Continuous photocatalytic stripping machine with online measurement and control and detection and control method thereof

A technology of photocatalysis and color stripping, which is applied in the continuous processing of textile materials, the treatment of textile materials, textiles and papermaking, etc., can solve the problems of complex process flow, low degree of integration and intelligence, ecological pollution, etc., and achieve damage Small, the effect of improving the degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

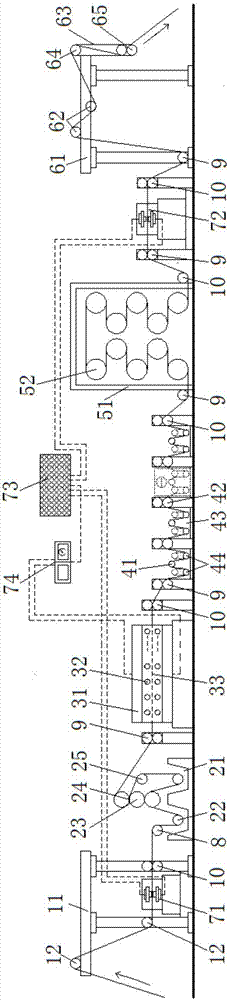

[0027] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

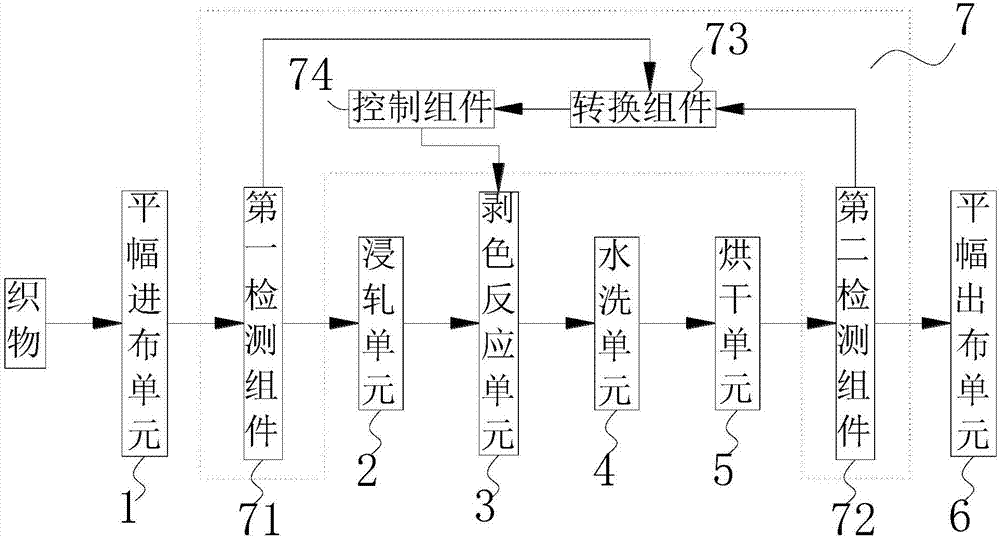

[0028] to combine Figure 1 to Figure 3As shown, a continuous photocatalytic stripping machine for on-line measurement and control of the present invention includes a cloth feeding unit 1, a padding unit 2, a color stripping reaction unit 3, a washing unit 4, a drying unit 5, Open-width cloth output unit 6 and online measurement and control unit 7.

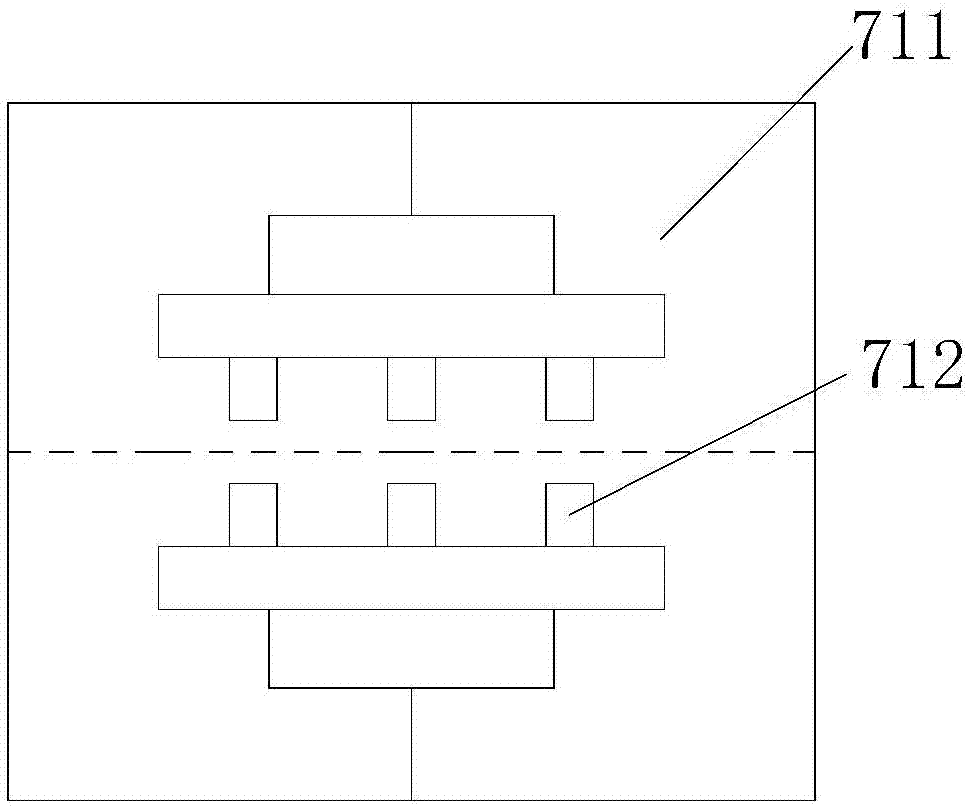

[0029] The on-line measurement and control unit 7 includes a first detection component 71 for detecting the light reflectance of the fabric before stripping, which is arranged between the open-width feeding unit 1 and the stripping reaction unit 3, and is arranged on the The second detection component 72 used to detect the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com