Patents

Literature

44 results about "Stripping ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In mining, stripping ratio or strip ratio refers to the ratio of the volume of overburden (or waste material) required to be handled in order to extract some tonnage of ore. For example, a 3:1 stripping ratio means that mining one tonne of ore will require mining three tonnes of waste rock. Stripping ratios are typically reduced to show the volume of waste removal required to extract one unit ton of ore, for example, 1.5:1 as opposed to 3:2.

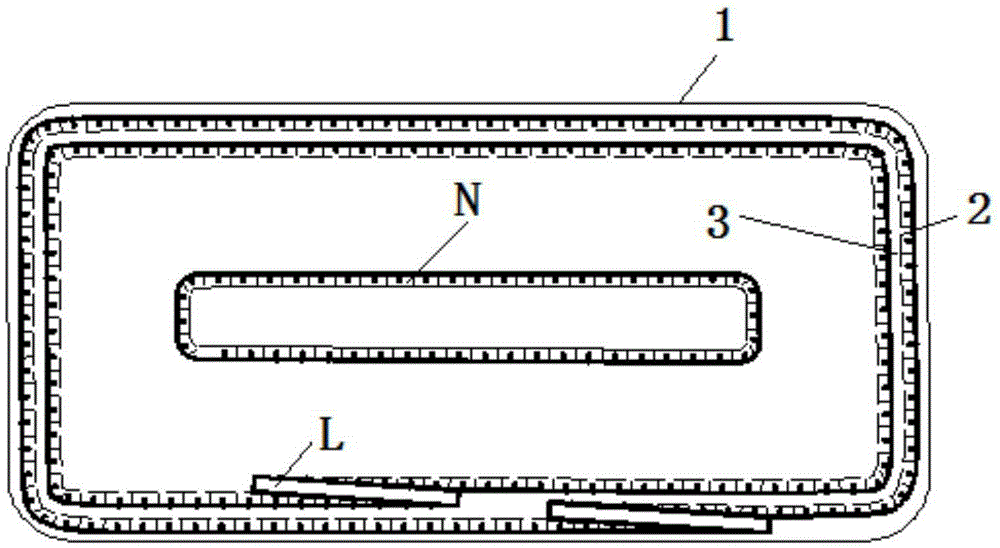

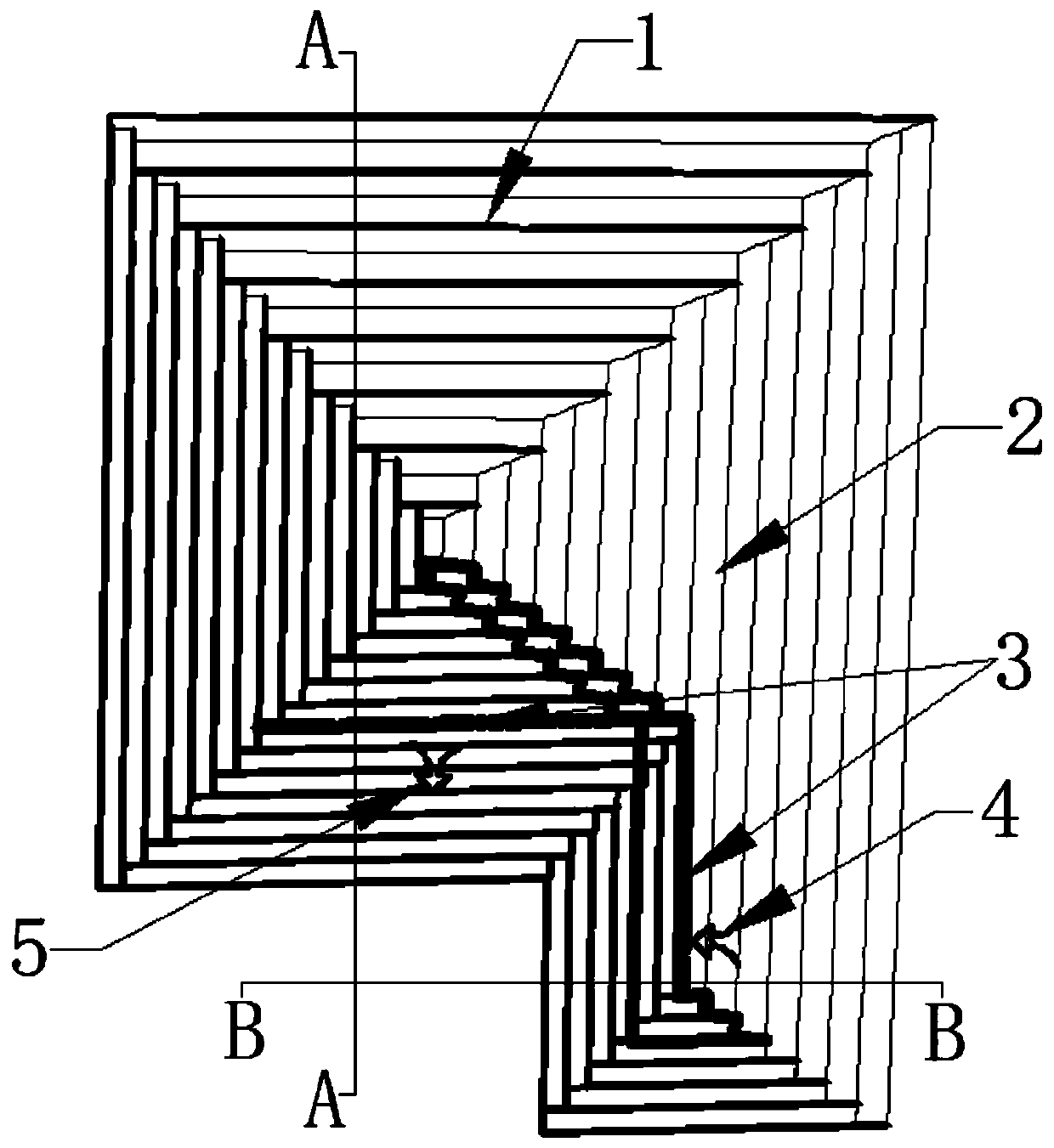

Opencast coal mine end slope filling mining method

InactiveCN103758568AReduce wasteSolve the problem of reduced recovery rateMaterial fill-upOpen-pit miningMining engineeringCoal pillar

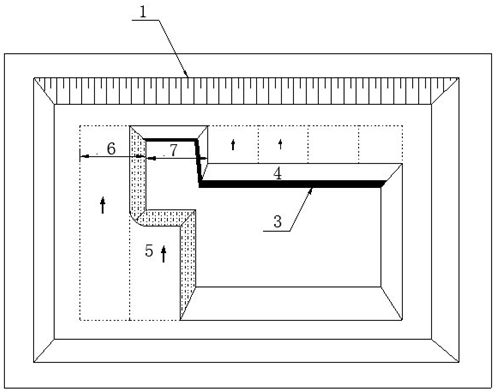

Provided is an opencast coal mine end slope filling mining method. The opencast coal mine end slope filling mining method includes the steps that a coal pillar reserved at an opencast coal mine end slope is divided into a plurality of stalls which are equal to an end slope coal mining machine roller in width; a stowboard is tunnelled to the position of an earth surface safety boundary line in the coal seam trend direction, and a stowboard is tunnelled in the coal seam inclination direction; an end slope coal mining machine is used for mining the stalls on the side of the stowboard in the coal seam inclination direction at intervals, after mining of the stalls is completed, the end slope coal mining machine is removed, mining openings in the sides of stall side slopes are sealed, and filling is performed on the stalls which are mined at intervals; then, mining is performed on stalls at intervals, the stalls are not mined, filling is performed on the mined stalls, and the steps are repeated until mining of all the stalls which are not mined is completed. According to the opencast coal mine end slope filling mining method, rock and soil discharged by an opencast coal mine can be effectively used, the discharge amount of the rock and soil of the opencast coal mine is reduced, the stripping ratio is lowered, mines end slope coal resources are mined in a maximization mode, meanwhile the side slope safety is guaranteed, and the efficient environment-friendly production process of the opencast coal mine is achieved.

Owner:CHINA UNIV OF MINING & TECH

Method for recovering coal in easily sliding area of strip mine

InactiveCN102606160AReduce stripping ratioLow costUnderground miningSurface miningOpen-pit miningSlope angle

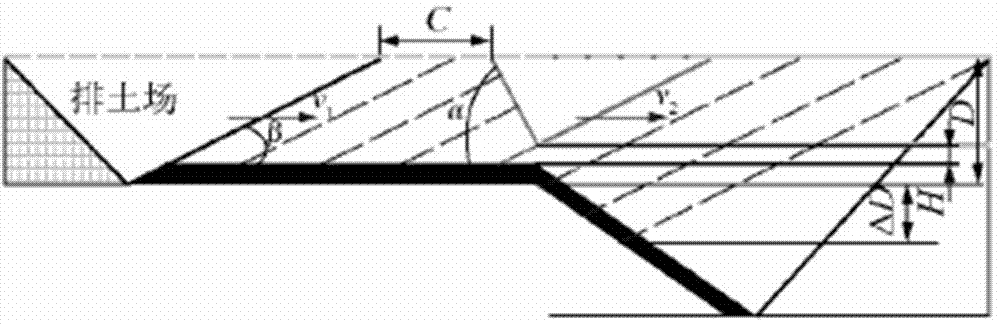

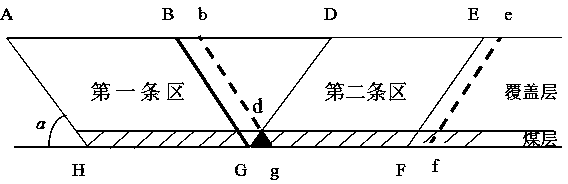

The invention discloses a method for recovering coal in an easily sliding area of strip mine, which is most suitable for recovering coal in a slope of the easily sliding area with a remarkable sliding surface. In a process of strip mining, the sliding surface is existent inside the slope of the easily sliding area; and when the coal in the easily sliding area are mined, the lower part of the sliding surface is located in the mining range. For preventing the exposed length of the sliding surface from being too long, the slope of the easily sliding area is divided into a plurality of mining strips for mining according to the trend, and the width of the mining strip is 2 times the working radius of a used electric shovel. The method comprises the steps of firstly mining the first mining strip, which is perpendicular to the trend of the slope or is pushed in the trend of the slope; timely following by an internal waste dump; after mining the previous mining strip, continuously mining the next mining strip; covering the exposed surface of the previous mining strip after reaching the boundary by the internal waste dump in sequence; and running in cycle until all the mining strips are mined. The method can be used for reducing the exposed length of the sliding surface of the easily sliding area, guaranteeing the slope to be stable, increasing the slope angle, recovering the coal and lowering the stripping ratio.

Owner:CHINA UNIV OF MINING & TECH

Mining method for passing open-pit coal mine of coal barren area through leaving island to build bridges

InactiveCN104405396AReduced transport distanceReduce shipping costsUnderground miningSurface miningEconomic benefitsTruck

The invention belongs to the field of coal mining, and particularly relates to a mining method for passing an open-pit coal mine of a coal barren area through leaving an island to build bridges. The mining method comprises the following steps: when an open pit is advanced to the coal barren area, determining the range of an island body according to the range of the coal barren area, establishing an island-back transportation conveyer bridge between the island body of the pit and an inner dump, and building an island-front conveyer bridge when the inner dump crosses the island body of the pit. The mining method has the advantages of decreasing the overburden amount in the ore field, reducing the production stripping ratio, saving the land occupation of an outer dump, being environment-friendly, decreasing the mining disturbance of the pit, shortening the truck load distance, reducing the stripping and transportation costs, increasing the economic benefit and having wide practicability.

Owner:LIAONING TECHNICAL UNIVERSITY

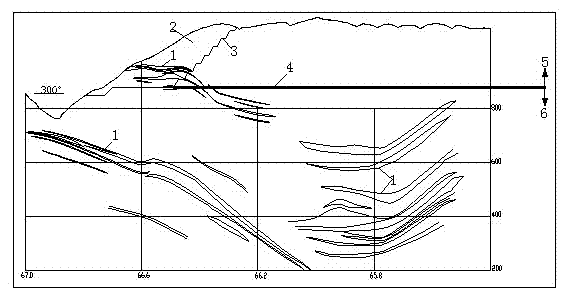

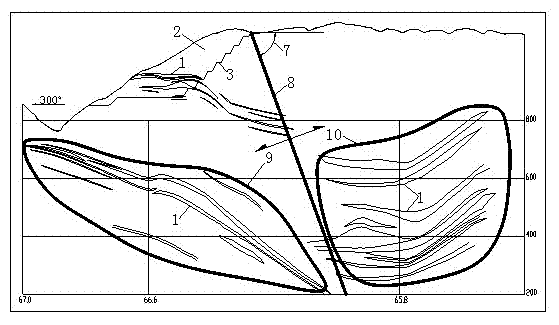

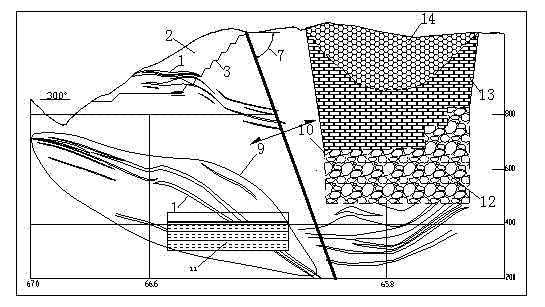

Open pit and underground space-time synchronous mining method for multiple-ore body

ActiveCN103590830ASafe miningGuaranteed thicknessUnderground miningSurface miningOpen-pit miningTime space

The invention discloses an open pit and underground space-time synchronous mining method for a multiple-ore body. According to the technical scheme, the method comprises the following steps: marking the demarcation line of the ore bodies at the shallow and deep positions so as to divide the multiple-ore body into a shallow-position ore body and a deep-position ore body according to an economical and reasonable stripping ratio; delineating the demarcation line of an open-pit mining protection zone according to a moveable angle (7) determined by underground mining by taking the largest demarcation ring of the open-pit mining as a protection line, wherein the deep-position ore body in the protection zone is a filling-process mining zone section (9) and the deep-position ore body outside the protection zone is a caving-process mining zone section (10); filling the waste stone stripped in open pit back to a waste stone back filled region (14) in a rubber belt conveying manner and carrying out cemented filling on the dead zone of the filling-process mining zone section (9) with tailings so as to form a tailings cemented filling region (11). According to the method, the technological characteristics of different mining manners such as open-pit mining, filling-process milling and caving-process mining are organically combined, so that the open-pit, underground space-time synchronous, environment-friendly and efficient mining of the multiple-ore body can be realized.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

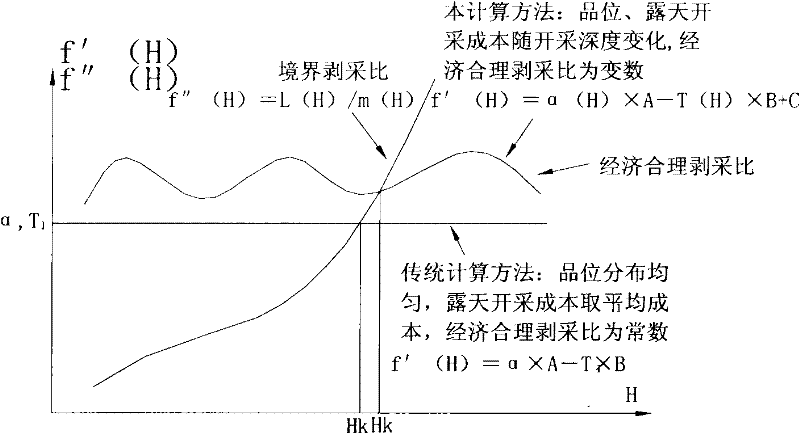

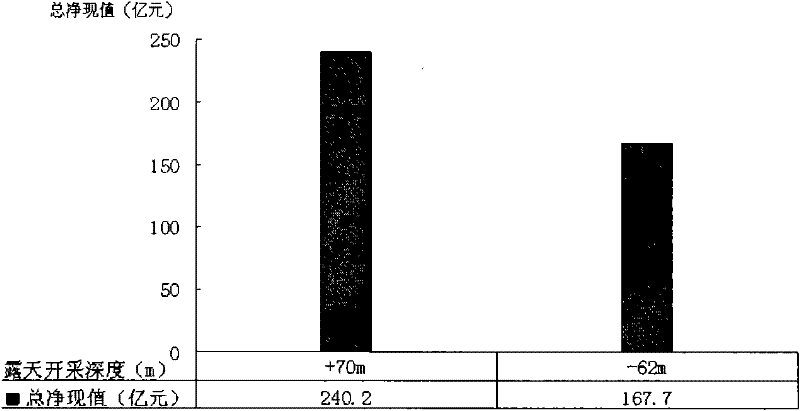

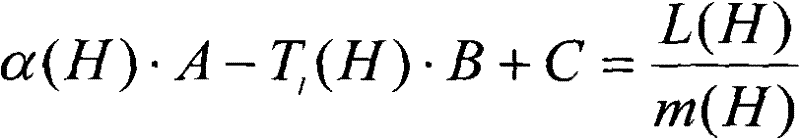

A method for determining the reasonable boundary of open-pit to underground mining in mines

InactiveCN102287189AReduce market riskStrong filtering functionUnderground miningSurface miningComputer scienceComputational analysis

The invention discloses a method for determining a reasonable boundary for converting strip mining into underground mining for a mine, which is determined by calculation in the following two steps: 1, constructing the economic and reasonable stripping ratio and the state stripping ratio function of a grade variable and a cost variable, and carrying out static computational analysis; 2, carrying out dynamic economic comparison for a possibly suggested boundary scheme by combining with the practical situation of the mine on the basis of the first step; building a dynamic economic model with themining depth; comprehensively considering the investment, the profit and the fund time value of the whole mine life cycle to carry out optimized comparison; and obtaining the reasonable boundary for converting strip mining into underground mining for the mine by the principle that the total net present value of the mine is maximum. The method has strong function for screening the deep scheme for converting strip mining into underground mining for the mine. According to the practical situation, a mine enterprise can automatically select a plurality of deep schemes to make a comparsion, and market risks brought by scheme selection can be effectively reduced.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

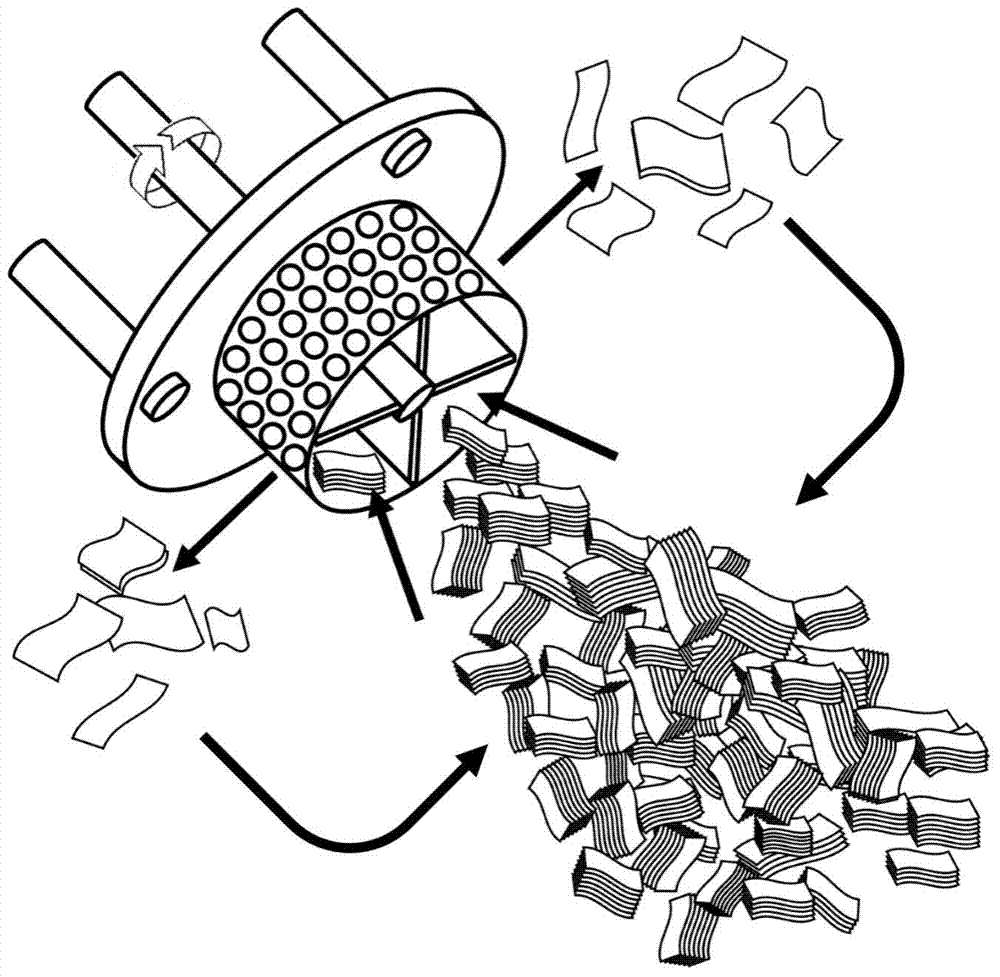

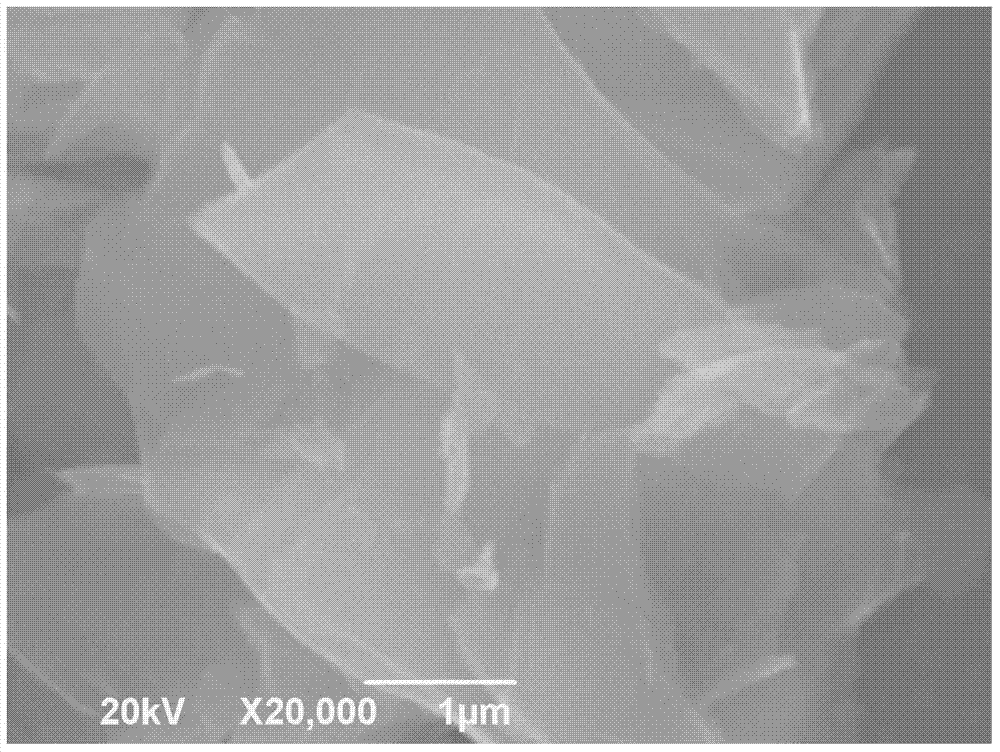

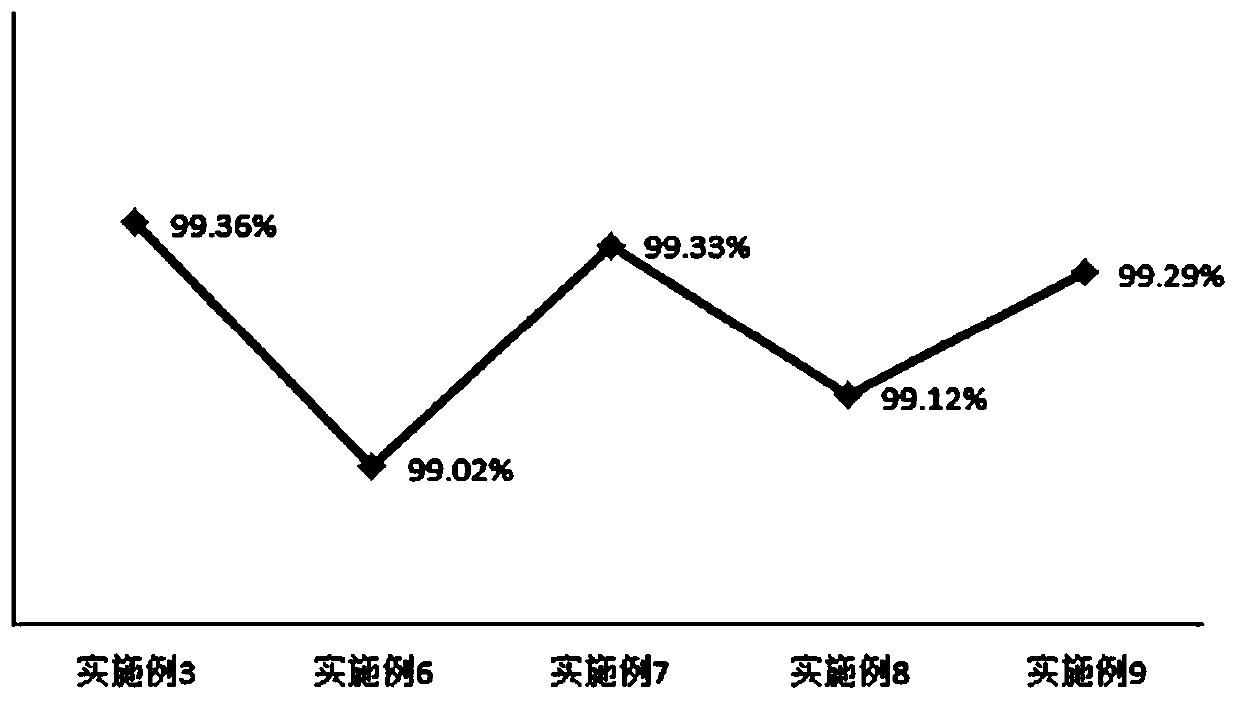

Preparation method of stratified molybdenum disulfide nano material

InactiveCN104495936AGood physical propertiesImprove stripping rateMaterial nanotechnologyMolybdenum sulfidesSolventDislocation

The invention provides a preparation method of a stratified molybdenum disulfide nano material. The preparation method comprises the following steps: adding molybdenum disulfide blocks to a container and adding a stripping solvent to prepare a molybdenum disulfide dispersion; performing hydraulic shearing treatment on molybdenum disulfide dispersion by use of a high-shear emulsifying machine; and centrifuging the hydraulically sheared molybdenum disulfide dispersion, filtering the centrifuged top suspension and drying in vacuum to obtain stratified molybdenum disulfide nanosheets. According to the preparation method of the stratified molybdenum disulfide nano material, the molybdenum disulfide blocks are under a strong combined action in a narrow gap between a stator and a rotor to arouse horizontal dislocation and slippage motion of crystal faces between the molybdenum disulfide layers, and therefore, the molybdenum disulfide is stripped, and finally, stable single-layer or few-layer molybdenum disulfide sheets are obtained; the preparation method is a pure physical method, and is simple in process, low in cost, small in danger, high in stripping ratio, green and environment-friendly; the prepared stratified molybdenum disulfide nanosheets are kept excellent in physical properties and suitable for large-scale industrial production after a pilot plant test.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

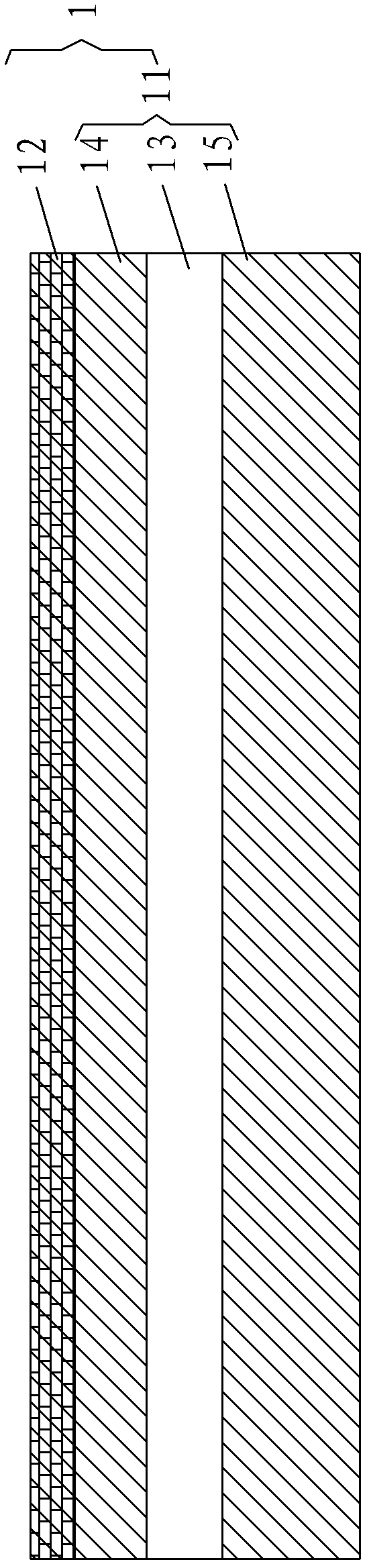

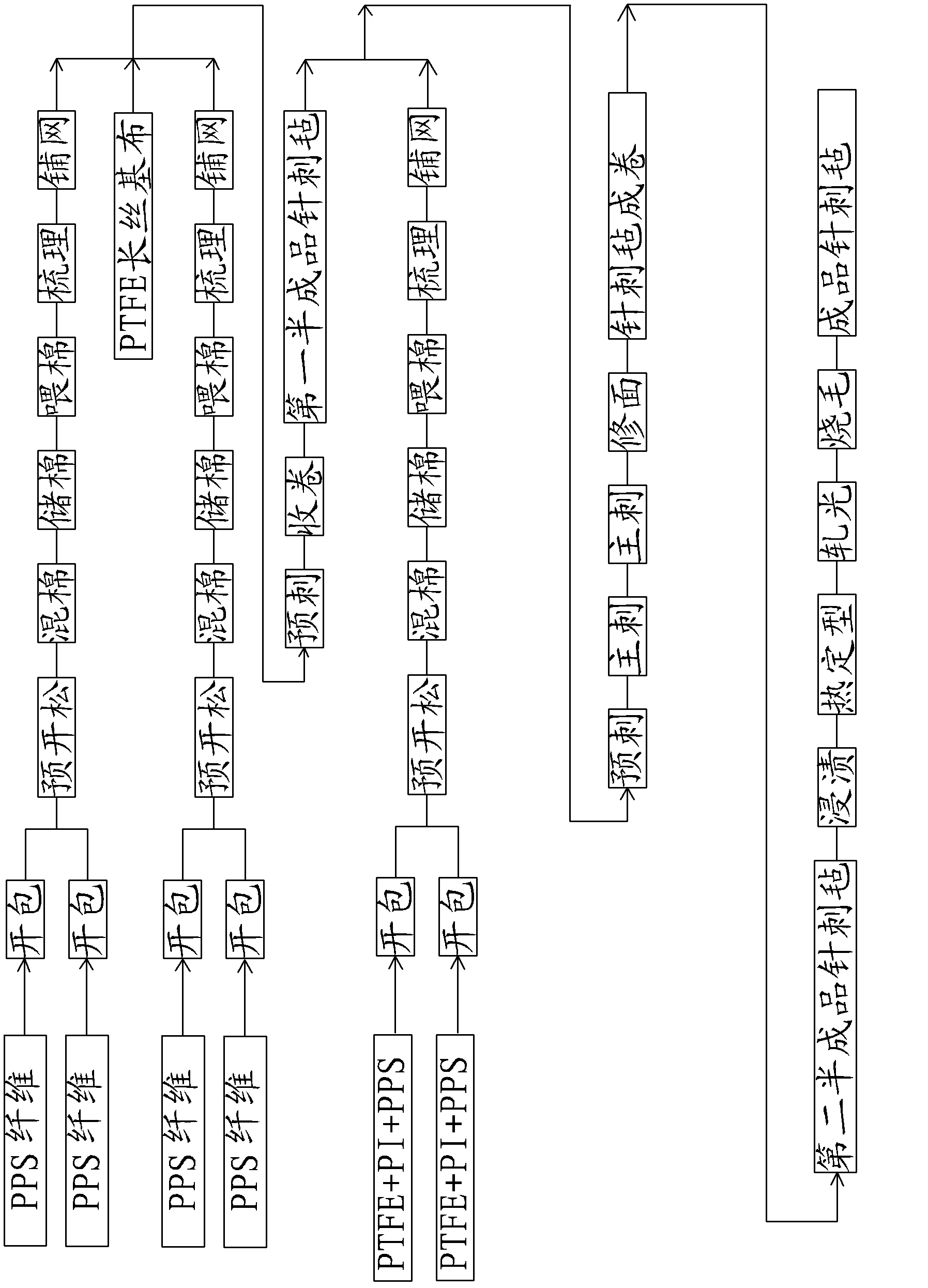

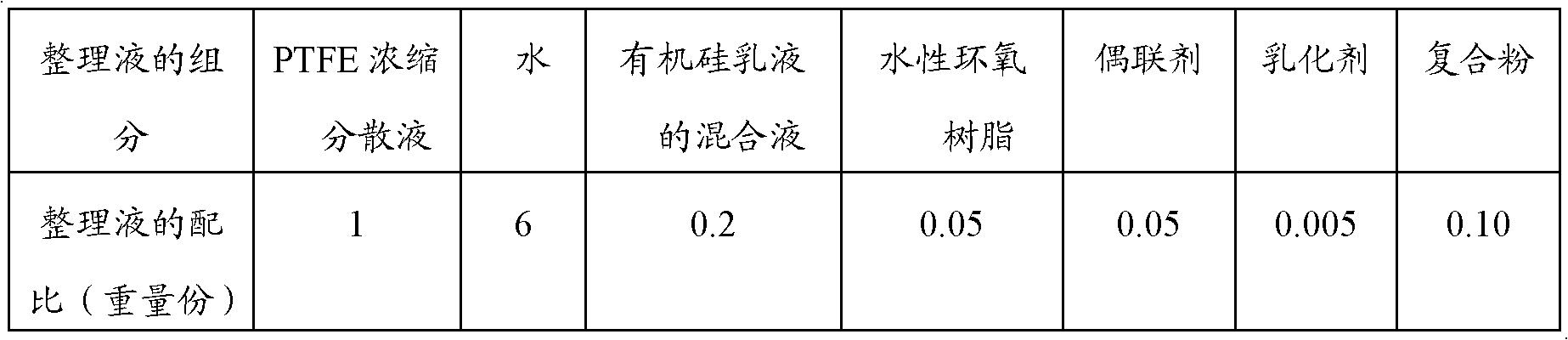

Special-purpose needled felt for complex condition coal fired power plants and preparation method thereof

ActiveCN102671467AExtended service lifeIncrease the instantaneous use temperatureFibre treatmentSingeingOxidation resistantEngineering

The invention discloses a special-purpose needled felt for complex condition coal fired power plants, which comprises a dust receiving surface, an auxiliary filter layer, an strengthen base cloth layer and a support layer which are orderly composited together by needling, wherein the dust receiving surface is blended by polyphenylene sulfite (PPS) fibers, polytetrafluoroethylene (PTFE) fibers and polyimide (PI) fibers according to proportion of 1:(0.2-0.5):(0.2-0.5), the auxiliary filter layer and the support layer are respectively needled by the PPS fibers, and the strengthen base cloth layer is interlaced by PTFE filament yarns in longitude and latitude. The invention further discloses a method for preparing the special-purpose needled felt for the complex condition coal fired power plants. The dust receiving surface is blended by the PPS fibers, the PTFE fibers and the PI fibers, thereby being low in cost, and increasing transverse and longitudinal strength of the special-purpose needled felt. Probability of intercept and filter precision of dust are increased through element felt preparation, immersion treatment, calendering processing and singeing process, thereby leading instantaneous using temperature of the special-purpose needled felt to increase and to be less affected by ozone, increasing oxidation resistance, prolonging service life, being further capable of improving strip ratio of the dust, increasing ventilation property of the special-purpose needled, and reducing operation energy consumption.

Owner:福建鑫华股份有限公司

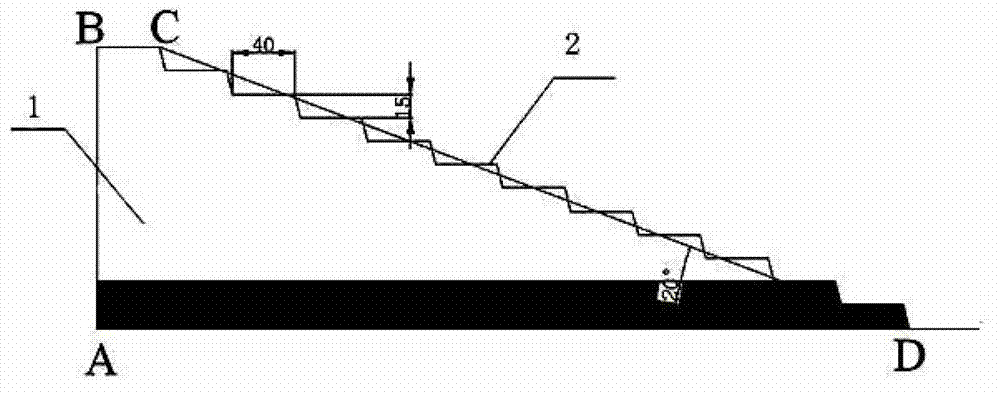

Method for determining surface mine exploiting limit

ActiveCN105275471AConducive to straightening out spatial imaginationImprove design efficiencyUnderground miningSurface miningWorkloadGeological section

The invention discloses a method for determining surface mine exploiting limit, and belongs to the field of mine exploiting design. The method comprises the steps that 1, the economic reasonable stripping ratio is determined according to the economic rationality; 2, feasibility, safety and reliability of the technology serve as principles, and open mine final slope forming elements are determined according to existing design specifications and safety procedures; 3, on a topographical and geological map and a geological section map of a deposit serving as a design basis, an upper port of an open mine final realm is delimitated along a mining right range line, and the mining right range line forms a bench edge of a first step; 4, according to the open mine slope forming elements determined in the second step, the steps are delimitated in sequence from top to bottom; 5, in the process of delimitating the final exploiting realm, the exploiting realm is optimized, and meanwhile a transportation system L is arranged and exploited; 6, the layered ore-rock volume and the average stripping ratio Np in the open mine exploiting realm are calculated. The method for determining the surface mine exploiting limit reduces workload, the design efficiency is high, the method is simple, and the practicability is good.

Owner:ANHUI MASTEEL ENG & TECH GRP

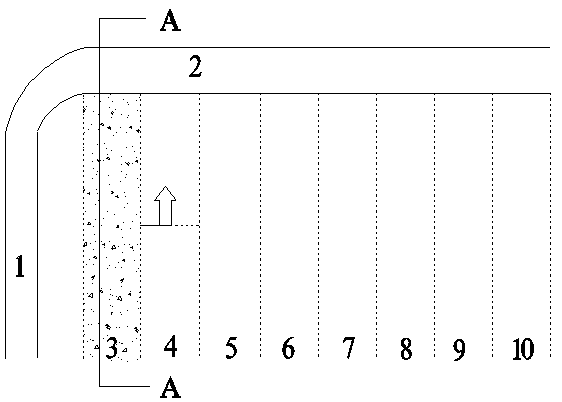

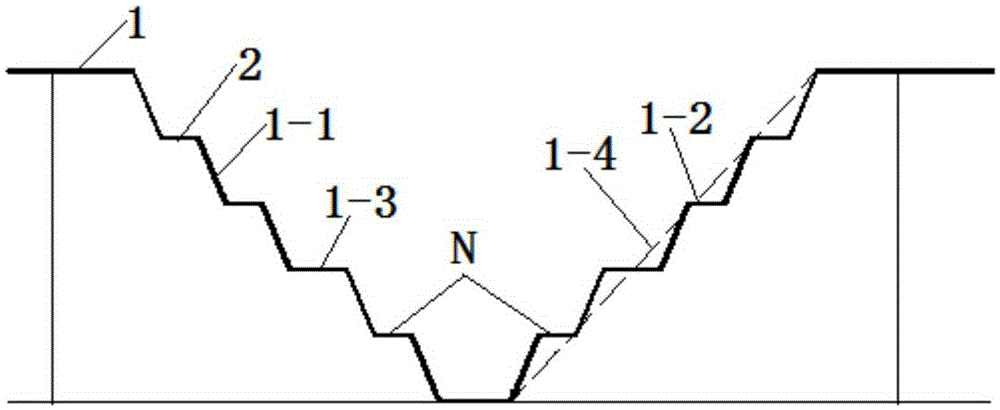

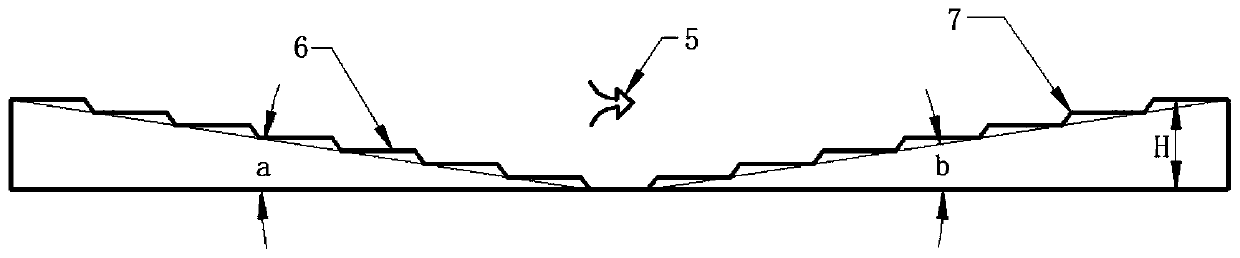

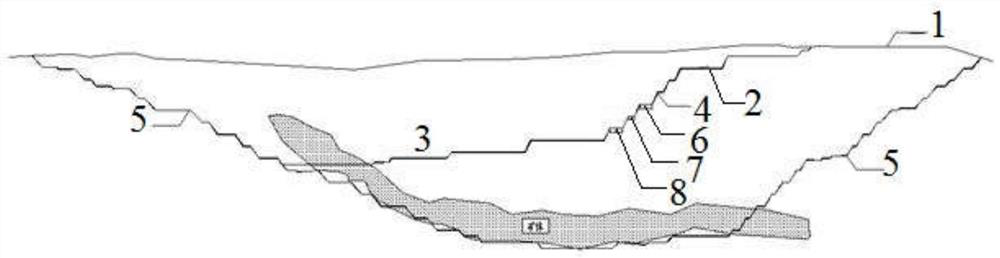

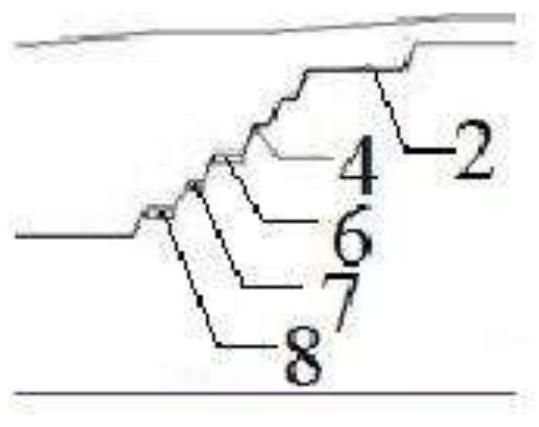

Method for stripping rock layer of end slope

InactiveCN103046929AImprove the efficiency of transportation operationsReduce stripping ratioOpen-pit miningGeomorphologyStripping ratio

The invention discloses a method for stripping a rock layer of an end slope, and the end slope comprises a rock layer including a plurality of standard steps and a coal layer under the rock layer. The method comprises the steps as follows: combining and stripping more than three standard steps down from a highest point of the rock layer to form a new step; and continuing to combine and strip more than three standard steps down from the new step until stripping the coal layer. According to the method, more than three standard steps formed on the rock layer are combined each time, each combination operation corresponds to a transport channel, fewer transport channels are configured, the end slope transport efficiency is improved, and the stripping ratio is reduced at the same time.

Owner:CHINA SHENHUA ENERGY CO LTD +1

Method for optimizing mining boundaries of underlying seams of strip mines

InactiveCN104612689AEconomic stripping ratio optimizationReasonable adjustmentUnderground miningSurface miningEconomic benefitsEngineering

The invention provides a method for optimizing mining boundaries of underlying seams of strip mines. The method comprises steps as follows: establishing a model for the cost caused by increase of the internal drainage distance of overburden materials of overlying seams due to mining of the underlying seams; establishing a model for the extra unit mining cost for mining of the underlying seams with the optimized overall economic benefit of ore deposit mining as the goal; determining the extra unit mining cost for mining of the underlying seams; establishing an average thickness function of the underlying seams and an average thickness function of overlying strata of the underlying seams; delineating the mining boundaries of the underlying seams of the composite seam strip mines. According to the method, the extra unit mining cost for mining of the underlying seams is considered, so that the economic stripping ratio of the underlying seams of the horizontal or near-horizontal composite seam strip mines is optimized, the reasonable economic stripping ratio is determined, the mining boundaries of the underlying seams are adjusted reasonably, and the better economic benefit can be created.

Owner:LIAONING TECHNICAL UNIVERSITY

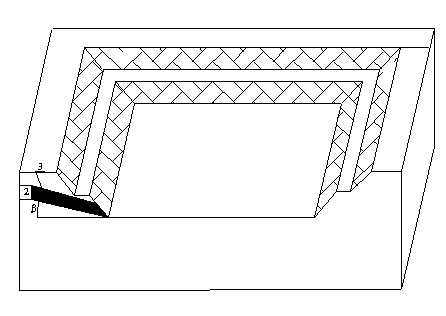

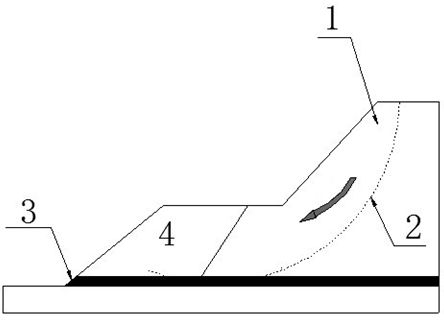

Dismantling method of open-pit coal mine end slope bridge

ActiveCN105626068AShorten construction timeImprove efficiencyDisloding machinesOpen-pit miningEngineeringBuilding construction

The invention discloses a dismantling method of an open-pit coal mine end slope bridge. The end slope bridge is formed by an ouerbvrden material, wherein one end of the end slope bridge is covered on a coal bed slope side of a coal bed, and the other end of the end slope bridge extends to the inside of a refuse dump. The method comprises the following steps: step one, determining a coal-rock interface between the end slope bridge and the coal bed; step two, arranging a hydraulic backhoe on the coal-rock interface; step three, stripping the ouerbvrden material in the surface to be stripped layer by layer according to a reverse mining manner till the construction is completed. The dismantling method of the open-pit coal mine end slope bridge is characterized by carrying out secondary stripping from an overlapping surface of the end slope bridge, separating the coal from the rock and mining the coal resource pressed and covered by the ouerbvrden material. Through the method, an optimally economical and reasonable stripping ratio is achieved; the production cost can be reduced to minimum.

Owner:CHINA SHENHUA ENERGY CO LTD +1

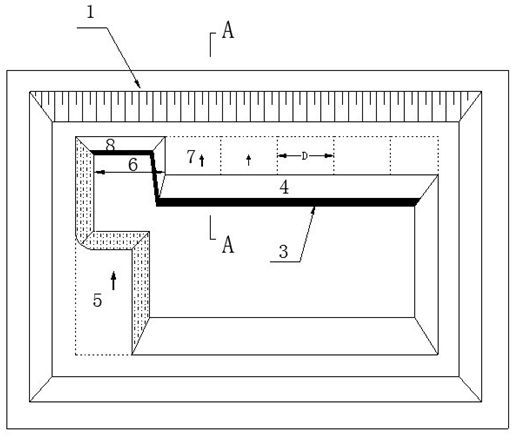

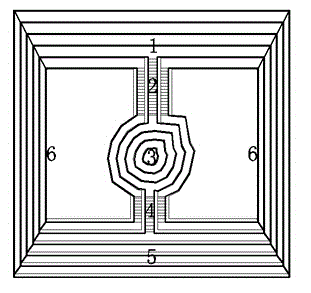

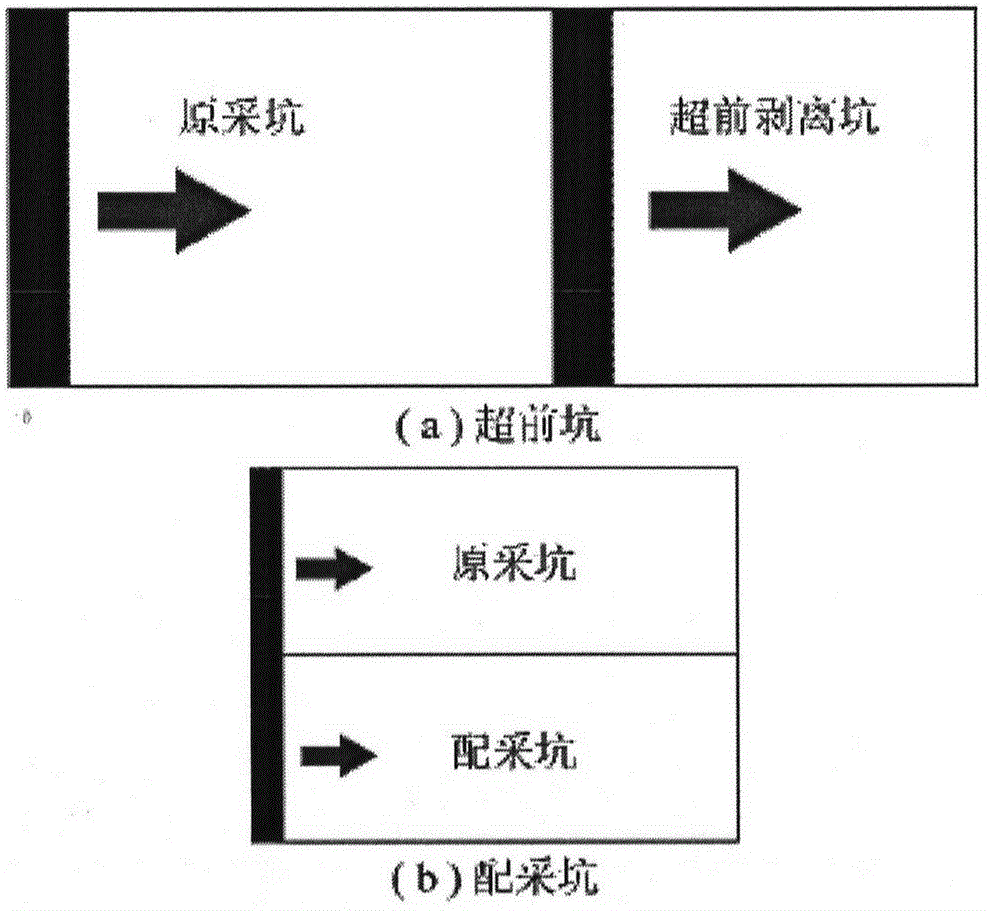

Method and apparatus of adjusting opencast coal mine production stripping ratio

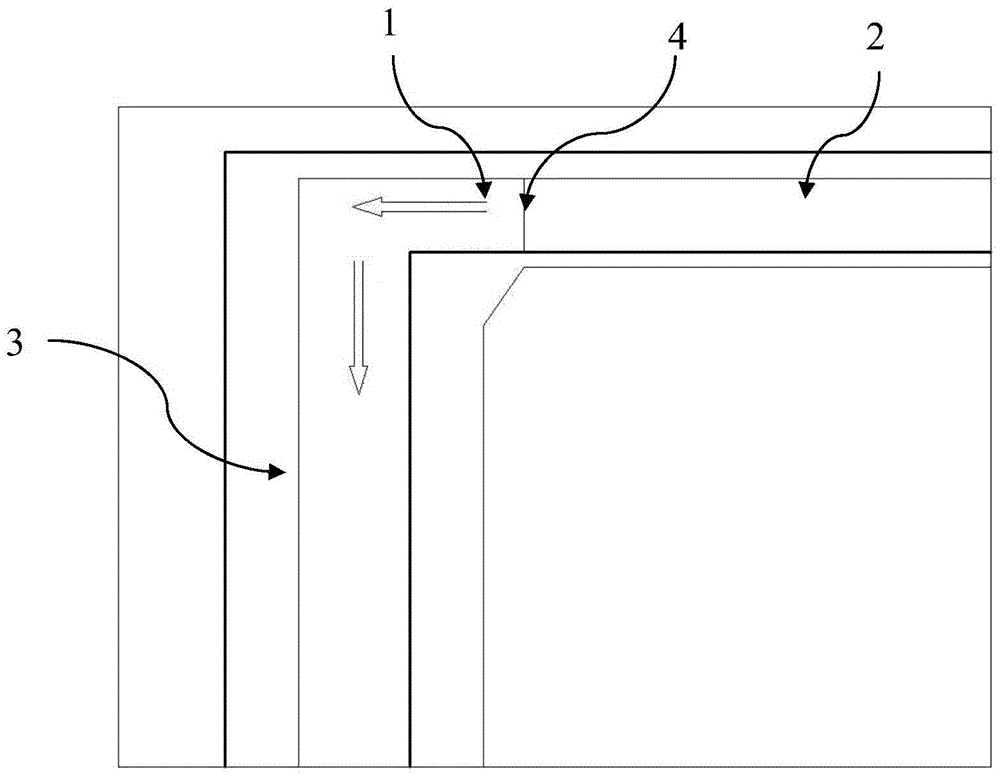

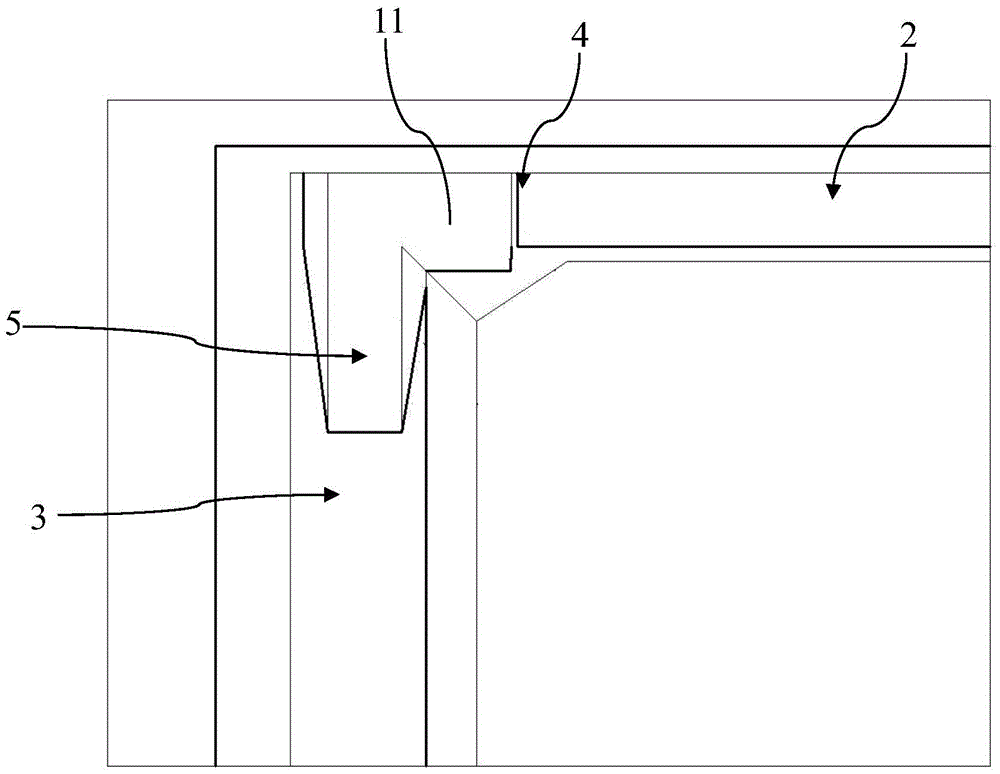

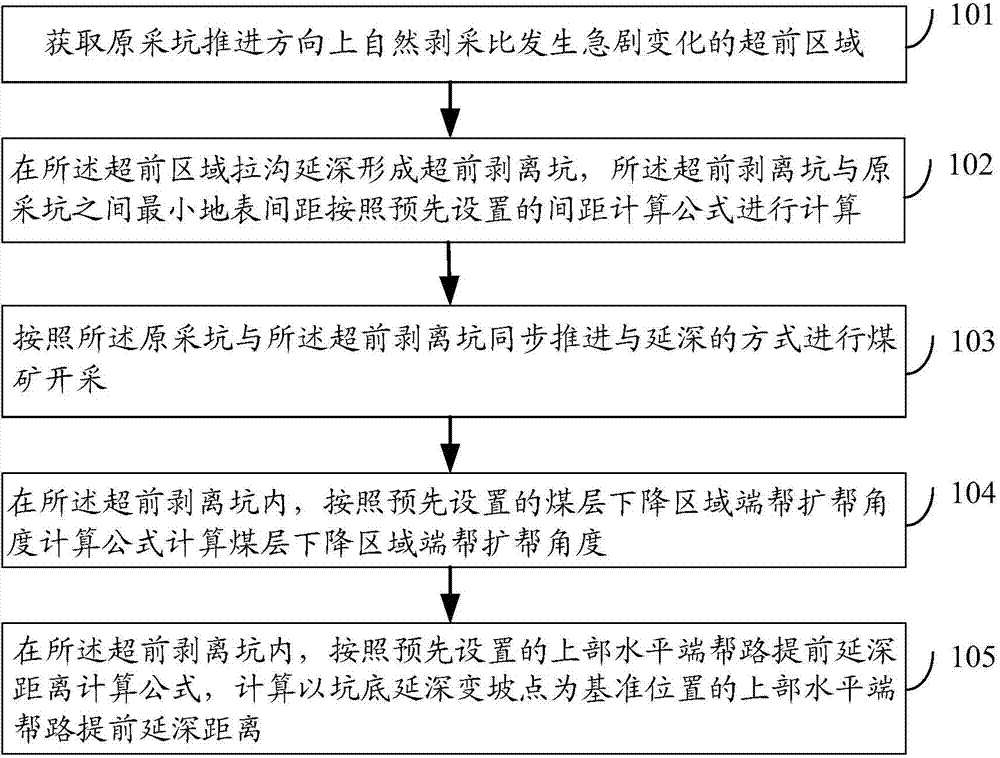

InactiveCN104763429AAdjust production stripping ratioProduction stripping ratio is stableUnderground miningSurface miningEngineeringEarth surface

In the invention, the embodiment discloses a method and an apparatus of adjusting opencast coal mine production stripping ratio. The method comprises following steps: obtaining an advanced area, in which the natural stripping ratio is intensively changed in an advancing direction of an original mining pit; performing grooving and deepening in the advanced area to form an advanced stripping pit, wherein a minimum earth surface distance between the advanced stripping pit and the original mining pit is calculated according to a preset distance calculating formula; and performing coal mining in a manner of synchronization advancing and deepening of the original mining pit and the advanced stripping pit. By means of the method and the apparatus, ore production efficiency can be optimized.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

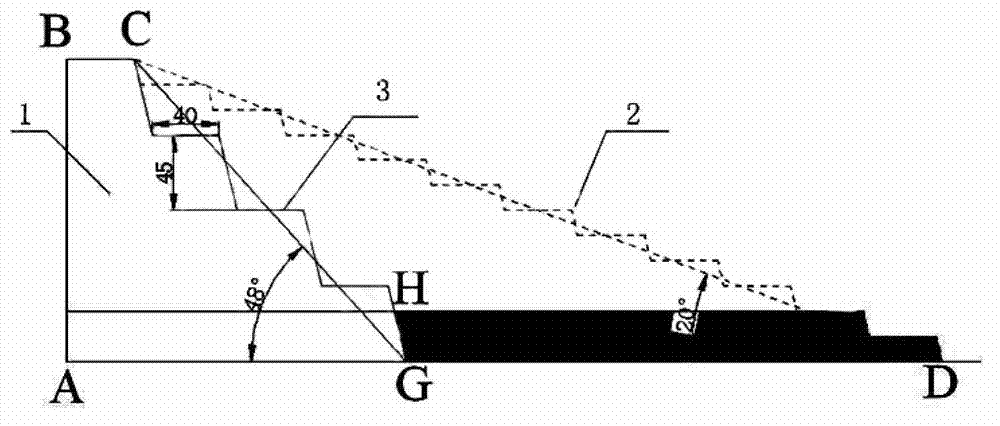

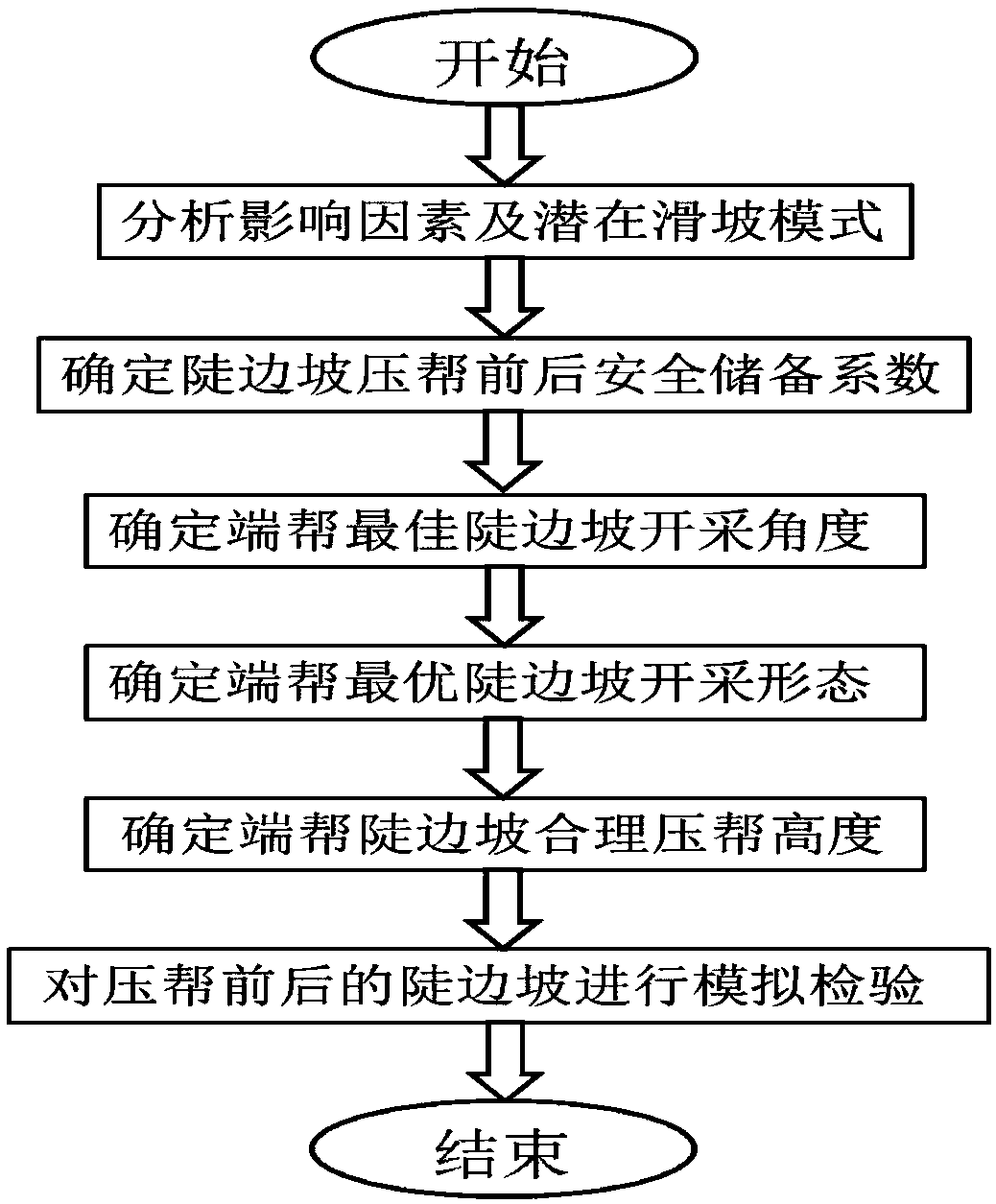

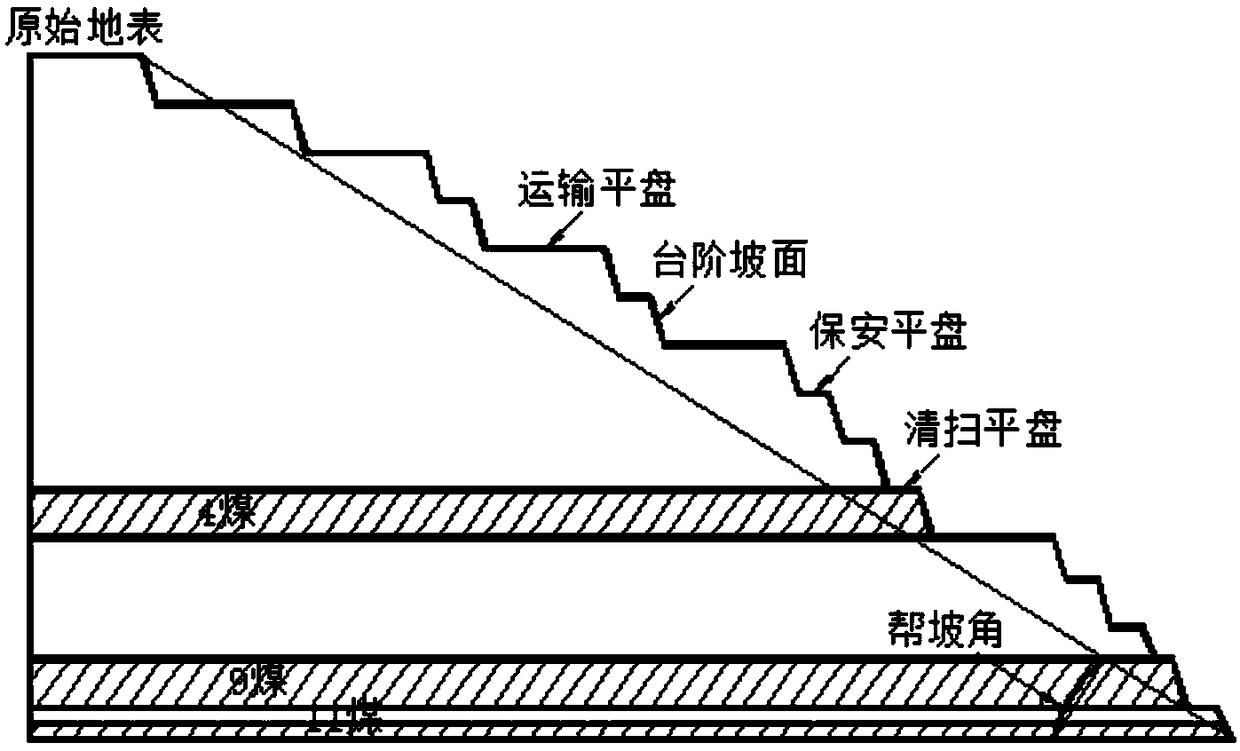

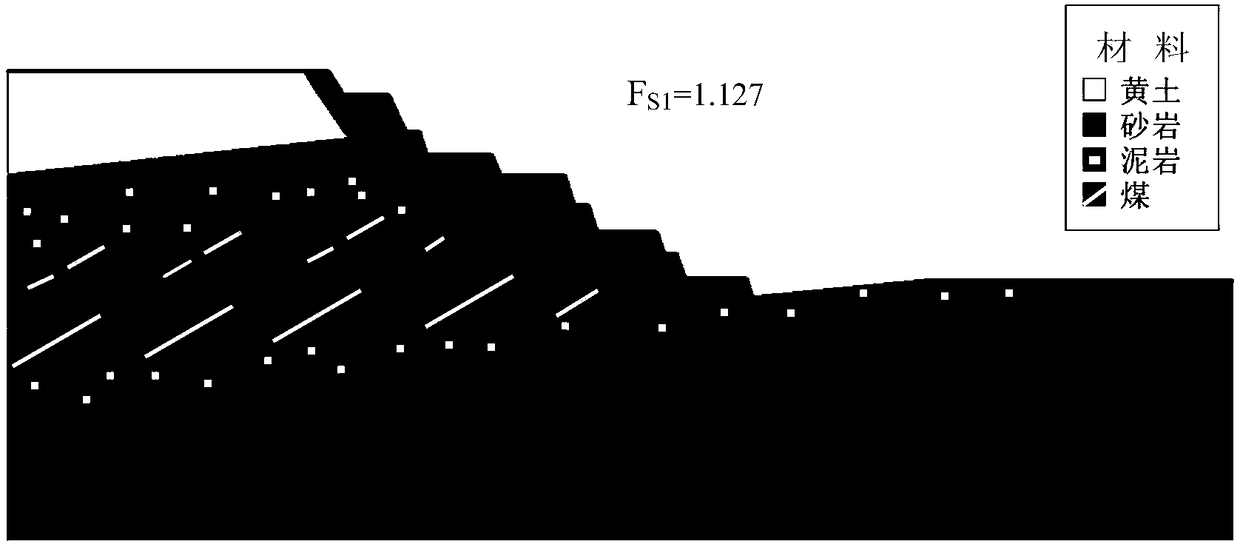

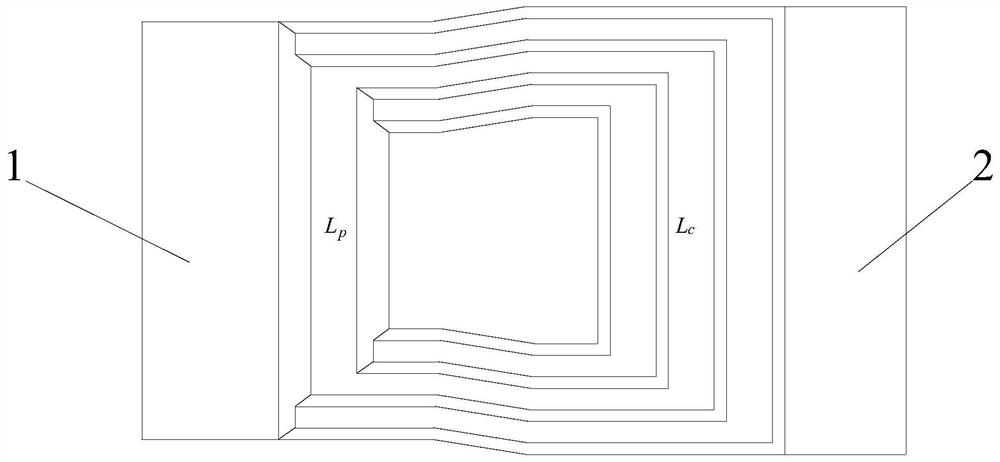

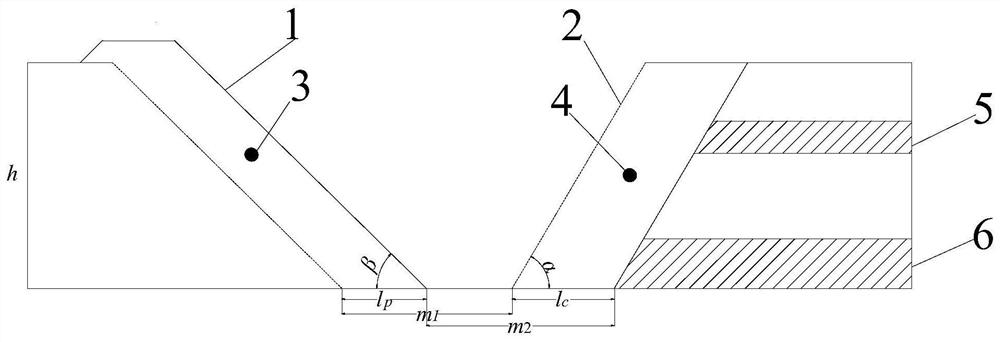

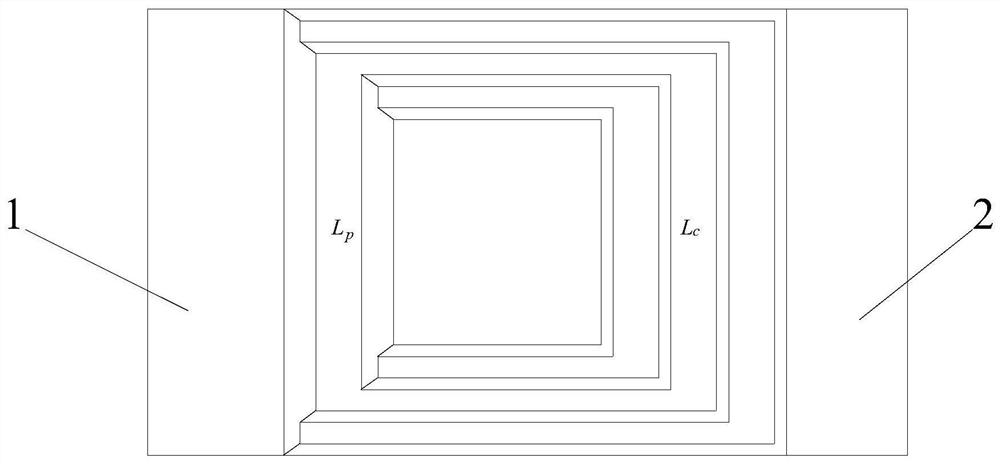

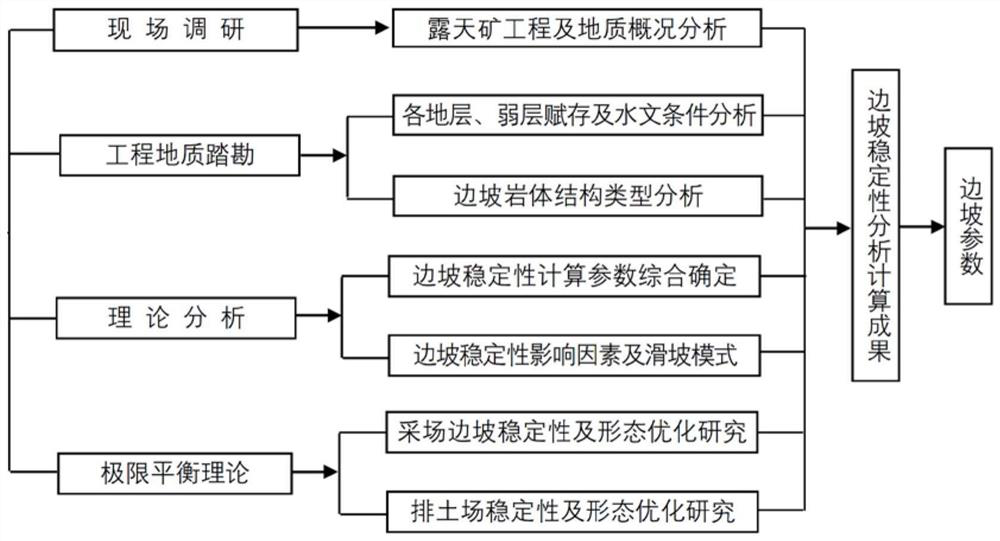

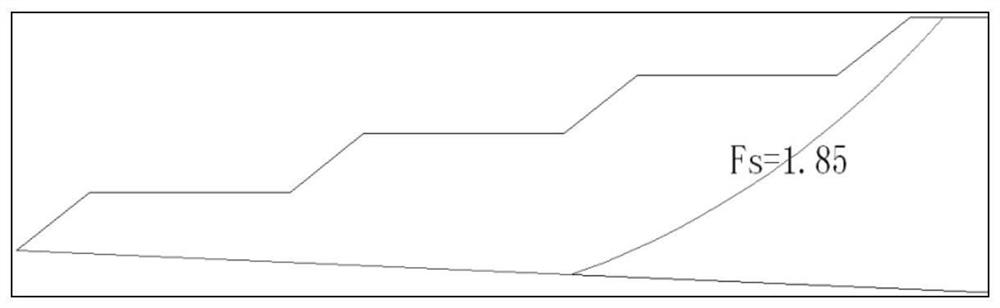

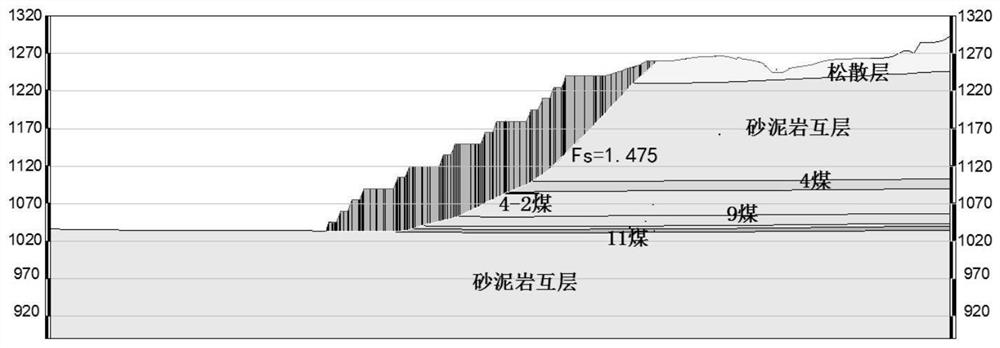

Shape optimization method for steep slope of an end wall of an open-pit coal mine

ActiveCN109376465AAccurately reflects the stability stateMaximize the benefitsClimate change adaptationDesign optimisation/simulationOpen-pit miningEconomic benefits

The utility model relates to a shape optimization method for steep slope of an end wall of an open-pit coal mine, belonging to the field of open-pit mining. This method qualitatively analyzes the influencing factors of the slope stability and the potential landslide model of the open-pit coal mine. The importance, service time and physical and mechanical indexes of slope are analyzed, and the safety reserve coefficient of steep slope before and after pressure slope is determined. Selecting typical engineering geological section, steepening is carried out on the basis of the current situation of end-slope angle, and the quantitative relationship between slope stability and slope angle is analyzed to determine the best mining angle of steep slope. According to the definite angle, the different mining patterns of steep slope are put forward by adjusting the width of the conveyance flat plate in the lower part of the slope, and the optimum mining pattern of steep slope is obtained by giving consideration to economy and safety. Calculate the stability of steep slope under different pressure height, get the quantitative relationship between slope stability and pressure height, and then determine the pressure height. By using this method, the coal resources can be fully recovered, the stripping ratio can be reduced, and the economic benefit can be improved.

Owner:LIAONING TECHNICAL UNIVERSITY

Strip mine mining boundary and mining program collaborative optimization method under complex coal seam conditions

PendingCN112214867AReduce strip mining costsEnsure coordinationUnderground miningSurface miningMining engineeringWaste dump

The invention provides a strip mine mining boundary and mining program collaborative optimization method under a complex coal seam condition. The optimization method comprises the steps that a miningboundary model and an external dumping site boundary model are constructed; constructing a three-dimensional geological model; determining a mining program scheme; determining a production stripping ratio, compiling a strip mine stripping and mining project progress plan, and determining a stripping project position and a project amount of each year; planning each engineering position in the stopeand the flow direction and flow of each stripped object, and optimizing the utilization scheme of the internal and external waste dump; the service range of each mining process of stripping and coalmining and a process system arrangement scheme are optimized; and determining an optimal mining procedure. By means of the optimization method, synchronous collaborative optimization can be well conducted on the mining boundary and the mining program, operability is high, the stripping mining cost of the strip mine can be remarkably reduced, and meanwhile coordination of stripped object discharging and dumping site planning can be guaranteed.

Owner:LIAONING TECHNICAL UNIVERSITY

Mining scheme optimization method based on strip mine partitioned mining process

PendingCN112364474AGood effectReliable continuation of production capacityUnderground miningSurface miningWaste dumpProcess engineering

The invention provides a mining scheme optimization method based on an open-pit mine partitioned mining process. The optimization method comprises the following steps that S1, an ore deposit geological model, a stope dump current situation model and resource mining conditions being analyzed; S2, determining the form and parameters of the slope; S3, optimizing the shape and parameters of the side slope of the refuse dump; S4, delineating a mining boundary, dividing mining areas and determining a mining sequence scheme; S5, determining a mining and discharging scheme of the end slope of the current mining area and the end slope of the adjacent mining area; S6, determining a stripping and mining program, a mining interval transition connection scheme and a stope, and making a waste dump construction and development plan; and S7, compiling a mining and discharging project progress plan and an implementation scheme. The method is advanced in technology, economical, reasonable, safe and reliable, and the purposes of shortening the transportation distance, reducing the stripping ratio and reliably continuing the productivity can be achieved.

Owner:LIAONING TECHNICAL UNIVERSITY

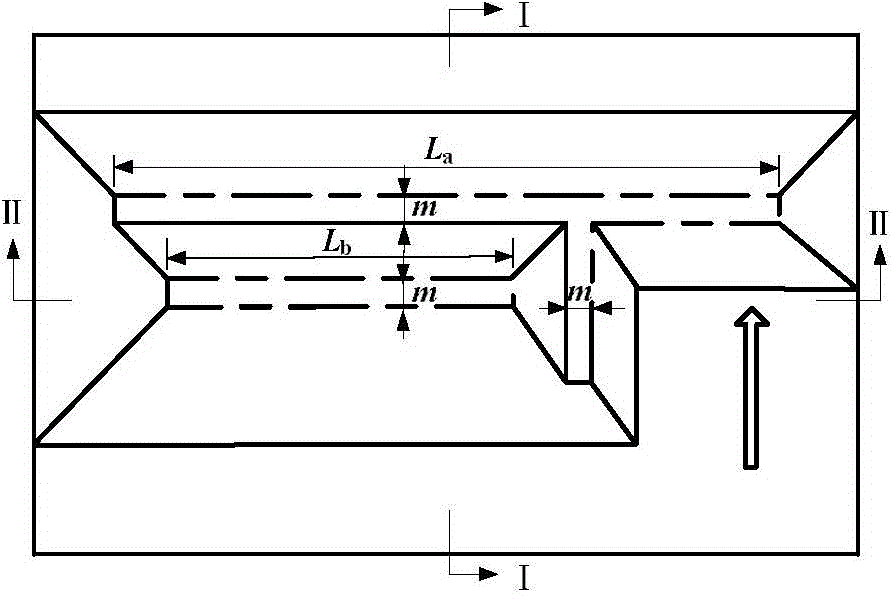

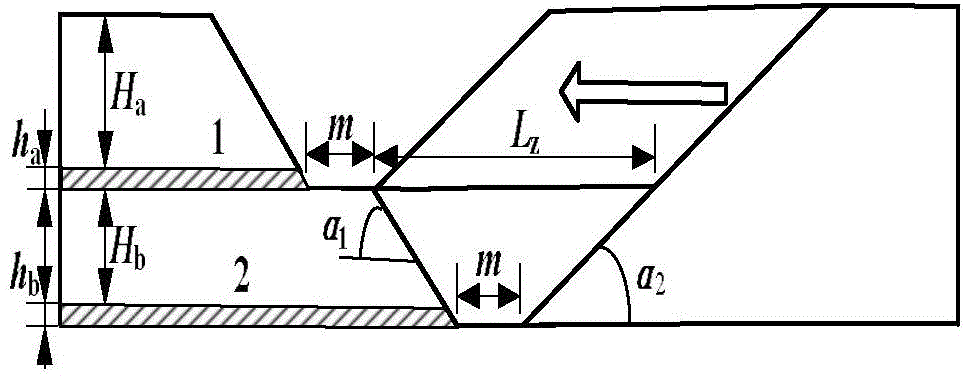

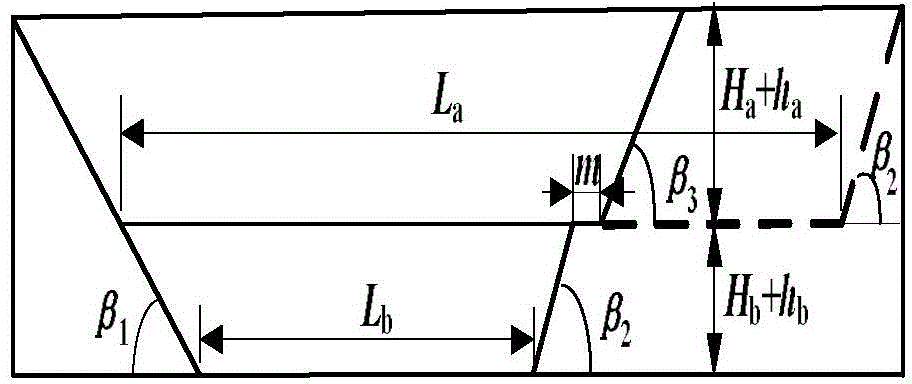

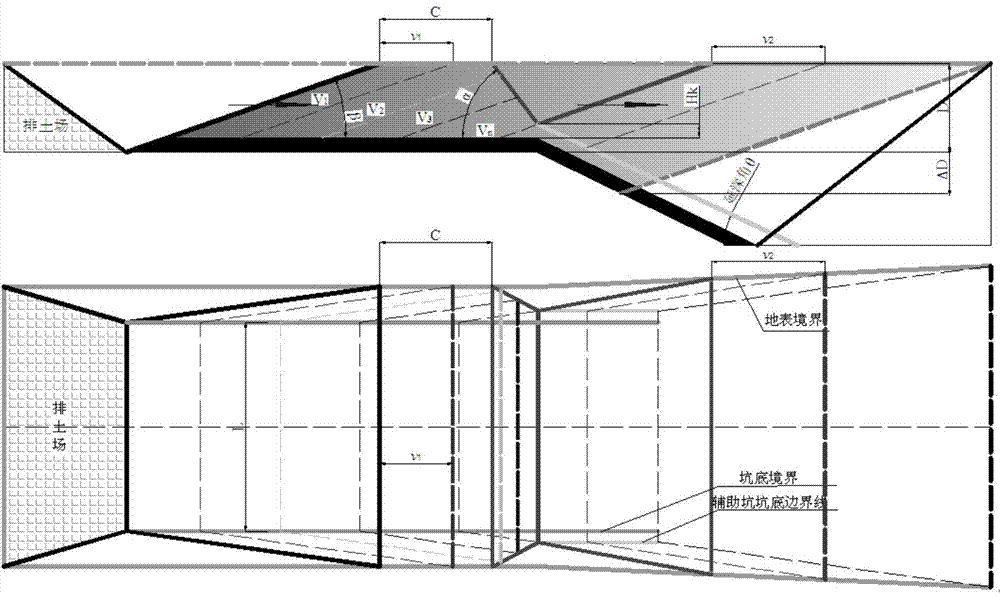

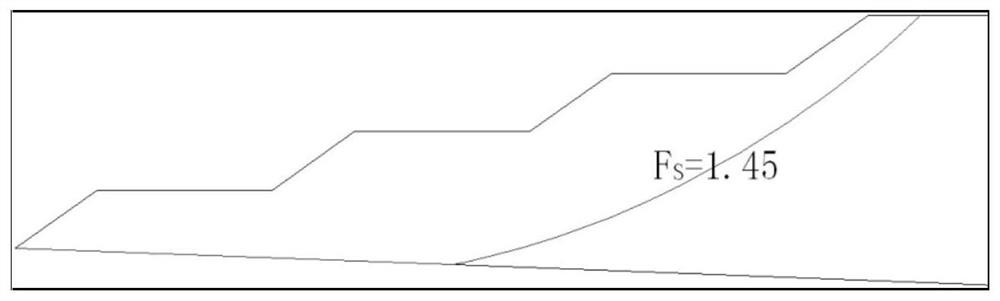

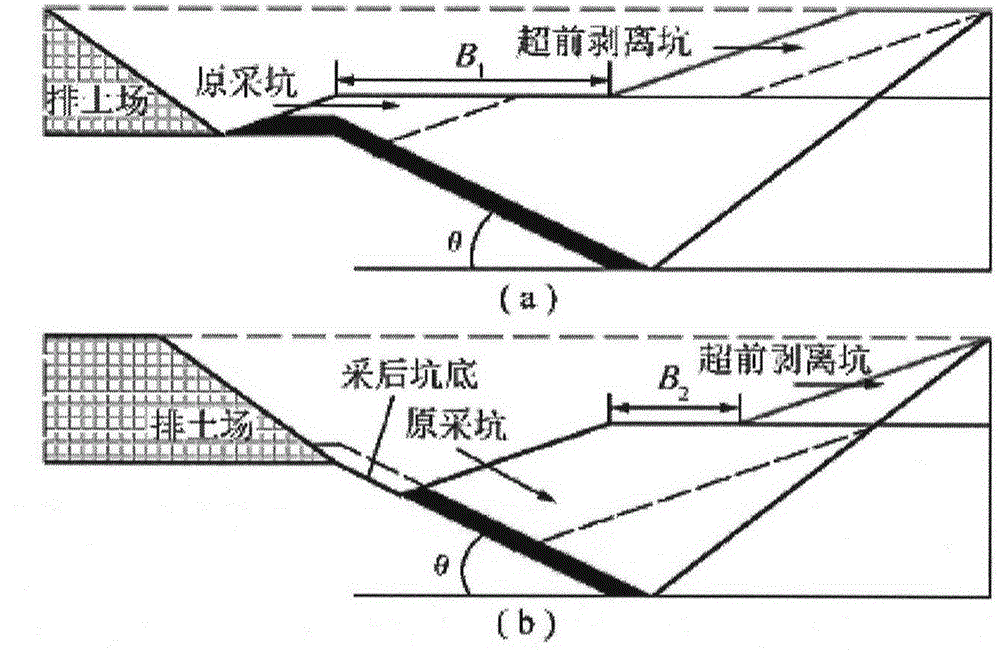

Open-pit coal mine double-pit dynamic stripping ratio adjusting method

The invention provides an open-pit coal mine double-pit dynamic stripping ratio adjusting method and belongs to the technical field of mining industry. The invention mainly solves a problem of adjusting and controlling a stripping ratio under a situation that a conventional adjusting method is not available for carrying out effective stripping adjustment since an inclined seam or a seam is turned from an approximately horizontal situation into an inclined situation and the stripping ratio is changed sharply under a complicated geological condition. The adjusting method comprises two adjust modes: a mode of an original mining pit and an advanced pit and a mode of the original mining pit and an auxiliary mining pit, wherein the mode of the original mining pit and the advanced pit includes an A method and a B method. A main technical scheme includes following steps: developing an advanced stripping stope through a groove-forming deepening operation, performing deepening and an advancing operation in the stripping stope, and combining the original mining pit and the advanced stripping pit until a new working pit edge is formed. To the open-pit coal mine in which an inclined seam and an approximately horizontal seam being turned into the inclined seam, the double-pit dynamic stripping ratio adjusting method can effectively balancing the production stripping ratio, can ensure a stable production yield and can increase economic benefit of a mine.

Owner:赵红泽 +1

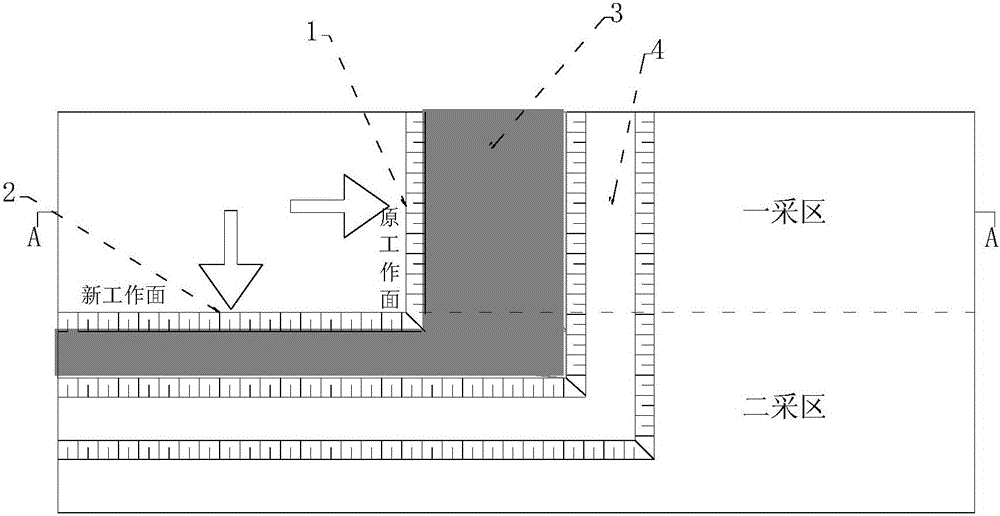

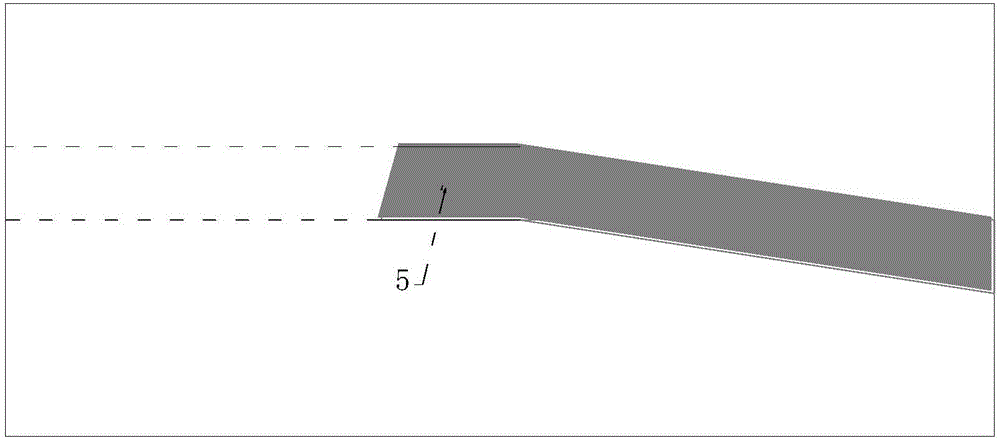

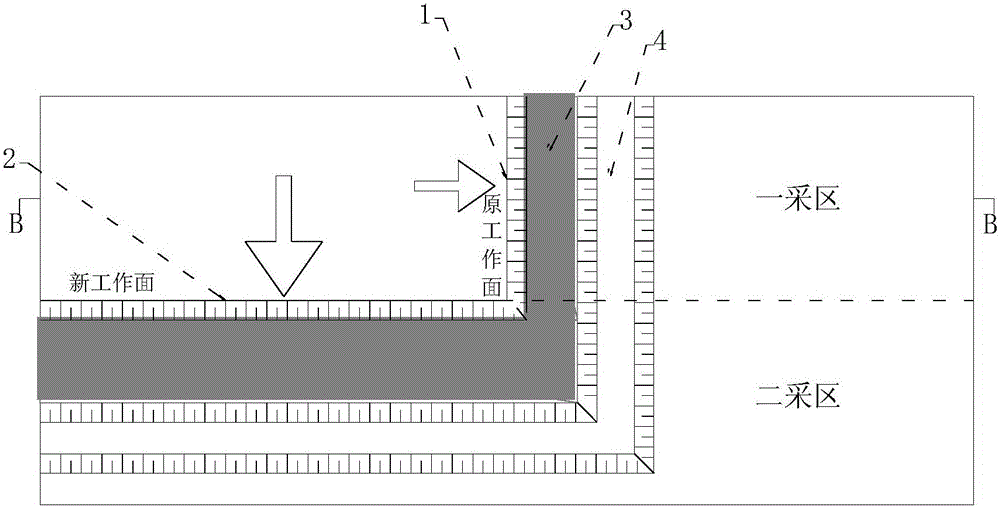

Gentle wall milling method at parallel milling area end under complex geological structure

ActiveCN105781553AGuarantee normal productionGuaranteed outputUnderground miningSurface miningEconomic benefitsEngineering

Provided is a gentle wall milling method at a parallel milling area end under a complex geological structure. When a coal milling layer of an open coal mine becomes obliquely downwards from the nearly horizontal mode along the advancing direction, advance stripping is conducted on a prior coal working face in advance; a new coal working face of a second milling area is built in the gentle wall position of one side end of the prior coal milling face of a first milling area; advancing is conducted in the advancing direction perpendicular to the prior coal working face, and a high mineable coal quantity can be obtained by conducting advance stripping on the new coal milling face of the second milling area; meanwhile, the stripping speed of the prior coal working face of the first milling area is decreased, and the coal milling speed is increased; when a coal bed of the prior coal working face of the first milling area starts to oblique downwards, the stripping quantity is increased, the coal milling quantity is reduced, the advancing speed is decreased, and the coal milling speed of new coal working faces is increased. The gentle wall milling method is suitable for milling parallel milling area open mines with coal beds becoming obliquely downwards from the horizontal mode in the advancing direction, the overall stability of the stripping ratio for mine production can be maintained, the milling cost is reduced, and economic benefits are increased.

Owner:CHINA UNIV OF MINING & TECH

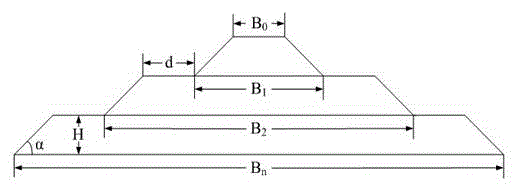

Open air mine semicontinuous conveying system single line slope conveying designing method

InactiveCN1556306AIncrease final slope angleReduce the amount of rock strippingRoadwaysUnderground miningTransit systemSlope angle

In the invention, transportation from exploitation breaking station down to bottom of surface mine is designed according to normal motor vehicle transportation, and main transportation road includes dual lanes. Character is that road going up from exploitation breaking station is designed according to condition of single line and high slope. Width of platform of transportation line or single vehicle is 14-19m, longitudinal slope as 12-15%. Buffering platforms are setup in middle staggering zone in width 25-30m and length 40-60m of gentle slope in use for staggering vehicles or breakdown maintenance. The invention increases slope angle, reduces quantity of stripping rock, and stripping ratio.

Owner:UNIV OF SCI & TECH BEIJING

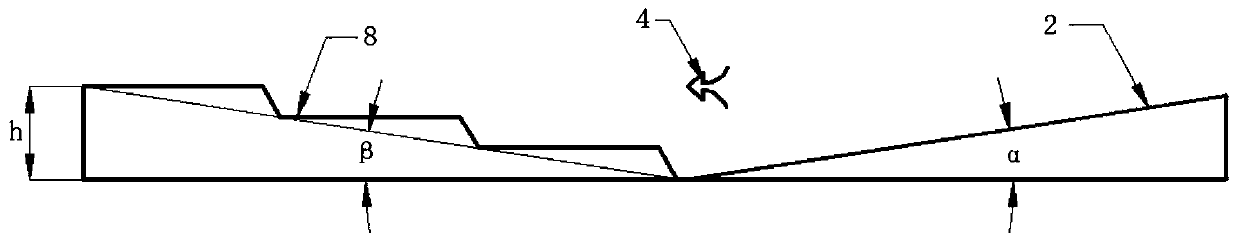

Inclined seam strip mine mining method achieving deep transverse mining and shallow longitudinal mining

ActiveCN110318759AReduce production stripping ratioReduce the comprehensive distanceOpen-pit miningMineralogyBuilding construction

An inclined seam strip mine mining method achieving deep transverse mining and shallow longitudinal mining comprises the following steps that (1) the transverse mining and longitudinal mining boundarydepth h is confirmed according to technical parameters confirmed by a strip mine; (2) mining is carried out in a transverse mining manner at the early stage of strip mine construction, and transversemining is started after the propulsion direction is confirmed; (3) after mining is carried out according to the step (2) to the pit bottom, after the longitudinal mining conditions are met at the level of the depth h or above, and the original transverse mining manner is charged into the longitudinal mining manner at the level of the depth h or above of the strip mine; (4) after the strip mine meets the conditions of shallow longitudinal mining and deep transverse mining, deep transverse mining and shallow longitudinal mining are carried out at the same time; (5) shallow longitudinal mining continues to be pushed towards the final state direction, deep transverse mining continues to follow up, and the steps (2)-(4) are circulated; and (6) after shallow longitudinal mining is pushed to thefinal state, deep transverse mining continues to mine a deep coal layer till all coal in the state is mined. According to the method, secondary reserving is simple, the stripping ratio of early-stageproduction is small, and the comprehensive stripping distance is small.

Owner:LIAONING TECHNICAL UNIVERSITY

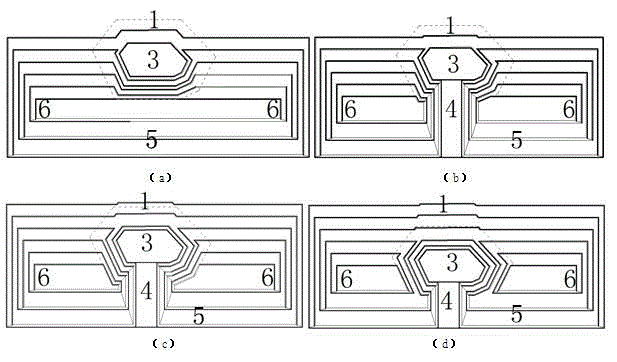

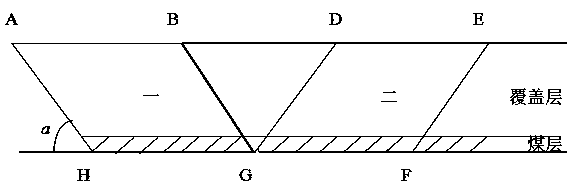

Open-pit mining method for triangular ore quantity between layered flat deposit strip areas

InactiveCN103726850AReduce the average stripping ratioReduce the amount of repeated strippingUnderground miningSurface miningOpen-pit miningParallel mining

The invention discloses an open-pit mining method for triangular ore quantity between layered flat deposit strip areas. Firstly, a deposit is divided into a plurality of parallel mining strip areas, cross sections of two adjacent strip areas are overlapped, side slopes of the overlapped areas intersect on a boundary between a coating layer and a coal seam, and a triangular area is formed between the two adjacent strip areas under the point of intersection; then the mining strip areas are mined one by one, when any strip area is mined, the triangular area with a next strip area is mined simultaneously, and an exposed face after mining to the boundary is covered in a matched stripping and internal dumping mode; and mining is performed in cycles until all the mining strip areas are mined. According to the method, repeated stripping quantity between the strip areas and the average stripping ratio of a mine are reduced effectively, triangular ore quantity pressed by two adjacent strip areas are recovered in advance, so that not only is the mining cost reduced, but also the overall economic benefit of the mine is improved.

Owner:CHINA UNIV OF MINING & TECH

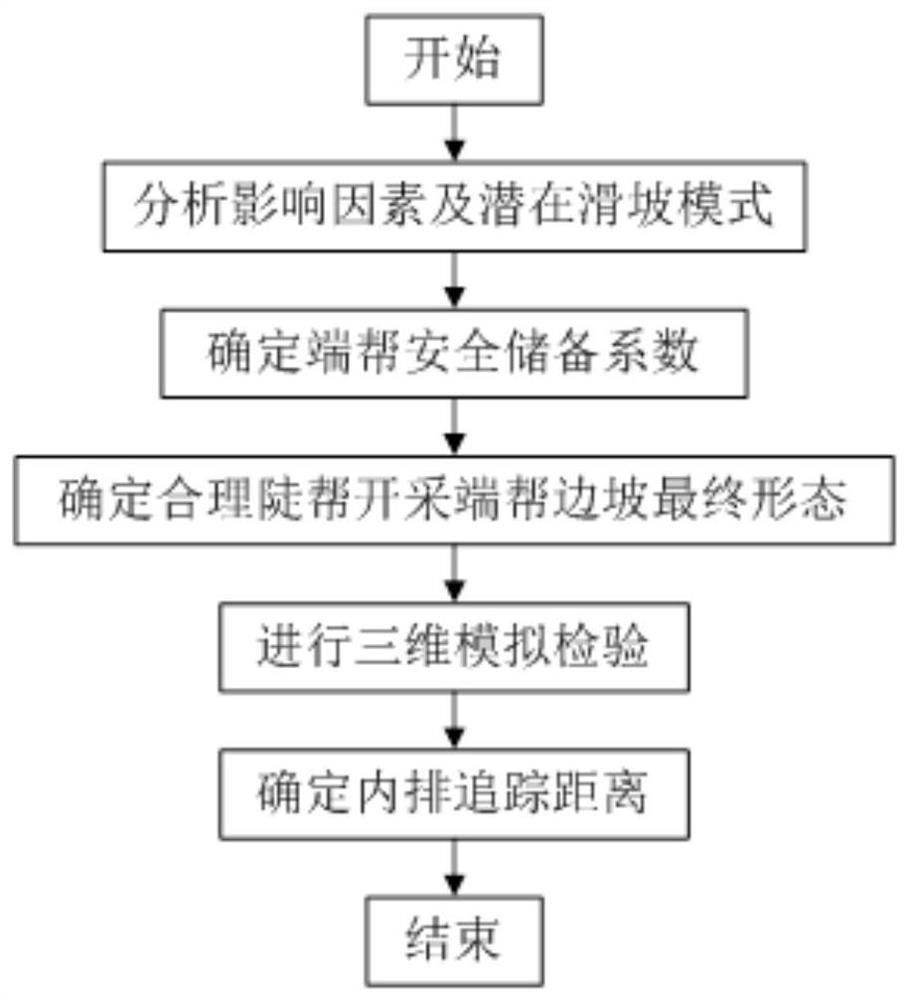

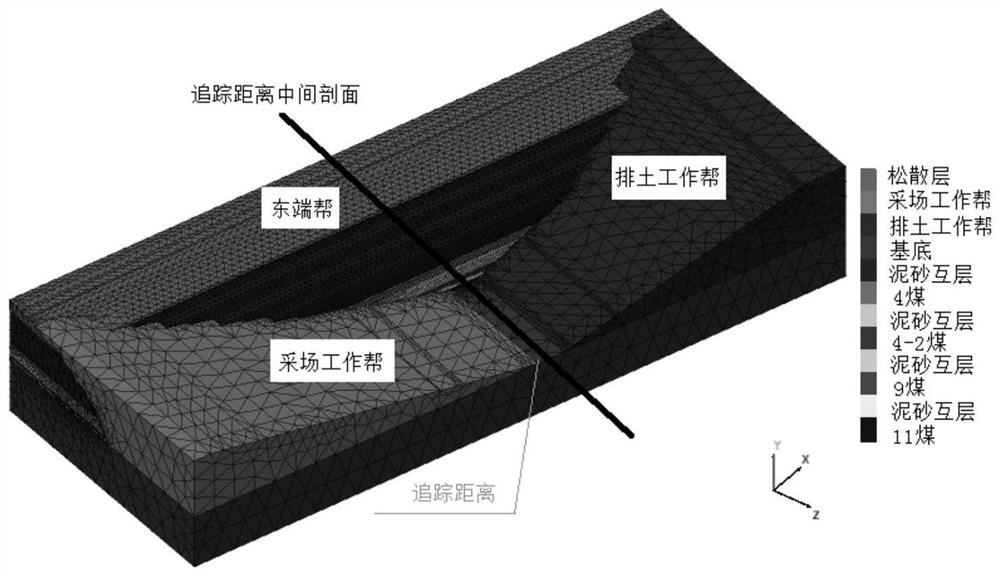

End slope and side slope stability analysis method for open pit coal mine steep slope mining

PendingCN113420457AMaximizeReduce production stripping ratioDesign optimisation/simulationResourcesMining engineeringSlope stability analysis

The invention discloses an end slope stability analysis method for open pit coal mine steep slope mining. The method comprises the steps of analyzing stability influence factors and a potential landslide mode of an end slope of an open pit coal mine; determining an end slope safety reserve coefficient; determining the final form of the steep slope mining end slope side slope; establishing a three-dimensional numerical model to analyze change characteristics of an end slope deformation failure rule and a slope stability coefficient under different tracking distances; and determining an inner row tracking distance, and implementing steep slope mining. According to the end slope stability analysis method for open pit coal mine steep slope mining, the slope where steep slope mining cannot be conducted is judged through a two-dimensional slope analysis method, new mining possibility is achieved, benefit maximization after the overall slope angle design is achieved, coal resources can be fully recycled, the production stripping ratio is reduced, and economic benefits are improved.

Owner:LIAONING TECHNICAL UNIVERSITY

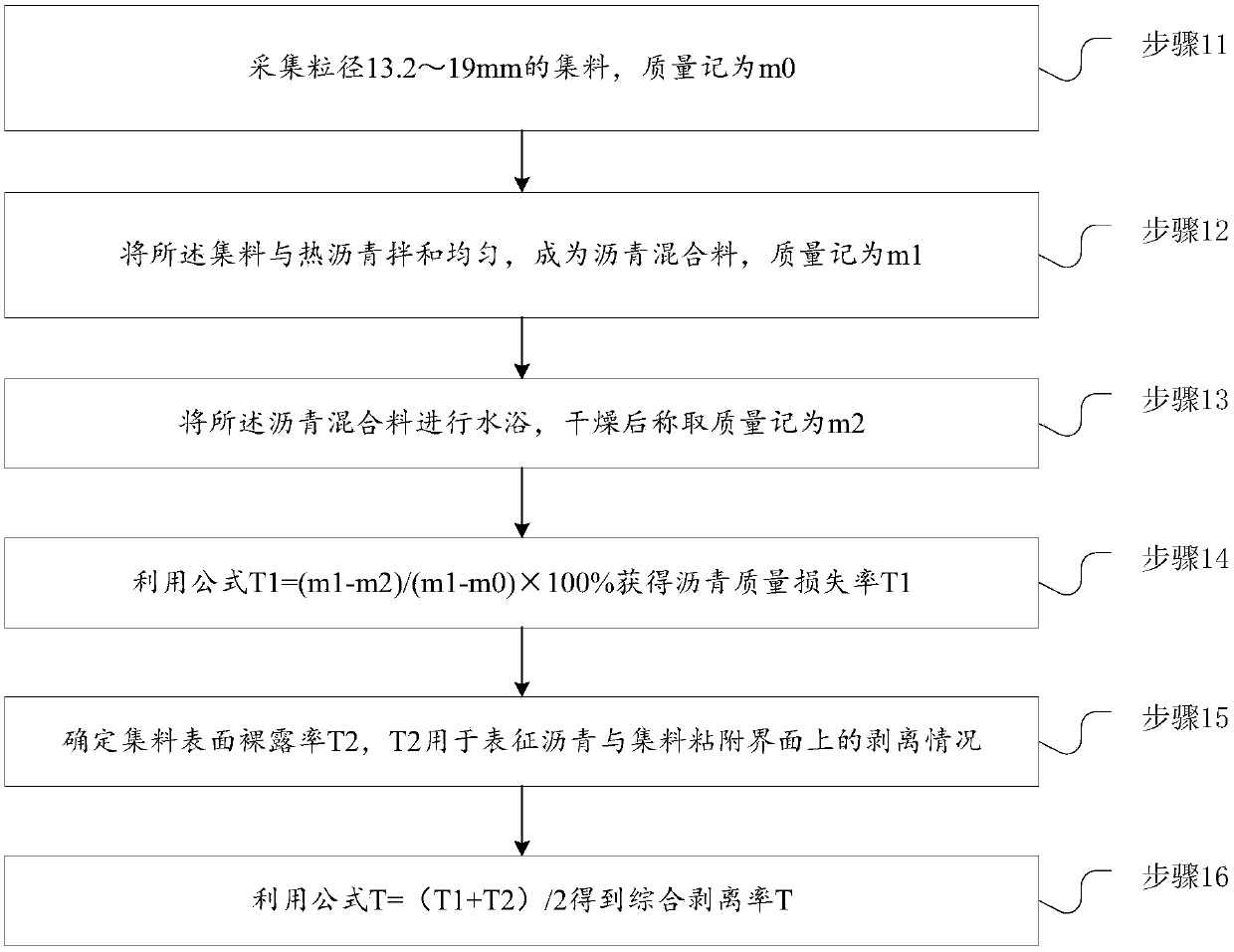

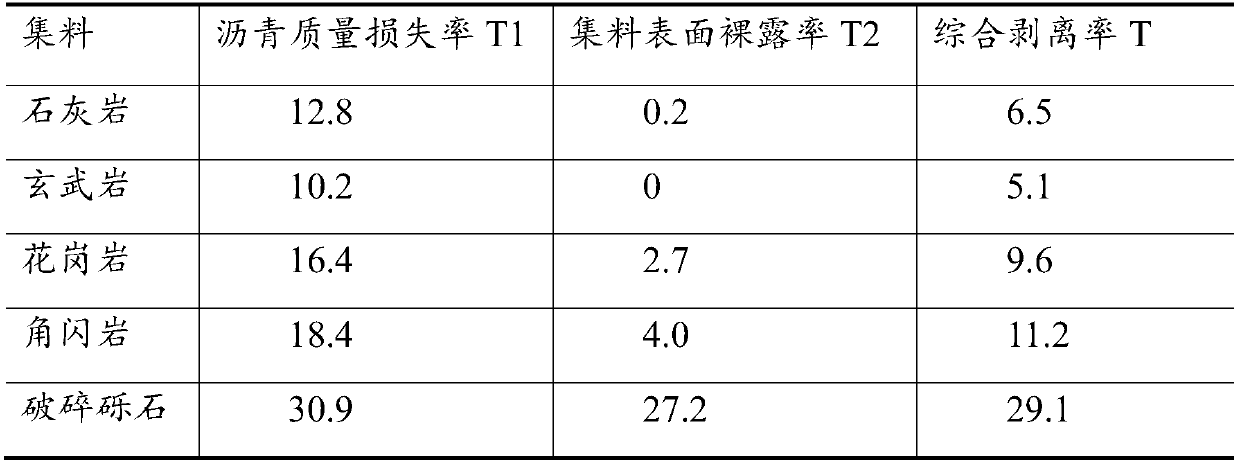

Quantitative evaluation method for water-resistant stripping performance of asphalt and aggregate

InactiveCN109100256AReduce human errorEvaluation results are objectiveWeighing by removing componentMaterial analysis by optical meansLoss rateWater baths

The invention discloses a quantitative evaluation method for water-resistant stripping performance of asphalt and aggregate. The quantitative evaluation method comprises the steps of acquiring aggregate with grain sizes being 13.2-19 millimeters, and marking mass as m0; uniformly stirring the aggregate and hot asphalt to form an asphalt mixed material, marking mass as m1; performing water bath one asphalt mixed material, and weighing and marking mass as m2 after drying; acquiring asphalt mass loss rate T1 according to a formula: T1=(m1-m2) / (m1-m0)*100%, wherein the T1 is used for representingstripping condition between asphalt membranes; determining surface exposure rate T2 of the aggregate, wherein the T2 represents stripping condition between the asphalt membranes and aggregate pastinginterface; and obtaining integral stripping rate T according to a formula: T=(T1+T2) / 2. According to the method, the water-resistant stripping capability is evaluated in a quantitative form, and personal error is reduced to the greatest extent; and therefore, the stripping conditions between the asphalt membranes and between the asphalt membranes and the aggregate surface are comprehensively considered, and the evaluation result is more comprehensive and objective.

Owner:CHINA GEZHOUBA GRP HIGHWAY OPERATION CO LTD

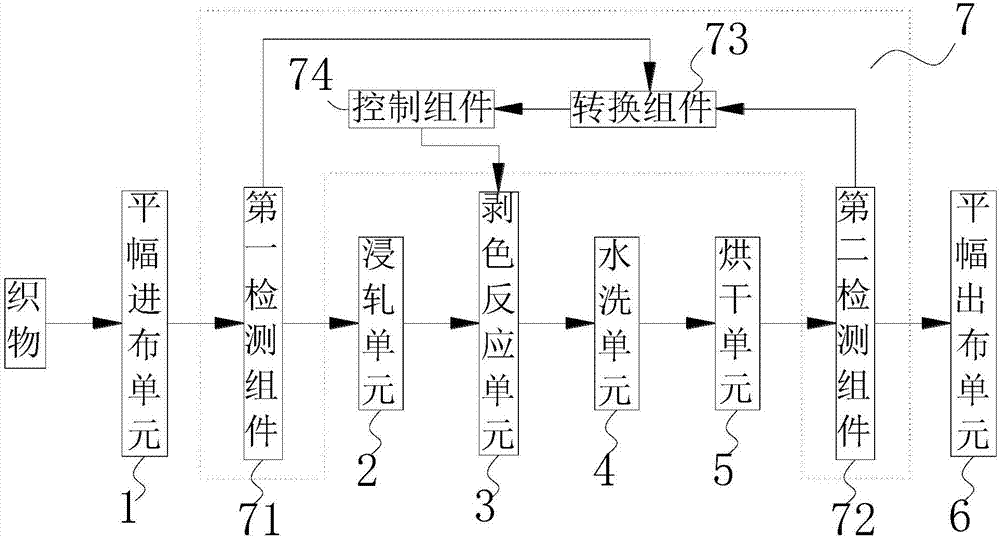

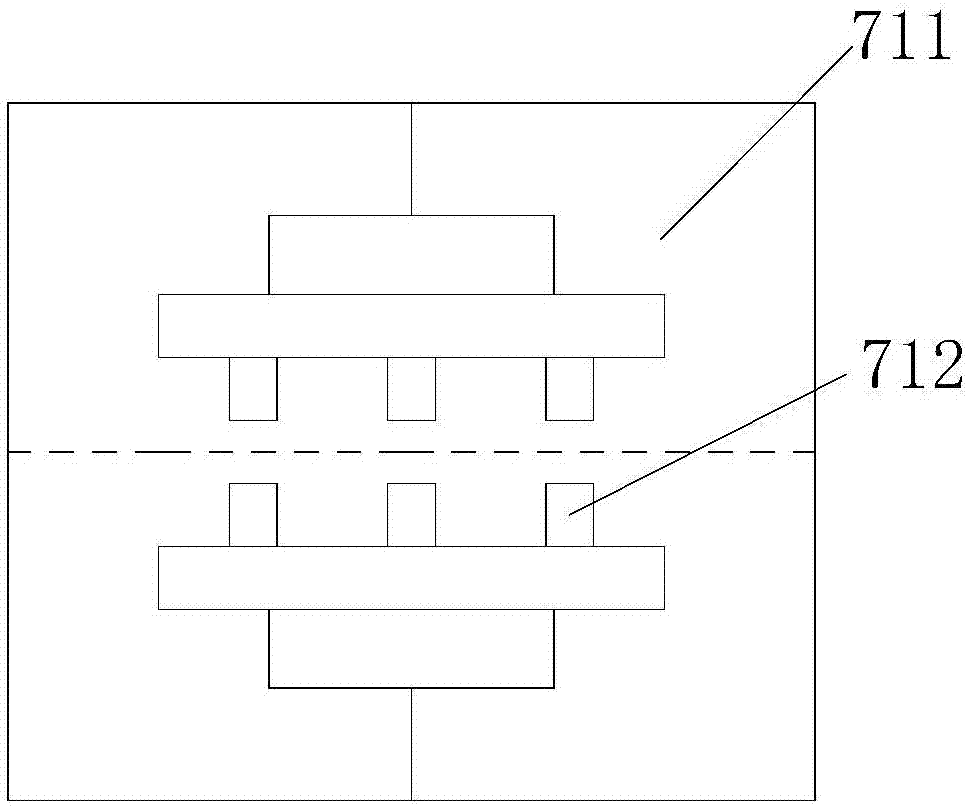

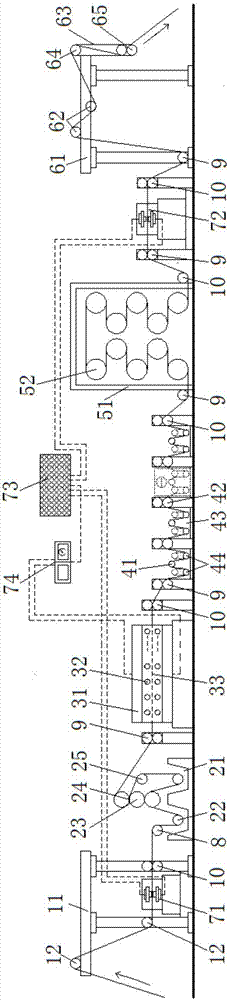

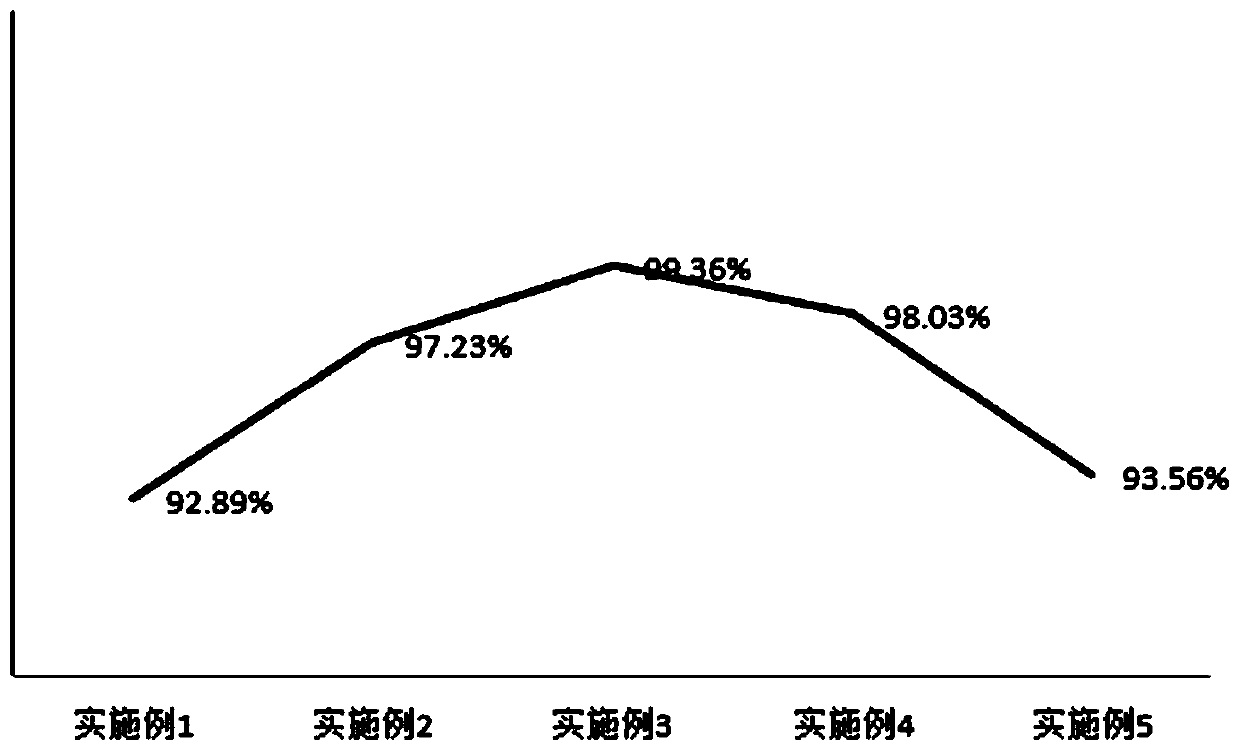

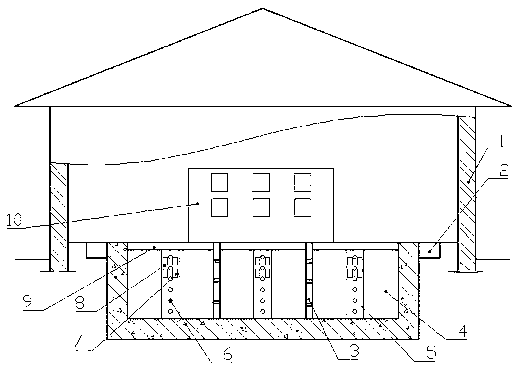

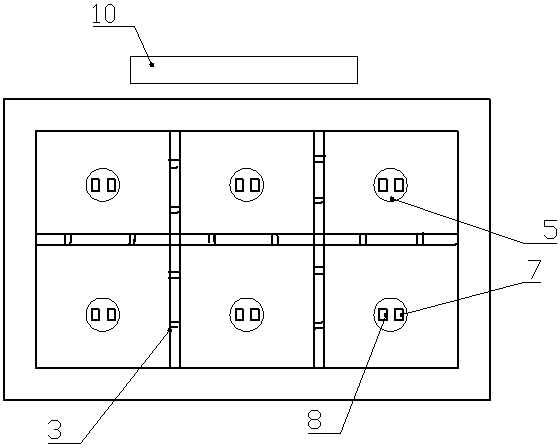

Continuous photocatalytic stripping machine with online measurement and control and detection and control method thereof

ActiveCN107099960AFast and effective peelingAvoid damageSucessive textile treatmentsTextile treatment machine arrangementsElectricityEngineering

The invention discloses a continuous photocatalytic stripping machine with online measurement and control and a detection and control method thereof. The machine comprises an open-width cloth feeding unit, a padding unit, a stripping reaction unit, a washing unit, a drying unit, an open-width cloth discharging unit and an online measurement and control unit. The online measurement and control unit comprises a first detection component and a second detection component which detect the reflection rate of fabric for light and a conversion component which is electrically connected with the first detection component and the second detection component separately, wherein the conversion component comprises a digital convertor which is capable of obtaining the color depth value of the fabric surface, the average value of the surface color depth, the variance of the surface color depth, the standard deviation of the surface color depth and the stripping ratio by calculation treatment. The stripping reaction unit is a photocatalytic stripping reaction unit, and comprises a reaction tank and a reaction light component, wherein the reaction tank is provided with a cloth conveying channel which is irradiated by the reaction light component. The machine and the method have at least the following advantages of high degrees of integration and intelligence, continuous stripping, simple technological process, short stripping time, energy conservation, environment protection, and low damage to fabrics.

Owner:SUZHOU UNIV

Method for detecting granularity and surface feature of diamond micro-powder by using flow cytometer

ActiveCN107515149AImprove clarityEfficient removalPreparing sample for investigationParticle size analysisGranularityUltrasonic dispersion

The invention discloses a method for detecting the granularity and surface feature of diamond micro-powder by using a flow cytometer. The method comprises the steps of putting a detecting sample diamond micro-powder into a container, adding a prepared sodium chloride solution, stirring to obtain a diamond micro-powder solution; putting the container containing the diamond micro-powder solution into an ultrasonic cell pulverizer for ultrasonic dispersion, so as to obtain a primarily dispersed diamond micro-powder solution; standing the obtained solution, then adding a prepared octylphenoxypolyethoxyethanol solution and evenly shaking; then putting the solution into the ultrasonic cell pulverizer for ultrasonic dispersion again, so as to obtain a to-be-detected diamond powder solution; finally, automatically detecting the to-be-detected diamond powder solution by adopting the flow cytometer and automatically storing data; finally calling out data of diameter, circularity, breadth length ratio, strip ratio and granularity distribution, and analyzing a result. The detection method provided by the invention can reduce agglomeration to a large extent; the operation is simple, and the effect is obvious.

Owner:惠丰钻石股份有限公司

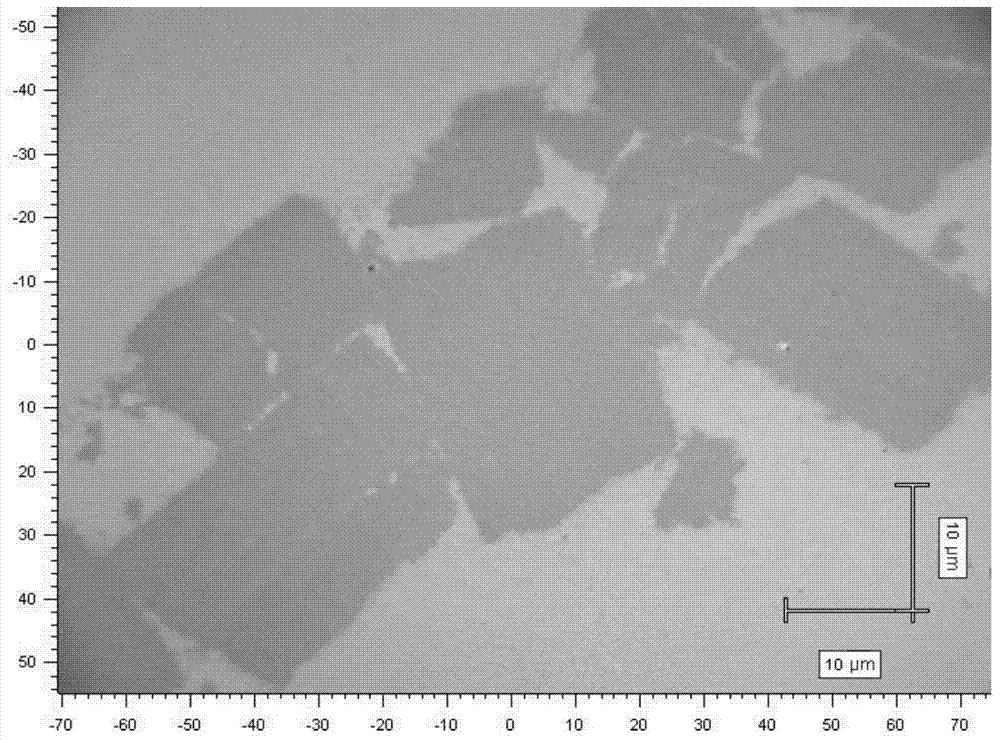

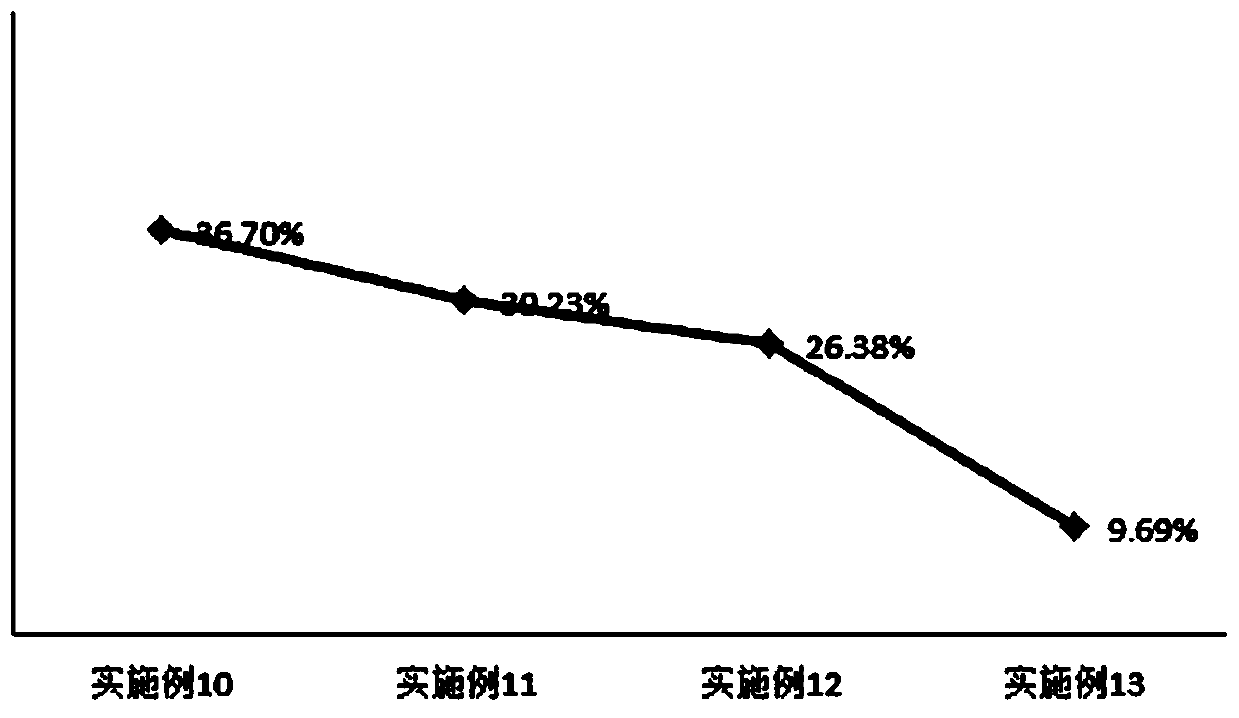

Preparation method of high-concentration MoS2 nanosheet

The invention discloses a preparation method of a high-concentration MoS2 nanosheet, and belongs to the technical field of biological nanomaterials. The preparation method specifically comprises the following steps that S1, a certain amount of molybdenum disulfide polycrystalline powder or a certain number of molybdenum disulfide single crystal blocks are added into an airtight blue-cap ultrasonicbottle, then a certain quantity of a polar solvent is added into the blue-cap ultrasonic bottle, and a solution system is formed; S2, the solution system in the blue-cap ultrasonic bottle is subjected to inert gas bubbling treatment; S3, the blue-cap ultrasonic bottle is placed in an ultrasonic cleaning machine for ultrasonic treatment, ice blocks are added into the ultrasonic cleaning machine during ultrasonic treatment to create a low temperature environment and have an ice-bath cooling effect, and a dark green MoS2 nanosheet dispersion solution is obtained; S4, the dark green MoS2 nanosheet dispersion solution is separated. According to the preparation method, the high-concentration MoS2 nanosheet is prepared by utilizing the dispersity between the solvent and a solute and selecting anultrasonic stripping method, and the nanosheet dispersion solution which has a high stripping ratio and high stability and maintains the block semiconductor properties is obtained.

Owner:南京倍格电子科技有限公司

Processing method of Taoyuan big leaf dark tea

The invention relates to a processing method of Taoyuan big leaf dark tea, comprising the following steps: selecting one bud and three leaves or one bud and four leaves of raw material Taoyuan big leaf tea, and carrying out enzyme deactivation till the leaf color is changed into dark green from blue green and faint scent comes out, wherein the enzyme deactivation time is 2-4 min; then rolling till the leaves are in strip shapes primarily for creating conditions for pile fermentation, wherein the foliar cell damage ratio is 30-35% and the strip ratio of tea leaves is more than 90% after rolling, the strip-shaped leaves are rolled tightly, the tea juice is fully overflown and can be extruded out among fingers when grasped with hands tightly, and the pile fermentation after rolling is carried out in a tea leaf pile fermentation cellar; and baking and drying after pile fermentation to prepare a finished product. The processed product takes Taoyuan big leaf tea as raw material, and is refined and prepared through the process steps of enzyme deactivation, rolling, fermentation in pile fermentation cellar, drying and the like. The dark tea is uniform and tidy in shape, dark brown and bright in color, and smells like pine black; the tea water is brilliant red and clear in color and tastes mellow, smooth and sweet. The Taoyuan big leaf dark tea has the characteristic that the longer the age is, the stronger the fragrance is, and overcomes the defects of the traditional pile fermentation that since pile fermentation completely depends on manual operation and experience, the pile fermentation time is long, the middle part of the pile is often over-fermented and the edge of the pile is ofen under-fermented, and the quality is hard to control.

Owner:HUNAN GUDONGCHUN TEA IND

A mining method for inclined coal seam open-pit mining with deep horizontal mining and shallow longitudinal mining

ActiveCN110318759BReduce production stripping ratioReduce the comprehensive distanceOpen-pit miningOpen-pit miningMechanical engineering

An inclined seam strip mine mining method achieving deep transverse mining and shallow longitudinal mining comprises the following steps that (1) the transverse mining and longitudinal mining boundarydepth h is confirmed according to technical parameters confirmed by a strip mine; (2) mining is carried out in a transverse mining manner at the early stage of strip mine construction, and transversemining is started after the propulsion direction is confirmed; (3) after mining is carried out according to the step (2) to the pit bottom, after the longitudinal mining conditions are met at the level of the depth h or above, and the original transverse mining manner is charged into the longitudinal mining manner at the level of the depth h or above of the strip mine; (4) after the strip mine meets the conditions of shallow longitudinal mining and deep transverse mining, deep transverse mining and shallow longitudinal mining are carried out at the same time; (5) shallow longitudinal mining continues to be pushed towards the final state direction, deep transverse mining continues to follow up, and the steps (2)-(4) are circulated; and (6) after shallow longitudinal mining is pushed to thefinal state, deep transverse mining continues to mine a deep coal layer till all coal in the state is mined. According to the method, secondary reserving is simple, the stripping ratio of early-stageproduction is small, and the comprehensive stripping distance is small.

Owner:LIAONING TECHNICAL UNIVERSITY

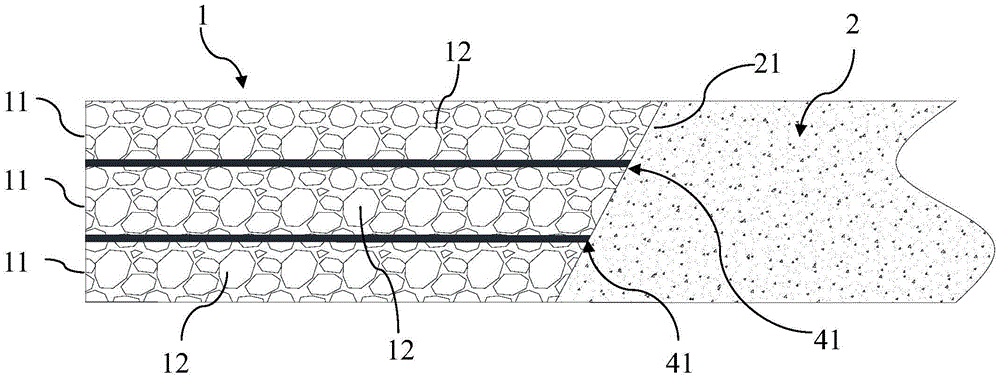

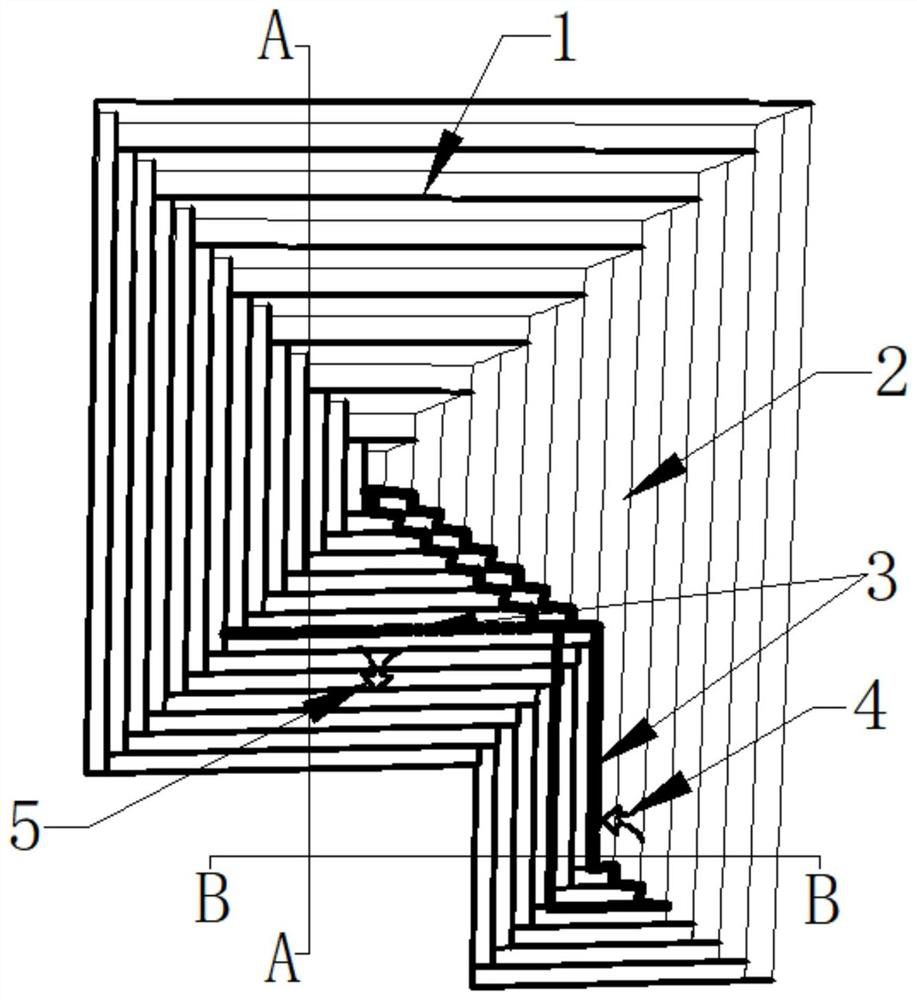

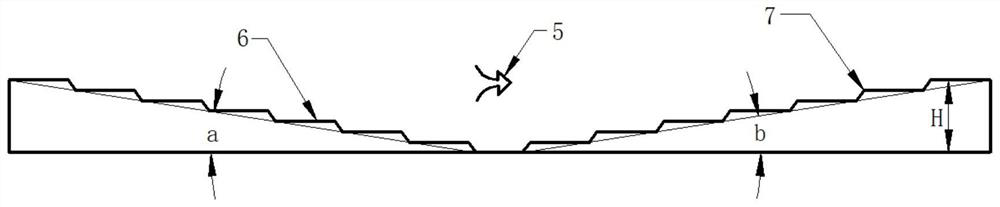

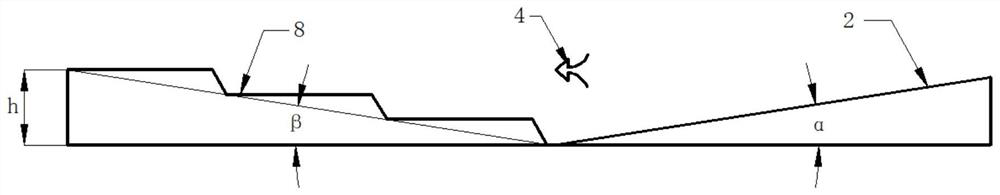

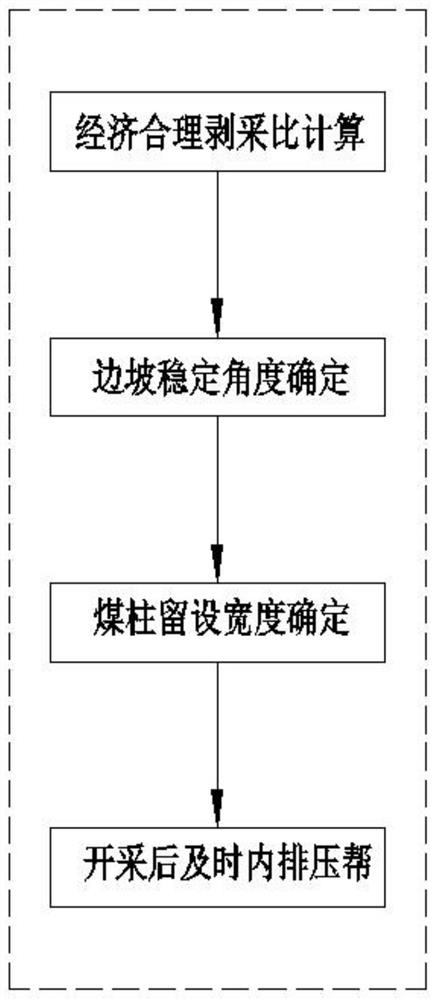

Open pit mine internal dumping and covering resource mining method

ActiveCN112855164AIncrease mining volumeMining a lot of coalOpen-pit miningOpen-pit miningCoal pillar

The invention relates to the field of open pit mining, in particular to an open pit mine internal dumping and covering resource mining method. The method comprises the steps of calculating an economic and reasonable stripping ratio, determining a stable slope angle, determining a coal pillar leaving width, and performing timely internal dumping and wall compression after mining. The method considers the economy and safety, and the maximum coal mining amount can be ensured under the conditions of safety and economy. According to traditional open pit mine internal dumping and covering mining area mining, raw coal mining is carried out only according to a designed slope angle, so that the coal pillar leaving width is large and the loss of coal pillar resources is excessive. In the method, the raw coal mining amount can be increased, and the mining method is more reliable.

Owner:中煤科工集团沈阳设计研究院有限公司 +1

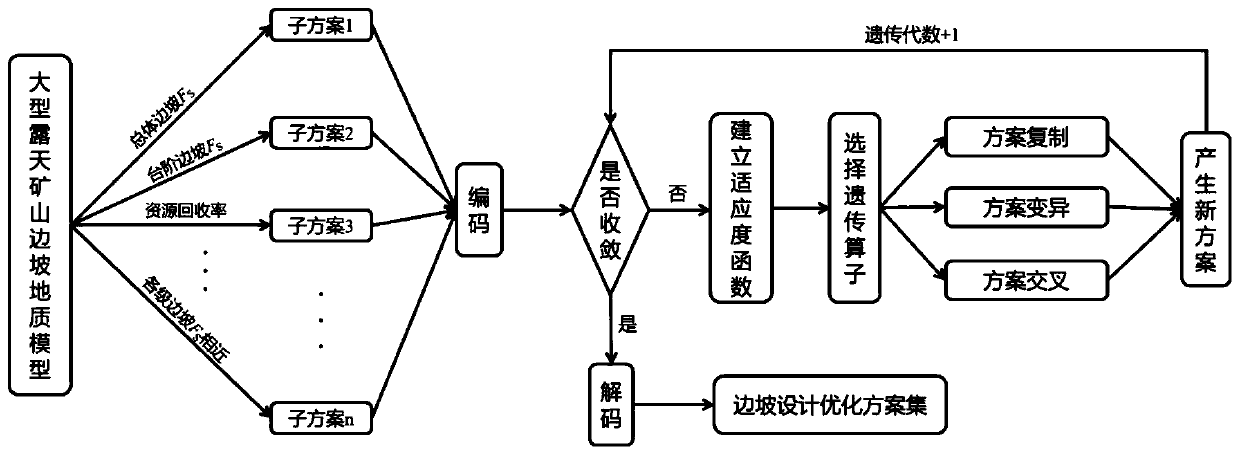

Large surface mine slope collaborative design method based on multi-objective genetic algorithm

ActiveCN111008460ACollaborative active prevention and control design and implementationAvoid investmentDesign optimisation/simulationConstraint-based CADAlgorithmGenetics algorithms

The invention discloses a large surface mine slope collaborative design method based on a multi-objective genetic algorithm. The method comprises the steps: constructing a surface mine slope three-dimensional geomechanical model according to the engineering general situation of a selected large surface mine slope; establishing a fitness matrix according to the reasonable stripping ratio range, theparameter requirements of each stage of platform and the safety factor FS design specification values of each stage of slope; selecting a genetic operator and performing copying, variation and crossprocessing on the local parameters of the slope engineering to obtain a new mine slope design scheme set, introducing global convergence, judging whether the data of the mine slope design sub-scheme set reach an optimal solution and obtaining an optimization scheme set of mine slope design; and performing collaborative active prevention and control design on an unmined mine multi-stage slope according to an optimization scheme set of mine slope design, reinforcing an unstable mine slope through the anchor rod and anchor cable technology, and performing collaborative passive prevention and control design on the mined mine multi-stage slope. According to the method, the accuracy and the scientificity of the mine slope design scheme are improved.

Owner:NINGBO UNIV

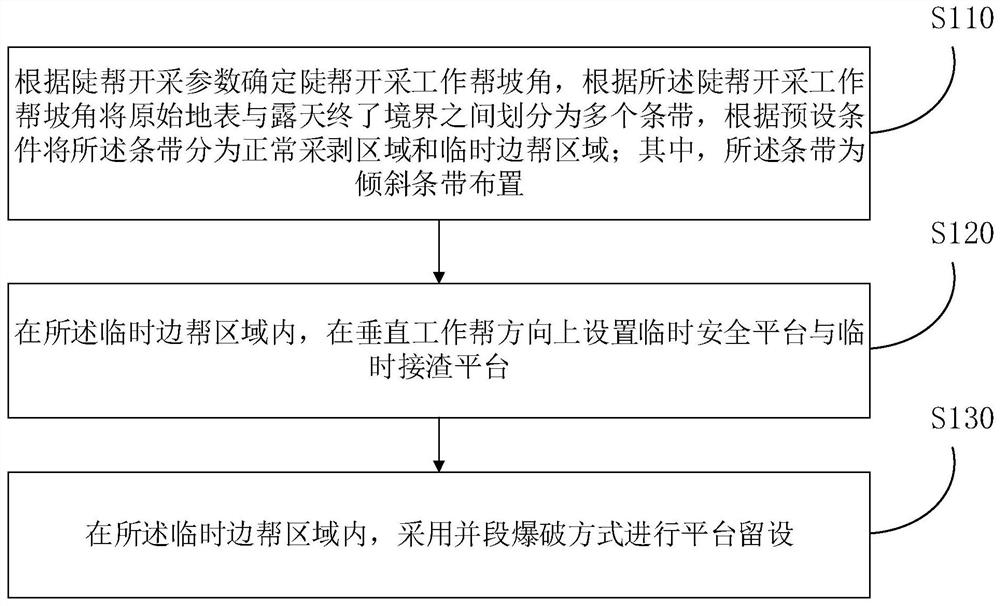

Steep slope mining platform reserving method

PendingCN112049639AIncrease intervalIncrease widthUnderground miningSurface miningMining engineeringSlag

The invention provides a steep slope mining platform reserving method, and belongs to the technical field of strip mining. According to the steep slope mining platform reserving method, a temporary safety platform and a temporary slag receiving platform are arranged in a direction vertical to a working slope in a temporary side slope area arranged by an inclined strip, a temporary transportation platform is arranged in the temporary side slope area, and in the temporary side slope area, platform reserving is carried out in a merged blasting mode. According to the method, the technical effectsof improving a working slope angle in the side slope area, delaying stripping, balancing a stripping ratio and further improving the economic benefit of a mine are achieved by increasing an interval between steep side slope platforms and additionally arranging the temporary safety platform and the temporary slag receiving platform.

Owner:中冶北方(大连)工程技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com