Side-by-side mining method in open-pit mines

A mining method and open-pit mining technology, applied in open-pit mining, earth drilling, special mining, etc., can solve the problems of low overall economic benefits of coal mines, small side slope angles, waste of side coal resources, etc., to achieve Extensive practicability, reduced transportation costs, and reduced stripping ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

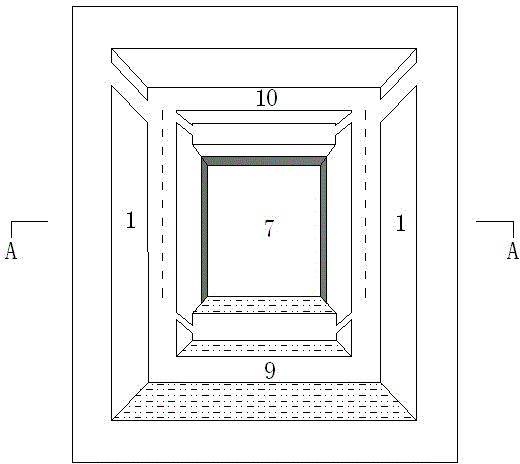

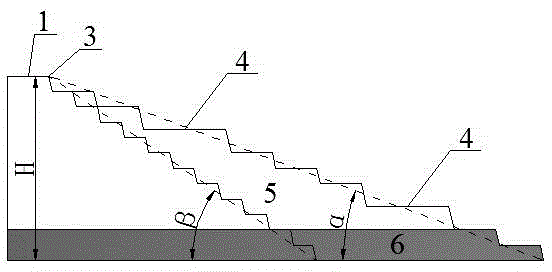

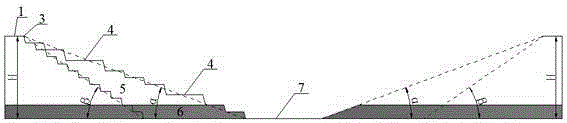

[0014] like figure 1 , figure 2 , Figure 4 Shown: in the open-pit mining method of the present invention, in the process of open-pit mining, for the overall slope of the end walls 1 on both sides of the stope level, mining is close to the boundary according to the initially designed stability angle α, and the inner dump site The bottom pressing step 2 is followed up in time to shorten the distance to the bottom of the pit D , reduce the overall height of the side slope of end side 1 H , on this basis, keep the coal seam mining height 3 unchanged, advance from the bottom of the sidewall 1 to the sidewalls on both sides, cancel the sidewall road 4, increase the slope angle to β, strip the rock mass 5, and recover the residual coal on the sidewall 6. An intermediate bridge 8 is built at the bottom of the stope, and the stripped rock mass 5 is transported...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com