Mining area steering method for full-mechanized production super-huge open pit coal mine

It is an open-pit coal mine and extra-large technology, which is applied in special mining, surface mining, earth square drilling and mining, etc. It can solve problems affecting the normal production of open-pit mines, confusion in the transportation system, and production reduction in open-pit mines, so as to reduce the stripping ratio and divert transportation. Short distance, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. As a part of this specification, the principles of the present invention will be described through examples. Other aspects, features and advantages of the present invention will become clear through the detailed description. In the referenced drawings, the same reference numerals are used for the same or similar components in different drawings.

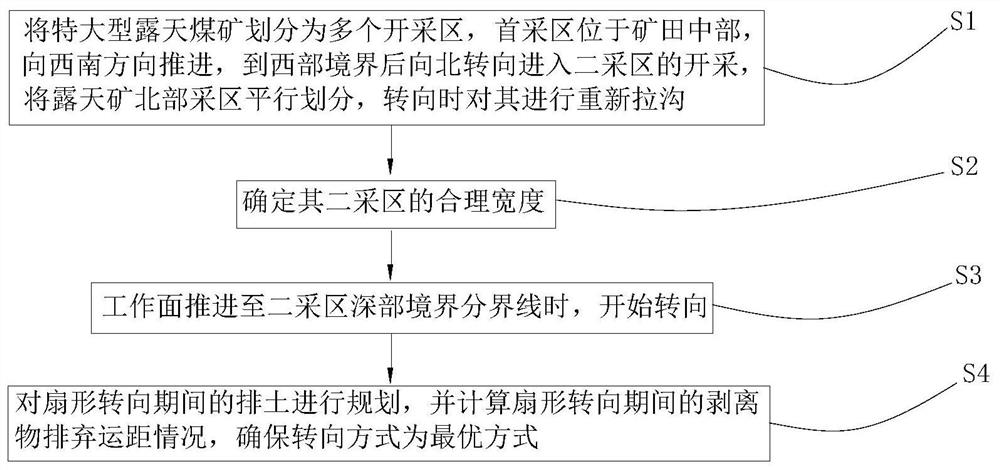

[0017] Such as figure 1 Shown, the extra-large open-pit coal mining area turning method of fully mechanized production of the present invention may further comprise the steps:

[0018] 1) Divide the extra-large open-pit coal mine into multiple mining areas. The first mining area is located in the middle of the ore field and advances to the southwest. After reaching the western boundary, it turns north to enter the second mining area. The northern mining area of the open-pit mine is divided in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com