Shape optimization method for steep slope of an end wall of an open-pit coal mine

A technology of open-pit coal mines and optimization methods, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve problems such as waste of coal resources, small slope angles, and no consideration, etc., to reduce the production stripping ratio and improve Economic benefits, the effect of sufficient coal resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

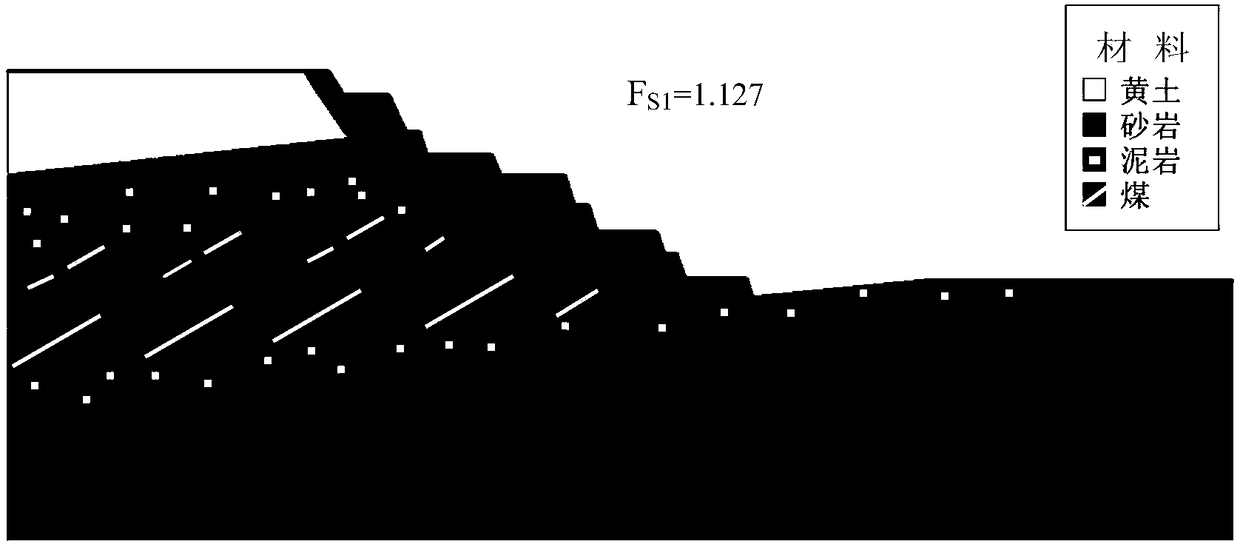

[0032] The coal seam occurrence state of an open-pit coal mine is nearly horizontal, the first mining area advances from west to east, and the slopes on both sides of the north and south sides are side walls. If the slope stability coefficient exceeds 1.3, the steep slope technology of side-side pressure can be implemented to achieve the economic effect of more coal mining and less stripping.

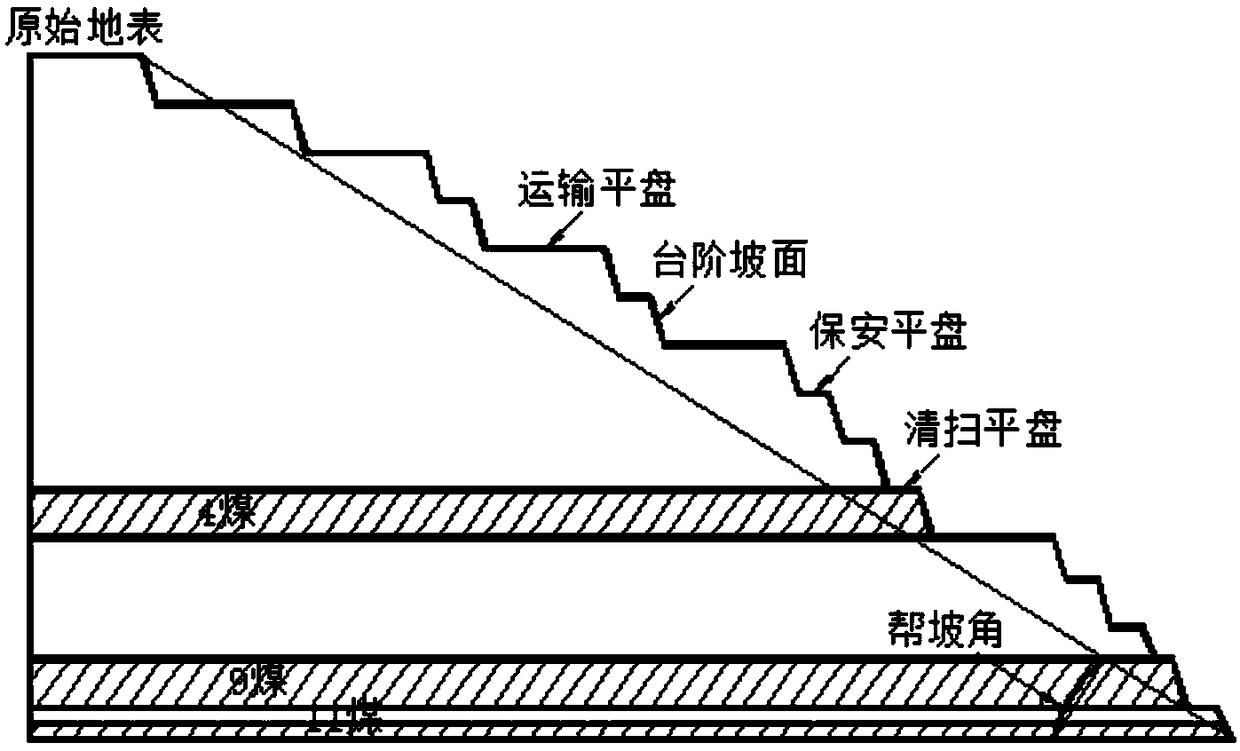

[0033] figure 2 It is a schematic diagram of the composition elements of the end side of the open-pit mine.

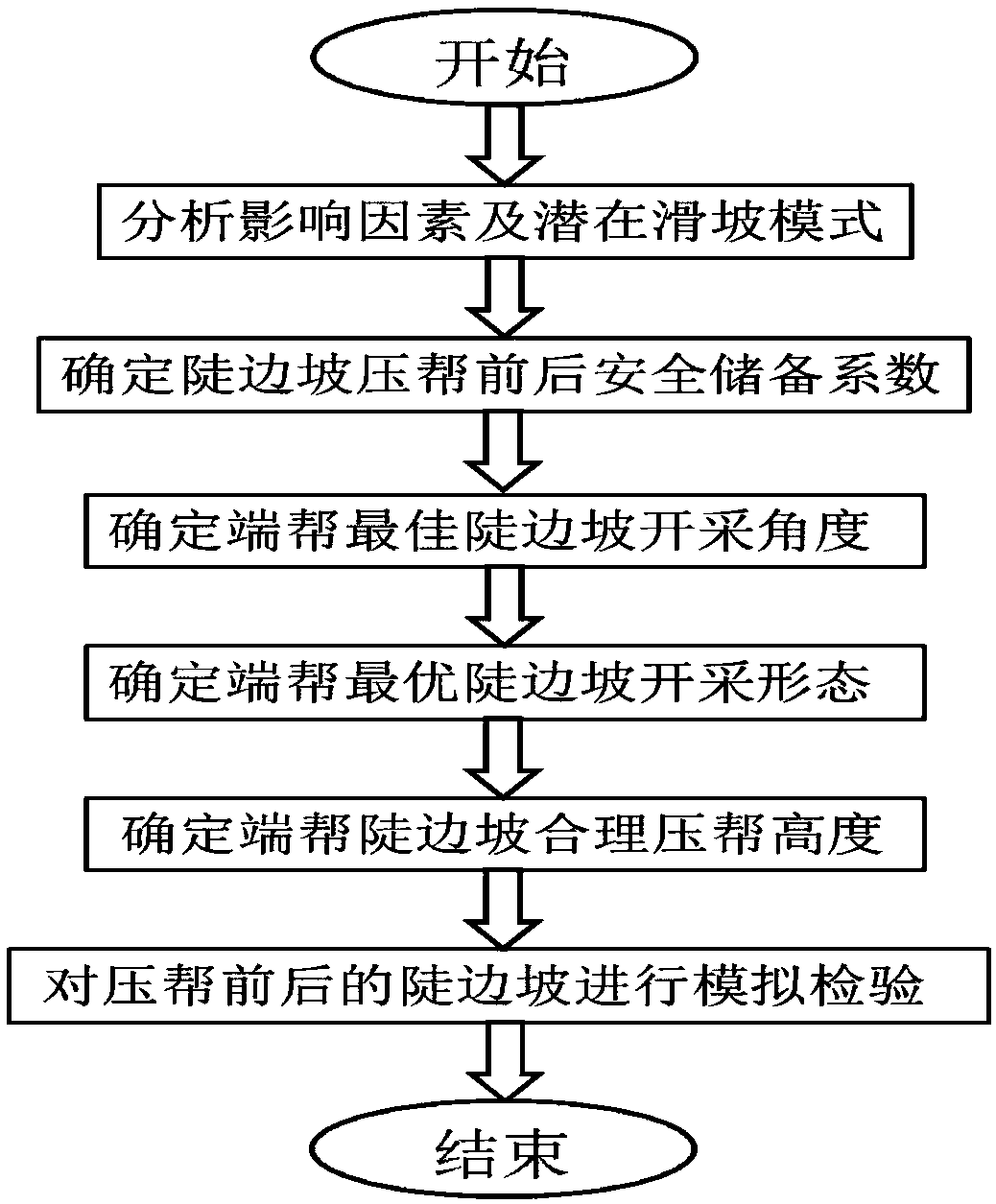

[0034] The main mining coal seams of the example open-pit coal mine are 4, 9, and 11 coals, and they all occur below the 1330 level. Using the present invention to implement the steep slope technology on the side of the open-pit coal mine, that is, a kind of steep side slope of the side of the open-pit coal mine The shape optimization method of the method, the process flow chart is shown in figure 1 ,Specific steps are as follows:

[0035] Step 1. Qualitative analysis of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com