A mining method for inclined coal seam open-pit mining with deep horizontal mining and shallow longitudinal mining

A technology of open-pit mining and horizontal mining, which is applied in open-pit mining, special mining, earth drilling and mining, etc. It can solve the problems of difficult dilution, large ore and rock transportation distance, frequent up and down movement of mining equipment, etc., to reduce production The effect of the stripping ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

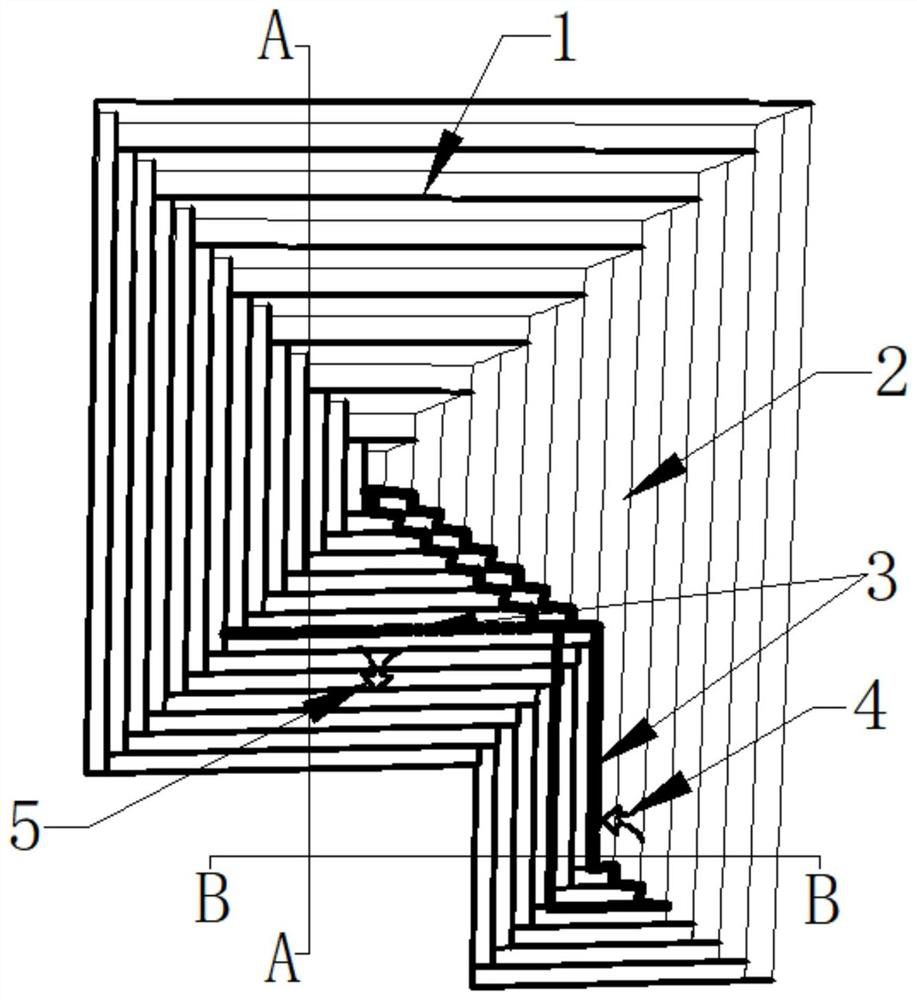

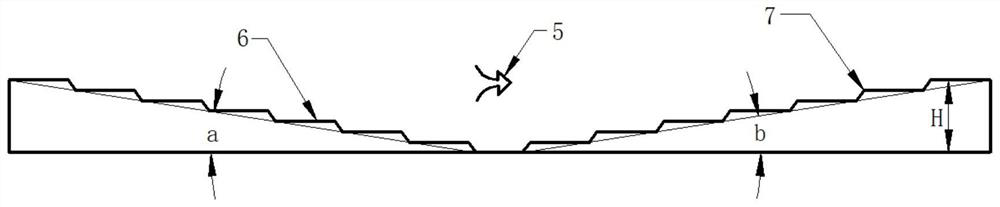

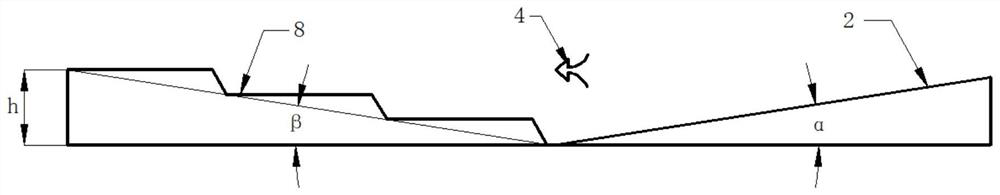

[0053] A method for mining an inclined coal seam open-pit mine with deep horizontal mining and shallow longitudinal mining, comprising the following steps:

[0054] Step 1: If Figure 1~3 As shown, according to the design production capacity, stripping amount, production stripping ratio, length of horizontal mining line, length of vertical mining line, depth of horizontal mining, advancing degree of horizontal mining line, working side slope foot, coal seam The inclination angle determines the boundary depth h between shallow vertical mining and deep horizontal mining, that is, determines the boundary line of horizontal and vertical mining. The specific method is as follows:

[0055] First of all, the problem of the second quantity of open-pit mines should be solved to solve the problem of production continuation of the new plan. In order to meet the requirements of the second quantity of open-pit mines and achieve the purpose of continuous production of open-pit mines, the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com