Patents

Literature

43 results about "Slope mining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Slope mining is a method of accessing valuable geological material, such as coal or ore. A sloping access shaft travels downwards towards desired material. Slope mines differ from shaft and drift mines, which access resources by tunneling straight down or horizontally, respectively. In slope mining, the primary access to the mine is on an incline. Mine hoists may still be used to raise and lower loads on the incline if it is steep, but on shallower slopes, conveyor belts, locomotives or trucks may do the work. Drainage and ventilation of slope mines may be done using the primary slope, or it may be done using auxiliary shafts or bore-holes.

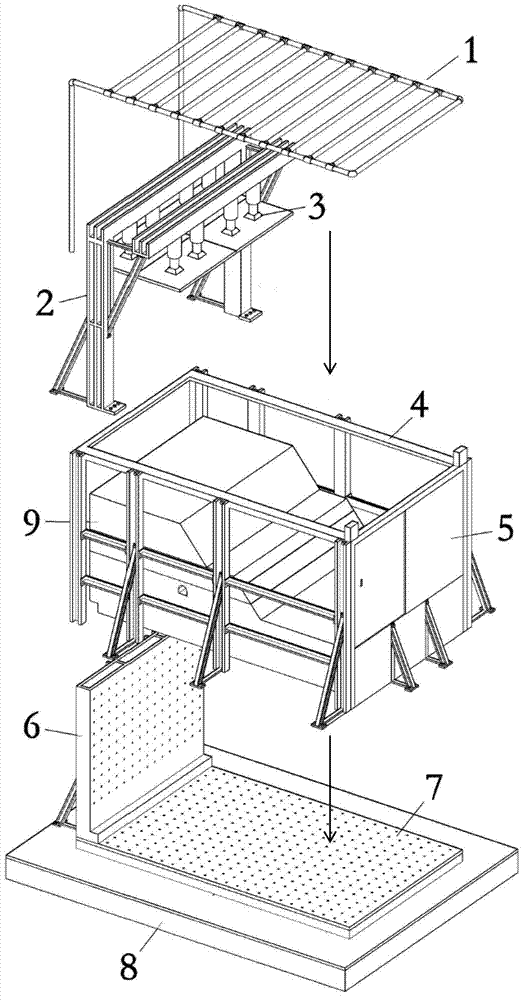

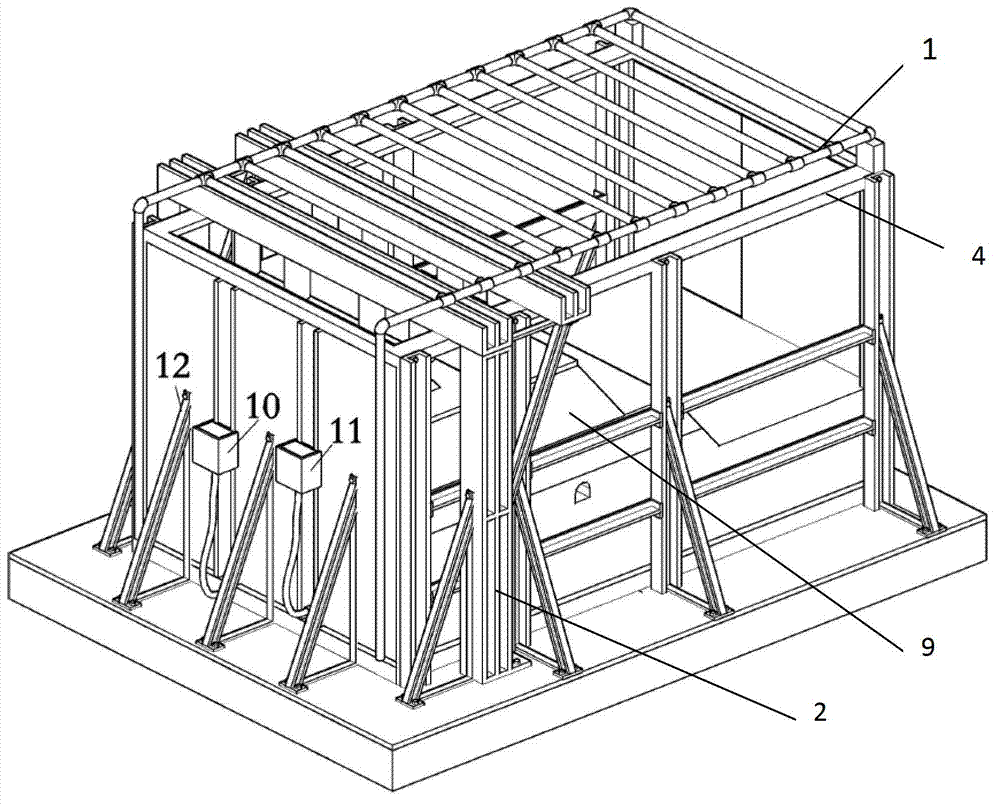

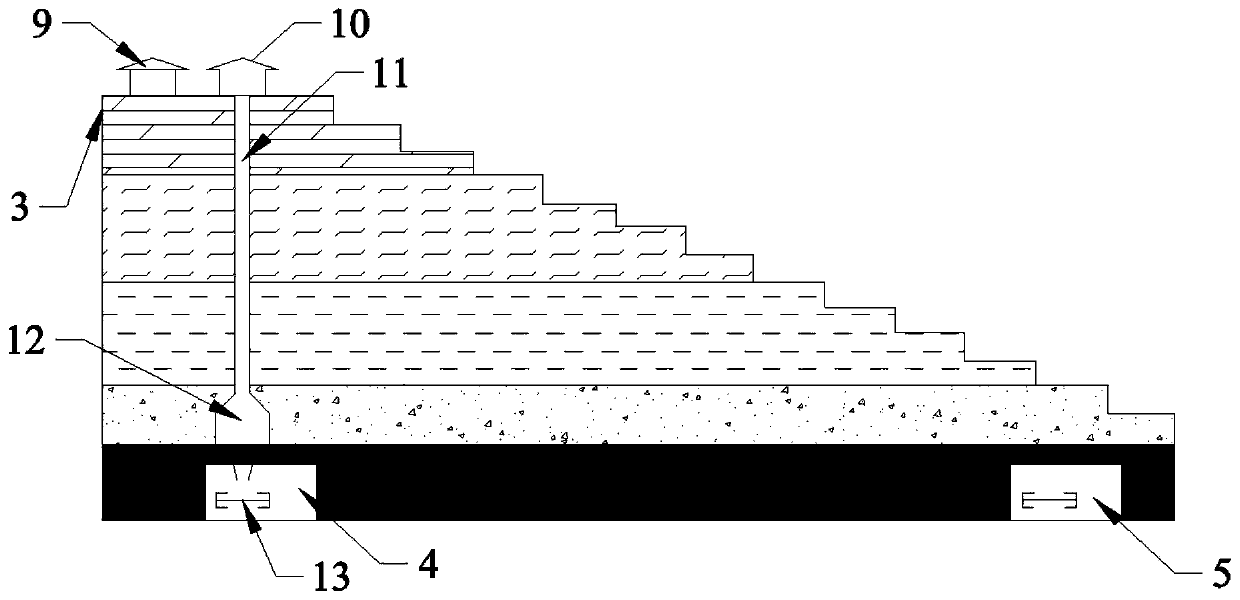

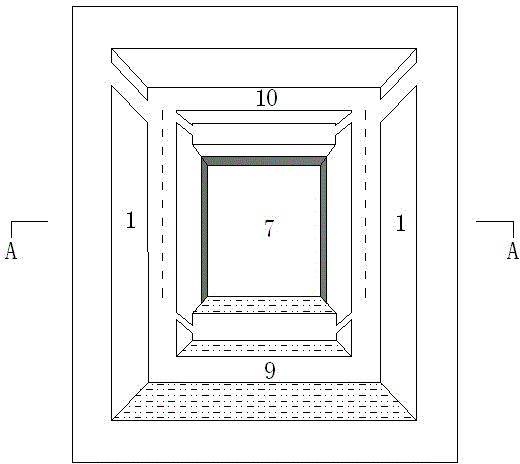

Side slope mining model testing device and method under action of surface and underground water

InactiveCN103197043ARealize simulationObserving changes clearlyEarth material testingRainfall simulationModel testing

The invention relates to a side slope mining model testing device and method under the action of surface and underground water, which can effectively meet experiment requirements, improve experimental efficiency and greatly facilitate experimental operation and is high in comprehensiveness. The device comprises a vertical baffle wall with holes and a vertical side slope base plate with holes; the side slope base plate with holes is arranged on a device base; a steel frame is arranged outside the vertical baffle wall with holes and the vertical side slope base plate with holes; visible glass is installed around the steel frame; a lane opening is formed in the front side of the steel frame; side slope soil is arranged inside a space formed by the whole steel frame; a vertical counter force rack is installed on the outer side of the steel frame; a rainfall simulation device is installed at the upper part of the vertical counter force rack; a ground stress simulation jack is further arranged on the inner side of the vertical counter force rack; the vertical baffle wall with holes and the side slope base plate with holes are respectively connected with a corresponding lifting water supply device; and the steel frame and the vertical baffle wall with holes are respectively connected with a support device.

Owner:SHANDONG UNIV

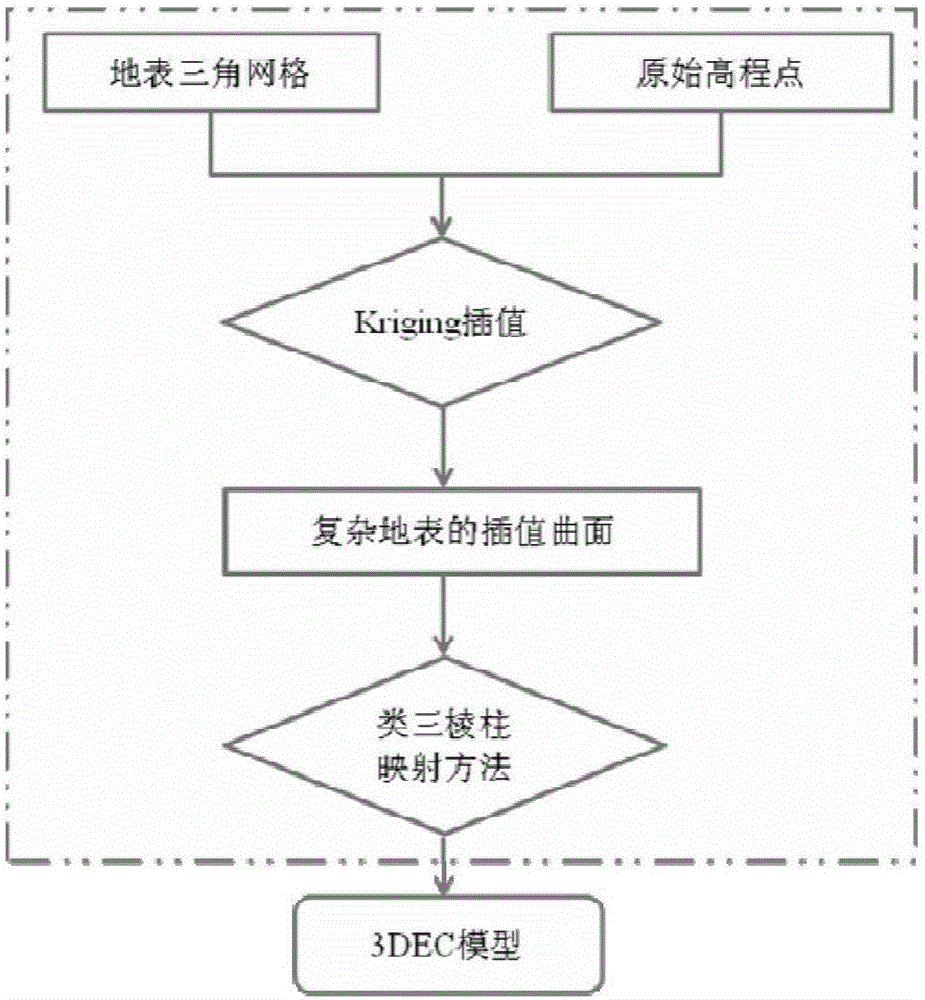

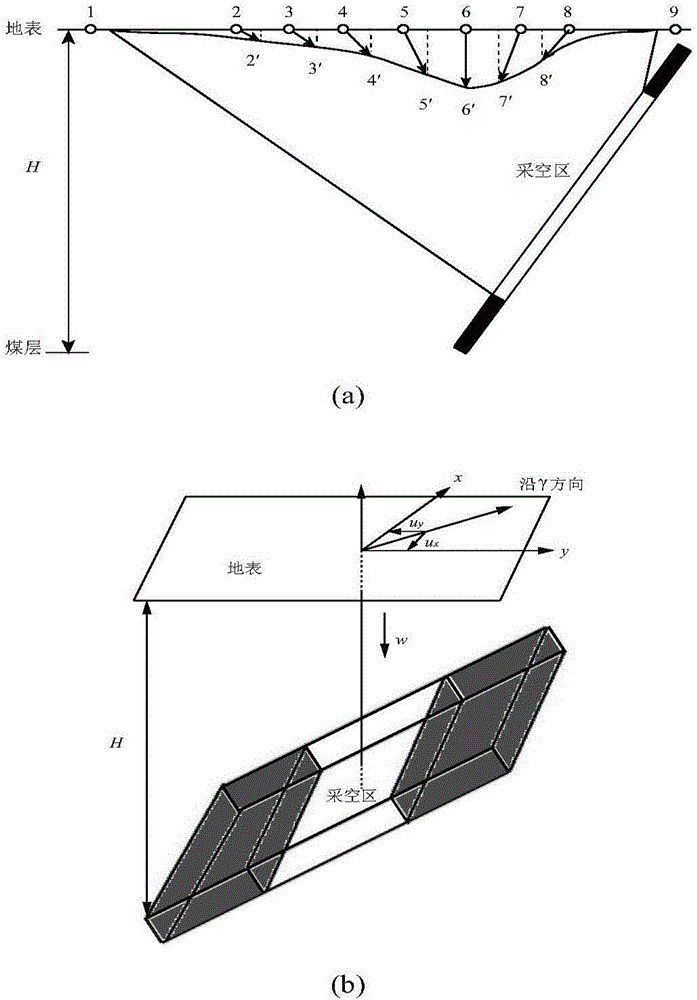

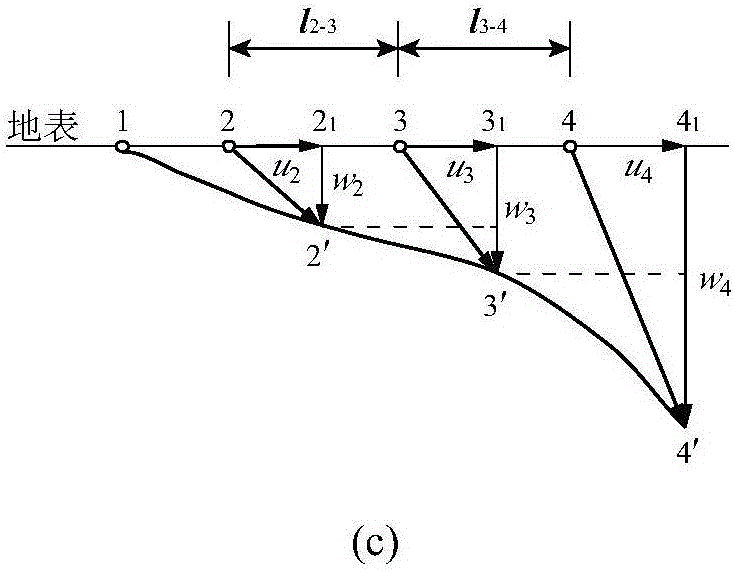

Method for predicting distribution rule of ground surface fissures induced by underground mining of surface mine end slope

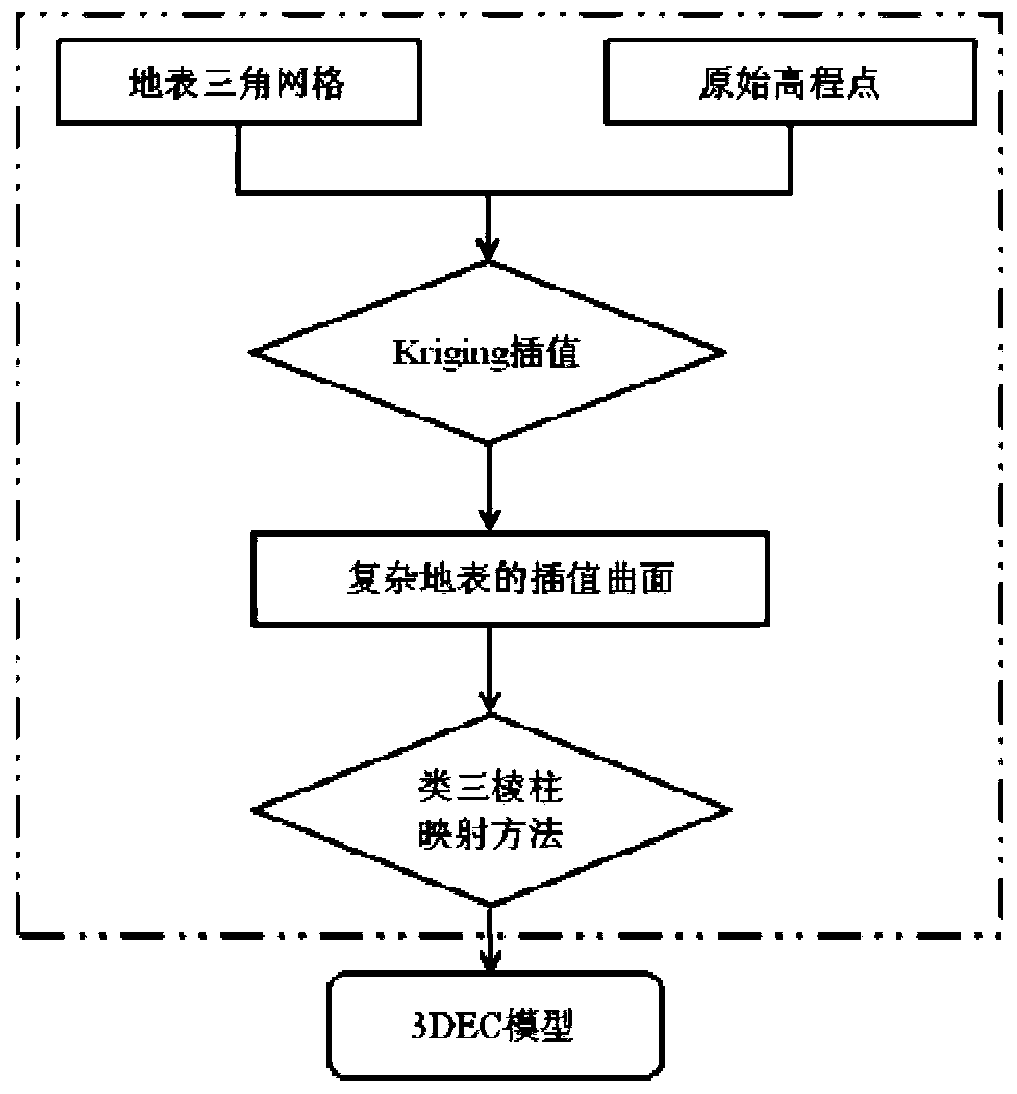

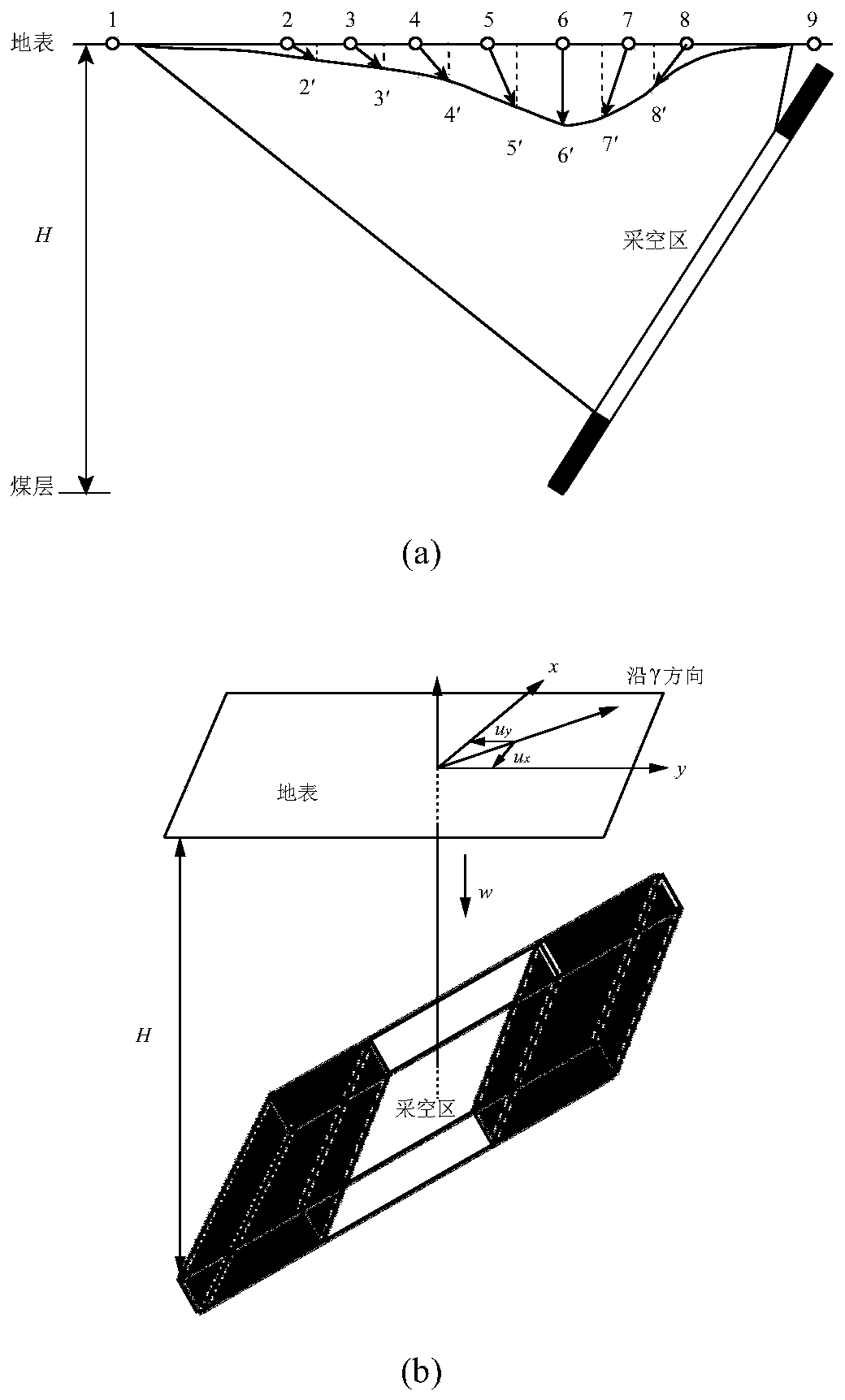

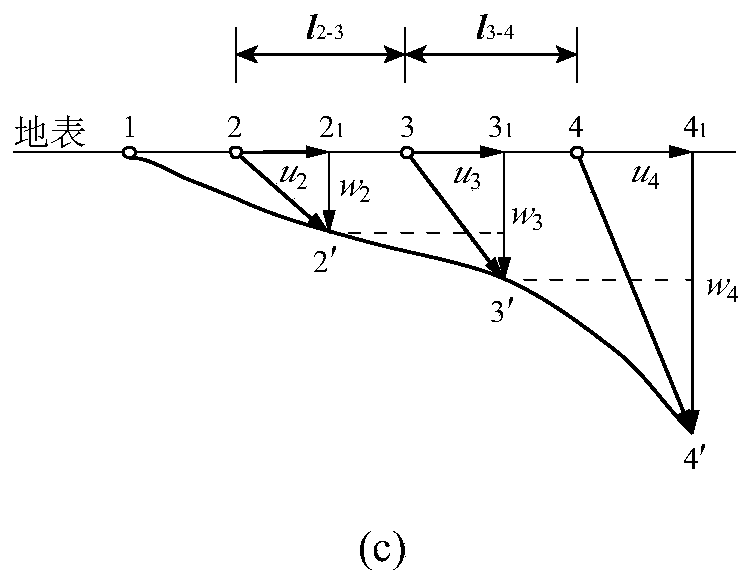

ActiveCN106326528ASolving the Crack Prediction ProblemData processing applicationsDesign optimisation/simulationTerrainModel parameters

The invention provides a method for predicting a distribution rule of ground surface fissures induced by underground mining of a surface mine end slope. The method comprises the following steps of collecting terrain and geology data of a surface iron mine; building an underground mining model of the surface iron mine end slope; determining the parameters of the underground mining model of the surface iron mine end slope; numerical simulation of underground mining: utilizing a three-dimensional discrete element method to calculate the numerical simulation of mining of the surface iron mine end slope, so as to obtain a rock layer and ground surface movement rule; predicting the ground surface fissures. The method has the advantages that the problem of predicting of ground surface fissures caused by the end slope mining from the surface iron mine into the underground mine is solved; a three-dimensional geology model of the rock body of the surface iron mine is established by a three-dimensional geology modeling method, and is divided into a discrete block model suitable for the 3DEC calculation; the distribution scope and type of the ground surface fissures in the underground mining process can be predicted, and the support is provided for the safety production of mines.

Owner:ANSTEEL GRP MINING CO LTD

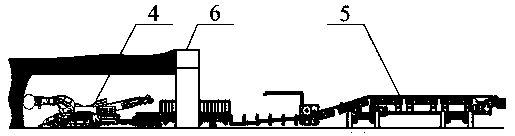

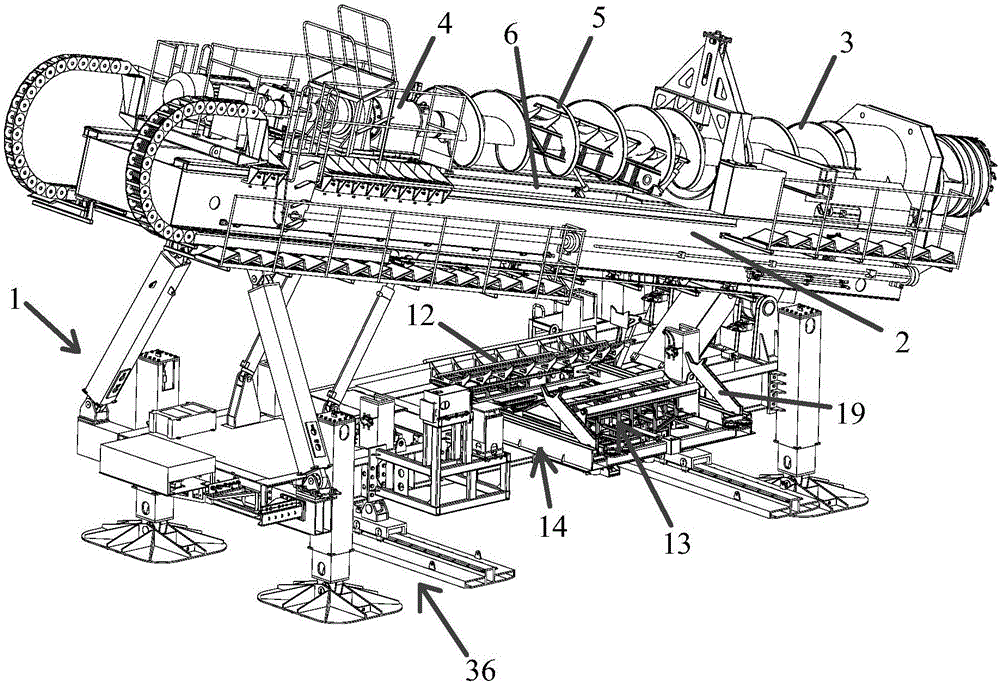

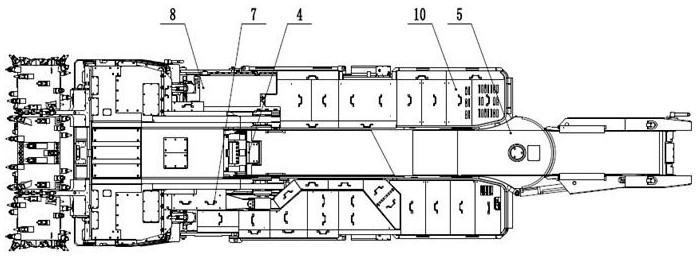

End slope mining method by using open-air end slope ore continuous miner

ActiveCN108194084AMeet the requirements of mechanized miningIncrease the level of mechanizationUnderground miningSurface miningEngineeringMechanization

The invention belongs to the technical field of application of coal mining equipment and coal mining methods, and particularly relates to an end slope mining process by using an open-air end slope orecontinuous miner. The end slope mining process comprises the following steps that 101, a mining face is arranged; 102, an equipment mounting and preparation area is arranged; 103, equipment is arranged and mounted; 104, a ventilation system is arranged; and 105, mining is conducted by using the continuous miner. The end slope mining process adopts continuous miner complete set mining equipment, the requirement of mechanized mining of end slope ore is met, the mechanization level of mining of the end slope ore is improved, the production efficiency is greatly improved, the labor intensity of workers is reduced, the stripping volume of rock and soil is reduced, and damage and disturbance to the environment is reduced.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

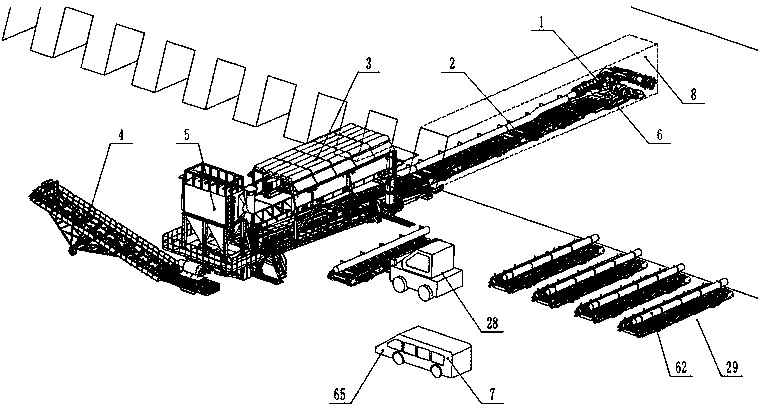

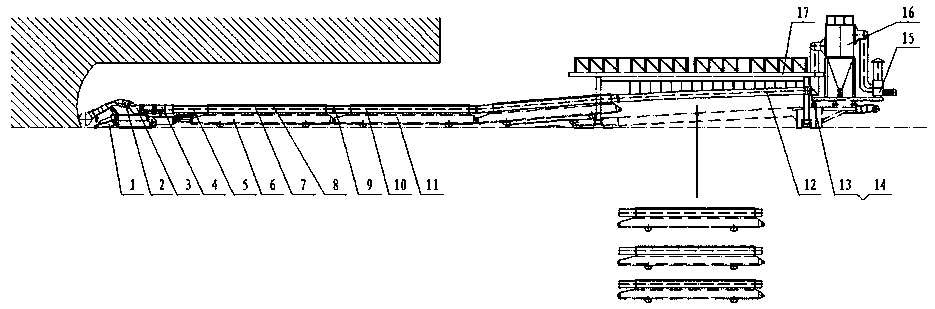

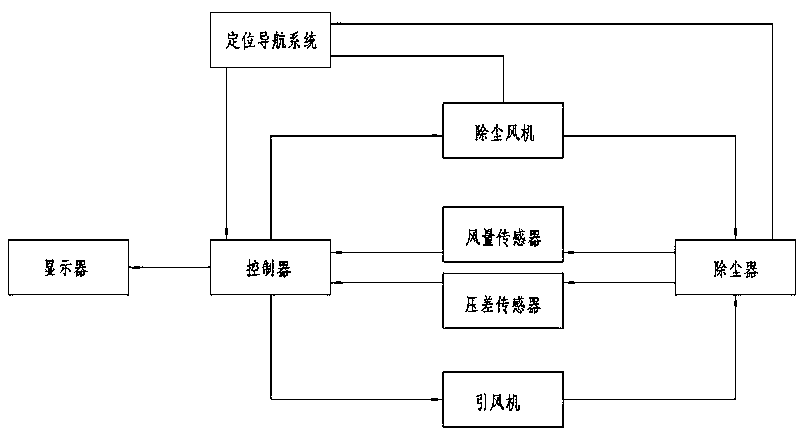

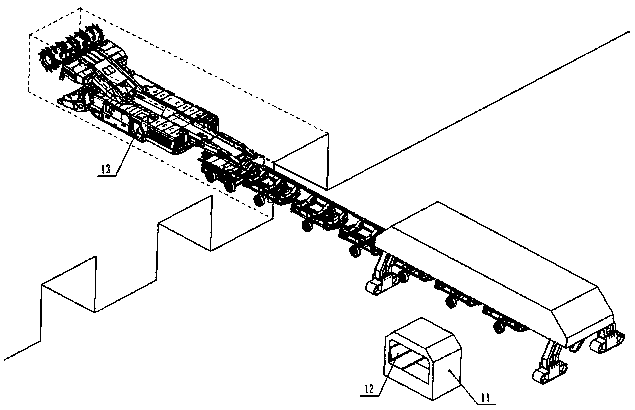

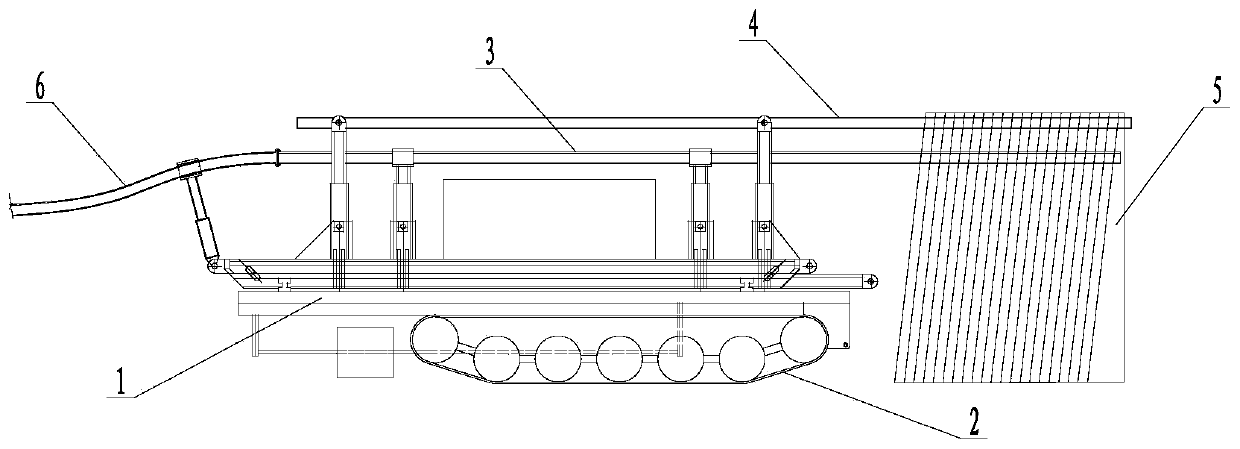

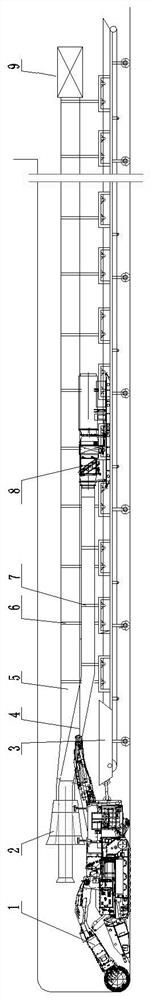

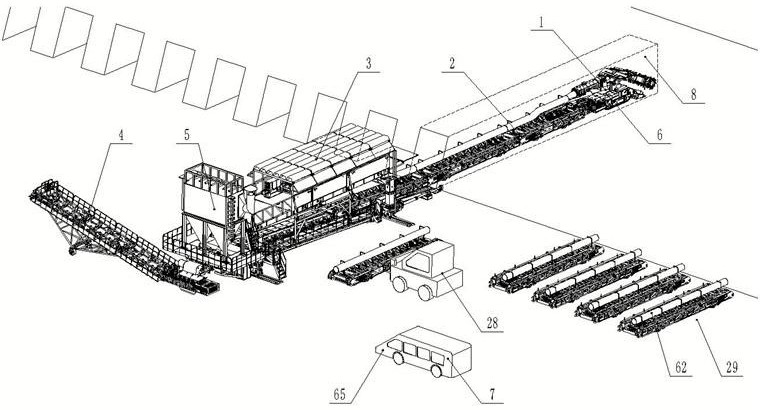

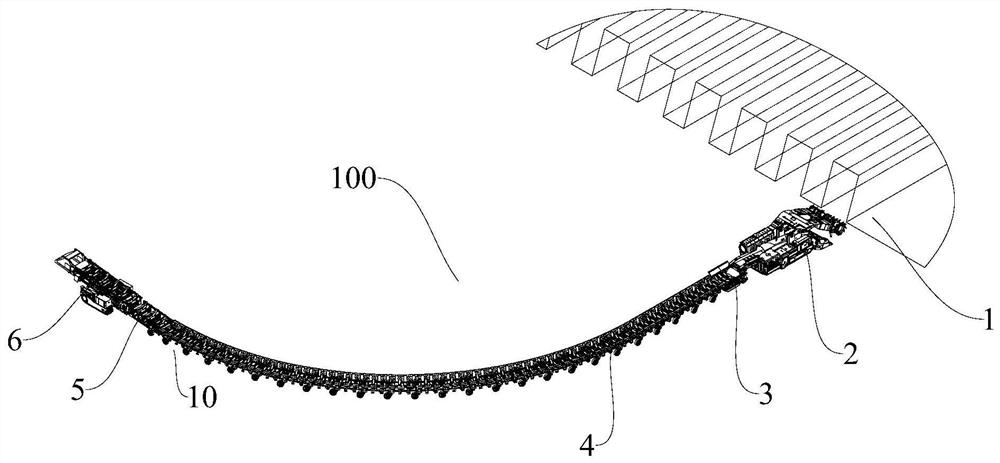

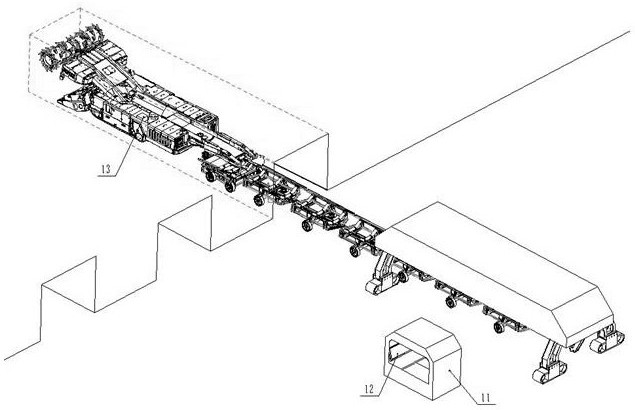

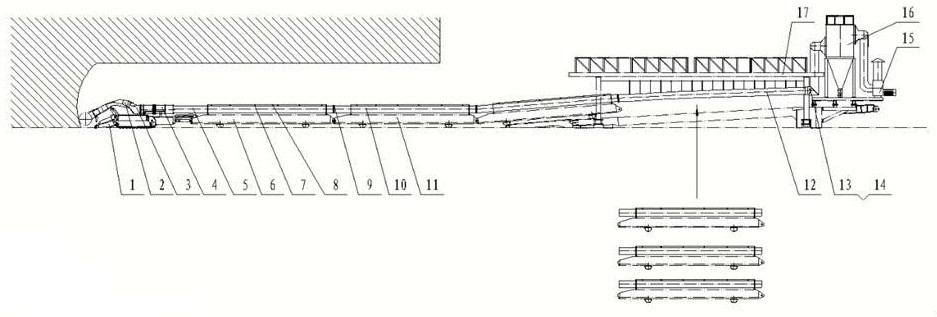

Slope mining system for open-pit mines

ActiveCN109931066AImproving the technical strength of side miningRealize intelligenceDust removalFire preventionAdhesiveEngineering

The invention relates to the technical field of slope mining of open-pit mines and particularly relates to a slope mining system for the open-pit mines, and realizes safe, efficient and green mining of slope briquettes of the open-pit mines. The slope mining system comprises a slope continuous coal mining machine for carrying out roadway type mining, a multi-unit rapid connection adhesive tape conveying system for carrying out rapid conveying, a stepping type walking platform for carrying out external propelling and whole movement, a movable type unloading part for carrying out external conveying, a pulling-out type ventilation and dust removal system for carrying out roadway ventilation and dust removal, a navigation and stability monitoring system for carrying out remote accurate controland slope stability monitoring, and a remote control platform for carrying out remote control. According to the slope mining system for the open-pit mines, provided by the invention, the safe, efficient and green mining of slope briquette resources can be realized, the strength of an slope mining technology of the open-pit mines in China can be remarkably improved, and remarkable economic benefits and social benefits can be brought for enterprises.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

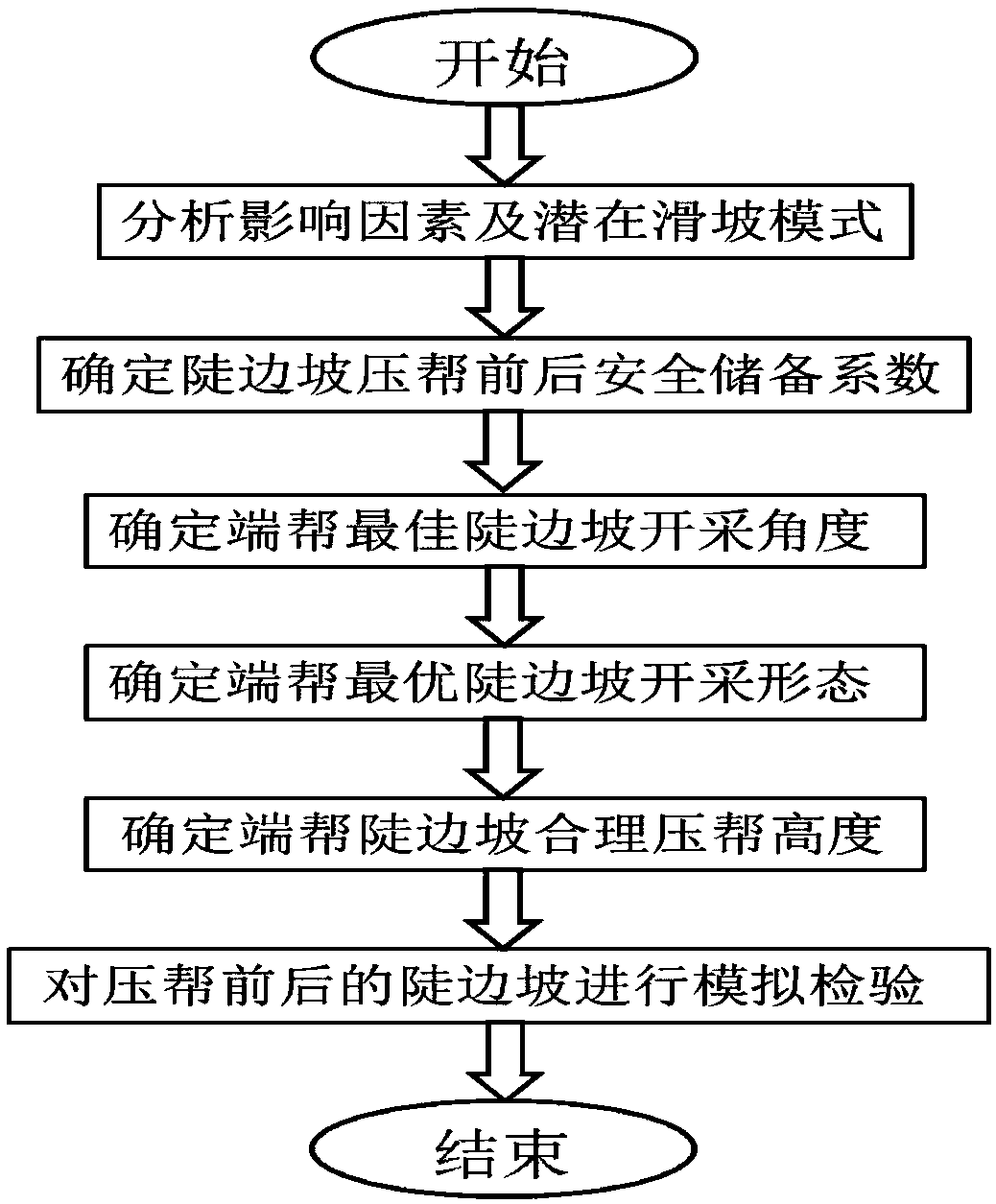

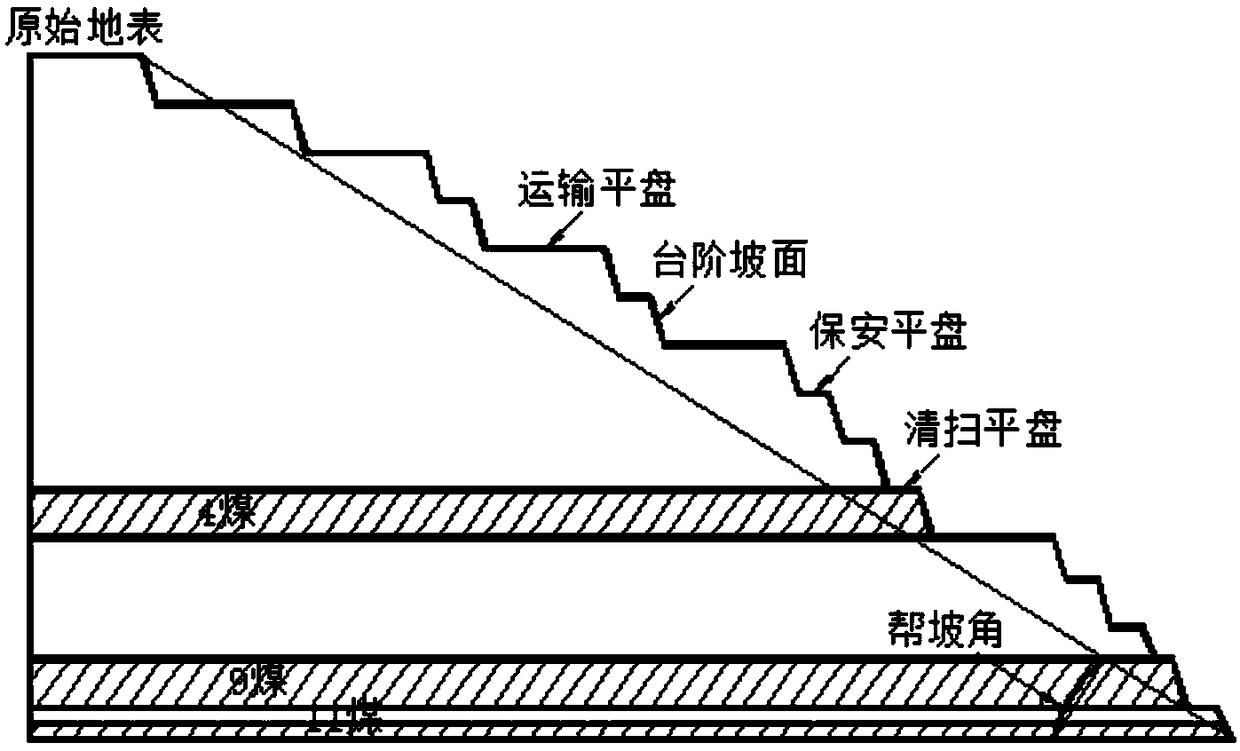

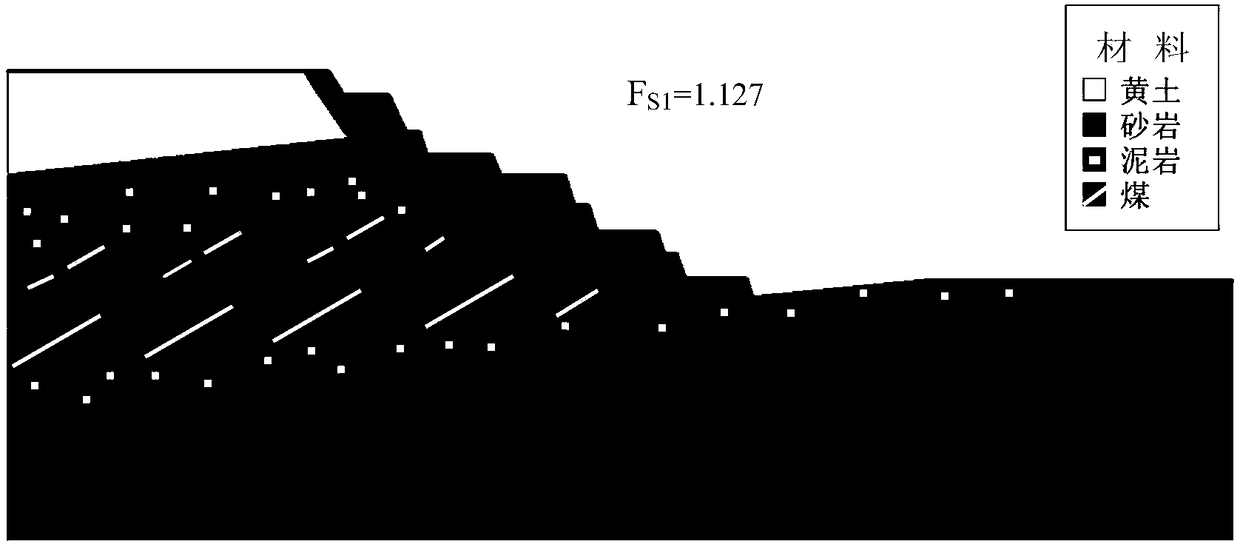

Shape optimization method for steep slope of an end wall of an open-pit coal mine

ActiveCN109376465AAccurately reflects the stability stateMaximize the benefitsClimate change adaptationDesign optimisation/simulationOpen-pit miningEconomic benefits

The utility model relates to a shape optimization method for steep slope of an end wall of an open-pit coal mine, belonging to the field of open-pit mining. This method qualitatively analyzes the influencing factors of the slope stability and the potential landslide model of the open-pit coal mine. The importance, service time and physical and mechanical indexes of slope are analyzed, and the safety reserve coefficient of steep slope before and after pressure slope is determined. Selecting typical engineering geological section, steepening is carried out on the basis of the current situation of end-slope angle, and the quantitative relationship between slope stability and slope angle is analyzed to determine the best mining angle of steep slope. According to the definite angle, the different mining patterns of steep slope are put forward by adjusting the width of the conveyance flat plate in the lower part of the slope, and the optimum mining pattern of steep slope is obtained by giving consideration to economy and safety. Calculate the stability of steep slope under different pressure height, get the quantitative relationship between slope stability and pressure height, and then determine the pressure height. By using this method, the coal resources can be fully recovered, the stripping ratio can be reduced, and the economic benefit can be improved.

Owner:LIAONING TECHNICAL UNIVERSITY

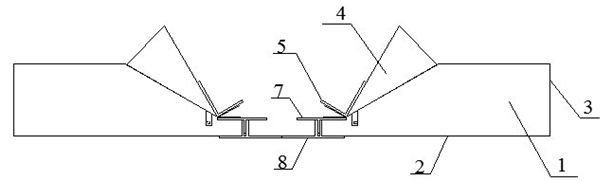

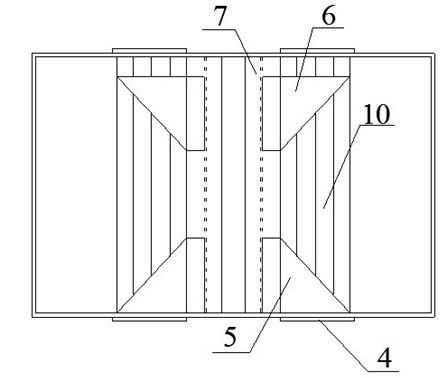

Simulation experiment table and method for open-pit mine

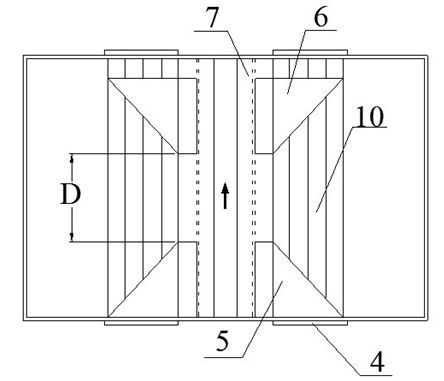

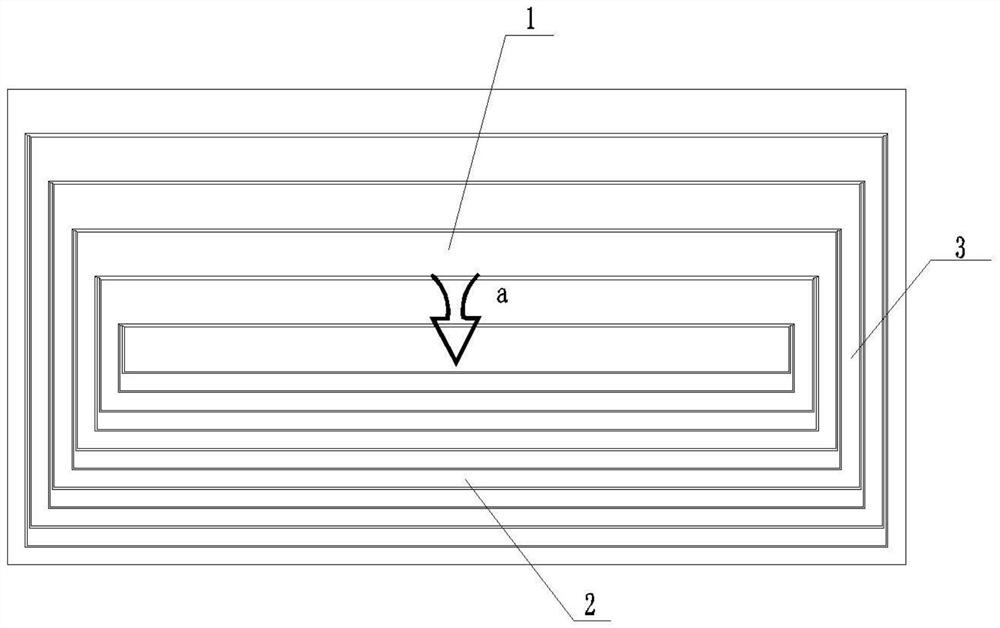

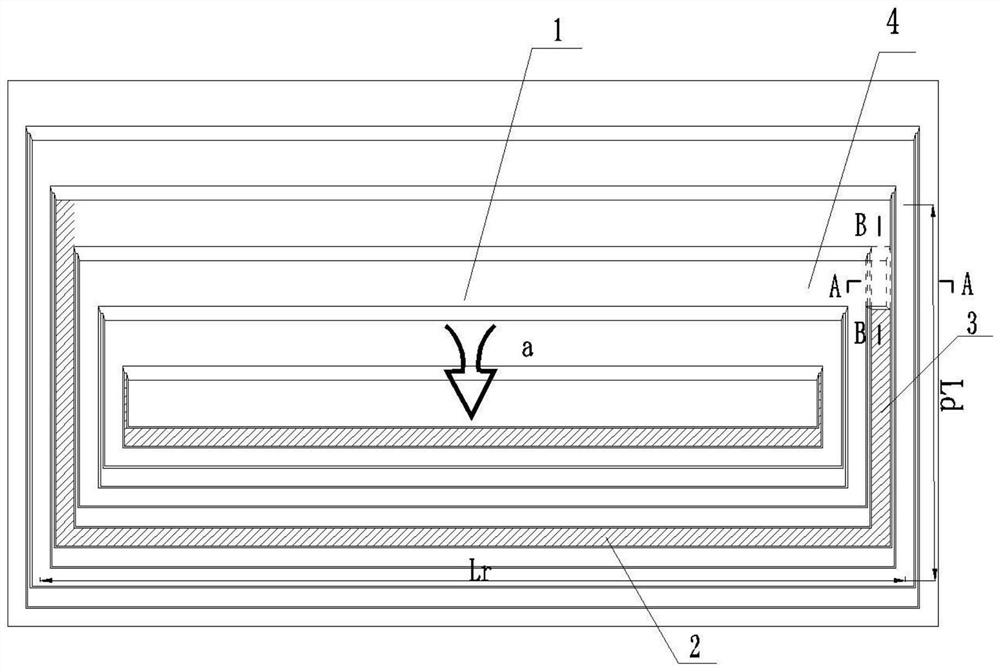

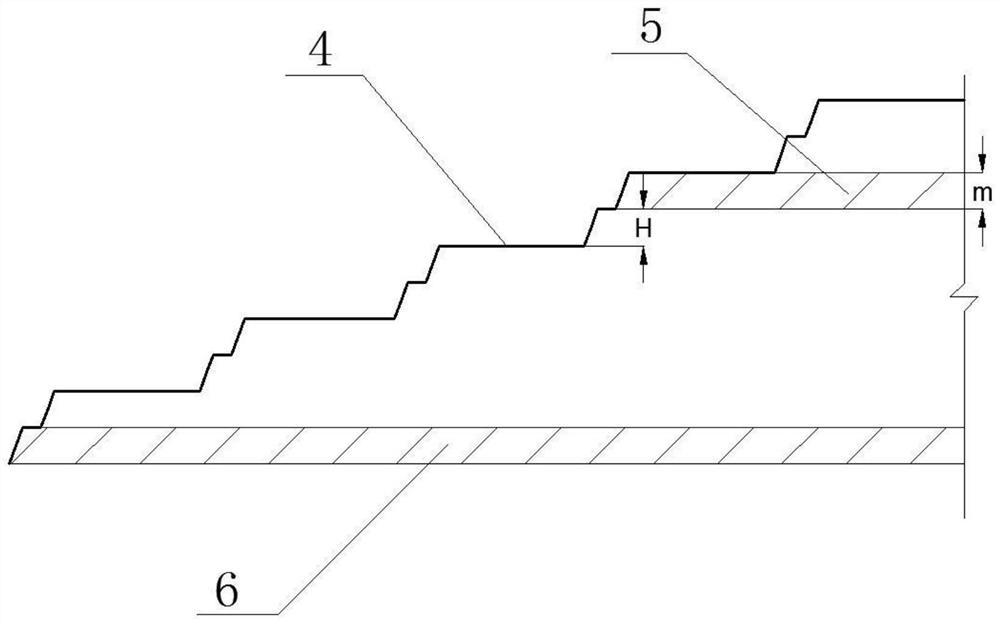

InactiveCN102663953AAvoid interferenceLow application costEducational modelsOpen-pit miningSlope angleSlide plate

The invention discloses a simulation experiment table and a method for an open-pit mine, relating to a technical scheme of exploitation technology that can visually simulate the open-pit mine. The simulation experiment table comprises side plates, a bottom plate, a rear baffle plate and rotational triangular baffle plates, wherein refuse dump simulation plates and working pit edge simulation plates are respectively arranged on the top surfaces of two sliding plates, and the sliding plates can be locked in slide ways and slide back and forth in slide ways. The rock-soil materials are filled into the space of the experiment table, for simulating a slope rock mass stratum structure of an end slope of the open-pit mine. The refuse dump simulation plates and the working pit edge simulation plates are both pushed forwards, for simulating the pushing speed and process of a stope; and the refuse dump simulation plates follow up, the pit degree distance D gradually reduces, and a simulated t internal refuse dump timely follows up. The triangular baffle plates are rotated anticlockwise for increasing the slope angle of the end slope, so that the triangular baffle plates are next to the rock and soil backfilled and separated from the slope surface of the simulated internal refuse dump, thereby covering the free surface of the end slope and simulating the steep end slope mining in the open-pit mine. The simulation experiment table and method for the open-pit mine disclosed by the invention can visually simulate the existing exploitation technologies and visually check the simulation result, with a wide practicability.

Owner:CHINA UNIV OF MINING & TECH

Mining method for upper coal seam of composite coal seam strip mine close-to-slope mining end slope

ActiveCN112855162AVerify feasibilityConfirm interruption timeUnderground miningSurface miningMining engineeringMechanical engineering

The invention belongs to the technical field of strip mine mining, provides a mining method for an upper coal seam of a composite coal seam strip mine close-to-slope mining end slope, and provides a criterion for segmented recovery of the upper coal seam of the end slope. The first condition and the second condition of the feasibility of the end slope recovery of the coal resource pressing and covering at the upper coal seam transportation road position are provided, so that the feasibility of the end slope recovery of the coal resource pressing and covering at the upper coal seam transportation road position can be verified. According to the method, an operation space is formed by utilizing inner dump step dumping, excavation equipment is arranged, segmented recovery operation of end slope upper coal seam pressing and covering resources is carried out by utilizing an inner dump step working flat plate, and the upper coal seam and dirt bands between the coal seam and the mining level are mined together.

Owner:LIAONING TECHNICAL UNIVERSITY

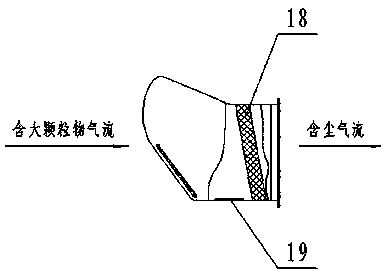

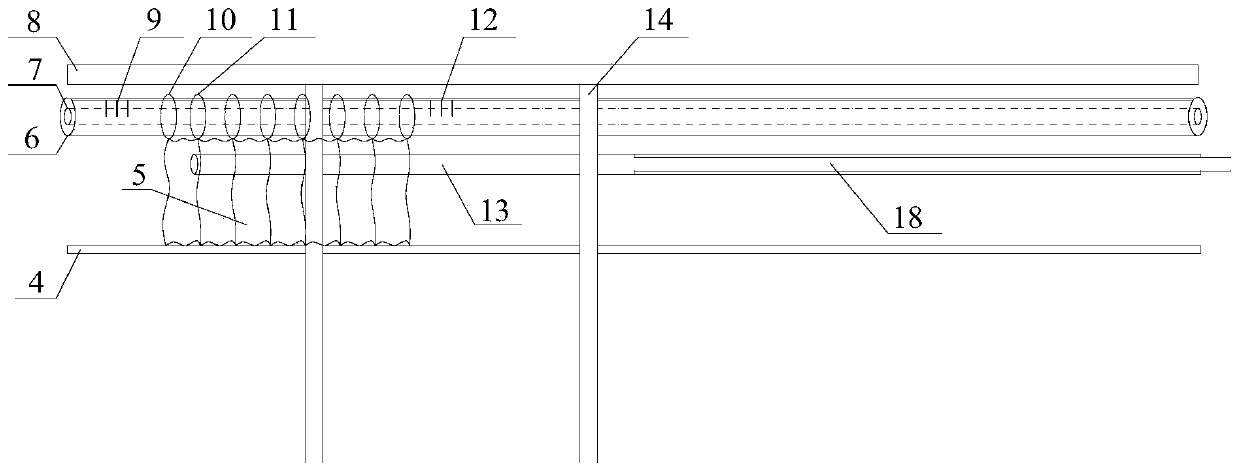

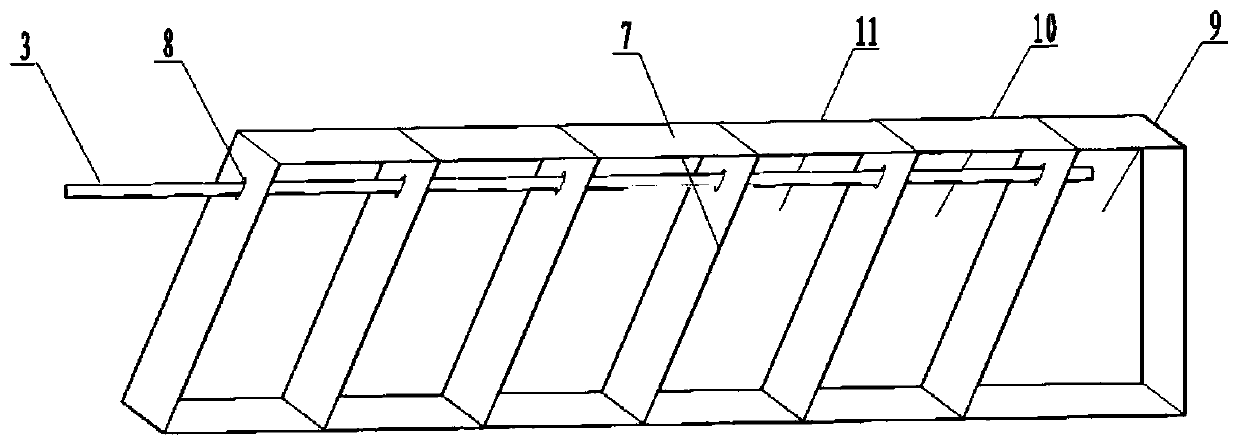

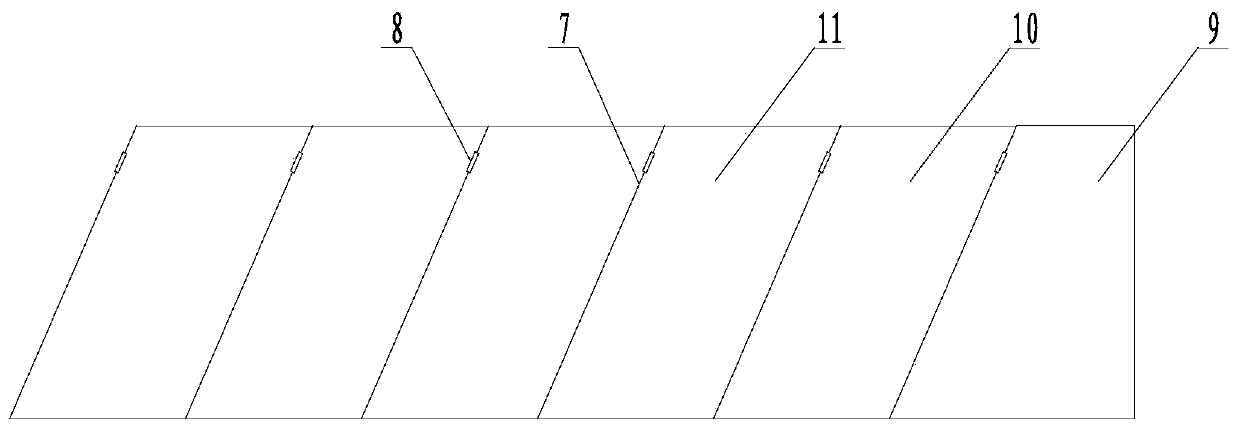

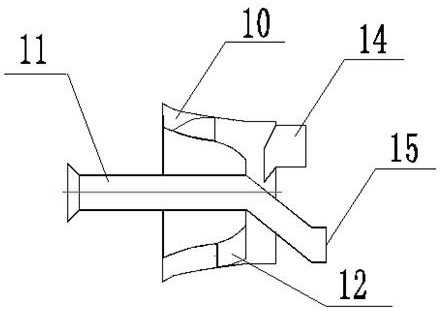

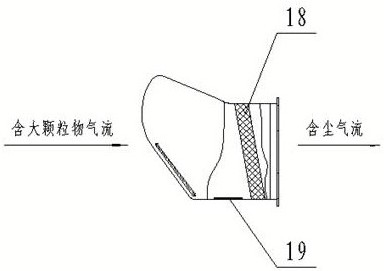

Dust removal device and dust removal method for side slope mining equipment

ActiveCN110080761AReduce concentrationAvoid pollutionMining devicesDust removalCantileverWaste management

The invention belongs to the technical field of coal mining dust removal, and particularly relates to a dust removal device and a dust removal method for side slope mining equipment. An air bellow isfixed on a cantilever of a coal mining machine, and an air outlet of the air bellow is flexibly connected with the transition section; one end of the transition section is flexibly connected with theair outlet of the air bellow, the other end is connected with the suction opening of a dust removal fan, and an air outlet of the dust removal fan is connected with one end of a head unit air duct; the head unit air duct is hung on a steel wire rope of a head transportation unit through a hanging ring, the other end of the first unit air duct is connected with one end of a standard unit air duct through an air duct connector, the standard unit air duct is hung on a steel wire rope of a standard transportation unit through a hanging ring, and the other end of the standard unit air duct is connected with the next standard unit air duct through an air duct connector, and so on; and a telescopic air duct is hung on a steel wire rope below a platform through a hanging ring, one end of the telescopic air duct is connected with the last standard unit air duct, and the other end of the telescopic air duct is connected with a dust remover air inlet pipeline.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

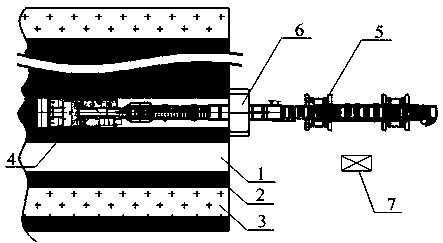

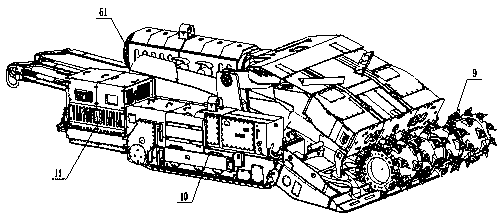

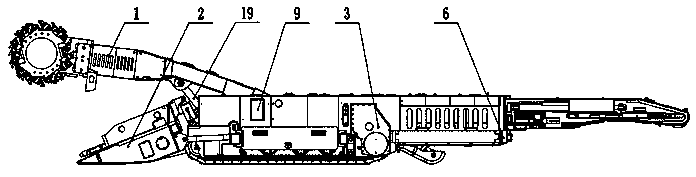

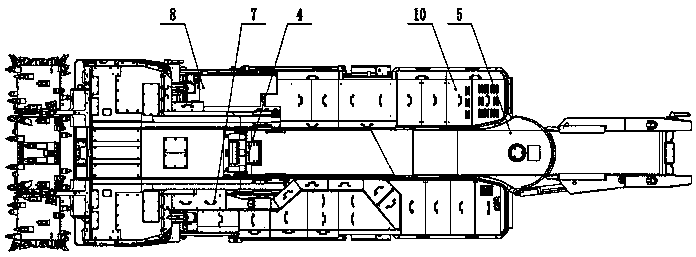

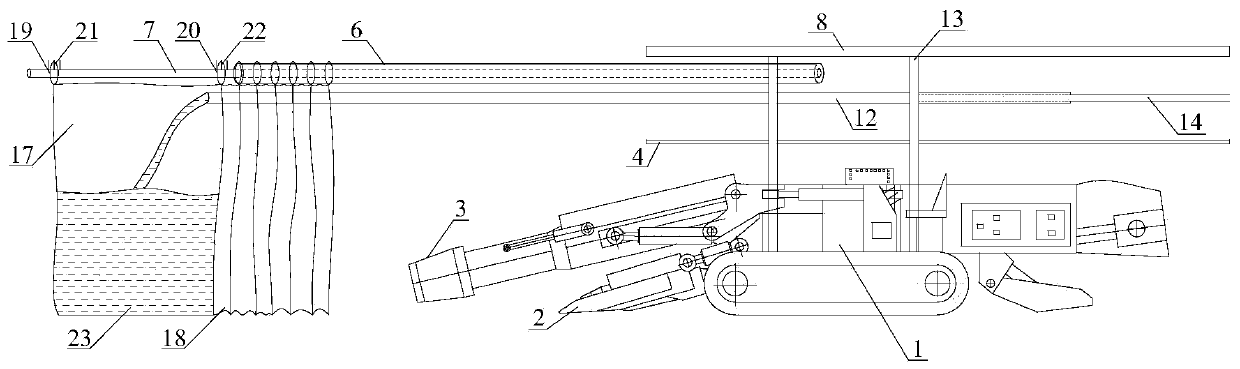

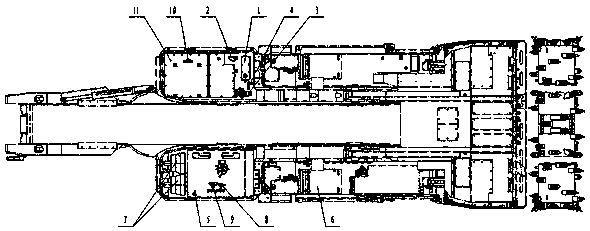

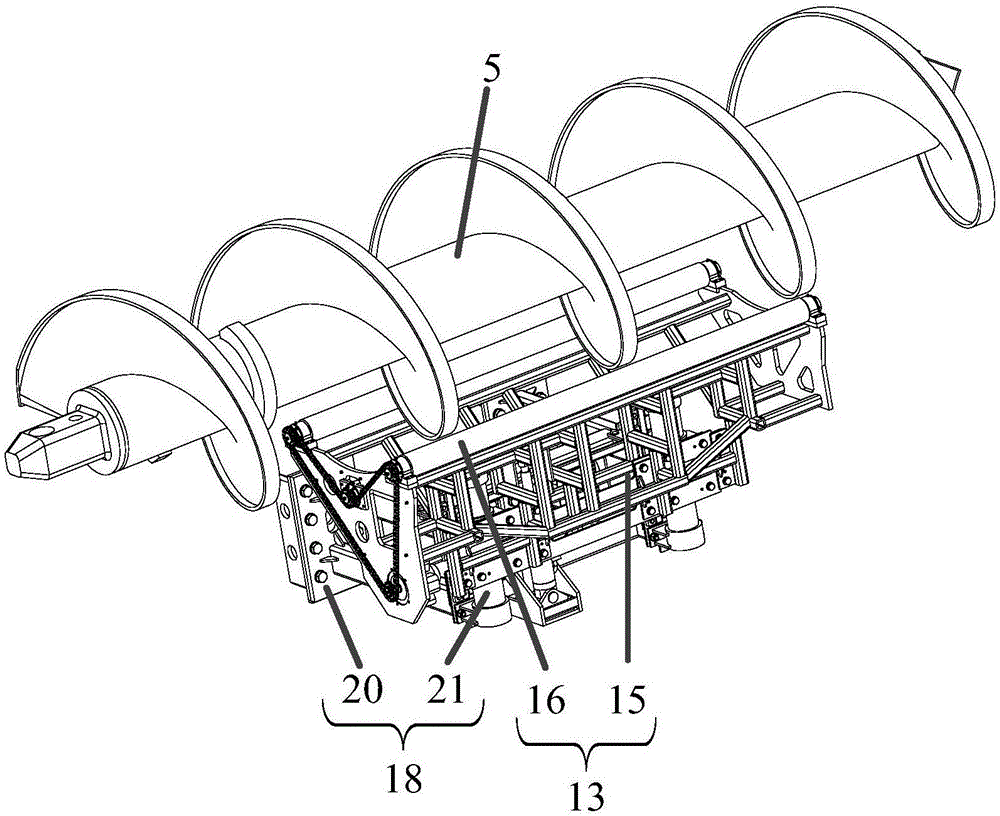

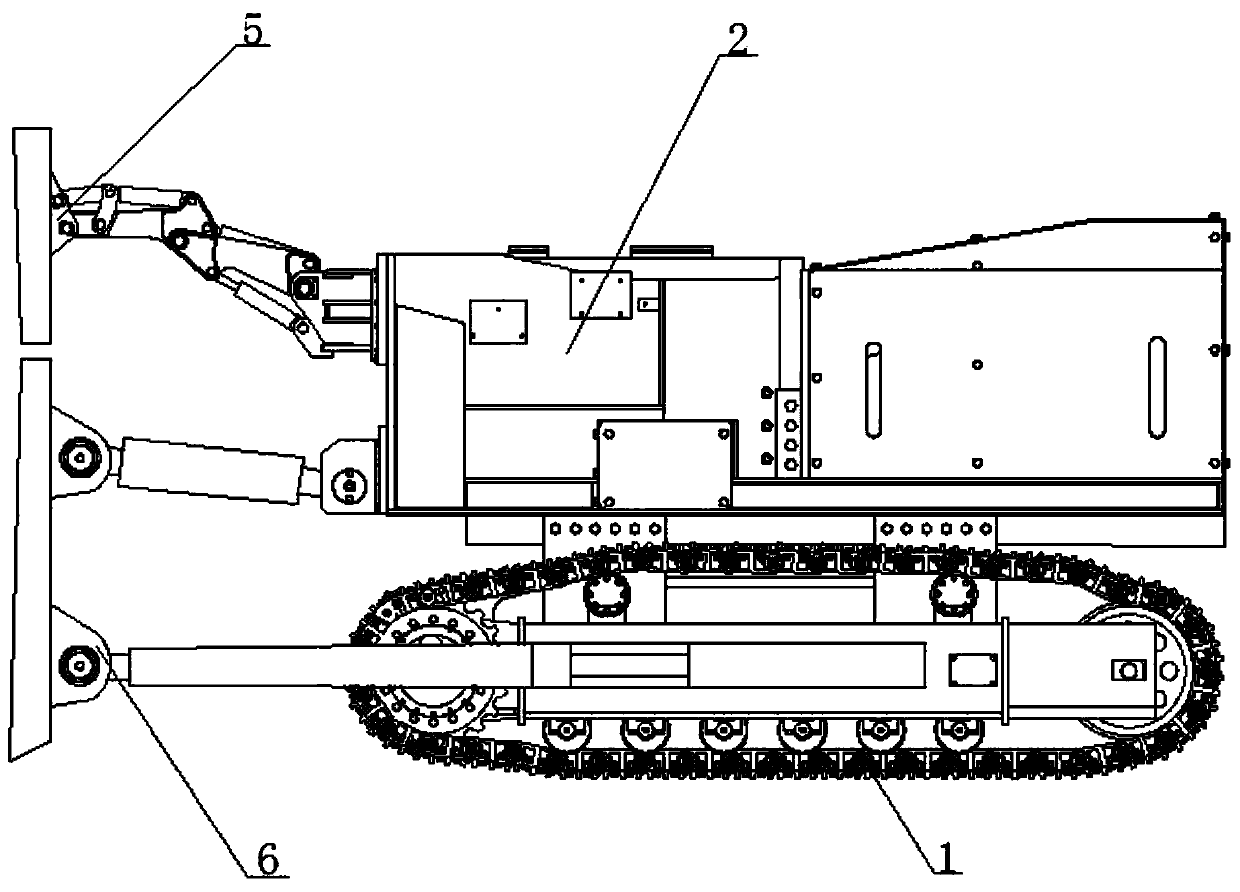

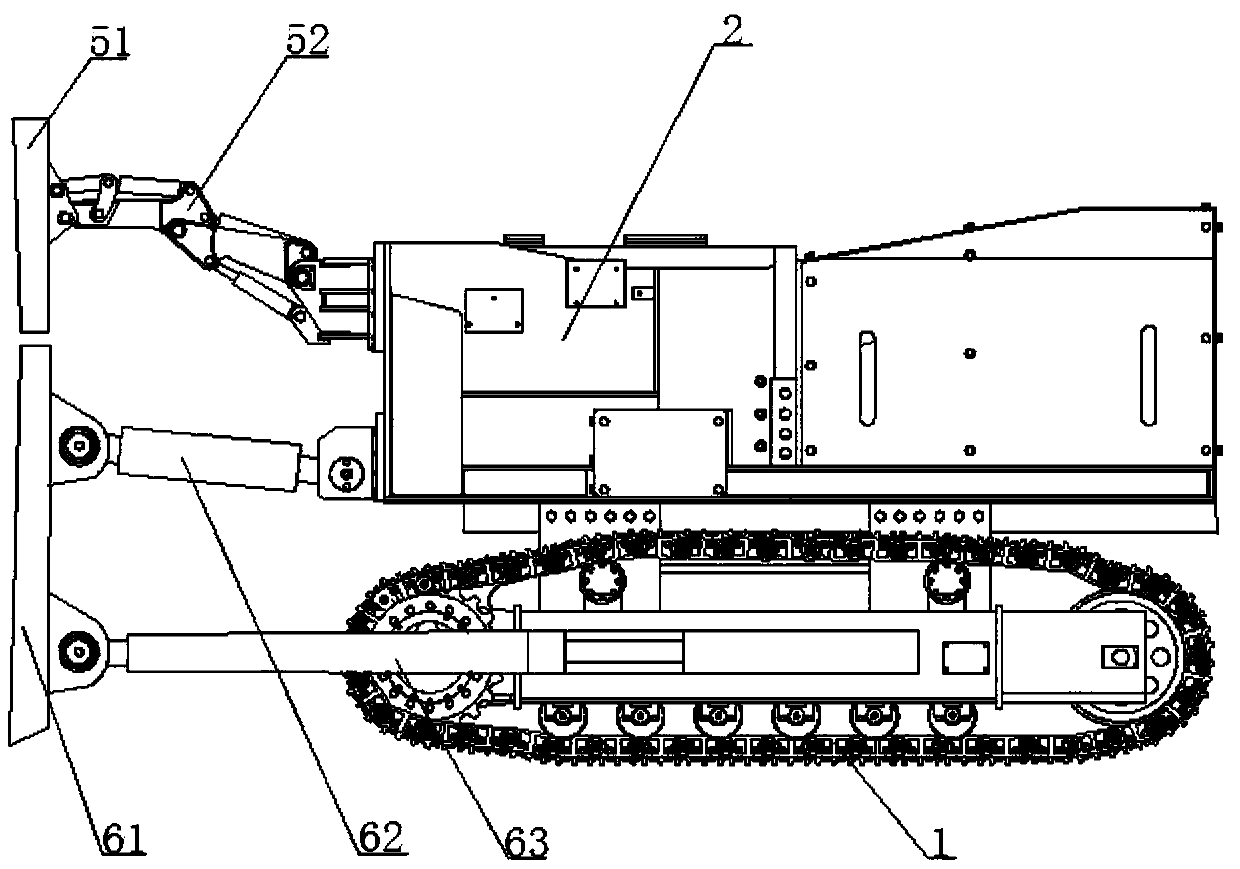

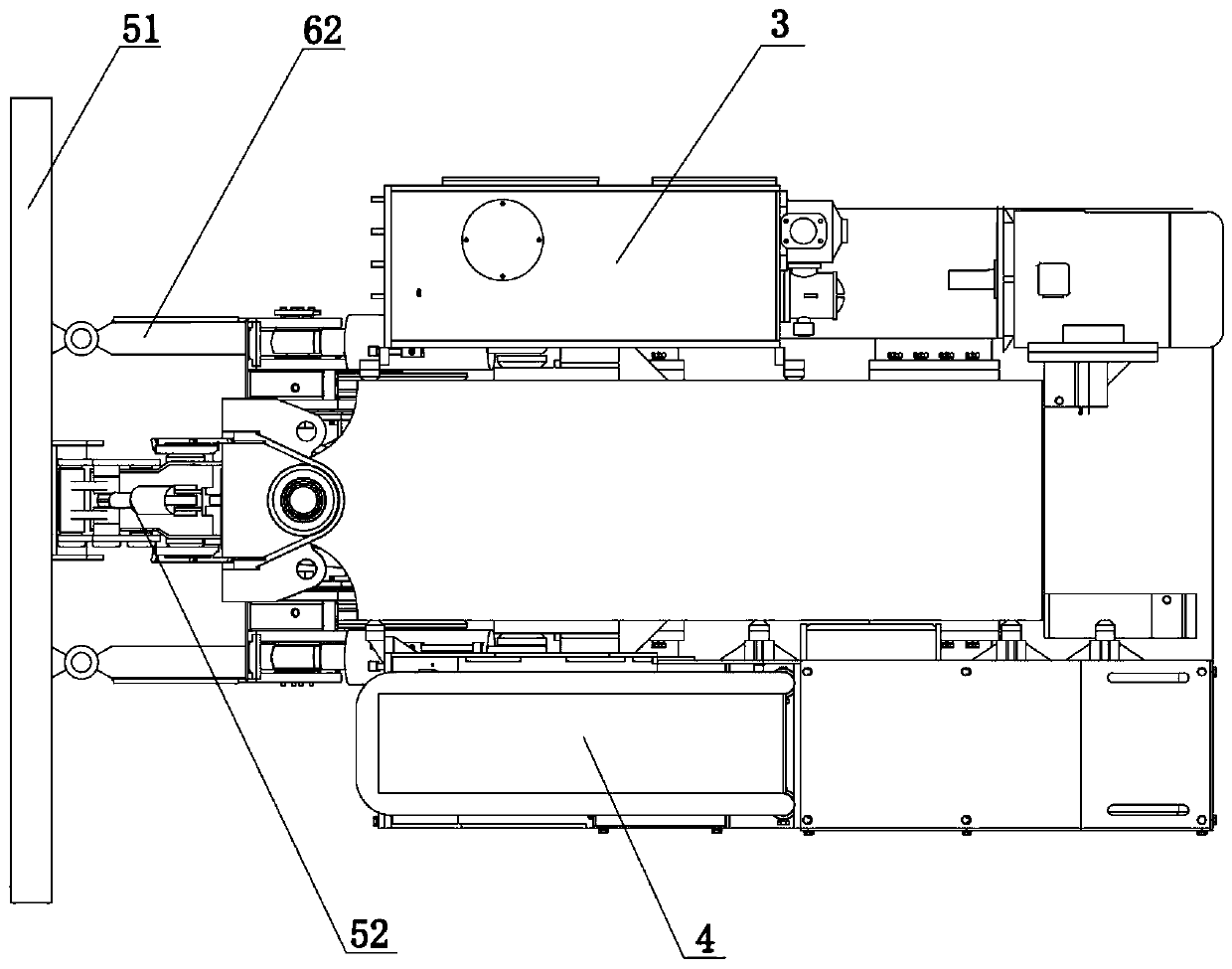

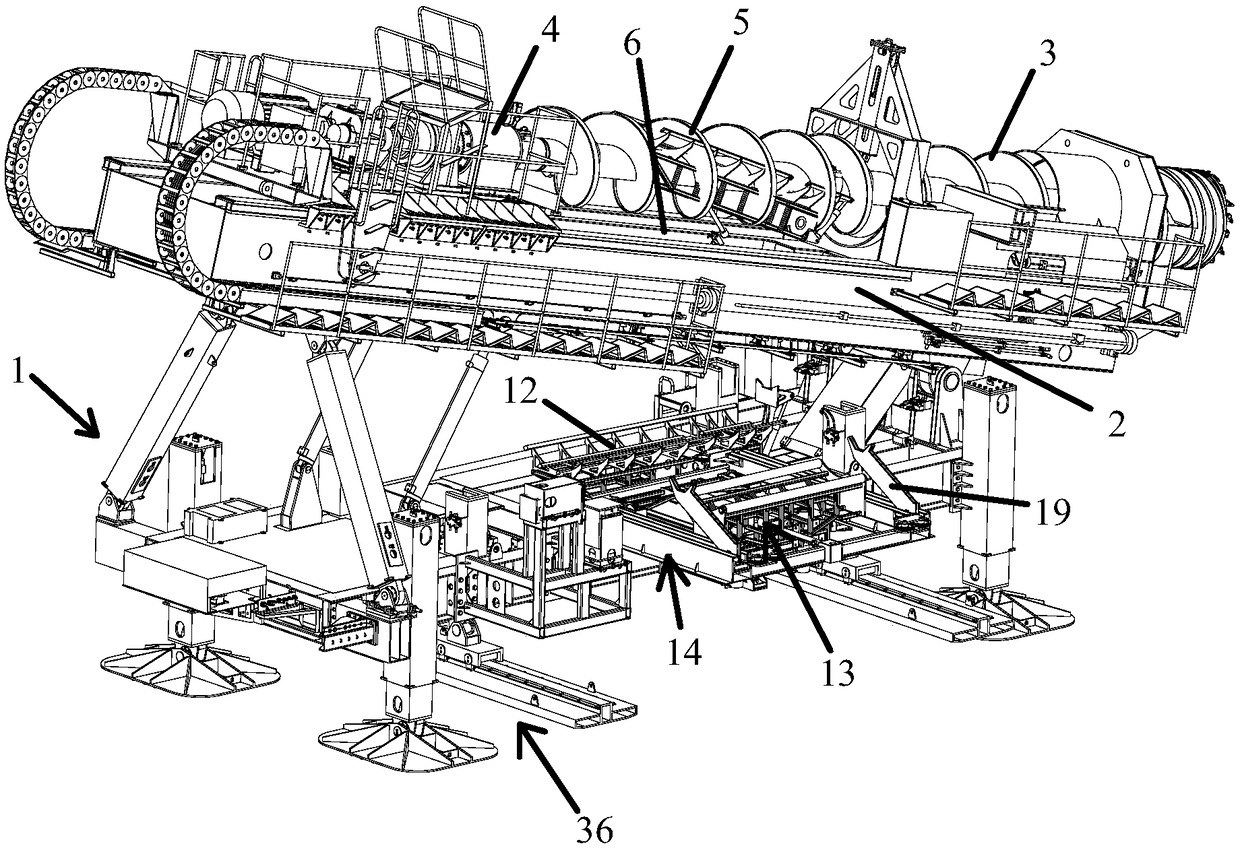

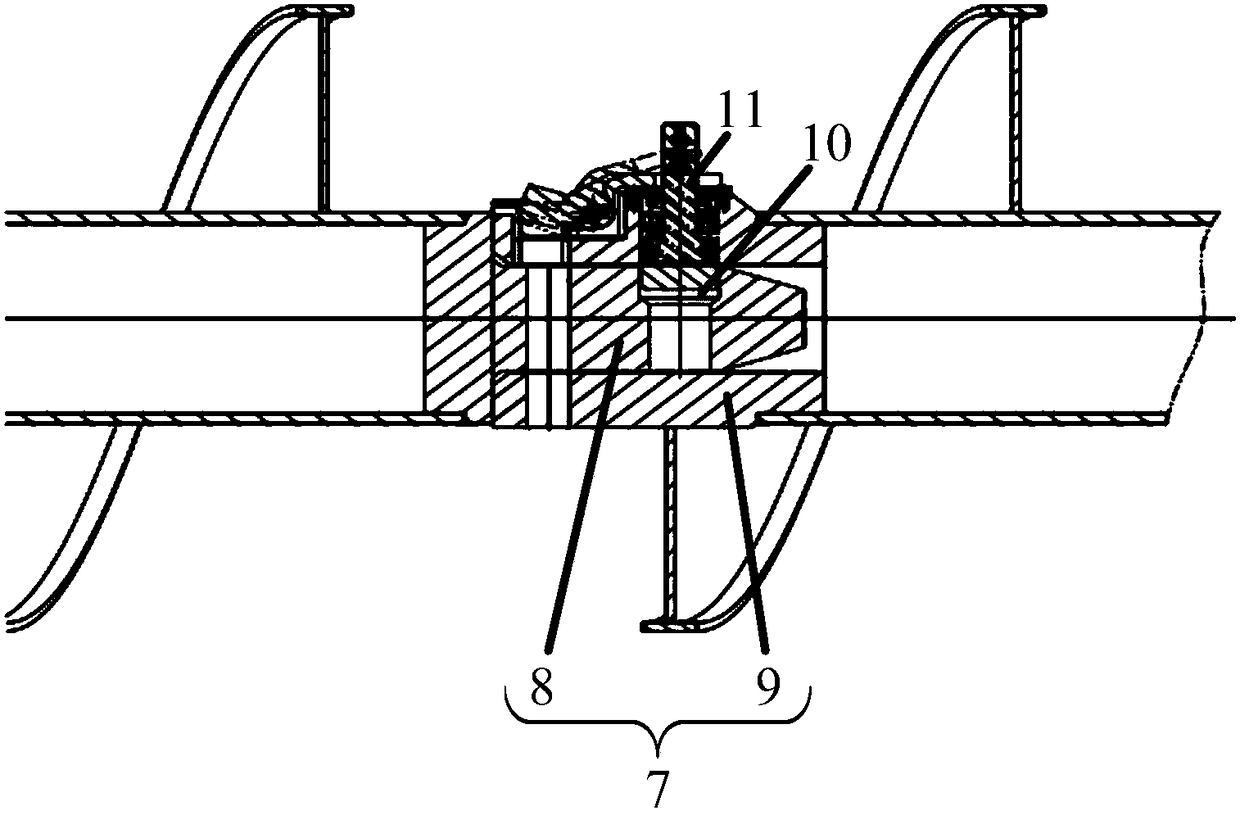

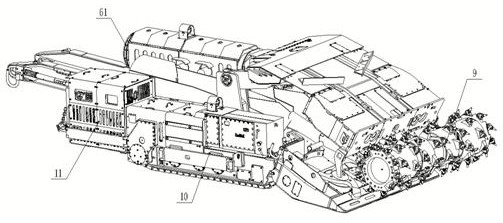

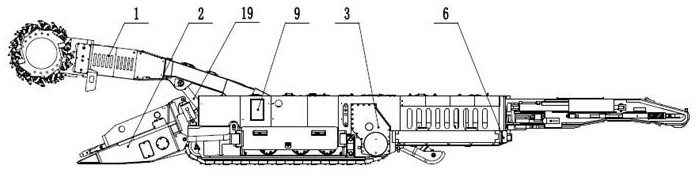

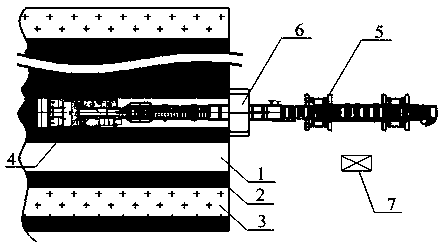

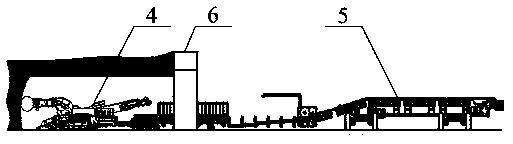

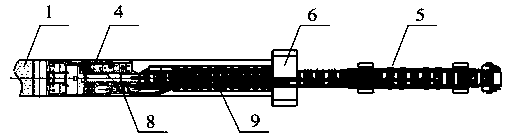

Continuous miner for open-pit mine end slope mining

ActiveCN108798664AGuaranteed accuracyAdvancedDriving meansCutting machinesRemote controlAgricultural engineering

The invention belongs to the field of open-pit mine end slope mining equipment, in particular to a continuous miner for open-pit mine end slope mining. The problems that an existing continuous miner cannot realize remote and accurate control of end slope coal pressing and unmanned mining are solved. The continuous miner for open-pit mine end slope mining comprises a cutting part, a loading part, left and right travel parts, a main machine frame, a conveying part, a rear machine frame, a dust removal system, an electrical system, a hydraulic system and a cooling system. The cooling system adopts a self-circulation cooling system, the cooling system is arranged on the right rear part of a machine body, the dust removal system comprises a dust removal fan and an air duct, and the dust removalair duct is integrated into the cutting part and the machine body. The continuous miner for open-pit mine end slope mining further comprises an external control center and an interactive remote control platform. The external control center comprises an inertial navigation system, a remote operating system and a fault diagnosis system. All monitoring data and control operating mechanisms are integrated on an interactive remote control platform. The continuous miner for open-pit mine end slope mining can obviously improve the efficiency and safety of end slope coal pressing.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

Forward-movement coal cutting and retracting filling mining method for open-air end slope

ActiveCN111236943AHigh recovery rateImprove mining efficiencyUnderground miningSurface miningCoal briquetteMining engineering

The invention discloses a forward-movement coal cutting and retracting filling mining method for an open-air end slope. On a strip mine end slope pit bottom, a tunnelling machine inwards automaticallycarries out forward-movement type mining and roadway coal cutting, then, a loading mechanism is used for conveying falling coal to a coal conveying belt through a scraper chain in the tunnelling machine, and finally, the coal is conveyed out of the roadway through a coal conveying belt machine. When the tunnelling machine carries out tunnelling to a mining stop line, the tunnelling machine automatically lowers a cutting head, a filling device on the tunnelling machine is controlled to lower a filling bag, and then, slurry is injected into the filling bag through a slurry injection pipeline through a retracting way. According to the forward-movement coal cutting and retracting filling mining method, the problems that an open-air end slope coal briquettes are difficult to recover and an endslope structure is poor in stability by traditional mining are solved, a coal resource recovery rate is improved, earth surface subsidence brought by end slope mining is reduced, and environmentally-friendly mining is realized. In addition, according to the method disclosed by the invention, quick pipe arrangement and mining and filling automation can be realized, the mining efficiency and the production safety of coal resources can be obviously improved, and coal production cost and the labor intensity of workers can be greatly lowered.

Owner:中煤能源研究院有限责任公司

Bag type filling machine for open-air end slope coal-pressing filling mining

PendingCN110847956ADesign scienceEasy to operateUnderground miningSurface miningThermodynamicsCoal pillar

The invention discloses a bag type filling machine for open-air end slope coal-pressing filling mining. The bag type filling machine comprises a machine body, a walking device, a filling pipeline, a suspension device and a filling bag, wherein the bag type filling machine is operated to the end of a filling roadway, then filling materials are injected into the filling bag through the filling pipeline, and in the process that the bag type filling machine retreats outwards from the end of the filling roadway, and the whole filling roadway is filled with the filling materials in the mode of injecting the filling materials into the filling bag, so that the stability of an open-air end slope is guaranteed. According to the bag type filling machine, the filling rate of the open-air end slope mining roadway can be effectively increased, the filling mining efficiency is greatly improved, the strength of a filling body can be improved, and the stability of the open-air end slope is guaranteed;meanwhile, coal pillars between the open-air end slope filling mining roadways can be greatly reduced or omitted, the recovery rate of open-air end slope covering resources is greatly increased, and the economical efficiency and applicability of the open-air end slope coal-pressing filling mining technology are improved.

Owner:中煤能源研究院有限责任公司

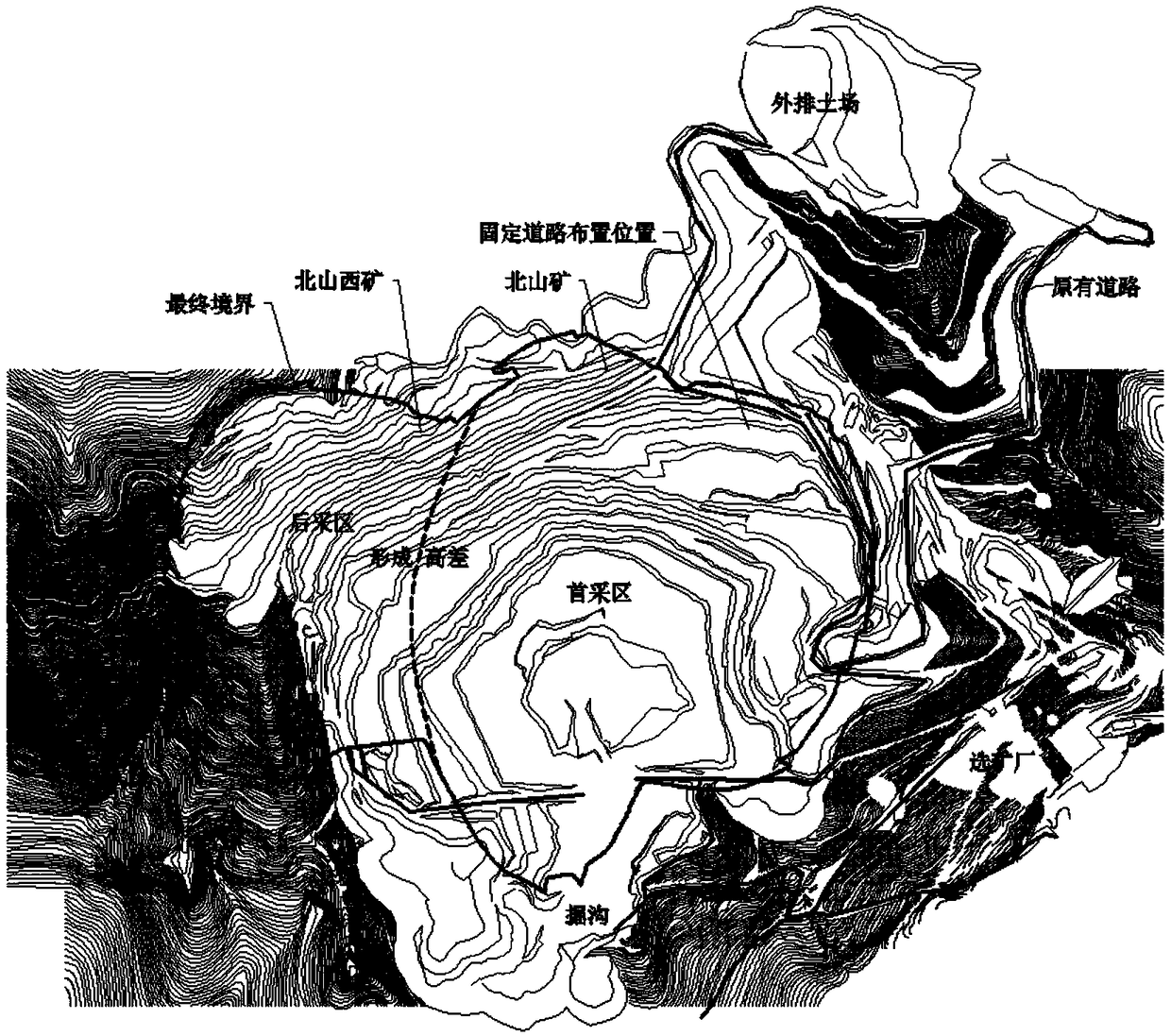

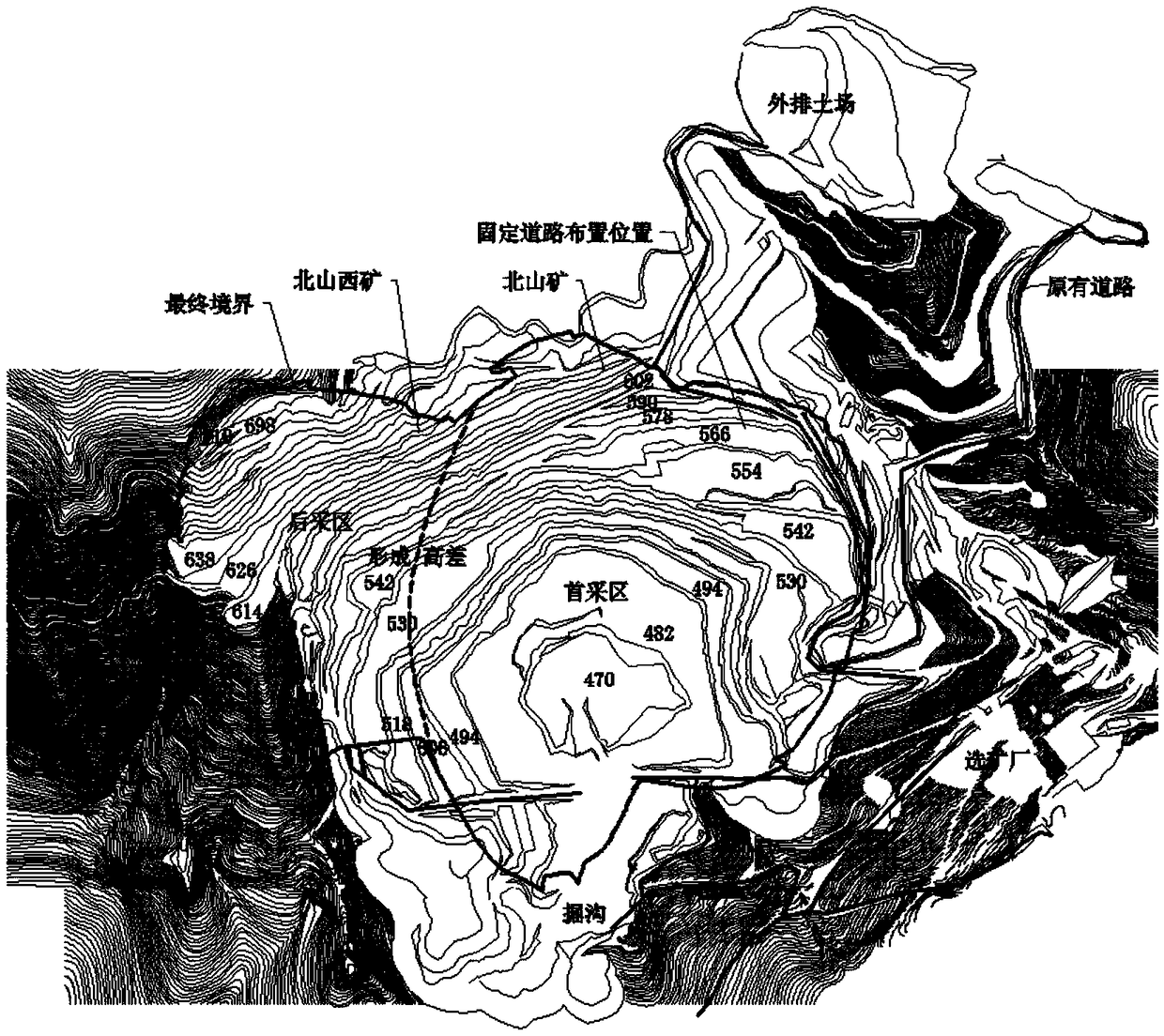

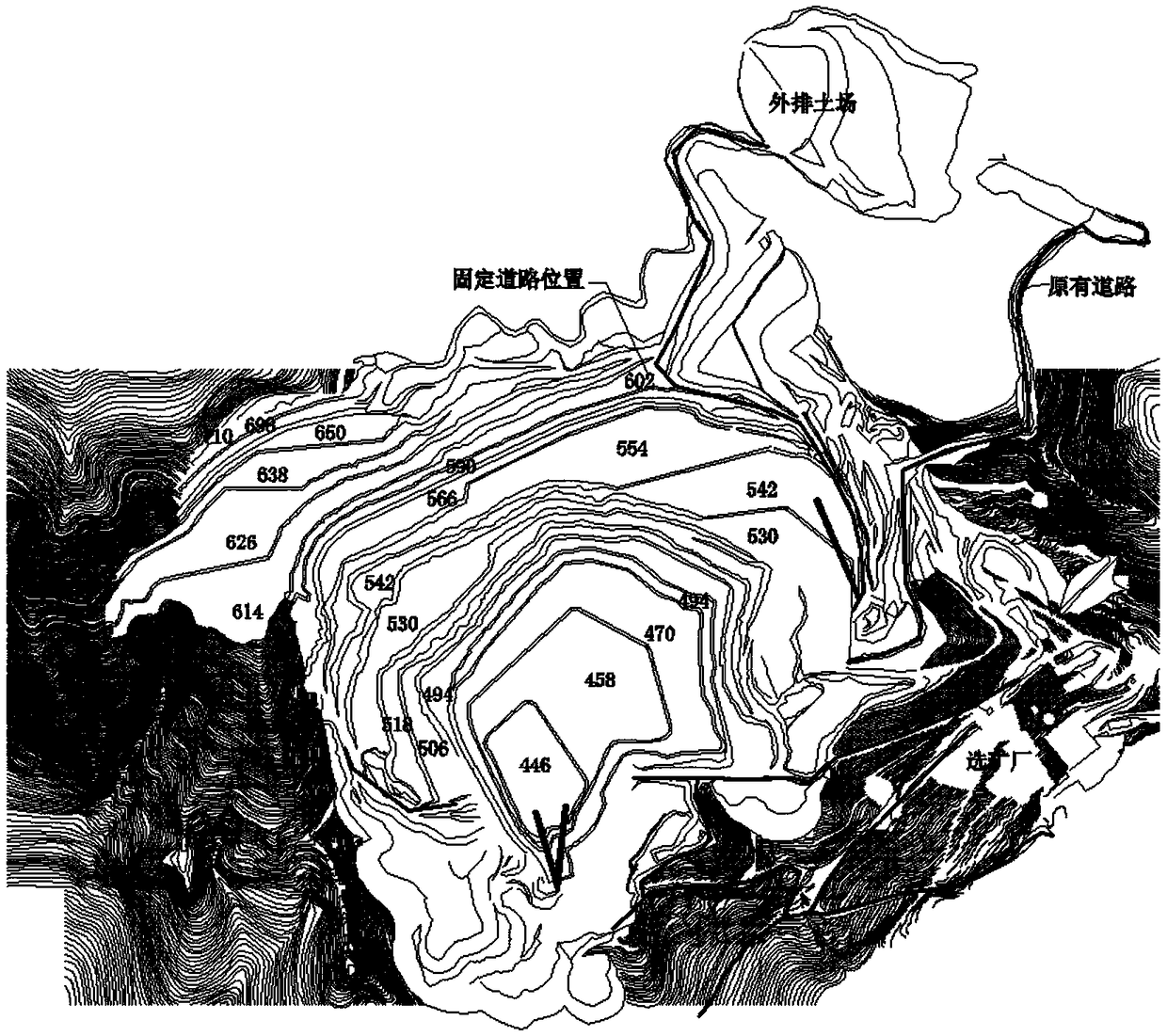

Internal discharge process design method for period transition from metal strip mine mountain slope mining to deep concave mining

ActiveCN108756886ADouble optimized production efficiencyDouble optimized environmental benefitsUnderground miningSurface miningMetal stripsEngineering

The invention provides an internal discharge process design method for period transition from metal strip mine mountain slope mining to deep concave mining, and relates to the technical field of stripmine mining. The internal discharge process design method includes the steps that step 1, during a transition period from metal mountain slope strip mine mining to deep concave mining, sectional mining advancement is adopted, and a stope forms different areas, namely, a first mining area and a post mining area; step 2, a development system is arranged on the final boundary of one side of the first mining area, after the first mining area leans on a wall, a fixed route is built, less temporary roads are built, and a fixed road which leans on the wall is adopted for transportation and dischargeof ore rock; step 3, trenching and excavating are carried out on the other side of the first mining area to build a temporary road, as the first mining area gradually leans on the wall and the bottomis exposed, an internal discharge route from the post mining area to the first mining area is planned one to two years in advance, and proper mining of the post mining area is carried out; and step 4, if a bottom pit of the first mining area is sufficient in space, an inner discharge area can be arranged in the first mining area, and enough safety distance is reserved in space between a mining area of the first mining area and the inner discharge area of the first mining area, the internal discharge can be started.

Owner:NORTHEASTERN UNIV

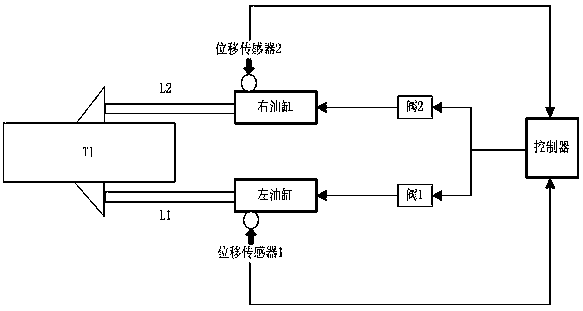

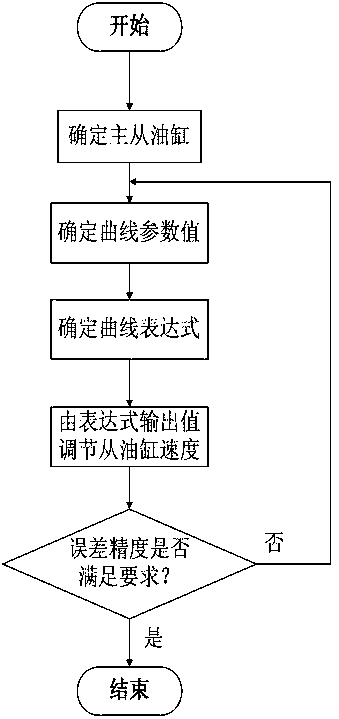

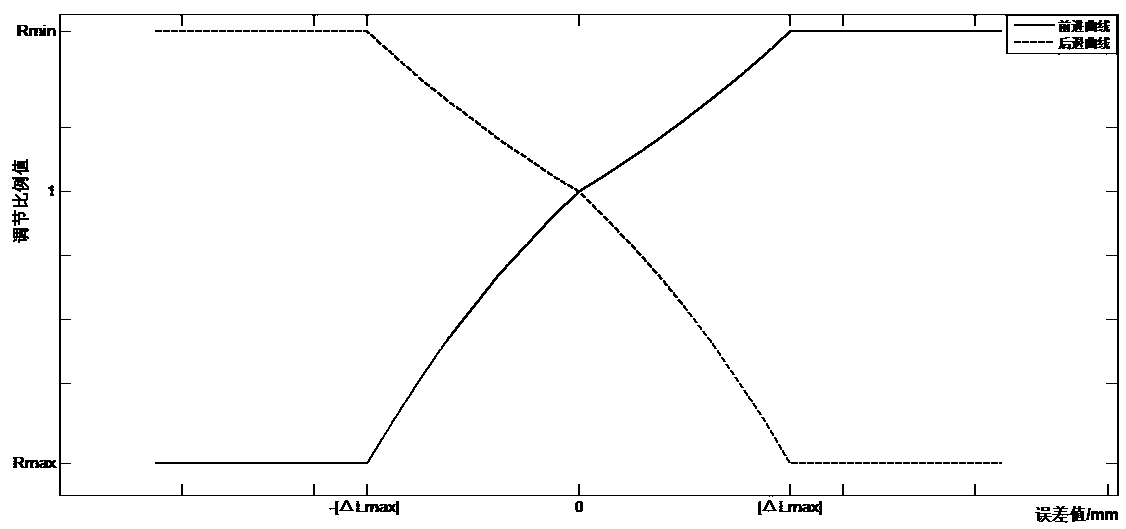

Synchronous control method for pushing oil cylinders of slope mining transporting unit

ActiveCN111207123AMake up for the errorReduce complexityFluid-pressure actuator testingServomotor componentsThermodynamicsSynchronous control

The invention belongs to the technical field of open pit coal mine equipment control, and particularly relates to a synchronous control method for pushing oil cylinders of a slope mining transportingunit. The synchronous control method comprises the following steps that S100, a main oil cylinder and a slave oil cylinder are determined; S200, a parameter value of a control curve is determined; S300, a curve is fitted to obtain a curve expression; and S400, the current speed Vs of the slave oil cylinder is obtained according to the obtained output variable y. The synchronous control method forthe pushing oil cylinders of the slope mining transporting unit acts on a specific transporting unit driving device of slope equipment, synchronous control over the oil cylinders on the two sides is achieved by obtaining the specific curve through multiple times of demonstration in combination with slope mining working condition requirements and existing conditions, the error of mechanical designis made up, the complexity of hydraulic control is reduced, the slope mining cost is saved, and the curve parameters are adjustable; and further adjustment can be conducted according to the working conditions and the like to achieve the expected effect, and flexibility and operability are achieved.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

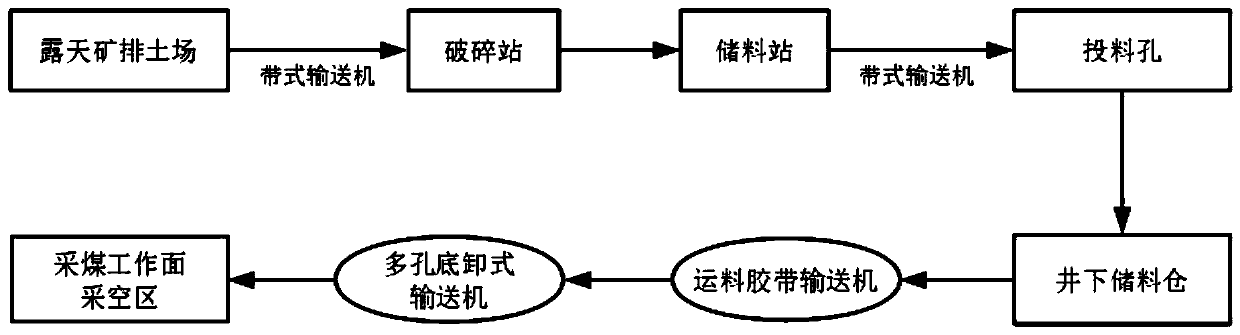

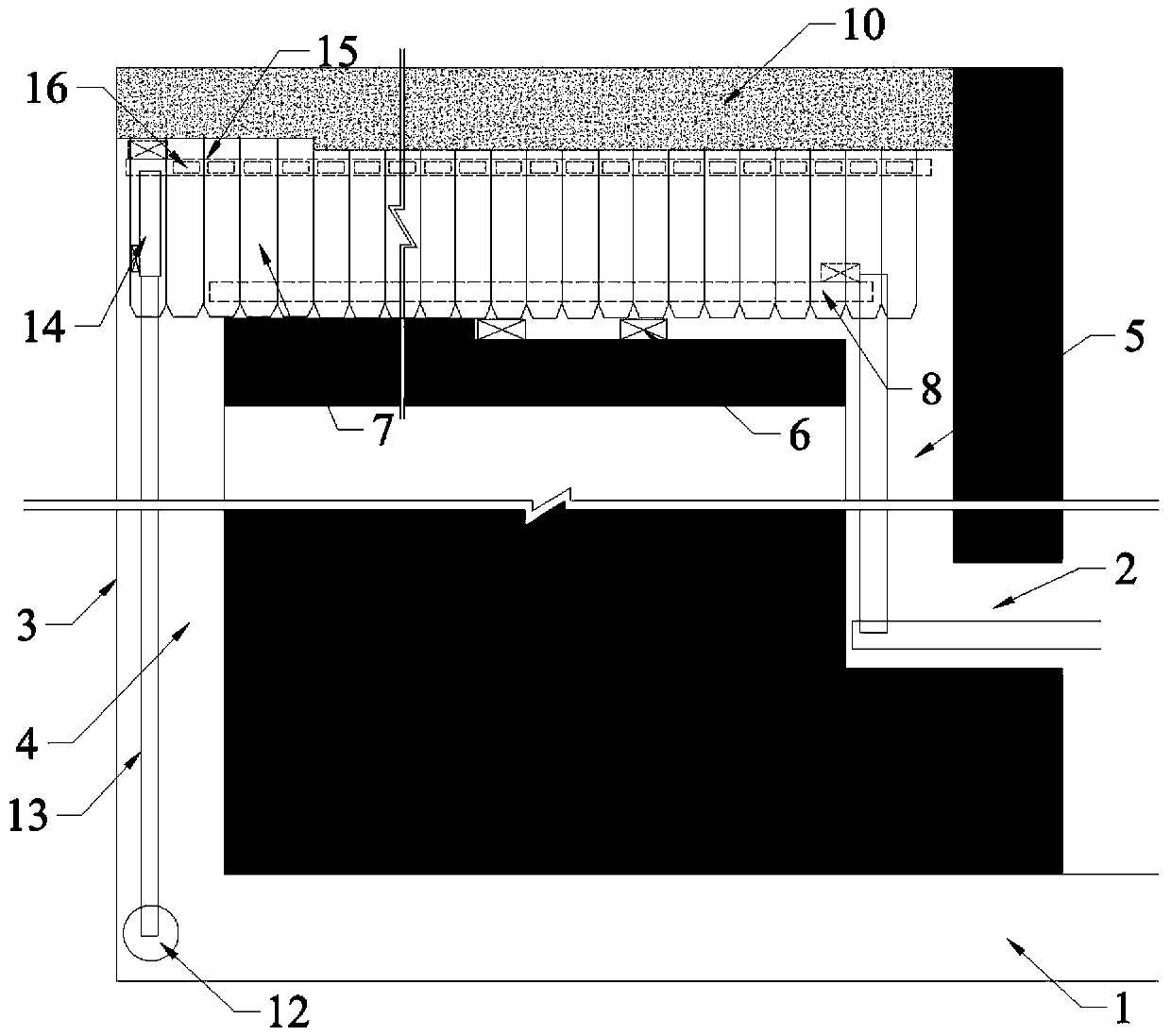

Open coal mine end slope mining, discharging and filling mining method

InactiveCN110284883AIncrease recoverable reservesReduce pollutionUnderground miningSurface miningMining engineeringSlag

The invention discloses an open coal mine end slope mining, discharging and filling mining method. Firstly, a main gateway and an auxiliary gateway are tunneled at the position of a pit bottom of an open coal mine end slope in parallel in the inclination direction of a coal seam, a transportation roadway and a rail roadway are tunneled in the trend direction of the coal seam in parallel, and an open-off cut and an integrated ventilating system are formed in the manner of penetrating through the transportation roadway and the rail roadway; a stoping and filling working face is arranged on the open-off cut, a crushing station is arranged near a mining right boundary, and meanwhile a vertical transportation system is arranged near the crushing station; and open slag is transported to a goaf while coal cutting of a coal cutter is carried out, filling work is carried out, and a repetitive cycle is carried out until stoping and filling of the stoping and filling working face of the whole end slope are completed. According to the method, the problem of coal accumulation of the end slope can be solved, the recoverable reserve of an open coal mine is increased, meanwhile, environmental pollution caused by open refuse dump slag can be reduced, and the mining method is a green mining technology which is safe, efficient and high in adaptability, and has broad application prospects.

Owner:CHINA UNIV OF MINING & TECH

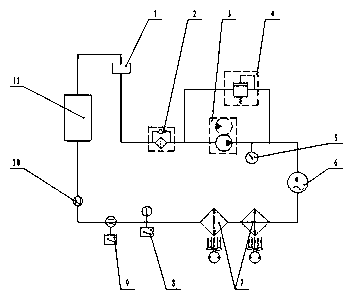

Closed-cycle cooling system of continuous coal mining machine

InactiveCN108811435AEasy maintenanceSuitable for underground workCooling/ventillation arrangementCooling/ventilation/heating modificationsWater sourceWastewater

The invention relates to a closed-cycle cooling system of a continuous coal mining machine, which solves a problem that the component cooling of the existing continuous coal mining machine depends onan external water source. According to the invention, a water inlet of a water pump is connected with a water outlet of a water supplementing tank, a water outlet of the water pump is connected with awater inlet of a water-cooled motor, a water inlet of a safety valve is connected with the water outlet of the water pump and the water inlet of the water-cooled motor, and a water outlet of the safety valve is connected with the water inlet of the water pump and a water outlet of a filter; a liquid control opening of each radiator is connected with the complete machine hydraulic system, a waterinlet of each radiator is connected with the water outlet of the water-cooled motor, the water outlet of the water-cooled motor is connected with a water inlet of a water tank, a water inlet of the water tank is connected with a water outlet of each radiator, and the water outlet of the water tank is connected with a water inlet of the water supplementing tank; and the water inlet of the water supplementing tan is connected with the water outlet of the water tank, and the water outlet of the water supplementing tank is connected with the water inlet of the water pump. The closed-cycle coolingsystem solves the problems that the continuous coal mining machine depends on external cooling water when being applied to open pit slope mining and that a large amount of cooling wastewater results in damages of the roadway floor.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

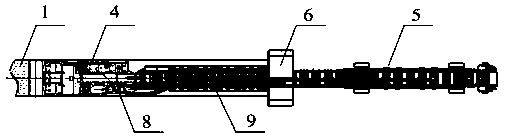

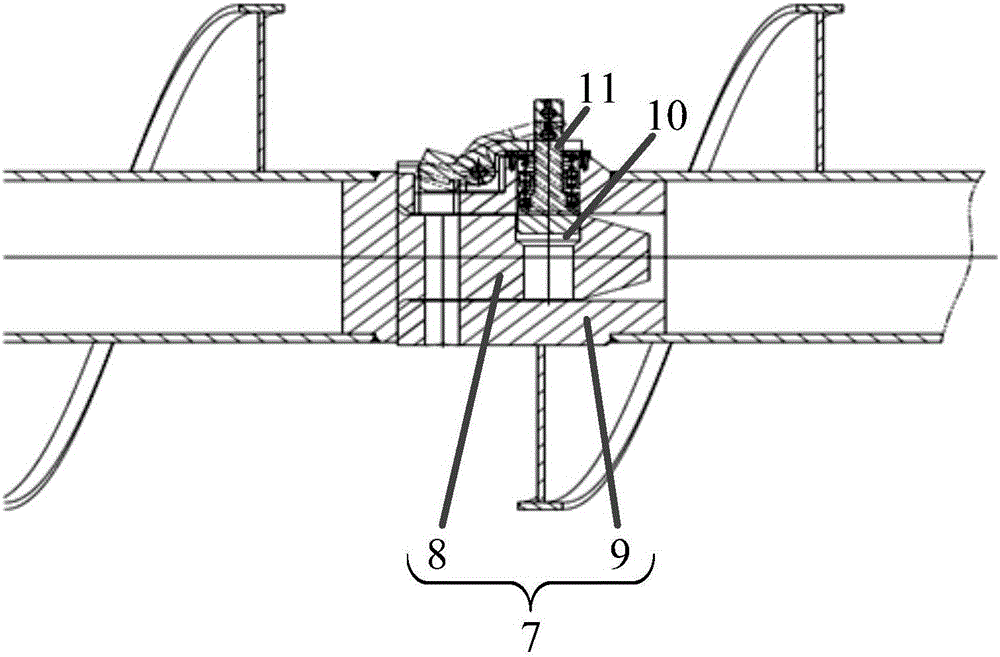

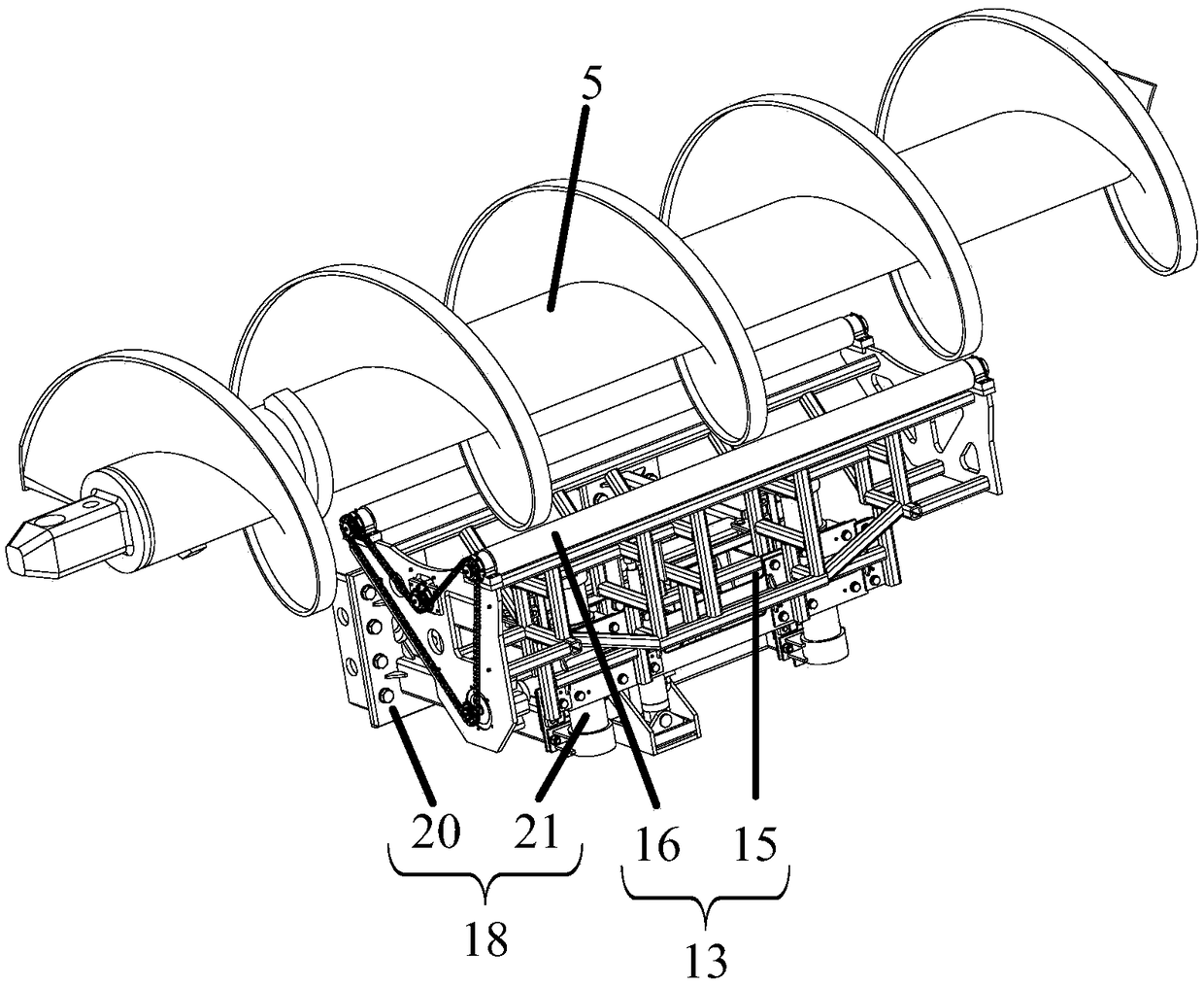

Engineering driller for automatically loading and unloading drill stem

ActiveCN106703691ASolve the problem of the need to separately occupy the construction channel space other than the drilling rig to transport the drill pipeSmall footprintDrilling rodsDrilling casingsPropellerEngineering

The invention discloses an engineering driller for automatically loading and unloading a drill stem, and particularly to a coal mining driller specific to end slope mining of an open mine. The engineering driller comprises a driller frame body; a driller platform which is arranged on the driller frame body and used for placing the drill stem and a propeller to be loaded and unloaded, wherein a loading-unloading drill stem transfer channel is arranged on the driller platform corresponding to the position between the drill stem to be loaded and unloaded and the propeller for placing the loaded and unloaded drill stem; a drill stem angle phase position adjusting mechanism, which is arranged at the bottom part of the driller platform and used for adjusting the circumference angle of the loading and unloading drill stems thereon, so that the drill stem is normally abutted; a drill stem horizontal transfer mechanism; a drill stem vertical transfer mechanism. The angle phase positions of the loading and unloading drill stems are adjusted from the bottom part of the driller platform, and the drill stem to be loaded and unloaded is transported; the engineering driller solves the problem that the drill stem angle phase position adjusting mechanism and the drill stem conveying device of the existed engineering driller need to be arranged at the side face of the driller, and construction channel space out of the driller shall be occupied independently, and auxiliary hoisting device needs to configure.

Owner:LIAONING HANSHI MACHINERY MFG CO LTD

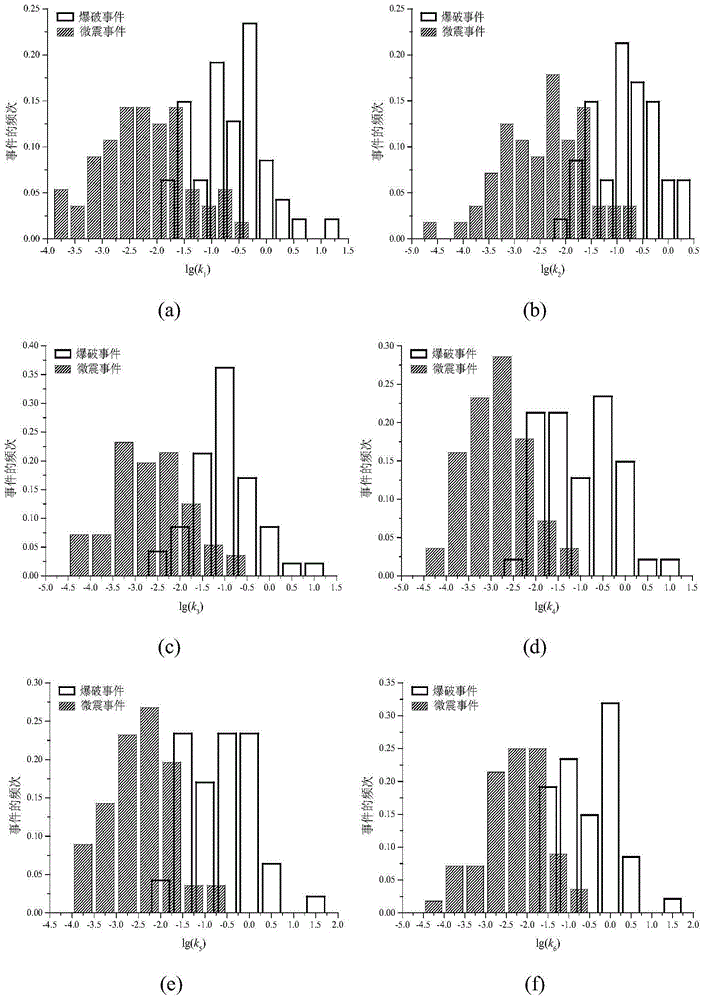

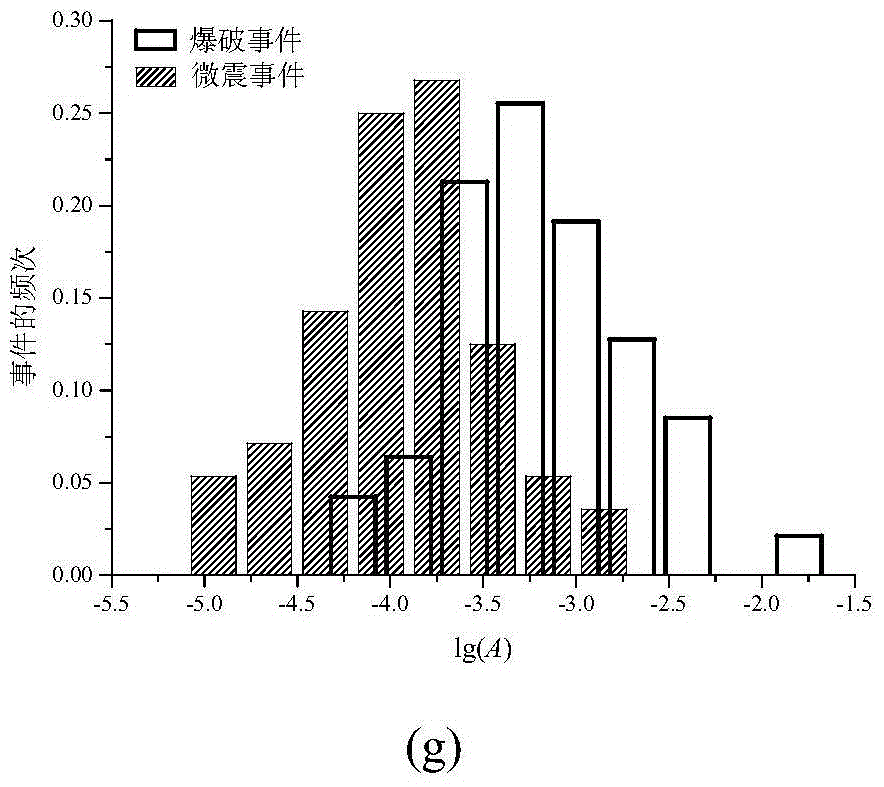

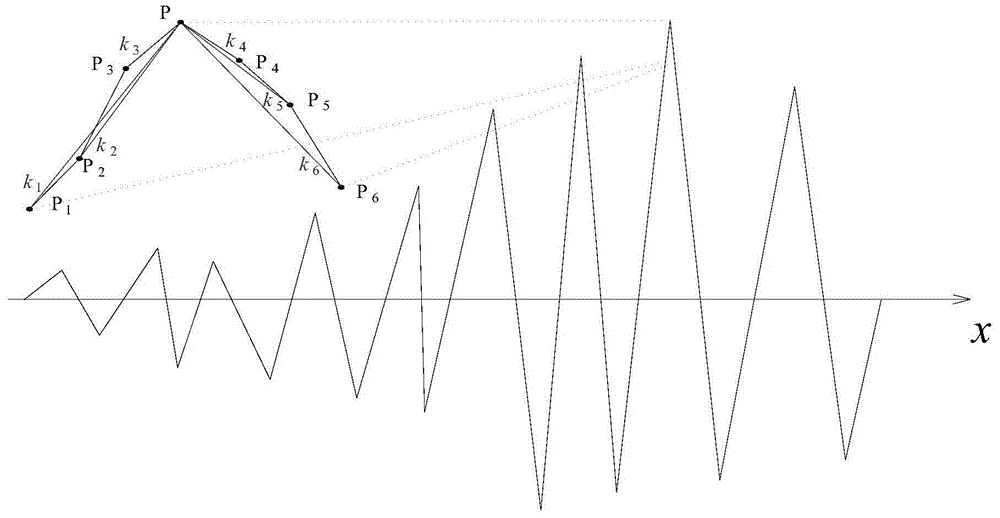

Recognition method of mine microseismic and blasting signals based on waveform slope before and after the peak

ActiveCN104834004BUnaffected by background noiseNot easy to pick upSeismic signal processingPeak valueComputer science

The invention discloses a mine slight shock and blasting signal identification method based on waveform slope before and after a peak value. The method comprises: step 1, acquiring a linear identification equation: based on N times of slight shock events and M times of blasting events, obtaining a linear identification equation with logarithm of A, logarithm of k1, logarithm of k2, logarithm of k3, logarithm of k4, logarithm of k5, and logarithm of k6 as characteristic parameters, the linear identification equation being Y=a1* lg(k1)+a2*lg(k2)+a3*lg(k3)+a4*lg(k4)+a5*lg(k5)+a6*lg(k6)+b*lg(A)+c; step 2, calculating a distinguishing threshold value Yd; step 3, based on the linear identification equation and the distinguishing threshold value Yd, identifying a to-be-identified event; and calculating a distinguishing value Y of the to-be-identified event, if Y<=Yd, the to-be-identified event being a slight shock event, and if not, the to-be-identified event being a blasting event. The method is low in calculated amount, and identification results are not influenced by signal noise, and the method is high in accuracy.

Owner:CENT SOUTH UNIV

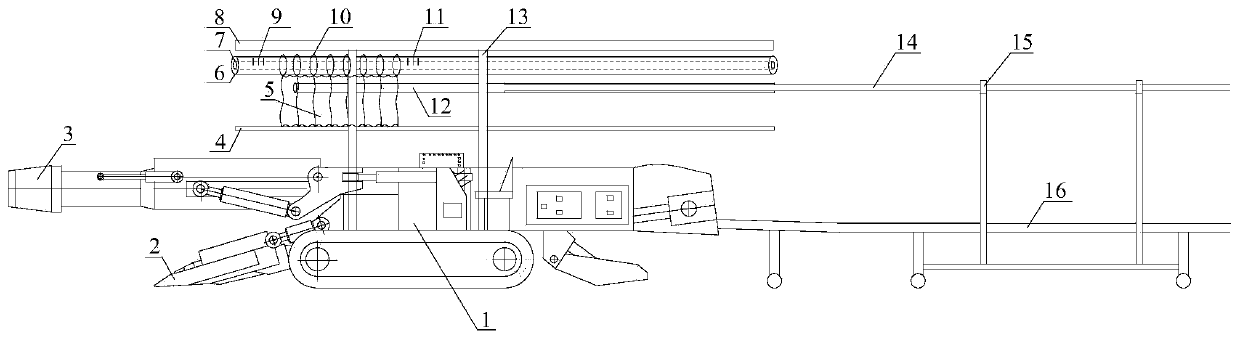

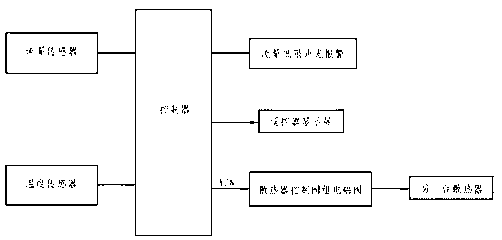

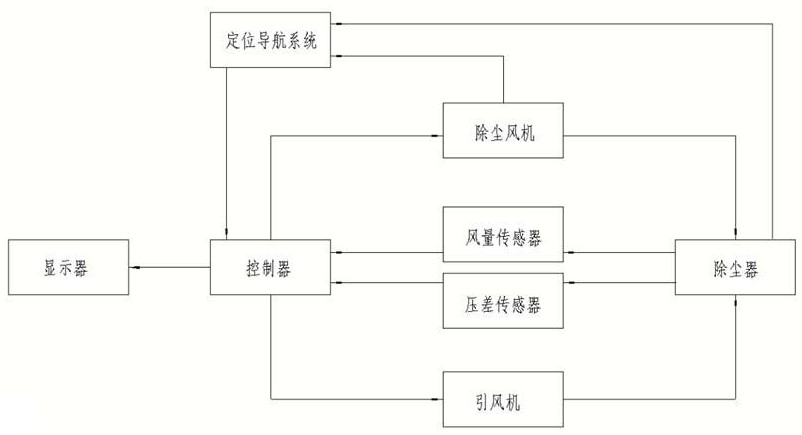

Continuous coal mining machine end slope mining ventilation and dust removal system and method

InactiveCN111997609AEasy to install and use on siteGuaranteed ease of useDust removalFire preventionVideo monitoringAtmospheric contamination

The invention belongs to the technical field of ventilation and dust removal for end slope mining of an open pit mine, and particularly relates to a continuous coal mining machine end slope mining ventilation and dust removal system and method. The system and method aim to solve the problems that dust of a continuous coal mining machine end slope mining working face is difficult to control, accordingly normal work of electric control systems such as video monitors and the adaptability of a dust removal device to the length change of a mining cave are influenced, and air of a stope is polluted.The system comprises a local ventilator, an air supply duct, a combined ventilation dust control device, a dust remover and a dust removal air duct which are sequentially distributed on the working face from outside to inside. One end of the air supply duct is connected with the combined ventilation dust control device, the other end of the air supply duct is connected with the press-in type local ventilator, and the air supply duct is distributed on a belt conveying system through a suspension device. One end of the dust removal air duct is connected with the combined ventilation dust control device, the other end of the dust removal air duct is connected with the dust remover, the dust removal air duct and the dust remover are both distributed on the belt conveying system, and the press-in type local ventilator is arranged outside the mining cave.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

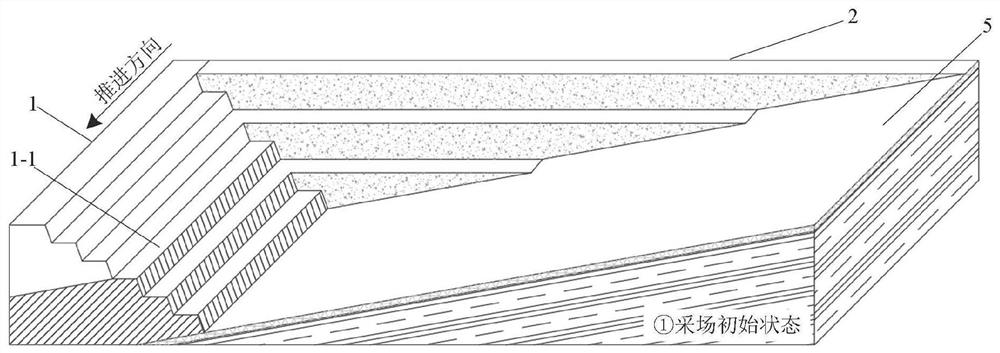

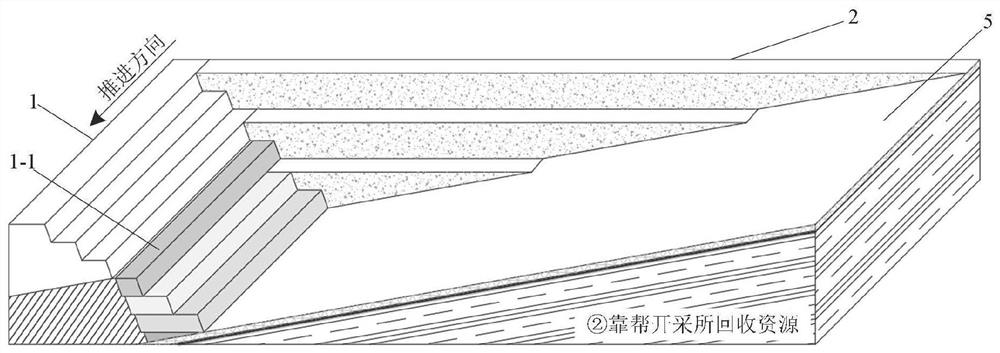

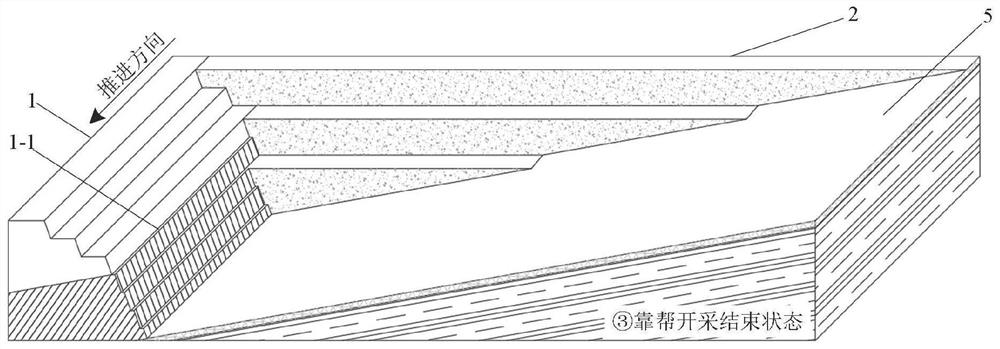

Method for planning dump of strip mine of ultra-thick inclined coal seam and efficiently recycling end slope resources

ActiveCN113047839ADoes not affect normal productionMining devicesUnderground miningOpen-pit miningMechanical engineering

The invention provides a method for planning a dump of a strip mine of an ultra-thick inclined coal seam and efficiently recycling end slope resources, and is applicable to the field of open-pit coal mining. The method comprises the following steps: firstly, performing slope mining; secondly, planning the mined dump, and changing the dump of the strip mine from a previous straight working line into a current broken line working line to provide a site for mining of an end slope coal mining machine; thirdly, arranging the end slope coal mining machine on a step of the dump close to an end slope to mine the strip mine of the ultra-thick coal seam in a state after the slope mining is finished, wherein the mining direction of the coal mining machine is perpendicular to the advancing direction of the strip mine; and fourthly, filling a roadway after end slope coal resources are recycled, wherein after the filling is finished, a lagging dumping area follows up the width of the roadway. According to the method, the site is provided for the end slope coal mining machine through lagging dumping; the method is simple in step and convenient to implement; the end slope coal resources of the end slope can be recycled as much as possible, and normal production of other parts of the mine is not influenced.

Owner:CHINA UNIV OF MINING & TECH

End slope mining goaf filling machine and filling method thereof

ActiveCN111520185AAutomate fillingFulfill filling needsMaterial fill-upMining engineeringHydraulic pump

The invention discloses an end slope mining goaf filling machine and a filling method thereof, and relates to the technical field of coal mine goaf gangue filling. The end slope mining goaf filling machine comprises a crawler walking part, a machine body, a driver control room, a hydraulic pump station, an upper push plate mechanism and a lower push plate mechanism. According to the disclosed theend slope mining goaf filling machine and the filling method thereof, roadways and large-section goaf after open-pit mine end slope mining can be filled, automatic goaf roadway filling is realized, and compacting and solidifying operations on filling materials can be carried out, so that the filling rate of the filling materials is ensured, the top contact rate of the filling materials is improved, the filling effect is enhanced, the problems of uneven filling, roof descending and the like are effectively prevented; and meanwhile, the filling machine is high in maneuverability, can be used incooperation with other conveying and filling equipment for open-pit mine end slope mining, further saves the filling cost, improves the filling effect, and has high innovativeness and wide practicability.

Owner:CHINA UNIV OF MINING & TECH

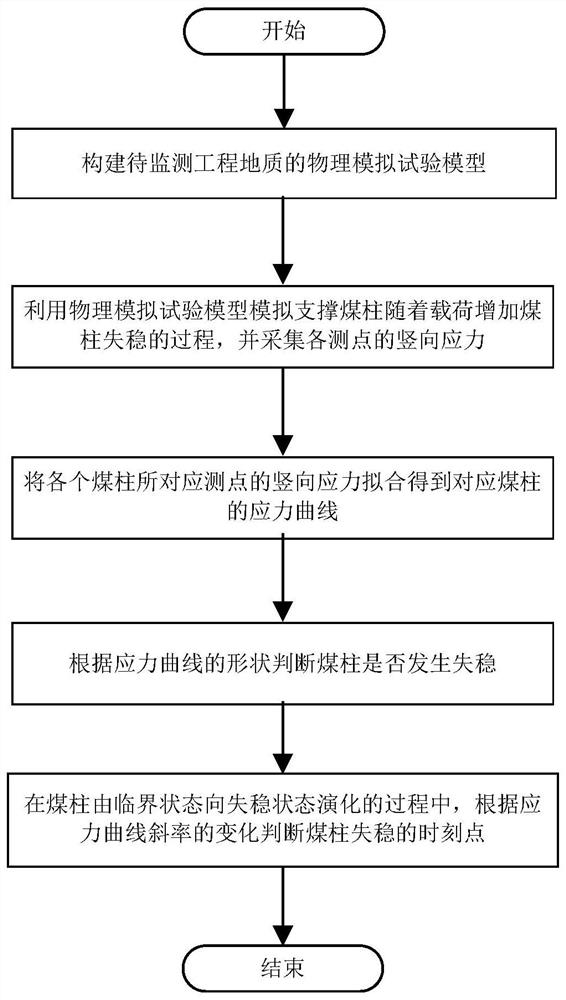

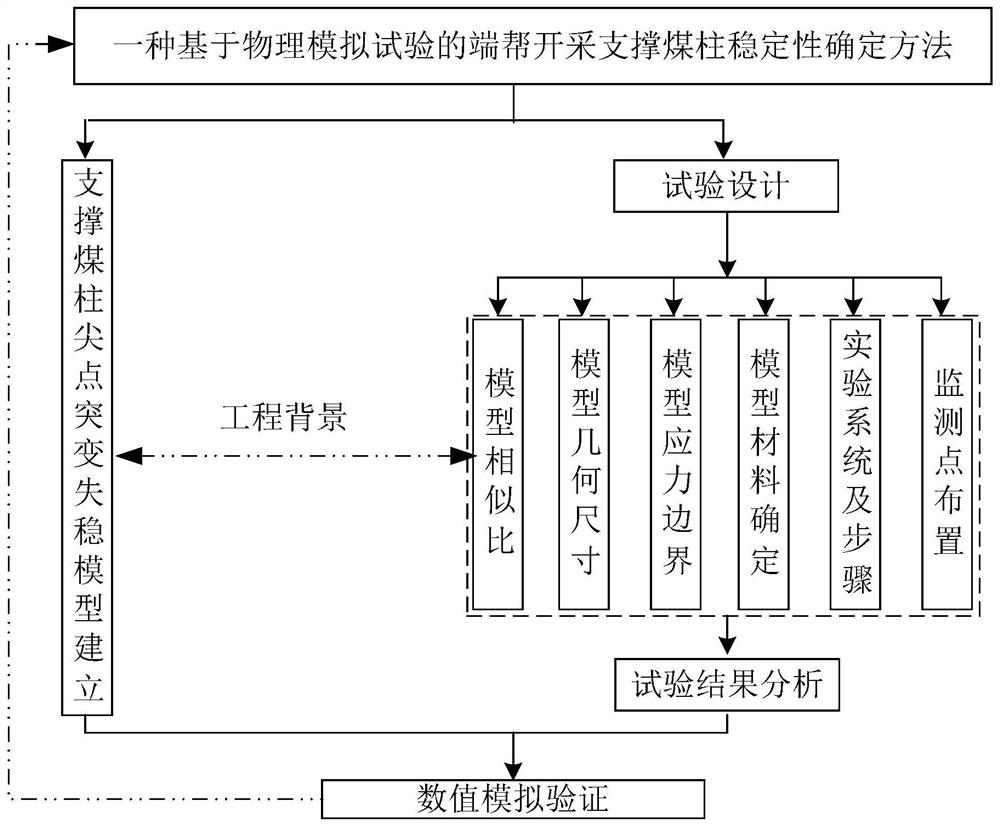

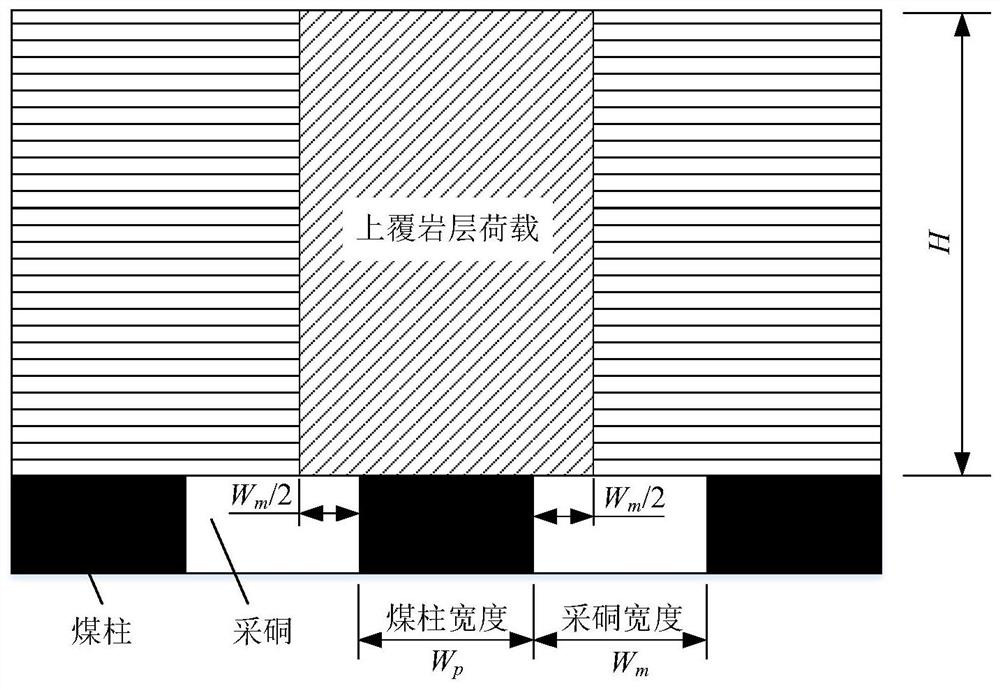

Method for determining stability of end slope mining supporting coal pillar based on physical simulation test

PendingCN113790961AMethod results are reliableTimely warningMaterial strength using tensile/compressive forcesMining engineeringStructural engineering

The invention provides a method for determining stability of an end slope mining supporting coal pillar based on a physical simulation test, which comprises the following steps of: firstly, establishing a physical simulation test model of engineering geology to be monitored, simulating a process that the supporting coal pillar is unstable along with load increase, and collecting vertical stress of each measuring point to draw a stress curve; judging whether the coal pillar is unstable or not according to the shape of the stress curve, wherein the vertical stress of the coal pillar is distributed in a saddle shape in the recovery process and is in a stable state, in the graded loading process, the widths of the coal pillars are sequentially subjected to shear failure from small to large, sudden increase of vertical stress in the middles of the coal pillars is a premonition of instability, and vertical stress sudden change inflection points serve as coal pillar instability early warning criteria. According to the invention, the actual situation of an engineering site can be accurately simulated, and a reasonable design basis is provided for relevant parameters of the support coal pillar.

Owner:LIAONING TECHNICAL UNIVERSITY +1

An engineering drilling rig for automatically loading and unloading drill pipes

The invention discloses an engineering driller for automatically loading and unloading a drill stem, and particularly to a coal mining driller specific to end slope mining of an open mine. The engineering driller comprises a driller frame body; a driller platform which is arranged on the driller frame body and used for placing the drill stem and a propeller to be loaded and unloaded, wherein a loading-unloading drill stem transfer channel is arranged on the driller platform corresponding to the position between the drill stem to be loaded and unloaded and the propeller for placing the loaded and unloaded drill stem; a drill stem angle phase position adjusting mechanism, which is arranged at the bottom part of the driller platform and used for adjusting the circumference angle of the loading and unloading drill stems thereon, so that the drill stem is normally abutted; a drill stem horizontal transfer mechanism; a drill stem vertical transfer mechanism. The angle phase positions of the loading and unloading drill stems are adjusted from the bottom part of the driller platform, and the drill stem to be loaded and unloaded is transported; the engineering driller solves the problem that the drill stem angle phase position adjusting mechanism and the drill stem conveying device of the existed engineering driller need to be arranged at the side face of the driller, and construction channel space out of the driller shall be occupied independently, and auxiliary hoisting device needs to configure.

Owner:LIAONING HANSHI MACHINERY MFG CO LTD

A side mining system for an open-pit mine

ActiveCN109931066BImproving the technical strength of side miningRealize intelligenceDust removalFire preventionSocial benefitsAdhesive belt

The invention relates to the technical field of slope mining of open-pit mines and particularly relates to a slope mining system for the open-pit mines, and realizes safe, efficient and green mining of slope briquettes of the open-pit mines. The slope mining system comprises a slope continuous coal mining machine for carrying out roadway type mining, a multi-unit rapid connection adhesive tape conveying system for carrying out rapid conveying, a stepping type walking platform for carrying out external propelling and whole movement, a movable type unloading part for carrying out external conveying, a pulling-out type ventilation and dust removal system for carrying out roadway ventilation and dust removal, a navigation and stability monitoring system for carrying out remote accurate controland slope stability monitoring, and a remote control platform for carrying out remote control. According to the slope mining system for the open-pit mines, provided by the invention, the safe, efficient and green mining of slope briquette resources can be realized, the strength of an slope mining technology of the open-pit mines in China can be remarkably improved, and remarkable economic benefits and social benefits can be brought for enterprises.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

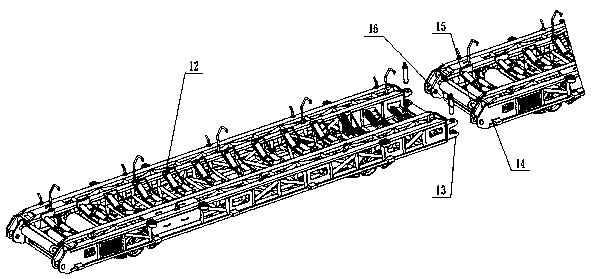

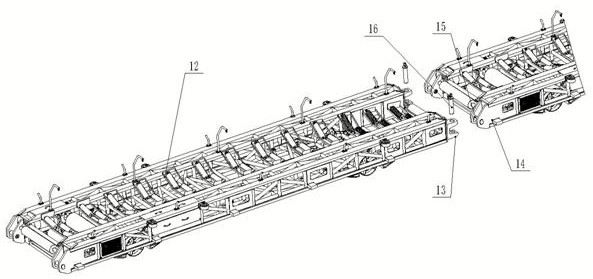

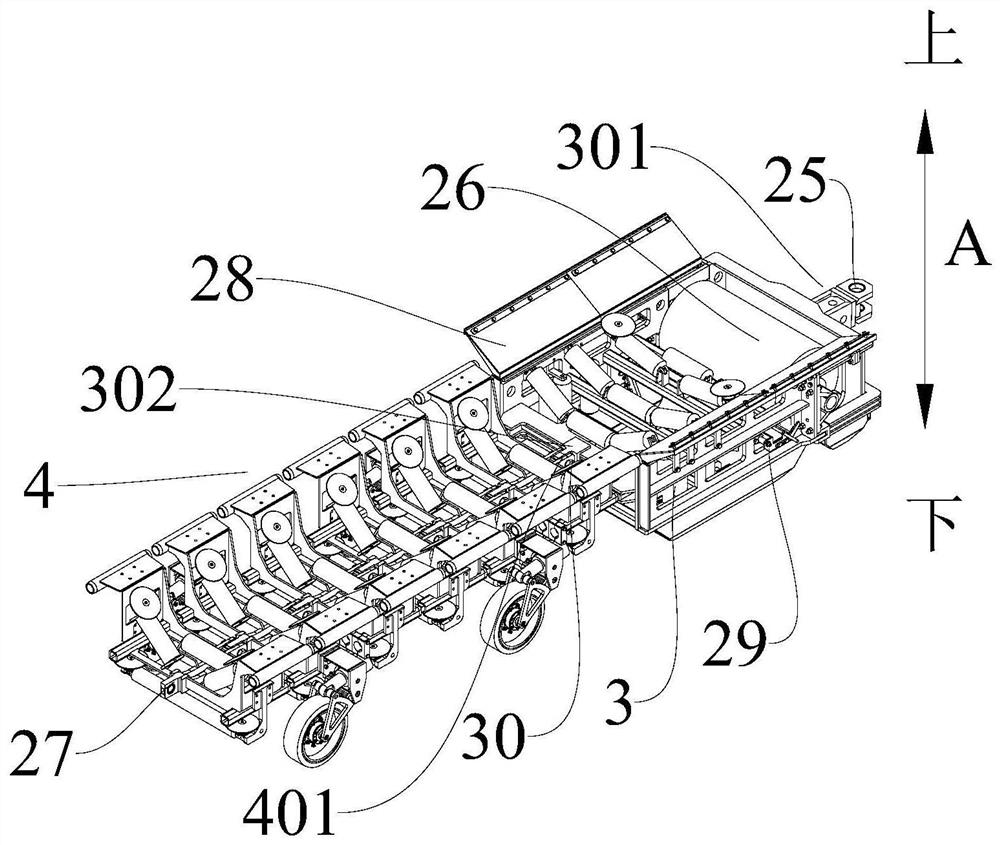

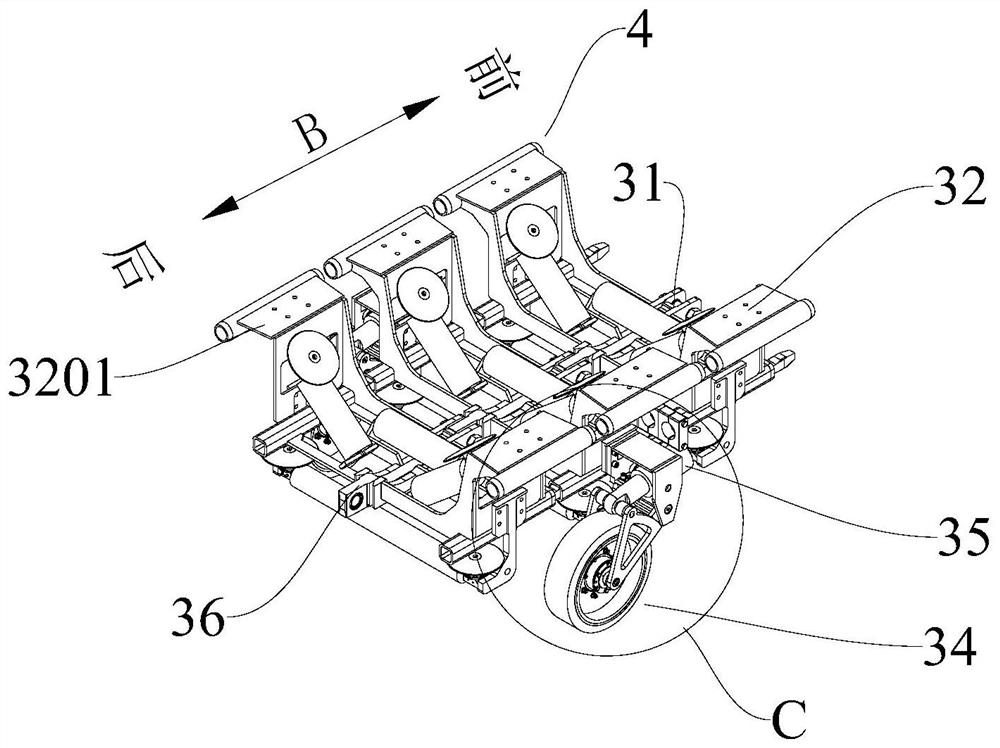

Open-pit mine side slope mining system

PendingCN112627825ASimple structureLow investment costMining devicesUnderground miningMining engineeringStructural engineering

The invention relates to the technical field of open-pit mine side slope mining, in particular to an open-pit mine side slope mining system. The open-pit mine side slope mining system comprises a side slope continuous mining machine, a loading part, a belt conveying system and a movable reversed loader. The loading part is provided with a first connecting part and a second connecting part, and the first connecting part of the loading part is connected with the side slope continuous mining machine so that the side slope continuous mining machine can drive the loading part to move. The belt conveying system is provided with a first connecting part and a second connecting part, and the first connecting part of the belt conveying system is connected with the second connecting part of the loading part so that the loading part can drive the belt conveying system to move. The movable reversed loader is connected with the second connecting part of the belt conveying system so that the belt conveying system can drive the movable reversed loader to move, and the movable reversed loader is a crawler-type reversed loader or a wheel-type reversed loader. The system has the advantages of being simple in structure, low in investment cost and the like.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

A continuous coal mining machine for end-side mining in an open-pit mine

ActiveCN108798664BAdvancedImprove mining efficiencyDriving meansCutting machinesMining engineeringRemote control

The invention belongs to the field of open-pit mine end slope mining equipment, in particular to a continuous miner for open-pit mine end slope mining. The problems that an existing continuous miner cannot realize remote and accurate control of end slope coal pressing and unmanned mining are solved. The continuous miner for open-pit mine end slope mining comprises a cutting part, a loading part, left and right travel parts, a main machine frame, a conveying part, a rear machine frame, a dust removal system, an electrical system, a hydraulic system and a cooling system. The cooling system adopts a self-circulation cooling system, the cooling system is arranged on the right rear part of a machine body, the dust removal system comprises a dust removal fan and an air duct, and the dust removalair duct is integrated into the cutting part and the machine body. The continuous miner for open-pit mine end slope mining further comprises an external control center and an interactive remote control platform. The external control center comprises an inertial navigation system, a remote operating system and a fault diagnosis system. All monitoring data and control operating mechanisms are integrated on an interactive remote control platform. The continuous miner for open-pit mine end slope mining can obviously improve the efficiency and safety of end slope coal pressing.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

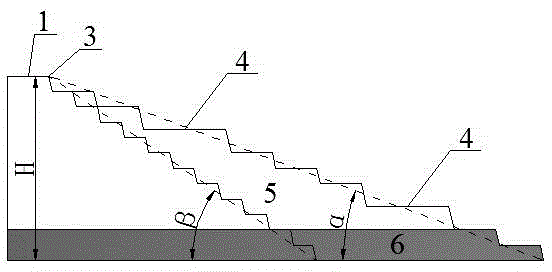

Side-by-side mining method in open-pit mines

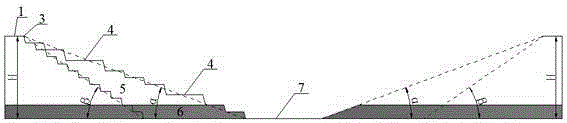

ActiveCN103133003BReduce stripping ratioLow application costOpen-pit miningOpen-pit miningSlope angle

The invention discloses an opencast mine end slope near-slope mining method. During an opencast mining process, for integral side slopes of end slopes on two horizontal sides of a mining field, near-border mining is carried out according to a stable angle alpha as in an initial design; according to a timeliness slope principle, inner dump is followed up in time; a pit bottom distance is shortened to a minimal safety distance Dmin required by mining, and integral height H of the side slope of the end slope is reduced; according to a side slope stable condition, the side slope angle is increased to beta; and near-slope mining is realized. The height of inner dump bottom layer slope-pressing step is 2-3 times that of mining working slope step. Stripped soil and rock are transported to the inner dump bottom layer slope-pressing step through a built soil-discharge bridge. With the method provided by the invention, side slope angle can be increased on a basis that slope end stability is ensured. Therefore, end slope residual coal can be recovered; stripping ratio can be reduced; and transportation cost can be reduced.

Owner:CHINA UNIV OF MINING & TECH

A method for predicting the distribution of surface cracks induced by underground mining of side walls in open-pit mines

ActiveCN106326528BSolving the Crack Prediction ProblemData processing applicationsDesign optimisation/simulationTerrainModel parameters

The invention provides a method for predicting a distribution rule of ground surface fissures induced by underground mining of a surface mine end slope. The method comprises the following steps of collecting terrain and geology data of a surface iron mine; building an underground mining model of the surface iron mine end slope; determining the parameters of the underground mining model of the surface iron mine end slope; numerical simulation of underground mining: utilizing a three-dimensional discrete element method to calculate the numerical simulation of mining of the surface iron mine end slope, so as to obtain a rock layer and ground surface movement rule; predicting the ground surface fissures. The method has the advantages that the problem of predicting of ground surface fissures caused by the end slope mining from the surface iron mine into the underground mine is solved; a three-dimensional geology model of the rock body of the surface iron mine is established by a three-dimensional geology modeling method, and is divided into a discrete block model suitable for the 3DEC calculation; the distribution scope and type of the ground surface fissures in the underground mining process can be predicted, and the support is provided for the safety production of mines.

Owner:ANSTEEL GRP MINING CO LTD

A dust removal device and dust removal method for side mining equipment

ActiveCN110080761BReduce concentrationAvoid pollutionMining devicesDust removalMining engineeringDust control

The invention belongs to the technical field of coal mining dust removal, and particularly relates to a dust removal device and a dust removal method for side slope mining equipment. An air bellow isfixed on a cantilever of a coal mining machine, and an air outlet of the air bellow is flexibly connected with the transition section; one end of the transition section is flexibly connected with theair outlet of the air bellow, the other end is connected with the suction opening of a dust removal fan, and an air outlet of the dust removal fan is connected with one end of a head unit air duct; the head unit air duct is hung on a steel wire rope of a head transportation unit through a hanging ring, the other end of the first unit air duct is connected with one end of a standard unit air duct through an air duct connector, the standard unit air duct is hung on a steel wire rope of a standard transportation unit through a hanging ring, and the other end of the standard unit air duct is connected with the next standard unit air duct through an air duct connector, and so on; and a telescopic air duct is hung on a steel wire rope below a platform through a hanging ring, one end of the telescopic air duct is connected with the last standard unit air duct, and the other end of the telescopic air duct is connected with a dust remover air inlet pipeline.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

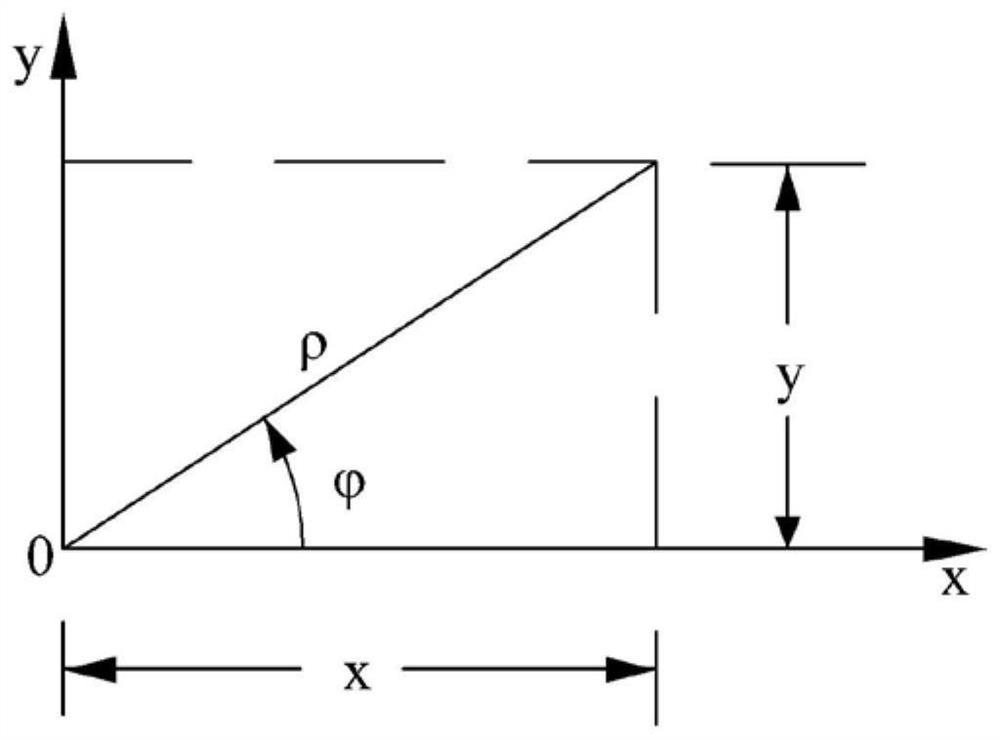

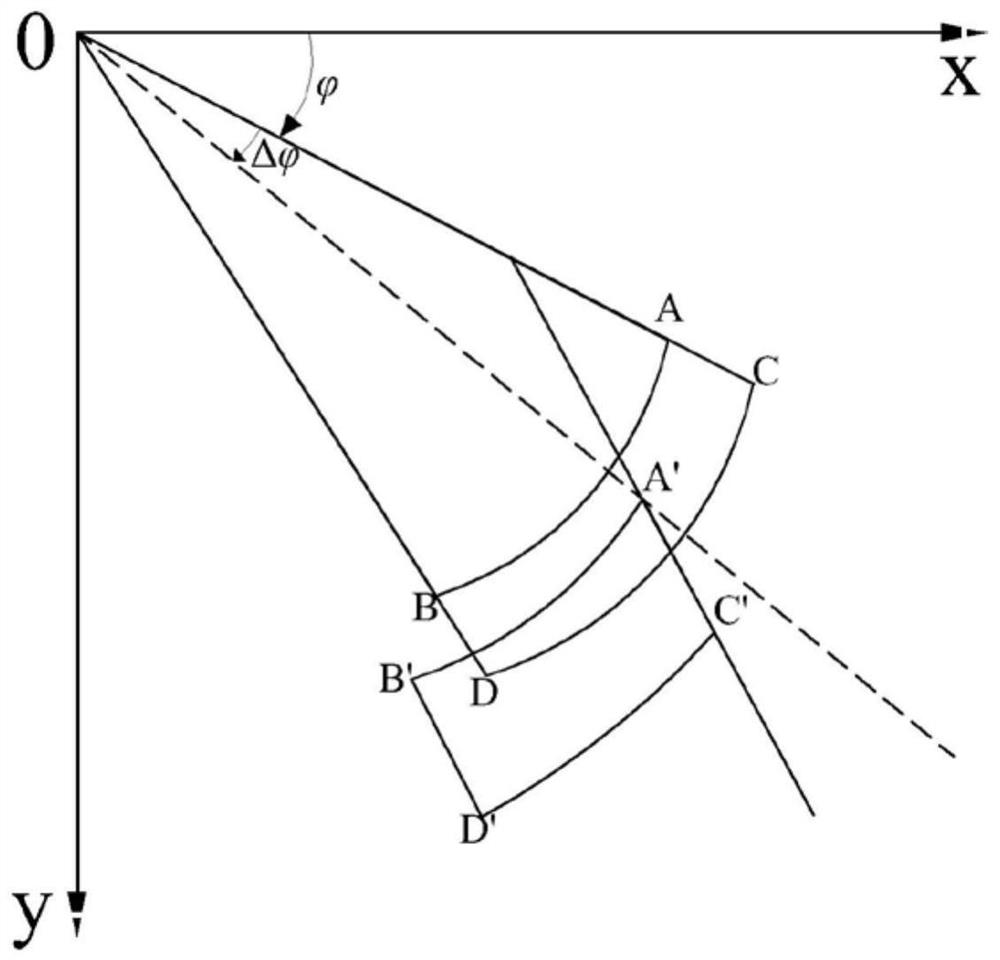

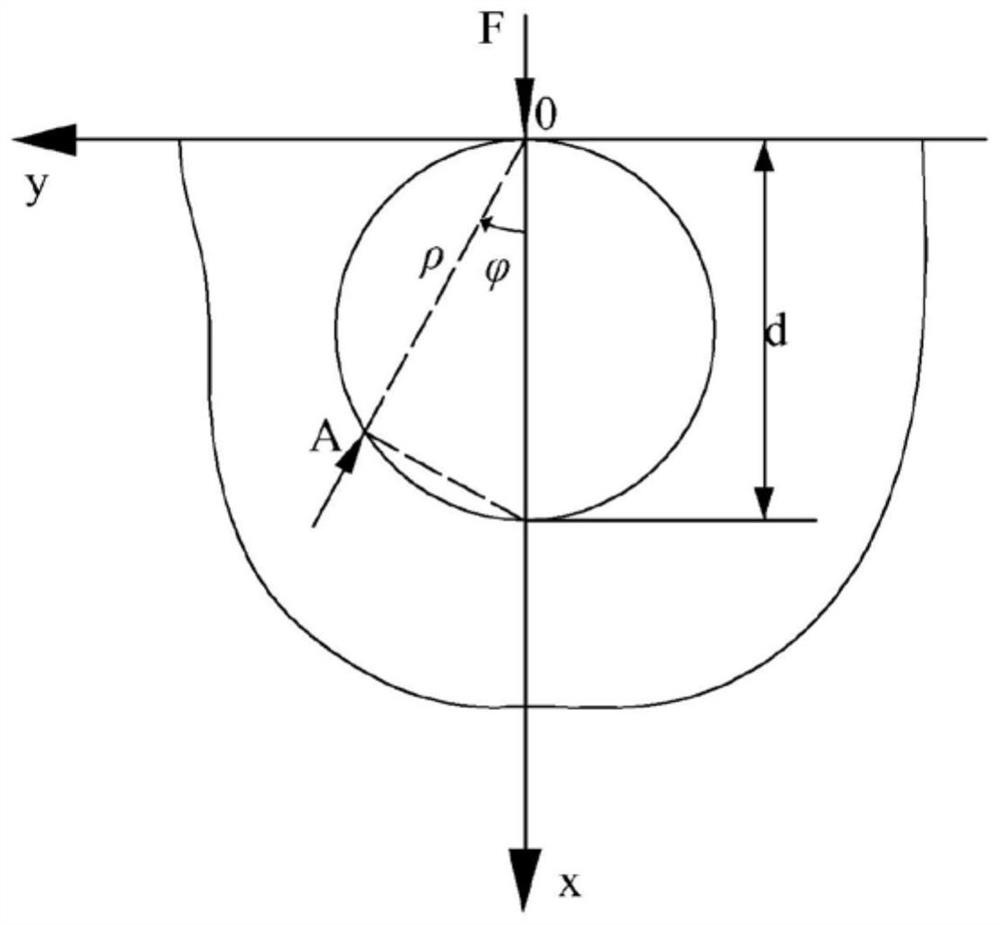

Elastic analysis method for deformation of soil around refuse dump

The invention discloses an elastic analysis method for surrounding soil deformation of a refuse dump, and belongs to the field of strip mine slope mining. The method comprises the following steps: 1,analyzing polar coordinates of semi-infinite plane elastic deformation, 2, calculating the horizontal (vertical) displacement of any point in the foundation under the dumping site, and 3, calculatingthe deformation of the soil body around the refuse dump At present, key points concerned in the engineering field are still not reported in the research under the action of excavation unloading and refuse dump load. Obviously, the deformation of the surrounding soil body is not paid attention to sufficiently under the load effect of the refuse dump, a relatively uniform method is not formed, and engineering design cannot be effectively guided. The displacement change of any point in the soil body is solved by applying an elastic analysis method based on the load distribution characteristics ofthe waste dump, so that the relative deformation value of the peripheral earth surface of the waste dump is obtained. Engineering practice is guided, and very important significance is achieved for safety of the strip mine.

Owner:LIAONING TECHNICAL UNIVERSITY

End-side mining method of continuous coal mining machine in open-pit end-side mine

ActiveCN108194084BMeet the requirements of mechanized miningIncrease the level of mechanizationUnderground miningSurface miningMining engineeringMechanical engineering

The invention belongs to the technical field of application of coal mining equipment and coal mining methods, and particularly relates to an end slope mining process by using an open-air end slope orecontinuous miner. The end slope mining process comprises the following steps that 101, a mining face is arranged; 102, an equipment mounting and preparation area is arranged; 103, equipment is arranged and mounted; 104, a ventilation system is arranged; and 105, mining is conducted by using the continuous miner. The end slope mining process adopts continuous miner complete set mining equipment, the requirement of mechanized mining of end slope ore is met, the mechanization level of mining of the end slope ore is improved, the production efficiency is greatly improved, the labor intensity of workers is reduced, the stripping volume of rock and soil is reduced, and damage and disturbance to the environment is reduced.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com