Vitamin D3 soft capsule and preparation method thereof

A technology of vitamins and soft capsules, which is applied in capsule delivery, pharmaceutical formulations, medical preparations containing active ingredients, etc. It can solve the problems of single vitamin D products, inconvenient carrying and taking, and the need for refrigerator storage, etc., and achieve huge social and economic benefits. Benefits, good antioxidant properties, easy application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

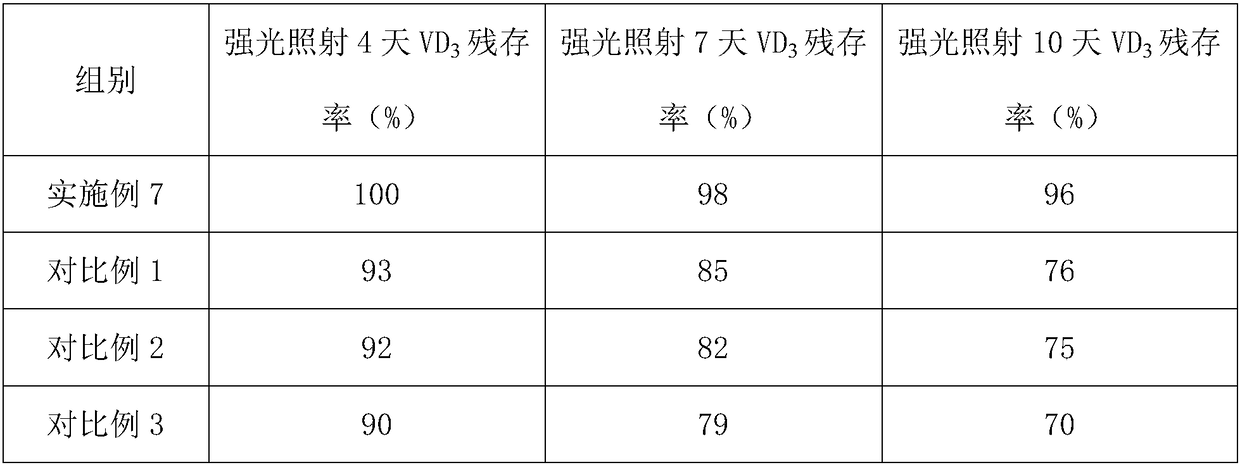

Examples

Embodiment 1

[0027] A vitamin D3 soft capsule, consisting of contents and a capsule skin, the contents include the following raw materials in parts by weight: 25 parts of vitamin D3, 1 part of asparagus extract, 1 part of cornstarch, 0.4 part of white beeswax, 4 parts safflower oil, 25 parts olive oil, 0.5 part soybean lecithin. Wherein, the preparation method of the asparagus extract is to wash the asparagus, then put it into a steam pressure cooker, add an appropriate amount of deionized water for high-temperature and high-pressure extraction, the pressure of the high-temperature and high-pressure extraction is 0.7MPa, and the time is 35min. Concentrate under reduced pressure to obtain the asparagus extract; the capsule skin includes the following raw materials in parts by weight: 11 parts of gelatin, 3 parts of glycerin, 0.01 part of sweetener, and 1 part of walnut oil; the sweetener is wood sugar alcohol.

[0028] In the present embodiment, the preparation method of the vitamin D3 sof...

Embodiment 2

[0035] A vitamin D3 soft capsule, consisting of contents and a capsule skin, the contents include the following raw materials in parts by weight: 45 parts of vitamin D3, 8 parts of asparagus extract, 8 parts of cornstarch, 3 parts of white beeswax, 15 parts safflower oil, 45 parts olive oil, 4 parts soybean lecithin. Wherein, the preparation method of the asparagus extract is to wash the asparagus, then put it into a steam pressure cooker, add an appropriate amount of deionized water to carry out high-temperature and high-pressure extraction, the pressure of the high-temperature and high-pressure extraction is 0.7MPa, and the time is 35min. Concentrate under reduced pressure to obtain the asparagus extract; the capsule skin includes the following raw materials in parts by weight: 11 parts of gelatin, 3 parts of glycerin, 0.01 part of sweetener, 1 part of walnut oil; the sweetener is wood sugar alcohol.

[0036] In the present embodiment, the preparation method of the vitamin ...

Embodiment 3

[0043] A vitamin D3 soft capsule, consisting of contents and a capsule skin, the contents include the following raw materials in parts by weight: 35 parts of vitamin D3, 4.5 parts of asparagus extract, 4.5 parts of cornstarch, 1.7 parts of white beeswax, 9.5 parts safflower oil, 35 parts olive oil, 2.3 parts soybean lecithin. Wherein, the preparation method of the asparagus extract is to wash the asparagus, then put it into a steam pressure cooker, add an appropriate amount of deionized water to carry out high-temperature and high-pressure extraction, the pressure of the high-temperature and high-pressure extraction is 0.7MPa, and the time is 35min. Concentrate under reduced pressure to obtain the asparagus extract; the capsule skin includes the following raw materials in parts by weight: 11 parts of gelatin, 3 parts of glycerin, 0.01 part of sweetener, 1 part of walnut oil; the sweetener is wood sugar alcohol.

[0044] In the present embodiment, the preparation method of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com