Design method of streamline tunnel type turbocharger

A turbocharger and design method technology, applied in design optimization/simulation, instruments, mechanical equipment, etc., can solve problems affecting turbine efficiency and life, large gap leakage loss, thin frontal blades, etc., to ensure rotor stability , reduce weight, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

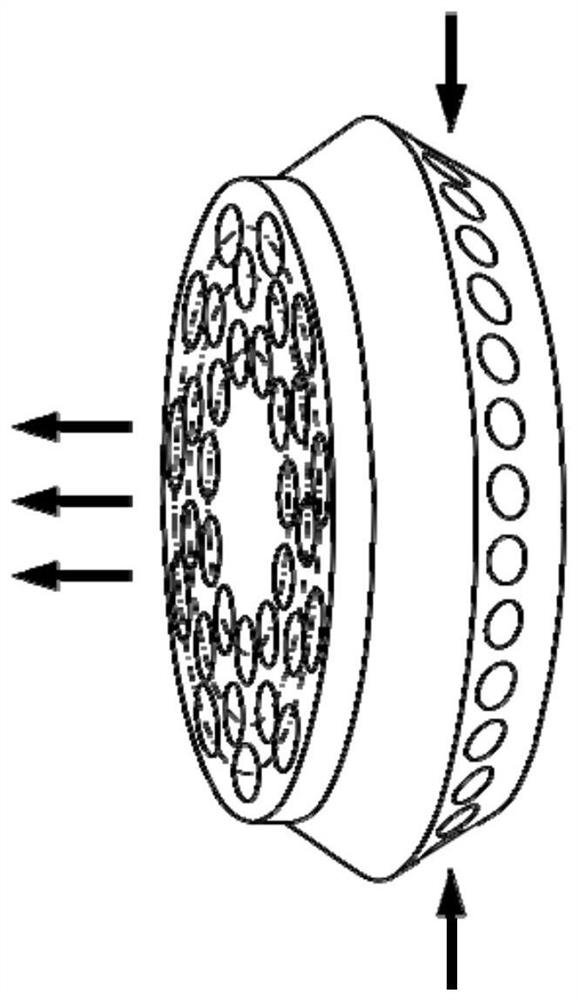

[0023] Such as figure 1 As shown, the present invention first adopts the design and forming method of the channel of the streamline tunnel type rotary fluid machine, obtains the equation of the actual center line according to the relevant constraint parameters, and then forms a complete channel to form a streamline tunnel turbine.

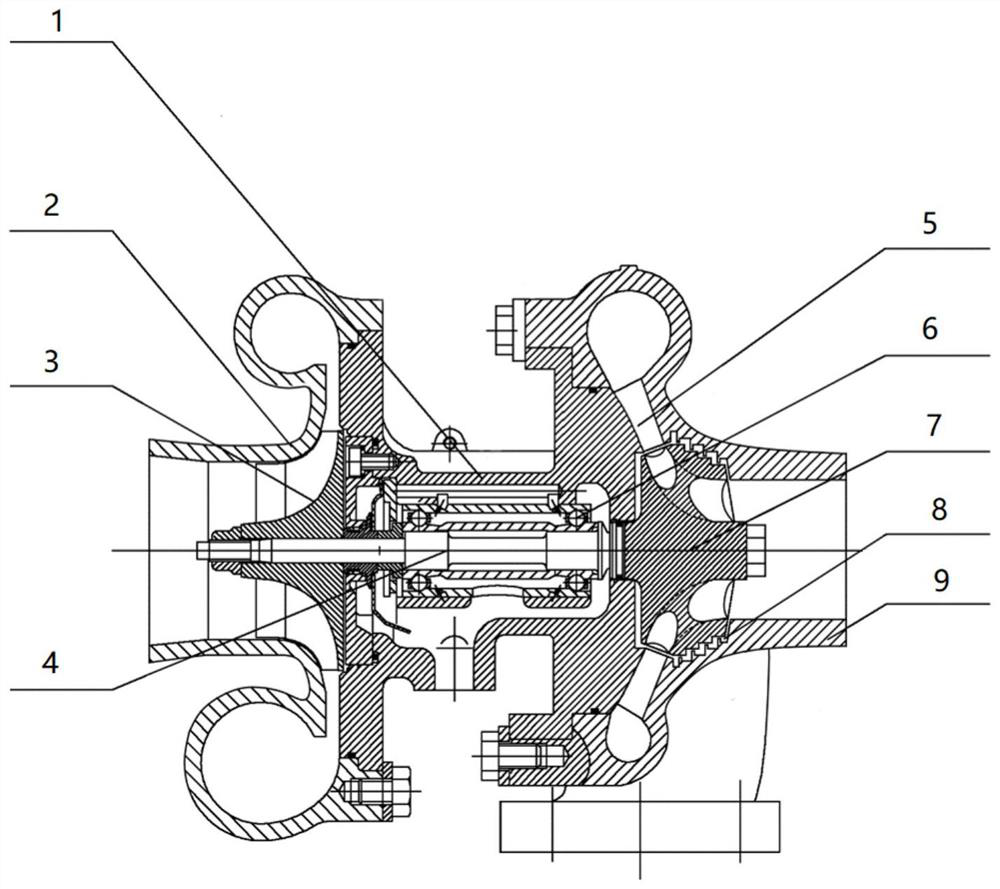

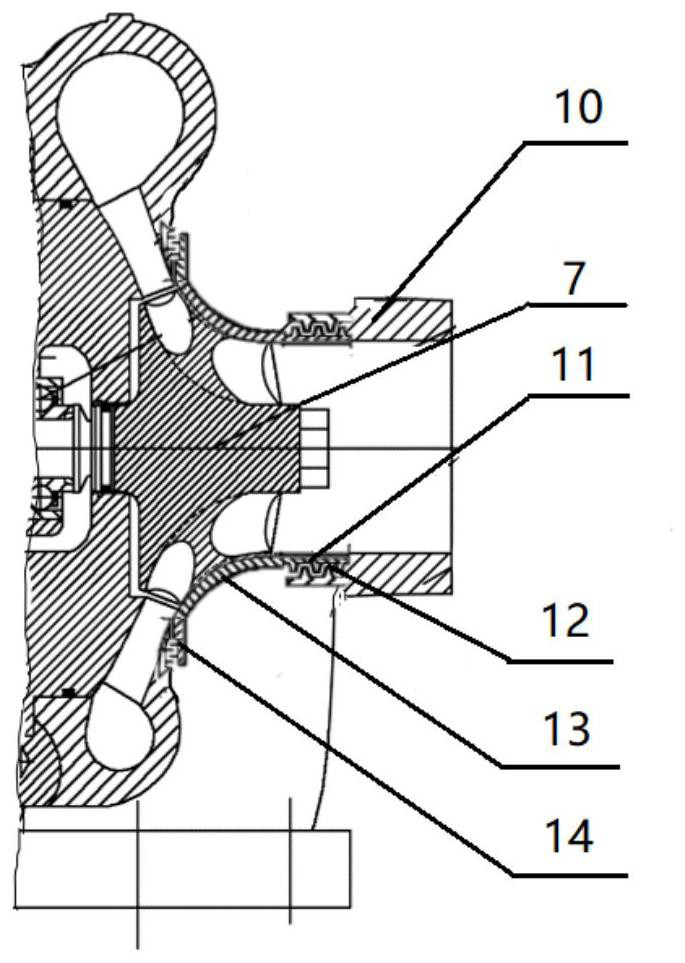

[0024] Such as figure 2 As shown, the overall structure of a streamlined tunnel turbocharger of the present invention includes a compressor impeller 3 and a streamlined tunnel turbine 7, and the compressor impeller 3 and the streamlined tunnel turbine 7 are connected through a shaft 4 and a bearing 6; The compressor casing 2 and the turbine casing 9 are connected through the middle casing 1 and form a stator tunnel flow area 5 with the rotor structure; the flowline tun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com