Method for adsorptively removing sulfate ions in water by using composite material with laminated structure

A sulfate ion and composite material technology, applied in the direction of adsorption water/sewage treatment, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of special reaction devices required for operation, high cost of modifying reagents, complex preparation process, etc. , to achieve the effect of low cost, little pollution and good settlement performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation method of L-glutamate zinc aluminum hydrotalcite / nitrate zinc aluminum hydrotalcite composite material: weigh 26.73gZn(NO 3 ) 2 ·6H 2 O, 11.25gAl(NO 3 ) 3 9H 2 O is completely dissolved in 120ml of water, and the content of metal ions in the solution is 1mol / L; 4.41g of L-glutamic acid is dissolved in 300ml of water to obtain a 100mmol / L glutamic acid solution; 40g of NaOH is dissolved in 1L of water, A 1mol / L NaOH solution was obtained. in N 2 protection, under the condition of 60℃ water bath, Zn(NO 3 ) 2 ·6H 2 O and Al(NO 3 ) 3 9H 2 The mixed solution of O was gradually added dropwise to the glutamic acid solution, stirred during the dropwise addition, and the pH value was controlled to be 8 during the reaction process with 1mol / L NaOH solution. After the dropwise addition was completed, it was left to age for 4 hours. Wash 3 times with boiled deionized water and filter. The obtained precipitate was dried at 60° C. for 24 hours, and groun...

Embodiment 2

[0027] Structural characterization of L-glutamate zinc-aluminum hydrotalcite / nitrate zinc-aluminum hydrotalcite composites.

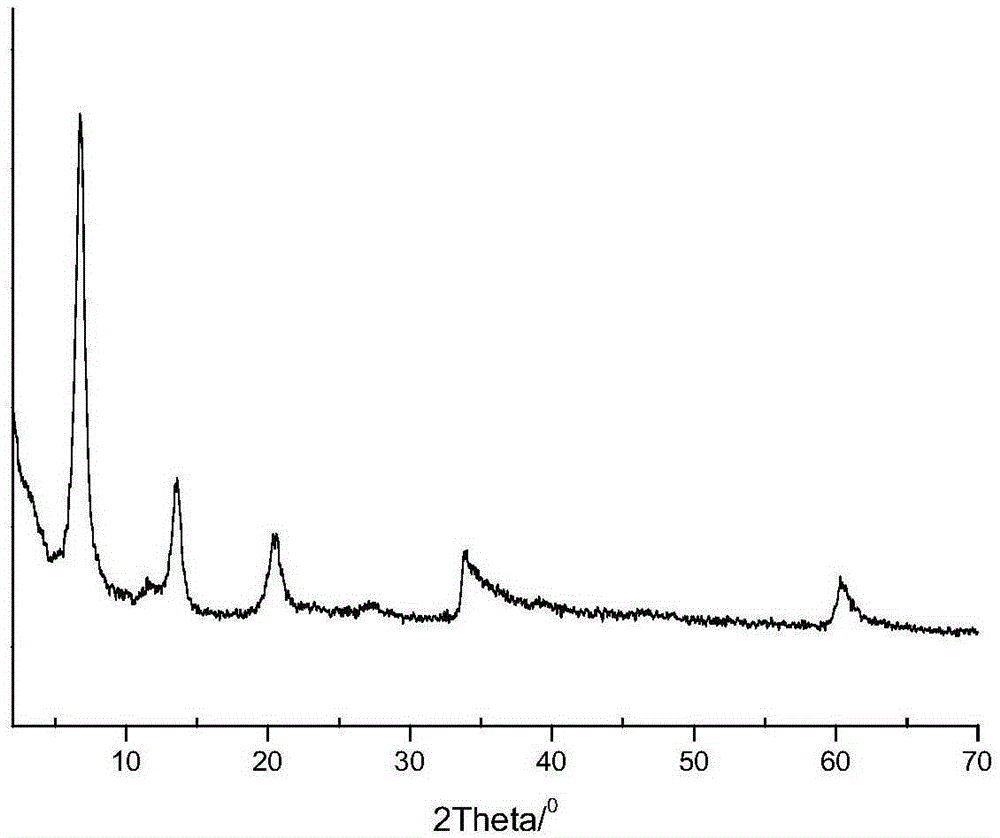

[0028] (1) Crystal form: X-ray powder instrument, the model is D8ADVANCE of Bruker Company in Germany, the experimental conditions are copper target, incident ray wavelength 0.15418 nm, Ni filter, tube pressure 40KV, tube flow 40mA, scan step size 0.02 degrees, scan speed 0.1 second / step, scanning range 2° to 70°, the result is as follows figure 1 As shown, the baseline of the X-ray diffraction pattern of the material of the present invention is stable, and there are strong diffraction peaks at 2θ of 6.8°, 13.5°, 20.5°, 34°, and 60°, showing that L-glutamate zinc aluminum hydrotalcite and nitric acid The characteristic diffraction peaks of zinc-aluminum hydrotalcite show that the L-glutamate zinc-aluminum hydrotalcite / nitrate zinc-aluminum hydrotalcite composite has a single crystal phase and a complete crystal structure.

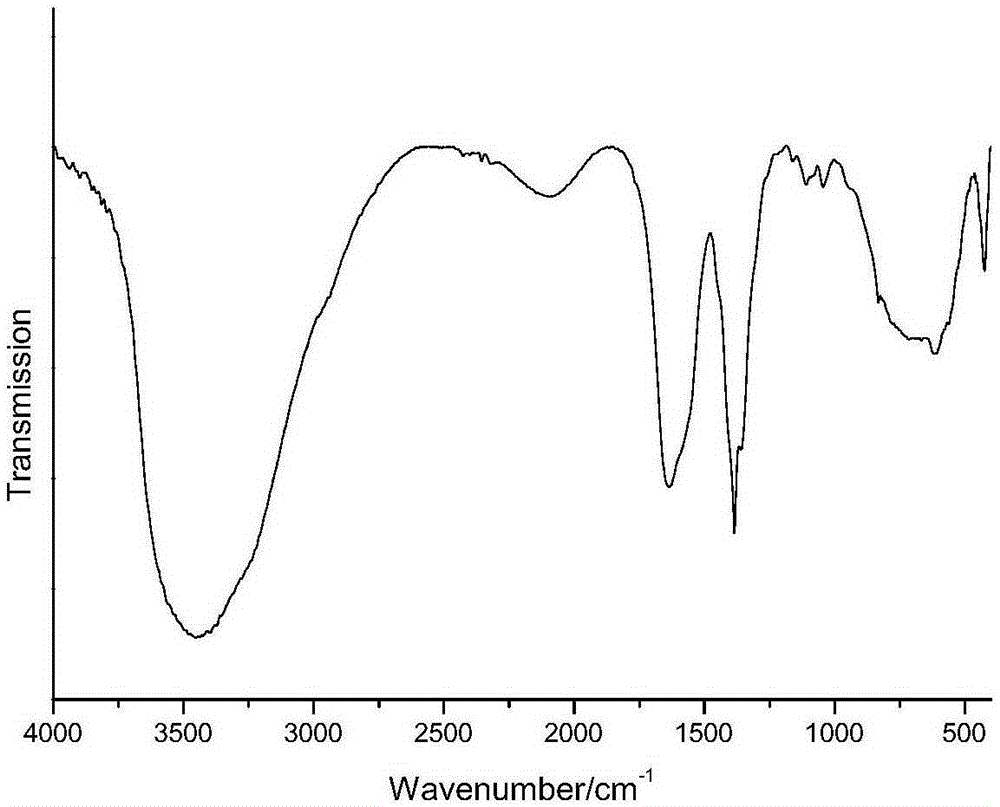

[0029] (2) Qualitative analy...

Embodiment 3

[0031] L-glutamic acid zinc aluminum hydrotalcite / nitrate zinc aluminum hydrotalcite composite material adsorption to remove sulfate ion adsorption experiment in water, after the reaction solution was diluted 5 times, sulfate ion was determined by ICS-90 produced by Diane Company concentration.

[0032] (1) Determination of adsorption capacity under different adsorbent contents: at a temperature of 25°C and an oscillation rate of 180rpm, a shake flask experiment was carried out, and 0.16g, 0.14g, 0.12g, 0.10g, 0.08g of newly prepared L - The zinc-aluminum glutamate hydrotalcite / nitrate zinc-aluminum hydrotalcite composite material was added to 100ml of an aqueous solution with an initial sulfate ion concentration of 125mg / L, and the reaction time was 55min. The results are shown in Table 1. The experimental results show that the solid-liquid ratio is 1.4g / L, the adsorption effect is the best, and the adsorption capacity reaches 279.74mmol / g. The results of this implementation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com