Eutectic solvent and application of eutectic solvent in lignin extraction

A deep eutectic solvent and lignin technology, applied in the field of biomass refining, can solve problems such as instrument corrosion, fiber degeneration, and acceleration equipment, and achieve the effects of low environmental pollution, low cost, and low molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

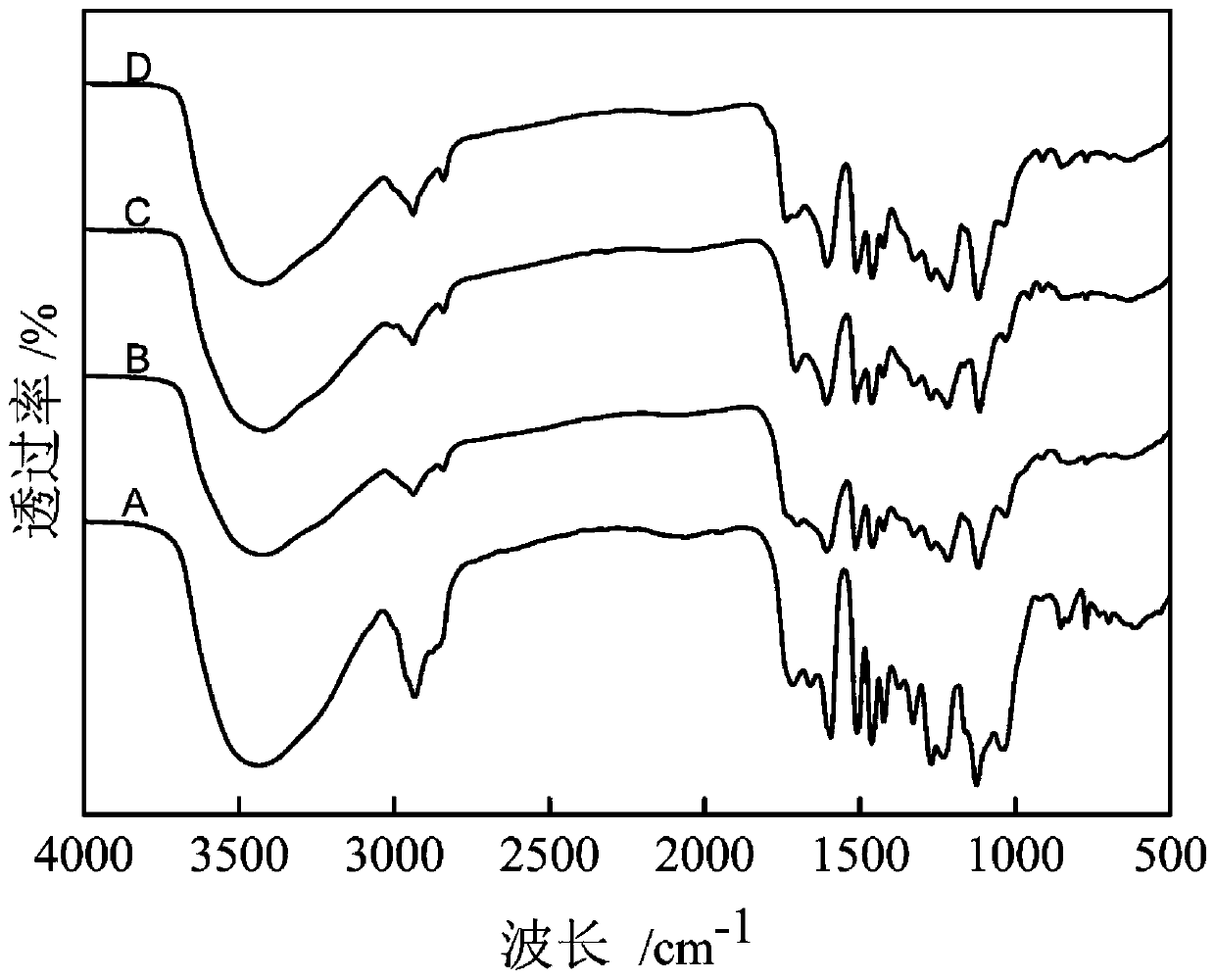

[0067] Lignin was extracted by treating poplar raw material with lactic acid choline-lactic acid deep eutectic solvent.

[0068] (1) Raw material pretreatment: Take relatively uniform wood chips, air-dry, crush, and then sieve to get 40-60 mesh wood powder.

[0069] (2) Benzyl alcohol extraction: use a benzene-ethanol mixed solution with a volume ratio of 2:1 to carry out benzene alcohol extraction on the wood flour, extract for 6-8 hours, dry and constant weight.

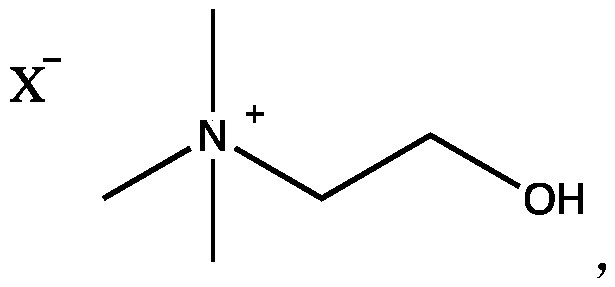

[0070] (3) Preparation of deep eutectic solvent: mix choline chloride and potassium hydroxide according to the amount of substance 1:1, in ethanol solvent, heat and stir at a reaction temperature of 60°C for 4h, filter, keep the supernatant, and mix according to the substance Lactic acid was added in an amount of 1:1, and after drying by rotary evaporation, it was mixed with lactic acid at a ratio of 1:10, heated at 60°C for 5 hours, and cooled to room temperature to obtain a choline lactate-lactic acid deep eutect...

Embodiment 2

[0076] Poplar raw material was treated with choline formate-formic acid deep eutectic solvent to extract lignin.

[0077] (1) Raw material pretreatment: Take relatively uniform wood chips, air-dry, crush, and then sieve to get 40-60 mesh wood powder.

[0078] (2) Benzyl alcohol extraction: use a benzene-ethanol mixed solution with a volume ratio of 2:1 to carry out benzene alcohol extraction on the wood flour, extract for 6-8 hours, dry and constant weight.

[0079] (3) Preparation of deep eutectic solvent: mix choline chloride and potassium hydroxide according to the amount of substance 1:1, in ethanol solvent, heat and stir at a reaction temperature of 60°C for 4h, filter, keep the supernatant, and mix according to the substance Add formic acid at a ratio of 1:1, dry by rotary evaporation, mix with formic acid at a ratio of 1:10, heat at 60°C for 5 hours, and cool to room temperature to obtain a choline formic acid-formic acid deep eutectic solvent.

[0080] (4) Deep eutect...

Embodiment 3

[0085] The poplar raw material was treated with choline propionate-propionate deep eutectic solvent to extract lignin.

[0086] (1) Raw material pretreatment: Take relatively uniform wood chips, air-dry, crush, and then sieve to get 40-60 mesh wood powder.

[0087] (2) Benzyl alcohol extraction: use a benzene-ethanol mixed solution with a volume ratio of 2:1 to carry out benzene alcohol extraction on the wood flour, extract for 6-8 hours, dry and constant weight.

[0088] (3) Preparation of deep eutectic solvent: mix choline chloride and potassium hydroxide according to the amount of substance 1:1, in ethanol solvent, heat and stir at a reaction temperature of 60°C for 4h, filter, keep the supernatant, and mix according to the substance Propionic acid was added at a ratio of 1:1, and after drying by rotary evaporation, it was mixed with propionic acid at a ratio of 1:10, heated at 60°C for 5 hours, and cooled to room temperature to obtain a choline propionate-propionate deep e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com