Equipment and method used for solid particle or solid-liquid mixture washing and purification

A technology of solid-liquid mixture and solid particles, which is applied in the direction of liquid cleaning methods, separation methods, chemical instruments and methods, etc., can solve the problems of low material concentration, high cost, and limited washing effect, and achieve simple equipment structure and easy operation. The effect of easy control and short production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

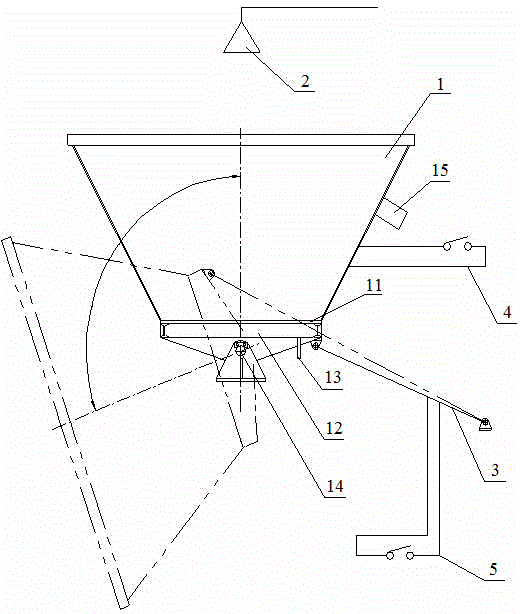

[0025] Embodiment 1: the equipment embodiment that is used for solid particle or solid-liquid mixture washing purification

[0026] Such as figure 1 As shown, the embodiment of the equipment for washing and purifying solid particles or solid-liquid mixtures of the present invention includes: a tank body 1, a spray device 2, an electro-hydraulic push rod 3 and a limit switch 4; the spray device 2 is located in the tank Above the body 1; the inside of the tank body 1 is provided with a filter layer 11, a filtrate chamber 12 is provided under the filter layer 11, and a drain port 13 is provided at the bottom of the filtrate chamber 12; a rotating shaft 14 is provided at the bottom of the tank body 1, and the tank body 1 The bottom is connected with the electro-hydraulic push rod 3; the limit switch 4 is set on the tank body 1; the electro-hydraulic push rod 3 can drive the tank body 1 to turn around the rotating shaft 14, and the turning angle is from the central axis of the ta...

Embodiment 2

[0027] Embodiment 2: Embodiment 1 equipment is used for the method embodiment I of solid particle washing purification

[0028] (1) Spray washing: the potassium chloride solid particle material (purity 90wt%) placed on the filter layer 11 in the tank body 1 with an average particle diameter of 0.3 mm is statically sprayed and washed twice by the spray device 2, The first washing liquid is the washing mother liquid, and the second washing liquid is clear water, which is used as the washing mother liquid of the next batch of materials after washing, and left on the filter layer 11 after spraying and washing, and the filter layer 11 has a pore size less than 0.3 mm; (2) Water control and draining: the solid particle material after step (1) spraying and washing was left to stand for 0.3h, and then water control and draining was performed. Enter the filtrate chamber 12, and discharge from the discharge port 13 below the filtrate chamber 12; (3) Turn over and unload: start the ele...

Embodiment 3

[0029] Embodiment 3: Embodiment 1 equipment is used for the method embodiment II of solid-liquid mixture washing purification

[0030] (1) Filtration: transport the solid-liquid mixture material containing 30wt% potassium nitrate (the average diameter of potassium nitrate solid particles is 0.2mm) into the tank body 1, and let it stand on the filter layer 11 for 0.05h, and the seeped liquid is filtered The layer 11 enters the filtrate chamber 12, and is discharged from the drain port 13 below the filtrate chamber 12, and the filter cake is left on the filter layer 11; (2) Spray washing: the filter cake obtained in step (1) is statically sprayed by the spray device 2 Drenching and washing 3 times, the first two washing liquids are the washing mother liquor, the third washing liquid is clear water, and the clear water is used as the washing mother liquor of the next batch of materials after washing, and is left on the filter layer 11 after spraying and washing. The pore size o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com