Self-slippage mining method of gentle dip ore body

A mining method and gently inclined technology, which is applied in the field of self-sliding mining of gently inclined ore bodies, can solve problems such as high labor intensity, large ore loss, and potential safety hazards, and achieve the effects of reducing mining costs, rapid recovery, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the required protection scope is not limited to the description;

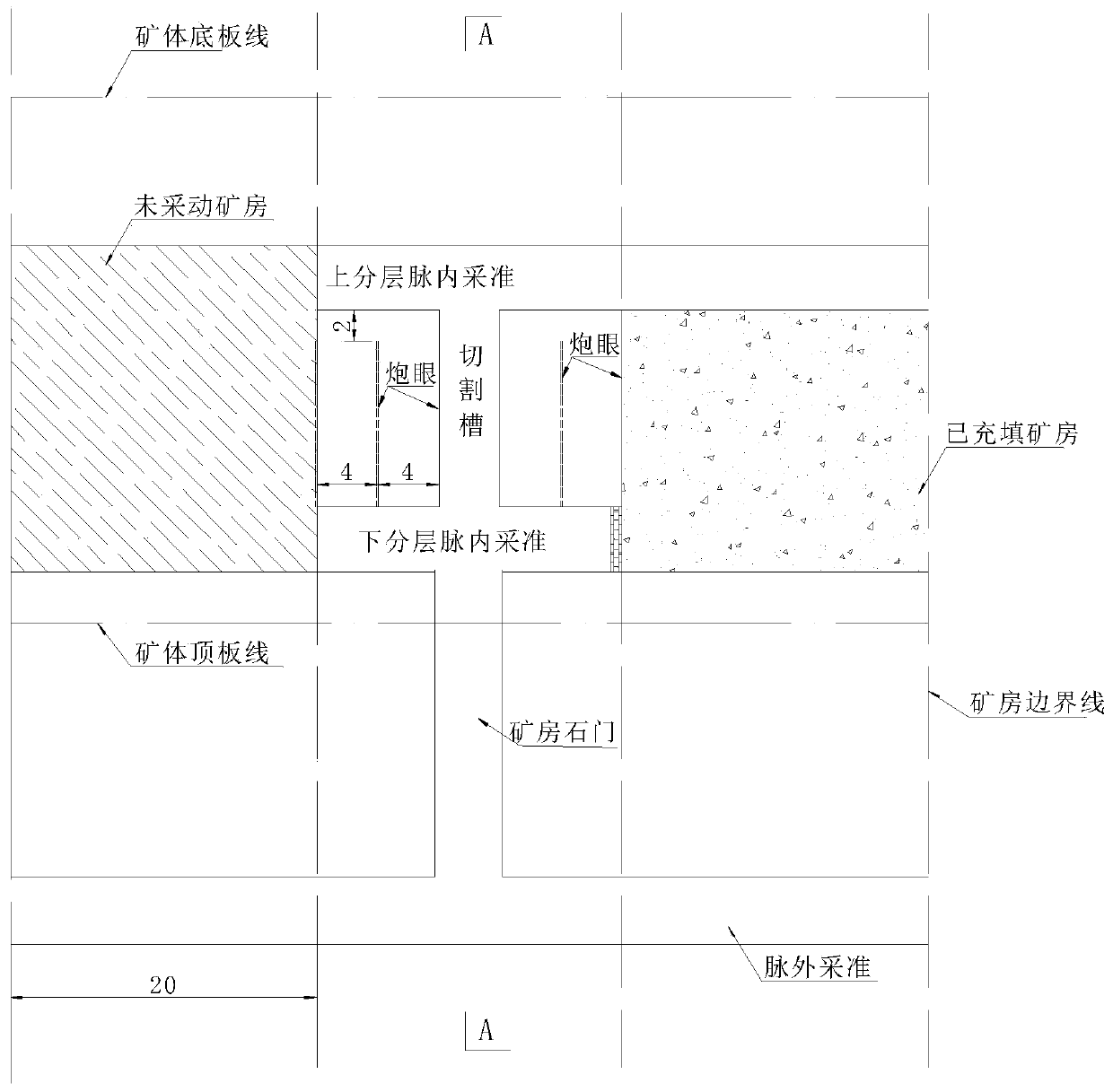

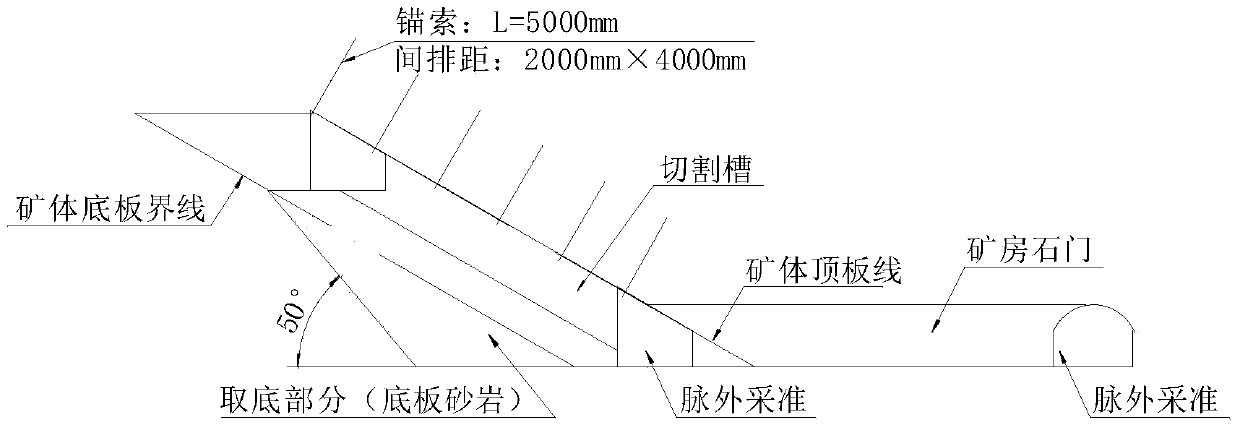

[0033] Example: When filling and mining the middle section of Qingcaichong Mine 820 in the central part of Guizhou, the inclination angle of the ore body is only about 35°, which cannot make the ore after blasting self-slip under the action of gravity, resulting in a large loss of ore, and must be exposed to the whole Anchor nets and cable supports are carried out in an empty field, resulting in high support costs and low work efficiency.

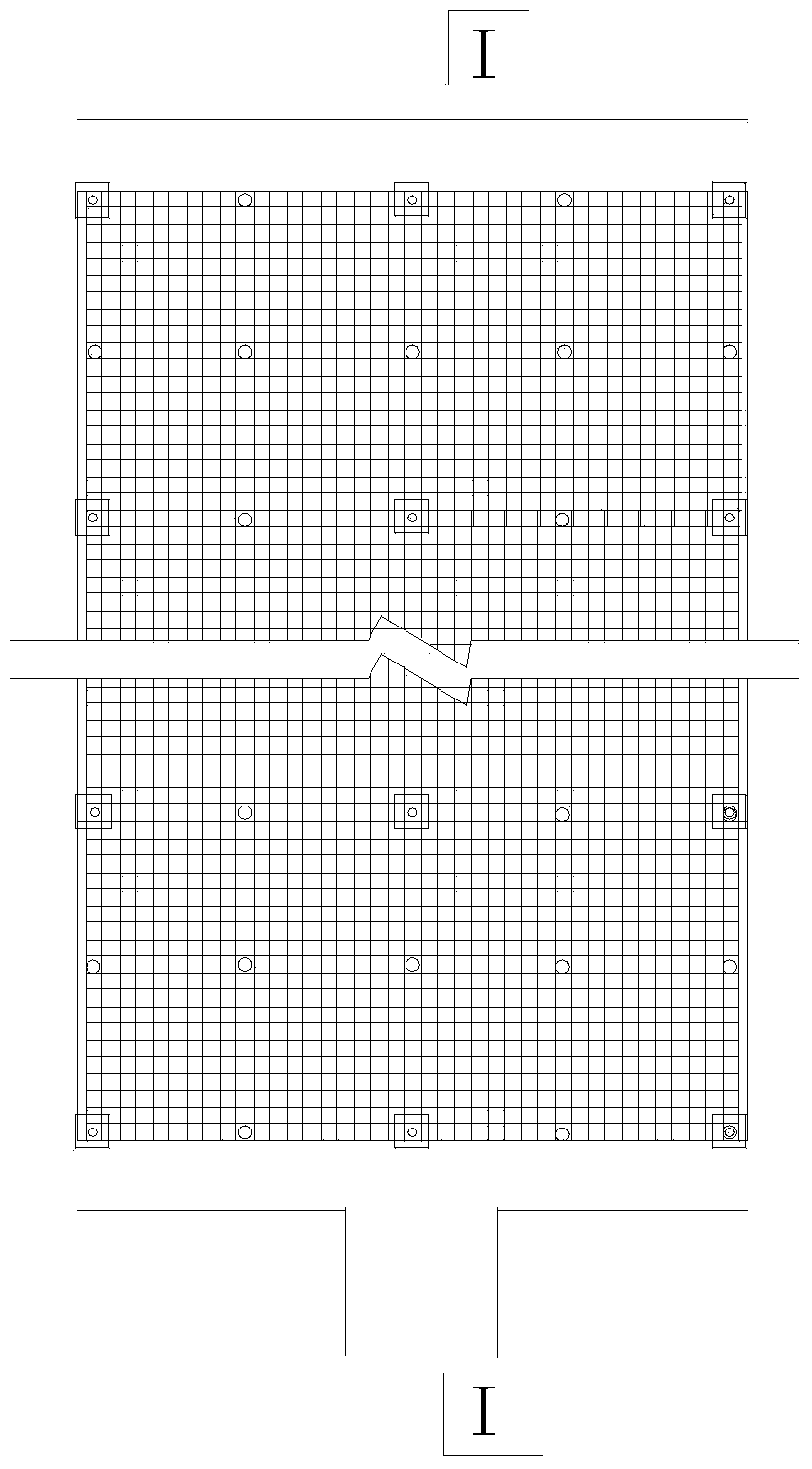

[0034] Now adopt the gently inclined ore body self-slip mining method provided by the invention to carry out filling and mining of the ore body. First divide the ore body: divide the ore body into several panels along the ore body trend, each panel is evenly divided into several mine houses, and divide the mine houses into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com