Patents

Literature

64results about How to "Rapid industrialization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

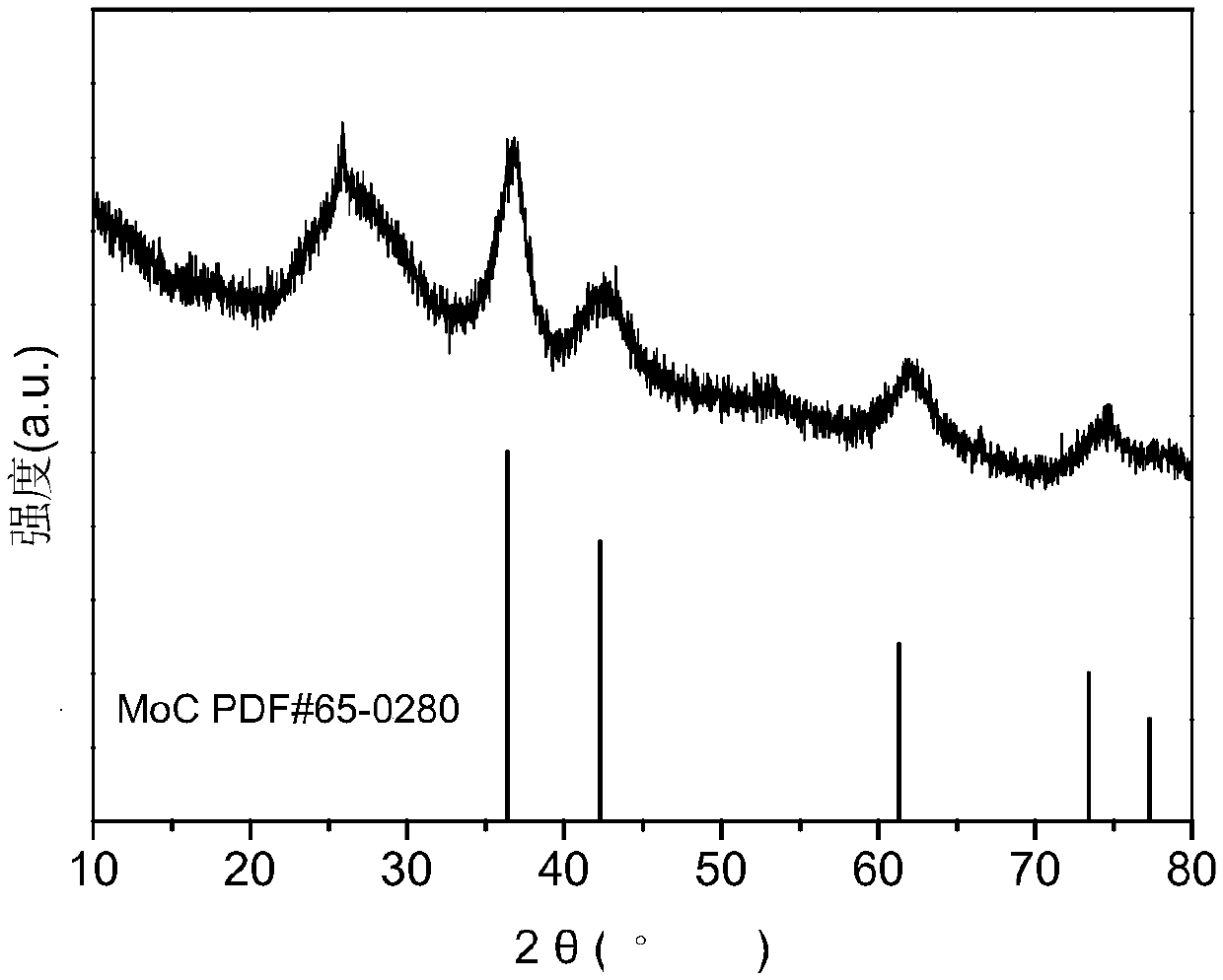

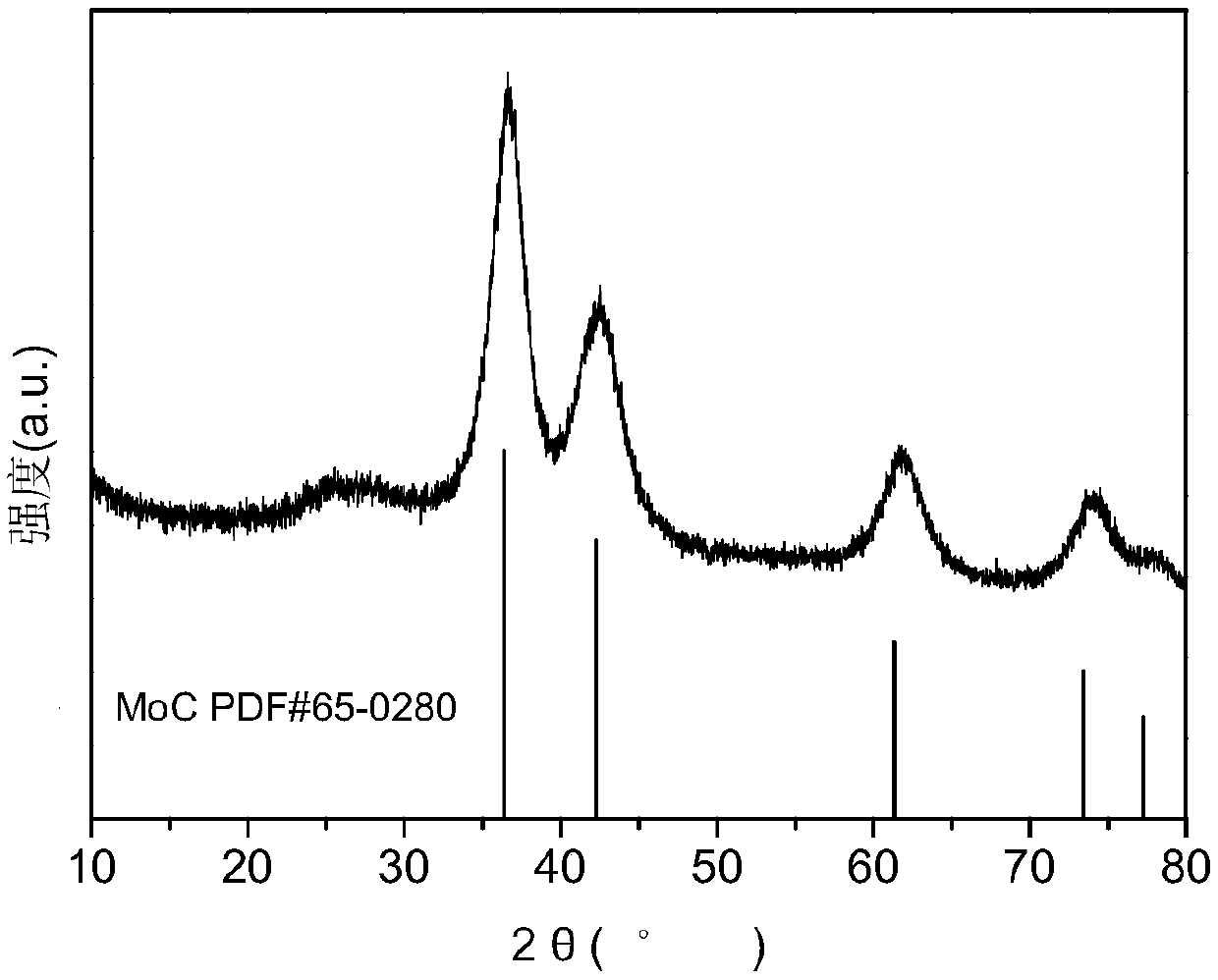

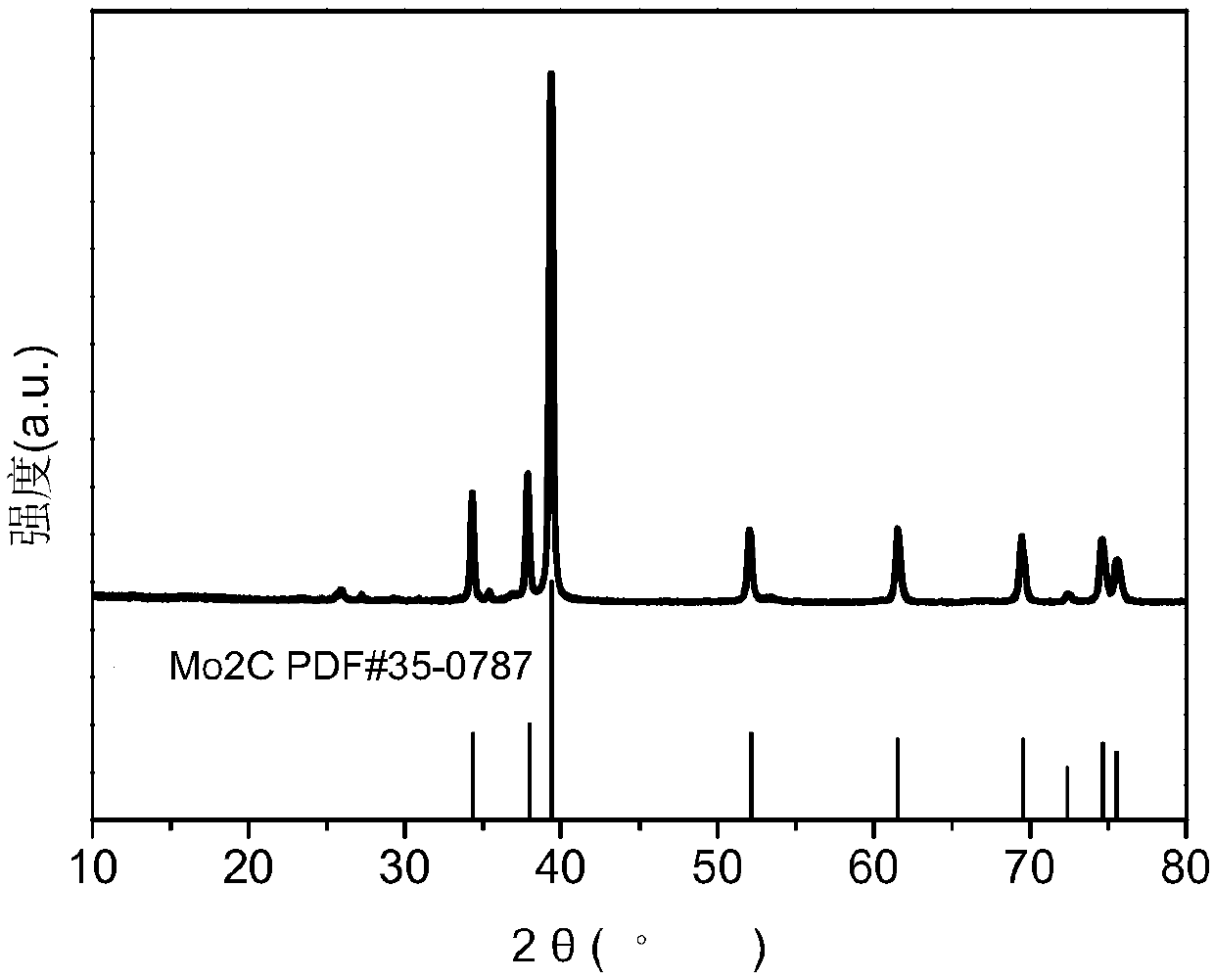

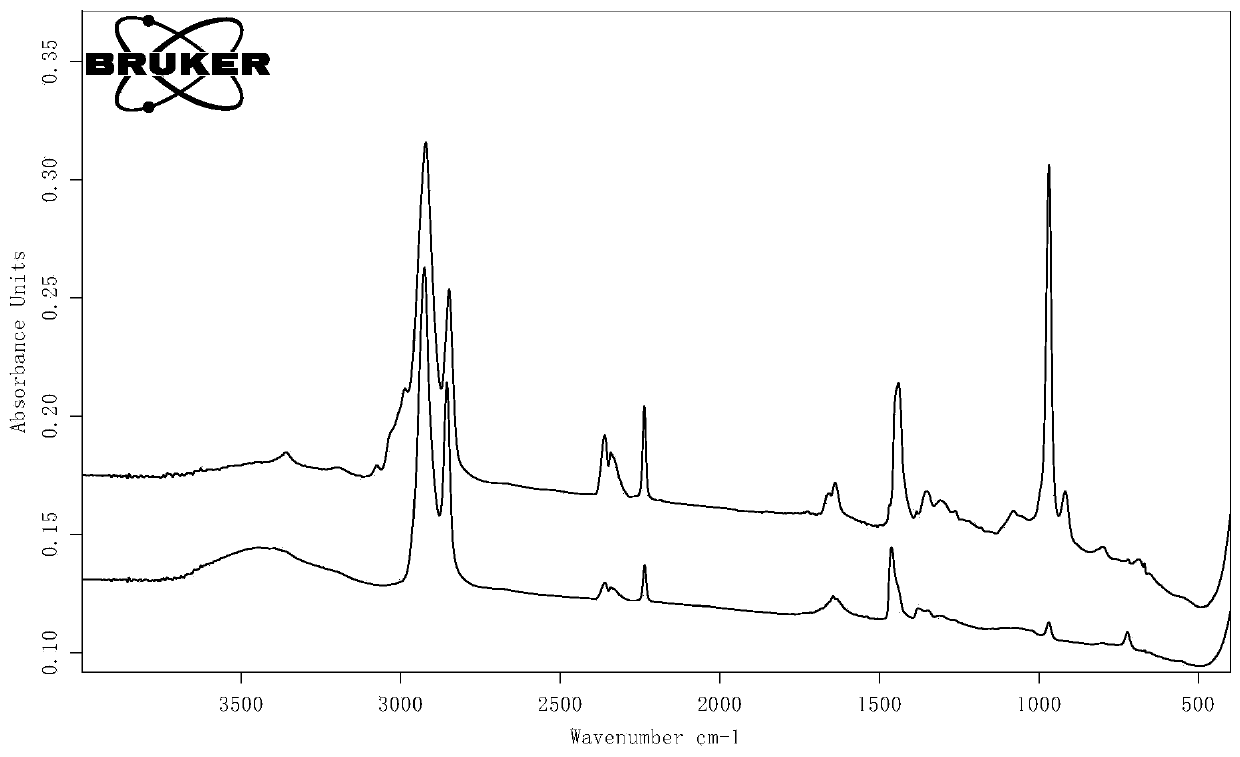

Three-dimensional mesoporous carbon-loaded molybdenum carbide and preparation method and application thereof

ActiveCN109621998AAchieving controllable synthesisNovel structurePhysical/chemical process catalystsElectrodesCarbonizationMolybdenum carbide

The invention belongs to the field of preparation of nanomaterials and discloses three-dimensional mesoporous carbon-loaded molybdenum carbide and a preparation method and application thereof. The preparation method comprises the following steps of dissolving a soluble molybdenum salt in water, adding an organic carbon source and a template agent, adjusting the pH value of the solution to be 0-7.0, stirring and evaporating the solution to obtain gel, further dehydrating the gel to obtain xerogel, and calcining the xerogel at the high temperature in the atmosphere of inert gas or reducing gas;carbonizing the organic carbon source to obtain carbon, reducing and carbonizing molybdenum through reducing substances generated in the carbonization process of the organic carbon source to obtain nano molybdenum carbide, soaking nano molybdenum carbide in dilute acid to remove impurities, and then obtaining a target product. Compared with a bulk molybdenum carbide material, the three-dimensionalmesoporous carbon-loaded molybdenum carbide has the advantages that a conductive three-dimensional carbon network structure is obtained, the specific surface area is greater, more reactive sites aregenerated, a carbon-loaded structure prevents molybdenum carbide from agglomerating during high-temperature calcination, and therefore three-dimensional mesoporous carbon-loaded molybdenum carbide hasexcellent electrocatalytic performance.

Owner:SOUTH CHINA AGRI UNIV

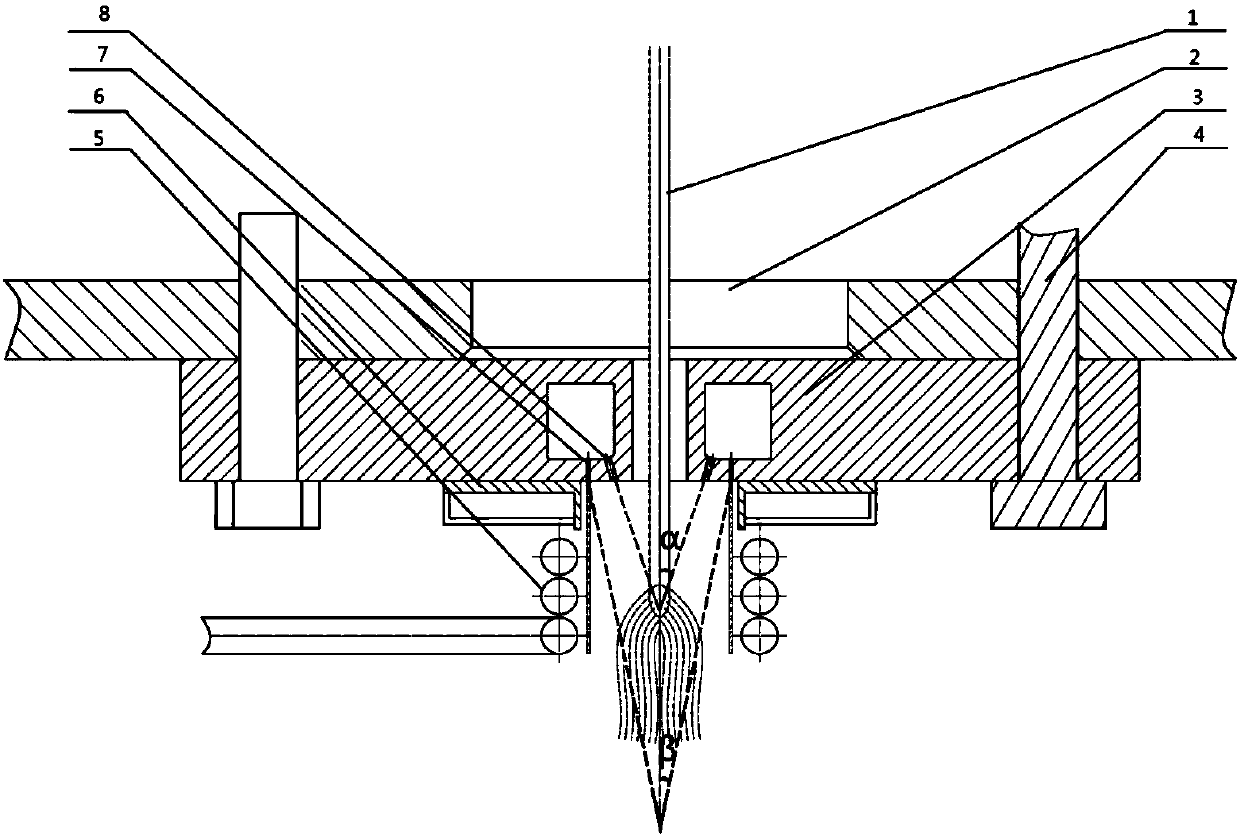

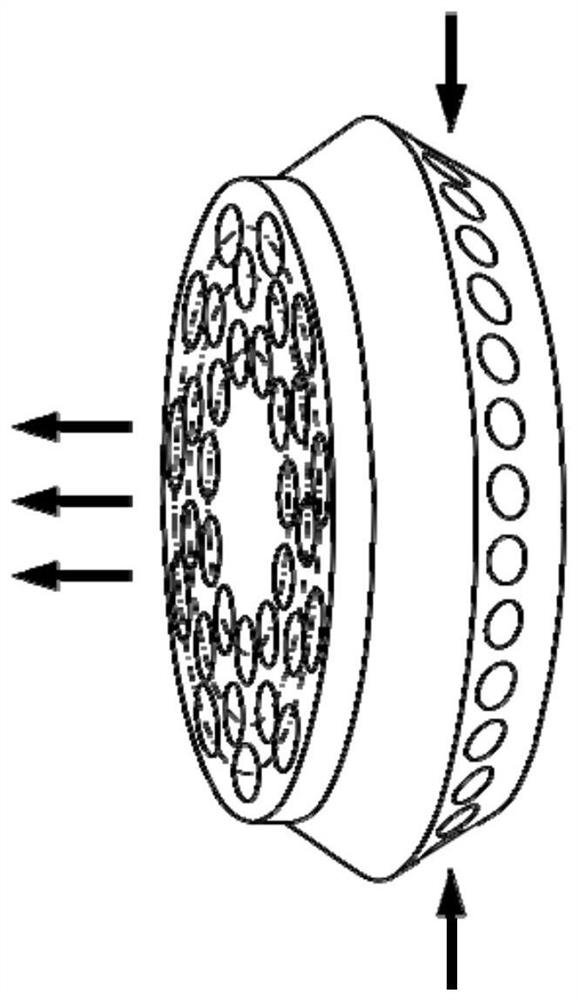

Device and method for continuously preparing titanium or titanium alloy powder for 3D printing through gas atomization

ActiveCN107900366AIncrease productivityReduce lossesAdditive manufacturing apparatusHeat lossesTitanium

The invention relates to a device and a method for continuously preparing a titanium or titanium alloy powder for 3D printing through gas atomization. The device comprises an atomization spray disc fixing top plate, an atomization spray disc, an electromagnetic shielding ring and a high-frequency induction coil from top to bottom, wherein the atomization spray disc and the fixing top plate are fixed through a fixing bolt; continuous conveying feeding holes for a titanium or titanium alloy wire material are formed in the central positions of the atomization spray disc fixing top plate and the atomization spray disc; the atomization spray disc and the electromagnetic shielding ring are coaxially installed about the axes of the conveying feeding holes; the atomization spray disc comprises a main atomization gas flow nozzle and auxiliary protection gas flow nozzles; and atomization gas flow sprayed out via the main atomization gas flow nozzle is collected on the wire material to form an atomization centre, and the atomization centre is superposed with a melting centre formed due to the heating of the high-frequency induction coil for the end part of the wire material. Therefore, melting flow is immediately limited and atomized by the main atomization gas flow after being generated, so that a superheating degree is furthest ensured, heat loss is reduced, and a high fine powder yieldof titanium or titanium alloy atomization is realized.

Owner:BEIJING COMPO ADVANCED TECH

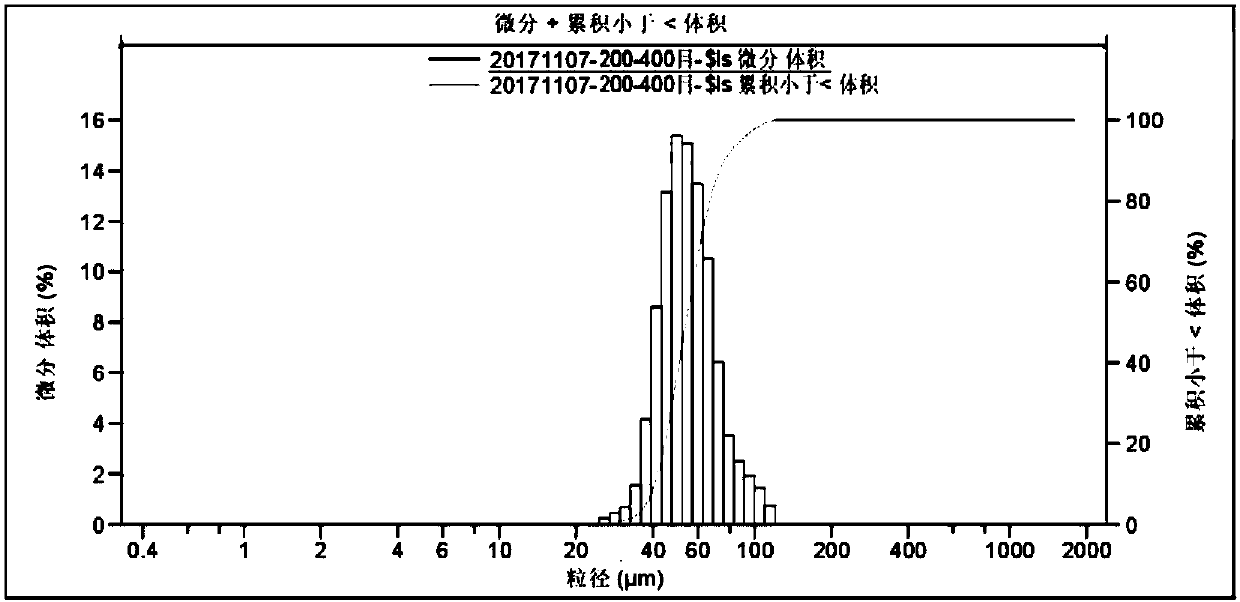

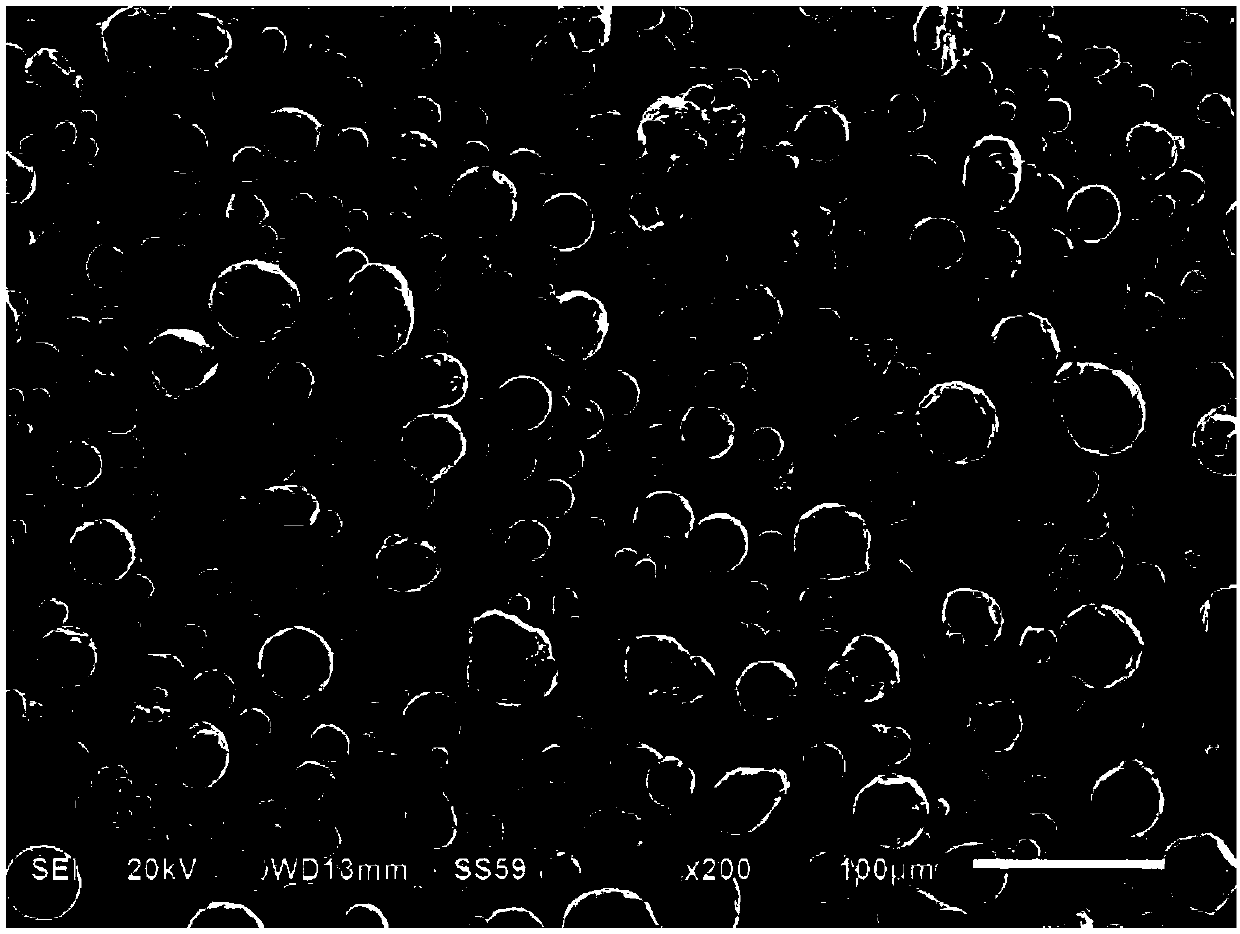

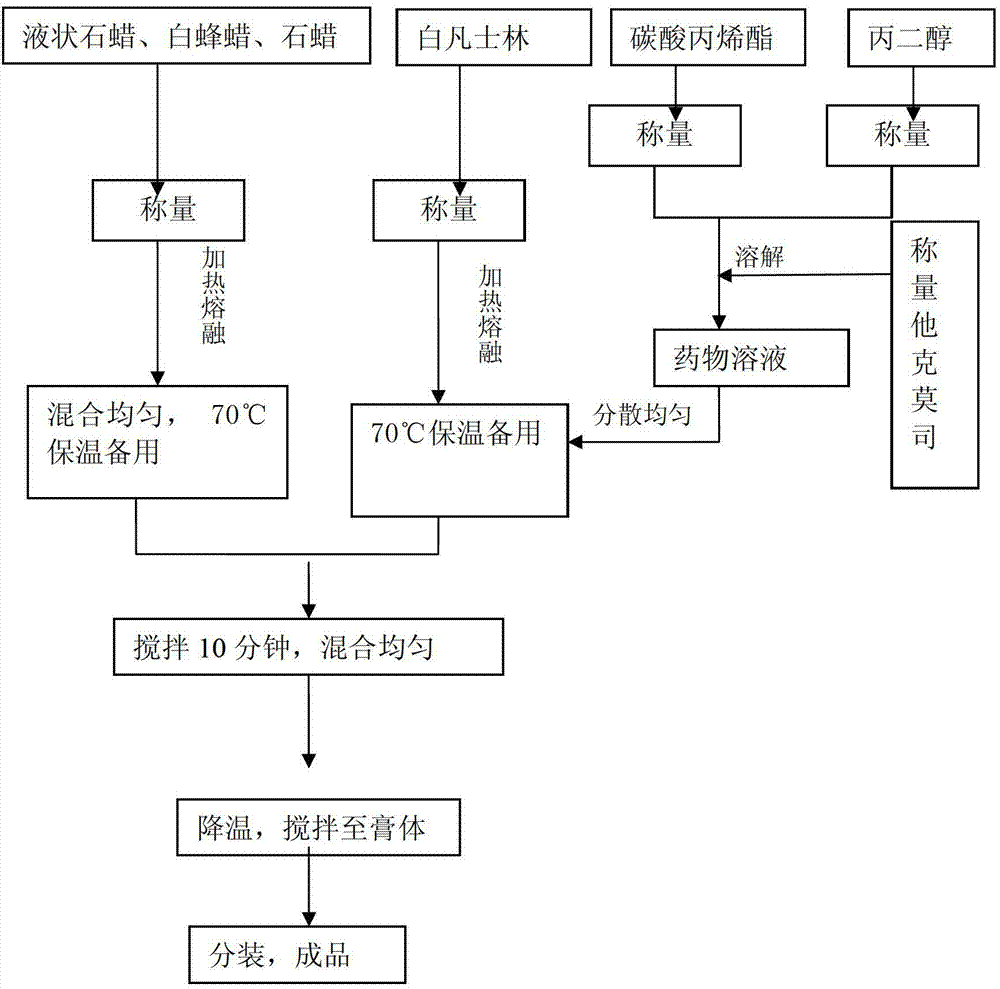

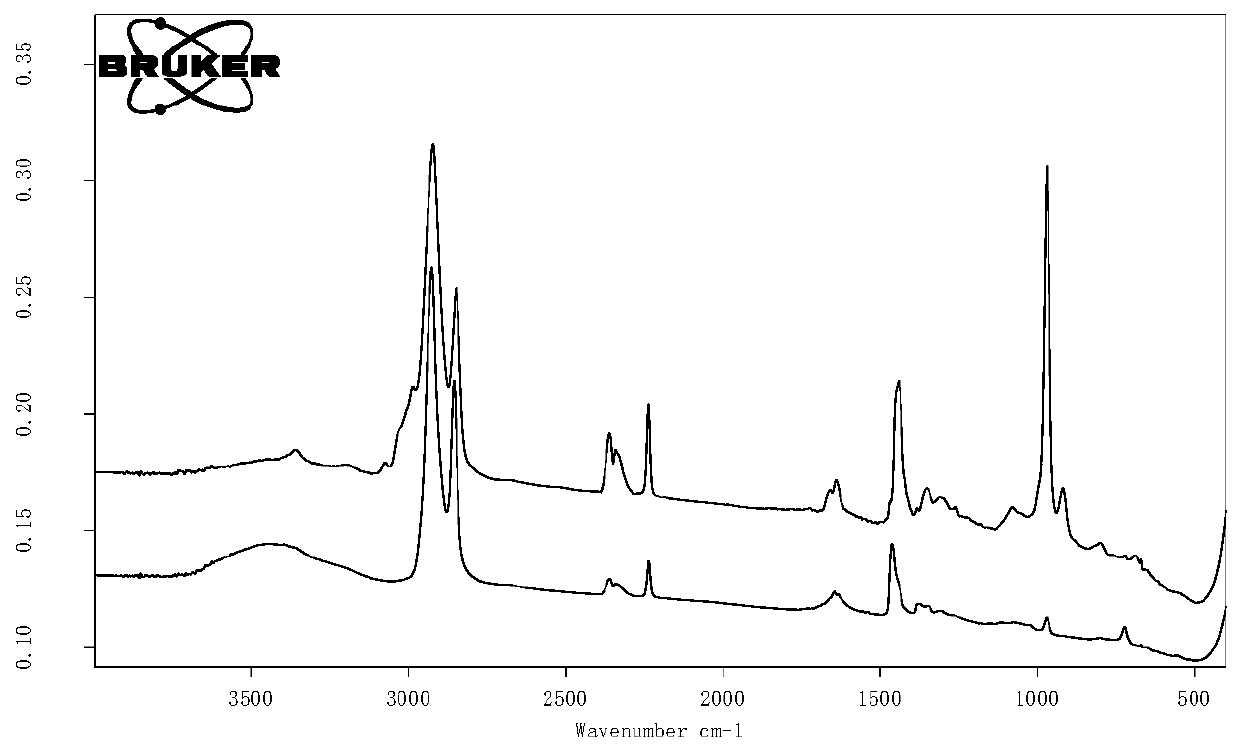

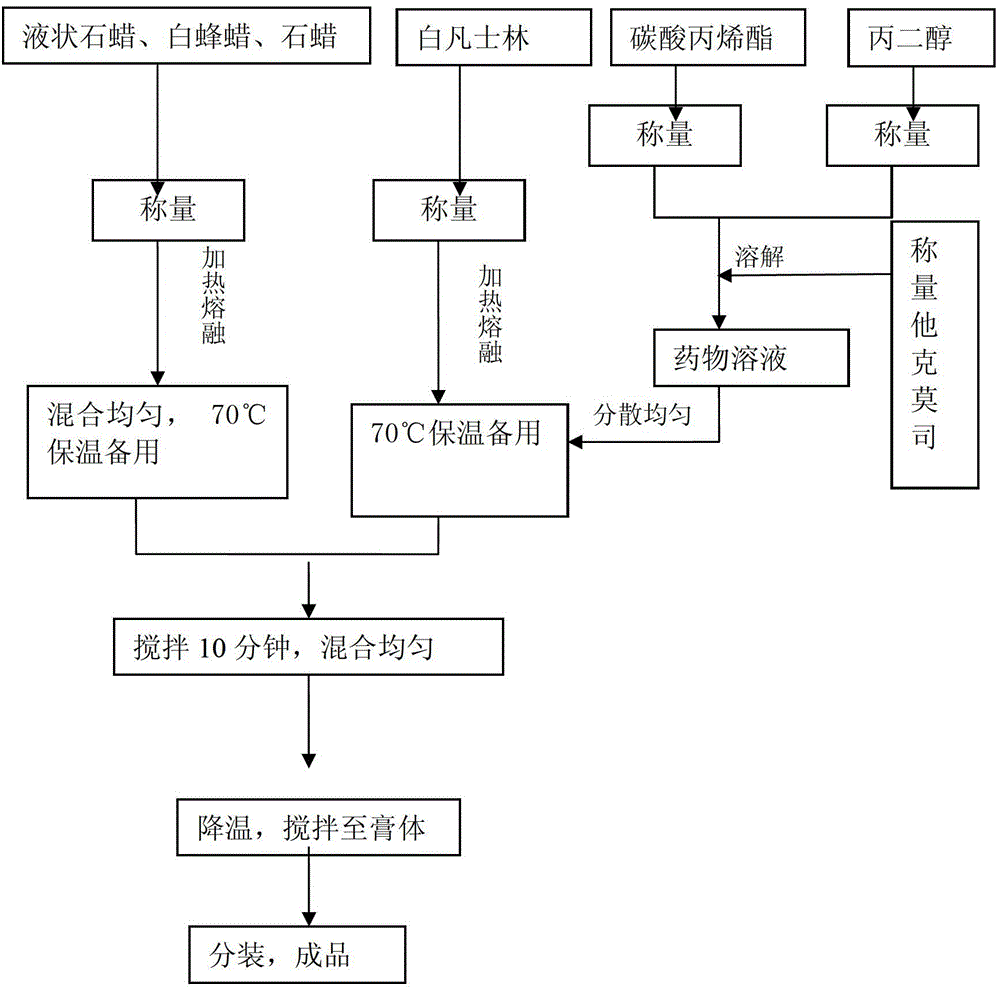

Method for preparing tacrolimus ointment

ActiveCN102885761AReduce manufacturing costRapid industrializationOrganic active ingredientsAerosol deliveryPhysical chemistryWhite Beeswax

The invention provides a method for preparing a tacrolimus ointment. The method comprises the following steps of: 1, weighing purified tacrolimus, white beeswax, liquid paraffin, paraffin, white Vaseline, propene carbonate and propanediol in the mass ratio of 1:30:40:30:520:10:10; 2, mixing the white beeswax with the liquid paraffin and the paraffin, heating for melting, mixing uniformly to obtain a mixed solution I, and preserving heat at the temperature of 70 DEG C for later use; 3, heating white Vaseline for melting to obtain a white Vaseline solution, and preserving heat at the temperature of 70 DEG C for later use; 4, mixing propanediol and propene carbonate uniformly in the ratio of 1:1 to obtain a mixed solution 2; 5, dissolving tacrolimus into the mixed solution of propanediol and propene carbonate to obtain a mixed solution 3, and preserving heat at the temperature of 70 DEG C for later use; and 6, dispersing the mixed solution 3 into the white Vaseline solution to obtain a mixed solution 4, adding the mixed solution 4 into the mixed solution I to obtain a solution 5, stirring at the temperature of 70 DEG C for 10 minutes, cooling, and continually stirring till the solution 5 is condensed into an ointment.

Owner:ZHEJIANG WAN SHENG PHARMA CO LTD

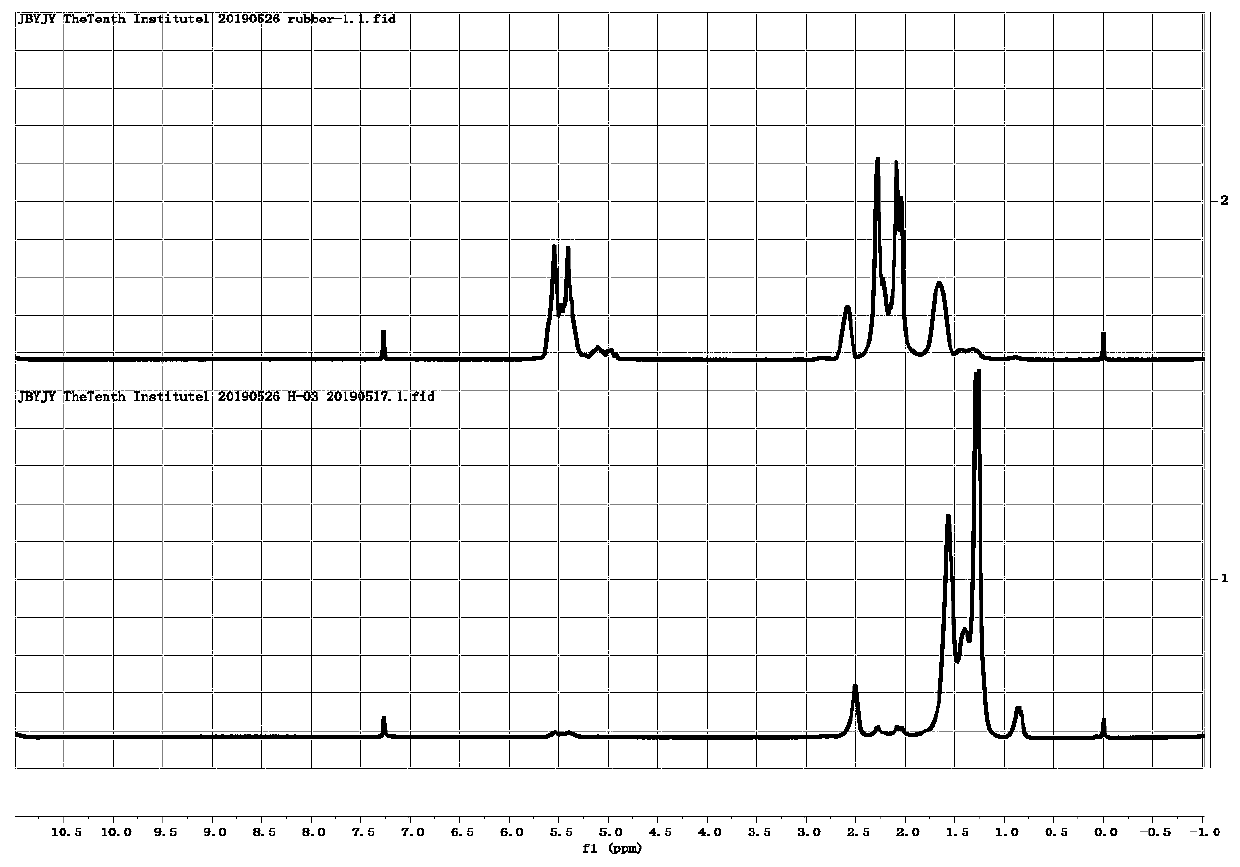

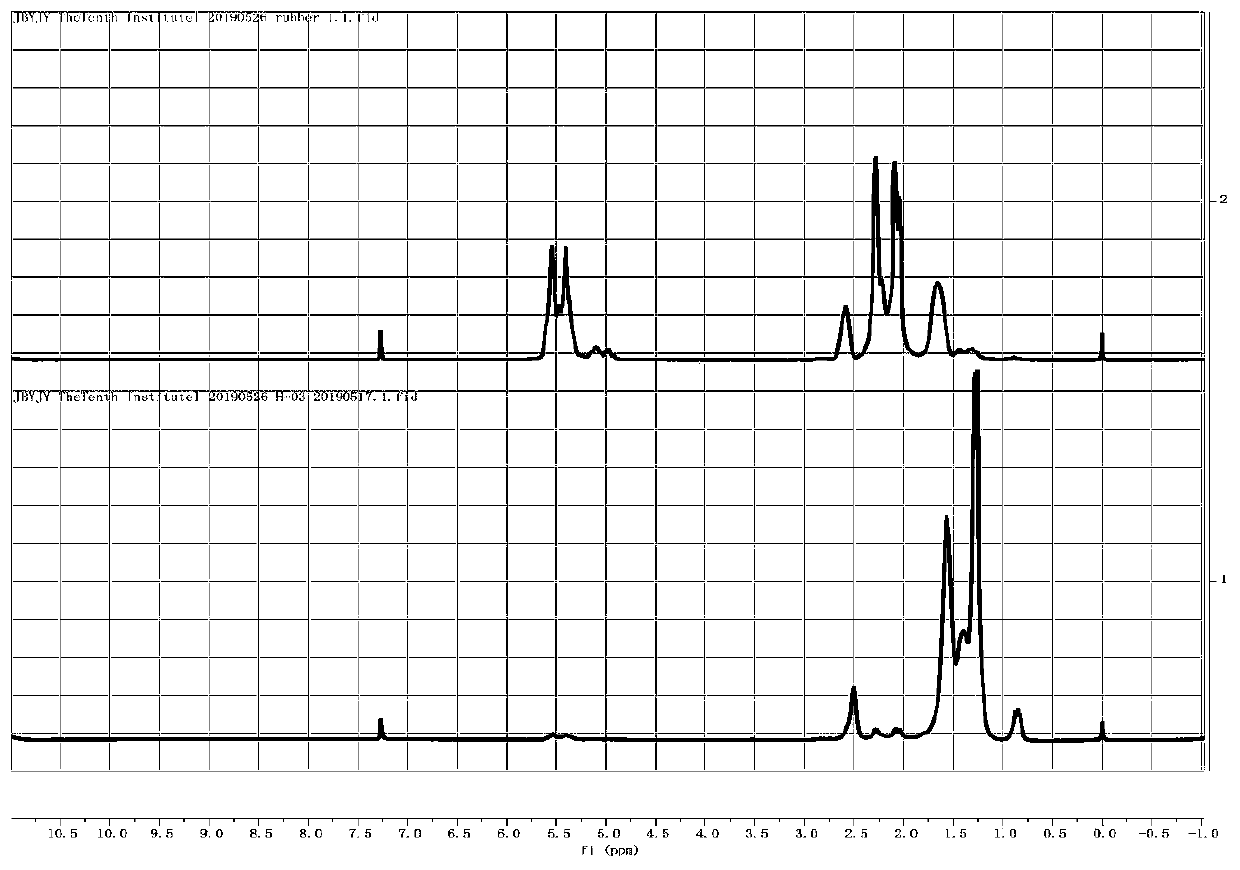

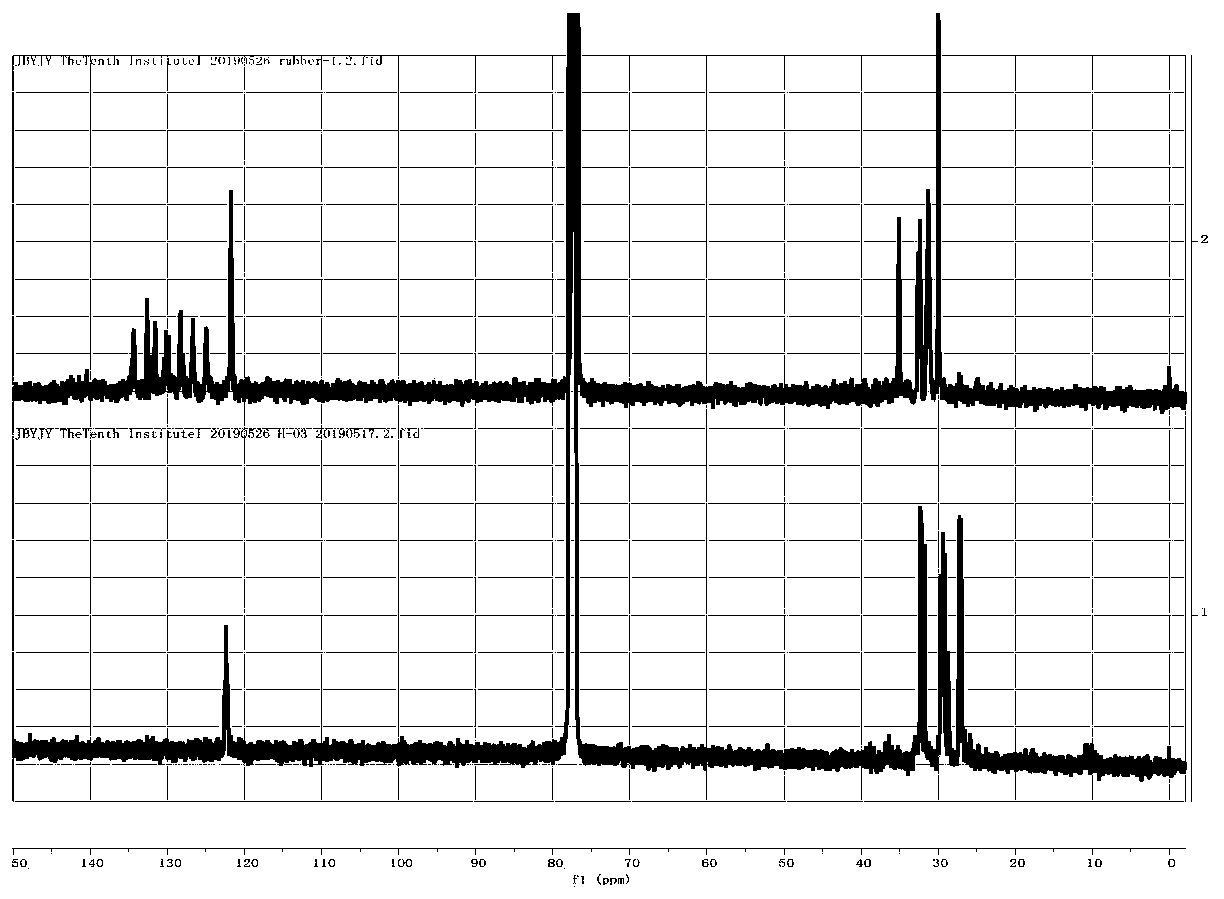

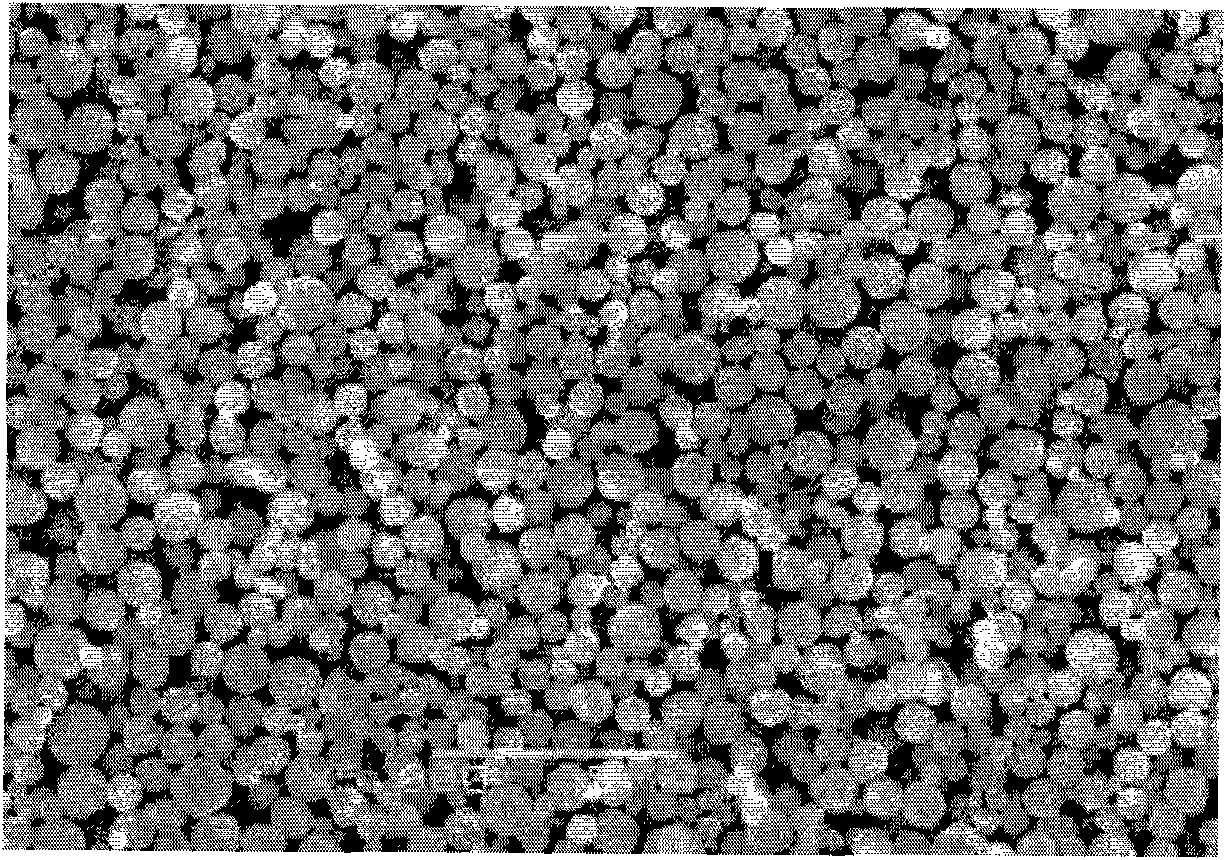

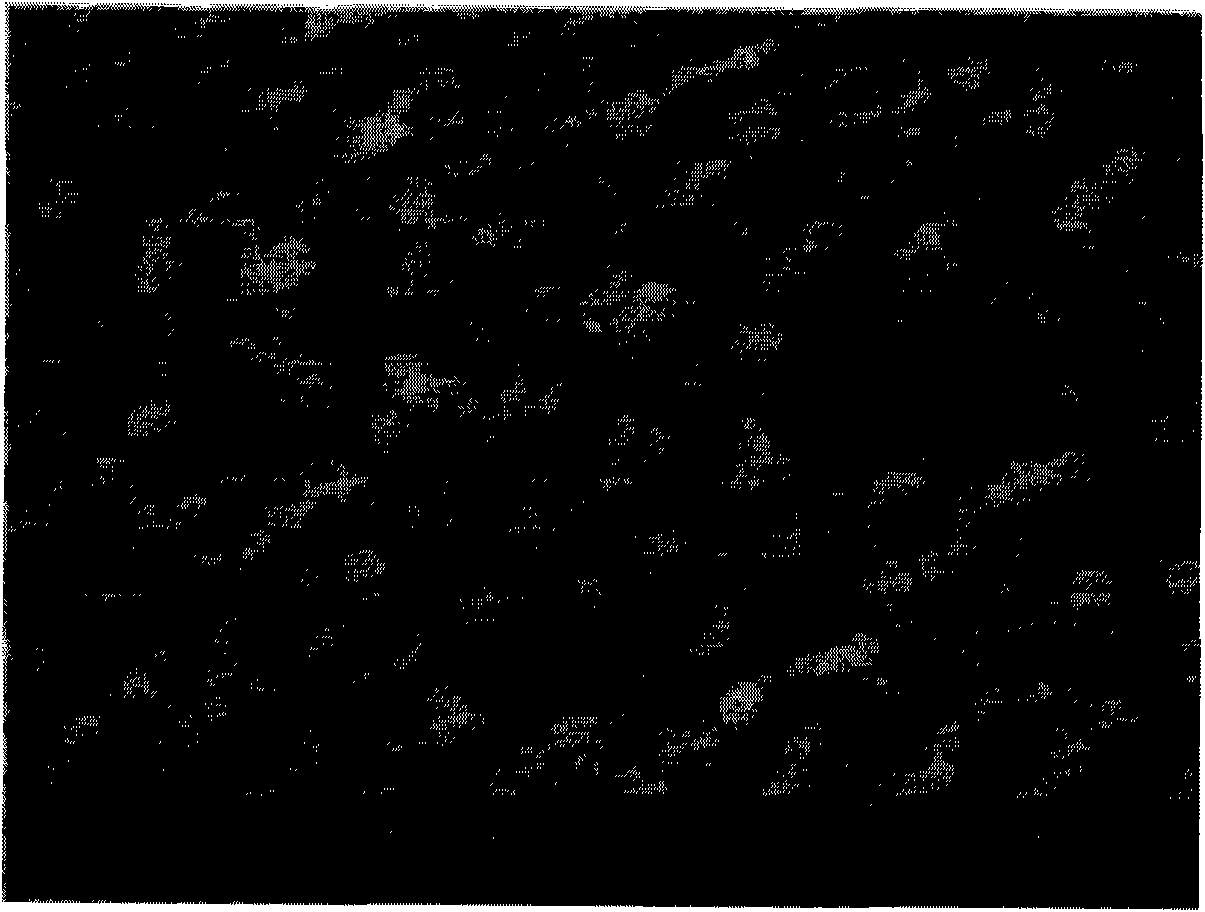

Method for producing hydrogenated copolymer through hydrogenation of conjugated diene

ActiveCN110627928AEfficient realization of selective hydrogenation reactionReduce dosageHydrogenation reactionHydrogen pressure

The invention provides a method for producing a hydrogenated copolymer through hydrogenation of conjugated diene. The method for producing the hydrogenated copolymer through hydrogenation of the conjugated diene comprises the following steps: (1) mixing part of conjugated diene latex and a Hoveyda-Grubbs II catalyst to obtain a mixture A; (2) mixing the rest of conjugated diene latex, the mixtureA and assistants to obtain a mixture B, wherein the assistants are potassium oleate and / or sodium oleate; (3) introducing hydrogen into the mixture B for stirring and degassing treatment, and then conducting stirring treatment continuously to obtain a mixture C; and (4) heating the mixture C, and improving hydrogen pressure for a hydrogenation reaction to obtain the hydrogenated copolymer. According to the method for producing the hydrogenated copolymer through hydrogenation of the conjugated diene, through a mixing mode where the conjugated diene latex and the Hoveyda-Grubbs II catalyst are added in batches, introduction of the specific assistants, and a treatment method where the hydrogen is adopted for degassing treatment in advance, and stirring is conducted after degassing treatment is conducted, the selective hydrogenation reaction of the conjugated diene can be efficiently achieved without solvents to obtain a product with a high hydrogenation degree.

Owner:SHANDONG JINGBO PETROCHEM +2

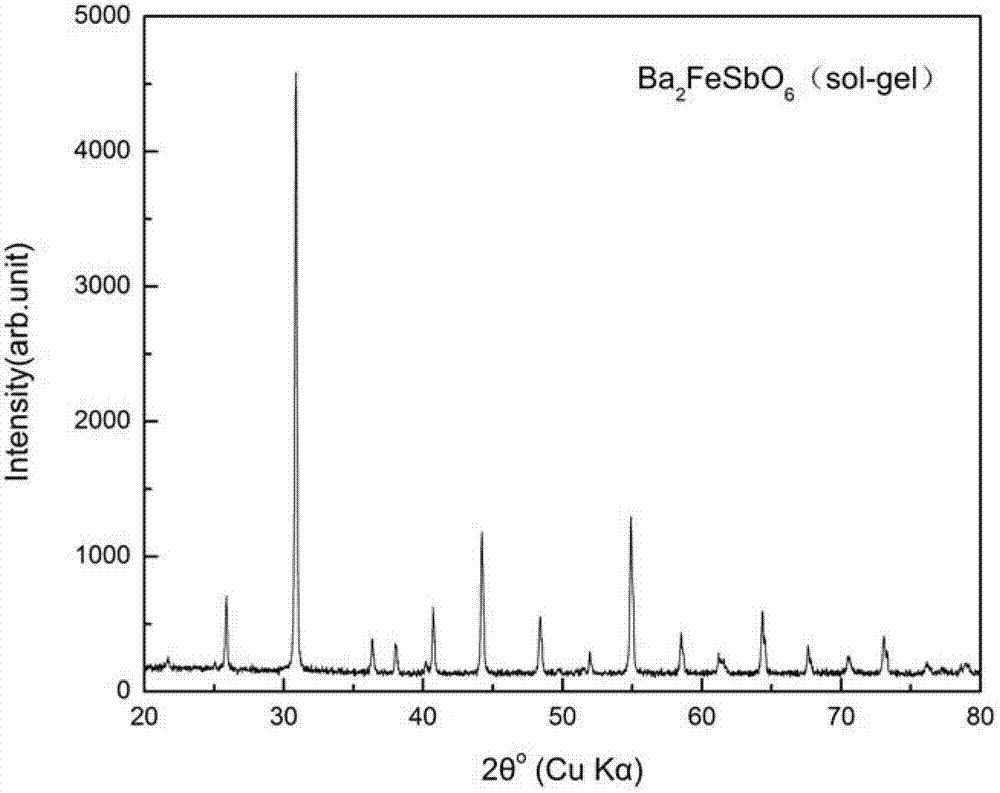

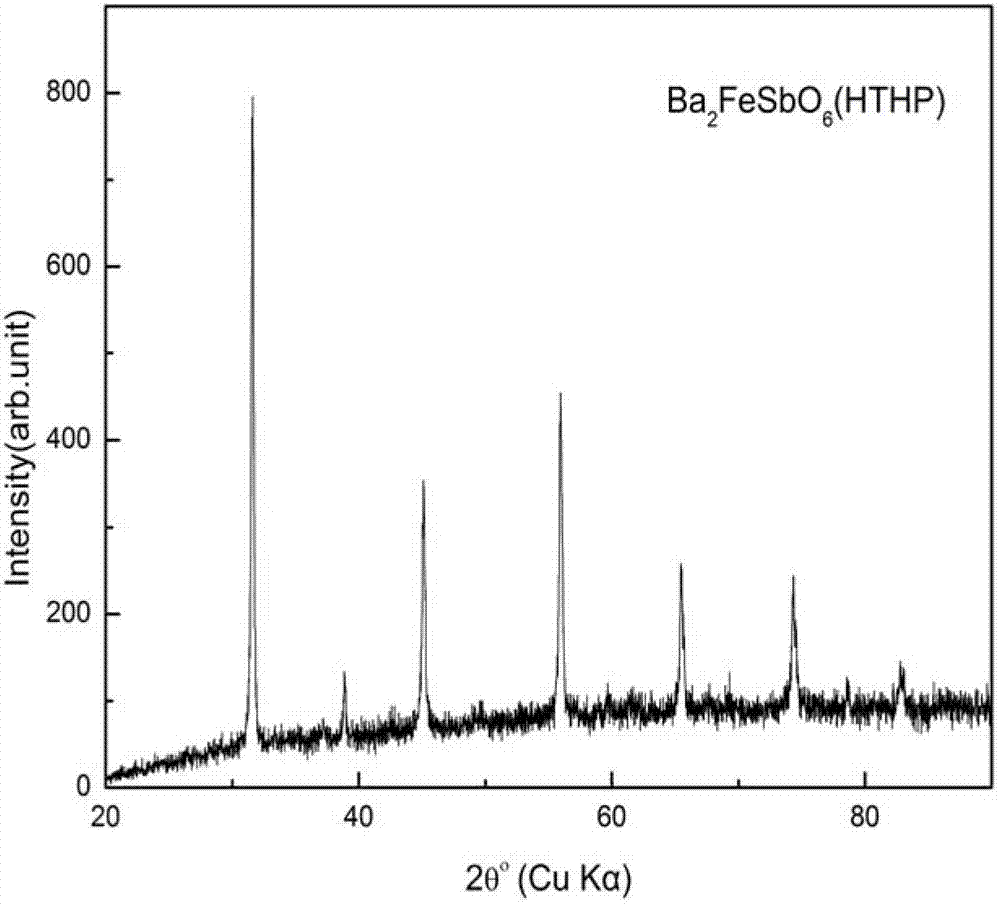

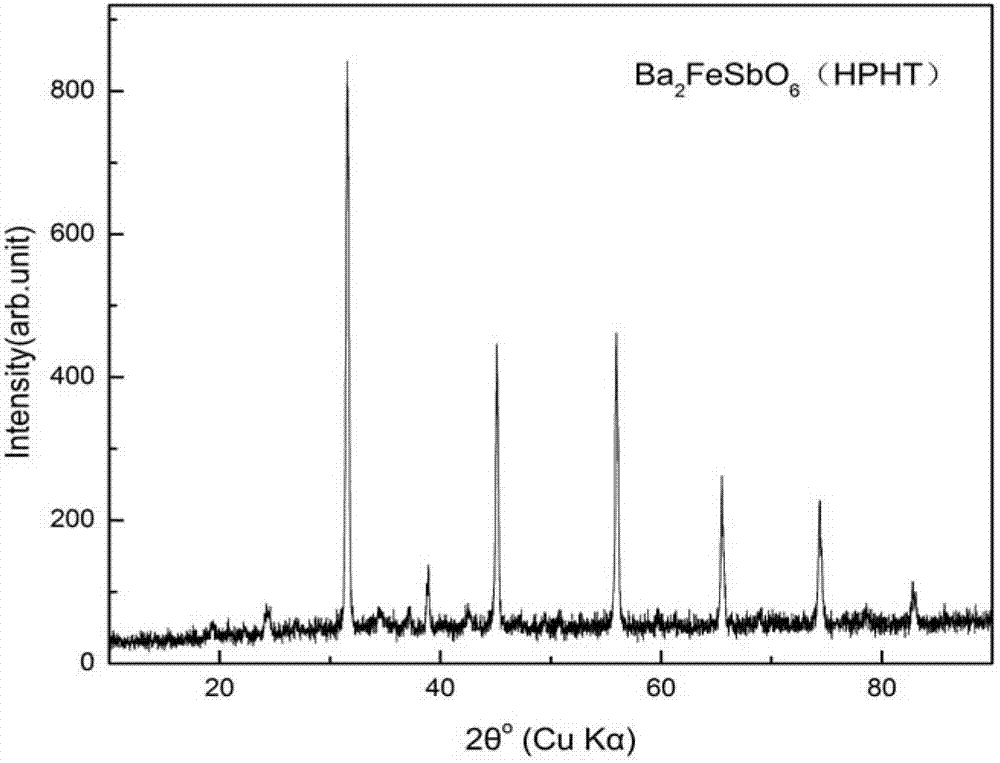

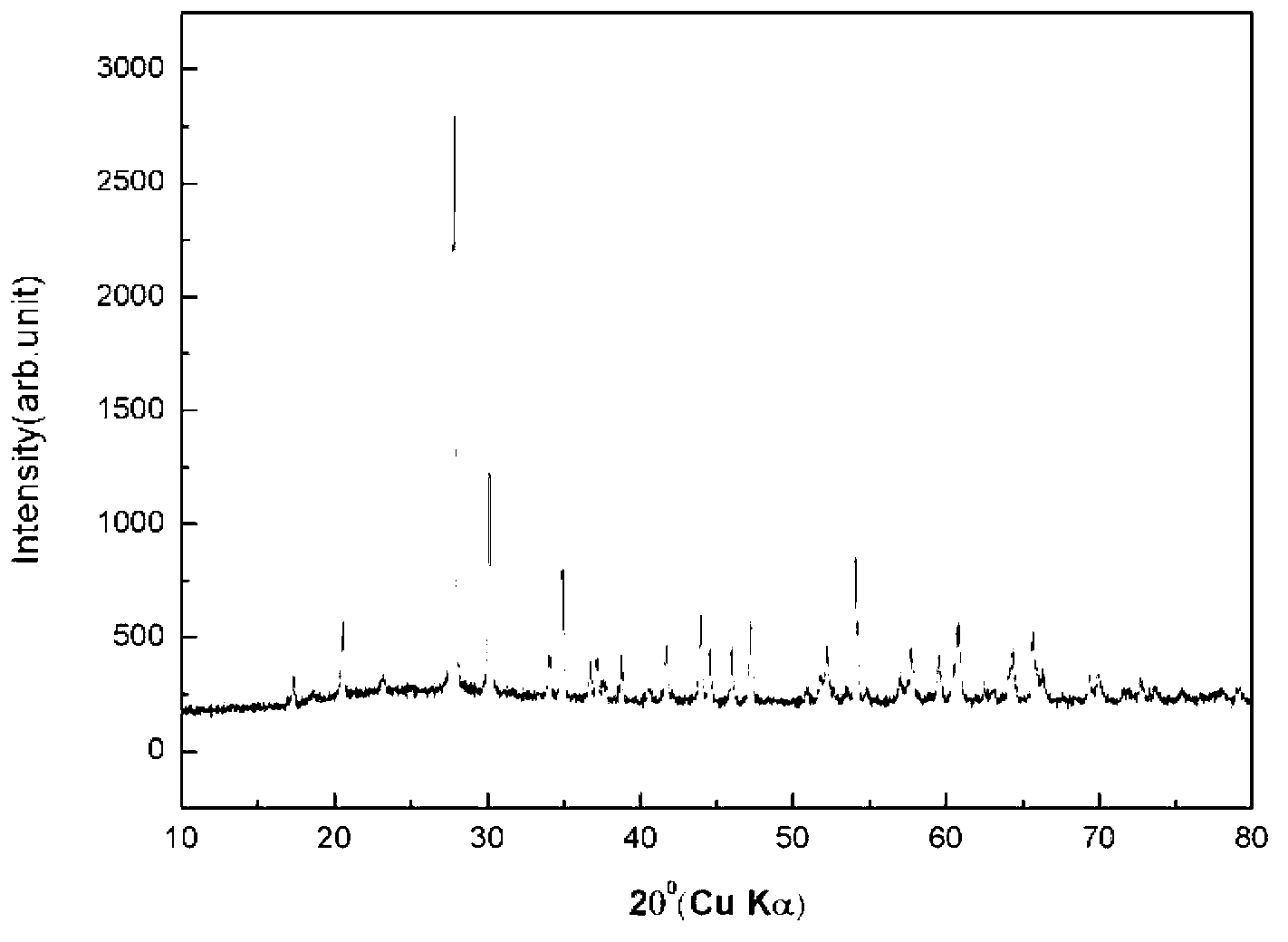

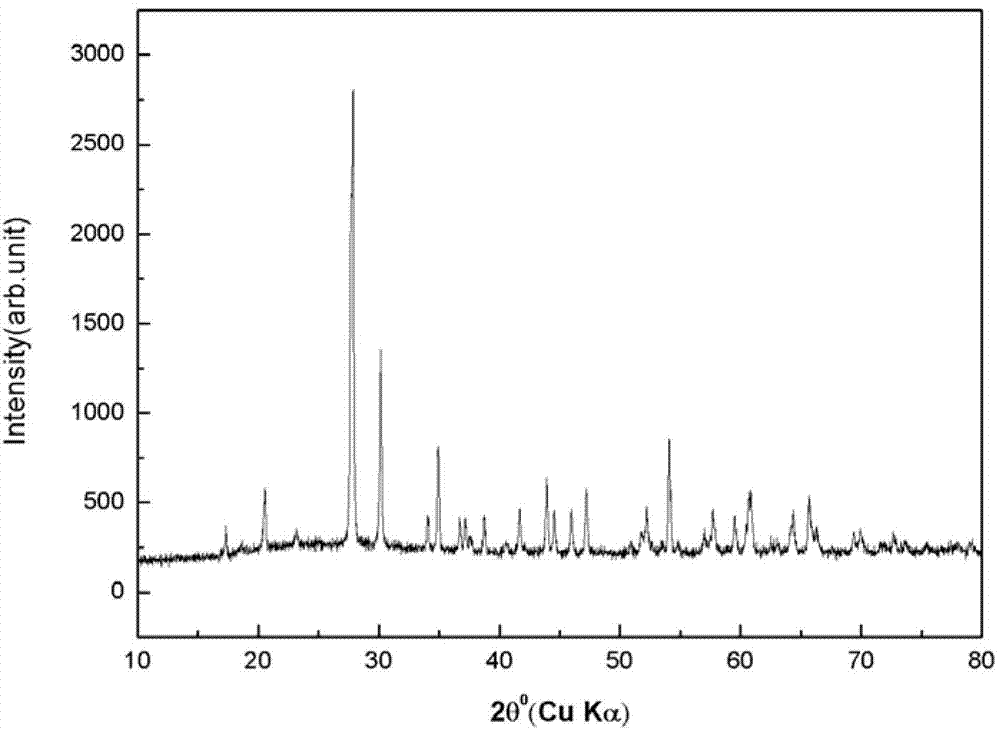

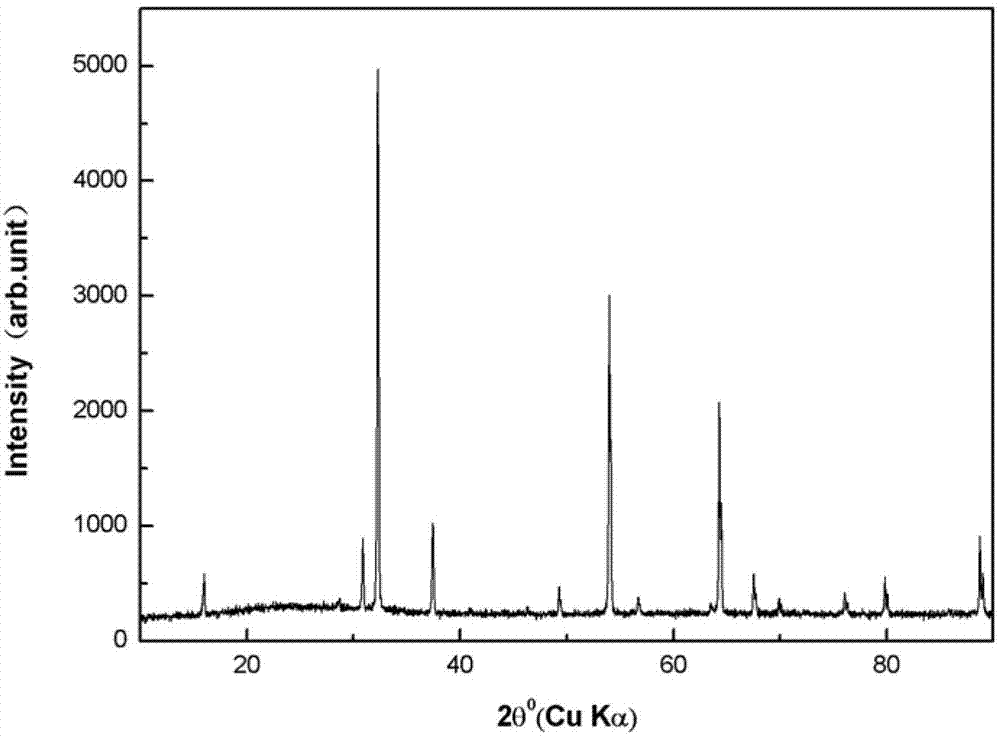

High-temperature and high-pressure preparation method for cubic phase barium-iron-antimony oxide

InactiveCN102897845AWell mixedSmall particle sizeIron oxides/hydroxidesAntimony trioxideHigh pressure

The invention discloses a high-temperature and high-pressure preparation method for a cubic phase barium-iron-antimony oxide, and belongs to the technical field of preparation of low field magneto-resistance materials. Barium nitrate, ferric nitrate and antimony trioxide are used as raw materials; the method comprises the process of preparation of a precursor and high-temperature and high-pressure synthesis; the precursor is prepared by mixing raw materials through a sol-gel method; and according to the high-temperature and high-pressure synthesis, heat and pressure are preserved for 1 to 2 hours under the pressure of 5GPa and at the temperature of between 1,100 and 1,300 DEG C, and cooling and pressure relief are carried out to obtain a Ba2FeSbO6 material with a cubic structure. According to the method, the precursor is prepared by using the sol-gel method, so that the reactants are mixed uniformly, and the purity of the final product is high; by adopting the conventional high-temperature and high-pressure equipment, the method is easy to operate and can quickly implement industrialization; and the obtained high-quality barium-iron-antimony oxide is a cubic phase material.

Owner:JILIN UNIV

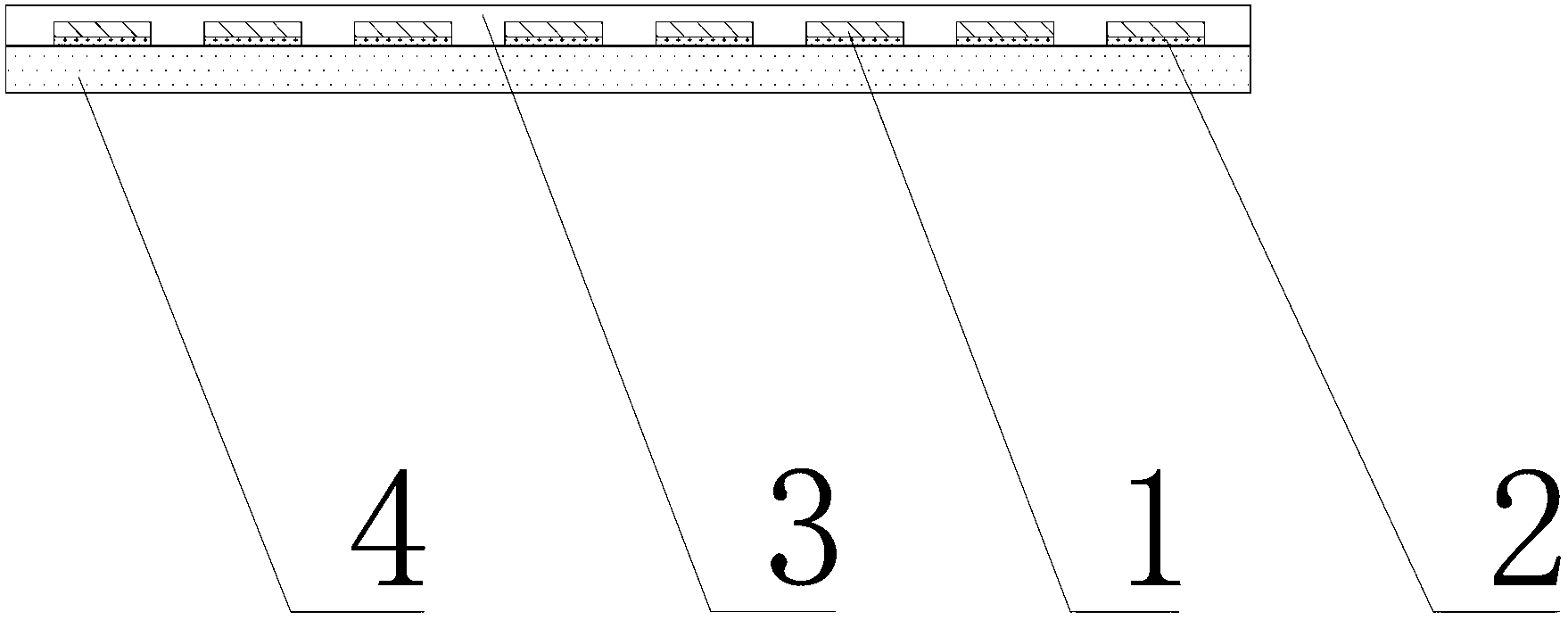

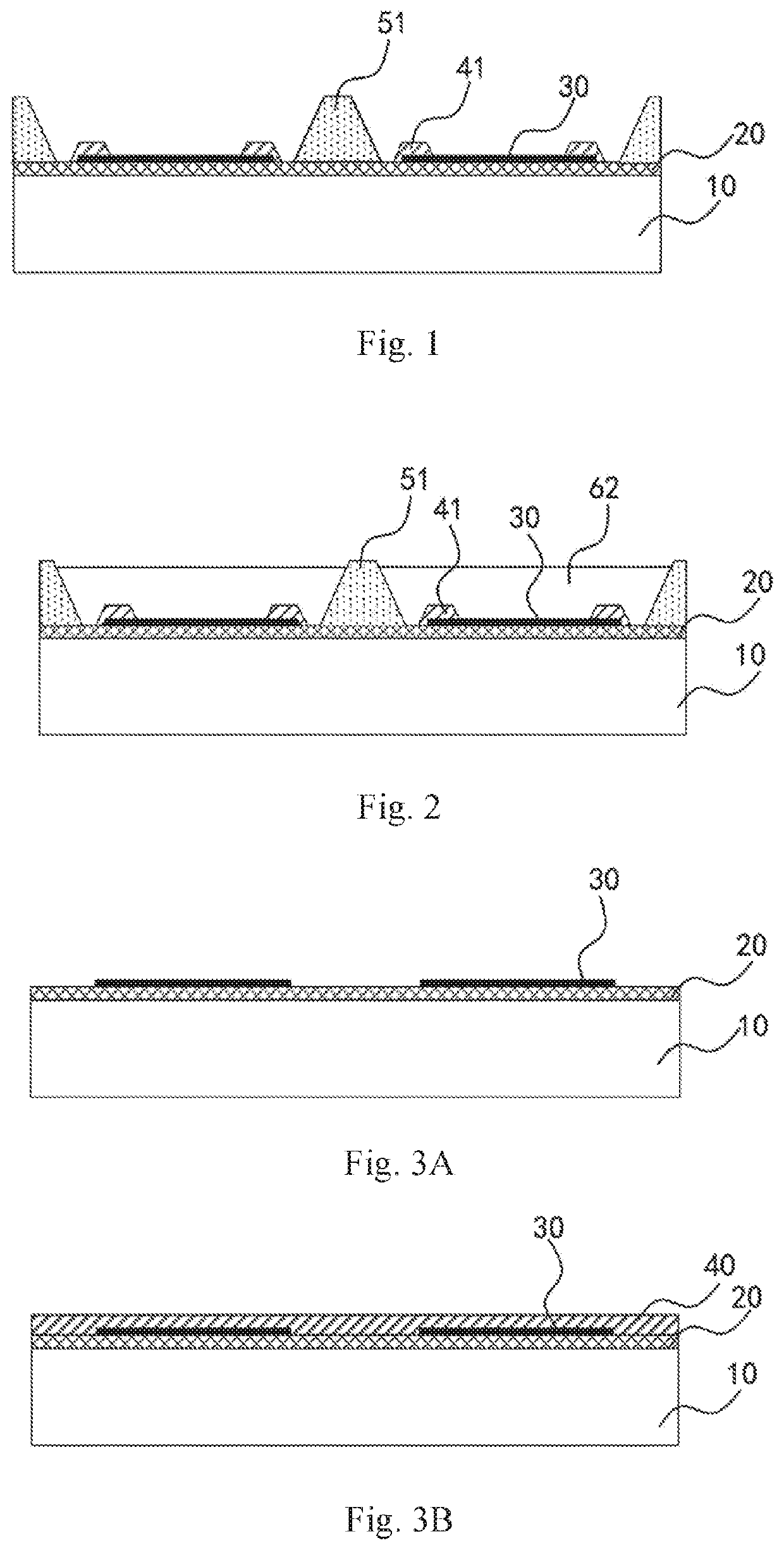

LED (light-emitting diode) packaging structure using transparent oxide substrate and packaging method thereof

InactiveCN102709458AReduce usageImprove light extraction efficiencySemiconductor devicesLead bondingFluorescence

The invention discloses an LED (Light-Emitting Diode) packaging structure using a transparent oxide substrate, comprising a plane type transparent oxide substrate, a fluorescent thin film and more than one LED chip, wherein a conductive pattern is arranged on the front face of the transparent oxide substrate; an LED bonding region is reserved on the conductive pattern and the LED chips are arrayed on the LED bonding region; and the fluorescent thin film is packaged on the front face of the transparent oxide substrate to seal the LED chips between the transparent oxide substrate and the fluorescent thin film. According to the LED packaging structure using the transparent oxide substrate provided by the invention, a traditional structure for emitting light from one side is broken through, the light emitting efficiency is extremely improved, and the heat radiation capability is improved; the reliability and the consistency of a product are improved by a full-page packaging method, so that the LED packaging structure is suitable for industrial rapid and efficient production; and furthermore, isolating glue is avoided being used and the service life of the product can be prolonged effectively.

Owner:SUZHOU JINGPIN OPTOELECTRONICS

PH-sensitive allochroic inorganic material and preparation method thereof

The invention discloses a pH-sensitive allochroic inorganic material and a preparation method thereof. The preparation method includes compounding Li2CO3, ammonium polyphosphate, Al2O3, TiO2 and MnCO3to obtain LATP and LiMnPO4 ceramic powder, adding ethyl alcohol after mixing the LATP ceramic powder with 10-40% of LiMnPO4 ceramic powder, and performing ball grinding, drying and sieving to obtainmixed powder; adding binders into the mixed powder for pelleting, conducting preforming to prepare a blank, and calcinating the blank in an air atmosphere to prepare pH-sensitive allochroic ceramic; after direct calcination of the mixed powder in the atmosphere, subjecting the mixed powder to crushing, ball grinding and sieving to obtain pH-sensitive allochroic powder, mixing the allochroic powderwith other resin solutions or emulsion to obtain a pH-sensitive allochroic paint or film material. The prepared pH-sensitive allochroic inorganic material has the advantages of safety, reliability, simplicity in preparation process, economy and environment protection, and accordingly, industrial production can be realized.

Owner:SOUTH CHINA UNIV OF TECH

Hemp textile

The invention discloses a hemp textile which is formed by blending hemp fiber and other fiber including one or more of cotton fiber, tencel fiber and modal fiber. A manufacturing process of the hemp textile includes the following steps: raw material growth, mixing and loosening, lapping, sliver generating, pre-drawing, sliver lapping, combing, drawing, roving generating, spun yarn generating, spooling, warping, sizing, drafting, weaving, settling and packaging. By blending the hemp fiber, the cotton fiber, the tencel fiber and the modal fiber and by means of special fabrication processing, the hemp textile is soft in touch, smooth and straight, natural and comfortable, high in efficiency in processing and production, small in product loss and good in quality, improves the industry-university-research cooperation organizational degree, integrates hemp industry technology innovation resources, guarantees close join of scientific achievements and production practice, combines textile manufacturing and military supply devices closely and achieves fast industrialization of hemp research results.

Owner:TAICANG LITAI TEXTILE MILL

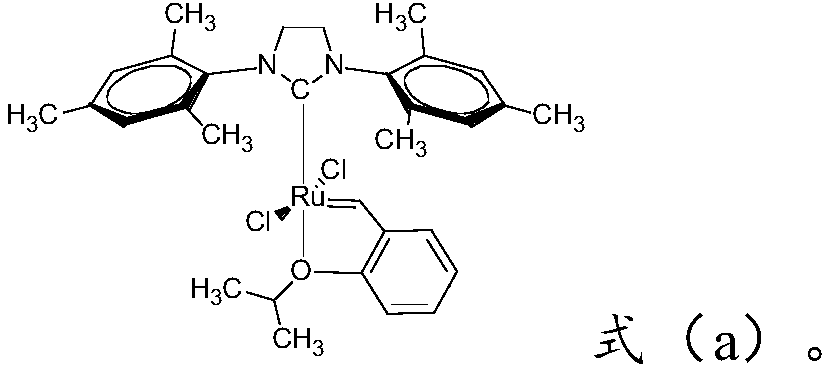

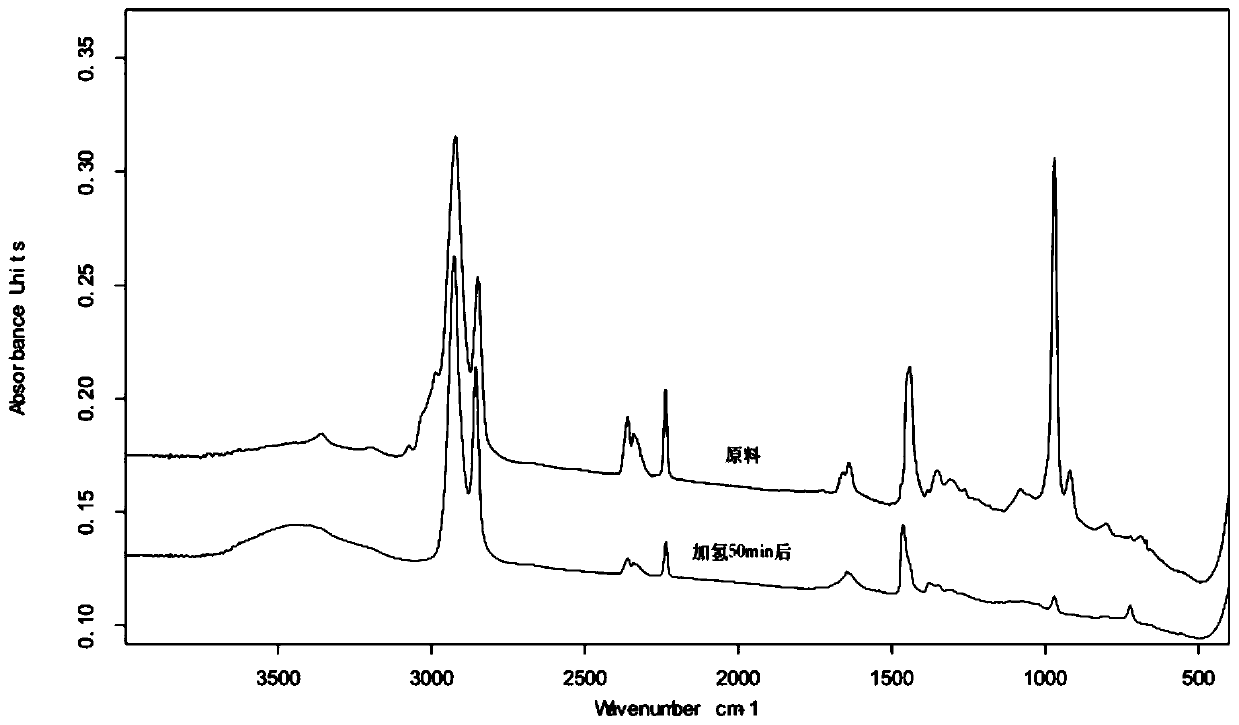

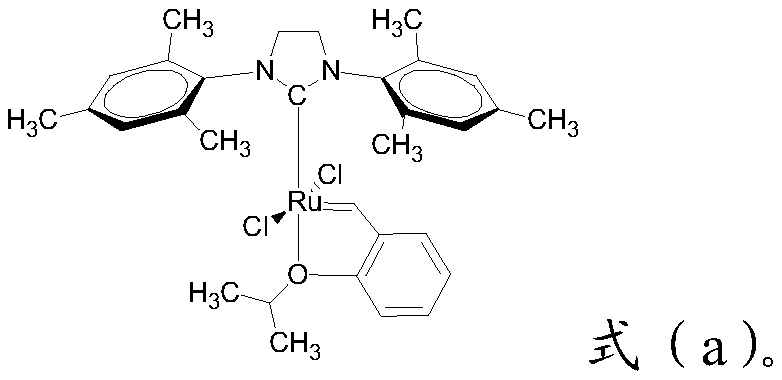

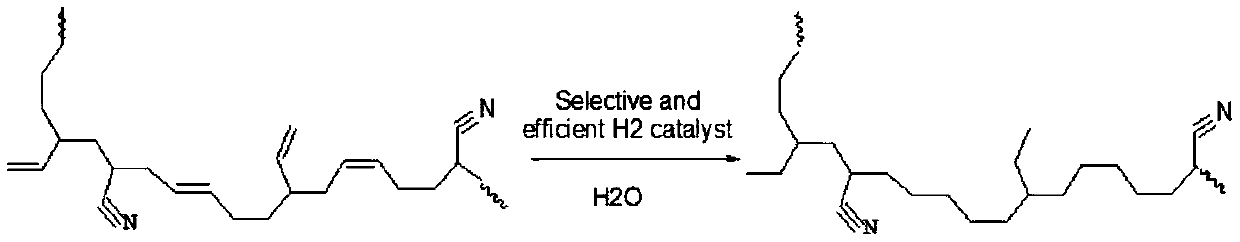

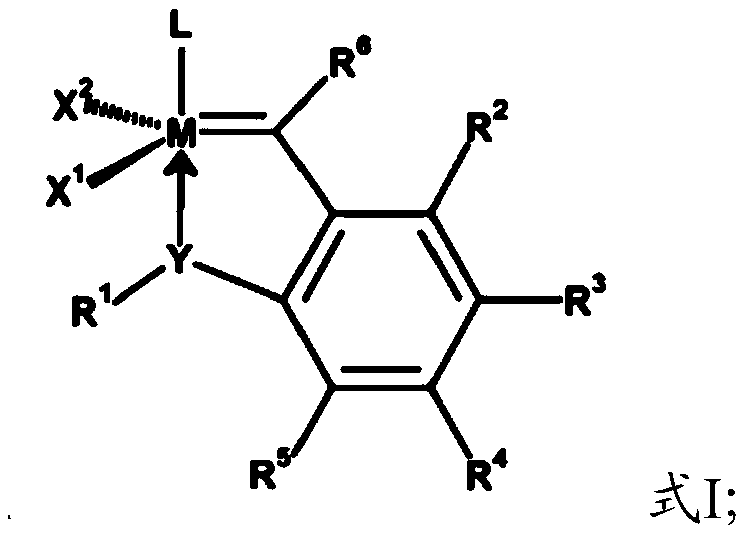

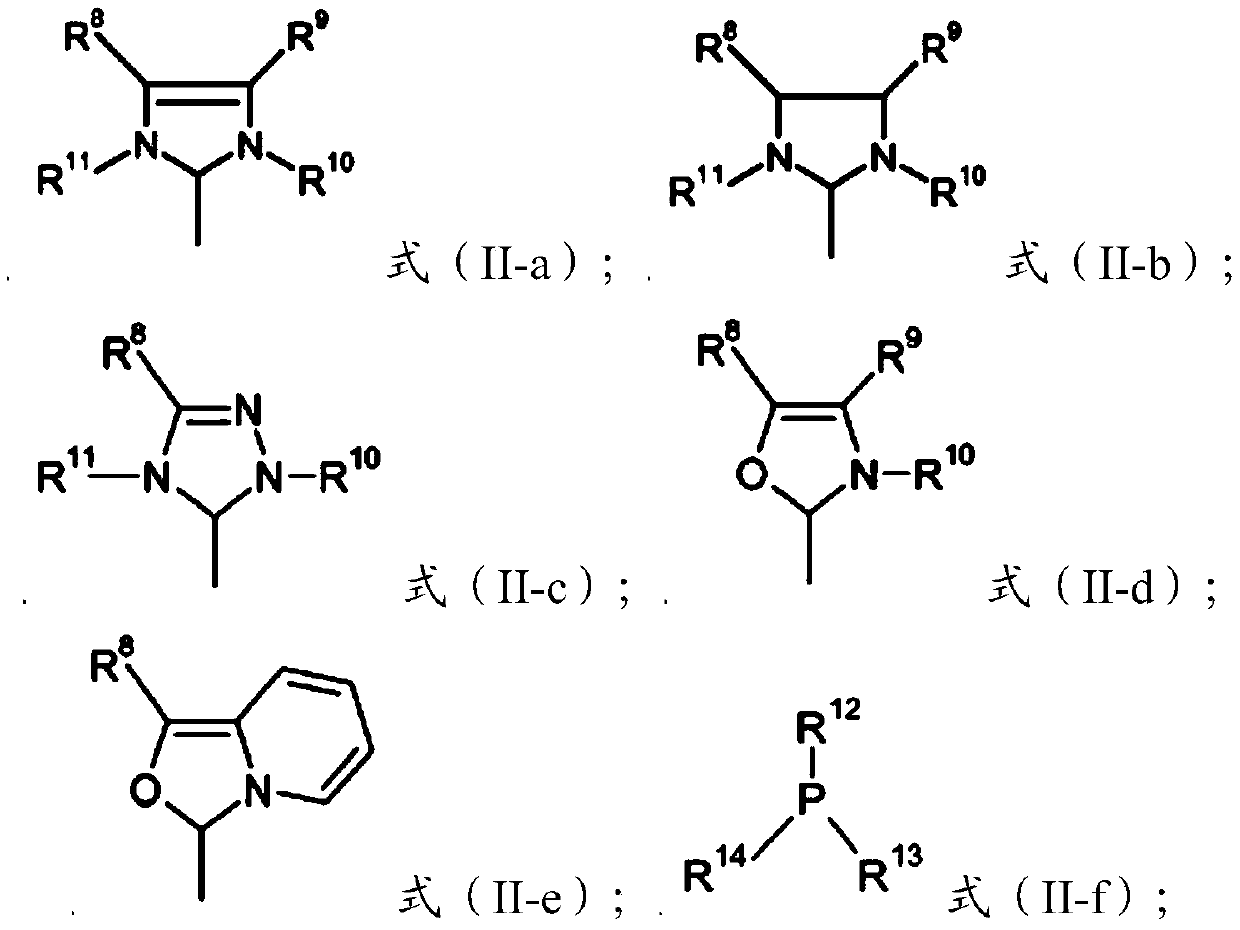

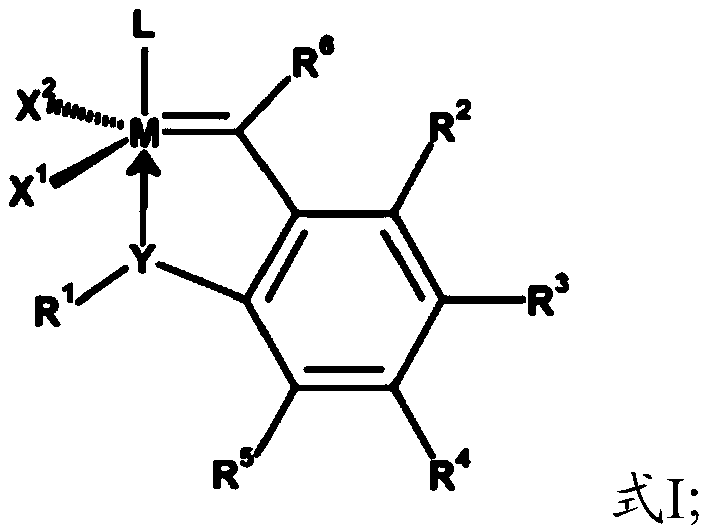

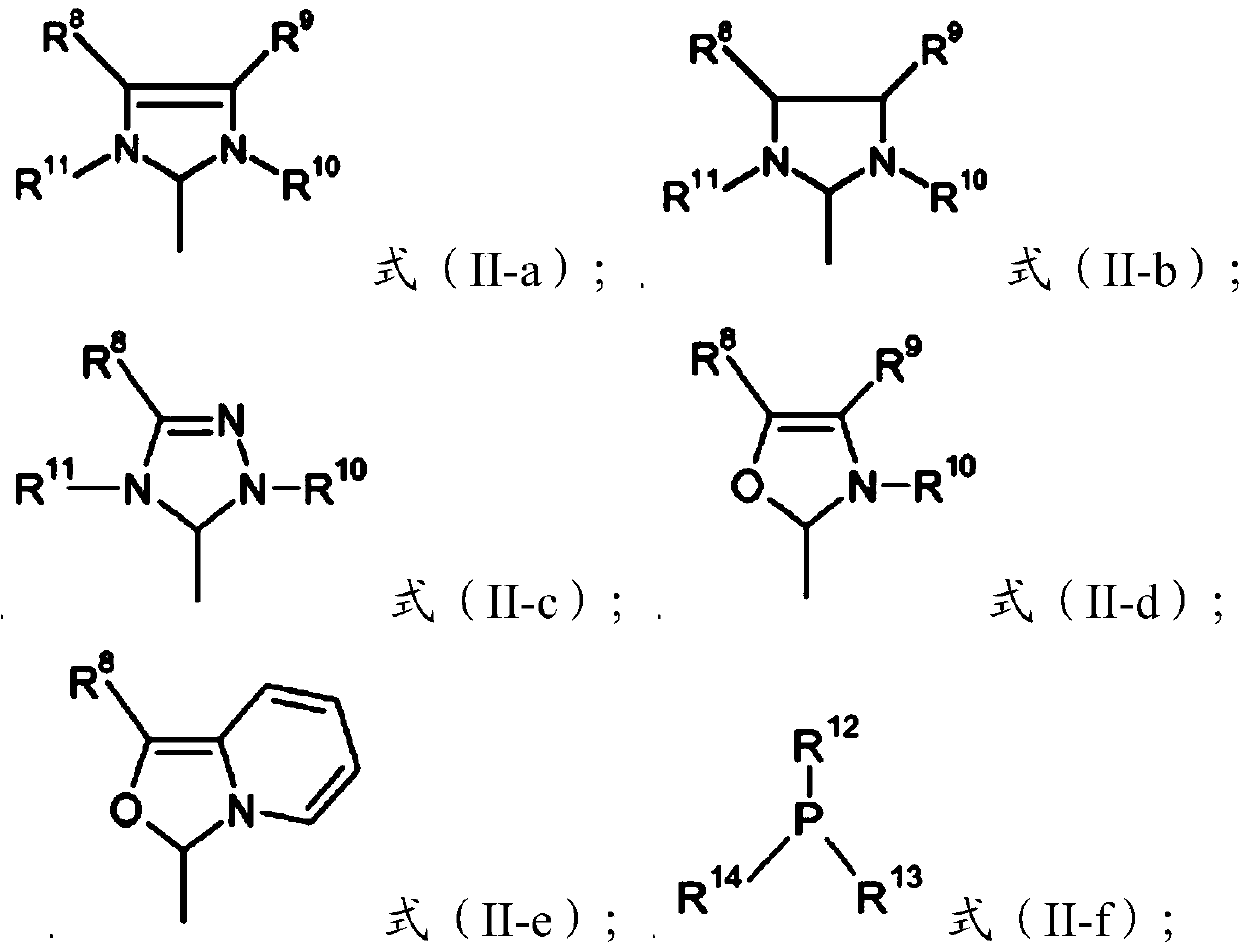

Selective hydrogenation method for conjugated diene latex

The invention provides a selective hydrogenation method for conjugated diene latex. The method comprises the step of subjecting the conjugated diene latex to a hydrogenation reaction with a compound catalyst of metal of a family VIII represented by a formula (I) shown in the description, thereby obtaining a hydrogenated polymer. According to the method, latex hydrogenation of the conjugated dienelatex is catalyzed by employing the compound catalyst of the metal of the family VIII represented by the formula (I); during the use of the catalyst, no cocatalyst and no organic solvent are employed,and no substance except for the catalyst is employed; compared with the prior art, the method has the advantages that the catalyst has high hydrogenation efficiency to NBR latex, and the consumptionof the catalyst is low; and hydrogenation conditions of the catalyst are not harsh, the temperature and pressure are not high, the catalyst has high catalyzing activity to the latex under the condition of moderate temperature and pressure, and thus, realization of rapid industrialization is facilitated.

Owner:QINGDAO UNIV OF SCI & TECH +2

Base metal nickel internal electrode slurry of microwave multiple-layer sheet ceramic capacitor

InactiveCN101567264ASmall volume changeReduce internal stressFixed capacitor electrodesNon-conductive material with dispersed conductive materialYttriumPalladium

The invention relates to base metal nickel internal electrode slurry of a microwave multiple-layer sheet ceramic capacitor, which comprises 40 to 50 of high-crystallinity nanometer nickel powder, 2 to 10 of yttrium oxide stable zirconia nanometer powder bodies and 40 to 58 of organic carriers according to the weight percentage, wherein the organic carriers comprise 2 percent to 6 percent of cellulosic resin and 38 percent to 52 percent of dihydroterpineol. Aiming at the stress problem of a metal part and a ceramic part of the microwave multiple-layer sheet ceramic capacitor, the invention can reduce the volume change caused by the phase change to reduce the internal stress, microcracks of a dielectric layer are reduced to increase the reliability of the microwave ceramic capacitor, and consequently, the microwave multiple-layer sheet ceramic capacitor can also use a base metal nickel electrode technology to replace the prior silver palladium noble metal technology. The invention saves social resources, greatly reduces the production cost and quickly realizes the industrialization.

Owner:广州三则电子材料有限公司

White birch liquid vinegar and preparation method thereof

The invention discloses white birch liquid vinegar and a preparation method thereof. According to the preparation method, white birch liquid and white sugar are used as raw materials, white birch liquid raw vinegar is obtained by carrying out alcoholic fermentation and acetic fermentation, clarifying, filtering, sealing and aging for one month or more, and the white birch liquid vinegar with totalacid content of greater than 3% is obtained by blending the white birch liquid raw vinegar with different acidities according to different ratios. The white birch liquid vinegar is clear in physicalappearance and uniform in color, is light yellow, glossy, sour in taste and soft, lasting in aftertaste and mellow in mouth feel, and has aroma of vinegar and faint scent of birch juice.

Owner:DAILING FORESTRY RES INST OF HEILONGJIANG PROVINCE

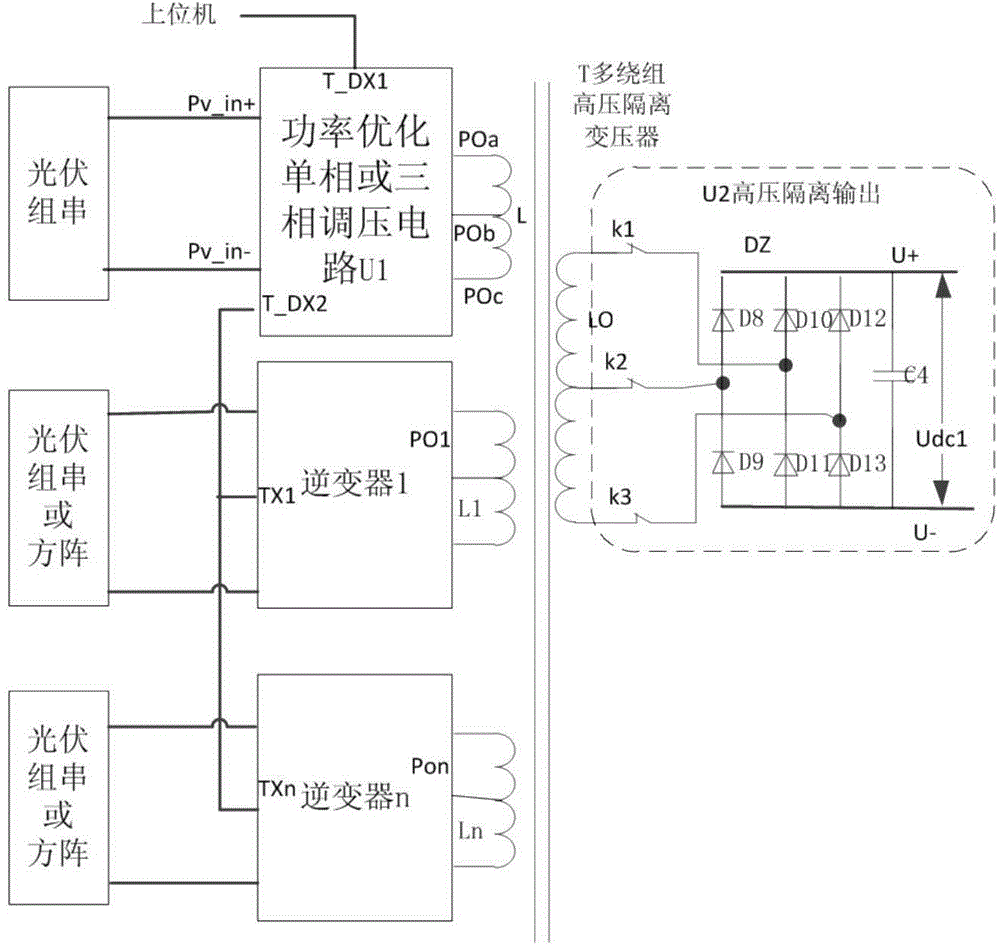

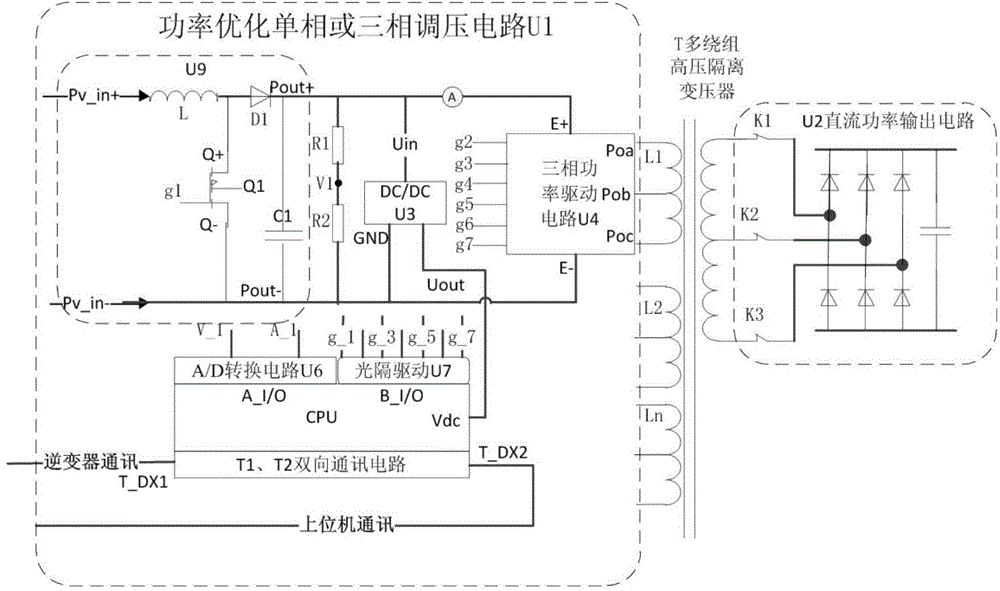

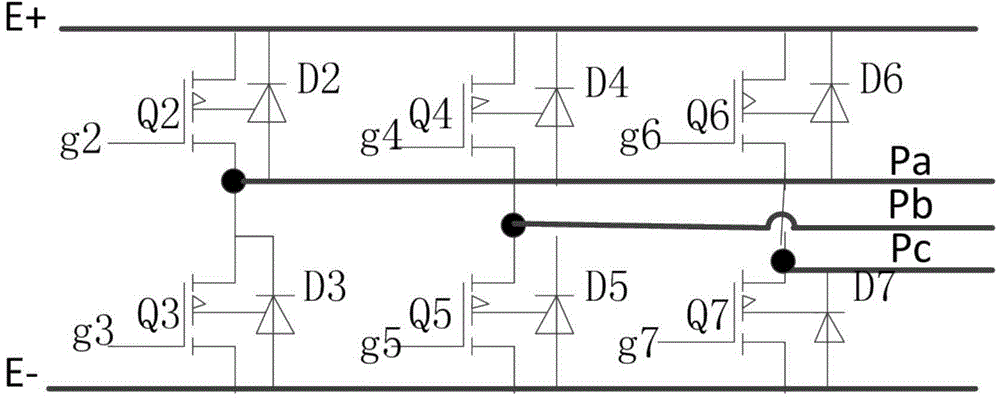

Serial photovoltaic array high-voltage isolation apparatus

InactiveCN104917394ARapid industrializationDc-dc conversionElectric variable regulationVoltage regulationThree-phase

A serial photovoltaic array high-voltage isolation apparatus consists of a multi-winding high-voltage isolation transformer, a power optimization single-phase or three-phase voltage regulation circuit and a direct-current power output circuit. The multi-winding high-voltage isolation transformer consists of n input windings, a voltage regulation input winding and a power output winding, and n is an integer not less than 1. the input ends of the n input windings of the multi-winding high-voltage isolation transformer are correspondingly connected with the output ends of n inverters respectively. The input end of the voltage regulation input winding is connected with the output end of the power optimization single-phase or three-phase voltage regulation circuit. The output end of the power output winding is connected with the input of the direct-current power output circuit.

Owner:北京科诺伟业科技股份有限公司

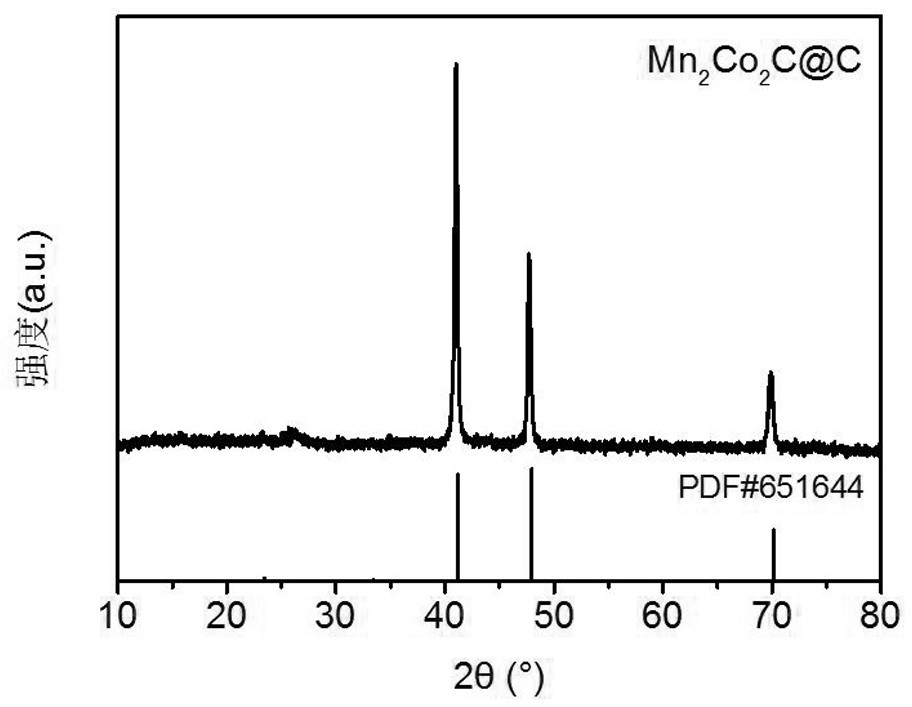

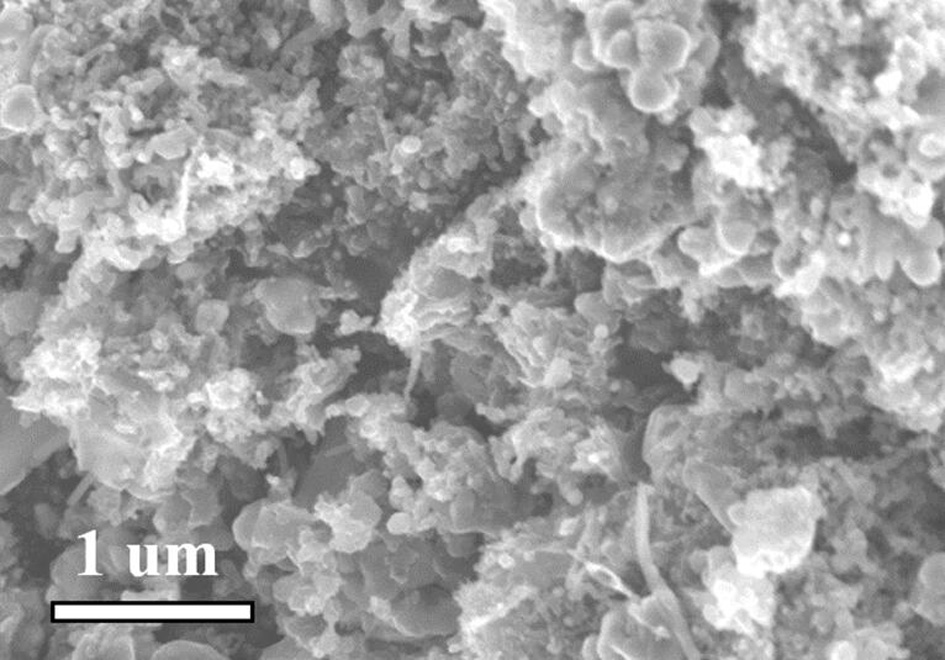

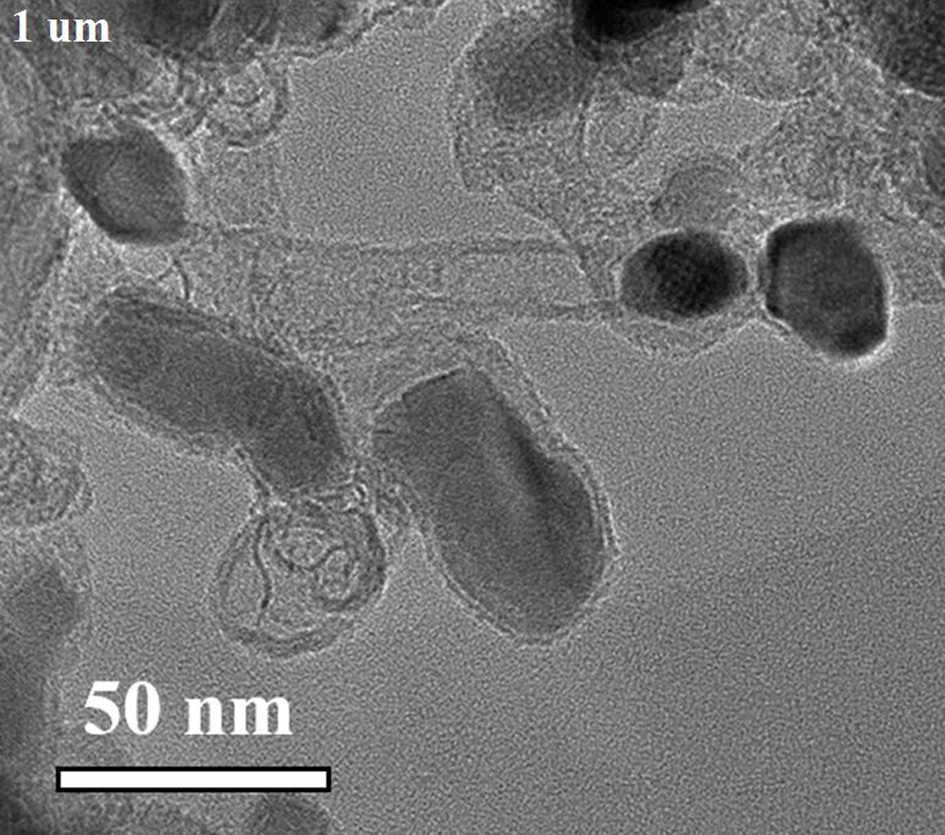

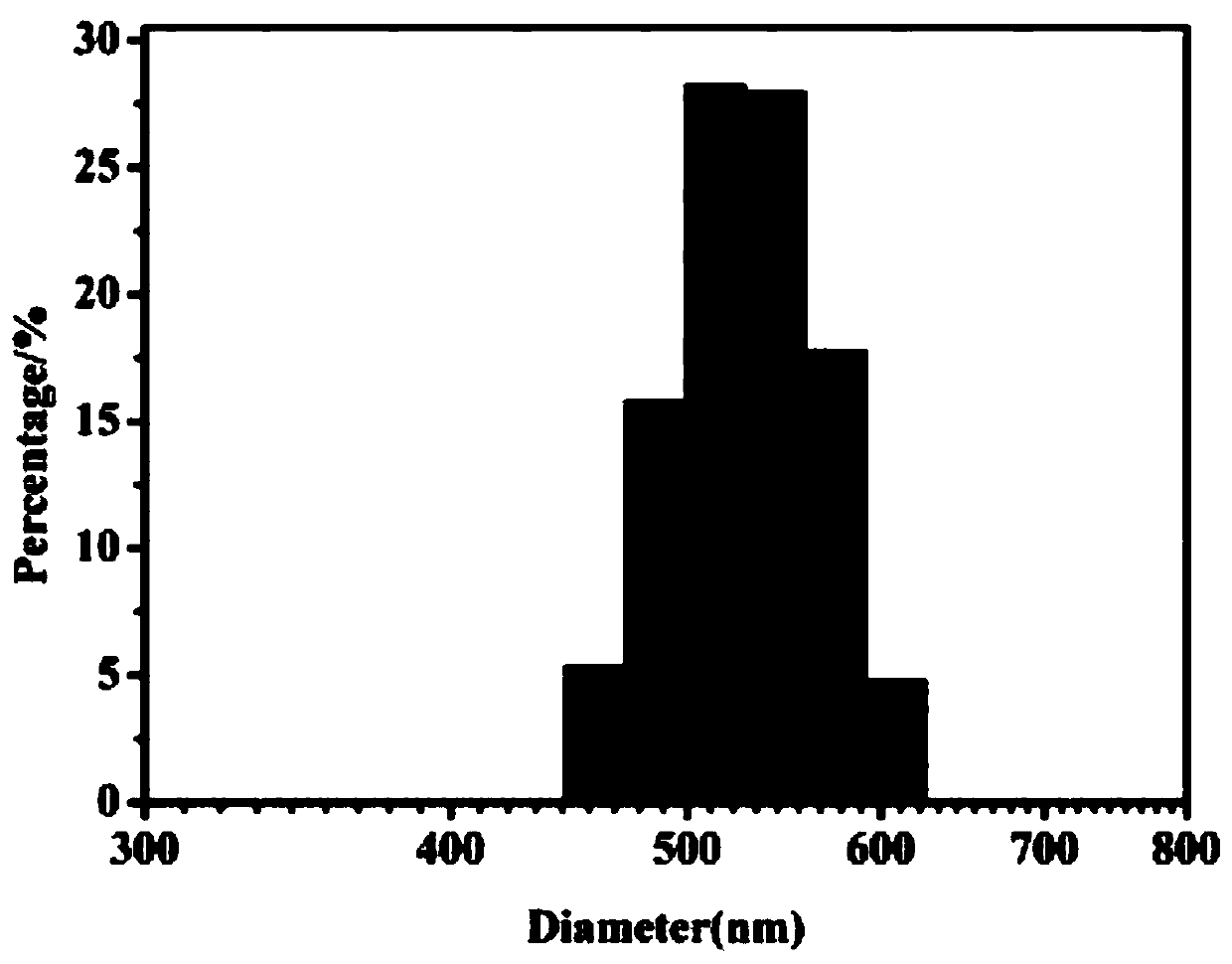

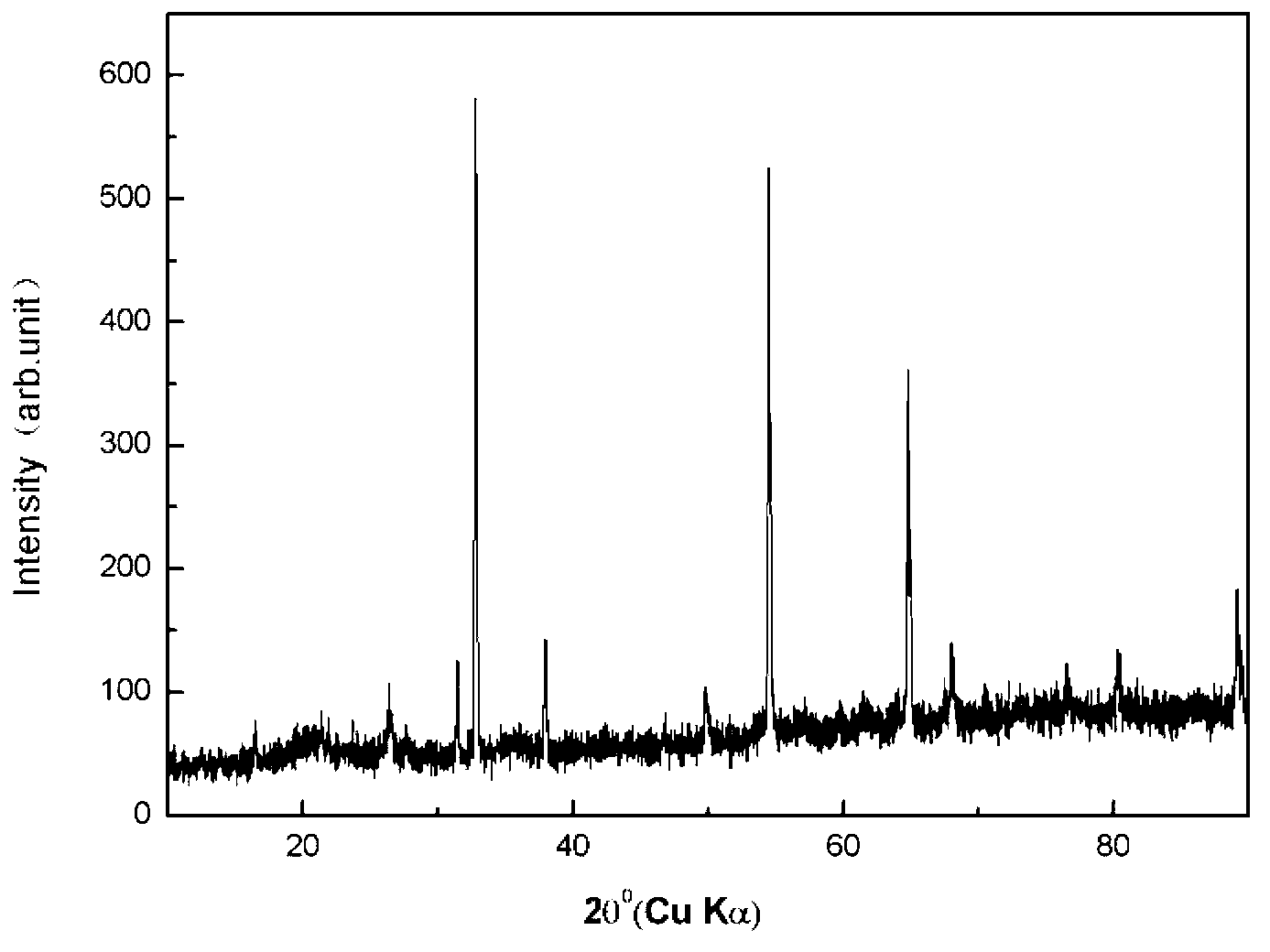

Nitrogen-doped carbon layer coated cobalt manganese carbide composite material and application thereof

ActiveCN111617790AEasy to synthesizeRapid industrializationEnergy inputCatalyst activation/preparationCarbon layerPtru catalyst

The invention belongs to the technical field of nano materials and photocatalysis, and particularly relates to a nitrogen-doped carbon-coated Mn2Co2C composite material which is prepared by the methodcomprising the following steps: reacting soluble positive bivalent cobalt salt, positive bivalent manganese salt and cobalt potassium cyanide to obtain precipitate, and reacting the precipitate at high temperature under the protection of N2 atmosphere to obtain the nitrogen-doped carbon-coated Mn2Co2C composite material. The nitrogen-doped carbon-coated Mn2Co2C composite material disclosed by theinvention can be used as a hydrogen production cocatalyst to accept electrons and promote a hydrogen evolution reaction, Mn2Co2C@C nanoparticles as a cocatalyst are loaded on the surface of g-C3N4 toobtain a g-C3N4 / Mn2Co2C@C composite photocatalyst material, and the g-C3N4 / Mn2Co2C@C composite photocatalyst material shows efficient activity of photocatalytic decomposition of water to produce hydrogen.

Owner:GUANGXI NORMAL UNIV

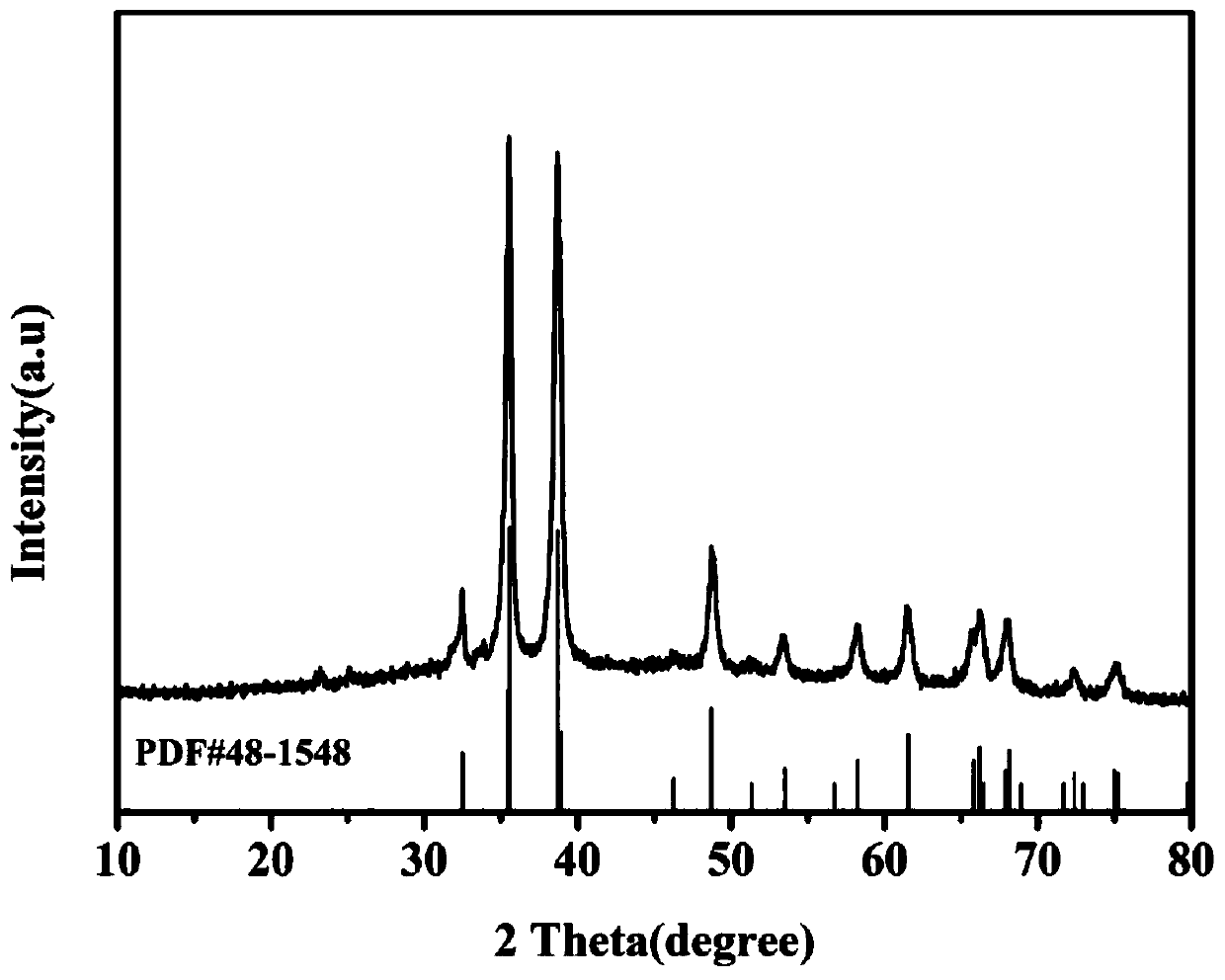

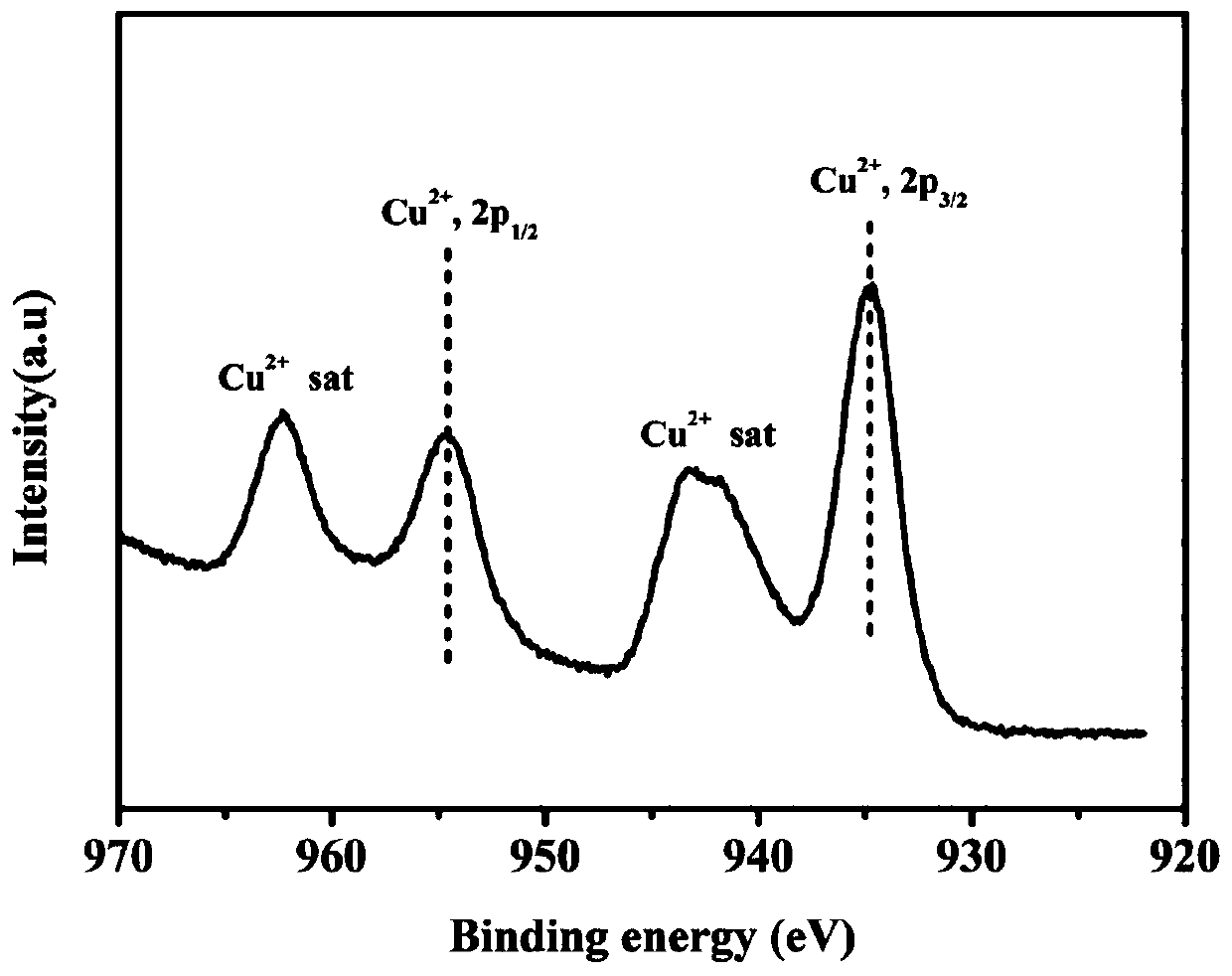

Method for continuously producing copper oxide

InactiveCN110092408AIncrease productivityControl granularityCopper oxides/halidesGranularityPhysical chemistry

The invention discloses a method for continuously producing copper oxide, belongs to the technical field of metal oxide preparation, and aims to provide a method for continuously producing the copperoxide with low energy consumption and high conversion efficiency. The technical key points of the method sequentially include the following steps: continuously introducing a copper-containing solutionand an alkali solution into a tubular reactor according to a mol ratio of 2: 1-1.3, reacting in the tubular reactor under the condition of pH value of 8-14 to obtain a copper hydroxide-containing solution, and using reaction heat to raise the temperature of the solution to partially decompose the solution into the copper oxide; continuously heating to raise the reaction temperature to 60-95 DEG Cfor further decomposing copper hydroxide into the copper oxide, and controlling the length of a reaction tube and the flow rate of the reaction solution to control the granularity of the copper oxideproduct; and separating the reacted product mixture by a continuous centrifuge to obtain the copper oxide.

Owner:GUANGDONG UNIV OF TECH

Method for preparing hydrogenated copolymer from conjugated diene hydrogenated latex

ActiveCN111303317AAchieving selective hydrogenation reactionsReduce dosagePolymer sciencePtru catalyst

The invention provides a method for preparing a hydrogenated copolymer from a conjugated diene hydrogenated latex. The method comprises the following steps: mixing a part of a conjugated diene latex with a Hoveyda-Grubbs II catalyst so as to obtain a mixture A; mixing the residual conjugated diene latex, the mixture A and a composite auxiliary agent so as to obtain a mixture B, wherein the composite auxiliary agent is a combination of two or more selected from the group consisting of sodium oleate, potassium oleate, sodium tetradecenylsulfonate, potassium tetradecenylsulfonate, linear alkyl sulfate and alkyl betaine; introducing nitrogen into the mixture B, carrying out stirring and degassing treatment, and continuing stirring treatment so as to obtain a mixture C; and heating the mixtureC, introducing hydrogen, and carrying out a hydrogenation reaction so as to obtain the hydrogenated copolymer. According to the invention, through a batch-adding mixing mode, introduction of a specific composite auxiliary agent and stirring after nitrogen degassing treatment, selective hydrogenation of conjugated diene is realized; the usage amount of a catalyst is reduced; a high-hydrogenation-degree product is obtained; the reaction rate is increased; and the catalytic efficiency is improved.

Owner:山东京博中聚新材料有限公司 +2

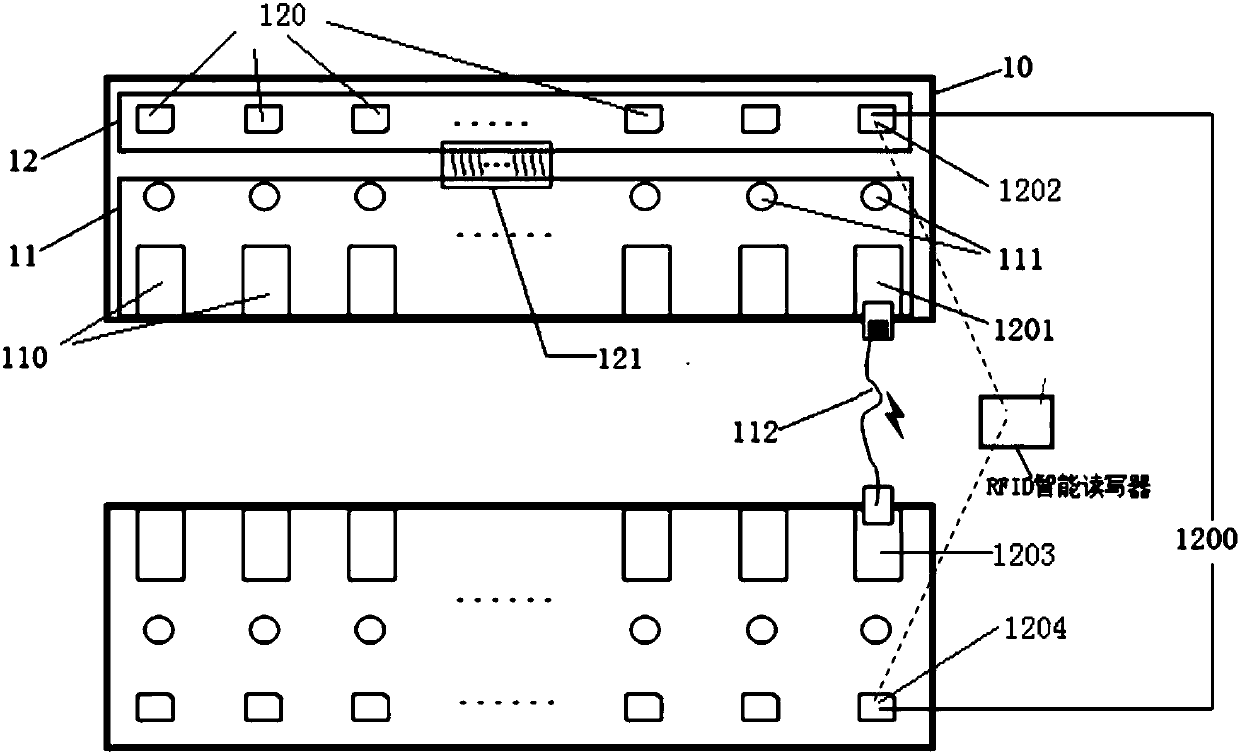

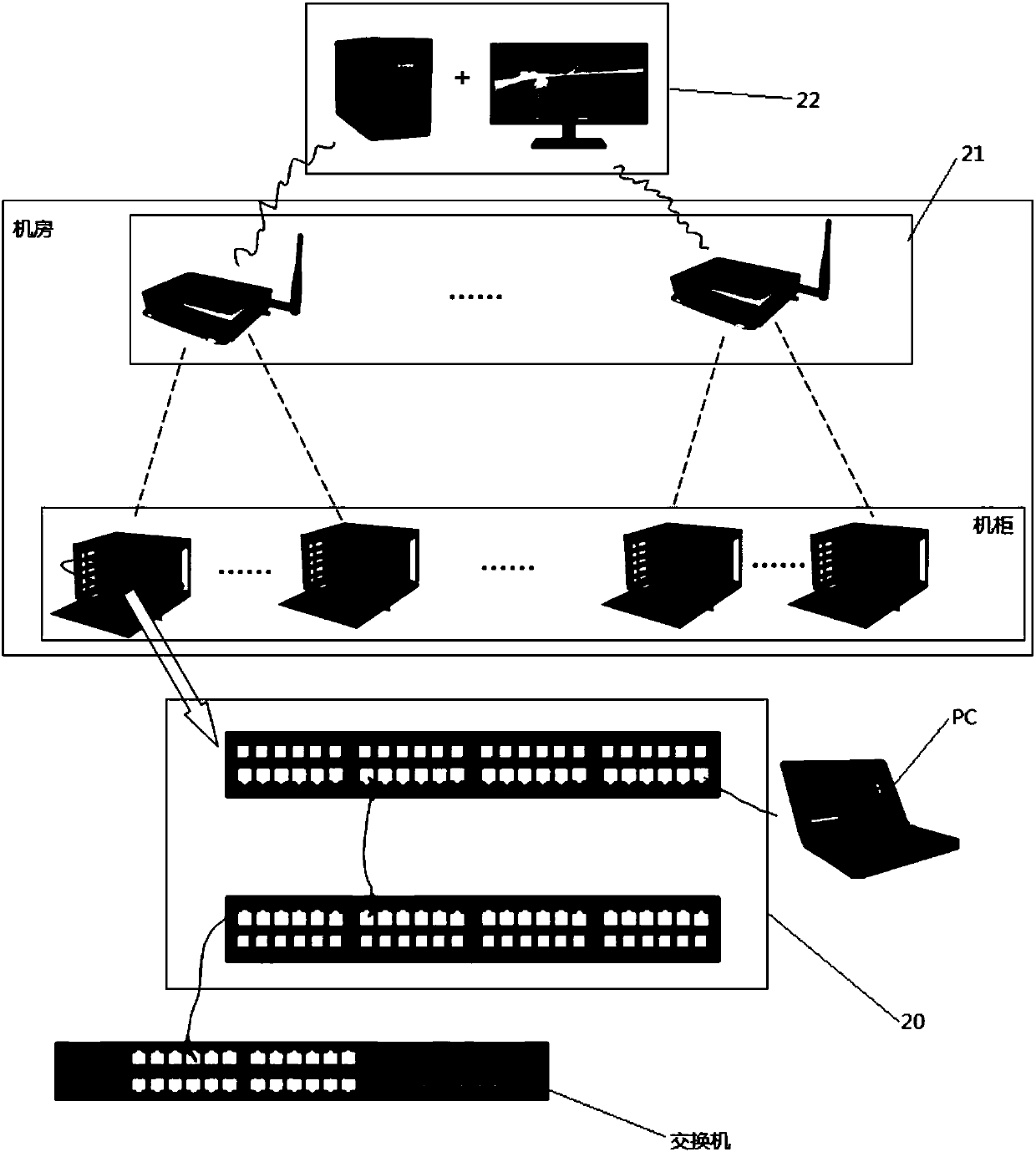

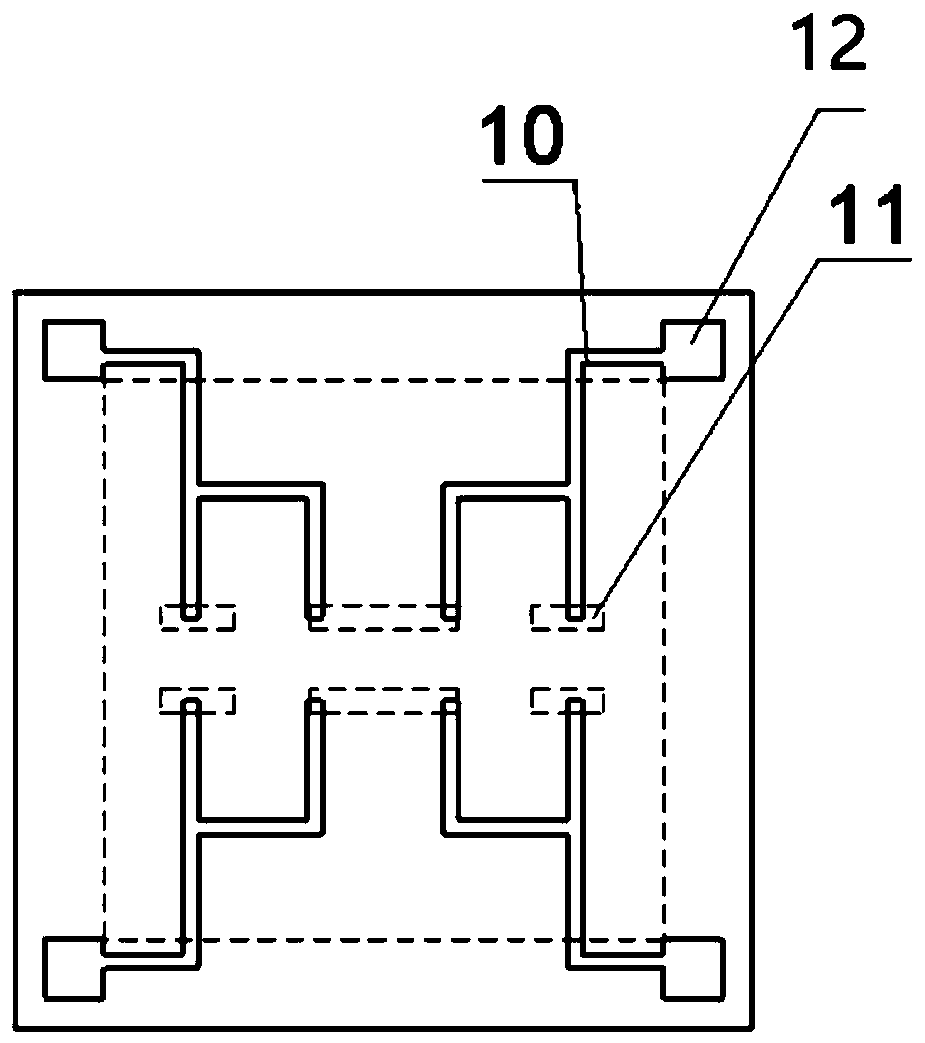

Intelligent electronic distribution frame based on RFID and management system

InactiveCN107872736ALow costSimple structureNear-field in RFIDSelection arrangementsRadio frequencyCable network

The invention provides an intelligent electronic distribution frame based on RFID. Distribution ports arranged on the two intelligent electronic distribution frames are connected through a jumper wire. RFID radio frequency identifications arranged on the two intelligent electronic distribution frames are connected through an idle line in the jumper wire. The RFID radio frequency identifications ontwo ends of the jumper wire form an RFID radio frequency identification pair. The invention also provides a management system of the intelligent electronic distribution frame based on the RFID. The system comprises the intelligent electronic distribution frame of the RFID, an RFID intelligent reader and writer and a background service manager, wherein the RFID intelligent reader and writer carries out reading and writing with the intelligent electronic distribution frame through the RFID; and the background service manager is connected to the RFID intelligent reader and writer through a wirednetwork or a wireless network. By using the intelligent electronic distribution frame based on the RFID and the management system, cost is low, the structure is concise, gradation is distinct, an error rate and a failure rate of an integration wiring system are greatly reduced, simultaneously fault processing time during a wiring link is greatly shortened, and communication safety is further increased.

Owner:广东华纬伦智能科技有限公司

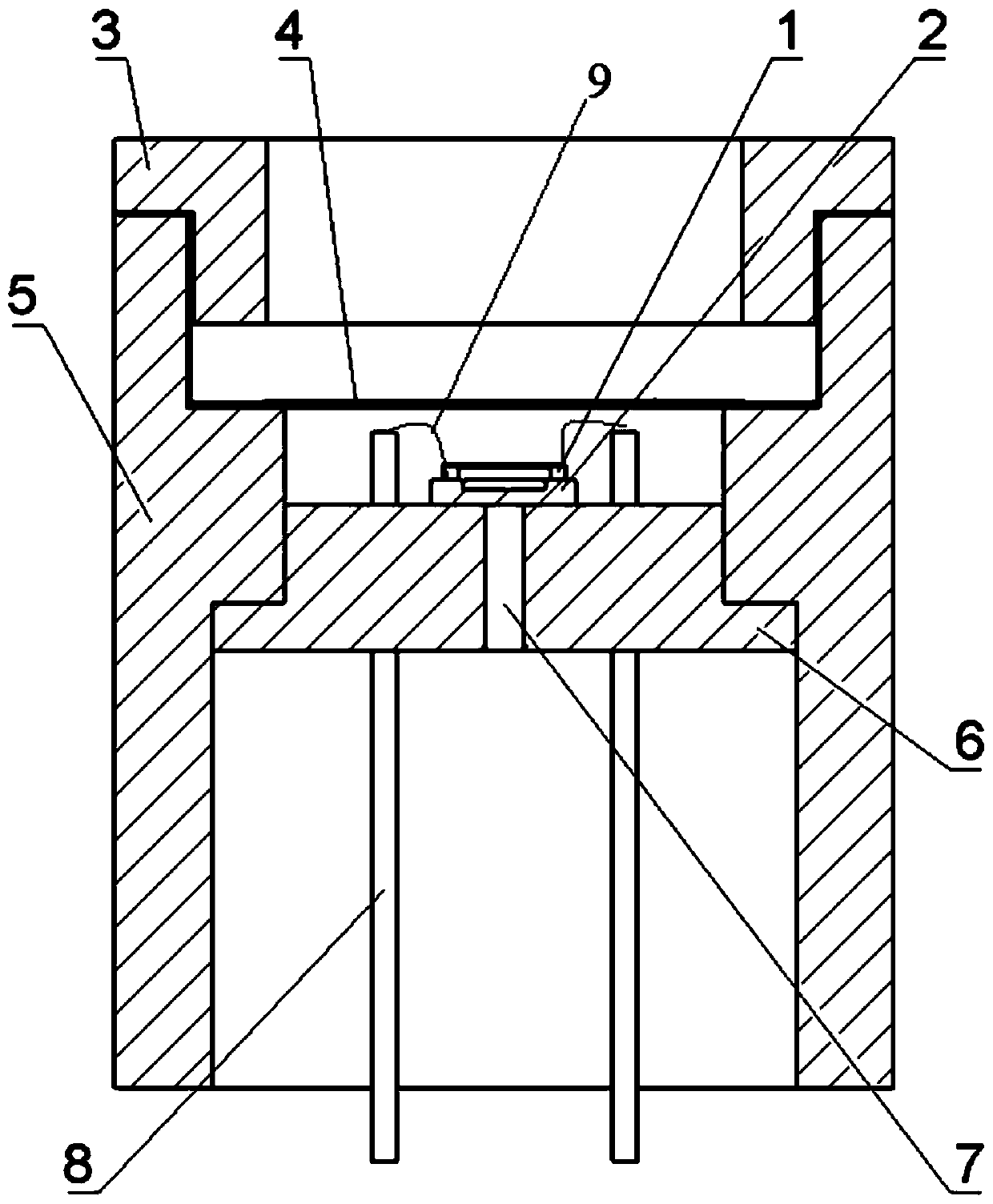

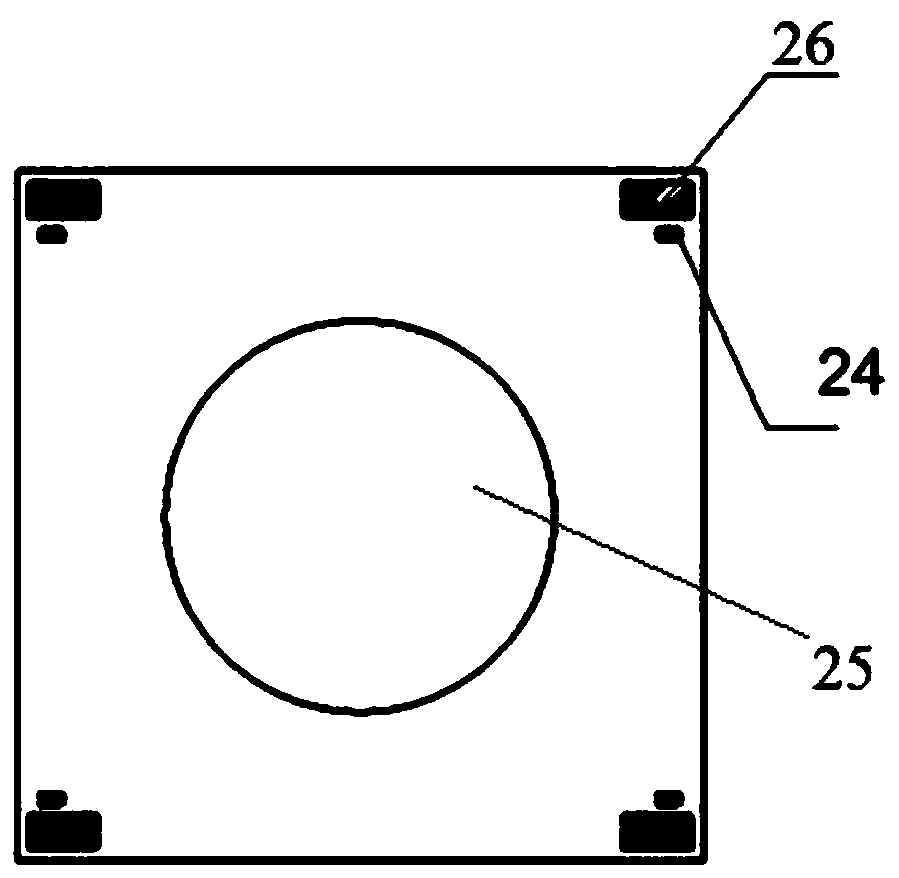

SiC high-temperature pressure sensor and packaging method thereof

ActiveCN111003683AReduce manufacturing costHigh hardnessThermometer detailsTelevision system detailsEngineeringSilicone oil

The invention discloses a SiC high-temperature pressure sensor and a packaging method thereof. The sensor comprises a SiC MEMS chip, an AlN carrier, an elastic metal film, a supporting tube shell, a heat conduction base and a plurality of conductive binding posts; the heat conduction base is installed in the supporting tube shell; the AlN carrier is fixedly installed on the heat conduction base; the SiC MEMS chip is fixedly arranged on the AlN carrier; the elastic metal film is arranged on the supporting tube shell above the SiC MEMS chip; a thinned self-sealing cavity is etched in the face, attached to the AlN carrier, of the SiC MEMS chip; the conductive binding posts penetrate through the heat conduction base from the lower end of the supporting tube shell and then are connected with anelectrode of the SiC MEMS chip; and an insulating layer is arranged between the conductive binding posts and the heat conduction base. The assembly structure is put into heat conduction silicone oil,and the elastic metal film is pressed into the supporting tube shell in a matched mode through an annular plug cap, so the SiC high-temperature pressure sensor packaging is completed. The chip packaging structure is low in packaging cost and good in reliability, completely isolates the chip from a medium, and can continuously work at the high temperature of 500 DEG C or above.

Owner:WUHAN UNIV

China hemp textile

The invention relates to a hemp textile. It is characterized in that the hemp textile is manufactured by blending hemp fiber and other fibers, and the other fiber is one or more of cotton fiber, tencel fiber and modal fiber, and the hemp textile is The manufacturing process includes the following steps: Raw material preservation - mixing and loosening - coiling - card sliver - pre-drawing - coiling - combing - drawing - roving - spinning - winding - warping - sizing - dressing - weaving ‑Organize‑Package. The hemp textiles of the present invention are made by blending hemp fibers with cotton fibers, tencel fibers and modal fibers, and through a special process, so that the hemp textiles feel soft, flat and wide, natural and comfortable, and have high efficiency in processing and production. The loss is small and the quality is good, which improves the degree of organization of the combination of industry and research, integrates the technological innovation resources of the hemp industry, and ensures the close connection between scientific research results and production practice.

Owner:威海恒沃贸易有限公司

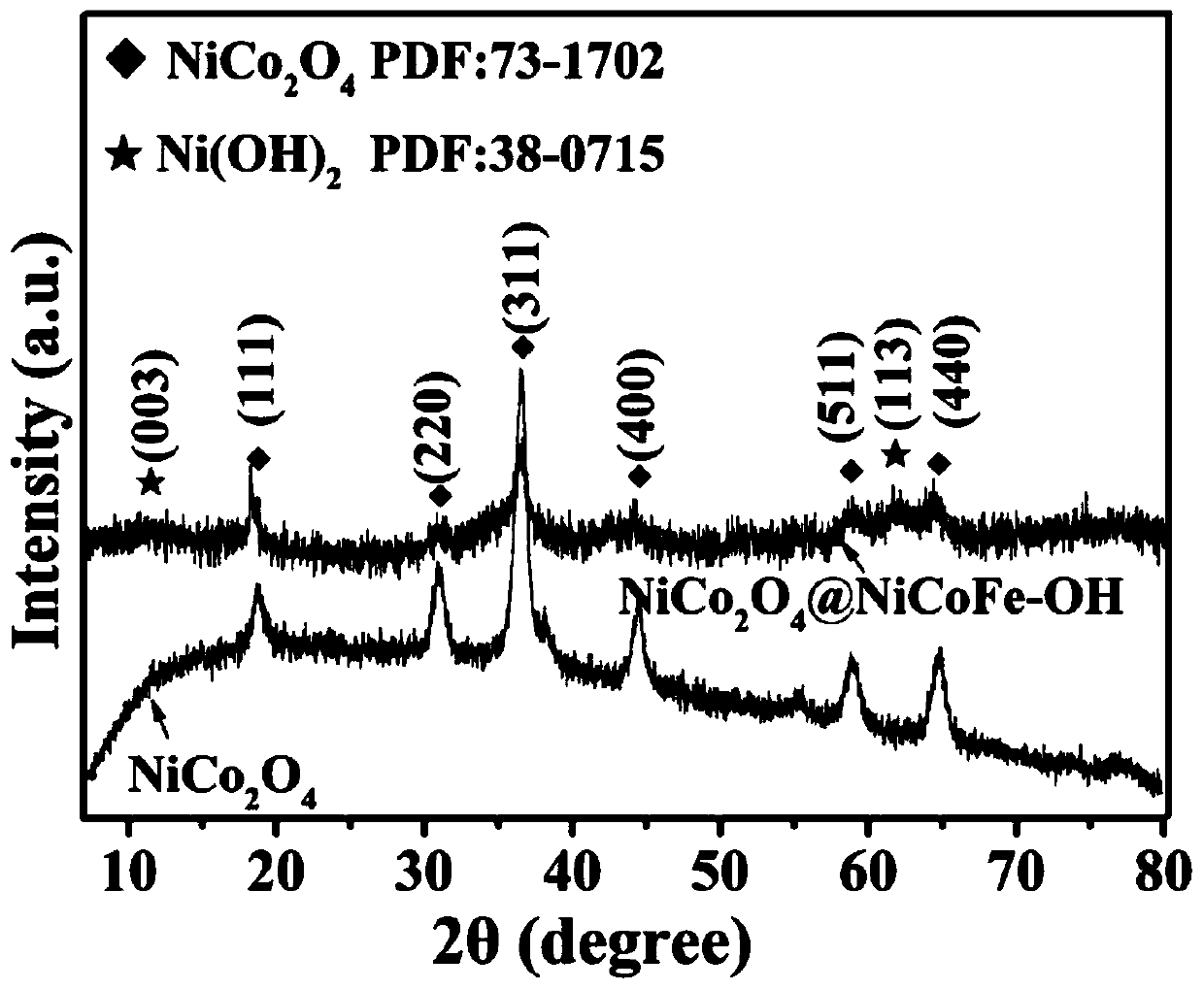

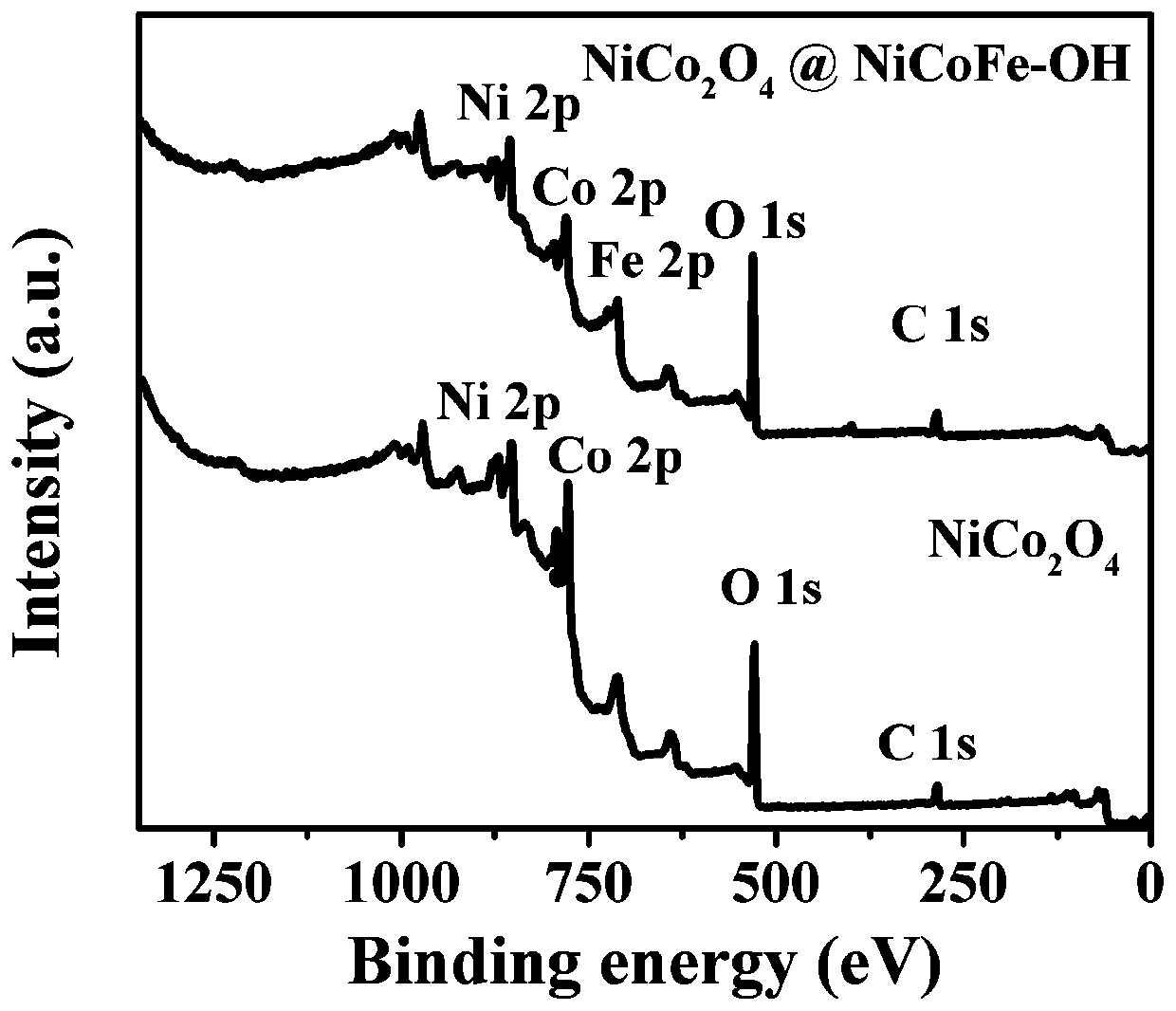

Nickel cobalt iron hydroxide coated nickel cobaltate flexible electrode material and preparation and application thereof

InactiveCN111193038AImprove electrochemical activityImprove cycle performanceFuel and primary cellsCell electrodesOxygen evolutionMaterials science

The invention belongs to the field of zinc-air battery air electrode materials, and discloses a nickel cobalt iron hydroxide coated nickel cobaltate flexible electrode material and preparation and application thereof. The preparation method comprises the following steps: performing in-situ solvothermal growth and air calcination on a conductive substrate to obtain a nickel cobaltate nano array, and performing solvothermal deposition on nickel cobalt iron hydroxide on the surface of the nickel cobaltate nano array by using soluble salts of three transition metals including nickel, cobalt and iron to obtain the nickel cobaltate flexible electrode material coated with the nickel cobalt iron hydroxide. According to the nickel cobalt iron hydroxide coated nickel cobaltate flexible electrode material disclosed by the invention, ion transmission and electrolyte diffusion are promoted by utilizing a three-dimensional porous network structure; the nickel cobaltate nanowire and the nickel-cobalt-iron hydroxide shell layer are combined to increase the number of active specific surfaces and active sites, so that the composite electrode material has excellent oxygen evolution reaction and oxygen reduction reaction performance, and high specific discharge capacity, high energy density and outstanding cycling stability are realized when the composite electrode material is applied to a rechargeable zinc-air battery.

Owner:SOUTH CHINA AGRI UNIV

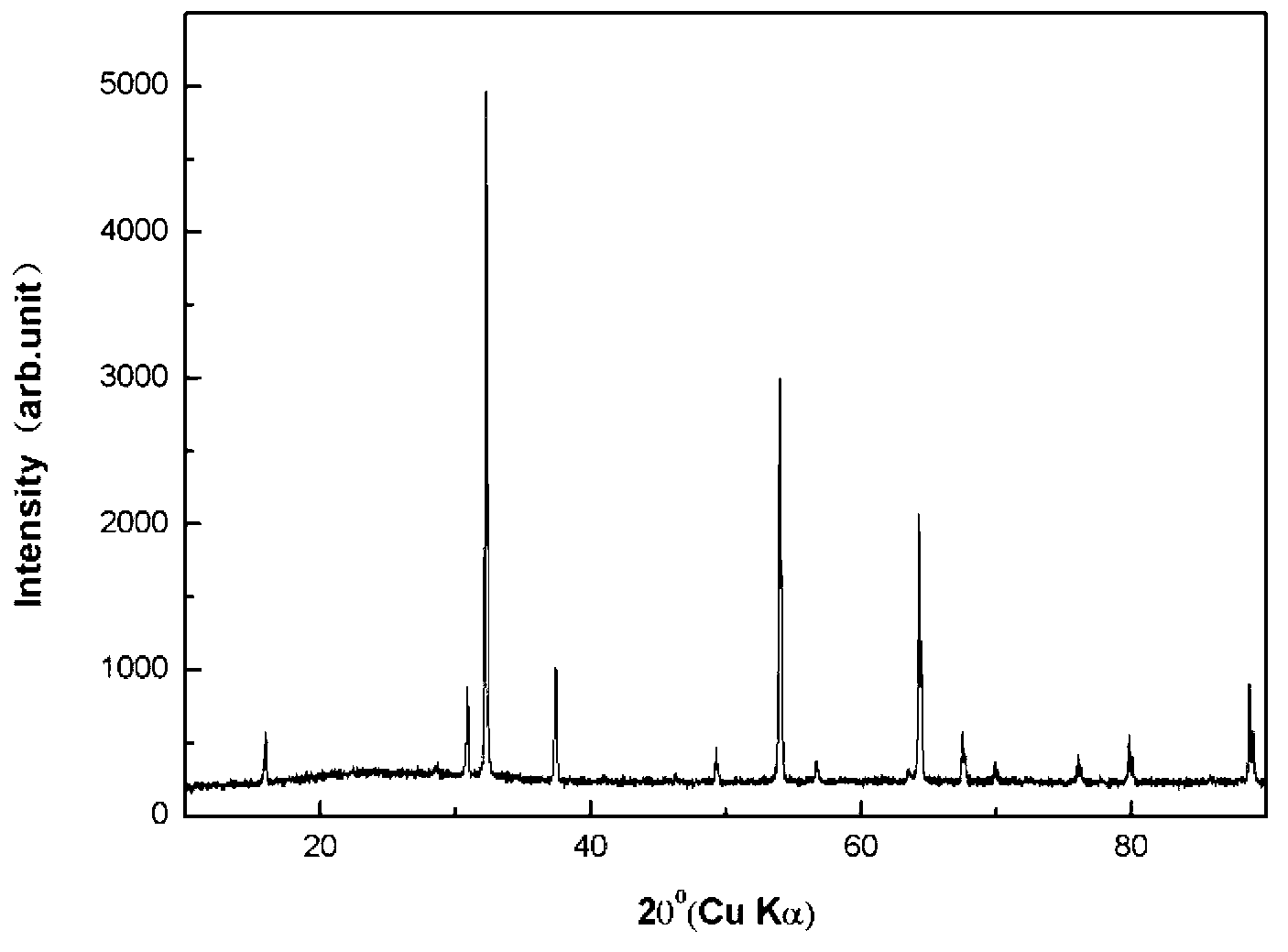

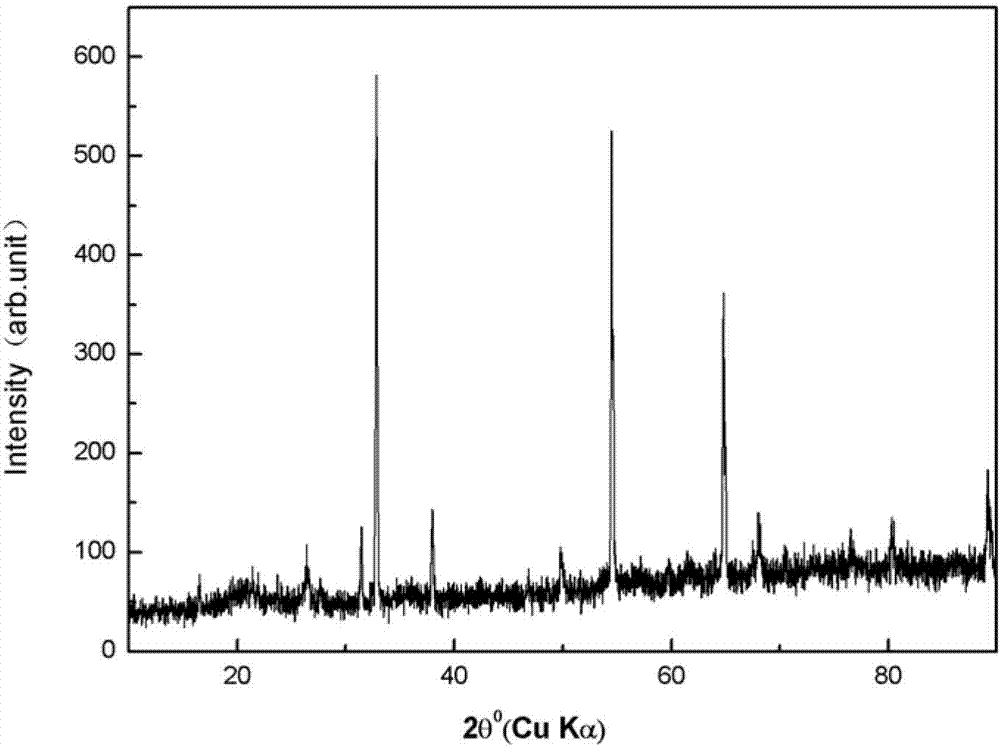

High-temperature and high-pressure preparation method of cubic-phase scandium germanium oxide

InactiveCN103198912AHigh purityImprove qualityInorganic material magnetismMaterials preparationHigh pressure

The invention discloses a high-temperature and high-pressure preparation method of cubic-phase scandium germanium oxide, and belongs to the technical field of magnet material preparation. The high-temperature high-pressure preparation method includes taking scandium oxide and germanium oxide as raw material and preparing the cubic-phase scandium germanium oxide through technical processes of material mixing and briquetting, packaging, high-temperature and high-pressure combination, cooling and pressure releasing. The high-temperature and high-pressure combination includes keeping temperature at 1300-1500 DEG C and pressure at 5 GPa for 15-60 minutes, and finally cooling and releasing pressure. The high-temperature and high-pressure preparation method is completely processed in the environment without water and modifier, unnecessary impurities can be avoided radically, so that the obtained cubic-phase scandium germanium oxide is high in purity. Equipment adopted by the method is largely used for producing adamas, and is easy to operate; industrialization can be realized early; and high-quality cubic-phase scandium germanium oxide can be obtained.

Owner:JILIN UNIV

Catalyst composition and use thereof in selective hydrogenation of conjugated diene latex

PendingCN111330647AReduce usageHydrogenation conditions are not harshOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsPtru catalystReaction rate

The invention provides a catalyst composition, which comprises a VIII group metal compound catalyst shown as formula I and an auxiliary agent, wherein the auxiliary agent is sodium dodecyl benzene sulfonate. The catalyst system provided by the invention can realize effective hydrogenation of latex, can significantly reduce the use amount of the catalyst, improve the catalytic efficiency and reducethe industrial cost by adding a small amount of the auxiliary agent, has no participation of an organic solvent in the reaction process, and is beneficial to green chemical industry. The reaction rate of the reaction system is increased, the usage amount of the catalyst is low, the cost can be reduced, the reaction conditions are mild, the reaction efficiency is high, and rapid industrializationis facilitated.

Owner:山东京博中聚新材料有限公司 +2

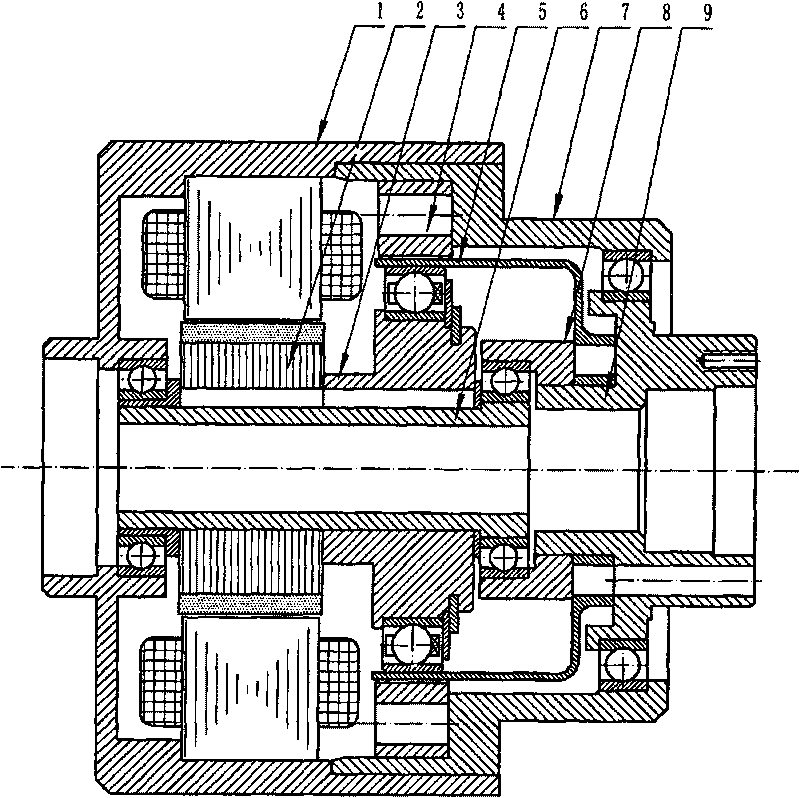

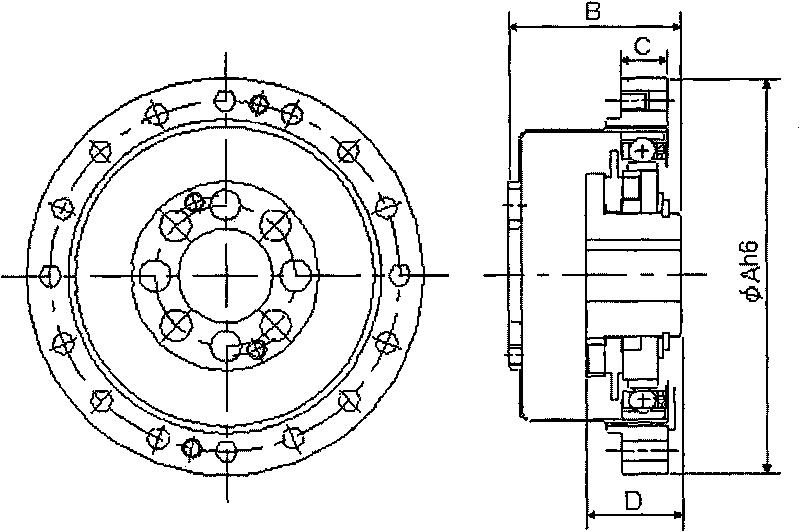

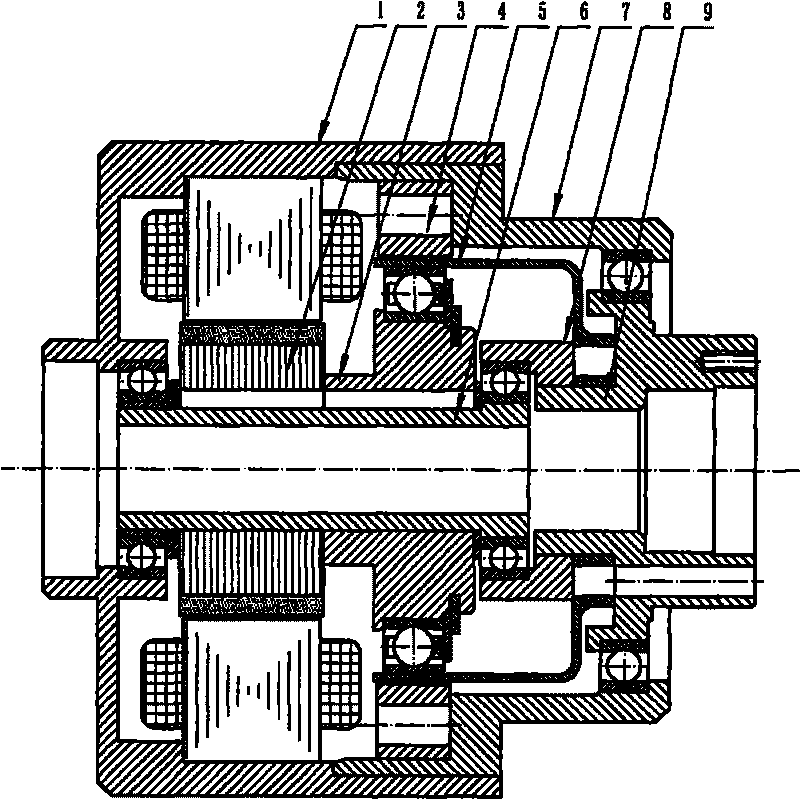

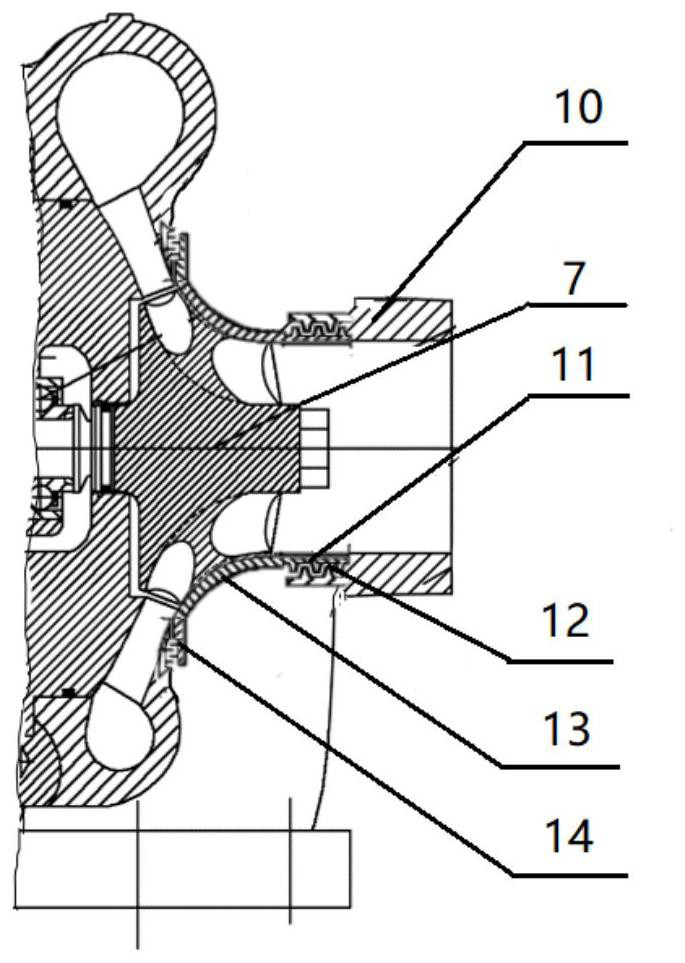

Standard harmonic assembly speed-reducing mechanism of electric bicycle

InactiveCN101734342AReduce manufacturing costRapid industrializationVehicle transmissionManufacturing cost reductionHarmonic

The invention provides a standard harmonic assembly speed-reducing mechanism of an electric bicycle, which totally uses a marketized general standard harmonic transmission assembly, adds accessories, i.e. an inner sleeve and an outer sleeve of a flexible gear, on the flexible gear of the standard harmonic transmission assembly and increases the functions of the standard harmonic transmission assembly to meet the special requirements of the electric bicycle so that a standard part commodity of a core part, i.e. the harmonic transmission assembly, of a harmonic speed-reducing driving machine of the electric bicycle can be purchased in the market. The invention greatly reduces the manufacturing cost, provides the production efficiency and fast realizes the industrialization of a harmonic speed-reducing electric bicycle technology.

Owner:王乐琳

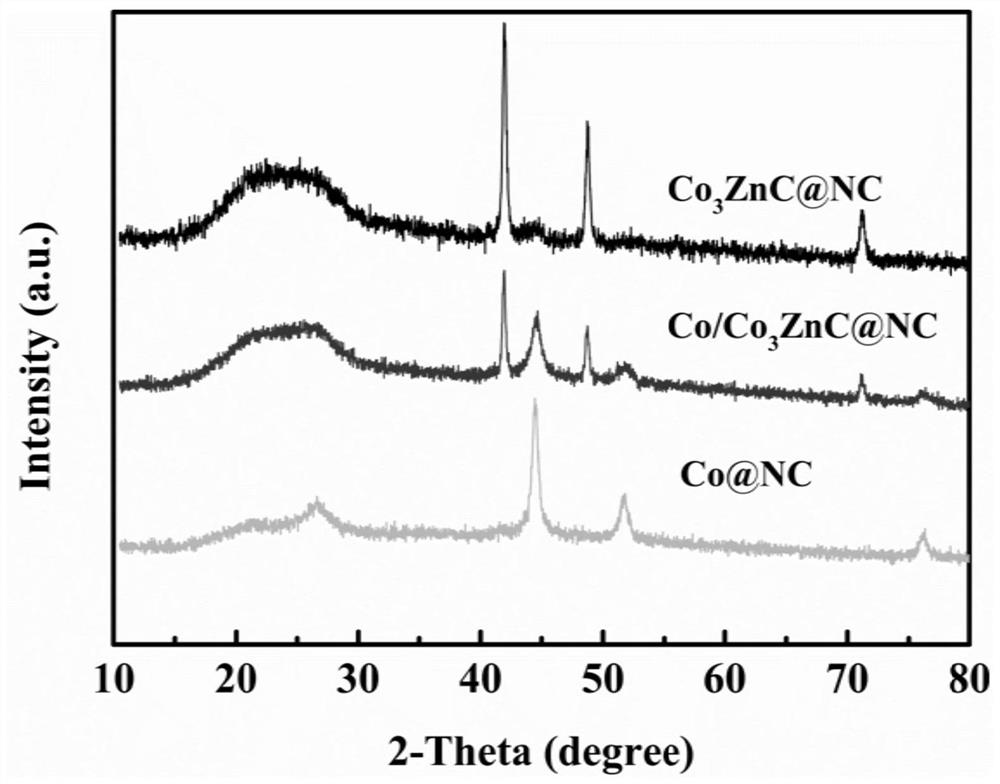

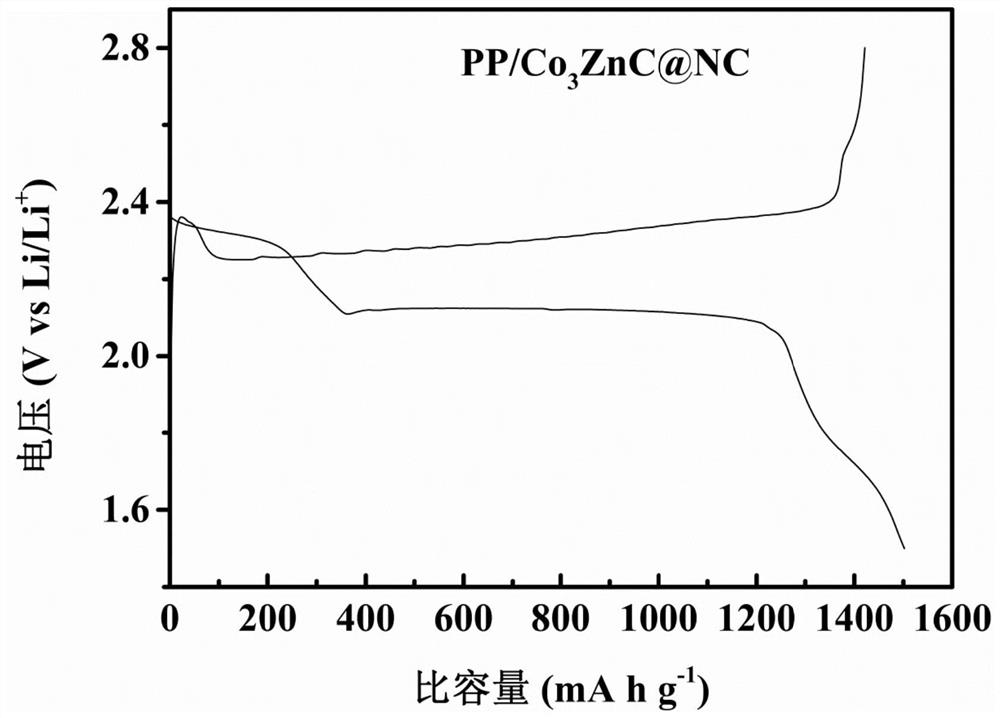

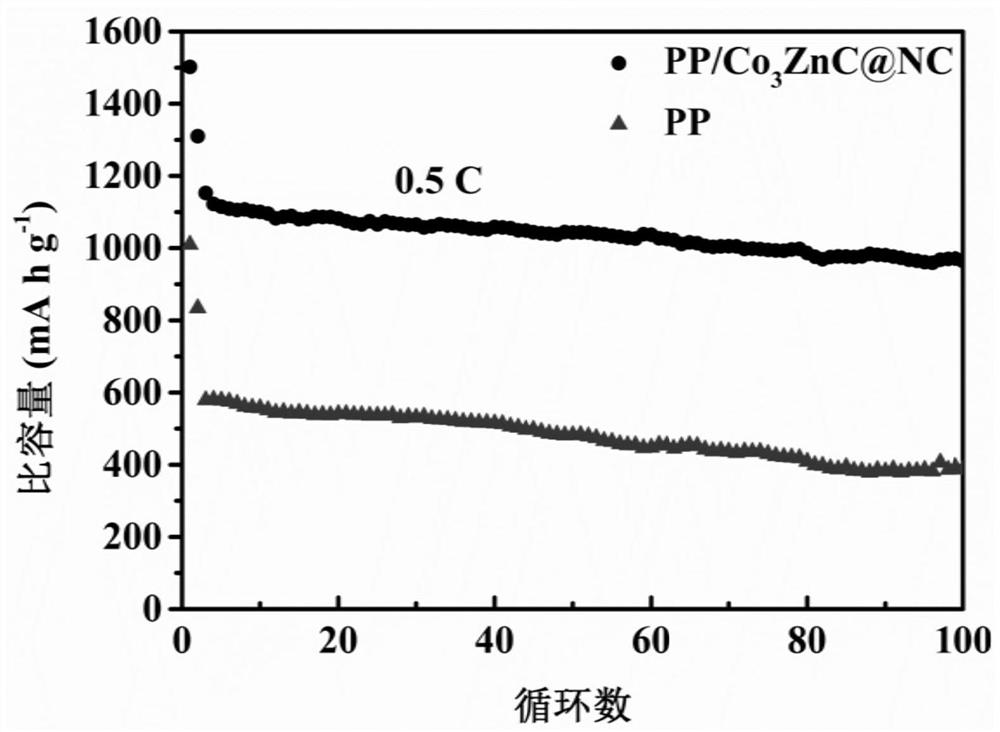

Application of nitrogen-doped carbon-coated Co and/or Co3ZnC composite material in preparation of lithium-sulfur battery diaphragm

PendingCN112670669AThe synthesis process is simpleNovel structureCarbon preparation/purificationLi-accumulatorsComposite materialCarbon source

The invention belongs to the field of nano materials and lithium-sulfur batteries, and discloses an application of a nitrogen-doped carbon-coated Co and / or Co3ZnC composite material in preparation of a lithium-sulfur battery diaphragm. The preparation method comprises the following steps: dissolving Pluronic F-127 in water, adding a carbon source dicyandiamide, adding a positive bivalent cobalt salt and a positive bivalent zinc salt, performing further stirring, evaporating water to dryness to obtain a solid compound, and carrying out high-temperature carbonization under the protection of N2 gas. In the process, dicyandiamide is carbonized to obtain N-doped carbon, reducing substances such as carbon monoxide, carbon dioxide, nitric oxide and carbon generated in the carbonization process of dicyandiamide can reduce and carbonize cobalt and zinc to obtain Co or Co3ZnC, and a target product is obtained after the reaction is completed. The N-doped carbon-coated Co and / or Co3ZnC composite material is used as a diaphragm modification material and is coated on a commercial diaphragm by a scraper method, and the electrochemical performance of the lithium-sulfur battery can be effectively improved when the N-doped carbon-coated Co and / or Co3ZnC composite material is applied to the lithium-sulfur battery.

Owner:SOUTH CHINA AGRI UNIV

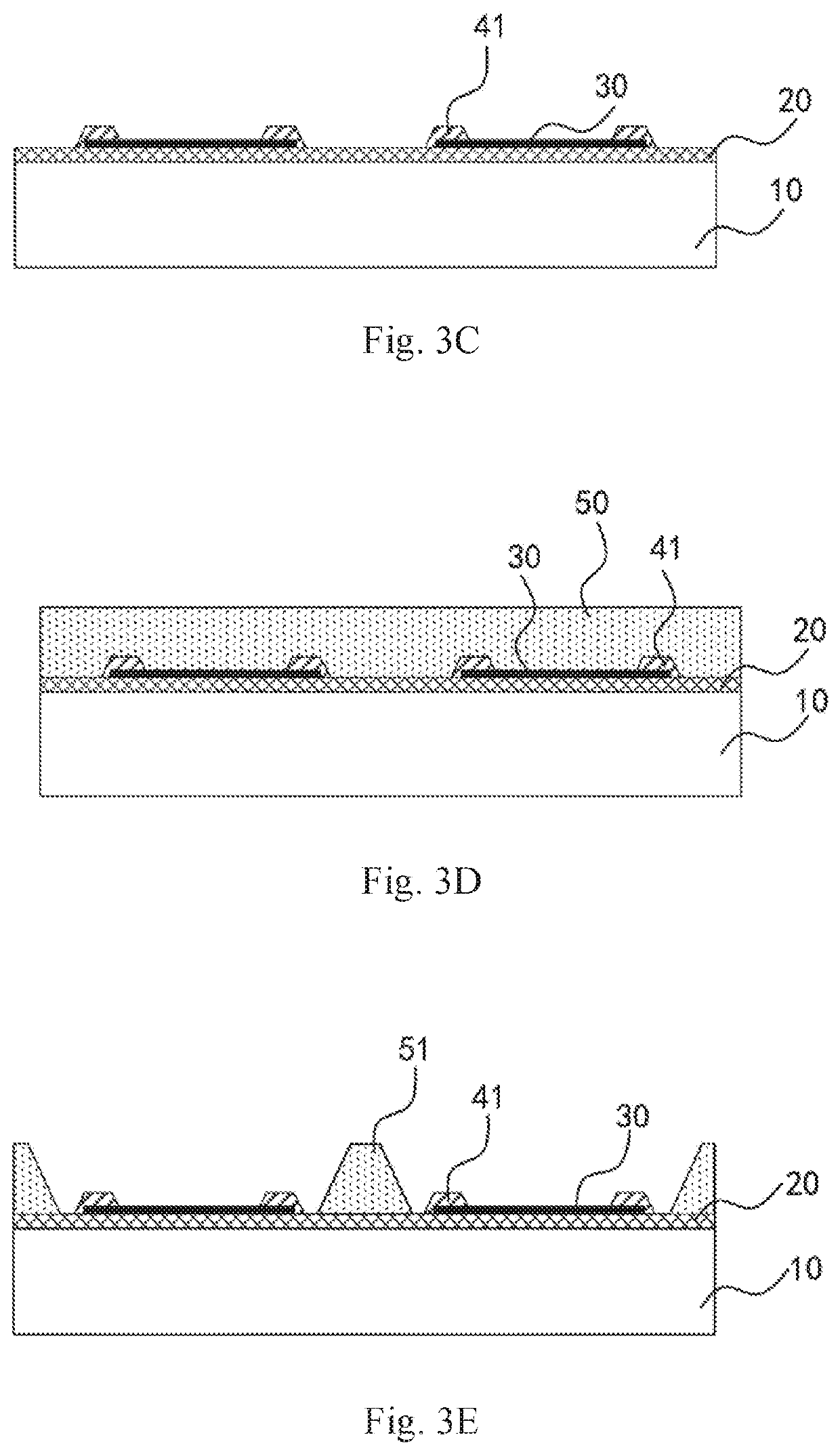

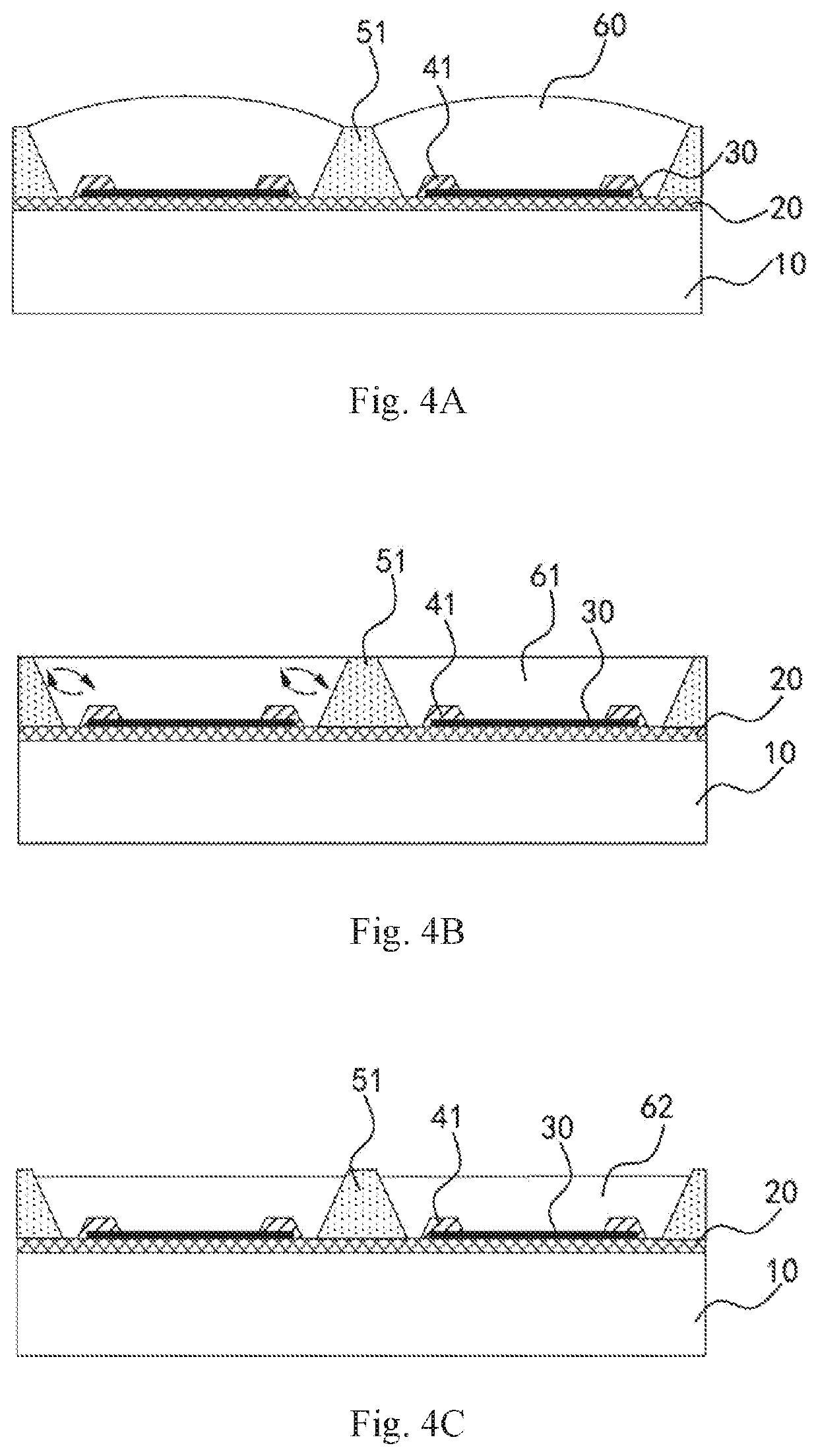

Array substrate and method for preparing the same, display panel and display device

ActiveUS11315992B2Easy to operateLow costSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceMaterials science

The present disclosure provides an array substrate, including: a base substrate; a planarization layer formed on the base substrate; a plurality of pixel electrodes formed on the planarization layer; and a pixel definition layer including a first pixel definition layer and a second pixel definition layer, the first pixel definition layer covering a periphery of each pixel electrode and exposing a central area of each pixel electrode, the second pixel definition layer being formed on the planarization layer between adjacent pixel electrodes and having a plurality of openings defining each sub-pixel unit; a bottom of a dam portion of the second pixel definition layer and a bottom of a dam portion of the first pixel definition layer adjacent thereto are separated by a predetermined distance, and a thickness of the second pixel definition layer is greater than a thickness of the first pixel definition layer.

Owner:BOE TECH GRP CO LTD

Catalyst composition and application thereof on selective hydrogenation of conjugated diene latexes

PendingCN111359665AReduce usageHydrogenation conditions are not harshOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsPtru catalystReaction rate

The invention provides a catalyst composition, which comprises a VIII group metal compound catalyst represented by a formula I and an auxiliary agent, and the auxiliary agent is lauryl sodium sulfate.The catalyst system provided by the invention can realize effective hydrogenation of latex, the use amount of the catalyst is obviously reduced by adding a small amount of the auxiliary agent, the catalytic efficiency is improved, and the industrial cost is reduced. No organic solvent participates in the reaction process, and green chemical industry is facilitated. The reaction rate of the reaction system is increased, the usage amount of the catalyst is low, the cost can be reduced, the reaction conditions are mild, the reaction efficiency is high, and rapid industrialization is facilitated.

Owner:山东京博中聚新材料有限公司 +2

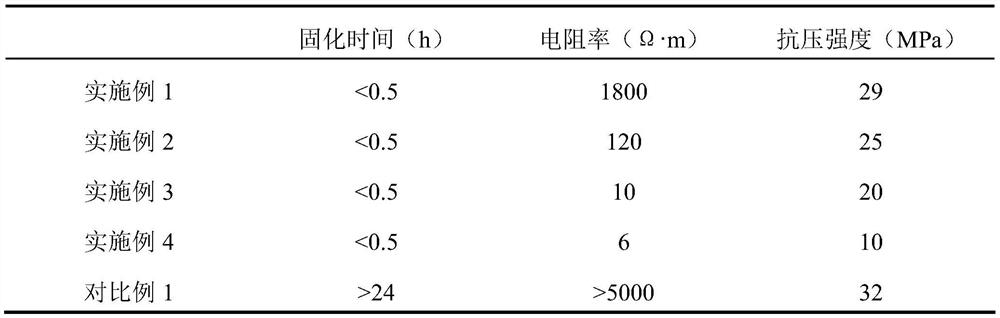

Conductive concrete composition capable of being rapidly cured and molded, preparation method and application thereof

The invention discloses a conductive concrete composition capable of being rapidly cured and molded, a preparation method and application thereof. The conductive concrete composition capable of being rapidly cured and molded comprises rapidly cured cement serving as a base material and conductive concrete combined slurry taking the base material as a benchmark, and the conductive concrete combined slurry comprises the following components by mass percentage: 0.05-2% of graphene, 0.5-3% of a graphene dispersing agent, 0-40% of a conductive filler and 15-30% of water. The rapidly cured cement is phosphorus-magnesium cement. The conductive concrete composition provided by the invention has the advantages of rapid mass production of concrete products with good conductivity, high mechanical strength, stable resistivity and good durability, not only improves the conductivity (the resistivity can reach 10ohm.cm) of a base material, but also accelerates the molding process (room temperature curing within 30min), and can be widely applied to the fields of electric heating, electric heating pavements and the like.

Owner:仙居科信智陶新材料有限公司

A kind of method for preparing tacrolimus ointment

ActiveCN102885761BReduce manufacturing costRapid industrializationOrganic active ingredientsAerosol deliveryMedicineWhite Beeswax

The invention provides a method for preparing a tacrolimus ointment. The method comprises the following steps of: 1, weighing purified tacrolimus, white beeswax, liquid paraffin, paraffin, white Vaseline, propene carbonate and propanediol in the mass ratio of 1:30:40:30:520:10:10; 2, mixing the white beeswax with the liquid paraffin and the paraffin, heating for melting, mixing uniformly to obtain a mixed solution I, and preserving heat at the temperature of 70 DEG C for later use; 3, heating white Vaseline for melting to obtain a white Vaseline solution, and preserving heat at the temperature of 70 DEG C for later use; 4, mixing propanediol and propene carbonate uniformly in the ratio of 1:1 to obtain a mixed solution 2; 5, dissolving tacrolimus into the mixed solution of propanediol and propene carbonate to obtain a mixed solution 3, and preserving heat at the temperature of 70 DEG C for later use; and 6, dispersing the mixed solution 3 into the white Vaseline solution to obtain a mixed solution 4, adding the mixed solution 4 into the mixed solution I to obtain a solution 5, stirring at the temperature of 70 DEG C for 10 minutes, cooling, and continually stirring till the solution 5 is condensed into an ointment.

Owner:ZHEJIANG WAN SHENG PHARMA CO LTD

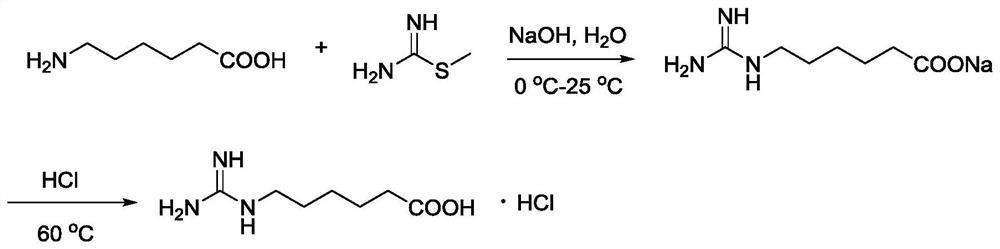

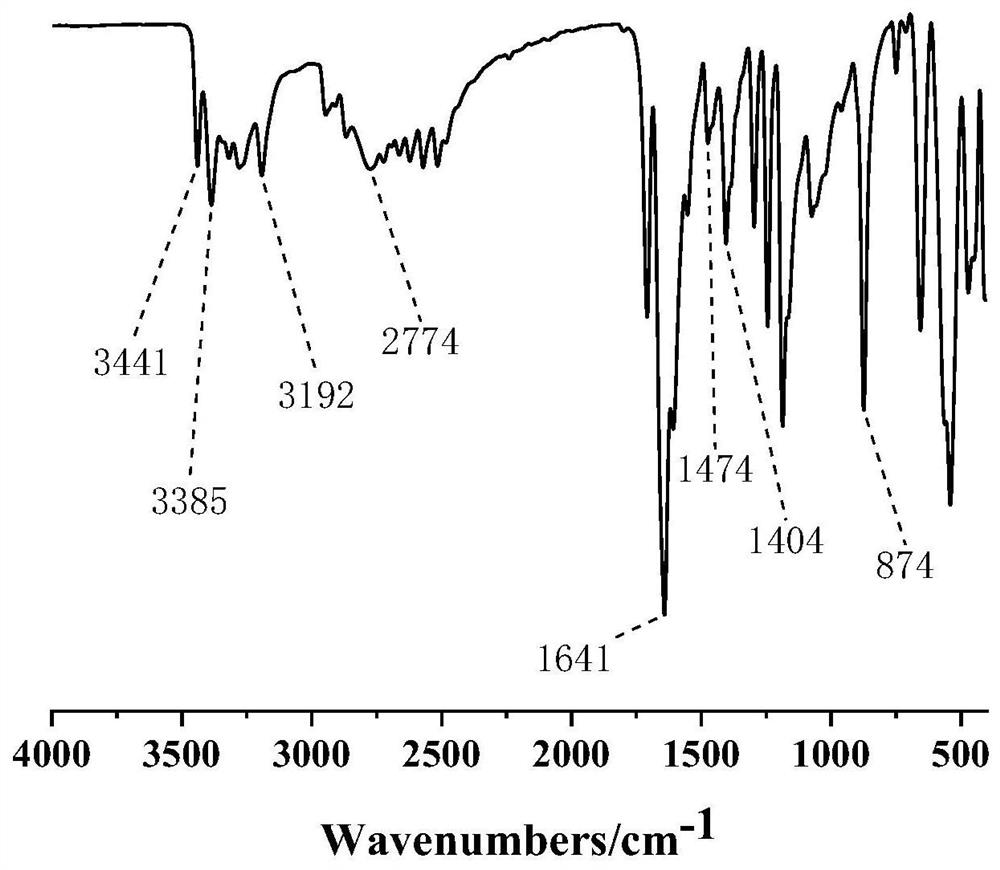

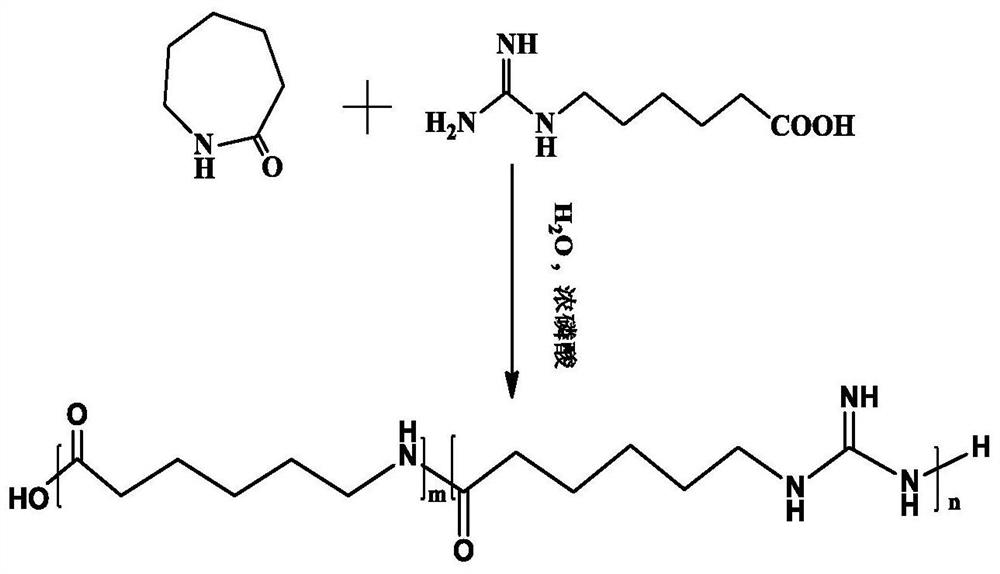

Antibacterial nylon 6 containing guanidyl group and preparation method thereof

ActiveCN114181389AEvenly distributedAvoid drug resistanceAgainst vector-borne diseasesPolymer scienceEngineering plastic

The invention provides antibacterial nylon 6 containing guanidyl groups and a preparation method of the antibacterial nylon 6. According to the antibacterial nylon 6, an organic small molecule guanidine salt compound is modified, and a 6-guanidino hexanoic acid antibacterial agent which has relatively strong interaction with nylon is developed. 6-guanidino hexanoic acid has an active reactive group and can be directly copolymerized and grafted into a nylon polymer chain, and the antibacterial agent not only can have certain binding capacity with a nylon matrix, but also can be uniformly distributed in the nylon matrix, and can effectively prevent the generation of bacterial drug resistance so as to obtain a better antibacterial effect. The invention provides an effective way for the novel structure and the preparation method of the antibacterial nylon 6, and the antibacterial nylon 6 can be widely used for preparing antibacterial fibers, antibacterial films, antibacterial engineering plastics and the like.

Owner:HANGZHOU JUHESHUN NEW MATERIAL CO LTD +1

High-temperature and high-pressure preparation method of cubic-phase scandium germanium oxide

InactiveCN103198912BHigh purityImprove qualityInorganic material magnetismMaterials preparationHigh pressure

The invention discloses a high-temperature and high-pressure preparation method of cubic-phase scandium germanium oxide, and belongs to the technical field of magnet material preparation. The high-temperature high-pressure preparation method includes taking scandium oxide and germanium oxide as raw material and preparing the cubic-phase scandium germanium oxide through technical processes of material mixing and briquetting, packaging, high-temperature and high-pressure combination, cooling and pressure releasing. The high-temperature and high-pressure combination includes keeping temperature at 1300-1500 DEG C and pressure at 5 GPa for 15-60 minutes, and finally cooling and releasing pressure. The high-temperature and high-pressure preparation method is completely processed in the environment without water and modifier, unnecessary impurities can be avoided radically, so that the obtained cubic-phase scandium germanium oxide is high in purity. Equipment adopted by the method is largely used for producing adamas, and is easy to operate; industrialization can be realized early; and high-quality cubic-phase scandium germanium oxide can be obtained.

Owner:JILIN UNIV

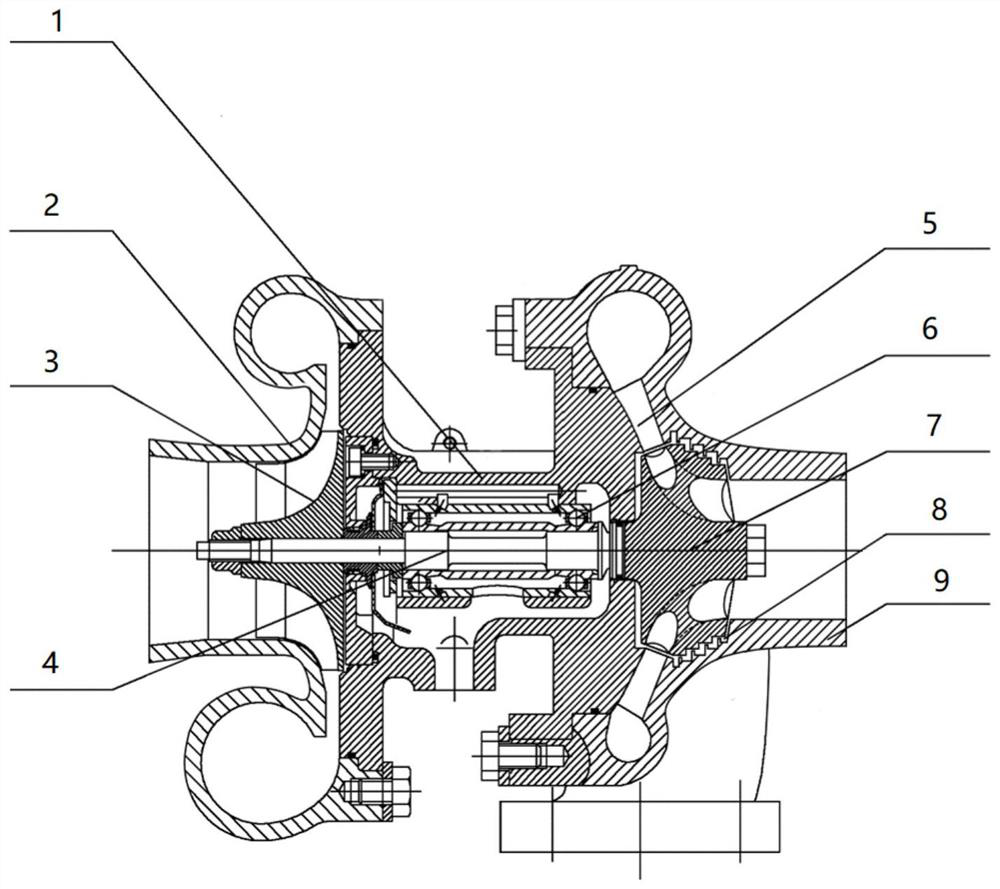

Design method of streamline tunnel type turbocharger

PendingCN112100776AAccelerate the process of industrializationHigh strengthGeometric CADInternal combustion piston enginesTurbochargerStructural engineering

The invention discloses a design method of a streamline tunnel type turbocharger. The design method comprises the following steps: 1, forming a streamline tunnel turbine by applying a streamline tunnel type rotating fluid mechanical runner design and forming method; 2, on the basis of the structure of a traditional turbocharger, matching the streamline tunnel turbine with a traditional radial-flowtype air compressor, and obtaining a streamline type tunnel turbocharger rotor structure; 3, designing a turbine end volute according to the rotor structure obtained in the step 2, and performing aerodynamic performance simulation analysis; 4, establishing a rotor kinetic model according to the rotor structure obtained in the step 2; and 5, performing rotor dynamic characteristic simulation research according to the rotor dynamic model obtained in the step 4 to verify the stability of the rotor dynamic model. The design method of the streamline tunnel type turbocharger has the advantages thatthe strength is high, the turbocharger is not prone to damage, the weight can be reduced, and the cost is reduced.

Owner:科诺泰博(北京)科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com