High-temperature and high-pressure preparation method for cubic phase barium-iron-antimony oxide

A technology of antimony oxide, high temperature and high pressure, applied in the direction of iron oxide/iron hydroxide, etc., to achieve the effect of fast industrialization, simple operation and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

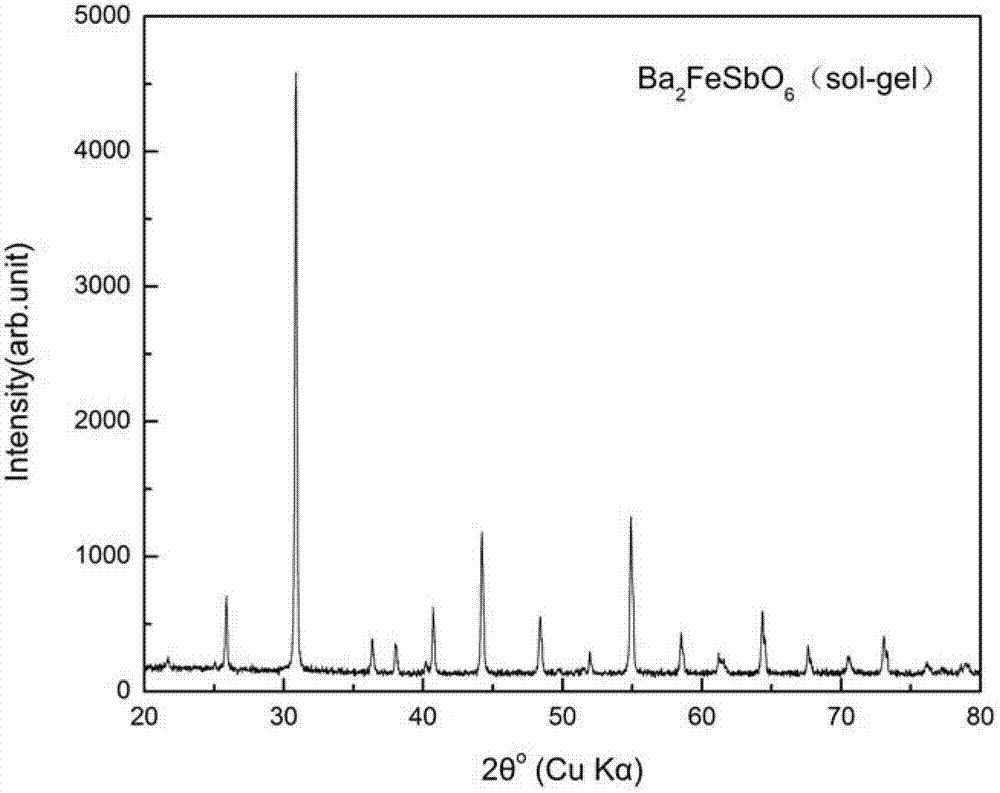

[0022] Embodiment 1: prepare Ba with sol-gel method 2 FeSbO 6 :

[0023] Weigh 3 grams C 4 h 6 o 6 (tartaric acid), completely dissolved in 150ml of distilled water as a solvent. Then add 0.0015mol of Sb 2 o 3 (0.4373 g), heated and stirred. Wait for Sb 2 o 3 When completely dissolved in tartaric acid solution, weigh 0.003mol of Fe(NO 3 ) 3 , 0.006mol of Ba(NO 3 ) 2 Dissolve in tartaric acid solution, adjust the temperature to 90°C, continue heating and stirring until the solution becomes viscous and forms a sol. Put the obtained sol-like product into an oven and bake it at 100°C for about 12 hours to obtain a dry and bulky colloid, then put the colloid in a muffle furnace for sintering for 12 hours (800°C) to obtain a sol-gel Precursor. The precursor is ground into a fine powder, put into a muffle furnace and sintered again to obtain the final sample (precursor). The hexagonal structure Ba prepared under this condition 2 FeSbO 6 X-ray results see figure 1 ....

Embodiment 2

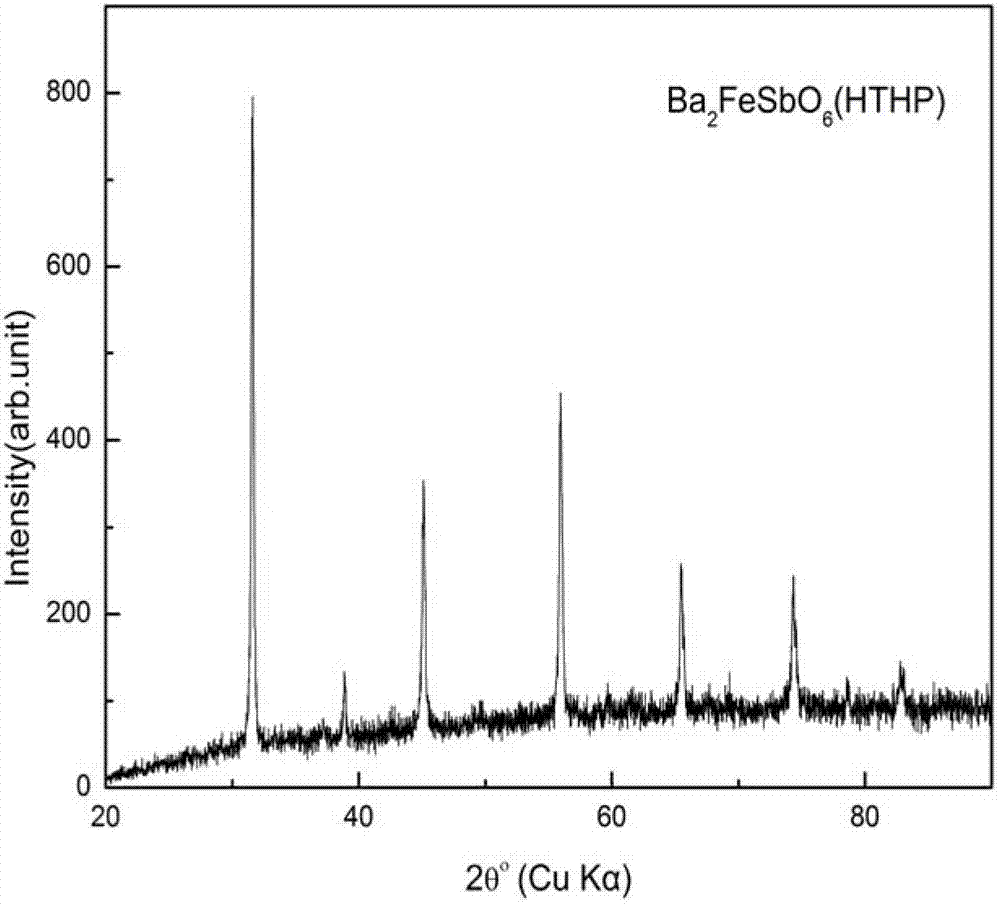

[0025] Embodiment 2: prepare Ba with the method for high temperature and high pressure 2 FeSbO 6

[0026] Using the precursor prepared in Example 1, press the precursor powder and wrap it with a layer of BN (you can put the pressure-induced precursor into the BN tube), and put the sample into the pyrophyllite synthesis chamber body. Graphite is used as the heating tube in the synthesis chamber, and pyrophyllite is used as the insulating tube. The synthesis pressure is 5GPa, the temperature is 1373K, and the pressure holding time is 1 hour. After the heating is stopped, the sample is naturally cooled to room temperature and then the pressure is released. The cubic structure Ba prepared under this condition 2 FeSbO 6 The degree of crystallization is the best, the purity is the highest, and the X-ray results can be seen figure 2 .

Embodiment 3

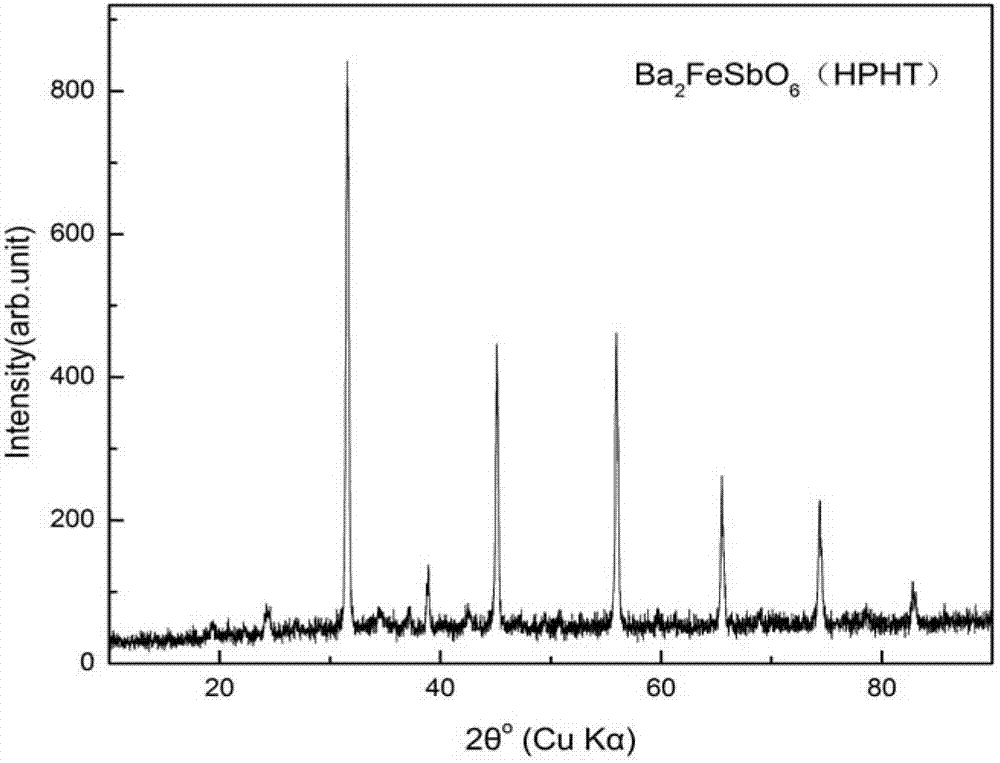

[0027] Embodiment 3: prepare Ba with the method for high temperature and high pressure 2 FeSbO 6

[0028] Using the same assembly and raw materials as in Example 2, the synthesis pressure is 5GPa, the temperature is 1473K, and the pressure holding time is 1 hour. After the heating is stopped, the sample is naturally cooled to room temperature and then the pressure is released. The cubic structure Ba prepared under this condition 2 FeSbO 6 Contains oxide impurities. For specific X-ray results, see image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com