Patents

Literature

267results about How to "To achieve the purpose of purification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for extracting carnosic acid

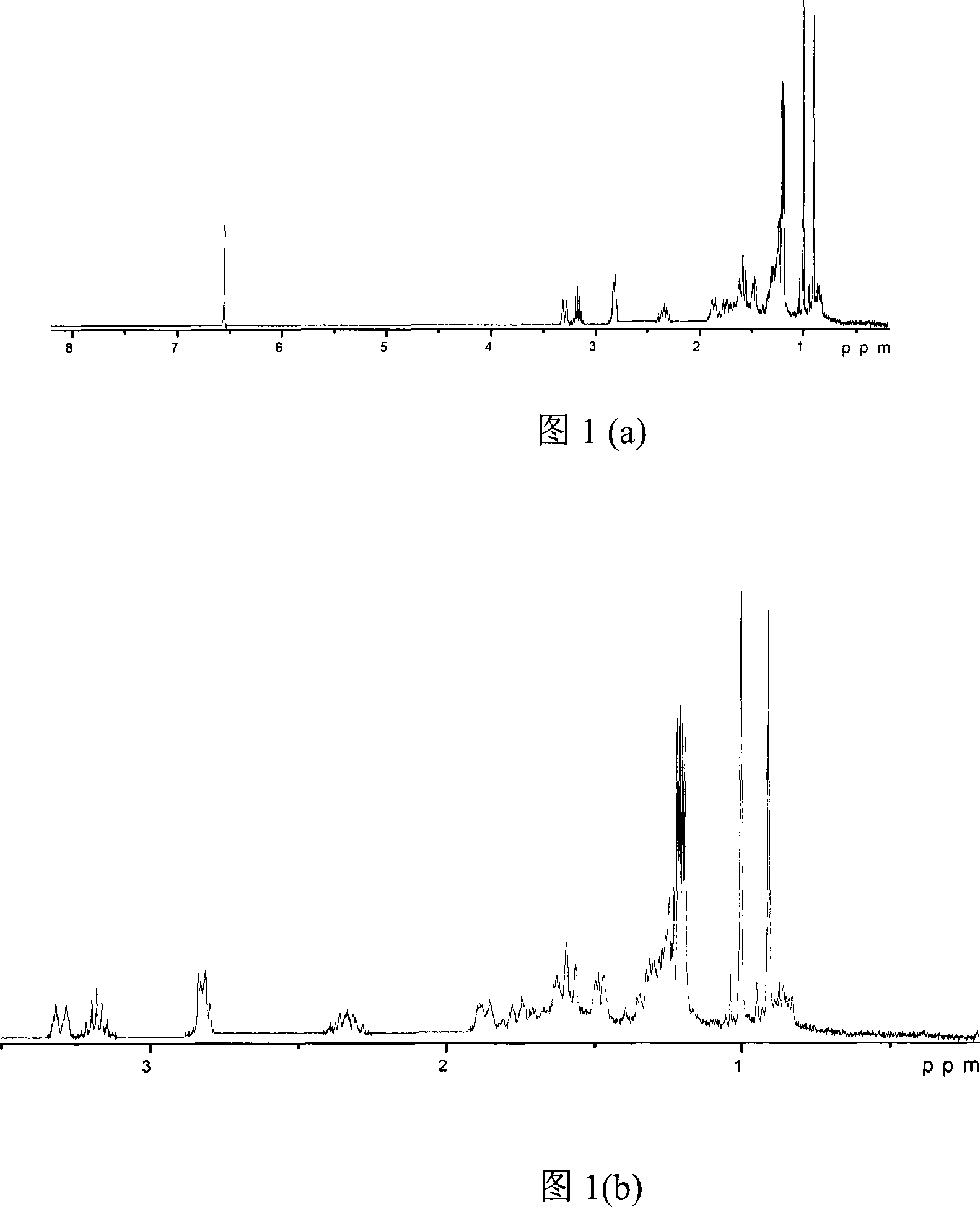

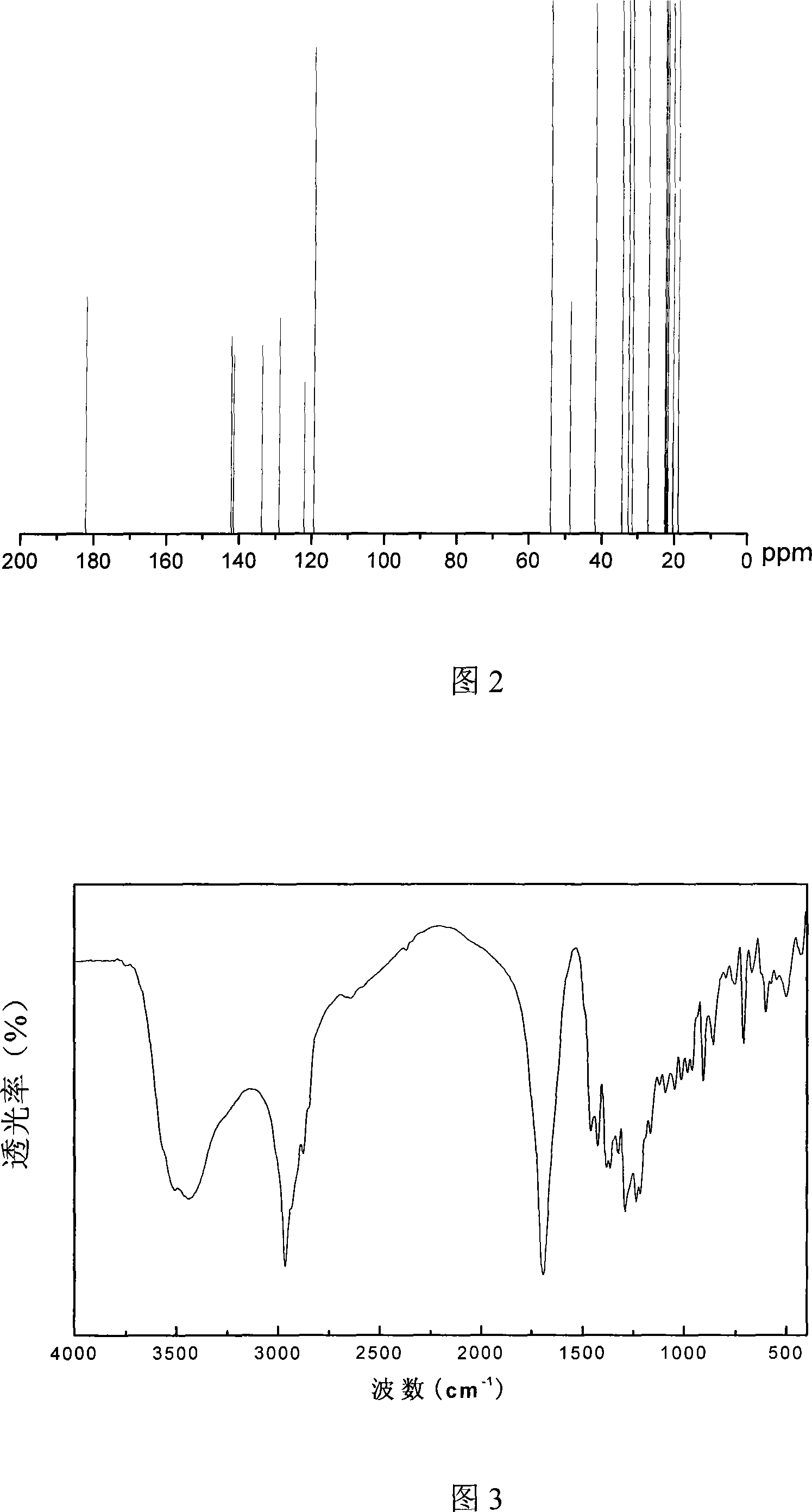

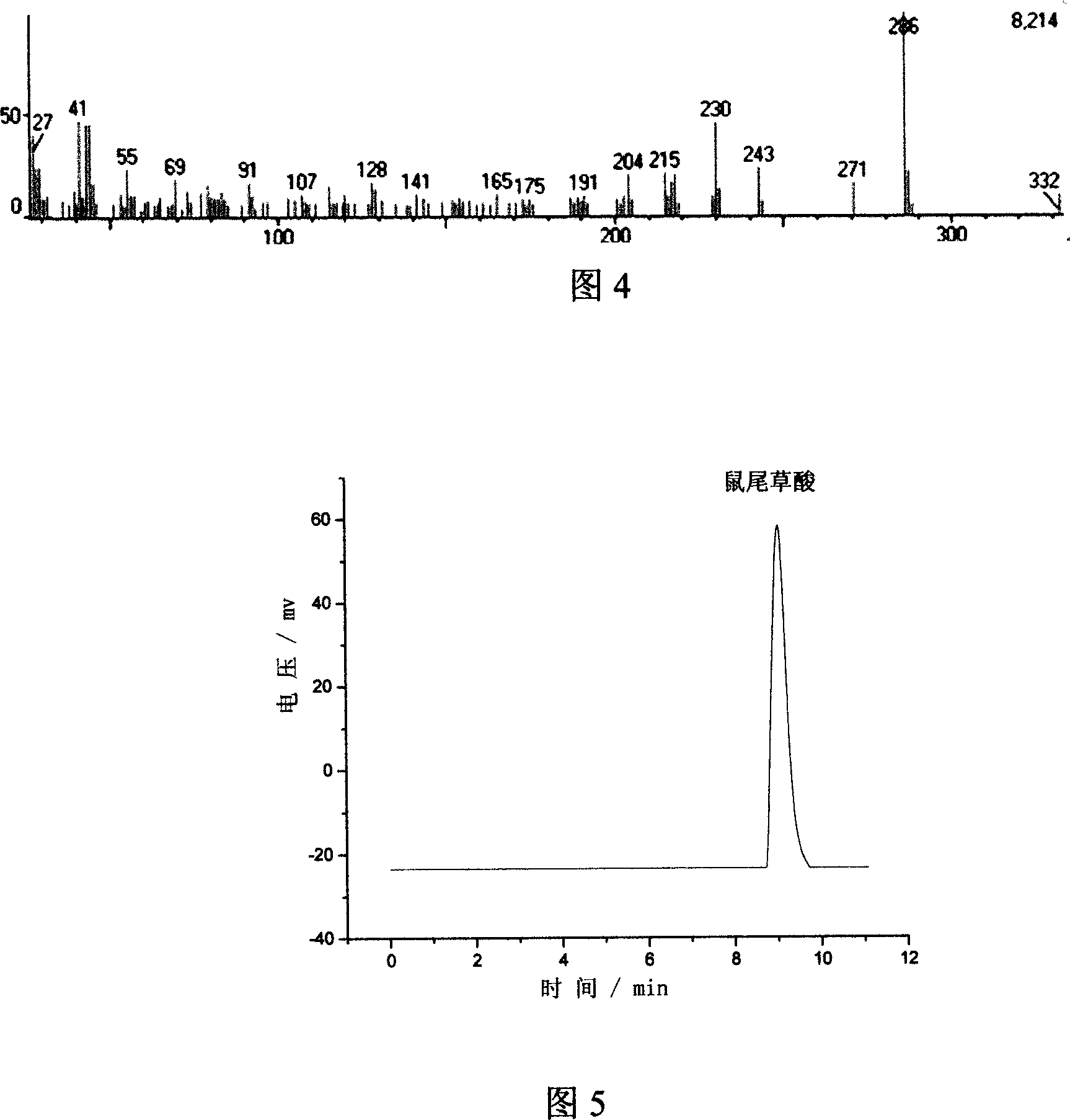

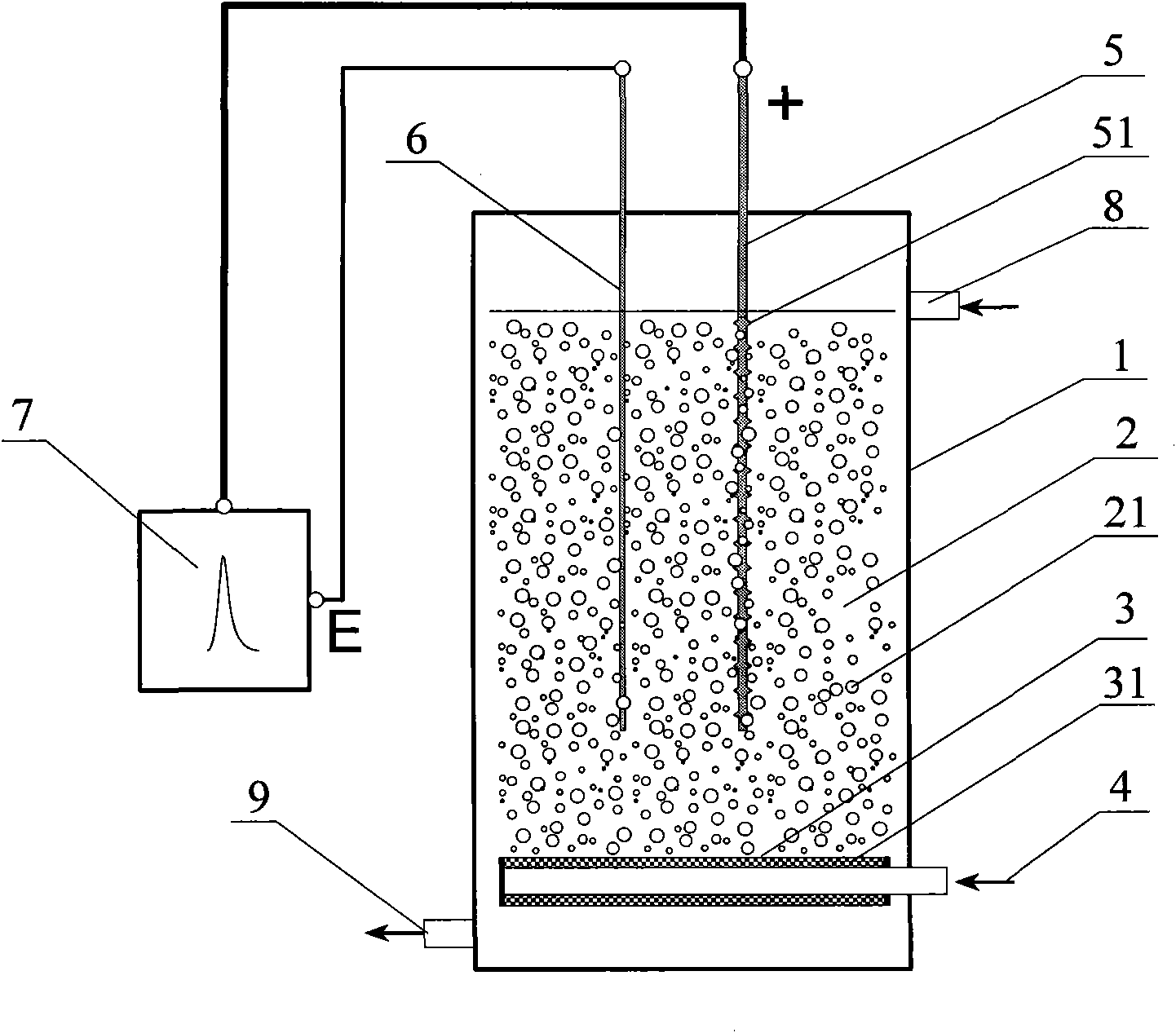

InactiveCN101113133ATo achieve the purpose of purificationNo need to crystallizeCarboxylic compound separation/purificationChemistryCarnosic acid

The invention discloses a preparation method of extracting carnosin, that is, dry rosemary is immersed in organic solvent, and extracted for 10-60 min in 20-55 DEG C ultrasonic, and filtered to acquire the extract of dry rosemary, and acticarbon is added into the extract of dry rosemary, the quality ratio of the acticarbon and dried rosemary extract is 1: 15- 1: 25; the extract is decolored for 5- 20 min in 25-45 DEG C ultrasonic, and the extract liquid is acquired before being filtering for 1-2 times; the extract liquid is distilled to dryness to acquire the solid. Ethylenediamine tetraacetic disodium is added into the solid to dissolve the solid, then alkali is added to adjust PH to 8.0-9.5 before getting the colature.liquid finally, and acid is added to adjust PH to 2.3-3.0 till precipitation is produced in the colature liquid, and then carnosin is acquired after the precipitation is dried. Without any crystallization, the purity of carnosin can reaches as high as 99.42%, and the extraction process is simple and can be easily operated in short time.

Owner:中科检测技术服务(广州)股份有限公司

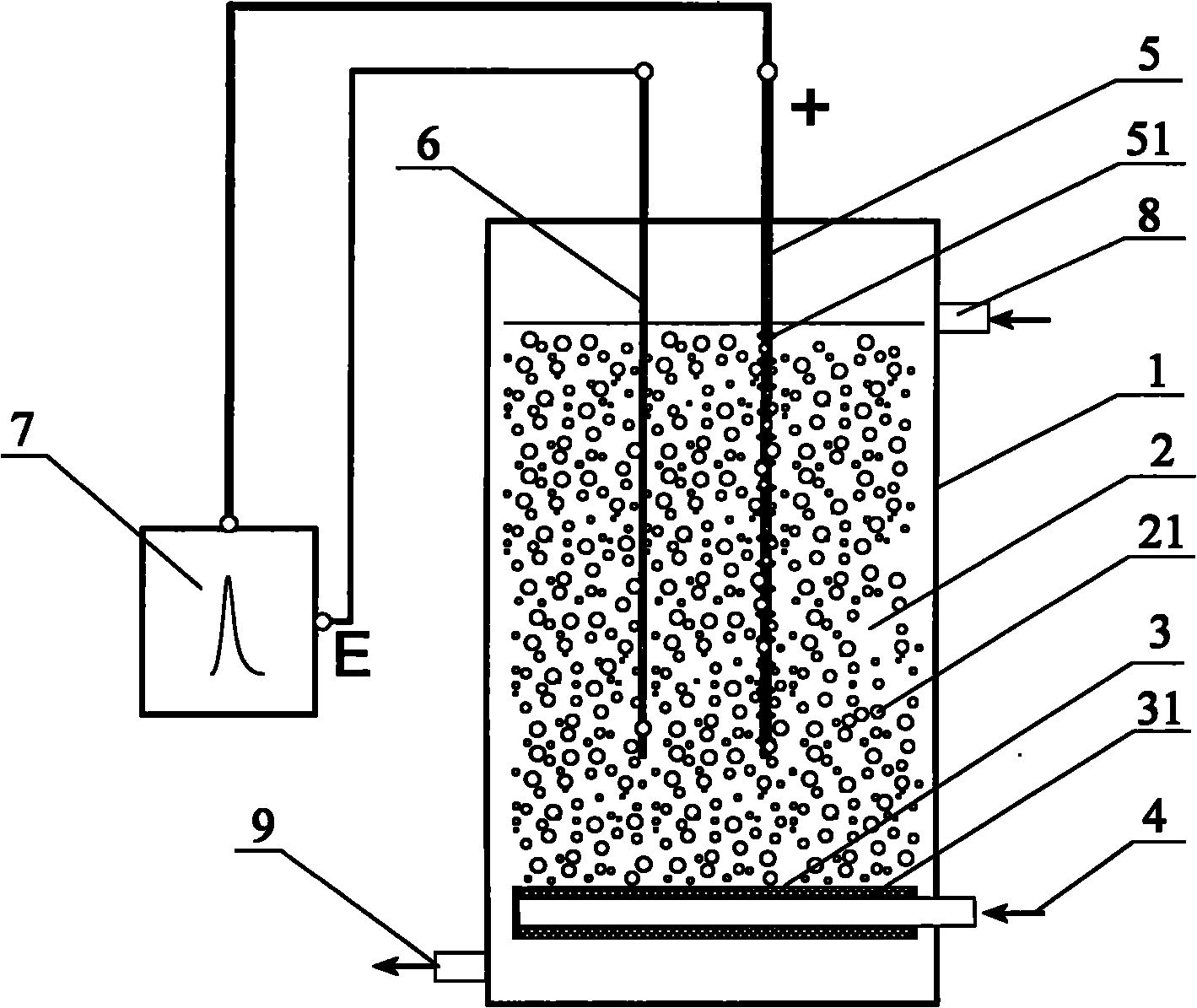

Water treatment device for combining low-temperature plasma and air oxidation

InactiveCN101935092AAchieve mass transferTo achieve the purpose of purificationWater/sewage treatment by magnetic/electric fieldsWater/sewage treatment by oxidationWastewaterOxygen

The invention discloses a water treatment device for combining low-temperature plasma and air oxidation. The device comprises a reaction vessel, an oxidation device and a discharging device, wherein the oxidation device is arranged at the bottom of the reaction vessel and used for forming bubbles in the reaction vessel and improving the mass transfer of oxygen and water; the discharging device comprises an electrode and a power supply which are arranged in the reaction vessel; and the electrode is used for generating free radicals, ozone and UV-light by discharging to initiate oxygen participated chain reaction in water. In the invention, air is blown in wastewater by the oxidation device, and the tiny bubbles are formed in the aqueous solution, and the mass transfer between the oxygen and the water is realized in the movement process of the bubbles. The invention strengthens the oxidation reaction with pollutants in water under the action of the plasma, degrades the pollutants in thewater and achieves the aim of purification.

Owner:BEIJING JIAOTONG UNIV

Treatment technology for small runoff and heavily-polluted river branches

InactiveCN102249384ATo achieve the purpose of purificationReduce pollutionMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationFlocculationWater flow

The invention discloses a treatment technology for small runoff and heavily-polluted river branches. The technology is characterized by the processes of: blocking a river to set a drop dam, in front of which a dirt accommodating pit is digged, and the dirt accommodating pit is in connection with the drop dam; determining a certain distance in front of the dirt accommodating pit for hanging and immersing a slow release medicine package on the basis of a large flocculating unit forming before currents arriving the drop dam, and installing a spoiler between the slow release medicine package hanging and immersing point and the dirt accommodating pit for perturbing the currents so as to improve the flocculation efficiency, so that pollutant colloids, dissolved phosphorus or solid pollutants in the water body can be flocculated before reaching the drop dam and the generated flocculating unit, when blocked by the drop dam, sinks to the dirt accommodating pit so as to be removed at a fixed point, leaving the upper clear water that undergoes flocculation to overflow the drop dam and move ahead. And the forward moving currents also provide a water body oxygen enriching function. The technology of the invention can obviously improve the water quality and greatly reduce the river branch treatment cost.

Owner:QUANZHOU NORMAL UNIV

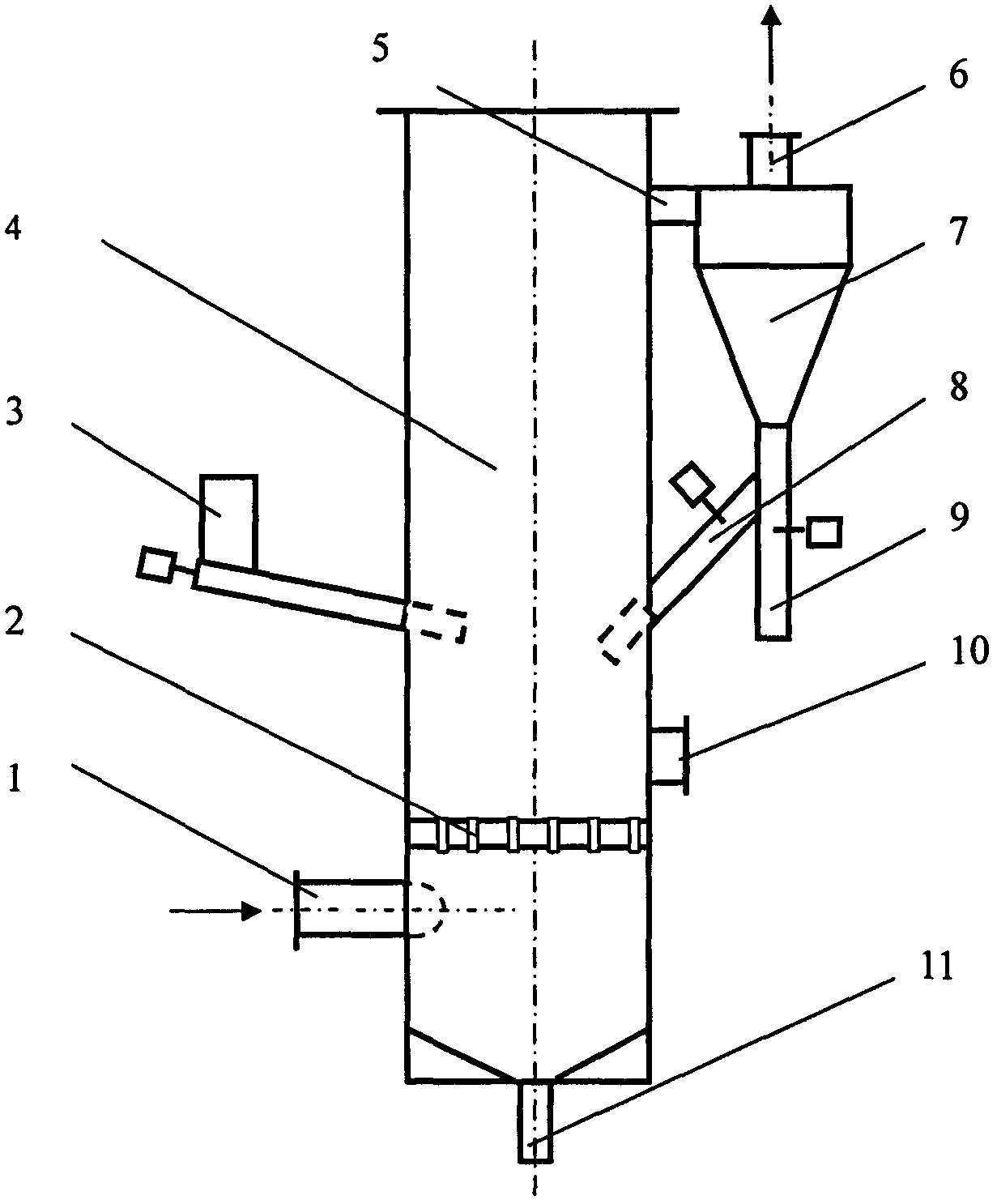

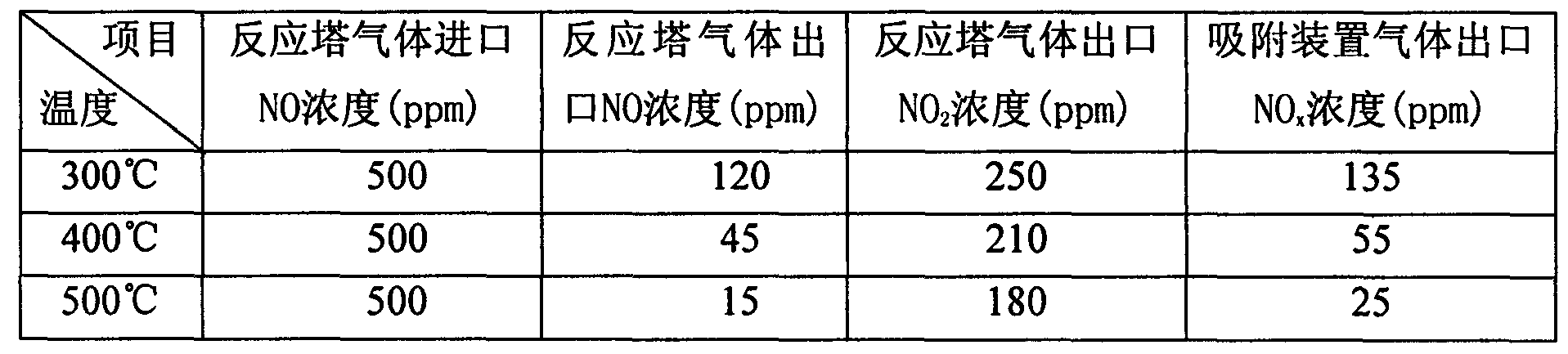

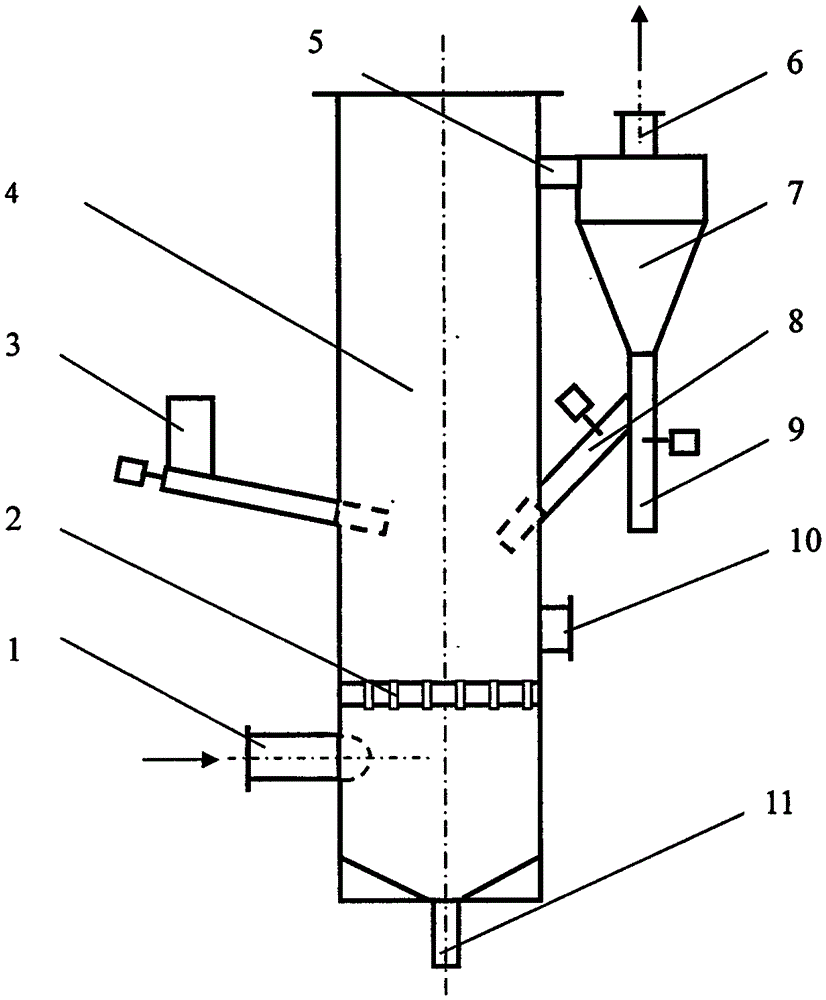

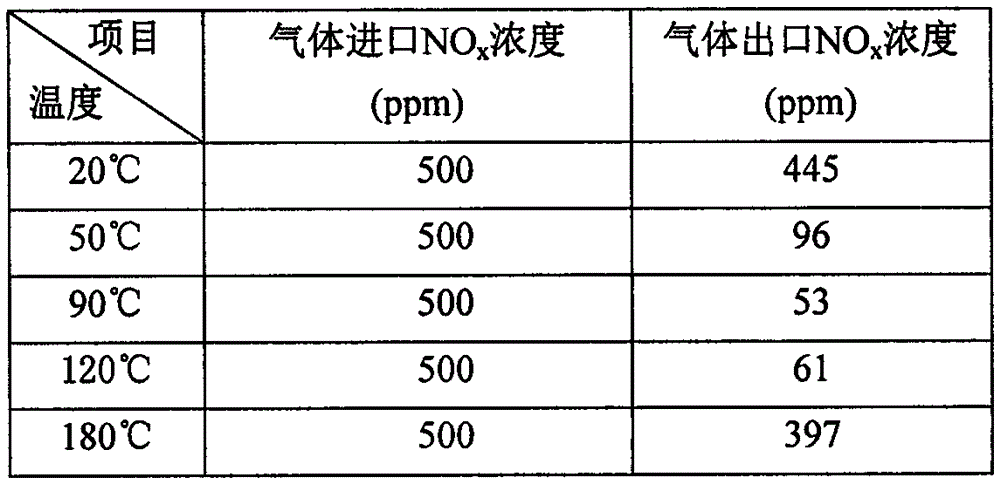

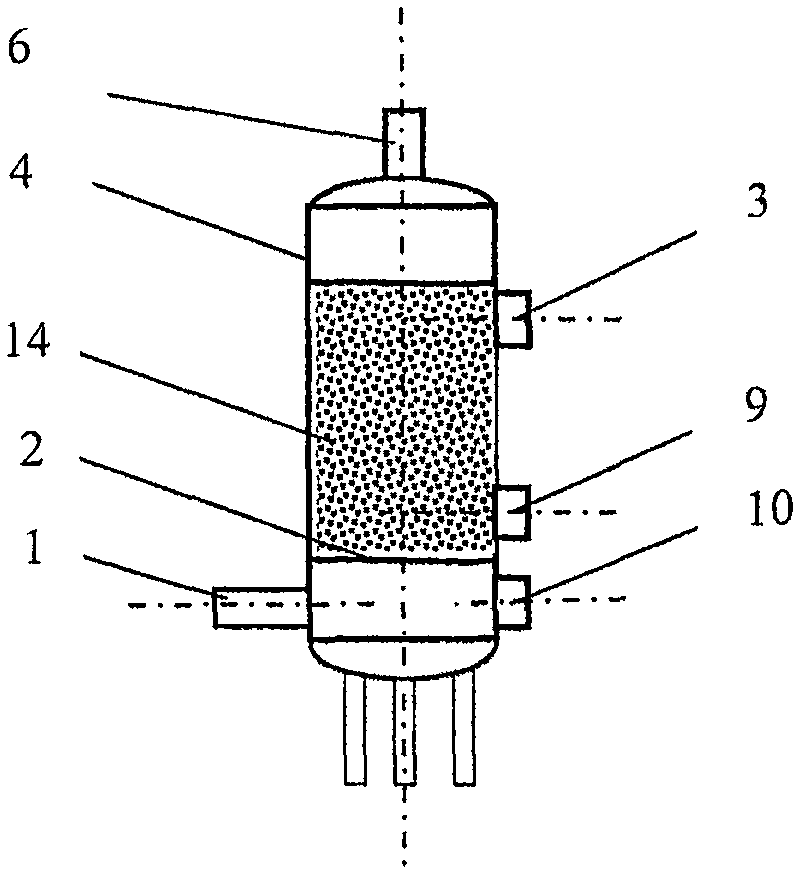

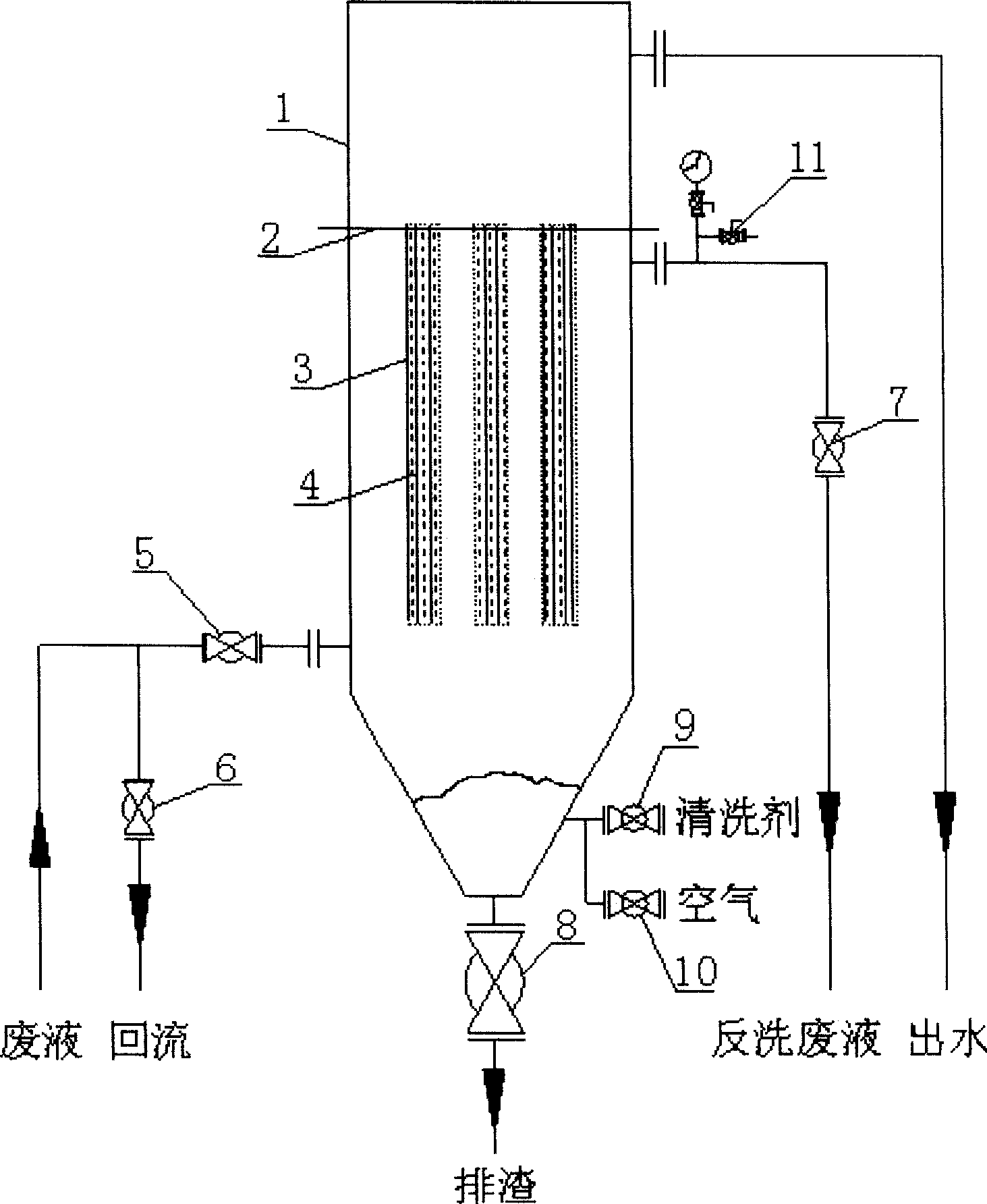

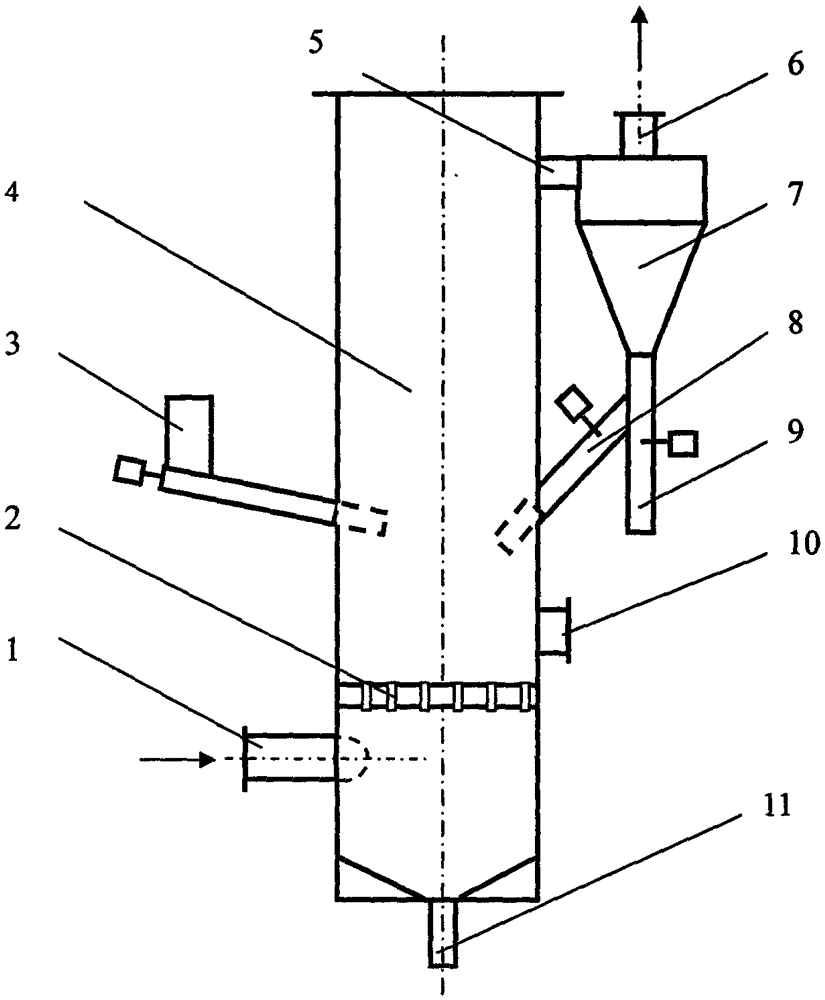

Method and device for simultaneous reduction and oxidation of nitrogen oxides from airflow

InactiveCN104353347ATo achieve the purpose of purificationImprove processing efficiencyDispersed particle separationAir quality improvementMetal chlorideNitrogen dioxide

The invention discloses a method and a device for simultaneous reduction and oxidation of nitrogen oxides from airflow. According to a treating process, the treated airflow is guided into a gas-solid reaction tower, solid ferrous chloride, ferric chloride, manganese chloride or magnesium chloride metal chloride particles are guided into the gas-solid reaction tower simultaneously, and the metal chloride is decomposed at the high temperature and reacts with nitric oxide in the airflow, so that part of nitric oxide contained in the airflow is reduced to nitrogen, the rest nitric oxide is oxidized into nitrogen dioxide, generated nitrogen dioxide reacts with an alkaline absorbent easily to be removed, and the purpose of gas purification is achieved. The invention further discloses the special device. The method and the device have the characteristics of low investment cost as well as operation and application cost, simplicity in operation, high treatment efficiency and high treatment capacity.

Owner:黄立维

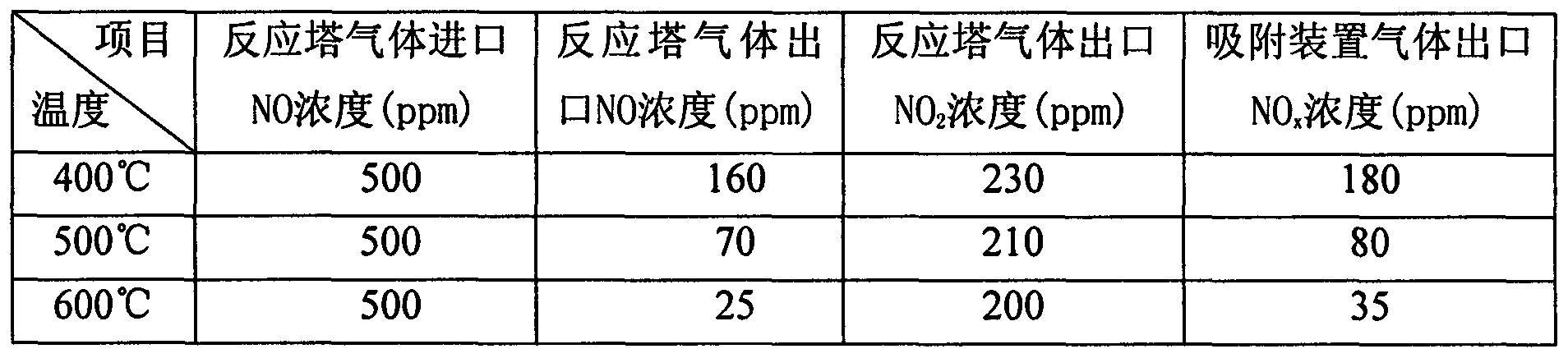

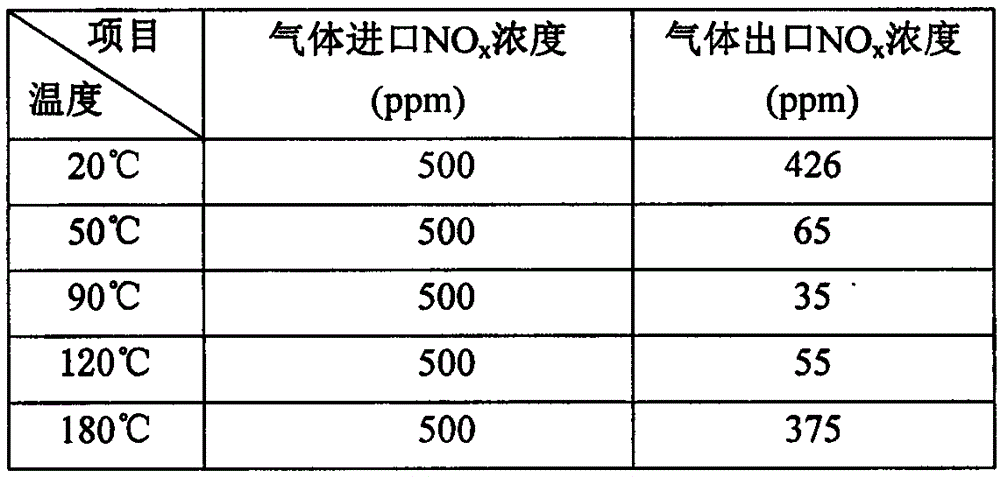

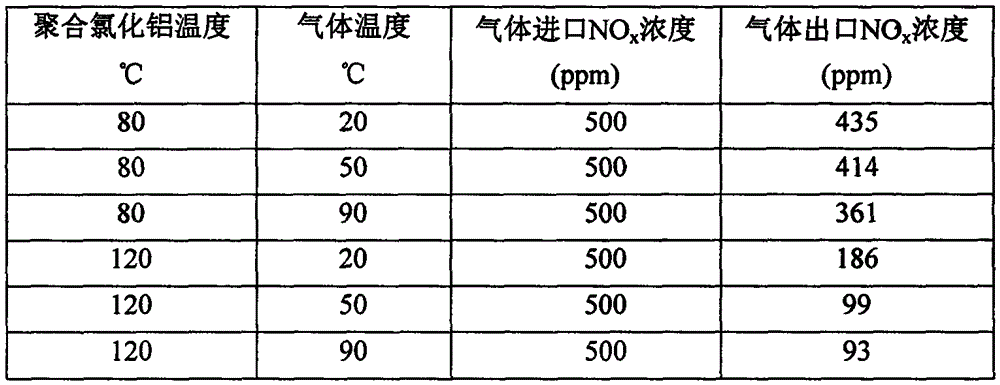

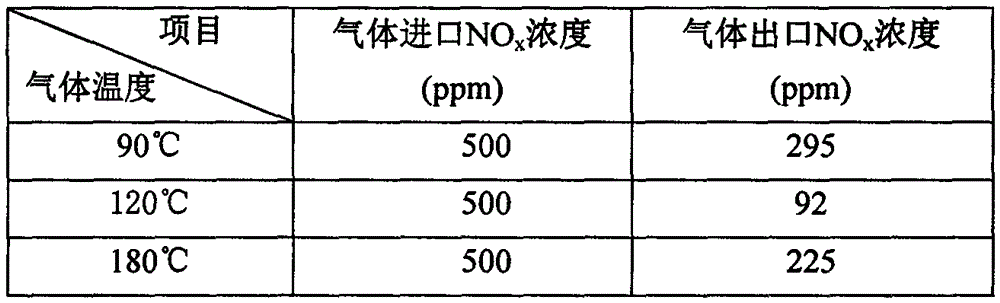

Method for removing nitric oxide from airflow

InactiveCN105536503ATo achieve the purpose of purificationLow costGas treatmentDispersed particle separationAluminium chlorideChemical reaction

The invention relates to a method for removing a nitric oxide from airflow, and belongs to the technical field of air pollution control and environment protection. The method comprises the treatment processes that treated gas is guided into a gas-solid reaction tower, meanwhile, aluminum chloride solid particles are guided into the gas-solid reaction tower, the nitric oxide in the airflow is subjected to a gas-solid adsorption chemical reaction with aluminum chloride in the gas-solid reaction tower to be absorbed and removed, and therefore the gas purification purpose is achieved. The invention further discloses a special device. The method has the advantages that the investment cost and operation cost are low, by-products can be recycled, operation is easy, the treatment efficiency is high, and the handling capacity is large.

Owner:黄立维

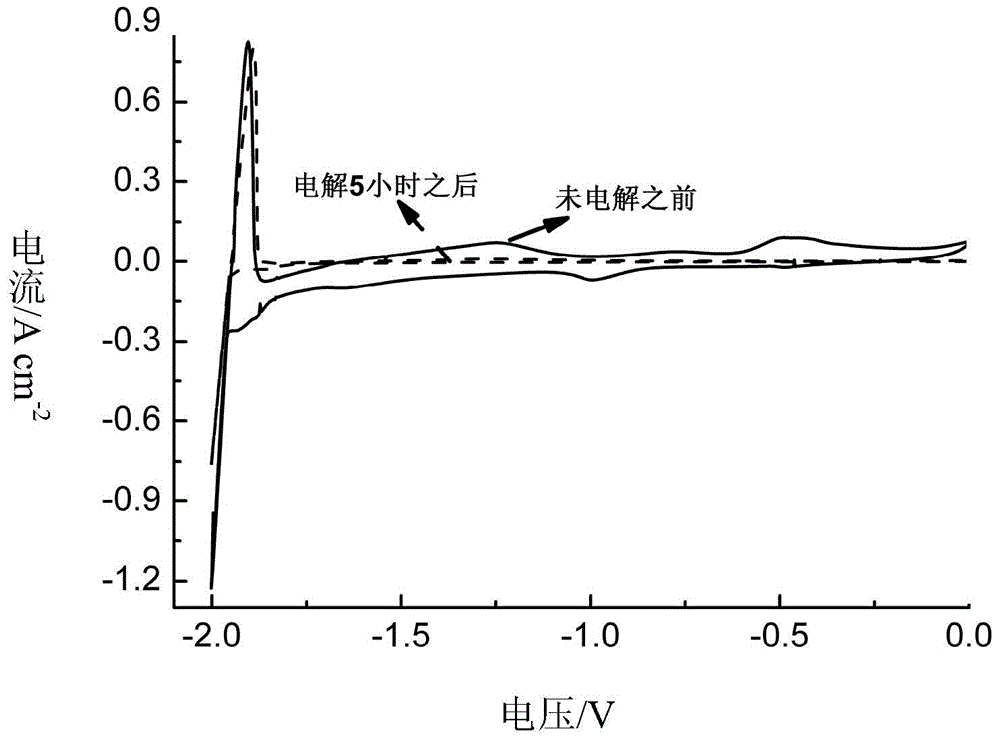

Electrochemical purification method for molten salt

InactiveCN106283112AAvoid secondary pollutionTo achieve the purpose of purificationPurification methodsElectrolysis

The invention discloses an electrochemical purification method for molten salt. The electrochemical purification method for the molten salt comprises the steps that (1), three electrodes of a cathode, an anode and a reference electrode are used, and an electrochemical window of the molten salts to be purified and an electrochemical reduction spike potential of impurities in the electrochemical window of the molten salts to be purified are confirmed; graphite serves as an anode material, inert metal serves as a cathode material, and the inert metal is the metal which does not react with the molten salt to be purified; and (2), electrolysis is conducted under the voltage which is negative than the electrolytic reduction peak potential of the impurities determined in the step (1) and larger than or equal to the electrochemical window of the molten salt to be purified. The method is not only suitable for a chloride molten salt system but also suitable for a fluoride salt dissolving salt system, metal cationic impurities and oxygen-containing anion impurities in the molten salt are purified and removed at the same time through single experiment operation, it is not necessary to add other chemical reagents to the molten salt system, and secondary pollution to the molten salt in the purification process is avoided.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Health food for protecting liver and adjusting blood fat and method for preparing the same

InactiveCN1466990AHigh activityReduce cholesterolDigestive systemUnknown materialsCordycepsActive component

A health-care food for protecting liver and regulating blood fat is prepared through extracting active components from red sage root, peach kernel and gynostemma pentaphyllum in sub-boiling water, adding chitosan, flocculating setting, filter, mixing with fermented cordyceps powder, spray drying, adding starch and dextrin, mixing, granulating, drying, tabletting and coating.

Owner:SHANGHAI MODERN CHINESE TRADITIONAL MEDICINE TECH DEV

Pickling impurity removal method and equipment and method and system for purifying polysilicon

InactiveCN101671026AReduce contentOptimizing the pickling processSilicon compoundsGranularityMaterials science

The invention discloses a pickling impurity removal method for removing impurities after metallurgical silicon drawacharge and before melting purification. The method comprises the following steps: slowing down the cooling process of the drawacharge of the metallurgical silicon, smashing the cooled metallurgical silicon into silicon powder with certain granularity, and selecting a plurality of acids to carry out pickling operation on the silicon powder according to a certain sequence. The invention also discloses pickling impurity removal equipment, a metallurgical silicon purification methodand a metallurgical silicon purification system. In the invention, optimized cooling process and reasonable pickling sequence are adopted, and proper granularity and suitable temperature are selected,therefore, the pickling process flow is optimized to realize the optimal pickling effect, the content of Fe, Al, Ca, Mn, Ti, Ni and other metal impurities are effectively reduced, and the purification purpose is realized.

Owner:BAOTOU SHANSHENG NEW ENERGY

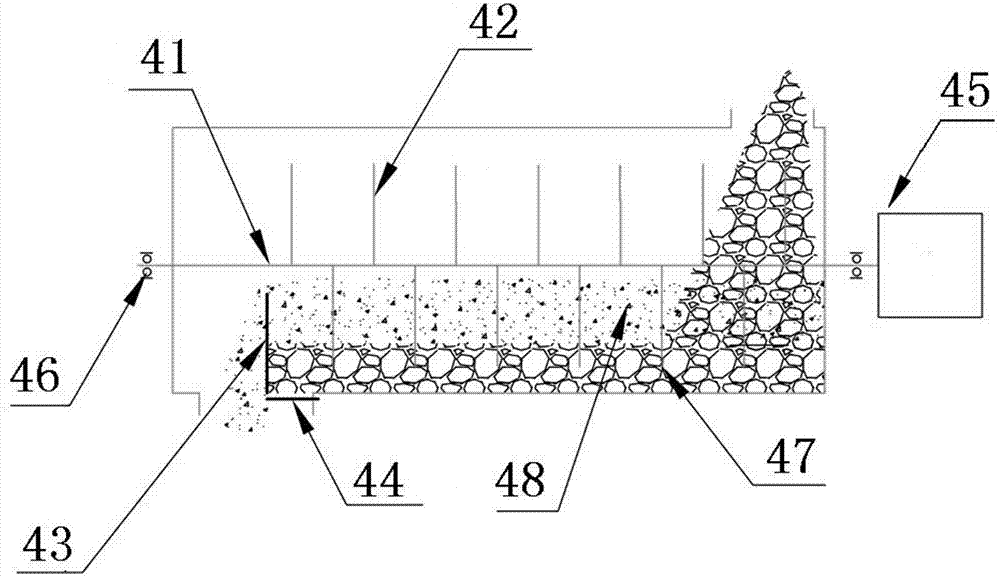

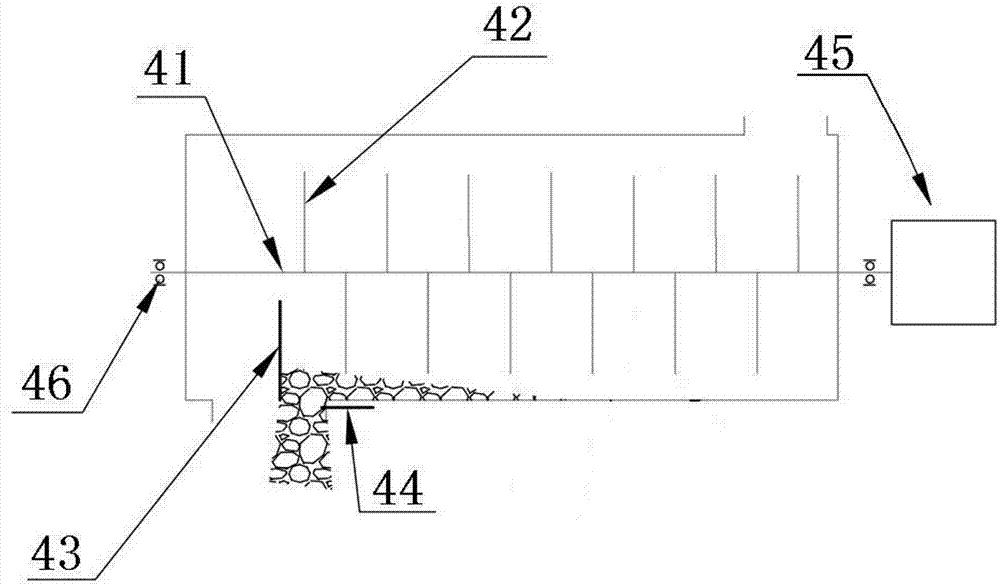

Carbon tetrachloride polluted water source treatment device and application thereof

InactiveCN104163483AFlexible replacementEasy constructionWater/sewage treatment by sorptionWater/sewage treatment by reductionPollutantPollution

The invention provides a carbon tetrachloride polluted water source treatment device and application thereof. The device comprises a water inlet tank, a simulated soil layer tank and a water outlet tank, wherein the water inlet tank is connected with the simulated soil layer tank through a left partition; the simulated soil layer tank is connected with the water outlet tank through a right partition; the lower part of the left partition is provided with an influent water guide tube set; the influent water guide tube set is communicated between the simulated soil layer tank and the water outlet tank; and the inner side of the bottom of the simulated soil layer tank is vertically provided with a reaction well casing set. The treatment device provided by the invention can effectively remove the carbon tetrachloride pollutant in the water body, and can not generate secondary pollution.

Owner:XUZHOU UNIV OF TECH

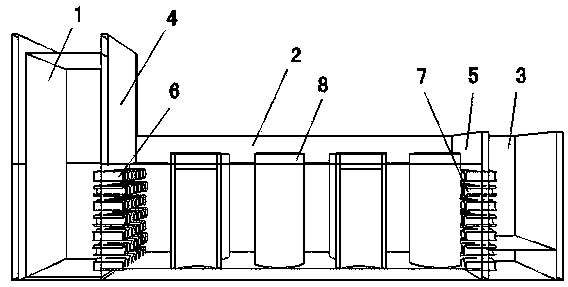

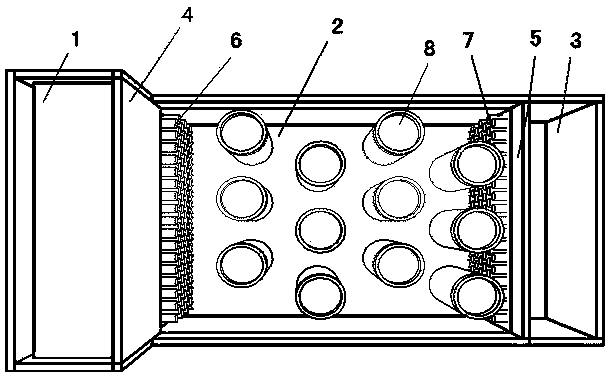

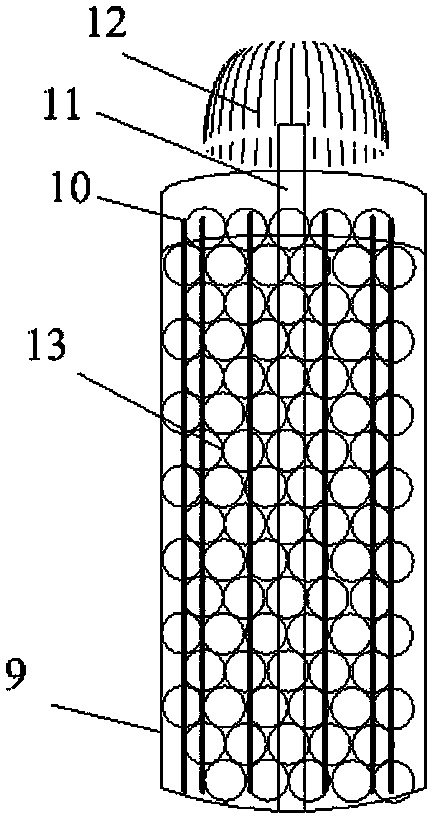

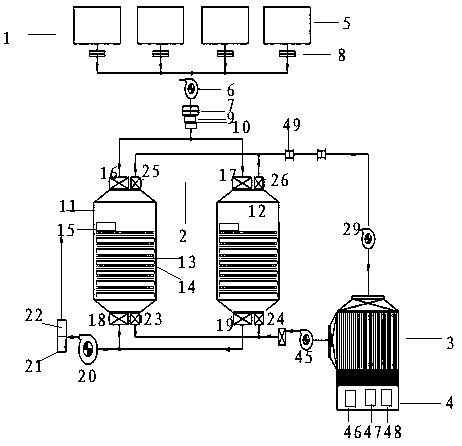

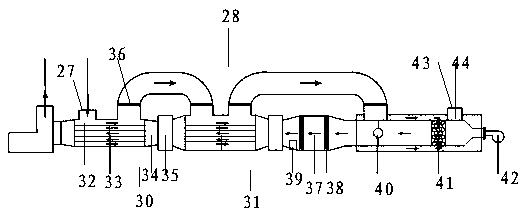

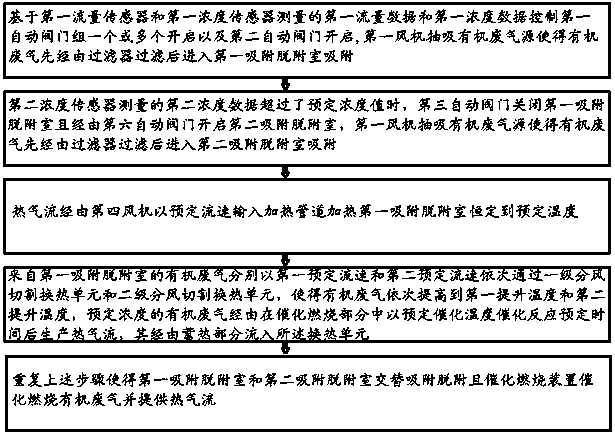

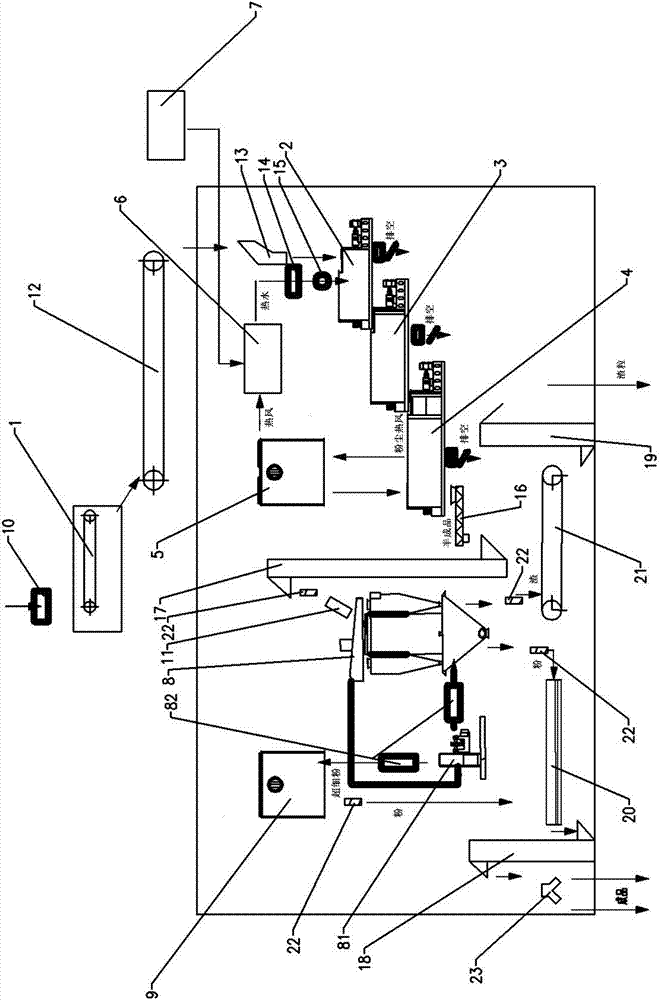

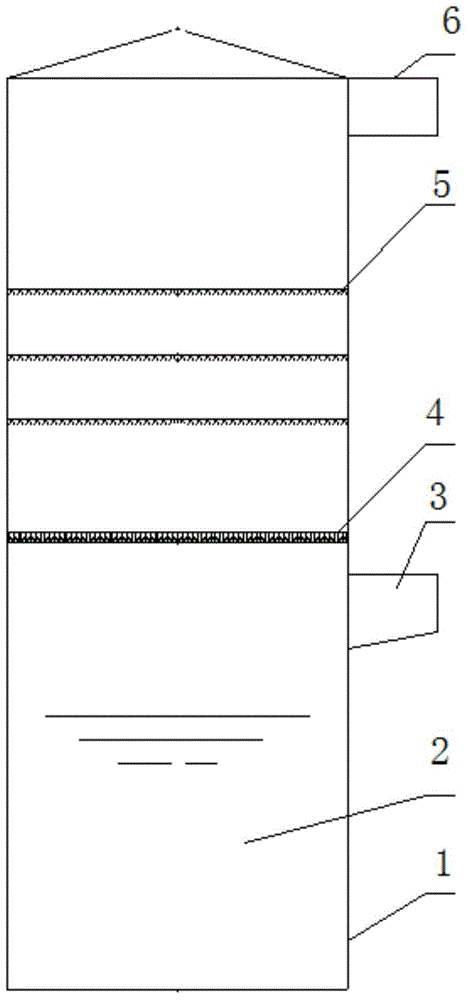

Organic waste gas treatment system and treatment method thereof

PendingCN108273358AImprove desorption efficiency and adsorption performanceProvide service lifeGas treatmentDispersed particle separationChemistryVariable-frequency drive

The invention relates to an organic waste gas treatment system and a treatment method thereof. The organic waste gas treatment system comprises a plurality of organic waste gas supply devices (1), anadsorption and desorption device (2), a catalytic combustion device (3) and a control device (4); and the adsorption and desorption device (2) comprises a first adsorption and desorption chamber (11)and a second adsorption and desorption chamber (12) which are used alternately, the catalytic combustion device (3) comprises a wind dividing cutting heat exchanging part (28), a heat storage part (37) and a catalytic combustion part (40), the control device (4) comprises a frequency converter (46) controlling the flow velocity or the flow quantity, a constant temperature control unit enabling a preset temperature, a first rising temperature, a second rising temperature and a heating temperature of heating of a burner to be constant within a preset range, and a treatment unit (78) which is connected with the frequency converter (46) and the constant temperature control unit (47). The treatment method automatically conducts high-efficiency purification treatment on a plurality of organic waste gas sources simultaneously, the heat is utilized maximumly, and the purifying effect is stable.

Owner:山东亚泰新材料科技有限公司

Method for purifying waste water and recovering waste materials on line in electroplating and chemical plating processes

ActiveCN101717136AReduce pollutionQuality assuranceWater/sewage treatment by magnetic/electric fieldsWaste water treatment from metallurgical processCapacitanceProduction line

The invention provides a method for purifying waste water and recovering waste materials on line in electroplating and chemical plating processes. The method comprises the following steps of: directly arranging a capacitance deionizer in a water washing device on a production line to adsorb various negative ions and positive ions in waste water during charging a battery so as to purify the waste water; and then releasing and recovering waste materials through electrode discharge so as to realize zero release of pollutants. The invention ensures that the capacitance deionization method is suitable for the manufacturing processes of various electroplating or chemical plating products through the optimization of process parameters. Through on-line purification and recycle of washing water, the burden of the traditional waste water treatment system is obviously reduced, meanwhile, the quality of plating pieces is guaranteed because the water quality of the washing water is obviously improved, and the classified recovery of waste materials can be achieved. The method can also obviously reduce the COD in the waste water and has wide application prospect in the fields of electroplating and chemical plating.

Owner:TANTZ ENVIRONMENTAL TECH

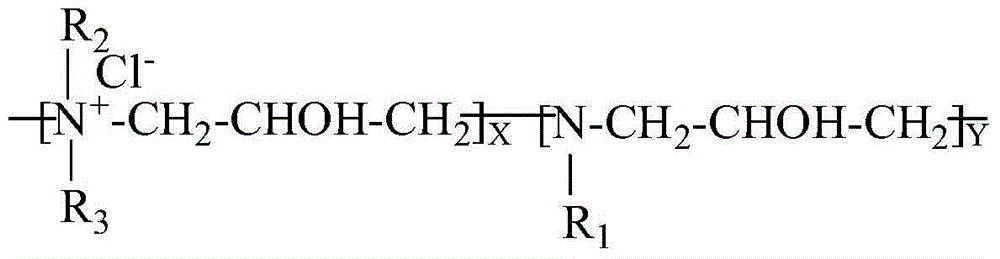

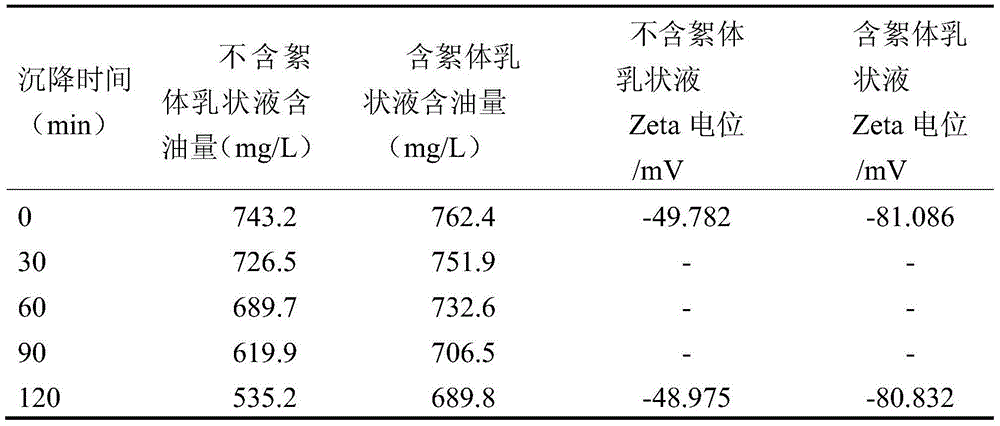

Composite type emulsion breaking flocculant

ActiveCN104817150AAchieve separationReach turbidityWaste water treatment from quariesWater/sewage treatment by flocculation/precipitationDemulsifierAluminium chlorohydrate

The invention relates to a composite type emulsion breaking flocculant, comprising 60-80wt% of a cationic demulsifier, 10-20wt% of poly-dimethyl-diallyl-ammonium chloride and 5-10wt% of aluminium polychlorid, as well as 5-10wt% of polymethylacrylic acid, wherein the cationic demulsifier is a polymer having a chemical formula shown in the specification, wherein R1 can be -(CH2)2NH2, -(CH2)3N(CH3)2, -(CH2)6NH2 and (CH2)9CH3; R2 can be -CH3, -CH2NH2, -C2H5, -CH2NHCH2NH2; R3 can be -CH3, -CH2NH2, -C2H5, -CH2NHCH2NH2; X is between 10 and 50; Y is between 1 and 5. The composite type emulsion breaking flocculant disclosed by the invention can be used for finishing the operations of emulsion breaking, flocculation, oil removal and sewage purification and has the advantages of low reaction temperature, high reaction speed, high oil removal rate and capability of greatly reducing turbidity of water with oil removed.

Owner:EAST CHINA UNIV OF SCI & TECH

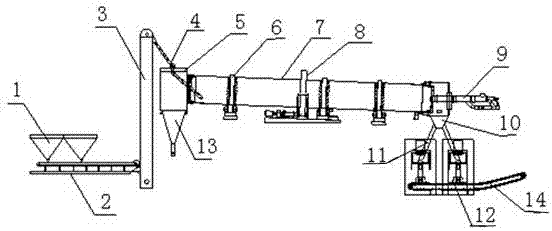

Energy-saving high-performance dry-process calcium hydroxide production line

The invention discloses an energy-saving high-performance dry-process calcium hydroxide production line. The production line comprises a material delivery device, a digestion device, a powder selecting device, a water source supply device and a PLC control system; the material delivery device is connected with the inlet of the digestion device by use of a conveying mechanism; the digestion device is provided with at least three digesters orderly connected with one another, and the outlets and the inlets of the adjacent digesters are orderly communicated with each other; a dust remover and a heat conversion system for digesters are arranged in the water source supply device; the water outlet of the heat conversion system is communicated with the water inlet of the primary digester; the powder selecting device comprises a powder selector and a dust remover for the powder selector; the feeding hole of the powder selector is communicated with the discharge hole of the digestion device via a conveying mechanism; the discharge hole of the powder selector is divided into a powder outlet and a slag outlet; the air outlet of the powder selector is connected with the air inlet of the dust remover for the powder selector; the discharge hole of the dust remover for the powder selector is communicated with a finished product output mechanism. According to the energy-saving high-performance dry-process calcium hydroxide production line, the purity of the finished product is improved, environmental pollution caused by accidental leakage during production can be prevented, the energy is saved, the emission is reduced, the automation degree is high and no production personnel is needed; in short, the production line conforms to the national environmental protection policy intention.

Owner:洛阳钙丰工贸有限公司

Casting resin sand regeneration production line

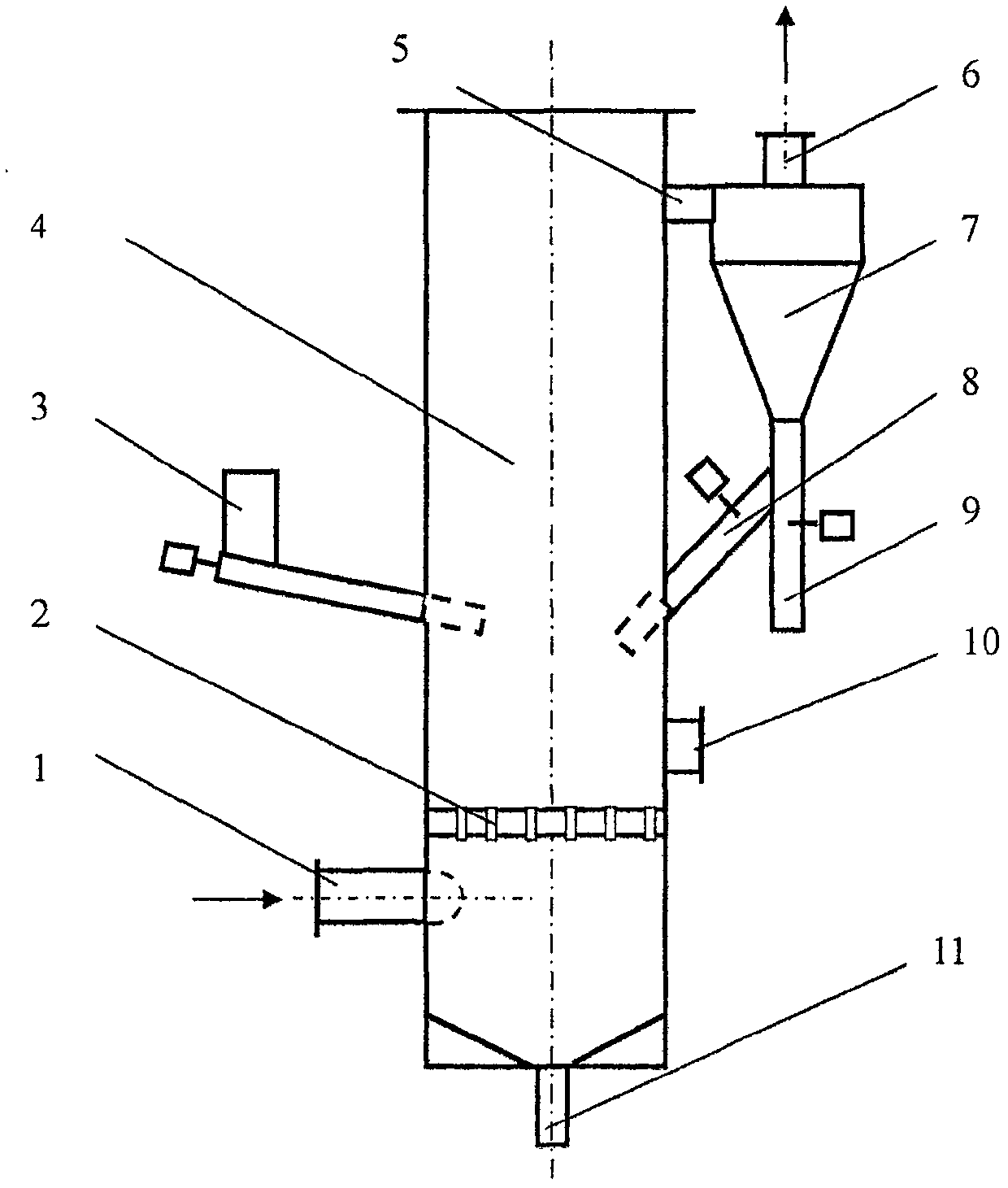

InactiveCN106623770AImprove cooling effectTo achieve the purpose of purificationMould handling/dressing devicesEngineeringCrusher

The invention discloses a casting resin sand regeneration production line. The production line comprises a vibration shakeout machine. A material outlet is arranged under the vibration shakeout machine. A vibration conveyor is arranged in the material outlet. The vibration conveyor delivers the materials to a bucket elevator (A). The bucket elevator (A) transports the materials to a sand bin (A). The sand bin (A) delivers the materials into a grinding machine to grind the materials. Then the materials are transported to a sand bin (B) through a bucket elevator (B). The materials in the sand bin (B) are delivered to a boiling cooling bed so as to cool the materials. After cooling, the materials are delivered to a sand bin (C) through a bucket elevator (C). The materials in the sand bin (C) are transported to a sand bin (D) by a force regenerator. The material outlet of the sand bin (D) is provided with a sand temperature regulator. After the temperature is adjusted by the sand temperature regulator, and the materials are delivered to a sand bin (E) through a bucket elevator (D) and then transported to a sand mixing machine by a pressure feeding system so as to reclaim the materials. The provided casting resin sand regeneration production line can improve the recovery rate of resin sand, moreover, the recovering effect is good, the cost is low, and no pollution is generated.

Owner:浙江品川精密机械有限公司

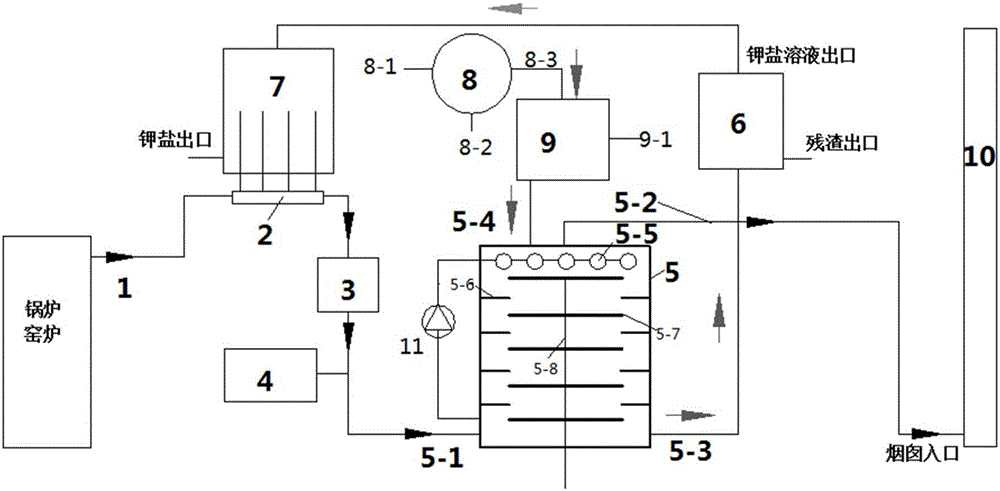

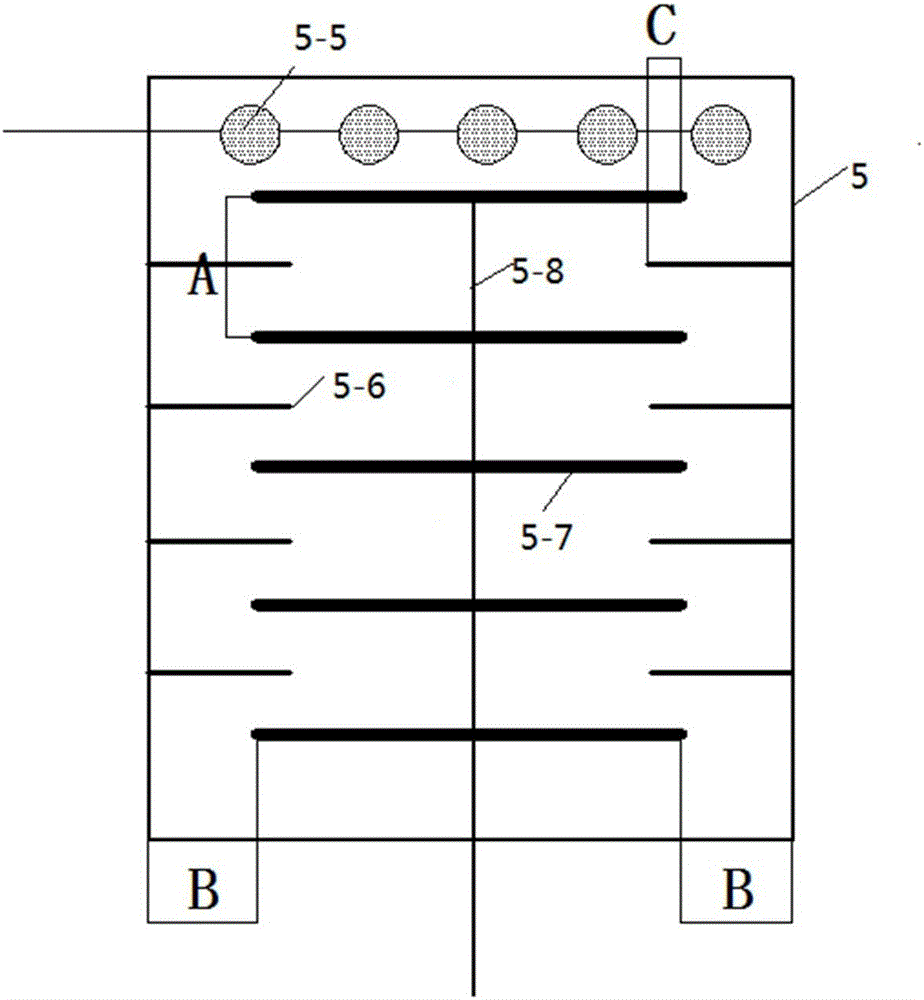

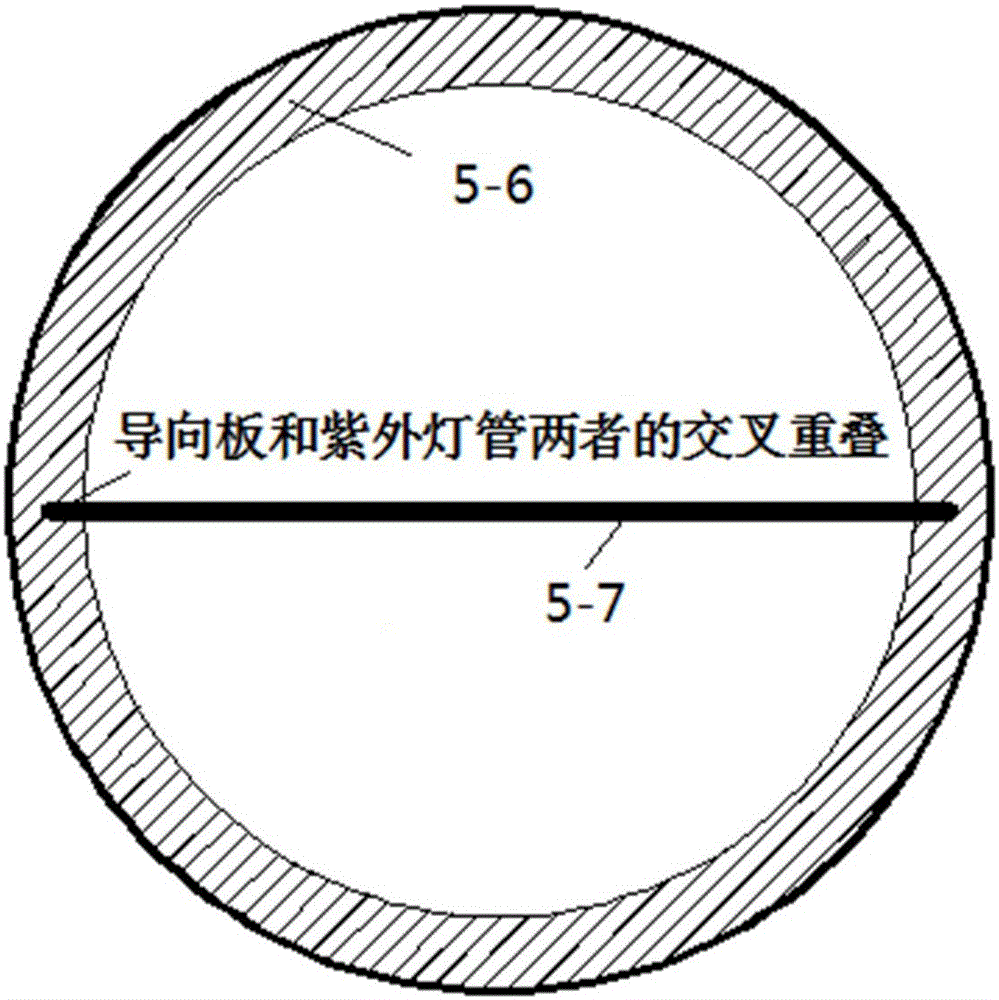

Method and device for integrally removing multiple pollutants in tail gas through plant ash seriflux

ActiveCN105771600AWell mixedAvoid secondary pollutionGas treatmentDispersed particle separationCombustionResource utilization

The invention relates to a method and device for integrally removing multiple pollutants in tail gas through plant ash seriflux. The method comprises the steps that plant ash seriflux is adopted for independently or jointly oxidize and remove SO2, NOx, Hg, H2S, HCl and HF in tail gas of a combustion or chemical device; tail gas containing SO2, NOx, Hg, H2S, HCl and HF from a boiler or kiln or chemical device is cooled and enters a rotary absorption reactor; soluble or acid gas SO2, NO2, Hg2+, H2S, HCl and HF can be directly washed and absorbed by a solution, and indissolvable gas NO and Hg0 can be absorbed by a solution after being pre-oxidized or oxidized by an additive into NO2, HNO2, HNO3 and Hg2+. According to the method, resource utilization can be achieved for solid waste produced by biomass burning, multiple pollutants can be integrally removed, the purpose of dealing with waste by waste is achieved, secondary pollution is avoided in the whole removal process, and the market development and application prospect is wide.

Owner:刘杨先

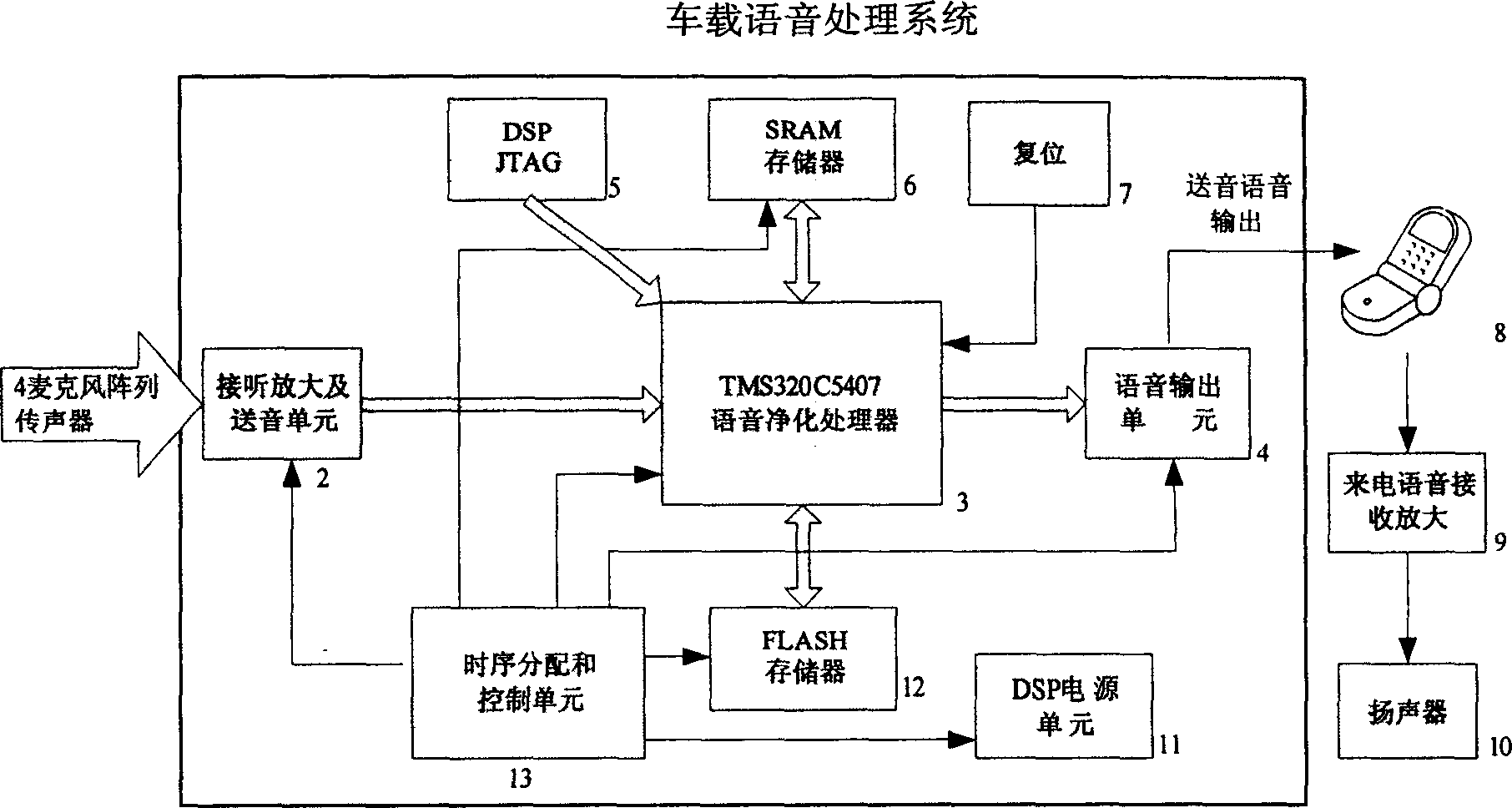

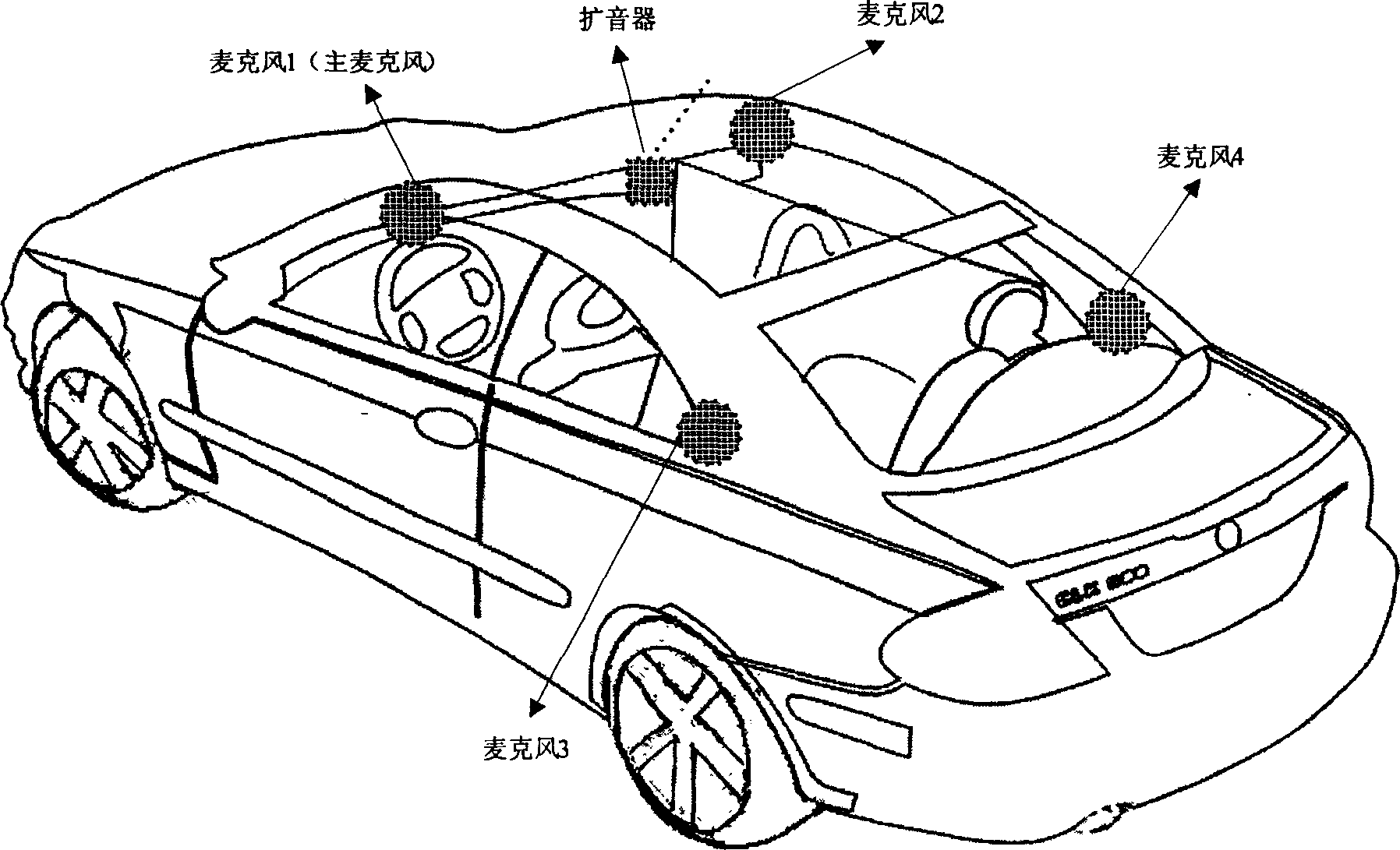

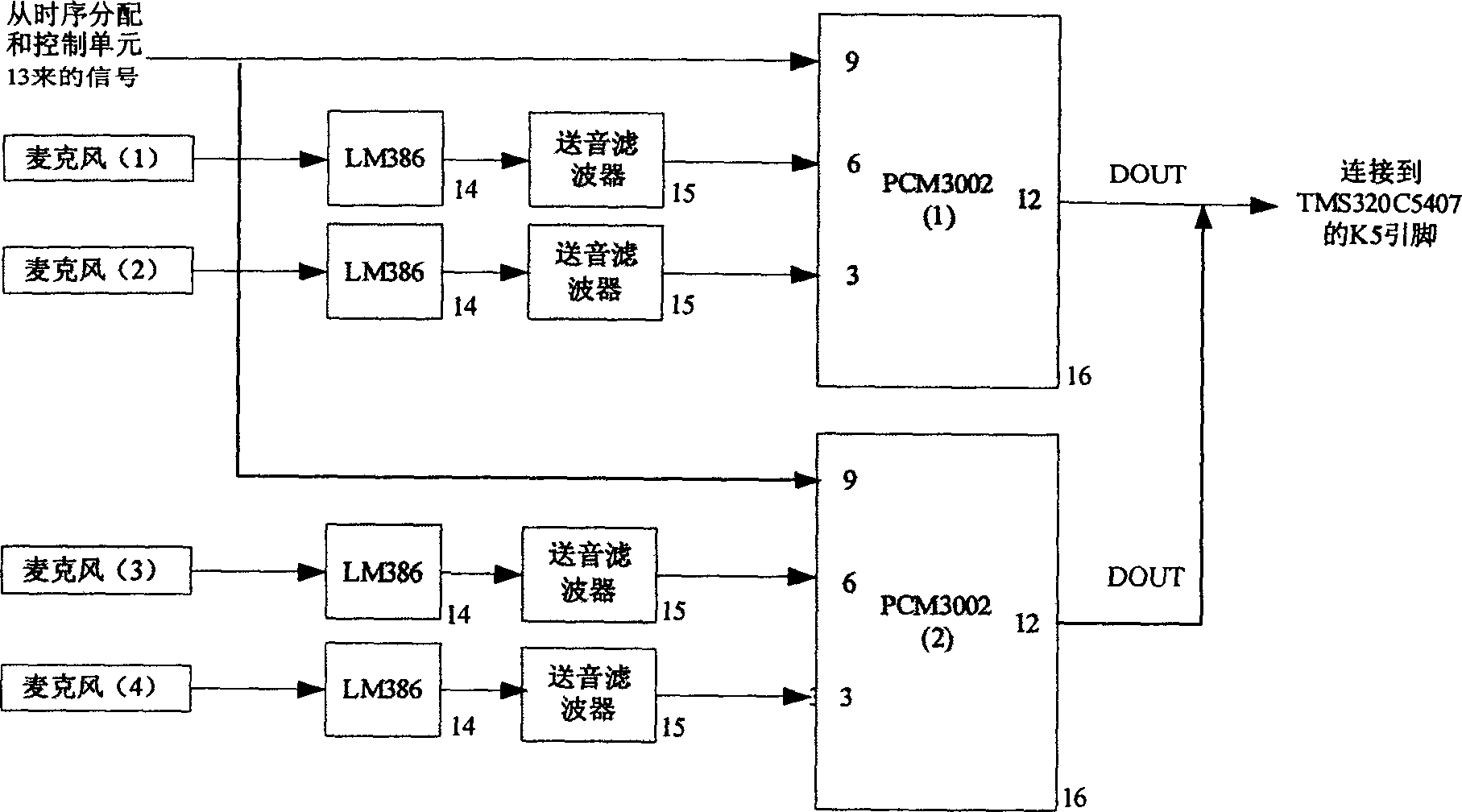

Vehicle-carried hands-free telephone device based on microphone array

InactiveCN1791143AImprove voice communication qualityQuality improvementTwo-way loud-speaking telephone systemsSubstation speech amplifiersJoint Test Action GroupHandling system

The invention relates to a vehicle-carrying hands-free telephone device based on microphone array, which comprises: a microphone with four microphone arrays connected to mobile phone by a vehicle-carrying speech processing system contained a receive amplification and send unit with one end connected to the microphone and another end connected to the speech output unit, a speech purification processor connected to a JTAG interface, two memories, and speech output unit; a SRAM and FLASH memory, a time-sequence allocation and control unit connected to the receive amplification and send unit, two memories, speech purification processor and power unit; a power unit, and a speech output unit with another end connected to mobile phone. This invention can connect to common mobile phone and form high-quality vehicle-carrying speech communication system.

Owner:SHANGHAI UNIV

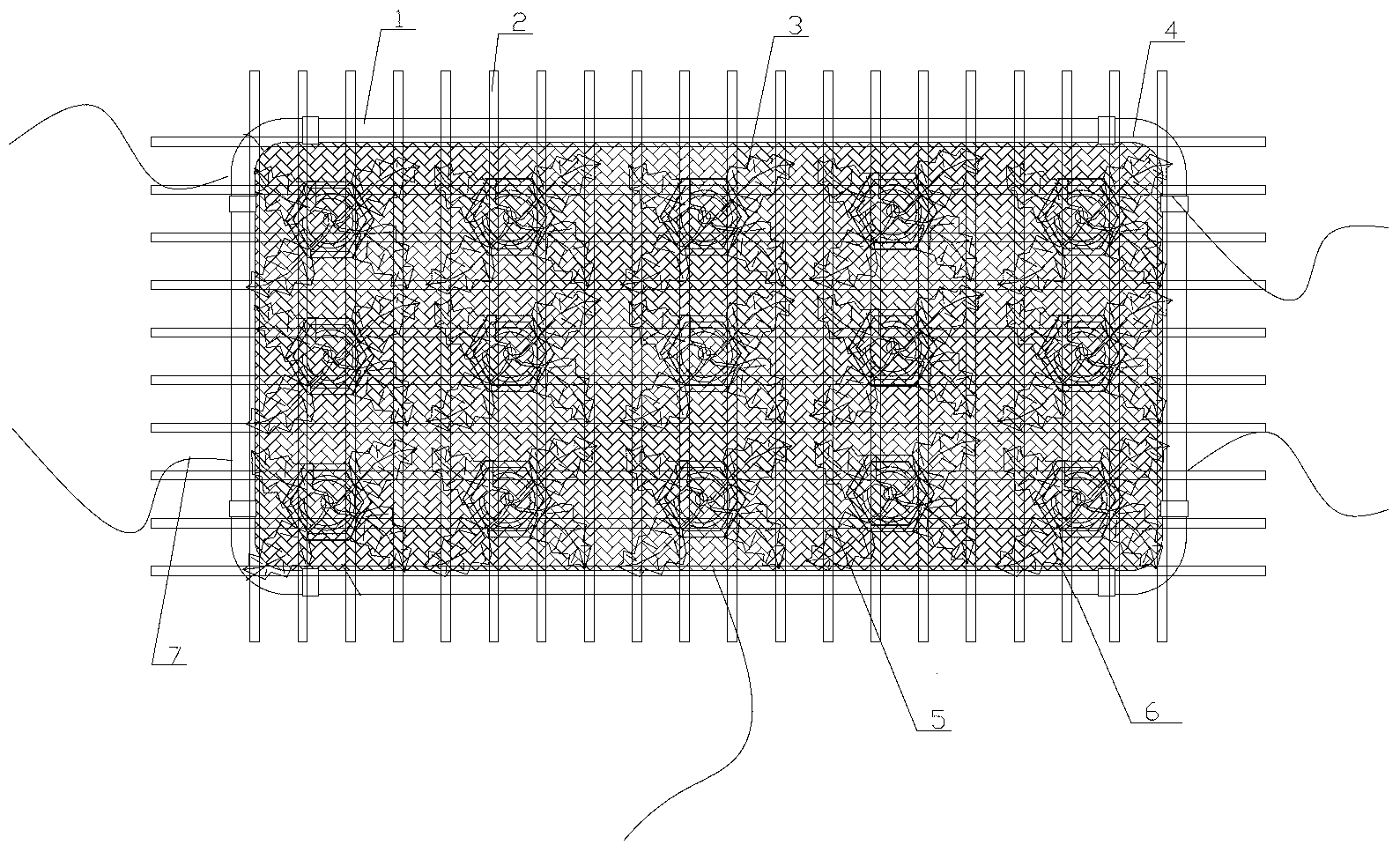

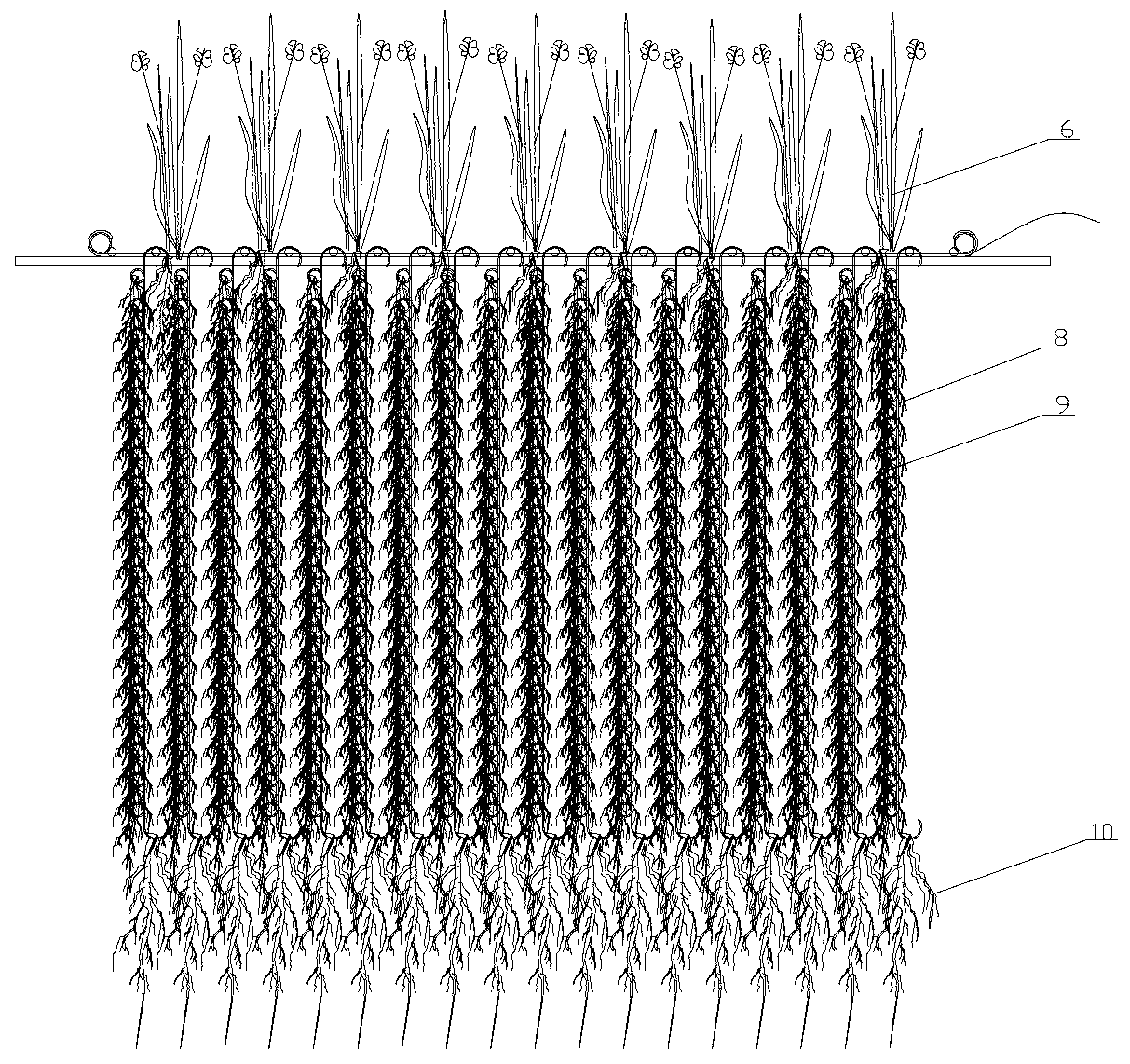

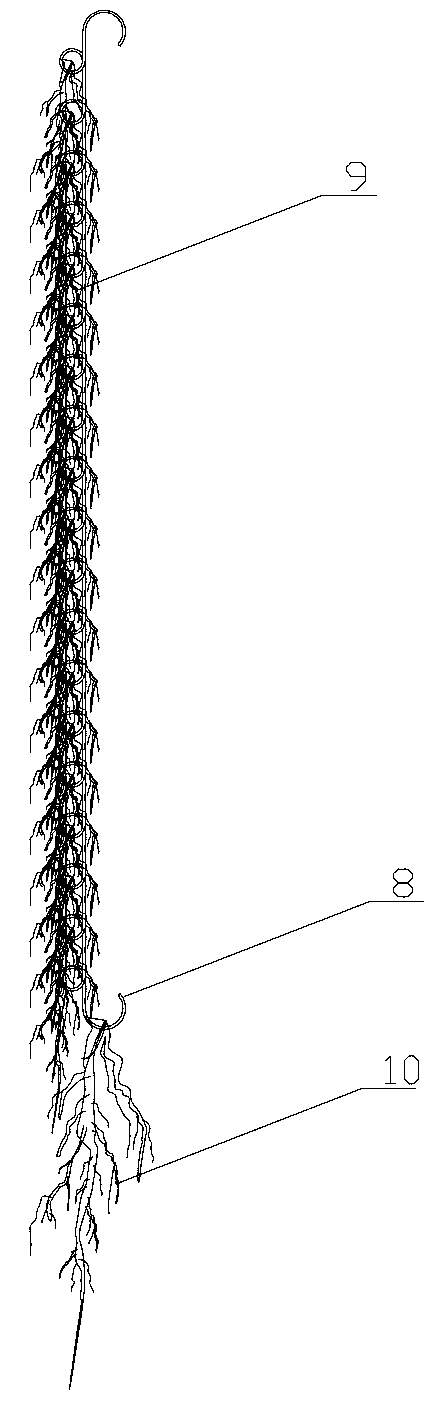

Bionic plant and ecological floating bed combination device for purifying polluted water

InactiveCN103288216AImprove water landscapeMaterial selection is reasonableSustainable biological treatmentBiological water/sewage treatmentRoot systemPollutant

The invention provides a method for purifying heavy polluted water by virtue of a 'bionic plant and ecological floating bed' combination device. The method is characterized in that the combination device comprises two parts including an ecological floating bed and bionic plants, wherein the ecological floating bed adopts a frame structure and comprises a frame, a bottom bracket and a covering net, and the bionic plants adopt fiber materials and iron wires with different specifications to respectively imitate the roots, the stems and the leaves of aquatic plants. The pollutant degradation principle of the combination device is that the comprehensive degradation of main pollutants in water can be realized by the absorption of ecological floating bed plants, the radial oxygen loss and the attachment of microorganisms of the bionic plants. The method solves the technological difficulties of short plant root systems and poor adhesion of root system microorganisms of an original ecological floating bed which is separately used in heavy polluted water, and also solves the problem that a processing system is low in content of dissolved oxygen when a bionic plant is separately used.

Owner:JIANGSU UNIV

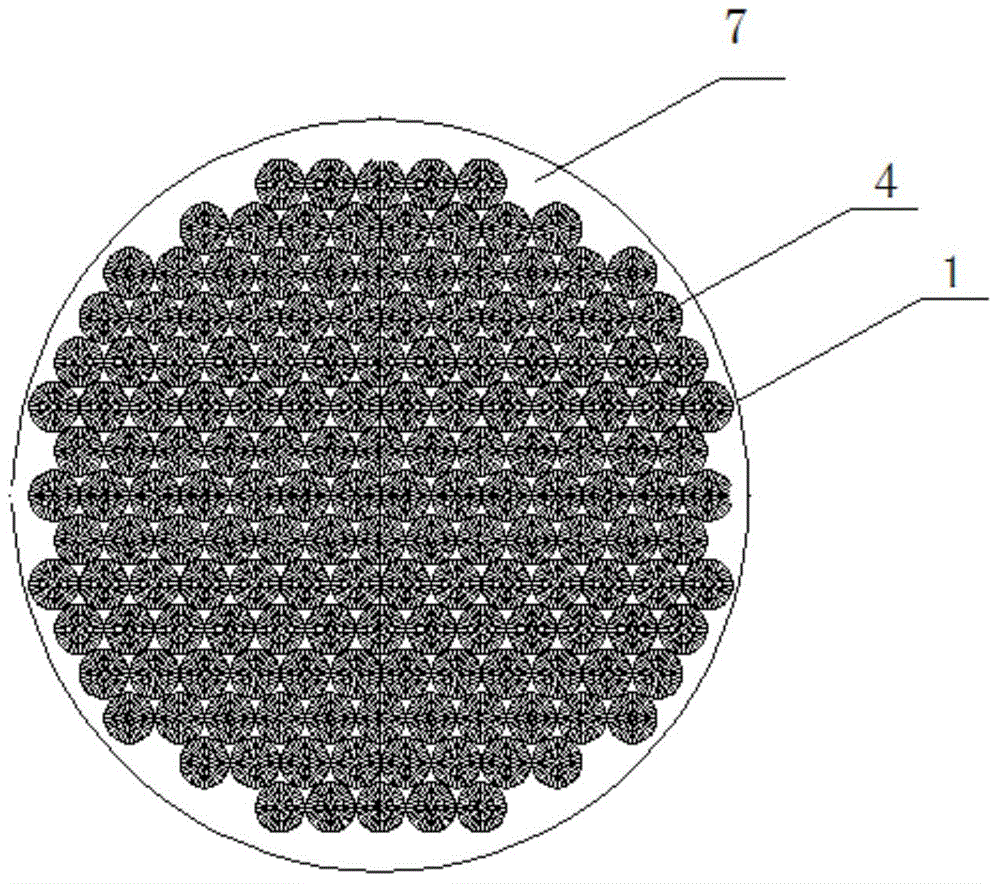

Dual-cyclone dust removal and desulfurization multiplier for wet flue gas desulfurization absorption tower

InactiveCN104888600ASystem resistance is smallImprove dust removal efficiencyCombination devicesUsing liquid separation agentProcess engineeringFlue gas

The invention relates to the technical field of flue gas purification, particularly to a dual-cyclone dust removal and desulfurization multiplier for a wet flue gas desulfurization absorption tower. According to the absorption tower utilizing the dual-cyclone dust removal and desulfurization multiplier, a dual-cyclone multiplier and spray layers are sequentially arranged between a flue gas inlet and a flue gas outlet from bottom to top, the dual-cyclone multiplier comprises the maximum quantity of dual-cyclone multiplier units regularly arranged, each dual-cyclone multiplier unit comprises an inner cyclone cylinder arranged inside an outer cyclone cylinder, a blind cylinder is arranged in the center of each inner cyclone cylinder, the inner cyclone cylinders are provided with inner cyclone blades, and the outer cyclone cylinders are provided with outer cyclone blades. By the aid of kinetic energy of flue gas in the absorption tower, tiny particulate matters in the flue gas collide with one another, are agglomerated and are condensed into large drops when the flue gas passes through the blades of the dual-cyclone multiplier and is subjected to gas-liquid impact on walls of the cyclone cylinders, then the large drops are captured by liquid membranes on surfaces of the cyclone cylinders, so that the purification purpose of removing tiny particulate matter is achieved, the SO2 removal reaction can also be accelerated, and the removal efficiency is improved.

Owner:田鹏程

Method and device for preparing and purifying carbon dioxide adsorbent

PendingCN110227408ATo achieve the purpose of purificationGas treatmentOther chemical processesSorbentManganese

The invention discloses a method and device for preparing and purifying a carbon dioxide adsorbent used for removing carbon dioxide from airflow and belongs to the technical fields of air pollution control and environmental protection. The method is characterized by comprising the following steps: mixing salts of iron or manganese or cobalt or copper and related derivative materials, alkali or alkaline substances and related derivative materials, water and a forming agent according to a certain ratio and procedure, drying and activating the obtained solid compound or mixture so as to obtain asolid product, namely the adsorbent. The adsorbent is introduced into a gas-solid reactor, the carbon dioxide in the airflow carries out a gas-solid reaction with the adsorbent at a certain temperature so as to be removed, and then the adsorbent is regenerated and recycled. The invention furthermore discloses a related purification device.

Owner:黄华丽

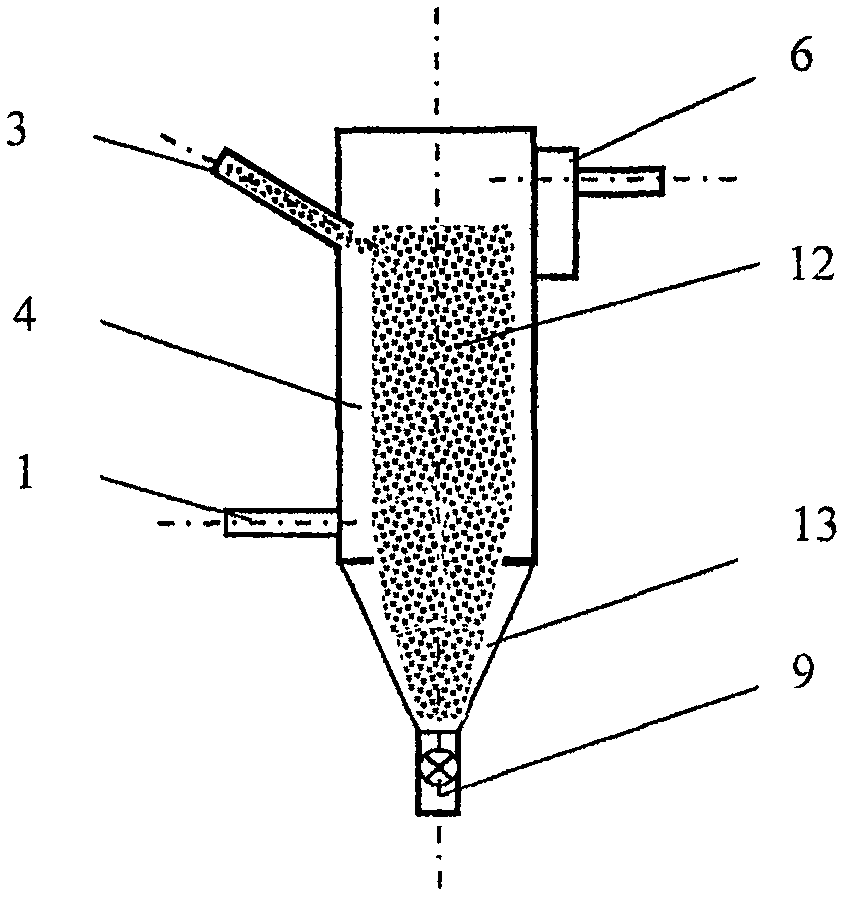

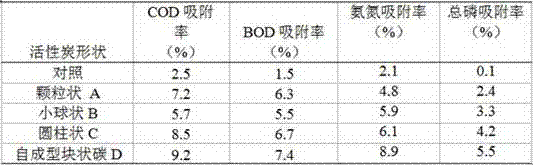

Water purifying agent of self-forming block carbon carrier immobilized microorganisms and preparation method thereof

ActiveCN107473404AGood compatibilityImprove contact effectWater treatment compoundsWater contaminantsCompression moldingMicroorganism

The invention belongs to the technical field of biological activated carbon and biological water purifying agents, and particularly relates to a water purifying agent of self-forming block carbon carrier immobilized microorganisms and a preparation method thereof. Self-forming block porous carbon is placed in a culture medium, compound bacterial strains are inoculated into the culture medium at the same time, and after oscillating co-culture and drying, the microbial water purifying agent is prepared; because porous blocks are formed in the synthesis process of carbon carriers, the compression molding process of the carbon carriers is not involved in the preparation of the microbial water purifying agent, the procedures are simplified, and the cost is saved; meanwhile, the self-forming block carbon has hydrophilicity, and the effect of adsorbing and fixing the microorganisms is improved in the co-culturing process of the carbon and the microorganisms; the water purifying agent has the advantages of achieving a double purification functions of adsorption and degradation and being stable in effect, easy to precipitate and treat and the like, and is very suitable for the large-scale treatment of anaerobic wastewater for culture.

Owner:INST OF AGRI ENG TECH FUJIAN ACAD OF AGRI SCI

Defluorinating ionic sieve of drinking water and production thereof

InactiveCN1712125AEasy to useWith adsorption functionOther chemical processesActive componentMontmorillonite

An ionic sieve for defluorinating the drinking water is compased of the powder of montmorillonite column compound as carrier and one or more of Cu, Ag, Ce and Gd as active component. Its preparing process includes such steps as preparing Ti columning agent, mixing with montmorillonite, calcining, immersing in the solution of said metals, and heating.

Owner:TIANJIN UNIV

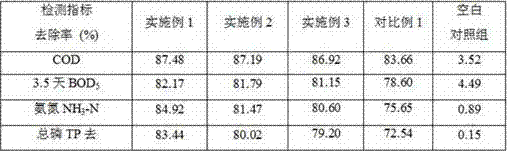

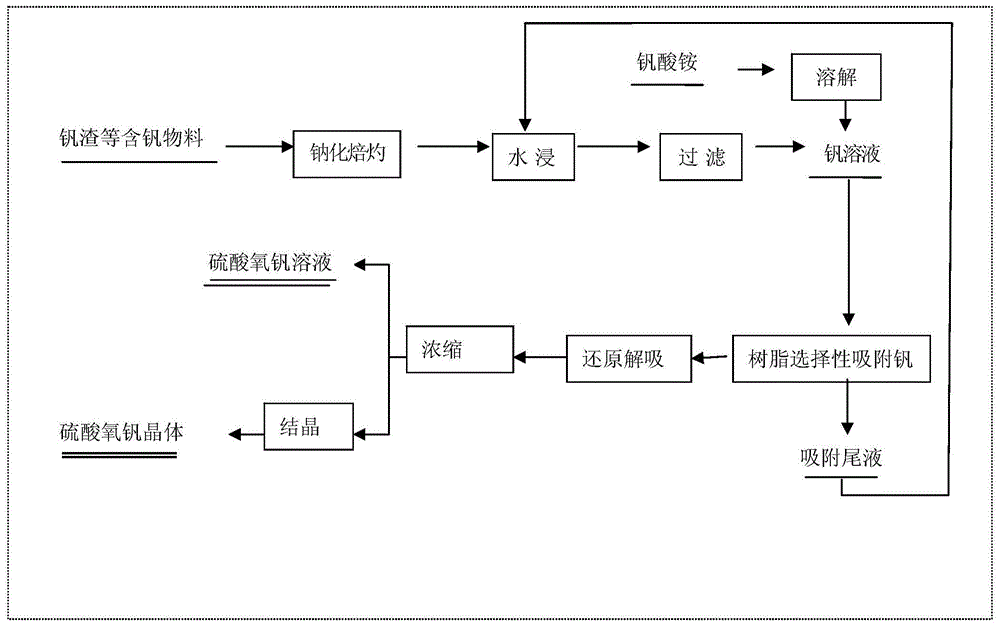

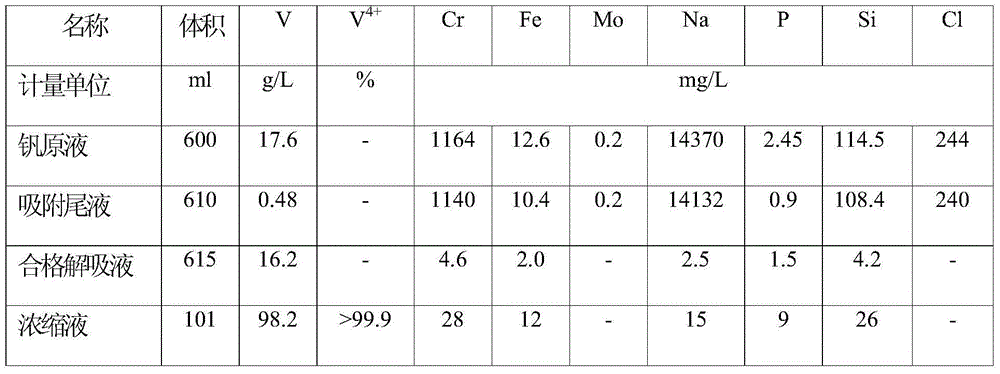

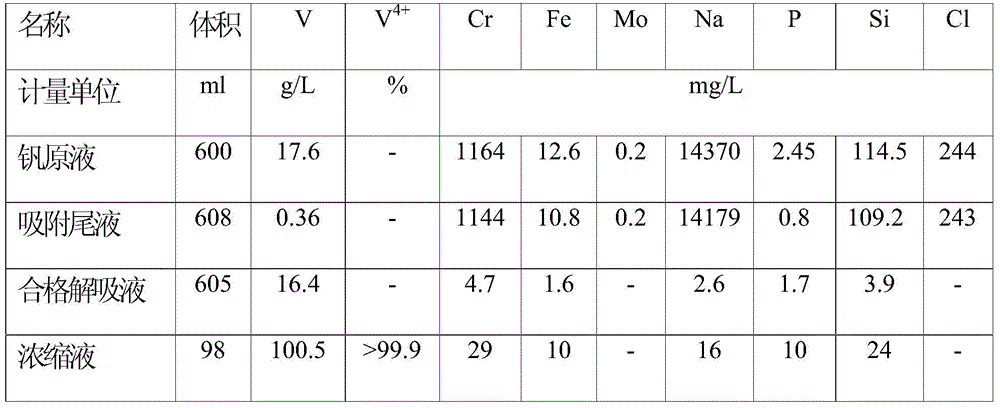

Method for preparing vanadyl sulfate

ActiveCN104310476ATo achieve the purpose of purificationProcess energy saving and environmental protectionVanadium compoundsVanadyl sulfatePhysical chemistry

The invention provides a method for preparing vanadyl sulfate. According to the method, a technical process that ion exchange resin is adopted to selectively adsorb vanadium and reduce and desorb vanadium so as to directly prepare vanadyl sulfate is adopted, so that a middle process in which powder high-purity vanadium pentoxide is prepared is canceled. In addition, as the decontamination process is evolved into direct selective pure vanadium extraction, contamination and the labor and material consumption in the decontamination process are avoided, the operation procedure is greatly simplified. Compared with a conventional vanadyl sulfate preparation process, the method has the advantages of short procedure, high vanadium yield, low cost, no waste discharge and the like.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY +2

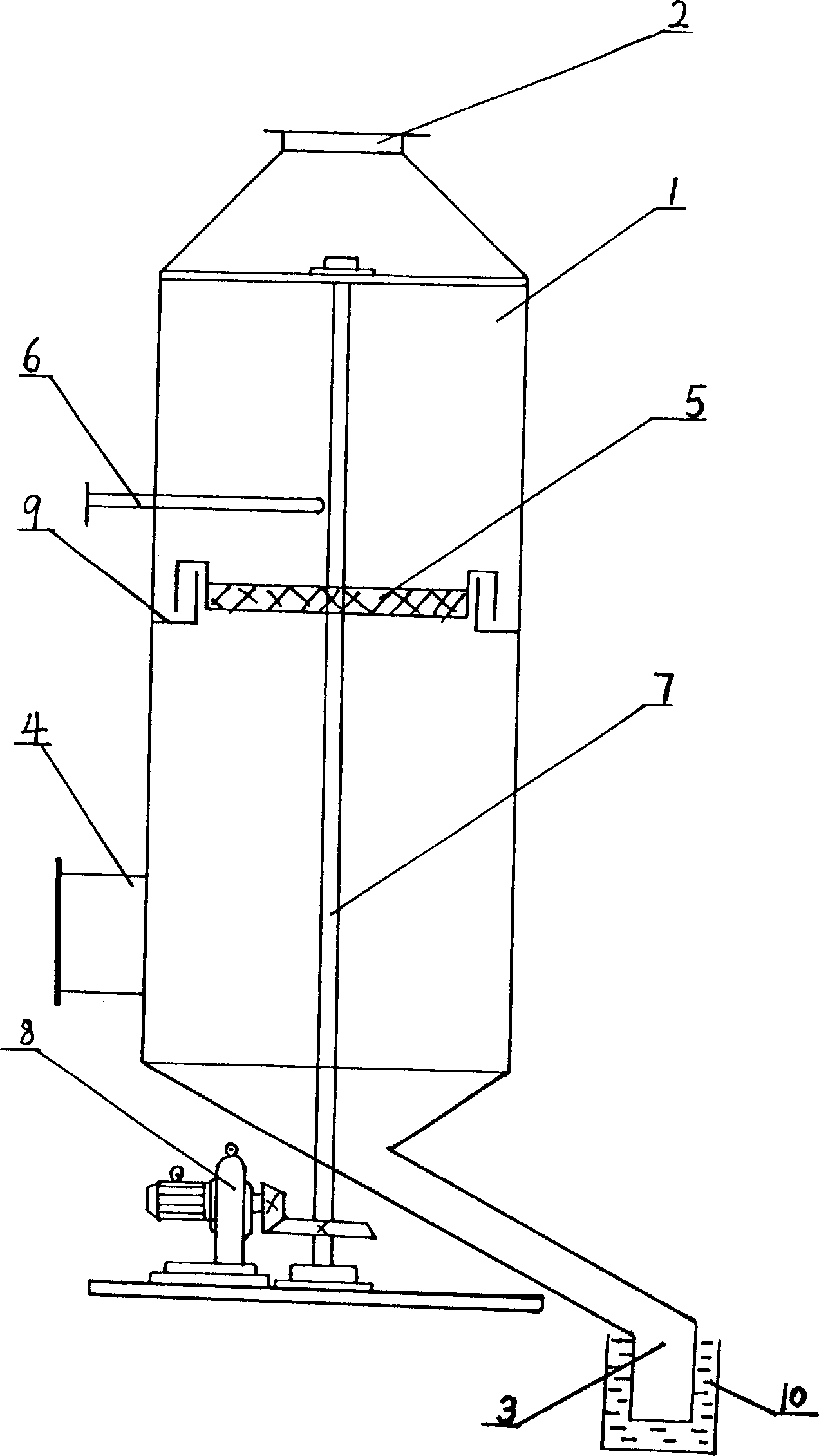

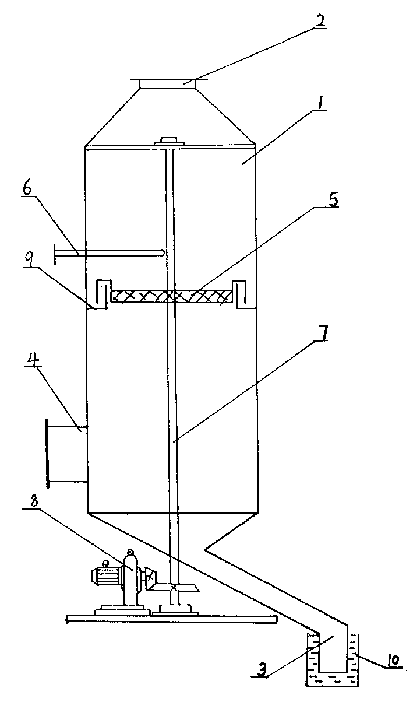

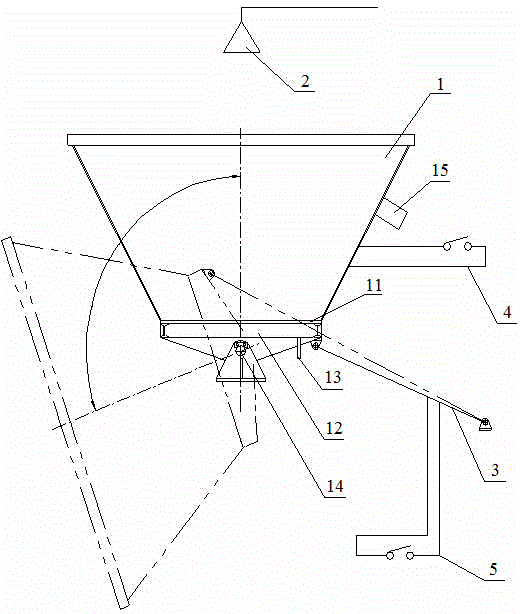

Desulfurizing duster

InactiveCN1403183AImprove efficiencyTo achieve the purpose of purificationUsing liquid separation agentEnvironmental engineeringWater pipe

The desulfurizing duster includes one casing, which has exhaust port in the top, water draining pipe with water seal in the bottom and intake in the lower side wall; steam-liquid filtering net, which is fixed horizontally onto a vertical shaft driven by some driving mechanism inside the casing with water sealing groove around the net; and one cleaning water pipe over the net. Fume from some kiln or furnace is entered to the duster directly or after being washed with desulfurizing liquid and is then exhausted after being purified. The desulfurizing duster is simple in structure, high in smoke-elimianting and dedusting efficiency and may be used widely for desulfurizing and dedusting fume from boilet, kiln, furnace, etc.

Owner:曹新忠 +1

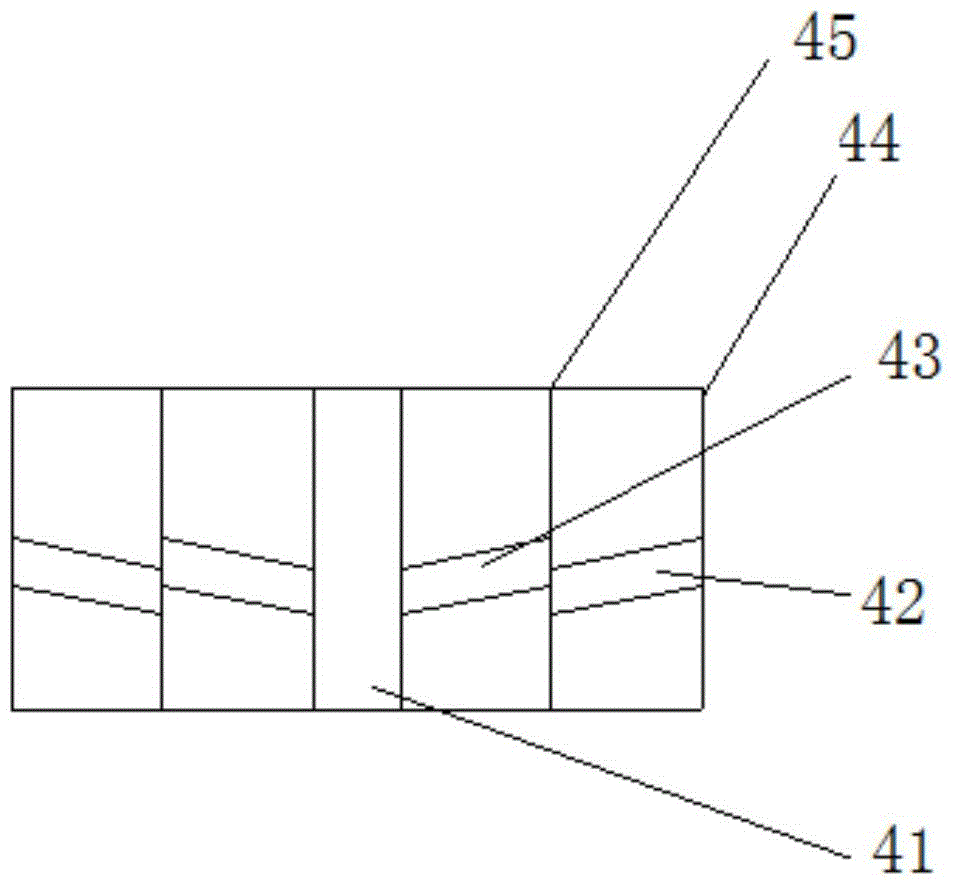

Equipment and method used for solid particle or solid-liquid mixture washing and purification

InactiveCN104815466ARealize solid-liquid separationHigh purityCleaning using liquidsStationary filtering element filtersProcess engineeringSolid particle

The invention discloses equipment and a method used for solid particle or solid-liquid mixture washing and purification. The equipment comprises a tank body, a spray device, an overturning device and a limit switch; the spray device is arranged above the tank body; a filter layer is arranged in the tank body, a filtrate chamber is arranged below the filter layer, and a liquid drain hole is formed in the bottom of the filtrate chamber; a rotating shaft is arranged at the bottom of the tank body, and the bottom of the tank body is connected with the overturning device; the limit switch is arranged on the tank body or overturning device. The method includes that (1) filtering, to be specific, placing solid-liquid mixture on the filter layer, wherein the liquid enters the filtrate chamber through the filter layer and is drained through the liquid drain hole; (2) spray washing, to be specific, carrying out spray washing on solid granular material or the filter cake of the step (1); (3) water controlling and draining, to be specific, carrying out water controlling and draining on the washed solid granular material or filter cake; (4) overturning to discharge material, to be specific, starting the overturning device to discharge the solid granular material or filter cake from the tank. The equipment cost is low; the method is short in flow, high in automatic degree and high in washed product purity.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN +1

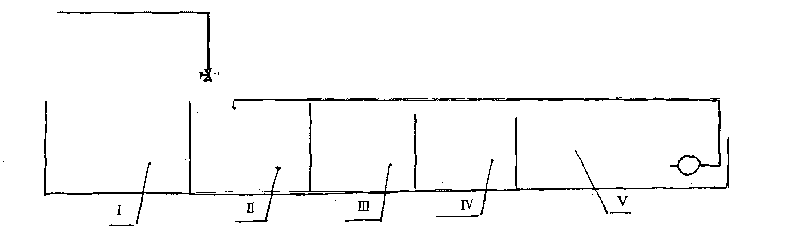

Courtyard-style landscape wetland

InactiveCN101759296ATo achieve the purpose of purificationAdjustable hydraulic retention timeSustainable biological treatmentBiological water/sewage treatmentEutrophicationAquatic animal

The invention relates to a courtyard-style landscape wetland, which consists of a nitrobacteria pond, a plant filtering bond, an aquatic plant settling pond, a conversion pond and an aquatic animal or fish pond. The wetland is mainly applied to the design of urban landscape water areas, the eutrophication control of the landscape water areas and an ecological purified circulating system of the purification of the front of inlets of various cities, parks, river banks or lake banks, families, parks and hotels. The sewage can be purified by the actions of precipitation, adsorption, nitration, denitrification and the like, thus the pollution load is reduced.

Owner:KUNMING UNIV OF SCI & TECH

Wood pulp denaturalization production process for producing viscose fibers

InactiveCN102943403AHigh fiber contentLow chemical usagePulp bleachingArtificial filaments from viscoseAlpha-CelluloseGram

A wood pulp denaturalization production process for producing viscose fibers is used for solving the problems of high energy consumption, serious pollution, low alpha cellulose content of produced products, poor reactivity and the like of an existing method. The wood pulp denaturalization production process includes the working procedures of wood pulping, repulping, alkali pre-impregnation, cooking, desanding by washing, xylanase treatment, seeping and rinsing, acid treatment, pulp washing and manufacturing paper with pulp. In the working procedure of cooking, 16-22% of alkali is used, 1.75% of additive sulfonate, and the bath ratio is 1:3.5-4. In the working procedure of xylanase treatment, the PH (potential of hydrogen) value is lower than 9, the temperature is 50 DEG C, enzyme is diluted to be 0.125%, reaction time is 1.5-2 hours, the concentration of the pulp is 5-8%, and the dosage of the enzyme is 45-80 grams / ton. The pulp is purified by combining chemical treatment with biological treatment, and compared with a pure chemical method, the process has the advantages that the produced wood pulp is high in alpha cellulose content, the dosage of chemical agents is low, and pollution is less.

Owner:SWAN FIBER

Method for separating and purifying lecithin through fixed-bed adsorption method

ActiveCN103254226AIncrease consumptionEasy to handleIon-exchange process apparatusIon-exchanger regenerationDistillationSorbent

The invention discloses a method for separating and purifying lecithin through a fixed-bed adsorption method. The method comprises the following steps of: dissolving a phosphatidylcholine raw material in a solvent to prepare a raw material liquid, enabling the raw material liquid to continuously pass through an adsorption column filled with an adsorbent to ensure that impurities in the raw material liquid are preferentially adsorbed, collecting an effluent liquid at an outlet of the adsorption column, enabling the effluent liquid to be subjected to reduced pressure distillation and concentration and obtaining a phosphatidylcholine product, wherein the impurities are cephalin, phosphatidylserine and sphingomyelin. The method disclosed by the invention has the advantages that by adopting a continuous feeding mode, the main impurities such as the cephalin, the phosphatidylserine, the sphingomyelin and the like in the phosphatidylcholine raw material liquid can be removed through a single adsorption operation, so that the process flow of purifying the phosphatidylcholine is greatly simplified and the phosphatidylcholine yield is increased.

Owner:ZHEJIANG UNIV

Microporous film filter for processing heavy metal wastewater

ActiveCN101468264ANew appearanceSimple structureStationary filtering element filtersSteel tubeHeavy water

The invention relates to a millipore membrane filter for treating heavy water waste water, which belongs to the technical field of wastewater treatment. The filter comprises a tank body, a stainless steel tube sheet, a bulky polyfluortetraethylene membrane filter bag, filter bag support cage frameworks, an acid feeding flexible valve, a reflux flexible valve, a backsurge flexible valve, a mud discharge flexible, a cleaning agent liquid feeding valve, an air electromagnetic valve and an exhaust electromagnetic valve, wherein the bulky polyfluortetraethylene membrane bag is sleeved on the filter bag support cage framework, and all filter bag support cage frameworks are fixed on the stainless steel tube sheet through screws. The stainless steel tube sheet divides the tank body into two parts, wherein the upper part is a clean water area, and the lower part is a waste liquid area (a filter area). The filter has a simple structure, and takes a membrane made of a bulky polyfluortetraethylene material as a filter material, so as to achieve the real surface filter effect, and completely retain impurities in an acid liquid on the surface of the membrane. Because the selected membrane has excellent acid resistance, hydrophobias and smaller friction coefficient, the block phenomenon of the filter material can not occur.

Owner:SHANGHAI TONGJI CLEARON ENVIRONMENTAL PROTECTION EQUIP ENG CO LTD

Method for removing nitric oxide from gas

InactiveCN105413448AReduce investment and operating costsSafe to useNitrous oxide captureGas treatmentNitric oxideChemistry

The invention discloses a method for removing nitric oxide from gas, and belongs to the technical field of air pollution control and environment protection. According to the treatment process of the method, the treated gas is led into a gas-solid reaction tower, meanwhile aluminum polychlorid solid particles are led into the gas-solid reaction tower, nitric oxide in the gas and aluminum polychlorid are subjected to a gas-solid chemical reaction at a certain temperature in the gas-solid reaction tower, then nitric oxide in the gas is absorbed and removed, and therefore the gas purification purpose is achieved. The invention further discloses a special device. The method and the special device have the advantages that investment cost and operating cost are low, use is safe, by-products can be recycled, operation is easy, treatment efficiency is high, and treatment capacity is large.

Owner:黄立维

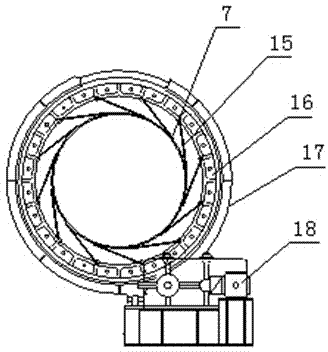

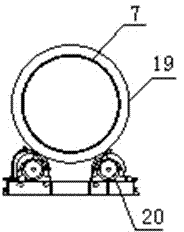

Hot-pressing molding production line for hot-pressed iron blocks

The invention relates to a hot-pressing molding production line for hot-pressed iron blocks and belongs to the technical field of hot-pressing molding equipment for the hot-pressed iron blocks. According to the technical scheme, the hot-pressing molding production line comprises a feeding system, a rotary kiln, a material guiding and separating device, a burner (9), a hot-pressing molding machine (12) and a finished-product conveyor (14), the rotary kiln comprises a kiln body (7) and a kiln rotating device (8), an included angle is formed between the kiln body (7) and the horizontal plane, the kiln rotating device (8) is fixed on the kiln body (7), the feeding system is arranged at one end, higher than the horizontal plane, of the kiln body (7), the material guiding and separating device and the burner (9) are arranged at the other end of the kiln (7), and the hot-pressing molding machine (12) and the finished-product conveyor (14) are sequentially arranged in the rear of the material guiding and separating device. The hot-pressing molding production line has the advantages that raw materials are heated evenly, heat loss is low, heating temperature is low, energy sources are saved, impurities in the materials are removed, the purpose of further purification is achieved, quality of products is improved, and equipment maintenance rate is lowered.

Owner:TANGSHAN CAOFEIDIAN DISTRICT TONGXIN RENEWABLE RESOURCE RECYCLING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com