Patents

Literature

73 results about "White Beeswax" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing tacrolimus ointment

ActiveCN102885761AReduce manufacturing costRapid industrializationOrganic active ingredientsAerosol deliveryPhysical chemistryWhite Beeswax

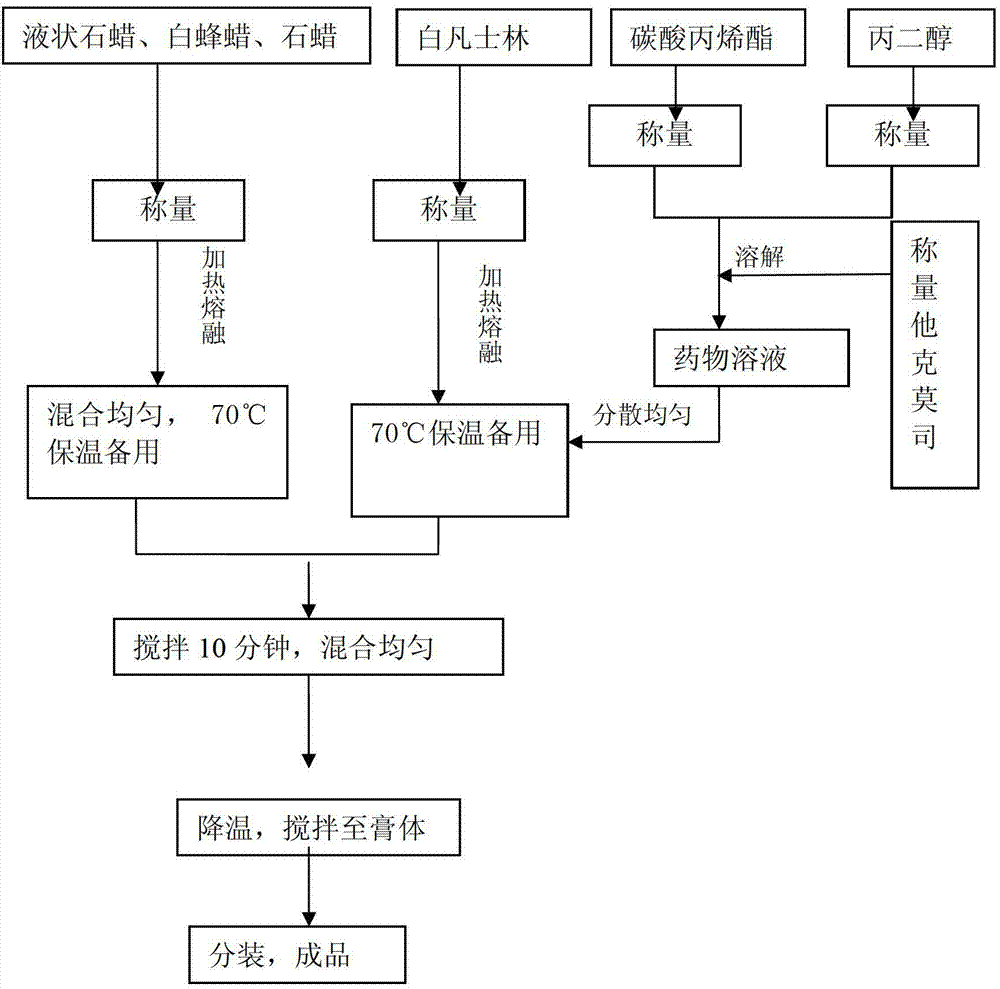

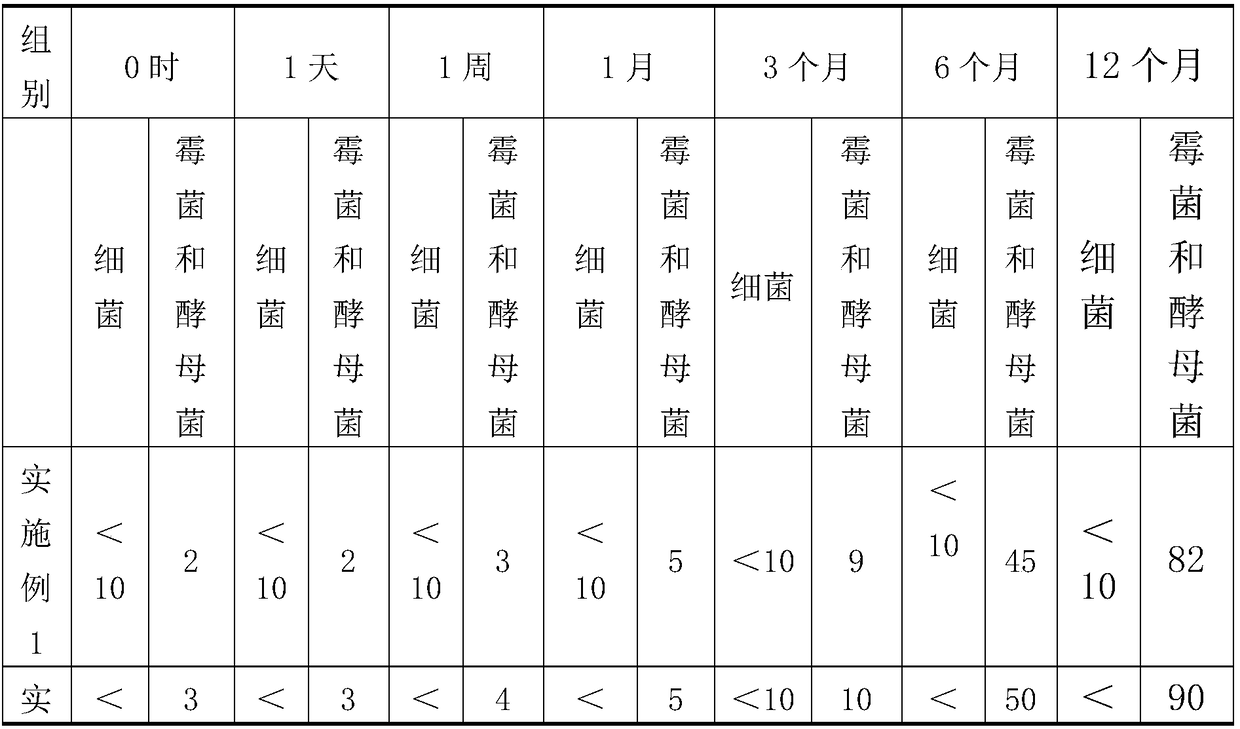

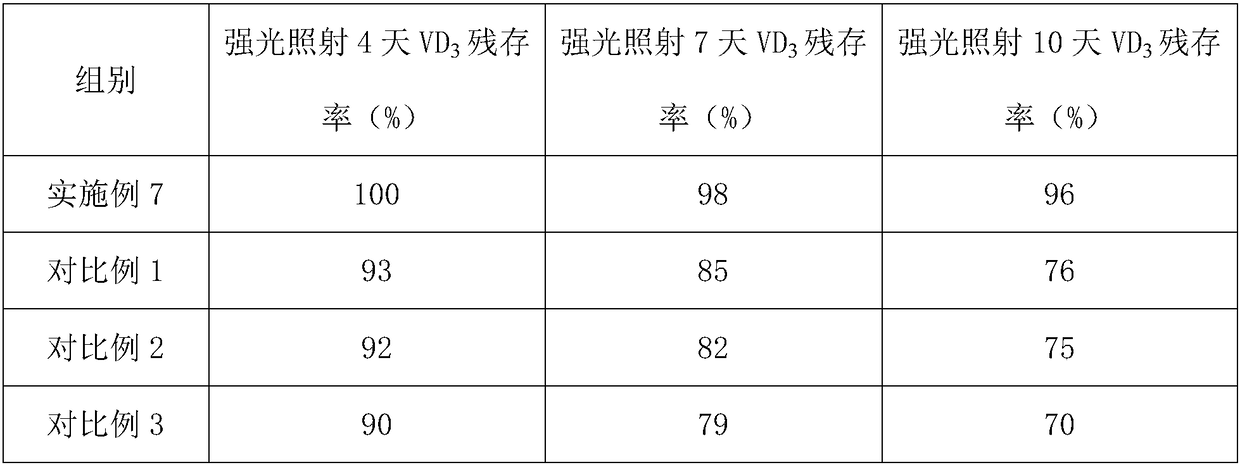

The invention provides a method for preparing a tacrolimus ointment. The method comprises the following steps of: 1, weighing purified tacrolimus, white beeswax, liquid paraffin, paraffin, white Vaseline, propene carbonate and propanediol in the mass ratio of 1:30:40:30:520:10:10; 2, mixing the white beeswax with the liquid paraffin and the paraffin, heating for melting, mixing uniformly to obtain a mixed solution I, and preserving heat at the temperature of 70 DEG C for later use; 3, heating white Vaseline for melting to obtain a white Vaseline solution, and preserving heat at the temperature of 70 DEG C for later use; 4, mixing propanediol and propene carbonate uniformly in the ratio of 1:1 to obtain a mixed solution 2; 5, dissolving tacrolimus into the mixed solution of propanediol and propene carbonate to obtain a mixed solution 3, and preserving heat at the temperature of 70 DEG C for later use; and 6, dispersing the mixed solution 3 into the white Vaseline solution to obtain a mixed solution 4, adding the mixed solution 4 into the mixed solution I to obtain a solution 5, stirring at the temperature of 70 DEG C for 10 minutes, cooling, and continually stirring till the solution 5 is condensed into an ointment.

Owner:ZHEJIANG WAN SHENG PHARMA CO LTD

Magnetic mask and preparation method thereof

InactiveCN106214580APromote absorptionGood at removing dust from the faceCosmetic preparationsToilet preparationsMicrocrystalline waxGlycerol

The invention discloses a magnetic mask and a preparation method thereof, relating to the field of cosmetic masks and particularly the field of a magnetic mask and a preparation method thereof. The mask comprises reduced iron powder, aloe juice, kaolin, dead sea mud, propanediol, glycerol, dimeticone, isopropyl myristate, cyclopolydimethyl siloxane, triglyceride decanoate, grape seed oil, jojoba seed oil, shea butter, white beeswax, diphenoxetol, Rosa Canina fruit extract oil, microcrystalline wax, vitamin E, camomile oil, perfume and the like. When in use, the mask is uniformly spread on the face with the thickness of 1 millimeter or so, stayed for 6 minutes, and wiped with a magnet from above the mask, so that the magnet can absorb all the mask. The magnet is a neodymium-iron-boron magnet. The mask has the effects of deeply cleaning the skin and promoting skin absorption, and can be easily removed.

Owner:CHANGZHOU ADAM BIOTECH

Mixture of and method of making a trancutaneous pain relief composition

InactiveUS7029711B2Promote absorptionPromote painBiocideMammal material medical ingredientsPeppermintsStearic acid

A transcutaneous pain relief composition for applying to the skin, comprising a mixture of dimethyl sulfoxide, stearic acid, emulsifying wax, glycerine, emu oil, sal butter, glucosamine, coconut oil, white beeswax, active calendula oil, slippery elm oil, Chamomile oil, arnica Oil, valenrian oil, peppermint oil, grapefruit seed extract, lavender oil and distilled water is disclosed.

Owner:FARRELL SHANNON LYNN

Dust-free chalk and manufacture method thereof

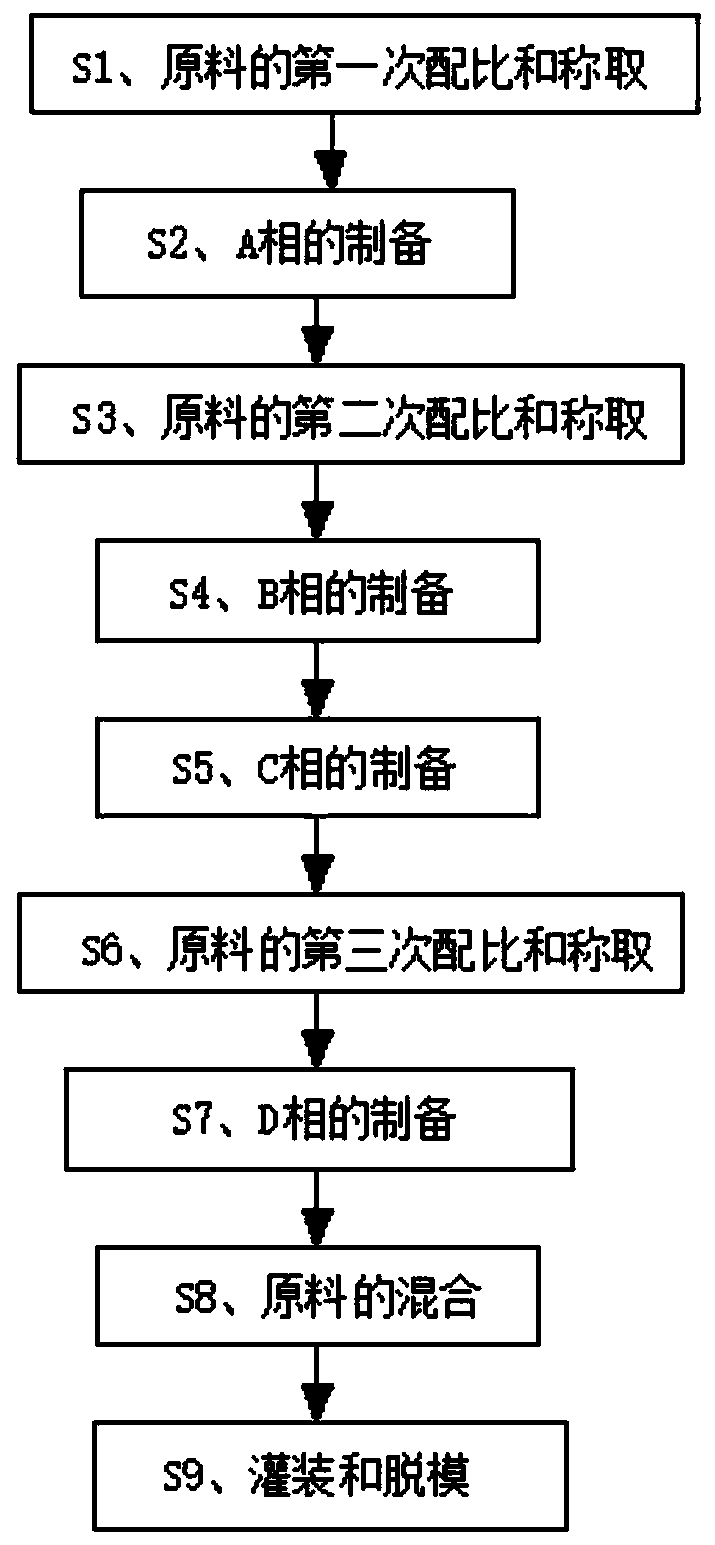

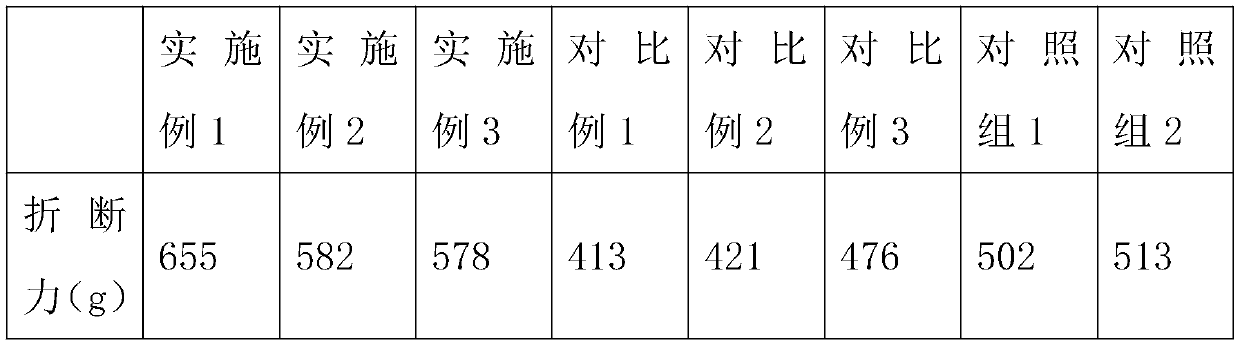

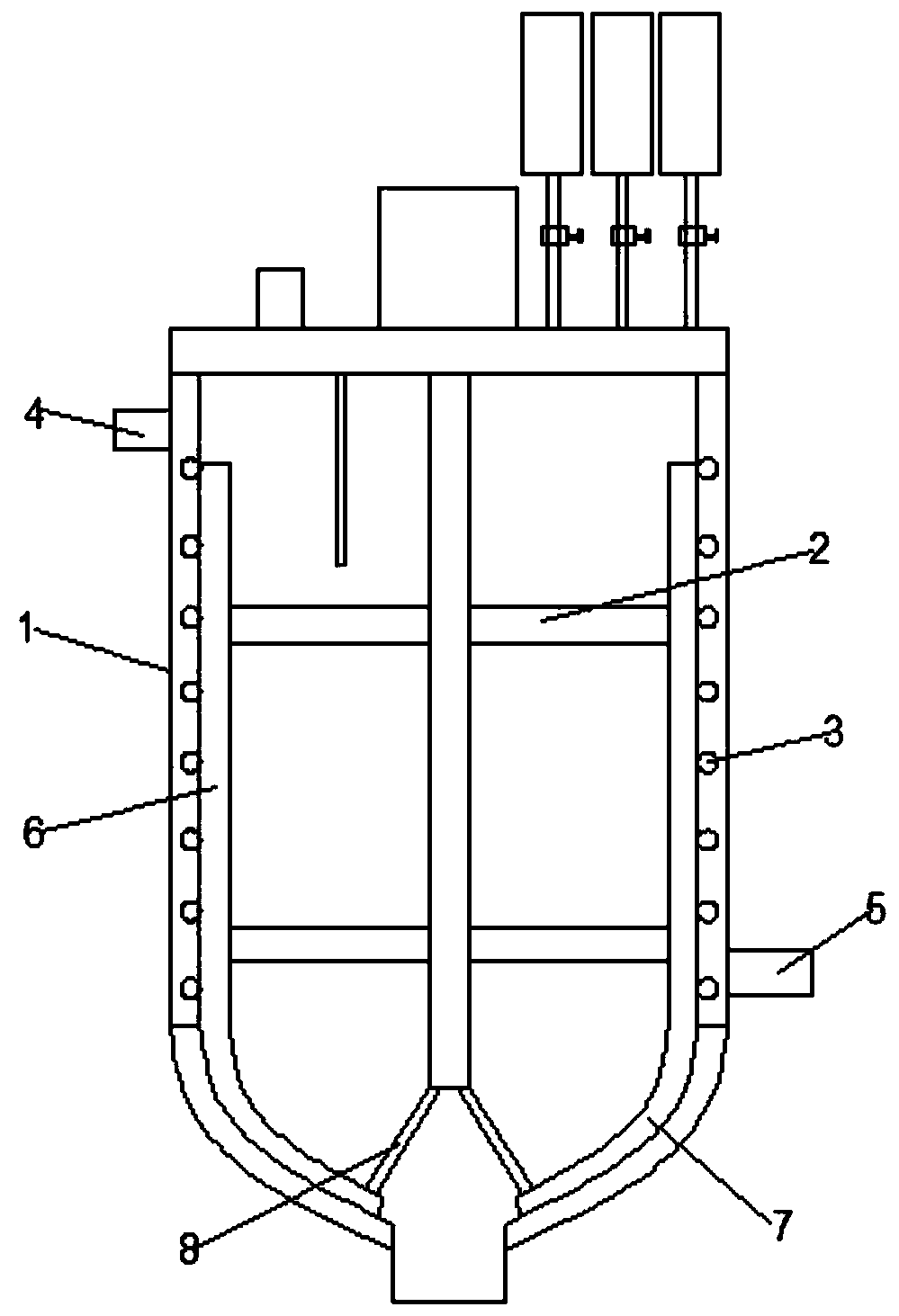

The present invention discloses a dust-free chalk and a manufacture method thereof. The dust-free chalk comprises a main ingredient and an auxiliary ingredient used as raw materials, wherein the main ingredient is composed of the following components in parts by mass: 10-16 parts of hardened oil, 12-18 parts of stearic acid, 3-6 parts of white beeswax, 1-3 parts of carnauba wax, 2-5 parts of propylene glycol, 1-2 parts of lecithin, 7-12 parts of fatty alcohol polyoxyethylene ether, 6-10 parts of epoxidized soybean oil and 0.1-0.5 part of paraben ester; and the auxiliary ingredient comprises the following components in parts by mass: 30-35 parts of titanium dioxide, 2-5 parts of nano calcium carbonate and 6-10 parts of mica powder. The manufacture method of the dust-free chalk comprises: firstly heating and stirring the main ingredient to obtain an emulsion, adding the auxiliary ingredient, stirring, then injecting the mixture into a mold for molding, condensing and demolding to obtain a finished product. The dust-free chalk has the advantages of good weathering resistance and moisture retention, writing lubricity, bright writing, moderate hardness, low possibility of breakage, no toxicity or odor and no dust generated during using and wiping processes. The selected materials are readily available soluble environmentally-friendly materials, and no pollutants are generated during the production process of the dust-free chalk.

Owner:许明铁 +1

Leather antiseptic

InactiveCN104388603AExtended service lifeEasy to sterilizeLeather surface finishingPolymer sciencePyrrolidinones

Owner:QINGDAO TOPLINK INFORMATION TECH

Edible fruit lip balm and preparation method thereof

The invention relates to the technical field of cosmetics, in particular to edible fruit lip balm and a preparation method thereof. The edible fruit lip balm is prepared from, by mass, 7-8% of white beeswax, 7-8% of Brazilian palm wax, 4-5% of apple peel wax, 4-5% of lecithin, 2-3% of jojoba esters, 5-6% of Simmondsia Chinensis seed Oil, 10-15% of Macadamia Ternifolia seed oil, 10-15% of grape seed oil, 5-10% of diisostearyl malate, 11.8-36.4% of ethylhexyl cocoate, 1-2% of tocopheryl acetate, 4-5% of Butyrospermum Parkii butter oil, 4-5% of bis-diglyceryl polyacyladipate-2, 0.5-1% of fruit extract and 0.1-0.2% of essence. The edible fruit lip balm made from pure natural ingredients is edible, better in lip moisturizing effect and capable of fading the lip texture and beautifying the lip shape.

Owner:广州丽彦妆生物科技有限公司

Nano sunscreen foundation cream and preparation method thereof

ActiveCN101361702AAvoid damageAvoid premature agingCosmetic preparationsBody powdersStearic acidPolydimethyl siloxane

The invention discloses a nano sun-screen foundation cream and a preparation method thereof, which belong to the field of cosmetics and the processing technology thereof. The foundation cream is prepared by using water, 15-100 nano titanium dioxide, isopropyl myristate, polyoxyethylene-21 stearic alcohol ether, melissyl PVP, octodecyl alcohol, 5-100 nano iron trioxide, white oil, propanetriol, propanediol, polyoxypropylene-15 Stearic ether, milkvetch root extract, white beeswax, polydimethyl siloxane fluid, stearic acid monoglyceryl ester, vitamin E nicotinic acid ester, alose, acrylic acid polymer, diazolidinyl urea, acetaldehyde di-uride and essence. The nano sun-screen foundation cream has safety and good sun-screen effects, and has the functions of sun screen, after-sun repair and covering facial flaw.

Owner:SHENZHEN OASIS PHARMA

Skin-care composition containing lotus active ingredients and preparation method of skin-care composition

ActiveCN105534815AMoisturizingIncrease elasticityCosmetic preparationsMake-upAdditive ingredientSkin color

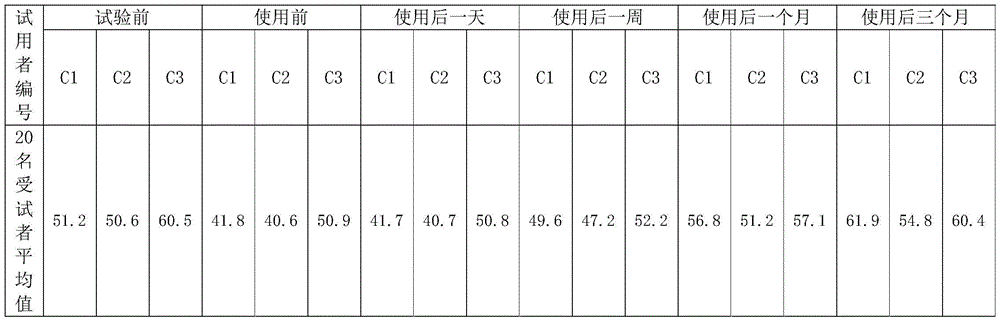

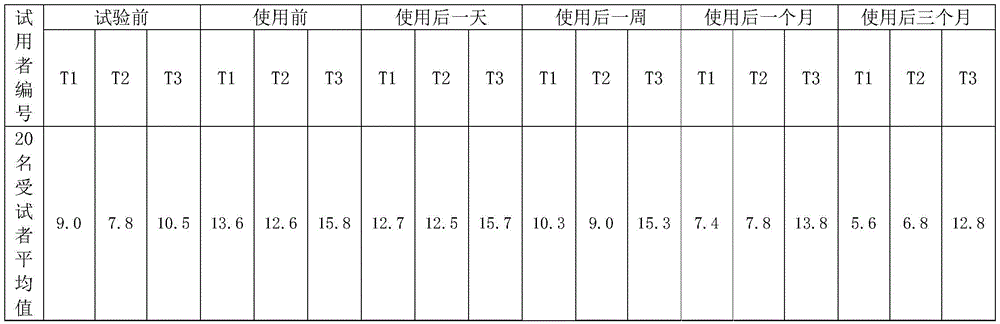

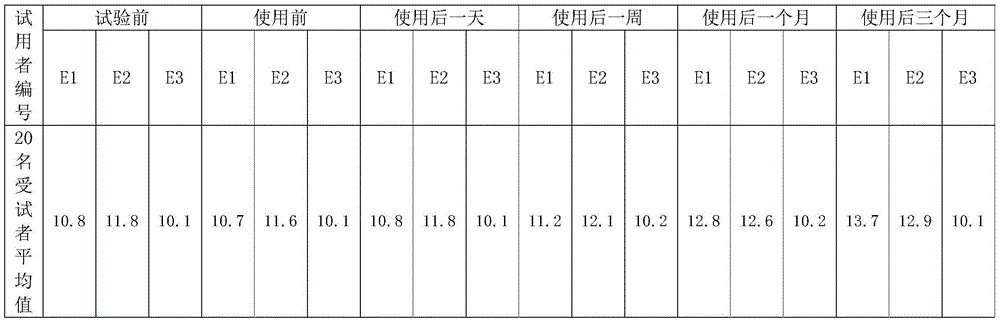

The invention provides a skin-care composition containing lotus active ingredients and a preparation method of the skin-care composition. The skin-care composition comprises the following components: glycerin, 1,3-butanediol, squalene, polydimethylsiloxane, modified polydimethylsiloxane, dicaprylyl carbonate, isopropyl myristate, cetearyl alcohol, white beeswax, titanium dioxide, iron oxides, sodium chloride, nuciferine, lotus pollen, allantoin, sodium hyaluronate, methylparaben, propylparaben, diazolidinyl urea, iron oxide red, iron oxide yellow, essence and deionized water. The skin-care composition is a powder product which takes full advantage of the lotus active ingredients, and the types and consumption of the various components are set reasonably; by adoption of the reasonable preparation method, the color of the prepared skin-care product approximates the human skin color, and the color difference is avoided after the skin-care product is applied to the skin surface; and meanwhile, the skin moisturizing degree is improved obviously, the skin trans-epidermal water loss is reduced, and the skin elasticity is improved.

Owner:CHONGQING PUPU BIOTECH

Lightweight rubber material

The invention discloses a lightweight rubber material which is composed of the raw materials of, by weight, 3-4 parts of maleic anhydride, 0.2-0.6 parts of 8-10% sulfuric acid, 1-2 parts of an accelerator MZ, 26-30 parts of melamine, 5-8 parts of a 37% formaldehyde solution, 7-10 parts of urea, 6-10 parts of microcrystalline cellulose, 210-230 parts of chloroprene rubber S40V, 3-6 parts of white beeswax, 4-5 parts of magnesium enhancement powder, 0.7-1 parts of stannous octoate, 2-3 parts of polyurethane, 16-20 parts of Suzhou soil, 28-34 parts of light calcium carbonate, 4-7 parts of bitetradecenoic alcohol ester, 2-3 parts of wood creosote, 3-4 parts of an anti-aging agent DOD, 2-3 parts of sulfur, and 1-1.2 parts of isopropanol. According to the invention, with the crosslinking effect of maleic anhydride, microcrystalline cellulose forms a closer network structure in melamine resin formed by melamine, urea and formaldehyde, such that resin viscosity and tensile deformation resistance are well improved, and certain reinforcement and tackifying functions are performed in the rubber material. Therefore, flexure cracking resistance, hot-air aging resistance and stability are improved. The rubber finished product provided by the invention has the advantages of light weight, no toxic or harmful substance volatilization, easy transportation, and easy processing.

Owner:FUYANG ANGU BOILER PRESSURE VESSEL MFG

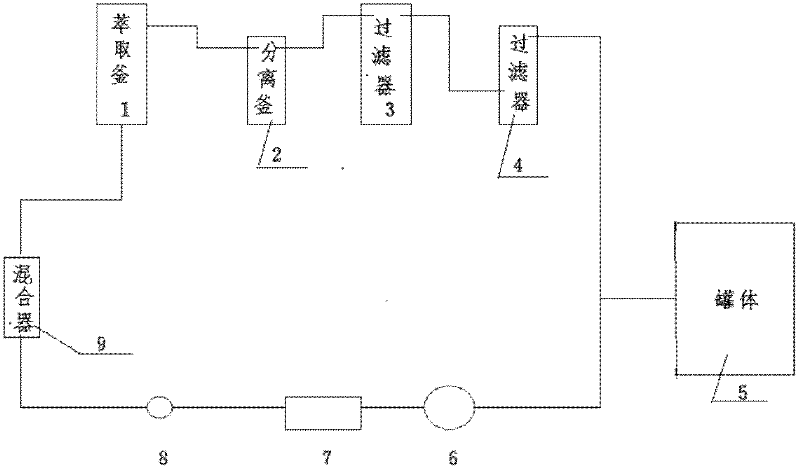

Method for separating beeswax in propolis through supercritical CO2

InactiveCN102370667APreserve active ingredientsImprove qualityFatty substance recovery/refiningAnthropod material medical ingredientsOrganic solventPropolis

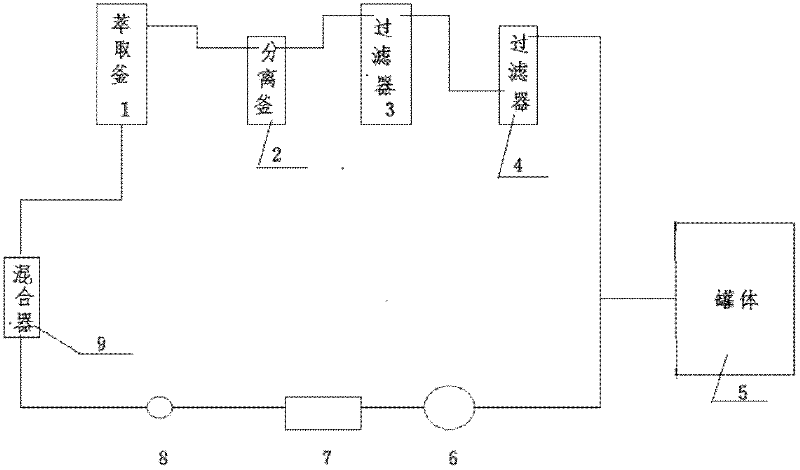

The invention discloses a method for separating beeswax in propolis through supercritical CO2, which comprises the following steps: carrying out cryogenic crushing on propolis raw material; then extracting with CO2 in an extraction kettle; and separating out white beeswax through a separator. By utilizing the supercritical fluid to extract and separate the beeswax component in propolis at low pressure, the method preserves other active components in the propolis raw material and is not involved with the carrying of any organic solvent, thereby greatly improving the quality of propolis extract.

Owner:JIANGSU JIANGDAYUAN ECOLOGICAL BIOLOGICAL TECH

Sebum-like membrane component and preparation method thereof

InactiveCN111743813AEnsure safetyHealth injuryCosmetic preparationsToilet preparationsVegetable oilTriglyceride

The invention discloses a sebum-like membrane component and a preparation method thereof. A sebum-like membrane comprises the following components: triglyceride, wax, a squalane-like component and cholesterin / ester in a mass ratio of (50-70): (10-30): (10-30): (1-10). Substances similar to a skin component structure form a sebum-like membrane component so as to apply on skin, wherein triglyceridein the sebum-like membrane component accounts for 50-70% by weight, the triglyceride is at least one kind of grease selected from vegetable grease, and the wax is at least one kind of wax selected from Brazil wax palmitate wax, white beeswax, white pyrophyllite wax, beeswax, bitter orange flower wax and candelilla wax. The invention discloses a sebum-like membrane component and a preparation method thereof, the safety of the components is ensured, no harm is caused to the health of the skin, meanwhile, the interior of the skin is better explored, the sebum-like membrane component acts on the skin, so the skin is moistened, fine and soft, the stable health state of the skin is better maintained, and then the skin is kept in the youth and vitality state.

Owner:杭州舒彩网络科技有限公司

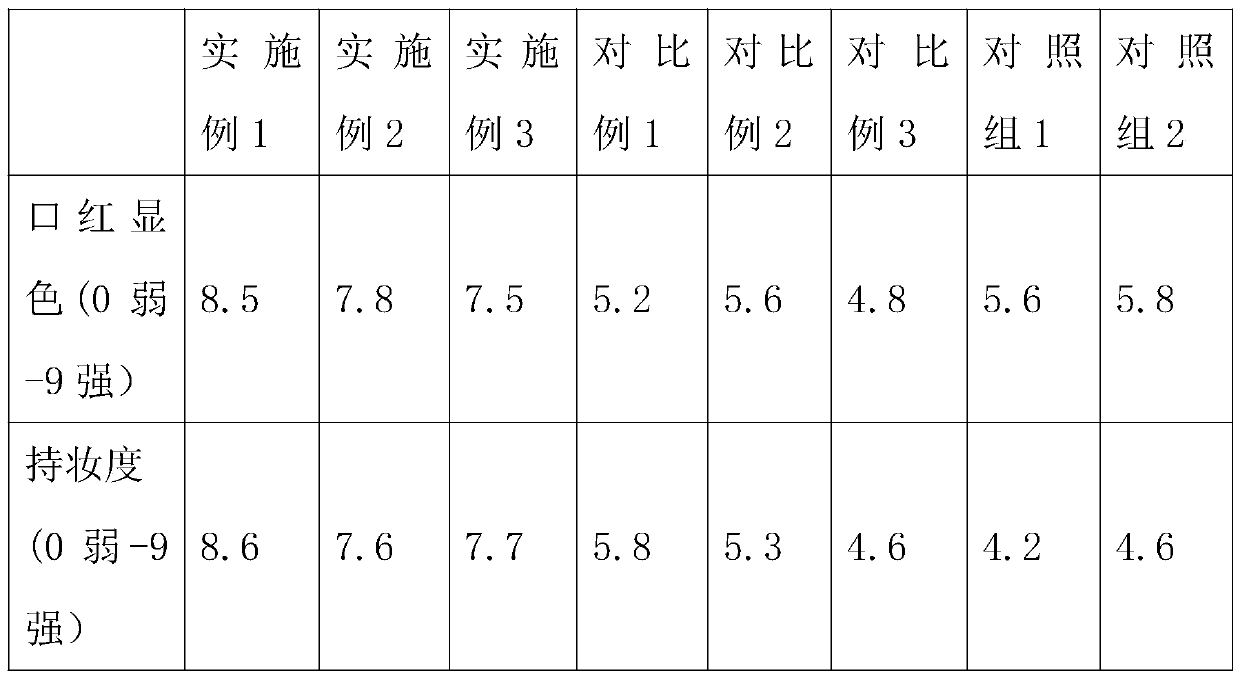

Fullerene color-changing lipstick and preparation method thereof

InactiveCN111388357AEasy to spreadEasy to develop colorCosmetic preparationsMake-upCaprylyl GlycolPolymer science

The invention discloses a fullerene color-changing lipstick and a preparation method thereof, and relates to the technical field of skin care products. The fullerene color-changing lipstick includes the following components in parts by weight: 10-15 parts of water, 3-6 parts of white beeswax, 1-3 parts of candelilla wax, 4-6 parts of polyethylene, 2-4 parts of polyisobutylene, 1-2 parts of bis-diglyceryl polyacyladipate-2, 2-7 parts of phytosteryl oleate, 7-10 parts of ethylhexyl palmitate, 12-15 parts of cetyl ethyl hexanoate, 18-25 parts of polyglyceryl-2 diisostearate, 8-12 parts of ozokerite, 0.1-1 part of caprylyl glycol, 15-18 parts of polyglyceryl-2 triisostearate, 0.1-0.2 part of fullerene, 0.1-0.15 part of polyvinylpyrrolidone, 5-7 parts of butanediol, 2-3 parts of orange 4, 0.5-0.8 part of red 28, and 0.1-0.2 part of iron black. The fullerene color-changing lipstick provided by the invention is easy to spread, easily develops color, has a good makeup holding effect without lip balm primer, has anti-inflammatory effects, effectively alleviates cleft lip, has no obvious lip lines, modifies lip contour, makes a lip appear a full and soft state, and is very translucent.

Owner:广州市拉凯尔干细胞研究所

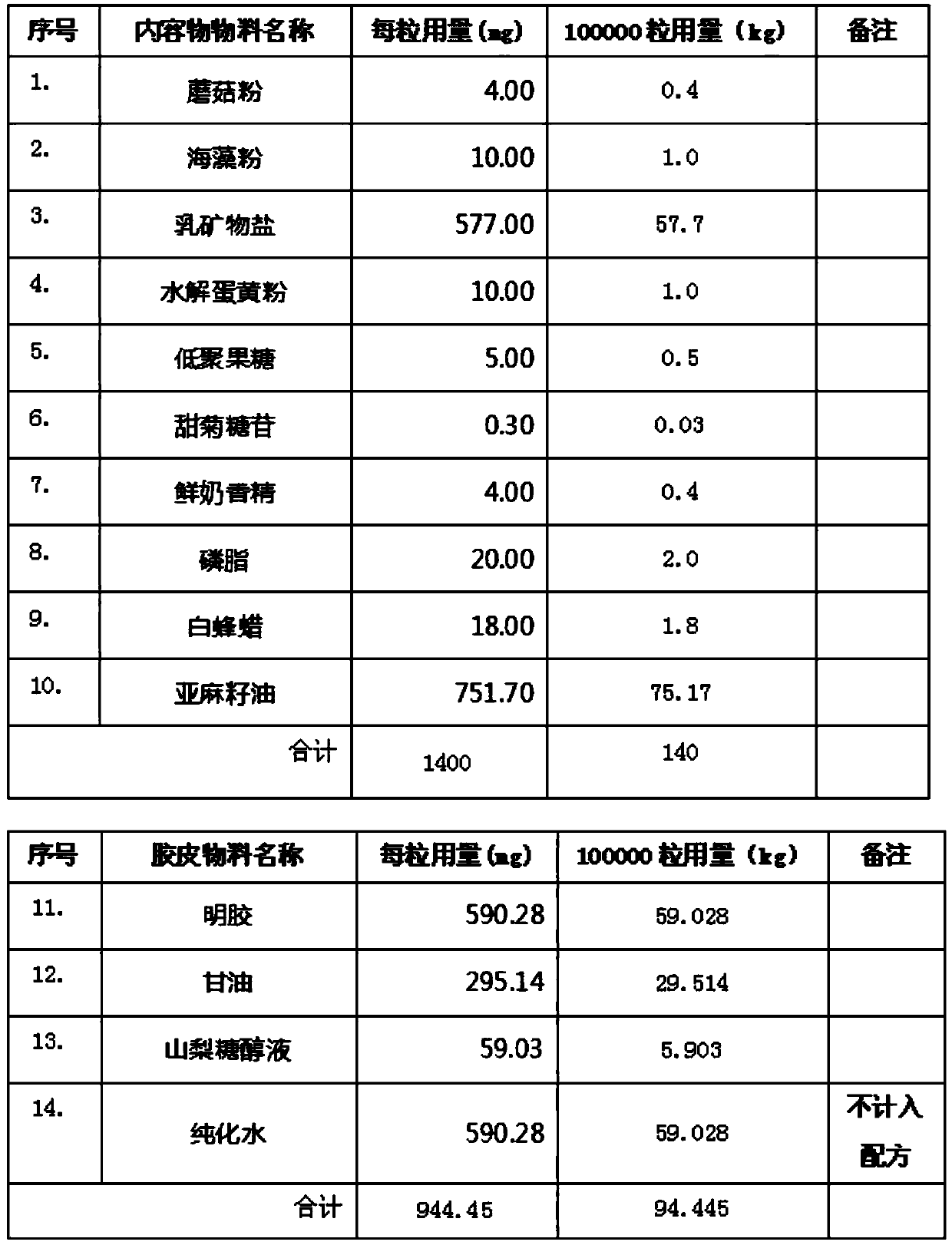

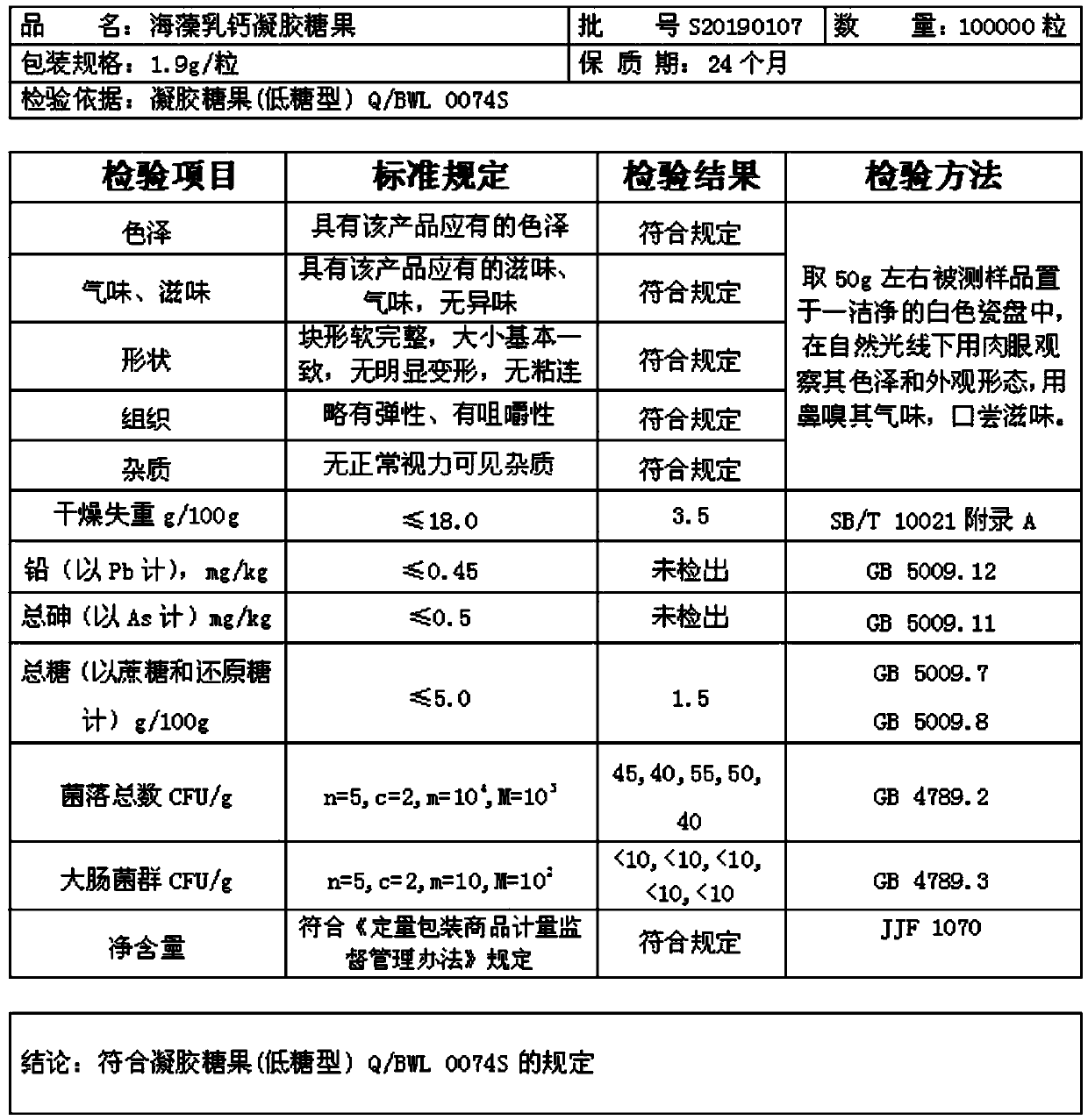

Preparation method of seaweed milk calcium gel candy

The invention discloses a preparation method of seaweed milk calcium gel candy. The method is characterized in that the seaweed milk calcium gel candy comprises a content and a capsule shell, whereinthe content materials in every thousand of seaweed milk calcium gel candies comprise 3-5g of mushroom powder, 8-12g of seaweed meal, 550-585g of milk mineral salt, 7-13g of hydrolyzed yolk powder, 4-6g of fructo-oligosaccharide, 0.2 g to 0.4 g of stevioside, 3.5-4.5 g of fresh milk essence, 17-23 g of phospholipid, 17-19 g of white beeswax and 700-800 g of linseed oil. The capsule materials in every 1000 seaweed milk calcium gel candies comprise 570-610 g of gelatin, 285-305 g of glycerin, 49-69 g of sorbitol liquid and 500-650 g of purified water. The preparation method comprises the following specific preparation steps: inspecting raw materials, weighing, preparing a content material liquid, preparing a glue solution, pressing pills, drying, sorting the pills, packaging, inspecting and warehousing. The method has the advantages of simple processing technique, high product quality, accurate dosage and favorable mouthfeel, and is suitable for children to take.

Owner:BRAVEIY BIOTECHNOLOGY (ANHUI) CO LTD

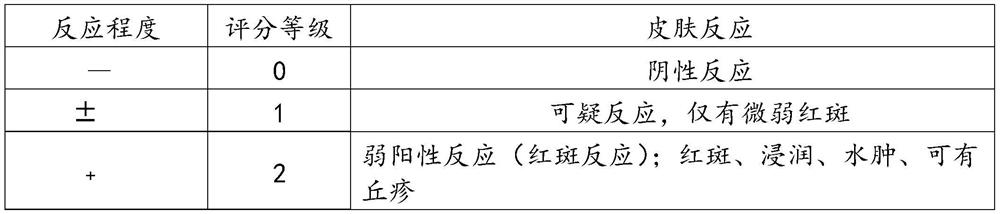

Medicine composition used for treating eczema, and preparation method thereof

ActiveCN103169764AFast and strong healing effectLower histamine levelsHydroxy compound active ingredientsKetone active ingredientsPatients symptomsTherapeutic effect

The invention belongs to the technical field of medicine, and relates to a medicine composition used for treating eczema, and a preparation method thereof. The eczema-treating medicine composition is obtained by mixing the raw materials of, by weight, 1-3 parts of white beeswax, 10-14 parts of white oil, 3-5 parts of C12-15 benzoate, 1-3 parts of isopropyl myristate, 1-3 parts of lanolin, 2-4 parts of shea butter, 1-3 parts of DC250 dimethyl silicone oil, 0.1 parts of methylparaben, 0.2 parts of ethylparaben, 2-4 parts of PEG-30 dimeric hydroxyl stearate, and the like. The eczema-treating medicine composition provided by the invention has fast and high treatment effect, and good nursing effect. Once eczema is cured by using the medicine composition, reoccurrence is prevented. The medicine composition also has three effects such as itching relieving and inflammation eliminating, sterilizing, and eczema skin histamine level reducing. As a result of experiments, the medicine composition has an ideal treatment effect against eczema patient symptoms such as erythema, skin lesions and itching.

Owner:福州中科伟创生物科技有限公司

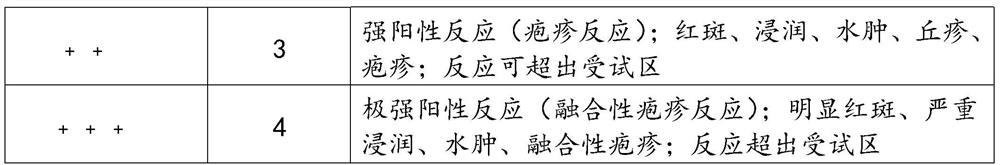

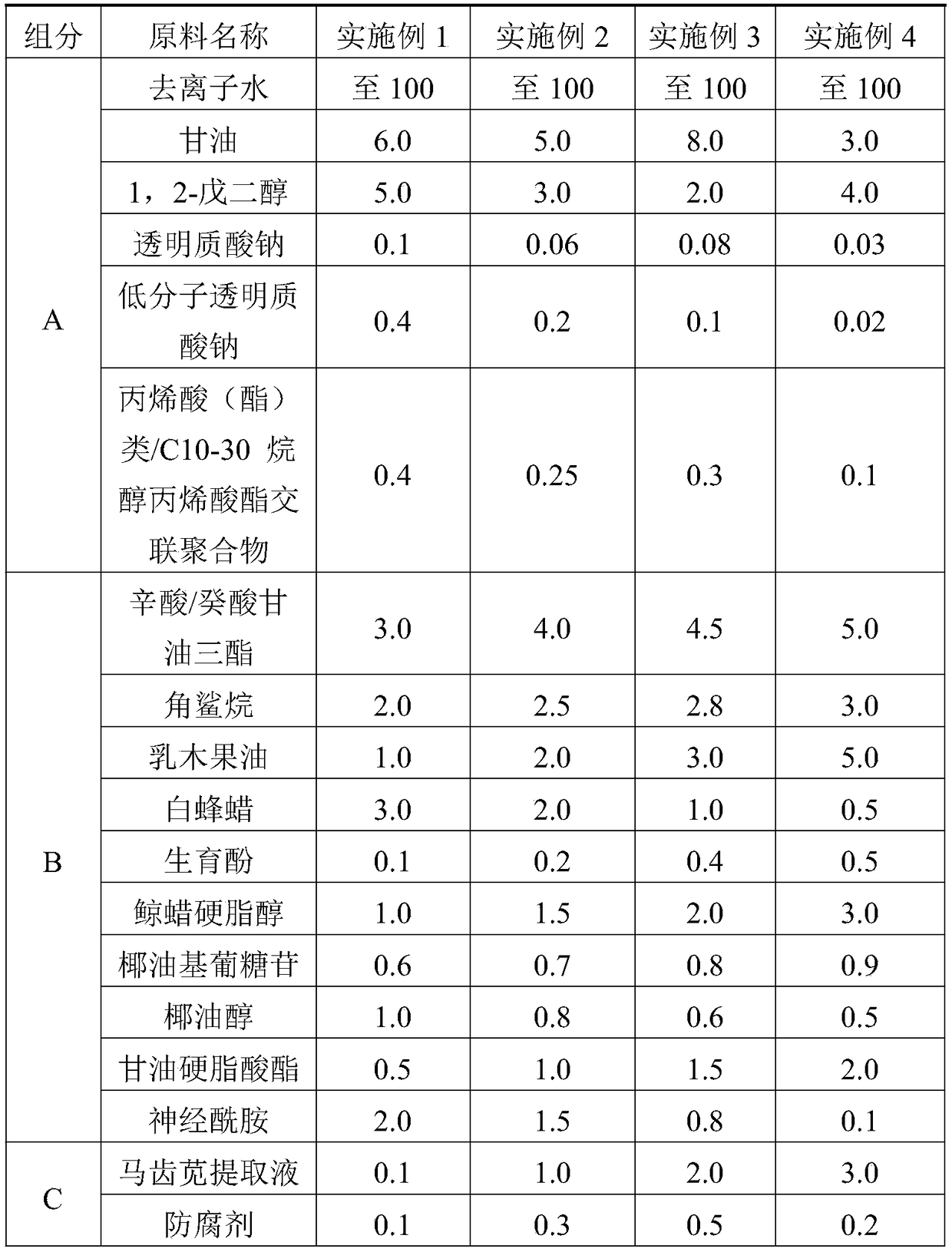

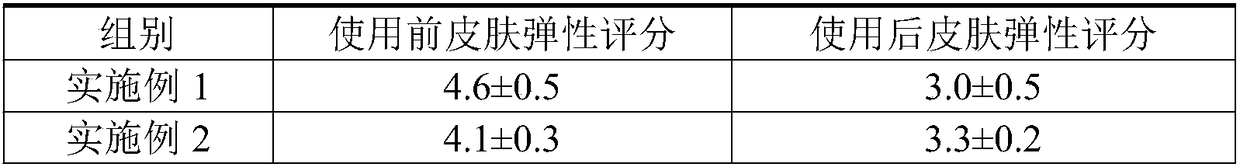

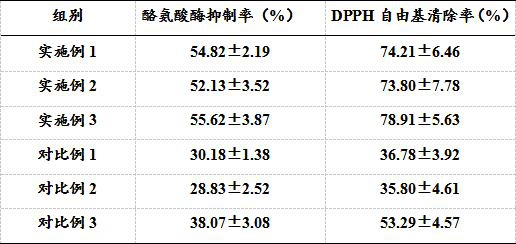

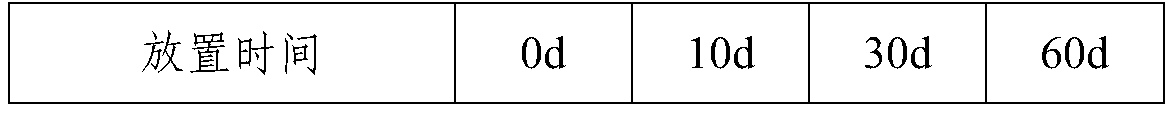

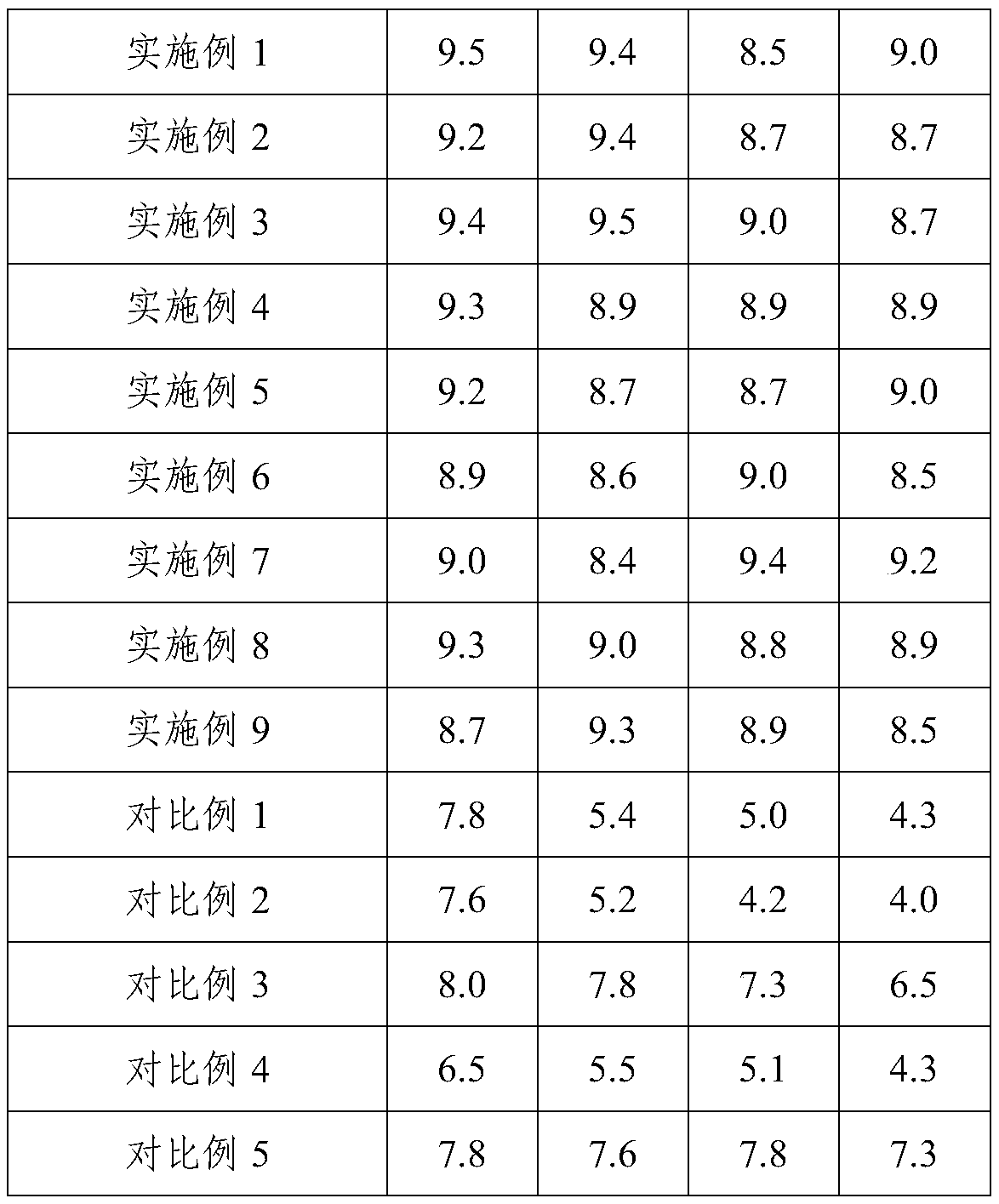

Skincare product with ceramide and preparation method of skincare product

InactiveCN109044864AIncrease drynessReduce desquamationCosmetic preparationsToilet preparationsCross-linkCuticle

The invention discloses a skincare product with ceramide and a preparation method of the skincare product. The skincare product comprises 0.1-2 parts of ceramide, 0.1-3 parts of a portulaca oleracea extract, 3-8 parts of glycerinum, 2-5 parts of 1,2-pentanediol, 0.1-0.4 part of an acrylic acid (ester) type / C10-30 alkanol acrylate cross-linked polymer, 3-5 parts of caprylic acid / tricaprin, 2-3 parts of squalane, 1-5 parts of shea butter, 0.5-3 parts of white beeswax, 0.1-0.5 part of tocopherol, 1-3 parts of cetostearyl alcohol, 0.6-0.9 part of coco-glucoside, 0.5-1 part of coconut alcohol, 0.5-2 parts of glyceryl stearate, 0.05-0.5 part of sodium hyaluronate, 0.1-0.5 part of a preservative and the balance of deionized water till 100 parts. By adopting the skincare product, the ratio of theceramide is adjusted, balance of cuticle moisture is kept, a skin barrier function which is lost because of use of organic solvents or surfactants can be recovered, and the skincare product has the advantages of nature and no side effect, meanwhile has multiple effects of skin protection, skin moisturizing and aging prevention, and has a function of auxiliary treatment on skin diseases related toskin barrier damage.

Owner:XIAN HUIPU BIOTECH CO LTD

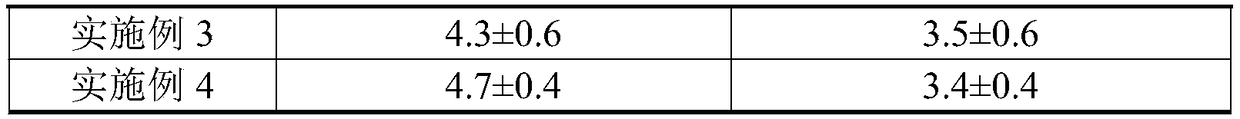

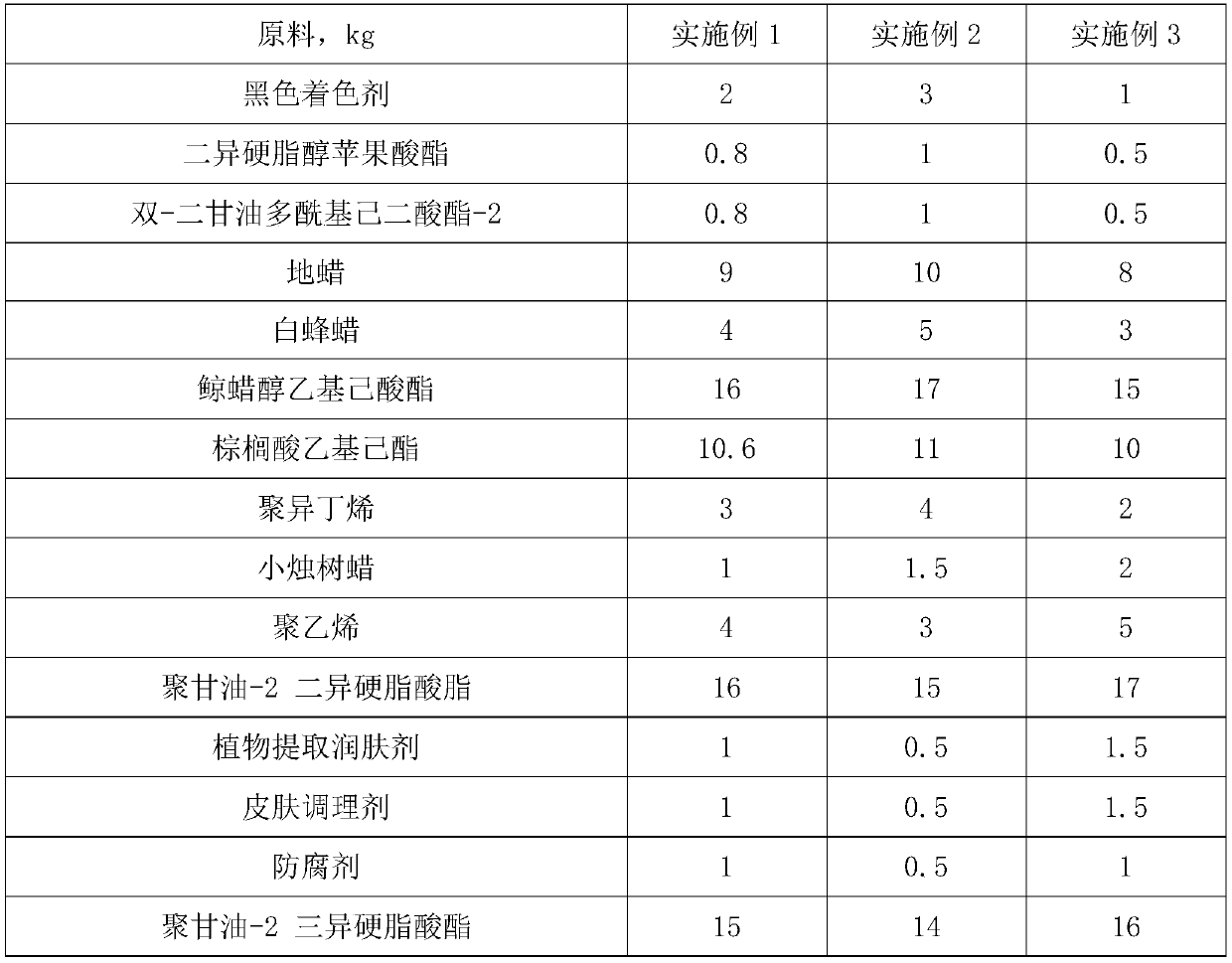

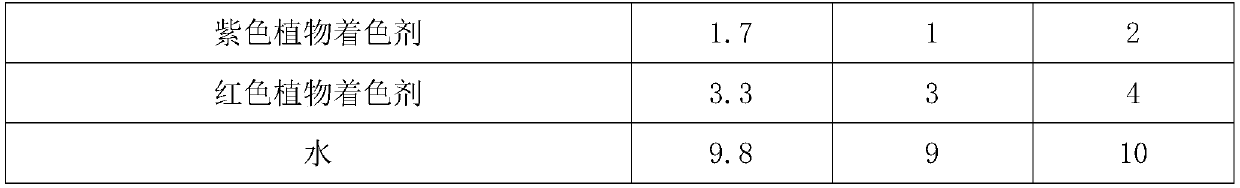

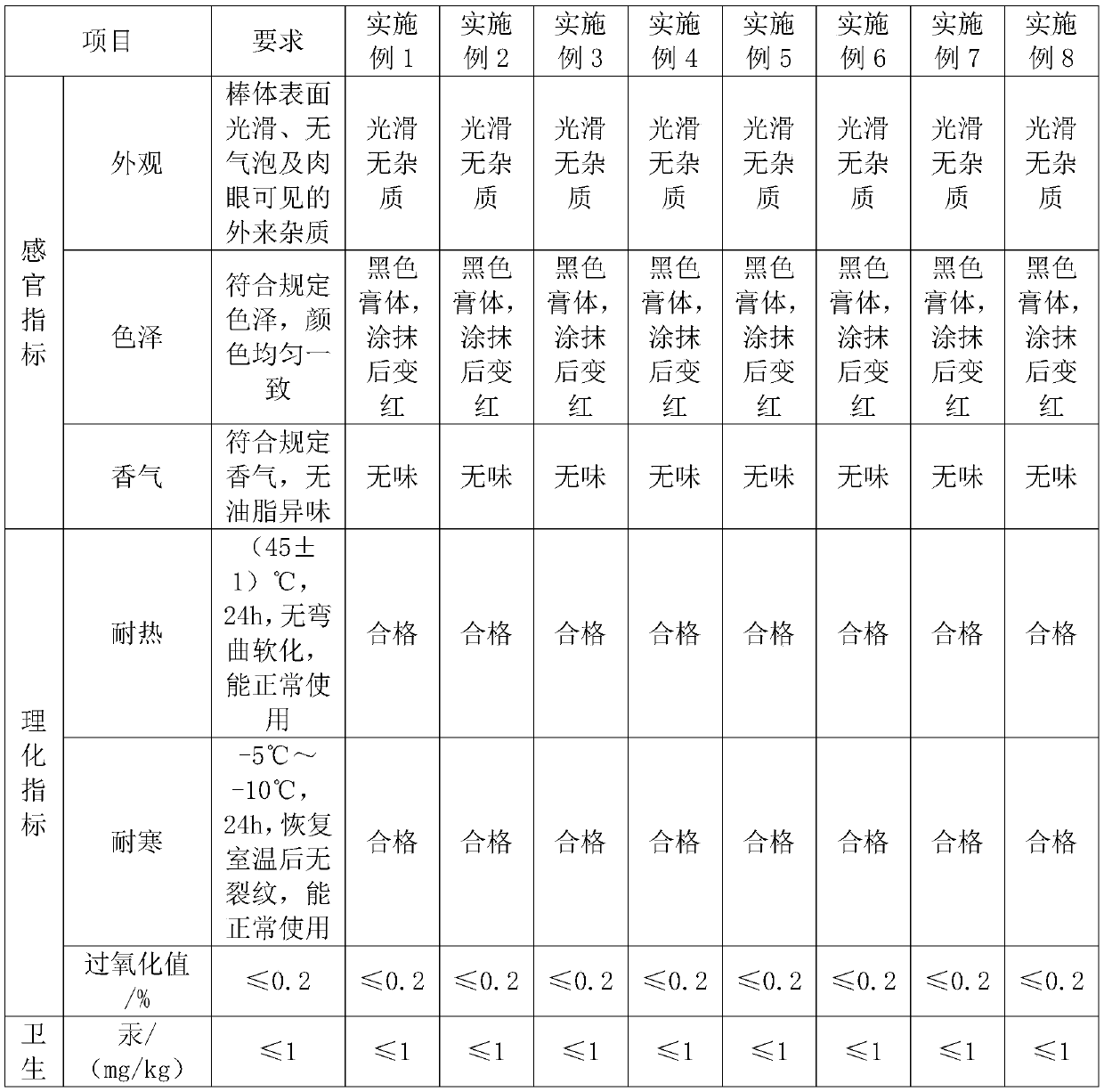

Natural color-changing lipstick and preparation method therefor

ActiveCN111568842AFresh and natural colorEvenly dispersedCosmetic preparationsMake-upEthylhexyl palmitateCetyl ethylhexanoate

The invention relates to the field of cosmetics and particularly relates to a natural color-changing lipstick and a preparation method therefor. The natural color-changing lipstick comprises the following ingredients: ceresine wax, white beeswax, cetyl ethylhexanoate, ethylhexyl palmitate, polyisobutylene, candelilla wax, polyethylene, polyglycerol-2-diisostearate, a plant extract emollient, a skin conditioner, a preservative, a black colorant, diisostearyl malate, bis-diglycerolpolyacyl adipate-2, polyglycerol-2-triisostearate, a purple plant colorant, a red plant colorant and water, whereinthe purple plant colorant is prepared from a sweet potato root extract, and the red plant colorant is prepared from a radish root extract. The natural color-changing lipstick disclosed by the invention has the effects of being moderate and safe in ingredient and having a very good moistening effect on lips.

Owner:HANGZHOU XINYUE COSMETICS CO LTD

A kind of skin care composition containing lotus active ingredient and preparation method thereof

ActiveCN105534815BPromote digestion and absorptionEnhance secretory functionCosmetic preparationsMake-upSkin colorPollen

Owner:CHONGQING PUPU BIOTECH

A kind of mascara containing foaming agent and preparation method thereof

The invention discloses a mascara containing a foaming agent, which consists of deionized water, butylene glycol, methyl p-hydroxybenzoate, panthenol, sorbitol, nicotinamide, EDTA-2Na, xanthan gum, Cellulose, iron black (and) water (and) sodium polyacrylate, white beeswax, ozokerite wax, candelilla wax, stearic acid, microcrystalline wax, sorbitan sesquioleate, tocopheryl acetate , Hydrogenated Polycyclopentadiene, Squalane, Propylparaben, Isododecane, Polysorbate‑60, Cetearyl Glucoside, Jojoba Oil, Distearyl Dimethyl Ammonium Hectorite, Rice Bran Wax, Polyisobutylene, Dimethicone, Dimethiconol, Triethanolamine, Cellulose, Phenoxyethanol, Novec HFE‑7100. The mascara containing the foaming agent of the present invention has good application effect, and the mascara is denser, softer and more natural after use.

Owner:SHANGHAI ZHONGYI DAILY CHEM CO LTD

Light-sensitive magic lipstick and preparation method thereof

InactiveCN108553339AMoisturizes lips wellWon't dryCosmetic preparationsMake-upButylated hydroxyanisoleWax

The present invention relates to a light-sensitive magic lipstick, which comprises, by weight, the following components: A phase components: 8-15 parts of white beeswax, 4-8 parts of petrolatum and 5-9 parts of ground wax; B phase components: 4-8 parts of hydrogenated polyanemone, 35-45 parts of squalane and 2-5 parts of lauryl alcohol laurate; C phase components: 8-30 parts of light-variable powder; D phase componnets: 3-6 parts of No. 27 golden yellow slurry; E phase components: 0.06-0.10 parts of butylated hydroxyanisole and 0.03-0.05 parts of hydroxypropyl acrylate; F phase components: 1-3parts of tocopherols, the invention also discloses a preparation method thereof. The magic lipstick has the advantages that through the unique multi-dimensional light-sensitive variable formula, whenlighting conditions are different, the color of the lip is different according to the different illumination conditions, and is suitable for users who like changeable colors, and only one light-sensitive magic lipstick is needed.

Owner:广州琦莉化妆品有限公司

Method for preparing long-acting mascara

The invention discloses a method for preparing a long-acting mascara. The mascara is composed of component A, component B and component C through mutual cooperation. The mascara preparation comprisesthe steps that step one, in component A preparation, component A is composed of paraffin oil and bentonite glue, paraffin oil mass fraction is 35.6 grams, and bentonite glue mass fraction is 15 grams;step two, in component B preparation, the component B is composed of talc powder and cosmetic black, talc powder mass fraction is 1 gram, and cosmetic black mass fraction is 10 grams; step three, incomponent C preparation, the component C consists of N, N-dimethyl-3-1-propyl ammonium chloride, white beeswax, methyl paraben, butylparaben and sorbic acid. According to the method for preparing thelong-acting mascara, the mascara prepared by the method has low adhesion to eyelashes during use, does not become hard after drying, and does not agglomerate, thereby improving the use effect of the mascara, and the mascara can adhere to the eyelashes for a long time, thereby reducing the frequency of makeup.

Owner:吴玉婷

Edible chalk and production method thereof

The invention discloses an edible chalk. The chalk comprises beeswax base material: 51-57%, edible calcium carbonate: 4-8%, food-grade coloring material: 32-36%, glycerin: 2-4%. Oxidant: 2-4%, the beeswax base material includes surfactant: 14-18%, edible oil 8-11%, white beeswax: 52-57%, ethanol: 2-3%, palm oil: 16-22% %; The present invention is made from food-grade raw materials, and has the characteristics of non-toxic, edible and high safety.

Owner:华蓥市红军小学

anti chapped lipstick

InactiveCN102274135AImprove breathabilityGood anti-crackingCosmetic preparationsMake-upWhite BeeswaxOlive oil

The invention discloses an anti-drying and chapping lipstick, which is characterized in that the raw material components for making the lipstick include metronidazole, vaseline, white beeswax, vitamin E and olive oil. The lipstick of the invention has good air permeability, moist and glossy lips after rubbing, and good anti-cracking effect; the preparation method is simple, and the production cost is low.

Owner:NINGXIA MEDICAL UNIV

Environment-friendly viscosity reducer for printing ink and preparation method of environment-friendly viscosity reducer

The invention discloses an environment-friendly viscosity reducer for printing ink. The environment-friendly viscosity reducer is composed of the following raw materials in percentage by weight: 15-18% of Vaseline, 3-5% of white beeswax, 20-25% of resin oil, 15-18% of aluminum distearate, and 35-45% of linseed oil. The invention further discloses a preparation method of the environment-friendly viscosity reducer for the printing ink. The preparation method comprises the following steps: step 1, integrally adding linseed oil and resin oil into a reaction kettle according to formula data, and starting to stir when the temperature is increased to 88-95 DEG C; step 2, adding Vaseline and white beeswax into the reaction kettle, and continuously stirring; and step 3, uniformly mixing and stirring linseed oil and aluminum distearate to obtain a particle-free material, pumping the particle-free material into a high-level tank by a pump, slowly adding the particle-free material into the reaction kettle, continuously heating to 115-125 DEG C, carrying out heat preservation for 30-40 min, filtering, and taking out of the kettle. The prepared viscosity reducer can be added into ink to increasethe brightness of the ink, improve the wettability, improve the ink property, increase the printing speed and reduce the viscosity, and is environment-friendly and pollution-free.

Owner:苏州盛威科印刷器材有限公司

Beauty skin care pearl cream and preparation method thereof

ActiveCN112545970AGood conditionNourishing and rejuvenatingCosmetic preparationsToilet preparationsBiotechnologyPolyethylene glycol

The invention belongs to the technical field of daily cosmetics, and particularly relates to beauty skin care pearl cream and a preparation method thereof. The beauty skin care pearl cream contains simmondsia chinensis seed oil, squalane, magnesium stearate, polyethylene glycol-30, white beeswax, cocoa seed butter, caprylic / capric triglyceride, an emulsifier, deionized water, nano pearl powder, zinc oxide, biosaccharide gum-1, sodium hyaluronate, tocopherol, allantoin, a polyol humectant, CI77891, a natural plant extract and other components, and the beauty skin care pearl cream has multiple beautifying and skin-care effects of whitening, resisting oxidation and the like, and has a good conditioning effect on human skin.

Owner:何颖

Natural moisturizing lipstick formula for summer

InactiveCN109200006AWell mixedMix slowly and wellCosmetic preparationsMake-upAdditive ingredientCochineal

The invention discloses a natural moisturizing lipstick formula for summer, which comprises the following raw materials in parts by weight: natural beeswax 12-16 part, cochineal 2-6 part, pearl powder1-5 part of mica powder and 1-5 part, glycerin 3-7 parts, olive oil 6-10 part, white beeswax 12-16 parts, rose powder 1-5 parts, flavor 0.2-0.6 part, jojoba oil 9-17; S1, selecting an electronic balance, weighing natural beeswax, cochineal worm red, pearl powder, mica powder, glycerin, olive oil, white beeswax, rose powder, essence and jojoba oil in order according to mass, placing weighed raw materials in separate containers, labeling paper, and standby. As that pearl powder and the mica powder are added into the lipstick, the ingredients are sufficiently mixed, the texture of the lipstick is effectively enhanced, the moisturizing effect of the lipstick is improve, and the lipstick is convenient for people to use.

Owner:纪翠苗

Natural lip balm containing Dendrobium officinale component and preparation method of natural lip balm

ActiveCN111297784ANo side effectsSolve peelingCosmetic preparationsToilet preparationsBiotechnologyRose hip

The invention relates to a natural lip balm containing a Dendrobium officinale component and a preparation method of the natural lip balm. The natural lip balm is prepared from the following components in parts by weight: 100-500 parts of Dendrobium officinale concentrated juice, 200-700 parts of rose hip oil, 1000-1600 parts of white beeswax, 1-5 parts of vitamin E, 100-500 parts of shea butter,100-500 parts of honey and 1-5 parts of vitamin B2. All of the raw materials adopted by the Dendrobium officinale lip balm belong to pure natural plant extracts, so that the lip balm has the functionsof moisturizing, oxidation resistance and the like, does not contain any toxic or harmful chemical substances, does not cause any harm to human health and is wide in application range.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Preservative-free moisturizing cream and preparation method thereof

InactiveCN108078841APrevent intrusionFree from harmCosmetic preparationsToilet preparationsGlycerolMoisture

Owner:SHAANXI BIO REGENERATIVE MEDICINE CO LTD

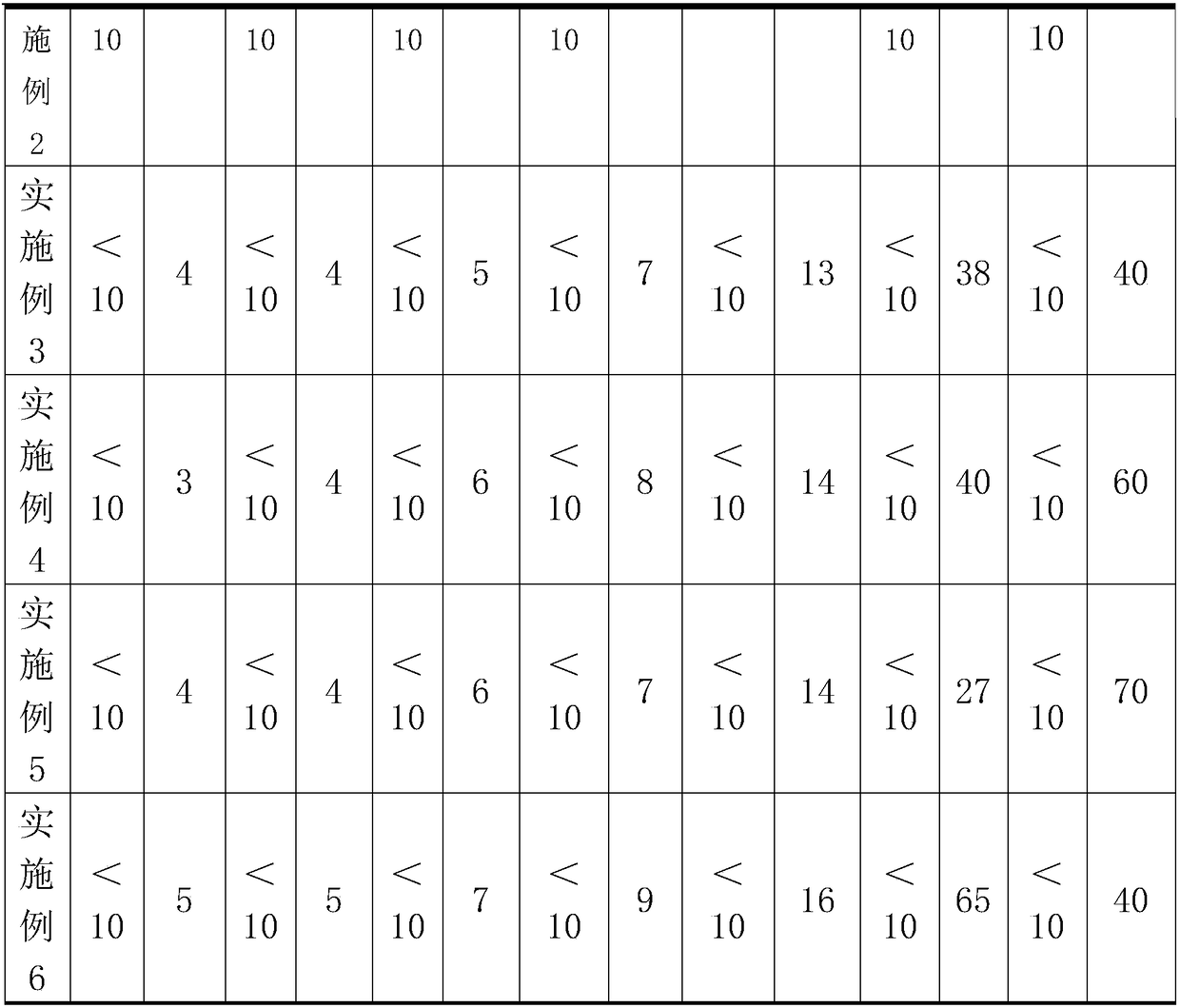

Vitamin D3 soft capsule and preparation method thereof

InactiveCN108403703AImprove stabilityImprove antioxidant capacityOrganic active ingredientsMetabolism disorderAntioxidantSoybean Phospholipids

The invention discloses a vitamin D3 soft capsule which is composed of an inclusion and a capsule skin. The inclusion comprises the following raw materials: vitamin D3, an asparagus extract, corn starch, white beeswax, safflower seed oil, olive oil and soybean phospholipid. The invention also discloses a preparation method of the vitamin D3 soft capsule. The prepared vitamin D3 soft capsule has good stability; through synergistic effect of the asparagus extract and the safflower seed oil, the vitamin D3 soft capsule has good antioxidant property without addition of an artificial synthetic antioxidant, is safe, has no toxicity and has no need for low-temperature storage. Moreover, since the product is made into the soft capsule, the soft capsule is convenient to carry and take, is more convenient to apply in medical and health care, and has social and economic benefits with great prospects.

Owner:桑艳红

A kind of method for preparing tacrolimus ointment

ActiveCN102885761BReduce manufacturing costRapid industrializationOrganic active ingredientsAerosol deliveryMedicineWhite Beeswax

The invention provides a method for preparing a tacrolimus ointment. The method comprises the following steps of: 1, weighing purified tacrolimus, white beeswax, liquid paraffin, paraffin, white Vaseline, propene carbonate and propanediol in the mass ratio of 1:30:40:30:520:10:10; 2, mixing the white beeswax with the liquid paraffin and the paraffin, heating for melting, mixing uniformly to obtain a mixed solution I, and preserving heat at the temperature of 70 DEG C for later use; 3, heating white Vaseline for melting to obtain a white Vaseline solution, and preserving heat at the temperature of 70 DEG C for later use; 4, mixing propanediol and propene carbonate uniformly in the ratio of 1:1 to obtain a mixed solution 2; 5, dissolving tacrolimus into the mixed solution of propanediol and propene carbonate to obtain a mixed solution 3, and preserving heat at the temperature of 70 DEG C for later use; and 6, dispersing the mixed solution 3 into the white Vaseline solution to obtain a mixed solution 4, adding the mixed solution 4 into the mixed solution I to obtain a solution 5, stirring at the temperature of 70 DEG C for 10 minutes, cooling, and continually stirring till the solution 5 is condensed into an ointment.

Owner:ZHEJIANG WAN SHENG PHARMA CO LTD

Preparation method of natural biomass carbon dots lipstick

InactiveCN110251407ASlow changeImprove stabilityCosmetic preparationsMake-upWater bathsBiomass carbon

The invention relates to the technical field of nano materials, in particular to a preparation method of a natural biomass carbon dots lipstick. The invention provides the preparation method of the natural biomass carbon dots lipstick, and the method includes the following steps: step 1. mixing and grinding a first humectant and pigment to obtain a first humectant containing pigment; step 2. mixing a second humectant and white beeswax and heating in a water bath to obtain a first mixture; step 3. adding the first mixture in the step 2 into the first humectant containing pigment, and continuously stirring until the mixture is uniformly mixed to obtain a second mixture; and step 4. adding an antioxidant into the second mixture obtained in the step 3, uniformly stirring, pouring into a mold, cooling, molding, and demolding to obtain the natural biomass carbon dots lipstick, wherein the pigment powder solution is a red pigment powder solution of pitaya peel with carbon dots. The invention provides the preparation method of the natural biomass carbon dots lipstick, which solves the technical problems that natural pigments in existing cosmetics are easy to degrade and fade, and application is limited.

Owner:GUANGDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com