Method for preparing calcium carbonate by using catalysis of microbial carbonic anhydrase

A carbonic anhydrase, catalytic preparation technology, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of ecological environment destruction, environmental pollution, high energy consumption, etc., and achieve low cost, clean environment, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

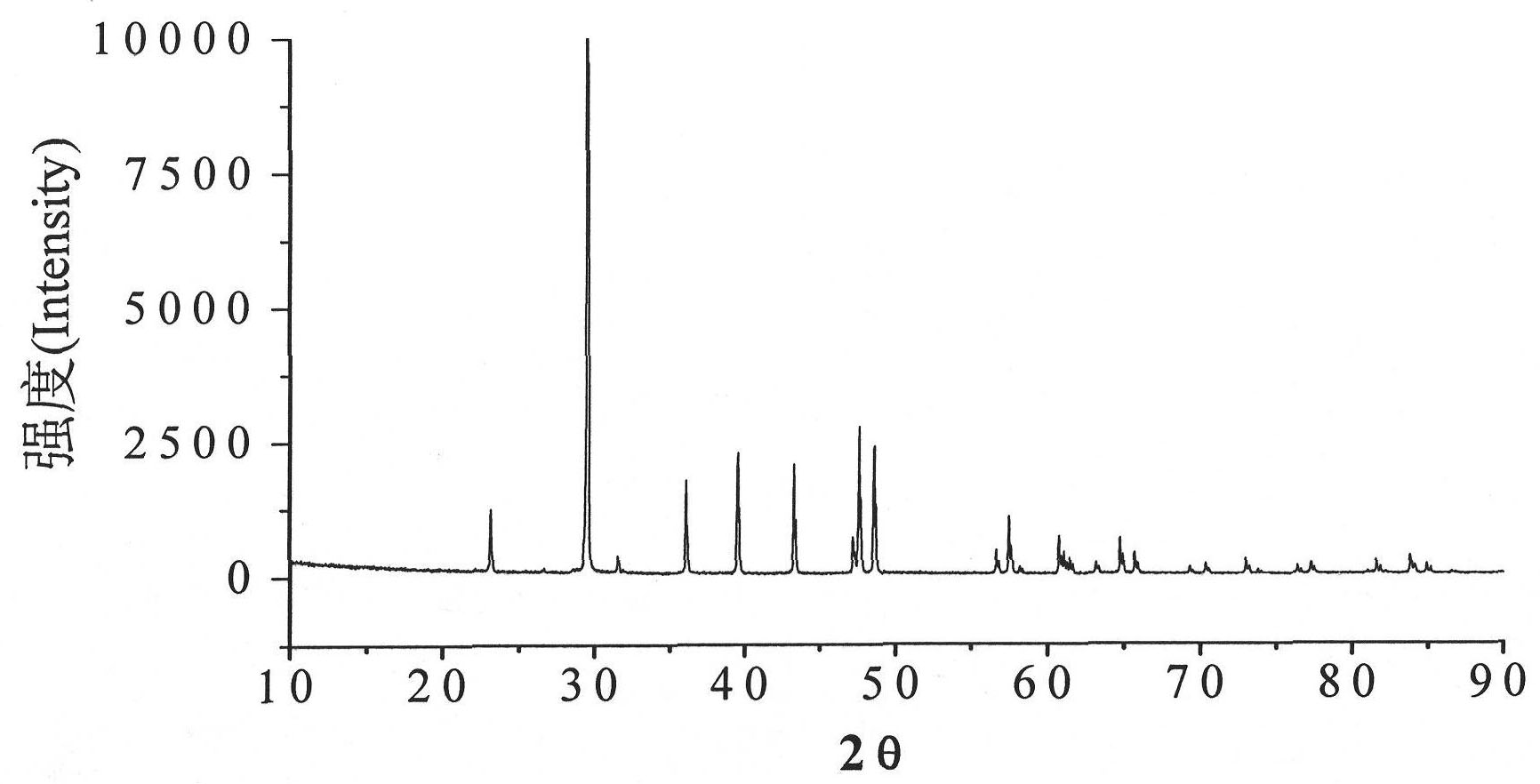

[0027] Preparation of microbial extracellular carbonic anhydrase and its catalytic preparation of calcium carbonate in a liquid system containing calcium chloride and sodium bicarbonate solution. Inoculate Bacillus cereus (Bacillus pasteurii) in bacterial culture medium supplemented with 10 μM zinc sulfate, culture at 30°C and 120 r / min for 24 hours, collect the supernatant after refrigerated centrifugation at 5000 r / min for 15 minutes, and refrigerate the bacteria Standby, the supernatant was salted out with 70% saturated ammonium sulfate for 12 hours, centrifuged to get the protein precipitate, and the protein precipitate was dissolved in 0.2mol / L phosphate buffer solution of pH8.0, passed through the G100 gel column, and washed with 0.2mol / L pH8.0 phosphate buffer for elution, collect the part with high enzyme activity, put it in a dialysis bag for dialysis for 24 hours, then pass the dialysate through a DEAE-cellulose ion exchange column, first use 0.2mol / L pH8.0 Equilibr...

Embodiment 2

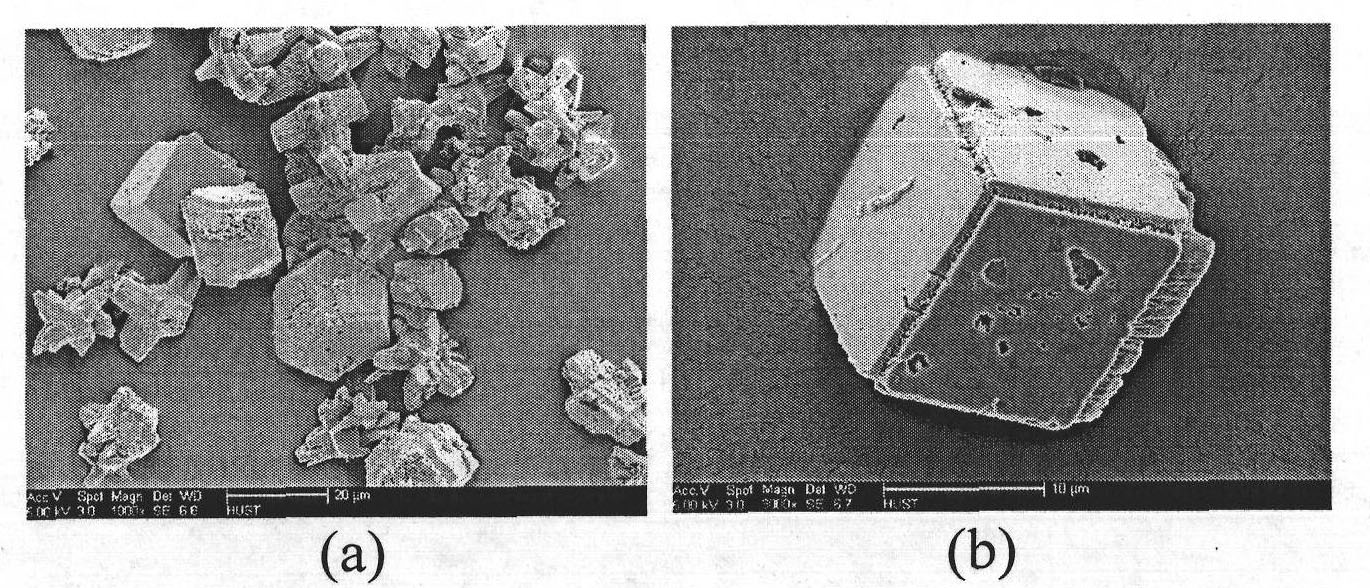

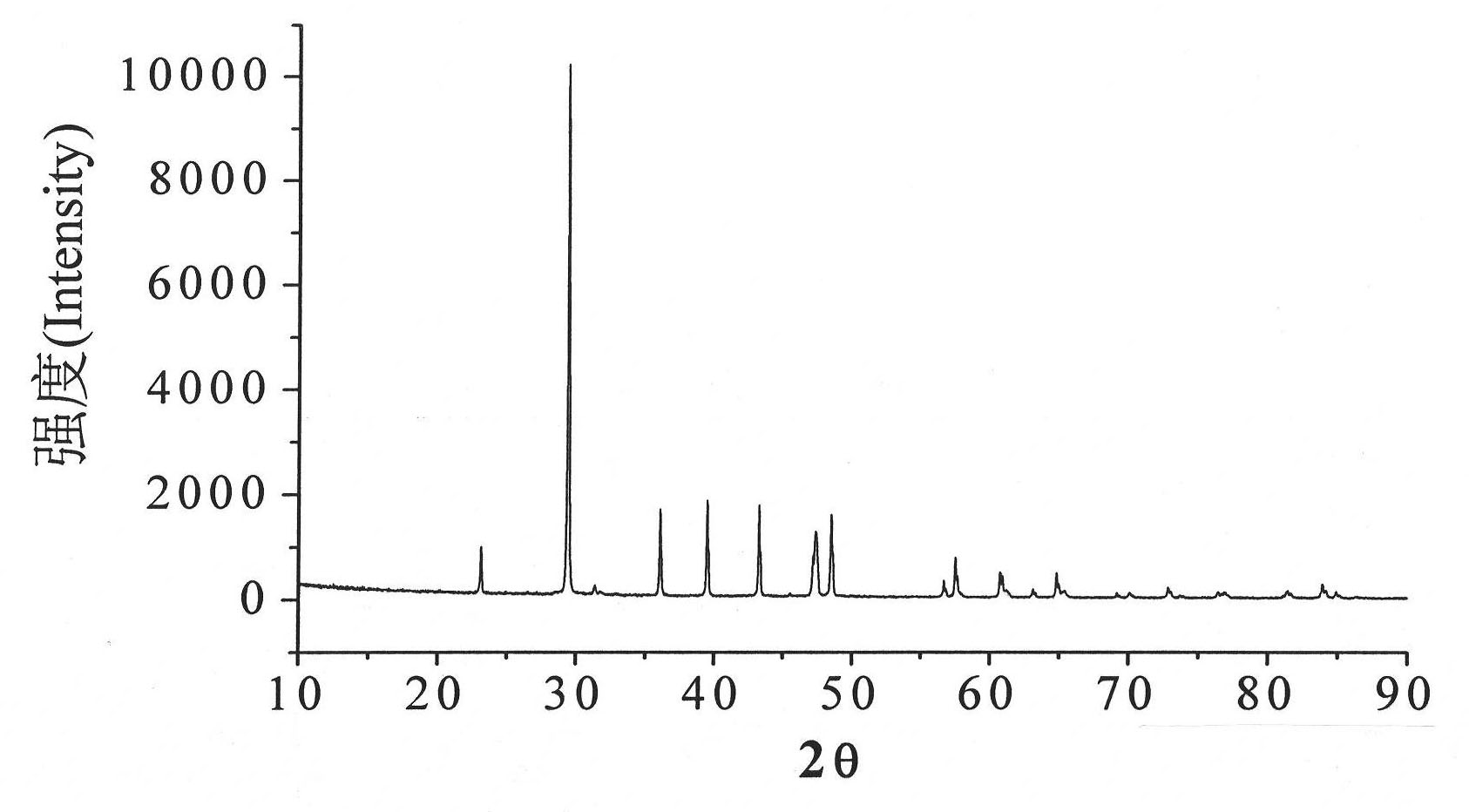

[0029]Preparation of microbial intracellular carbonic anhydrase and its catalytic preparation of calcium carbonate in a liquid system containing calcium chloride and sodium bicarbonate solution. The thallus obtained in Example 1 was added to 0.2mol / L pH8.0 phosphate buffer to make the thalline concentration 10%, ground for 30 minutes under ice-bath conditions, refrigerated and centrifuged for 15 minutes at 5000rpm, and the supernatant was taken solution, the supernatant was salted out with 70% saturated ammonium sulfate for 12 hours, and the subsequent steps were the same as the preparation method of extracellular carbonic anhydrase described in Example 1 to obtain an intracellular carbonic anhydrase solution, and detect its enzyme activity It is 8.2U / mL. Prepare sodium bicarbonate and calcium chloride solution and place in the Erlenmeyer flask, the concentration of sodium bicarbonate and calcium chloride is 25.2mmol / L, add the intracellular carbonic anhydrase solution of prep...

Embodiment 3

[0031] Microbial extracellular carbonic anhydrase catalyzes the production of calcium carbonate in a gas-diffusion system. The preparation method of extracellular carbonic anhydrase was the same as that in Example 1, and its enzyme activity was detected to be 8.0 U / mL. In a closed glass desiccator, place a 50mL small beaker on the upper layer, which contains 25.0mmol / L calcium chloride solution, in which extracellular carbonic anhydrase is added, the enzyme concentration is 1.8U / mL, and the initial pH is controlled at 6.5; The gas-permeable partition is bounded; the lower layer is filled with 400mL 0.1mol / L ammonium bicarbonate solution. Put the whole desiccator at 20°C and 100r / min to shake and react for 24 hours, take out the generated precipitate, filter, wash and dry to obtain calcium carbonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com