Patents

Literature

265results about How to "Improve sintering efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Comprehensive utilization method of aluminum ash

ActiveCN105347361AHarmlessAvoid pollutionAmmonium salt preparationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAtmospheric dustAluminum industry

The invention belongs to the technical field of comprehensive utilization of waste resources from the aluminum industry and specifically discloses a comprehensive utilization method of aluminum ash. According to the comprehensive utilization method of aluminum ash, metallic aluminium is extracted from aluminum ash through an ore grinding method; the aluminum ash obtained after aluminium extraction undergoes catalytic deamination; the aluminum ash obtained after deamination is mixed with alkali and granulation forming is then carried out; and the granulation product is sintered and the sintered product is finally dissolved out. By the above method, useful components in the aluminum ash can be recovered to the maximum; ammonia gas which has been ignored for a long time is effectively recovered; components such as aluminium oxide, villiaumite and the like are recovered and utilized to the maximum; pollution of aluminum ash processing to the environment is avoided; atmospheric dust pollution is avoided; atmospheric pollution is also avoided due to ammonia gas recovery; pollution of aluminum ash stacking to underground water and soil is avoided due to extraction and recovery of fluoride salt; and environmental safety during the treating process is guaranteed.

Owner:湖南绿脉环保科技股份有限公司

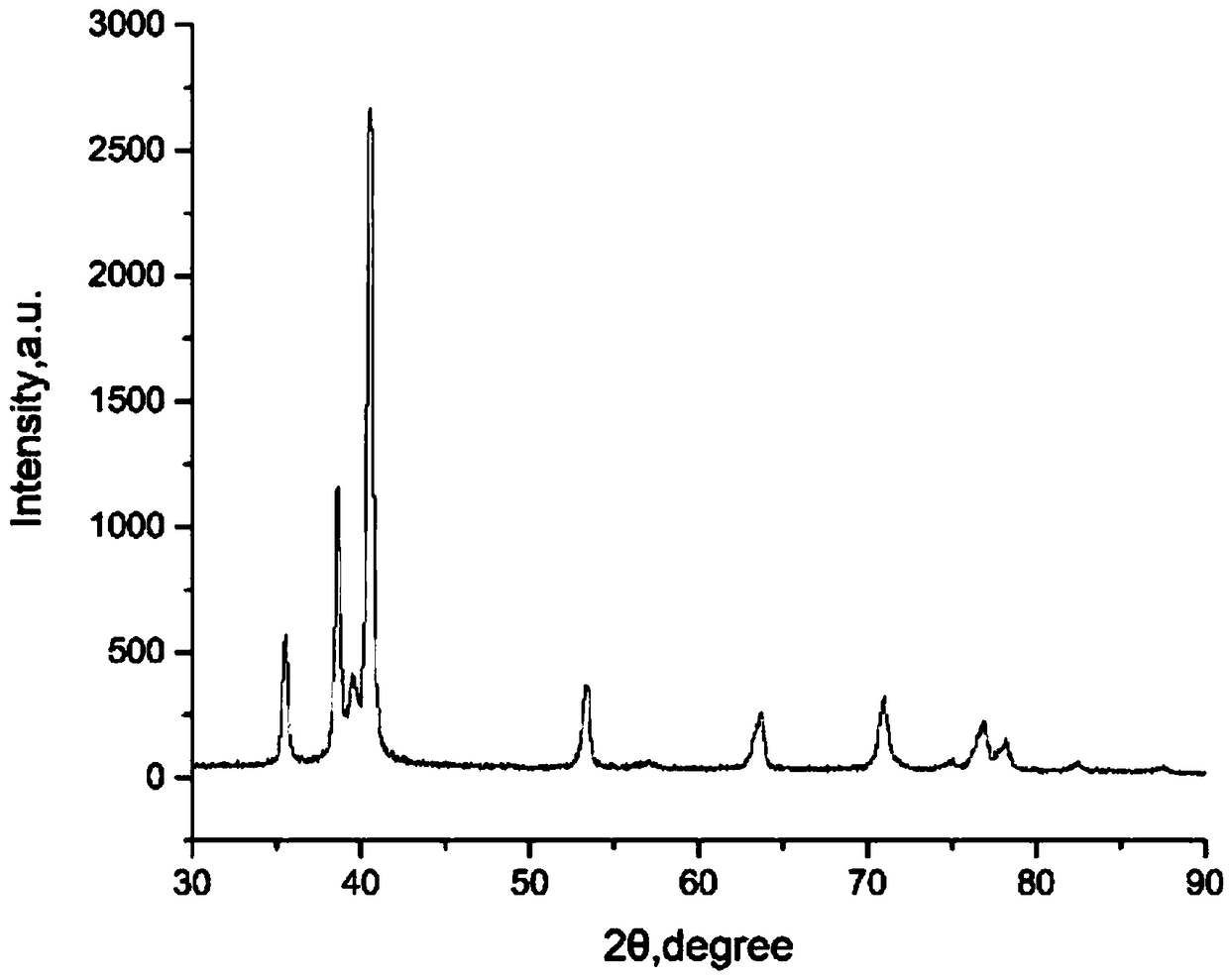

Method for controlling grain size to produce ITO target

The invention relates to a photoelectric material technique, in particular to a method for controlling the grain size to produce ITO target. ITO powder is passivated under different temperatures in advance, so that the grain size of the ITO powder can be preliminarily increased and activity is reduced, the materials passivated under different temperatures are then mixed according to different proportions and ball-milled, and finally, after processes such as spray granulation, pressing and normal-pressure atmosphere sintering, the fine-grain ITO target with the grain size of 4Mu m to 10Mu m is prepared. The invention can prepare small-grain size and uniformly distributed ITO target by way of normal-pressure atmosphere sintering, the sintering temperature is decreased, and the sintering efficiency is increased; the technique is simple, the production cost is low, continuous and mass production can be easily carried out, and large-specification, high-quality ITO target can be sintered.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

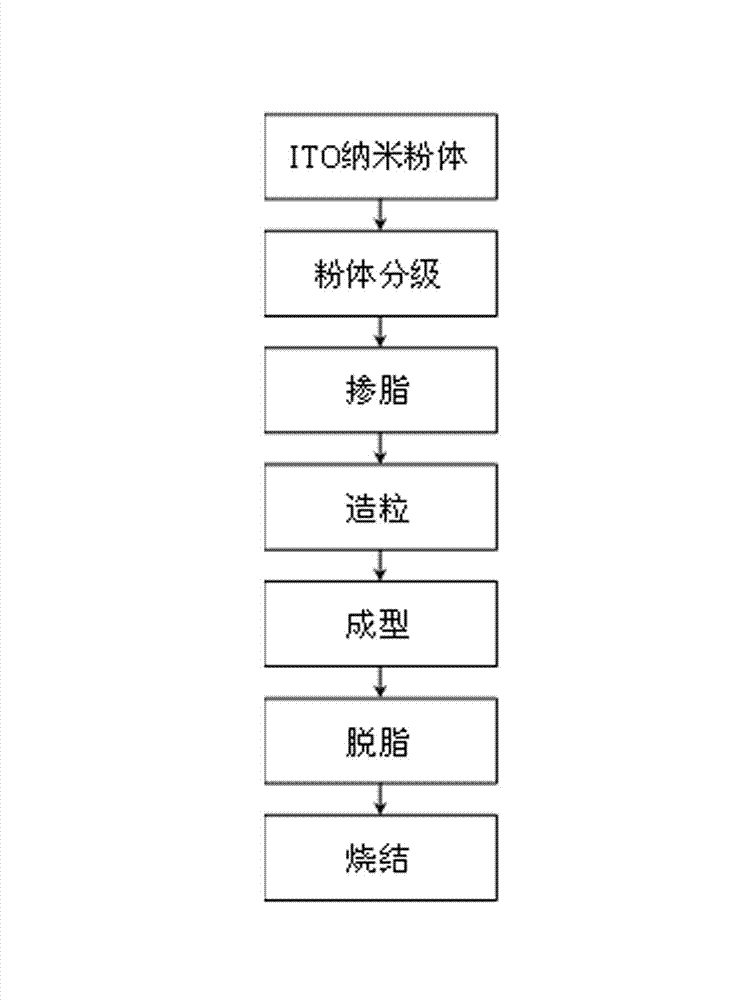

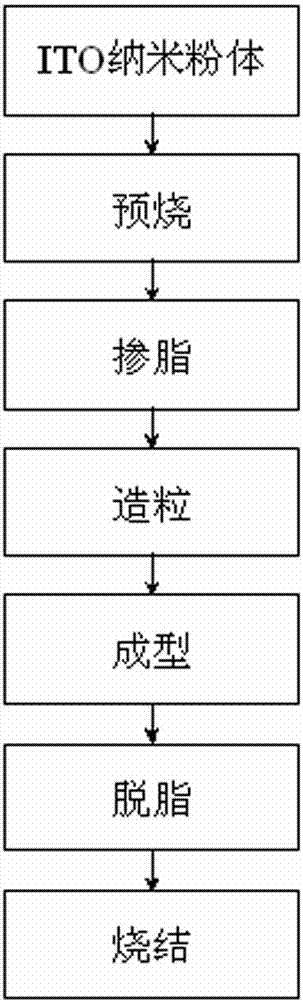

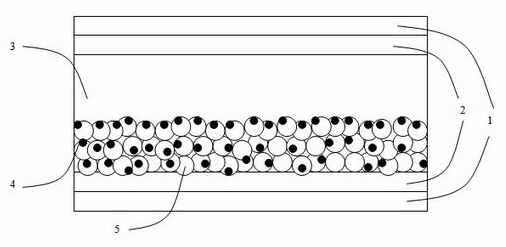

Preparation method of high-density ITO (indium tin oxide) evaporation target

The invention relates to a preparation method of a high-density ITO (indium tin oxide) evaporation target. The method comprises the following process steps: preparing powdery materials, mixing, doping grease, granulating, shaping, degreasing and sintering. By the above steps, the high-density ITO (indium tin oxide) evaporation target is prepared. Through the preparation method provided by the invention, the high-quality high-density ITO (indium tin oxide) evaporation target is beneficial to being sintered in the oxygen atmosphere under the normal pressure or without pressure; a plurality of functional additives are chosen for doping so as to improve the shaping capability and uniformity of the products; the sintering pressure is remarkably reduced, the sintering efficiency is improved and the production cost and the dangerousness are reduced; and, the preparation method provided by the invention is easy to realize continuous and scale production.

Owner:贵州法拉第磁电科技有限公司

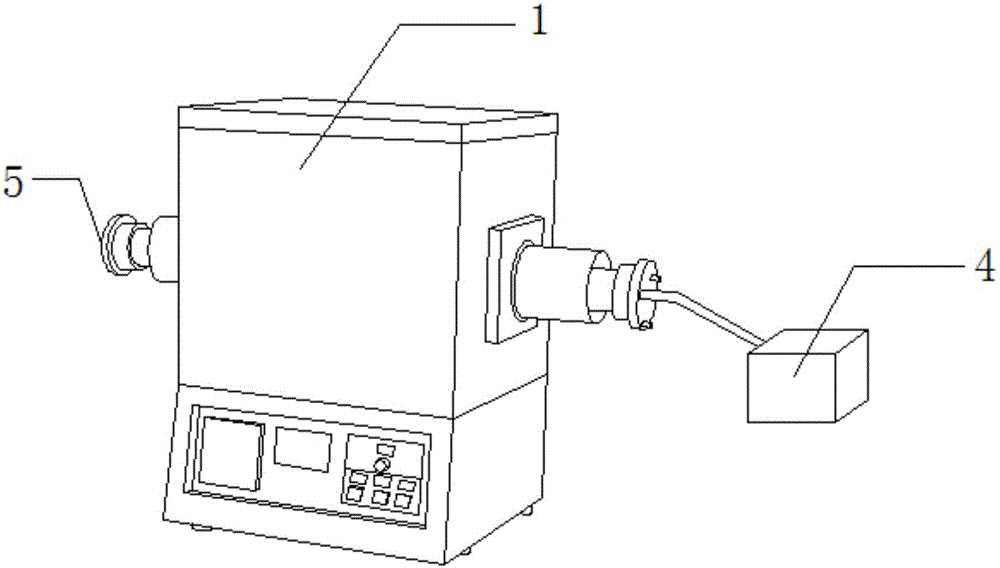

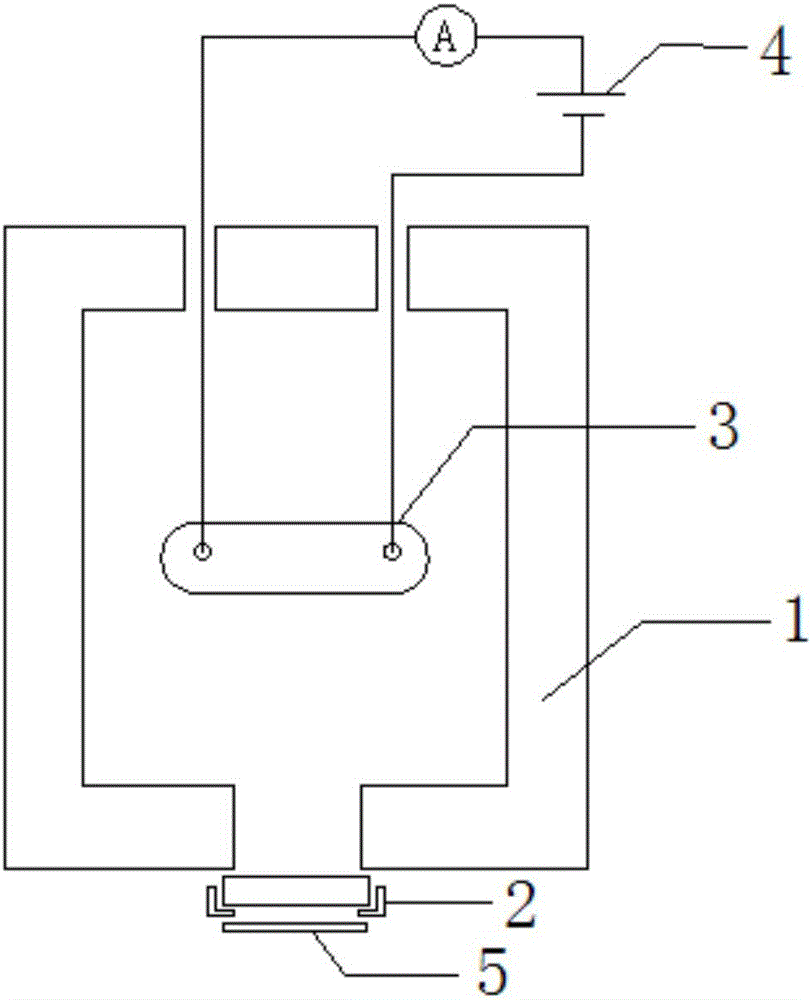

Flash sintering method of low-temperature flash sintering ceramic and obtained ceramic and device thereof

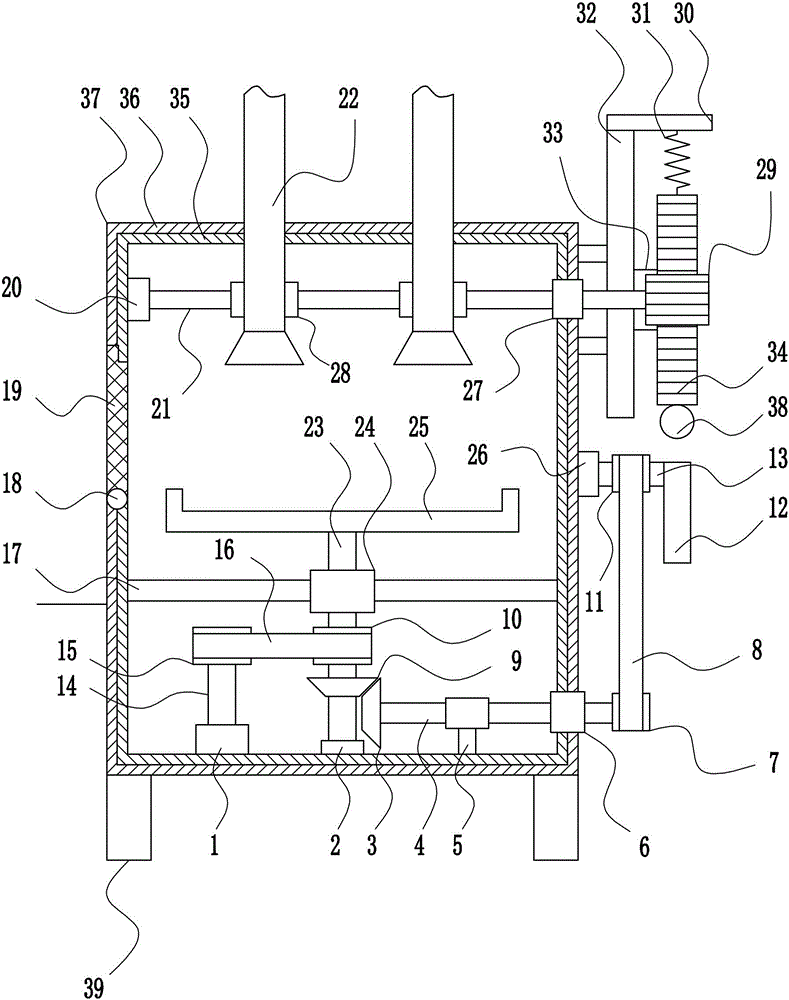

InactiveCN106630974ALower sintering temperatureShort sintering timeFurnace typesElectric heating for furnacesCeramic sinteringPower flow

The invention relates to the filed of ceramic sintering, in particular to a flash sintering method of a low-temperature flash sintering ceramic and an obtained ceramic and a device thereof. The flash sintering method of the low-temperature flash sintering ceramic comprises the following steps: loading a voltage at two ends of a ceramic green body, and setting a current upper limit; heating the ceramic green body, when the temperature reaches a characteristic temperature, the temperature suddenly rising and meanwhile bright spots appearing around an anode, then a flash phenomenon appearing, and completing sintering of the ceramic green body within several seconds. According to the method, the flash phenomenon occurs when the temperature is heated to a certain characteristic temperature through voltage assist, and the sintering is completed within several seconds, so that the sintering temperature can be effectively reduced, and the sintering time can be greatly shortened. Moreover, according to the sintering method, the energy resources are saved, the sintering efficiency is improved, the production cost is reduced, ceramic products with large dimensions and complicated shapes can be produced, the density of a sintered ceramic block body is generally more than 95%, and the quality of the sintered and obtained ceramic is excellent.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Preparation method of directionally-distributed TiB whisker reinforced titanium-based composite material

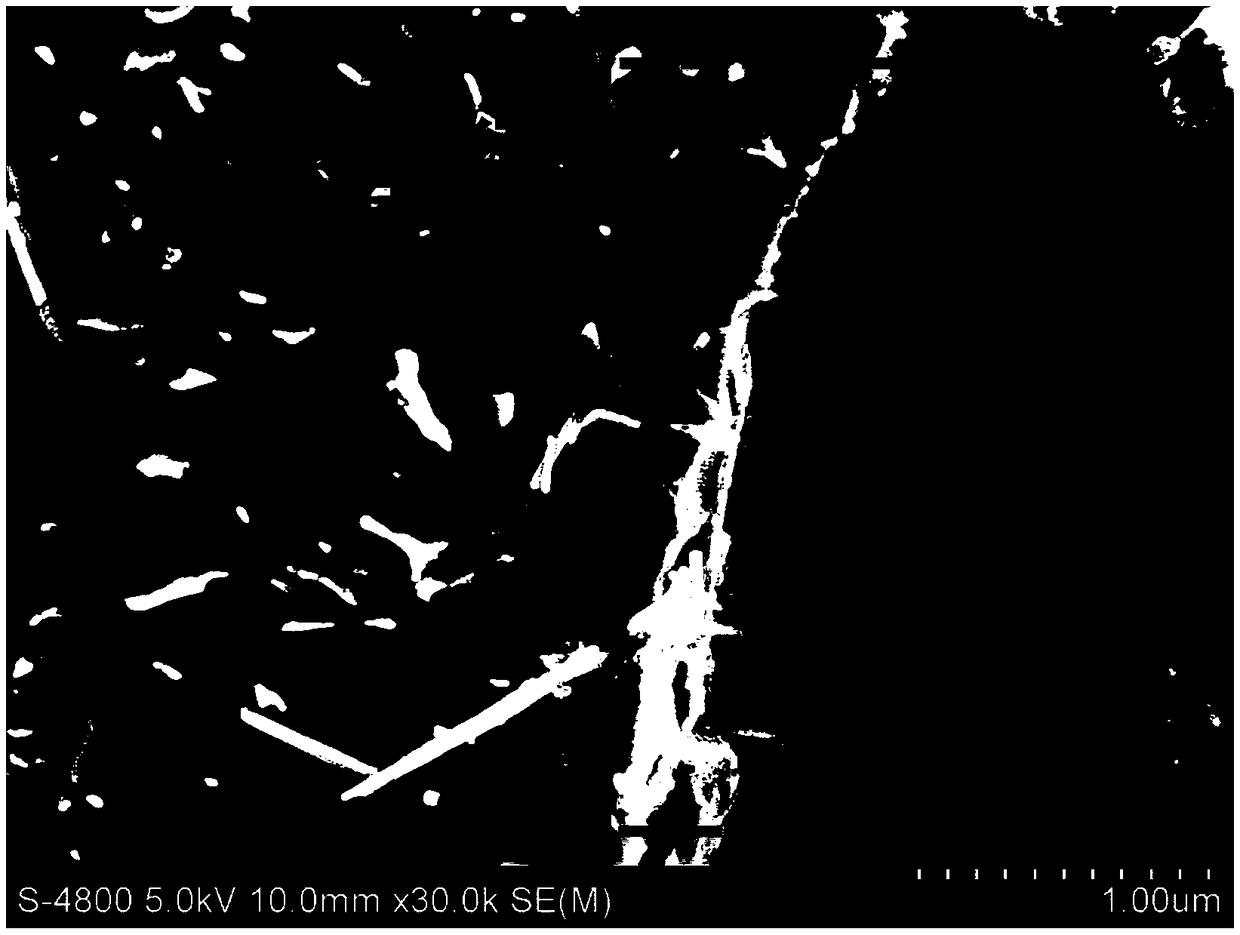

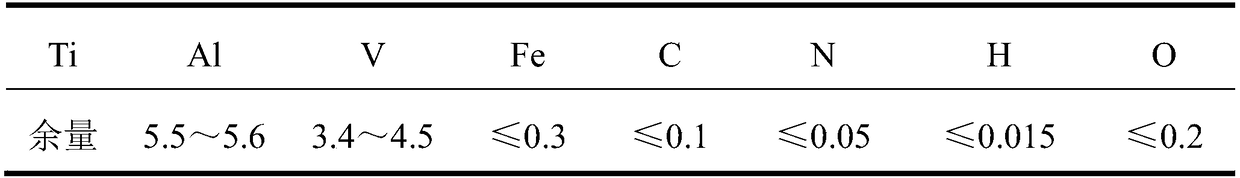

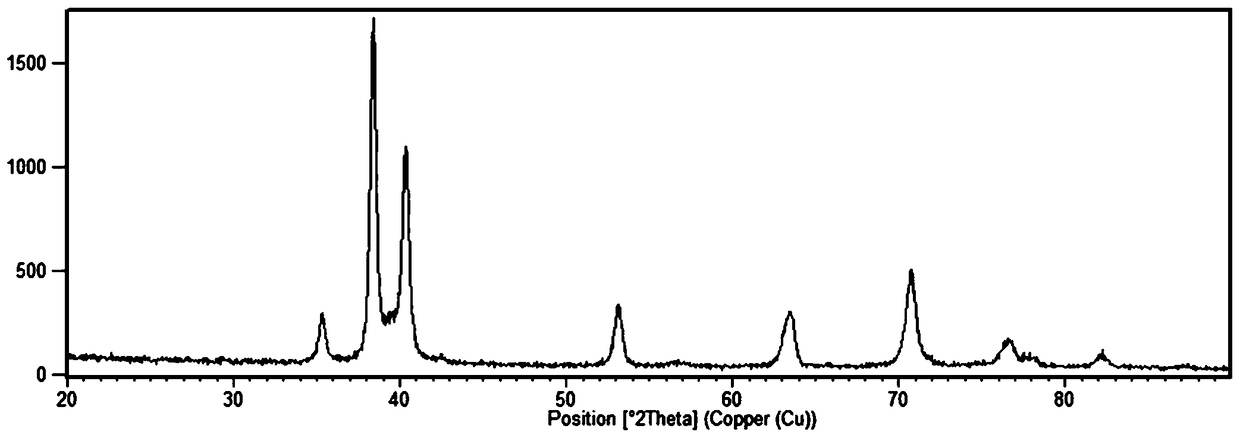

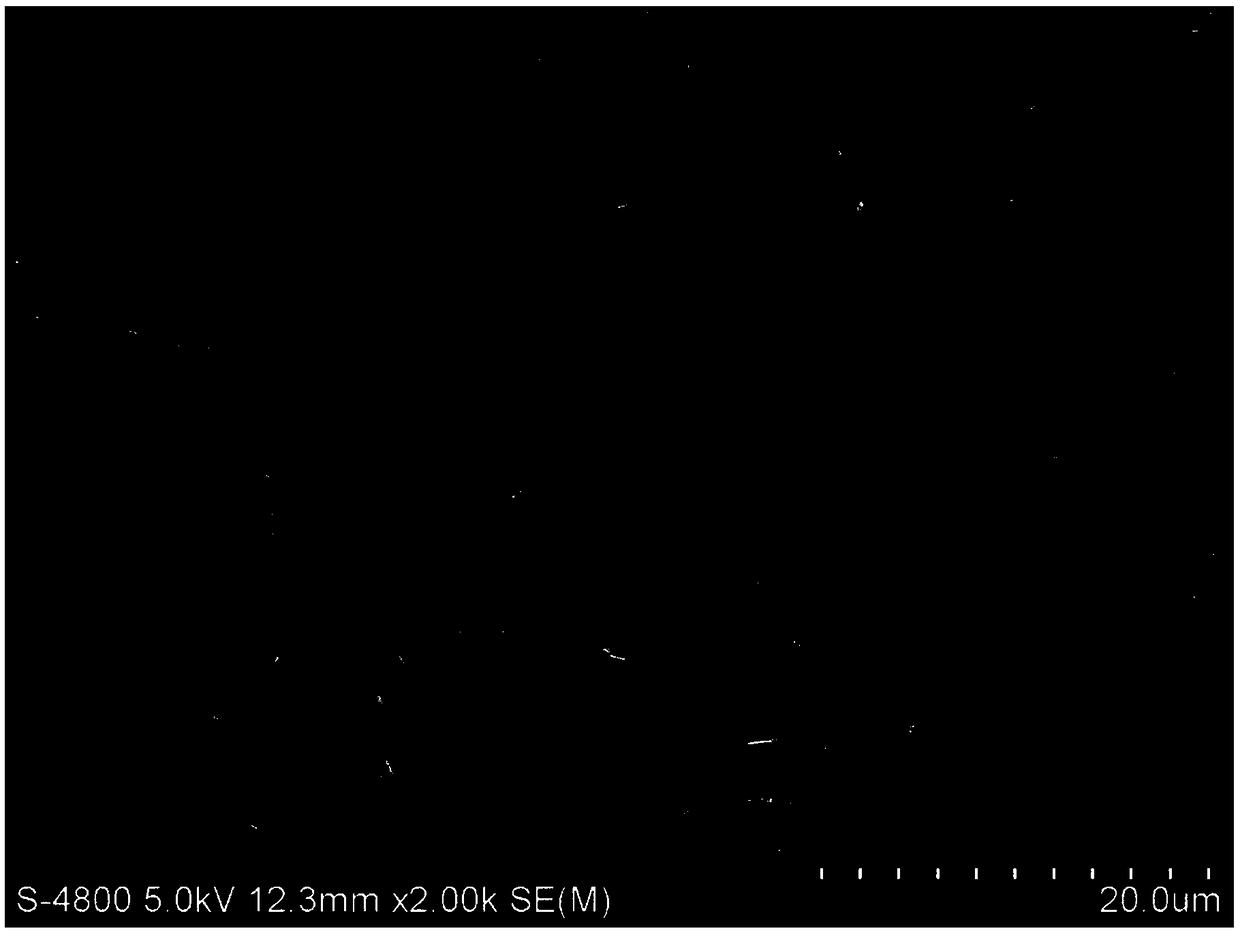

ActiveCN108796264AEffectively regulate organizational evolutionSolve problems such as a sharp drop in aspect ratioTitanium matrix compositesThermal deformation

The invention relates to a preparation method of a directionally-distributed TiB whisker reinforced titanium-based composite material, and belongs to the field of metal-based composite materials. Thepreparation method comprises the following steps that nano TiB2 powder and titanium powder, or nano TiB2 powder and titanium alloy powder are uniformly mixed; sintering treatment is carried out on themixed powder by adopting a discharge plasma system to obtain a composite material block body; and the dried composite material block body is packaged in a quartz tube in a vacuum mode, heat treatmentis carried out in a heat treatment furnace, and then the composite material is obtained by step-by-step cooling. The method can effectively regulate and control the organization evolution of a TiB whisker in the titanium-based composite material, the problem that the orientation regulation and control means of the TiB whisker is single is fully solved, a thermal deformation means is used for regulating and controlling the crystal whisker form, and the crystal whisker length-diameter ratio is greatly reduced and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Preparation method of TiB nano-reinforced titanium-based composite material

The invention relates to a preparation method of a TiB nano-reinforced titanium-based composite material, and belongs to the field of metal-based composite materials. According to the method, the composite material is prepared through ball milling, spark plasma sintering and hot rolling. The original powder is prepared through ball milling, the advantages that the sintering efficiency of the discharge plasma is high, and the external pressure and the sintering atmosphere can be controlled are utilized, so that under the low sintering temperature and the high pressure, and on the premise that the TiB2 particles and the surrounding titanium or titanium alloy matrix do not generate in-situ reaction, a sintering block body with high compactness is prepared; and finally, the TiB2 particles in the sintered block body are subjected to in-situ reaction with the surrounding titanium or titanium alloy matrix through hot rolling to form whiskers, and meanwhile, the crystal grains of the matrix are deformed, the porosity in the structure is reduced, and the strength and the plasticity of the composite material are improved. The TiB nano crystal whisker generated in situ in the method is cleanin surface and is uniformly distributed in a matrix and free of agglomeration, has good interface bonding and lattice relationship with the titanium matrix, and can effectively refine matrix crystal grains.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

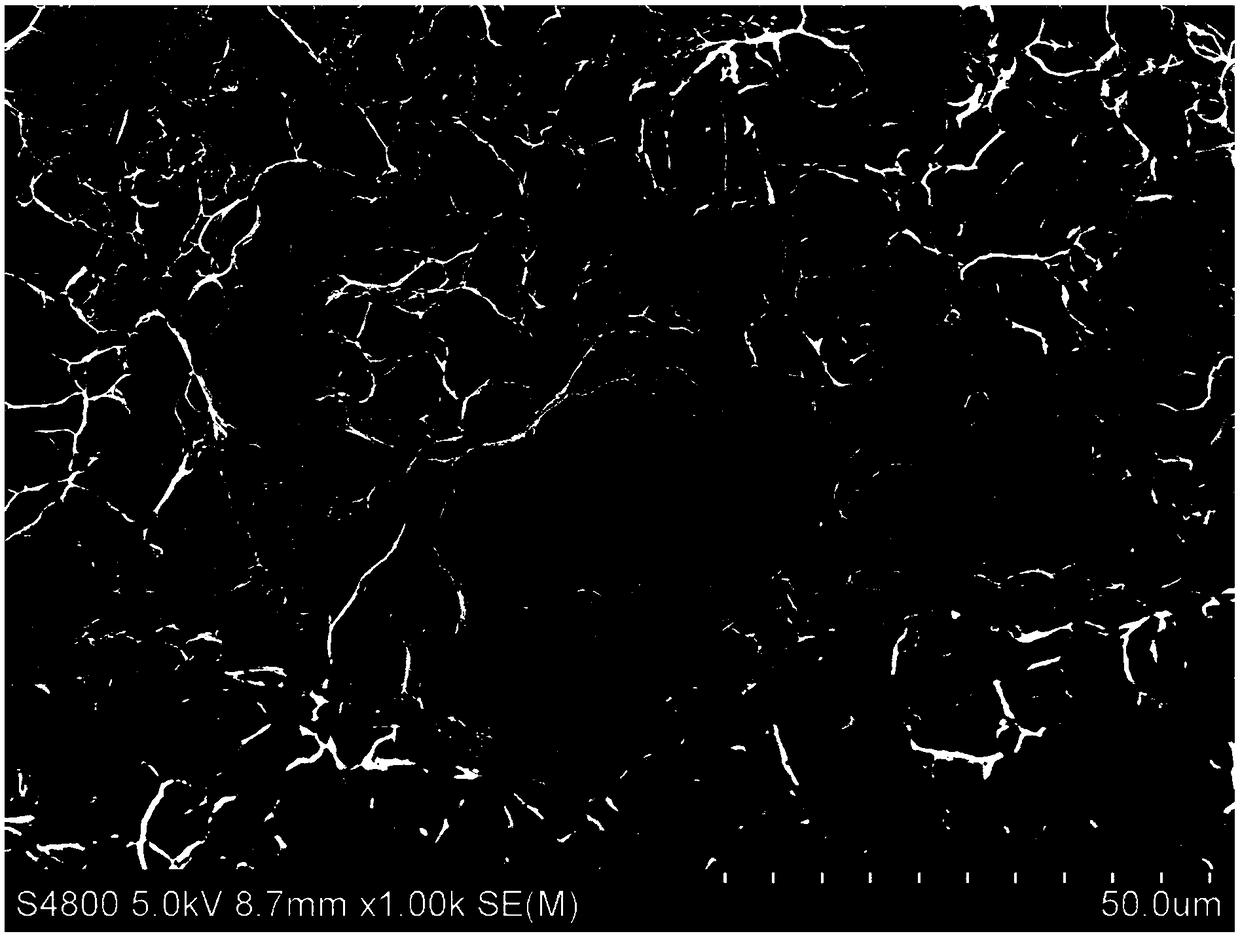

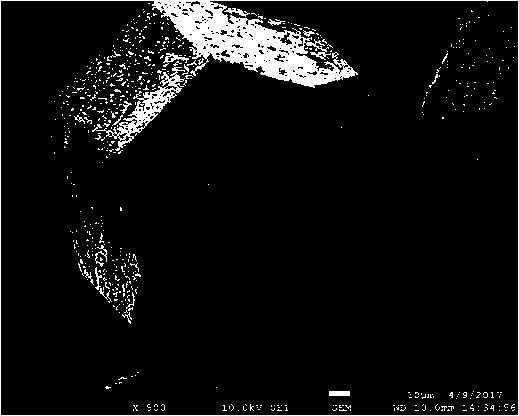

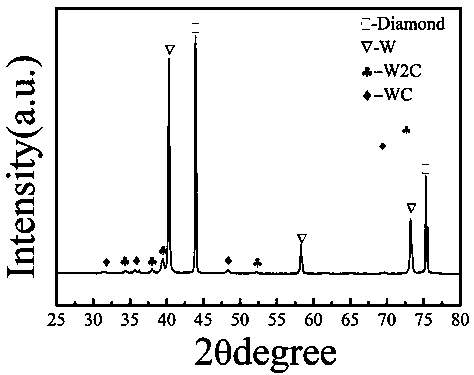

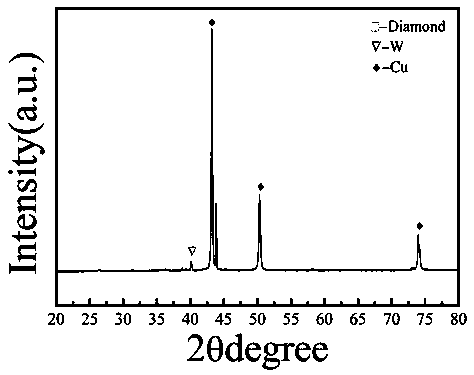

Preparation method of diamond/copper composite high in heat conduction performance

ActiveCN107916356AImprove protectionSimple separation processTransportation and packagingMetal-working apparatusPowder mixtureRoom temperature

The invention discloses a preparation method of a diamond / copper composite high in heat conduction performance. The preparation method comprises the following steps of 1, uniformly mixing diamond obtained after surface of the diamond is subjected to degreasing and roughening treatment with tungsten powder according to the mass ratio of 1: 4.5, heating a powder mixture under the vacuum condition, conducting heat preservation for 2-8 hours at the temperature of 1030 DEG C, and finally, separating out modified tungsten-plated diamond, wherein the vacuum degree is 10<-2>-10<-4> Pa, and the temperature rising rate is 5 DEG C / min; and 2, uniformly mixing the tungsten-plated diamond, with the mean particle size being 125 microns, obtained after surface modification with copper powder with the mean particle size being 45 microns with the total volume content of the tungsten-plated diamond accounting for 55%, sintering an obtained powder mixture, and then cooling the obtained power mixture to the room temperature, so that the diamond / copper composite is obtained, wherein the sintering parameters are that the pressing pressure is 40 MPa, the temperature is 1000 DEG C, the temperature risingrate is 100 DEG C / min, the sintering time is 10 minutes, and the atmosphere is vacuum.

Owner:ZHENGZHOU UNIV

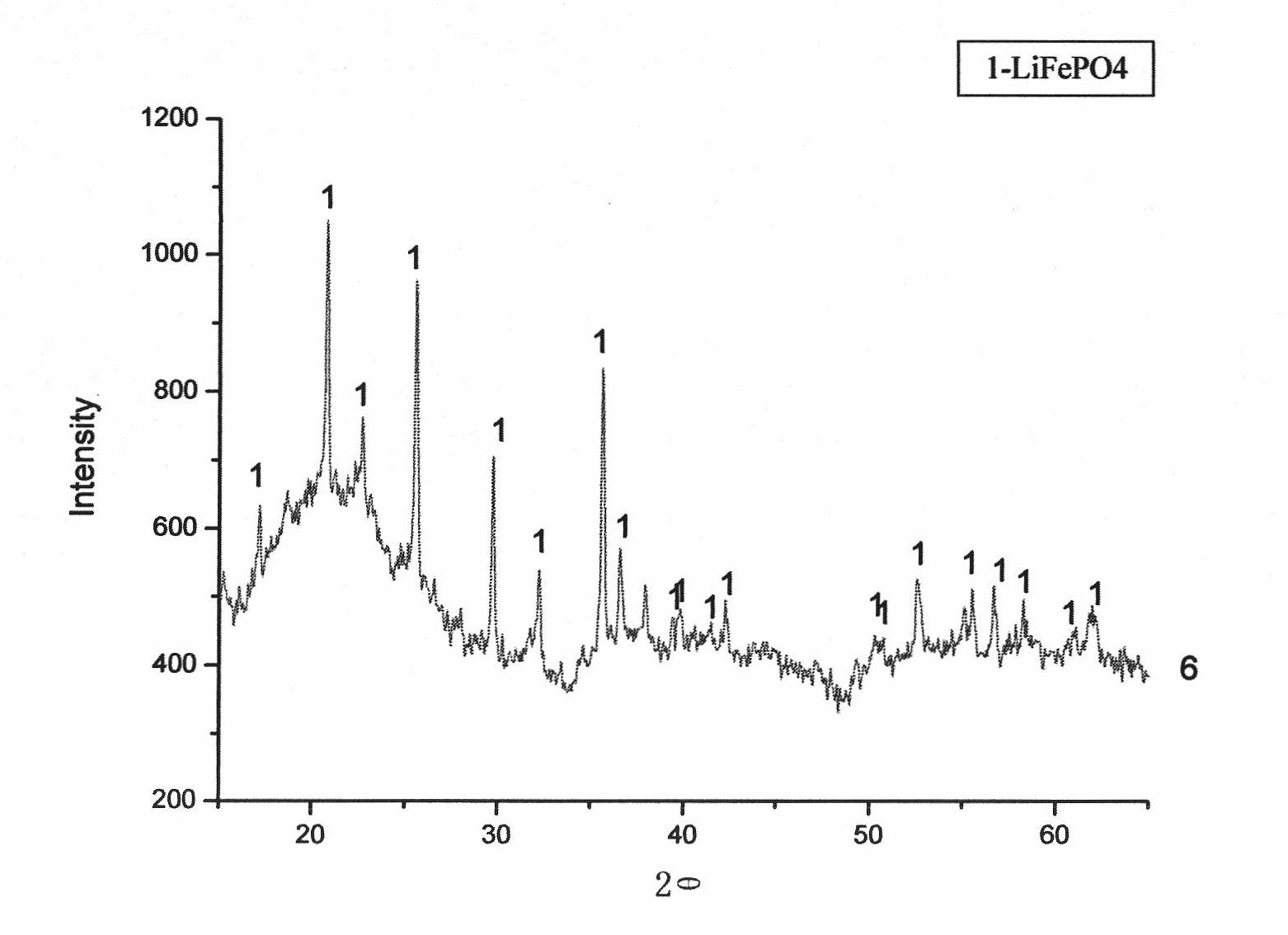

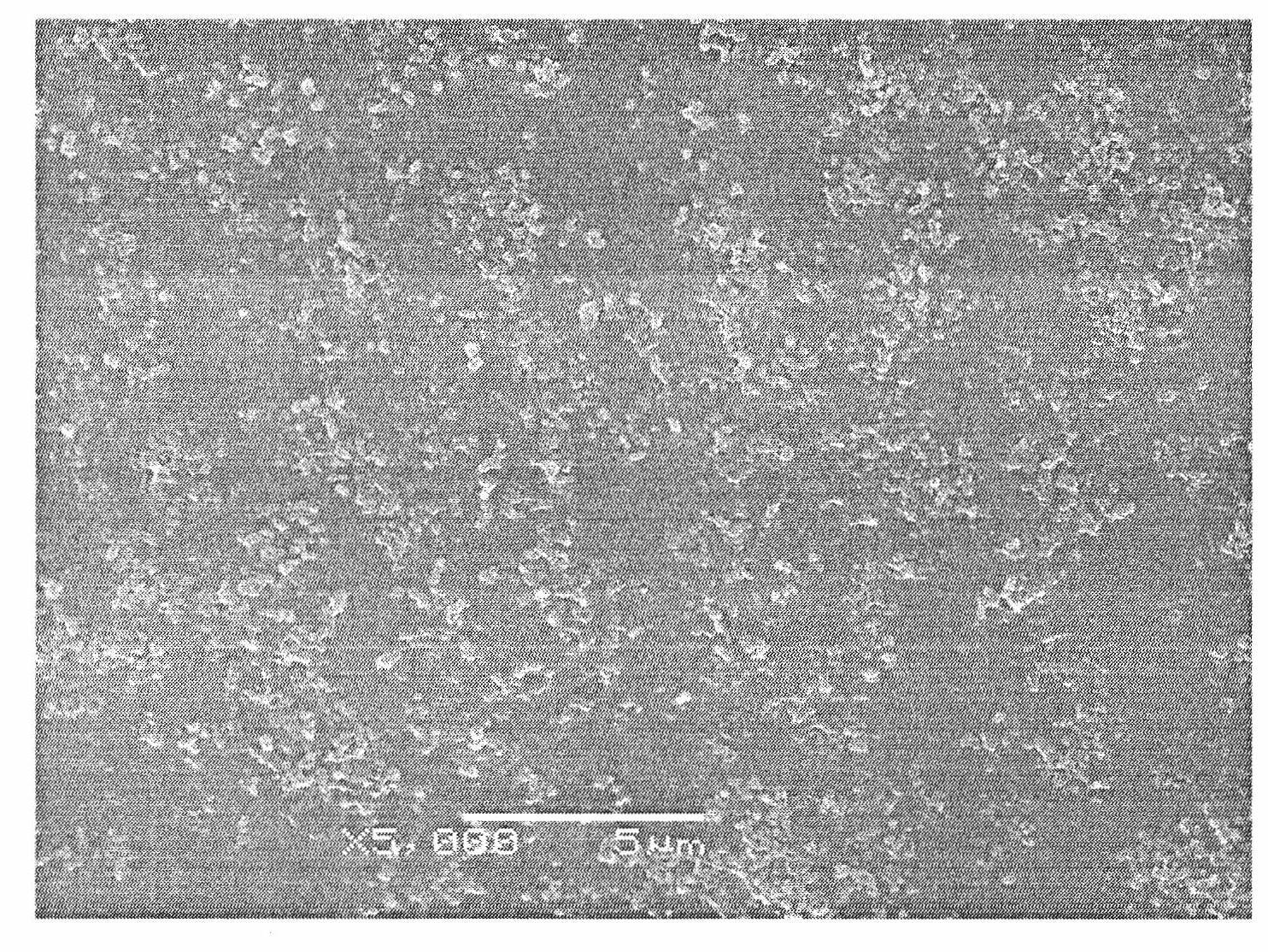

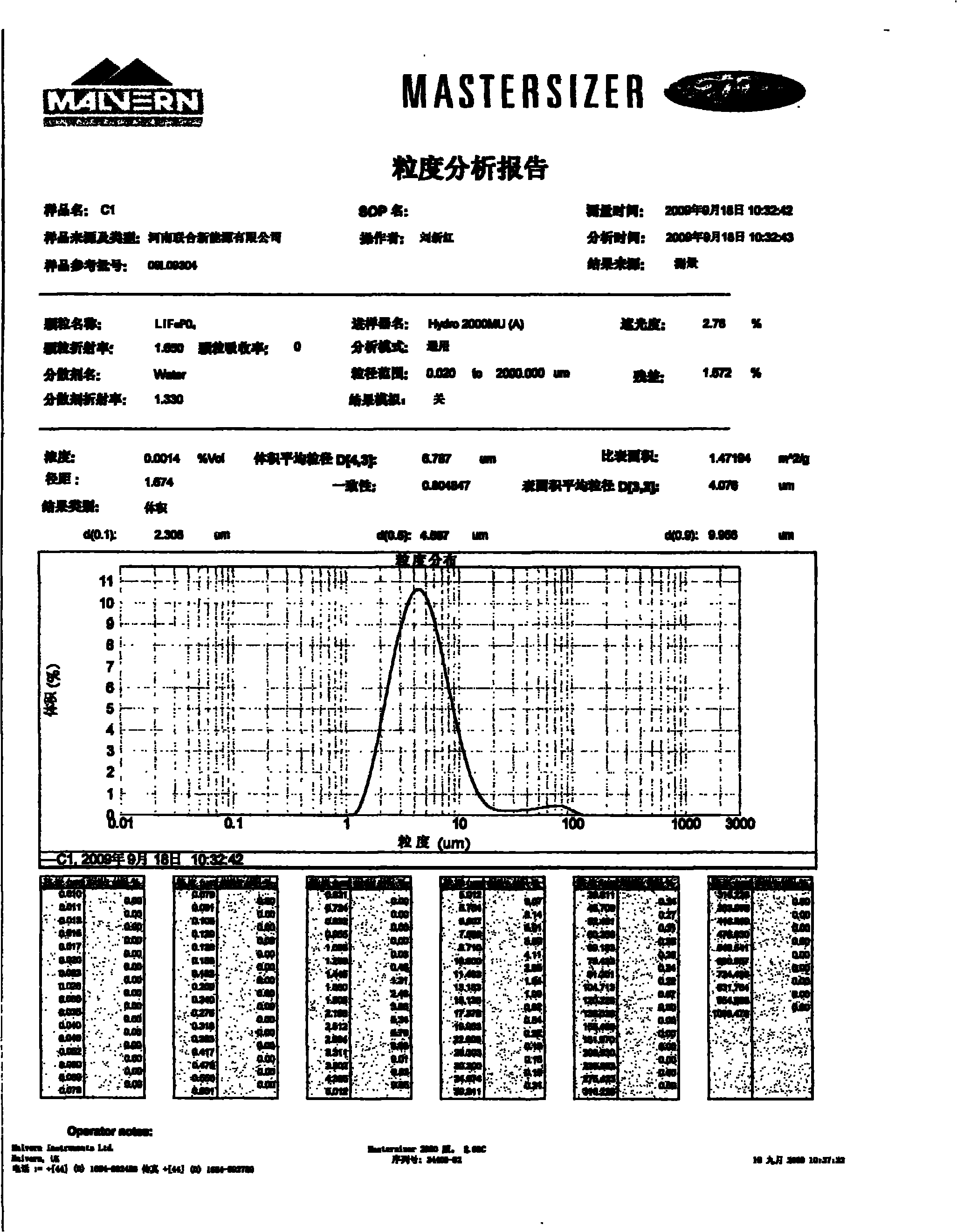

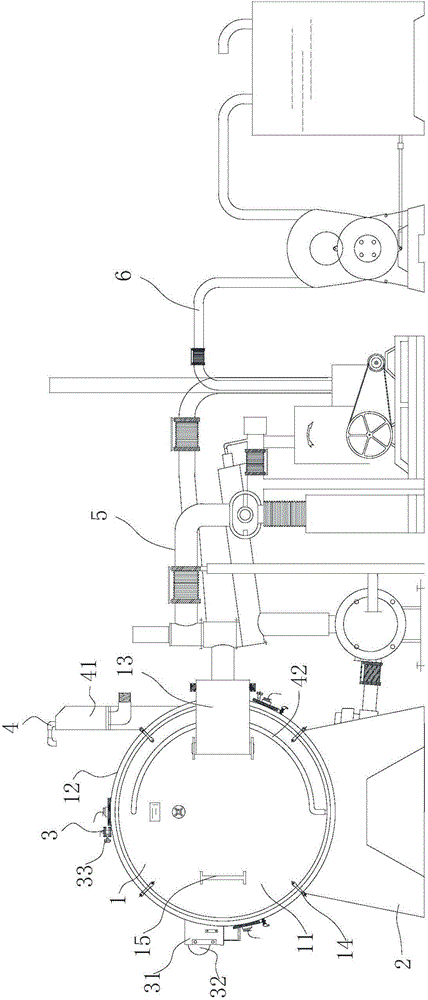

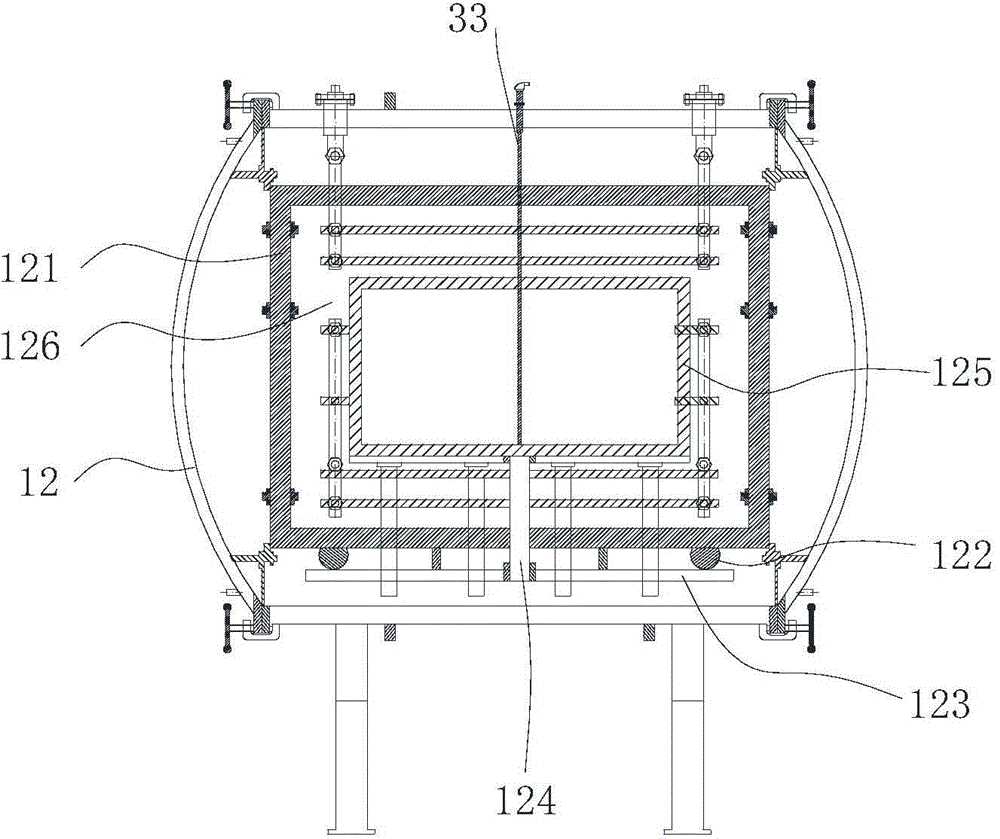

Method for preparing lithium iron phosphate by sintering lithium iron phosphate precursor and microwave sintering equipment

InactiveCN102092699APromote densificationEvenly distributedCell electrodesPhosphorus compoundsLithium iron phosphateControl treatment

The invention discloses a method and equipment for preparing lithium iron phosphate from a lithium iron phosphate precursor. The method comprises the three process steps of pretreatment of the lithium iron phosphate precursor material, pre-sintering and sintering; and in a non-oxidizing environment, the precursor material is heated by a certain number of microwave heaters, and the three process steps are finished by controlling treatment temperature and treatment time to finally prepare the lithium iron phosphate product. The equipment comprises a material inlet, a material feeding ventilation chamber, a pretreatment unit furnace, a pre-sintering unit furnace, a sintering unit furnace, a material discharging ventilation chamber, a cooling material discharging mechanism, a material outlet,a vacuumizing device, a protective gas input device and an equipment control circuit. In the method, the pretreatment and pre-sintering process steps are added to optimize a lithium iron phosphate microwave sintering process and solve keys problems on product quality control. The equipment provided by the invention realizes continuous microwave sintering by a plurality of unit furnaces so as to improve the sintering efficiency and realize large-scale industrial production.

Owner:HENAN UNION NEW ENERGY

Method for preparing ceramsite by utilizing chromium slag and coal ash

InactiveCN106278369AImprove curing effectFast sintering speedCeramic materials productionCeramicwareSlagReducing atmosphere

The invention discloses a method for preparing ceramsite by utilizing chromium slag and coal ash. The method comprises the following steps of: firstly drying and grinding the chromium slag to obtain powder, then compounding the chromium slag powder and the coal ash according to a certain proportion, adding a wave-absorbing component and a hole-forming agent to mix uniformly, and putting the mixture in a powder pressing machine for extrusion and formation to obtain a blank; finally, adopting a microwave sintering mode to sinter the blank for a period of time under the condition of high-temperature reducing atmosphere, and cooling to obtain a ceramsite product. The method disclosed by the invention realizes harmless and recycling treatment of the chromium slag and the coal ash, and the prepared ceramsite contains low chromium content and leaching, and conforms to the requirements of lightweight aggregates of buildings. The method also has the advantages of simple process, less energy consumption and good property of produced ceramsite and the like.

Owner:WUHAN UNIV OF TECH

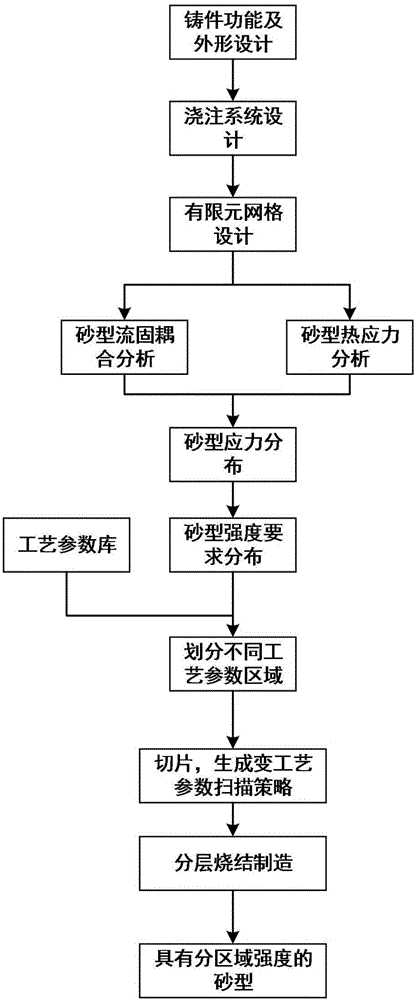

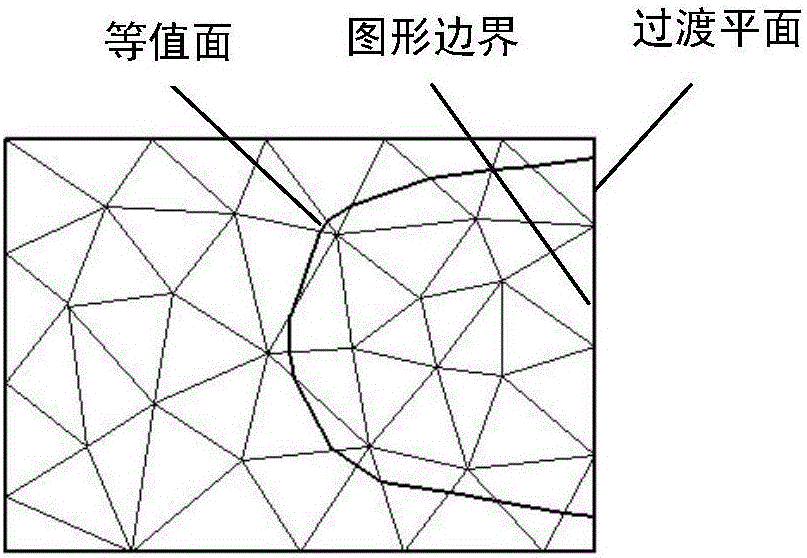

Design and manufacturing method used for selective laser sintering sand mould regional strength change

ActiveCN106682299AImprove adaptabilityGuaranteed basic performanceDesign optimisation/simulationSpecial data processing applicationsStress distributionSelective laser sintering

The invention provides a design and manufacturing method used for selective laser sintering sand mould regional strength change. Firstly, a belt casting system three-dimensional model is designed according to appearance characteristics of a cast part and divided into finite element meshes used for numerical simulation, fluid-solid coupling and thermal stress calculation are conducted on the finite element meshes, stress distribution of a sand mould in the filling and solidifying processes is obtained, the stress distribution is converted into equivalent stress according to a sand mould material strength standard, and strength required distribution of the sand mould is obtained; secondly, sintering efficiency is taken into consideration, process parameters meeting requirements are extracted from a process parameter library, and regions using different process parameters are divided out; thirdly, the sand mould model obtained after partition is sliced to generate a regional variable-process-parameter scanning strategy; fourthly, the regional variable-process-parameter scanning strategy is imported into a selective laser sintering device for layered sintering and manufacturing, and finally the sand mould with regional strength is obtained. The method is capable of improving efficiency of manufacturing the sand mould through the laser sintering technology and improving adaptability of the sand mould to the casting process.

Owner:XI AN JIAOTONG UNIV

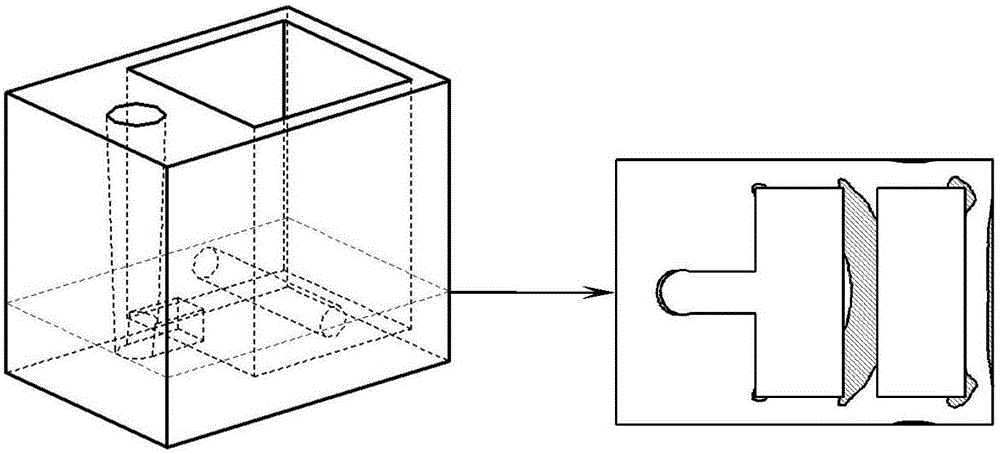

Method for preparing low-density ITO evaporation target material

The present invention relates to a method for preparing low-density ITO evaporation target material. The method includes the following steps of: adopting highly active and monodisperse ITO nanometer powder as raw materials; performing high-temperature pre-firing, grease blending, and granulation treatment to obtain granulated ITO powder with uniform properties; and performing sintering at oxygen atmosphere with constant pressure or no pressure after molding and degreasing treatment to obtain the low-density ITO evaporation target material. The method is advantaged in production safety, low cost, capability of effectively preventing cracking and spray phenomenon in evaporation, good uniformity and favorable film-forming characteristic.

Owner:贵州法拉第磁电科技有限公司

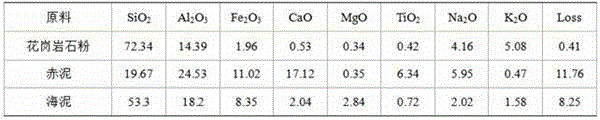

Microwave sintering method for granite rock flour ceramsite

The invention discloses a microwave sintering method for granite rock flour ceramsite. The granite rock flour ceramsite is prepared from the following raw materials in mass percent: 60% to 80% of granite rock flour, 10% to 30% of red mud, 0% to 29% of sea mud, 0% to 20% of high-carbon coal cinder and 0.15% to 0.3% of microwave sensing agent. Bulk density of the prepared high-performance ceramsite is 430 to 1200kg / m<3>, apparent density is 850 to 1700kg / m<3>, water absorption is 5% to 19%, and cylinder compressive strength is 3.5MPa to 9.5MPa. According to the granite rock flour ceramsite disclosed by the invention, waste granite rock flour generated by stone processing plants, sea mud generated by sea dredging and metro construction, industrial solid waste red mud drained by aluminum manufacturers and the like are utilized as the raw materials, and waste utilization rate can be 95% or more; the microwave sintering method has high sintering efficiency, can save sintering energy consumption by 20% to 30% and has better social and economical benefits.

Owner:FUJIAN JIANGXIA UNIV

Clay ceramsite used for highway greening

InactiveCN104909796ALow costImprove sintering efficiencyCeramic materials productionCeramicwareAbsorption rateGreening

The invention discloses a clay ceramsite used for highway greening. Clay, copper mine tailings, fly ash and a paper pulp waste liquid are adopted as raw material, so the cost is greatly reduced, and wastes are recycled. A preparation method of the clay ceramsite has the advantages of simplicity, easy industrialization and wide sources of the raw materials. The water absorption rate of the clay ceramsite is greater than 93%, the unit weight is greater than 590kg / m<3>, the compressive strength is greater than 30Mpa, and the granularity is 1-10[mu]m, so the clay ceramsite is very suitable for being used in highway greening.

Owner:淄博萃智工业设计咨询有限公司

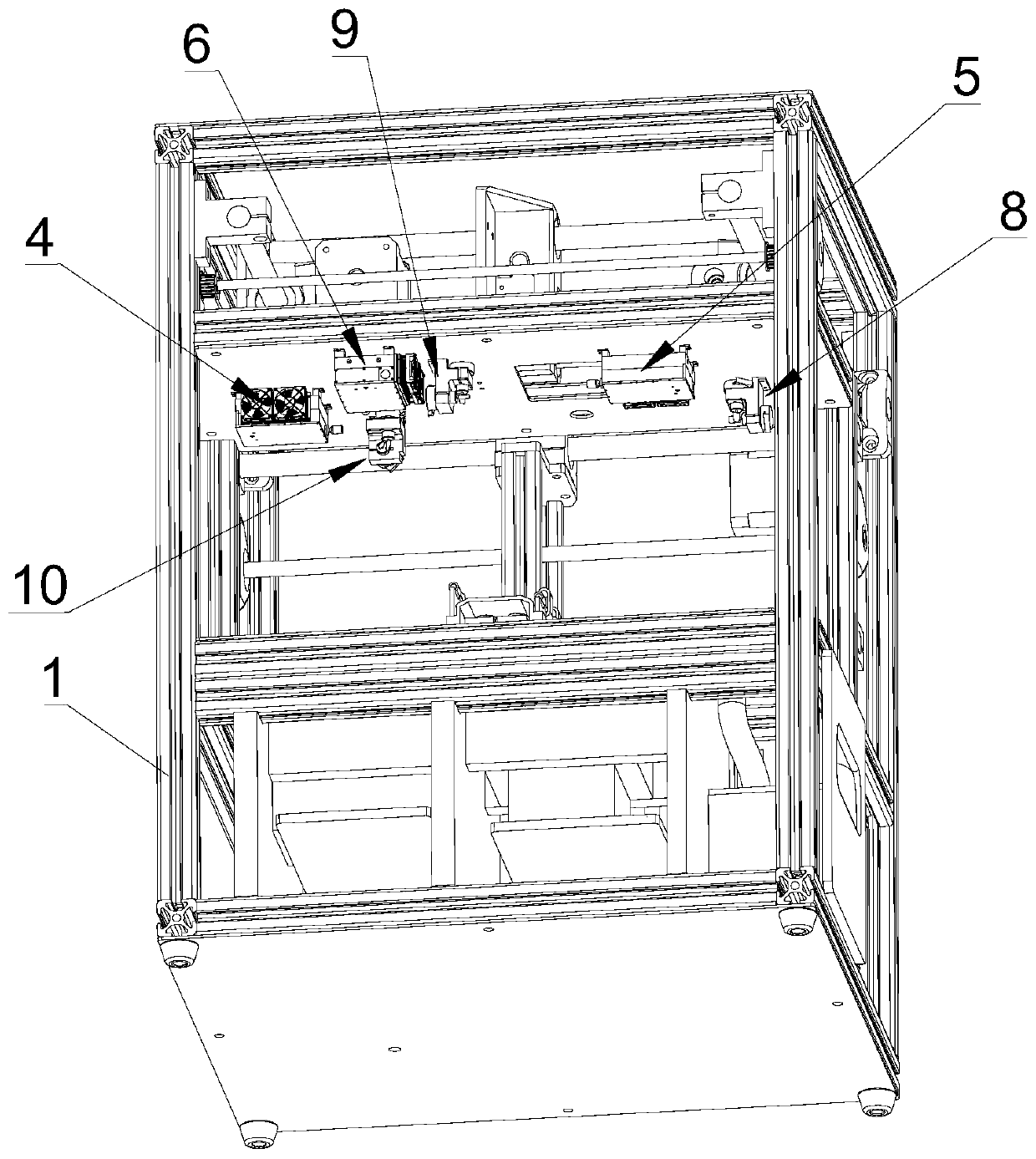

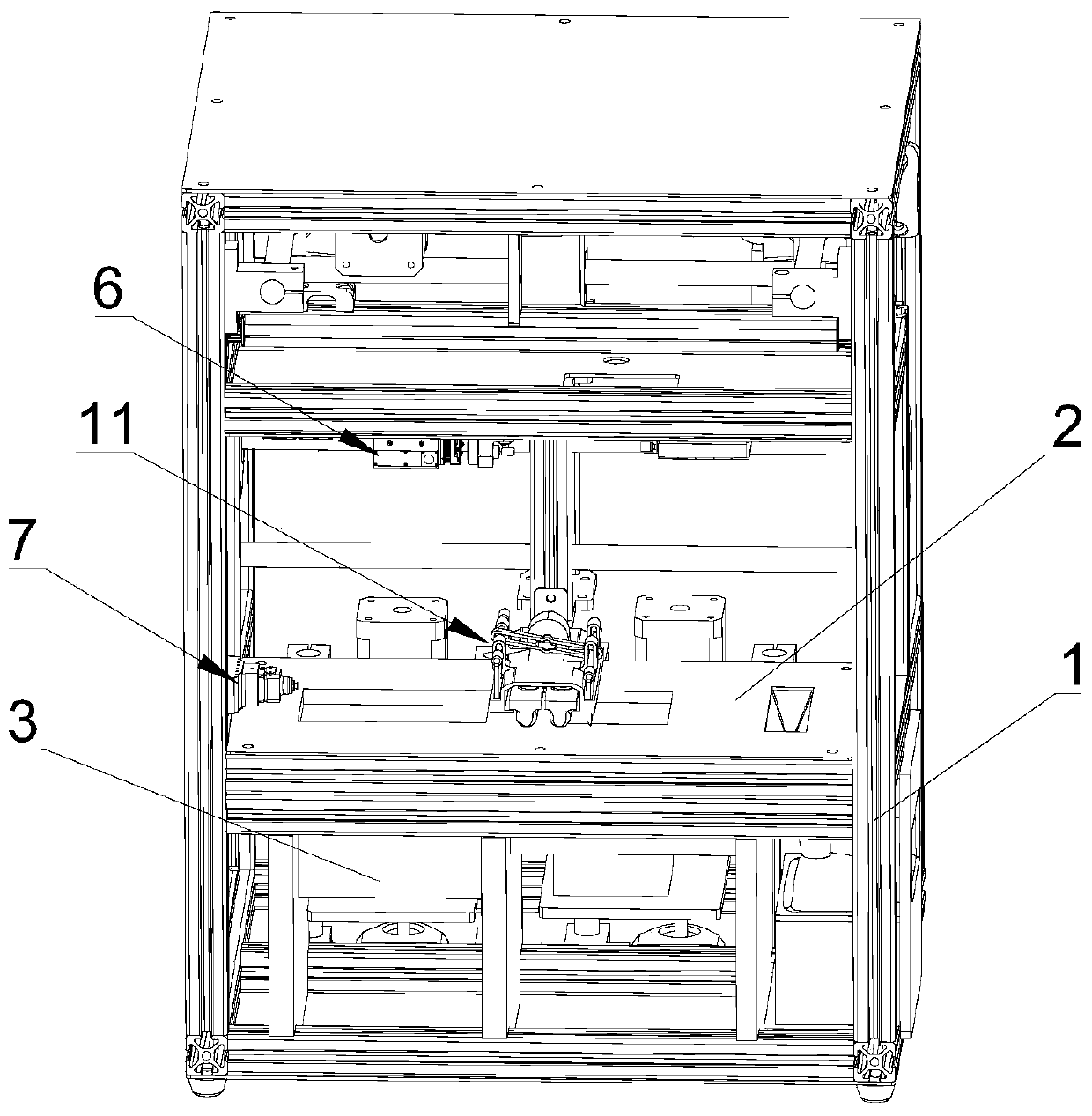

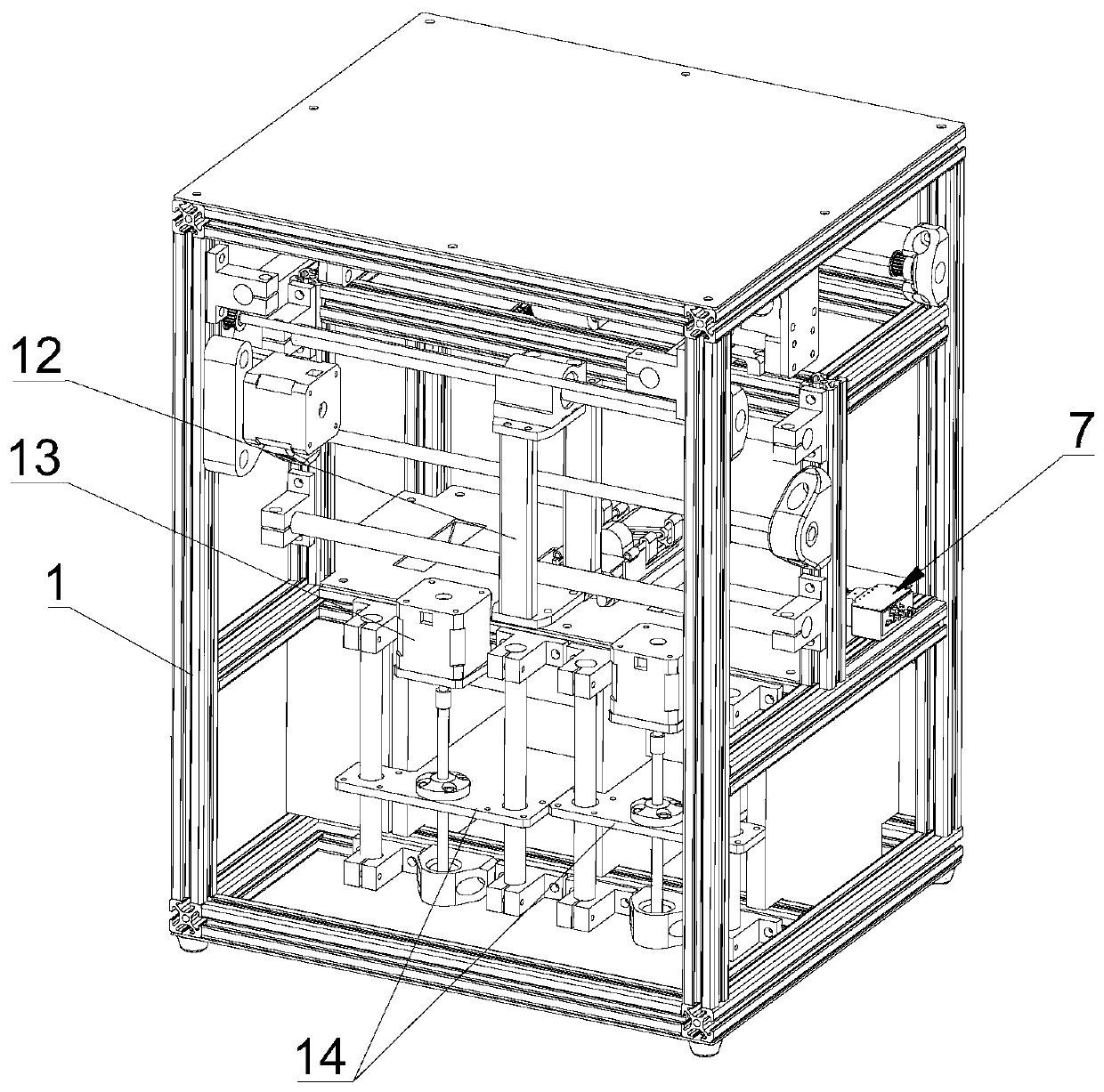

Multi-laser high-precision 3D printer and printing method thereof

ActiveCN110666166AHigh precisionImprove surface accuracyAdditive manufacturing apparatusIncreasing energy efficiencyComputer printingErbium lasers

The invention discloses a multi-laser high-precision 3D printer and a printing method thereof. The printer comprises a power distributing module, a sintering platform and a laser sintering module. Thelaser sintering module comprises a preheating scanning module, a sintering scanning module and a trimming scanning module, wherein the preheating scanning module comprises a preheating laser for emitting a preheating laser beam and a preheating conducting assembly for conducting the preheating laser beam to the sintering platform, the sintering scanning module comprises a sintering laser for emitting a sintering laser beam and a sintering conducting assembly for conducting the sintering laser beam to the sintering platform, the trimming scanning module comprises a fine trimming laser for emitting a fine trimming laser beam and conducting the fine trimming laser beam to the sintering platform, and the temperature of the preheating laser beam is lower than that of the sintering laser beam.By sintering and processing powder by laser beams in a combined manner, the quality and precision of a formed part are improved from multiple aspects.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

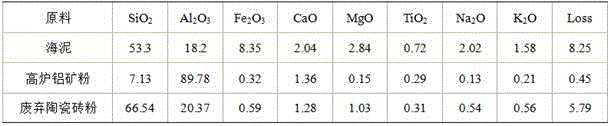

Microwave sintering method of sea mud ceramsite

InactiveCN106747559AImprove sintering efficiencyReduce sintering energy consumptionCeramic materials productionCeramicwareBrickSludge

The invention discloses a microwave sintering method of sea mud ceramsite. The sea mud ceramsite is prepared from raw materials in percentage by mass as follows: 60%-100% of sea mud, 0%-30% of waste ceramic tile powder and 0%-20% of blast-furnace aluminium ore powder. In terms of the prepared high-performance ceramsite, bulk density is 400-1,100 kg / m<3>, apparent density is 800-1,600 kg / m<3>, water absorption is 5%-18% and cylinder compressive strength is 3.0 MPa-10.0 MPa. The raw materials comprise marine sludge produced through marine dredging and metro construction, waste ceramic pulverized powder of a ceramic tile factory and the blast-furnace aluminium ore powder produced in an aluminium factory, utilization rate of waste reaches 95% or higher, and good social benefit is obtained; the microwave sintering method is high in sintering efficiency, can reduce sintering energy consumption by about 25% and has better economic benefit.

Owner:FUJIAN JIANGXIA UNIV

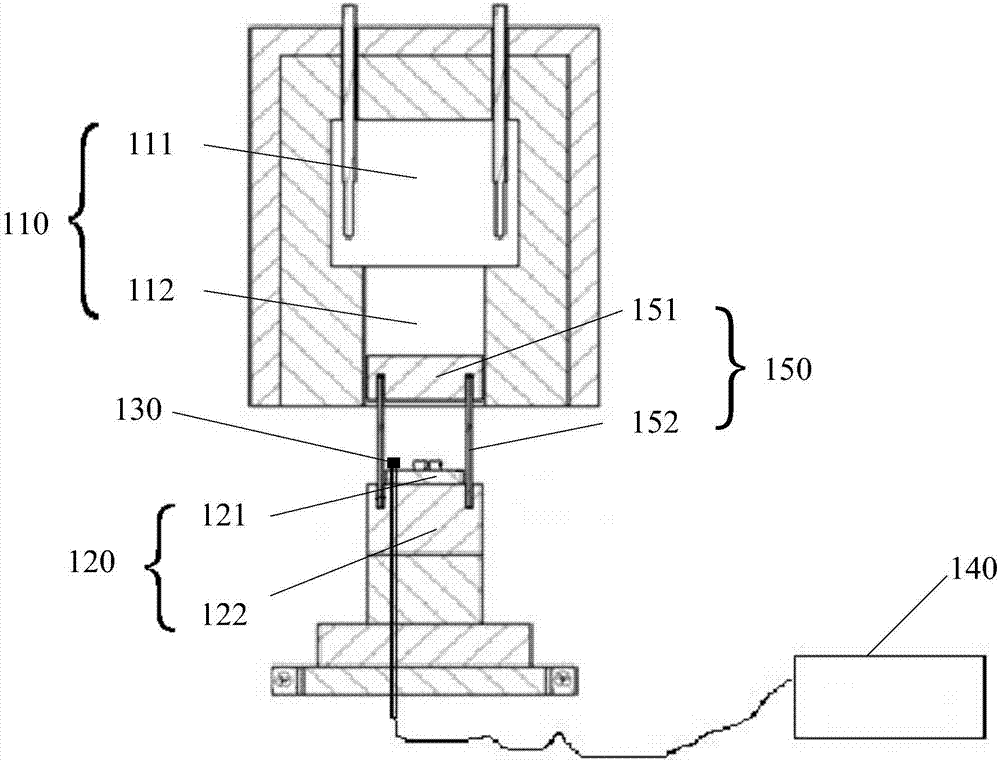

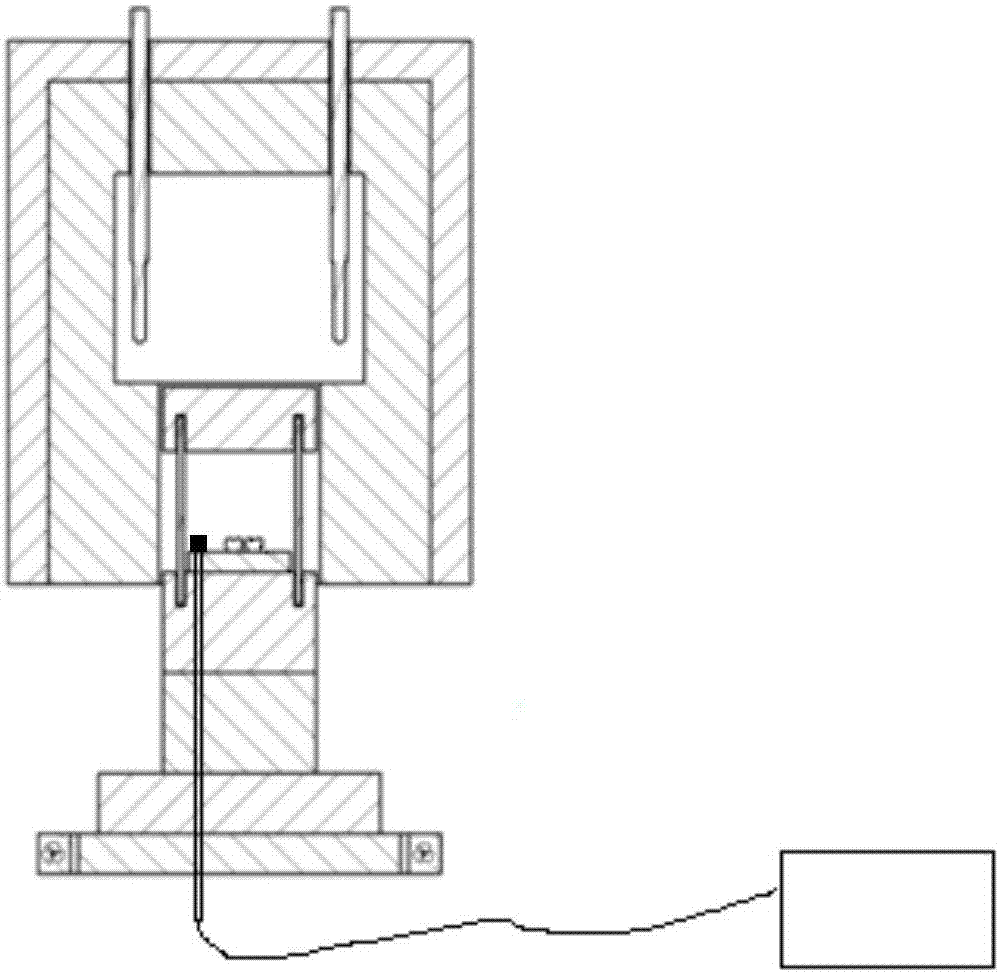

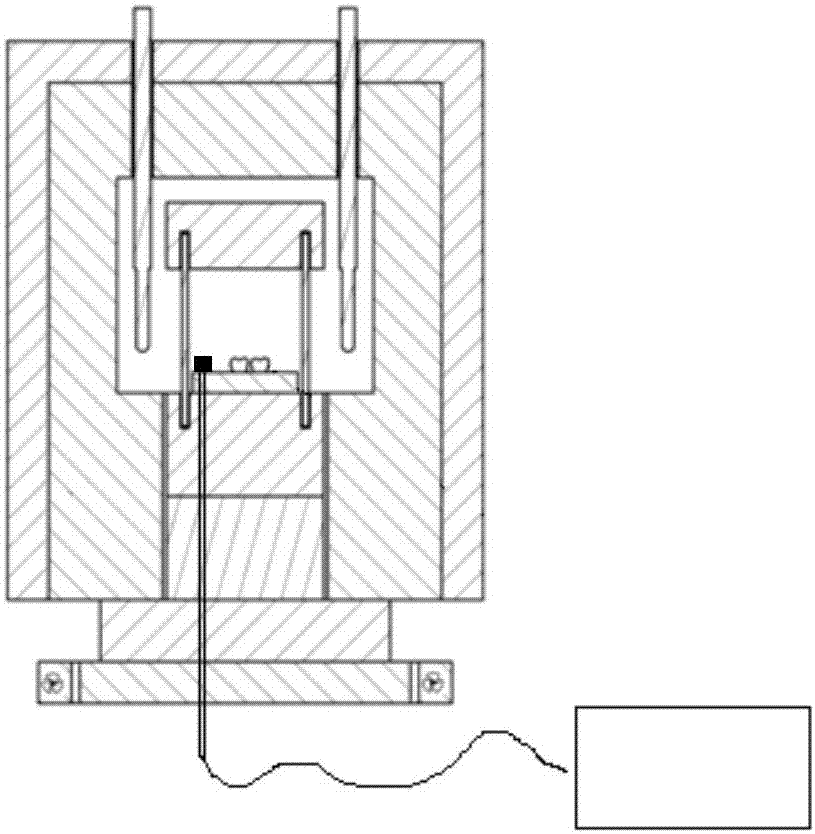

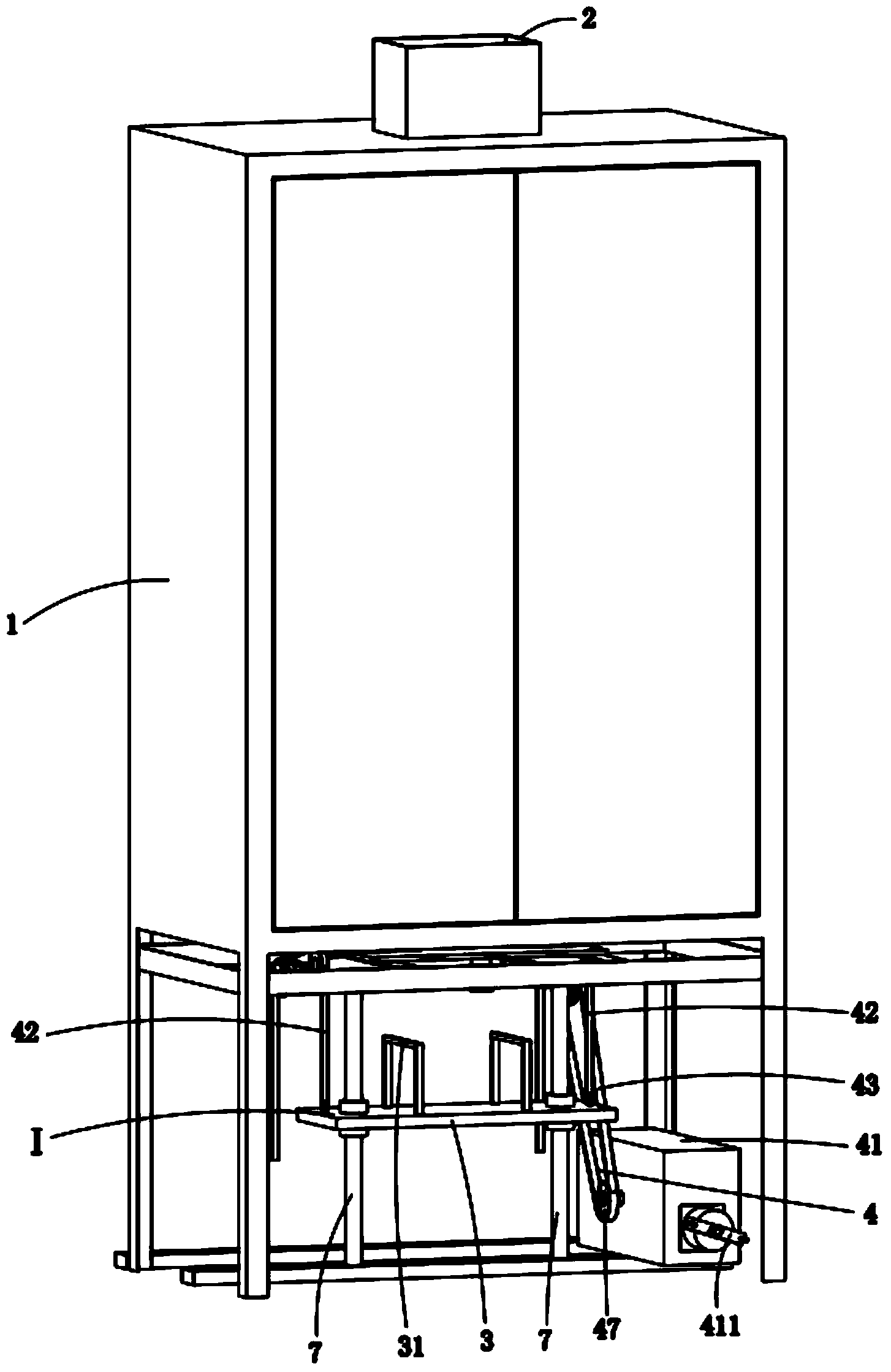

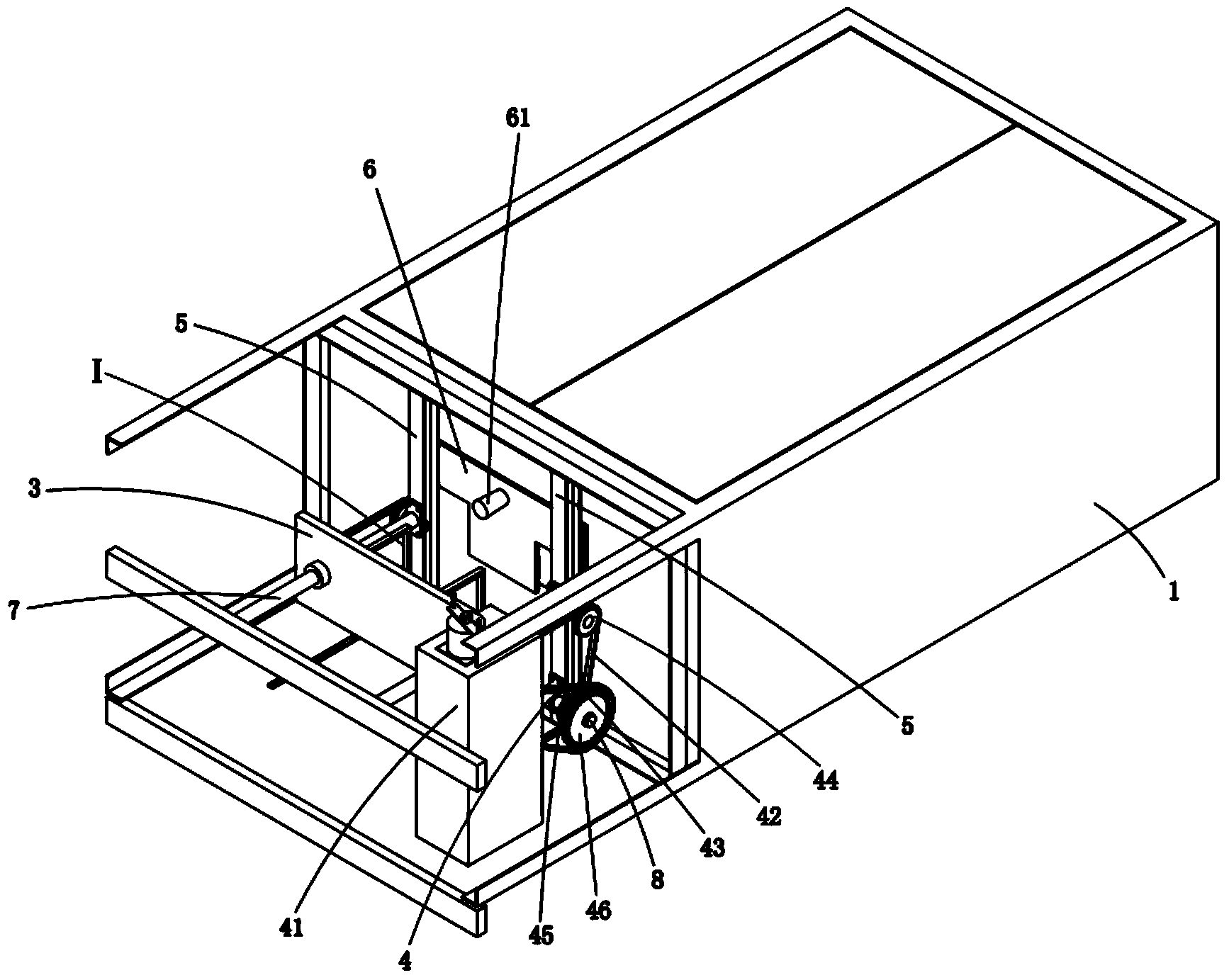

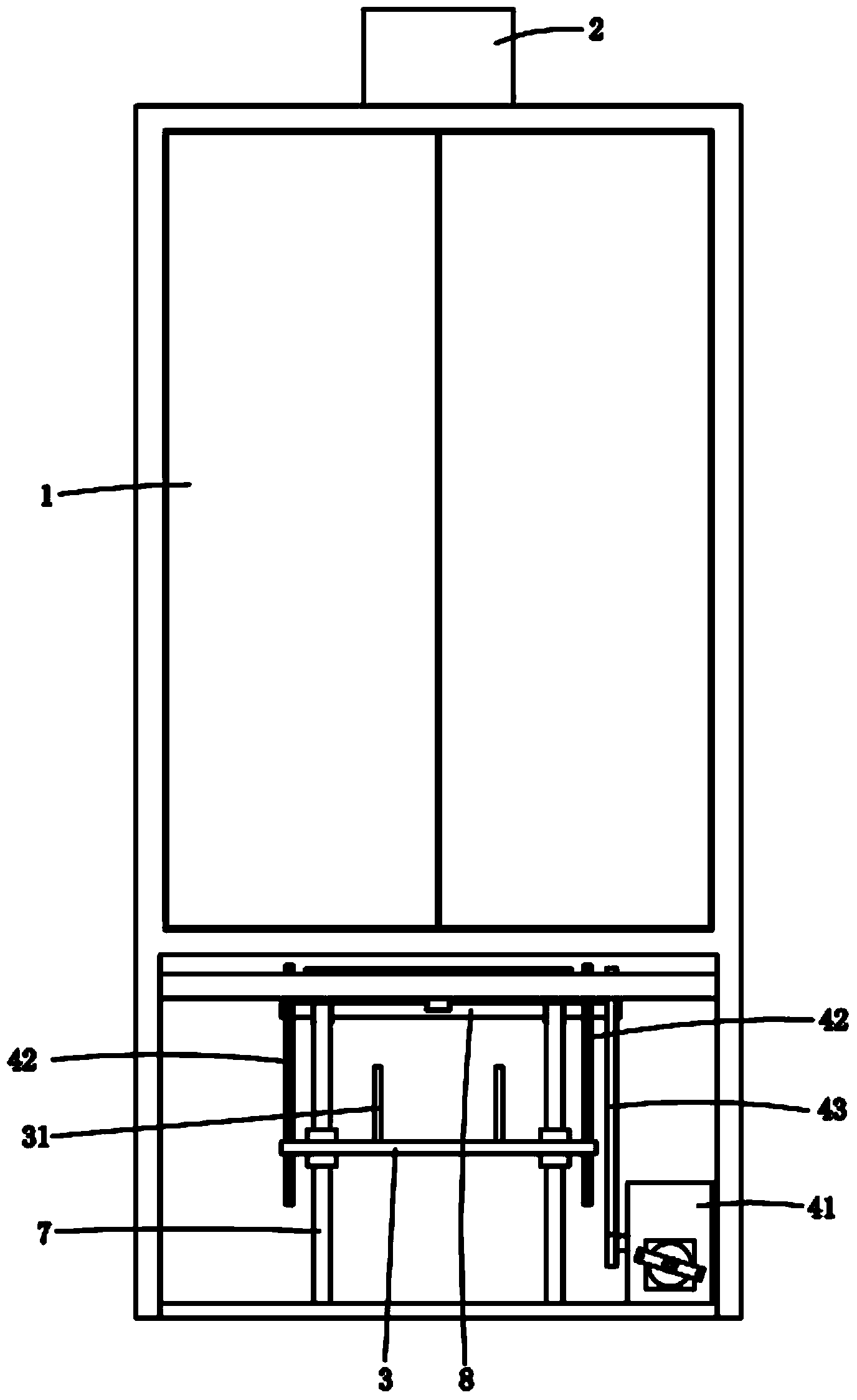

Rapid sintering system and rapid sintering method

ActiveCN108007203AFast sinteringHeating up fastFurnace typesArtificial teethMaterials scienceSintering

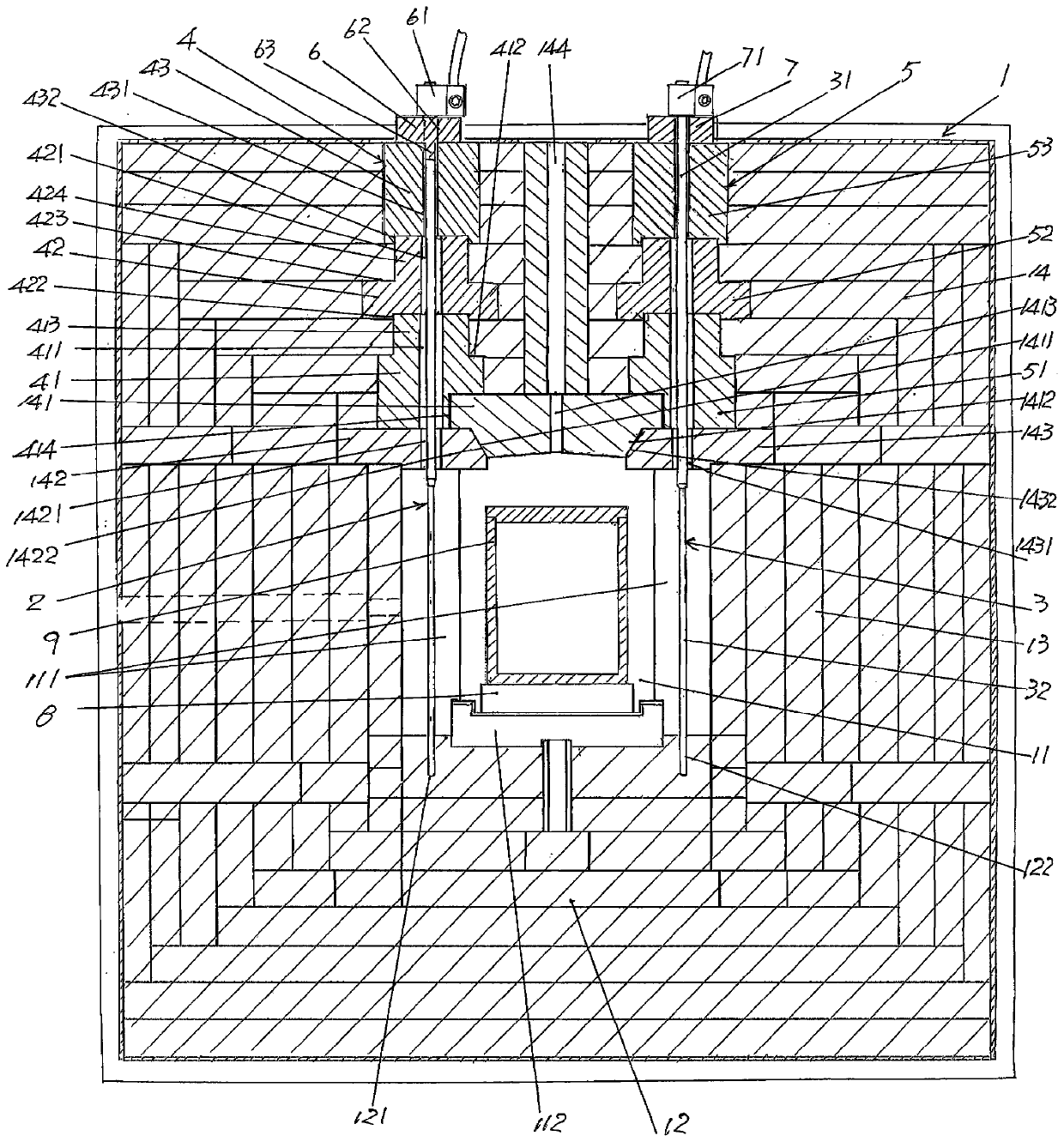

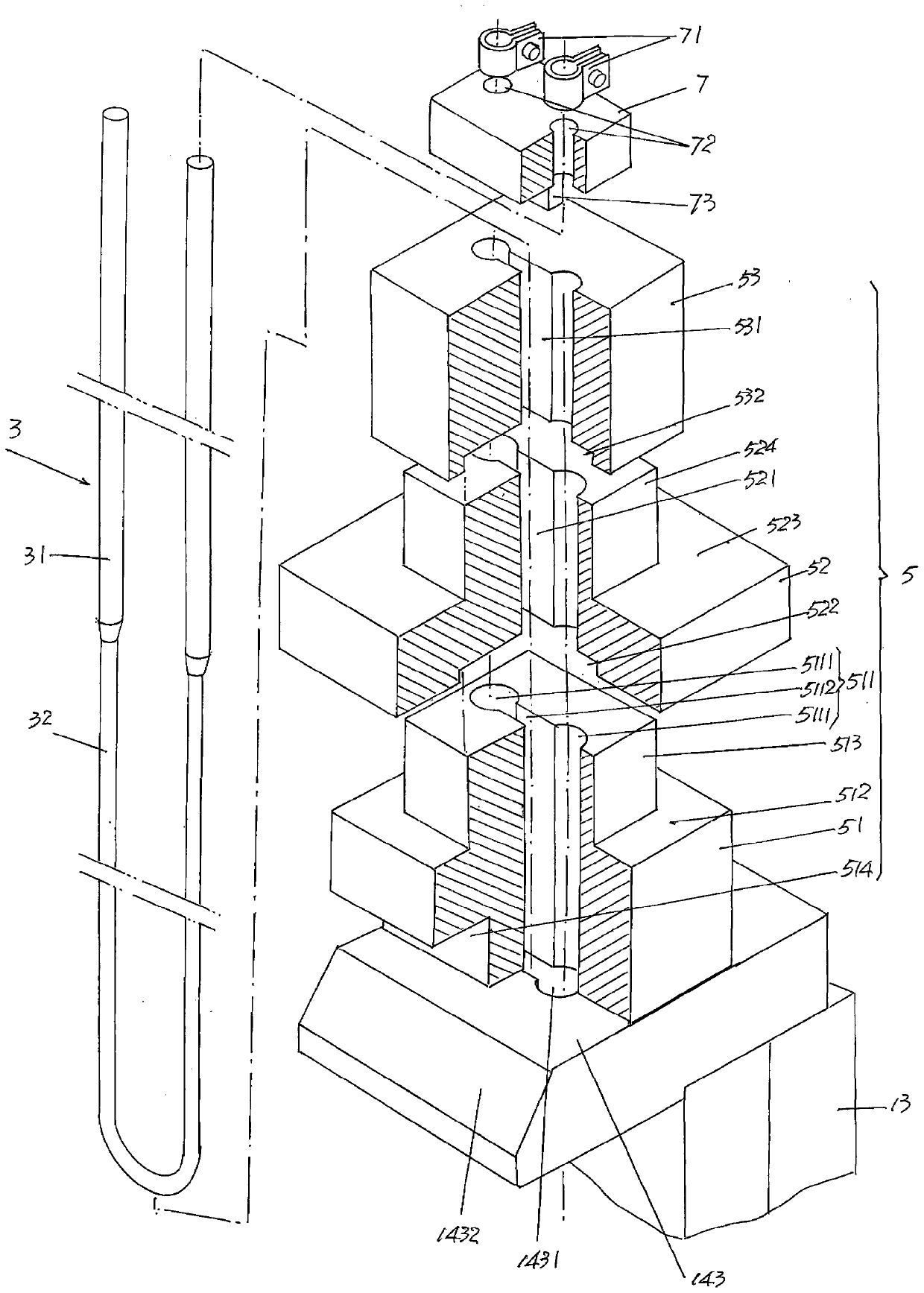

The embodiment of the invention provides a rapid sintering system and a rapid sintering method. The rapid sintering system comprises a furnace body, a lifting device, a temperature acquisition device,a control device and a partition plate component; the furnace body comprises a hearth and a furnace mouth which communicate with each other; the lifting device is arranged below the furnace mouth andcomprises a support and a sample table, wherein the sample table is arranged on the support; the temperature acquisition device is arranged on the sample table; the control device is arranged outsidethe hearth, is electrically connected with the lifting device and the temperature acquisition device, and is used for controlling the lifting device to ascend and descend according to the temperatureobtained by the temperature acquisition device and a preset sintering condition; and the partition plate component is arranged at the first end of the lifting device, a first interval is formed between the partition plate component and the sample table, and when the rapid sintering system is in a charging or discharging working condition, the partition plate component is used for blocking the furnace mouth. According to the rapid sintering system and the rapid sintering method, rapid sintering of a to-be-sintered sample can be realized, so that the sintering efficiency of the product is improved.

Owner:LIAONING UPCERA CO LTD

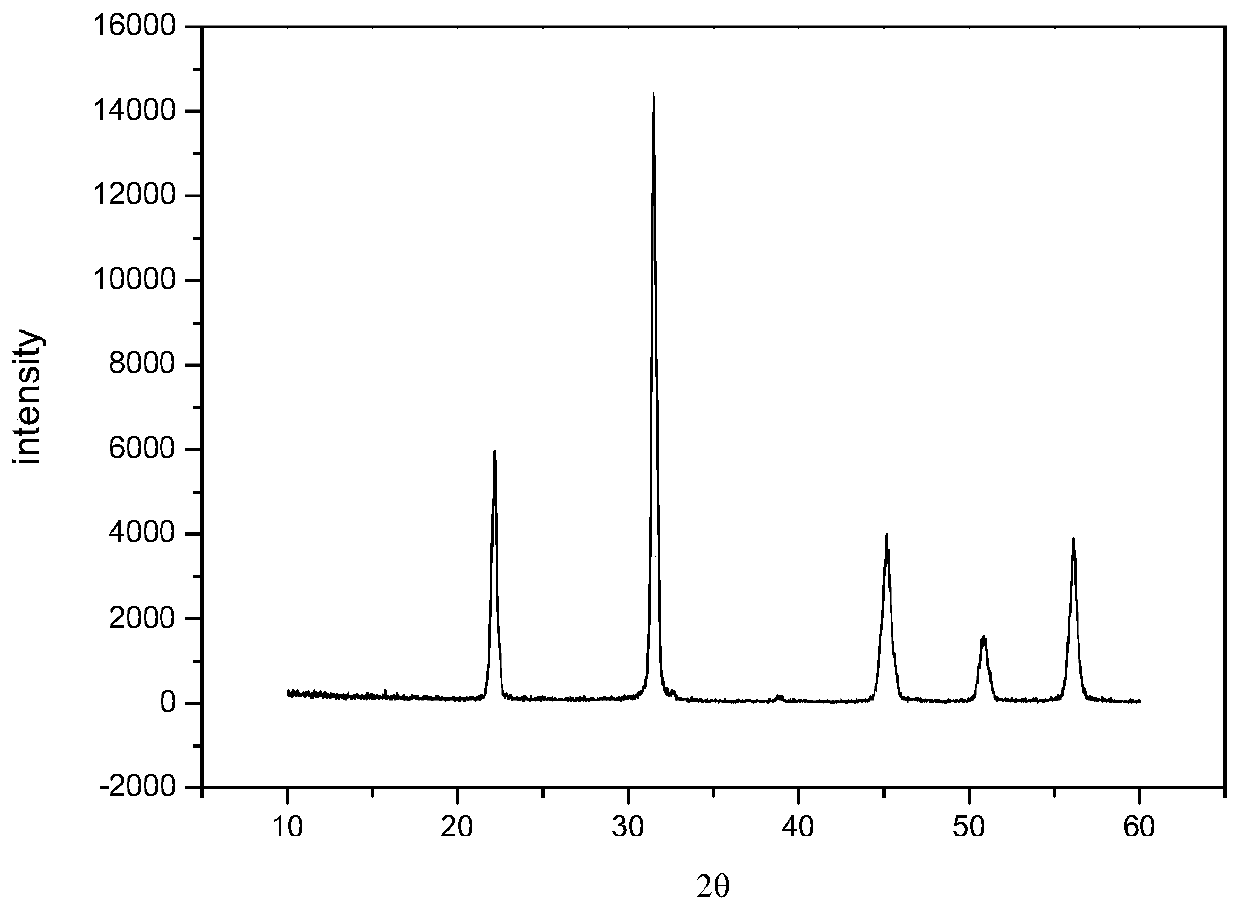

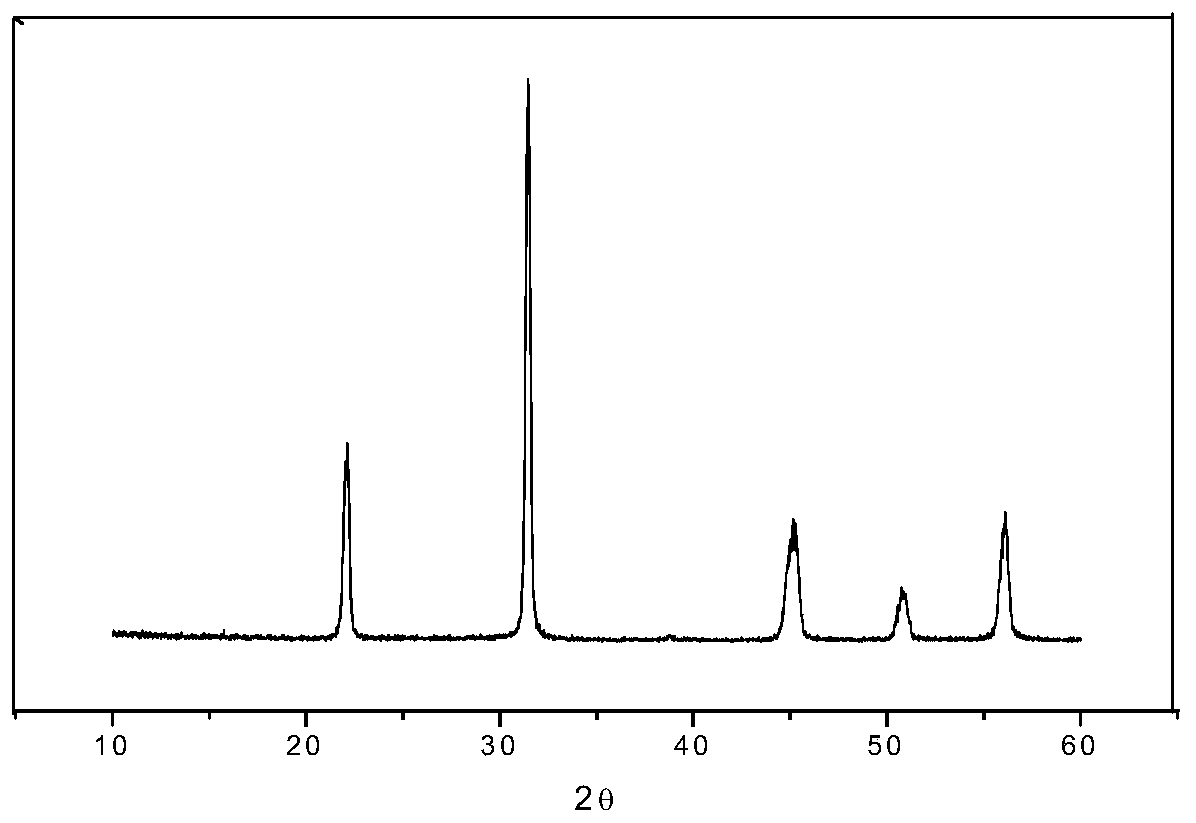

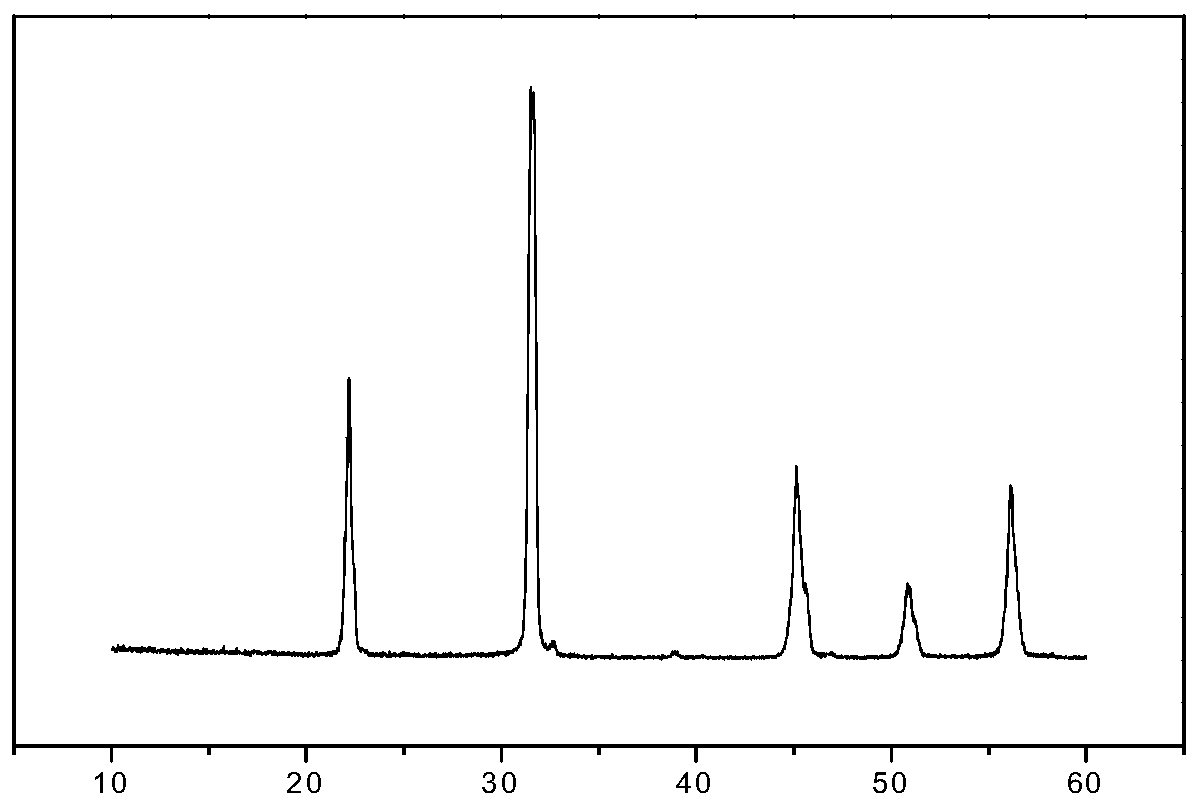

Ta-doped potassium sodium niobate-based piezoelectric ceramic material and preparation method thereof

The invention provides a Ta-doped potassium sodium niobate-based piezoelectric ceramic material and a preparation method thereof. The general formula of the piezoelectric ceramic is Na<0.5>K<0.5>Nb<1-y>Ta<y>O<3>, wherein y is greater than or equal to 0.11 and less than or equal to 0.2; the invention discloses a preparation method of the piezoelectric ceramic material. The preparation method comprises the following steps: carrying out microwave hydrothermal synthesis of Na0.5K0.5Nb1-yTayO3 powder; taking a 7mol / L mixed alkali liquor of NaOH and KOH as a solvent, taking Nb2O5 and Ta2O5 as reactants, wherein the ratio of Na+ to K+ is 1: 1 6, the adding total amount of Nb2O5 and Ta2O5 to the mass molar ratio of the solvent is 1: 8-1: 12, the mass molar ratio of Nb2O5 to Ta2O5 is 8: 1-4: 1, theadding amount of a dispersing agent is 1.5 wt%, the microwave reaction temperature is 160-180 DEG C, and the reaction time is 2-4 hours. The invention also discloses a preparation method for preparing piezoelectric ceramic from the powder by spark sintering, annealing treatment is carried out in an oxygen atmosphere, and the obtained piezoelectric ceramic has good electrical properties.

Owner:夏璐

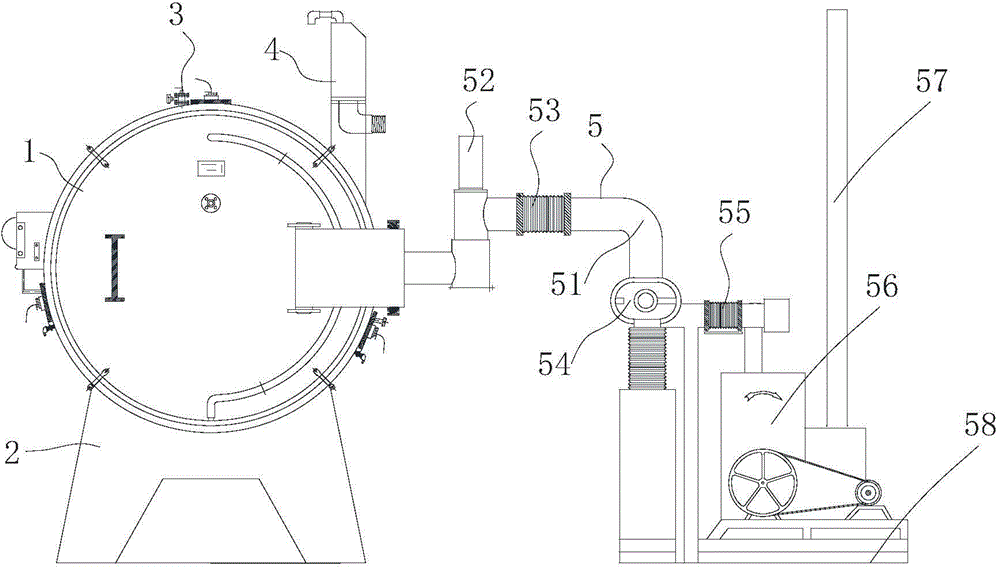

Vacuum degreasing sintering furnace

The invention relates to a method for metal powder vacuum sintering forming. The method for metal powder vacuum sintering forming comprises the following steps in sequence: (1) material loading: putting a metal powder product to be processed in a hearth of a vacuum degreasing sintering furnace; (2) vacuumizing: carrying out vacuumizing treatment on the hearth of the vacuum degreasing sintering furnace; (3) degreasing: clearing a forming agent in the metal powder product; (4) high temperature sintering. The method for metal powder vacuum sintering forming has the advantages of novel technology, convenient degreasing and high primary degreasing rate.

Owner:宁波优戈新材料科技有限公司

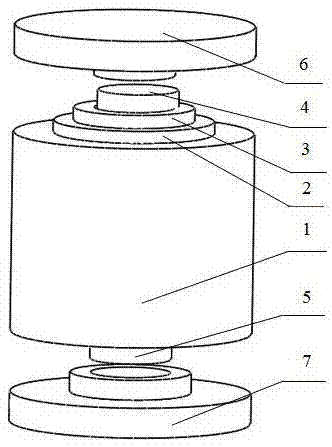

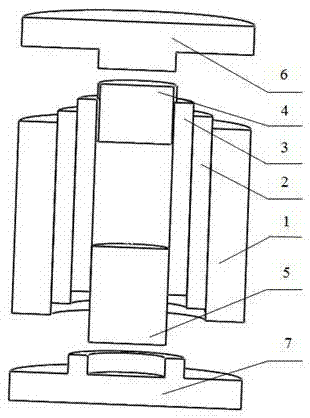

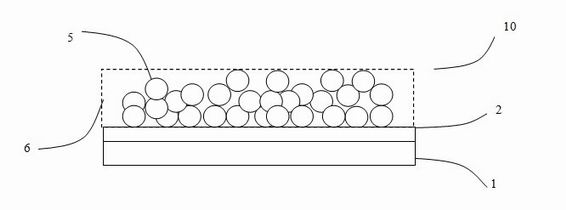

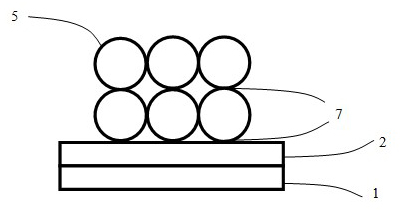

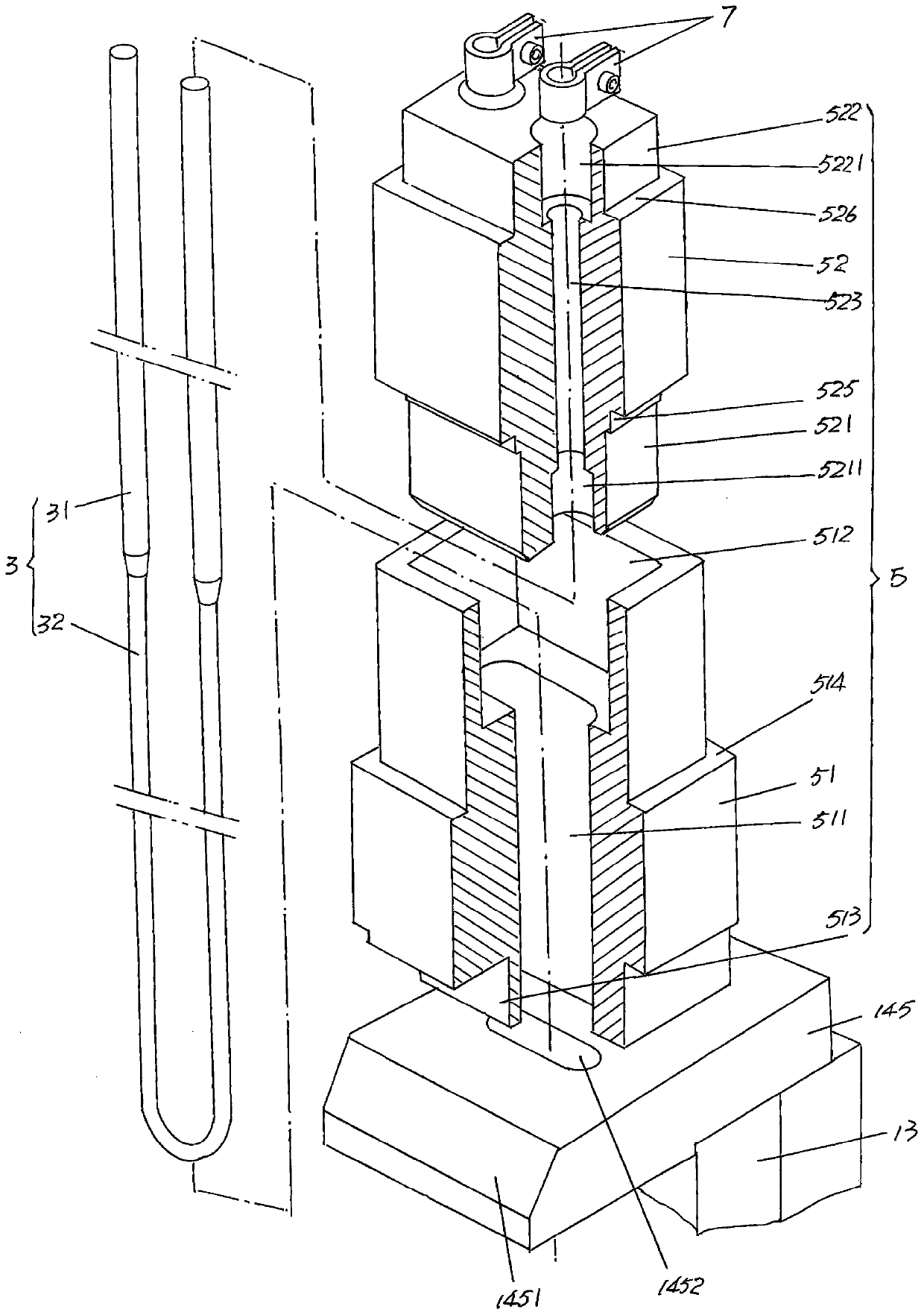

Combined die for preparing powder metallurgy part

The invention discloses a combined mold for preparing powder metallurgy parts. The mold consists of an outer mold, a sleeve I, a sleeve II, an inner mold I and II placed in the sleeve II, and an upper and a lower pressing head. The inner diameter of the outer mold is equal to the outer diameter of the sleeve I, and the inner diameter of the sleeve II is equal to the diameters of the inner mold I and the inner mold II. The cylindrical protrusion corresponding to the groove; an annular cavity is formed by the sleeve Ⅰ, the sleeve Ⅱ, the inner mold Ⅱ and the lower pressure head; a cylindrical cavity is formed by the sleeve Ⅱ, the inner mold Ⅰ and the inner mold Ⅱ, The cavity is filled with metal powder or alloy powder for the preparation of powder metallurgy parts. The beneficial effect of the present invention is that: the mold can be simultaneously sintered to prepare annular parts and shaft parts with different proportions, which improves the sintering efficiency and the service life of the mold, and the mold structure is simple, easy to operate, and graphite is used as raw material, and the cost is relatively low. Low.

Owner:韩莹 +1

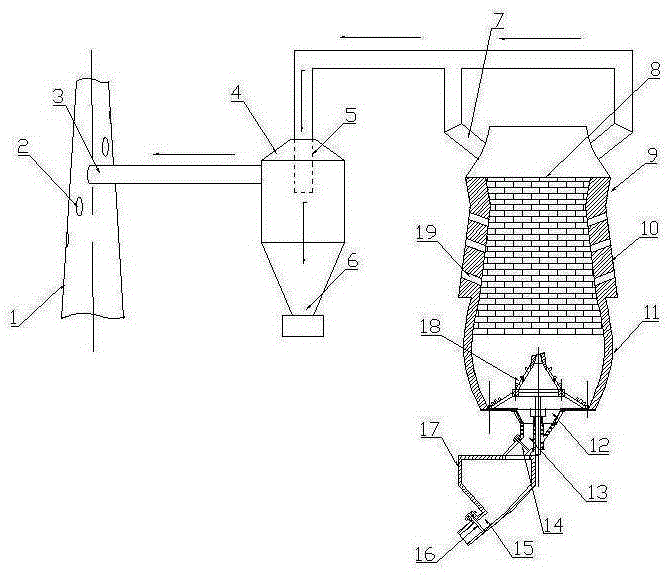

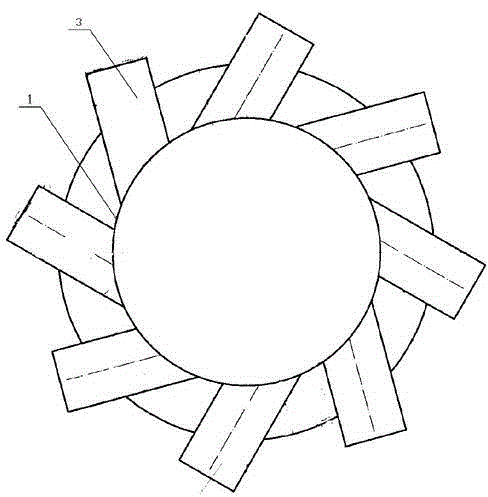

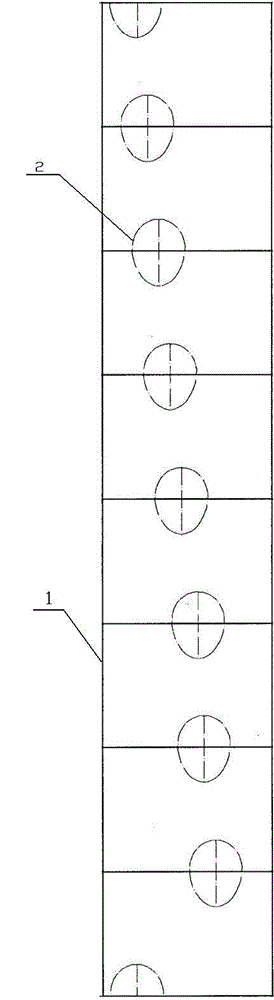

Vertical sintering furnace

InactiveCN103913059AIncrease profitImprove sintering efficiencyInductances/transformers/magnets manufactureVertical furnacesEnergy consumptionSintering

The invention relates to a vertical sintering furnace. The vertical sintering furnace comprises a sintering furnace body and a heating passage, wherein a heat insulating material covers the inner walls of the sintering furnace body, the heating passage is arranged in a hearth arranged along the vertical direction of the sintering furnace body and penetrates through the whole hearth, the upper end of the heating passage is a feeding port while the lower end of the same is a discharging port, loading clamps for loading green magnetic cores are vertically and neatly arranged in the heating passage for sintering, a discharging device is arranged below the sintering furnace body and comprises a carrying plate and a lifting mechanism, slide rails are symmetrically arranged on two sides of a discharging port, a stop plate is connected onto the slide rails in a matched manner, a vertical column is fixed at the bottom of each slide rail, and the carrying plate sleeves the vertical columns. By means of repeatedly utilizing heat from bottom to top, sintering time is effectively shortened, sintering efficiency is effectively improved, energy consumption is saved, and production cost is reduced.

Owner:HUZHOU KEFU ELECTRONICS TECH

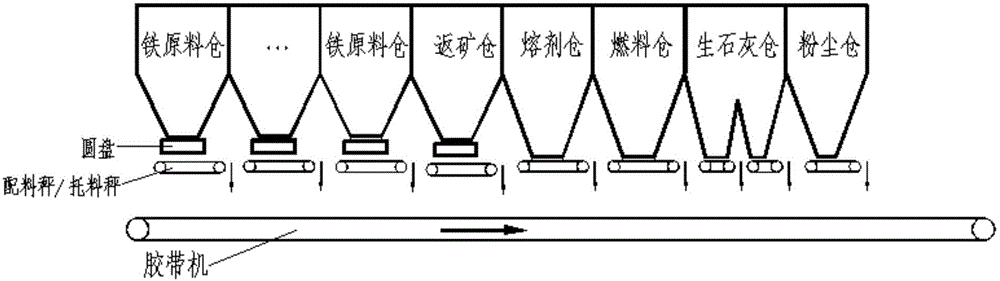

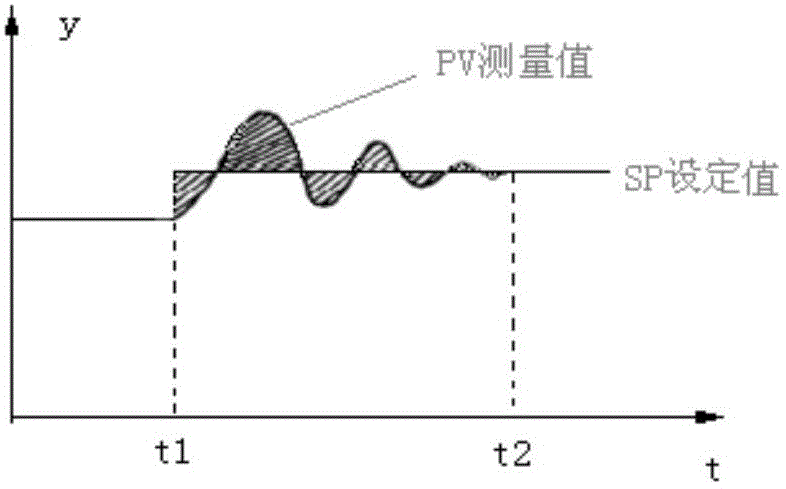

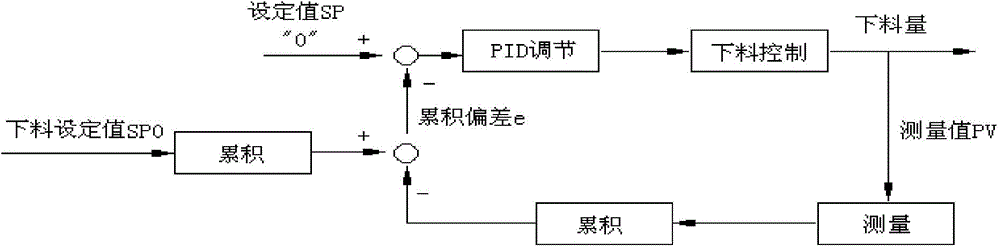

Method and device for controlling feeding in sintering burden process

The embodiment of the invention discloses a method and a device for controlling feeding in a sintering burden process. The method comprises the following steps: obtaining the set feeding amount at current moment, and detecting the actual feeding amount at current moment; calculating the sum of the set feeding amount obtained within the latest statistics cycle as the set feeding aggregate value, and calculating the sum of the actual feeding amount detected with the latest statistics cycle as the actual feeding aggregate value; calculating the difference between the set feeding aggregate value and the actual feeding aggregate value as an aggregate deviation value; and correcting the set feeding amount with the aggregate deviation value to obtain the correction value of the set feeding amount, so as to carry out feeding control according to the correction value of the set feeding amount. Through the method disclosed by the embodiment of the invention, the aggregate compensation is achieved at a certain extent; the raw material proportioning deviation caused by aggregate compensation is avoided; and the efficiency of the sintering process and the yield of agglomerate are improved.

Owner:HUNAN CHANGTIAN AUTOMATION ENG CO LTD

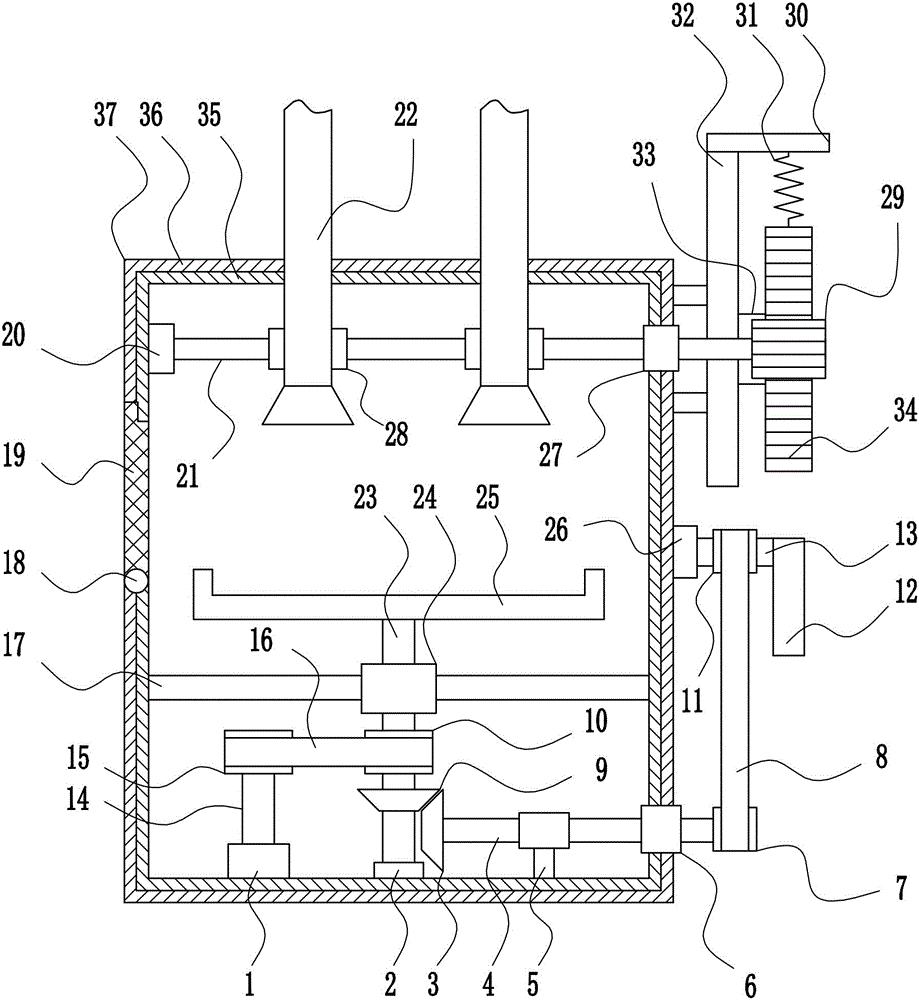

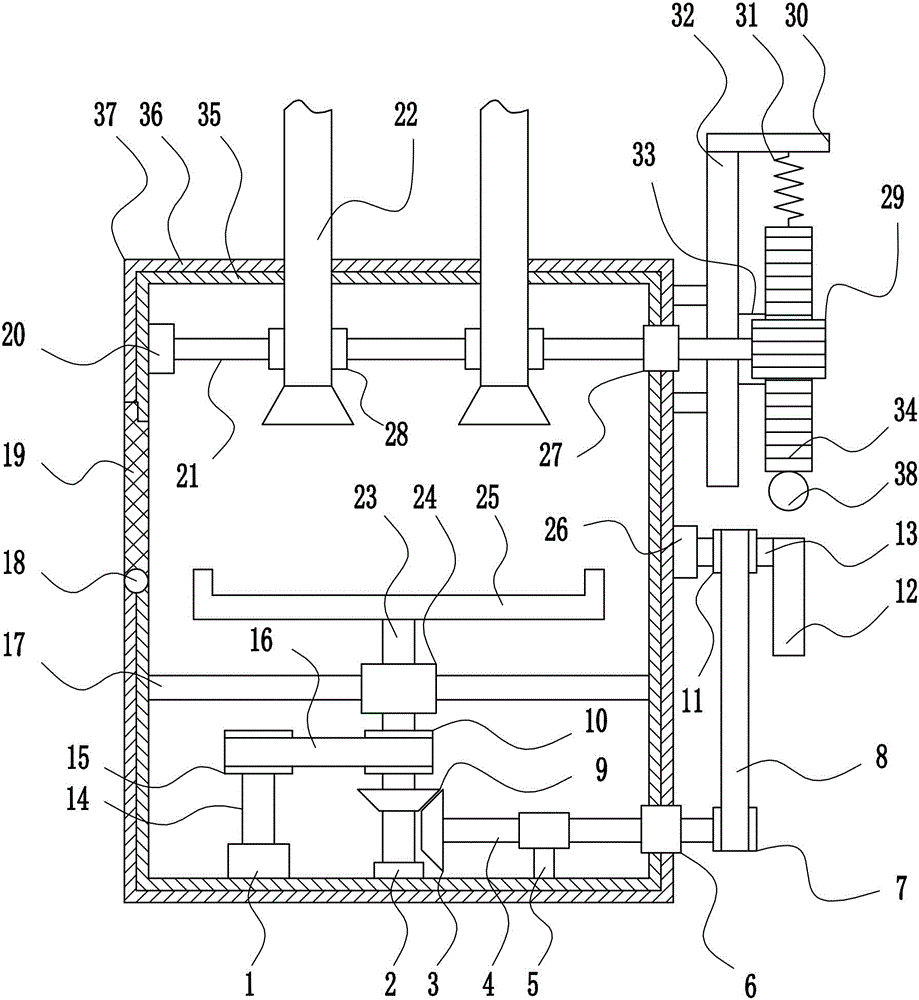

Sintering furnace for preparing nanometer ceramics

The invention relates to a sintering furnace and especially relates to a sintering furnace for preparing nanometer ceramics. The technical problem to be solved by the invention is to provide the sintering furnace for preparing nanometer ceramics with excellent heat-insulating effect, uniform sintering and high sintering efficiency. For solving the technical problem, the sintering furnace for preparing nanometer ceramics provided by the invention comprises a rotating motor, a first bearing base, a first bevel gear, a first rotating shaft, a second bearing base, a third bearing base, a first belt pulley, a first flat belt and a second bevel gear, wherein a fire-resistant heat insulating brick is arranged in a shell; an aluminum silicate fiber felt is filled between the fire-resistant heat insulating brick and the shell; a cover plate is hinged on the left side of the shell through a hinge part; the cover plate is matched with the shell; a fixing plate is welded on the middle part in the shell. According to the invention, a fourth belt pulley is driven to rotate by the rotating motor, the second belt pulley is driven to rotate by the fourth belt pulley through a second flat belt and a storing plate is driven to rotate by the second belt pulley through a fifth rotating shaft.

Owner:铜陵市祥云碳化硅烧结设备有限公司

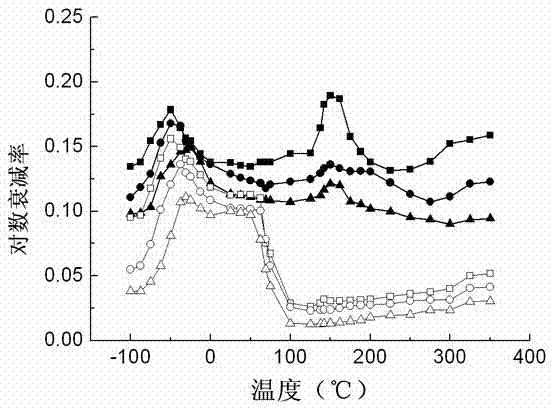

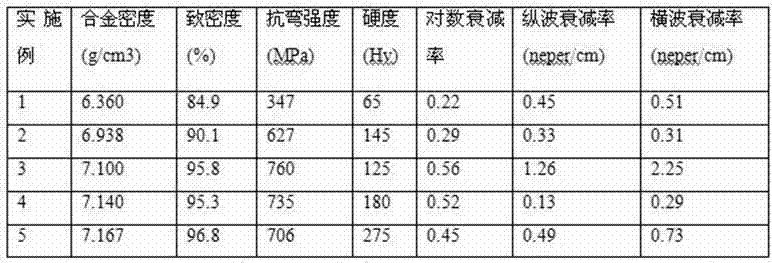

High-damping MnCu alloy and powdery metallurgy preparation technology thereof

The invention discloses a high-damping MnCu alloy and a powdery metallurgy preparation technology thereof. According to the high-damping MnCu alloy, Mn, Cu, Al, Ni and Fe are used as main components, the damping property can be enhanced by adding one or more of strongly magnetic particles Co3B, Co2B, Fe2B, FeB and MnB, and the sintering performance of the high-damping MnCu alloy can be effectively improved by adding one or more of Bi, Si, Sn and B as a sintering auxiliary. Compared with the traditionally cast MnCu-based damping alloy, the high-damping MnCu alloy has the characteristics of being higher in damping property, wider in damping temperature range, more flexible in formability and the like, and further the energy consumption can also be decreased. The formability of the prepared high-damping alloy is more flexible, so that the processing load of the subsequence procedures of rolling, grinding, cutting and the like can be reduced, and the cost reduction and mass production can be facilitated.

Owner:TIANJIN YINLONG HIGH TECH NEW MATERIAL RES INST

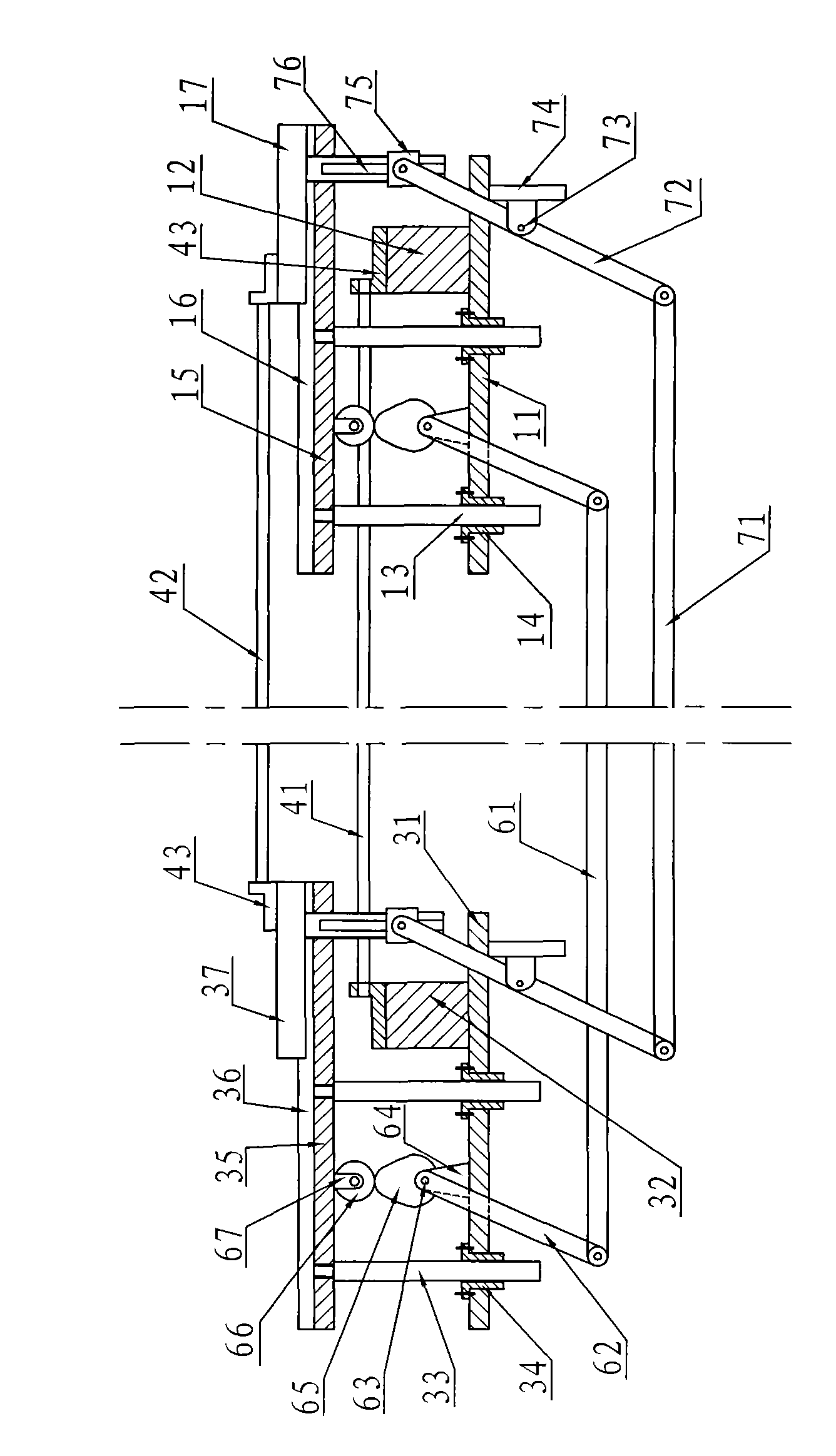

Method and device for preparing photo anode in flexible solar cell through selective laser sintering

ActiveCN102013332AImprove sintering efficiencyShort laser sintering timeLight-sensitive devicesSolid-state devicesSelective laser sinteringLight guide

The invention discloses a method and device for preparing a photo anode in a flexible dye-sensitized solar cell through selective laser sintering. The method is characterized in that the laser beams with the wavelength of 355nm-3.4mu m are adopted to act on the porous membrane with nanometer semiconductor particles to convert physical point contact between the nanometer semiconductor particles in the porous membrane and between the nanometer semiconductor particles and the conducive membranes to neck type chemical bound; and the power density of laser is 1-100W / cm<2> and the scanning speed of laser is 1-900mm / s. The device comprises a laser, an equipartition mirror, a beam expanding and collimating mirror, a diaphragm, a light guide mirror and a focusing mirror which are arranged on the same light path in sequence, wherein the diaphragm is movably installed and can be replaced according to the requirement of the focal spot of laser; and the equipartition mirror is a shaping mirror or an integral mirror. Through the method, the porous membrane with nanometer semiconductor particles on the flexible dye-sensitized solar cell can be subjected to sintering and heat treatment under high temperature, without causing damage on the flexible plastic substrate of the photo anode.

Owner:武汉飞能达激光技术有限公司

Electronic product high-temperature sintering furnace

InactiveCN110425886AShorten the timeImprove efficiencyElectric heating for furnacesFurnace crowns/roofsBrickSilicon

The invention provides an electronic product high-temperature sintering furnace and belongs to the technical field of electronic kiln furnace facilities. The electronic product high-temperature sintering furnace comprises a furnace body, the center of the furnace body is provided with a furnace cavity, silicon molybdenum bar left heating units and silicon molybdenum bar right heating units are distributed to the rear end of the furnace cavity from the front end of the furnace cavity at the positions corresponding to the left side and the right side of the furnace cavity, the electronic producthigh-temperature sintering furnace is characterized by further comprising left plug brick mechanisms, right plug brick mechanisms, left extraction release bricks and right extraction release bricks,the left plug brick mechanisms and the right plug brick mechanisms are built inside furnace top bricks at the positions corresponding to the silicon molybdenum bar left heating units and the silicon molybdenum bar right heating units, the left extraction release bricks and the right extraction release bricks are located at the top of the furnace body, the lower ends of the silicon molybdenum bar left heating units penetrate through the left plug brick mechanisms and stretch to the bottom of the furnace cavity, the upper ends of the silicon molybdenum bar left heating units penetrate through the left extraction release bricks from bottom to top and poke out of the upper surfaces of the left extraction release bricks, the lower ends of the silicon molybdenum bar right heating units penetratethrough the right plug brick mechanisms and stretch to the bottom of the furnace cavity, and the upper ends of the silicon molybdenum bar right heating units penetrate through the right extraction release bricks from bottom to top and poke out of the upper surfaces of the right extraction release bricks. By means of the electronic product high-temperature sintering furnace, the engineering cost of silicon molybdenum bar replacement is reduced, and the sintering efficiency is improved.

Owner:SUZHOU HUIKE EQUIP CO LTD

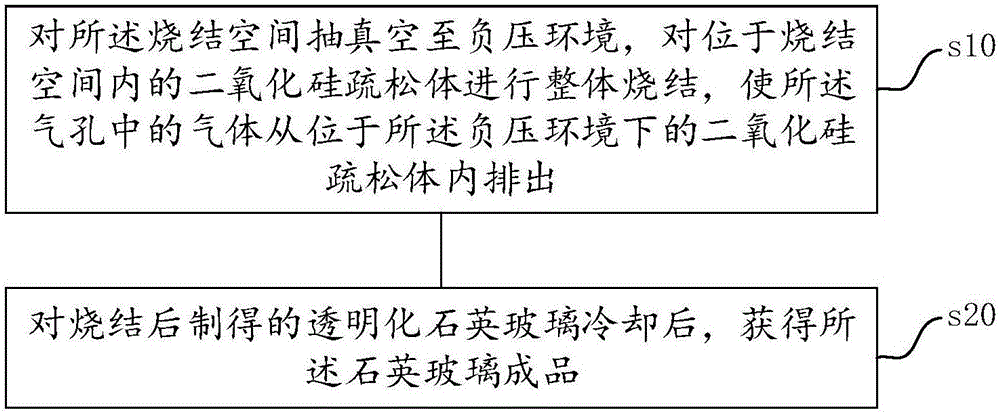

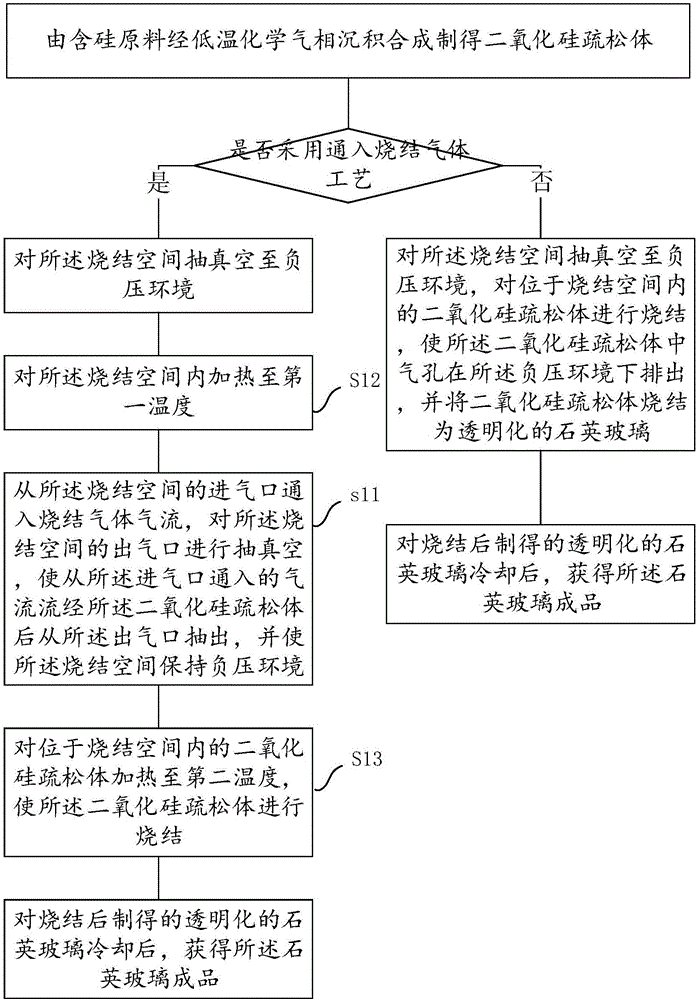

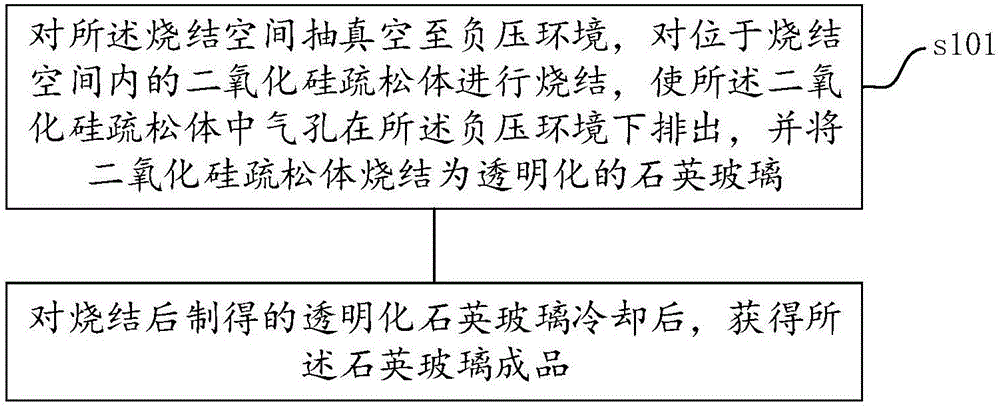

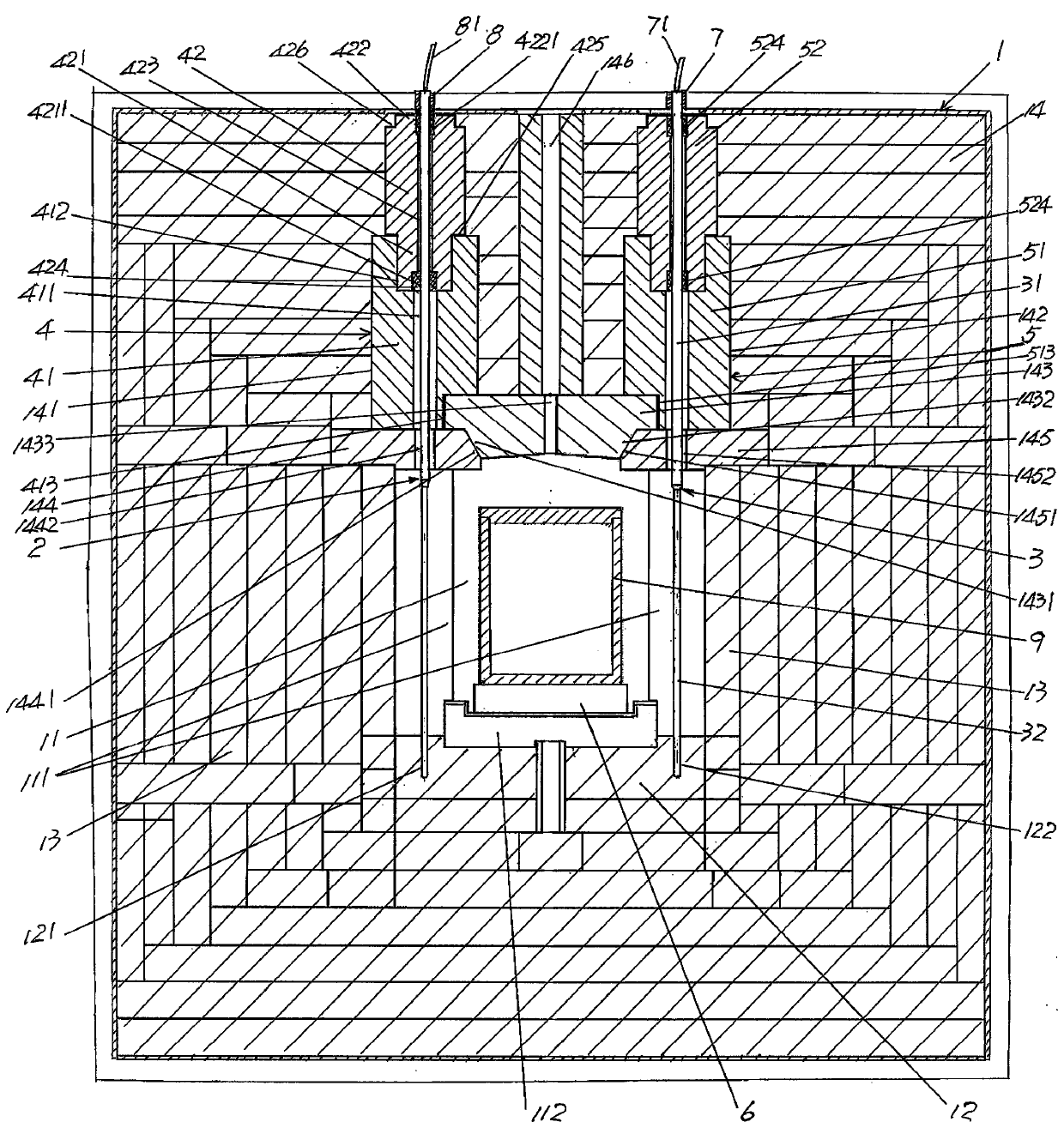

Sintering device and system for preparing quartz glass

ActiveCN106116122AImprove sintering efficiencyImprove product qualityGlass shaping apparatusWhole bodySynthesis methods

The invention relates to a sintering device and system for preparing quartz glass, relating to the field of preparing quartz glass and mainly aiming at avoiding or reducing the generation of bubbles in preparation of the quartz glass by adopting indirect synthesis method technology, and improving the sintering efficiency of the quartz glass and lowering the cost. The sintering device for preparing quartz glass comprises a furnace body, wherein a vacuumizing channel communicated with a sintering space is also arranged on the furnace body, and used for vacuumizing the sintering space to a negative pressure environment so as to sinter silica loose body in the sintering space, pores in the silica loose body are discharged under the negative pressure environment, and the silica loose body is sintered to transparent quartz glass. According to the sintering device and system for preparing quartz glass, the sintering device for preparing the quartz glass can conduct sintering under the negative pressure environment, and the content of bubbles in the obtained finised quartz glass after sintering can be decreased, so that the quality of the quartz glass product is improved, the whole body is heated and sintered simultaneously, the sintering efficiency of the silica loose body is increased and the cost is lowered.

Owner:CHINA BUILDING MATERIALS ACAD

Novel high-temperature sintering furnace

PendingCN110425878AImprove sintering efficiencyEffect of sintering efficiencyLinings repairCharge manipulationHOLDING CHAMBERHeating element

The invention relates to a novel high-temperature sintering furnace, and belongs to the technical field of kiln facilities. The novel high-temperature sintering furnace comprises a furnace body, wherein a hearth is arranged in the center of the furnace body; a silicon molybdenum rod left heating element is distributed at the position corresponding to the left side of the hearth from the front endof the hearth to the back end; and a silicon molybdenum rod right heating element is distributed at the position corresponding to the right side of the hearth from the front end of the hearth to the back end. The novel high-temperature sintering furnace is characterized in that a left brick filling mechanism holding chamber is formed at the position, corresponding to the silicon molybdenum rod left heating element, on furnace top bricks; a right brick filling mechanism holding chamber is formed at the position, corresponding to the silicon molybdenum rod right heating element, on furnace top bricks; a left brick filling mechanism is arranged in the left brick filling mechanism holding chamber; a right brick filling mechanism is arranged in the right brick filling mechanism holding chamber;the upper end of the silicon molybdenum rod left heating element is matched with the left brick filling mechanism via insertion; and the upper end of the silicon molybdenum rod right heating elementis matched with the right brick filling mechanism via insertion. The engineering cost for replacing silicon molybdenum rods is reduced, the sintering efficiency is improved, a sealing effect of the top part of the hearth cannot be influenced, and the convenience in replacement is realized.

Owner:SUZHOU HUIKE EQUIP CO LTD

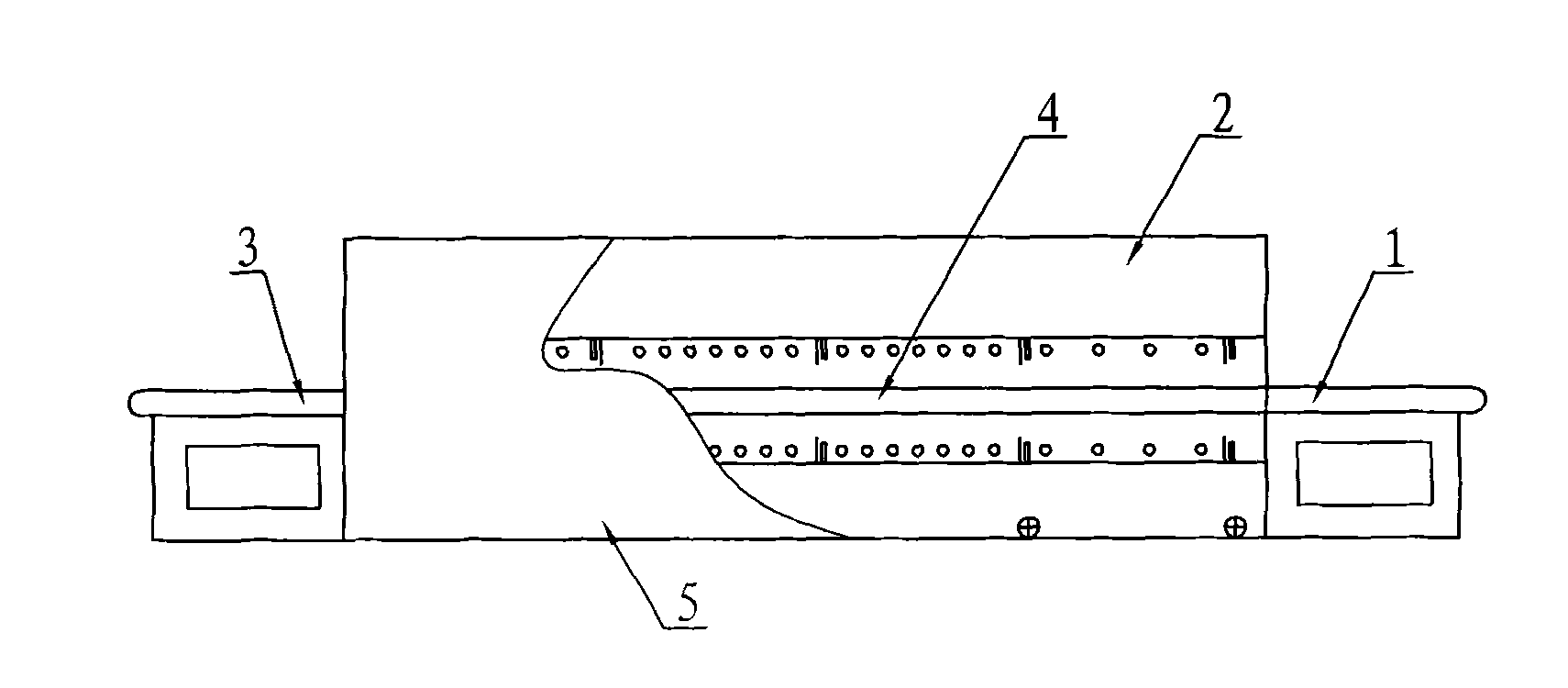

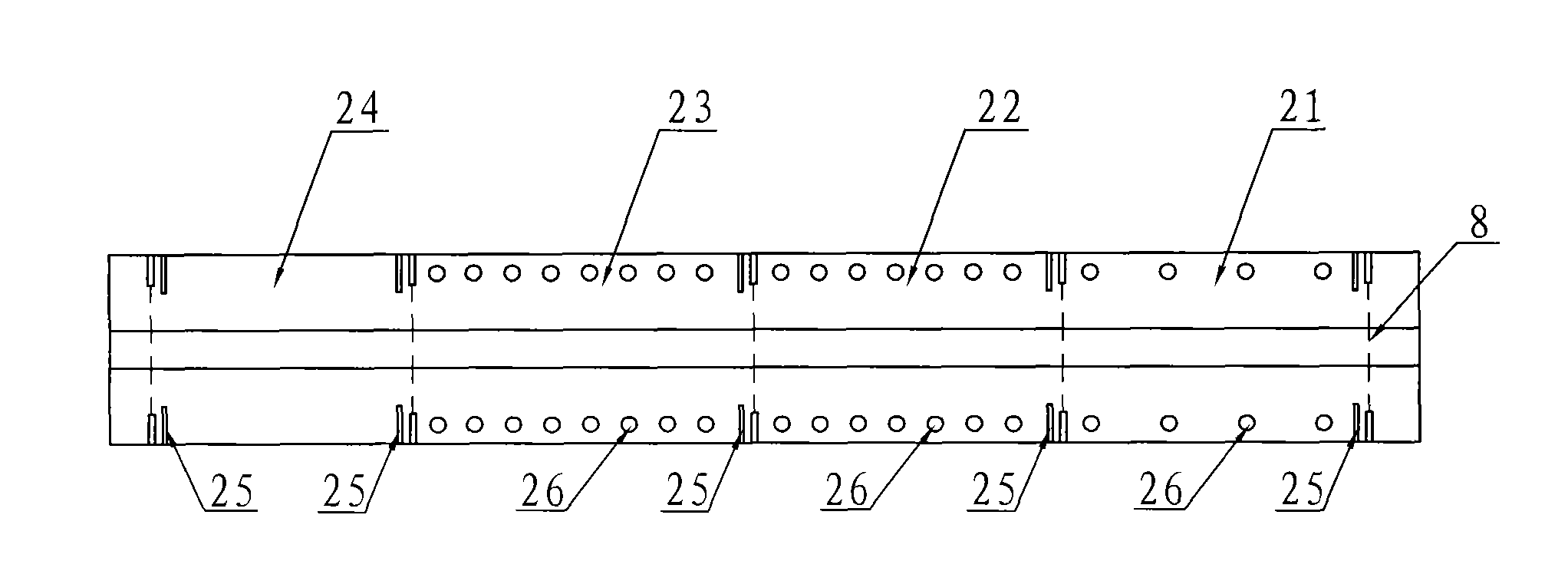

Mesh tape-free silicon cell slice sintering furnace

ActiveCN102062529AEffective separationReduce consumptionFinal product manufactureFurnace typesMetallurgySlide plate

The invention provides a mesh tape-free silicon cell slice sintering furnace which comprises a material charging table, a tunnel type sintering box, a material discharging table and a silicon slice transporting device, wherein a preheating glue discharging region, a temperature rising region, a sintering region and a temperature reducing region are sequentially arranged along the lengthways direction of the tunnel type sintering box; a plurality of heat isolating plates and a plurality of air flow heat isolating doors are evenly arranged among a plurality of temperature regions; the preheating glue discharging region, the temperature rising region and the sintering region are internally provided with a plurality of heating lamp tubes; a reciprocating lift mechanism is arranged between a fixed base plate and a movable base plate; a reciprocating translation mechanism is arranged between the fixed base plate and a sliding plate; and the sliding plate sequentially can upwards lift, forwards move, downwards move and backwards move relative to the fixed plate. The silicon slice transporting device comprises a fixed support bracket and a movable support bracket. The heat isolating plates and the air flow heat isolating doors are arranged among the regions, so that the temperature regions can be effectively separated, and the temperature in each temperature region is more close to the requirement of a sintering technology; and a tunnel sintering region is isolated from the atmosphere, so that the sintering efficiency is improved, and the heat dissipation of the sintering furnace is reduced; and therefore, the length of the whole sintering furnace body is shortened.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

Nickel ore sintering machine

The invention discloses a nickel ore sintering machine comprising a plurality of vertical kilns and a smoke pipe for concentrated discharge of tail gas, wherein a dust removal cylinder is arranged between each vertical kiln and the smoke pipe; each vertical kiln comprises a kiln body composed of an upper section kiln body, a middle section kiln body and a lower section kiln body; a feed port and a tail gas discharge port are formed in the top part of the upper section kiln body; a center tower gate is arranged at a discharge port of the lower section kiln body; the lower section kiln body relative to the center tower gate is set as an arc-shaped kiln body which is formed by expanding the middle part outwards and can guide side wind in a furnace to converge to the center of the furnace; a side air inlet is formed in the middle section kiln body; and a plurality of air inlets are formed in the wall of the smoke pipe, and different air inlets are formed in different cross sections of the smoke pipe. By forming the plurality of the air inlets, the nickel ore sintering machine disclosed by the invention improves the tail gas discharge amount of a unit time and improves the discharging efficiency; and by virtue of the arc-shaped kiln body, the wind is delivered to center tower gate and the center of an internal furnace combustion zone, and thus the nickel ore sintering efficiency is improved.

Owner:连云港泓聚莱釉料有限公司

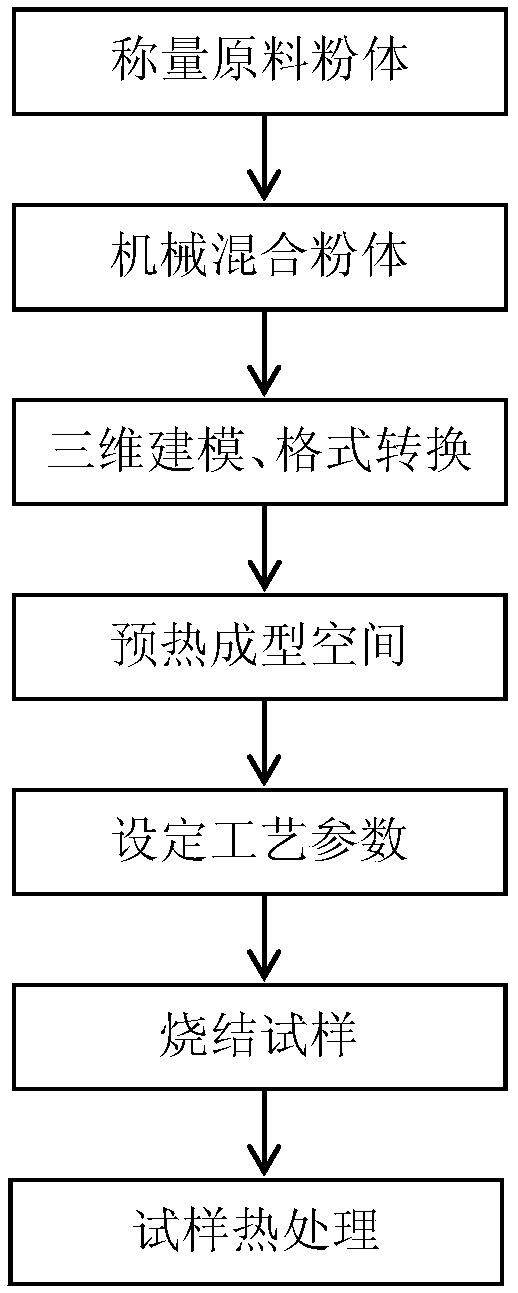

Method for forming bismuth telluride based thermoelectric material through 3D printing

The invention discloses a method for forming a bismuth telluride based thermoelectric material through 3D printing. The method includes following steps: preparing bismuth telluride / epoxy resin 3D printing mixed powder, performing 3D printing forming on a blocky thermoelectric material sample, and performing thermal treatment on the blocky thermoelectric material sample. The method is simple in process, high in forming accuracy, high in material utilization rate and capable of quickly preparing the Bi2Te3 based thermoelectric material with high performance; selective laser sintering 3D printingtechnology is utilized, so that heating speed and cooling rate are high, and grain structure can be refined; compared with other preparation methods, the method has the advantages of being short in preparation time, high in sintering efficiency and pollution-free in the process of sintering; by adopting the technology for Bi2Te3 based thermoelectric material powder forming, the defects of conventional processing methods are overcome, and workpiece quality and efficiency are improved, so that industrial application of thermoelectric devices is promoted.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com