Patents

Literature

394 results about "Radical ion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A radical ion is a free radical species that carries a charge. Radical ions are encountered in organic chemistry as reactive intermediates and in mass spectrometry as gas phase ions. Positive radical ions are called radical cations whereas negative radical ions are called radical anions.

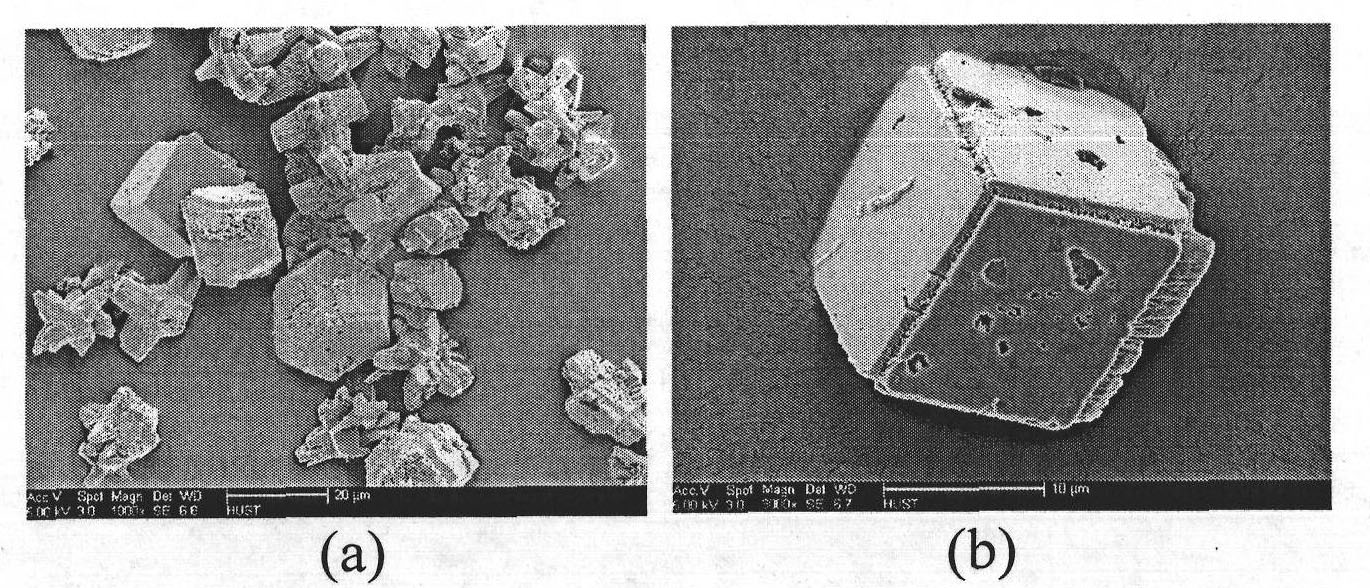

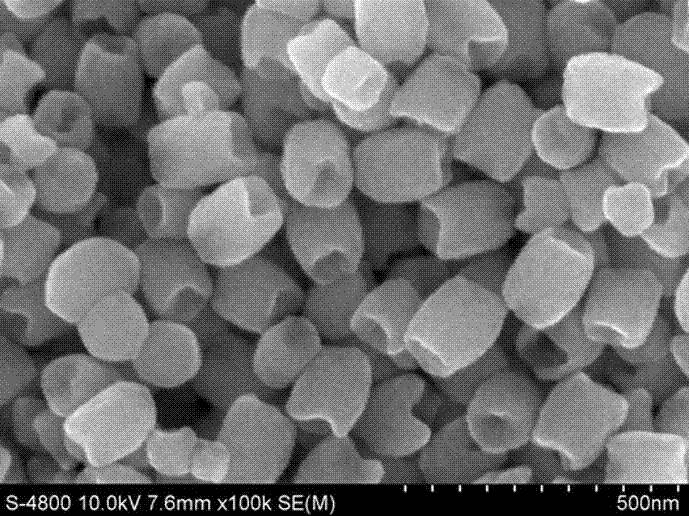

Particle appearance regulatory lithium iron phosphate preparation method

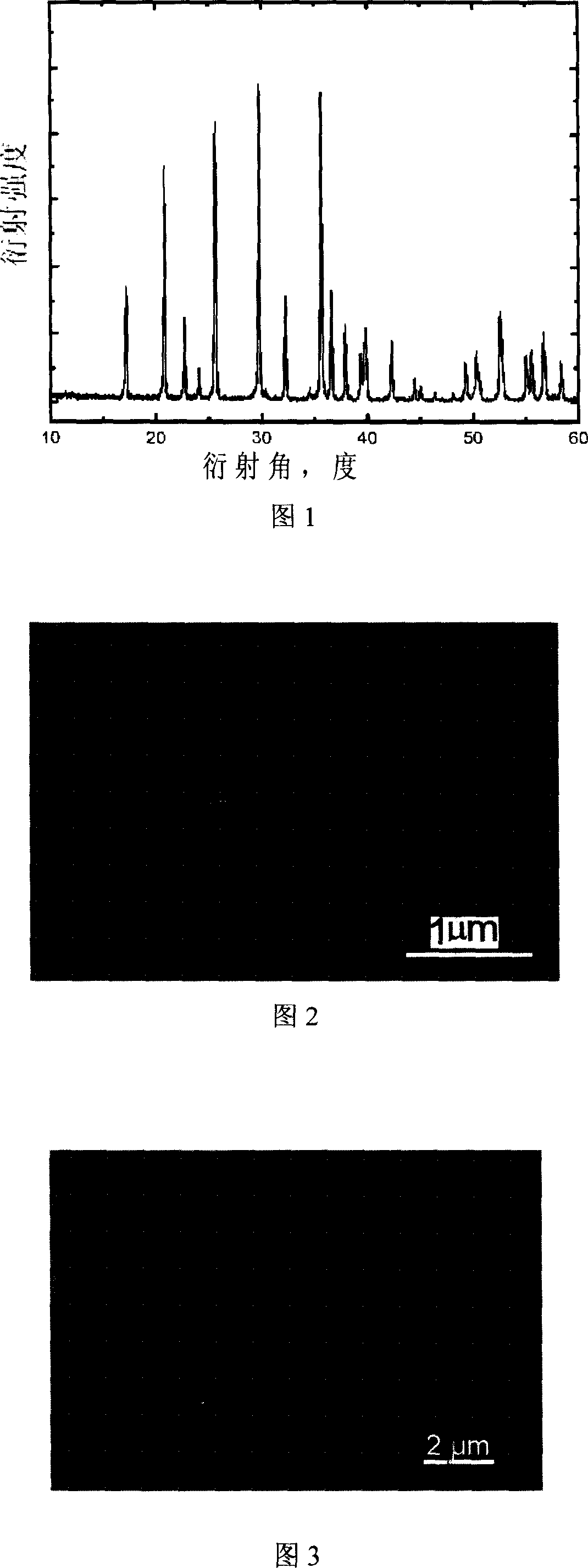

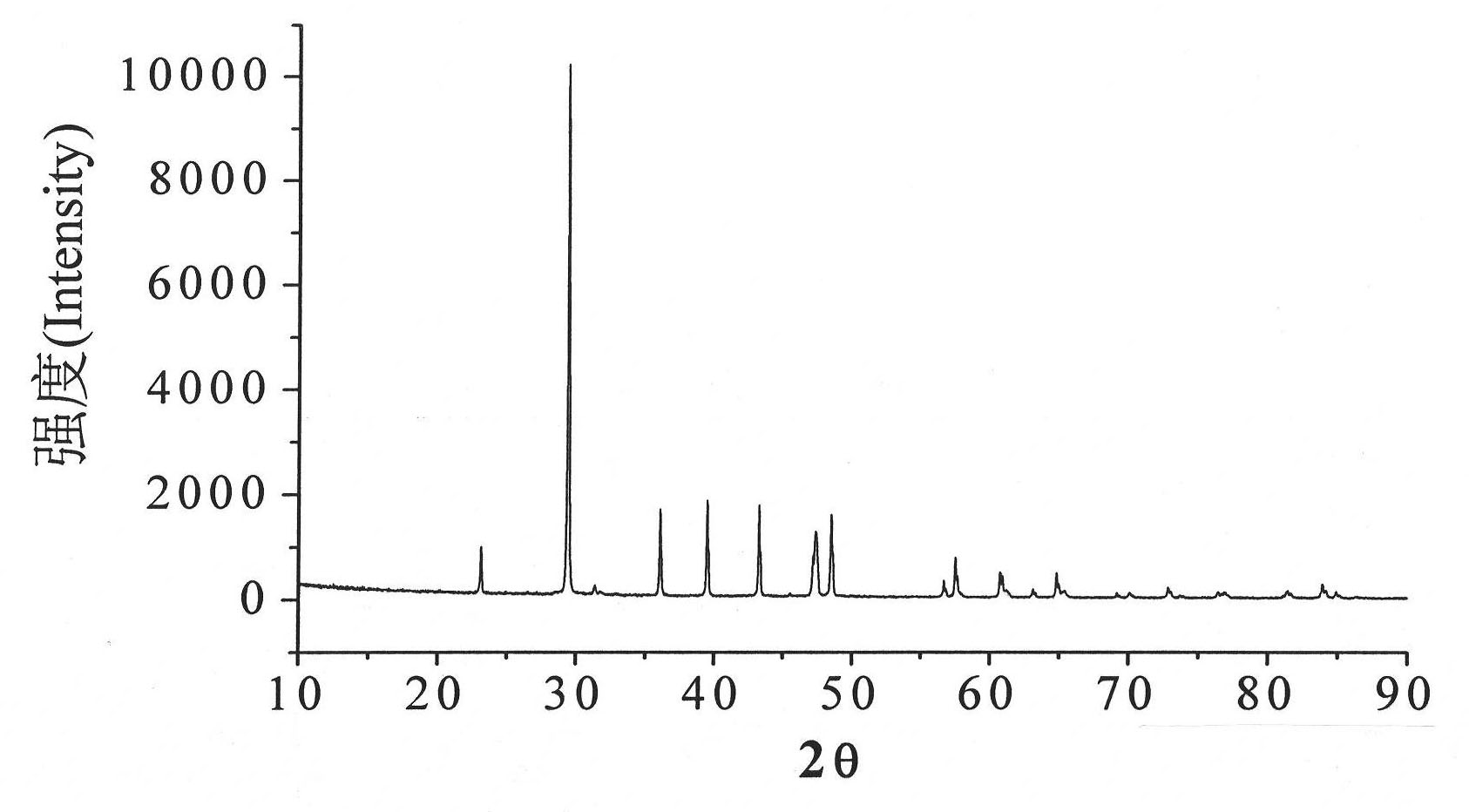

ActiveCN101007630AGood for solid phase diffusionUniform size distributionCell electrodesPhosphorus compoundsLithium iron phosphatePhosphate ion

The invention discloses a modulating method of LiFePO4 particle shape, which comprises the following steps: blending one or more composition with lithium ion, ferric ion and phosphate radical ion; adding solvent and certain quantity of crystal growing inhibitor; proceeding solvent heat reaction under certain temperature; washing; filtering; drying; sintering to improve crystallizing property; obtaining the product with regular shape and size.

Owner:QINGHAI TAIFENG XIANXING LITHIUM ENERGY TECH CO LTD

Process for producing carbon coated iron lithium phosphate

InactiveCN101172599AElectrode manufacturing processesPhosphorus compoundsShortest distancePhosphate ion

The invention relates to a preparation method of lithium iron phosphate for the carbon cladding of a lithium ion battery. The prior lithium iron phosphate preparation technical art is complex, and has high cost. The invention has the synthetic process that: ferric oxide, phosphoric acid, simple organics and doped element compound are mixed and dried, the mol ratio of phosphate radical ion, ferric ion and doped element ion is 1:y:z, wherein, y is larger than or equal to 0.95 and smaller than or equal to 1, and y plus z is equal to 1; the mixture is added with lithium source compound, added with water to be mixed and dried, the mol ratio of lithium ion and phosphate radical ion is x:1, and x is larger than or equal to 0.95 and smaller than or equal to 1.05; the mixture which reacts for 2 to 20 hours under 500 to 800 DEG C is cooled in a furnace. The invention finally produces the precursor uniformly mixed with superfine crystal grain, and during the subsequent high temperature solid phase reaction, the end product lithium iron phosphate can be produced through shorter distance diffuseness of atoms. The end product has high purity, the crystallisation is good, the capacity is high, and the cycle stability is good.

Owner:HANGZHOU DIANZI UNIV

Ternary Zn-Ni-Mn phosphorizing solution

InactiveCN1847455AImprove stabilityExtended service lifeMetallic material coating processesPhosphate ionElectrophoresis

The present invention discloses one kind of ternary Zn-Ni-Mn phosphorizing solution and its preparation process. The ternary Zn-Ni-Mn phosphorizing solution consists of zinc ion, phosphate radical ion, nickel ion, manganese ion, chlorate radical ion, nitrate radical ion, fluorine ion, promoter A, additive B and complexing agent C in certain proportion. The present invention can form compact and homogeneous phosphide film with high base resistance and high corrosion resistance, and is suitable for the phosphorizing treatment of cathode before electrophoresis coating.

Owner:WUHAN UNIV

Method of preparing hydroxyl apatite bioceramic film by plasma micro-arc oxidization method

InactiveCN101054708AComposition is stableStable structureSurface reaction electrolytic coatingPlasma electrolytic oxidationMicro arc oxidation

The present invention relates to a process for preparing hydroxylapatite bio-ceramic membranes at titanium or titanium alloy surfaces by utilizing differential arc oxidation process. Firstly, preparing electrolytic solution A by using calcium ion salts and phosphate radical ion-containing salts, or preparing electrolytic solution B by adding metal silver ions to the electrolytic solution A; or preparing electrolytic solution C by adding metal silicon ions to the electrolytic solution A; and then, selecting titanium or titanium alloy as anodes and putting them respectively into the electrolytic solution A, B and C, selecting the non-corrodible steel container for containing the electrolytic solutions as cathodes, controlling conditions such as impulse electrical source positive phase voltage, frequency for differential arc oxidation of titanium or titanium alloy, then hydroxylapatite bio-ceramic membrane layers possessing different performances are prepared. Said titanium based bio-ceramic compound material prepared according to said process possesses not only intensity and toughness of metals but also biological activity of hydroxylapatites, and is capable of being applied in the fields such as jackstraw chirurgery implantation body and tooth planting body.

Owner:QINGDAO UNIV OF SCI & TECH

Process for synthesizing LiFePO4 as positive electrode materials of lithium ion cell

InactiveCN1837033AEvenly distributedImprove charging capacityCell electrodesPhosphorus compoundsCompound aPhosphate ion

The invention discloses a Synthesis of lithium ferrous phosphate which is anode material of lithium ion battery. The material synthesis is as follows: geeting lithium salt, malysite and mammonium dihydrogen phosphate, according to the mole ratio of lithium ion: iron ion: phosphate radical ion is (0.8-1.2):(0.8-1.2):(0.8-1.2), getting compound A of equal proportion, joining some compound A in aqueous solution B which contains soluble salt and soluble organic species, putting it in high temperature furnace, then cooling naturely, compounding ferrous phosphate powder containing carbon and adulterating metal ion, milling the synthetical aqueous lithium solution powder, controllong the grain diameter between 1-50 mum. The synthetical material of this invention distribute equally, using this material as positive material can improve batteries' charging capacity effectively.

Owner:SHANDONG UNIV OF SCI & TECH

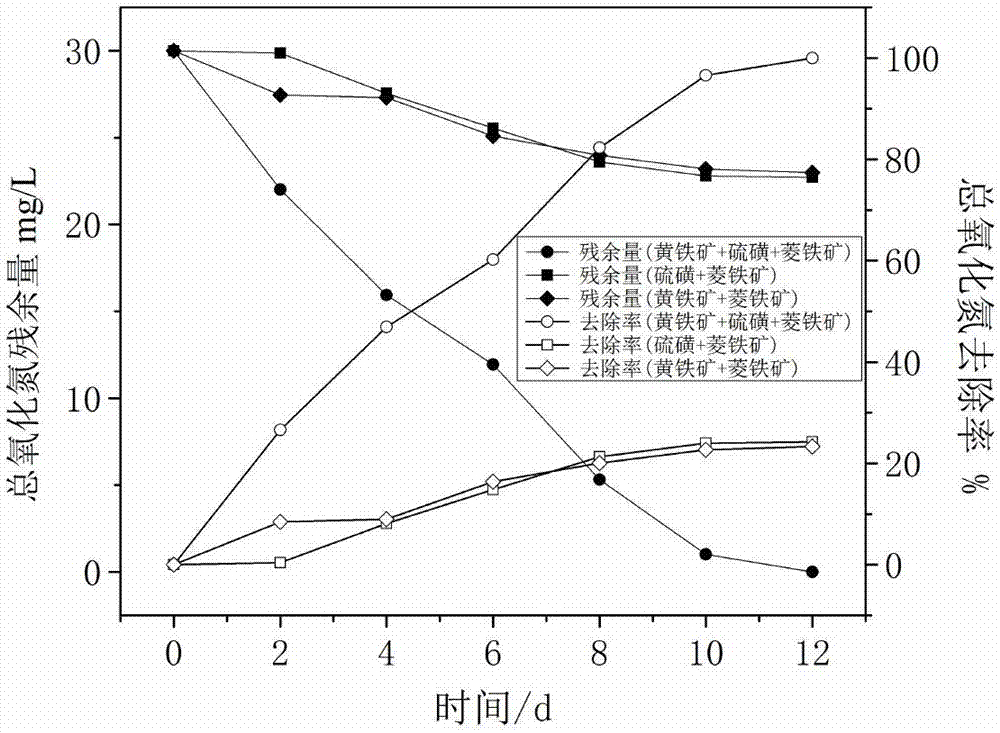

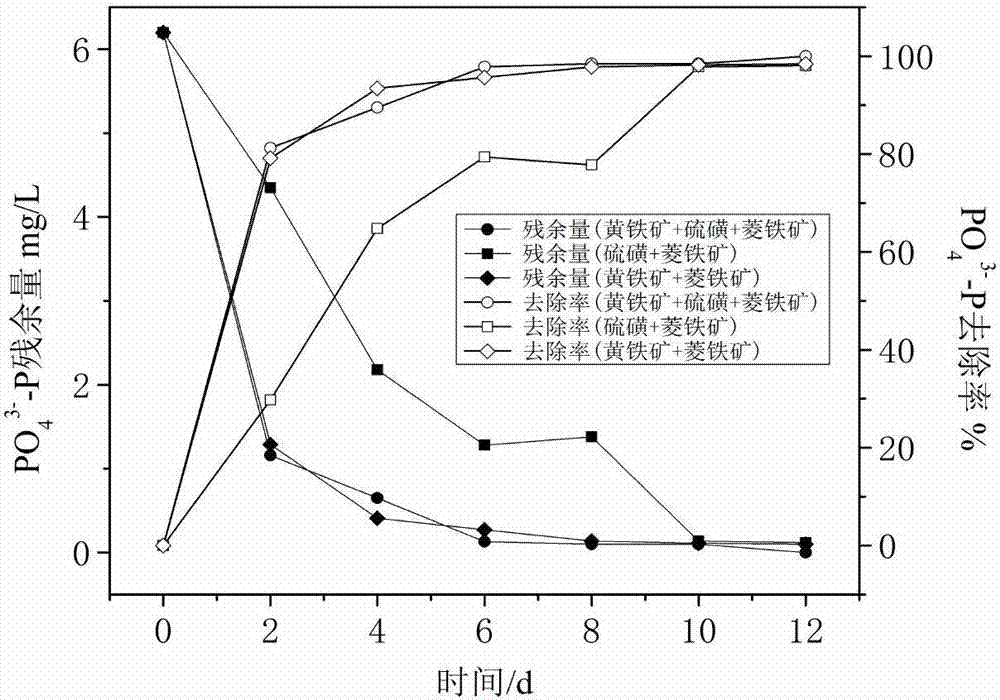

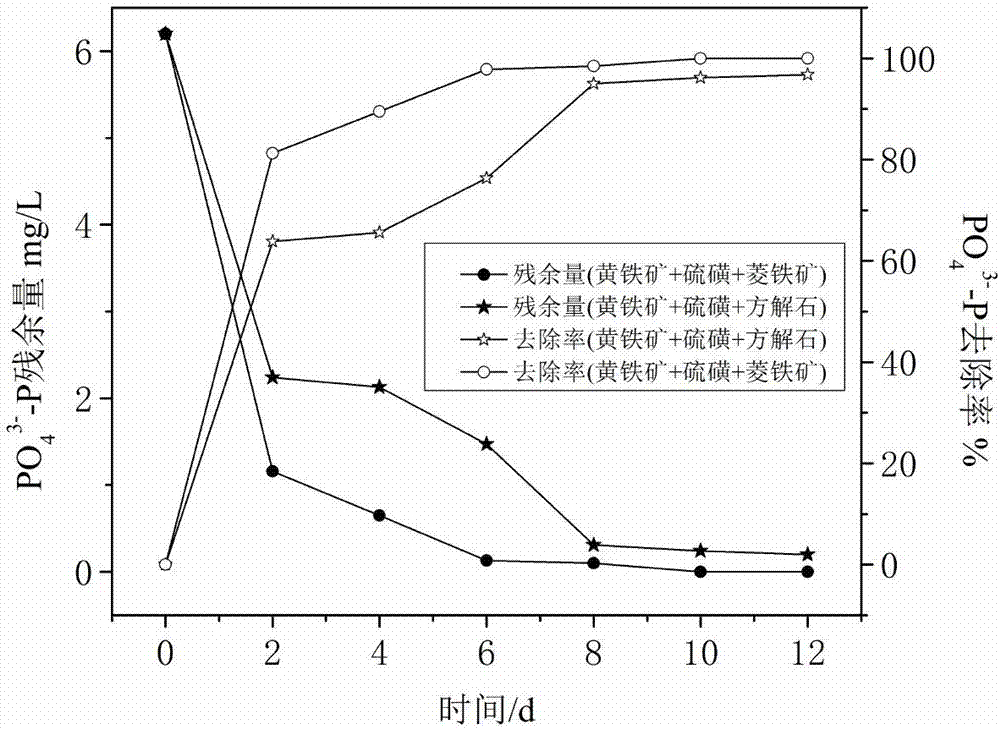

Sewage treatment method for simultaneously removing phosphor and nitrogen in process of reinforcing autotrophic denitrification of sulfur

ActiveCN107176702AOptimizationImprove denitrification effectWater treatment compoundsWater contaminantsPhosphate ionSiderite

The invention discloses a sewage treatment method for simultaneously removing phosphor and nitrogen in a process of reinforcing autotrophic denitrification of sulfur and belongs to the technical field of sewage treatment. According to the method, pyrite, sulfur and siderite are adopted for strengthening a denitrification process of the wastewater and the effect of simultaneously removing phosphor and nitrogen is promoted. According to the method, pyrite and sulfur are used as sulfur sources and siderite is used as a carob source in a reaction system. The synergistic effect of the pyrite and sulfur can strengthen the utilization of the thalli for the siderite, so that the denitrification capacity can be reinforced. The ferric and ferrous ions, which are released by pyrite and siderite, and phosphate radical ions can form the ferric phosphate sediment, so that the dephosphorization capacity is reinforced. The method has an excellent effect, is low in cost and is suitable for engineering application.

Owner:NANJING UNIV

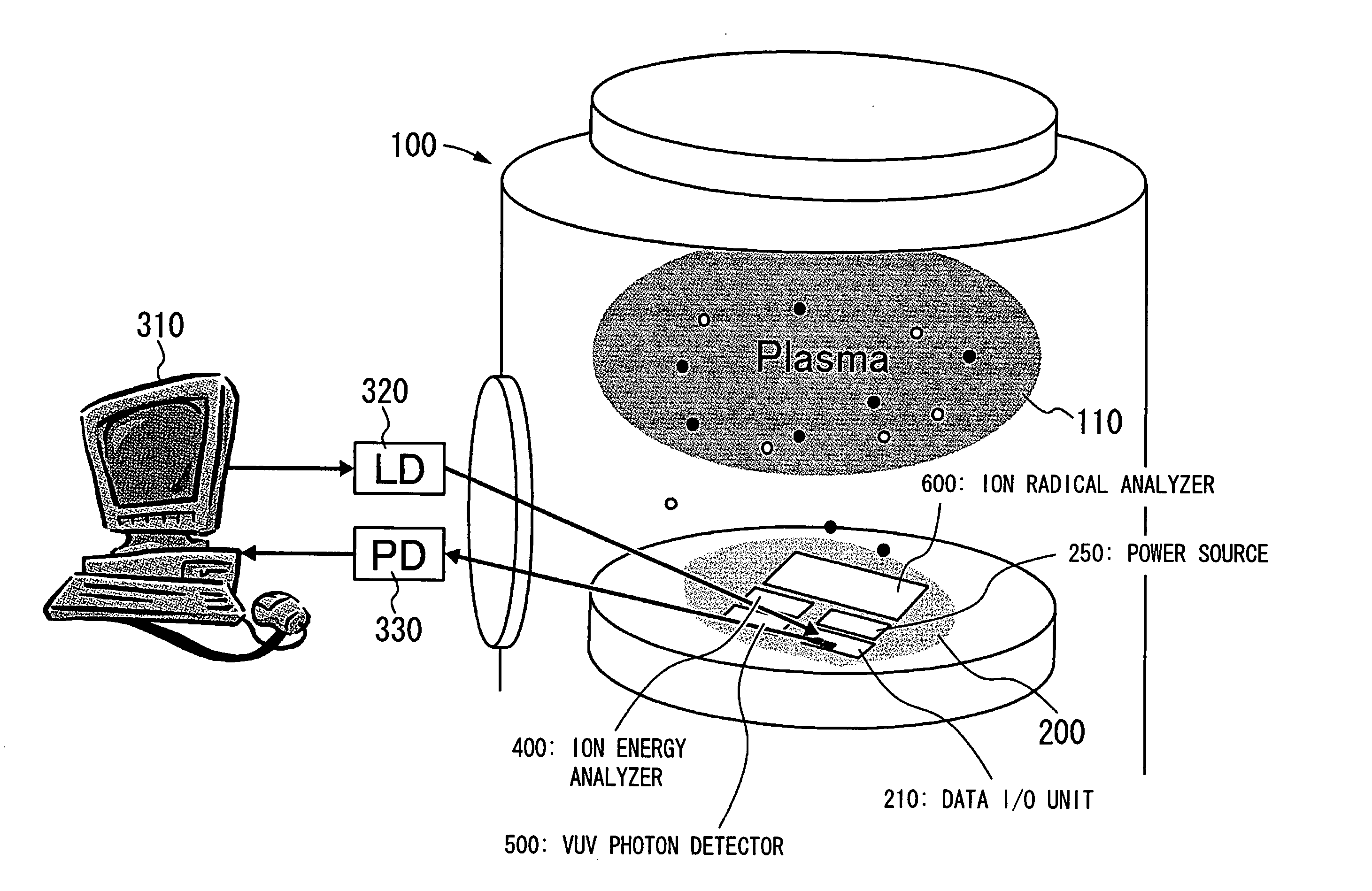

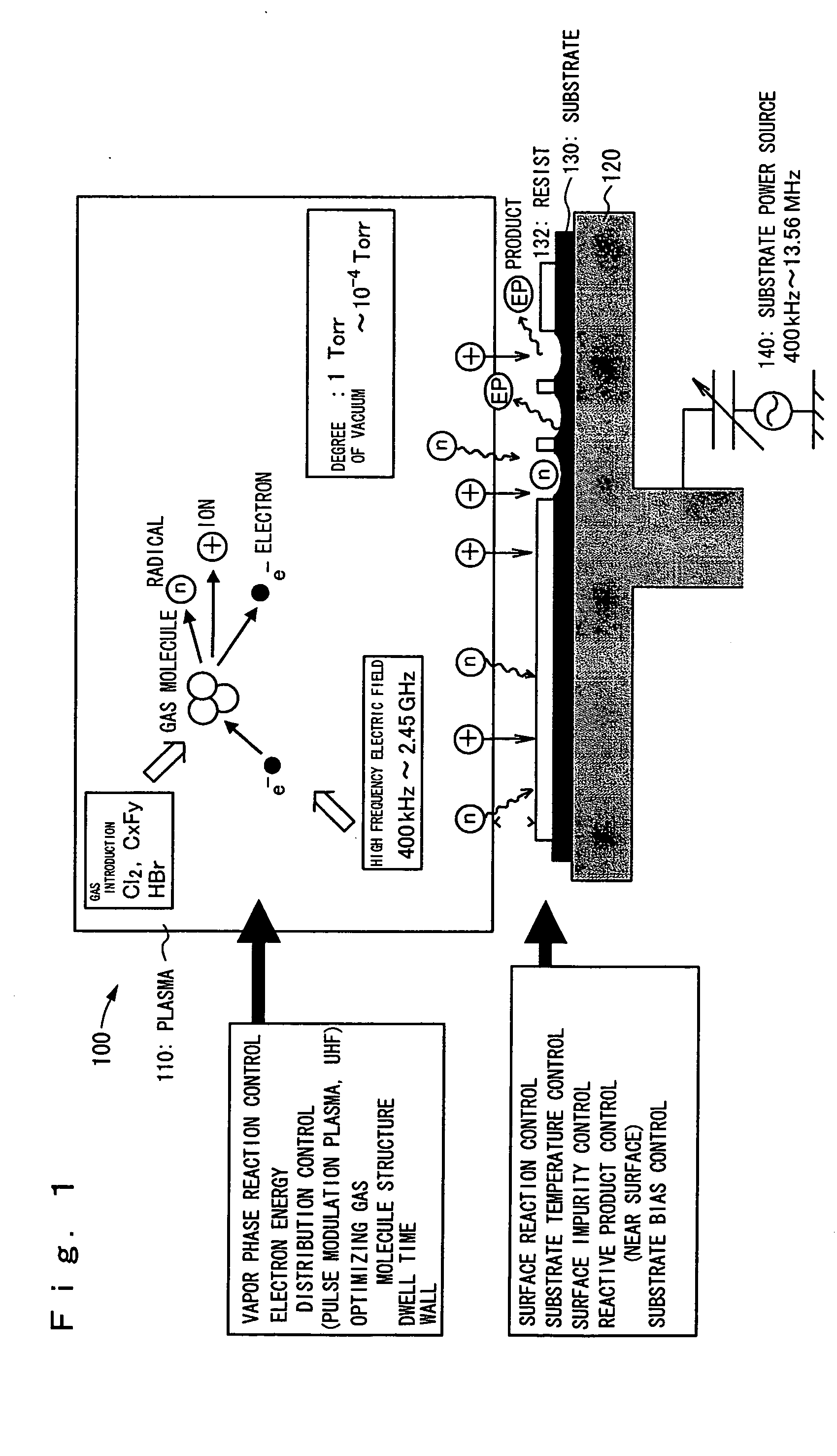

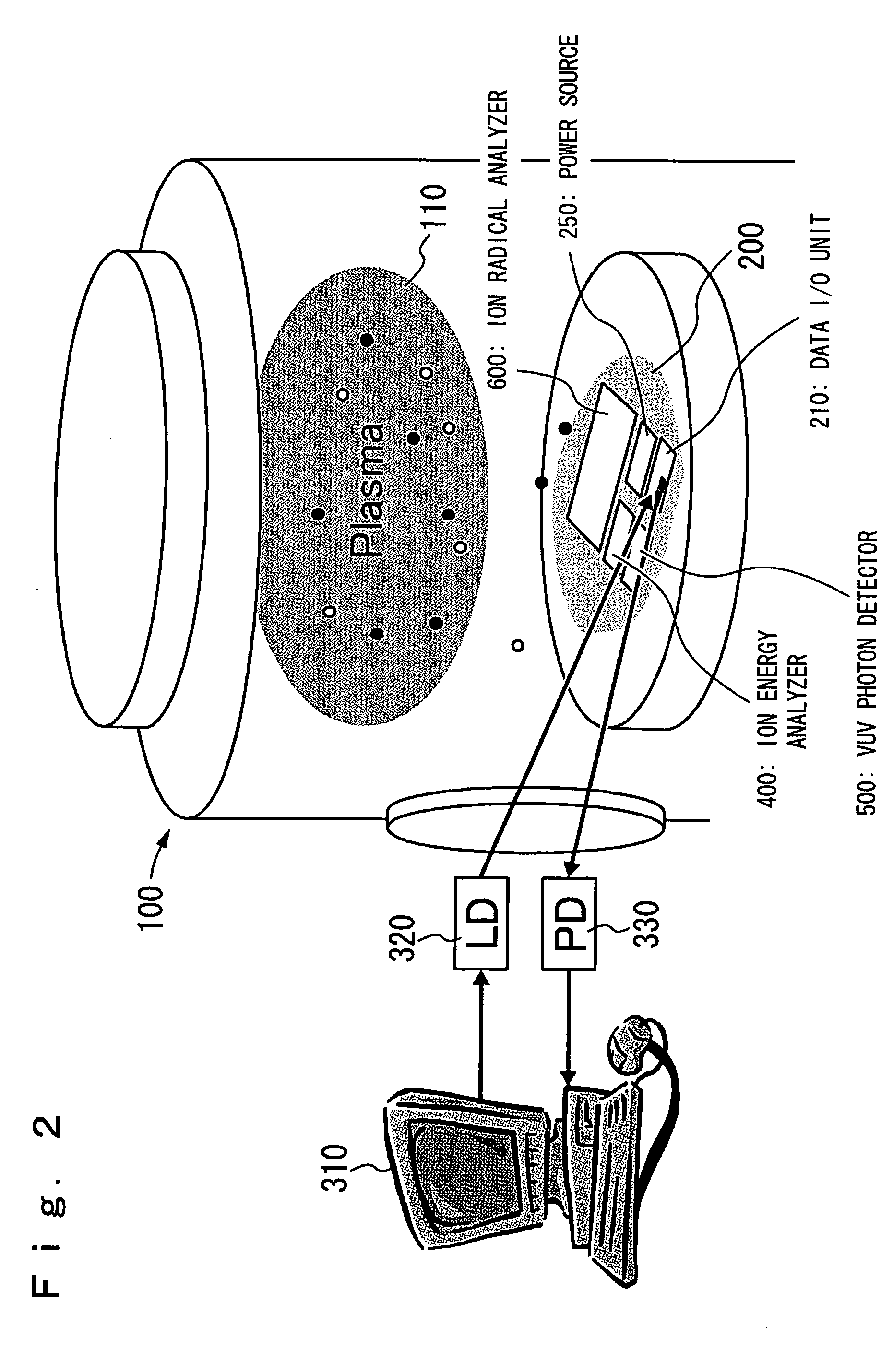

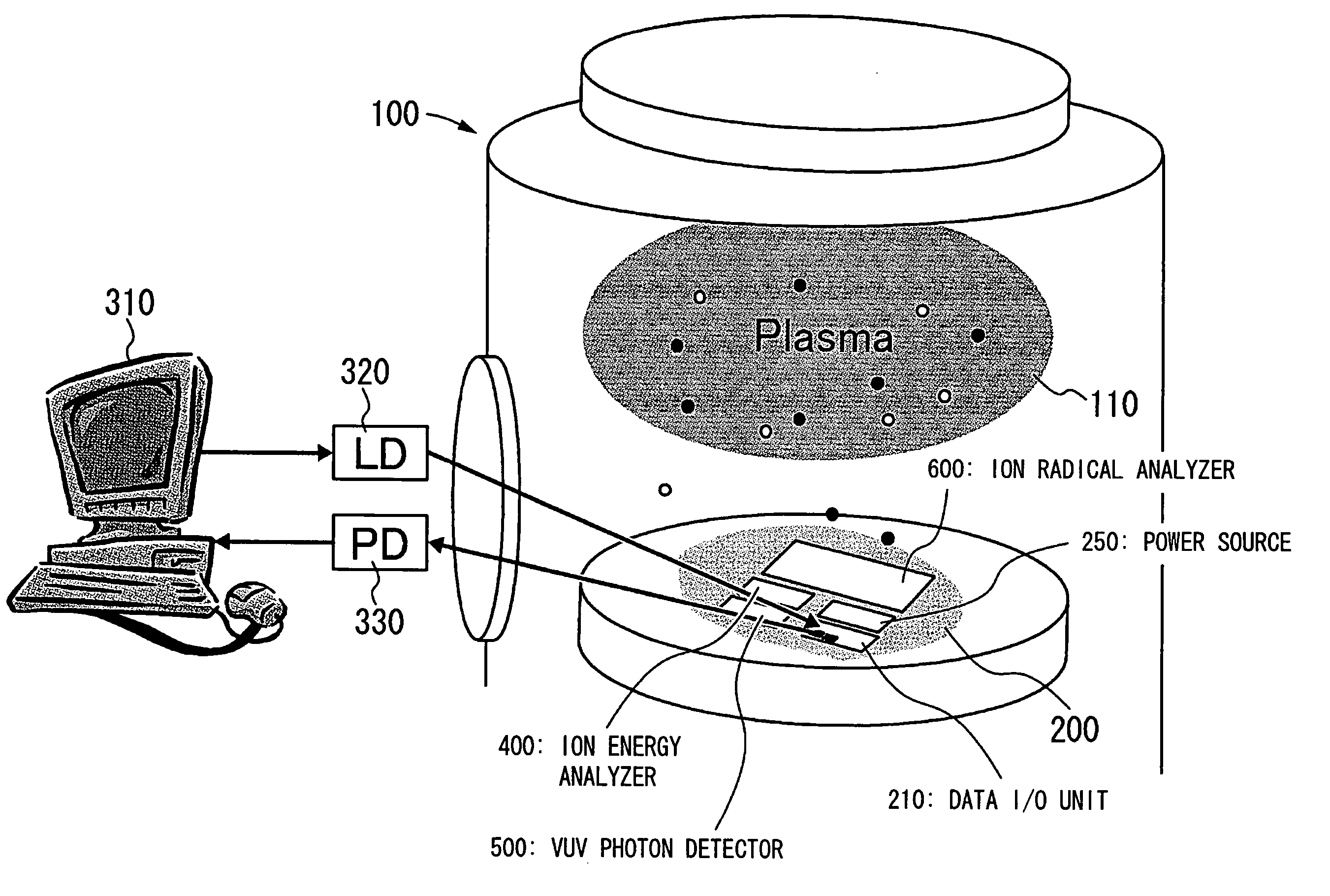

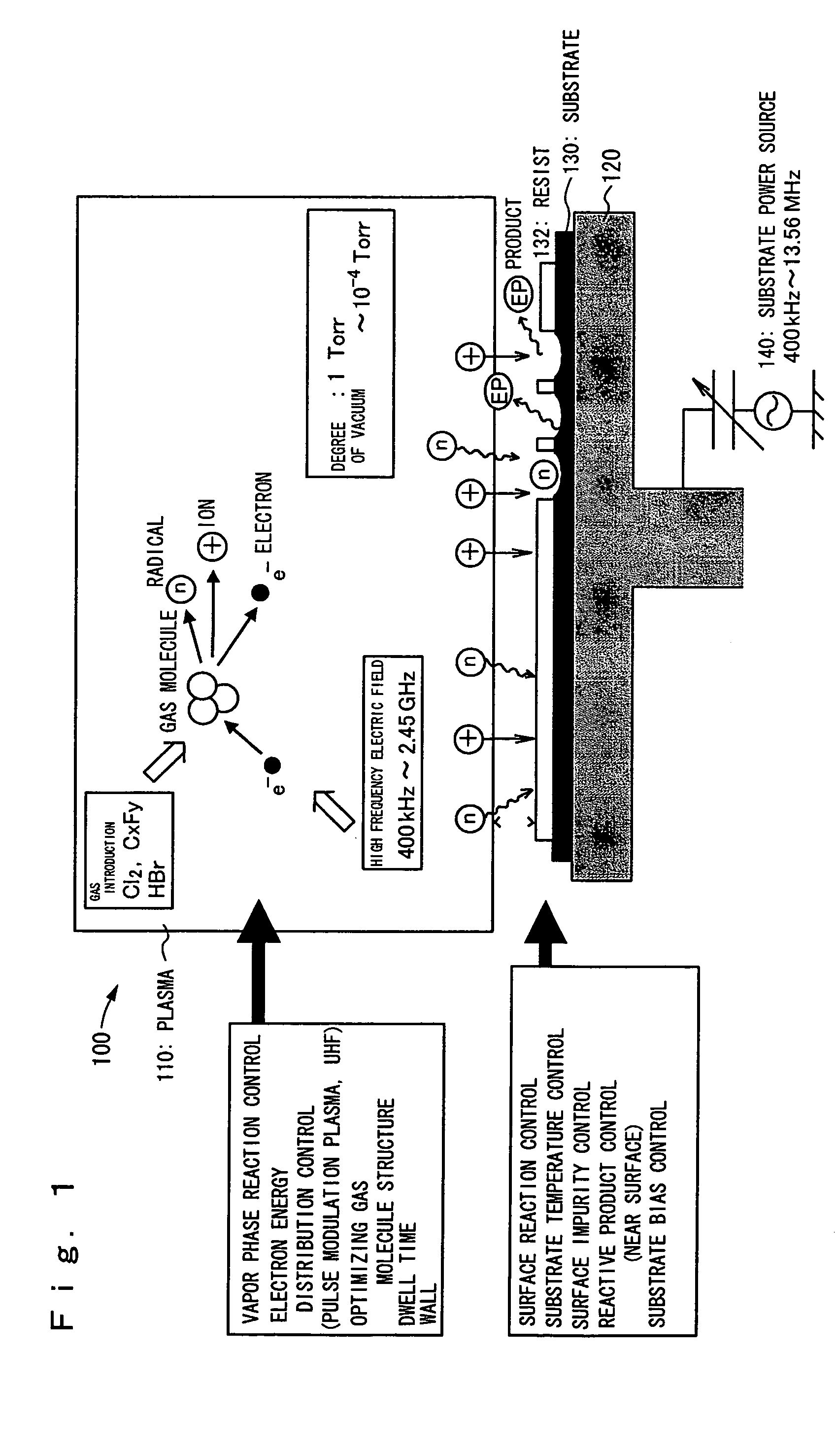

On-wafer monitoring system

InactiveUS20050115673A1Semiconductor/solid-state device testing/measurementResistance/reactance/impedenceMonitoring systemPhotodiode

An on-wafer monitoring system (200) is placed at a position of a substrate to be treated in a plasma treatment device (100). The on-wafer monitoring system (200) includes various sensors, a data I / O unit (210) for optically inputting / outputting data to / from outside, and an internal power source unit (250) for supplying power to them. The on-wafer data I / O unit (210) is connected to a laser diode (LD) (320) and a photo diode (PD) (330) which are optical I / O units installed outside. The data I / O unit (210) receives an instruction from outside and transmits monitored data to outside. Sensors arranged on the substrate are an ion energy analyzer (400), a VUV photon detector (500), and a radical ion species emission spectrophotometer (600).

Owner:TOHOKU TECHNO ARCH CO LTD

On-wafer monitoring system

InactiveUS7520956B2Semiconductor/solid-state device testing/measurementResistance/reactance/impedenceMonitoring systemEngineering

An on-wafer monitoring system is placed at a position of a substrate to be treated in a plasma treatment device. The on-wafer monitoring system includes various sensors, a data I / O unit for optically inputting / outputting data to / from outside, and an internal power source unit for supplying power to them. The on-wafer data I / O unit is connected to a laser diode (LD) and a photo diode (PD) which are optical I / O units installed outside. The data I / O unit receives an instruction from outside and transmits monitored data to outside. Sensors arranged on the substrate are an ion energy analyzer, a VUV photon detector, and a radical ion species emission spectrophotometer.

Owner:TOHOKU TECHNO ARCH CO LTD

Strontium containing hydroxyapatite biologically active film and preparation method thereof

InactiveCN1927410ANo side effectsHigh bonding strengthProsthesisElectrolytic agentPlasma electrolytic oxidation

The invention relates to the means of active biological film, especially the titanium radicel porous nanometer Strontium hydroxyapatite active biological film and the Process for the manufacture. The differential arc oxidation technology is used in the method, the film is generated in the surface of titanium and titanium alloy, a electrolyte solution with phosphate radical ion, calcium ion and Strontium ion is supplied; the titanium and titanium alloy is the anode and the rustless steel or the titanium is the cathode, the direct current power supply or the direct current impulsing power source is applied to differential arc oxygenize the titanium and titanium alloy; the oxidate time is 3-60min; the temperature of electrolyte is not above 50DEG C. There is no interface between the porous hydroxyapatite containing Strontium film produced by the invention and the basal body, the modulus of elasticity is approximate with the sclerotin, the porous hydroxyapatite containing Strontium film produced by the invention which has perfect bioactivity can be the alternate material of several parts with heavy load, such as femur, hip joint and teeth root.

Owner:SOUTH CHINA UNIV OF TECH

Agricultural and forestry waste carbon-based slow release filter and preparation method thereof

InactiveCN102775236ALow costWidely distributedClimate change adaptationAgriculture gas emission reductionPhosphate ionRelease time

The invention discloses an agricultural and forestry waste carbon-based slow release filter and a preparation method thereof. The preparation method comprises the following steps: crushing agricultural and forestry waste into biomass particles, carrying out pyrolysis to prepare charcoal, dissolving monoammonium phosphate and monopotassium phosphate in water to prepare a saturated water solution of monoammonium phosphate and a saturated water solution of monopotassium phosphate, soaking charcoal prepared in step a in the saturated water solution of monoammonium phosphate and the saturated water solution of monopotassium phosphate so that adsorption capacity of charcoal to phosphate radical ions, ammonium ions and potassium ions is up to 80-90% of balanced adsorption capacity, then taking out charcoal, and drying at the drying temperature of 100-105 DEG C until the moisture content of the slow release filter is less than 5%, thus the agricultural and forestry waste carbon-based slow release filter is obtained. The agricultural and forestry waste carbon-based slow release filter disclosed by the invention is low in cost, long in slow release time and good in slow release effect, can be used for long term and can maintain soil fertility for a long time.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

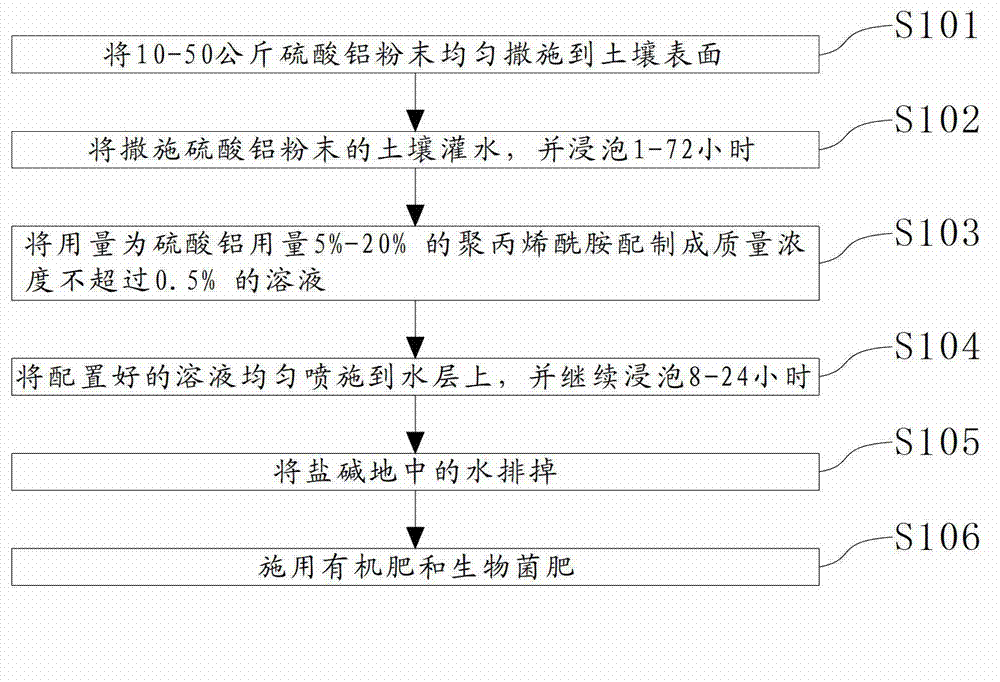

Improvement method for saline-alkali soil

ActiveCN103109615AImprove propertiesImprove permeabilitySoil-working methodsAlkali soilPolyacrylamide

The invention relates to the agricultural field, in particular to an improvement method for saline-alkali soil. The improvement method for the saline-alkali soil comprises the following steps: sprinkling 10 to 50 kilograms of aluminum sulfate powders on the surface of the saline-alkali soil evenly; irrigating the soil with the aluminum sulfate powders and soaking the soil with the aluminum sulfate powders for 1 hour to 72 hours; compounding polyacrylamide with a dosage which is 5% to 20% of the dosage of the aluminum sulfate powders into a solution, wherein the mass concentration of the solution is no more than 0.5%; evenly spraying the compounded solution onto the water layer, and continuing to soak the soil with the aluminum sulfate powders for 8 hours to 24 hours; draining the water in the saline-alkali soil; and applying organic fertilizer and biological bacterial fertilizer to the saline-alkali soil. The improvement method for the saline-alkali soil can improve the sodium ions, the carbonate ions and the bicarbonate radical ions in the soil, so that the potential of hydrogen (pH) value of the solution of the soil can be reduced. The aluminum sulfate is increased, so that the soluble salts released by the soil particles are also increased, so that the salt materials in the soil can be reduced remarkably. Due to the fact that the macromolecule polyacrylamide is added, the soil can congeal into bigger particles like pea grains, so that permeability and water and fertilizer preserving capability of the soil can be improved.

Owner:黑龙江省汉通生物工程有限公司

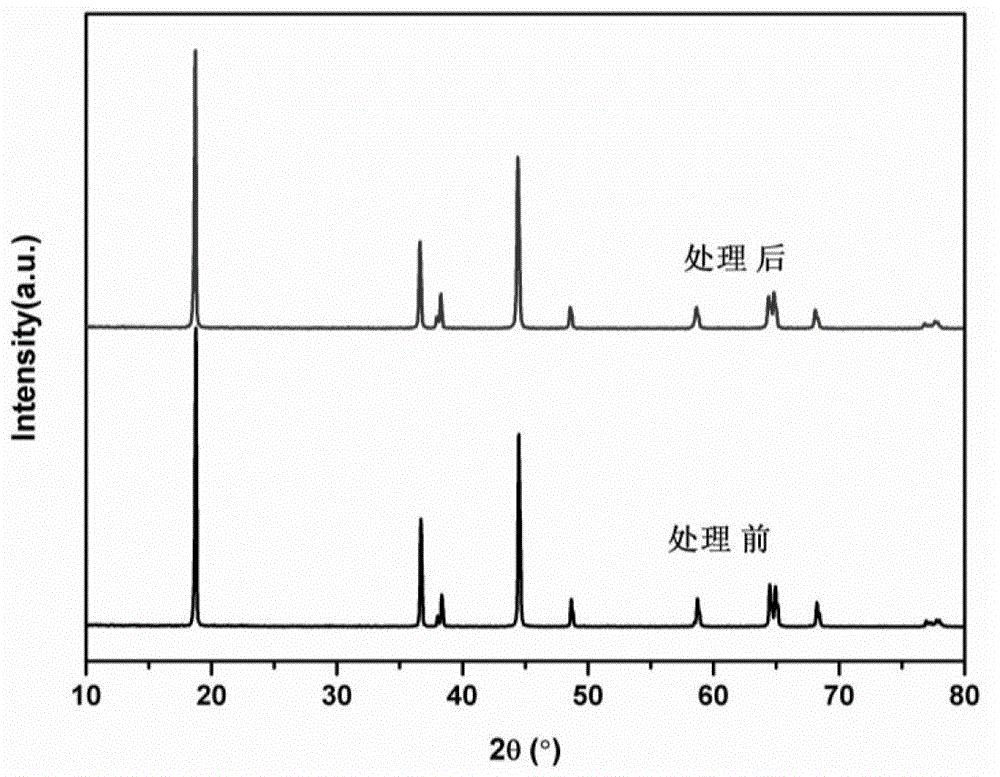

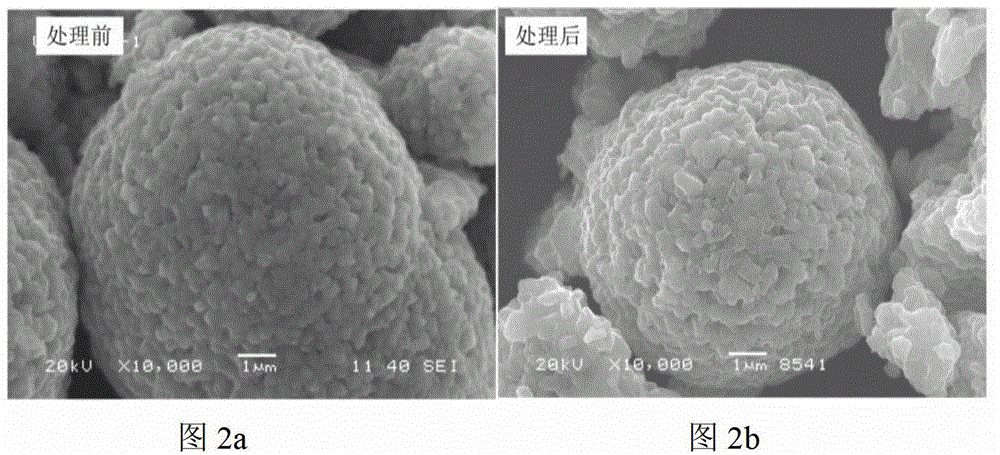

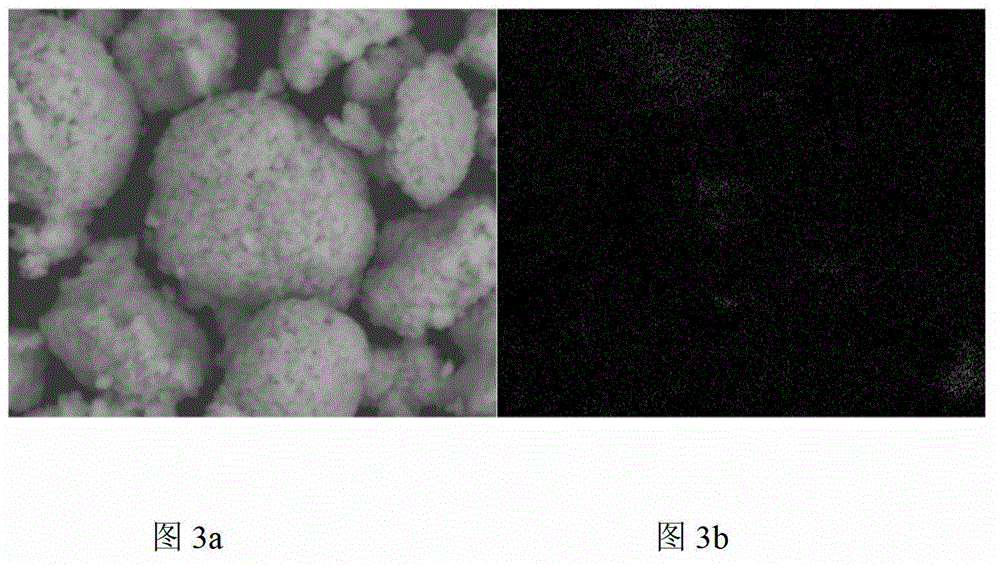

Method for removing lithium ion battery nickel-rich material surface lithium residues by liquid phase precipitation method

ActiveCN102881911ALow hygroscopicityGood hygroscopicityCell electrodesMoisture absorptionMaterial physics

The invention discloses a method for removing lithium ion battery nickel-rich material surface lithium residues by a liquid phase precipitation method. The method for removing the lithium ion battery nickel-rich material surface lithium residues by the liquid phase precipitation method includes the steps: dispersing lithium ion battery nickel-rich materials into phosphate solution, combining the nickel-rich material surface lithium residues with phosphate radical ions so as to form precipitation, nucleating on the material surface, and calcining so that a material with the surface wrapped with a compact Li3PO4 layer is obtained. The wrapping layer prepared by the method is more uniform and compact than a traditional wrapping layer, and storage performance of the material in air is obviously improved; and the moisture absorption performance of the nickel-rich materials can be improved while water brought into electrolyte by electrode materials is reduced, and structural stability of the material is enhanced. Moreover, Li3PO4 is better in stability in the electrolyte than in the battery materials, so that the comprehensive electrochemical performance of a positive electrode material can be effectively improved. The method for removing the lithium ion battery nickel-rich material surface lithium residues by the liquid phase precipitation method is simple in preparation process, short in flow path and low in production cost, and the prepared positive electrode material is excellent in physical performance and electrochemical performance.

Owner:CENT SOUTH UNIV

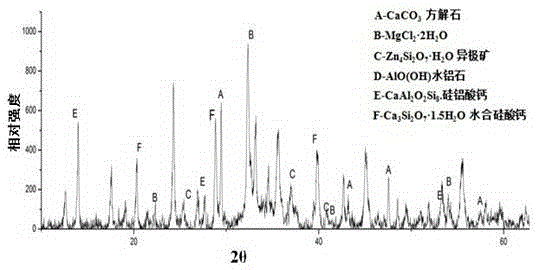

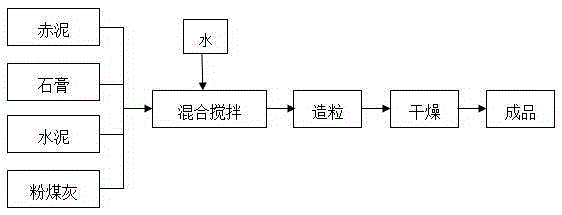

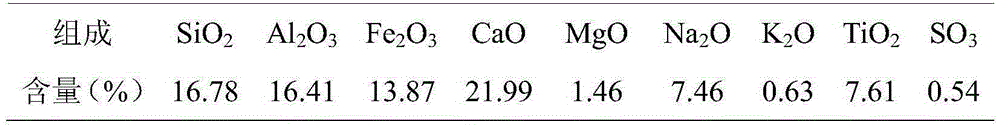

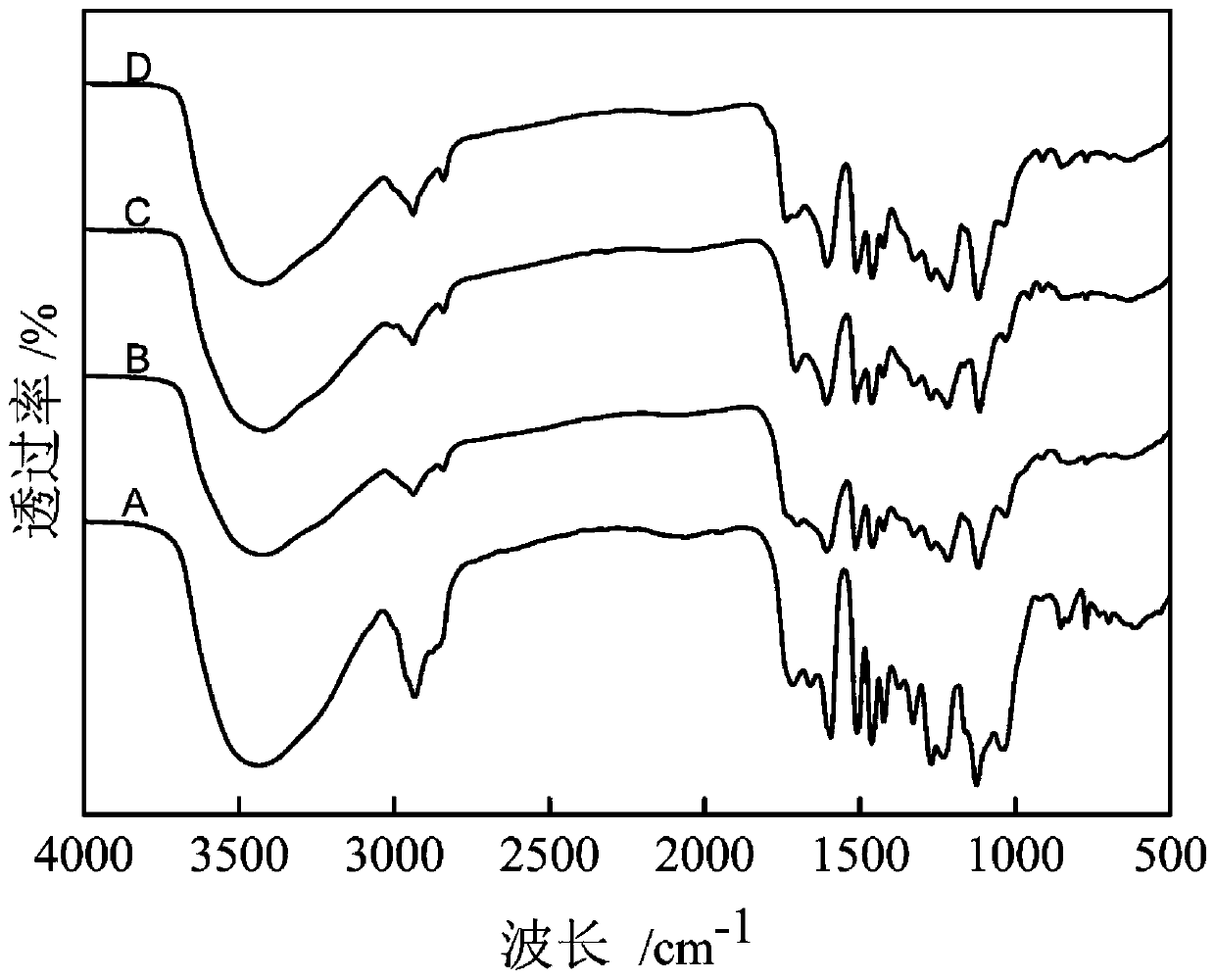

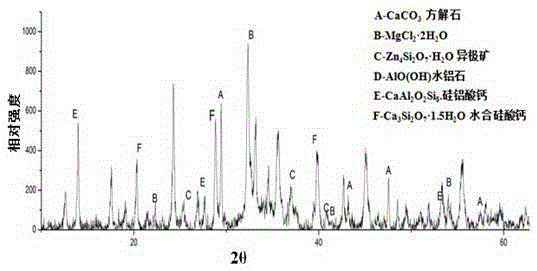

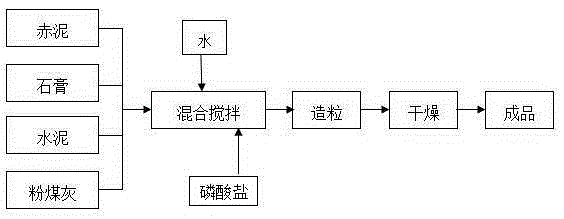

Red mud particle soil repairing adhesives and preparation method thereof

The invention discloses red mud particle soil repairing adhesives and a preparation method and application thereof. The red mud particle soil repairing adhesives are prepared through a series of steps of water adding, mixing, ball forming, room-temperature drying and solidifying by using red mud as the raw material, mixing gypsum into the red mud and using binding material Portland cement and powdered coal in a compound mode to achieve the synergistic interaction result and remarkably improve the red mud gelling property. Red mud powder is granulated and prepared at a room temperature, the obtained red mud particle soil repairing adhesives have certain mechanical strength and quite good heavy metal stabile solidifying performance, soil or mud polluted by heavy metal can be effectively treated, and meanwhile OH radical ions can be slowly released; the pH of soil is kept between 6.7 and 8.1 after soil is repaired through the repairing adhesives, the problems that when soil is repaired through red mud powder, the pH of soil rises too fast and plant growth is not facilitated can be effectively solved, and high application value and environment benefits are achieved.

Owner:国家电投集团山西铝业有限公司 +1

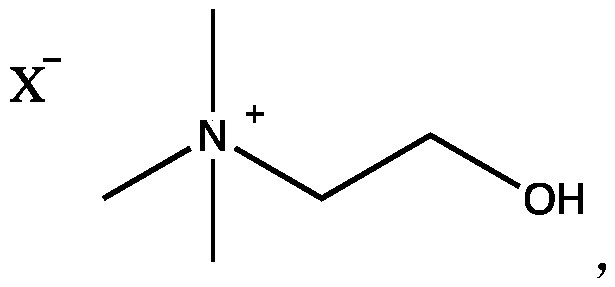

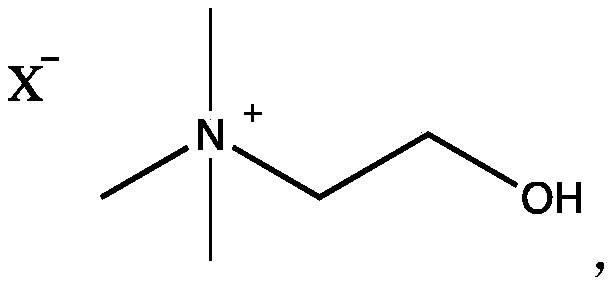

Eutectic solvent and application of eutectic solvent in lignin extraction

ActiveCN110540508AHigh extraction rateHigh purityOrganic compound preparationLignin derivativesCelluloseOrganic acid

The present disclosure belongs to the technical field of biomass refining, and particularly relates to an eutectic solvent and an application of the eutectic solvent in lignin extraction. Eutectic solvents are composed of a certain amount of hydrogen-bond donors and hydrogen-bond acceptors, and are economical and environment-friendly green solvents, and among the eutectic solvents, choline-based eutectic solvents are widely used in lignocellulose extraction. Inventors find that due to the presence of chloride ions in the choline chloride-based eutectic solvents, negative charges can be intensively distributed, the extraction efficiency can be reduced, and the aging of an instrument can be accelerated. The present disclosure provides the eutectic solvent with a low halogen content, and organic acid radical ions are adopted to replace halogen anions in choline chloride. Research of the present disclosure proves that the method has a high lignin extraction rate, high purity, simple operation, an obvious effect, high practicability, small pollution, and easy promotion.

Owner:QILU UNIV OF TECH

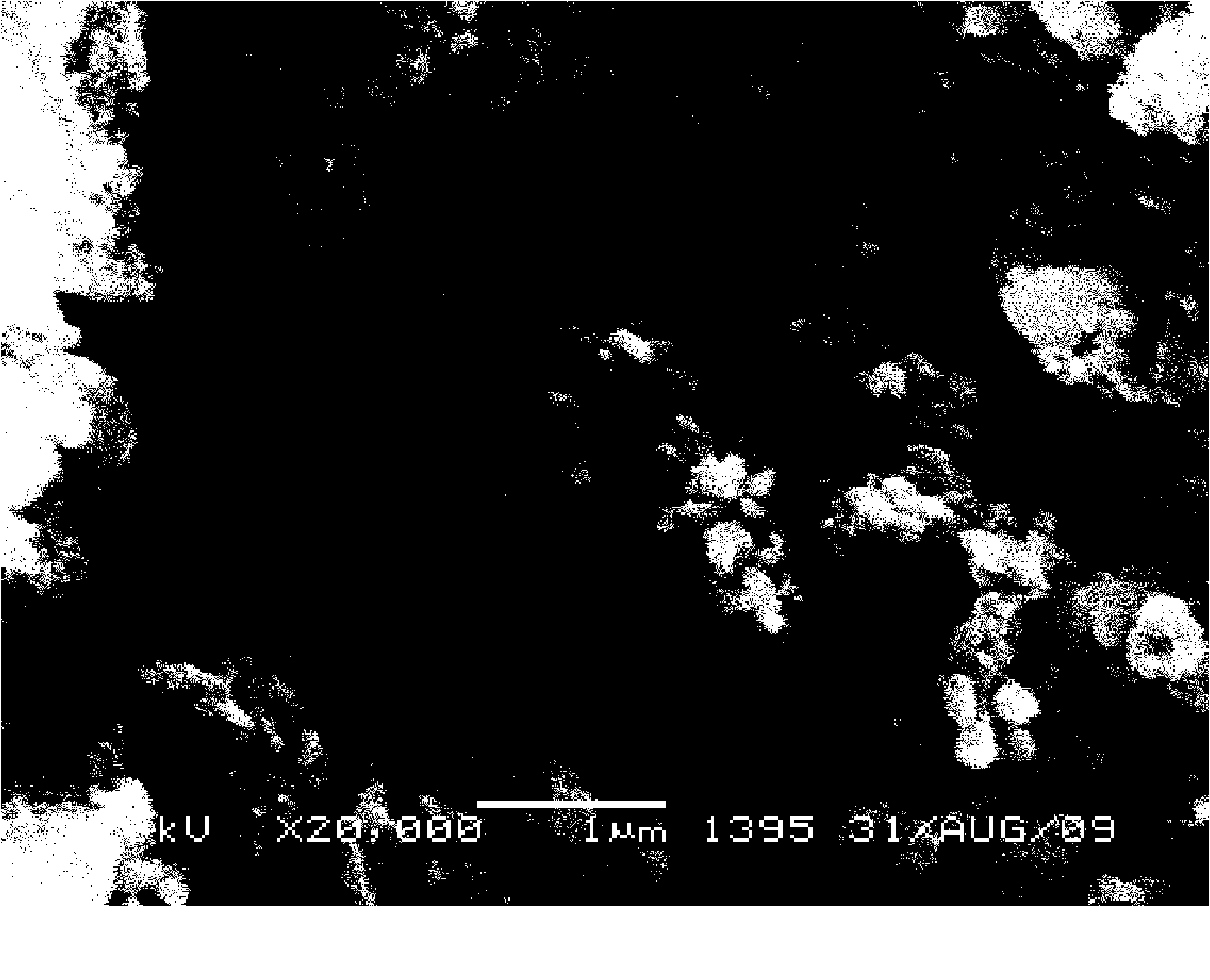

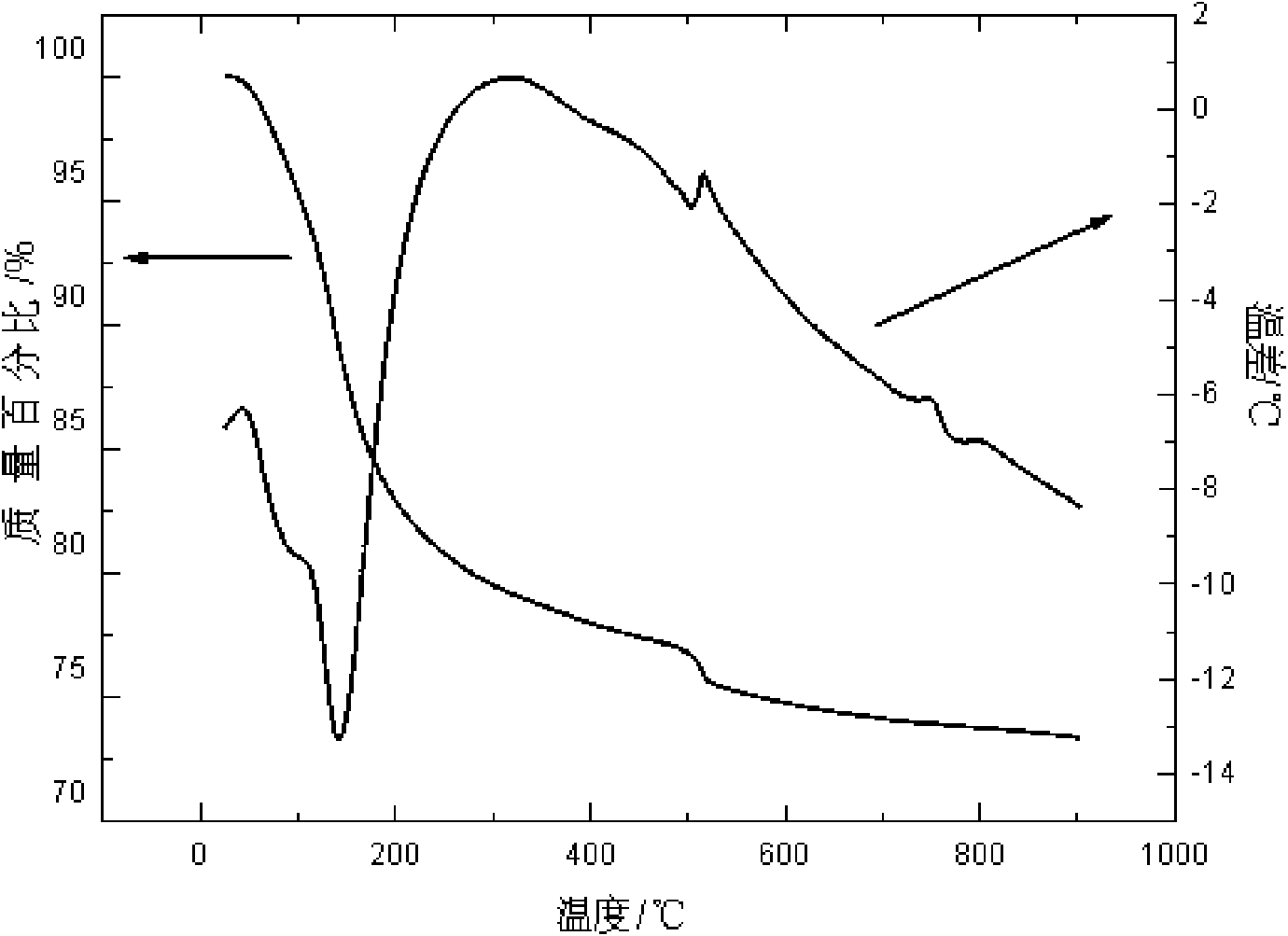

Preparation method of precursor iron phosphate of cathode material lithium iron phosphate of lithium ion battery

InactiveCN101640268AUniform particle size distributionSmall particle size distributionElectrode manufacturing processesPhosphate ionReaction temperature

The invention discloses a preparation method of precursor iron phosphate of cathode material lithium iron phosphate of a lithium ion battery, which comprises the following steps: simultaneously addingferrous ion aqueous solution with the concentration of 0.05-2mol / L and phosphate radical aqueous solution into a reactor according to the stoichiometric ratio of ferrous ions and phosphate radical ions of 0.8-1.2: 1 and at the speed of 400-1000mL / h, and reacting for 0.2-2h under the conditions that the reaction temperature is 50-90 DEG C and the stirring speed is 400-1200rpm; adding hydrogen peroxide with excessive stoichiometry and reacting for 0.2-2h, and ageing for 2-8h, filtering, washing and drying to obtain iron phosphate powder with two crystallization water; and in the obtained iron phosphate, the total ferric content (Fe) is 29.5-30.5 percent, the P content is 16.0-16.9 percent, the particle size is 0.1-1Mum, and D50 is 1-5Mum. The invention has simple and convenient operation process, simple device, easy control, low energy consumption, even and fine particle size distribution and high reaction activity and is suitable for preparing the lithium ion battery cathode material lithium iron phosphate.

Owner:CENT SOUTH UNIV

Recovery method of phosphate discharge liquid

InactiveCN101254966AEasy to operateWater/sewage treatment by ion-exchangeLiquid wasteRecovery method

The invention relates to a method for treating and reclaiming phosphatic waste liquor with low concentration. The method comprises the following steps: firstly solid impurity is removed through filtering the waste liquor containing phosphoric acid, then ion exchange is performed through anion exchange resin to ensure phosphate radical ion to be attached to the resin, and therefore the phosphoric acid is separated from the waste liquor. Then elution is performed to the anion exchange resin by using sodium salts, such as sodium chloride or sodium carbonate, and ammonia salt solution, to displace the phosphate radical ion, and to generate phosphatic sodium salt with higher concentration or ammonium saltwater solution. Then ion-exchange treatment is performed to the water solution by using the anion exchange resin, sodium ion or ammonia ion is replaced by hydrogen ion, and phosphatic water solution with higher concentration is generated. At last, moisture in the phosphatic water solution is removed by using vacuum evaporation, and pure phosphoric acid is obtained to be circularly used. The method is applied to other phosphatic waste liquor with little dissoluble impurity.

Owner:BEIJING TEX STRONG NEW MATERIAL DEV

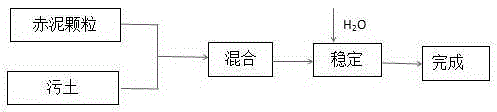

Method for repairing heavy metal-polluted soil by using red mud granular material

The invention discloses a red mud granular material and an application thereof. A red mud particle soil repairing agent takes red mud powder, gypsum, cement and fly ash as main materials, phosphate is doped as an activation material, thereby, gelling capability of red the mud powder and capability for fixing heavy metal ions in a stable mode can be increased, a series of processes of mixing by adding water, balling, and drying solidification at normal temperature can be carried out, so that the spherical particle soil repairing agent can be obtained by composite moulding of the red mud raw ore powder material. The method realizes preparation of the red mud powder with granulation at normal temperature, the obtained red mud particle soil repairing agent has certain mechanical strength and good heavy metal stable solidification performance, the heavy metal-polluted soil or sludge can be effectively processed, OH radical ions can be slowly released simultaneously, a pH value of the soil after restoration by the repairing agent is basically stabilized below 7.5, problems of fast increase of the pH value of the soil and poor growth condition for plants during a soil restoration process by the red mud powder can be effectively overcome, and the method has high application value and environment benefit.

Owner:SUN YAT SEN UNIV

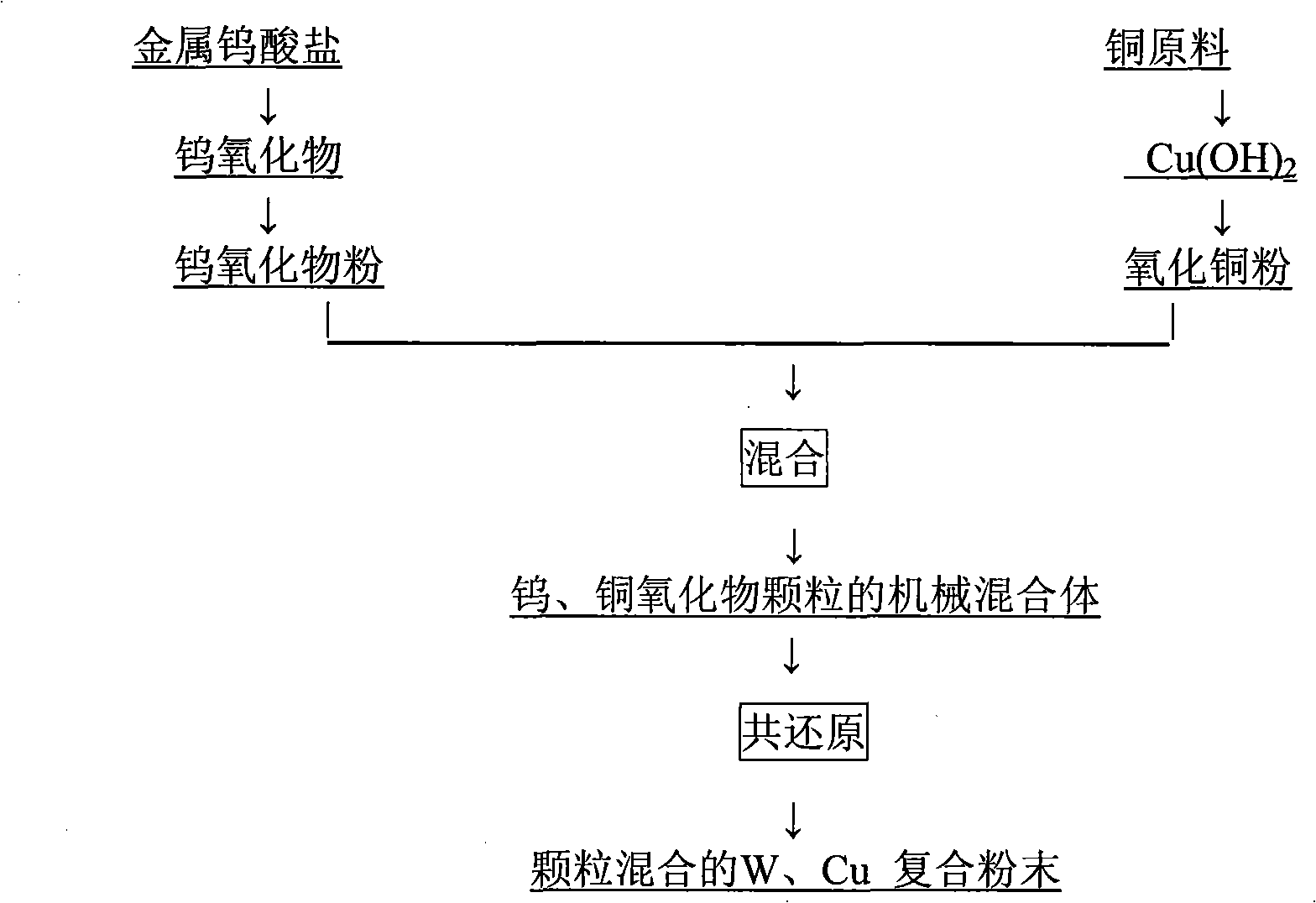

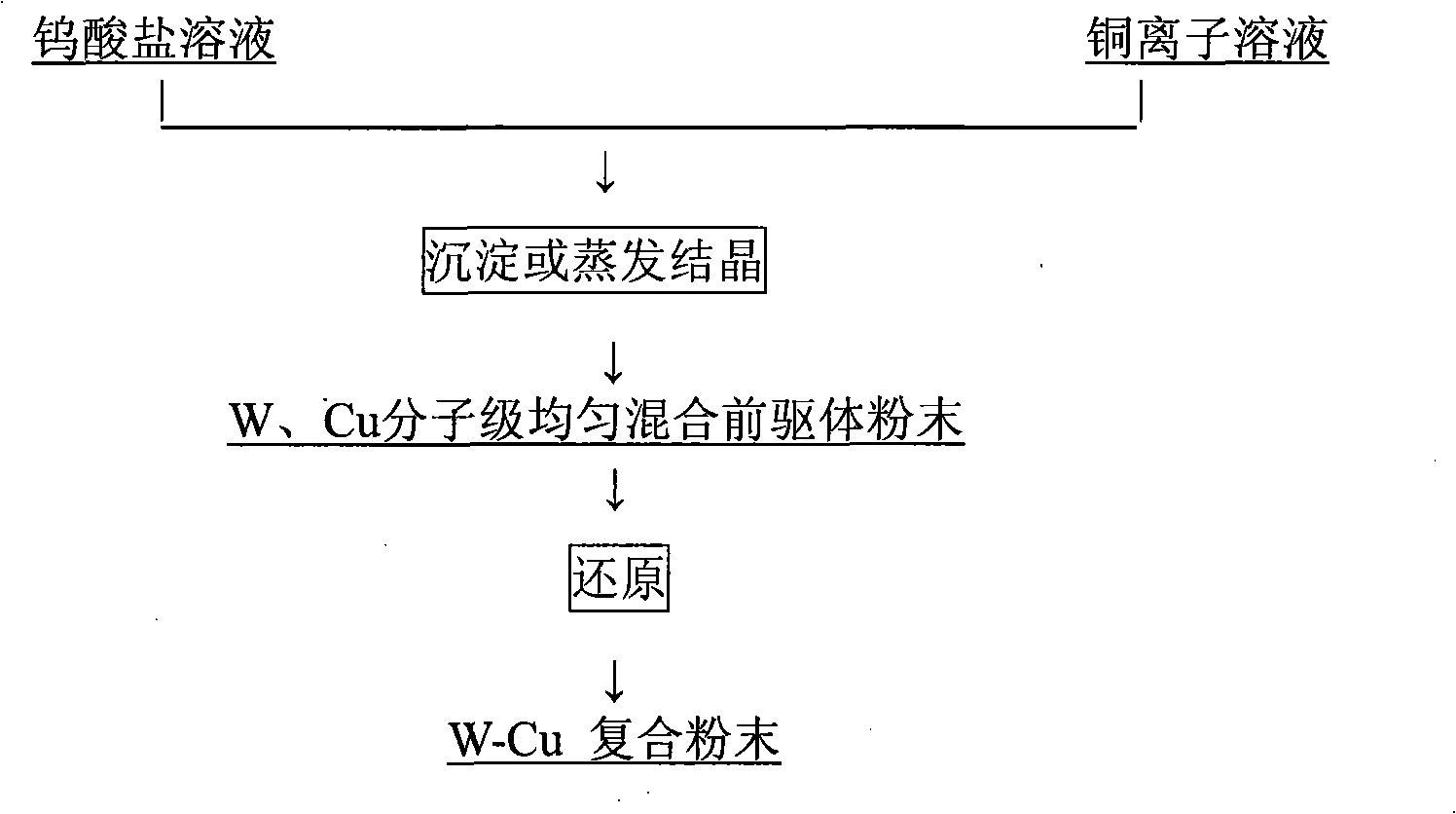

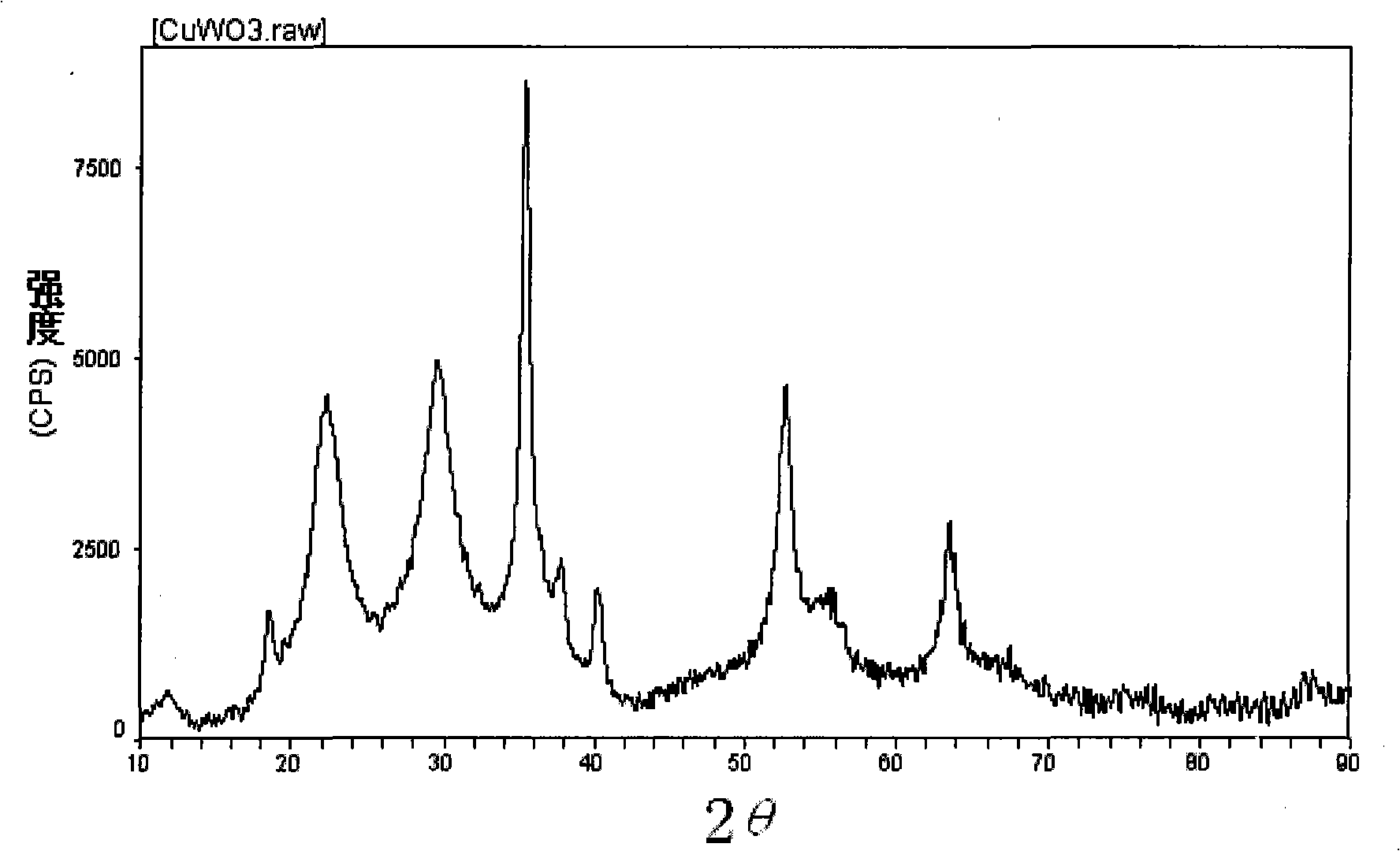

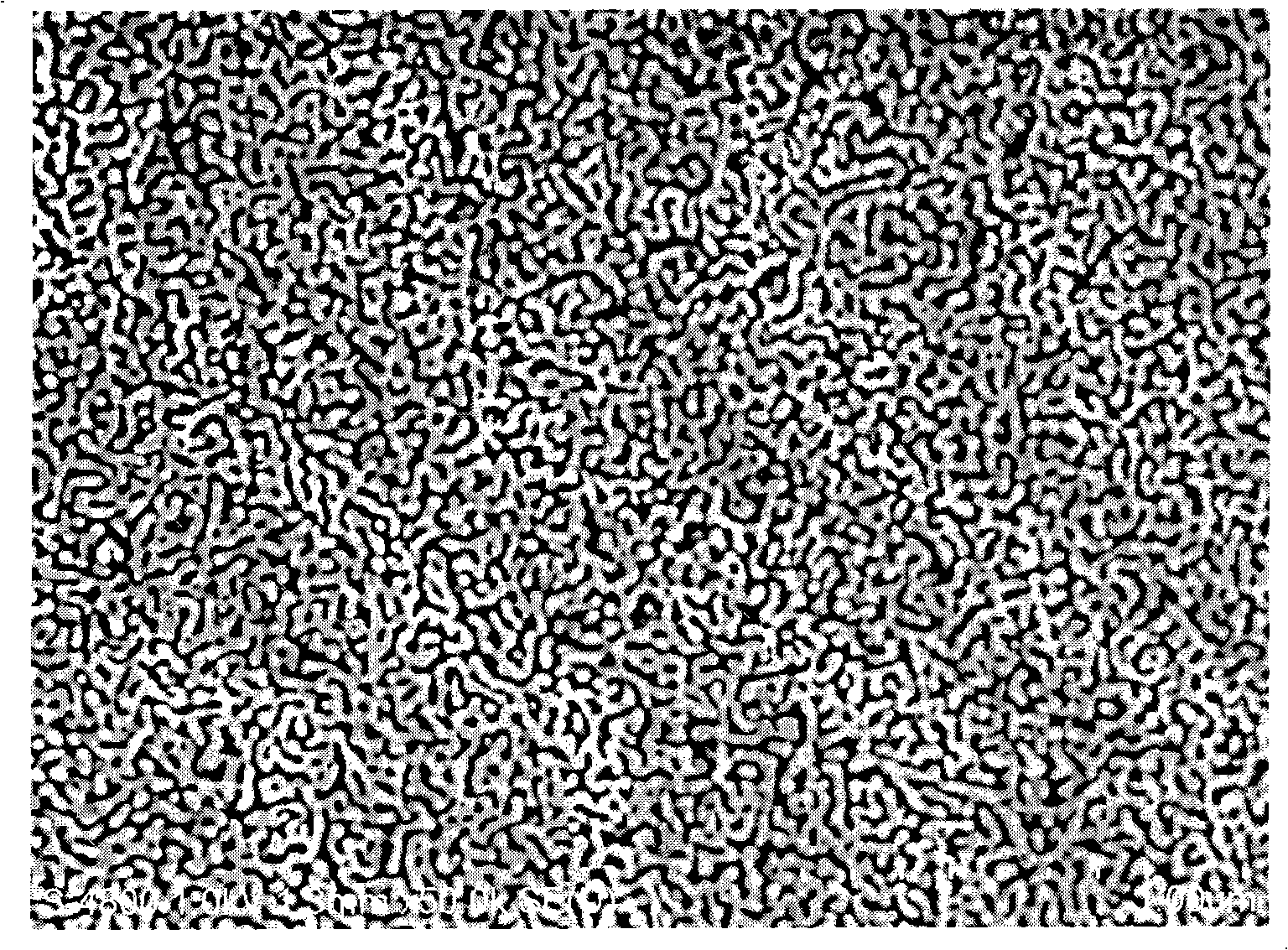

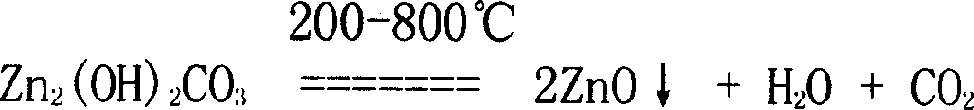

Process for producing nano-scale W-Cu composite powder with even dispersion

The present invention discloses a process for preparing the uniformly-dispersed nanometer-level W-Cu compound powder; tungstate and cupric salt solution are respectively prepared firstly; secondly, the wolframate radical ion in the tungstate solution and the copper ion in the cupric salt solution are precipitated in the compound form of tungstenic acid cupric salt by the precipitation or crystallization way, thereby forming the fore-carrier that is combined with W molecule and Cu molecule, and the fore-carrier is reduced to be the nanometer-level W-Cu compound powder. The method of the present invention has simple process, less equipment investment and convenient and simple control, and is applicable to the industrialized production; the produced compound powder can reach the nanometer-level and uniform dispersion.

Owner:CENT SOUTH UNIV

Method for coating noble metal on nano porous gold and prepared catalyst

InactiveCN101332438AIncrease profitModified implementationCell electrodesCatalyst activation/preparationAlloyRadical ion

The invention discloses a method for finishing a noble metal coating of a porous gold and the method comprises the following steps: the nanoporous gold is made by corroding gold-silver alloy; the nanoporous gold is soaked into a certain concentration of a solution containing chloroplatinic acid radical ions (or chloroplatinous acid radical ions, or chloropalladic acid radical ions, or chloropalladic acid radical ions, or the mixture) for an appropriate time to cause the surface of the nanoporous gold to absorb some noble metal ions, the other noble metal ions except for the noble metal ions absorbed on the surface of the nanoporous gold are washed clean, and the noble metal ions absorbed are reduced to a noble metal simple substance under proper electrochemical conditions, and the noble metal simple substance is tightly bonded on the pore wall of the nanoporous gold. The method of the invention can be used for preparing a catalyst which combines porous metals with ultra-low content of noble metals and can be applied in the catalytic fields of fuel cells and the like.

Owner:SHANDONG UNIV

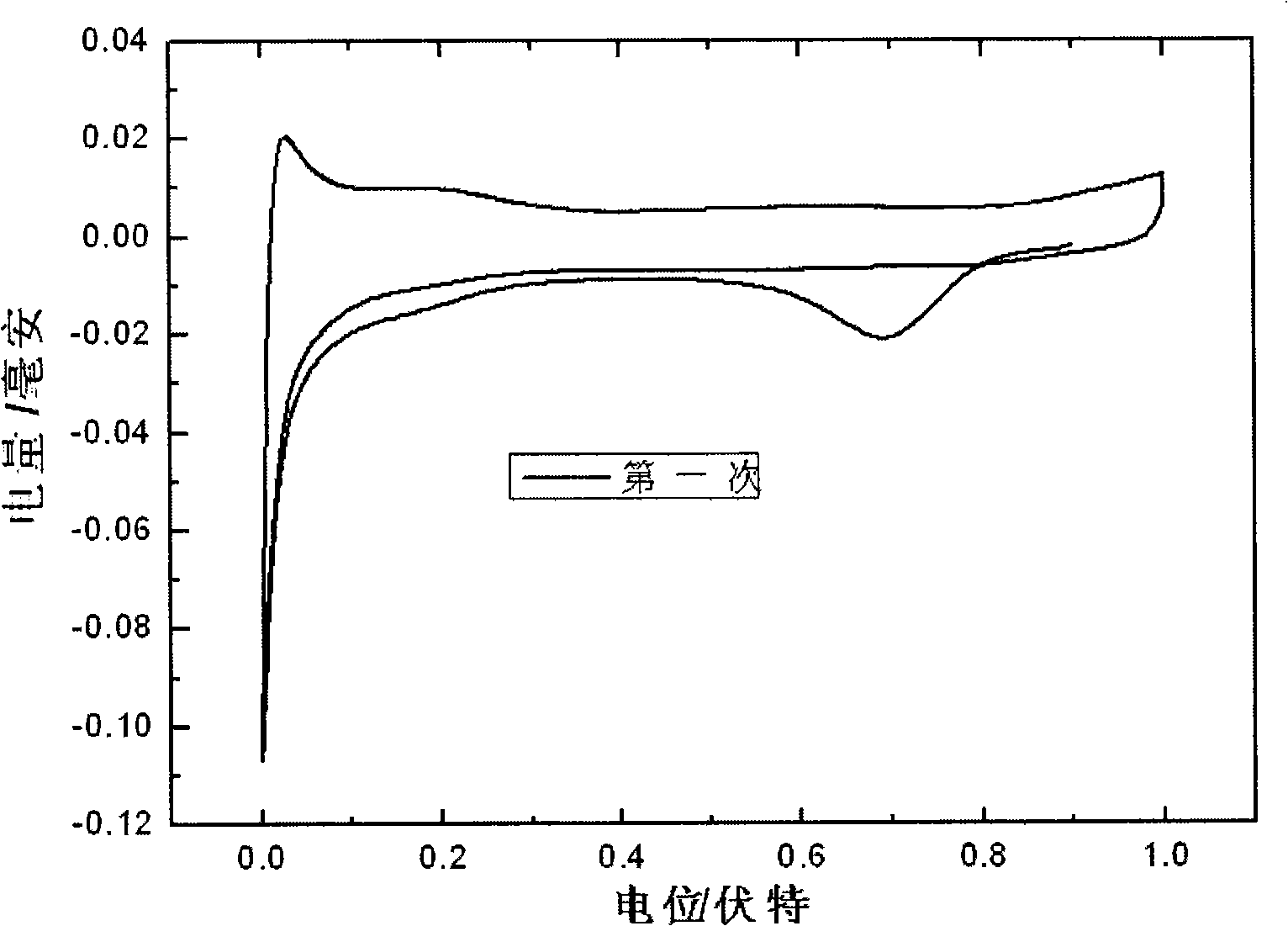

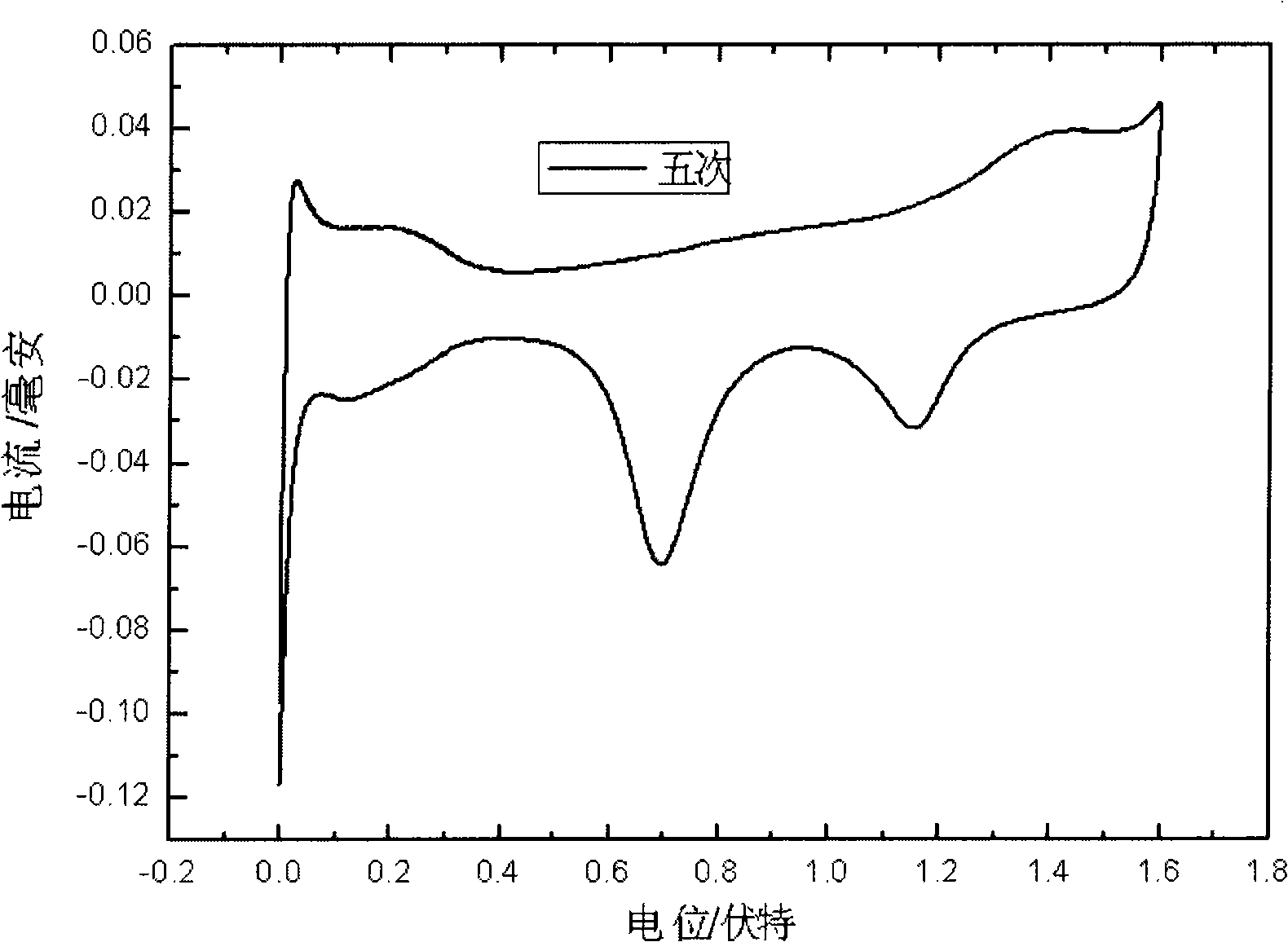

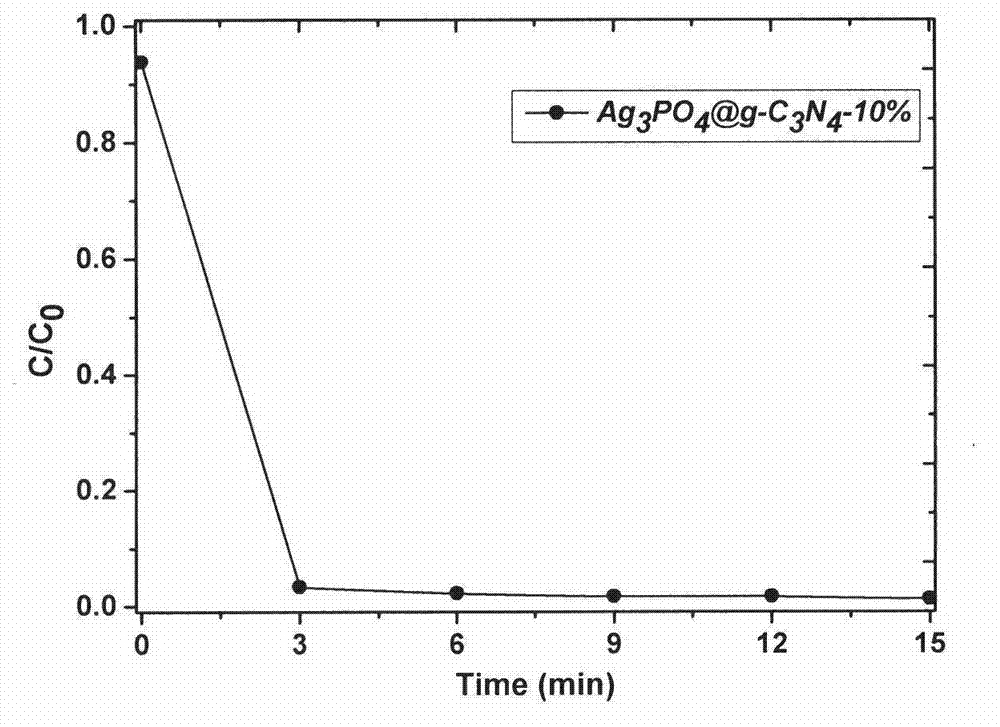

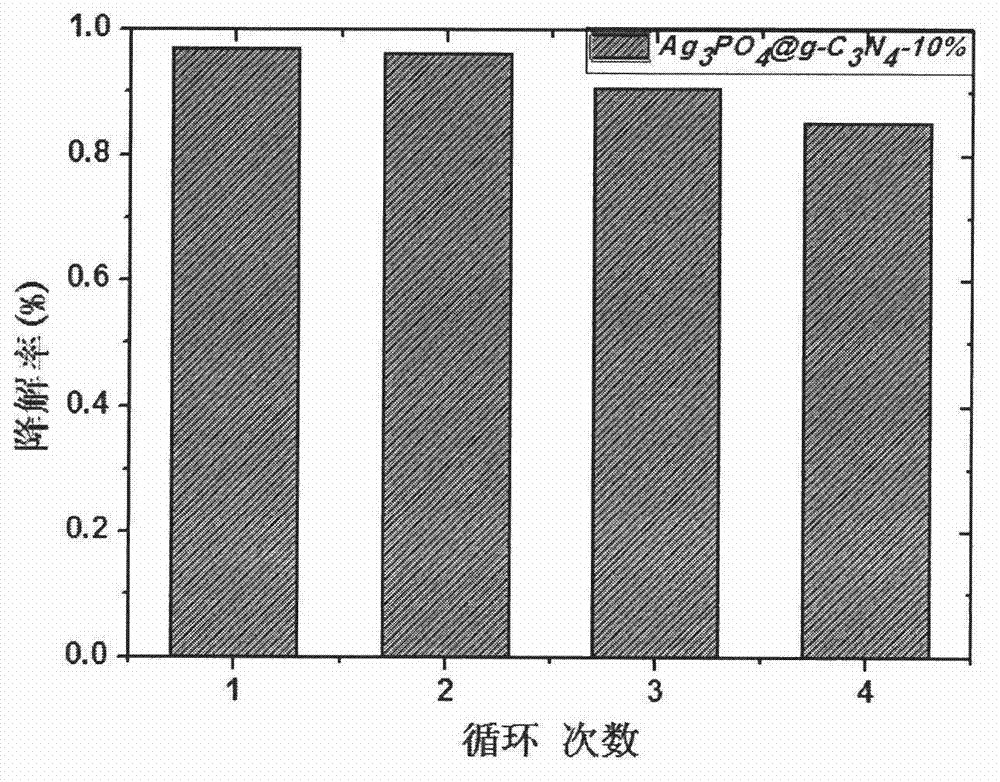

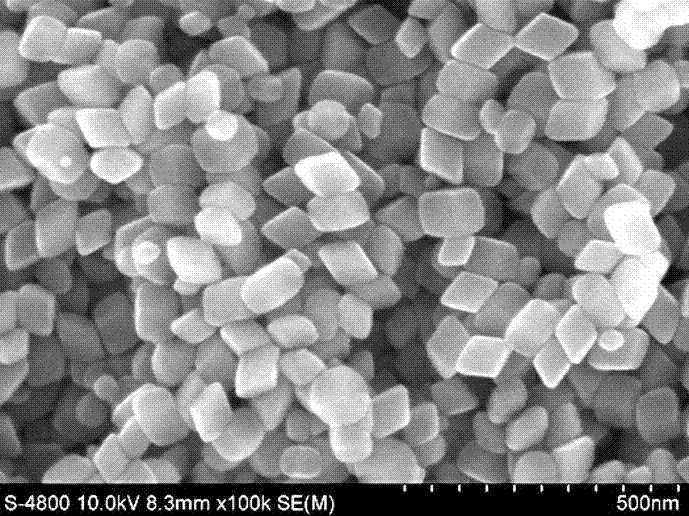

Method for preparing composite visual light catalytic material Ag3PO4 and g-C3N4

InactiveCN103028428ASimple manufacturing methodSynthetic conditions are mildPhysical/chemical process catalystsWater/sewage treatment by irradiationPhosphate ionSodium phosphates

The invention discloses a method for preparing a novel efficient composite visual light catalytic material Ag3PO4@g-C3N4. First, g-C3N4 in a flaky structure is processed in a silver salt solution under ultrasonic action so as to load silver ions on the surface of g-C3N4. Then, a sodium phosphate solution is dropped in and continuously agitated, and the composite material Ag3PO4@g-C3N4 is formed through the in-situ precipitation reaction of the silver ions loaded on the surface of the g-C3N4 and phosphate radical ions. The method has the advantages of simple and easily-controlled preparing process, convenience in operation, low cost and high product visual light catalytic activity.

Owner:EAST CHINA UNIV OF SCI & TECH

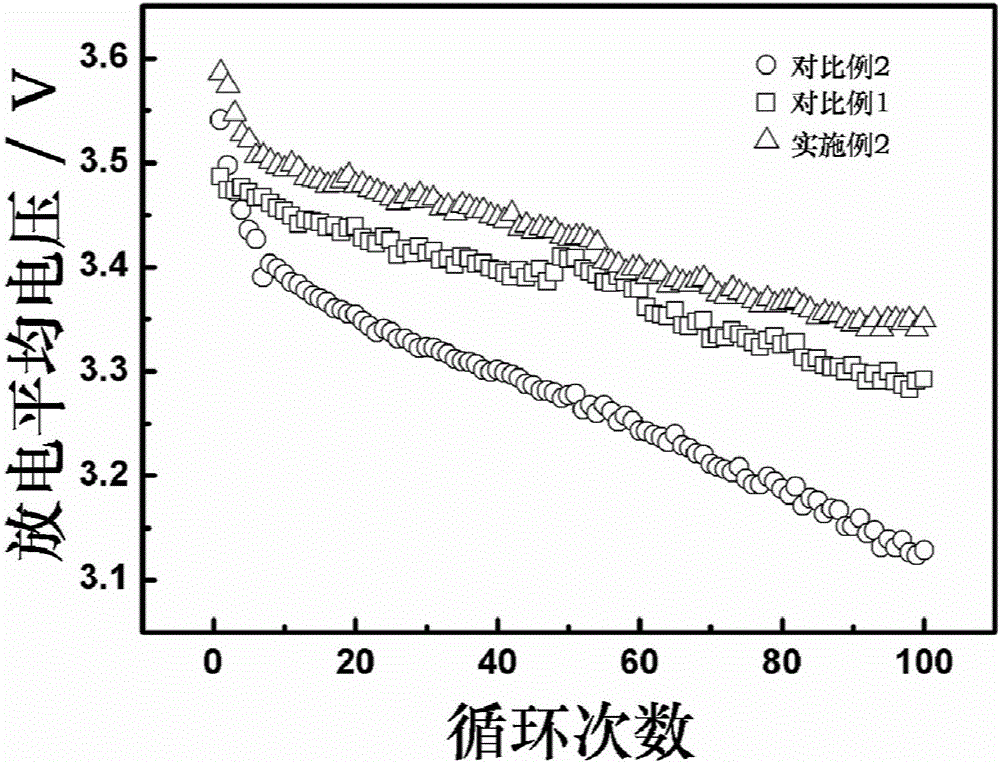

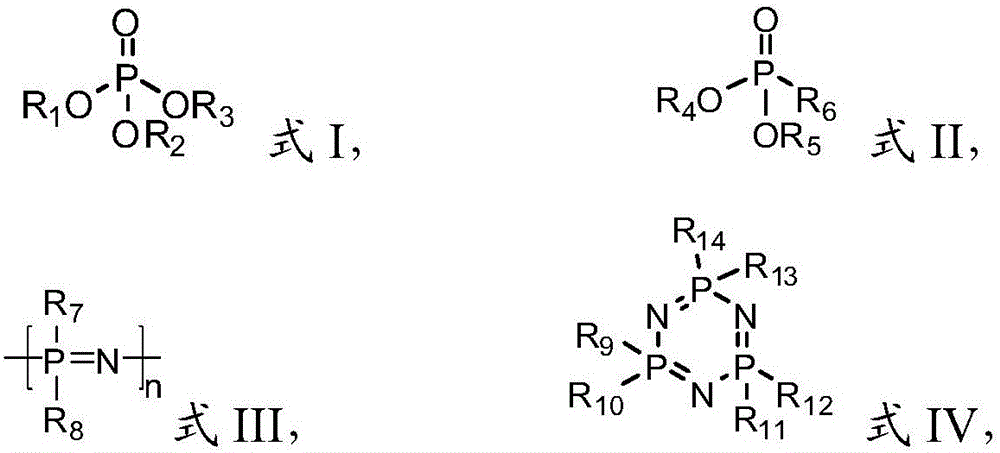

Nonaqueous electrolyte and lithium-ion battery

ActiveCN105720304AGood resistance to nucleophilic attackImprove antioxidant capacitySecondary cellsOrganic electrolytesSolventLithium-ion battery

The invention provides a nonaqueous electrolyte, which comprises an organic solvent and a lithium salt, wherein the organic solvent is selected from a non-carbonate solvent. The provided nonaqueous electrolyte has relatively good nucleophilic attack resistance; high-activity radical ions O2.<-> and these solvents are not easily subjected to nucleophilic reaction, so that Li2O loss in the material is effectively inhibited; the structure of a lithium-rich cathode material is stabilized; and the voltage hysteresis phenomenon of the material is effectively relieved. Meanwhile, the provided nonaqueous electrolyte has good oxidation resistance and non-combustible characteristics, so that a lithium-rich battery prepared from the nonaqueous electrolyte has relatively good cycle performance and relatively high safety.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

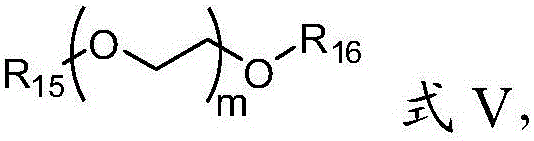

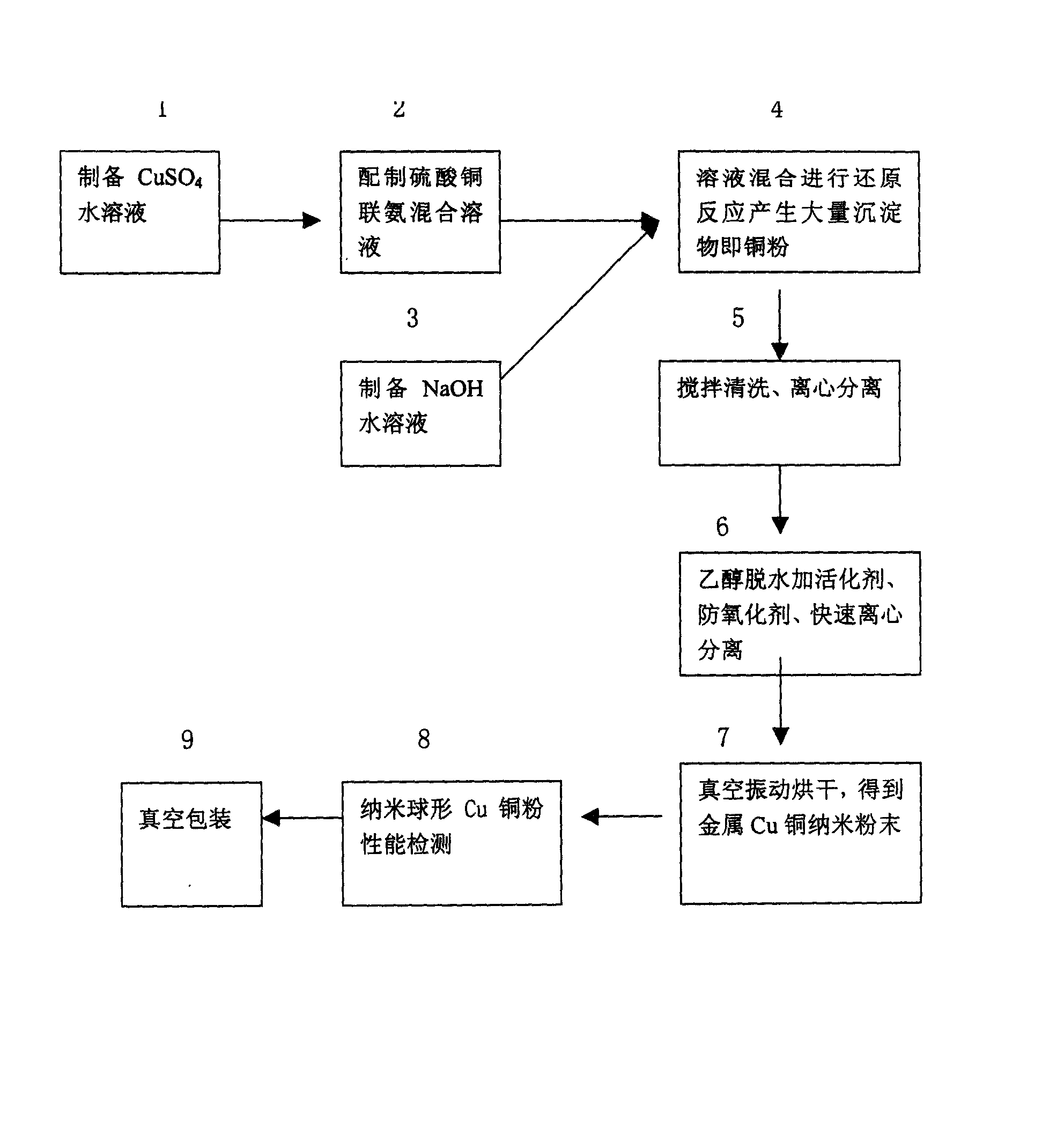

Method for mfg nano copper powder

THe present invention provides a method for preparing nano-grade ultrafine copper powder, and its preparation process. Said process includes the following steps: dissolving CuSO4 containing copper ion in water, and using hydrazine to make CU(2+) ion be reduced into supperfine Cu granules, and in the reaction product using water to clean out SO4(2-) radical ion, and using ethyl alcohol to remove residual water and adopting the continuous rapid centrifugal separation method to separate waste liquor from precipitate, finally low-temp. drying in vacuum vibration drying machine so as to obtain nano Cu powder.

Owner:UNIV OF SCI & TECH BEIJING

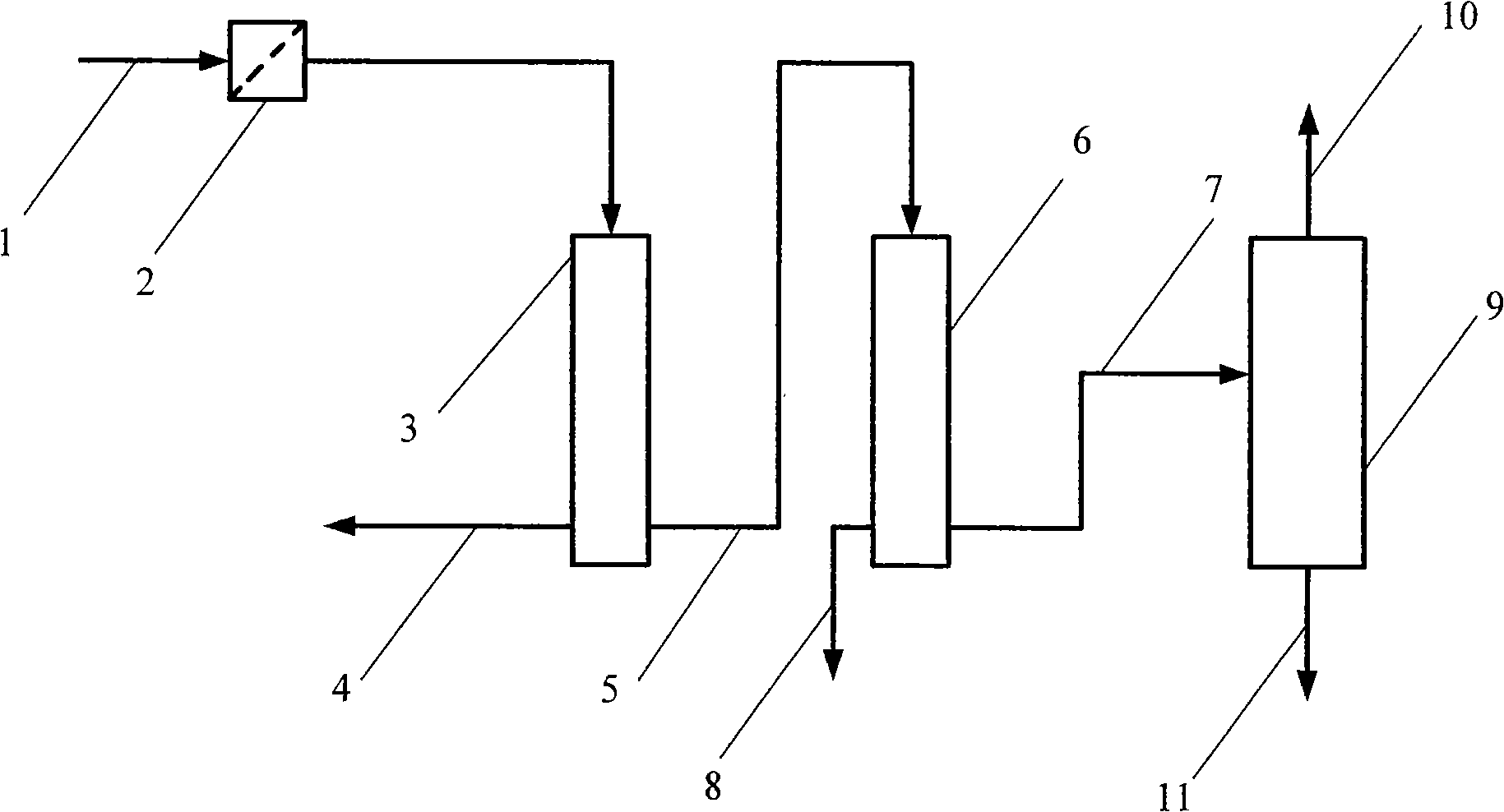

Method for removing hydrogen sulfide from gas

InactiveCN102527214AAbsorption pressure dropReduce sulfur pluggingDispersed particle separationSulfur preparation/purificationSulfurSulfur hydride

The invention relates to a method for removing hydrogen sulfide from gas, and belongs to the technical field of gas purification. The method mainly comprises the steps: firstly introducing the gas containing hydrogen sulfide to a kinetic wave absorber for removing a large amount of hydrogen sulfide, and then entering the gas containing a small amount of hydrogen sulfide to a filled tower for fine desulfurization; converting hydrogen sulfide in the gas into sulfhydryl radical ion in the absorption process by using a complex iron absorbing liquid; oxidizing rich solution absorbing hydrogen sulfide with air for regeneration so as to convert the sulfhydryl radical ion into simple substance sulfur harmless to environment, wherein the treated gas achieves the discharge requirement; and entering the gas containing sulfur into the kinetic wave absorber, and carrying out countercurrent contact with a complex iron desulfurizing liquid sprayed from bottom to top so as to form a stable form layer, so that the absorbing liquid carries out quick rotary cutting, and the gas and liquid are sufficiently contacted, thus the mass transfer efficiency is obviously improved, and the purification requirements that the hydrogen sulfide gas is quickly absorbed, most of hydrogen sulfide is removed by the kinetic wave, and a small amount of hydrogen sulfide in the gas is removed by the filled tower are achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

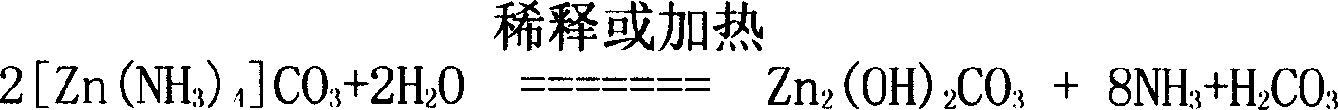

Uniformly coordinating precipitation method for preparing nano zinc oxide

InactiveCN1616354AReduce concentrationEvenly distributedOxygen/ozone/oxide/hydroxideZinc oxides/hydroxidesZno nanoparticlesSulfide

The present invention relates to uniformly coordinating precipitation process of preparing nanometer zinc oxide. The technological scheme includes the reaction between zinc oxide or zinc salt material and ammonia and carbonate as coordinating agent to produce water soluble coordinating compound tetraammonium-zinc carbonate solution; adding sulfide solution to eliminate heavy metal ion inside the coordinating compound solution; adding surfactant, water for dilution or heating decomposing the coordinating compound solution to separate zinc ion and to react with carbonate radical ion to produce fine basic zinc carbonate precipitate; washing the precipitate with ethanol, methanol or acetone, filtering, stoving at 40-80 deg.c and heating at 200-800 deg.c to decompose into nanometer zinc oxide. The production process is simple and has low cost.

Owner:XIANGTAN UNIV

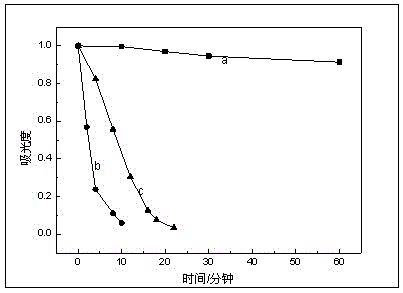

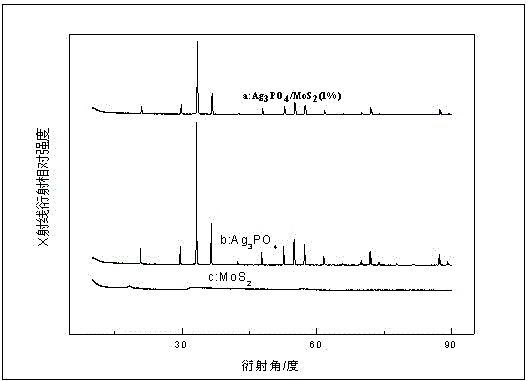

Silver phosphate/molybdenum disulfide compound visible-light-driven photocatalyst and preparation method thereof

InactiveCN103551173AImprove photocatalytic activityReduced photodegradation timePhysical/chemical process catalystsPhosphoric acidSilver phosphate

The invention discloses a preparation method for a silver phosphate / molybdenum disulfide compound visible-light-driven photocatalyst. The silver phosphate / molybdenum disulfide compound visible-light-driven photocatalyst is formed by loading silver phosphate onto a molybdenum disulfide flaky material, the mass ratio of the silver phosphate and molybdenum disulfide is 1.0:(0.005-0.015). The preparation method comprises steps of firstly preparing the molybdenum disulfide flaky material through a hydrothermal method, then mixing with silver ions so as to obtain a uniform solution, adding phosphate radical ions for stirring and reacting, then filtering, and carrying out vacuum drying on the obtained filter cakes so as to obtain the silver phosphate / molybdenum disulfide compound visible-light-driven photocatalyst. The silver phosphate / molybdenum disulfide compound visible-light-driven photocatalyst has high reactivity when being used for photocatalysis and degradation of organic pollutant rhodamine B, and the preparation method is simple and easy to operate, has low production cost, has no contamination in the production process, and is suitable for industrial scale production.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Method for treating glyphosate mother liquor by oxidation method

ActiveCN101757761AReduce pollutionReduce compactionChemical protectionPhosphate ionInorganic compound

The invention provides a method for treating glyphosate mother liquor by an oxidation method, which comprises the following steps: firstly, using regulating agents for regulating the pH value of the glyphosate mother liquor with organic phosphor or glyphosate or nitrogenous compounds or salt to 0.1 to 14; then, carrying out the pressurized oxidation reaction with strong oxidizing gas under the condition of the existence of catalysts; oxidizing phosphorus-containing impurities such as glyphosate, glyphosine, orthophosphorous acid, methyl glyphosate, aminomethyl phosphonic acid, N-(Phosphonomethyl) iminodiacetic acid and the like into phosphate radical ions; oxidizing nitrogenous organic impurities such as glycin, triethylene ammonia, diethanolameine, aminomethyl phosphonic acid, hydroxyethyl glycine and the like into ammonia radical ions; and then, carrying out concentration and separation to obtain phosphate and amine salt inorganic compounds for recovery and reuse. The invention can effectively oxidize the complicated organic phosphor and the nitrogenous compounds in the glyphosate mother liquor into single phosphate radicals and amine salt inorganic compounds for convenient recovery and reuse, and can simultaneously reduce the environment pollution and the soil hardening caused by the mother liquor. Thereby, the total conversion rate of the phosphorus-containing compounds reaches 60 to 90 percent, the conversion rate of the nitrogenous compounds reaches more than 90 percent, in addition, the removal rate of the glyphosate reaches 95 to 99 percent, a large amount of produced phosphate and amine salt can be used for agricultural fertilizers, and the goal of changing waste materials into valuable materials is achieved.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

Method for preparing calcium carbonate by using catalysis of microbial carbonic anhydrase

InactiveCN102121033AHigh purityAbundant resourcesMicroorganism based processesFermentationAtherion elymusFiltration

The invention provides a method for preparing calcium carbonate by using catalysis of microbial carbonic anhydrase, which comprises the following steps of: adding the carbonic anhydrase extracted from a microbial culture into a liquid system containing calcium ion and bicarbonate radical ion solution or a gas diffusion system containing calcium ion solution and releasing CO2 by using ammonium hydrogen carbonate solution, performing oscillating reaction at room temperature, controlling initial pH at 5 to 10, taking out the produced sediment, and performing filtration, washing and drying to obtain the calcium carbonate. The method makes full use of microbial resources and characteristics of specificity and high efficiency of enzyme catalytic reaction, prepares the calcium carbonate by accelerated deposition, and has the advantages of riche resources, simple process, clean environment, low cost, high efficiency, quickness and the like. The calcium carbonate prepared by deposition has high purity, is calcite crystal calcium carbonate, can be used as an industrial filler, and can also be used for repairing cracks of building engineering, buildings, stone landscapes and carved stone cultural relics.

Owner:HUAZHONG UNIV OF SCI & TECH

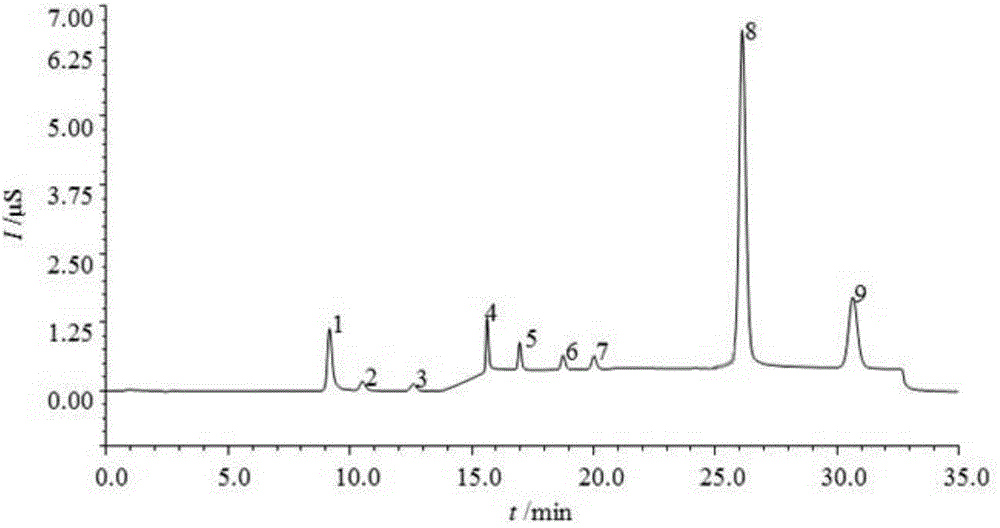

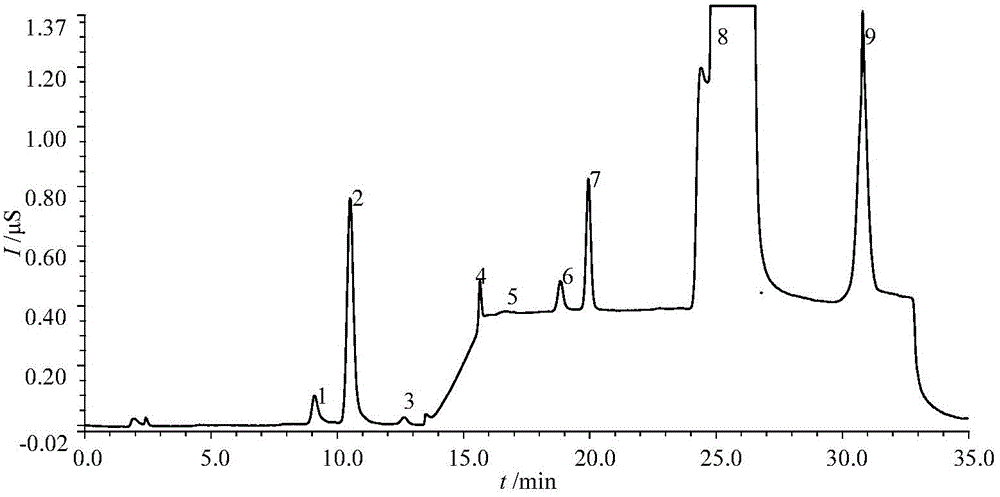

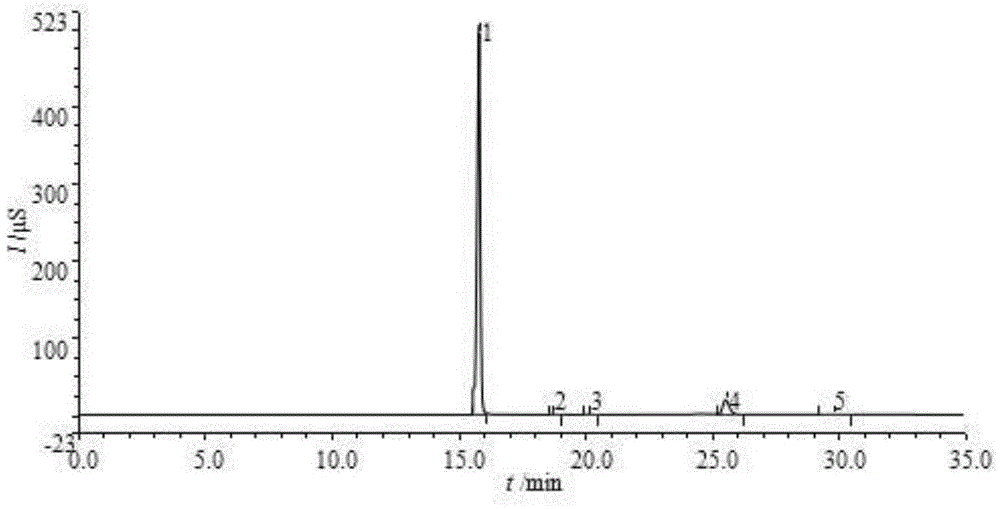

Method for simultaneously determining inorganic anions and organic acid radical ions in salt lake brine

The invention discloses a method for simultaneously determining inorganic anions and organic acid radical ions in salt lake brine. The method is characterized by preprocessing a certain quantity of samples of the salt lake brine, simultaneously separating and determining 6 types of inorganic anions comprising F<-1>, Cl<-1>, NO2<-1>, Br<-1>, NO3<-1> an SO4<2-> and 3 types of organic acid radical ions comprising CH3COO<-1>, HCOO<-1> and C2O4<2-> in the salt lake brine by carrying out secondary gradient elution through an ion chromatography. The result shows that the method is simple and convenient, high in accuracy and capable of providing the important reference basis for simultaneously separating and determining a plurality of anions in the salt lake brine and exploring resources of the salt lake.

Owner:QINGHAI UNIVERSITY

Method for treating high-COD (chemical oxygen demand) organic wastewater through microwave catalytic oxidation

InactiveCN103663609AEfficient removalEasily biodegradableWater/sewage treatment by irradiationWater contaminantsHigh concentrationPersulfate

The invention relates to a method for treating high-COD (chemical oxygen demand) organic wastewater through microwave catalytic oxidation. According to the method, microwaves are radiated to the surface of a microwave catalyst to produce a strong oxidizing group for oxidizing the high-COD organic wastewater, so that organic matters such as organic amine in the wastewater can be oxidized to be degraded into CO2 and water or inorganic acid radical ions. The method disclosed by the invention has the advantages of efficiently removing the organic matters and reducing the COD value of the high-concentration industrial wastewater from larger than 5,000-60,000 to smaller than 100 or facilitating biochemical degradation. In a use process of the method, strong oxidants such as hydrogen peroxide, O3 and ClO2 activated peroxysulphate do not need to be added and is a novel organic wastewater treatment method which is high in efficiency, low in energy consumption, low in cost, favorable for industrialization and secondary-pollution-free, occupies a small area and has a simple technology; the difficulties in biochemical treatment of high-concentration and high-salinity COD organic wastewater in the industries such as printing and dyeing, pesticides, pharmacy and chemical engineering are solved.

Owner:XIANGTAN UNIV

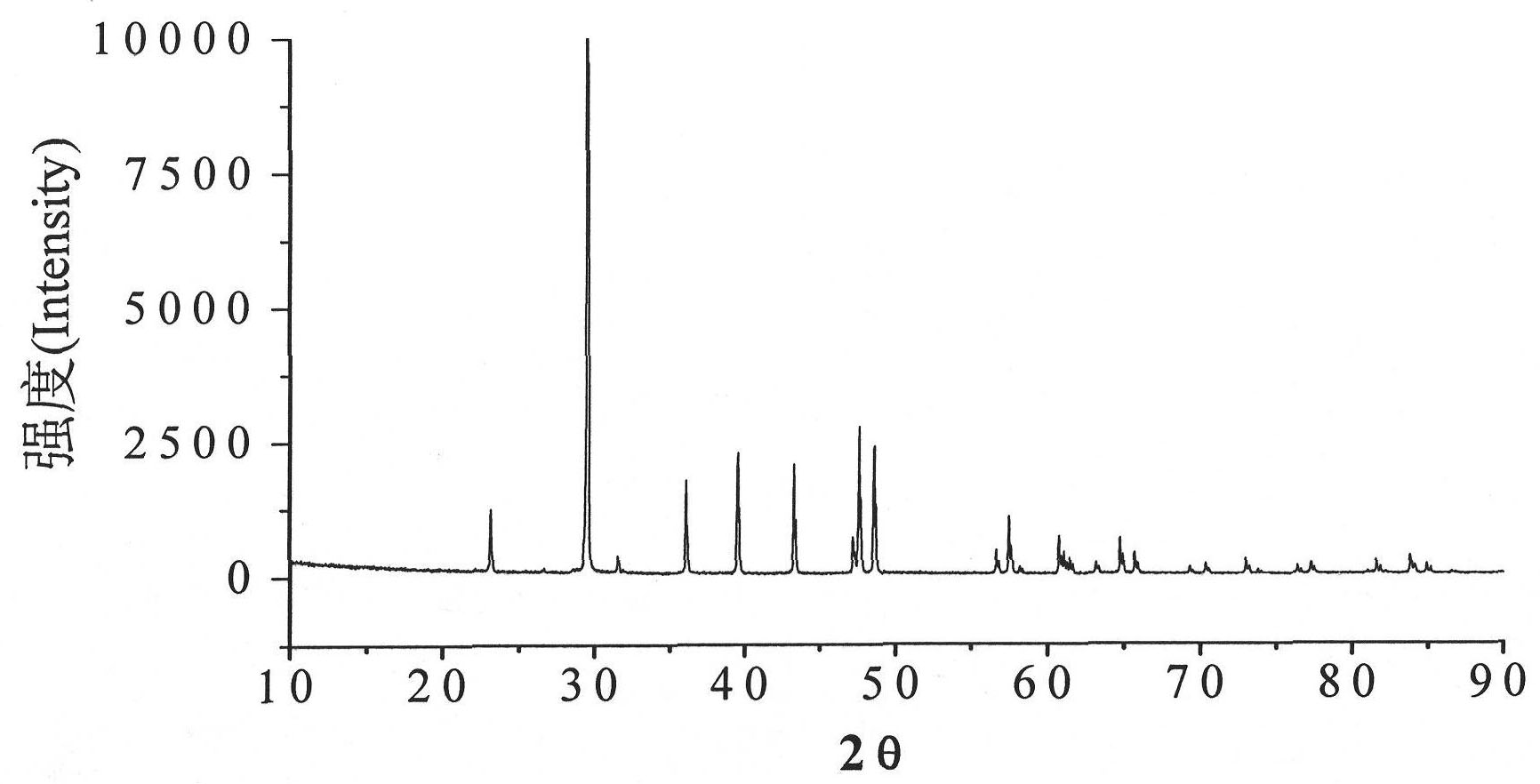

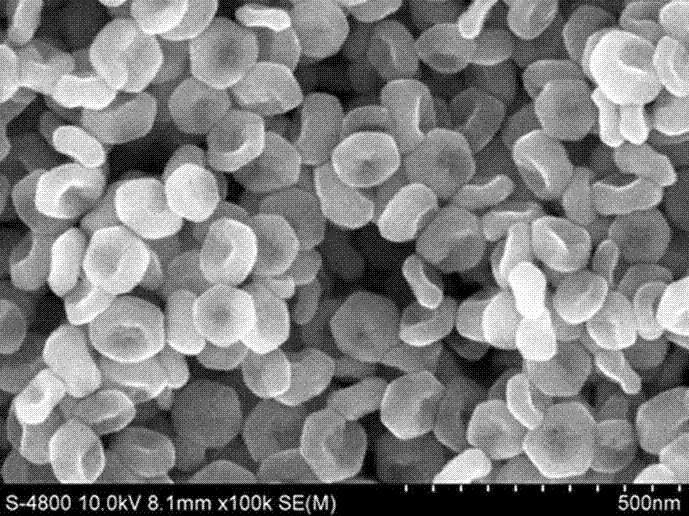

Hydro-thermal synthesis method for shape-controllable nano iron oxide

ActiveCN103754956AEffective control of morphologyEffective size controlMaterial nanotechnologyFerric oxidesIron saltsPhosphate ion

The invention relates to a preparation method for shape-controllable nano iron oxide and particularly relates to a hydro-thermal synthesis method for shape-controllable nano iron oxide. The hydro-thermal synthesis method comprises the following steps: (1) weighing dihydric phosphate, strong acid and strong alkali salts and trivalent iron salt; mixing and adding a mixture into de-ionized water; agitating until the mixture is completely dissolved to obtain a precursor solution, wherein the mol ratio of phosphate radical ions to trivalent iron ions in the precursor solution is (0-3) to 10; the mole ratio of the strong acid and strong alkali salts to the trivalent iron ions is (0-5) to 10; the mass of the de-ionized water is 50-300 times as much as the total mass of the dihydric phosphate, the strong acid and strong alkali salts and the trivalent iron salt; and (2) putting the precursor solution into a reaction kettle and heating to 150-250 DEG C and preserving the heat for 2-4 hours; cooling to the room temperature and adding the de-ionized water and alcohol into an obtained product; sufficiently shaking and centrifuging; removing liquid supernatant and transferring content matters into an electric heating vacuum drying box; drying until the weight is constant to obtain the nano iron oxide.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com