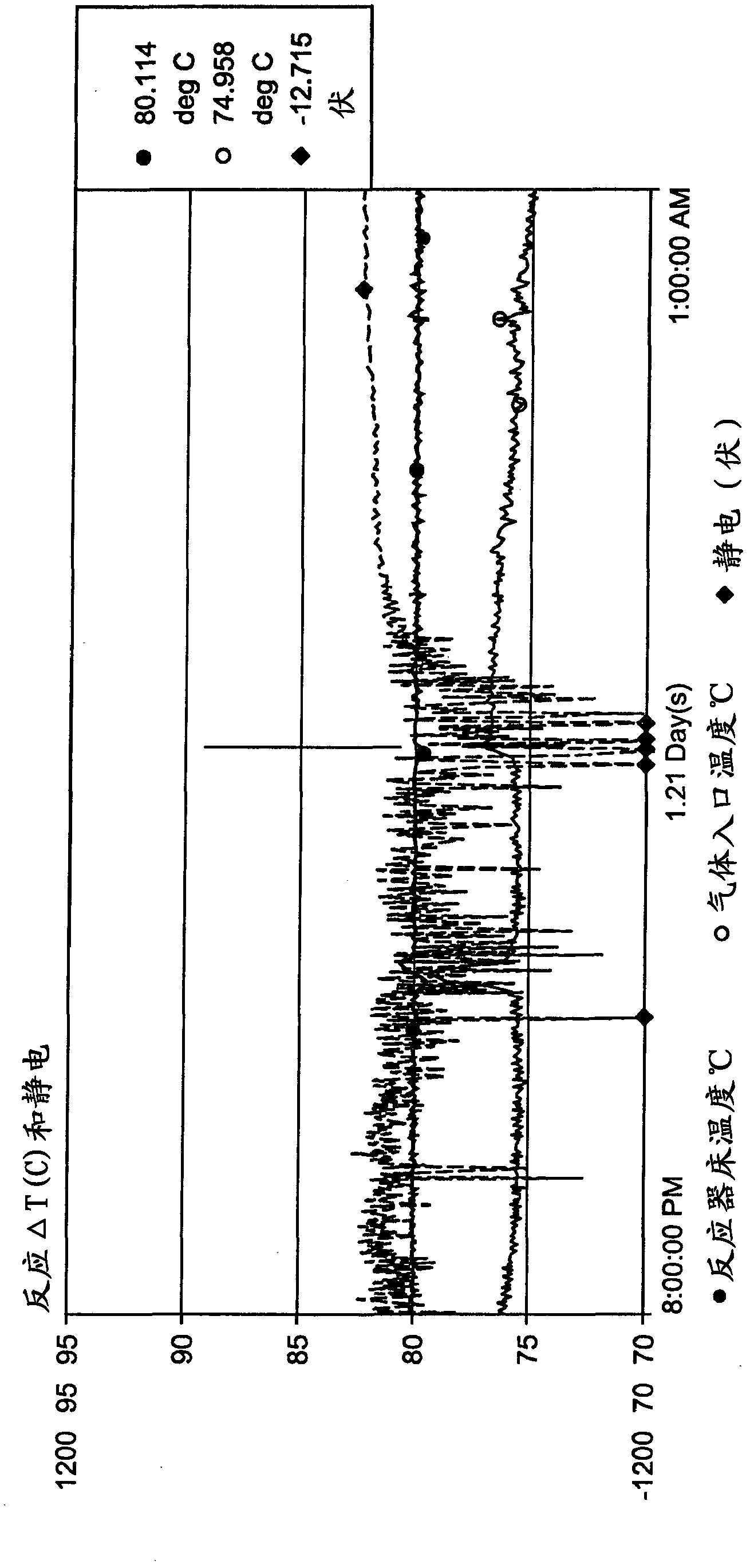

Polymerization process using a supported constrained geometry catalyst

A polymerization process includes contacting the following in a gas-phase reactor system under polymerization conditions for making a polymer product: a metallocene-based catalyst system including a supported constrained geometry catalyst, at least one monomer, and an additive selected from a group consisting of an aluminum distearate, an ethoxylated amine, and a mixture thereof. The additive may be selected from a group consisting of an aluminum distearate, an ethoxylated amine, polyethylenimines, and other additives suitable for use in the production of polymers for food contact applications and end products, including a mixture of a polysulfone copolymer, a polymeric polyamine, and oil-soluble sulfonic acid, in a carrier fluid, and mixtures thereof.

Owner:UNIVATION TECH LLC

Microcrystal stone profile

The invention discloses a microcrystaline section bar, which comprises the following parts: 20-50% PVC resin, 50-80% heavy calcium carbonate, 0.5-1.1% dihydroxytetra-n-octyloxydiphenyl ketone, 0.3-0.9% zinc stearate, 0.4-1% calcium stearate, 0.2-0.6% aluminum distearate or basic aluminum stearate or amide stearate and 0.2-0.6% dioctyl.

Owner:林国旺 +1

Building material environment-friendly, flame-retardant and acid-alkali-resistant treatment coating

InactiveCN106118166AExcellent flame retardantExcellent flame retardant acid and alkali resistanceFireproof paintsAntifouling/underwater paintsFatty acidChlorothalonil

The invention relates to a building material environment-friendly, flame-retardant and acid-alkali-resistant treatment coating. The coating is prepared from phenyltriethoxysilane, lithium phosphate powder, fatty acid sodium, soybean oil, chlorothalonil, camellia pollen, zinc sulfide powder, jade powder, asbestos powder, hydrogenated butadiene-acrylonitrile rubber, aluminum distearate, saccharose, a styrene-butadiene-styrene block copolymer, fluororubber, polyacrylonitrile fibers, hexahydrophthalic anhydride, tetrabutyl titanate, ethyl p-hydroxybenzoate, trichloroisocyanuric acid, menthol, 5-aminobenzimidazolidinone, tourmaline powder, molybdenum disilicide powder, ferric trichloride, oxidized paraffin, aromatic hydrocarbon oil, mandarin oil, polyacrylic emulsion, hydroxyethyl acrylate and alkyl diphenyl phosphate. The product has excellent flame-retardant, acid-alkali-resistant, anti-mildew and antibacterial resistant performance, and the performance of the product is improved.

Owner:余志娟

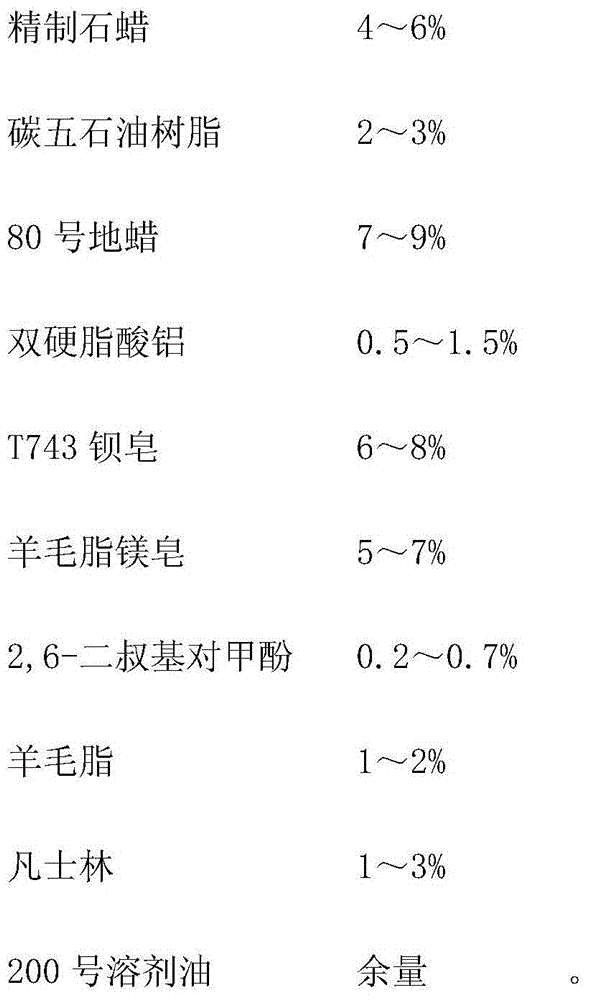

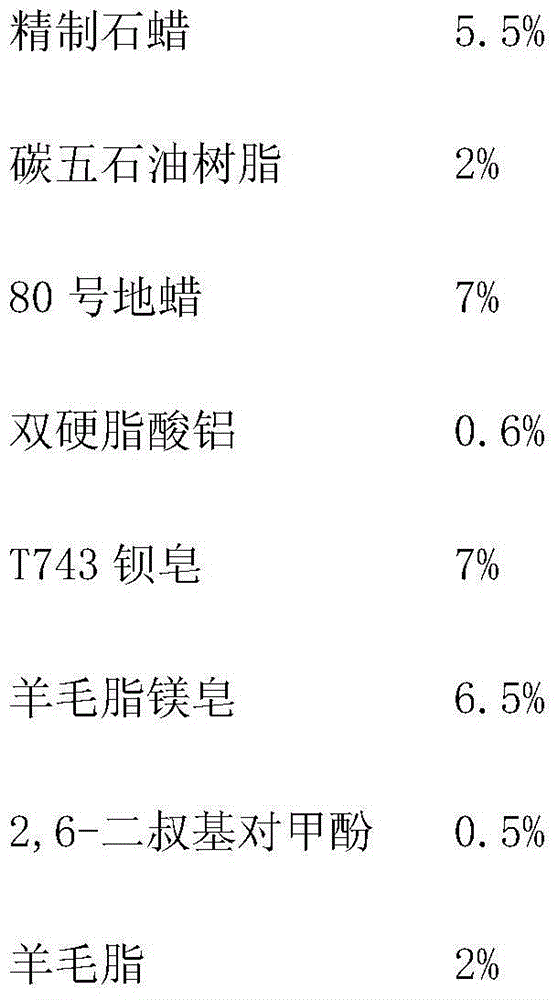

Liquid anti-rust wax for long-term protection of ferrous metal and preparation method thereof

ActiveCN104403755AImprove rust resistanceUniform without cracksLubricant compositionParaffin waxSpray coating

The invention relates to liquid anti-rust wax for long-term protection of ferrous metal. The liquid anti-rust wax comprises the following raw materials of refined paraffin wax, C5 petroleum resin, N0.80 ceresin wax, aluminum distearate, T743 barium soap, wool fat magnesium soap, 2,6-ditert-p-cresol, wool fat, vaseline and No.200 solvent soil; various components are blended according to the steps to obtain a finished product. When the liquid anti-rust wax disclosed by the invention is used, the anti-rust treatment is performed by adopting the modes of brush coating, dip coating and spray coating; after 24 hours, a film layer is uniform and is crack-free, and the thickness of the film layer is more than 25 micrometers; the salt fog resisting time of the film layer of No.45 steel can reach over 90 days; the film layer is good in adhesion, so the anti-rust effect cannot be influenced by general collision; the film layer is dry and cool, so the influence on normal package is avoided, and the flowing is avoided under the temperature condition of below 80DEG C; the liquid anti-rust wax is the anti-rust wax with good anti-rust effect and durability.

Owner:泰伦特生物工程股份有限公司

Modified pearl powder serving as cosmetic and skincare product additive

InactiveCN102670476ASolve the problem of easy reunion and poor dispersionImprove the lubrication effectCosmetic preparationsBody powdersEye shadowSilicone oil

The invention discloses modified pearl powder serving as a cosmetic and skincare product additive. The modified pearl powder is prepared by mixing 80-95% of common pearl powder, 2-15% of aluminum distearate, 1-5% of polymethylsilsesquioxane and 0.5-4% of simethicone in proportion and grinding the mixture. The surfaces of the modified pearl powder granules are changed from hydrophilism into lipophilicity after the modification treatment, thereby improving the compatibility of the pearl powder and the organic medium, the surfaces of the modified pearl powder granules are smooth and good in lubricity, so that the problems of agglomeration and bad dispersibility of the pearl powder in cosmetic and skincare products are solved, and the modified pearl powder can be extensively applied to various types of water-in-oil, water-in-silicon oil or oily skincare cosmetic products such as sun cream, whitening cream, foundation make-up or liquid foundation, lipstick and eye shadow so that the beautifying and skincare functions of wetting, whitening and anti-aging of the cosmetic and skincare products can be given a full play.

Owner:无锡丝源化妆品有限公司

Low-dielectric-loss and high-strength electronic material

InactiveCN108003560AImprove thermal conductivityLow dielectric constantArray data structurePolystyrene

The invention belongs to the technical field of electronic materials and relates to a low-dielectric-loss and high-strength electronic material. The low-dielectric-loss and high-strength electronic material is prepared from, by weight, 5-12 parts of heat-resistant glass, 25-30 parts of andalusite ceramic, 5-15 parts of phenol-formaldehyde resin, 45-65 parts of linear phenolic resin, 15-35 parts ofdimethyl hydantoin formaldehyde resin, 20-35 parts of benzocyclobutene resin, 10-15 parts of tributylamine, 10-25 parts of acrolein, 2-7 parts of graphite powder, 4-7 parts of titanium dioxide, 2-7 parts of cyclopropylmagnesium bromide, 3-8 parts of aluminum distearate, 15-25 parts of 4-nitro phthalimide, 15-22 parts of ethyl urethane, 15-20 parts of polystyrene, 1-3 parts of mica and 11-14 partsof natural rubber. The electronic material has high heat conductivity and low dielectric constant and dielectric loss, is capable of stopping currents from passing, high in compression strength and heat resistance and capable of resisting heat for a long time without significant changes.

Owner:XUZHOU DIYI ELECTRONICS CO LTD

Power cable for solar photovoltaic power distribution cabinet

InactiveCN106009451ASoft textureExcellent flame retardantClimate change adaptationInsulated cablesTrichloroethyl PhosphateAntimony oxide

The invention relates to a power cable for a solar photovoltaic power distribution cabinet, which includes a plurality of copper alloy wires and protective sleeves. The copper alloy wires are placed parallel to each other, and the outer layer of each copper alloy wire is covered with a protective sleeve. Composition of the following components: acrylate rubber powder, SEBS thermoplastic elastomer, styrene-modified alkyd resin, waste oil, glyceryl tricaprylate, sandalwood oil, styrene-acrylic emulsion, transformer oil, benzalkonium chloride, dibenzofuran , zinc pyrithione, bis-imidazolidinyl urea, lead oxide powder, fly ash, antimony oxide powder, sodium iodoacetate, potassium fluotitanate, pearl powder, mica powder, potassium aluminum sulfate, trichloroethyl phosphate, poly Benzimidazole imide, nano-magnesium hydroxide, polyethylene wax, sodium lauryl sulfate, bis-tert-butyl peroxycumene, tert-butyl hydroperoxide, aluminum distearate, tetra-titanate Butyl ester, neopentyl glycol diacrylate. The invention improves the performance of the product.

Owner:权周越

Waterproof and dampproof polyimide insulating rubber tape

InactiveCN105885720AImprove heat resistanceImprove insulation performanceNon-macromolecular adhesive additivesFilm/foil adhesivesLow-density polyethyleneSulfite salt

Owner:刘禾青

Environment-friendly viscosity reducer for printing ink and preparation method of environment-friendly viscosity reducer

The invention discloses an environment-friendly viscosity reducer for printing ink. The environment-friendly viscosity reducer is composed of the following raw materials in percentage by weight: 15-18% of Vaseline, 3-5% of white beeswax, 20-25% of resin oil, 15-18% of aluminum distearate, and 35-45% of linseed oil. The invention further discloses a preparation method of the environment-friendly viscosity reducer for the printing ink. The preparation method comprises the following steps: step 1, integrally adding linseed oil and resin oil into a reaction kettle according to formula data, and starting to stir when the temperature is increased to 88-95 DEG C; step 2, adding Vaseline and white beeswax into the reaction kettle, and continuously stirring; and step 3, uniformly mixing and stirring linseed oil and aluminum distearate to obtain a particle-free material, pumping the particle-free material into a high-level tank by a pump, slowly adding the particle-free material into the reaction kettle, continuously heating to 115-125 DEG C, carrying out heat preservation for 30-40 min, filtering, and taking out of the kettle. The prepared viscosity reducer can be added into ink to increasethe brightness of the ink, improve the wettability, improve the ink property, increase the printing speed and reduce the viscosity, and is environment-friendly and pollution-free.

Owner:苏州盛威科印刷器材有限公司

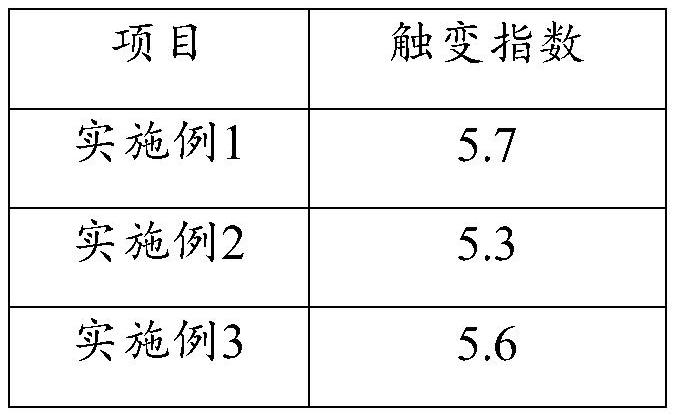

Thixotropic electrostatic spraying anti-rust oil composition as well as preparation method and application thereof

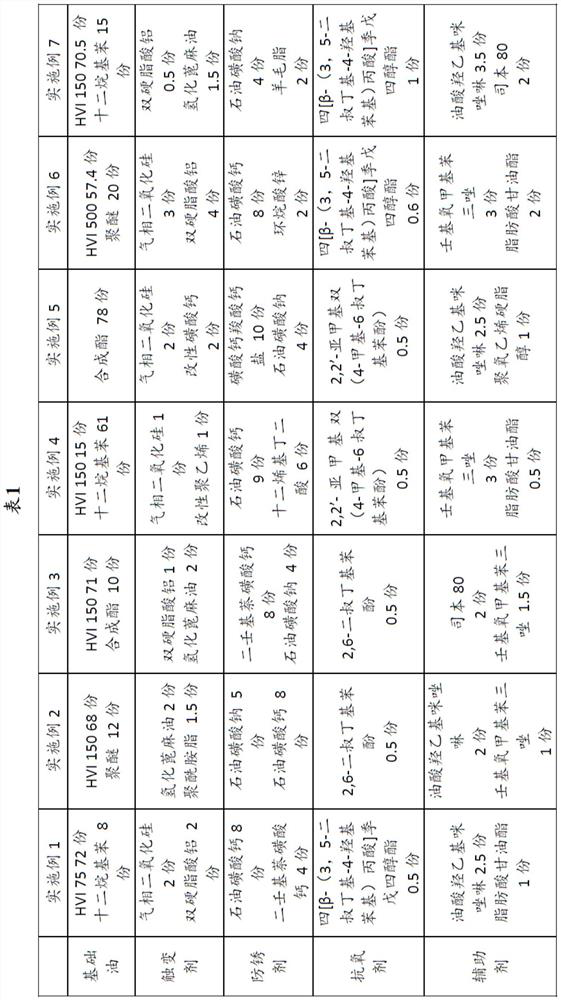

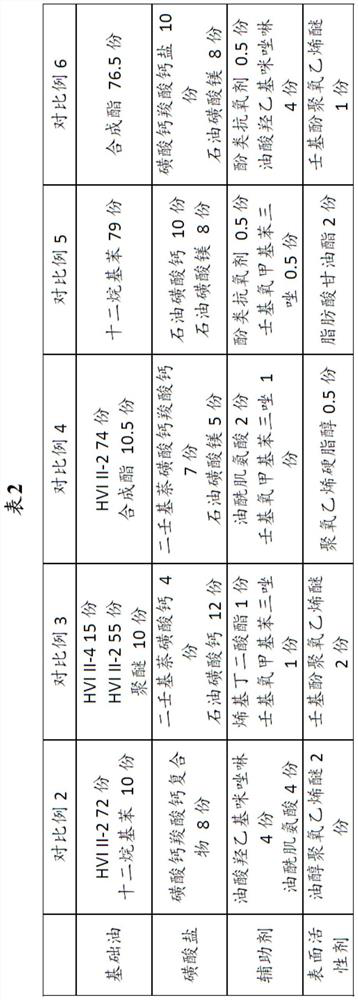

The invention discloses a thixotropic electrostatic spraying anti-rust oil composition as well as a preparation method and application thereof, and mainly solves the technical problem of poor thixotropic property of the thixotropic electrostatic spraying anti-rust oil composition in the prior art. According to the technical scheme, the invention provides a thixotropic electrostatic spraying anti-rust oil composition as well as a preparation method and application thereof, the thixotropic electrostatic spraying anti-rust oil composition comprises the following components in parts by weight: 70-90 parts of a base oil, 2-8 parts of a thixotropic agent, 5-15 parts of a barium-free anti-rust agent, 0.2-1 part of an antioxidant and 1-10 parts of an adjuvant, the thixotropic agent is selected from at least two of hydrogenated castor oil, fumed silica, polyamide, a polydiene compound, modified calcium sulfonate, aluminum distearate and organic bentonite, and the thixotropic agent at least comprises at least one of polyamide or a polydiene compound. The problem is well solved, and the thixotropic agent is suitable for being applied to electrostatic spraying anti-rust treatment of a cold-rolled steel sheet.

Owner:CHINA PETROLEUM & CHEM CORP

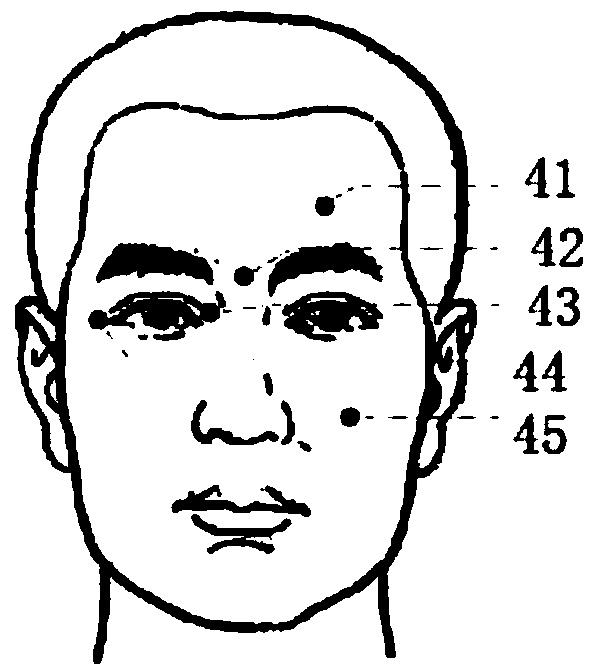

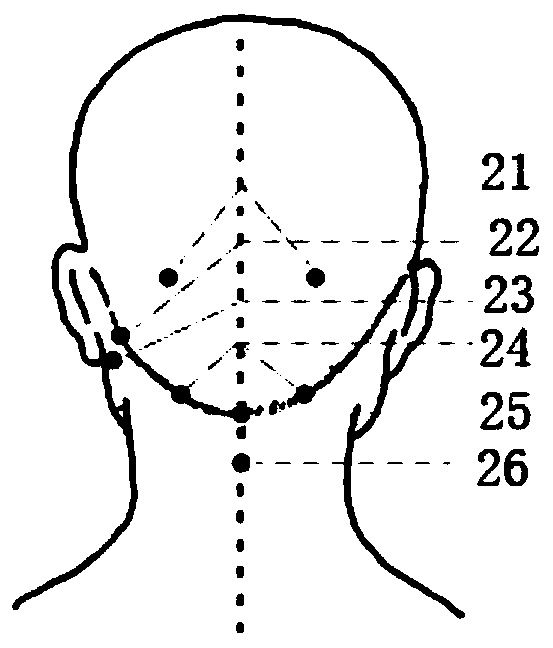

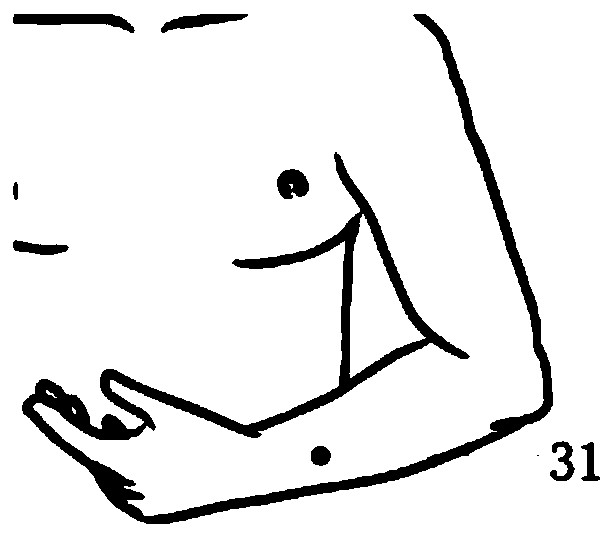

Gel ointment for promoting vision recovery and massage using method of gel ointment

InactiveCN110507701ARestoring and improving conditioningEnhance visual abilitySenses disorderElectrotherapyWhite petrolatumTraining - action

The invention discloses a gel ointment for promoting vision recovery and a massage using method of the gel ointment. The gel ointment comprises the following components: glyceryl monostearate, beeswaxwax, stearic acid, liquid paraffin, white petrolatum, aluminum distearate, calcium hydroxide, ethylparaben, purified water, mint and borneol. The massage using method of the gel ointment for promoting vision recovery comprises the following steps: removing stasis, dredging channels and collaterals, benefiting eyes by moxibustion, carrying out eye opening and closing training, and applying eyes with ointment plasters. The gel ointment has the advantages of restoring and improving the adjusting capacity of ciliary muscles, strengthening the vision forming capacity from the cornea to the brain vision center and gradually improving the naked eye vision to the normal vision through the pharmacology of penetration of the gel ointment in combination with the physical regulation effect of the traditional Chinese medical method and an eye massager on channels and collaterals, the regulation effect of eyeball training action on eye muscles and the stimulation effect of magnetic therapy and moxibustion on eye acupuncture points.

Owner:深圳市维视堂科技有限公司

Lubricating grease for tubular motor and preparation method of lubricating grease for tubular motor

InactiveCN104449984AStrong ability to formGood noiseLubricant compositionAluminum StearateMaterials science

The invention discloses lubricating grease for a tubular motor and a preparation method of the lubricating grease for the tubular motor. The lubricating grease is prepared from the following raw materials in parts by weight: 45-65 parts of 20# machine oil, 20-30 parts of poly alpha-olefin, 4-8 parts of glycerol tribehenate, 5-10 parts of aluminum distearate, 3-6 parts of calcium myristate, 5-10 parts of diisooctyl maleate, 6-9 parts of sodium lauroyl sarcosine, 2-3 parts of potassium dichromate, 1.5-2.5 parts of zinc sulfate, 1-2 parts of 2-mercaptobenzothiazole, 2-4 parts of molybdenum dibutyldithiocarbamate, 10-15 parts of organobentonite, 3-5 parts of a dimerized linoleic acid copolymer and 2-3 parts of N-phenyl-2-naphthylamine. The lubricating grease disclosed by the invention has the extremely high oil film forming ability, the good noise reduction and antiwear effects, the good lubricating property and heat resistance, the excellent oxidation stability, mechanical stability and ageing resistance, and the long service life, and is applied to lubrication, friction reduction and noise reduction of the various tubular motors.

Owner:任新年

Soft pottery clay and manufacturing method thereof

InactiveCN102503240BBeautiful colorTo achieve the effect of long-term placementWhite powderPolyvinyl chloride

The invention relates to soft pottery clay and a manufacturing method thereof. The soft pottery clay comprises the following components which are mixed together: polyvinyl chloride paste resin, aluminum distearate, zinc stearate, calcium stearate, dioctylphthalate, titanium white powder, mixed resins and silicon dioxide. The manufacturing method of the soft pottery clay comprises the following steps: 1) supplying polyvinyl chloride paste resin, aluminum distearate, zinc stearate, calcium stearate, dioctylphthalate, titanium white powder, mixed resins and silicon dioxide, mixing and stirring, and then standing by and cooling; 2) after cooling, placing into a stirrer for stirring, and then taking out and naturally cooling; 3) after cooling, placing into the stirrer for stirring again, and then taking out and naturally cooling; and 4) after cooling, mixing with white powder and uniformly stirring, and cooling, thereby obtaining an end product. The soft pottery clay can be processed into various patterns through a handicraft and the patterns can be attached to the surface and the interior of an object. If the soft pottery clay is not processed at high temperature, the soft pottery clay is reusable and is ultrahigh in plasticity and viscidity.

Owner:丁森

Fabric with good flame resistance and weather resistance

InactiveCN106280772AExcellent flame retardantGood acid and alkali resistanceFireproof paintsRubber derivative coatingsFatty acidFerric Pyrophosphate

The invention relates to a fabric with good flame resistance and weather resistance. A protective coating is adhered to a burlap fabric, and the coating consists of the following components of fluoroether rubber, chlorosulphonated polyethylene resin, hydrogenated nitrile rubber, diethylene glycol monoethyl ether, a pure acrylic emulsion, tall oil fatty acids, terpineol, amyl propionate, arbutin, a garlic extract, propiconazole, sodium monofluorophosphate, sodium ferric pyrophosphate, sodium alginate, SiC micro powder, sodium tetraborate decahydrate, zinc stearate, guanidine phosphate powder, phenyltriethoxysilane, zinc chromate, hexahydrophthalic anhydride, tetrabutyl titanate, zinc borate, nano zinc oxide, aluminum distearate, wool grease, sodium dodecylbenzenesulfonate, isooctanoic acid, glyceryl monostearate and dibutyl phthalate. The fabric disclosed by the invention has good properties of flame retardance, acid-base resistance, mildew prevention and bacteria resistance, and product quality is improved.

Owner:李红玉

Metal treatment agent for automotive radiator aluminium alloy heat exchanger

InactiveCN106065236AImprove thermal stabilityGood dispersionAnti-corrosive paintsPolyether coatingsGlycerolPolyethylene glycol

The invention discloses a metal treatment agent for an automotive radiator aluminium alloy heat exchanger. The metal treatment agent is prepared from the following raw materials (by weight): 0.3-0.5 parts of aluminum distearate, 40-50 parts of polyvinyl alcohol, 12-15 parts of polyethylene glycol, 0.4-0.6 part of an emulsifier op10, 0.3-0.5 part of glycerol, 0.6-0.8 part of triethanolamine, 6-8 parts of benzotriazole, 6-7 parts of sodium benzoate, 2-3 parts of sodium dodecyl sulfate, 0.4-0.6 part of butanediol, 4-5 parts of nanocellulose, 3.3-4 parts of paraffin, 0.3-0.5 part of Tween 80, 0.7-0.9 part of nano-silica, 1.1-1.3 parts of nanometer titanium dioxide, and a proper amount of deionized water. The metal treatment agent contains no solvent, meets environmental requirements, has high water resistance, oil resistance, temperature resistance, abrasion resistance and stripping performance, can also be used for surfaces of metal, stripping, plastic and the like simultaneously, and has a temporary rust protection effect.

Owner:HEFEI ZHENGHAO MECHANICAL TECH

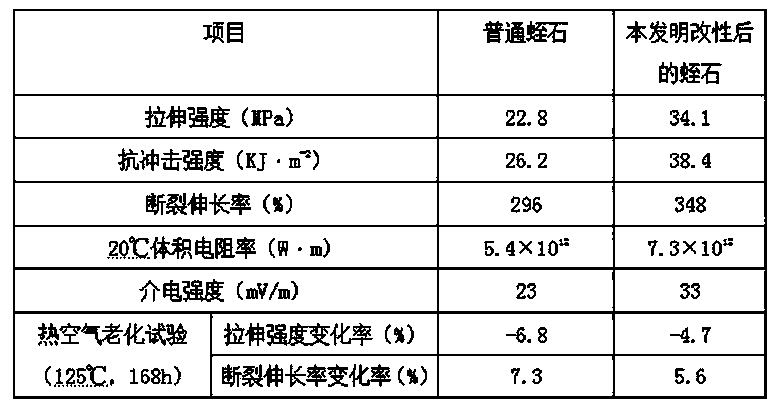

Modified sericite for impact-resistant polyolefin cable material and preparation method thereof

InactiveCN104177679AEnhanced interface bindingGood filling effectPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsDispersityPolymer science

The invention discloses a modified sericite for an impact-resistant polyolefin cable material and a preparation method thereof. The modified sericite is prepared from the following raw materials in parts by weight: 70-80 parts of sericite, 14-22 parts of molybdenum boride, 10-15 parts of triglyceryl trimellitate, 12-18 parts of gas-phase silicon dioxide, 7-13 parts of carbon fiber powder, 3-5 parts of polymerized rosin, 2-3 parts of 2,5-ditert-butylhydro quinone, 4-6 parts of rice bran wax, 5-10 parts of dimethyl oxalate, 8-12 parts of 2,4,6-tribromophenyl acrylate, 2-4 parts of hydroxy aluminum distearate, 4-6 parts of dimethylpropane carboxylate, 2-3 parts of ytterbium oxide, 3-5 parts of ethyl diethylaminomethacrylate, 1-2 parts of zinc pyrithione, 4-8 parts of bisphenol A epoxy chloropropane polymer isostearate and 3-6 parts of assistant. The modified sericite has favorable interfacial bonding property with the polyolefin material, higher compatibility with the polyolefin material and higher dispersity in the polyolefin base, thereby enhancing the filling effect of the sericite; and thus, the polyolefin cable material has the advantages of higher tensile strength, higher impact strength, higher elongation at break, excellent heat resistance, excellent wear resistance and excellent corrosion resistance.

Owner:ANHUI MINGDU ELECTRIC WIRE

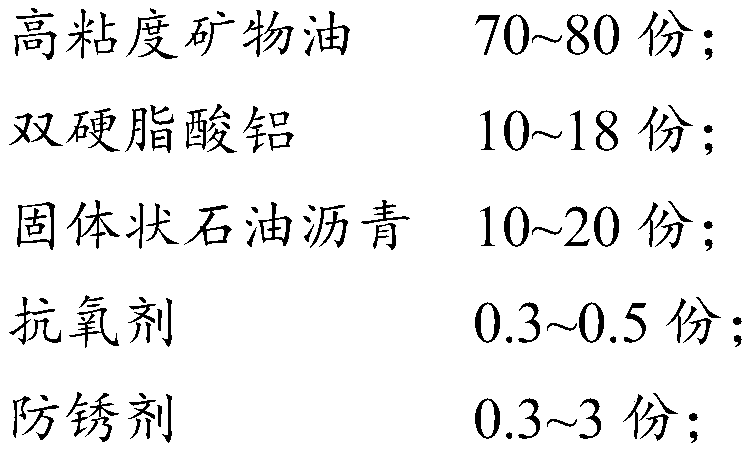

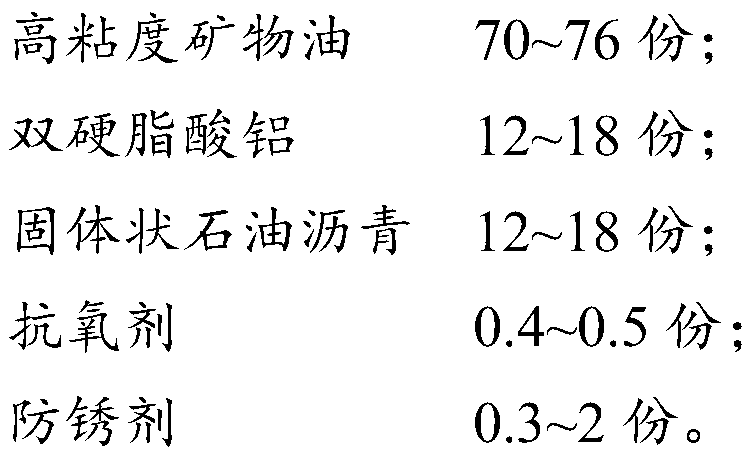

Special lubricating grease for ships and warships and preparation method of lubricating grease

ActiveCN111286388AResistance to intrusionImprove anti-corrosion performanceLubricant compositionAluminum StearateOil viscosity

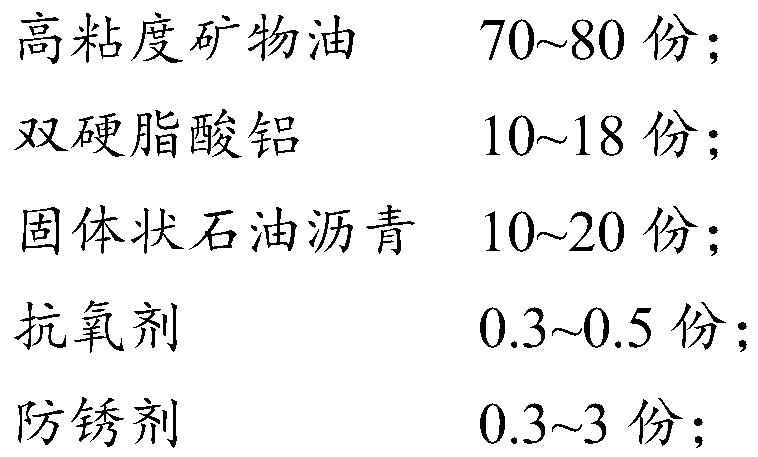

The invention provides special lubricating grease for ships and warships and a preparation method of the lubricating grease, and relates to the technical field of lubricating grease. The special lubricating grease for the ships and warships provided by the invention comprises the following components in parts by mass: 70-80 parts of high-viscosity mineral oil, 10-18 parts of aluminum distearate, 10-20 parts of solid petroleum asphalt, 0.3-3 parts of an antirust agent, and 0.3-0.5 part of an antioxidant; the viscosity of the high-viscosity mineral oil at the temperature of 100 DEG C is 16-32 cst, and the pour point is less than -5 DEG C; the dropping point of the special lubricating grease for the ships and warships is greater than or equal to 110 DEG C. Aluminum distearate with excellent water resistance and corrosion resistance is used as a thickening agent to thicken high-viscosity mineral oil, and the high-viscosity petroleum asphalt is added and matched with the antirust agent andthe antioxidant, so that the special lubricating grease for the ships and warships has excellent seawater corrosion resistance and strong adhesive force. The invention also provides a preparation method of the special lubricating grease for the ships and warships, and the preparation method is simple in process and easy for large-scale production.

Owner:山东耘勃环境科技有限公司

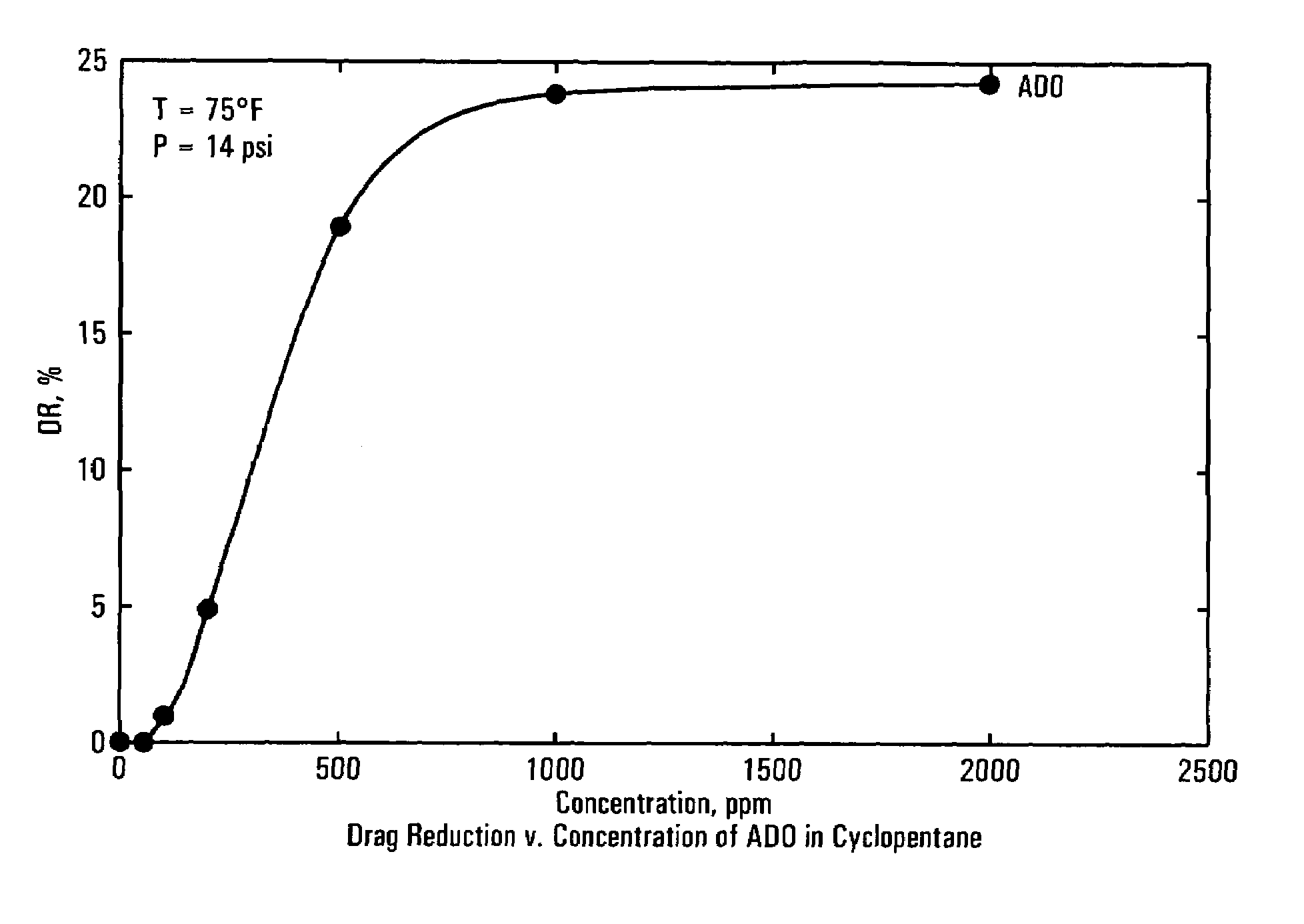

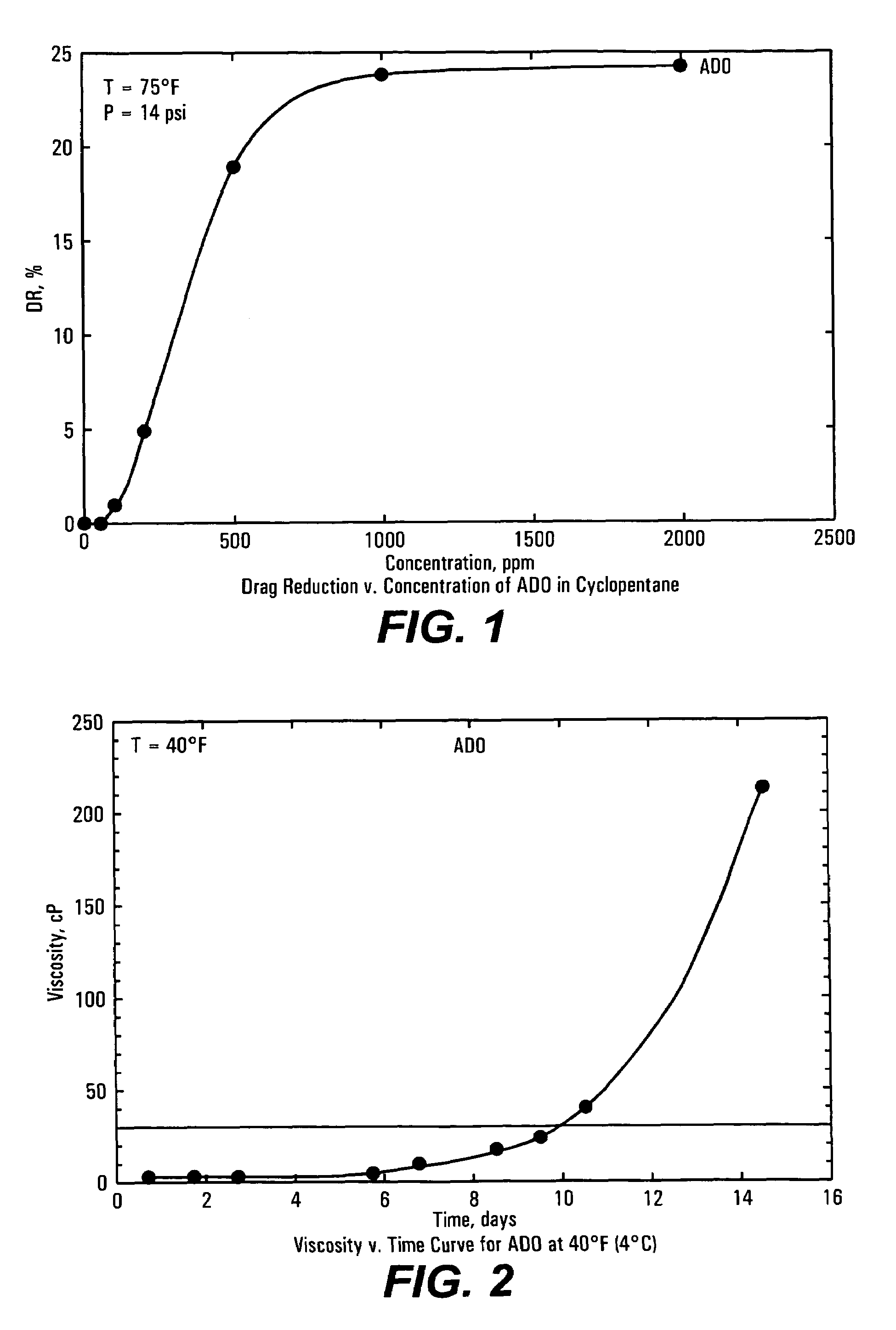

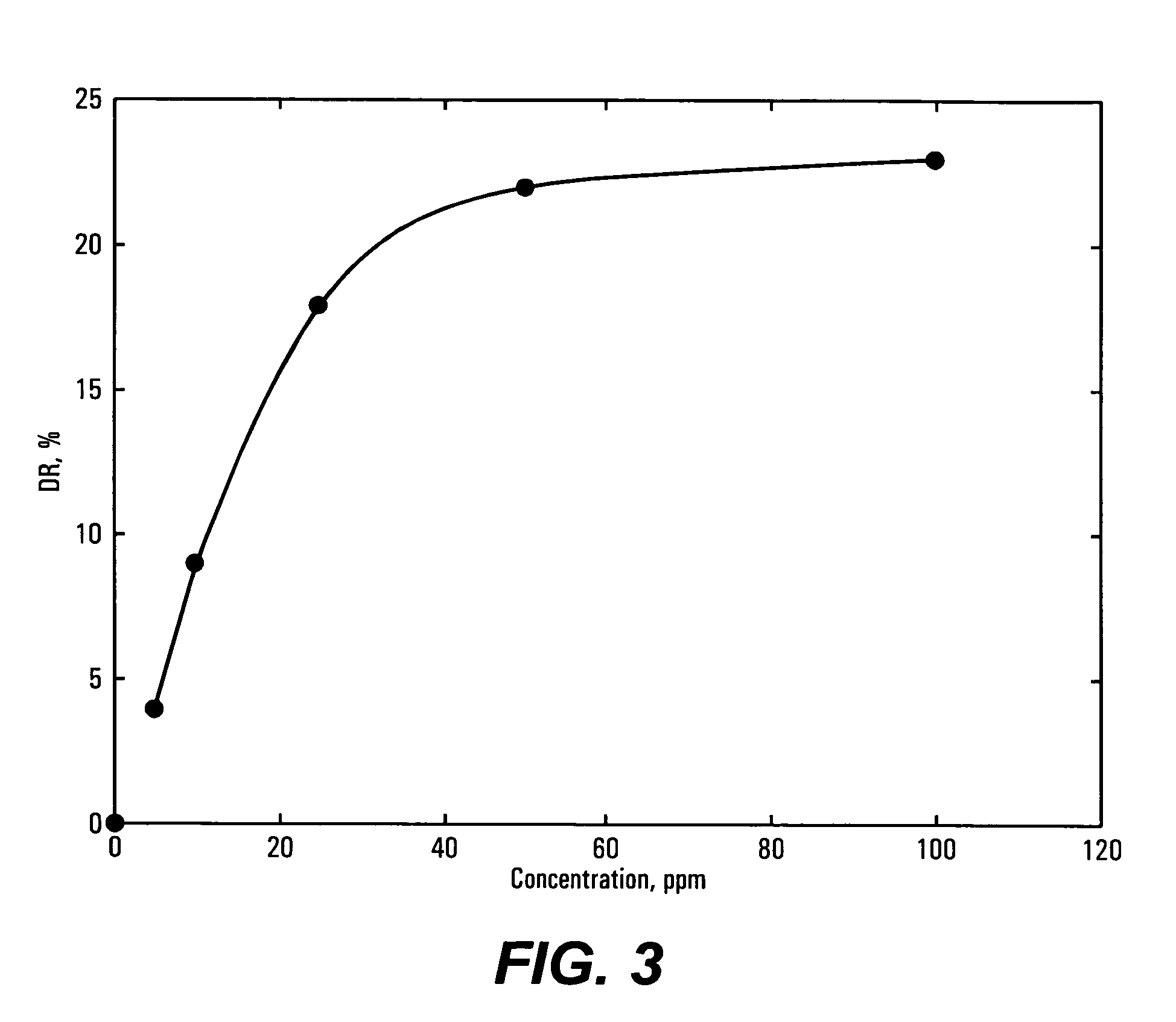

Aluminum carboxylate drag reducers for hydrocarbon emulsions

InactiveUS7288506B2Easy to manufactureReduce resistanceOrganic chemistryChain/belt transmissionEmulsion2-Ethylhexanoic acid

Aluminum carboxylate drag reducing agents are described herein. These materials are useful to reduce drag in hydrocarbon fluids and multiphase fluids of hydrocarbon(s) and water. No injection probes or other special equipment is expected to be required to introduce the drag reducing agent into the liquid stream. The drag reducing additives of the invention are not subject to shear degradation and do not cause undesirable changes in the emulsion or fluid quality of the fluid being treated, or undesirable foaming. In one non-limiting embodiment, an aluminum monocarboxylate is reacted with at least one carboxylic acid in situ. In another non-limiting embodiment, the aluminum carboxylate is introduced as a dispersion in a solvent such as paraffin oil. The drag reducing additives include aluminum dicarboxylates such as aluminum dioctoate, aluminum distearate, aluminum octoateoleate, aluminum octoatestearate, aluminum stearateoleate, hydroxyaluminum bis(2-ethylhexanoate) and mixtures thereof.

Owner:BAKER HUGHES INC

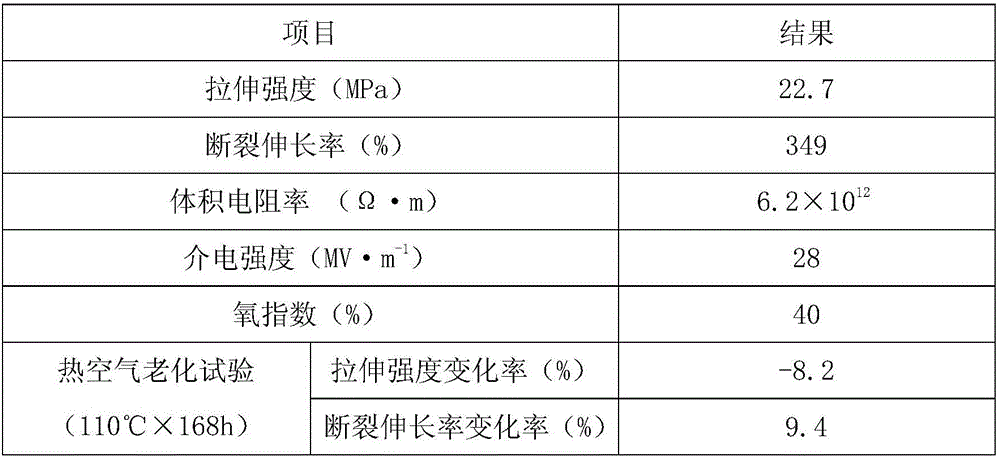

Anti-creeping cable material for automobile wire and preparation method of cable material

InactiveCN106750760AHigh mechanical strengthImprove high temperature resistancePlastic/resin/waxes insulatorsPolyetherimideSludge

The invention discloses an anti-creeping cable material for an automobile wire and a preparation method of the cable material. The cable material is prepared from raw materials in parts by weight as follows: 60-80 parts of polyethylene, 10-20 parts of neopentyl glycol dibenzoate, 15-25 parts of superfine silica whiskers, 4-9 parts of aluminum distearate, 11-22 parts of copper milltailings, 5-10 parts of boric sludge, 10-15 parts of diisodecyl adipate, 8-14 parts of magnesium reducing slag and 7-12 parts of tetrapod-like zinc oxide whiskers. With polyethylene, a metallocene cycloolefin polymer and polyetherimide as base materials, the cable material has high mechanical strength and good high-temperature resistance and fatigue resistance, and the superfine silicon whiskers, atomized magnesium alloy powder and the tetrapod-like zinc oxide whiskers are also added, so that the mechanical performance of the cable material can be improved, and the anti-creeping performance of the cable material is improved. The prepared cable material has the advantages of high mechanical strength, good toughness, good high-temperature resistance and excellent anti-creeping performance.

Owner:周先强

Anti-oxidation flame-retardant sheath material for air-conditioner wire harness and preparation method of anti-oxidation flame-retardant sheath material

InactiveCN105949689AImprove performanceAdapt to market demandPlastic/resin/waxes insulatorsInsulated cablesSlagTert butyl

The invention discloses an anti-oxidation flame-retardant sheath material for an air-conditioner wire harness and a preparation method of the anti-oxidation flame-retardant sheath material. The anti-oxidation flame-retardant sheath material is prepared from the following raw materials in parts by weight: 55-70 parts of poly-perfluorinated ethylene-propylene, 14-18 parts of dibromomethyl-benzene glycidyl ether, 22-27 parts of a vinyl chloride-acrylonitrile copolymer, 12-16 parts of amblygonite, 10-15 parts of porous powder quartz, 5-9 parts of zinc phosphate, 4-8 parts of aluminum distearate, 8-12 parts of hexaphenoxy cyclotriphosphazene, 15-20 parts of brominated polystyrene, 3-6 parts of tin antimony oxide, 11-17 parts of indianite nanotubes, 10-15 parts of antimony ore slag, 6-10 parts of chlorinated paraffin, 2-5 parts of red algae sugar acid sodium and 16-22 parts of phosphoric acid tert-butyl benzene diplenyl ester. The air-conditioner wire harness sheath material prepared from raw materials such as poly-perfluorinated ethylene-propylene, the vinyl chloride-acrylonitrile copolymer, hexaphenoxy cyclotriphosphazene, brominated polystyrene, porous powder quartz, tin antimony oxide and the indianite nanotubes has integrated properties of flame retardancy, oxidation prevention, weather resistance, chemical corrosion resistance and the like, is outstanding in performance, and is applicable to market requirements.

Owner:合肥得润电子器件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com