SiC high-temperature pressure sensor and packaging method thereof

A pressure sensor, high temperature technology, applied in the direction of piezoelectric/electrostrictive/magnetostrictive devices, measurement of the property and force of piezoelectric resistance materials, instruments, etc., can solve the problem of raising material costs, increasing production cycle, Problems such as difficulty in production, to achieve the effect of improving packaging reliability, reducing processing difficulty, and superior heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

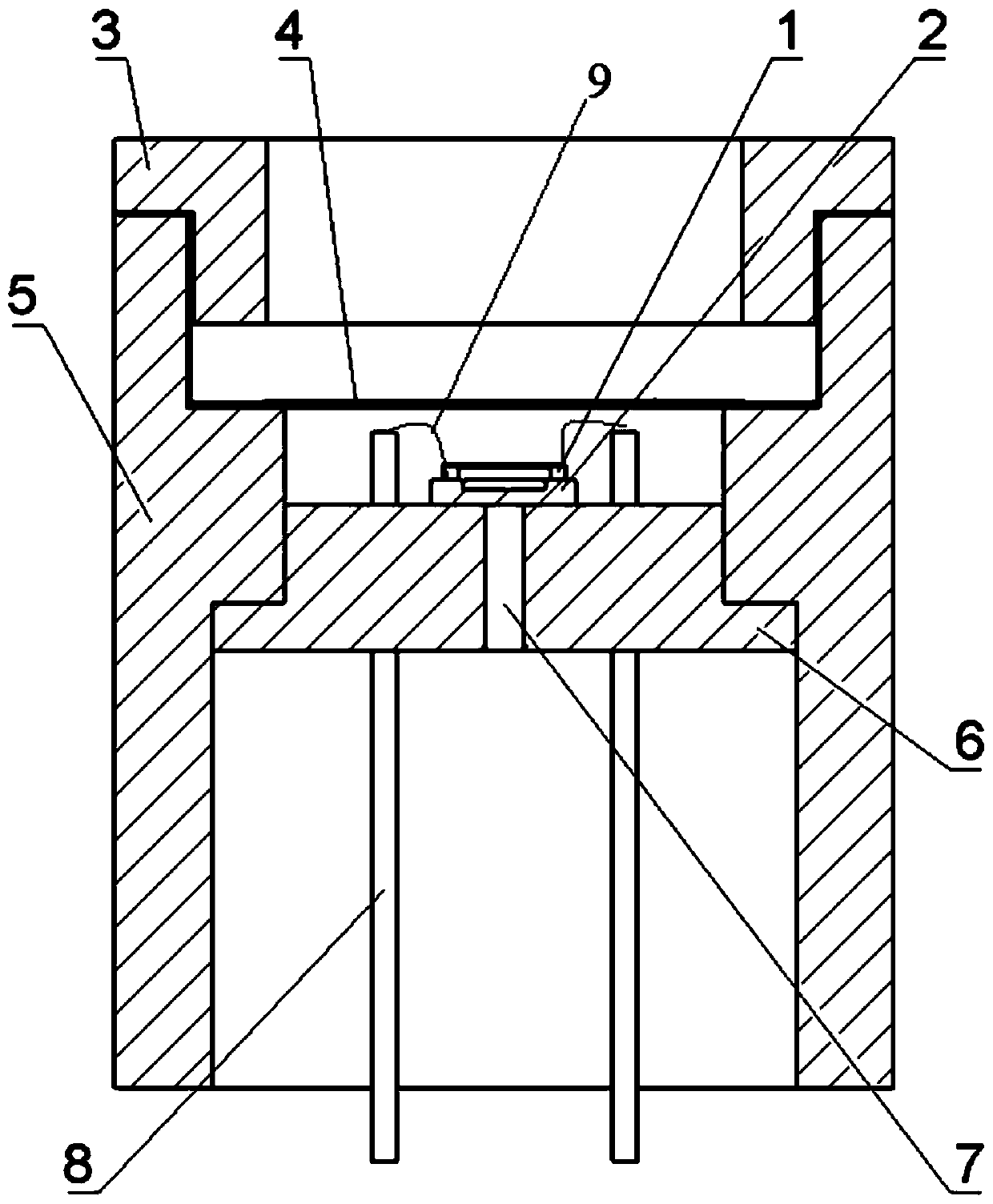

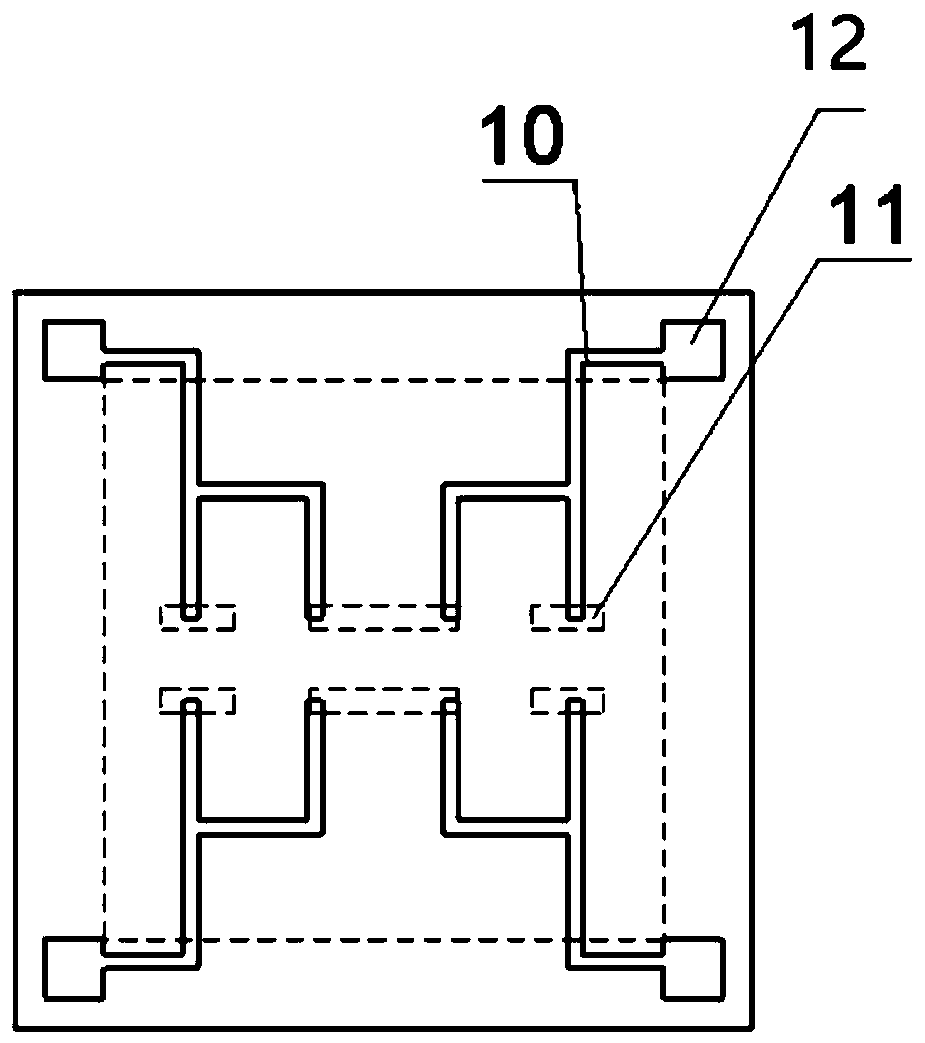

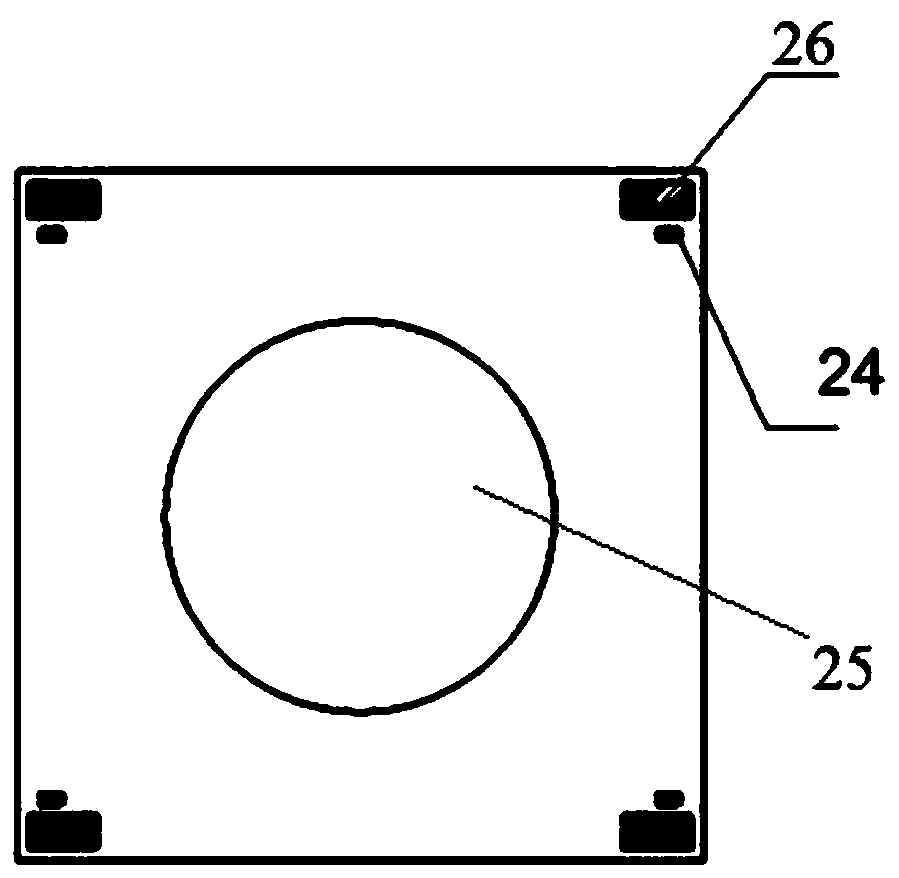

[0054] Such as Figure 1 to Figure 6 and Figure 13 As shown, a SiC high-temperature pressure sensor includes a SiC MEMS chip 1, an AlN carrier 2, an elastic metal film 4, an aluminum alloy shell 5, a copper alloy base 6 and a plurality of conductive terminals 8, and the copper alloy base 6 is installed in the aluminum alloy shell 5, the AlN carrier 2 is fixedly installed on the copper alloy base 6, the SiC MEMS chip 1 is fixedly installed on the AlN carrier 2, and the elastic metal film 4 is installed on the SiC MEMS chip On the aluminum alloy casing 5 above 1, the SiC MEMS chip 1 is isolated from the medium to be detected by the elastic metal film 4, and the conductive terminal 8 passes through the aluminum alloy casing 5 through the copper alloy base 6 and connects with the SiC MEMS The electrodes 12 of the chip 1 are connected, and an insu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com