Non-pillar sublevel mining cemented filling mining method

A technology of cemented filling and mining methods, applied in the direction of filling, ground mining, mining equipment, etc., can solve the problems of complex production process, low production efficiency, high mining cost, etc., and achieve simplified mining process, reduced filling cost, high filling density sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] An embodiment of the present invention is:

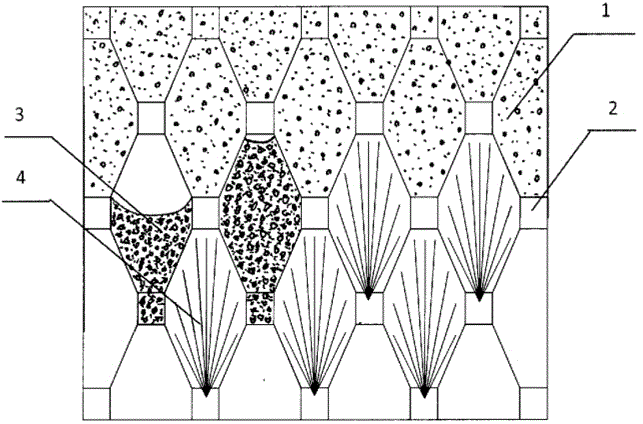

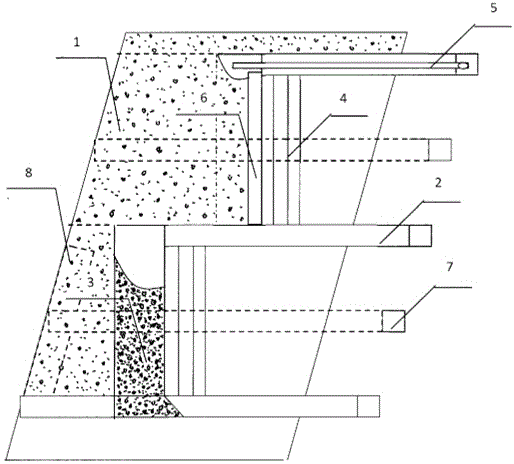

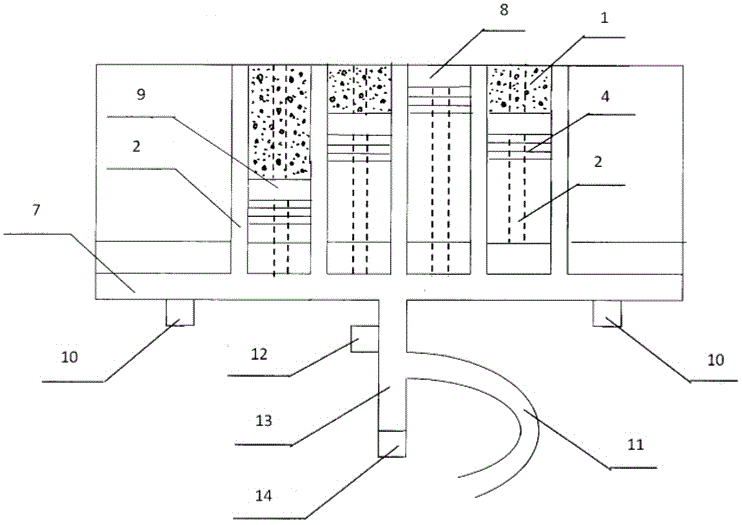

[0028] A. According to the determined segmental height (10-15m), arrange a segmental mining roadway to fill the connecting roadway according to a certain distance (usually about 20m) in the surrounding rock of the footwall (or hanging wall) of the ore body; According to the determined approach spacing (10-15m), a number of mining access routes are arranged vertically to the ore body, and at the same time, ensure that the upper and lower segmental mining routes are strictly in accordance with the principle of staggered arrangement and form a diamond-shaped mining interval structure; when arranging segmental mining and filling In the surrounding rock on the side of the connecting road, turn-back ramps and segmented connecting roads are arranged to establish the stope connection between each segment and between the segment and the mining approach. The support method of mining roadway, sub-section connecting roadway and sub-section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com