Method for efficiently extracting lithium from salt lake brine

A salt lake brine and extraction technology, applied in the direction of improving process efficiency, etc., can solve the problems of no practical industrial application significance, the price of diisobutyl ketone dissolution loss, and the inability to apply industrialization, etc., and achieve good recyclability, low price, and raw materials rich effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

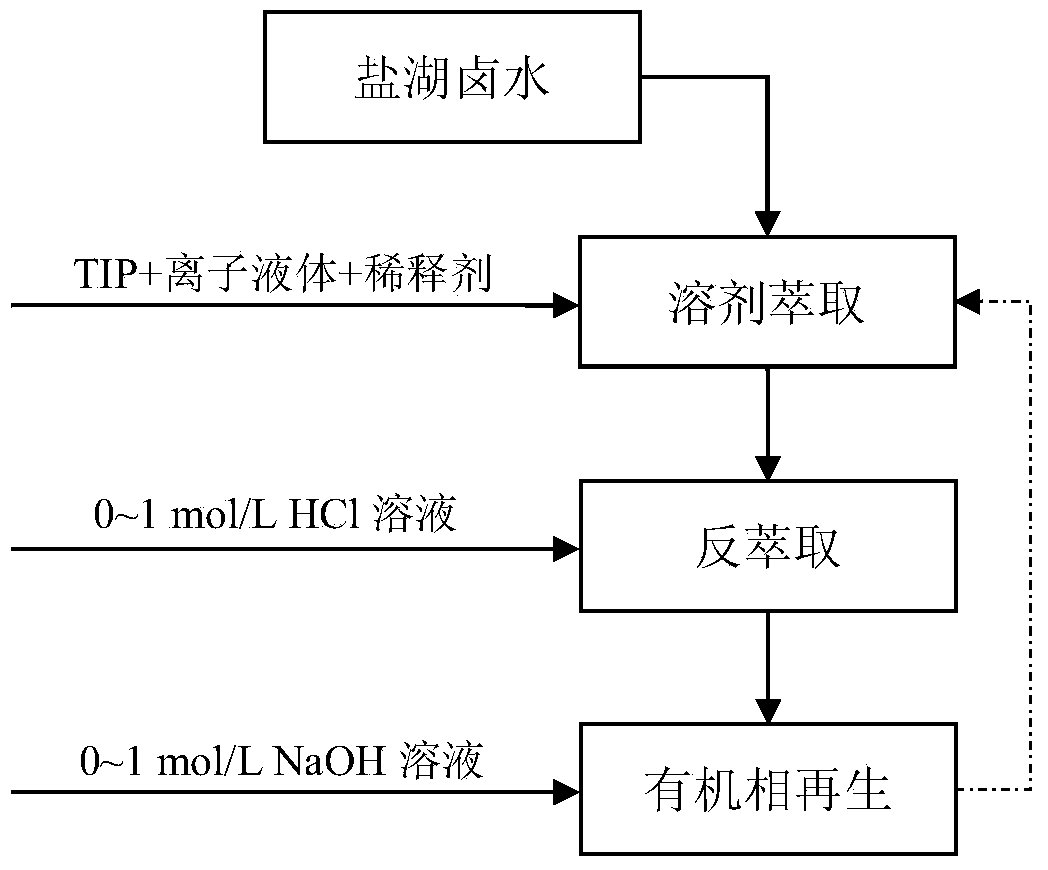

[0031] A method for extracting lithium from salt lake brine extraction method, the steps are as follows:

[0032] (1) Extraction: Take 24mL of TIP (triisopropyl phosphate), 3mL of kerosene and 3mL of 1-butyl-3-methylimidazolium hexafluorophosphate in a separatory funnel and mix evenly, then add lithium-containing 15mL of 2.2g / L salt lake brine, no need to adjust the pH value of the brine, after shaking for 10min, separate the aqueous phase and the organic phase, and perform a tertiary extraction on the aqueous phase.

[0033] (2) Stripping: the organic phase is stripped with 1mol / L HCl solution, the single stripping time is 2-10min, the stripping ratio is 3, the aqueous phase is collected to be an aqueous solution containing lithium ions, and the organic phase is stripped with 1mol / LNaOH solution After washing and regeneration, it can be recycled repeatedly, which greatly reduces the production cost, avoids environmental pollution, and produces no three wastes.

[0034] (3) A...

Embodiment 2

[0036] A method for extracting lithium from salt lake brine extraction method, the steps are as follows:

[0037] (1) Extraction: First take 24mL of TIP, 3mL of kerosene and 3mL of 1-ethyl-3-methylimidazolium bis(trifluoromethanesulfonyl)imide salt and mix them evenly in a separatory funnel, then add lithium containing 2.2g / L salt lake brine 20mL, no need to adjust the pH value of the brine, after shaking for 10 minutes, separate the aqueous phase and the organic phase, and carry out the tertiary extraction of the aqueous phase.

[0038] (2) Back extraction: the organic phase is back extracted with 1mol / L HCl solution, the back extraction ratio is 2, the water phase is collected to be an aqueous solution containing lithium ions, and the organic phase can be reused after being washed and regenerated with 1mol / L NaOH solution, greatly improving The production cost is reduced, environmental pollution is avoided, and no three wastes are generated.

[0039] (3) Analysis: ICP-OES ...

Embodiment 3

[0041] A method for extracting lithium from salt lake brine extraction method, the steps are as follows:

[0042](1) Extraction: First take TIP21mL, kerosene 4.5mL and N-methyl, propylpiperidine bis(trifluoromethanesulfonyl)imide salt 4.5mL and mix them evenly in a separatory funnel, then add lithium containing 2.2 g / L salt lake brine 20mL, no need to adjust the pH value of the brine, after shaking for 10 minutes, separate the aqueous phase and the organic phase, and carry out the three-stage extraction of the aqueous phase.

[0043] (2) Stripping: the organic phase is back-extracted with 1mol / L HCl solution, and the aqueous phase is collected to be an aqueous solution containing lithium ions. The organic phase can be reused after being washed and regenerated with 1mol / LNaOH solution, which greatly reduces production costs and avoids the Environmental pollution, no three wastes produced.

[0044] (3) Analysis: ICP-OES is used to analyze and measure the content of each ion. Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com