Mesh tape-free silicon cell slice sintering furnace

A technology for silicon cells and sintering furnaces, which is applied in the direction of furnaces, circuits, furnace types, etc., and can solve problems such as unsatisfactory sintering process, energy waste, and elevated working environment temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

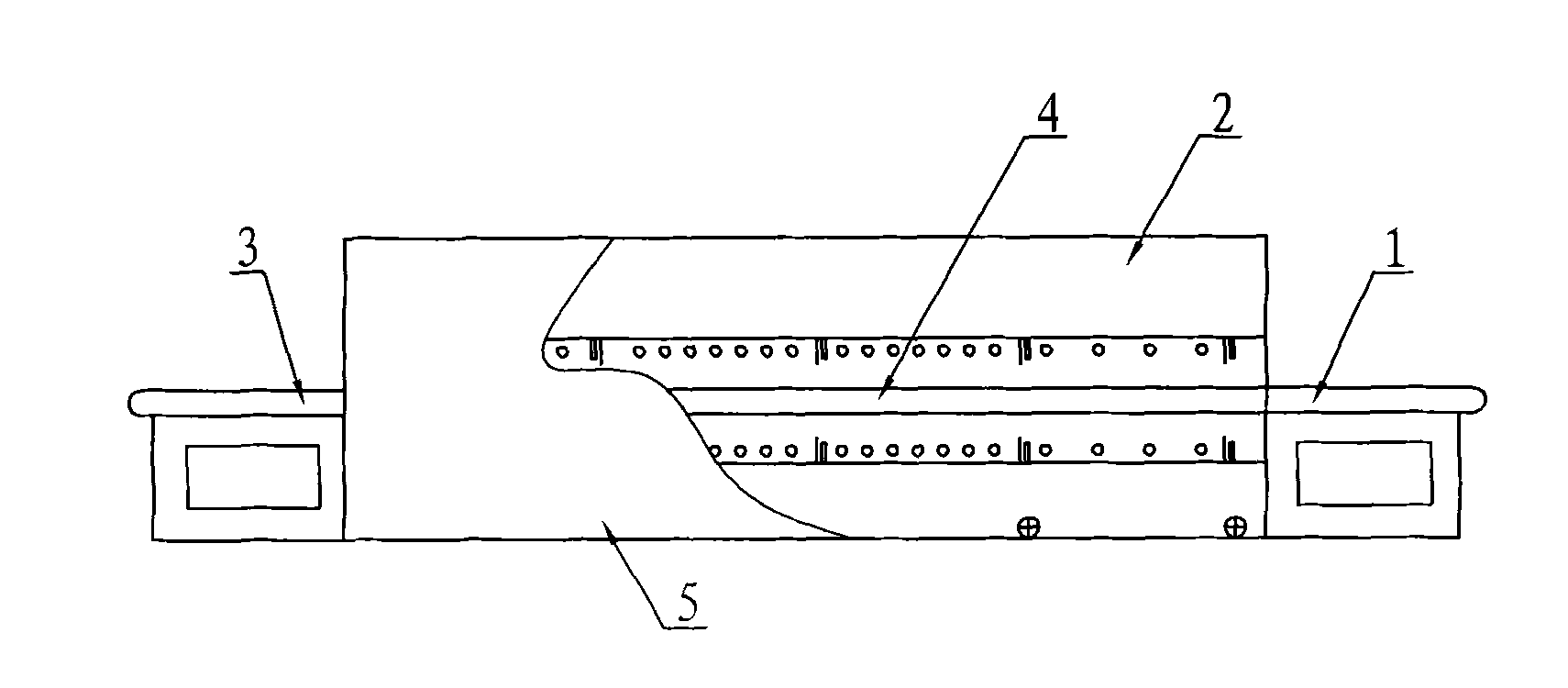

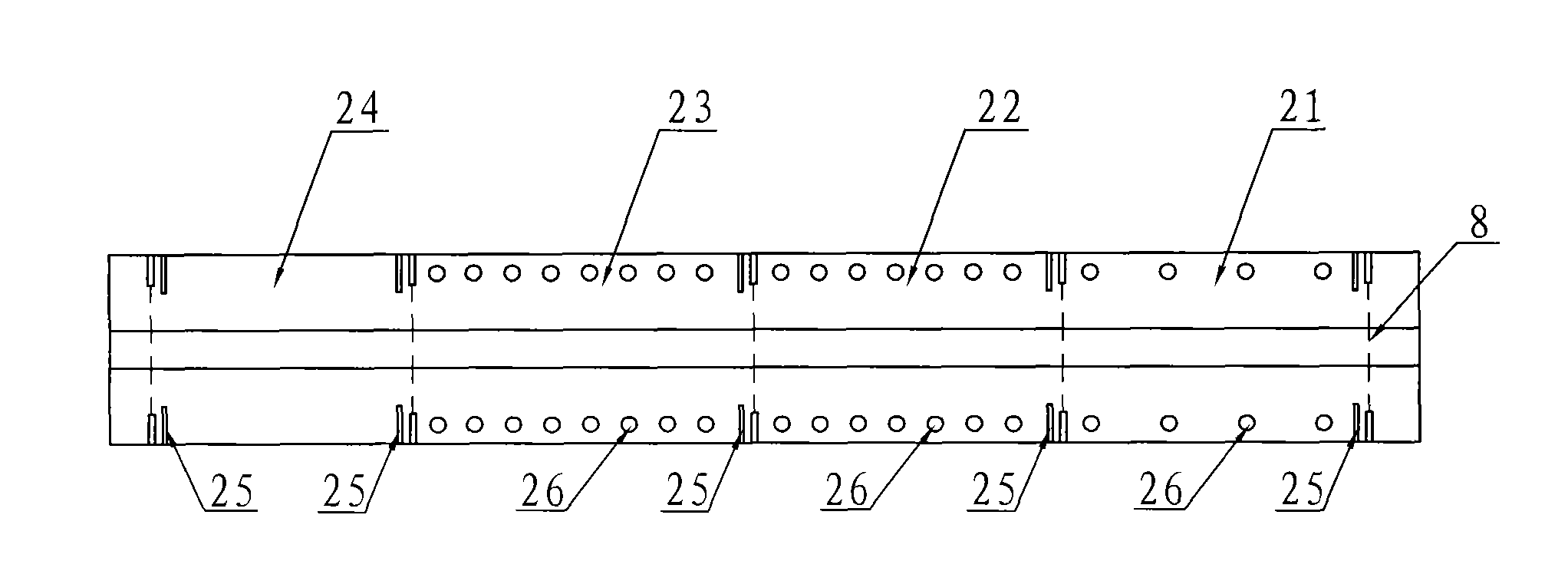

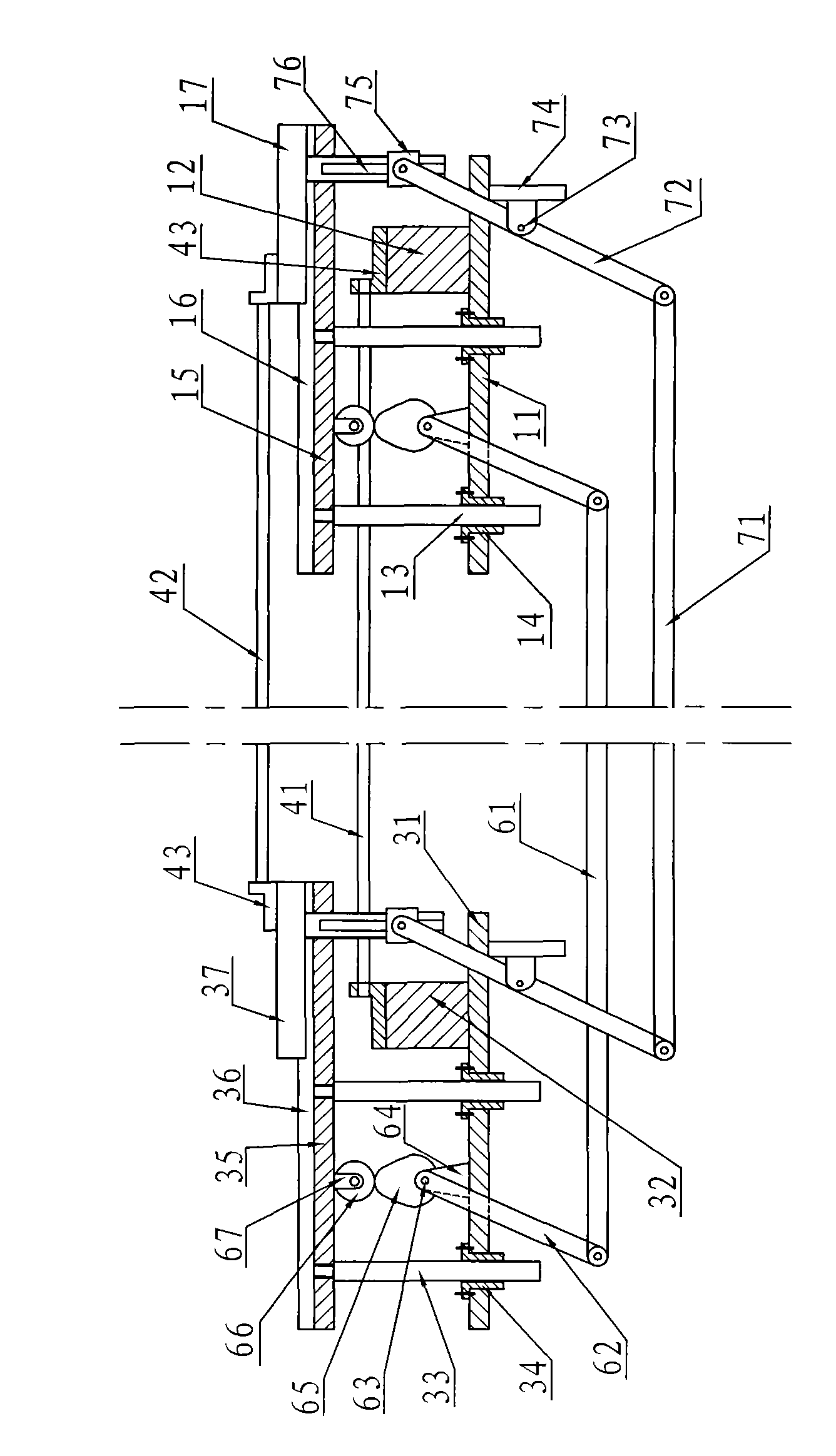

[0031] The non-mesh belt silicon cell sintering furnace is composed of a feeding platform 1, a tunnel type sintering box 2, a discharging platform 3, a silicon wafer conveying device 4 and a furnace frame 5, as figure 1 Shown; Among them, along the longitudinal direction of the tunnel type sintering box 2, there are four regions of preheating debinding area 21, heating area 22, sintering area 23 and cooling area 24, in the preheating debinding area 21, heating area 22, Between the sintering zone 23 and the cooling zone 24, a heat shield 25 and an air-flow insulation door 8 are provided, and a thermal radiation heating lamp tube 26, a heat shield 25 is arranged perpendicular to the direction of the tunnel, and the air-flow insulation door 8 is arranged on one side of the insulation board 25, such as figure 2As shown; the feed table 1 includes a fixed base plate 11, a fixed frame 12, a guide rod 13, a guide sleeve 14, a movable plate 15, a slide rail 16 and a sliding plate 17, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com