Patents

Literature

799results about How to "Reduce mining costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

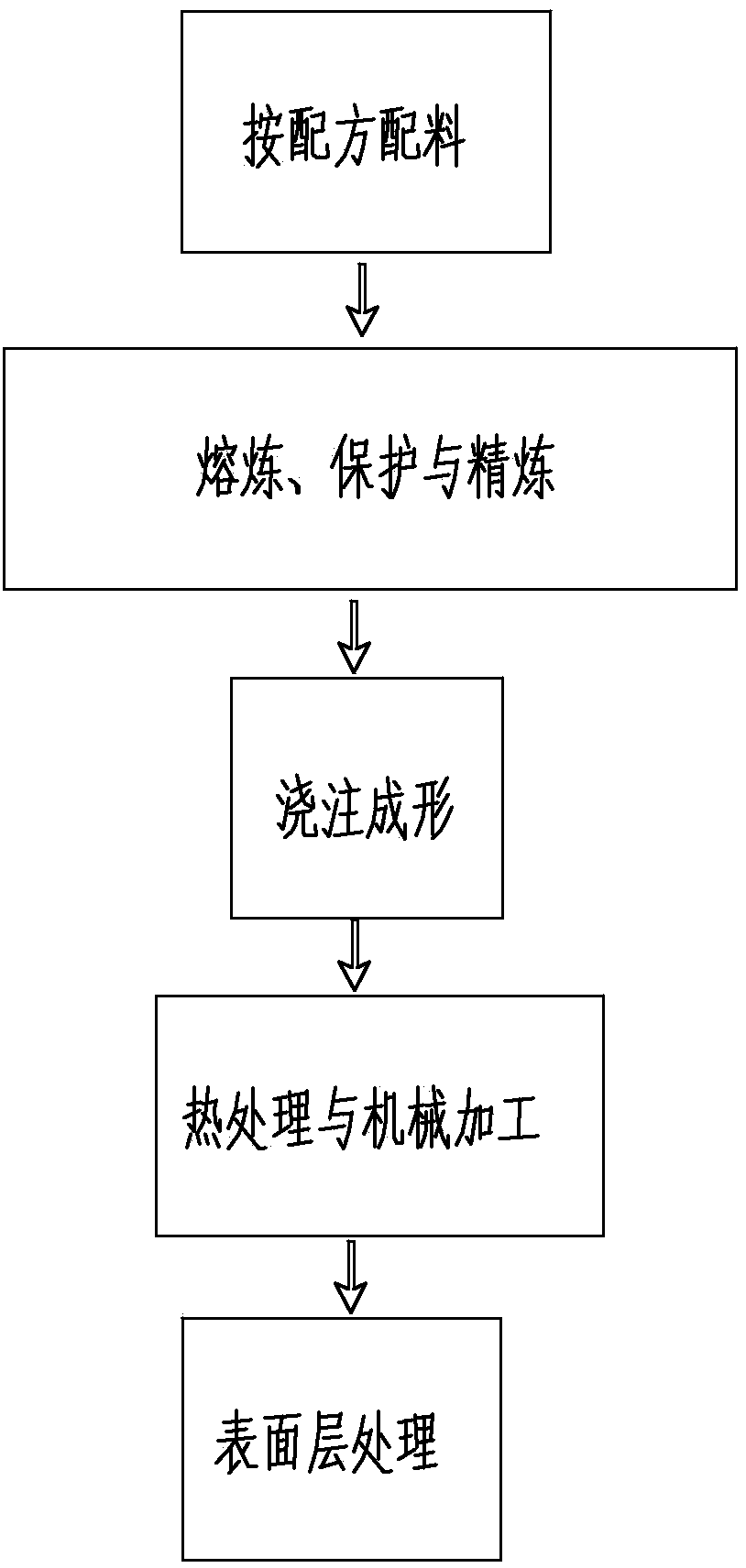

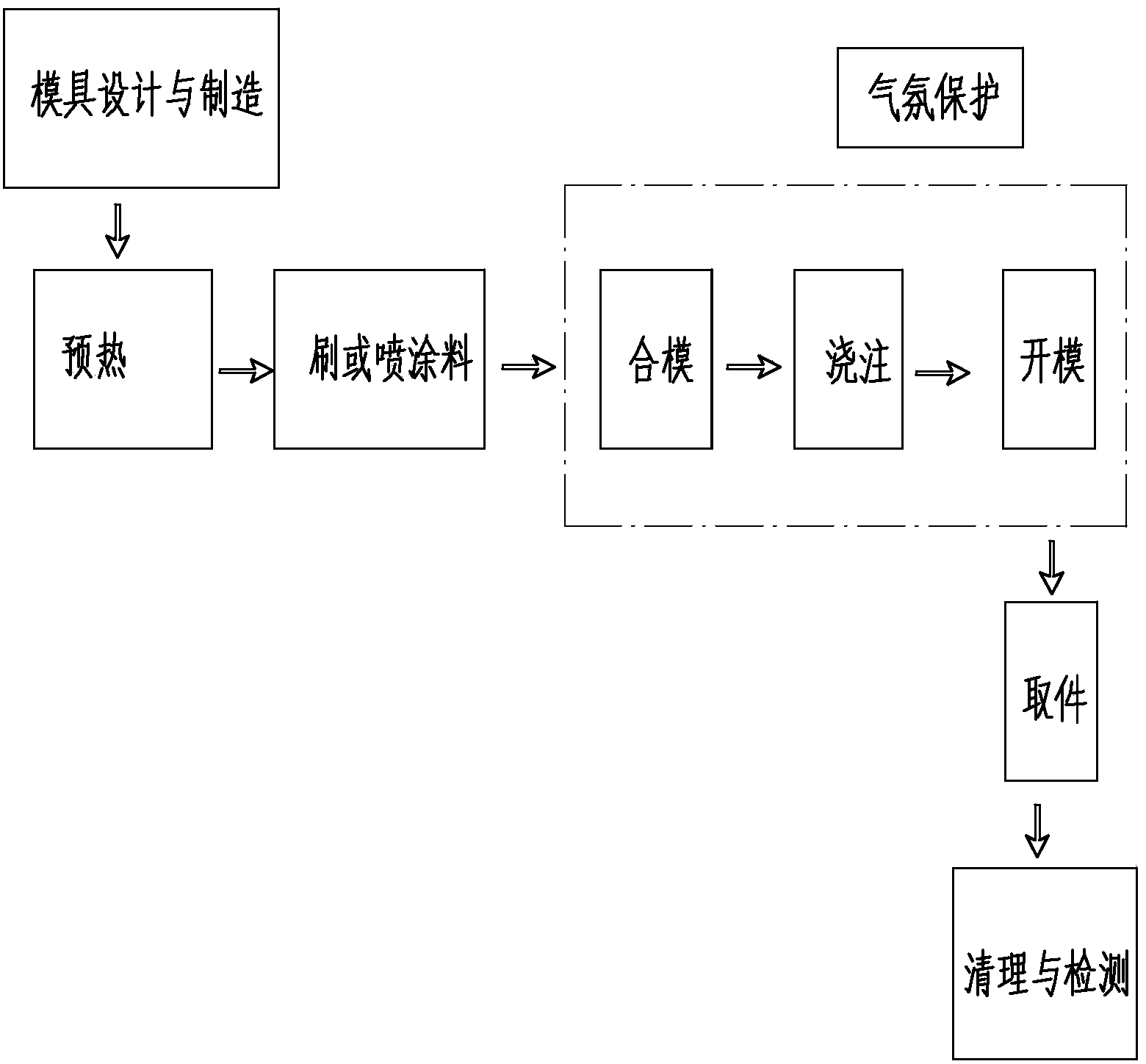

Easily-soluble magnesium alloy material as well as production method and application thereof

The invention discloses an easily-soluble magnesium alloy material which comprises the following elements such as Al, Li, Ca, Zn, In, Ga, Si, Zr, and the like. The invention further discloses a preparation method of the easily-soluble magnesium alloy material. The easily-soluble magnesium alloy material is used for producing products such as a ball sealer, a target, and the like, has technical characteristic of being easy to dissolve or quick to degrade, and can be designed into an oil exploitation underground component or an underground component which is used for performing a temporary function or is temporarily needed. Compared with the prior art, the easily-soluble magnesium alloy material has the advantages as follows: a high operation cost problem for secondary drilling or milling is solved or avoided, and technical and economic effects with low cost and high efficiency are obtained. Meanwhile, the magnesium alloy density is proper, molten slag or corrosion products of the magnesium alloy satisfy flow-back operation technical requirements, and technical effects with multiple advantages of being simple, efficient, environment-friendly, energy-saving, and the like, can be obtained.

Owner:NINGBO HIGH NEW DISTRICT RONGCHUANG NEW MATERIAL SCI & TECH

Exploitation method for wax precipitation oil reservoir

ActiveCN101839123AEfficient miningSolve the problem of wax analysisFluid removalDrilling compositionEconomic benefitsChemical agent

The invention discloses an exploitation method for a wax precipitation oil reservoir. The method comprises the step of adding a chemical agent and thermal fluid into an oil layer to make crude oil in the oil layer smoothly seep into an oil well and then rise to the ground surface. The method has the advantages of effectively solving the problem of wax precipitation of the crude oil in the oil layer and exploiting the wax precipitation oil reservoir, greatly reducing the exploitation cost of the wax precipitation oil reservoir, prolonging the production period and increasing the yield of the oil well and enhancing the final recovery efficiency of the oil reservoir, along with easy implementation, safety and reliability and obvious economic benefit.

Owner:盘锦河升大地石油科技有限公司

Exploitation method of thick oil type oil deposit

InactiveCN101839127AEfficient miningReduce mining costsFluid removalDrilling compositionEconomic benefitsOil type

The invention discloses an exploitation method of a thick oil type oil deposit, which comprises the following steps of: adding a chemical agent and hot fluid into an oil layer, enabling crude oil in the oil layer to be successfully seeped to an oil well and then enabling the crude oil to be raised to the ground from the inside of the oil well. The invention has the following advantages that: the invention can effectively solve the problem of phase precipitation of the asphaltene of the crude oil in the oil layer, can effectively exploit the thick oil type oil deposit, lowers the exploitation cost of the thick oil type oil deposit greatly, prolongs the production period of the oil well, increases the yield of the oil well, enhances the final recovery ratio of the oil deposit and has easy execution, high safety and reliability and obvious economic benefit.

Owner:盘锦河升大地石油科技有限公司

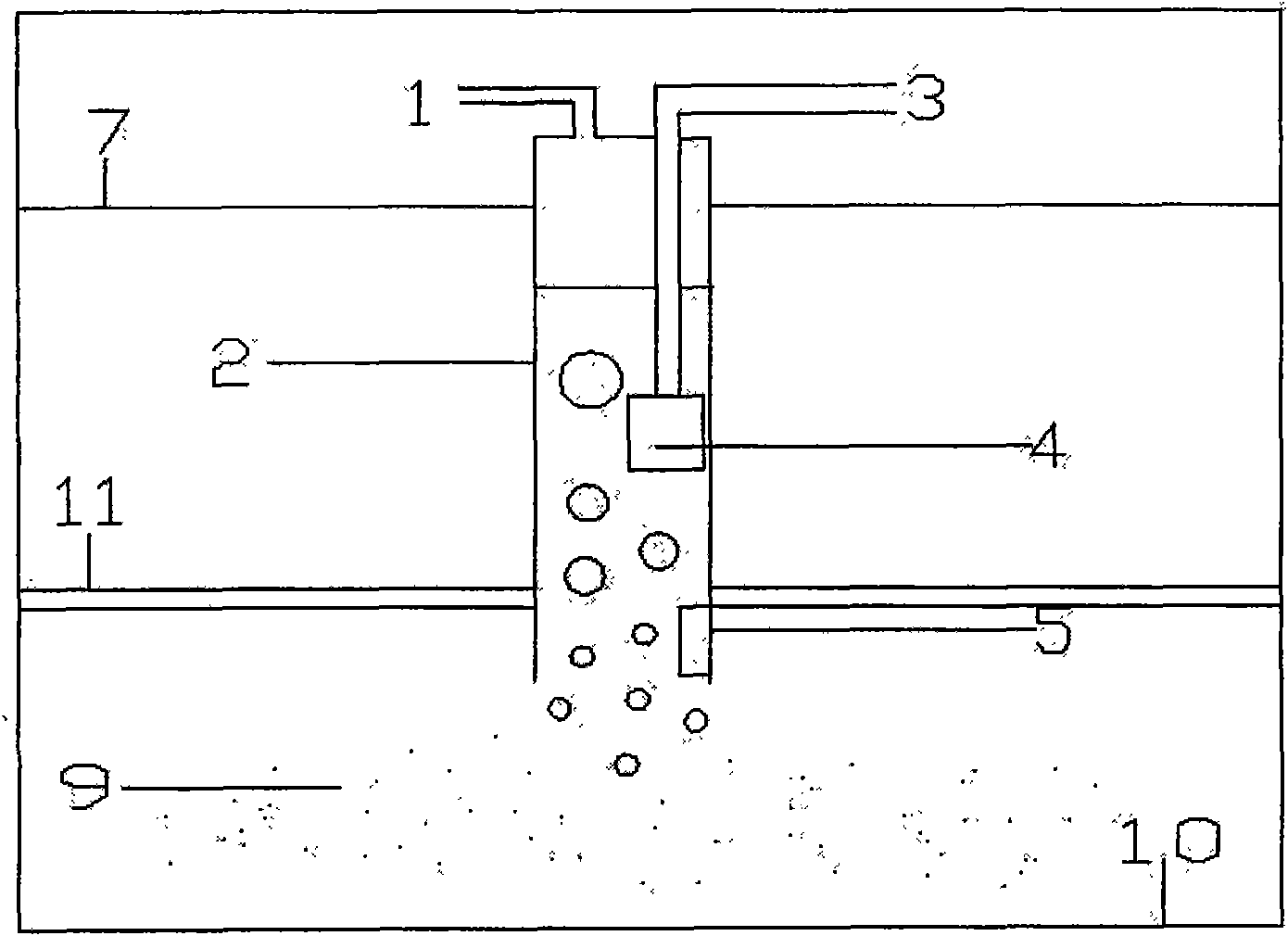

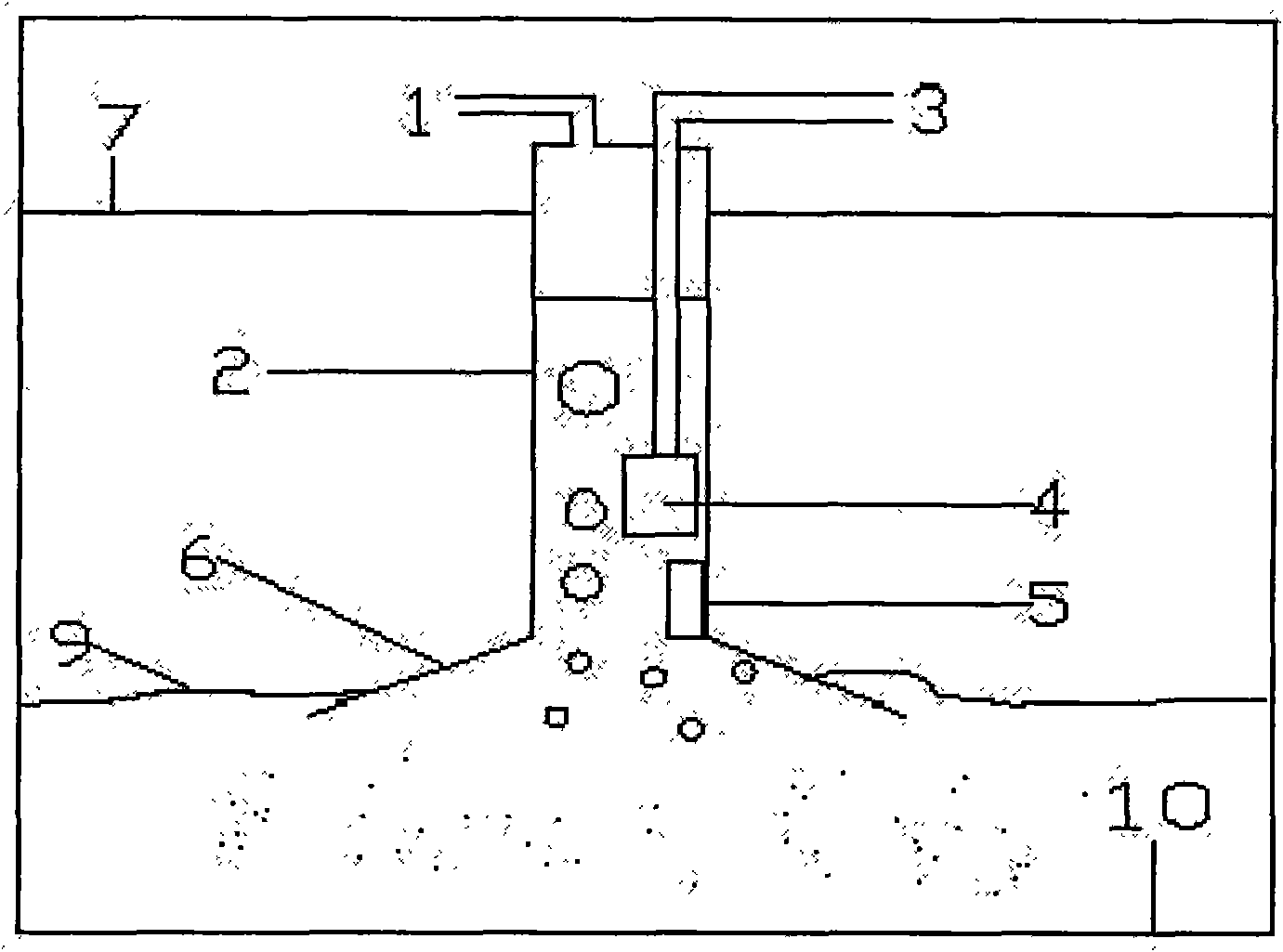

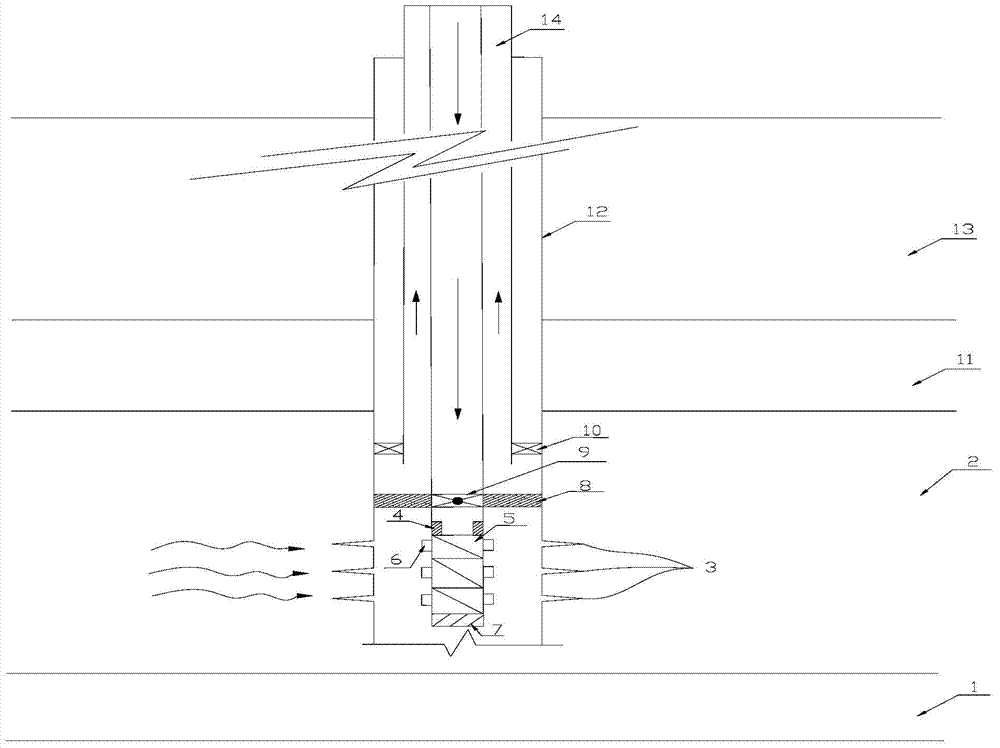

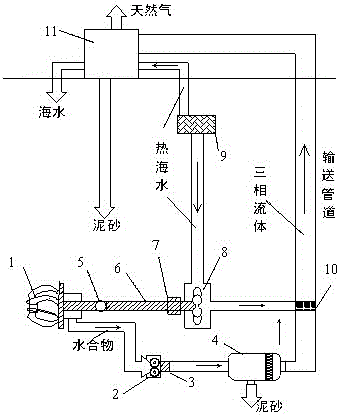

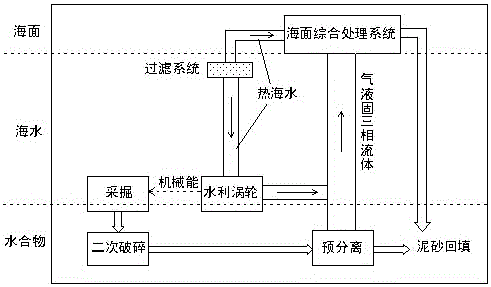

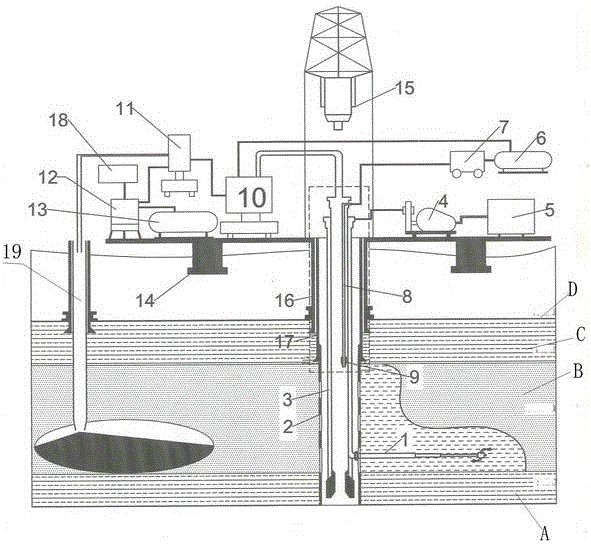

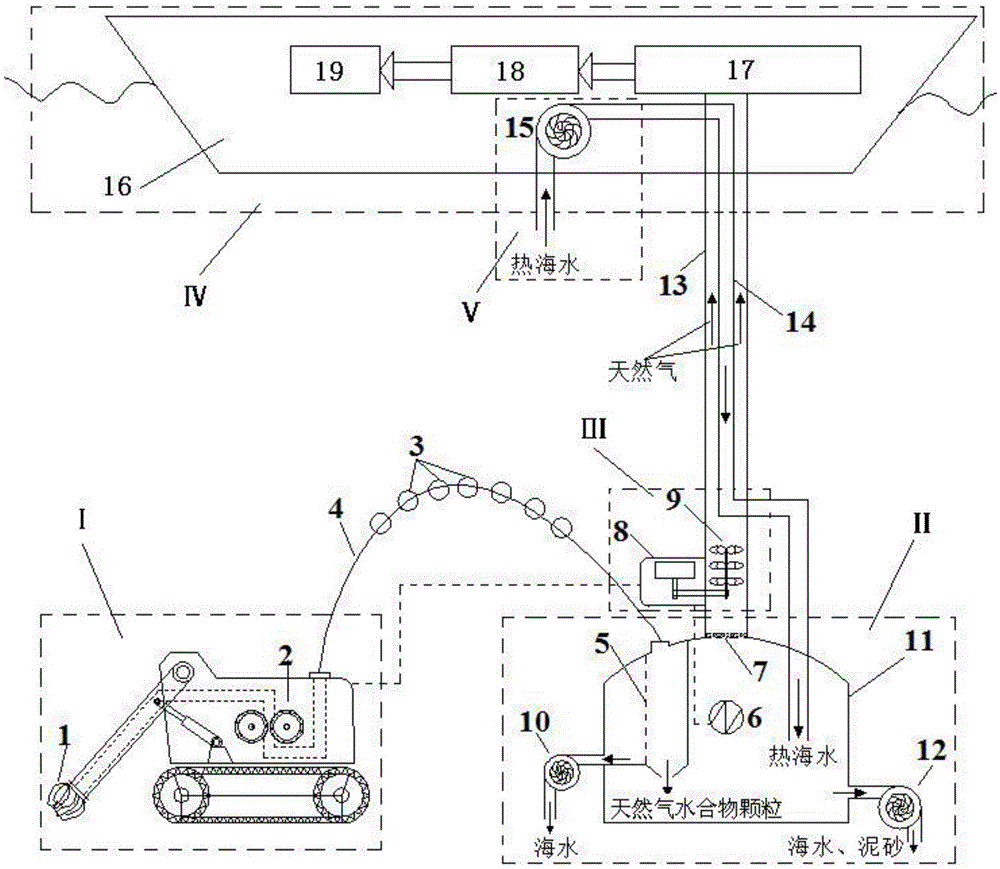

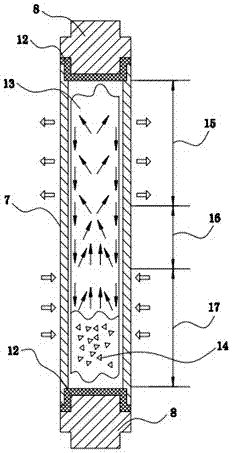

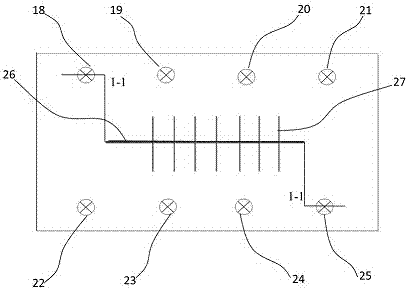

Extraction device for undersea gas hydrate and extraction method thereof

ActiveCN101555797AAchieve miningMining technology is simpleConstructionsMineral miningGas collecting tubeEngineering

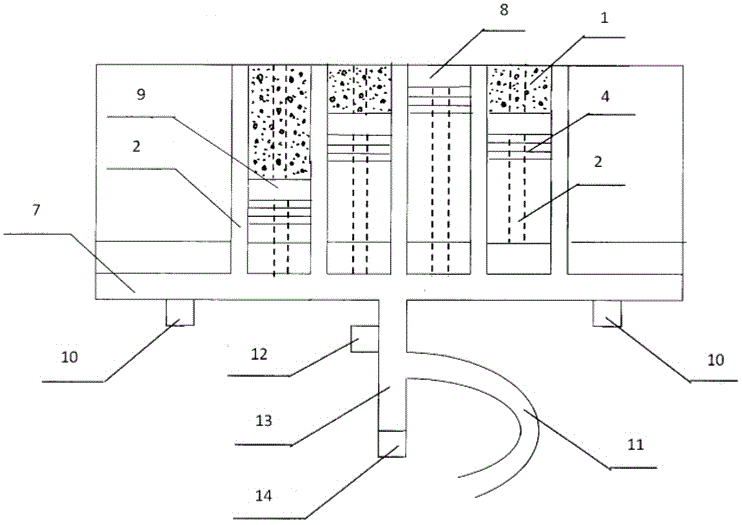

The invention discloses an extraction device for undersea gas hydrate and an extraction method thereof, which is characterized in that the device is directly communicated with undersea (10) gas hydrate layer (9) through a hollow rigid body (2); or the hollow rigid body is communicated with undersea (10) gas hydrate layer (9) through layers of sand and clay (8) or impermeable bed (11); a water pump (4) and a test and supervisory equipment (5) are provided on one side of the hollow rigid body, the water pump is connected with a drain pipe (3) which is above the sea level (7) through a pipe, the test and supervisory system is connected with an image pickup system and a pressure testing system, and a gas collecting pipe (1) is arranged on the top of the inside of the hollow rigid body. The extraction method comprises the following steps: 1) a hollow rigid body is built on the sea separated with water, and the hollow rigid body is communicated with undersea gas hydrate layer; 2) water in the hollow rigid body is drained out via a water pump to lower the water height in the hollow rigid body and reduce the pressure acting on the gas hydrate layer and the gas hydrate is decomposed into gas and water when the pressure acting on the gas hydrate layer is less than the balance pressure; 3) the decomposed gas escapes upward, is discharged through the gas collecting pipe and is collected.

Owner:SICHUAN UNIV

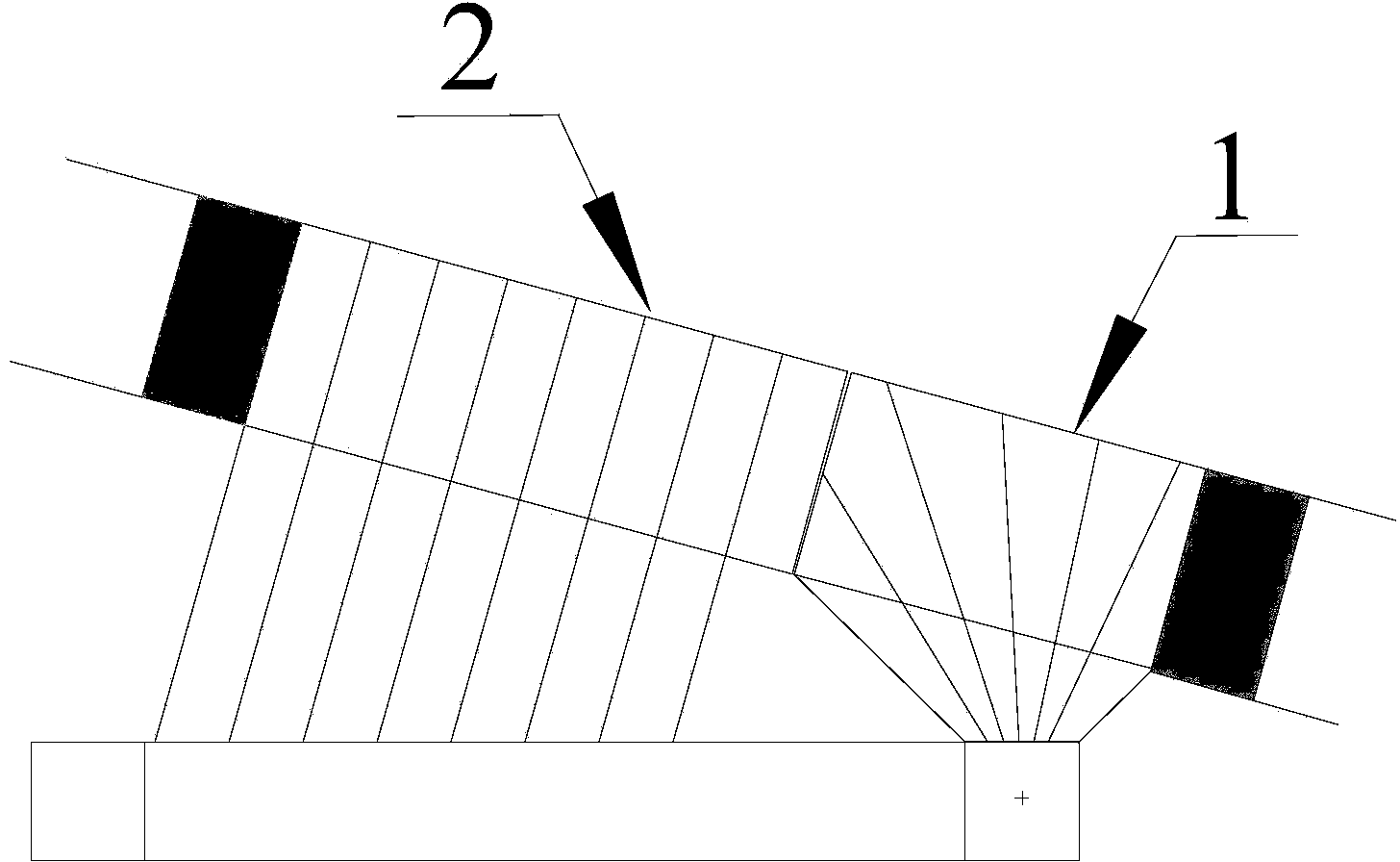

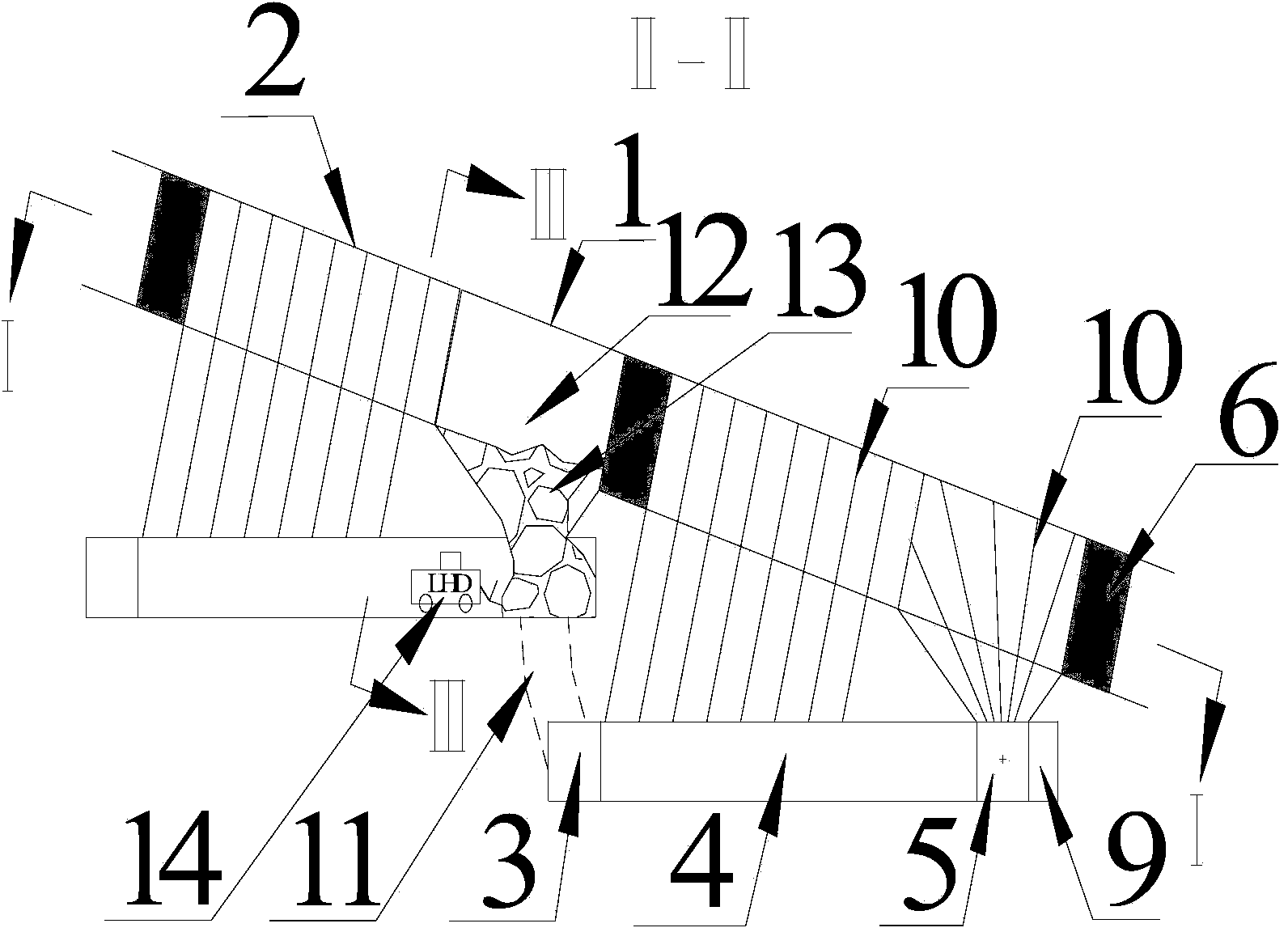

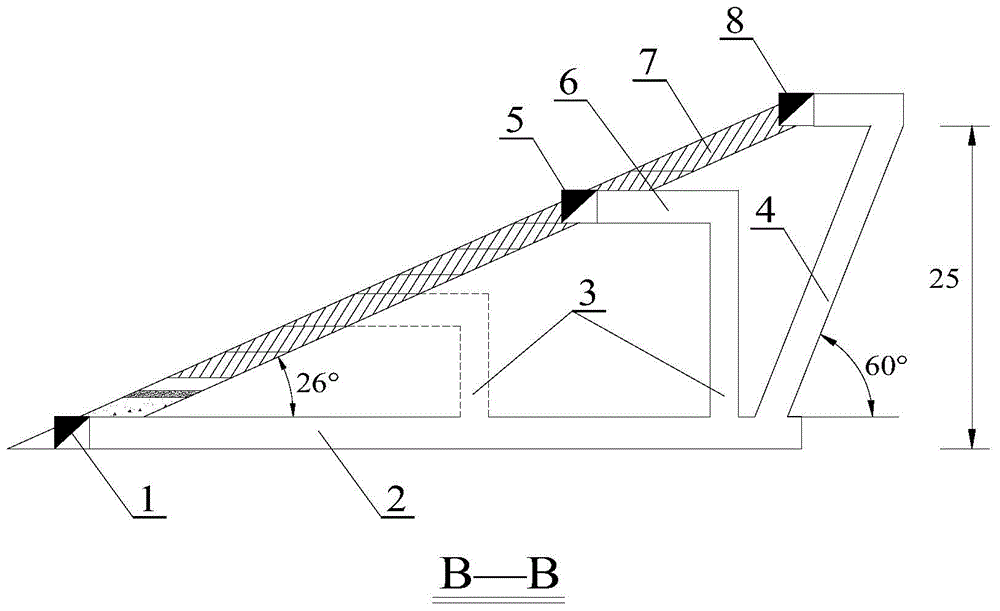

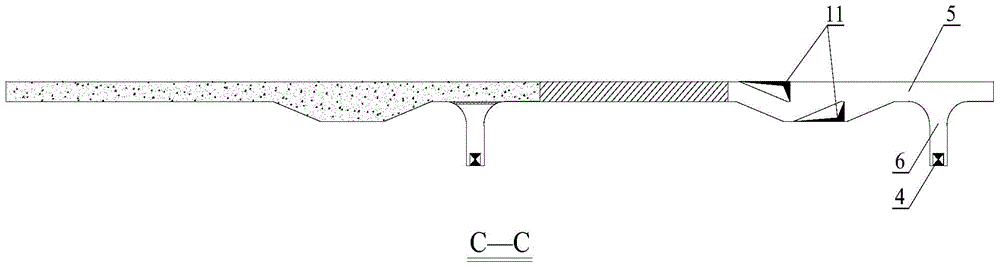

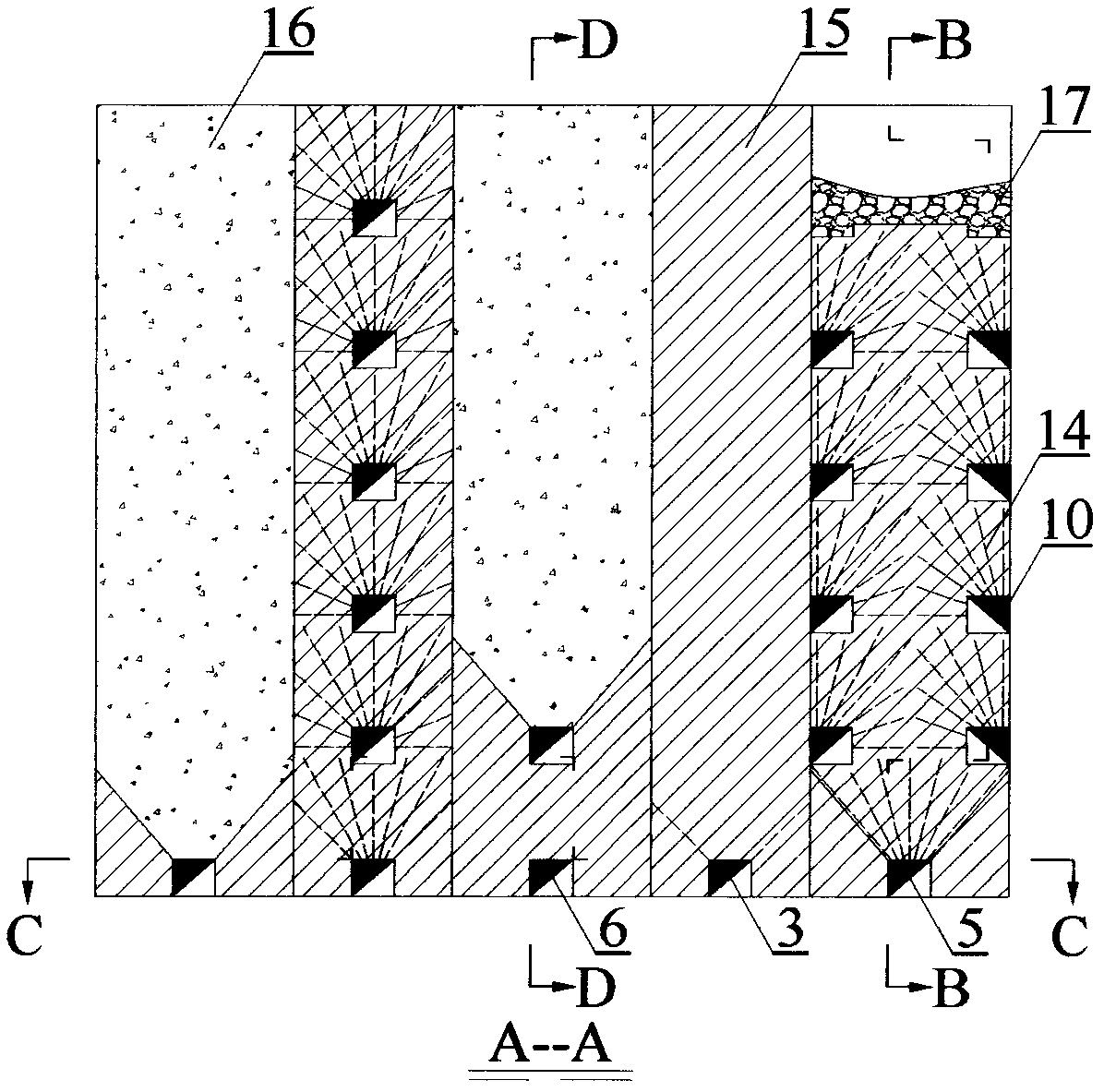

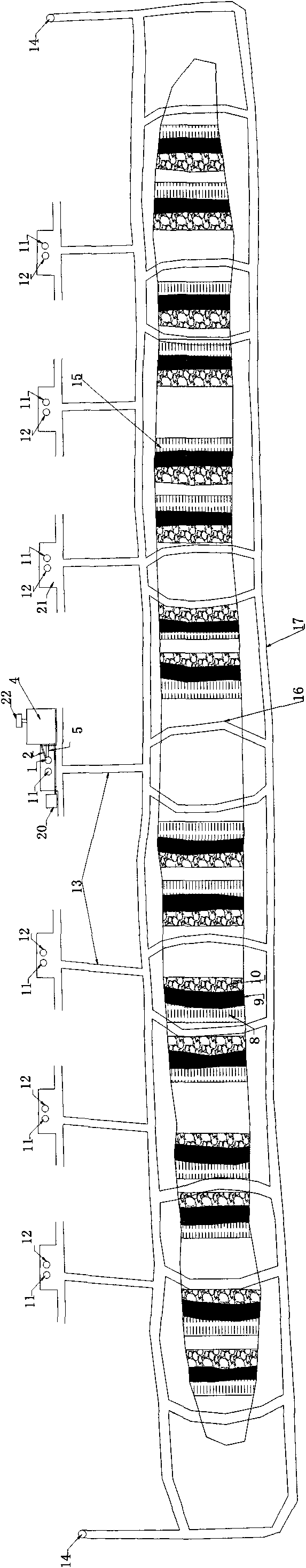

Novel mining method of gently-inclined thin and medium thickness ore bodies

InactiveCN103590831ARealize complementary advantagesJob safetyUnderground miningSurface miningWorkloadStoping

The invention discloses a novel mining method of gently-inclined thin and medium thickness ore bodies. According to the method, ore bodies in one stope are stoped by dividing the stope into two stope areas through steps: firstly, stoping is performed at the stope area (1) by using a pillarless sublevel caving method: the ore bodies are directly caved in single sublevel by using medium-length blastholes; a certain empty area formed after ore removal is used as a free surface for stoping of the stope area (2); then, the stoping is performed at the stope area (2) by using a blasting force carrying mining method; fan-shaped medium-length blastholes are arranged in a manner perpendicular to the ore body tendency, and are filled with powder according to sections, the decking parts are the parts from the lower disc boundaries of the ore bodies to the hole bottoms; the empty area formed during the stoping of the stope area (1) is used as a free surface for blasting row by row; ores in the stope area (2) are thrown in the empty area by using the blasting force. The method integrates the pillarless sublevel caving method and the blast force carrying mining method, so that the supporting difficulty and the workload are reduced, the operation is safer, the mining cost is low, and the labor productivity is high.

Owner:UNIV OF SCI & TECH BEIJING

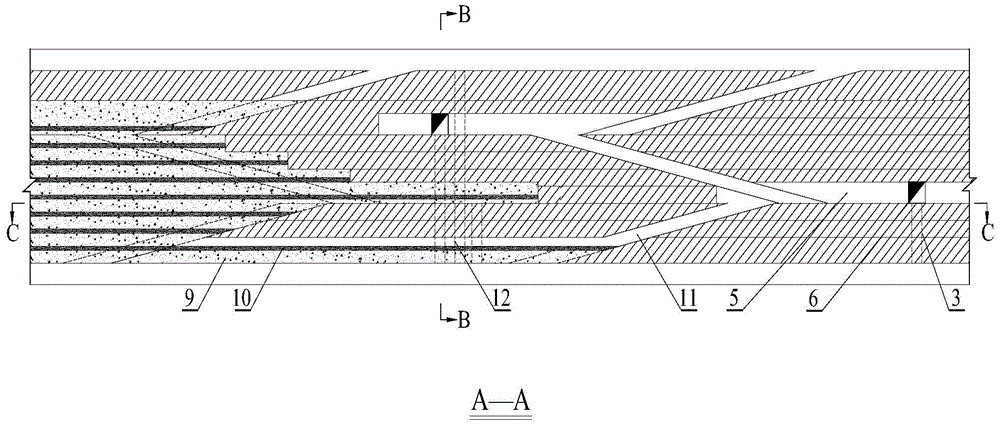

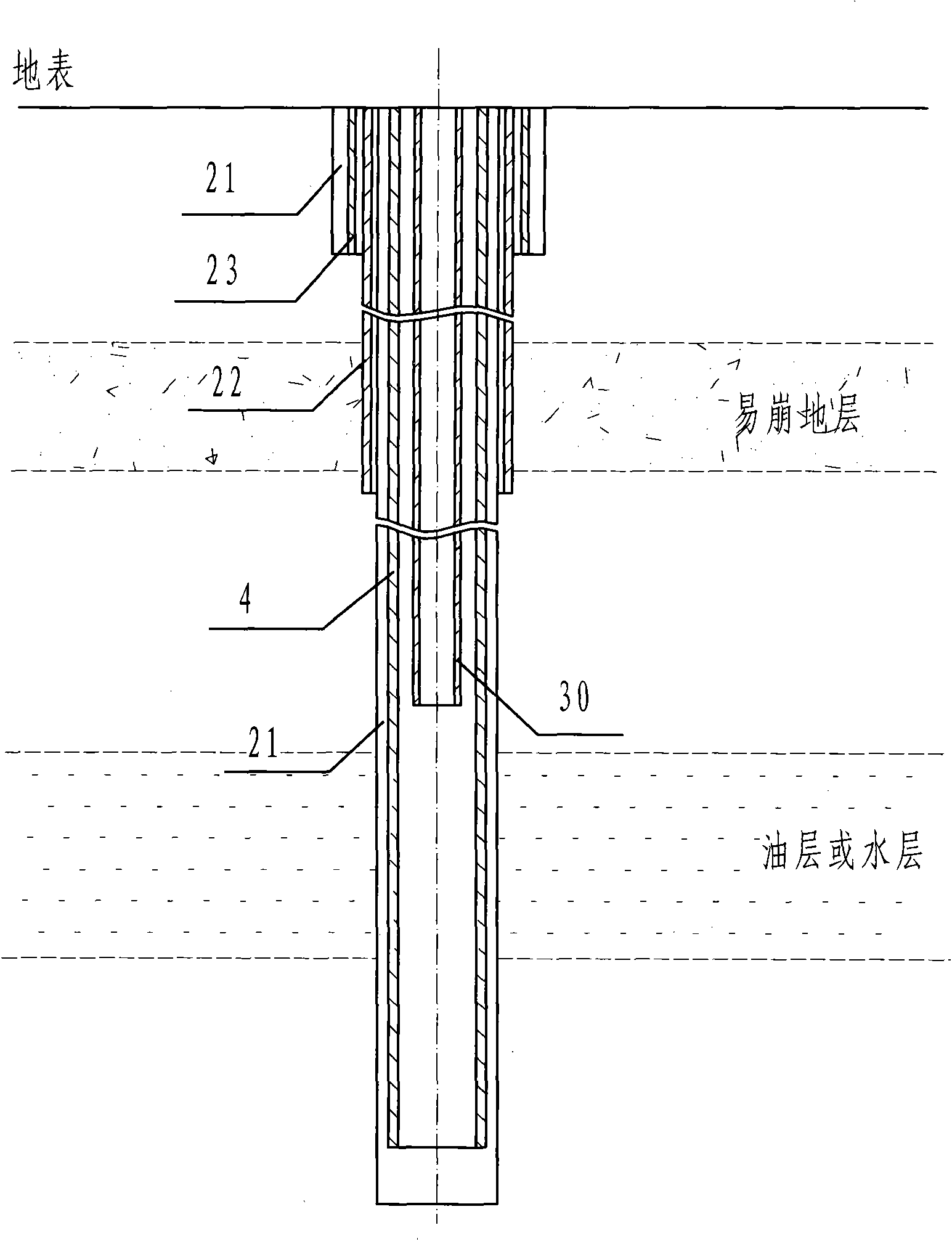

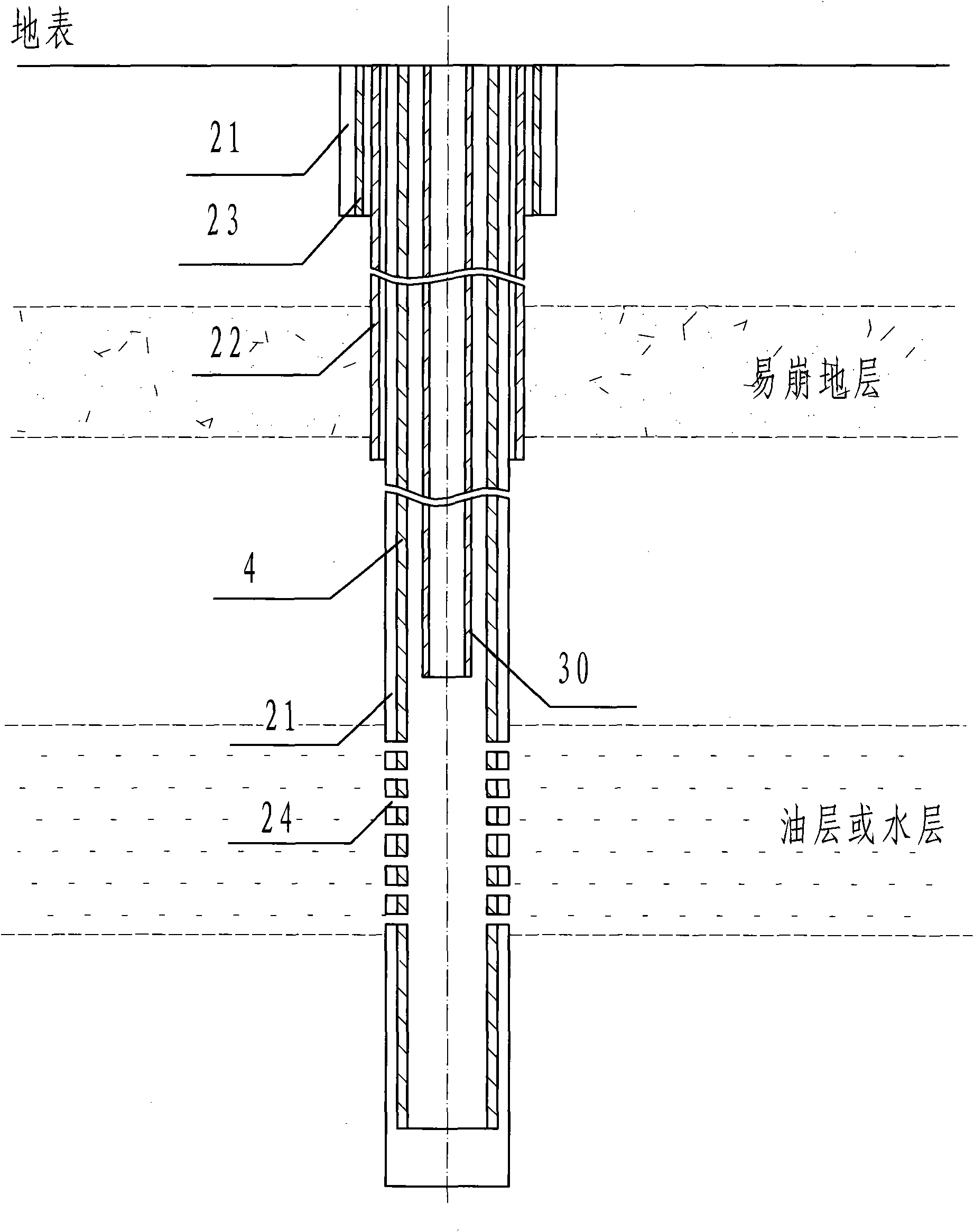

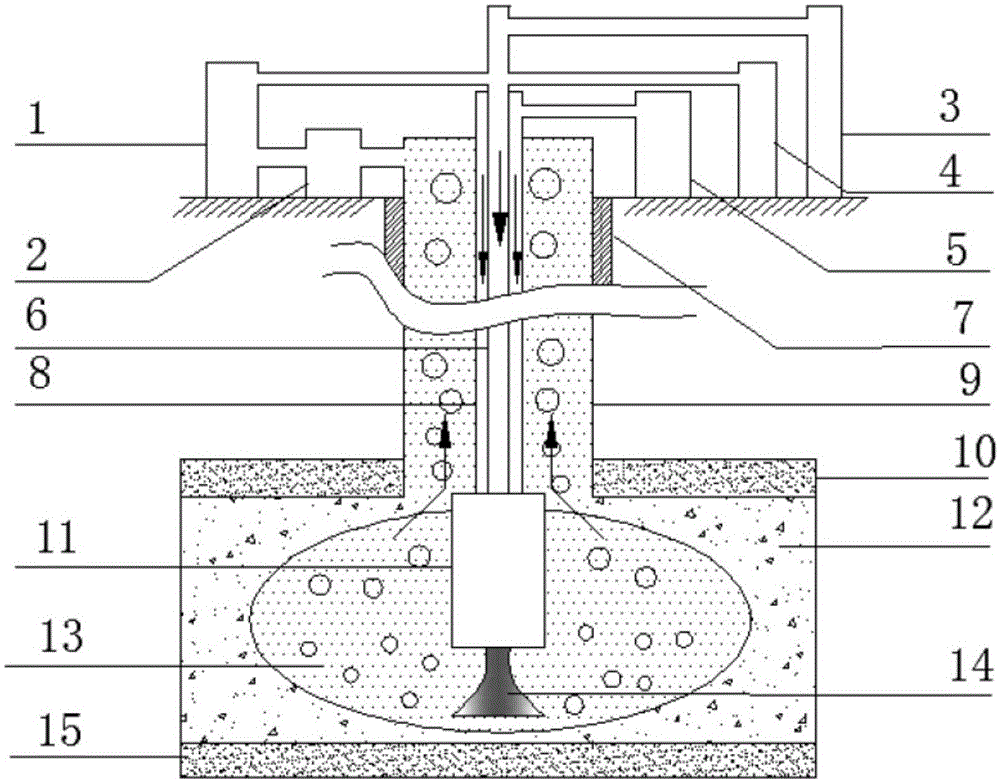

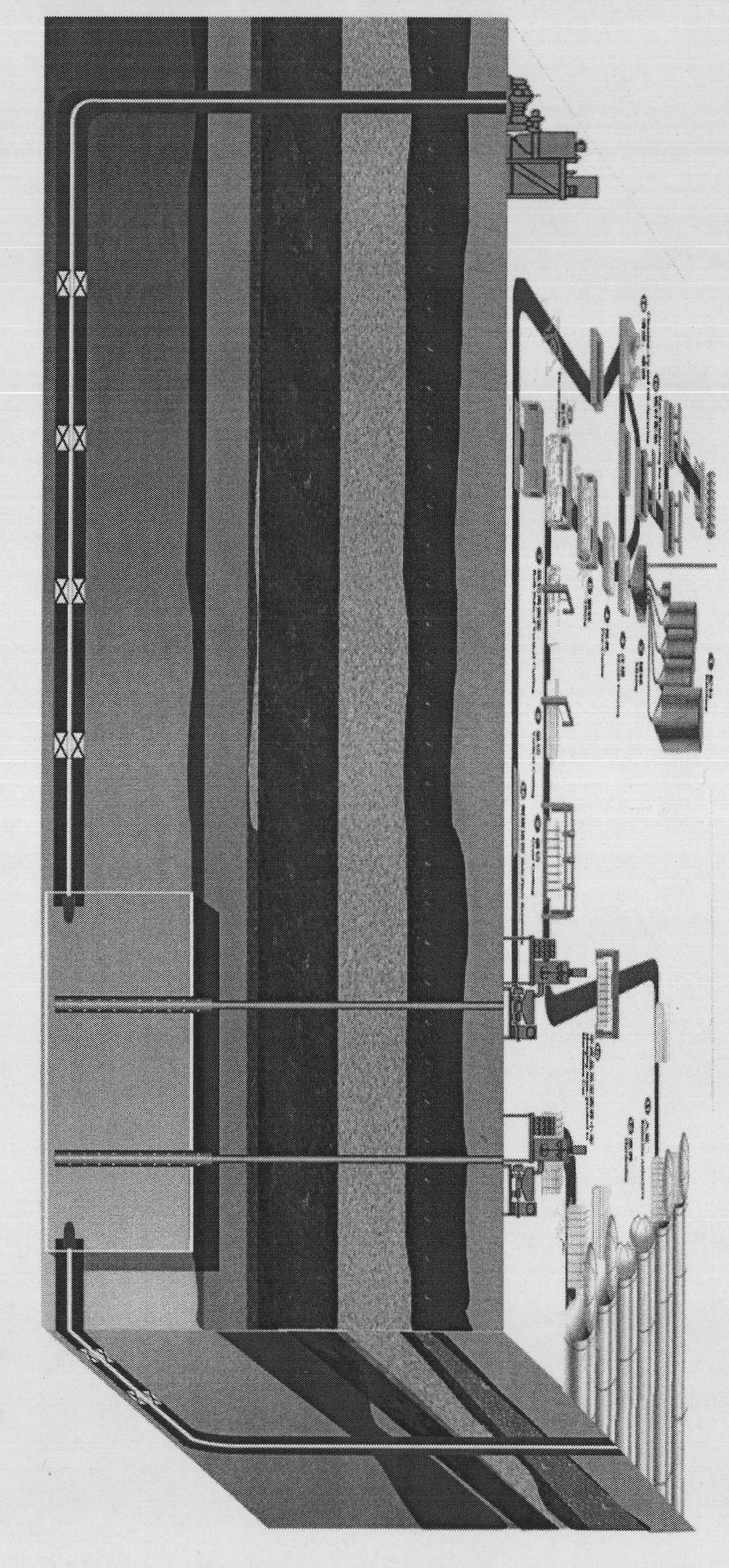

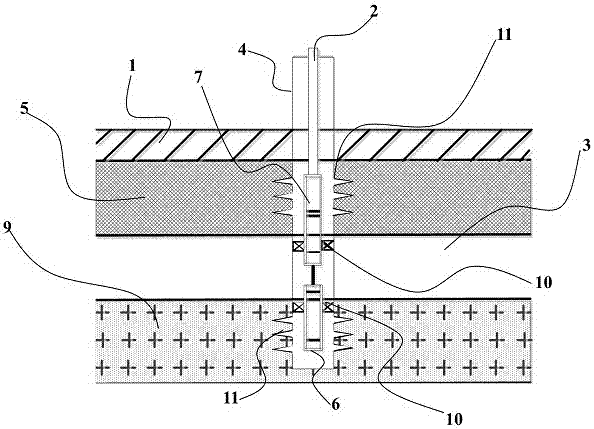

Method and device for exploiting aquo-complex through combination of pressure reducing technology and hydraulic fracturing technology

ActiveCN103498648AMining is effectively realizedMining realizedConstructionsFluid removalEngineeringProcess engineering

The invention discloses a method and device for exploiting aquo-complex through the combination of the pressure reducing technology and the hydraulic fracturing technology. Double pitshaft sleeve tubular columns are designed. An outer pitshaft tubular column is used for exploiting natural gas aquo-complex from storage layers in the mode of reducing pressure and pumping gas. Various sensors are arranged at the bottom of an inner pitshaft tubular column and are used for detecting and monitoring conditions of the storage layers. Meanwhile, fracturing liquid is injected into the storage layers according to actual requirements, and manual hydraulic fracturing operation is conducted, so that the permeability of the storage layers is improved, and fluid smoothly flowing through channels and smooth conduction of pressure reduction and gas exploitation are ensured. The method comprises the steps of constructing an exploiting well, and arranging the double pitshaft sleeve tubular columns and relevant exploiting and monitoring devices; reducing pressure of natural gas aquo-complex and decomposing the natural gas aquo-complex; monitoring storage layer information, and utilizing the hydraulic fracturing technology to ensure the permeability of the storage layers; collecting and outputting natural gas and water. The method and device integrate the advantages of the pressure reducing technology and the advantages of the hydraulic fracturing technology, can be used for exploiting natural gas aquo-complex resources and can grasp and feed back storage layer change information at the same time so as to achieve the purpose of economic, efficient and safe commercial exploitation of natural gas aquo-complex resources.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

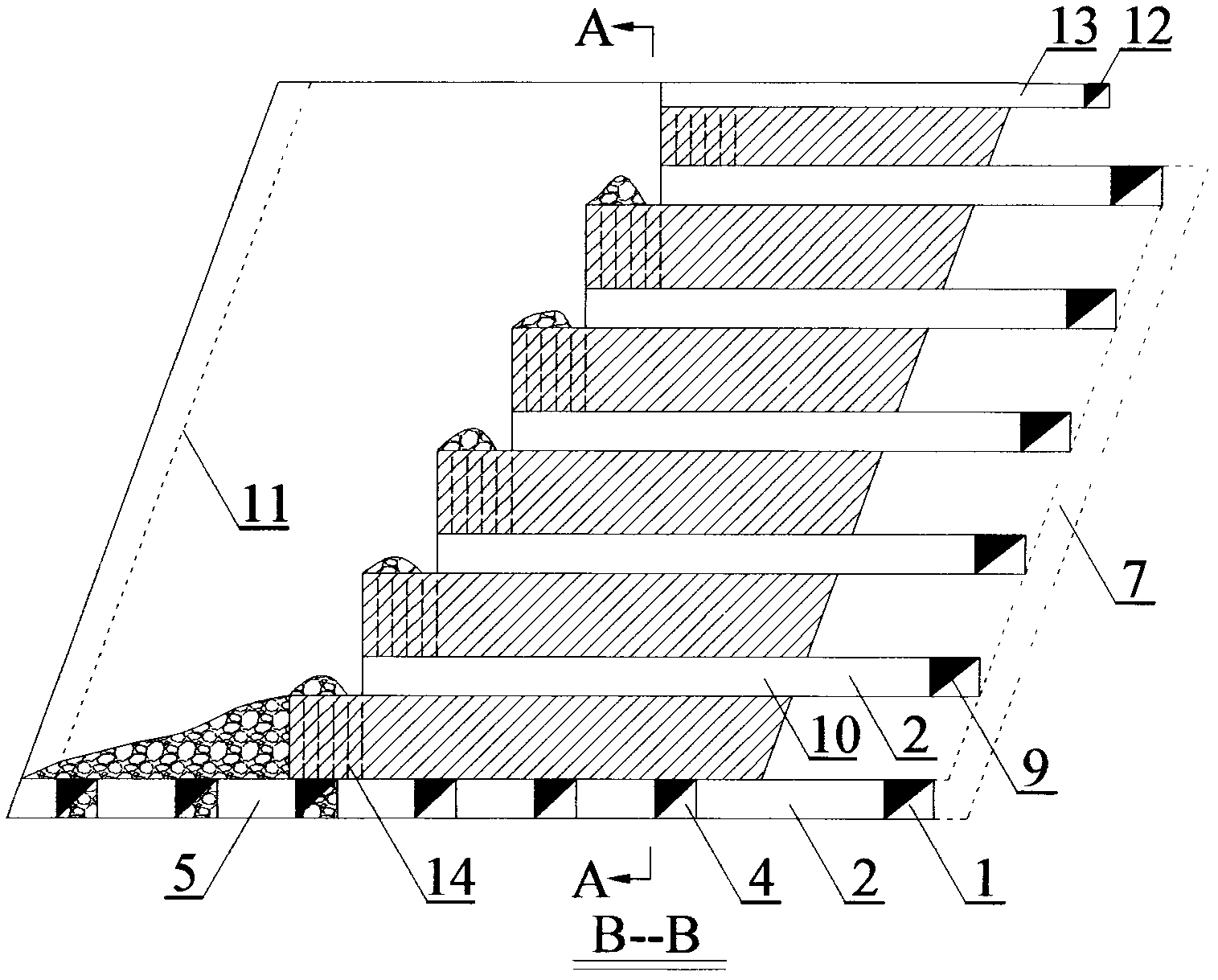

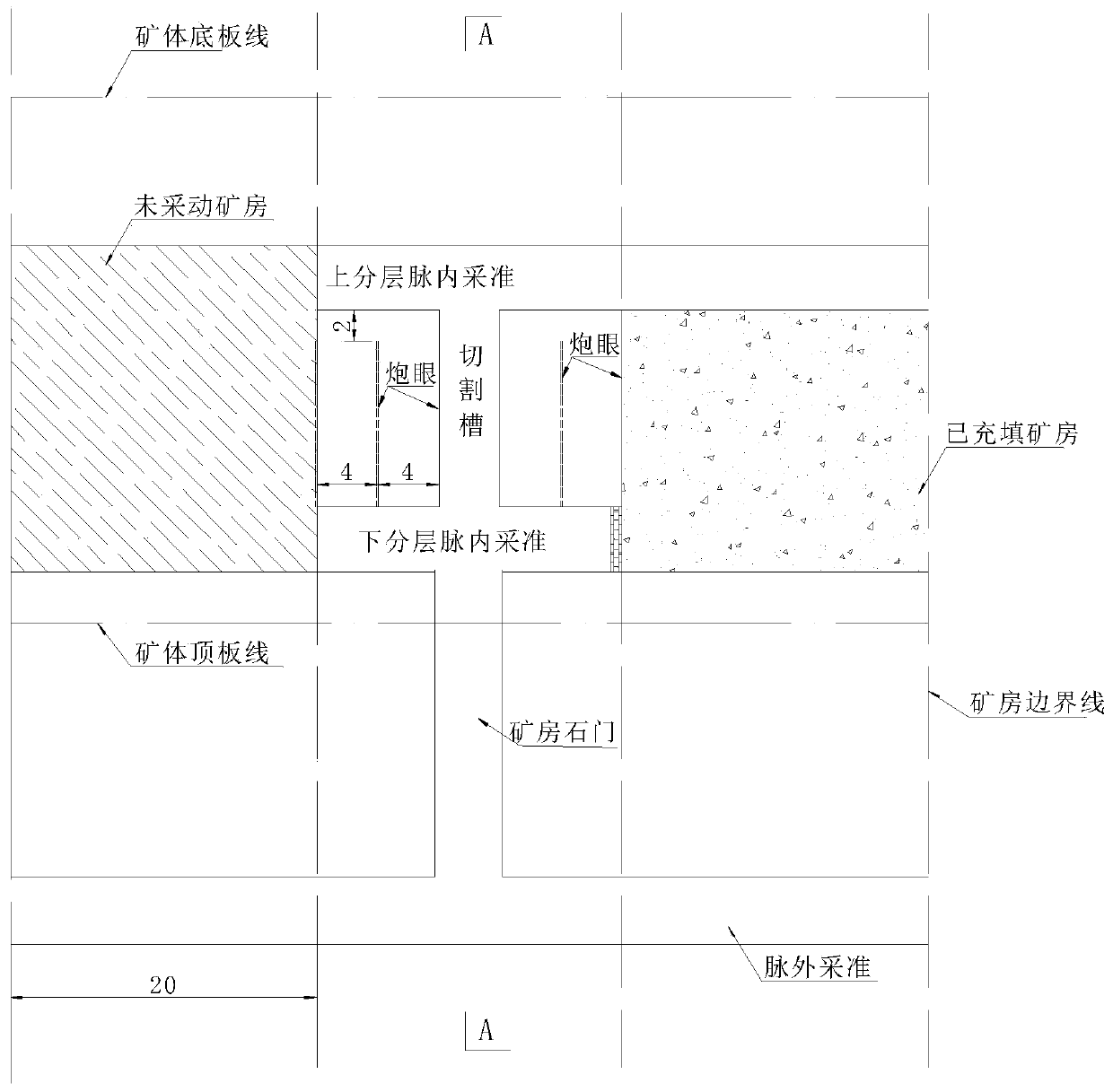

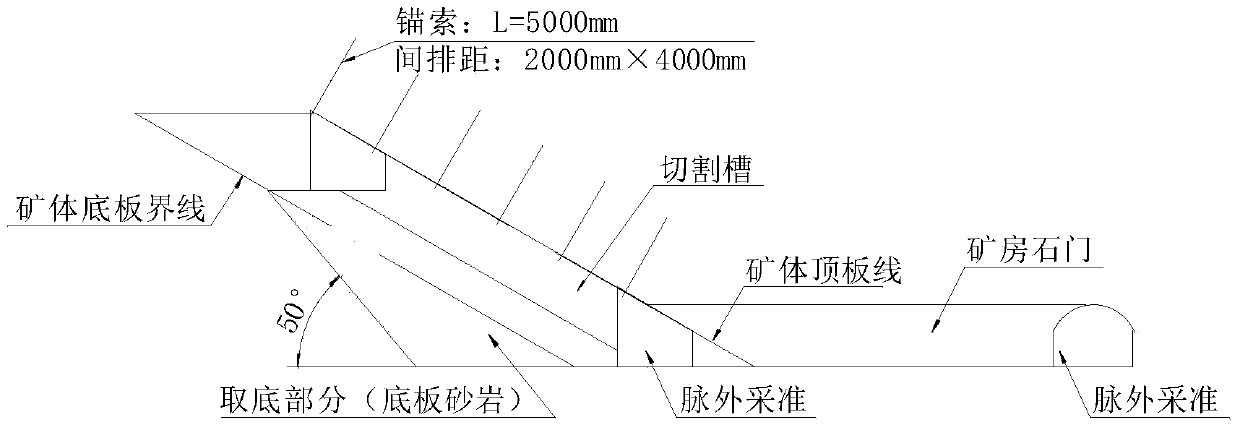

Upward cut-and-fill mining method for in-vein slope ramp of gentle dip thin vein

ActiveCN104060991AEnsure safetyImprove recovery efficiencyUnderground miningSurface miningVeinCut and fill

The invention discloses an upward cut-and-fill mining method for an in-vein slope ramp of a gentle dip thin vein. The method comprises the following steps: stoping layers of an ore body, tunneling a cross gateway from a bottom middle haulage drift to the ore body, tunneling a diagonal slope ramp along the vein to rise for certain height, and tunneling a slice drift, a reversing chamber and a sectional ore removal draw shaft forwards along the vein, wherein the reversing chamber and the sectional ore removal draw shaft are perpendicular to the slice drift; reversely tunneling the diagonal slope ramp along the vein from one side of the slice drift to rise for the certain height, and tunneling the slice drift, the reversing chamber and the sectional ore removal draw shaft along the vein; dividing a stope by using the diagonal slope ramp as the boundary, continuously propelling from one end of the vein to the other end of the vein, reaching all the layers of the ore body by virtue of the diagonal slope ramp which is tunneled in the vein, and sequentially stoping and filling from bottom to top by virtue of each layer stoping unit in the stope. The upward cut-and-fill mining method for the in-vein slope ramp of the gentle dip thin vein is high in mechanization degree, small in out-vein stope preparation engineering amount, low in labor intensity, low in ore dilution loss, safe to operate and high in efficiency.

Owner:河南发恩德矿业有限公司

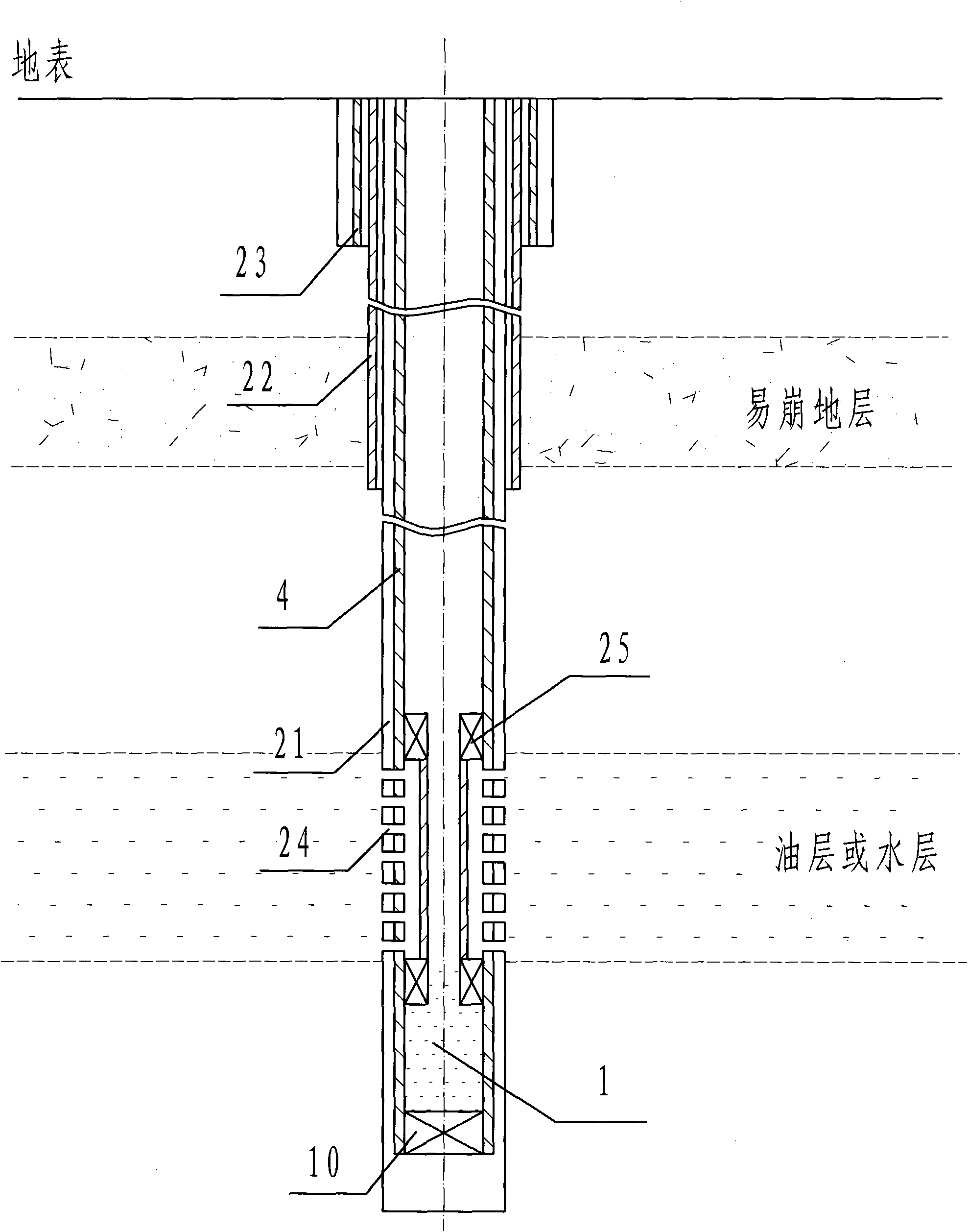

Method and device for conducting and recycling subterranean heat with production casings

ActiveCN101832673ALarge caliberAdd depthOther heat production devicesGeothermal energy generationThermal energyBoiling point

The invention relates to a method and device for conducting and recycling subterranean heat with production casings. The method comprises the following steps: previously selecting a discarded or idle or in-use well, respectively sealing the perforated pores at the well bottom and oil water layer by utilizing separators, closely connecting a heat radiator with the well mouth, vacuumizing the interior, and pressing a given amount of low boiling point medium or water to form a heat transfer unit for recycling subterranean heat with low-cost long-distance gravity assisted heat pipes. The low boiling point medium or water in the heat transfer unit vaporizes after absorbing subterranean heat, the vapor from latent heat of vaporization is continuously transferred to the heat radiator on the upper part, and the heat of the vapor from latent heat is transferred to a natural low-temperature liquid or temperature difference power generation module in the heat-storage energy-accumulation tank through the wall of the heat radiator, thereby recycling heat. The invention is used for solving the problems of high investment and difficulty in large-scale application in the application of subterranean heat, and greatly reduces the cost for utilizing subterranean heat.

Owner:大庆市三仁新能源科技开发有限公司

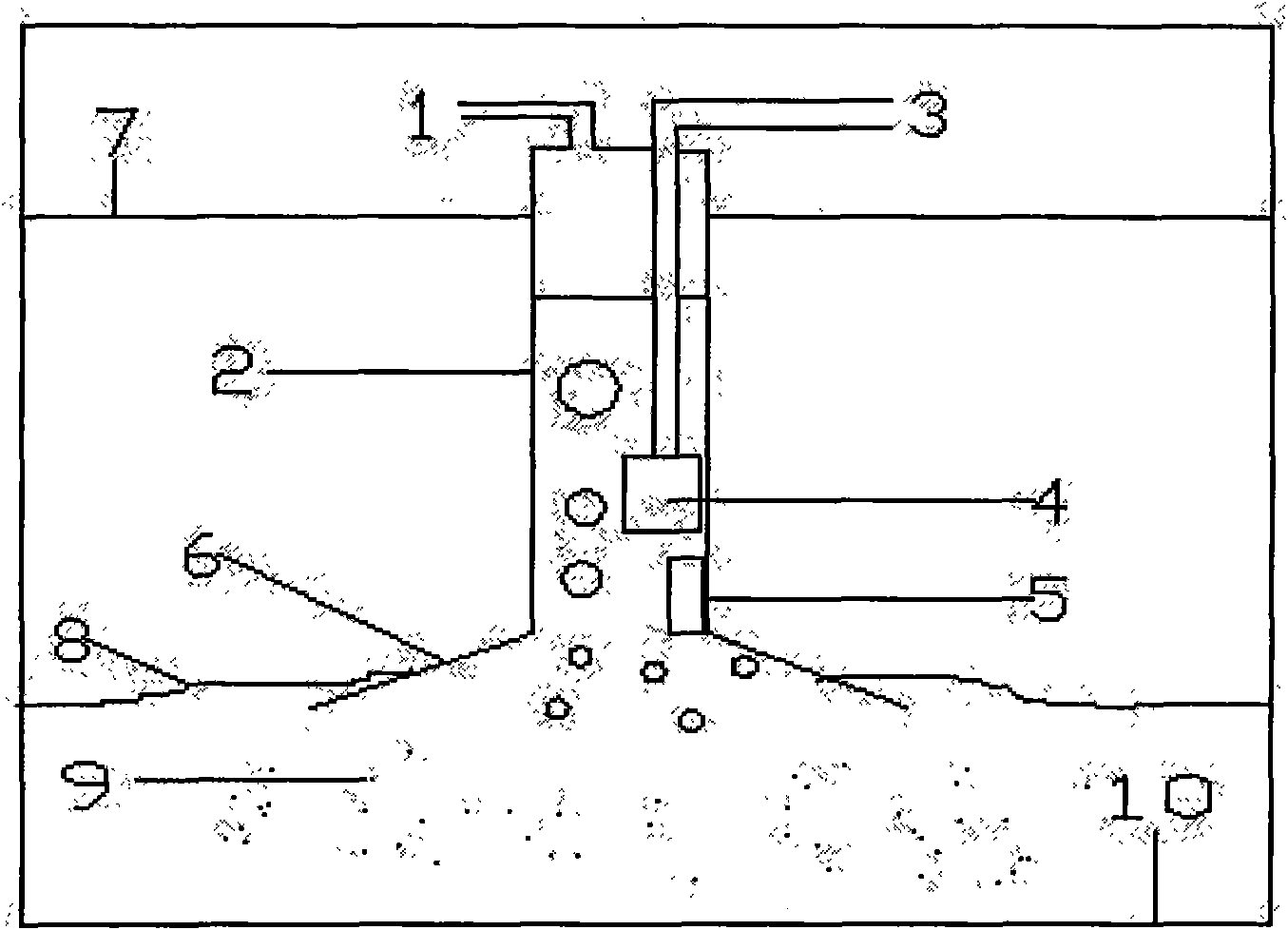

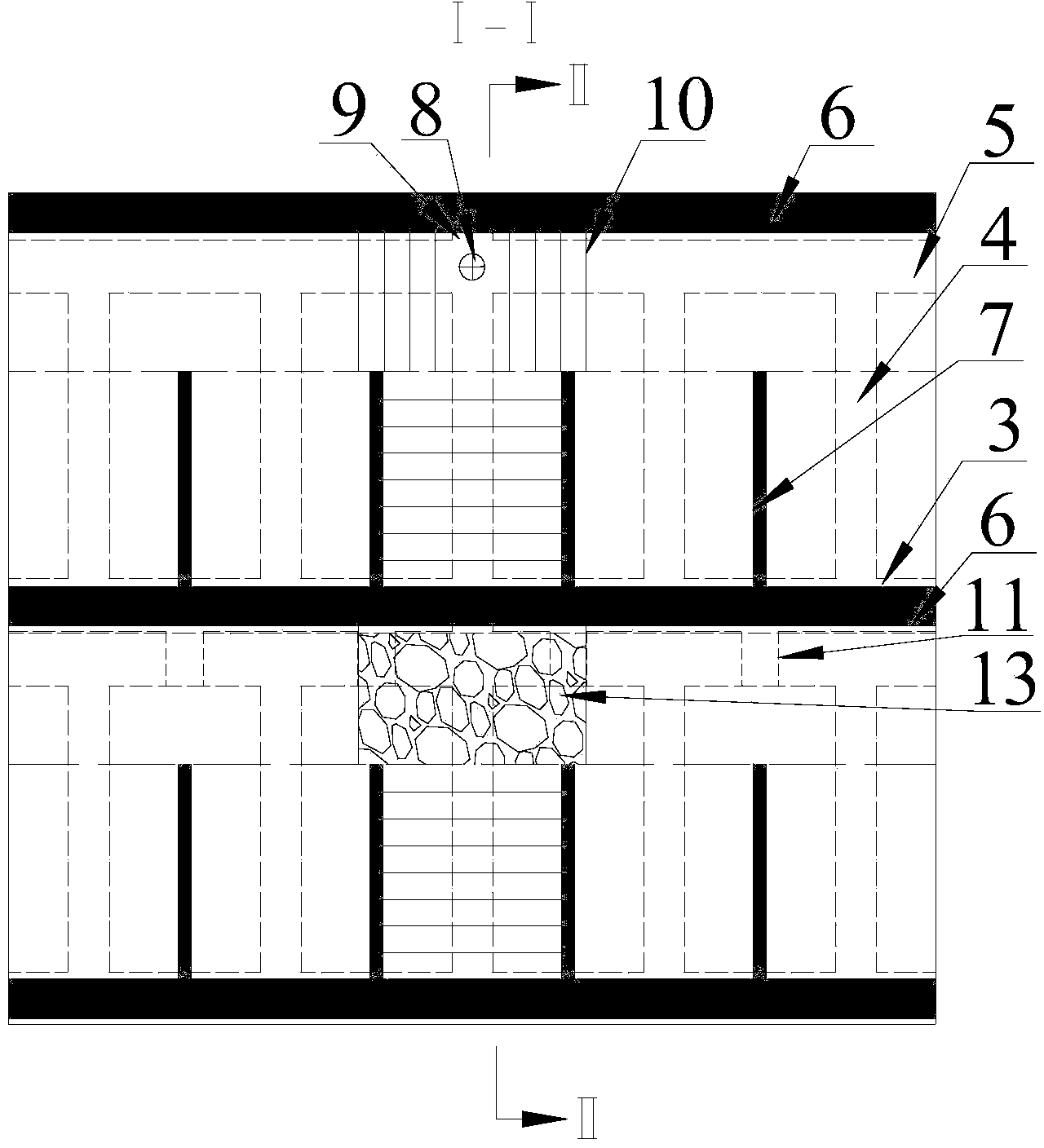

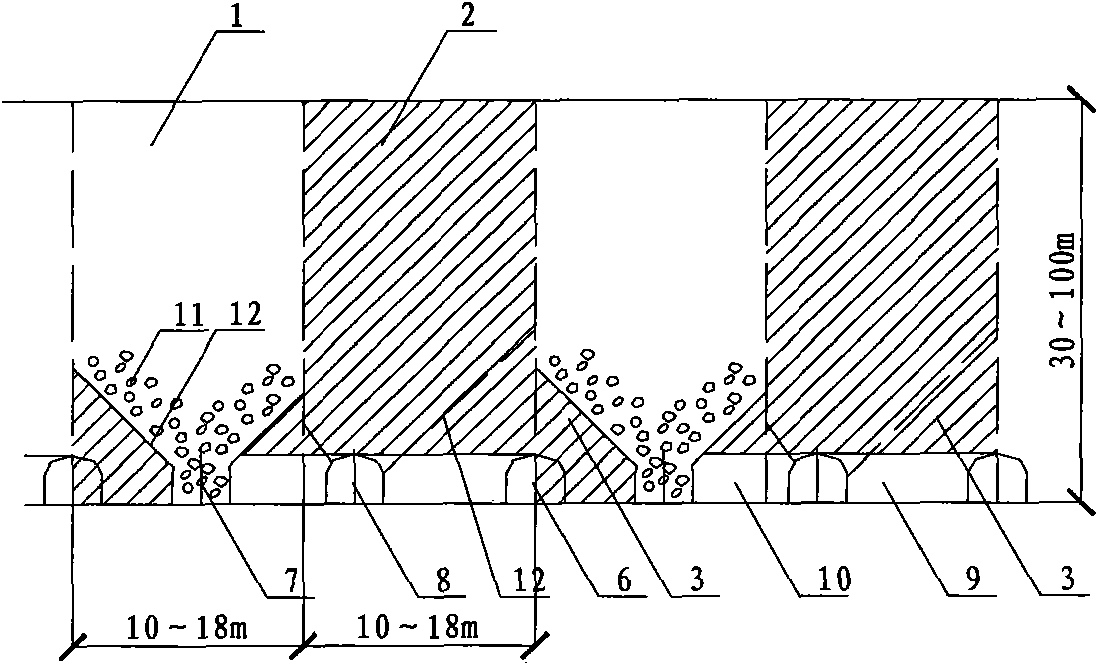

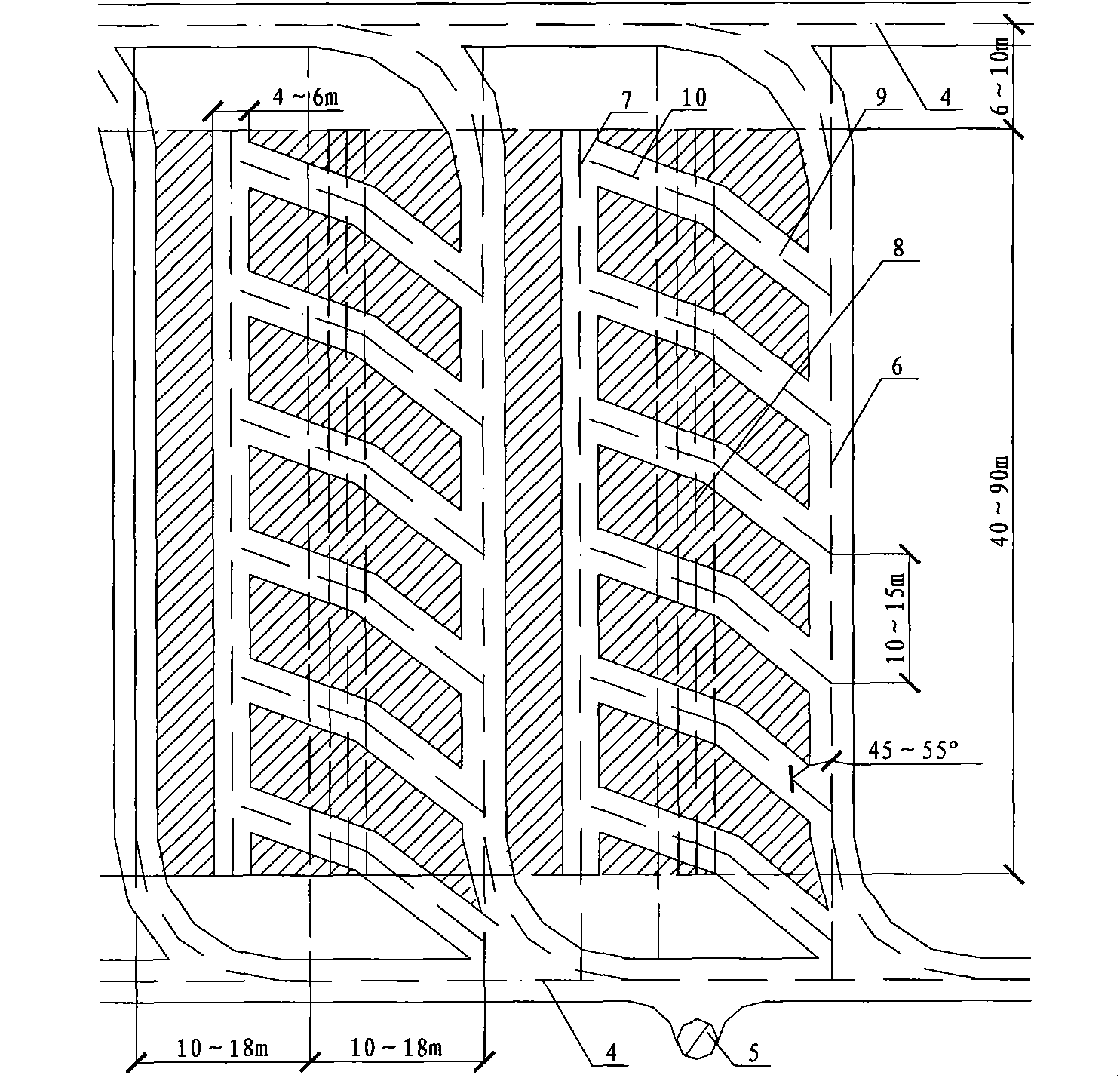

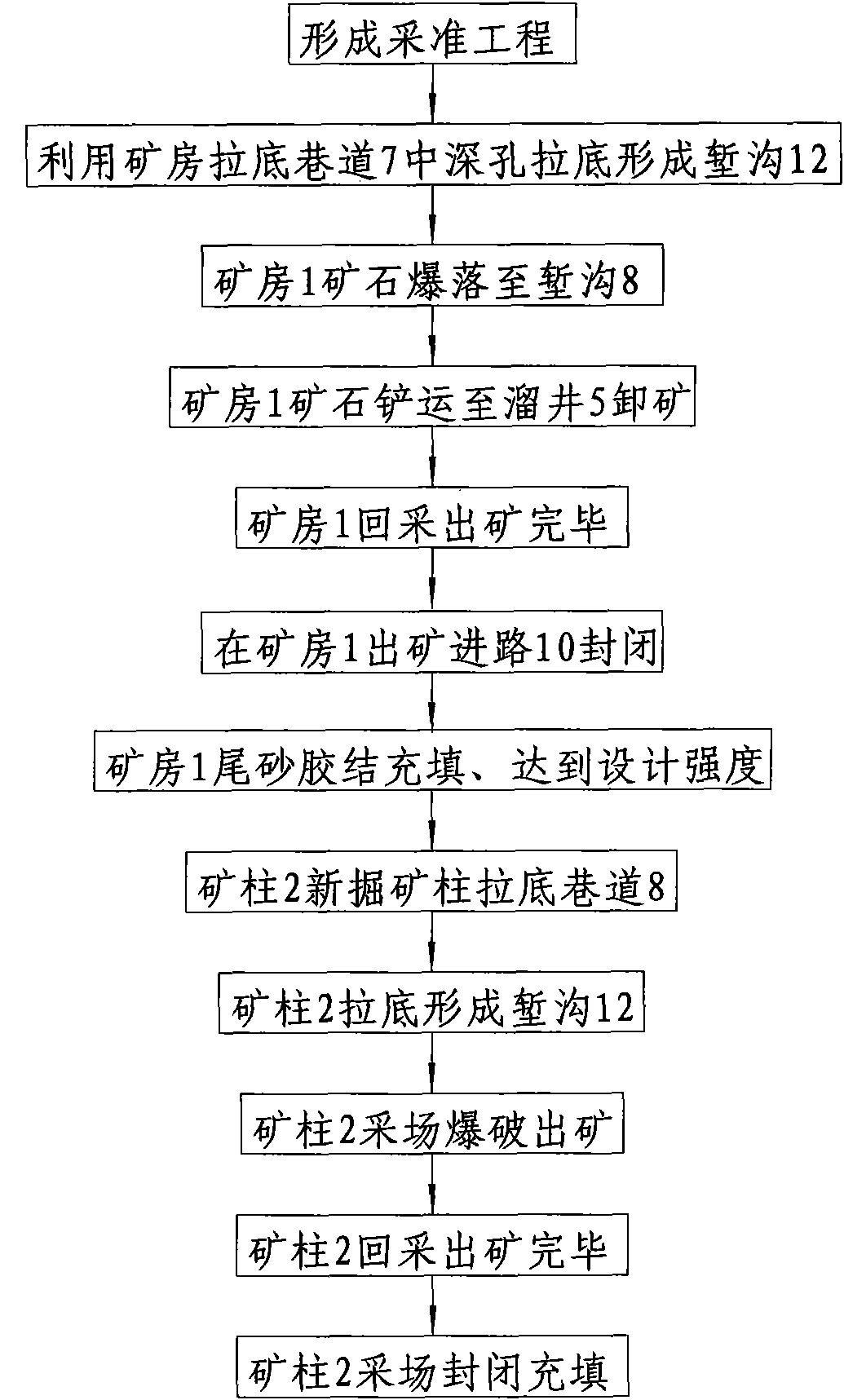

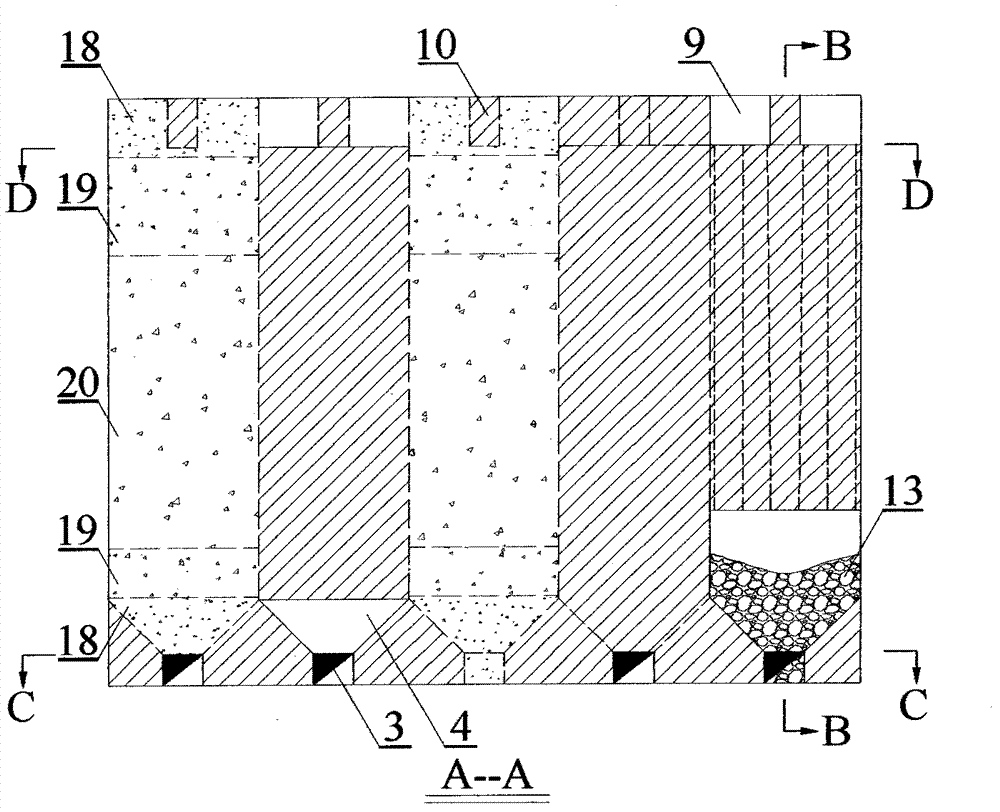

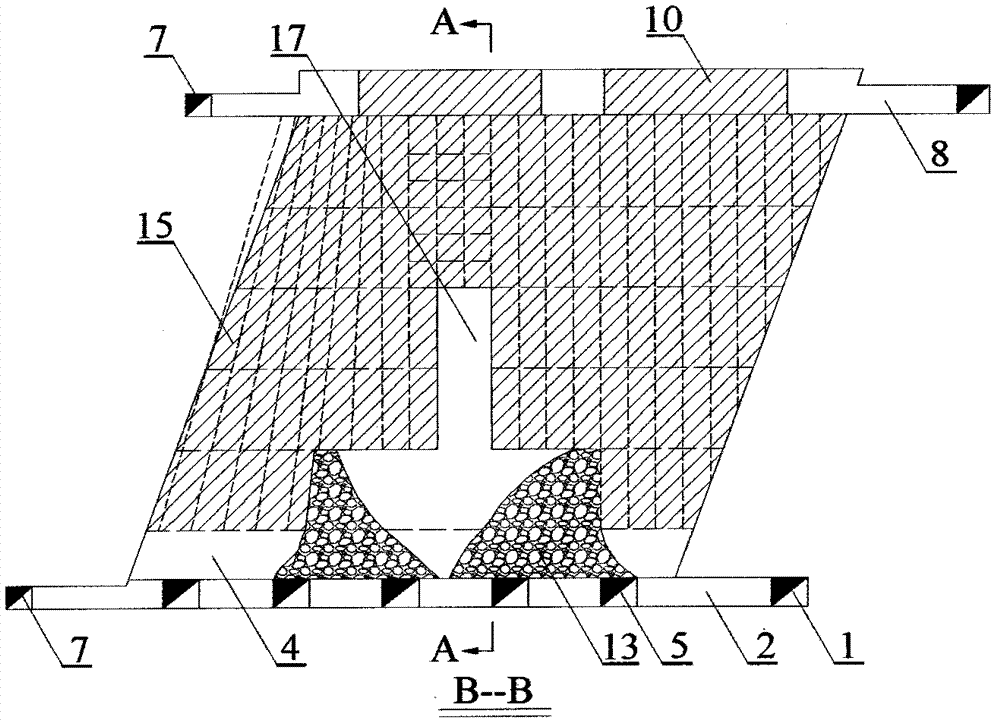

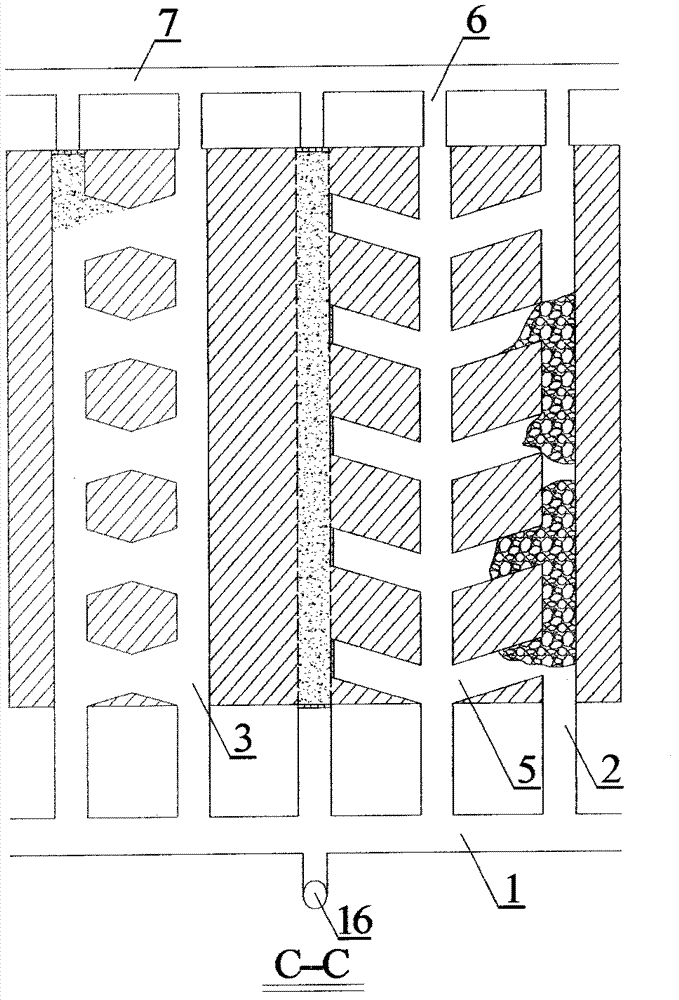

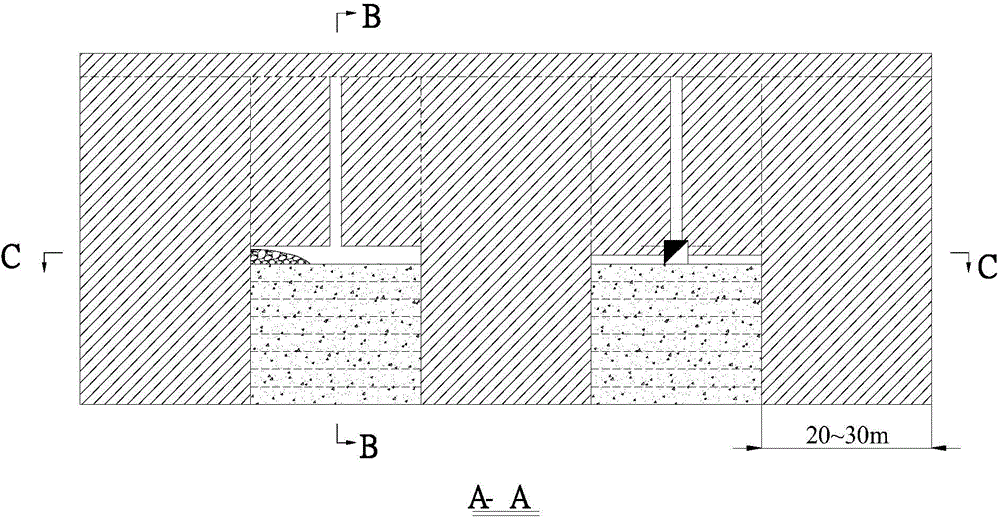

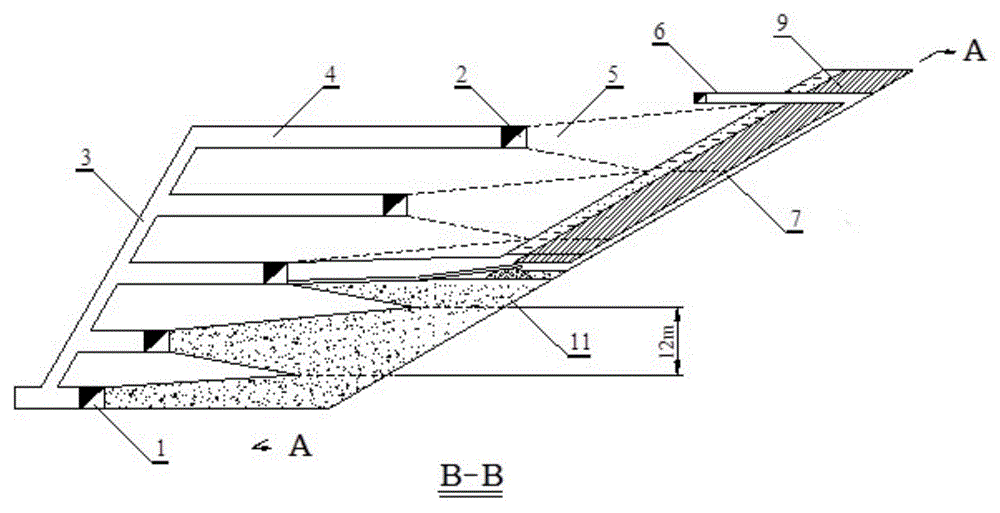

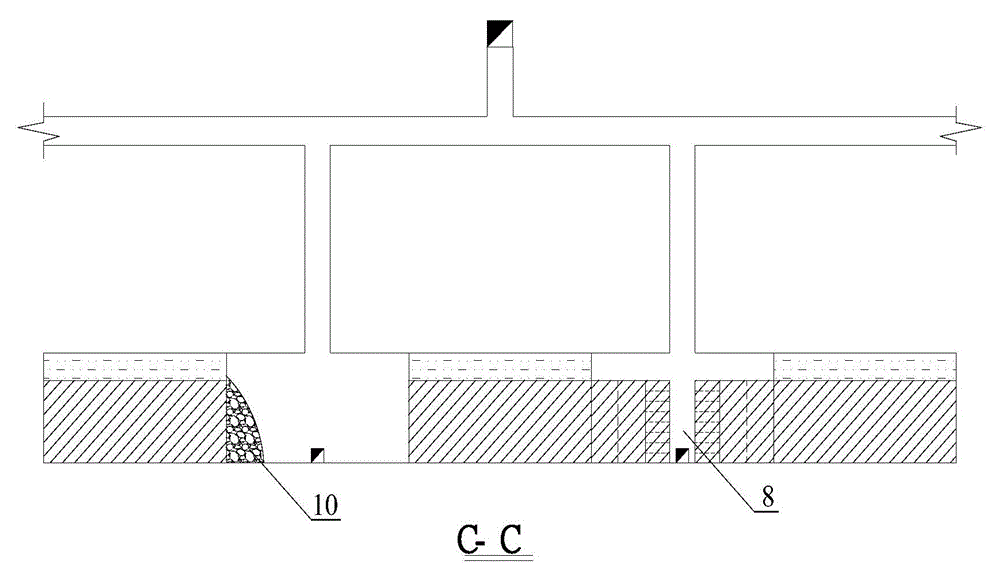

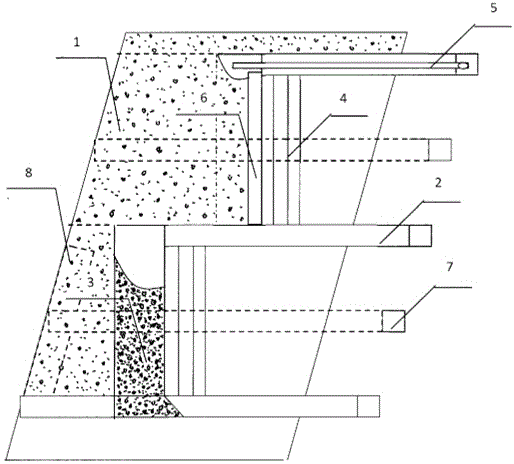

Stope bottom structure suitable for underground two-step mining and production process thereof

ActiveCN102011589ASmall amount of workAvoid secondary excavationUnderground miningSurface miningStructure of the EarthEngineering

The invention discloses a stope bottom structure suitable for underground two-step mining and a production process thereof. An underground stope is divided into a room stope and a pillar stope. Bottom pillars are reserved according to the bottom structure forms. Along-vein travelling roadways (4) and across-vein ore-drawing roadways (6) are utilized to handle the ores. The blasting ores (11) in the stope are blasted and fall in trenches (12). A scraper pours the ores into an ore pass (5) via a common ore-drawing drift (9) and a room ore-drawing drift (10). After tailing-cemented filling of the room of the stope, new pillar undercutting roadways (8) are driven in the bottom pillars (3) during mining the pillar stope. The trenches (12) for room mining are formed through drilling and blasting and undercutting. The goafs formed after mining and ore-drawing of pillars (2) are filled. The stope bottom structure can serve two stopes, reduce the quantities and support quantity, reduce the mining and development ratio of mining, improve the stability and save the mining cost and preparation time of two-step mining.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

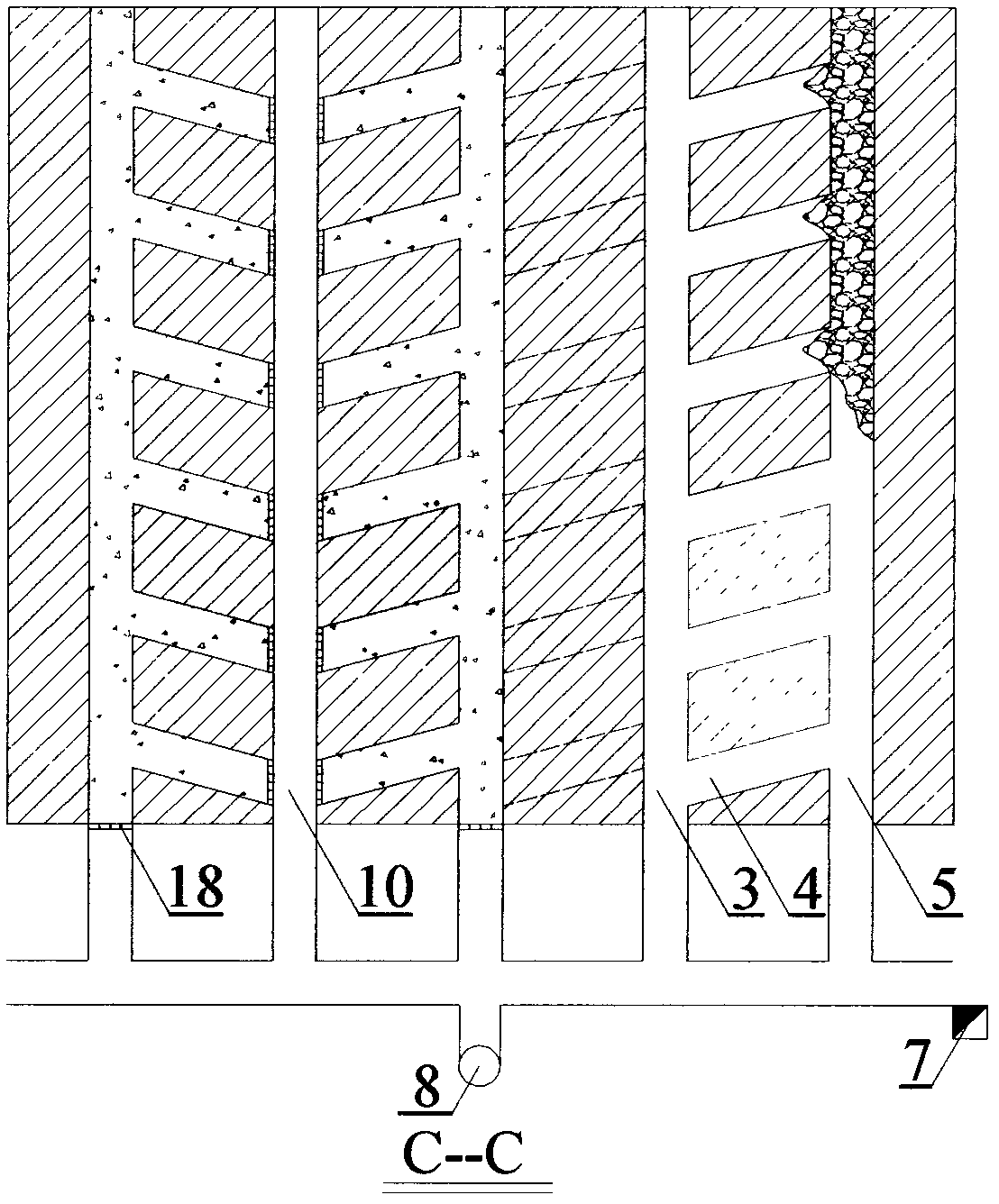

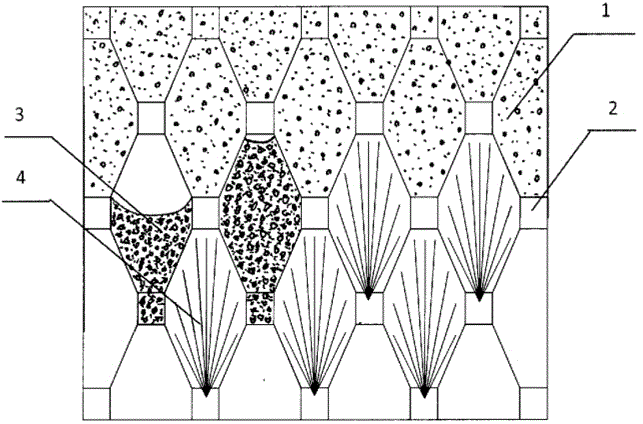

Room-and-pillar major-diameter longhole inverted-step-like segmented lateral caving subsequent filling mining method

InactiveCN102953732AImprove mining safetyGood for stope stabilityUnderground miningSurface miningRoom and pillar miningSingle stage

The invention discloses a room-and-pillar major-diameter longhole inverted-step-like segmented lateral caving subsequent filling mining method for a steeply-inclined medium-thick orebody and gently-inclined and inclined extremely-thick orebodies with steady surrounding rocks at upper and lower panels. The method is characterized in that: an orebody is divided into panels, then the panels are divided into continuous single-stage stoping units, and mining is carried out by using a stoping sequence of stoping one unit every other unit, i.e., mining a room at first and a pillar next; when mining a room, a V-shaped trench bottom structure is employed, a longhole drilling chamber is arranged at the upper part of stope, bar-shaped pillars are left to support the top plate of the chamber, a down-the-hole drill is used for drilling rocks, an explosion mode of light section VCR method underholing inverted-step-like lateral caving with a common emulsion explosive is employed, access roads towards the room for ore removal are arranged in the pillars, and cemented roof-contact filling is employed; and during stoping of the pillars, access roads for ore removal are dug towards the pillars in cemented bodies in the room, a stoping manner for the pillars is identical to that for the room, and non-cemented filling with tailings and waste is employed. The method provided by the invention has the advantages of high security, a low production cutting ratio, great production capacity, low operation cost and small loss and dilution of resources.

Owner:彭康

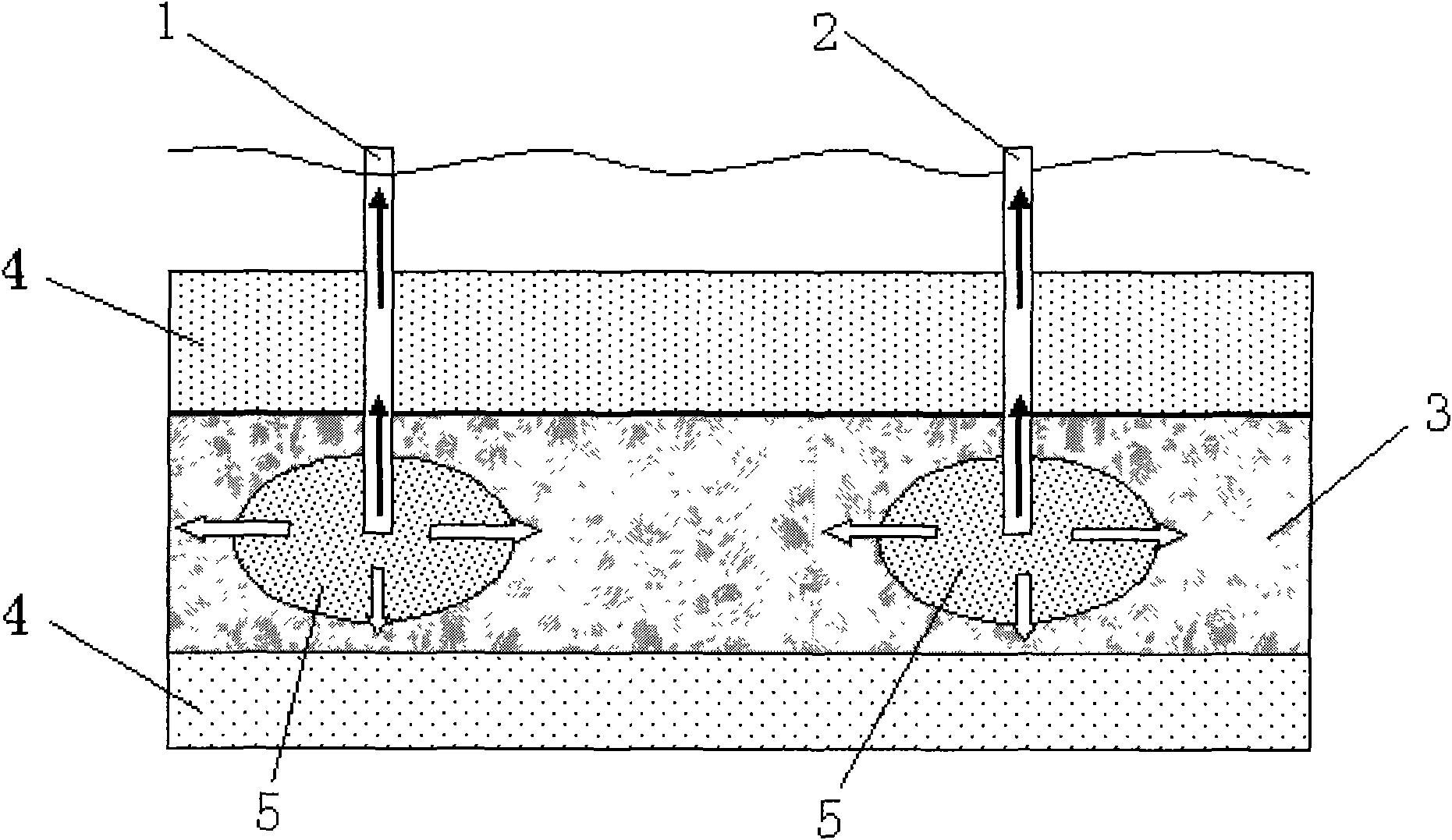

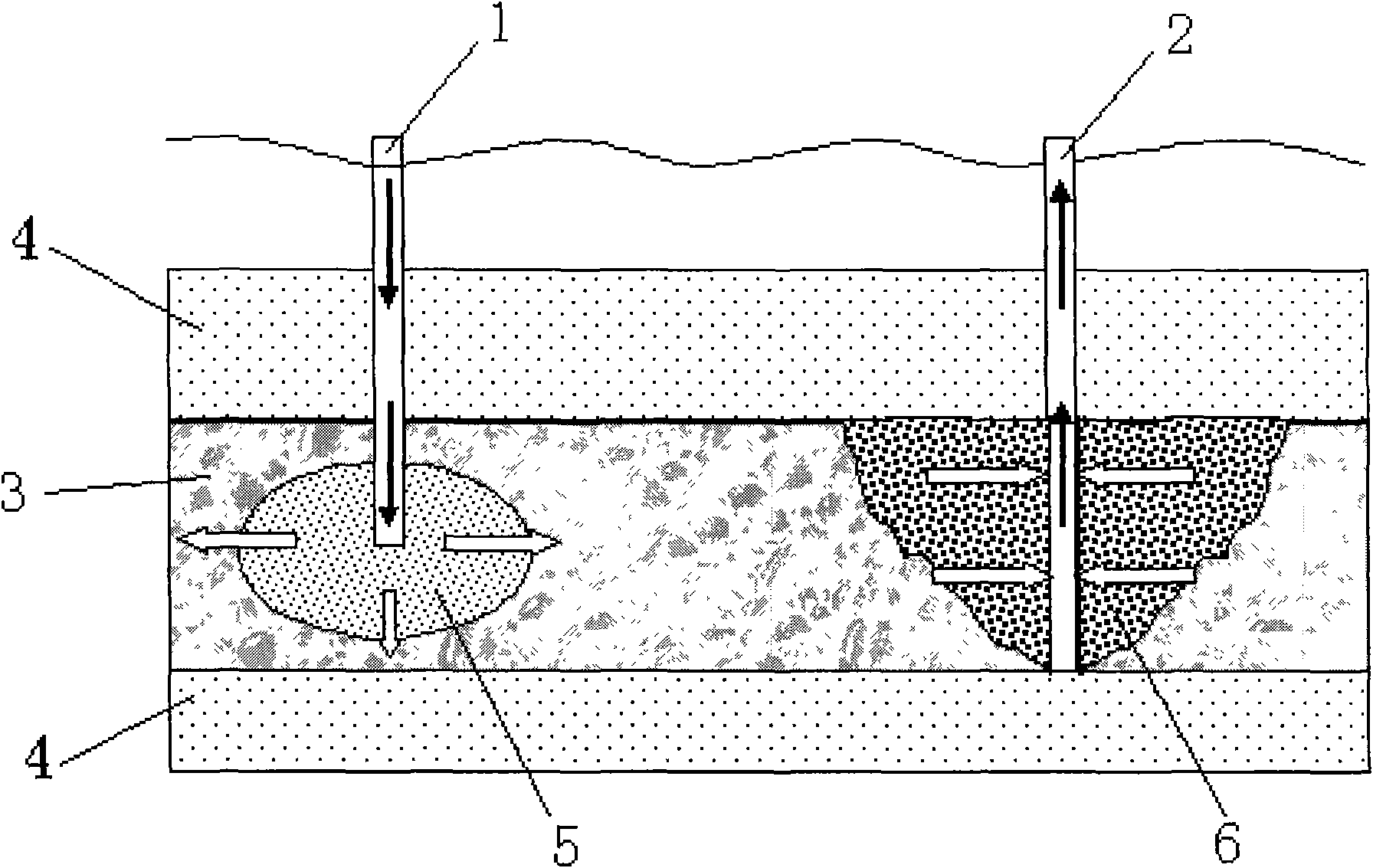

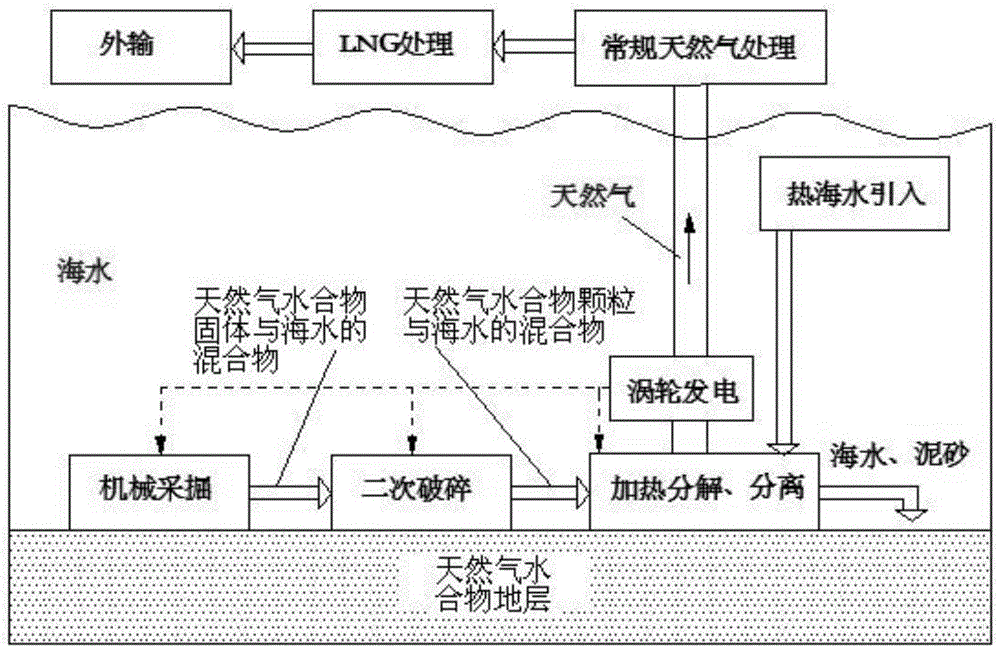

Exploitation method for sea bed gas hydrate

The invention relates to an exploitation method for sea bed gas hydrate, which comprises a depressurization decomposition stage and an ocean surface-layer warm water injection stage, wherein in the depressurization decomposition stage, the bottom parts of two exploitation wells can be drilled into the gas hydrate layer, the two exploitation wells can be used for sucking the fluid in the gas hydrate layer by a down-hole pump, the bottom-hole producing pressure can be controlled by controlling the delivery of the down-hole pump, and high-permeable areas are formed around wellbores at the bottomparts of the two exploitation wells; after the depressurization decomposition stage achieves the preset depressurization production time, the ocean surface-layer warm water injection stage is carriedout; in the ocean surface-layer warm water injection stage, a water injection pump is started for injecting ocean surface-layer warm water into the first exploitation well, the gas hydrate is decomposed, and the decomposed gas is output from the second exploitation well with lower pressure under the driving of pressure. The method can be widely used for exploiting the sea bed gas hydrate and particularly for exploiting the gas hydrate in the tropical sea area, the subtropical zone sea area, temperate zone sea area and other sea areas with ocean surface-layer warm water.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Boundary-controlled room column type sublevel open stoping subsequent stage filling mining method

InactiveCN103032070AImprove mining safetyMining safetyUnderground miningSurface miningEngineeringControl room

The invention discloses a boundary-controlled room column type sublevel open stoping subsequent stage filling mining method which is used for slight pitch-steep pitch very thick and big ore bodies with firm surrounding rocks of upper plates and lower plates. The method is characterized by comprising the following steps of: dividing a plate area of the ore body, incessantly dividing three ore rooms and two ore columns in the plate area, performing step-like retrusive sublevel rock drilling stage ore removal from an upper plate to a lower plate of the ore body by adopting bottom structures of V-shaped trenches, and connecting sublevel fringe drifts through a service raise; during mining of the ore rooms, respectively tunneling rock drilling cross drifts on the two sides of a stope, controlling the boundary of the stope by adopting pre-splitting blasting in side holes, arranging ore removal routes in the ore columns for ore removal, leaving a first sublevel in the middle ore room without mining, and performing top tight filling by adopting cemented bodies with different mixture ratios; and during the mining of the ore columns, tunneling the rock drilling cross drift at the center of the stope, arranging bilateral ore removal routes in the reserved sublevel in the middle ore room for serving the two ore columns for ore removal, and performing the top tight filling on the ore columns by adopting non-cemented bodies. The method has the advantages of high safety, great production capacity, low operation cost and low loss and dilution rate of ores.

Owner:彭康

Displacement developing method for artificial foamed oil of heavy oil reservoir

ActiveCN104265252AViscosity reduction by a large marginNot easy to degasFluid removalDrilling compositionFoaming agentHorizontal wells

The invention provides a displacement developing method for artificial foamed oil of a heavy oil reservoir. The method comprises the following steps: adopting a vertical well or a horizontal well to displace a well pattern; injecting an oil soluble viscosity reducer and a solvent based foaming agent in an injection well repeatedly and alternatively, or injecting an oil-in-water emulsified viscosity reducer solution and a high oil-resisting foaming agent in an injection well repeatedly and alternatively, wherein during the injection process, a producing well produces continuously. With the adoption of the method, the purposes that the heavy oil reservoir mined through steam injection and the heavy oil reservoir difficulty produced by a conditional mining method can be effectively produced and developed, heavy oil is economically and efficiently developed and the recovery efficiency is improved greatly are achieved.

Owner:PETROCHINA CO LTD

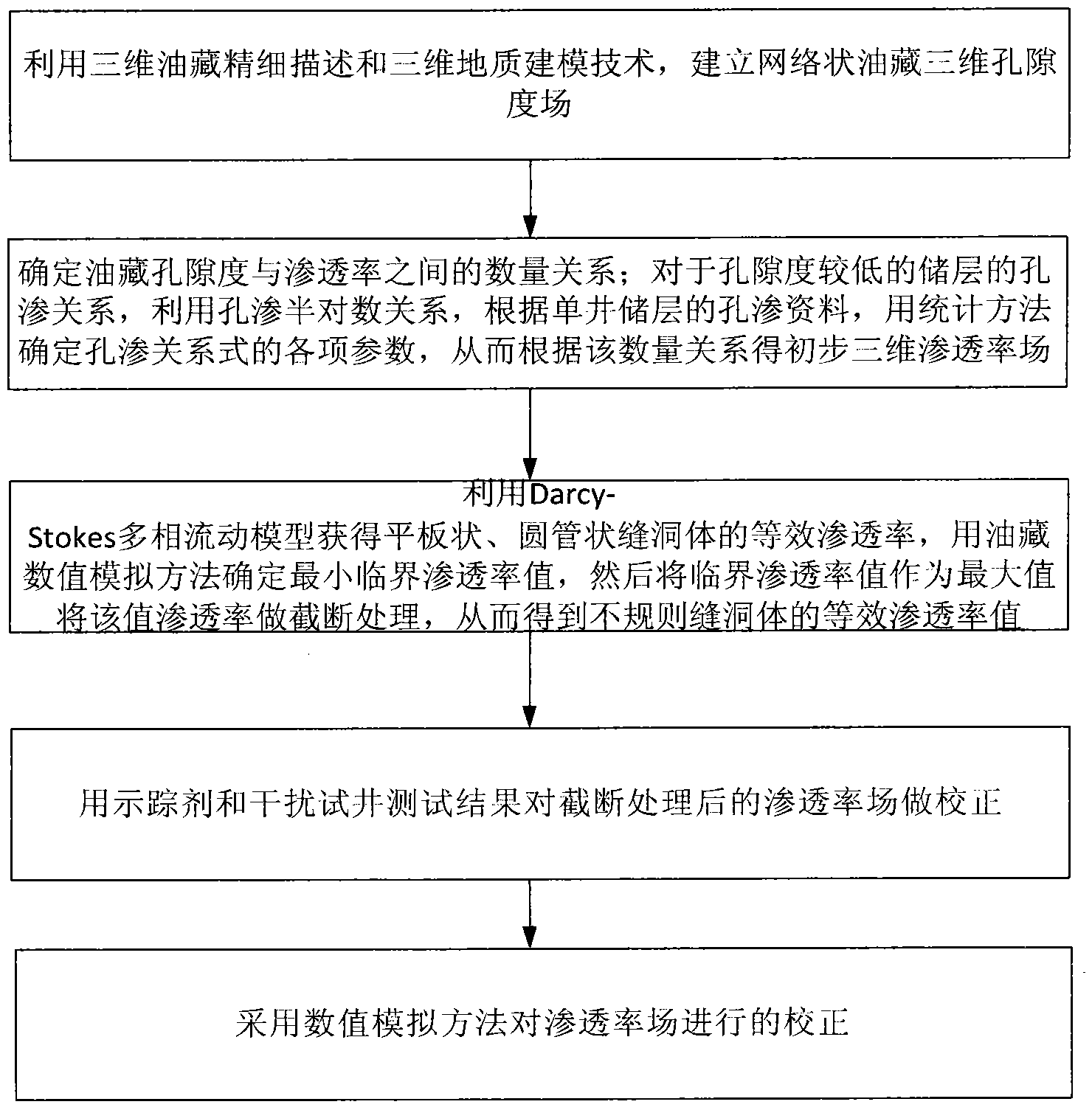

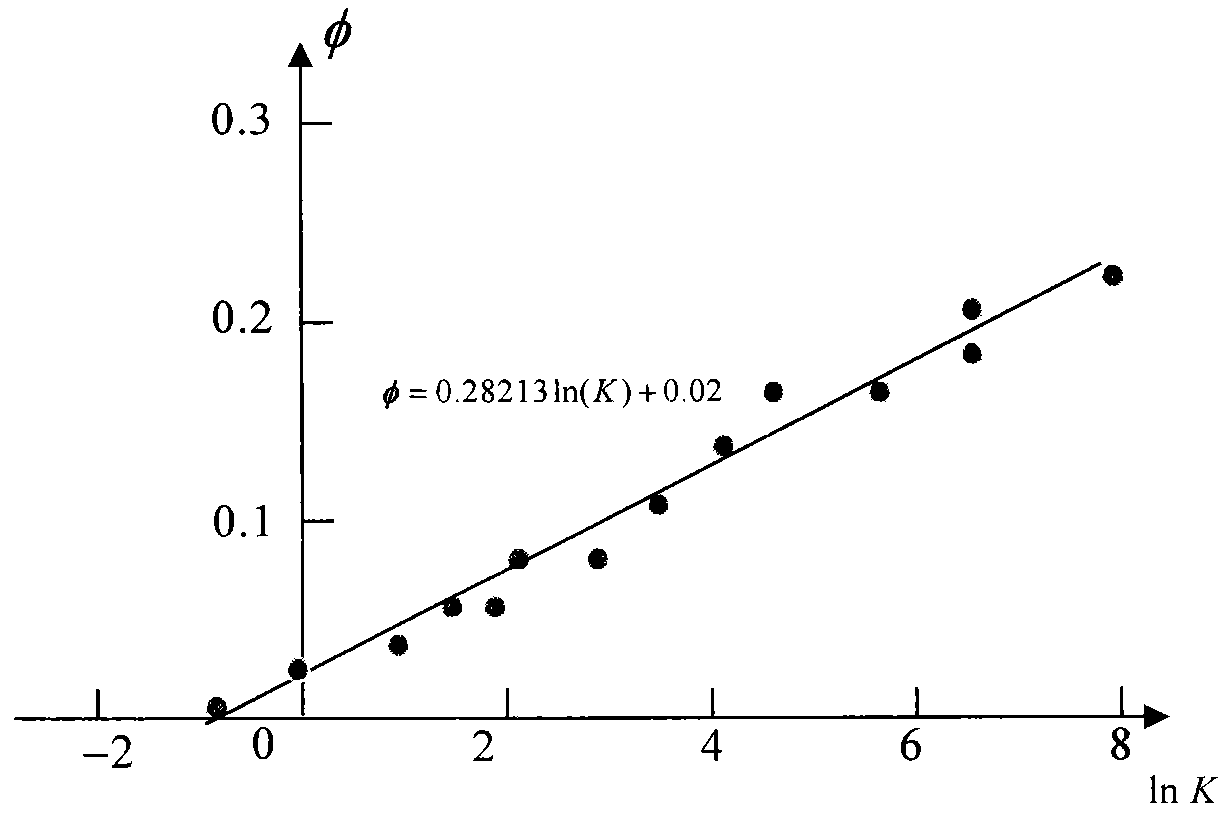

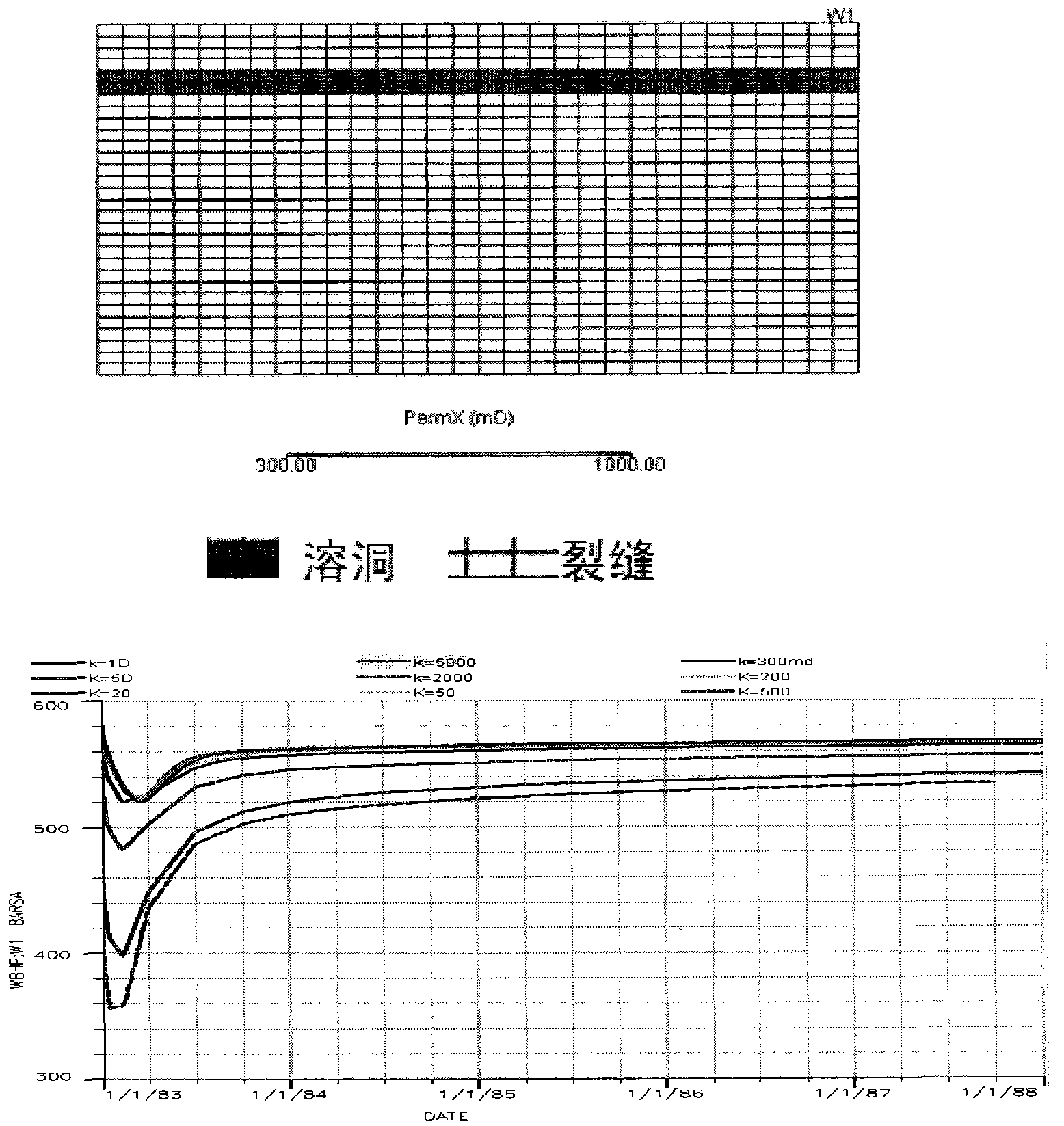

Method for acquiring three-dimensional permeability fields of netted fracture-cave oil reservoirs

The invention discloses a method for acquiring three-dimensional permeability fields of netted fracture-cave oil reservoirs. The method includes: establishing a three-dimensional porosity field of a netted oil reservoir, and determining quantitative relation between porosity and permeability of the oil reservoir; acquiring equivalent permeability of flat and tubular fractures and caves, determining the minimal critical permeability value, subjecting the permeability of the minimal critical permeability value to truncation processing by taking the critical permeability value as the maximal value so as to obtain an equivalent permeability value; correcting the permeability field subjected to the truncation processing with a tracer agent and an interference testing result; correcting the permeability field by the aid of the numerical simulation method. The permeability acquired plays a decisive role in knowing oil reservoir developing rules, predicting oil reservoir yield, optimizing and adjusting production layers, optimizing and adjusting well patterns and well spacing, researching residual oil exploiting rules, profile controlling and water blocking, formulating gas injection and water injection schemes, exploiting cost of the oil reservoirs is reduced, exploiting efficiency of the oil reservoirs is improved, and the purpose of increasing economic benefit of oil reservoir exploiting is achieved.

Owner:SOUTHWEST PETROLEUM UNIV +2

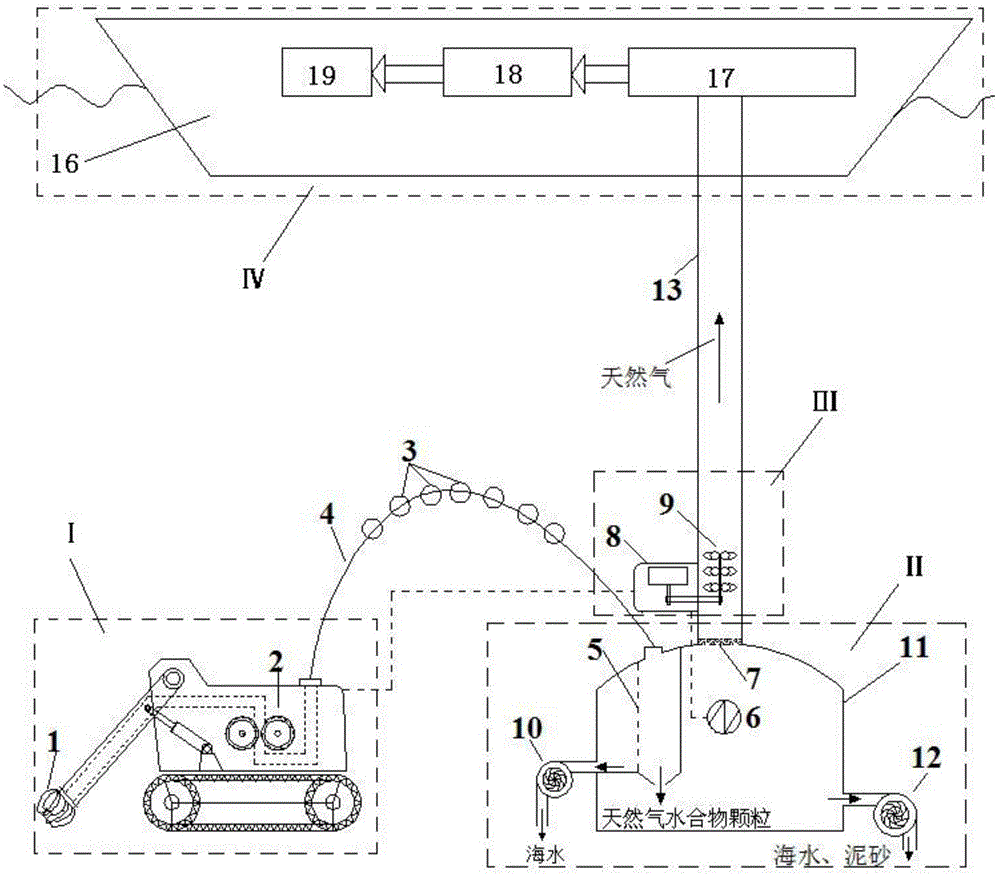

Method for green extraction of seabed unstratlfied rock natural gas hydrate

ActiveCN105064959ADoes not change temperatureDoes not change the pressureFluid removalExternal energySeawater

The invention discloses a method for green and energy-saving extraction of a seabed unstratlfied rock natural gas hydrate and belongs to the technical field of natural gas extraction. The method comprises the steps of pre-treatment of the natural gas hydrate, pre-collection of the natural gas hydrate, separation of the natural gas hydrate, and collection of the natural gas hydrate. The working principle is that on the premise that the ambient temperature and pressure of a natural gas hydrate formation are not changed, natural gas hydrate solid sediment is extracted through submarine mining, phase change is conducted on the natural gas hydrate by means of hot seawater to generate an airlift effect, and then the natural gas hydrate is lifted the sea surface to be processed and natural gas is collected finally. Meanwhile, the airlift effect serves as the power source of an extraction head, external energy consumption is reduced, and sea pollution is avoided. The method is a green natural gas collection method.

Owner:SOUTHWEST PETROLEUM UNIV

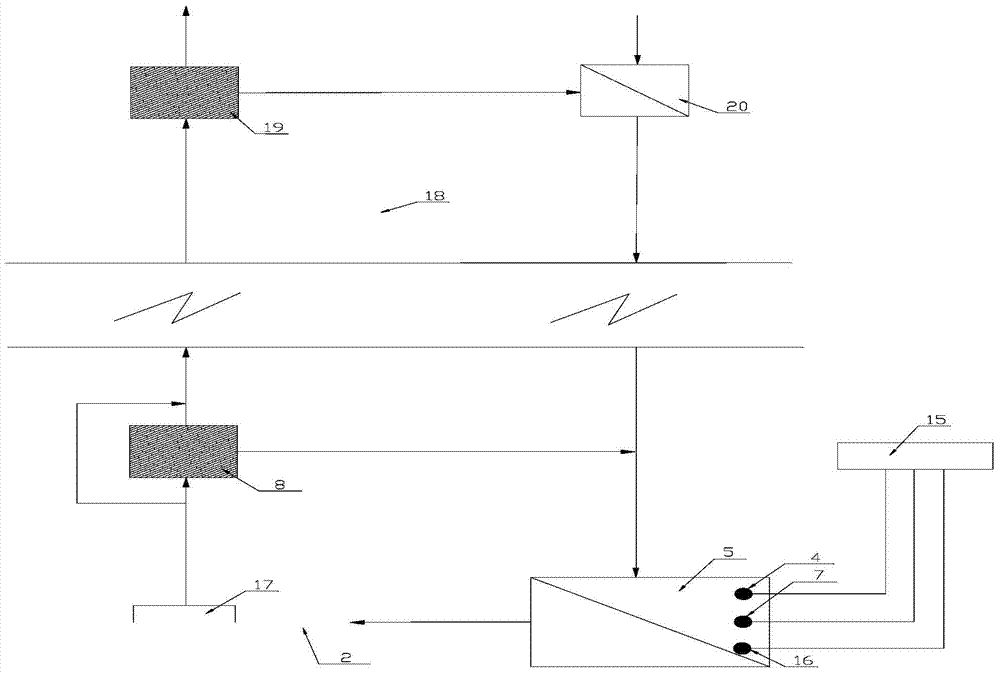

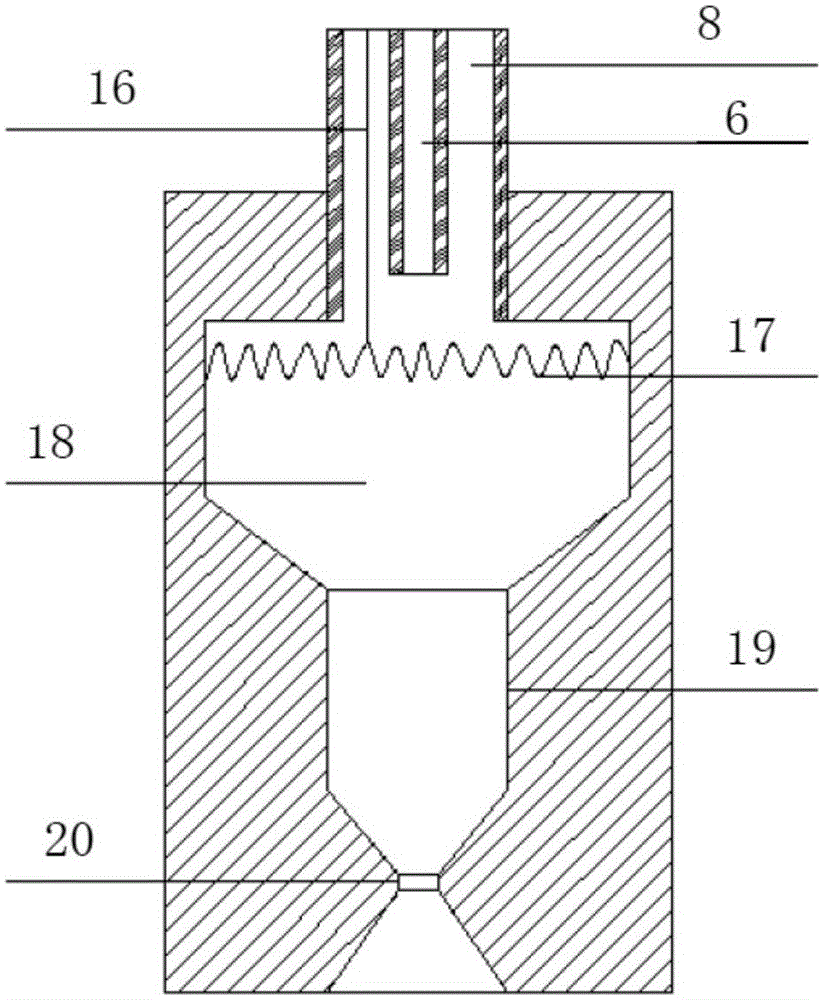

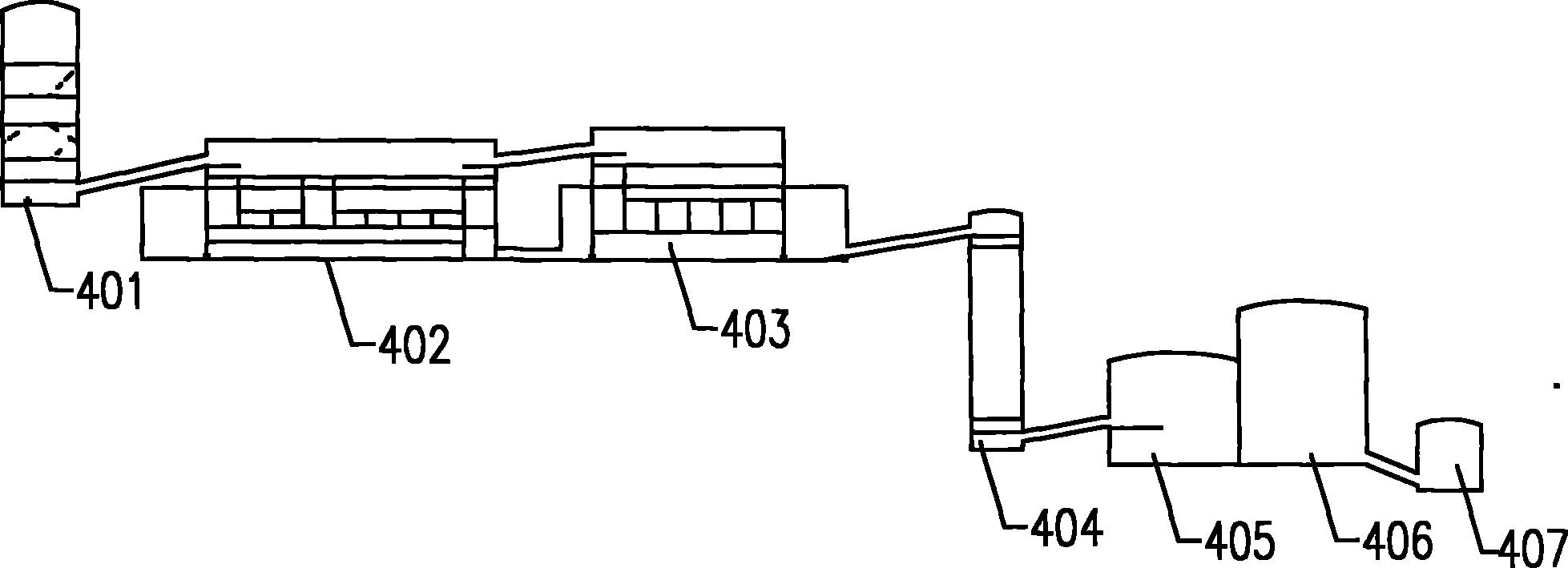

Slurry marine gas hydrate mining method and mining device achieved by means of jet breaking and reverse circulation delivering

ActiveCN106761588AImprove mine utilizationOvercome the shortcomings of low mining efficiencyFluid removalDecompositionCollection system

The invention discloses a slurry marine gas hydrate mining method and mining device achieved by means of jet breaking and reverse circulation delivering. The method comprises the steps that a marine gas hydrate stratum is broken through a high-pressure water jet method, and a multi-phase slurry mixture is jointly formed by jet water, broken rock soil and broken hydrates; the slurry mixture is delivered to a decomposition device and a separation device which are arranged on the sea level through a reverse circulation method; reduced pressure decomposition, solid-liquid separation and gas-liquid separation are conducted on the slurry mixture through the decomposition device and the separation device which are arranged on the sea level, and gas, solids and liquid are obtained separately and utilized and collected accordingly. Devices used in the method comprise a rock jet breaking and slurrying system, a reverse circulation delivering system, a decomposition, separation and collection system and an auxiliary system. According to the mining device and method, the defect that in existing marine gas hydrate mining, the mining efficiency is low is overcome, the hydrate deposit utilization rate is increased, the mining cost is reduced, the economic benefit is increased, and quick and sustainable mining is achieved.

Owner:JILIN UNIV

Method and system for extracting natural gas hydrate through thermal jet flow

ActiveCN105134152APromote decompositionInhibition of reformationConstructionsFluid removalProcess engineeringSystem structure

The invention provides a method and system for extracting natural gas hydrate through thermal jet flow. The method includes the steps that a combustion reaction device is lowered to a downhole target position of a natural gas hydrate reservoir, oxygen and fuel are injected into the downhole target position, the combustion reaction device is powered on, ignition is performed, combustion products are jet out of the combustion reaction device to form high-speed jet flow, the jet flow and heat generated during combustion act on the natural gas hydrate reservoir so that natural gas hydrate can be decomposed, and decomposed natural gas returns upwards to the ground; the amount of injected fuel is gradually reduced till injection stops, meanwhile part of the natural gas returning upwards to the ground and water are injected and mixed with oxygen for continuous combustion, and natural gas hydrate can be furthermore decomposed. The system at least comprises the combustion reaction device, a continuous oil tube inner tube, a continuous oil tube outer tube, a cable, a production sleeve, a water supply device, a fuel supplying device, an oxygen supplying device, a natural gas storing, collecting and supplying device and a pump set. The method and system for extracting natural gas hydrate through thermal jet flow have the advantages that extracting cost is low, extracting efficiency is high and the system structure is simple.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

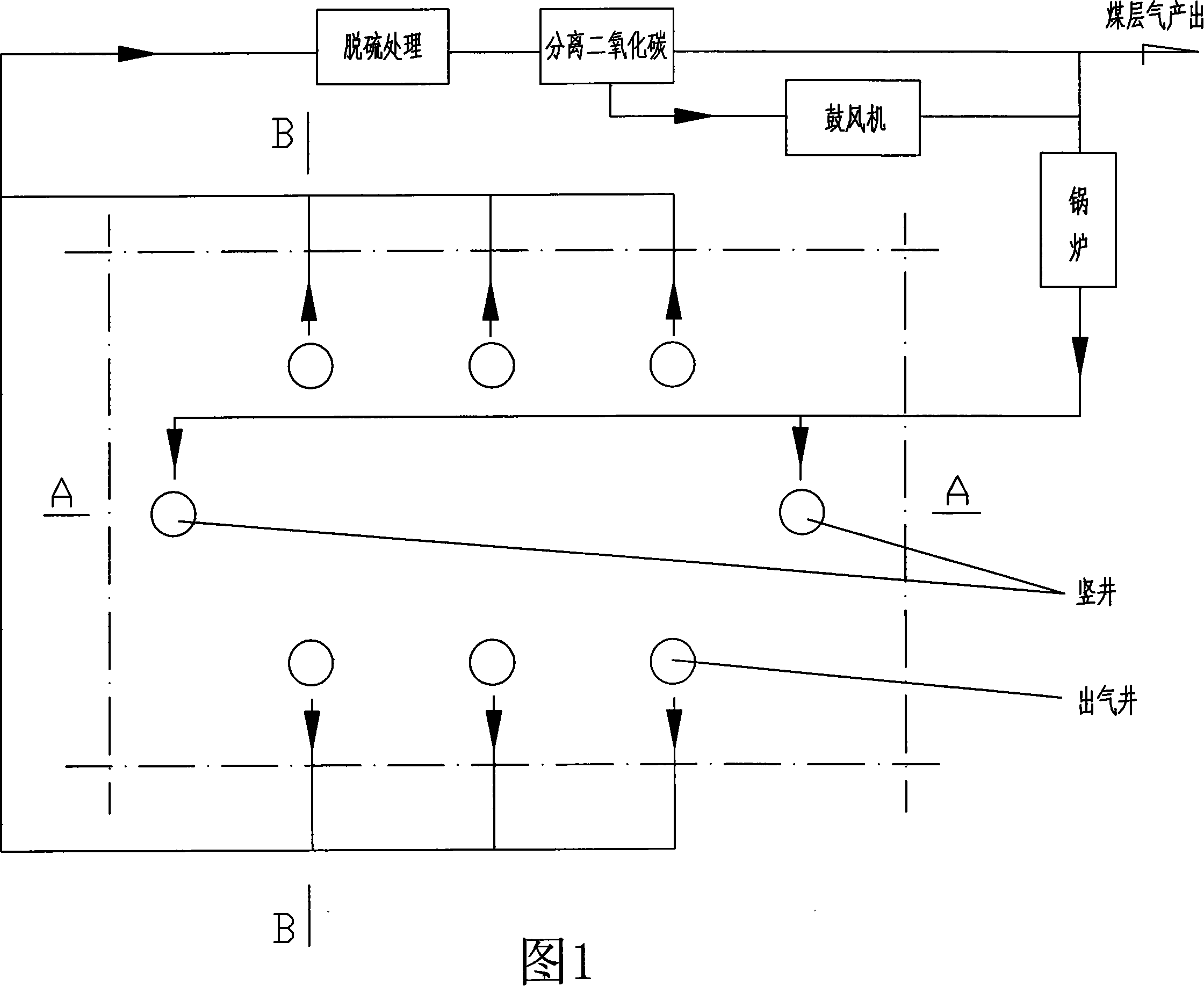

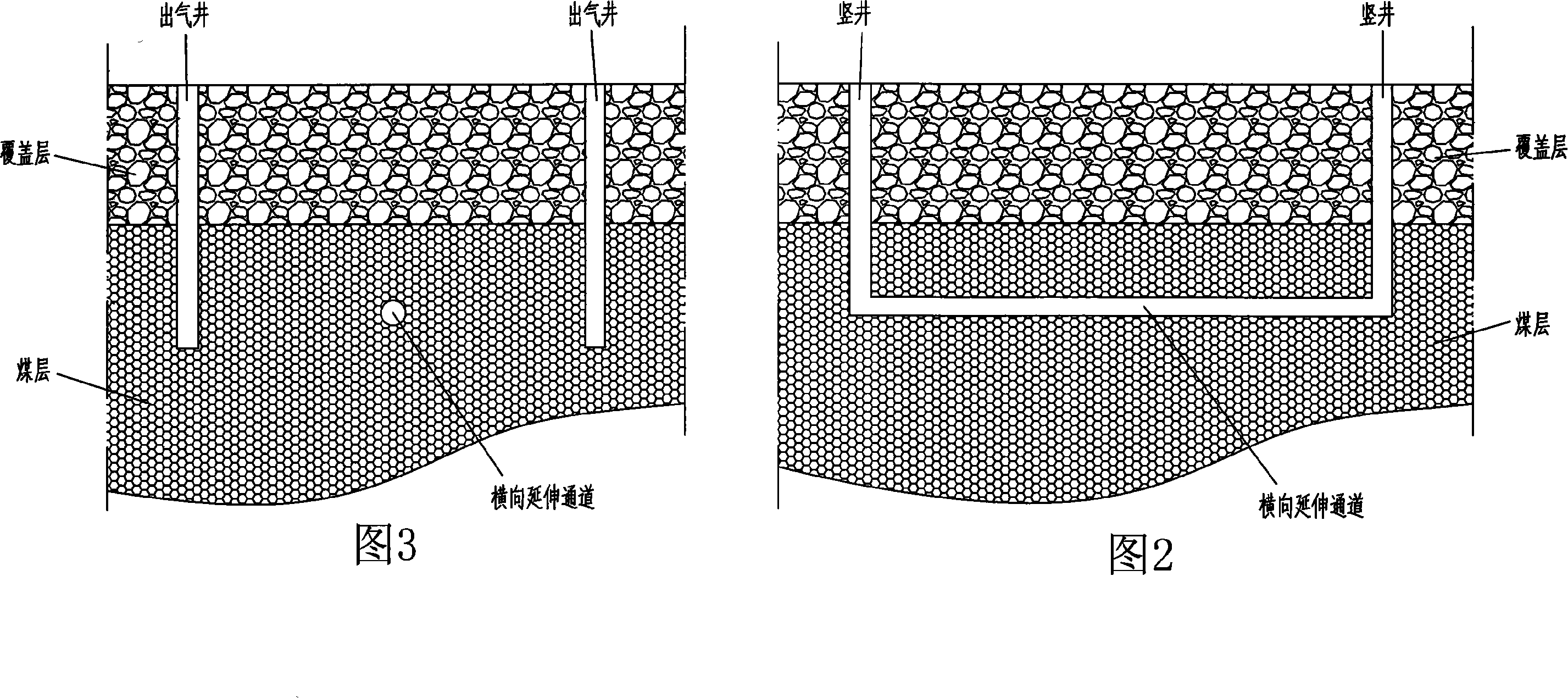

Coal bed gas mining novel technology

The invention discloses a new coal-bed methane exploitation technology and is divided into the following steps. (1) A gas intake mine comprising a vertical shaft and a passage extending transversely is arranged. (2) Then one side or both sides of the passage extending transversely is provided with an air outtake mine. (3) Fracturing treatment is done through high-pressure fluid with the prior art. (4) A coal bed at the bottom of the air outtake mine is burnt, meanwhile, the high-pressure air or oxygen is injected to the air intake mine. Thereby an air passage formed by cracks of coal bed is established between the air intake mine and the air outtake mine by making use of pressure difference between the air intake mine and the air outtake mine and the characteristics that water and oxygen in the coal mine tend to get close to the burning point at the air outtake mine. (5) Mixed gas discharged from the air outtake mine is collected and treated and then the coal-bed methane is obtained. Part of the obtained coal-bed methane is taken to be burnt completely and thermal smoke from burning is reinjected to the air intake mine to ensure a stable gas supply from the air outtake mine. The invention overcomes the effects caused by unfavorable factors such as low permeability, low pressure and low saturation and realizes commercial production of coal-bed methane.

Owner:ENN SCI & TECH DEV

Highly effective pour depressant for thermodynamic oil extraction process

ActiveCN101210173AImprove applicabilityStrong pouring capacityDrilling compositionWater basedDepressant

A high-efficiency pour point depressant for thermal recovery process comprises (1) biphenyl, polycyclic aromatic hydrocarbons or polycyclic aromatic hydrocarbon derivatives free of chlorine and sulfur elements; (2) liquid petroleum products containing arene larger than 5%, petroleum resin in liquid state at normal temperature or natural hydrocarbon aggregates in particle state at normal temperature; (3) surfactant; (4) fusel oil; (5) alcohol ethers having a closed cup flash point larger than 20 DEG C; and (6) oil-soluble or water-soluble polymers respectively having a nonpolar section eutectic with paraffin molecule and a polar section for twisting crystal form of wax crystal on a main chain and / or a branch chain. The high-efficiency pour point depressant of the invention performs all functions of both water-base pour point depressant and oil-base pour point depressant, and can efficiently assist the prior various thermal recovery processes in exploring high pour-point oil and heavy oil reservoirs, with the advantages of greatly reduced exploitation cost, prolonged production cycle of the oil well, increased output of the oil well, increased ultimate recovery of the oil reservoir,as well as significant economic benefit.

Owner:盘锦河升大地石油科技有限公司

Stratum catalytic oxidation thick oil thermal recovery method

InactiveCN101539012AReduce mining costsLow heating temperatureFluid removalCatalytic oxidationSurface-active agents

The invention relates to a stratum catalytic oxidation thick oil thermal recovery method which is as follows: a catalyst with a catalytic oxidation function and a cracking function is injected during a thick oil steam gorge and disgorge or steam drive process, and a certain amount of air is injected in an auxiliary way; catalytic oxidation and cracking reaction is generated inside a stratum during soaking and the steam drive to enable crude oil to lightly reduce viscosity, and a surface active agent which can improve the liquidity of the crude oil is also generated, thus the purpose of enhancing the thick oil recovery effect of thick oil is achieved. The invention is integrated with multiple modes such as the thick oil steam gorge and disgorge or the steam oil drive, stack gas oil drive, surface active agent oil drive and thin oil dilution method oil recovery and is a compound high-efficiency oil recovery technique; the thick oil inside an oil layer generates stack gas, hydrocracks, reduces the viscosity, generates the surface active agent and reduces the tension of an oil-water boundary on the spot under the action of the catalytic oxidation; and in addition, the stratum catalytic oxidation thick oil thermal recovery method can reduce the steam usage amount, the heating temperature of the oil layer and the thick oil recovery cost.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU

Green mining method and mining device for submarine shallow non-diagenetic natural gas hydrate

ActiveCN105587303ADoes not change temperatureDoes not change the pressureConstructionsFluid removalDecompositionEnergy supply

The invention discloses a green mining method and mining device for submarine shallow non-diagenetic natural gas hydrate. The green mining method comprises the following steps that on the condition that the ambient temperature and pressure of a submarine natural gas hydrate stratum are not changed, the natural gas hydrate is mined in a submarine mining mode and broken for two times to obtain a mixture of natural gas hydrate particles and seawater; thermal decomposition is directly performed on the mixture of the natural gas hydrate particles and the seawater at the bottom of sea in a sealed environment to obtain natural gas, wherein energy needed by thermal decomposition comes from energy generated through gas expansion work during thermal decomposition of the natural gas hydrate; the natural gas is delivered to the sea surface to be subjected to aftertreatment, and liquefied natural gas is obtained. The green mining device comprises a mining and breaking unit, a first transportation pipe, a decomposition unit, a natural gas transportation pipe, an energy supplying unit and a sea surface supporting unit.

Owner:SOUTHWEST PETROLEUM UNIV

Ultra-deep coal underground gasification technology

The invention relates to a super deep coal underground gasification technology, comprising: firstly detecting according to a coal buried depth and a delineation shape, designing a main axial line extending continuously in a deep gasified coal bed according to geological conditions, wherein a vertical shaft and a horizontal well are arranged every 300m in the main axial line; burning a deep passage; igniting to bidirectionally simultaneously burn by adopting butane and electricity through the pressure of an air compressor so as to generate a coal gas. The ultra-deep coal underground gasification technology carries out deep underground gasification by utilizing the shallow coal underground gasification technology and the oil extraction vertical well and horizontal well combination technology, enables the deep coal to be sufficiently utilized and the part of coal resources to play a role, has low extraction cost and thoroughly realizes the energy greening and the zero emission through a poly-generation recovery and reinjection technology.

Owner:邓惠荣

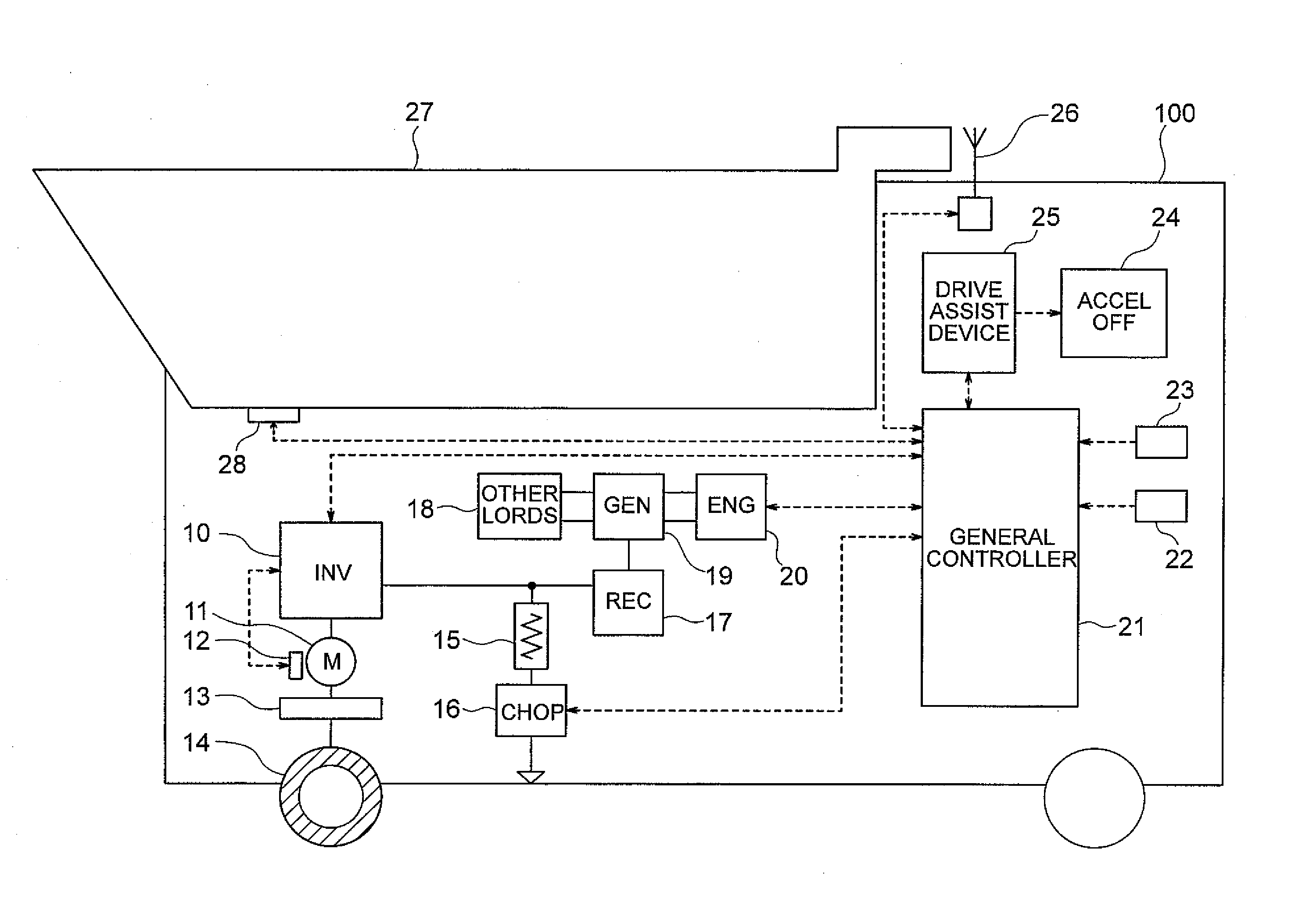

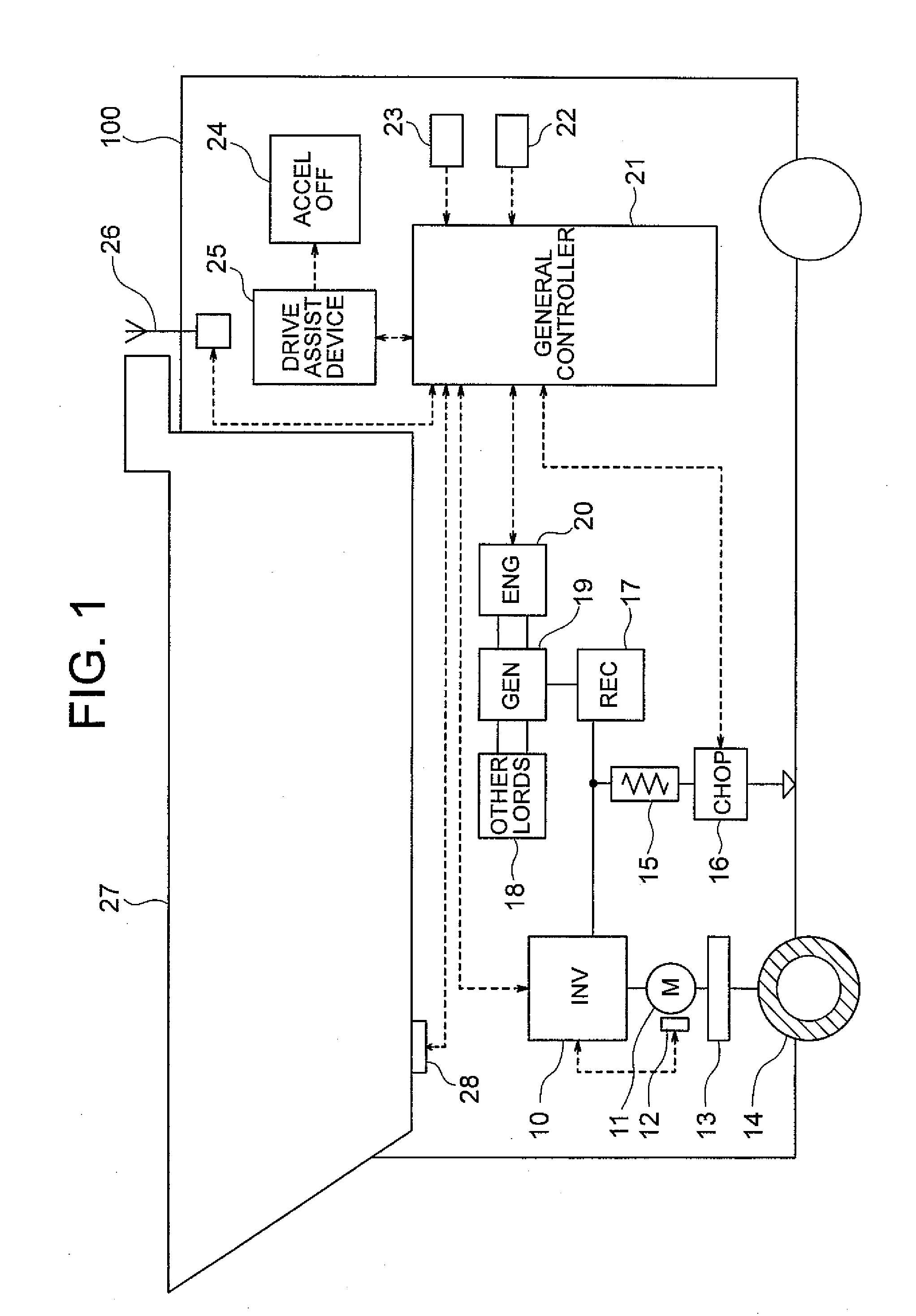

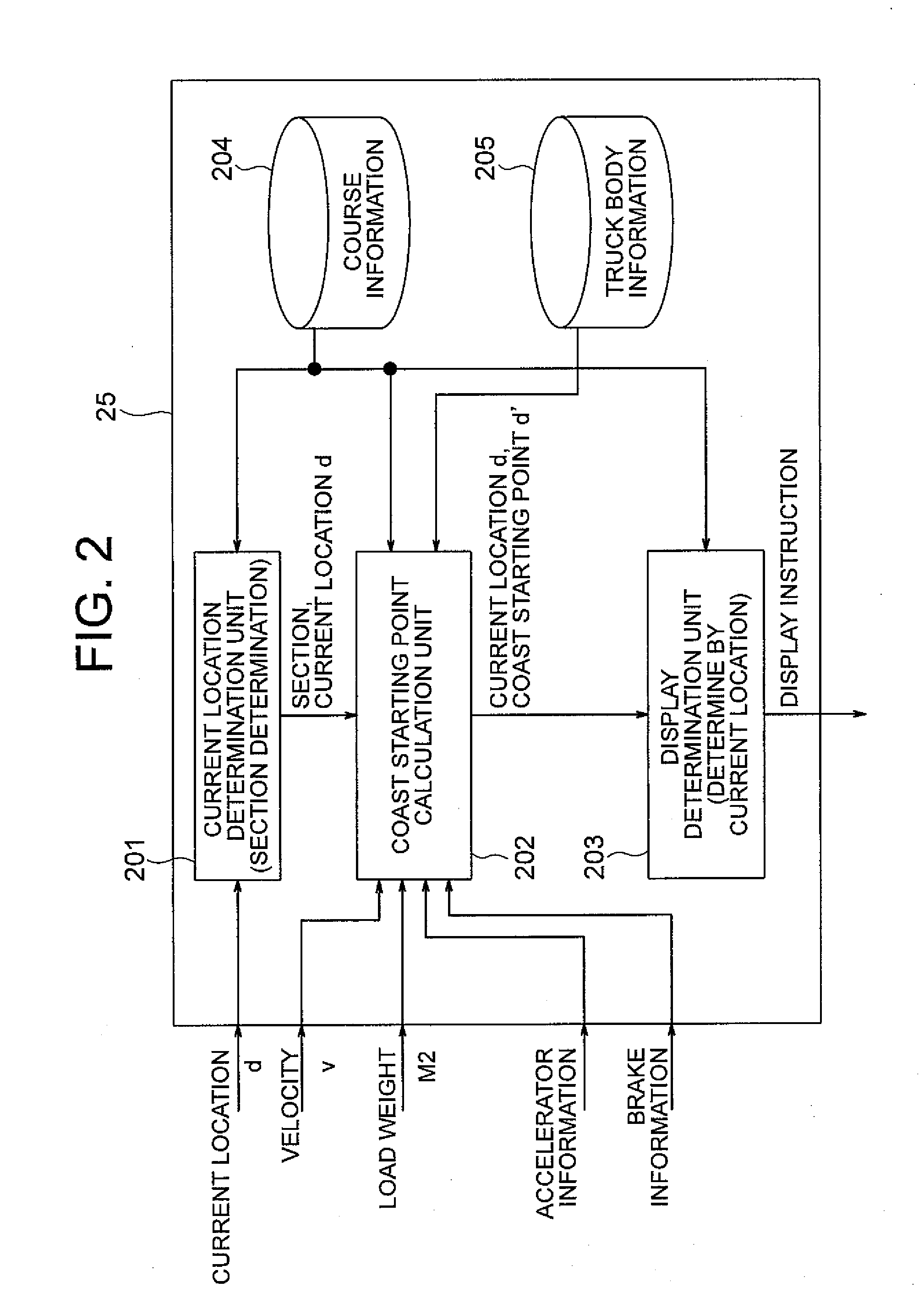

Drive assist device and method for motor driven truck

InactiveUS20100256848A1Reduce fuel consumptionReduce probabilityDigital data processing detailsPlural diverse prime-mover propulsion mountingDriver/operatorMotor drive

A drive assist device for a diesel-electric driven truck is provided to guide and assist a driver in starting to coast so that appropriate coasting deceleration suitable for load weight is realized. The drive assist device includes a course information database that stores information about a course, a truck body information database that stores information about the truck body, a current location determination unit that calculates current location information, a coast initiation timing calculation unit that calculates timing of coasting based on a current location and velocity of the truck and a target velocity at a predetermined point ahead of the truck, those of which being obtained from the databases and input information, the timing of coasting being used to achieve the target velocity at the predetermined point and a guidance unit that informs a truck driver of the timing of coasting according to an output of the calculation unit.

Owner:NIHON KENKI CO LTD

Divided mining method for inclined medium-thick ore body with unstable false roof

ActiveCN104018836AOut of stopeReduce the dilution loss rateUnderground miningSurface miningEngineeringNo removal

The invention discloses a divided mining method for an inclined medium-thick ore body with an unstable false roof. The ore body is divided into panels along the strike, ore pillars of chambers are divided in the panels and a top pillar is reserved during stoping; an outside-vein slice drift, a layered linking roadway and a trackless stope preparation project of a chute mine are distributed on the upper panel of the ore body, and an upward air roadway is filled and is distributed at a position at the center of the ore pillars of the chambers and close to the lower panel; chambers are mined firstly and the ore pillars are mined secondly in the panels, and the chambers and the ore pillars are mined in an up-down layering manner; the stoping is performed from an ore removal crossdrift, the false roof and the ore body are mined in sequence, after ores are conveyed out by a carry-scraper, the false roof at the lower sub-layer is subjected to caving in advance by shallow holes, waste stones of the false roof are reserved in a stoping field, and the ore breaking compensation height is compensated in a layering filling manner, the stoping is performed on the lower sub-layer, and the laying caving is performed on the false roof after layering ore breaking and ore conveyed out, the operation is repeated for multiple times until the stoping field is stoped completely, and the bottom layer of the stoping field is filled to close to the back. By using the method, the operating safety, high mechanical degree, no removal of the waste stones of the false roof, low production cost, and low ore dilution loss can be realized.

Owner:CENT SOUTH UNIV

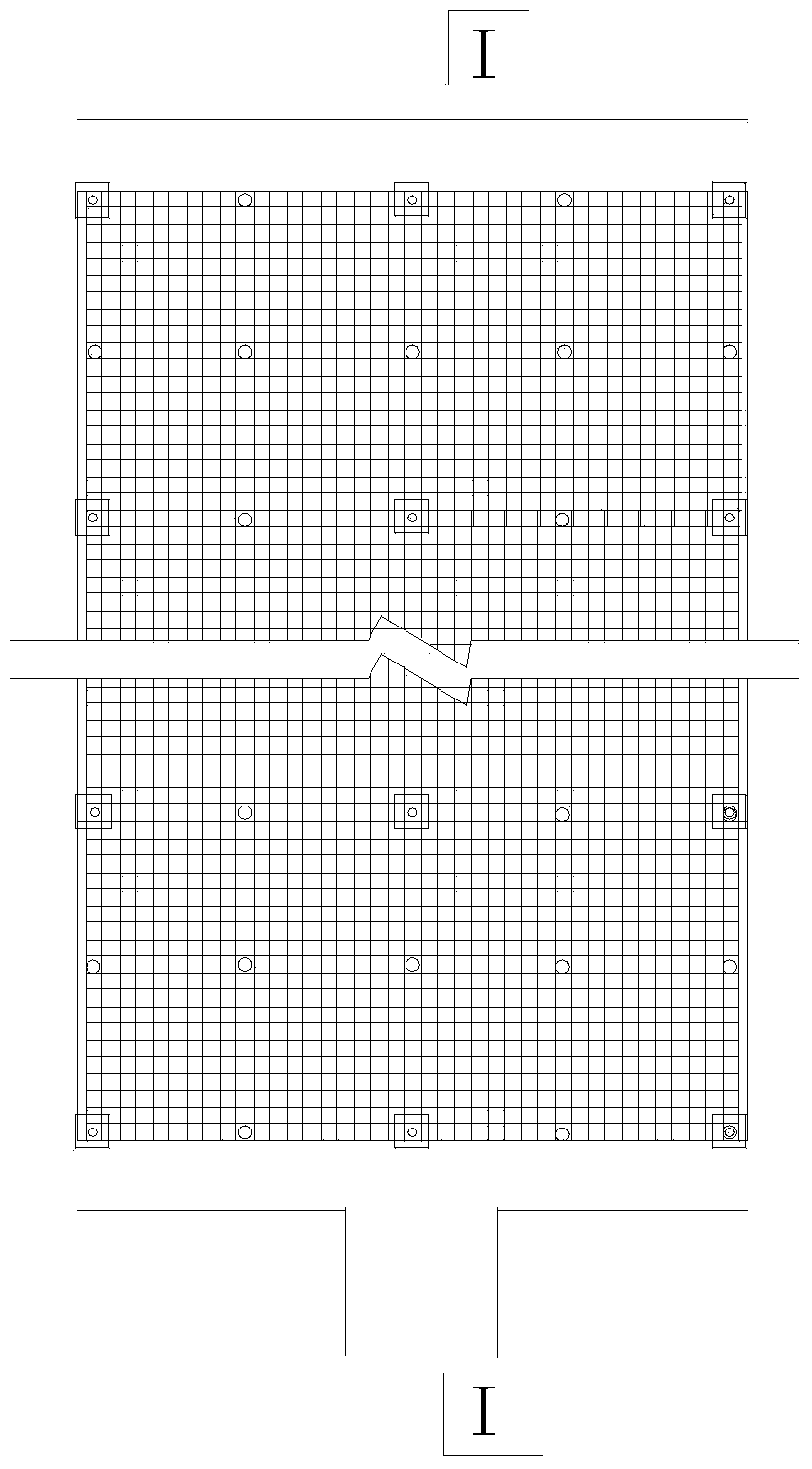

Self-slippage mining method of gentle dip ore body

ActiveCN103790588AReduce mining costsImprove stabilityUnderground miningSurface miningWhole bodyCable net

The invention discloses a self-slippage mining method of a gentle dip ore body. The method comprises the steps of ore body dividing-accurate mining-cutting slot constructing-cutting slot supporting-bottom removing-brushing and recovering-mine discharging-filling, etc. according to the method, only the cutting slot is supported by an anchor cable net, so that the mining cost can be greatly reduced; the cutting slot is supported by the anchor cable net, and an anchor cable is connected by a flexible steel belt, so that a top plate is a suspended whole body, the stability can be improved, and the safe recovery can be realized; ore bodies at two sides of the cutting slot are exploded in a brushing way, so that compared with the existing single-side retroactive mining method, the method shortens the recovery time by a half, the efficiency can be greatly improved, the stope exposure time can be reduced, and the safety can be improved; according to the bottom removing construction, the self-slippage degree of the ore can be enlarged, and the recovery efficiency can be improved.

Owner:贵州开磷设计研究院有限责任公司

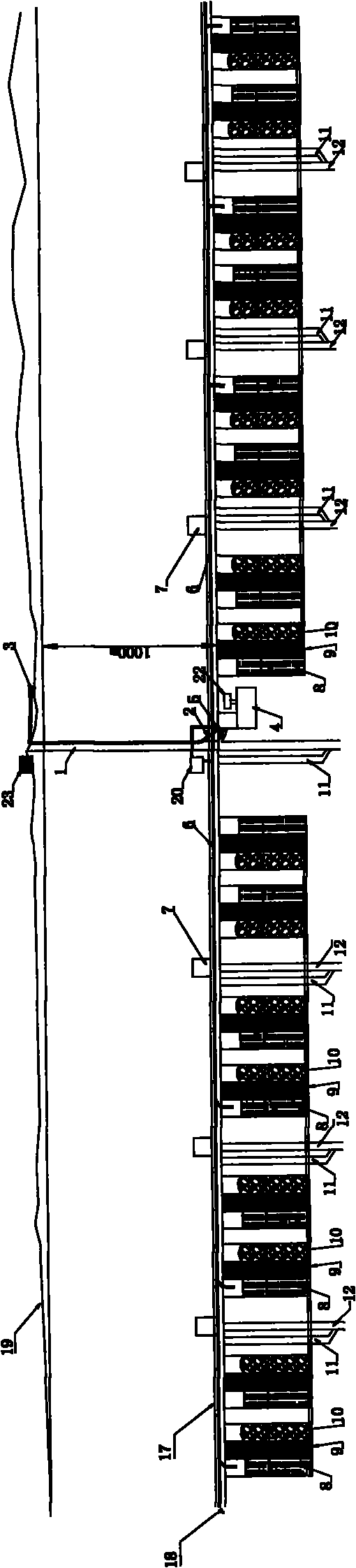

Deeply buried iron mineral resource underground mining and concentrating integration system

ActiveCN101775985AReduce the amount of excavationAchieve short-distance liftsUnderground chambersUnderground miningEcological environmentMineral Sources

The invention relates to a deeply buried iron mineral resource underground mining and concentrating integration system, which is characterized in that only one main hoisting shaft is arranged, positions adjacent to the main hoisting shaft are provided with an underground concentrating mill, an underground filling station and an underground water sump; the left side and the right side of the main hoisting shaft are uniformly provided with at least one blind shaft, and positions adjacent to the main hoisting shaft and the blind shaft are both provided with a main orepass; the footwall side of the top of an ore body is provided with a main horizontal haulage roadway, and both ends of the roadway are provided with air shafts; and the underground concentrating mill comprises a cycle chamber, a conical chamber, a screening chamber, a powder ore chamber, a grinding chamber, a sorting chamber and a product delivery chamber. The invention has the main characteristics that the concentrating mill, the underground filling station and the under water sump are arranged underground so as to realize short-distance hoisting of mined deeply buried mineral resources, the concentrated tailings and waste rocks are directly used underground, the overall mining cost can be reduced by 10 to 30 percent without damaging the earth surface, environment pollution is reduced, and the ecological environment is protected.

Owner:NORTHEASTERN UNIV

Non-pillar sublevel mining cemented filling mining method

InactiveCN105909247AImprove mining efficiency and mining equipment efficiencyReduce mining costsUnderground miningSurface miningCushionMineralogy

The invention discloses a non-pillar sublevel mining cemented filling mining method. The method is characterized in that sublevels are used as stoping units; stoping drifts are arranged in a staggered way in upper and lower sublevels; rhombic components are stoped in a sublevel mining way; the paces are the basic stoping units; deep hole breakdown is performed in upward fan shapes; multi-row hole short-delay blasting is performed; ore removal is performed under the barnyard condition; after the mining, the cemented filling is performed in time; and rhombic cushions capable of being cyclically used for filling partition wall reserved blasting compensation spaces, blasting free surfaces and the like of the partition wall are used, so that a series of problems of complicated and expatiatory production process, low mining efficiency, high mining cost and the like of the existing top slicing horizontal stoping drift cemented filling mining method can be solved under the condition of steeply-inclined large and thick ore bodies.

Owner:SOUTHWEAT UNIV OF SCI & TECH

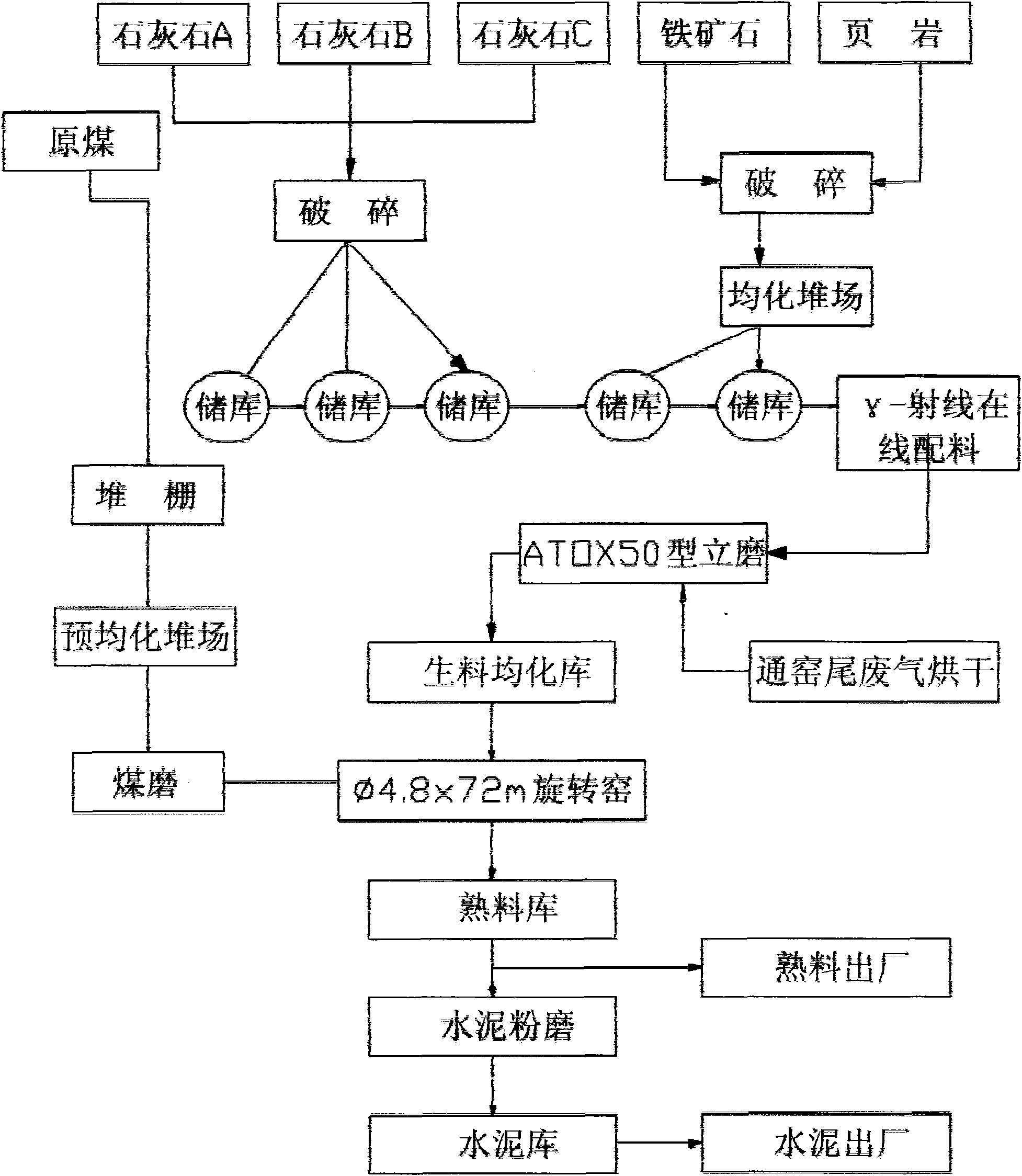

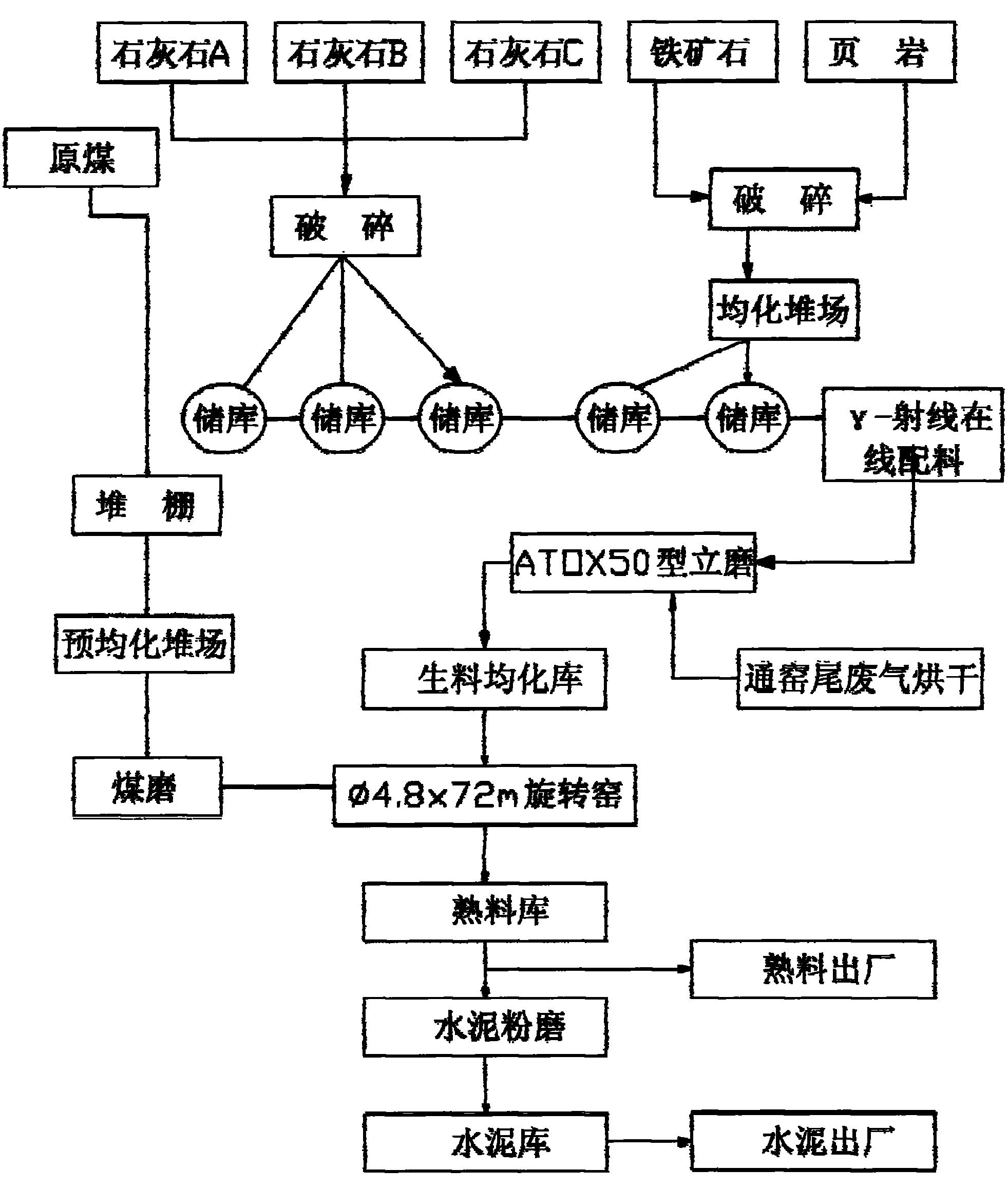

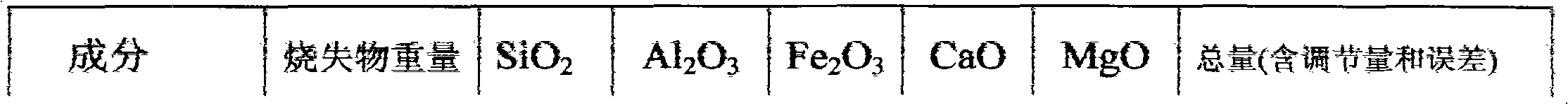

Method for producing cement by utilizing high-silicon low-calcium limestone

InactiveCN101781096AIt has the characteristics of "low calcium and high free silicon"Rich reservesIronstoneMining engineering

The invention relates to a method for producing cement by utilizing high-silicon low-calcium limestone. The cement comprises the following raw materials in percentage by weight: 48 to 50 percent of low-grade high-silicon limestone with CaO content between 42 and 45 percent and f-SiO2 content between 10 and 18 percent, 31 to 33 percent of high-magnesium limestone, 16 to 18 percent of matched limestone, 3 to 6 percent of shale and 2 to 4 percent of ironstone. The method is technology which utilizes low lime saturation ratio and ore of high silicon rate and high alumina rate and has an attribute of low silica modulus; online detection is performed on the mixture ratio of the raw materials by using a gamma ray instrument and a formula is adjusted by using one minute as a cycle; and a plate hammer counterpunch type crusher is used for crushing, a roller-type vertical grinding mill is used for grinding and waste gas at the tail of a kiln is used for drying the raw materials. The method has the advantages of capability of developing and utilizing low-grade limestone resource, accurate material burdening, timely regulation of the mixture ratio, and capability of reducing homogenization facilities and storage yard; and high quartziferous rock ore can be used in vertical milling and has high grindability. The method is suitable for utilizing high-dissociative silicon low-calcium limestone.

Owner:SINOMA TIANSHAN YUNFU CEMENT

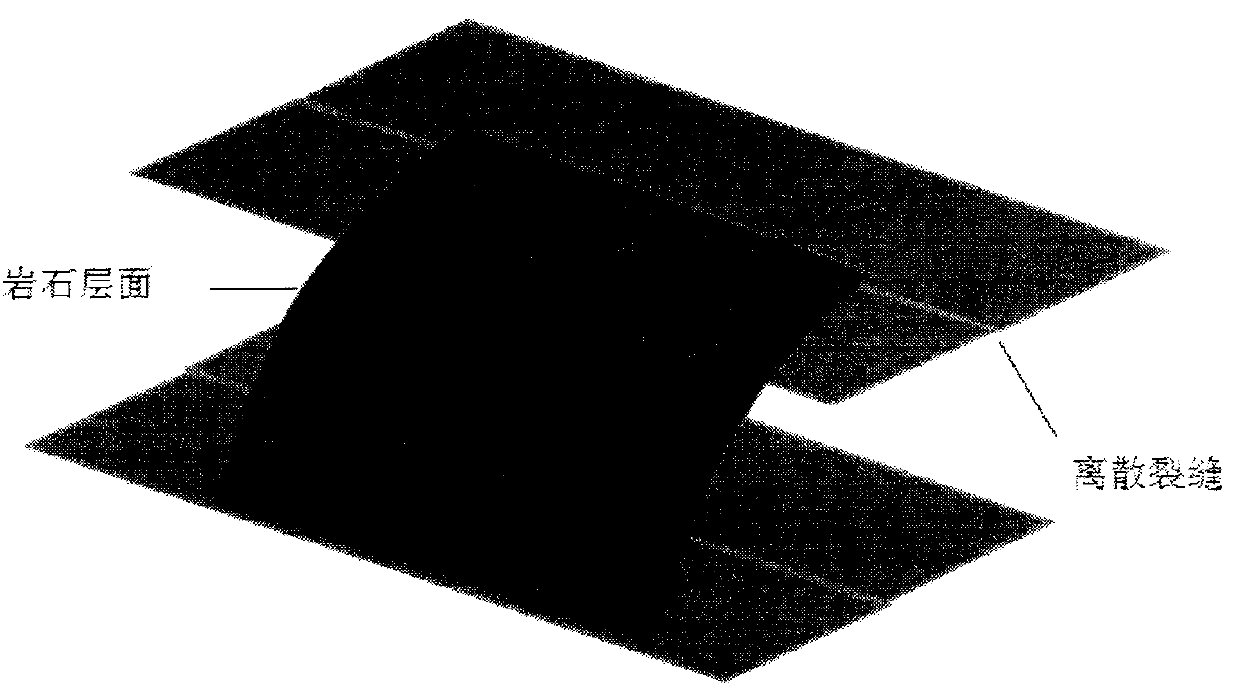

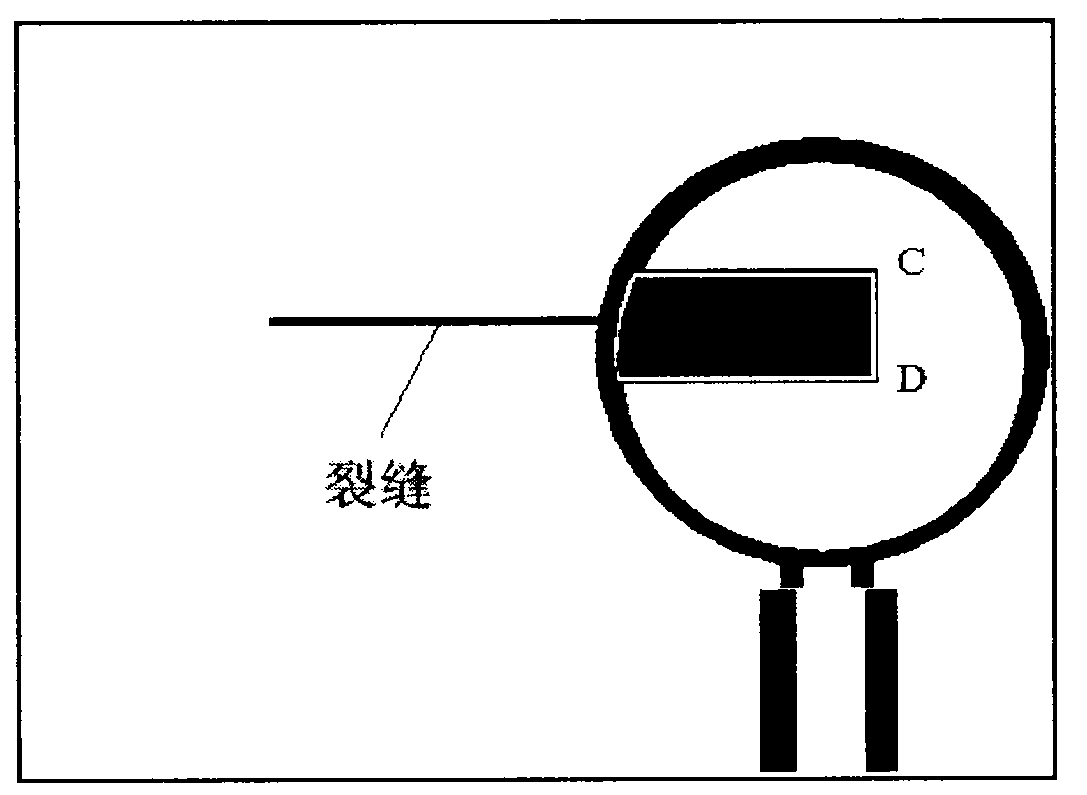

Method for improving oil reservoir exploitation effect by utilizing discrete fracture endpoint deformation numerical simulation

InactiveCN103279991AImprove accuracyImprove reliabilitySpecial data processing applications3D modellingResidual oilReservoir storage

The invention discloses a method for improving an oil reservoir exploitation effect by utilizing discrete fracture endpoint deformation numerical simulation. The method comprises the following steps of dividing an oil reservoir storage body into a continuous medium and a discrete medium according to a characteristic scale; deforming the end part of a discrete fracture from a square shape into a pointed shape to eliminate tiny grids, establishing rock stratum surface grids, and establishing three-dimensional oil reservoir grids; inputting measured oil reservoir parameters such as porosity, permeability and water saturation into a simulator, wherein a real value rather than a grid display value is used for the width of the discrete fracture; correcting the oil reservoir parameters by using a history matching method; and measuring and calculating the well productivity, residual oil and gas reserves and the distribution positions of residual oil and gas, and making a subsequent oil reservoir exploitation plan. According to the method, a discrete fracture numerical simulator can be prevented from measurement and calculation interruption and failures, the whole links of oil reservoir exploitation can be actually measured and calculated to improve the measurement and calculation accuracy of the well productivity and the residual oil and gas distribution of an oil reservoir, and a more effective development plan can be made to improve the oil reservoir exploitation effect.

Owner:SOUTHWEST PETROLEUM UNIV +1

Shale gas thermal recovery method and system by using deep geothermal resources

InactiveCN107044275AFacilitate desorption of adsorbed gasFacilitate desorptionOther heat production devicesGeothermal energy generationStructure of the EarthDesorption

The invention relates to shale gas thermal recovery technology by using deep geothermal resources, in particular to a shale gas thermal recovery method and system by using deep geothermal resources. The shale gas thermal recovery method includes the steps of well pattern arrangement, buried well drilling, installation of thermal recovery devices and thermal recovery of shale gas. The shale gas thermal recovery system comprises row-shaped well patterns located on two sides of a horizontal well, each row-shaped well pattern further comprises four buried wells in a same structure, and each buried well further comprises perforations formed in the pipe section of a casing located on the position of a shale gas reservoir layer and the pipe section of a casing located on the position of a hot dry rock layer; the perforations communicate inner cavities of the casings with the shale gas reservoir layer and the hot dry rock layer correspondingly; and gravity thermal pipes made of a working medium which can be gasified when being heated are internally mounted in the buried wells. The shale gas thermal recovery method and system by using the deep thermal resources have the advantages that the energy consumption is dramatically reduced, the desorption of absorption gas in the shale gas reservoir layer is promoted, the productivity is improved, and the recovery cost is reduced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com