Patents

Literature

1421 results about "SULFATE ION" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The sulfate ion is a polyatomic anion with the empirical formula SO42−. Sulfate salts have diverse applications. For example, magnesium sulfate (or Epsom salts) is used in therapeutic baths; gypsum, the mineral form of hydrated calcium sulfate, is used to produce plaster; and copper sulfate is an algaecide.

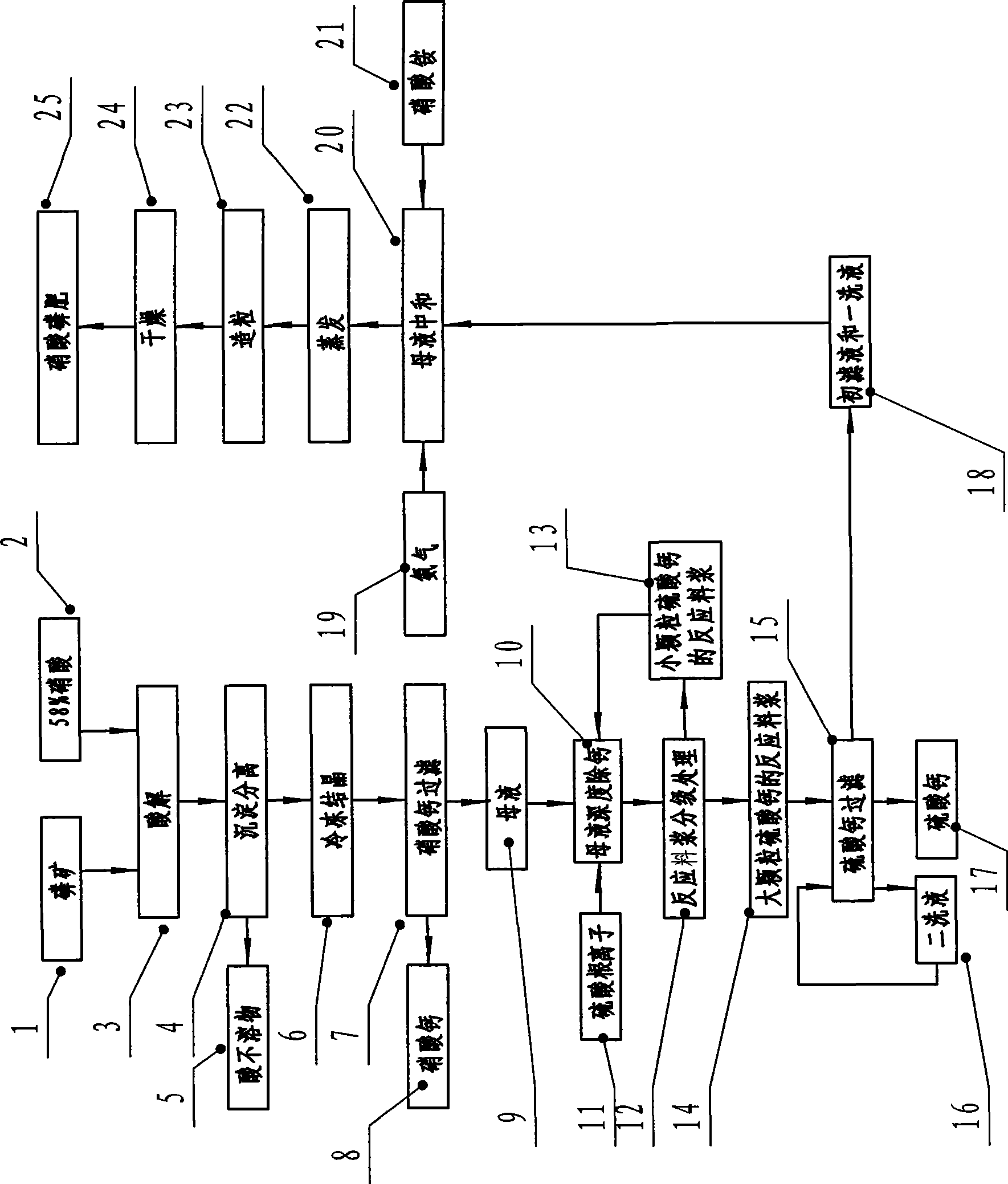

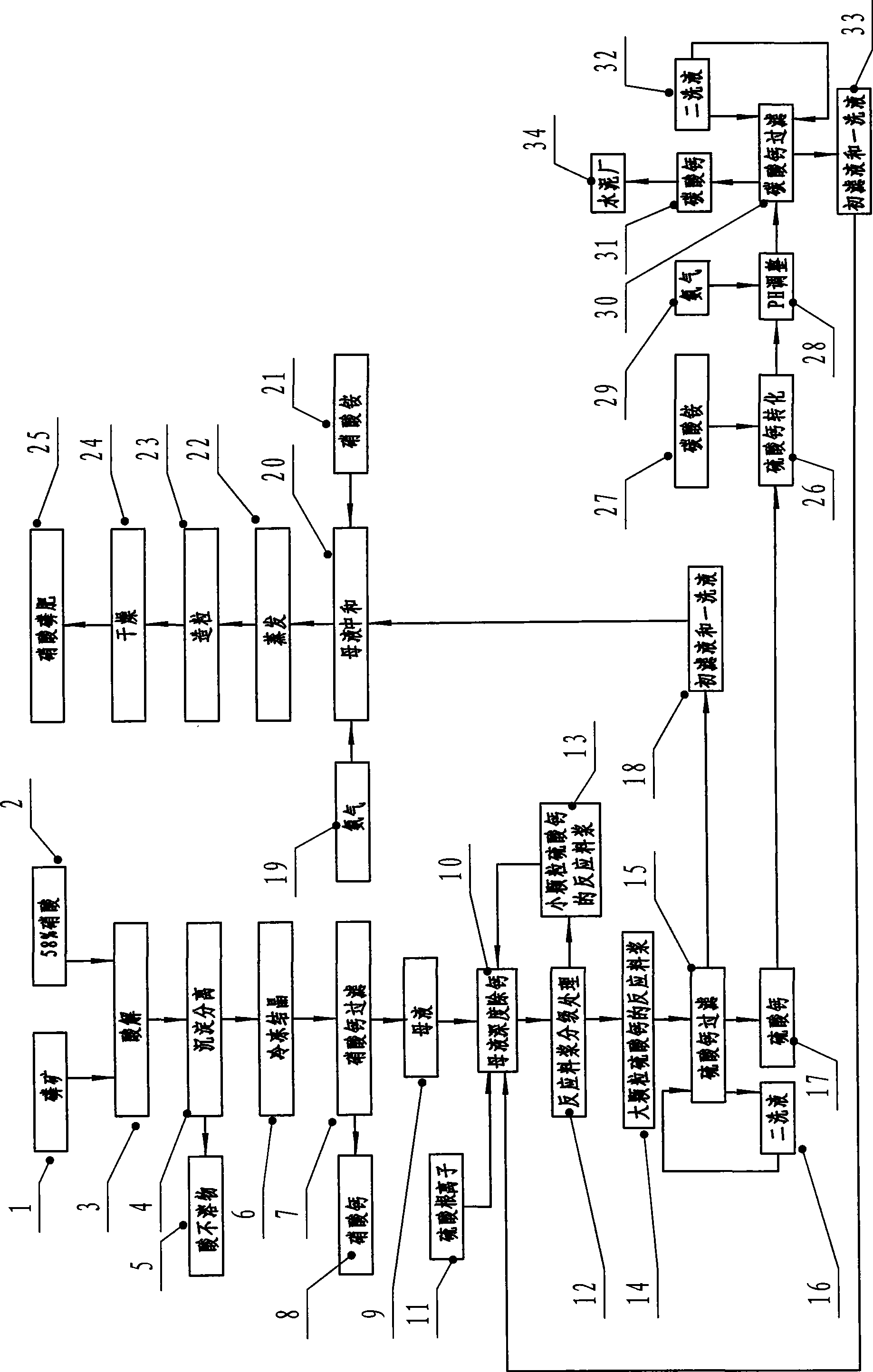

Technological process for producing high concentration nitric-phosphate fertilizer

The invention discloses a technique method for producing high-concentration nitric phosphate, which comprises the following steps of: adding nitric acid into phosphorus ore for acidolysis, depositing and separating acid non-soluble substance, freezing and crystallizing calcium nitrate, filtering the calcium nitrate, neutralizing the mother liquid, vaporization, pelleting and drying. The invention is characterized in that: a step of thoroughly removing the calcium of the mother liquid is arranged between the steps of filtering the calcium nitrate, and neutralizing the mother liquid. The steps comprise the following steps of: I) thoroughly removing the calcium of the mother liquid and adding sulfuric acid or ammonium sulfate; the calcium ions and the sulfate ions in the mother liquid generate dihydrate calcium sulfate crystal; II) the grading processing of reaction slurry: employing a grading device to carry out grading processing to the reaction slurry; returning the reaction slurry provided with small grain calcium sulfate to the mother liquid for thoroughly removing the calcium, and feeding the reaction slurry provided with large grain calcium sulfate to the calcium sulfate for filtering; and III) filtering and washing the filtering reaction slurry of calcium sulfate by a filter, feeding the primary filtrate and the primary lavage fluid into the working procedure of neutralizing, and returning the secondary lavage fluid to the filter. The invention has the advantage of using middle-low quality phosphorite to prepare the high-concentration nitric phosphate.

Owner:TIANJI COAL CHEM IND GROUP +1

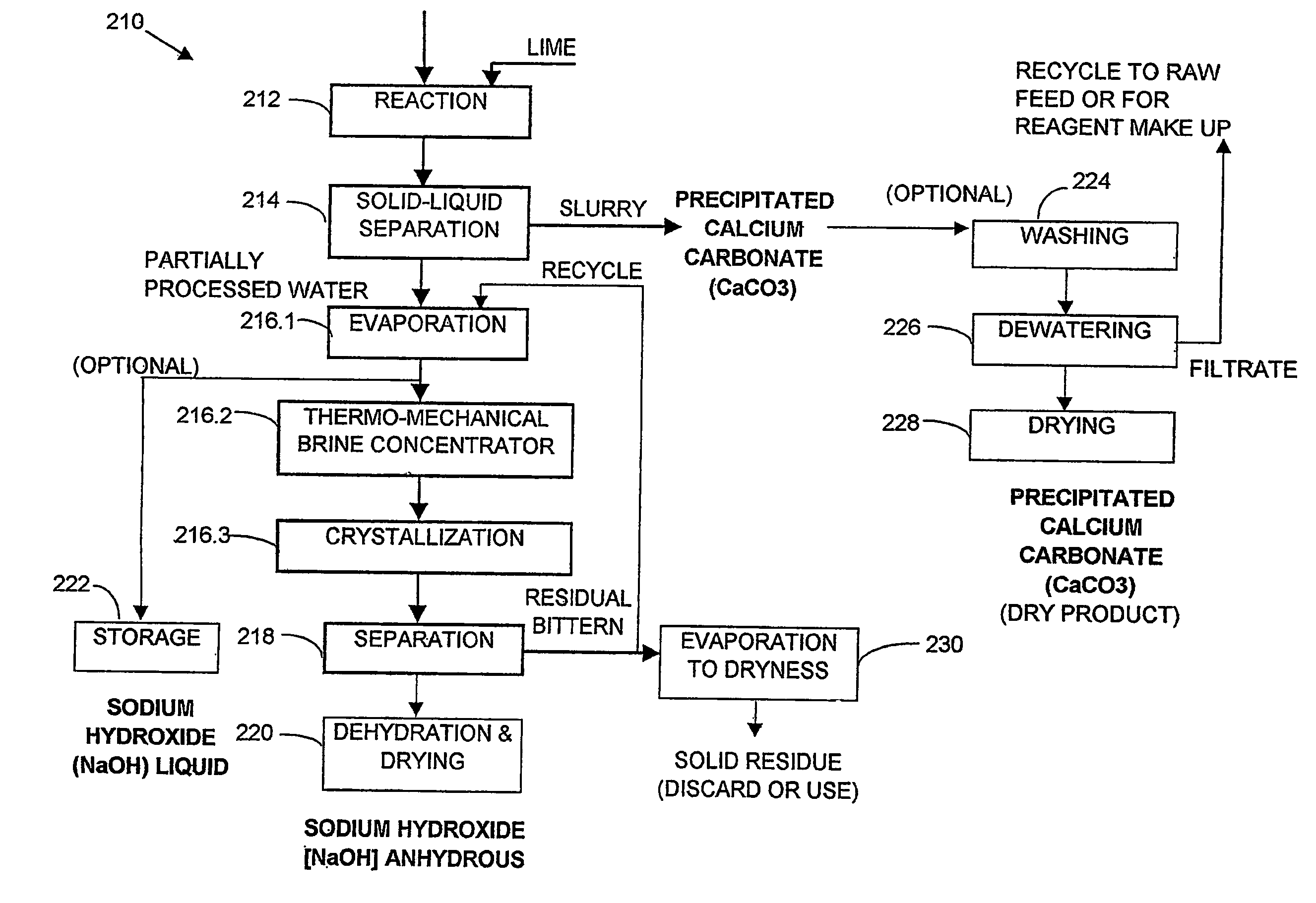

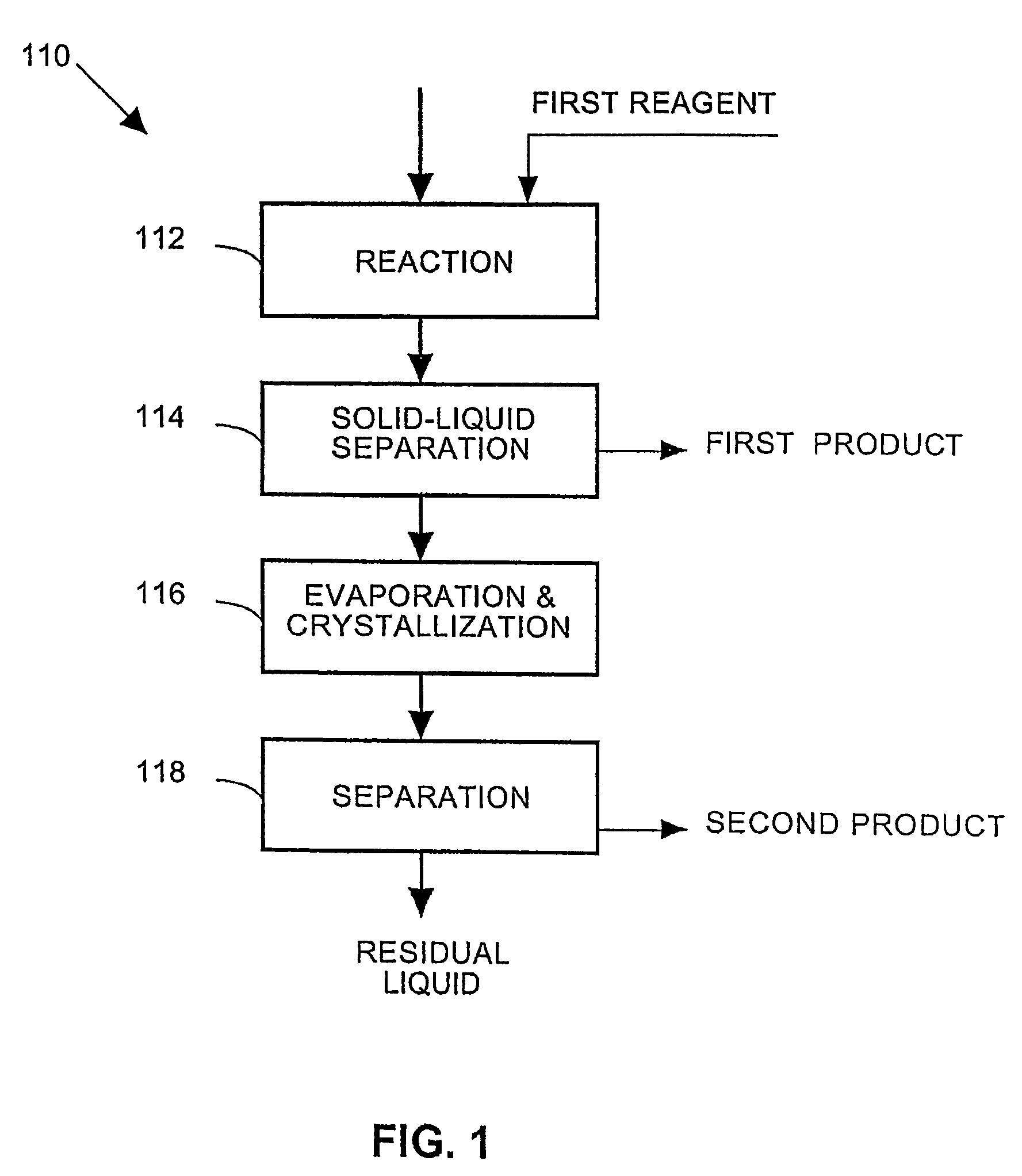

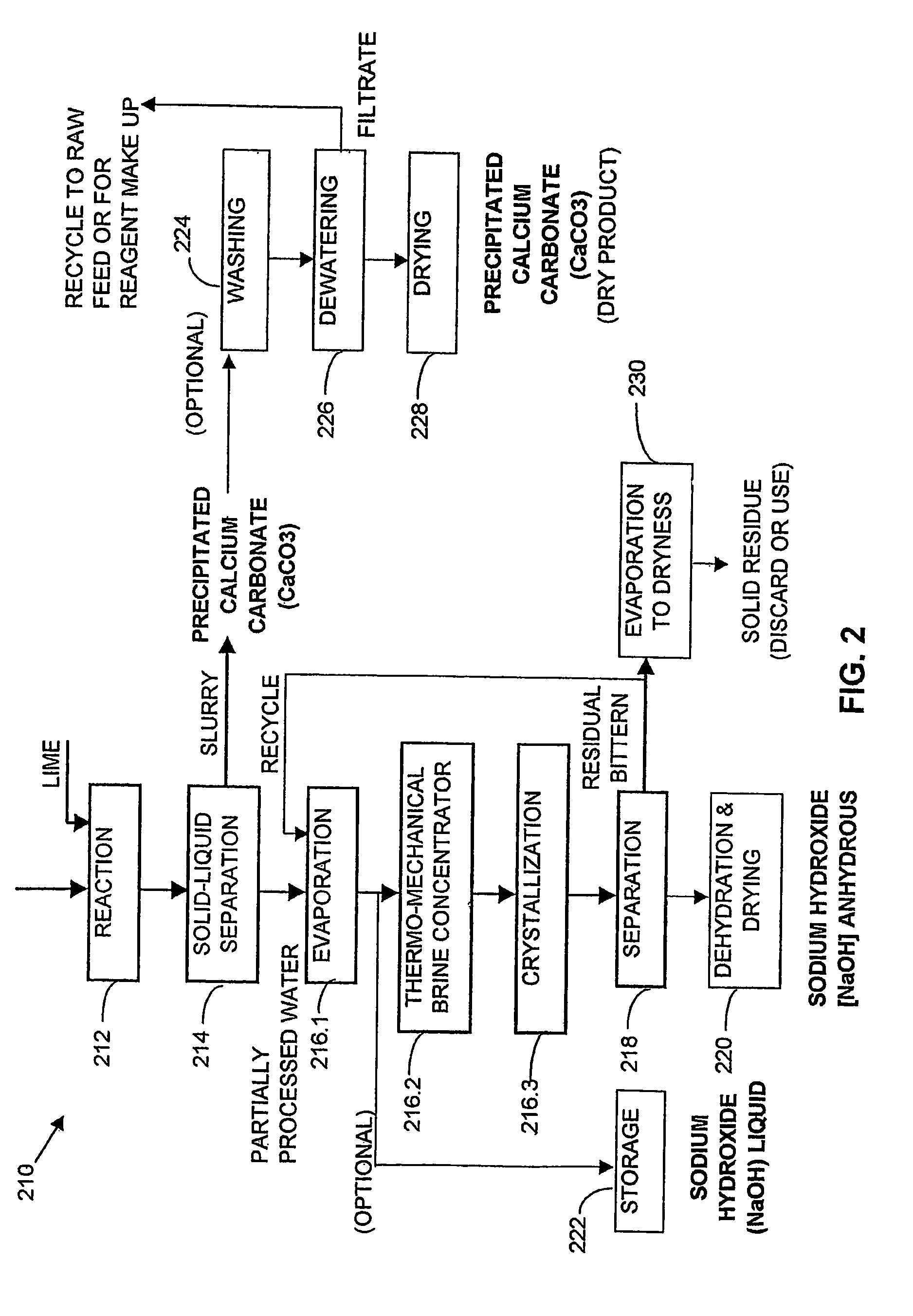

Process for the treatment of saline water

InactiveUS7595001B2Waste water treatment from quariesGeneral water supply conservationTotal dissolved solidsEvaporation

A process and an apparatus are described for treating seven types of saline waters each having a concentration of total dissolved solids exceeding 1 g / L, wherein the concentration of total dissolved solids, the ratio of the chloride ion concentration to the bicarbonate ion concentration and the ratio of the chloride ion concentration to the sulphate ion concentration of each of the water types are as indicated in Table 1. The process includes the steps of contacting the water with a first reagent comprising a source of calcium ions selected from calcium oxide and calcium hydroxide to form a first solid product which is recovered. The process includes a further step of subjecting at least a portion of the partially processed water to at least partial evaporation so as to promote the formation of a precipitate and a mother liquor. The precipitate is recovered as a second product.

Owner:GEO PROCESSORS

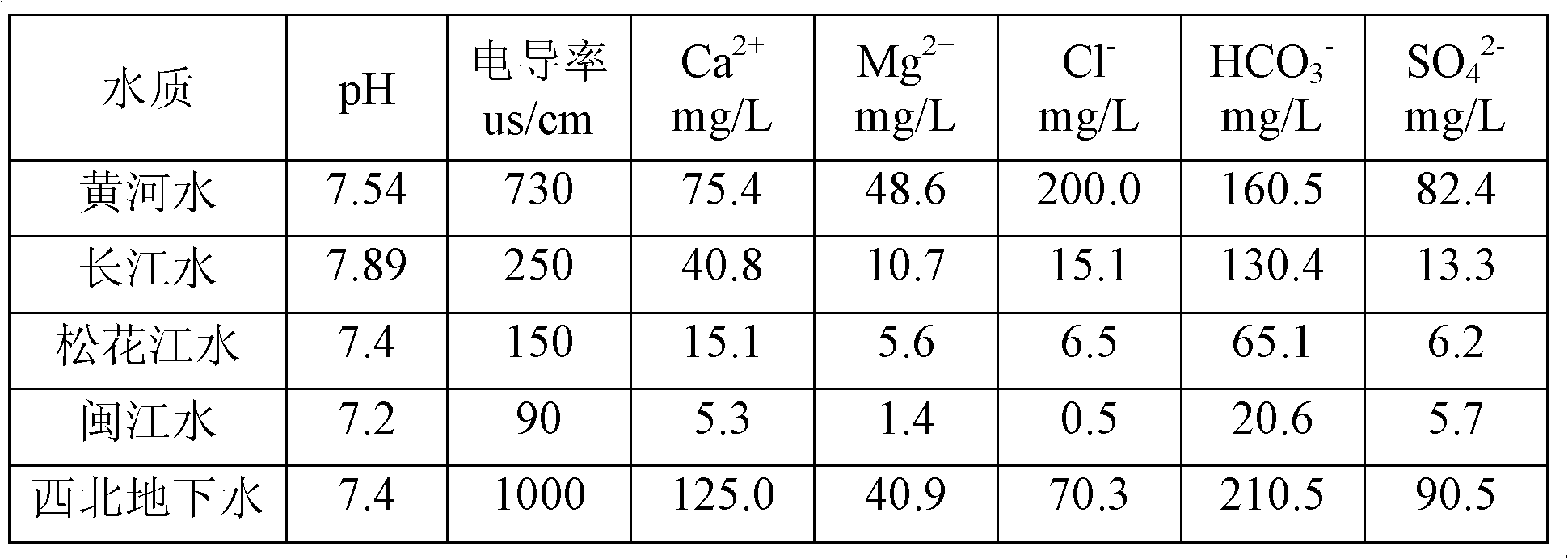

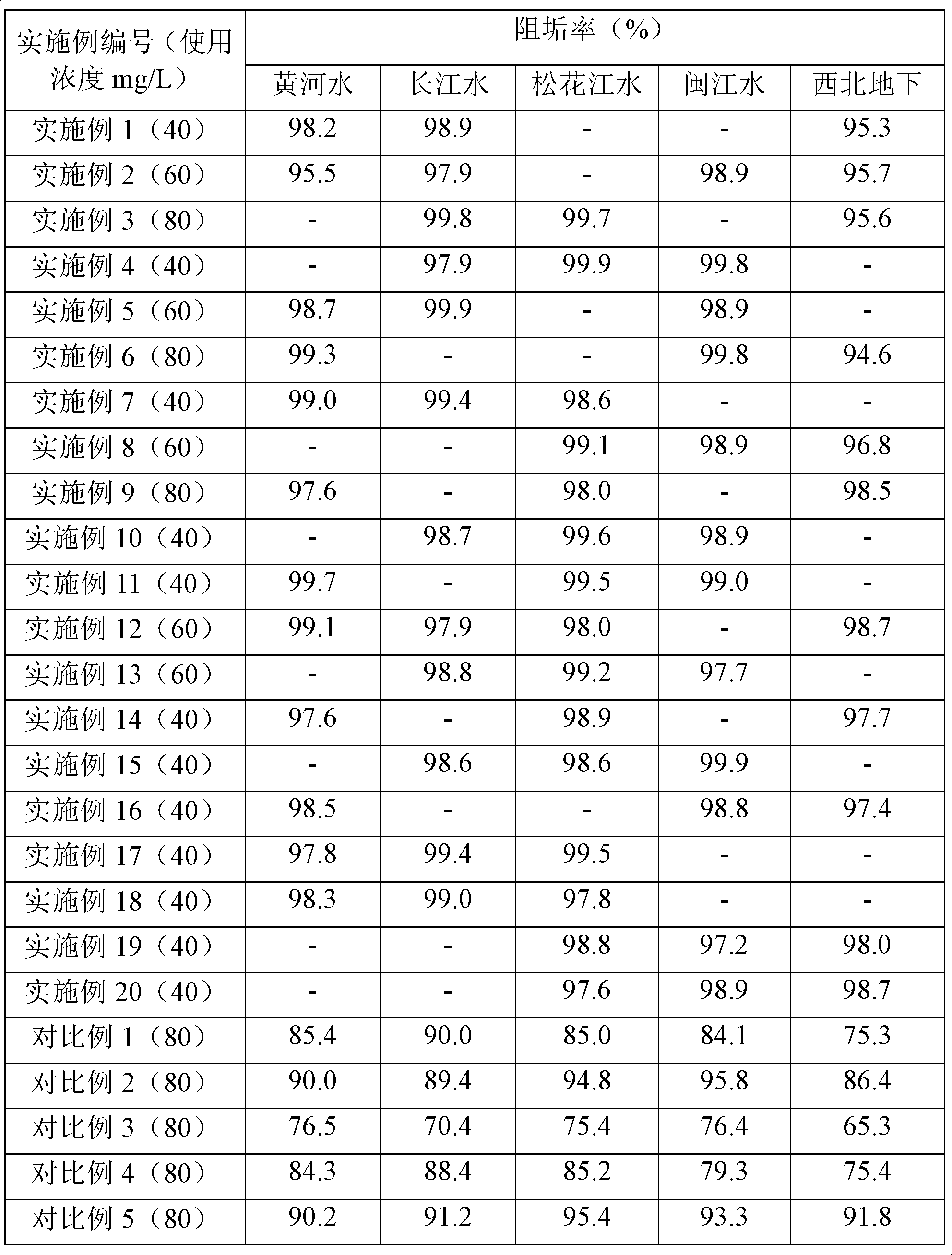

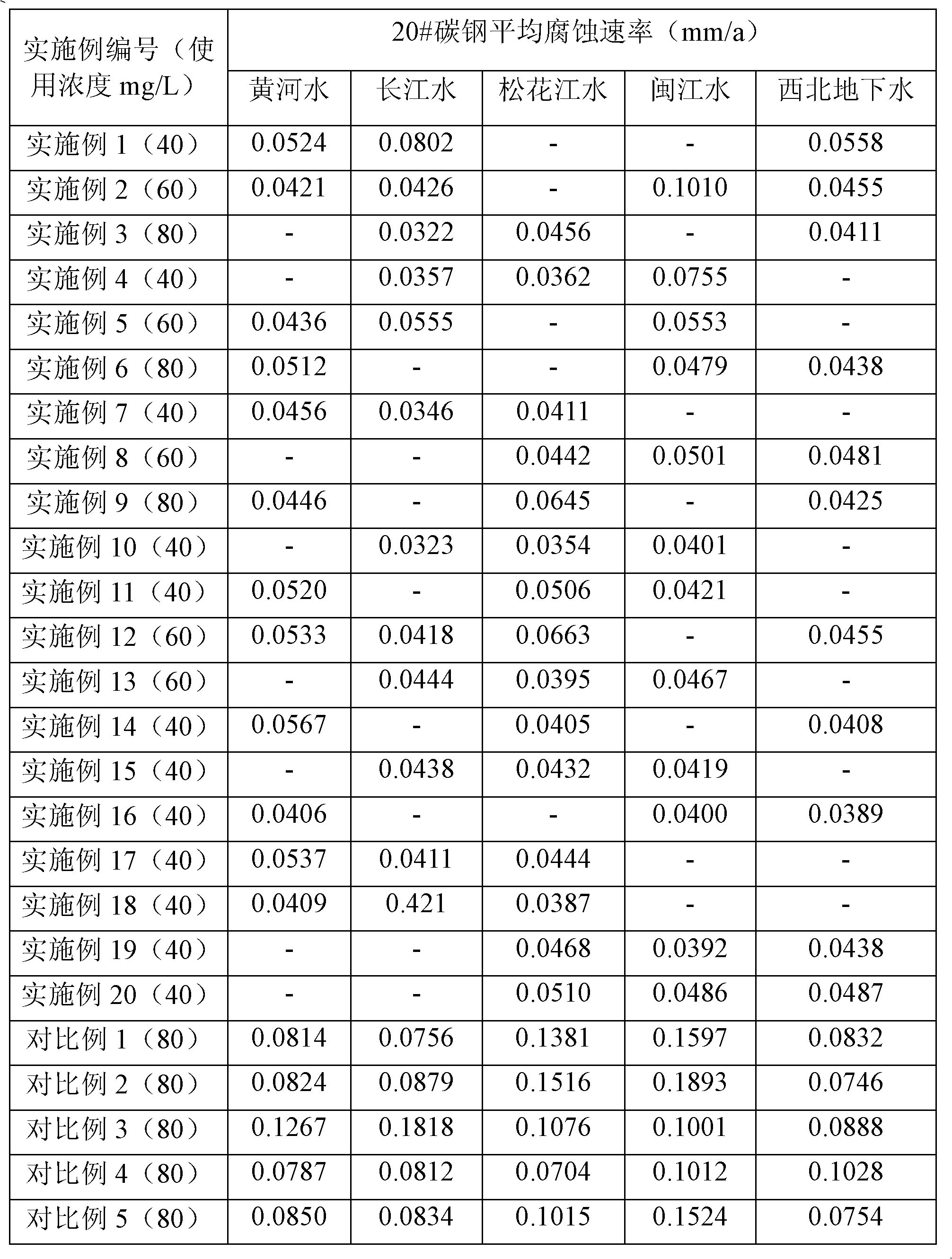

Composition used in scale-inhibition corrosion inhibitor, scale-inhibition corrosion inhibitor, and application thereof

ActiveCN103253777AHigh calcium and alkali toleranceGood scale and corrosion inhibitionScale removal and water softeningHigh concentrationTungstate

The invention discloses a composition used in a scale-inhibition corrosion inhibitor, a scale-inhibition corrosion inhibitor, and an application thereof. The composition used in the scale-inhibition corrosion inhibitor comprises cyclodextrin and / or a cyclodextrin derivative, a carboxylic-acid-group-containing homopolymer, a sulfonic-acid-group-containing copolymer, and selectively hydroxycarboxylic acid with a weight ratio of 1:0.2-20:0.04-15:0.2-30:0-20. The scale-inhibition corrosion inhibitor provided by the invention is environment-friendly. According to the invention, the application of phosphorus-containing compound or non-renewable molybdate or tungstate is prevented, such that the scale-inhibition corrosion inhibitor is phosphorus-free and nitrogen-free. The scale-inhibition corrosion inhibitor has high tolerance to calcium and alkali, resistance to corrosion of high-concentration chloride ion and sulfate ion, and wide applicability to water quality. Therefore, technical condition is provided for operation of circulation water under high concentration multiple and for reducing sewage discharge. The scale-inhibition corrosion inhibitor provided by the invention has excellent scale inhibition and corrosion inhibition performances in circulation water system application. With the scale-inhibition corrosion inhibitor, a dose is low, scale-inhibition treatment process is simple and substantial effect is provided. The scale-inhibition corrosion inhibitor is suitable for popularization.

Owner:CHINA PETROLEUM & CHEM CORP +1

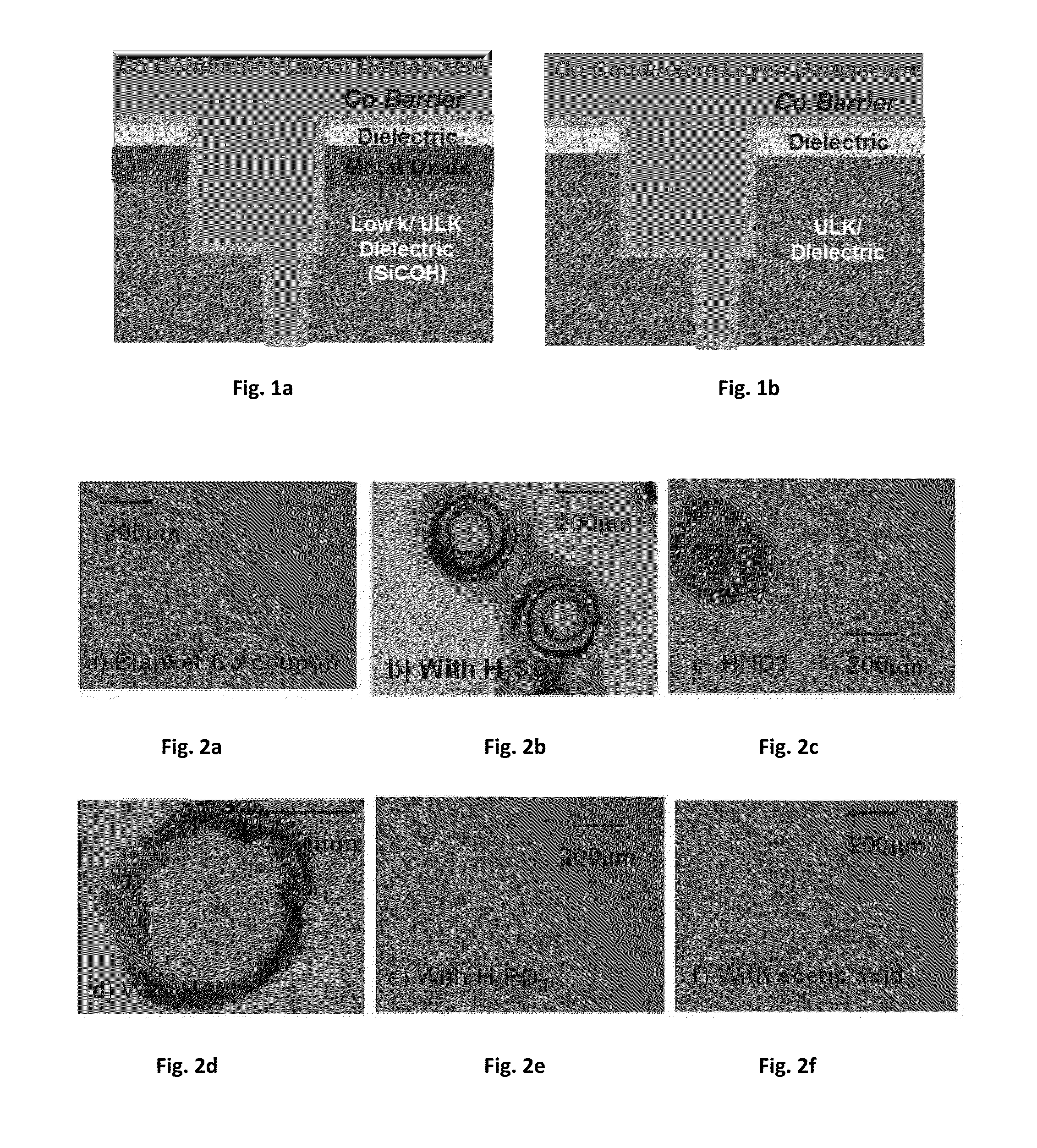

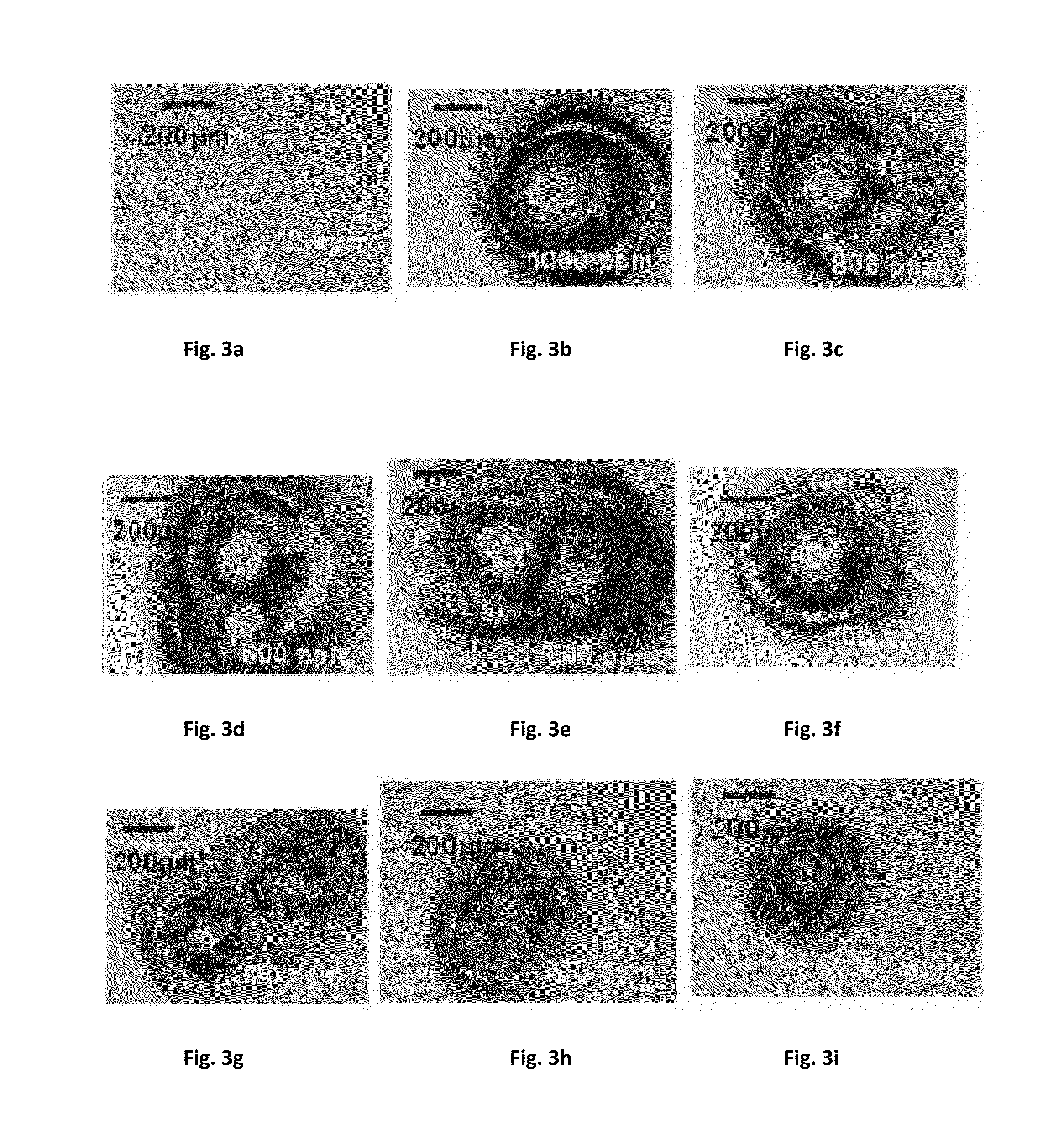

Polishing compositions and methods for polishing cobalt films

ActiveUS20160068710A1Good removal effectGood choiceSemiconductor/solid-state device manufacturingSurface treatment compositionsDielectricPhysical chemistry

The present disclosure relates to polishing compositions that can polish Cobalt (Co) films in semiconductor substrates containing a multitude of films including Co, metals, metal oxides and dielectrics. These polishing compositions comprise an abrasive, a weak acid acting as a removal rate enhancer (RRE), a pH adjuster, and an azole-containing corrosion inhibitor (CI). The RRE, pH adjuster and CI have a pKa in the 1-18 range (1 (pKamin)<pKa<18 (pKamax)). The pKa values of the individual components are related to the pH of the polishing composition / slurry (pHslurry) by the following equation: pKamin+6<pHslurry<pKamax−6. The polishing composition also has less than about 100 parts per million (ppm) of sulfate ions and less than about 100 ppm of halide ions, and operates in the 7-12 pH range.

Owner:FUJIFILM ELECTRONICS MATERIALS US

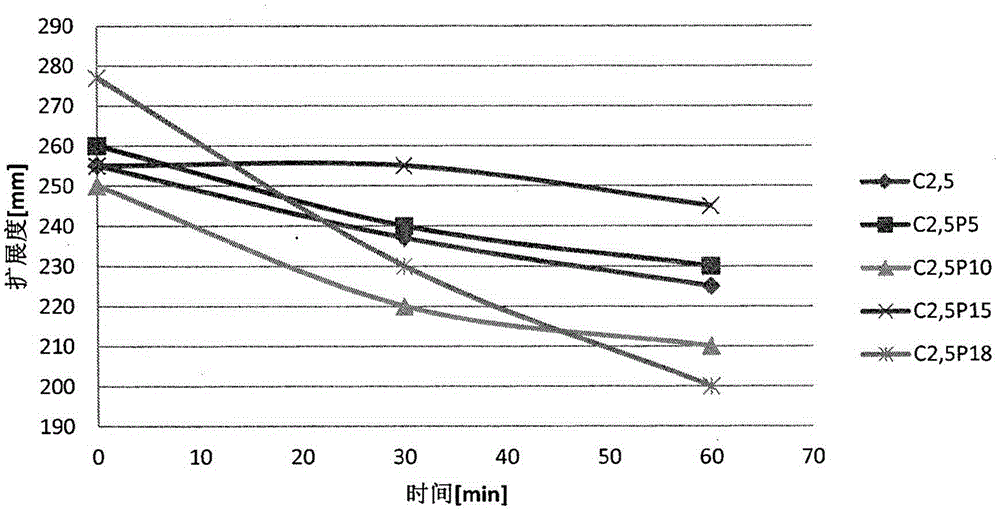

Phosphoric-acid-base modified polycarboxylic-acid water reducer with high adaptability and preparation method thereof

The invention discloses a phosphoric-acid-base modified polycarboxylic-acid water reducer with high adaptability and a preparation method thereof. The water reducer is prepared from the following raw materials: isopentenol polyoxyethylene ether, hydrogen peroxide, acrylic acid, an unsaturated phosphoric acid monomer, deionized water, a reducing agent, and a chain transferring agent. The chain transferring agent is one of mercaptoethanol, mercaptoacetic acid and mercaptopropionic acid. The unsaturated phosphoric acid monomer is prepared from 2-phosphono-1,2,4-butanetricarboxylic acid, p-toluenesulfonic acid and hydroquinone. The preparation method for the water reducer comprises adding isopentenol polyoxyethylene ether and deionized water into a reaction vessel, uniformly stirring, heating, keeping warm, adding oxygen peroxide, then dropwise adding a material solution by employing a constant-flow pump, continuing to keep warm for reacting for 1-1.5 h after dropwise adding of the material solution is finished, naturally cooling to room temperature, and adjusting the pH value of the obtained product to 5-6 by using an alkaline solution. The phosphoric-acid-base modified polycarboxylic-acid water reducer possesses good sulfate ion resisting capability and sludge resisting capability, thereby satisfying engineering demand.

Owner:SHIJIAZHUANG CHANGAN YUCAI BUILDING MATERIALS

Prepn of sodium alginate/chitosan mixture gel

InactiveCN1810867AStrong slow and controlled release performanceProcess safetyPharmaceutical non-active ingredientsCross-linkSulfate radicals

The present invention relates to preparation process of sodium alginate / chitosan mixture gel capable of being used as biodegradable medicine carrier. The preparation process includes the following steps: 1. forming homogeneous transparent alginate and chitosan solution in 1-5 wt% concentration each with alginate in 5-95 wt% and chitosan in 5-95 wt%, and adding acetic acid; 2. preparing alginate / chitosan mixture sol; 3. dropping the sol into 1.5-3 wt% concentration calcium chloride or sodium sulfate solution; 4. preparing alginate / chitosan-calcium ion-sulfate radical double cross-linked gel grain; and 5. soaking in absolute ethanol for 2-5 min, vacuum drying to obtain alginate / chitosan mixture gel grain of 300-1000 micron grain size. The alginate / chitosan mixture gel grain of the present invention has high pH sensitivity and the preparation process is safe and simple.

Owner:WUHAN UNIV OF TECH

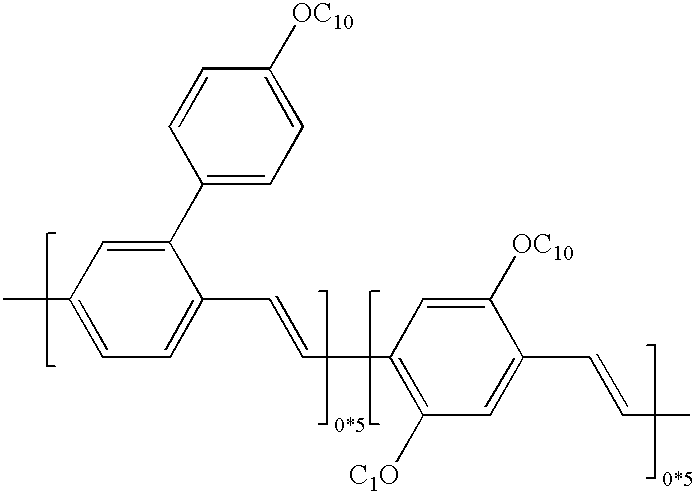

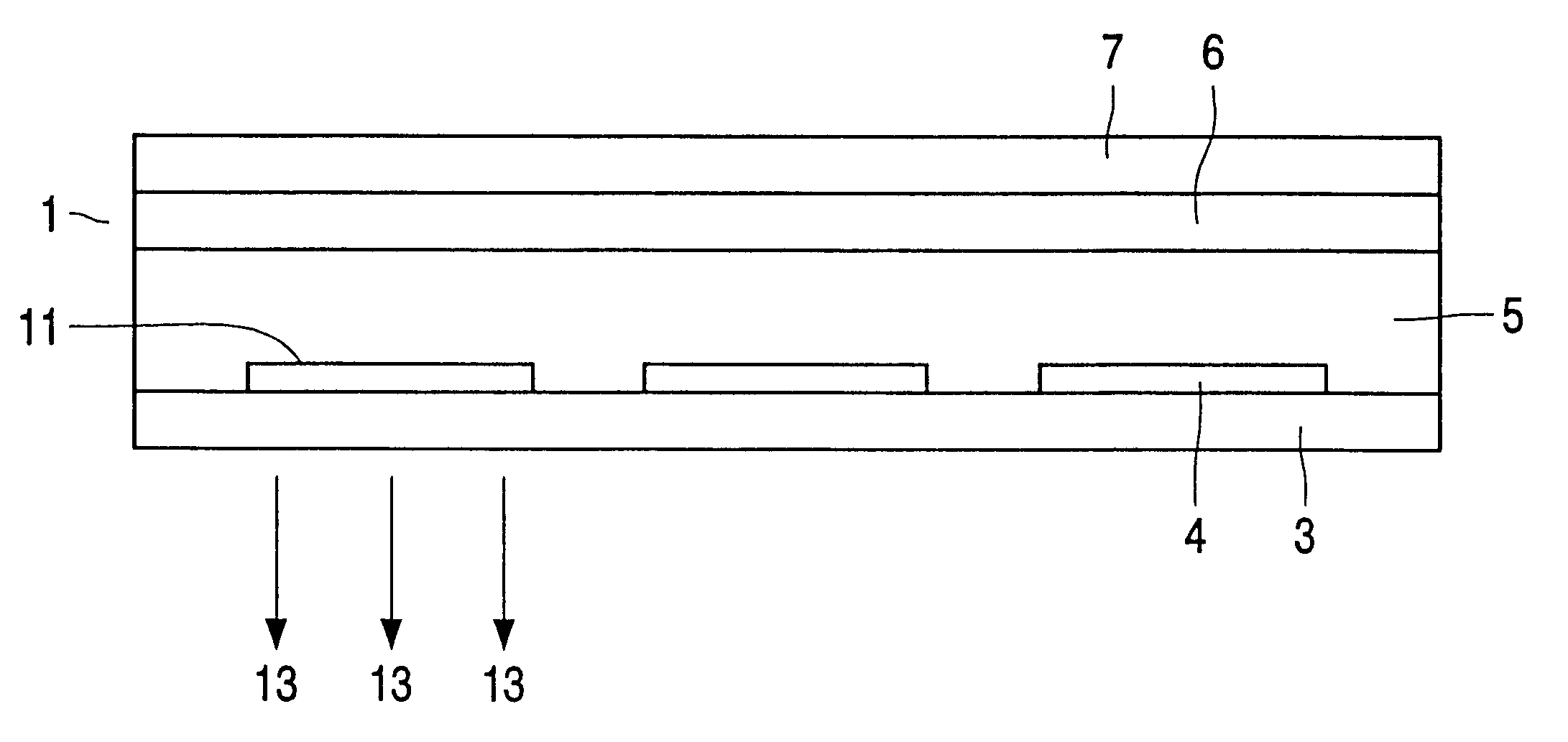

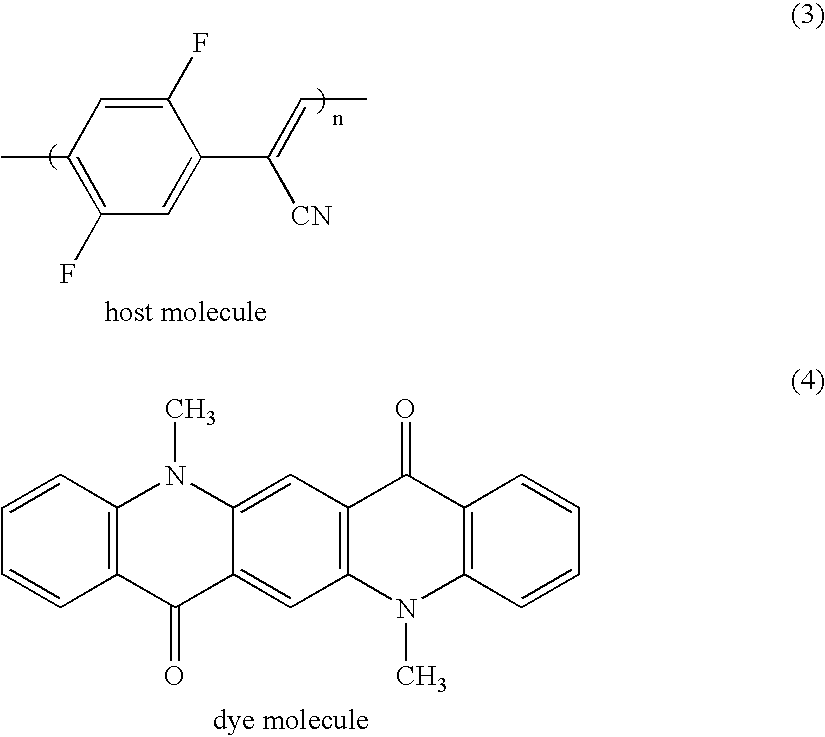

Antistatic polyester film and antistatic film laminate

InactiveUS6103368AIncrease resistanceIncrease productivityRecord carriersMagnetic materials for record carriersCarbon numberPolyester

PCT No. PCT / JP97 / 02341 Sec. 371 Date Feb. 27, 1998 Sec. 102(e) Date Feb. 27, 1998 PCT Filed Jul. 7, 1997 PCT Pub. No. WO98 / 02308 PCT Pub. Date Jan. 22, 1998The present invention provides an antistatic polyester film having an antistatic layer formed of an antistatic agent (A) composed mainly of a polymer having a recurring unit of a structure expressed by the following formula (I) on at least one surface of a polyester film wherein R1 and R2 are each H or CH3, R3 is an alkylene group having a carbon number of 2 to 10, R4 and R5 are each a saturated hydrocarbon group having a carbon number of 1 to 5, R6 is an alkylene group having a carbon number of 2 to 5, n is a number of 0 to 40, m is a number of 1 to 40, and Y- is a halogen ion, a mono- or polyhalogenated alkyl ion, nitrate ion, sulfate ion, an alkylsulfate ion, sulfonate ion or an alkylsulfonate ion.

Owner:TEIJIN LTD

Alkali-free liquid setting accelerator

ActiveCN101648785ANo lossNo irritating smellUnderground chambersBuilding material handlingO-Phosphoric AcidSulfate radicals

The invention discloses an alkali-free liquid setting accelerator which is prepared from the following components by weight percent: 18-40% of hydroxycarboxylic acid, 1-5% of phosphoric acid, 15-30% of aluminium hydroxide, 0-5% of alkylol amine, 0.01-0.2% of defoaming agent and the balance water. The alkali-free liquid setting accelerator of invention does not contain alkali metal ions, sulfate ions and other corrosive materials, is safe to use and has no bad effect on the durability of sprayed concrete, thus being capable to be used in the construction of sprayed concrete.

Owner:JIANGSU SOBUTE NEW MATERIALS

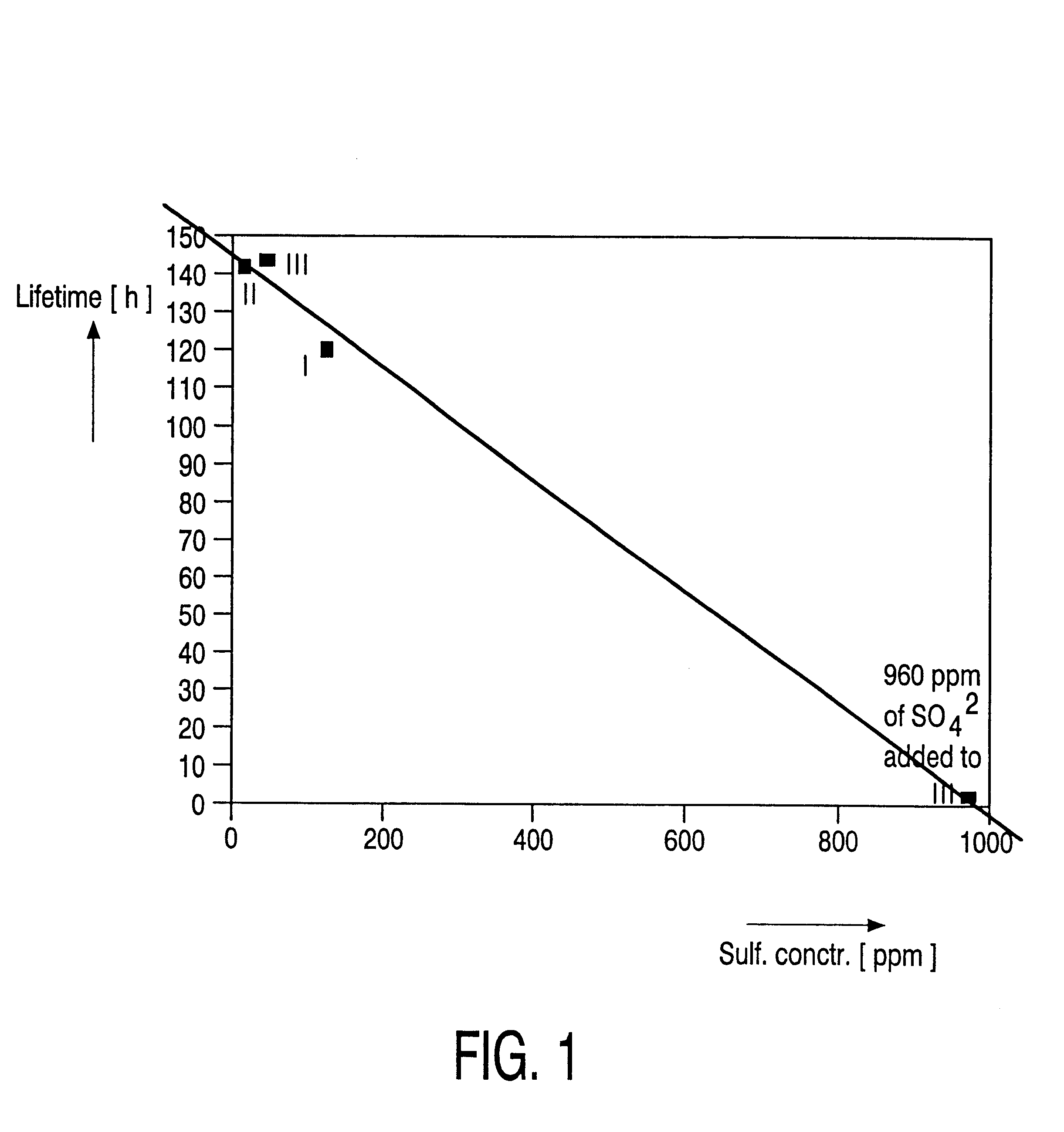

Led comprising a conductive transparent polymer layer with low sulfate and high metal ion content

InactiveUS6586764B2Extended service lifePrevent substantial absorption of visible lightElectroluminescent light sourcesConductive materialIon contentOligomer

The invention pertains to an organic light emitting diode (LED) comprising a transparent electrode, superposed by a layer of a conductive transparent polymer (CTP), superposed by a layer of a light emitting polymer, oligomer, or low molecular weight compound superposed by a metal cathode, characterized in that the CTP layer has a sulfate ion content of less than 7,500 ppm, and a metal ion content of more than 0.04 mmoles / g.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Methylsulfonic acid preparing process

InactiveCN1810780ANo pollution in the processRaw materials are easy to getSulfonic acid preparationSulfate radicalsWater insoluble

The environment friendly methyl sulfonic acid preparing process includes the following steps: the reaction of the water solution or solid of ammonium sulfite or mixture of ammonium sulfite and ammonium bisulfite with dimethyl sulfate at high temperature to produce ammonium methyl sulfonate; treating the reacted solution containing ammonium methyl sulfonate and ammonium sulfate with calcium hydroxide or other compound capable of producing precipitate with sulfate radical ion to produce water soluble calcium methyl sulfonate, water insoluble calcium sulfate and ammonium hydroxide; treating obtained calcium methyl sulfonate with strong acid capable of forming precipitate with calcium ion; and final decompression distilling to obtain methyl sulfonic acid. The present invention has facile material, simple technological process, high product quality, low cost and no environmental pollution, and is suitable for industrial production.

Owner:HEBEI YANUO CHEM IND

Electrolyte for all-vanadium redox flow battery and preparation method thereof, and all-vanadium redox flow battery including the electrolyte

ActiveCN101572319AHigh total vanadium concentrationImprove stabilityHybrid cell detailsFinal product manufactureRedoxSULFATE ION

The invention provides an electrolyte for an all-vanadium redox flow battery and a preparation method thereof, and an all-vanadium redox flow battery including the electrolyte. The electrolyte for an all-vanadium redox flow battery comprises anode electrolyte and cathode electrolyte which contain vanadiferous ions and sulfate ions, concentration of the sulfate ions in the anode electrolyte is more than that of the sulfate ions in the cathode electrolyte, the total vanadium concentration of the anode electrolyte and the cathode electrolyte is 2.0-8.0mol / L respectively. The preparation method of the electrolyte for an all-vanadium redox flow battery comprises the following steps: dissolving one or more vanadium oxides and optional reducers in sulfuric acid solution with a first concentration and a second concentration respectively to obtain an anode electrolyte precursor and a cathode electrolyte precursor with the total vanadium concentration of 2.0-8.0mol / L respectively, wherein, the first concentration is larger than the second concentration; and electrolyzing the anode electrolyte precursor and the cathode electrolyte precursor respectively to obtain the anode electrolyte and the cathode electrolyte of the all-vanadium redox flow battery.

Owner:大力储能技术湖北有限责任公司

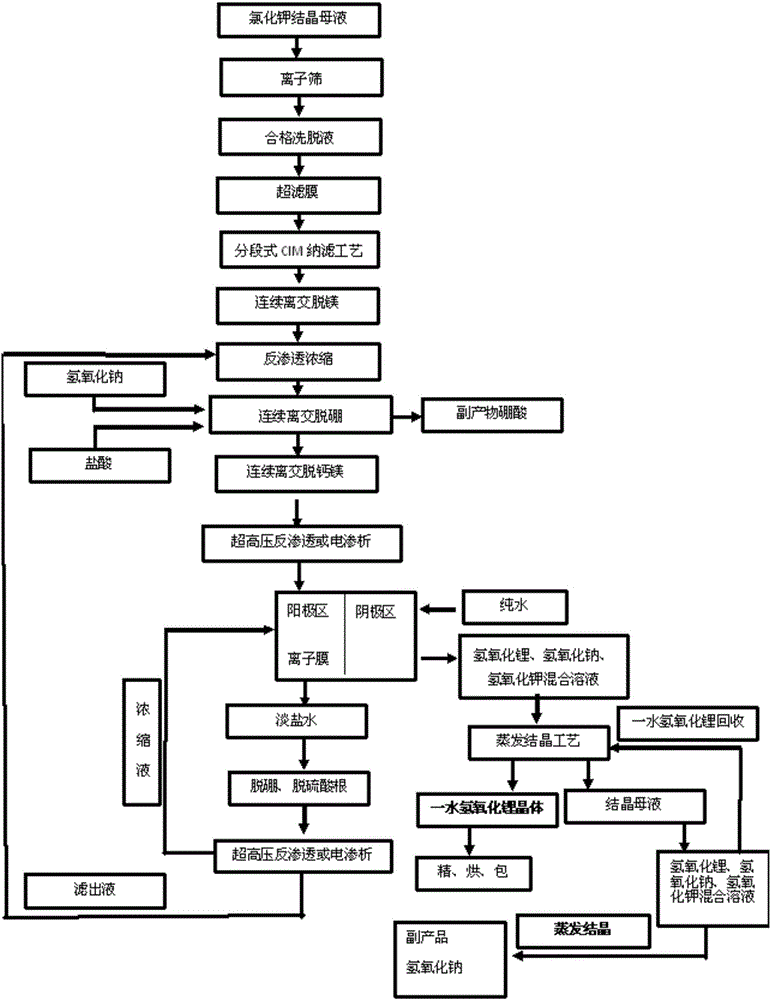

Production method of high-purity lithium hydroxide

ActiveCN106011917AHigh yieldReduce consumptionCellsBoron-oxygen compoundsLithium hydroxideUltrafiltration

The present invention relates to a production method of high-purity lithium hydroxide. A crystallization mother liquor waste water is obtained after production of potassium chloride by using a salt lake bittern as the raw material, a magnesium-lithium ratio of the crystallization mother liquor waste water is 200-500:1, an eligible eluant is obtained through ion sieve adsorption and elution of the crystallization mother liquor waste water, and after treatment of the eluant through the ultrafiltration membrane technology, the sectional type nanofiltration technology, the external regeneration continuous hybridization technology and the reverse osmosis technology, a reverse osmosis concentrated solution is obtained. In the reverse osmosis concentrated solution, the content of magnesium ions is <=300 ppm, the content of lithium ions is 4-6 g / L, the content of sodium ions is 3-5 g / L, the content of calcium ions is <=5 ppm, the content of sulfate ions is 1-30 ppm and the content of boron is <=400 ppm. According to the production method provided by the present invention, the reverse osmosis concentrated solution is used as the raw material, the process comprises ultrahigh pressure reverse osmosis continuous hybridization for boron-removing, continuous hybridization for sulfate radical removing, ion-exchange membrane electrolysis, and crystallizing evaporation, and by using the hybridization boron-removing technology, the ion-exchange membrane electrolysis technology and the crystallizing evaporation technology, the high-purity lithium hydroxide is obtained, with the byproducts being the boric acid and sodium hydroxide. The process is continuous, controllable, high in extraction rate, low in production cost and easy to industrialize.

Owner:启迪清源(上海)新材料科技有限公司

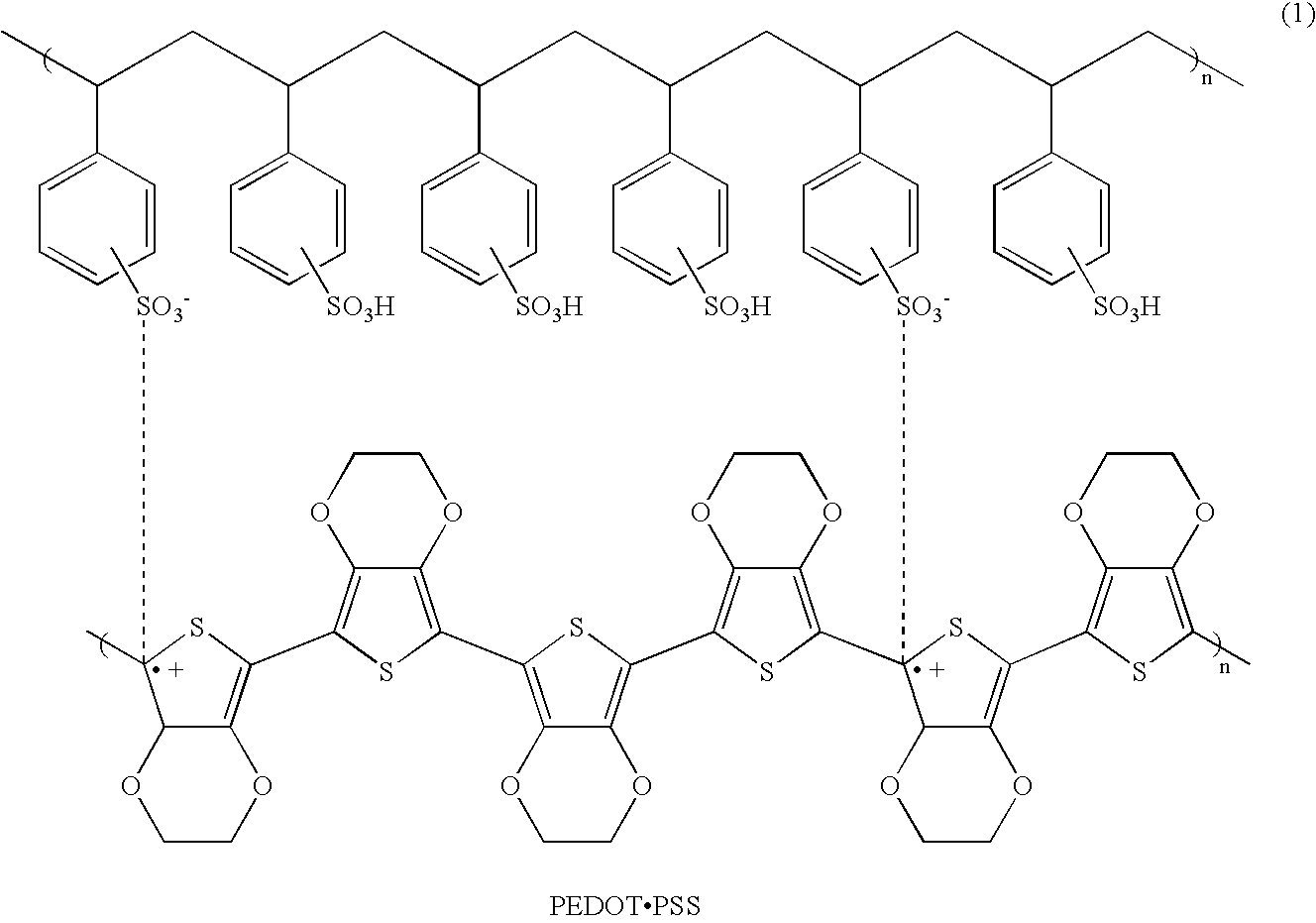

Ink for forming a hole injection layer of organic EL display devices and manufacturing method thereof, organic EL display devices, and manufacturing method of the same

There is disclosed an organic electro luminescence display device comprising a two-dimensional array of pixels comprising organic electro luminescence elements capable of emitting a of color or different plural colors, each of the organic electro luminescence elements being provided with an anode, a cathode, a polymeric luminescence layer located between the anode and the cathode, and a hole injection layer. The hole injection layer is constituted by solid matters containing a donor molecule comprising polythiophene and / or a derivative thereof, and an acceptor molecule comprising polystyrenesulfonic acid and / or a derivative thereof, a concentration of sulfate ion in the hole injection layer is 125 ppm or less, and components having a molecular weight of 110,000 or less is 35% or less based on an entire solid matters, the molecular weight being converted as sodium polystyrenesulfonate in an aqueous gel permeation chromatography measured by using UV of 254 nm in wavelength.

Owner:KK TOSHIBA

Process for producing cleaning water and cleaning water

InactiveCN1347850AImprove rust resistanceReduce areaElectrolysis componentsWater/sewage treatment by electrochemical methodsAlkaline waterChloride

The invention provides a higher rust preventive effect than alkaline water prepared by conventional electrolysis, and washing water compatible with safety and washing quality. In the method of preparing washing water, a process by which sulfate ions in raw water are made to be <=0.2 mmol / dm3 and / or chloride ions <=0.5 mmol / dm3, calcium ions <=1.0 mmol / dm3, and Mg ions <=1.0 mmol / dm3, is performed and subsequently a process by which sodium carbonate concentration in raw water is made to be 0.1-10.0 mmol / dm3, is performed, and then this water is electrolyzed to obtain washing water having >=8.0 and <=13.0 pH and / or 100 mV to 1,000 mV oxidation reduction potential.

Owner:TAKAHASHI METAL INDS

Production of silver sulfate grains using organo-sulfate or organo-sulfonate additives

ActiveUS7261867B1Uniform morphologyUniform sizePigmenting treatmentCosmetic preparationsOrganic sulfonic acidSulfonate

An aqueous precipitation process for the preparation of particles comprising primarily silver sulfate, comprising reacting an aqueous soluble silver salt and an aqueous soluble source of inorganic sulfate ion in an agitated precipitation reactor vessel and precipitating particles comprising primarily silver sulfate, wherein the reaction and precipitation are performed in the presence of an aqueous soluble organo-sulfate or organo-sulfonate additive compound, the amount of additive being a minor molar percentage, relative to the molar amount of silver sulfate precipitated, and effective to result in precipitation of particles comprising primarily silver sulfate having a mean grain size of less than 50 micrometers.

Owner:EASTMAN KODAK CO

Concrete preservative

InactiveCN102126842AGuarantee construction work performanceImprove compactnessSolid waste managementCoal measuresFreezing thawing

The invention relates to a concrete admixture, in particular to a composite cement preservative which can enhance the salty ion erosion resistance, freezing-thawing cyclic damage resistance and penetration resistance of concrete. The concrete preservative disclosed by the invention comprises the following components in percentage by weight: 30.0-50.0 percent of mineral admixture, 30.0-50.0 percent of expanding agent, 5.0-10.0 percent of corrosion inhibitor, 0.001-0.005 percent of air entraining agent and 1.0-10.0 percent of water reducing agent. By adopting the concrete preservative disclosed by the invention, the compactness of concrete can be enhanced, the concentration of sulfate ions capable of invading concrete can be lowered, the pore diameters of capillary pores can be reduced and the precipitating speed of calcium hydroxide from set cement can be restrained, so that the structural durability of concrete is enhanced. The concrete preservative is suitable for reinforced concrete structures in unfavorable geological regions, such as coal measure strata containing sulfate and magnesium and chloride ions, sulfide ore strata, seashore saline fields, coastal harbors and the like, as well as marine waters.

Owner:浙江五龙新材股份有限公司

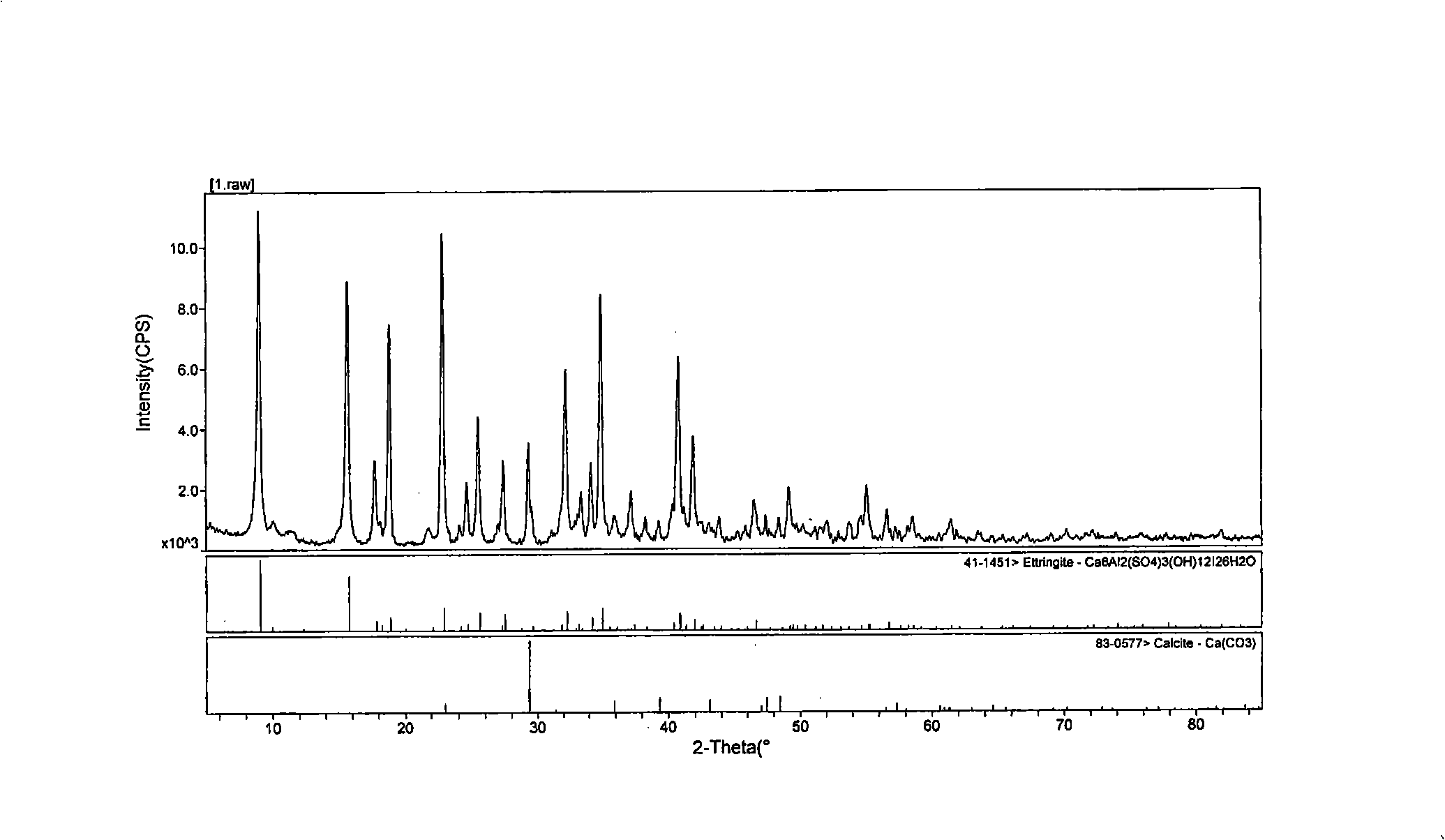

Method for removing sulfate radical in waste water

The invention discloses a sulfate radical wastewater treatment method by using a complex salt method, proposing that hydration aluminum nitrate and calcium hydroxide are taken as removing agents to remove the sulfate radical ions in the wastewater. Al (NO3)3 question mark 9H2O is added into metallurgy and mining industry sulfate radical wastewater with the initial concentration of 1300 to 2000mg / L according to the mol ratio of 0.8-1.1:1 of SO4<2-> / Al<3+>, reaction temperature is controlled at 20-40 DEG C, the pH value of the calcium hydroxide regulation system is 9-12, stirring reaction is carried out for 30-90min, SO4<2-> in the system, Ca<2+> and Al<3+> form compound Ca6Al2(SO4)3(OH)12 question mark 26H2O (ettringite) precipitation, then solid-liquid separation is carried out, and purifying water with water sulfate radical ion concentration of less than 100mg / L is obtained. The invention has the advantages of simple operation, high reaction speed, small temperature affect, highly-efficient treatment and the like.

Owner:CENT SOUTH UNIV

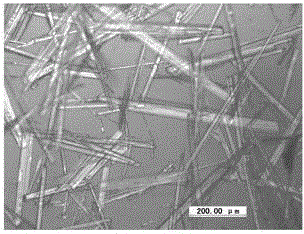

Method for preparing calcium sulfate whisker from phosphogypsum

InactiveCN104562180AImprove dissolution rateHigh purityPolycrystalline material growthFrom normal temperature solutionsChemistrySULFATE ION

The invention discloses a method for preparing calcium sulfate whisker from phosphogypsum. The method comprises the following steps: (1) crushing and grinding phosphogypsum serving as a raw material to obtain phosphogypsum powder; (2) mixing the obtained phosphogypsum powder and diluted acid to obtain a mixture, placing the mixture in a reactor with a stirring device, reacting by controlling a certain temperature to obtain an acidic mixed solution containing calcium, sulfate ions and insoluble matters; (3) filtering the obtained mixed solution while the solution is hot to obtain an acidic filtrate; and (4) cooling the obtained acidic filtrate and crystallizing, filtering, washing and drying to obtain the calcium sulfate whisker product. The calcium sulfate dihydrate whisker with large length-diameter ratio is directly prepared from the raw material by virtue of one-step acid leaching impurity removal method instead of pretreatment impurity removal and thus the advantages that the process flow is simple, the production cost is low, the energy consumption is small and the acidic wastewater and washing water can be recyclable are achieved; the obtained calcium sulfate whisker has the characteristics of high purity, large length-diameter ratio and the like and is conductive to popularization and application.

Owner:SOUTHWEAT UNIV OF SCI & TECH

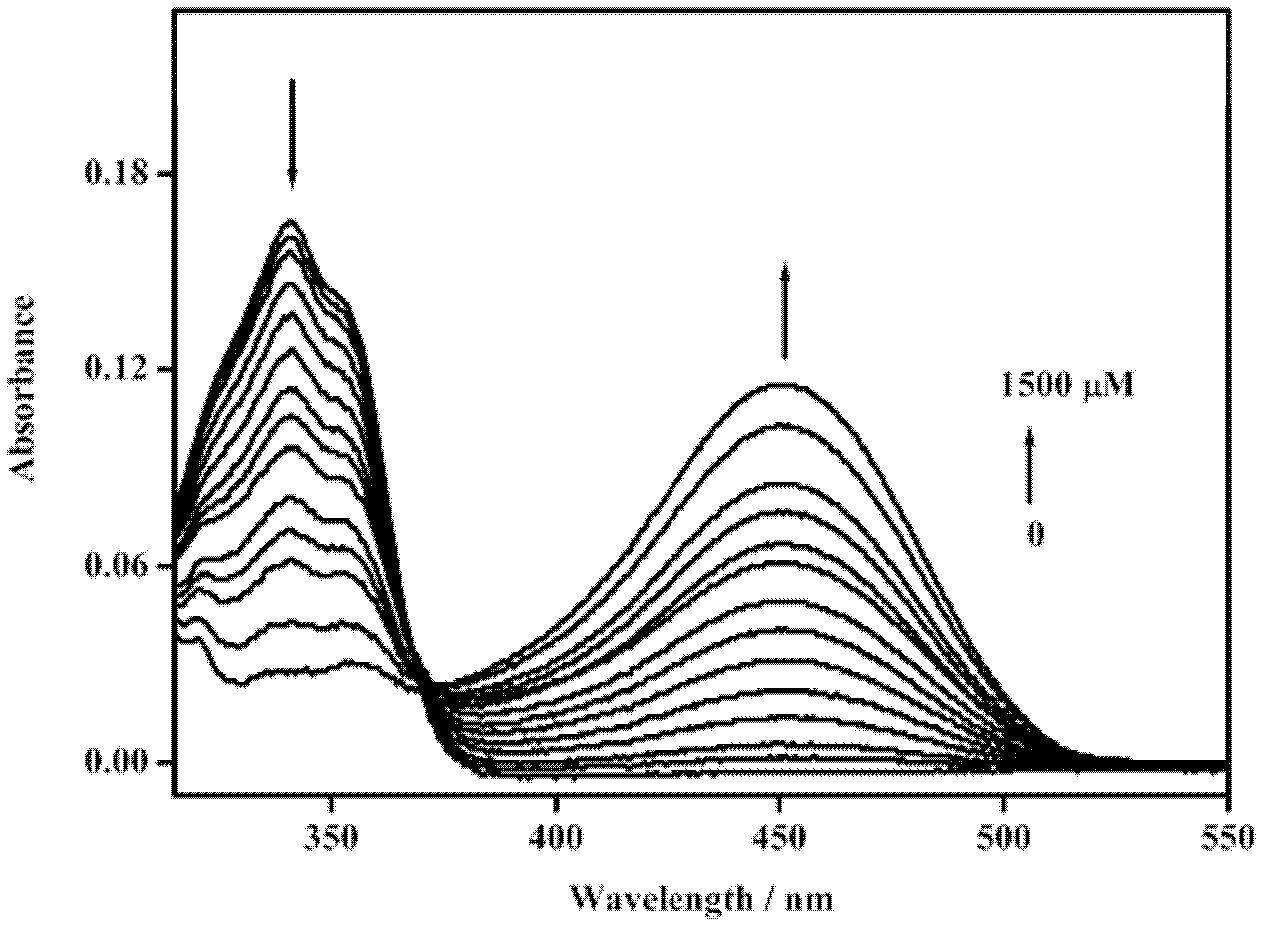

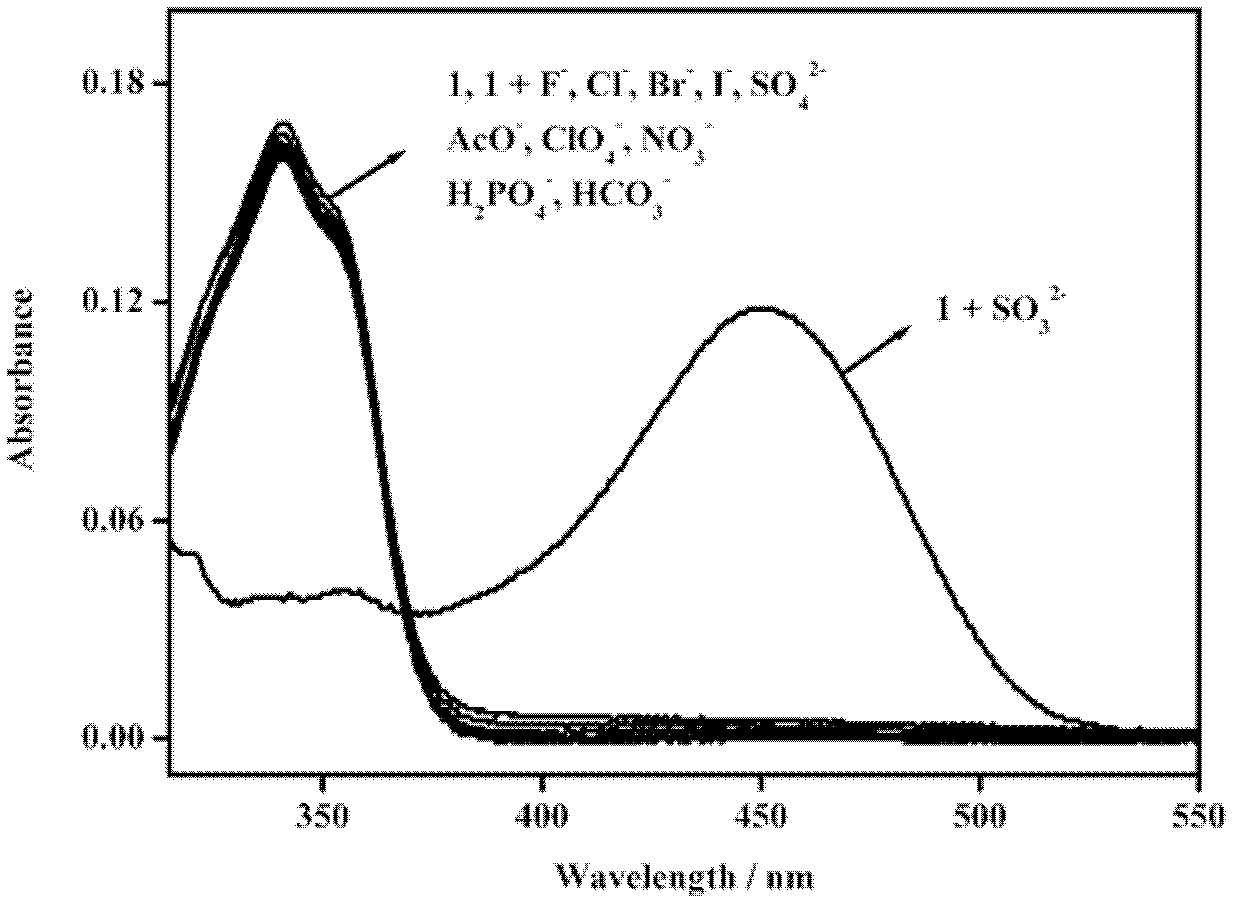

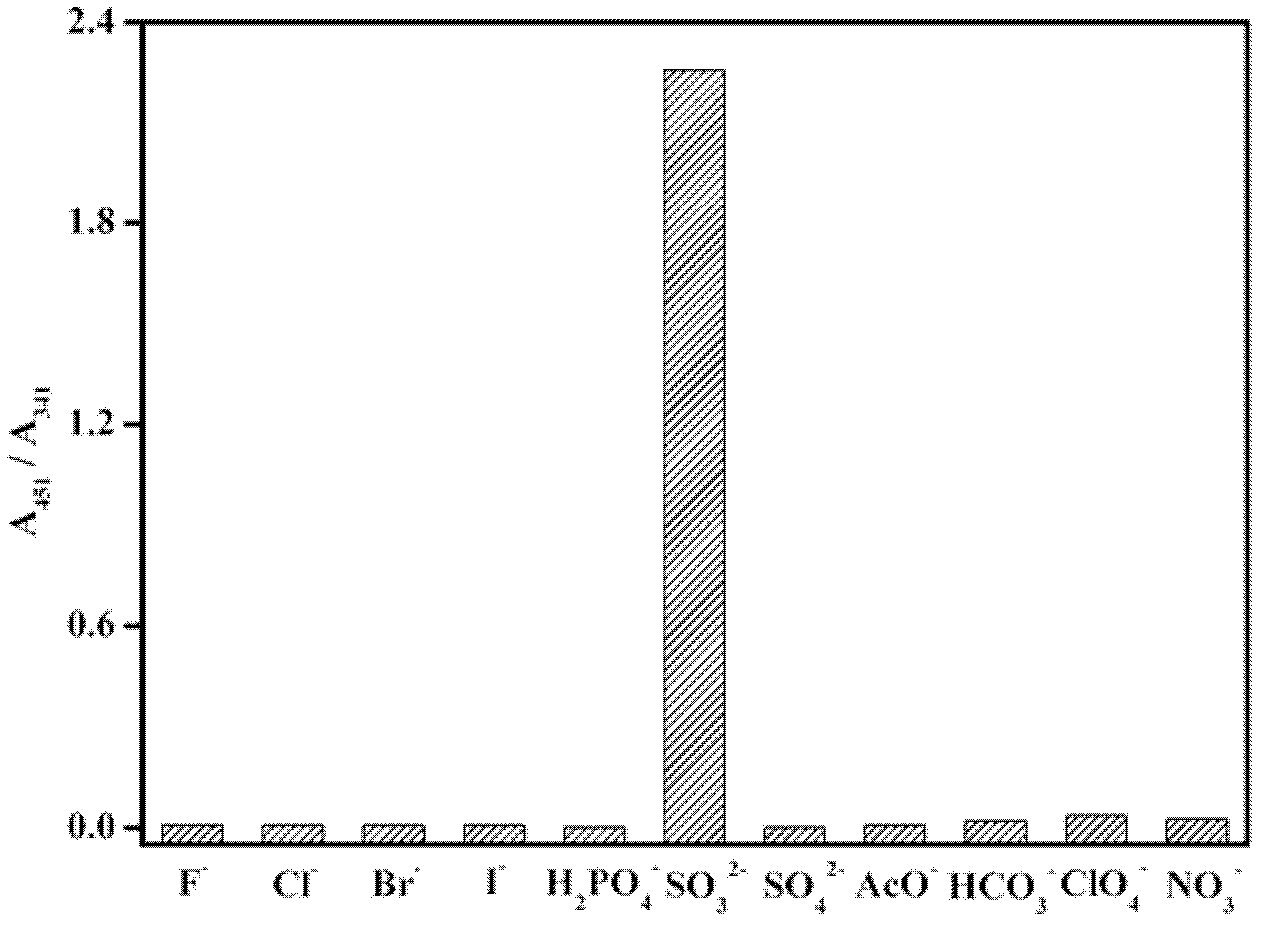

Fluorescent molecular probe for detecting sulfite ions through naked eyes and fluorescence ratio as well as synthesis and application thereof

InactiveCN102659677AHigh sensitivityStable fluorescenceOrganic chemistryColor/spectral properties measurementsMethylene DichlorideMolecular probe

The invention relates to a preparation method of a fluorescent molecular probe for detecting sulfite ions through naked eyes and fluorescence ratio as well as the application of the fluorescent molecular probe in detecting sulfite ions. The fluorescent molecular probe is prepared by condensing 4-hydroxy naphthalimide serving as raw material and acetylpropionic acid in refluent methylene dichloride. The synthesis is simple and convenient, and the reaction conditions are mild. The probe molecule provided by the invention has higher sensitivity, stable fluorescence performance, higher synthesis yield and good selectivity, and furthermore, the response range of the probe is 0-1500 mu m, the detection limit is 6 mu m; the detection range is wide, the lower detection limit is low, and the probe is suitable for naked eye detection. Meanwhile, the florescence-ratio detection is adopted to avoid errors caused by exciting light intensity, probe concentration and environment factors of an off-on type probe which detects ions only depending on the change of fluorescence intensity and the probe disclosed by the invention is not influenced by anions such as F<->, Cl<->, Br<->, I<->, HPO4<2->, SO4<2->, NO<3->, AcO<->, ClO<4->, N<3-> and HCO<3->. Even interfering ions exist, the probe has very good response to sulfite ions. Therefore, the fluorescent molecular probe has practical application value in the fields of biochemistry, environmental science and the like.

Owner:CENT SOUTH UNIV

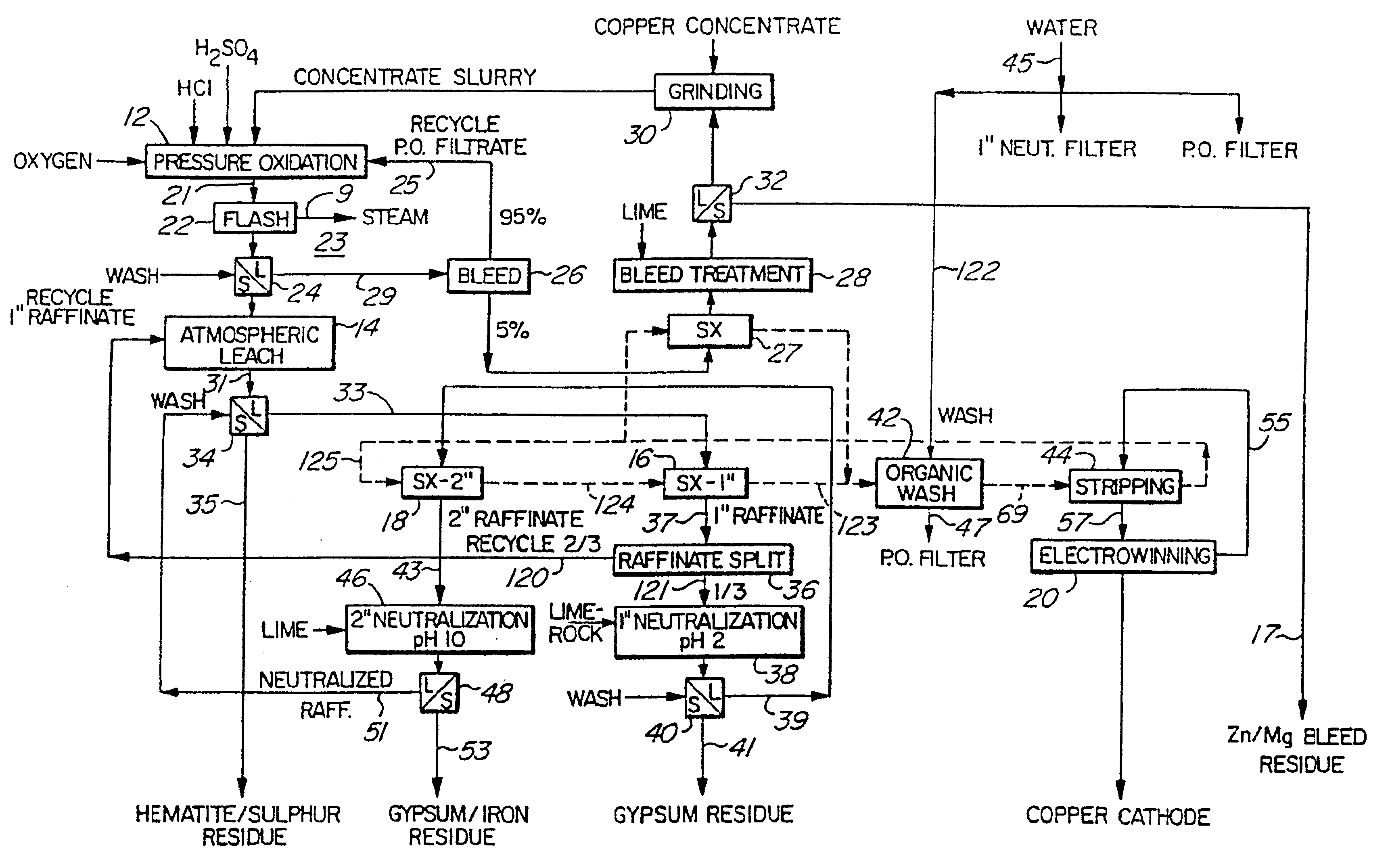

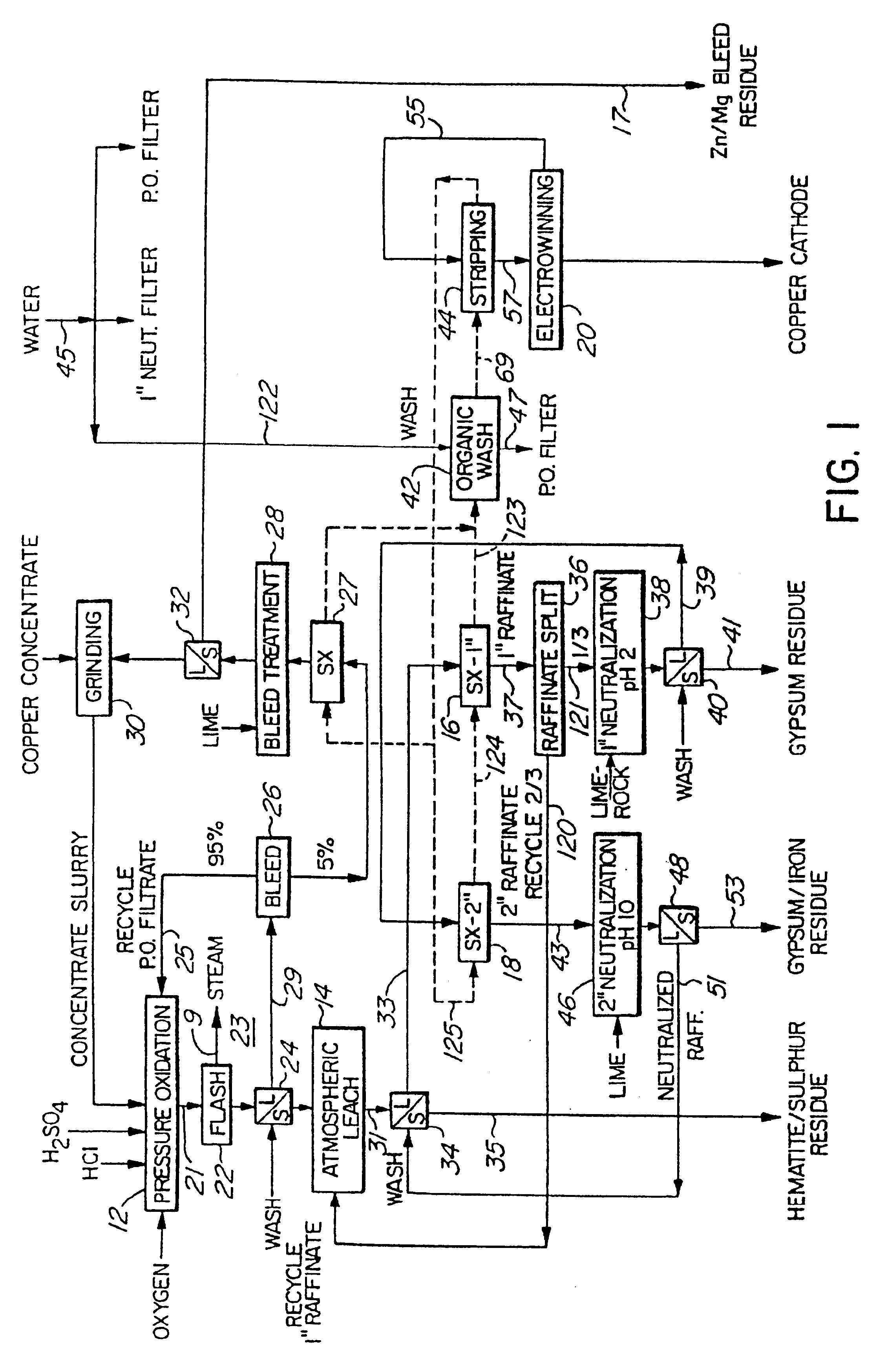

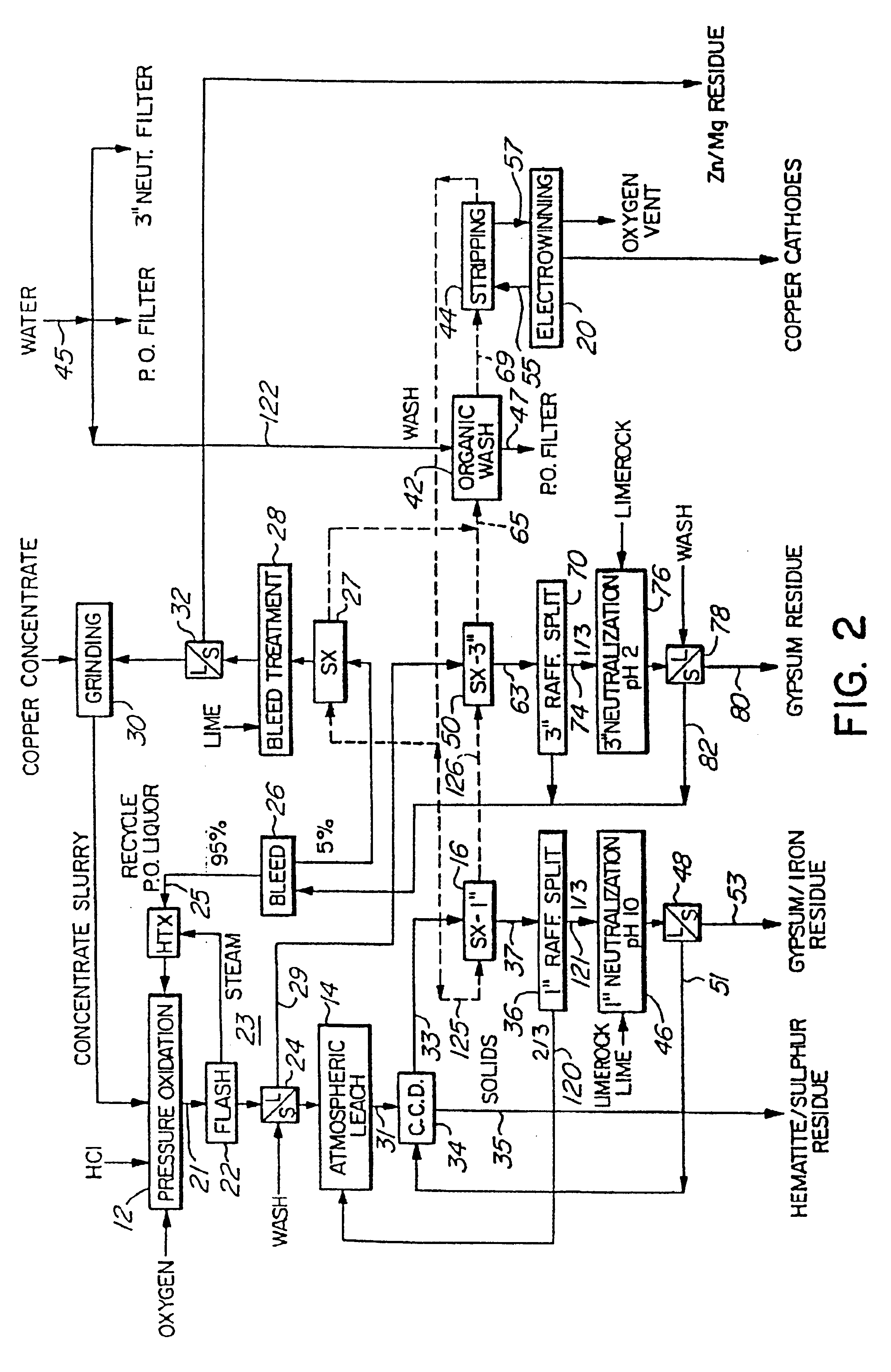

Chloride assisted hydrometallurgical extraction of metal

A process for the extraction of a metal from an ore or concentrate comprises subjecting the ore or concentrate to pressure oxidation in the presence of oxygen and an acidic solution containing halogen ions and a source of bisulphate or sulphate ions, such as H2SO4. The metals which can be extracted by the process comprises copper as well as non-cuprous metals such as zinc, nickel and cobalt. During pressure oxidation the metal may be precipitated as an insoluble basic salt, such as basic copper sulphate, or substantially completely solubilized and precipitated later as the basic metal salt.

Owner:CESL LIMITED

Purification method of wastewater containing heavy metal and arsenic

InactiveCN102765831AAdsorptiveReduce solubilityWater contaminantsMultistage water/sewage treatmentPurification methodsSlag

The invention provides a purification method of wastewater containing heavy metal and arsenic. The purification method mainly comprises the process steps as follows: adding sulfuric acid or soluble sulfate into the wastewater to supplement sulfate ions; then adding a reductant to reduce high-valence manganese, chromium and vanadium in the wastewater; adding calcium carbonate to pre-adjust the pH value of the solution; adding lime for neutralization, precipitating and separating out heavy metals and harmful elements such as arsenic from the wastewater, and packaging the precipitates in gypsum slag, discharging or reusing filtered liquid after satisfying standards, and recycling filter residue. The purification method provided by the invention has the advantages of being simple in process, good in purification effect, low in cost and environment-friendly.

Owner:CENT SOUTH UNIV

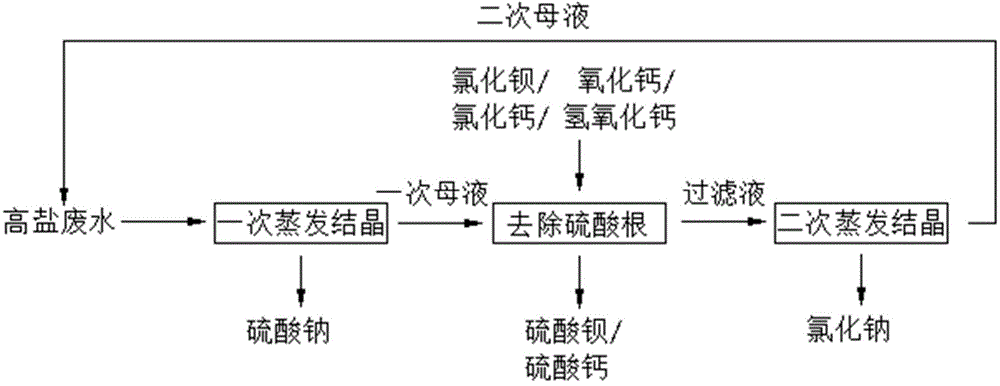

Recovery processing method of high salinity wastewater containing sodium chloride and sodium sulfate

InactiveCN104973726AHigh purityMeet quality requirementsEnergy based wastewater treatmentMultistage water/sewage treatmentResource utilizationSULFATE ION

The invention discloses a recovery processing method of high salinity wastewater containing sodium chloride and sodium sulfate, and belongs to the field of industrial wastewater treatment. According to the recovery processing method, sodium chloride and sodium sulfate are recycled via primary evaporative crystallization, removing of sulfate ions via adding of materials and generation of precipitations, and secondary evaporative crystallization. The recovery processing method can be used for effective recovery of sodium chloride and sodium sulfate in coal chemical industry high salinity wastewater; process conditions are simple and stable; the recovery processing method is convenient for industrialized popularization; recovered sodium chloride and sodium sulfate are capable of satisfying quality requirements of industrial-grade products, and can be recycled and reused directly or be sold as by-products; processing of high salinity wastewater is realized; environmental requirements are satisfied; waste is changed into valuables; salt resource utilization is realized; and factory income is increased.

Owner:SHIJIAZHUANG GONGDA CHEM EQUIP

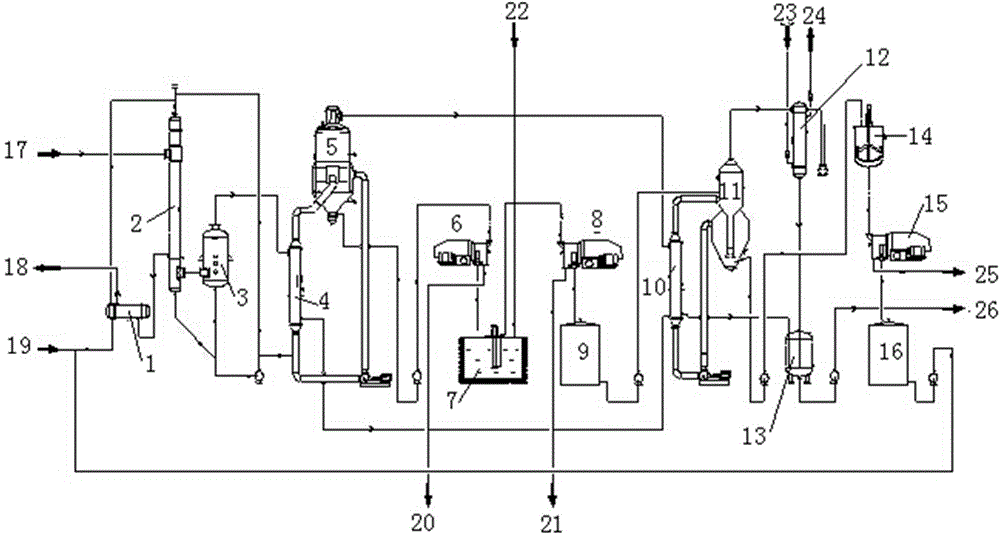

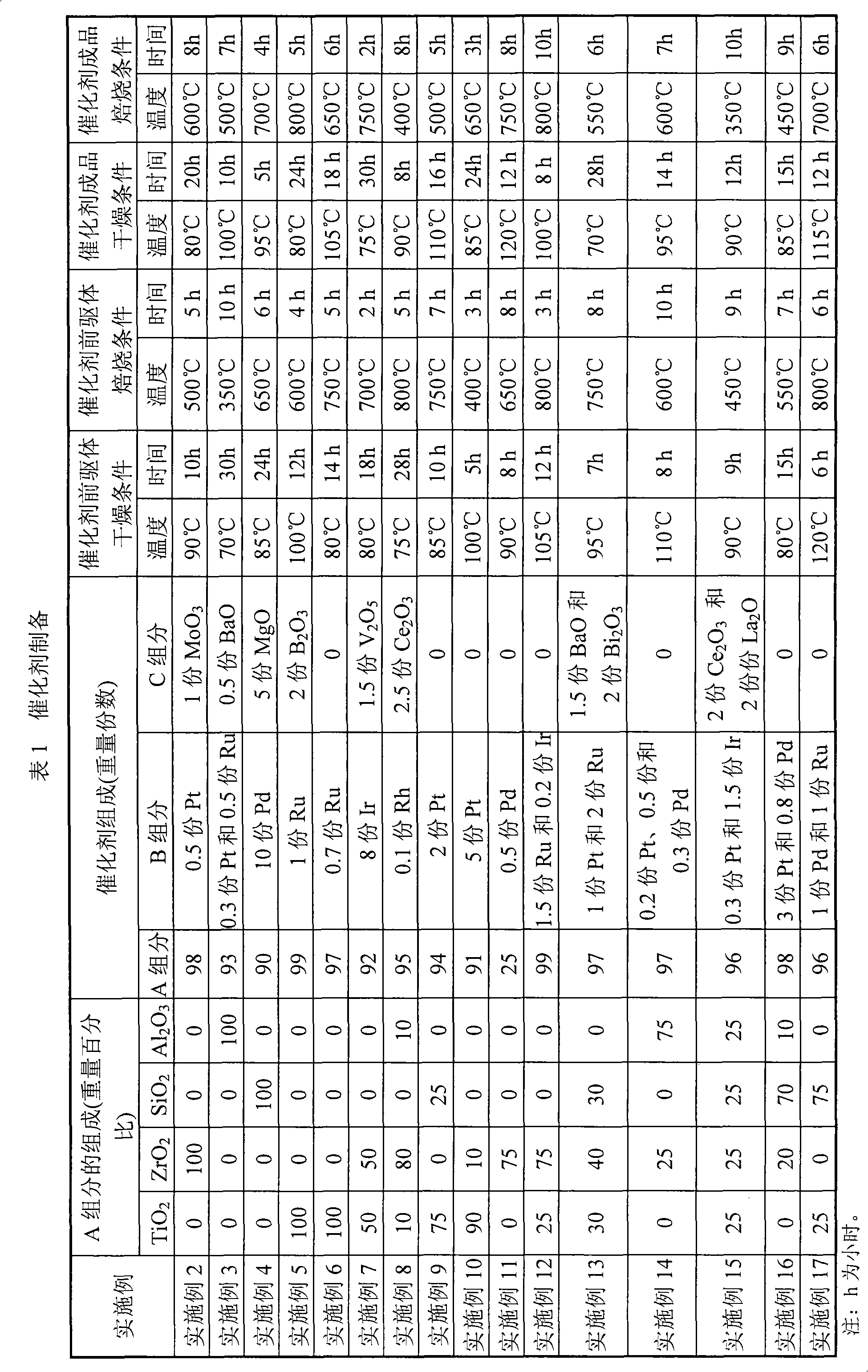

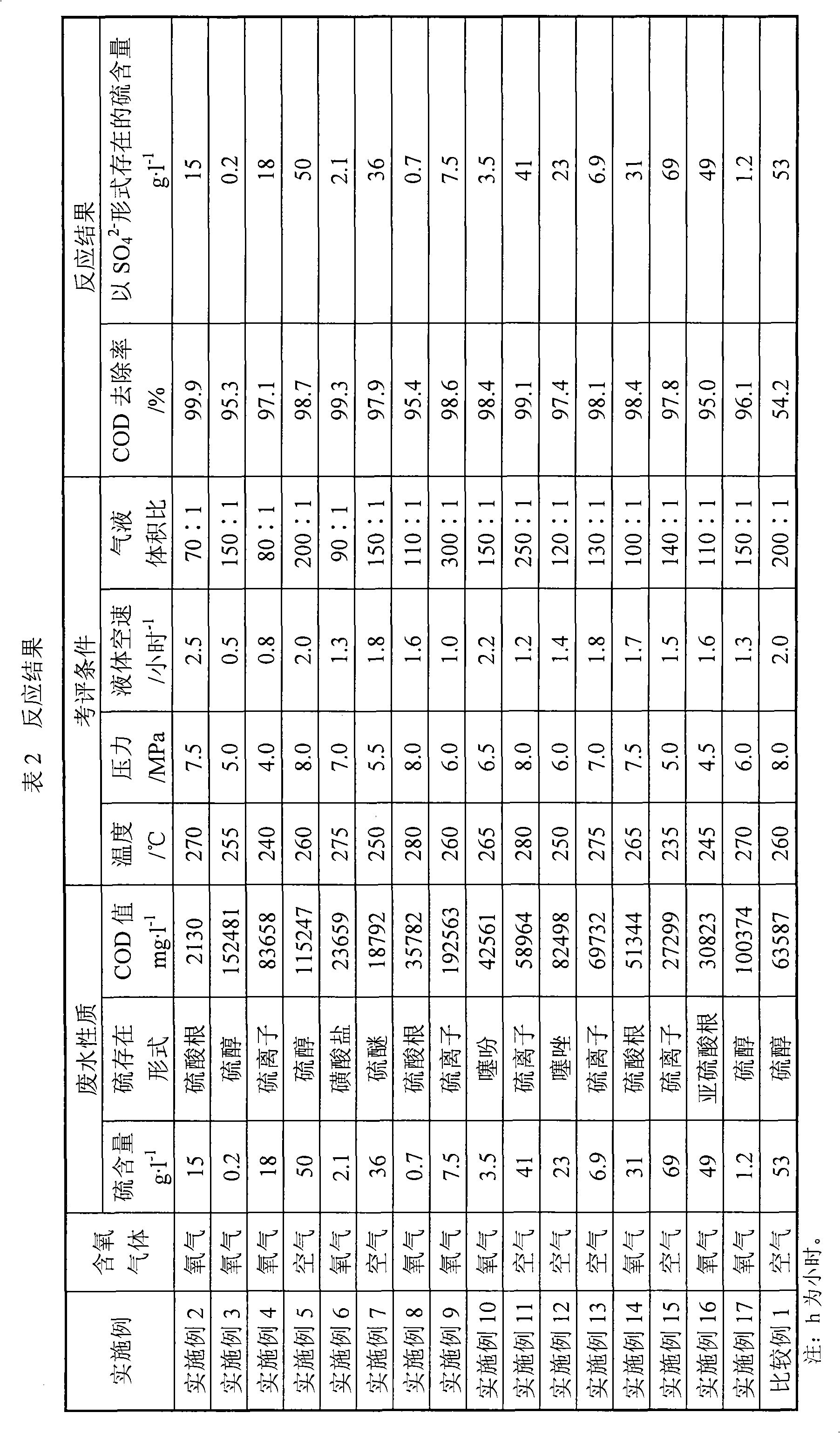

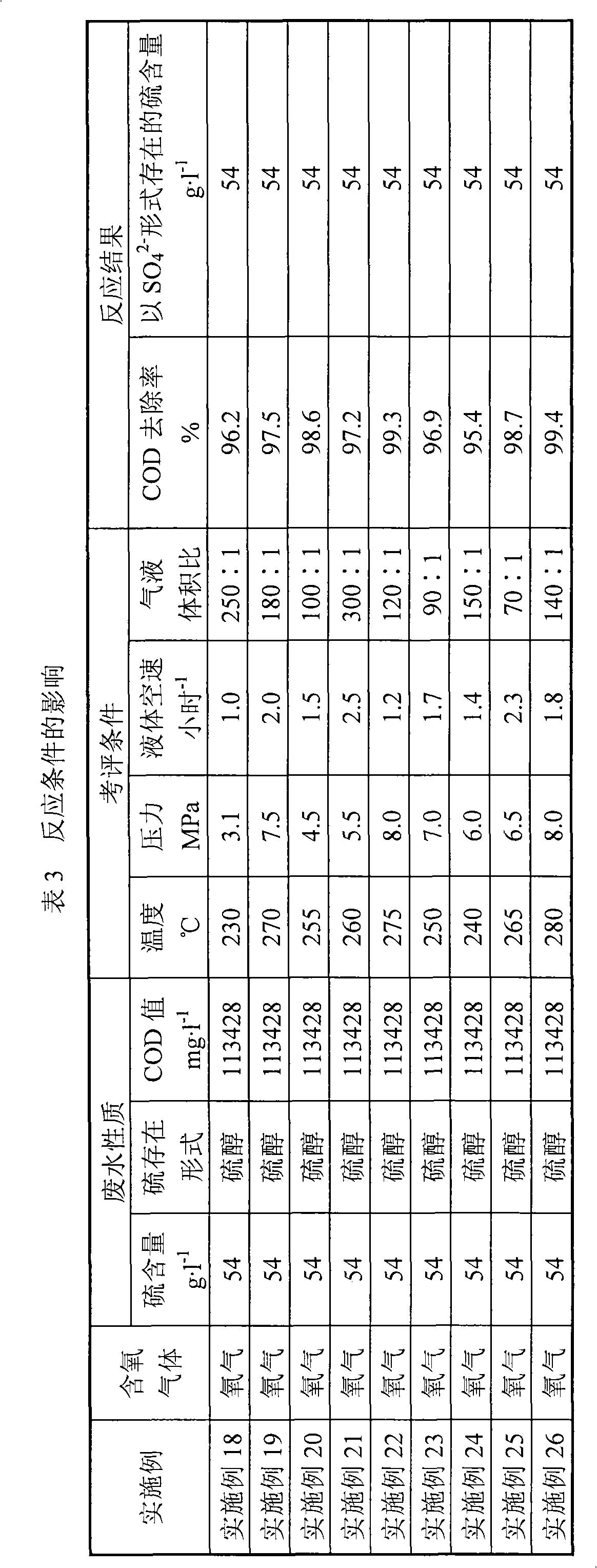

Catalysis wet-type oxidation treatment method for sulfur-containing wastewater

ActiveCN102040274ALow toxicityAvoid inhibitionMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationChemical oxygen demandReaction temperature

The invention relates to a catalysis wet-type oxidation treatment method for sulfur-containing wastewater, which is mainly used for solving the problems of biological inhibition, not high removal rate of COD (chemical oxygen demand) and complex technique for treating sulfur-containing wastewater. In the method, industrial wastewater of which the COD value is 2000mg / l to 200000mg / l and the sulfur content is less than 70g / l and gases containing elemental oxygen are taken as raw materials which are in contact with a catalyst under the conditions that the reaction temperature is 230 to 300 DEG C, the reaction pressure is 3 to 10MPa, the liquid space velocity is 0.5 to 2.5h<-1> and the volume ratio in a standard state of the gas and liquid materials is (70-300):1, and therefore, the removal rate of the COD is larger than 95% and sulfurs in the wastewater are all converted into sulfate ions, wherein the catalyst comprises at least one oxide carrier selected from TiO2, Al2O3, SiO2 or ZrO2 and at least one metal or oxide carried on the oxide carrier and selected from Pt, Pd, Ru, Ir or Rh in parts by weight. The problems are nicely solved with the technical scheme, and the catalysis wet-type oxidation treatment method for sulfur-containing wastewater can be used in the industrial treatment of sulfur-containing industrial wastewater.

Owner:CHINA PETROLEUM & CHEM CORP +1

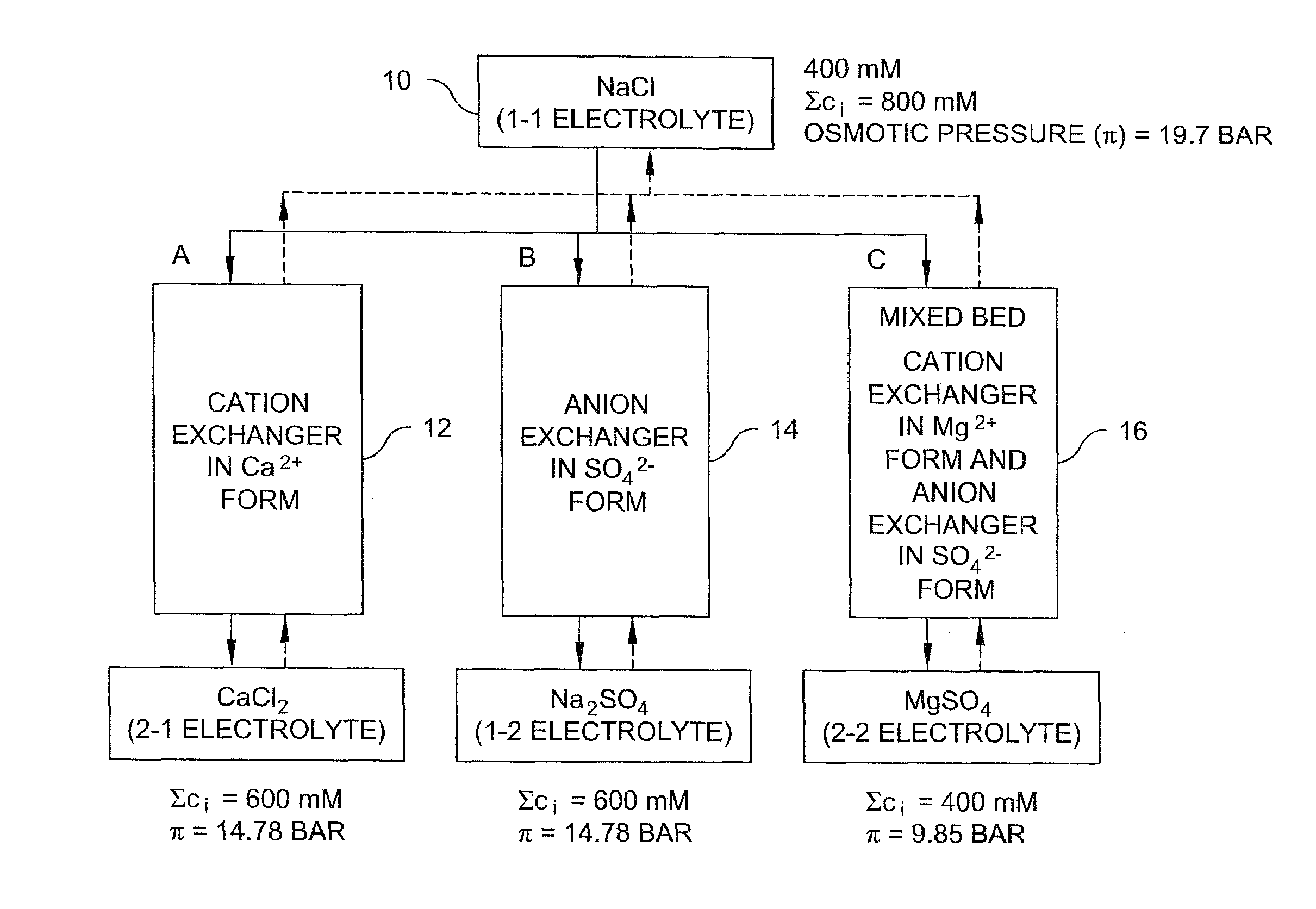

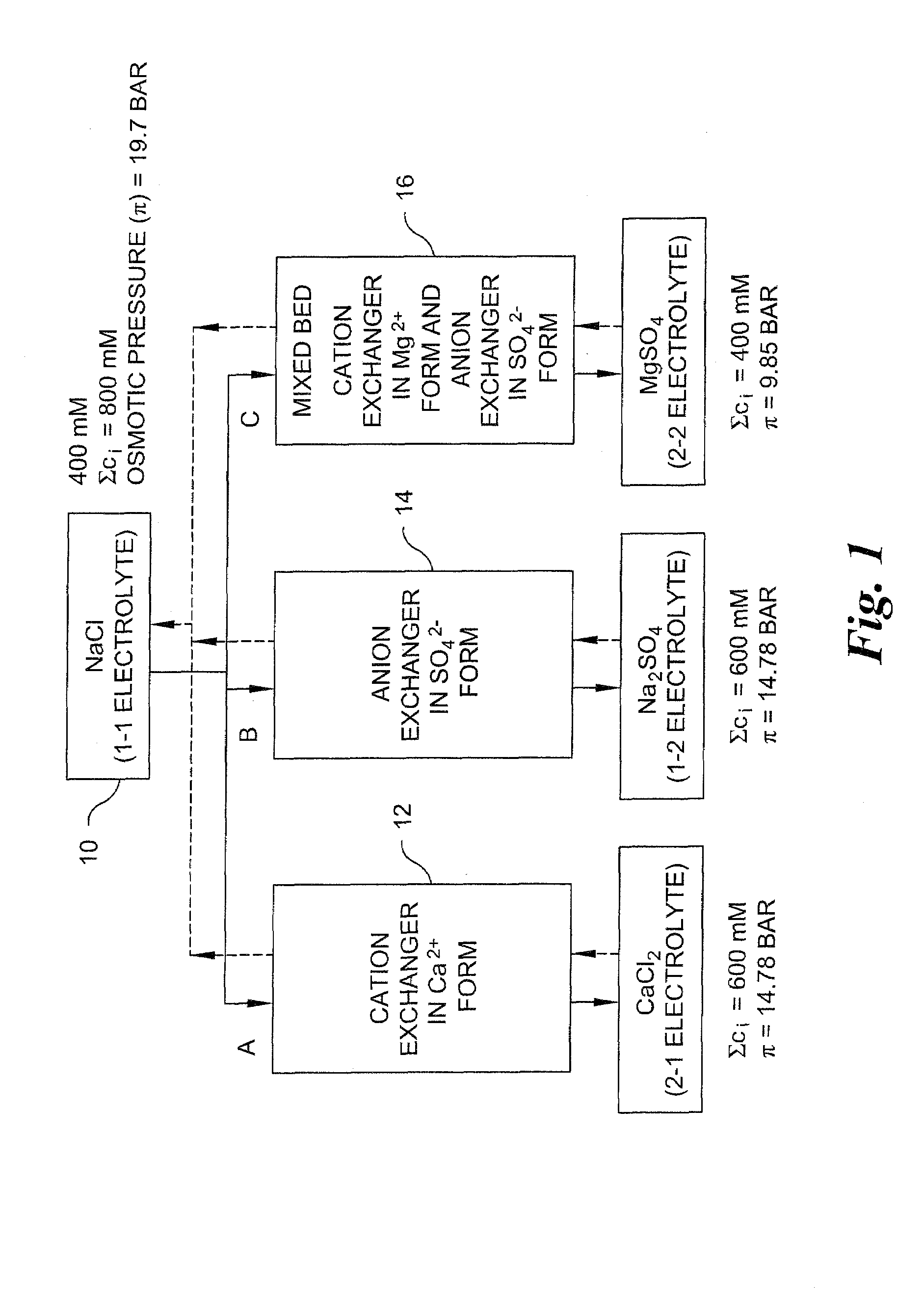

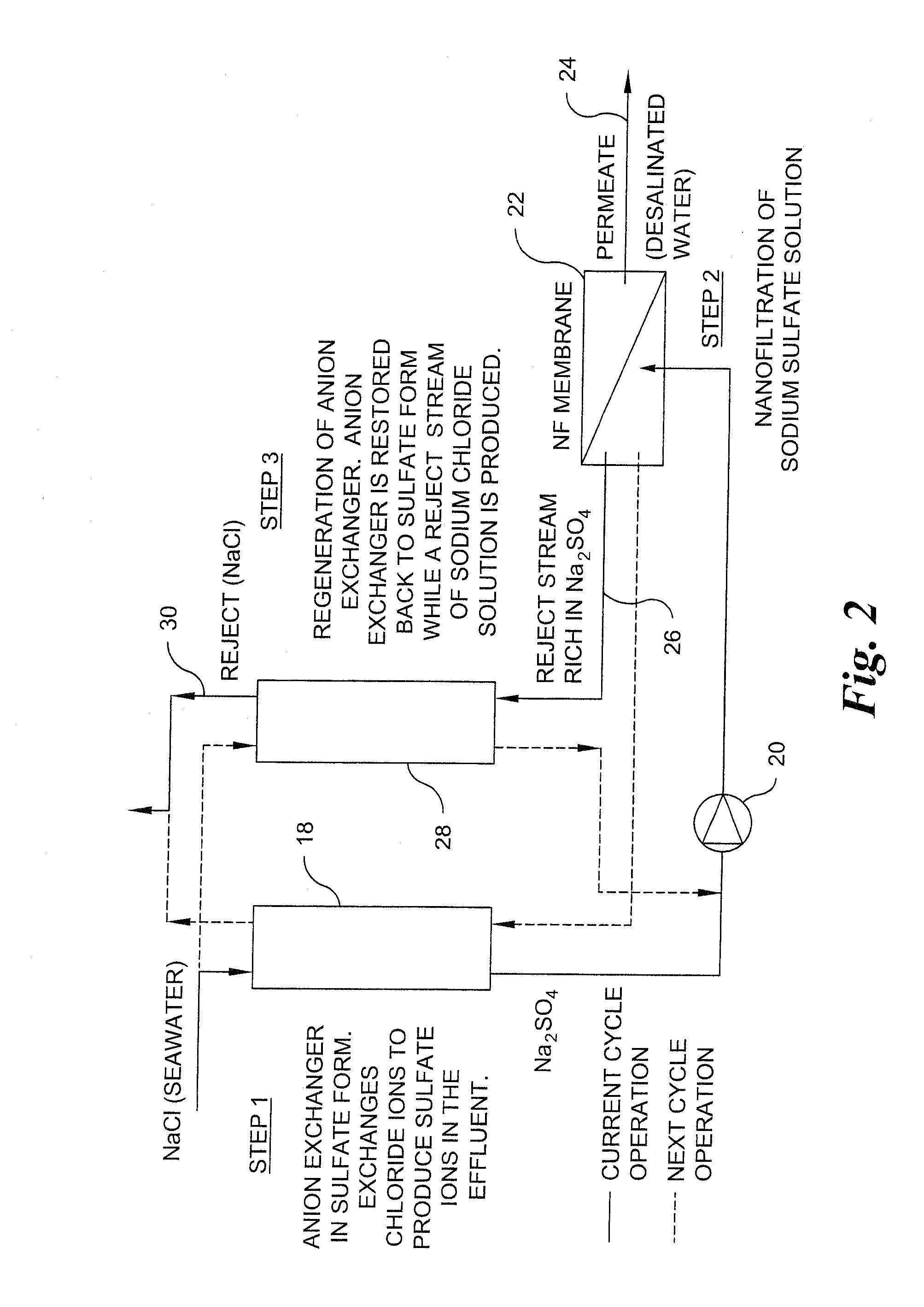

Brackish and sea water desalination using a hybrid ion exchange-nanofiltration process

InactiveUS20080277344A1Lower energy requirementsLower resistanceElectrolysis componentsGeneral water supply conservationWater desalinationPressure.drive

Desalination is carried out by a hybrid ion exchange-nanofiltration process in which ion exchange is followed by pressure-driven nanofiltration. Monovalent ions of sodium and chloride of saline water are exchanged for equivalent concentrations of poly-valent ions (for example, sodium ions for magnesium ions or chloride ions for sulfate ions) when passed through ion exchangers in the form of those poly-valent ions. The resultant solution has a lower osmotic pressure than the initial solution containing monovalent sodium and chloride ions, and requires less transmembrane pressure for membrane desalination compared to traditional reverse osmosis. The concentrated reject stream from the membrane process is used as regenerant for the exhausted ion exchanger, which has been converted to monovalent anionic or cationic form.

Owner:SENGUPTA ARUP K

Solution for etching copper surfaces and method of depositing metal on copper surfaces

InactiveCN1764739ANo loss of bond strengthImprove adhesion strengthInsulating substrate metal adhesion improvementSolid-state devicesSulfonateSULFATE ION

A solution used to etch copper or copper alloys to produce the brightest possible copper surface for subsequent metal plating. The solution has a pH of about 4 or less and contains no sulfate ions. The solution contains: a) at least one oxidizing agent selected from hydrogen peroxide and peracid; b) at least one substance selected from aromatic sulfonic acids and aromatic sulfonates; and optionally c) at least one N-heterocyclic compounds. The application also discloses a method of depositing metal onto the surface of copper or copper alloy. The method comprises the steps of a) contacting the surface with a solution according to the invention; and b) coating the surface with at least one metal. The solution and the method are particularly suitable for the production of circuit carriers, more particularly for semiconductor production.

Owner:ATOTECH DEUT GMBH

Highly hydrophobic antistatic composite coating and preparation method thereof

ActiveCN104130669AHigh strengthGood compatibilityPolyurea/polyurethane coatingsEpoxy resin coatingsSulfate radicalsPotassium manganate

The invention relates to a highly hydrophobic antistatic composite coating and a preparation method thereof. The hydrophobicity of a conventional hydrophobic material is improved mainly by adding fluorine-containing substances. The preparation method comprises the following steps: adding graphite powder and sodium nitrate into concentrated sulfuric acid, stirring in an ice bath, adding potassium permanganate, slowly dropwise adding distilled water, removing excessive potassium permanganate, filtering sulfate ions to obtain oxidized graphite, adding the oxidized graphite into an organic solvent, and ultrasonically processing to prepare an oxidized graphene solution; adding isocyanic acid, a long-chain modified substance and a reducer into the oxidized graphene solution in sequence to chemically modify oxidized graphene, washing and drying to obtain modified graphene; by taking resin as a base body, uniformly dispersing the resin and the modified graphene through ultrasonic blending or quick stirring to obtain the highly hydrophobic antistatic composite coating. The composite coating provided by the invention has hydrophobic and antistatic performances, does not contain the fluorine-containing substances, and is environment-friendly and excellent in durability.

Owner:SHAANXI UNIV OF SCI & TECH

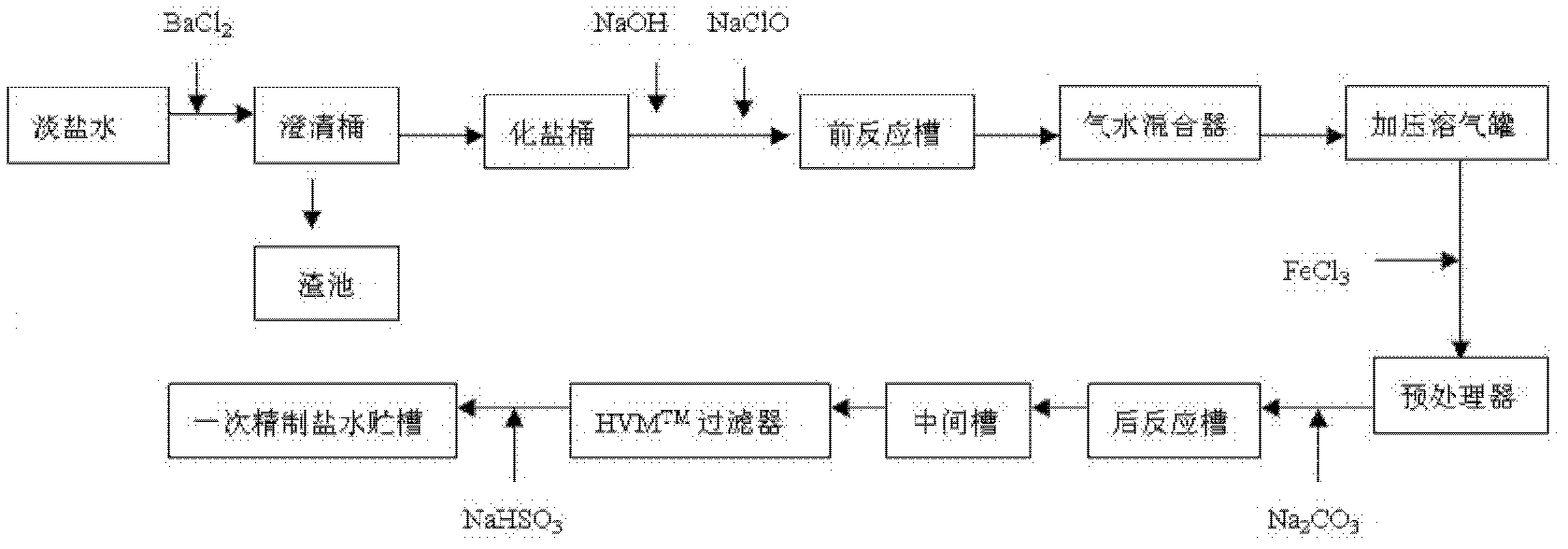

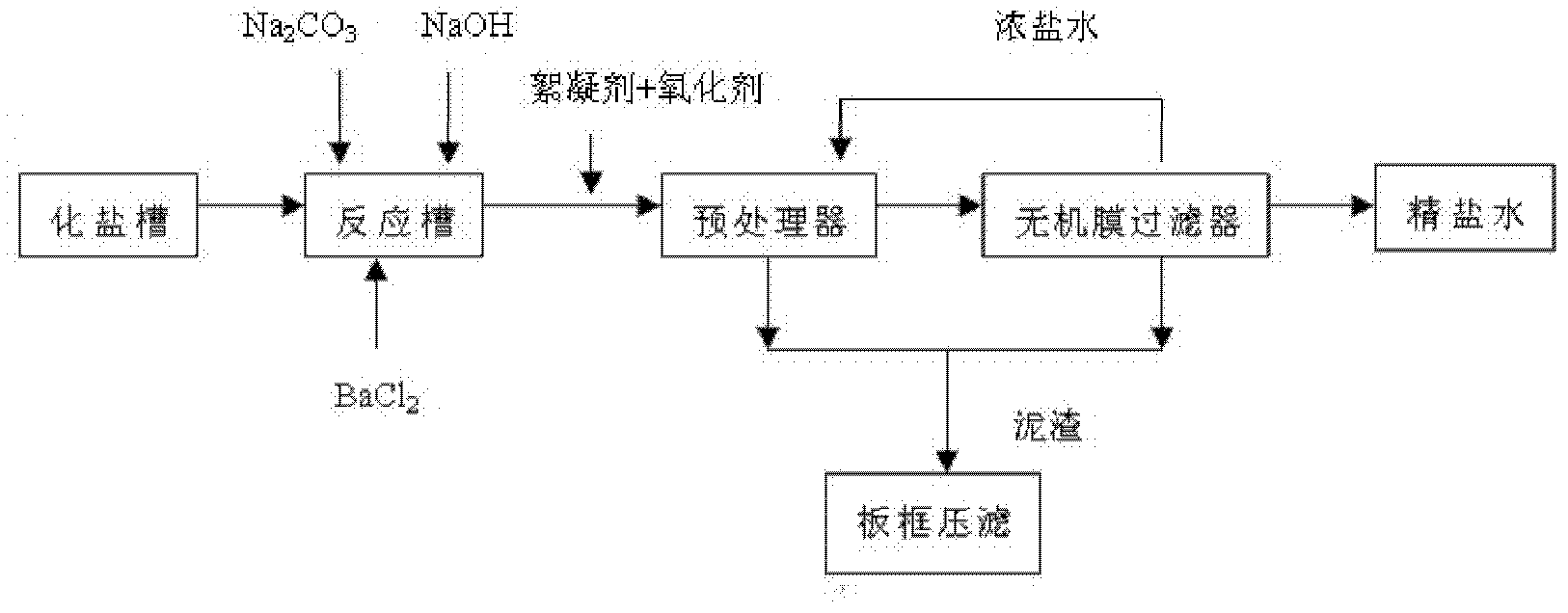

Double-membrane-method technology for refining brine and equipment for the same

ActiveCN102627300AAvoid secondary pollutionReduce manufacturing costAlkali metal halide purificationHigh concentrationUltrafiltration

The invention relates to double-membrane-method technology for refining brine and equipment for the same. After pretreatment, brine to be treated enters a filtration procedure to form high-concentration nitrate-containing water and refined brine; pretreatment refers to carrying out a removal procedure of calcium and magnesium ions, a removal procedure of ammonium, a reduction procedure and a pH adjusting procedure to the brine to be treated; the filtration procedure refers to the steps that: the pretreated brine is pumped to gas-stripping tubular type membrane module for ultrafiltration, thereby organic impurities, suspended matters and partial precipitates of the brine are intercepted; pressure raising is carried out to the brine which permeates a tubular type membrane, then the brine directly enters nanofiltration membrane module for nanofiltration; the brine which can not permeate the tubular type membrane returns the removal procedure of calcium and magnesium ions; and in a high pressure state, sulfate ions are intercepted by a nanofiltration membrane to form high-concentration nitrate-containing water, and chloride ions and sodium ions permeate smoothly the nanofiltration membrane to form refined brine. The technology in the invention is simple, low energy consumption, small land-occupation area, low investment and low production cost, a stable operation system, strong impact-resistance load capability and no secondary pollution.

Owner:CHINA PETROCHEMICAL CORP +3

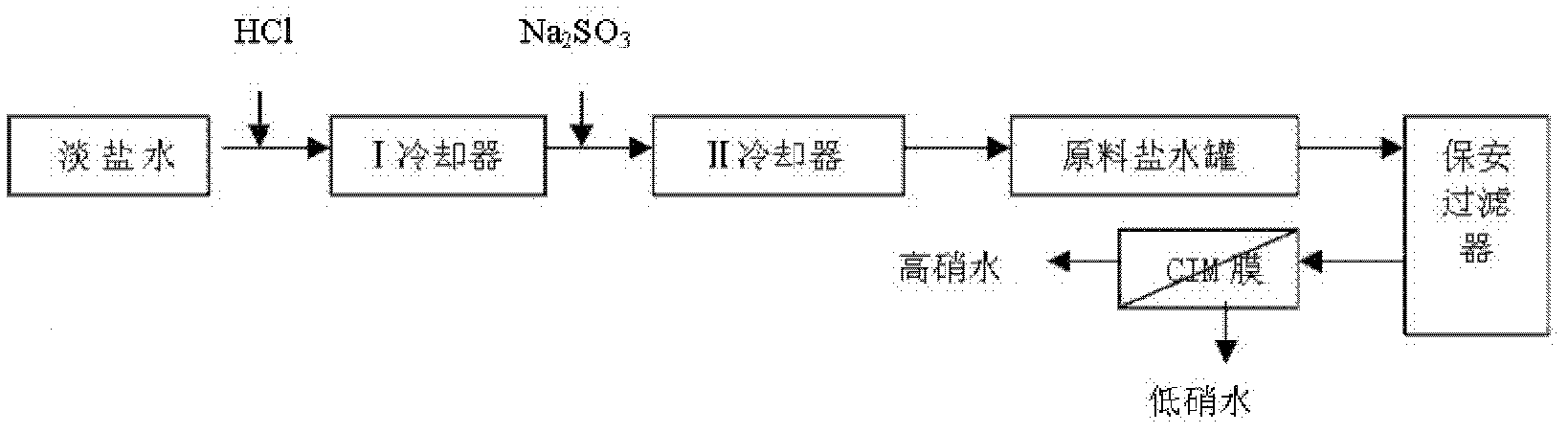

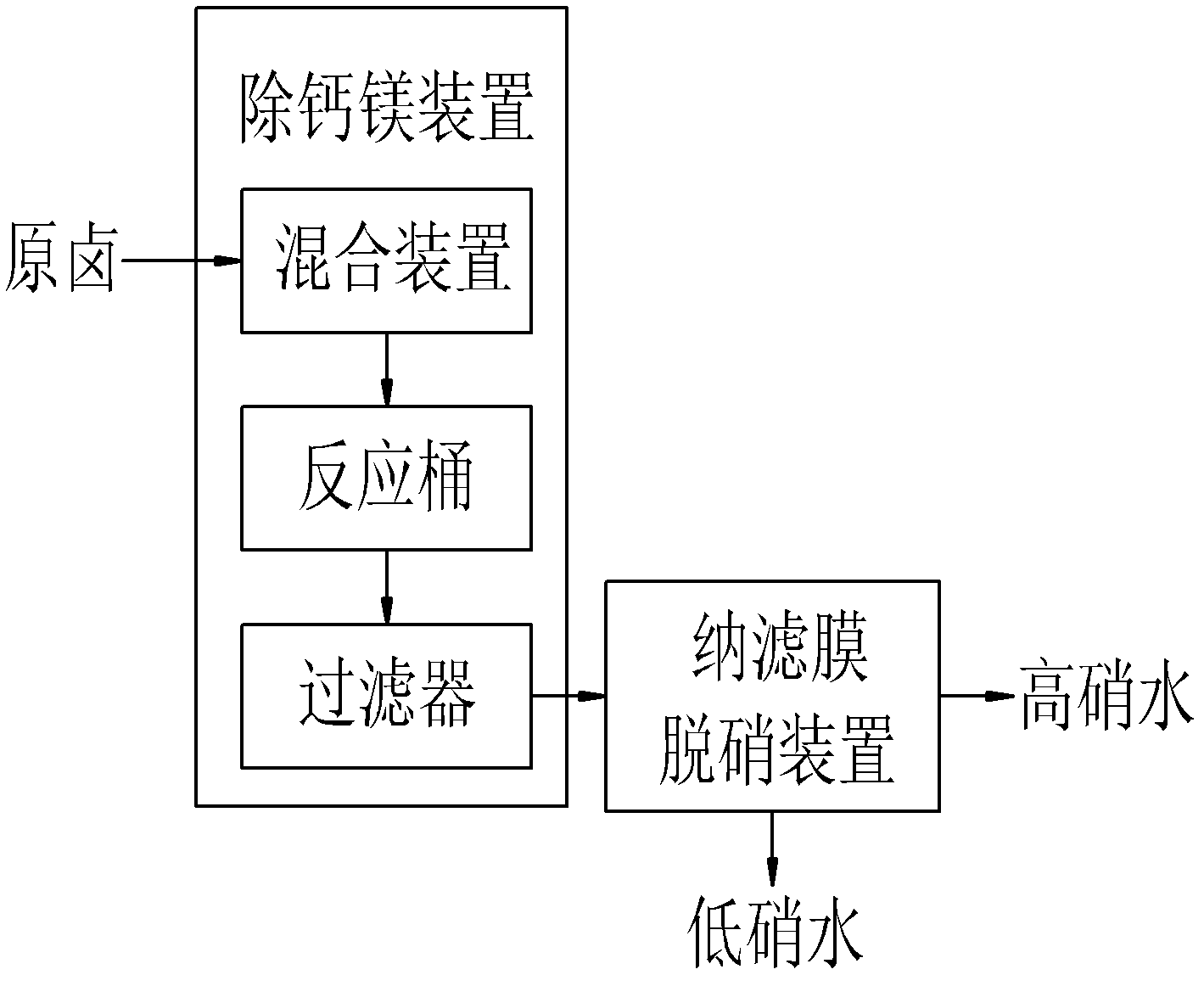

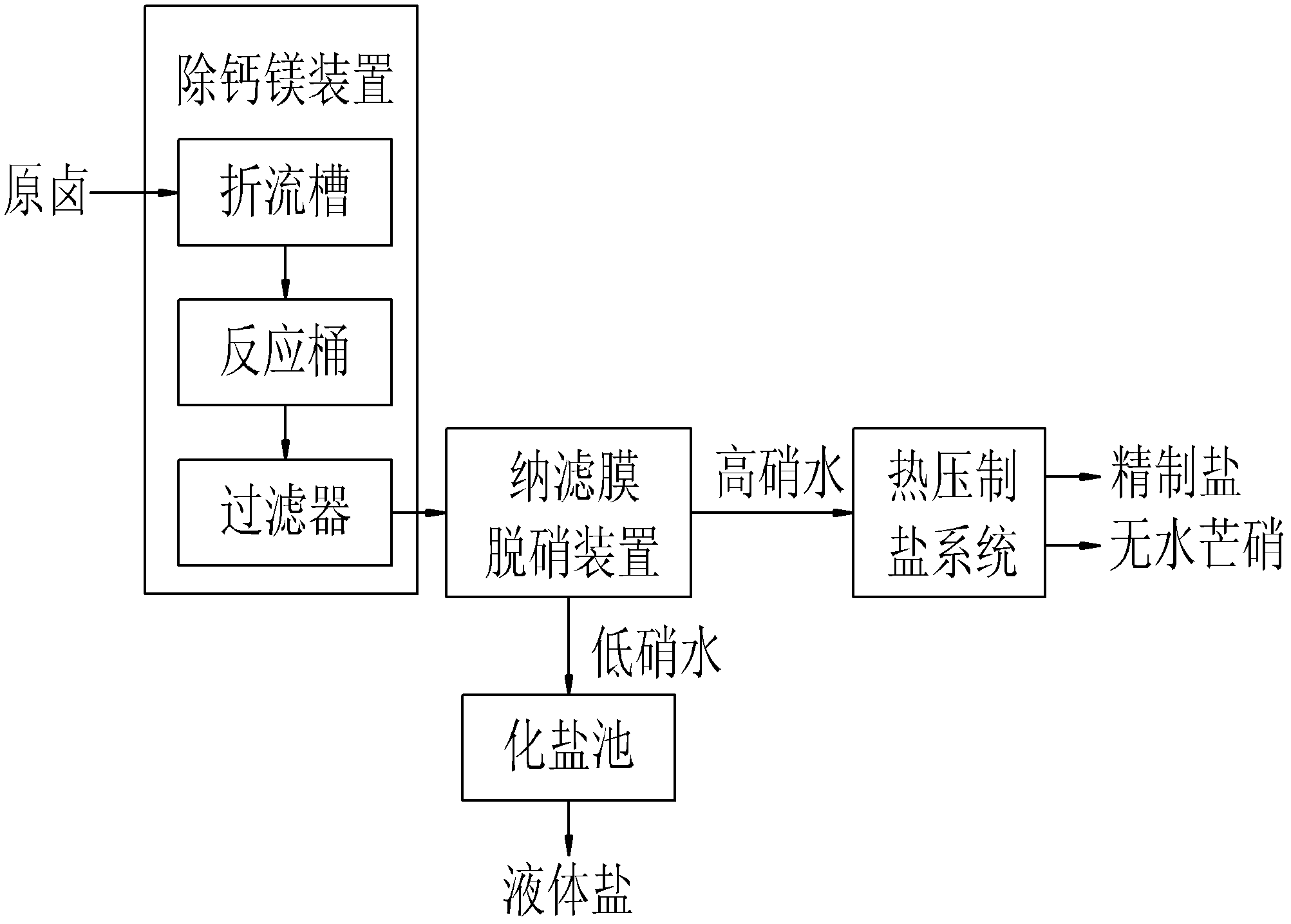

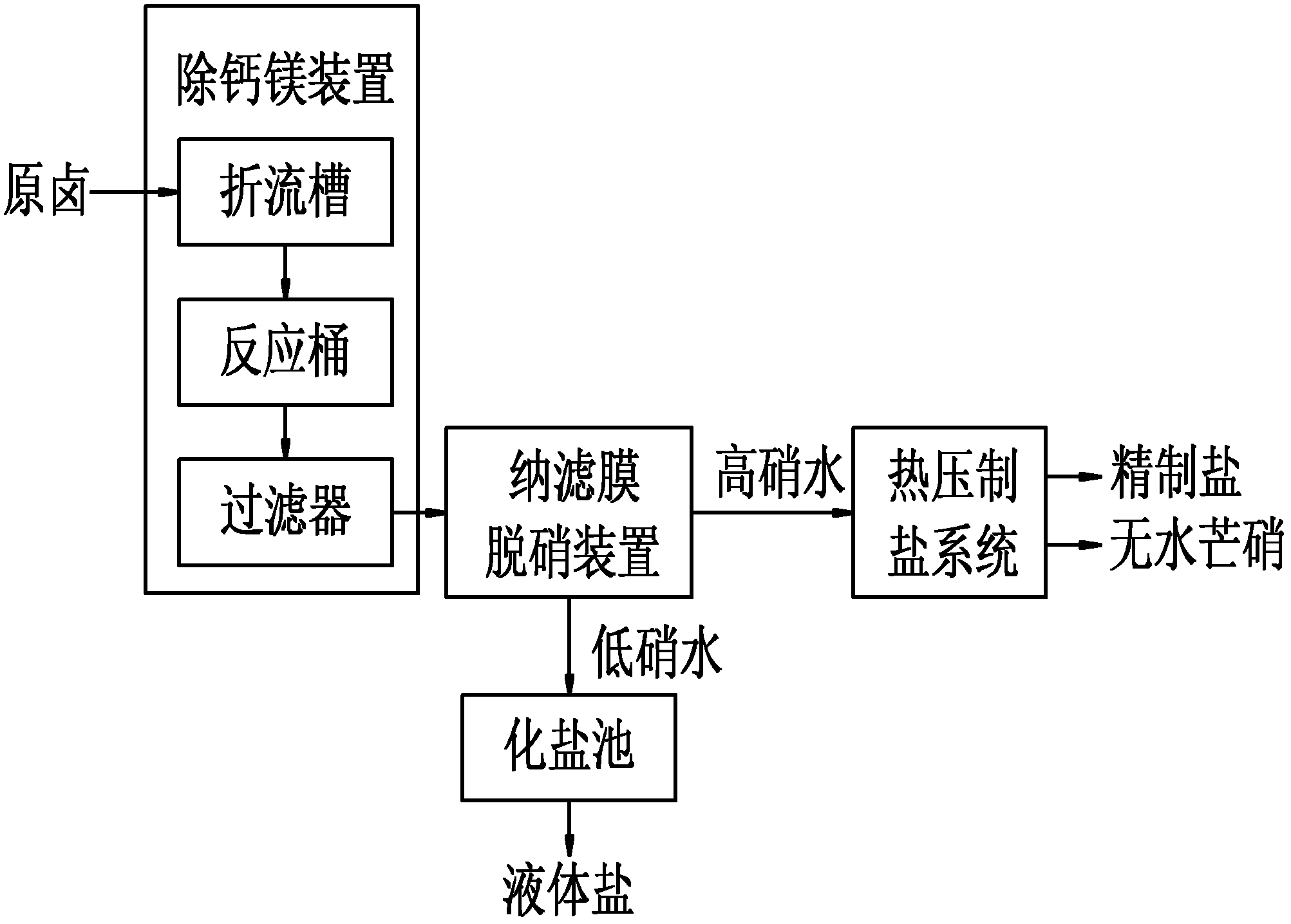

Original halogen denitration production process and production equipment

InactiveCN102432037AReduce energy consumptionReduce production energy consumptionAlkali metal chloridesAlkali metal sulfites/sulfatesFiltration membraneHalogen

The invention relates to an original halogen denitration production process and original halogen denitration production equipment. The process comprises the following steps of: 1, removing calcium ions and / or magnesium ions from original halogen extracted by a water solution method; 2, removing sulfate ions from the original halogen of which the calcium ions and / or the magnesium ions are removed by using a nano-filtration membrane denitration device; and 3, collecting high aqueous glauber salt and low aqueous glauber salt which are produced by the nano-filtration membrane denitration device respectively. In the invention, the nano-filtration membrane denitration device is used for denitrating the original halogen and can only be used for denitrating light salt brine generally in the prior art; the produced liquid salt reaches a standard of first-time salt brine, and the SO4<2-> content is less than 4g / l required by the requirement of the first-time salt brine and can be controlled to be less than 3g / l; the high aqueous glauber salt subjected to nano-filtration membrane denitration is used for preparing salt through hot press, and the energy consumption of the nano-filtration membrane denitration is about 20 percent less than that of multiple-effect vacuum evaporation; and the liquid salt has lower production energy consumption, salt slurry is not generated in the denitration method, and the denitration method is more environment-friendly compared with a chemical method.

Owner:CHINASALT JINTAN

Fine particle dispersion, coating solution for accepting layer for coloring agent for ink-jet recording sheet, ink-jet recording sheet using the dispersion, and method for producing fine particle dispersion

InactiveUS6919109B2High color densityIncrease stickinessCoatingsThermographyRoom temperatureWater soluble

The present invention provides an ink-jet recording sheet having a coloring agent accepting layer which contains a dispersion containing a cationic polymer with an average molecular weight of 60,000 or lower and having a sulfate ion concentration of 1.5% by mass or lower to the cationic polymer together with a water-soluble resin; an particle dispersion obtained by further granulating a pre-dispersion obtained by pre-dispersing a solution containing at least fine particles and a cationic polymer and the pre-dispersion and / or the particle dispersion is heated at room temperature for 5 hours or longer after pre-dispersion and / or after granulating; and a coating solution for coloring agent accepting layer obtained by adding a water-soluble resin to the particle dispersion.

Owner:FUJIFILM CORP +1

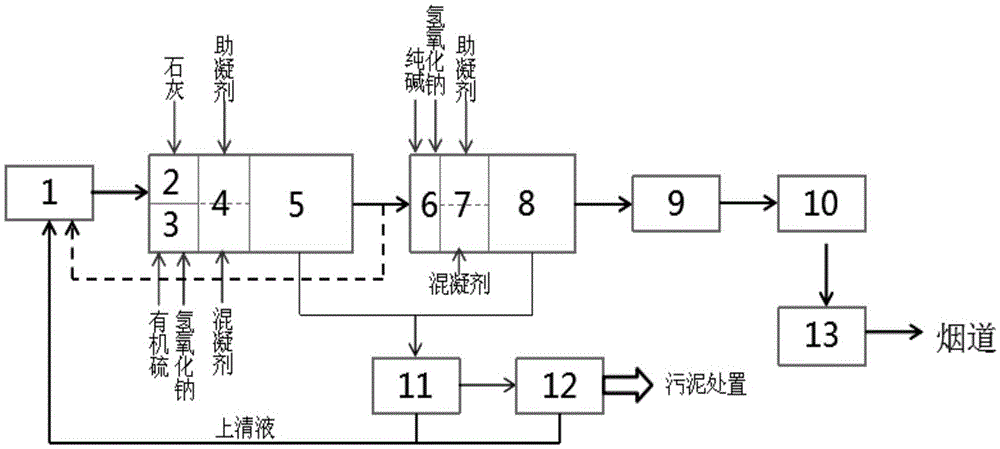

Desulfurized waste water treatment method and system

InactiveCN105540977ASimple processLow investment costWater contaminantsTreatment involving filtrationMagnesium ionSodium hydroxide

The invention provides a desulfurized waste water treatment method. The method comprises the steps that 1, desulfurized waste water enters an aeration adjusting pool, and sulfite ions in the desulfurized waste water are oxidized into sulfate ions under the action of an aeration device; 2, the desulfurized waste water is conveyed into a pH adjusting box, and lime is put into the pH adjusting box to relieve temporary hardness; 3, in a first-level reaction settling box, organic sulfur is added for further depositing heavy metal which can not be deposited in a hydroxide form; 4, in a first-level flocculation box divided into two cases, coagulant is added, many tiny floccules are condensed and formed; 5, the tiny floccules are conveyed into a first-level clarification tank so that the generated floccules and suspended solids in the waste water can be deposited and separated; 6, sodium carbonate and a sodium hydroxide solution are added into a second-level reaction settling box, and calcium ions and remaining magnesium ions in the waste water are deposited; a second-level clarification tank is used for depositing and separating the generated floccules; water produced by a multi-medium filter is sprayed into a flue to be vaporized through a spiral atomizing nozzle.

Owner:CEEP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com