Patents

Literature

42results about How to "High filling density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

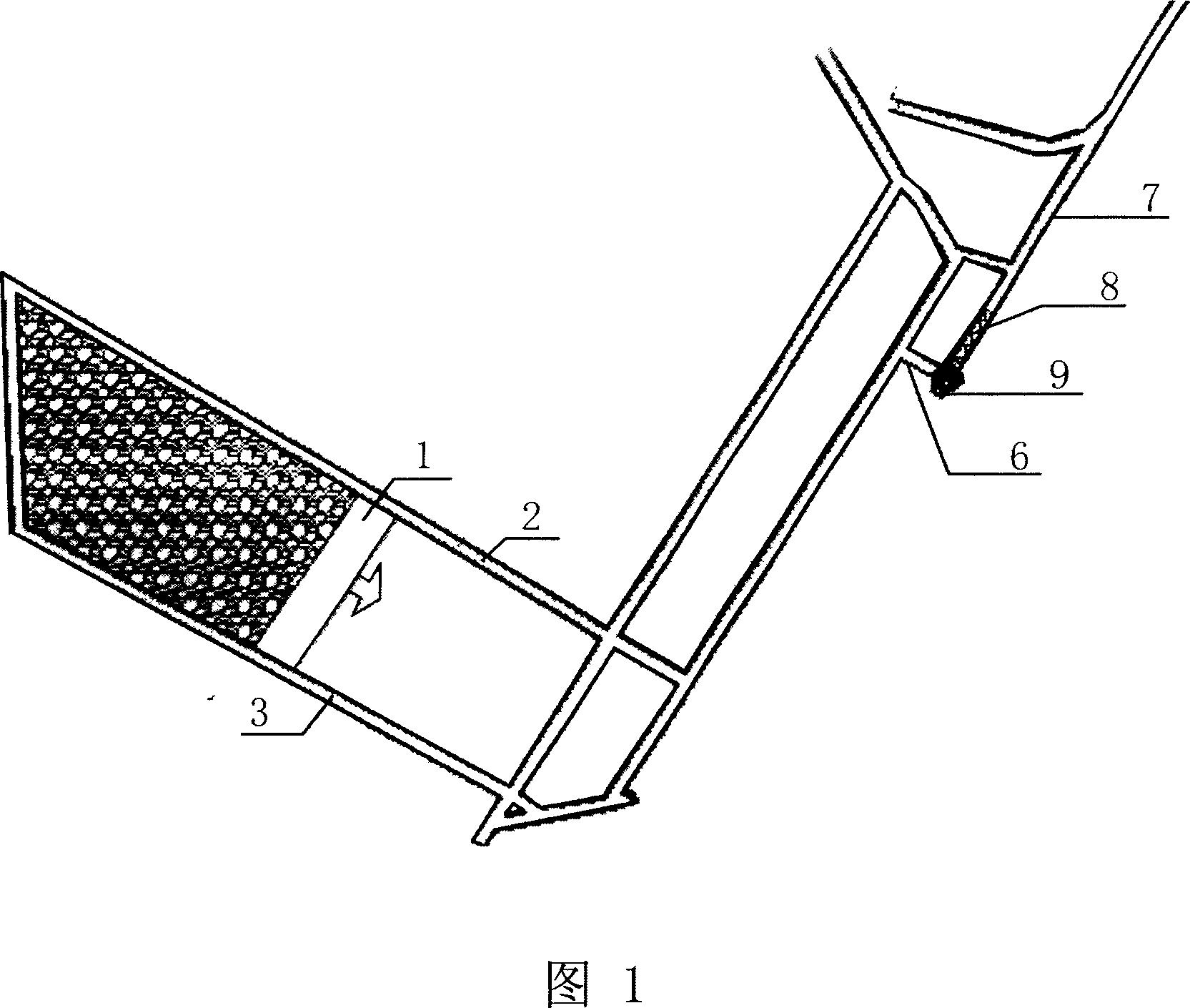

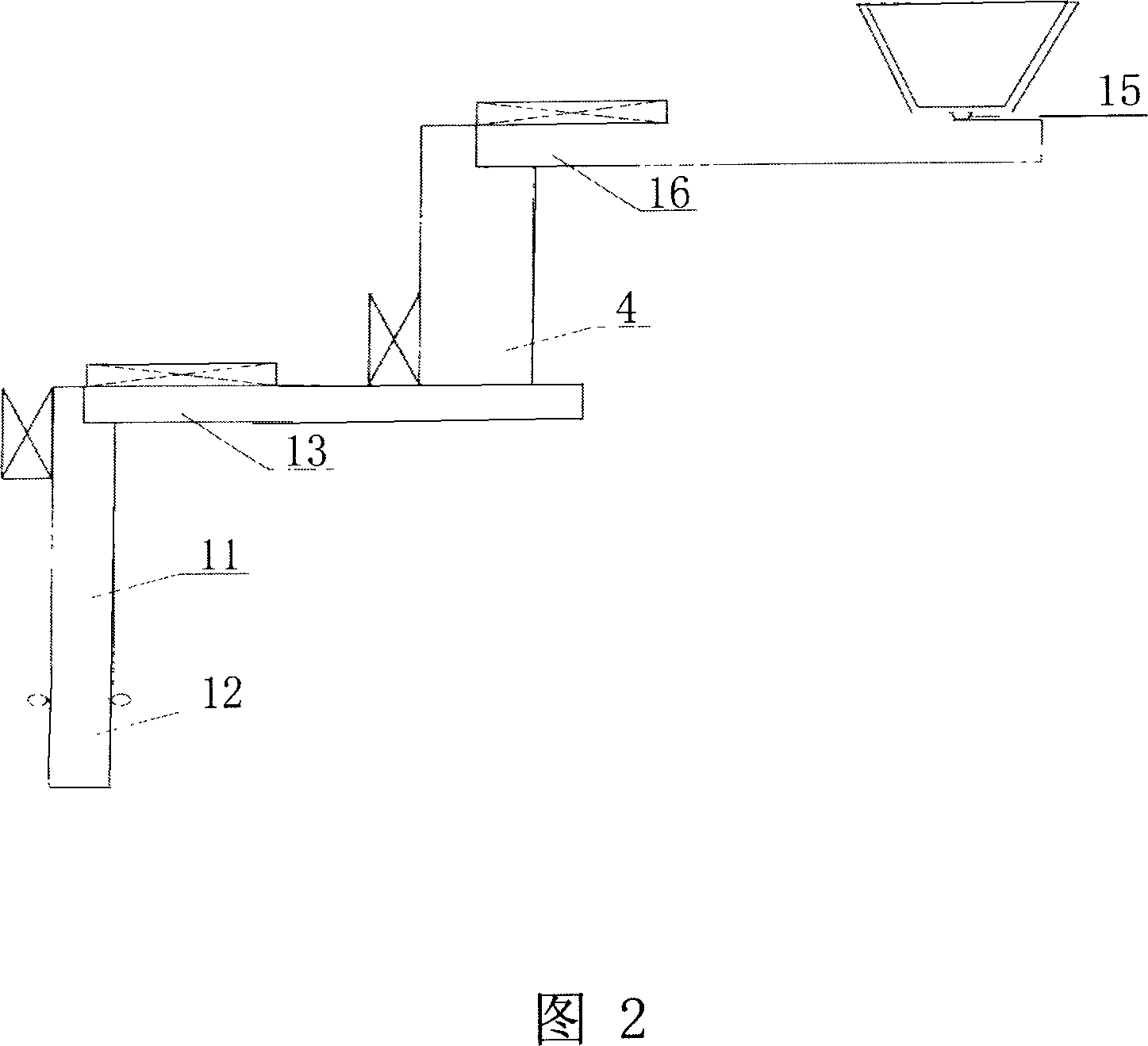

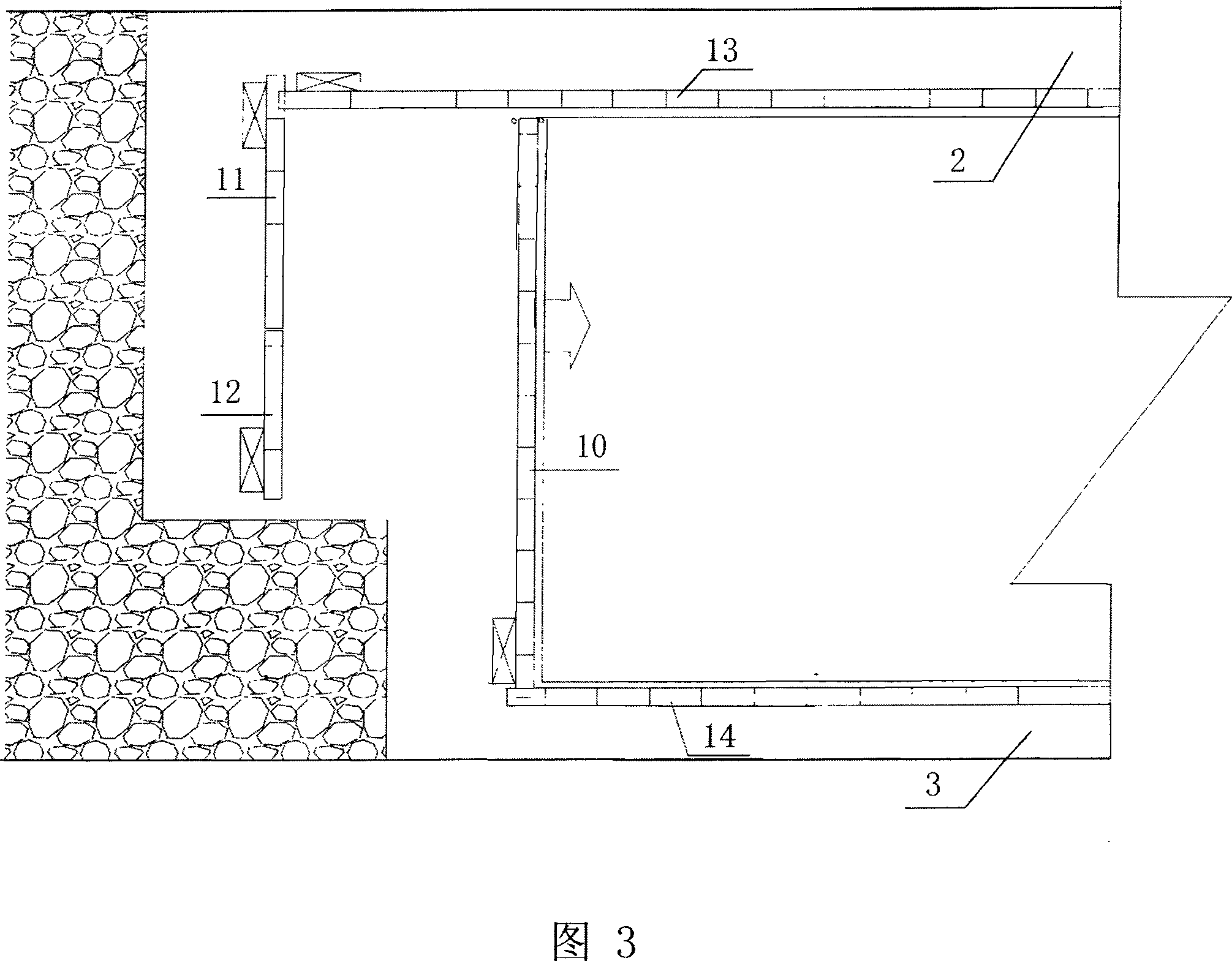

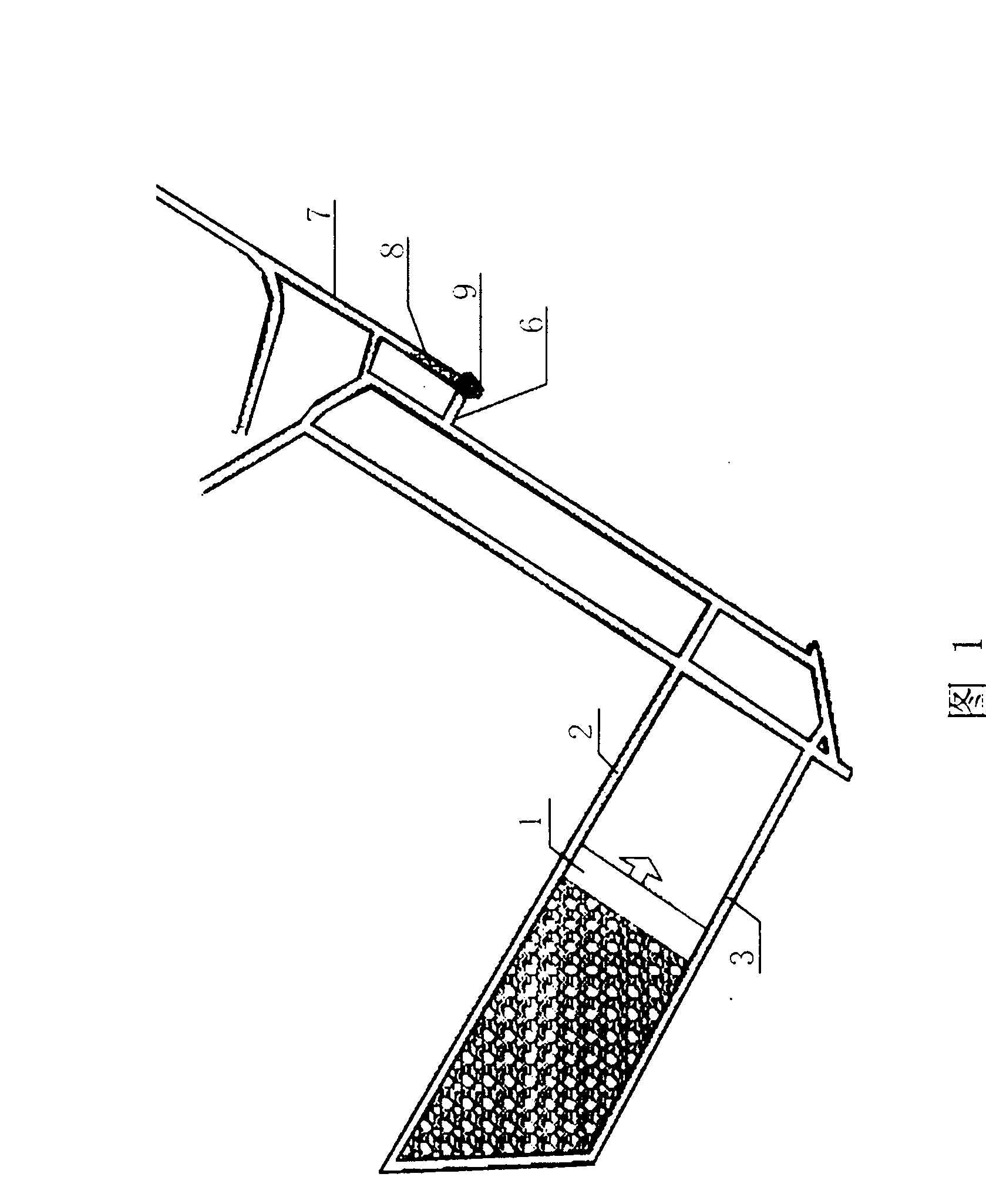

Method for filling coal-steam-free extraction working surface goaf by coal mine waste rock

InactiveCN1936271ARealize no MasuiImprove the environmentUnderground miningSurface miningMining engineeringCoal pillar

The invention relates to a method to filling non-coal column face workplace by gangue. It includes the following steps: directly transferring the gangue to gangue storehouse, discharging to the slat conveyer through hopper gate, transferring the gangue to face through gangue transferring belt, face slat conveyer, and high speed gangue throwing belt. It needs not to smash the gangue and could realize zero stacking of gangue to improve coal mine environment. The invention supplies a new coal mining method for realizing environment protecting exploitation.

Owner:SHANDONG SHENGQUAN MINING

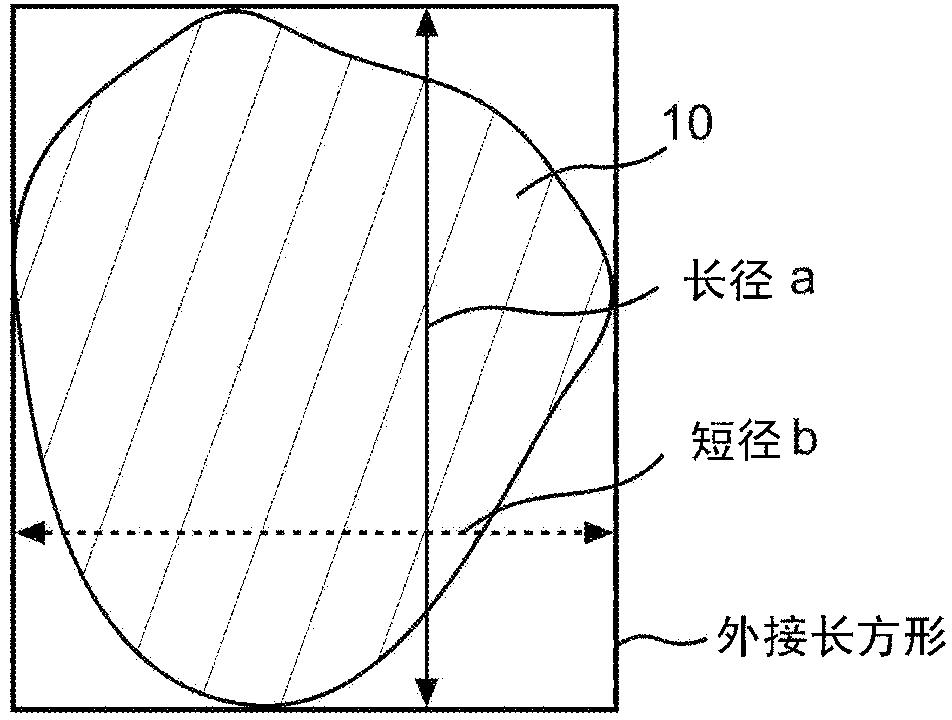

Negative electrode for non-queous electrolyte secondary battery, non-aqueous electrolyte secondary battery and production method for negative electrode for non-aqueous electrolyte secondary battery

ActiveCN103262306AIncreased ion storage capacityHigh filling densityCell electrodesLi-accumulatorsGraphiteMaterials science

The present invention provides a negative electrode for a non-aqueous electrolyte secondary battery which can be produced at a reduced cost and has a high graphite packing density and consistent quality. The negative electrode for a non-aqueous electrolyte secondary battery is characterized by comprising a negative-electrode current collector and a negative-electrode active material layer disposed on the negative-electrode current collector, and in that the negative-electrode active material layer contains flaky graphite formed through the graphitization of needle coke, granular graphite formed through the graphitization of coke, and a binder.

Owner:ELIIY POWER

Ceramic membrane with improved adhesion to plasma-treated polymeric support material and the manufacture and usage thereof

ActiveCN101301586APrecisely defined pore size distributionWeakened ionic conductivitySemi-permeable membranesMembranesCeramic membranePolymer

The invention relates to a flexible ceramic membrane which is suitable for batters as a spacer according to different embodiment manners, in particular for lithium battery. The invention further relates to the preparation method thereof, wherein plasma processing is carried out to the polymer nonwovens.

Owner:EVONIK DEGUSSA GMBH

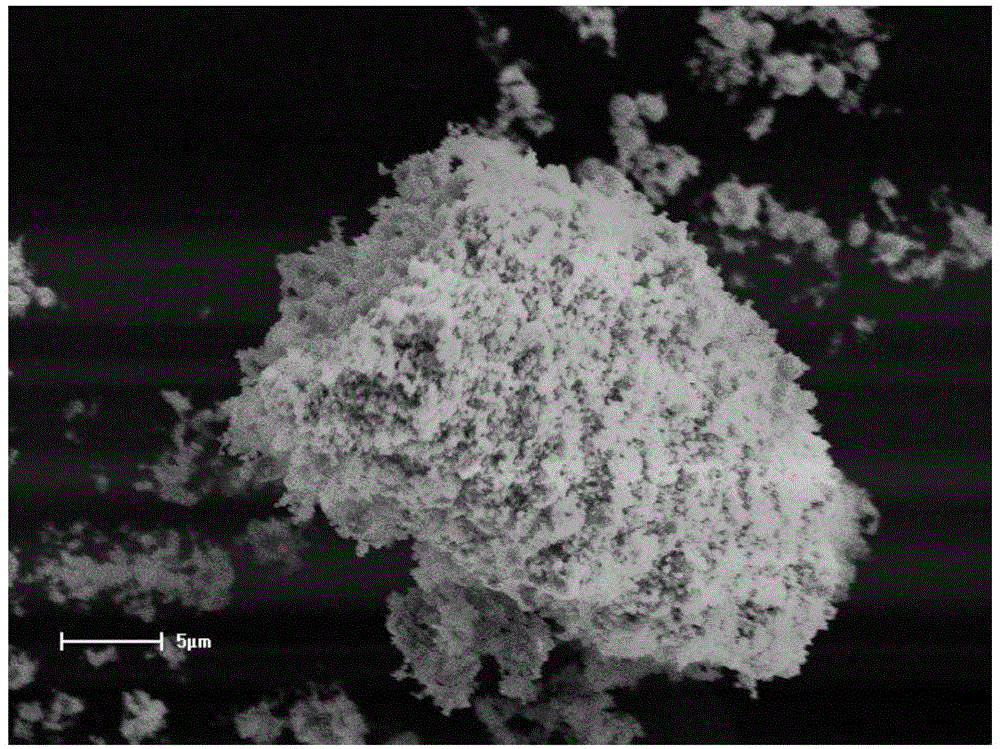

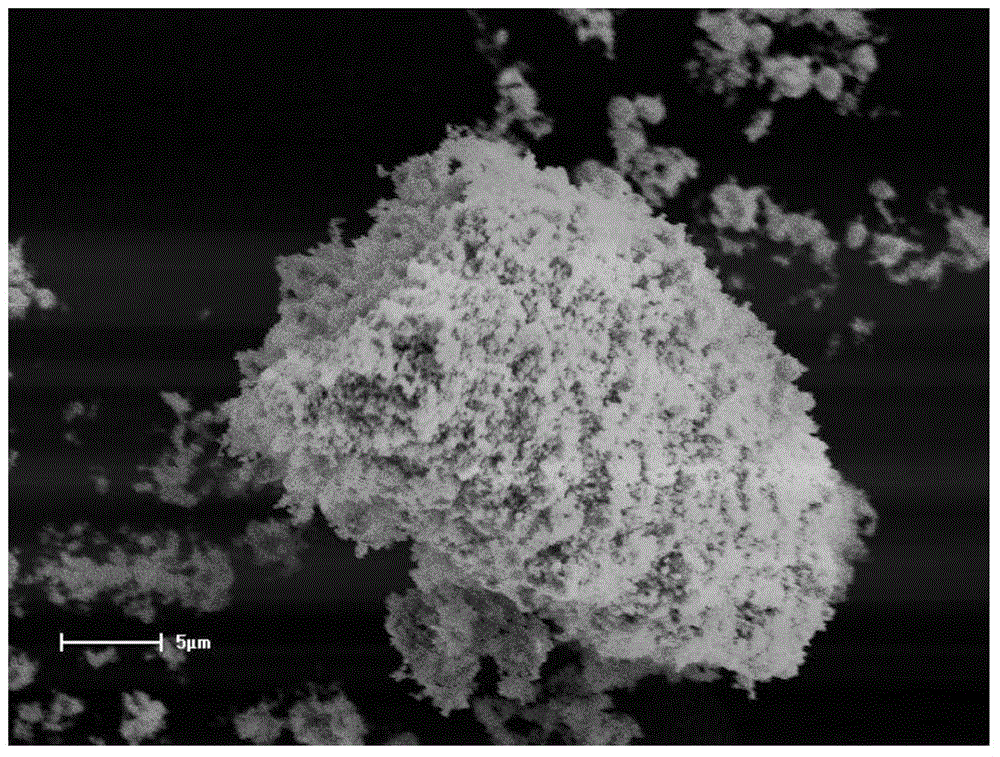

Preparation method of carbon coated Sn-Co/graphene microsphere negative electrode material of lithium ion battery

ActiveCN104409708AHigh filling densityIncrease volume capacityMaterial nanotechnologyNegative electrodesMicrosphereSodium-ion battery

In the prior art, there is no a lithium ion cell negative electrode material, which is based on a Sn-Co alloy and can have the advantages of large lithium storage capacity, high coulomb efficiency, long cycle life, and large filling density at the same time. In order to solve the problem mentioned above, the invention provides a preparation method of a carbon coated Sn-Co alloy / graphene microsphere negative electrode material of a lithium ion battery, and belongs to the technical field of lithium ion battery negative electrode materials. The preparation method comprises the following steps: depositing nano Sn-Co alloy onto the graphene surface through a wet process, then granulating nano intermediates through a spray drying method, coating the composite microsphere intermediates by asphalt, and finally heating to carbonize the intermediates so as to obtain the carbon coated Sn-Co alloy / graphene microsphere negative electrode material. The technology of the preparation method is simple, and thus the preparation method is suitable for massive industrial production. The prepared carbon coated Sn-Co alloy / graphene microsphere negative electrode material has the advantages of large lithium storage capacity, high coulomb efficiency, long cycle life, and large filling density.

Owner:江苏嘉明碳素新材料有限公司

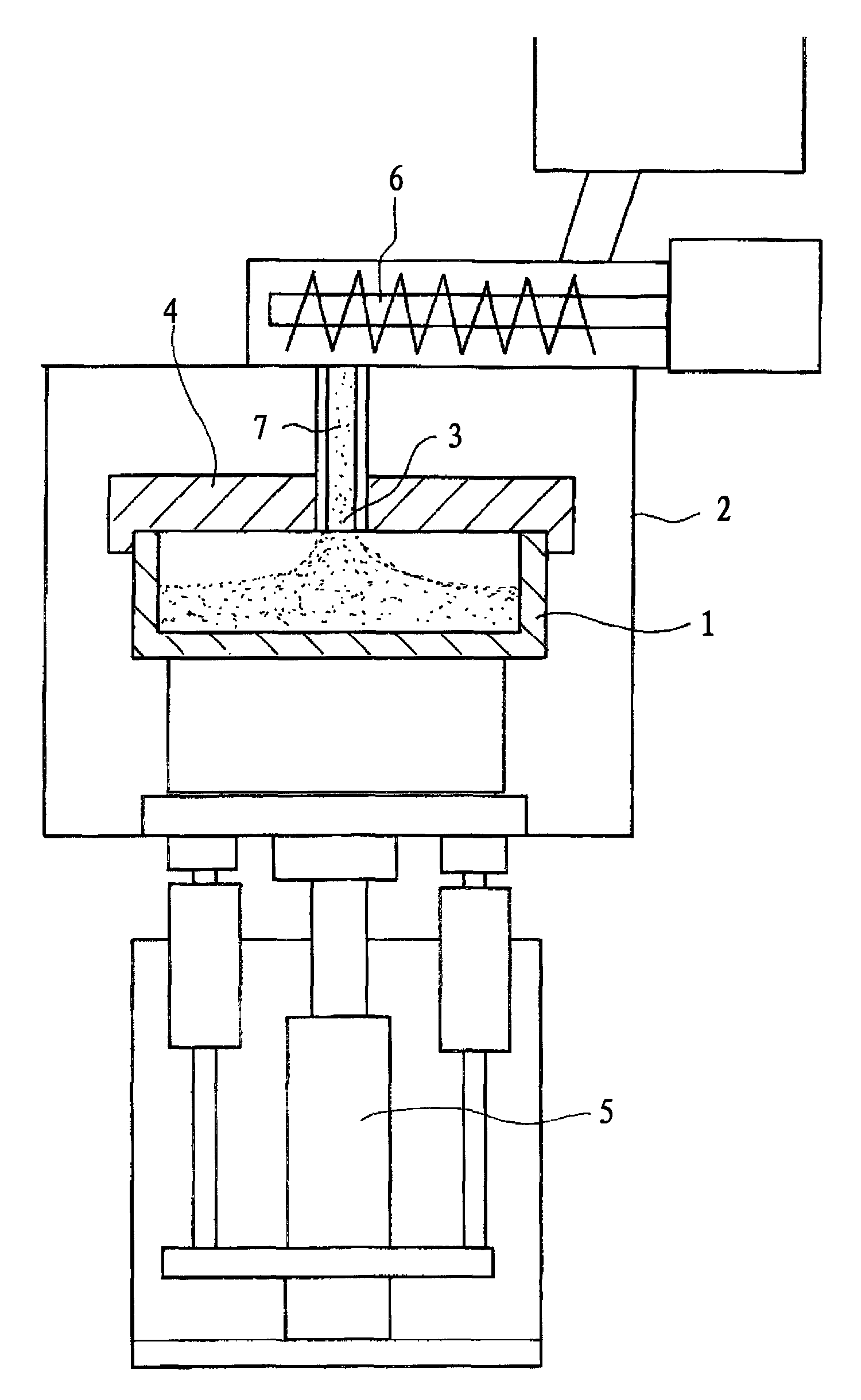

How to fill the inside of the sagger with powder

ActiveCN102275746AEasy transferWeight increaseElectrode manufacturing processesShaping press ramCooking & bakingMaterials science

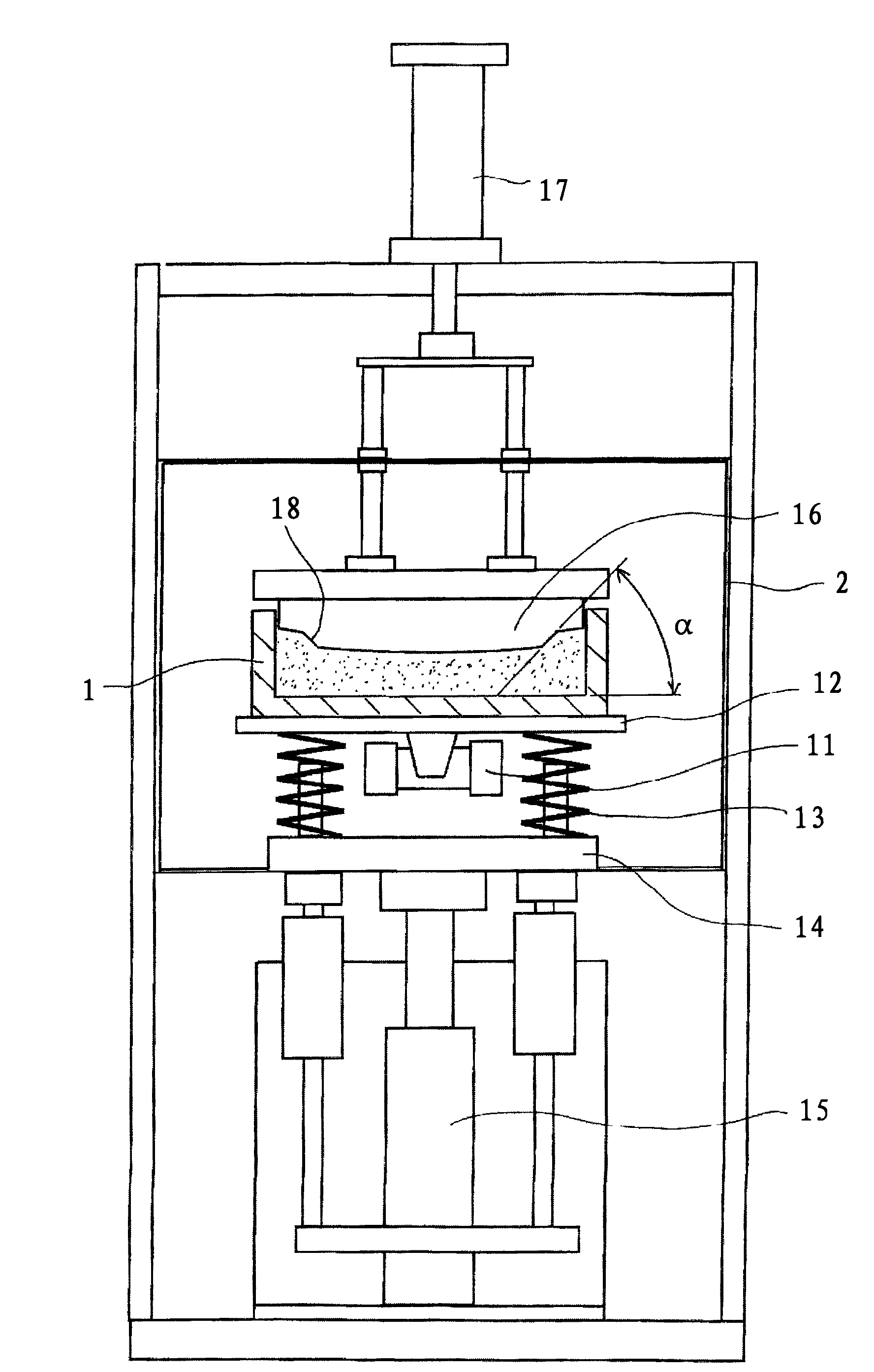

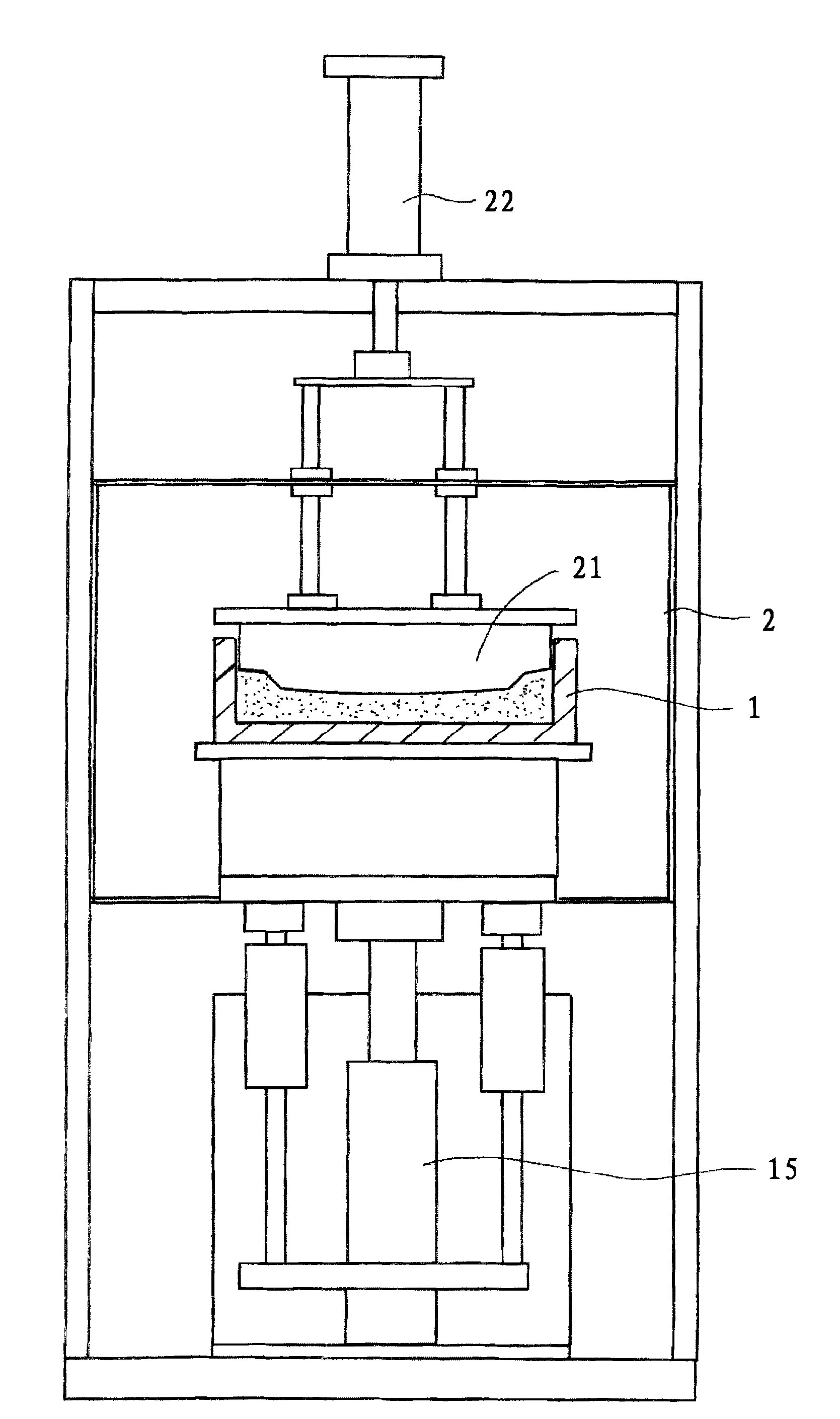

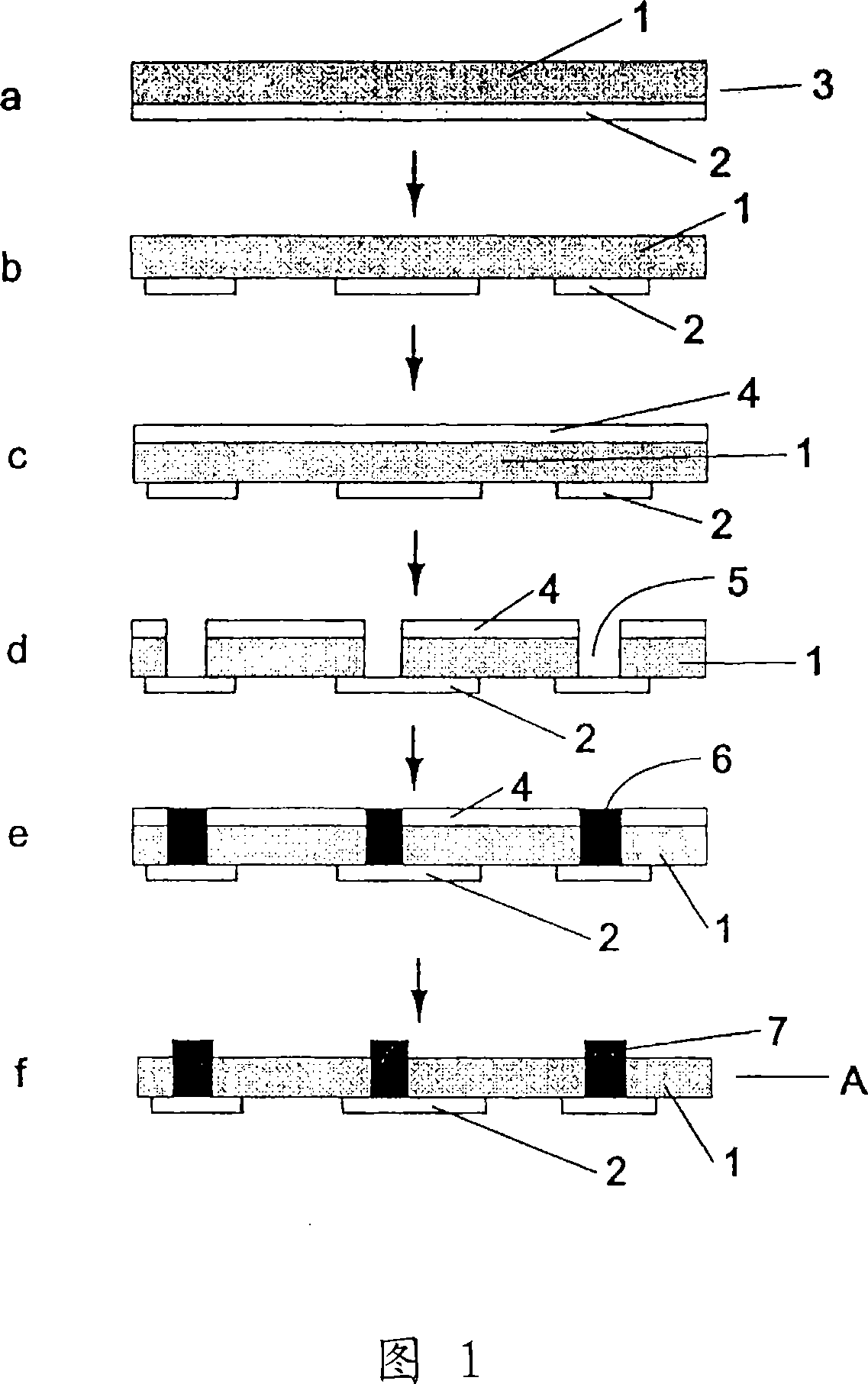

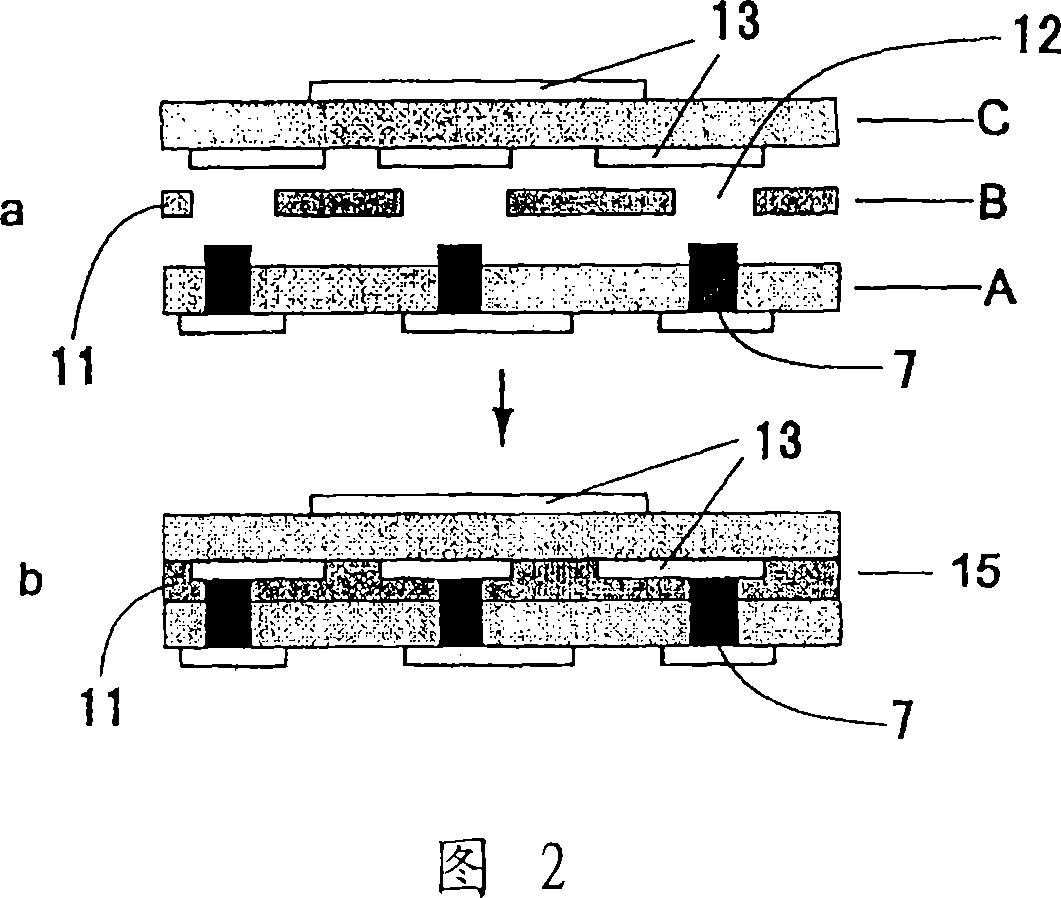

PROBLEM TO BE SOLVED: To provide a method for packing powder which is in a dry state and made to have a surface shape formed by making the thickness of the central part of the powder thicker and the thickness of the peripheral part of the powder thinner in a sagger in a compacted state.SOLUTION: A prescribed amount of the dry powder is supplied into the sagger 1. While a first pressing plate 16 is brought down to a prescribed position to a powder surface, vibration is applied to the sagger 1, and the powder surface is formed in a shape in which the middle is hollowed according to the lower surface shape of the first pressing plate. Next, the formed powder surface is pressed down further by a second pressing plate 17 to compact the powder. In this way, the productivity of a burning process and the quality of baking can be improved.

Owner:NGK INSULATORS LTD

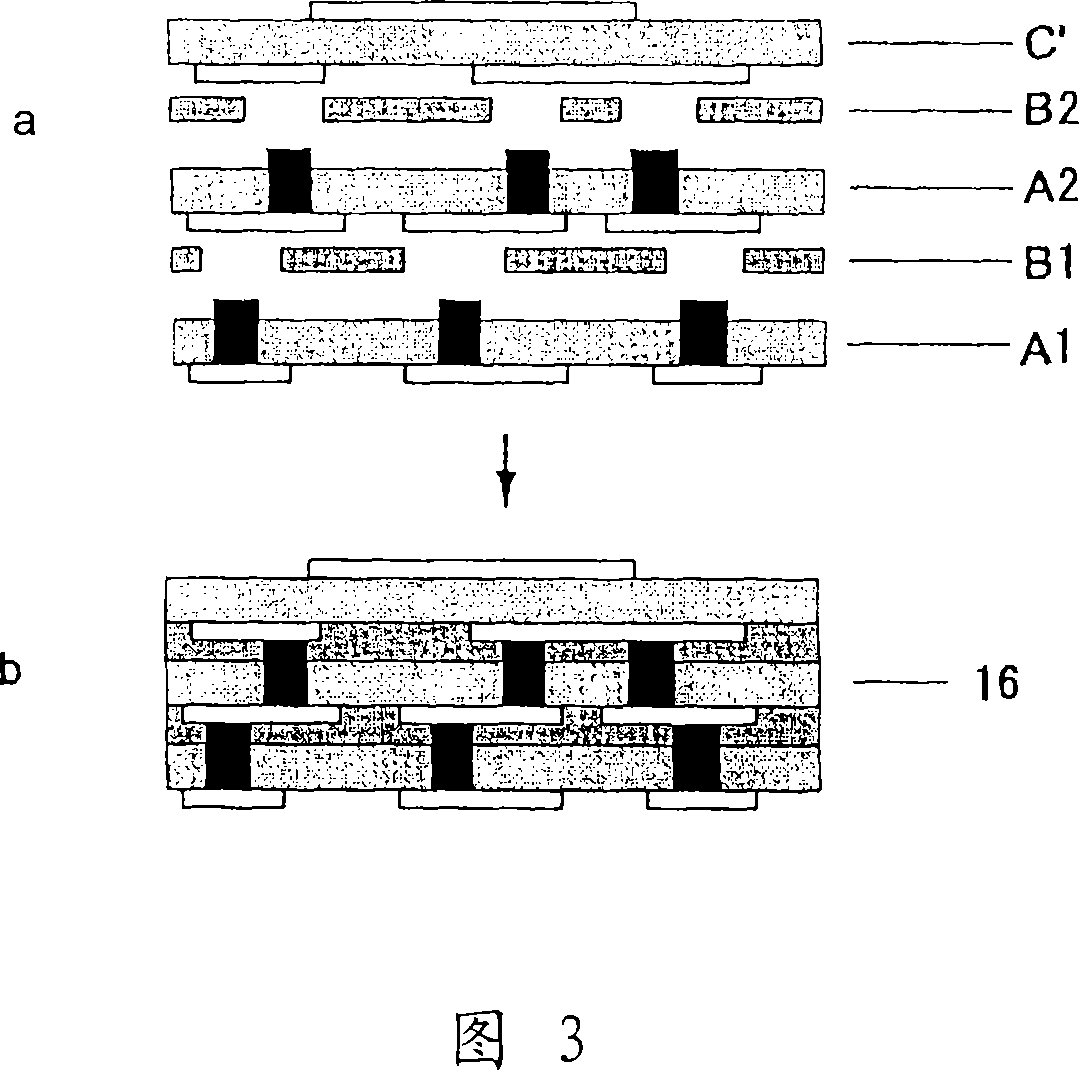

Conductive paste and multilayer printed wiring board using same

InactiveCN101031982AHigh filling densityReduce connectionsConductive materialPrinted circuit aspectsConductive pasteCopper foil

The present invention provides a conductive paste comprising flake conductive fillers having a 99% cumulative particle size of 25 [mu]m or less and a binder resin as essential components. The flake conductive fillers are metal particles having a silver-copper alloy surface layer. The conductive paste according to the present invention is fused with a part of a copper foil circuit to which the conductive paste is to be connected during connection by heating and pressurization, and has high electrical conductivity and high fill ration in a via hole. Thus, the conductive paste according to the present invention provides a multilayer printed wiring board that has high reliability of connection and excellent interlayer connection.

Owner:SUMITOMO ELECTRIC IND LTD

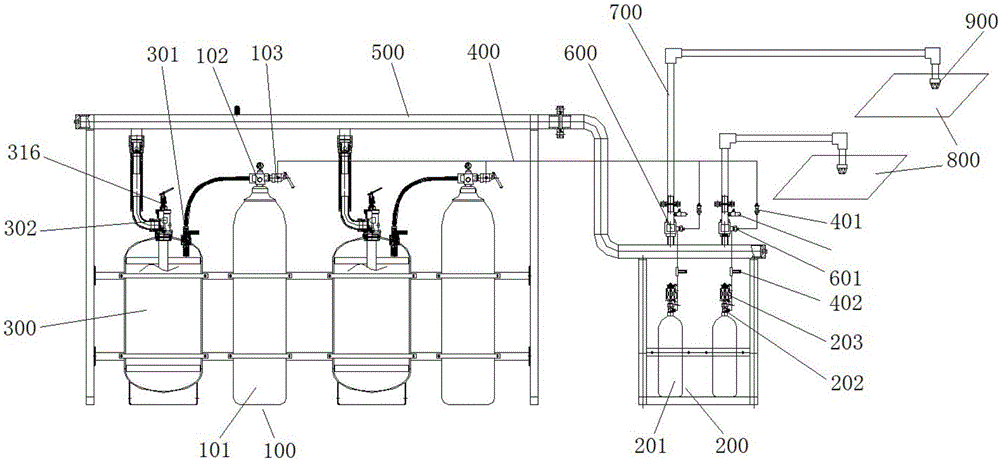

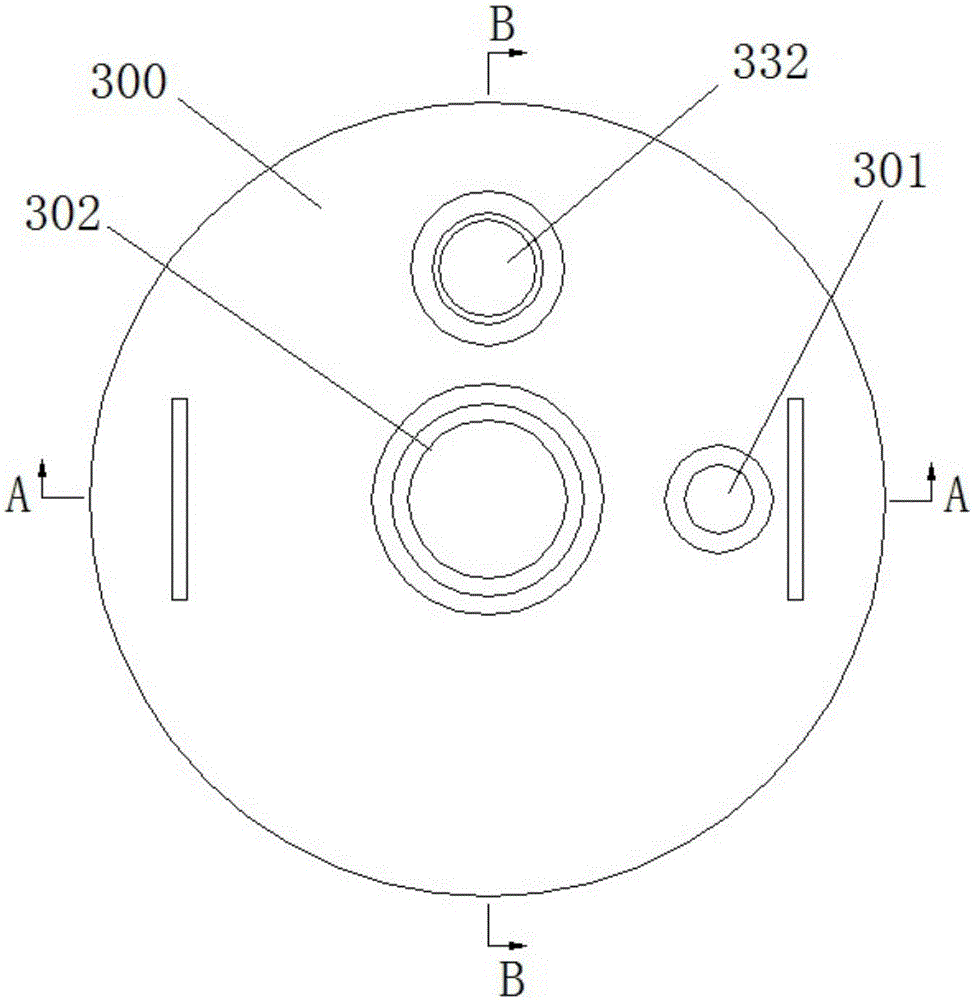

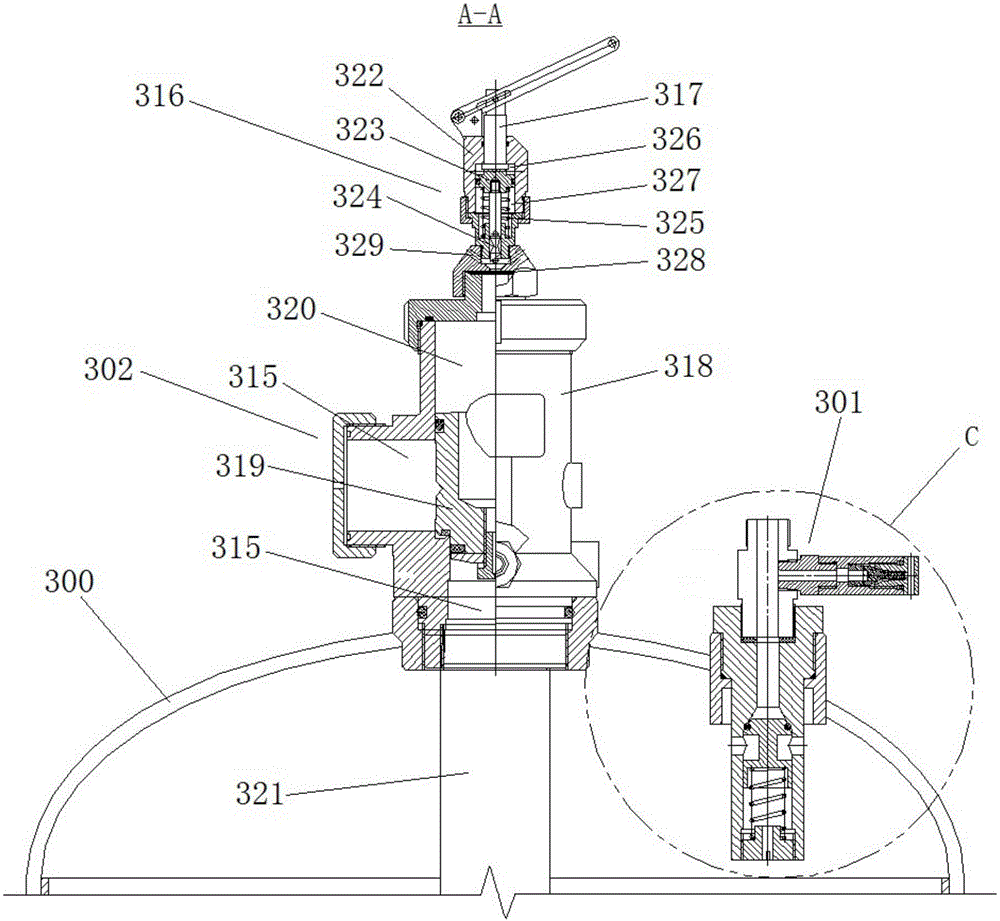

Spare pressure type heptafluoropropane fire extinguishing system

The invention provides a spare pressure type heptafluoropropane fire extinguishing system. The spare pressure type heptafluoropropane fire extinguishing system comprises a power gas cylinder set, a driving gas cylinder set, a heptafluoropropane storage cylinder, a fire extinguishing agent container valve, a pressure reducing device, a power gas container valve, a driving gas container valve, a first starter, a second starter and an electromagnetic starter. When a fire breaks out, the electromagnetic starter and the gas driving cylinder set act, released gas enters the first starter and the third starter respectively, the power gas container valve and a selection valve are opened, and gas released from the power gas cylinder set constantly enters the heptafluoropropane storage cylinder after being subjected to pressure reduction by virtue of the pressure reducing device and delayed; and when pressure of a fire extinguishing agent in the heptafluoropropane storage cylinder reaches a certain pressure, the fire extinguishing agent enters the second starter by virtue of a connecting pipe, the second starter acts to open the fire extinguishing agent container valve, and the fire extinguishing agent in the heptafluoropropane storage cylinder extinguishes a fire in a specified protection zone by virtue of a pipe network. By applying the spare pressure type heptafluoropropane fire extinguishing system provided by the invention, safety of the fire extinguishing system can be guaranteed, and constant pressure stable output of heptafluoropropane also can be guaranteed.

Owner:广东鹰穗消防设备有限公司

Anti-ultraviolet and moisture-absorption quick-dry yarn, and production technology and application thereof

ActiveCN109112688AIncreased durabilityReduce finishing processYarnMonocomponent polyesters artificial filamentFiberYarn

The invention relates to the production technology of an anti-ultraviolet and moisture-absorption quick-dry fabric. The technology is characterized by firstly, adopting a polyester resin and an addition agent to melt, extruding, and pelletizing to make polyester chips; then, through a spinning technology, forming a fine denier polyester staple fiber; and then, through siro spinning and weaving technologies, an alkali decrement technology and the like, making a finished product. The anti-ultraviolet and moisture-absorption quick-dry fabric has advantages that a lot of micropores and channels are distributed on a surface so that the fabric has a high capillary effect; sweat can be quickly transferred to an outer groove through the micropores so as to form a moisture-absorption quick-dry effect; and an environment-friendly ultraviolet absorbent, a shielding agent and the polyester chips are fused, and a high-performance anti-ultraviolet and moisture-absorption quick-dry fabric after a special spinning technology is formed.

Owner:ZHEJIANG LANTIANHAI FAB TECHNOLAGY CO LTD

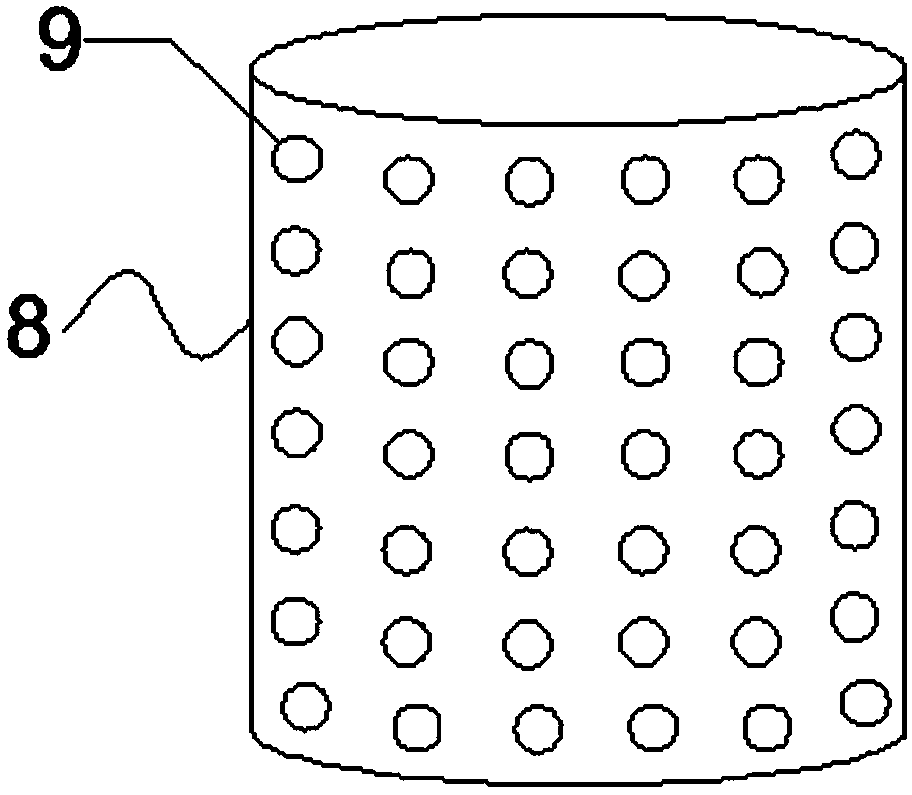

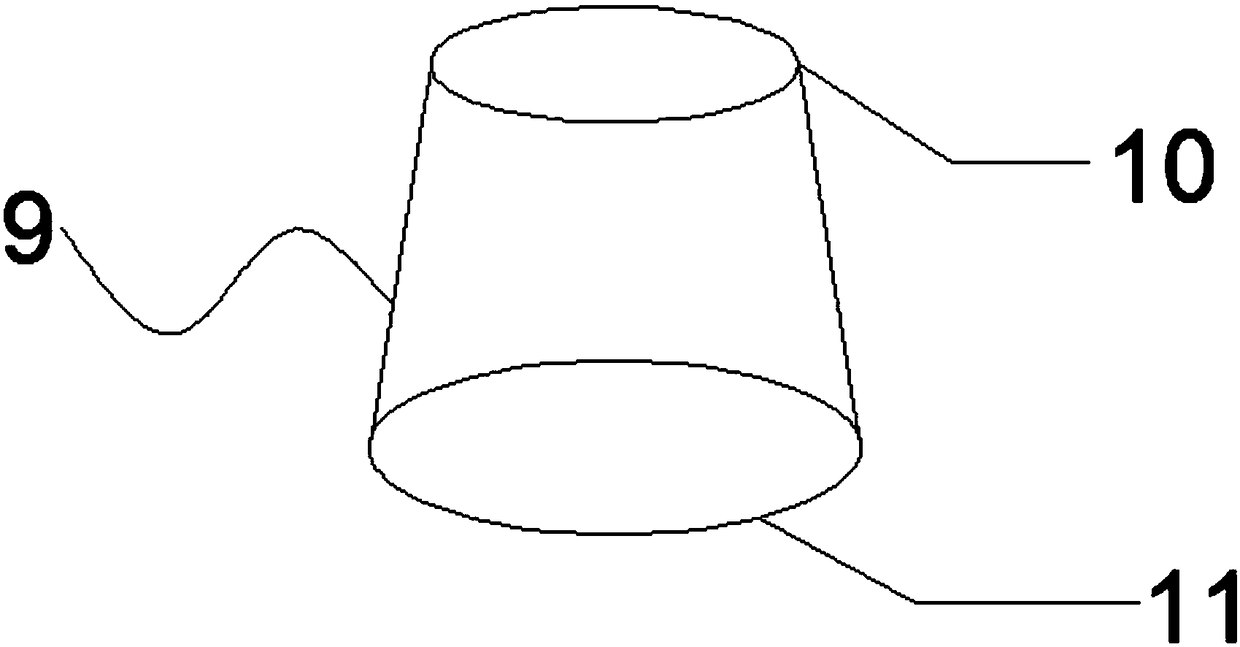

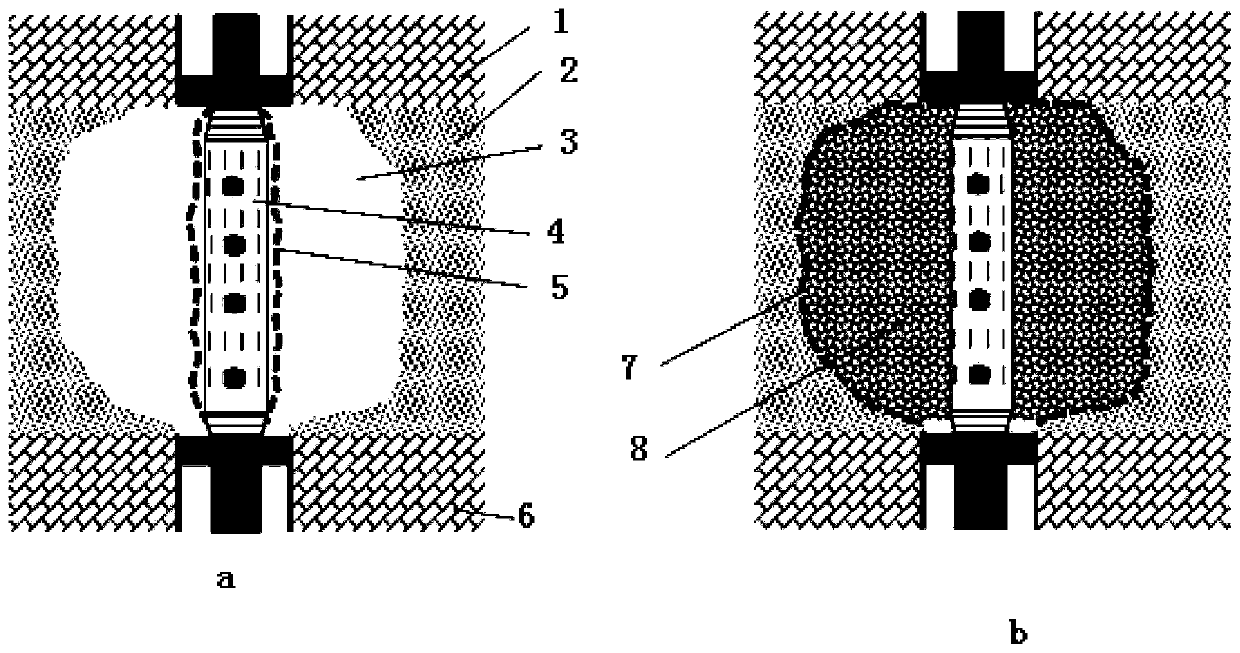

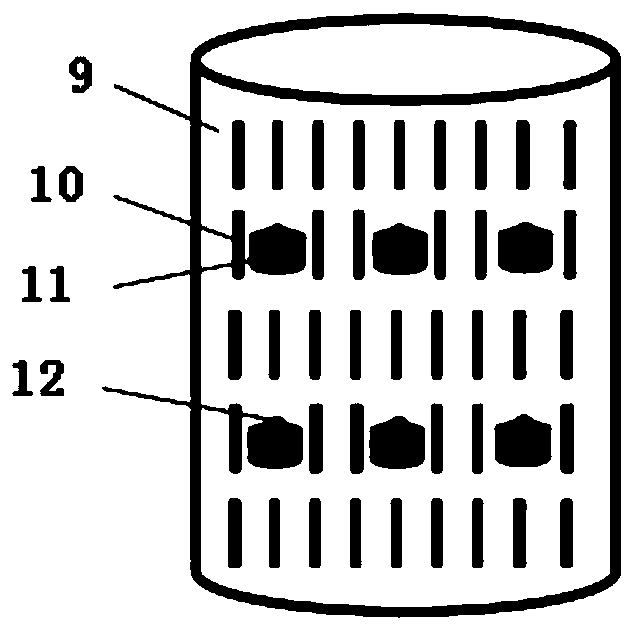

No-rinse pipe type membrane assembly for water treatment

PendingCN108579441AEasy to produceQuality is not easy to controlSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisUnit massVolumetric Mass Density

The invention provides a no-rinse pipe type membrane assembly for water treatment and relates to a no-rinse pipe type membrane assembly for water treatment. The invention aims to solve the problems that the existing inlet no-rinse DF membrane has large diameter and thick wall, the membrane prepared from raw materials with unit mass has small filtering area, low membrane silk filling density, low membrane porosity and high operation pressure, and the energy consumption is increased. The no-rinse pipe type membrane assembly for water treatment consists of a sealing head, a membrane pipe and a metal hoop; the sealing head consists of a water flow port, a sealing head screw cap and a sealing ring; and the membrane pipe consists of a plurality of core pipes, a sealing head screw cylinder, a clean water port, a membrane shell cylinder and pipe type membrane silk. The DF membrane assembly at the inlet can be replaced, and application in the fields of waste water treatment and recycling as well as material separation and concentration instead of the traditional settling pool or filtering pool.

Owner:HEILONGJIANG UNIV

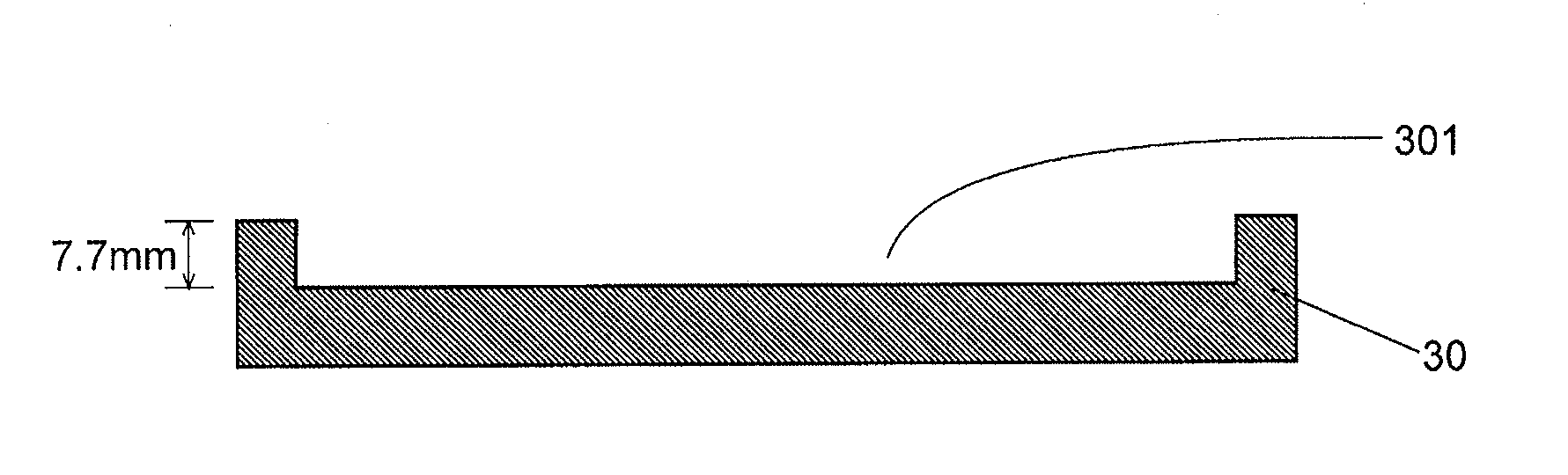

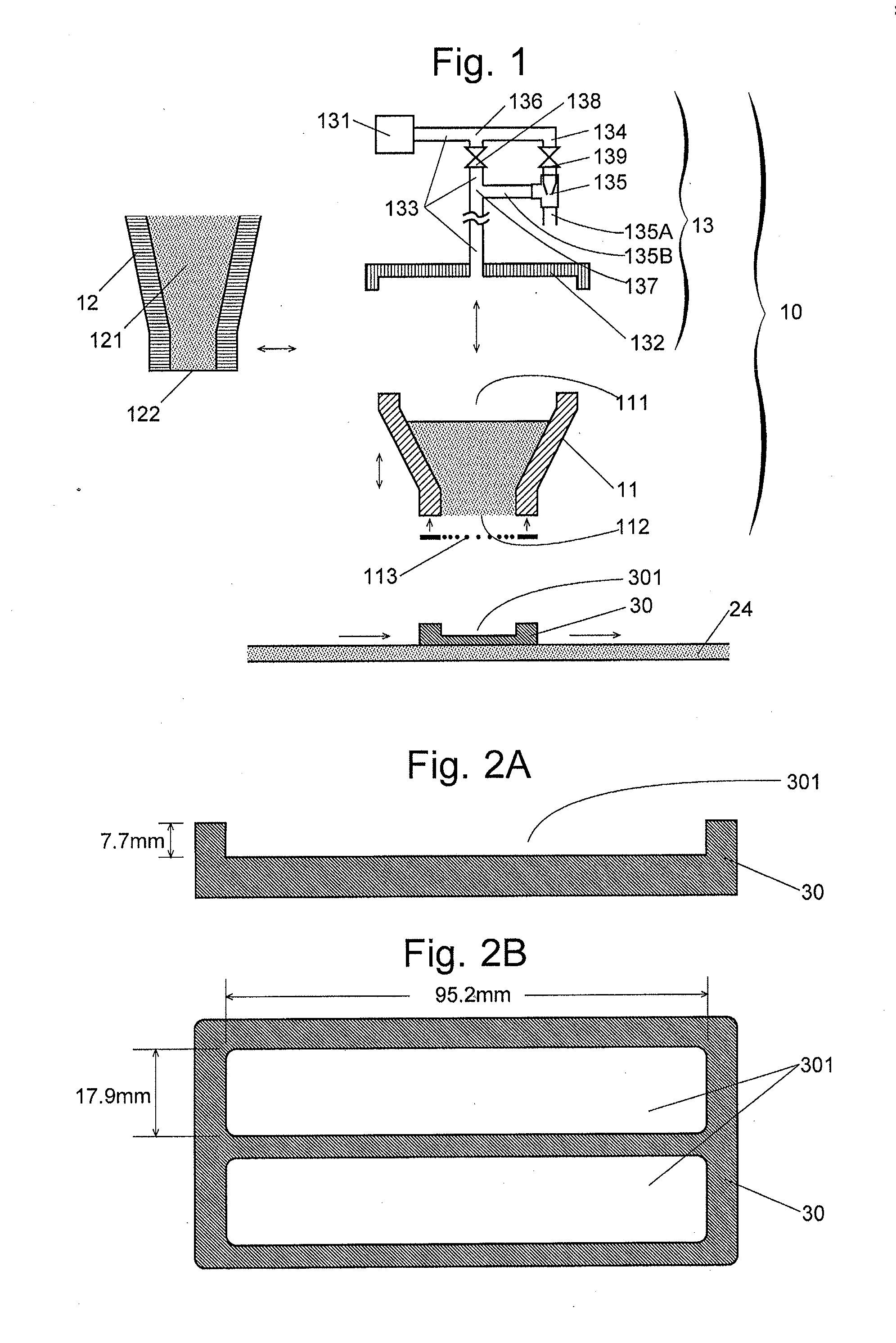

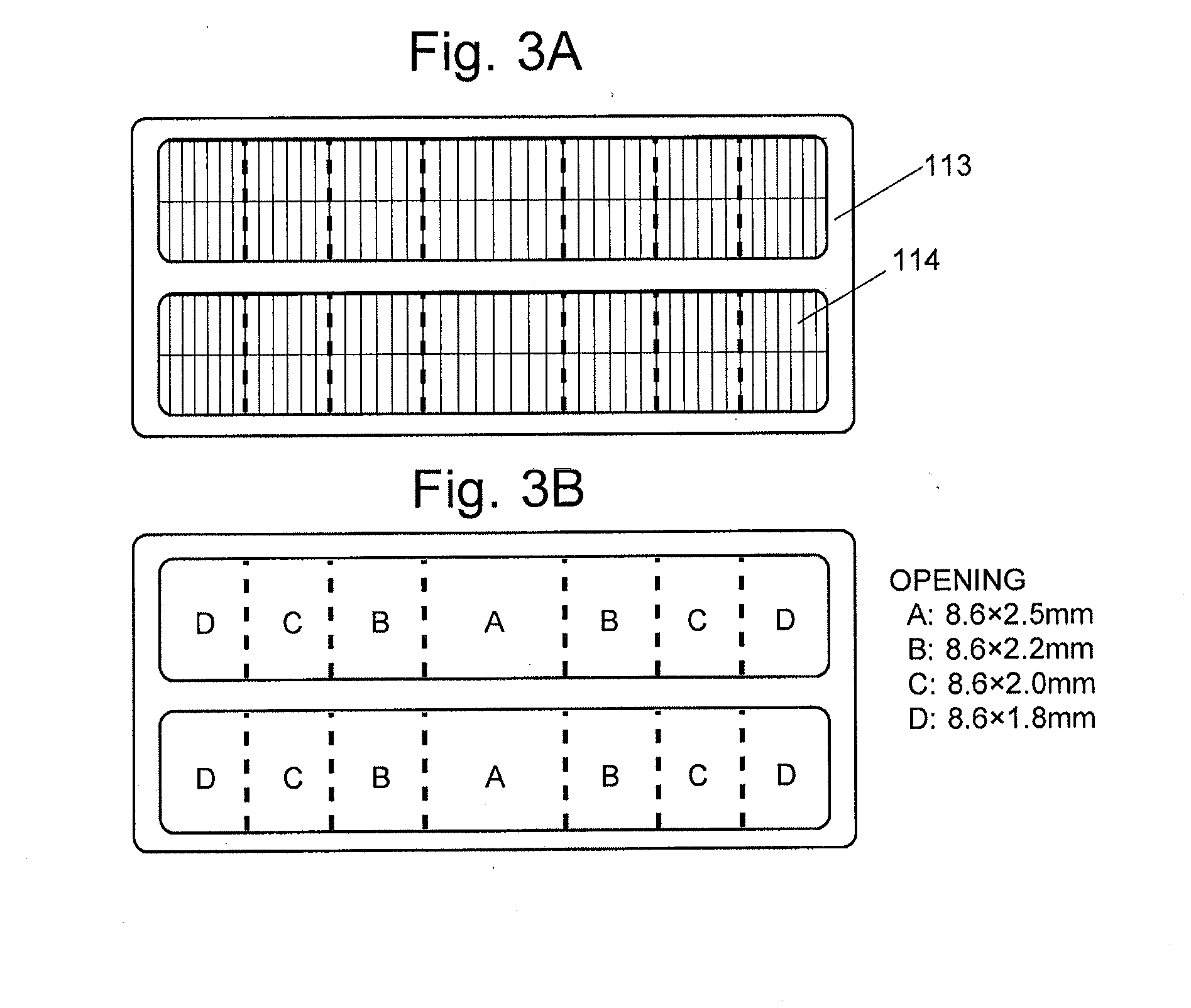

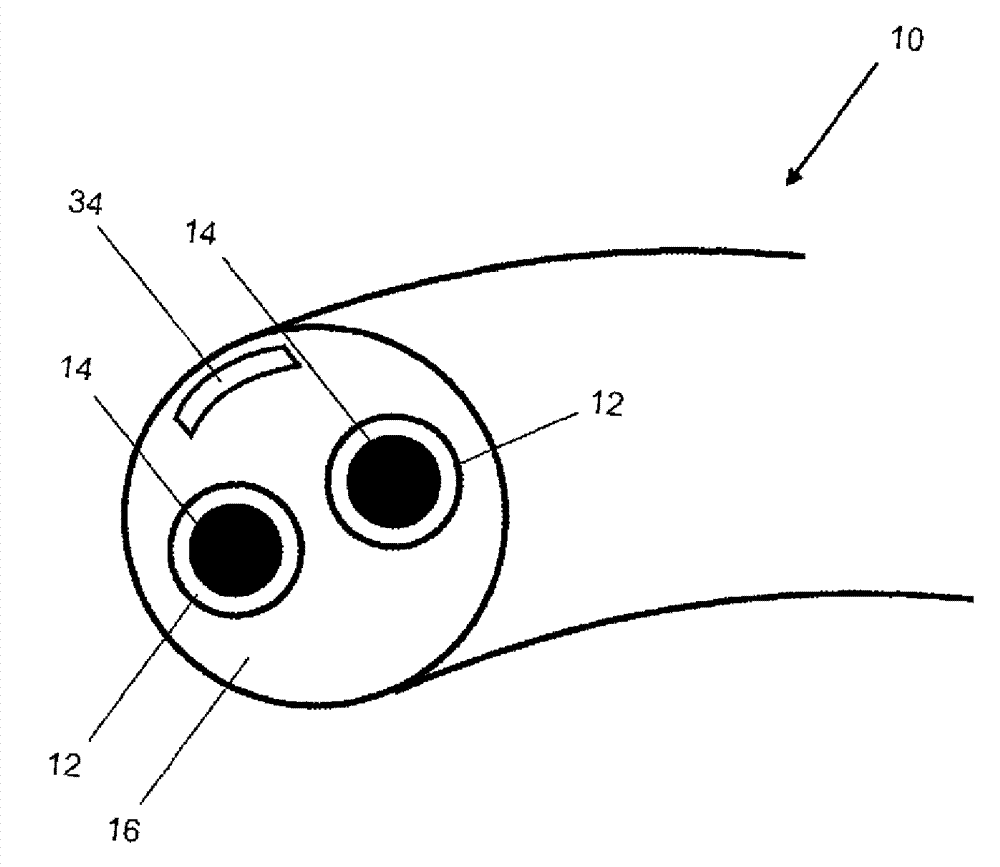

Powder-filling system

ActiveUS20150364252A1Uniform filling densityImprove fluidityAuxillary shaping apparatusInductances/transformers/magnets manufactureEngineeringMechanical engineering

A powder-filling system capable of filling a container with powder at an approximately uniform filling density has: a hopper having an opening removably and hermetically closably attached to the container, the hopper communicating with the container at the opening for supplying powder to a container; a powder supplier for supplying powder to the hopper; a gas supplier for repeatedly supplying compressed gas in a pulsed form to the hopper, with the hopper hermetically closably attached to the container; and a sieve member provided at the opening and having a smaller openings in a region near a side wall of the hopper than in its central region. The smaller openings in the region near the side wall of the hopper where the powder more easily falls from the hopper into the container impedes the fall of the powder in that region and improves the overall uniformity in the filling density.

Owner:DAIDO STEEL CO LTD

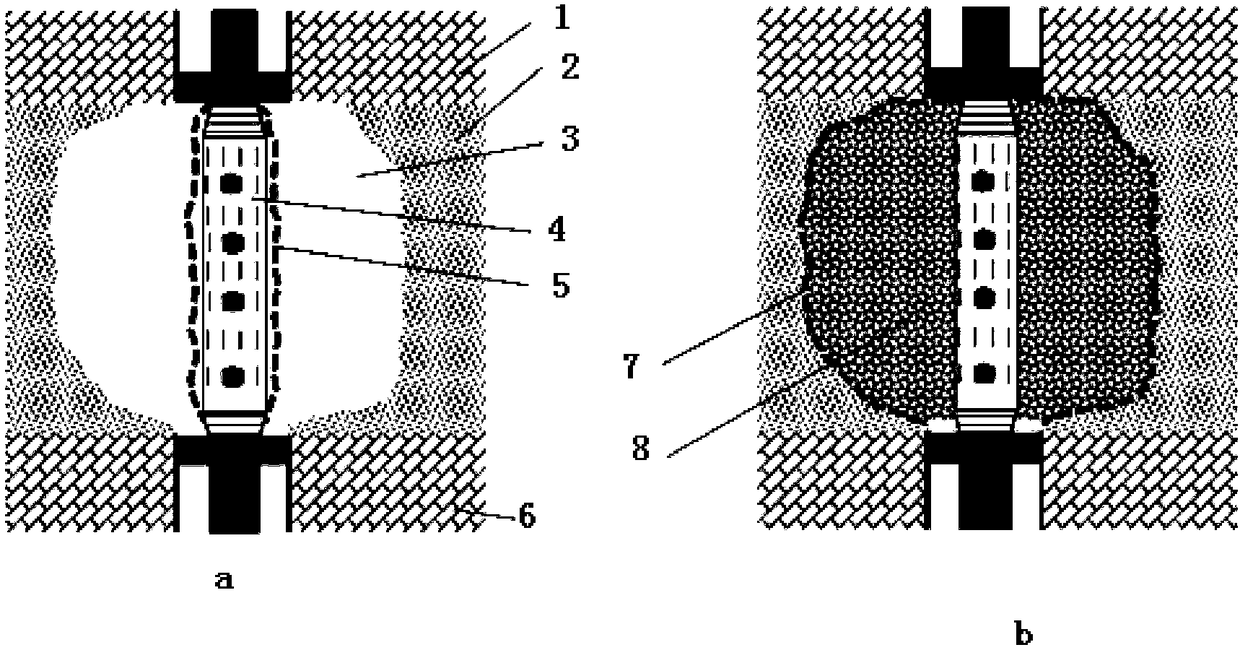

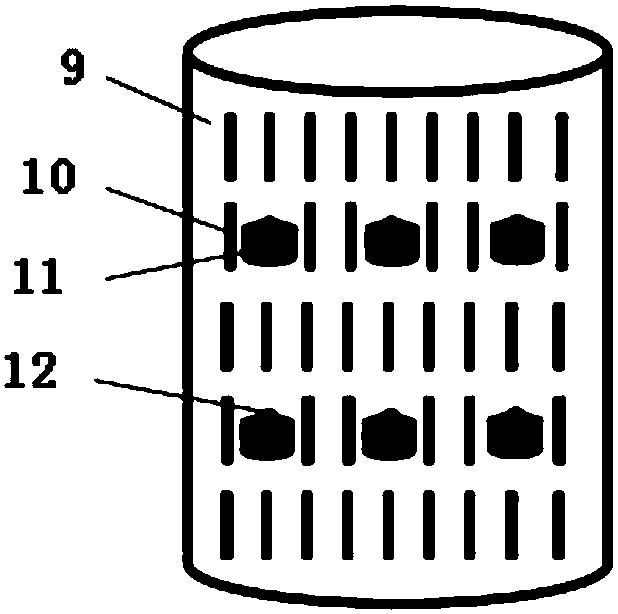

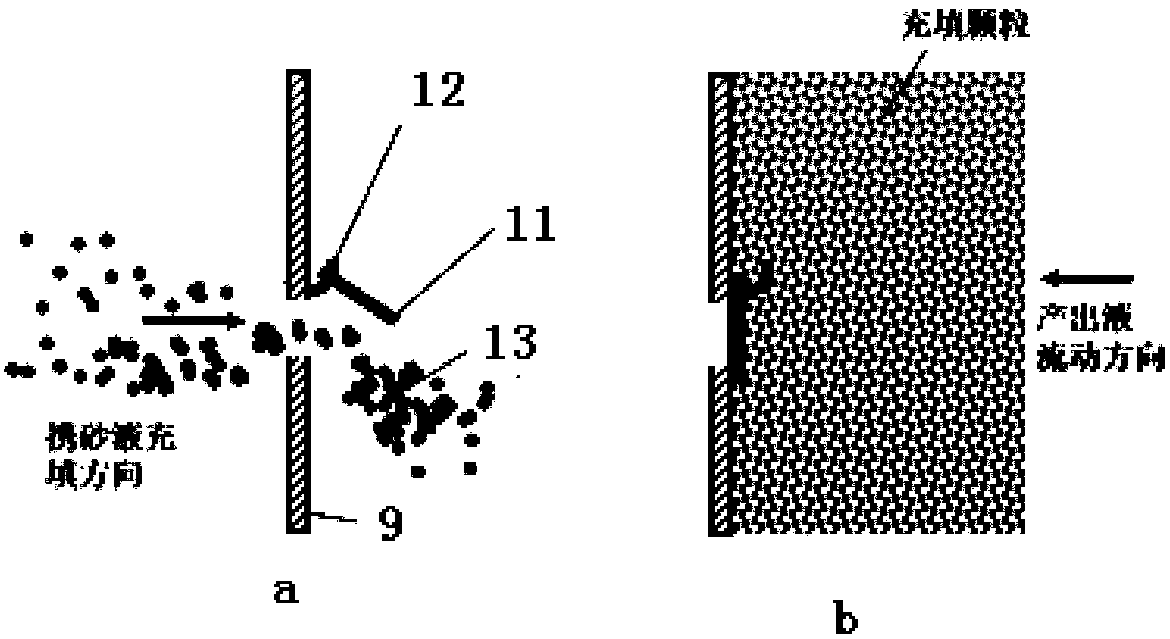

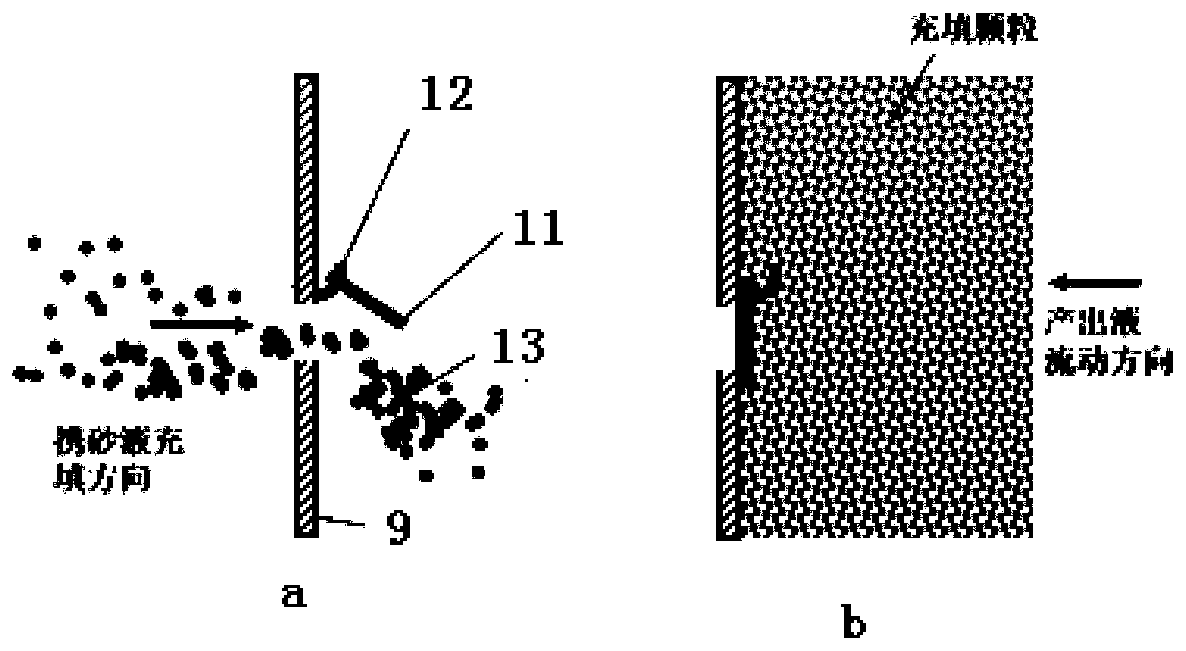

Open hole well external inclusion expansion packing sand control method

ActiveCN108533235AImprove sand control strengthReduce moisture contentFluid removalControl layerEngineering

The invention relates to an open hole well external inclusion expansion packing sand control method. An external inclusion high-expansion packing sand control screen is tripped into a voided space, afree extension external inclusion continuously stretches outwards under the action of high pushing pressure difference of sand-carrying fluid solid particles until the outer wall of the free extensionexternal inclusion is fitted with an open hole well wall, and packing sand control is realized. According to the sand control method, a high-thickness, high-filling-compactness and high-stability packing strip is formed in immediate vicinity of wellbore of a target sand control layer, and a sand barrier is high in overall sand control strength and long in sand control validity period. The overallsand control strength of the sand barrier is improved, the water content of an oil-gas well can be effectively reduced, and the sand control validity period is prolonged.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +2

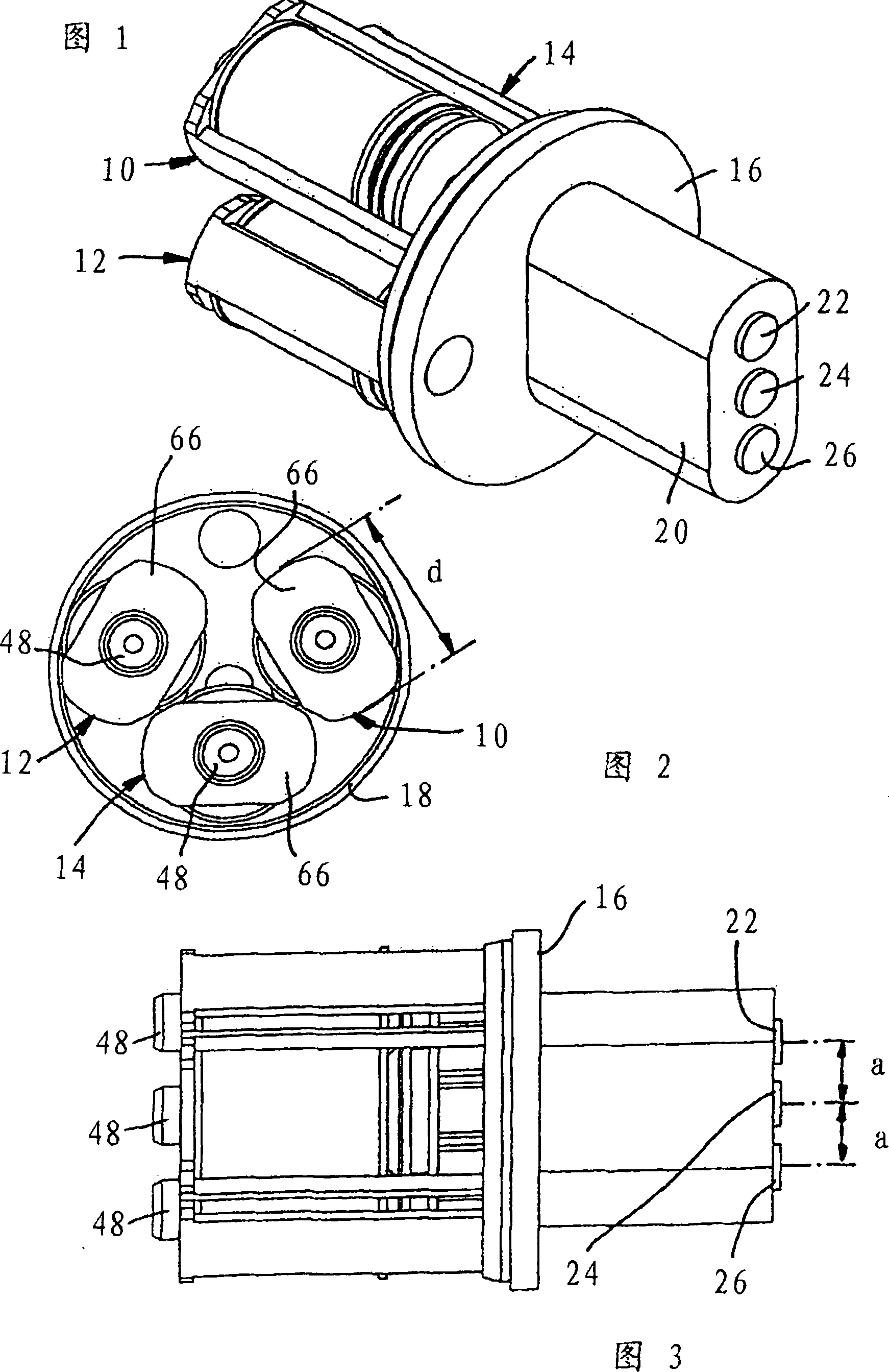

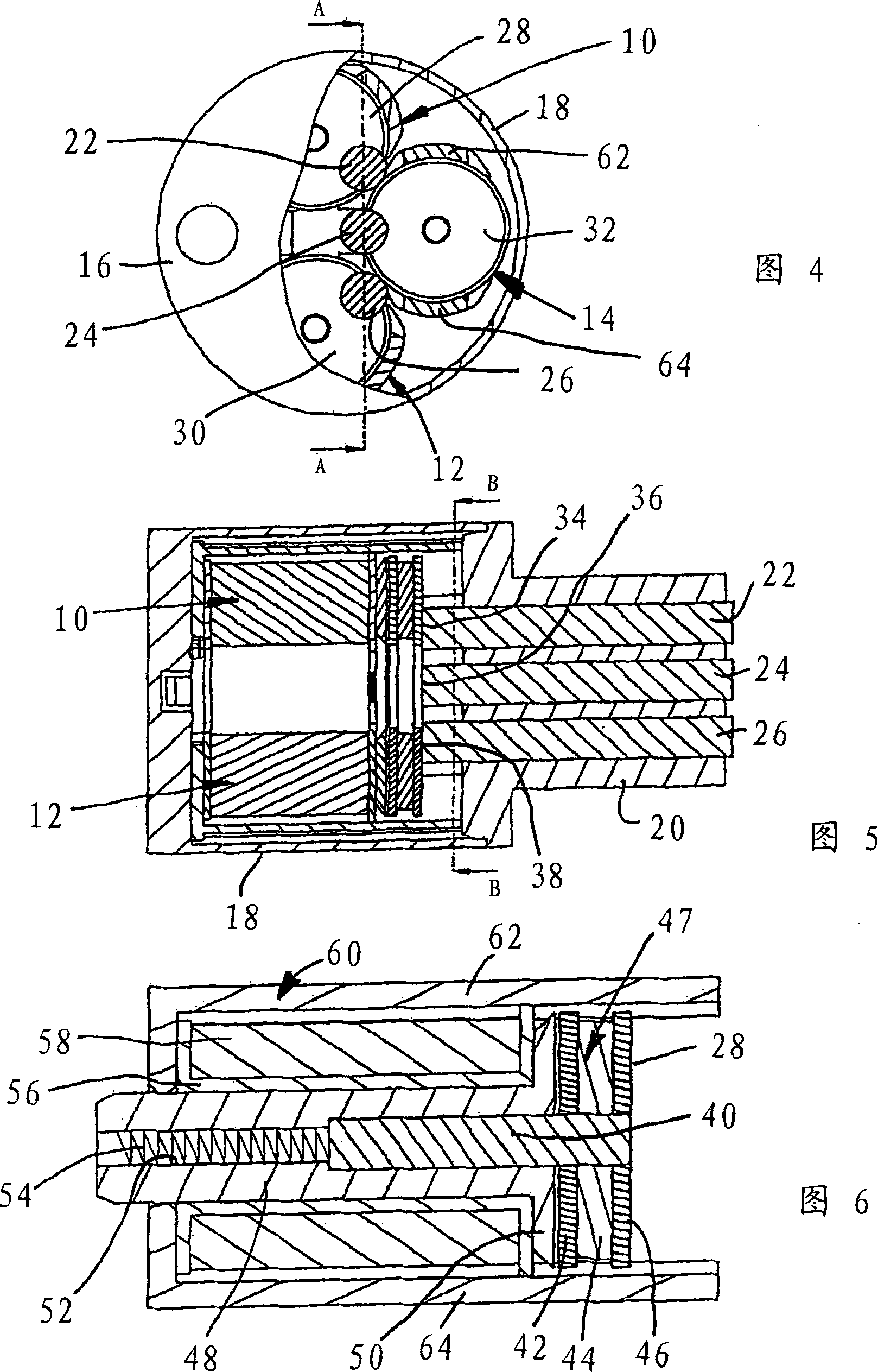

Electromagnetic Actuating Device

ActiveCN103971877ACompact configurationAxis distance is smallValve arrangementsMagnetsEngineeringMechanical engineering

Owner:ETO MAGNETIC GMBH

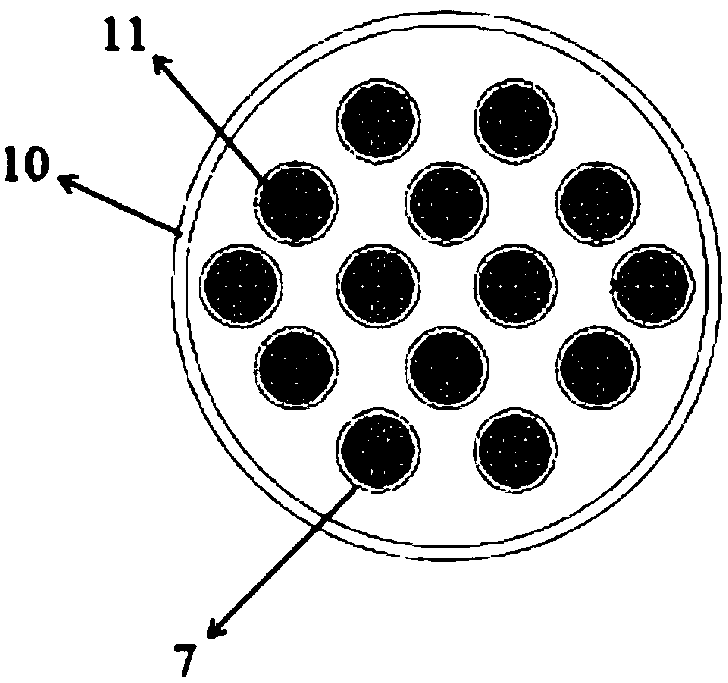

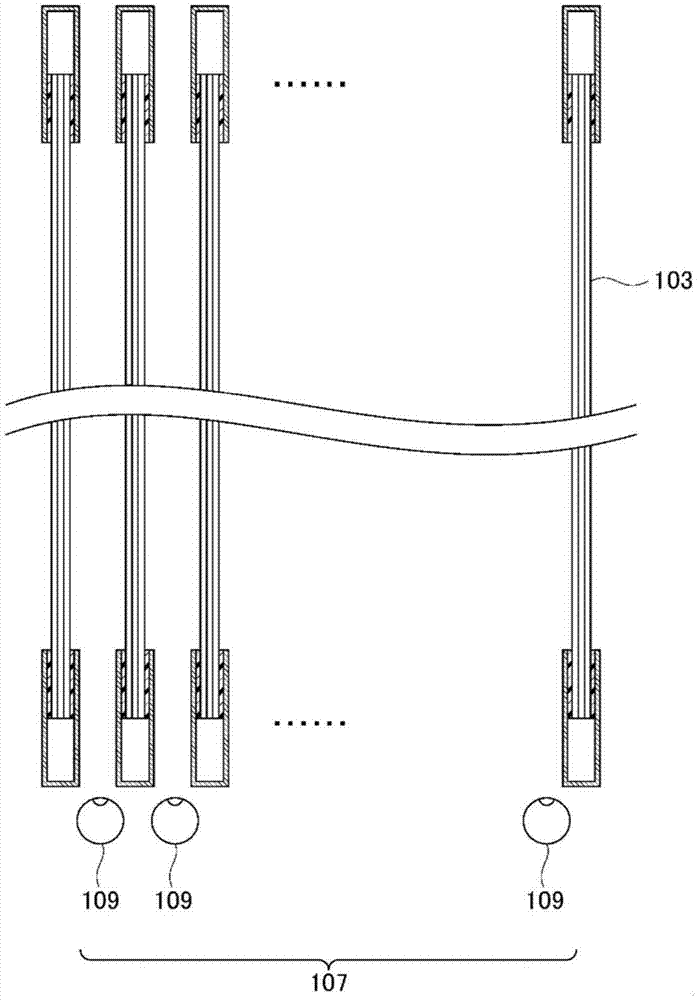

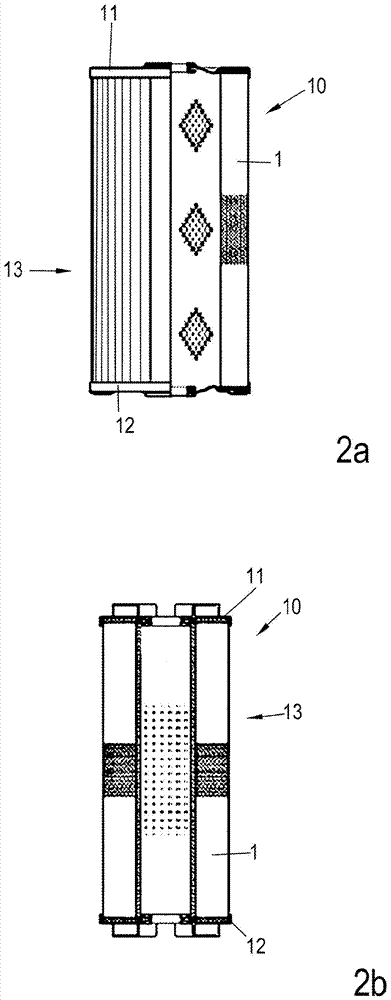

Hollow-fiber membrane module, process for producing hollow-fiber membrane module, and hollow-fiber membrane unit equipped with hollow-fiber membrane module

ActiveCN104334259AImprove cleaning efficiencyThrough speed dropSemi-permeable membranesMembranesWater collectionPermeation

Provided are a hollow-fiber membrane unit in which the membranes are prevented from decreasing in permeation rate and the membrane area per unit volume has been rendered suitable and which can hence treat water in an increased rate and a hollow-fiber membrane module which is for use in such hollow-fiber membrane unit. The hollow-fiber membrane module comprises either a hollow-fiber membrane sheet composed of hollow-fiber membranes disposed in a sheet arrangement or a stack of such sheets and a box-shaped water collection member which holds the hollow-fiber membrane sheet or stack, wherein one surface of the water collection member has an opening that is filled with a fixing resin (potting resin) and is for fixing the hollow-fiber membrane sheet stack. The water collection member has a thickness of 20 mm or smaller along the out-of-plane direction of the hollow-fiber membrane sheet, and the proportion of the total area of the cross-sections of the hollow-fiber membranes in the one surface having the opening formed therein is at least 45%.

Owner:MITSUBISHI CHEM CORP

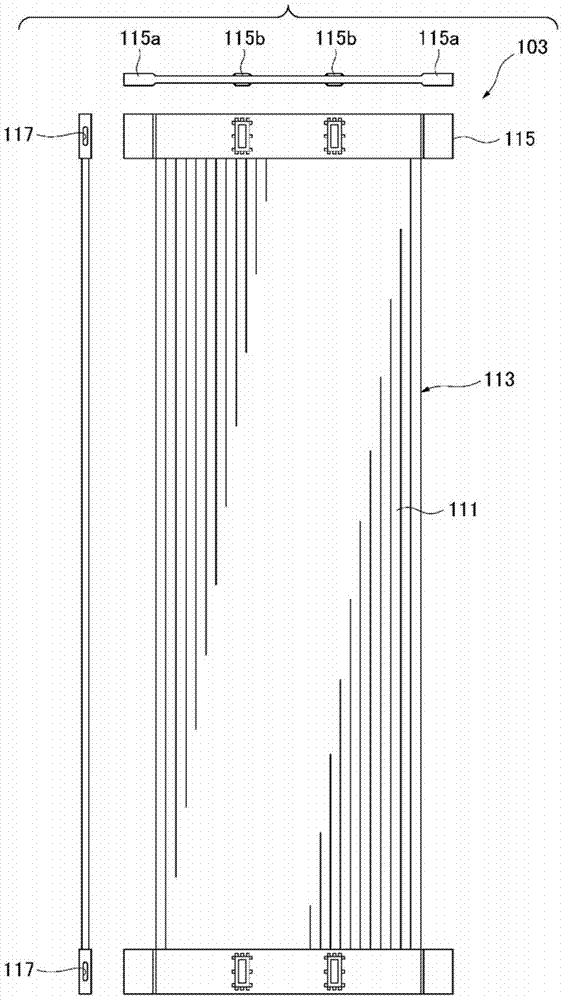

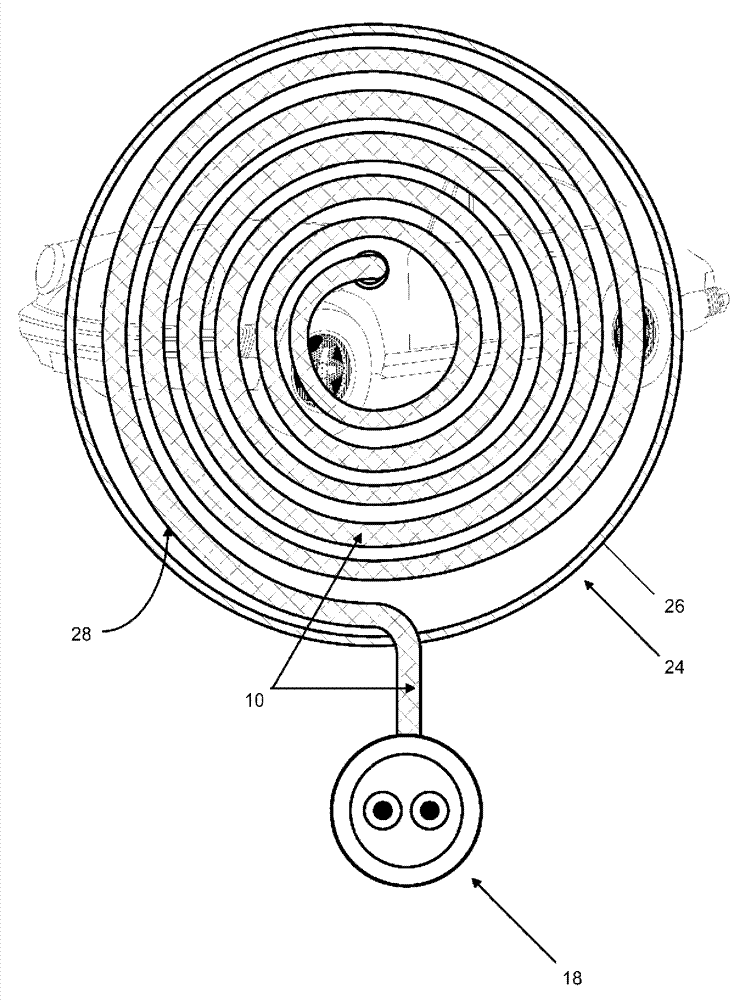

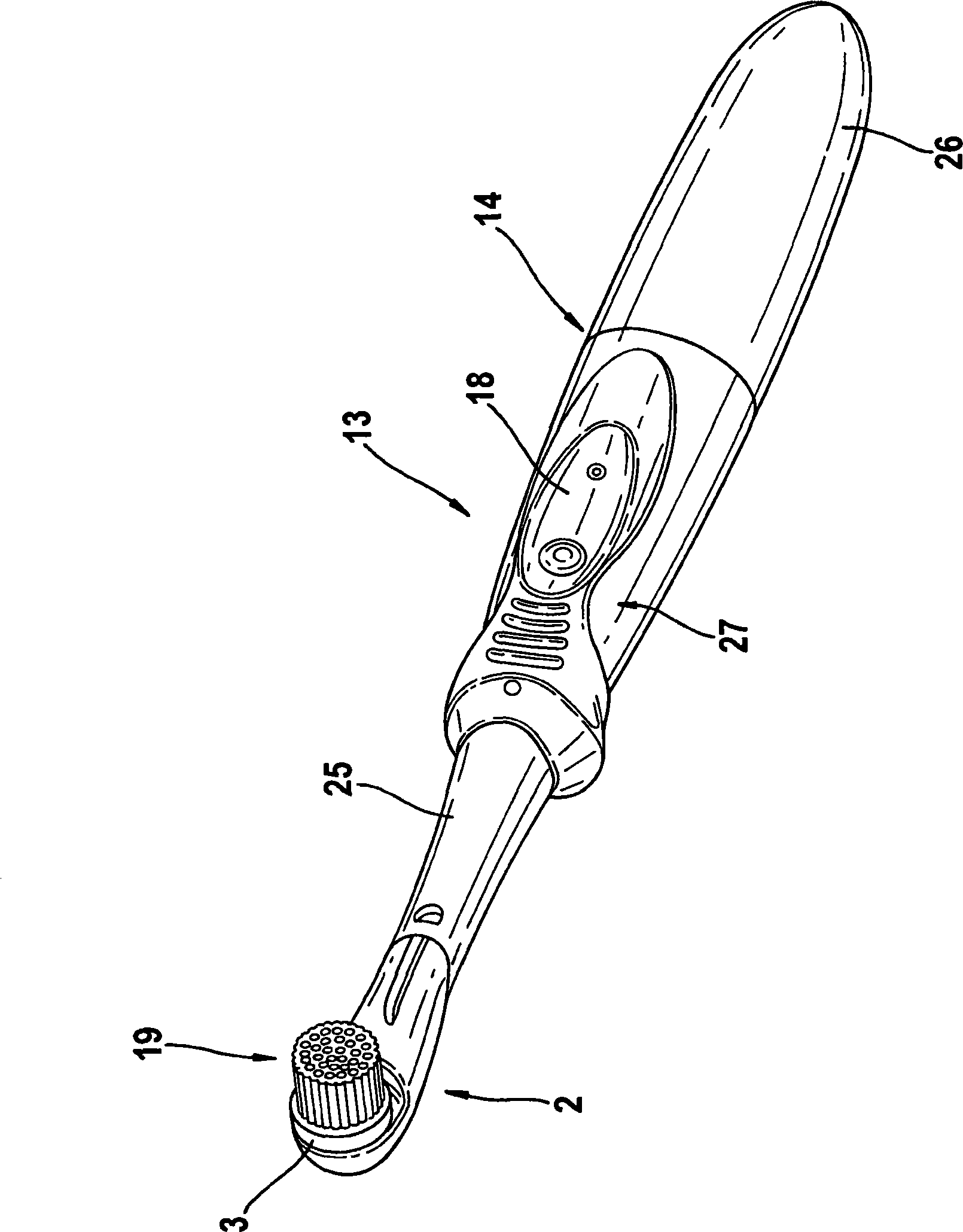

Electrical cable for the energy supply of vehicles

ActiveCN103597684ASmall space requirementLi IntegrationCharging stationsElectric vehicle charging technologyElectricityElectrical conductor

The invention relates to an electrical cable (10), in particular for the energy supply of a vehicle (50), comprising a sheath (16), within which at least two insulated electrical conductors (12) are provided, which are connected to at least one plug connector (18) at at least one first end of the cable (10). According to the invention, the sheath (16) and / or the conductors (12) and / or at least one shaping element (20) preferably provided in the cable (10) is designed in such a way that the cable (10) is held in a resting position by means of a restoring force, in which resting position the cable (10) has the shape of a spiral and is oriented along a flat or curved resting surface.

Owner:LAPP ENG

Method for recycling oxytetracycline hydrochloride from oxytetracycline hydrochloride crystallization mother liquid

ActiveCN107011204AAvoid sex changeNo lossCarboxylic acid amide separation/purificationUltrafiltrationOxytetracycline Hydrochloride

The invention discloses a method for recycling oxytetracycline hydrochloride from oxytetracycline hydrochloride crystallization mother liquid. The method comprises the following steps: (1) adjusting the pH value of oxytetracycline hydrochloride mother liquid, and filtering to remove insoluble impurities; (2) separating treated filtrate by virtue of an ultrafiltration system so as to obtain a concentrated solution rich in oxytetracycline hydrochloride and an alcohol solution containing a small amount of calcium salt, and recycling methanol from the alcohol solution; (3) carrying out alkalization crystallization on the concentrated solution obtained through ultrafiltration, adding an alkalization reagent during alkalization so as to adjust the pH value, and recycling oxytetracycline, wherein the recycling rate of oxytetracycline reaches 93%-96%; and (4) adding recycled oxytetracycline into absolute methanol which is 5 times of volume dose of oxytetracycline, adding a small amount of calcium chloride to aid dissolving, filtering, adding hydrochloric acid methanol, and crystallizing, so as to obtain oxytetracycline hydrochloride. According to the method, inorganic salt, namely calcium salt, is filtered and separated by virtue of a membrane, the concentrated solution is subjected to alkalization crystallization to generate oxytetracycline, oxytetracycline is refined by virtue of hydrochloric acid ethanol so as to generate oxytetracycline hydrochloride, and the content of obtained oxytetracycline hydrochloride reaches 96%.

Owner:扬州联博药业有限公司

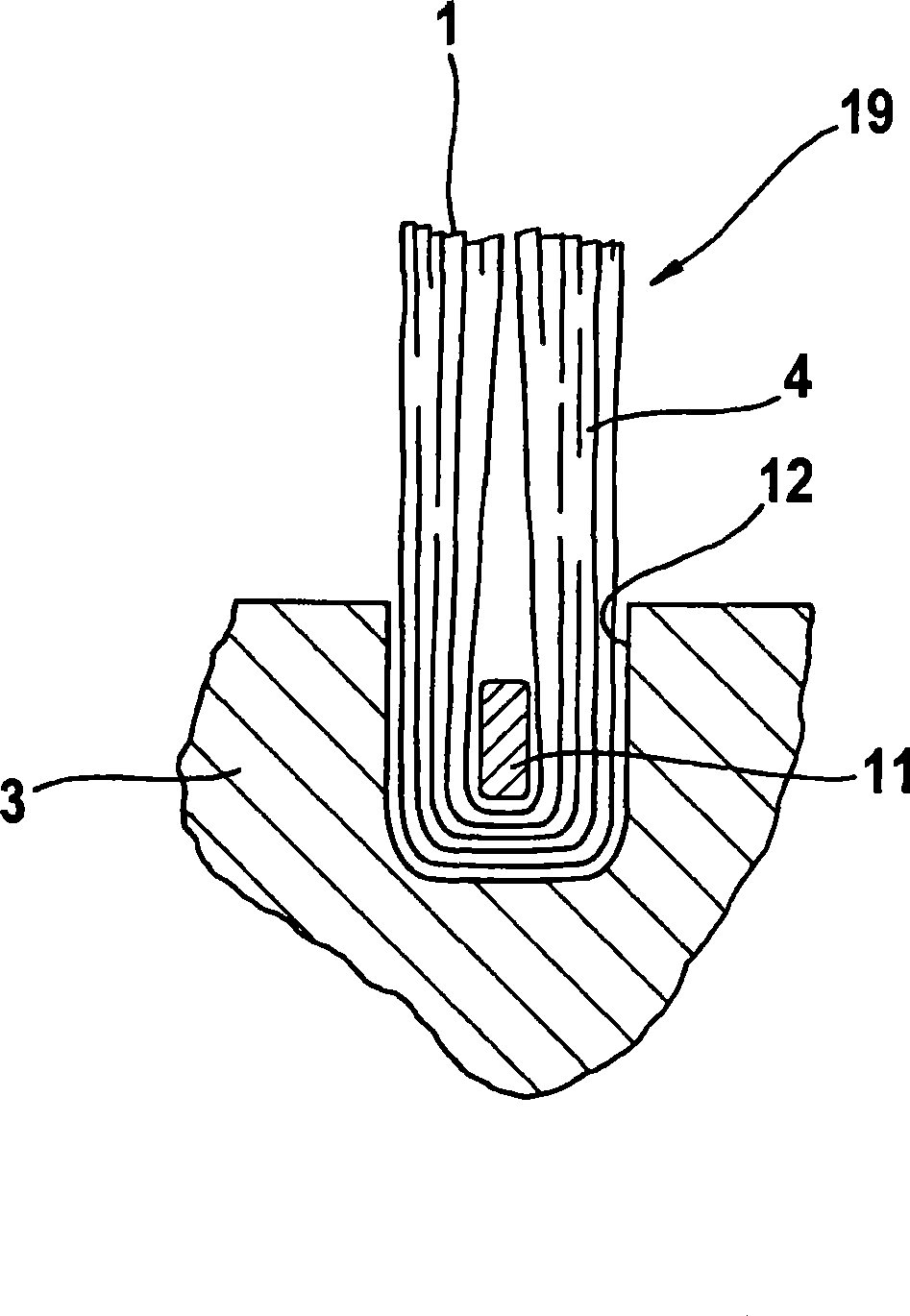

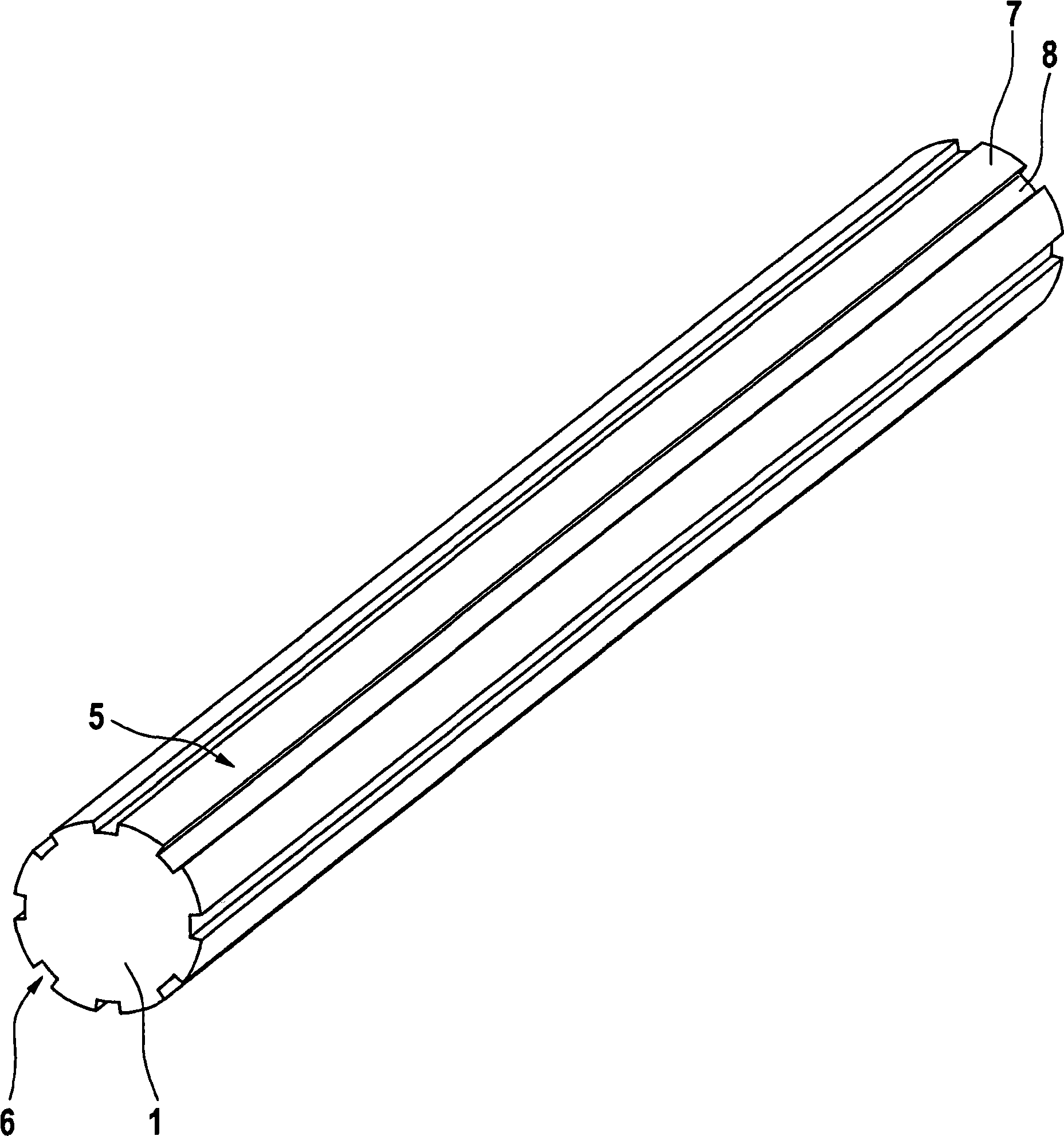

Toothbrush, toothbrush head and tooth cleaning bristle

The present invention relates to a tooth cleaning bristle which is formed as a monofilament and has a generated surface with a structured profile, preferably shaped like a longitudinal groove which, in the circumferential direction, has alternate projections and depressions. The invention also relates to a toothbrush head with a bristle support to which at least one such tooth cleaning bristle is attached and, finally, to a preferably electric toothbrush with such a toothbrush head. In order to be able simultaneously to satisfy the diverse requirements of a tooth cleaning bristle, the present invention envisages a special profile of the generated surface of the tooth cleaning bristles which makes it possible to fill the bristle support easily, and which prevents the bristles which are brought together in a bunch from interlocking and yet ensures an intensive cleaning action on the generated surface side. Thanks to the profile, the circumference of the tooth cleaning bristle has a specific relationship to the cross section surface of the bristle. According to the invention, the tooth cleaning bristle which is formed as a monofilament has a profile on the generated surface side which is designed such that the relationship of the circumference of the generated surface to the cross section surface of the tooth cleaning bristle is in the range of 30 mm<-1> to 50 mm<-1>. The generated surface of the tooth cleaning bristle is thus significantly larger compared to a circular cylindrical bristle with a comparable cross section surface, and so the cleaning action on the generated surface side improves accordingly, and toothpaste can better stick to and come off the tooth cleaning bristles on the generated surface side. Nevertheless, despite the profile on the generated surface side, the tooth cleaning bristle is still able to be attached to a suitable bristle support in the anchor connection method.

Owner:BRAUN AG

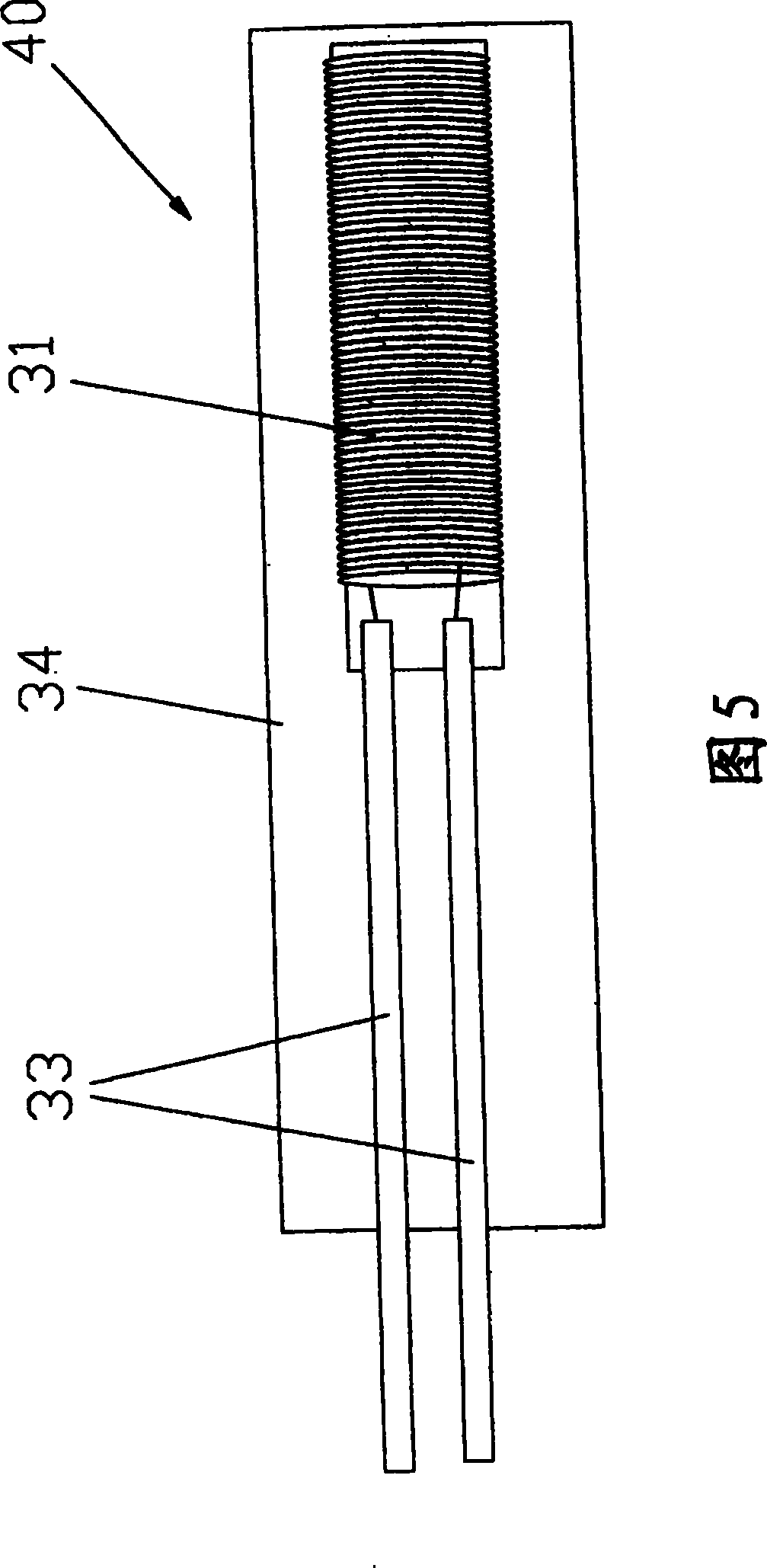

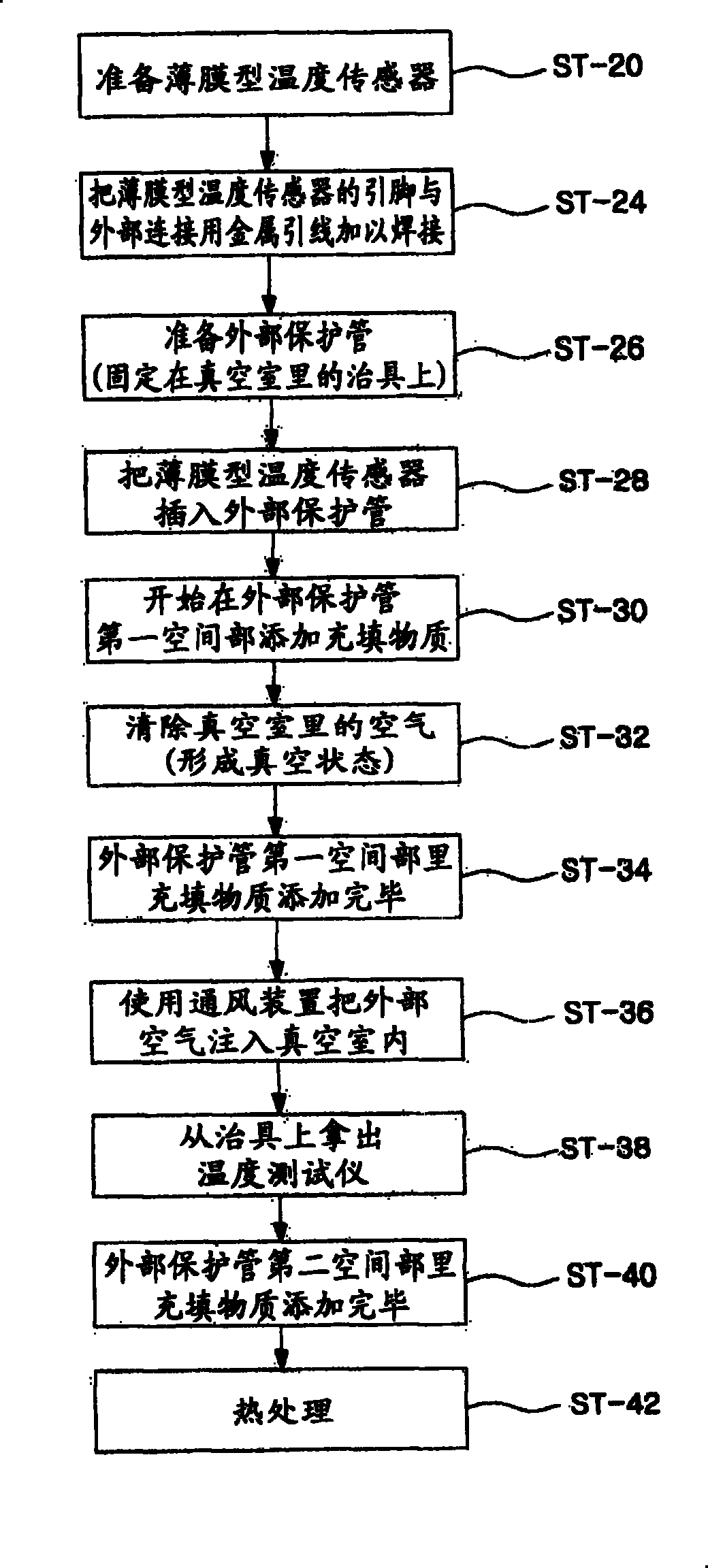

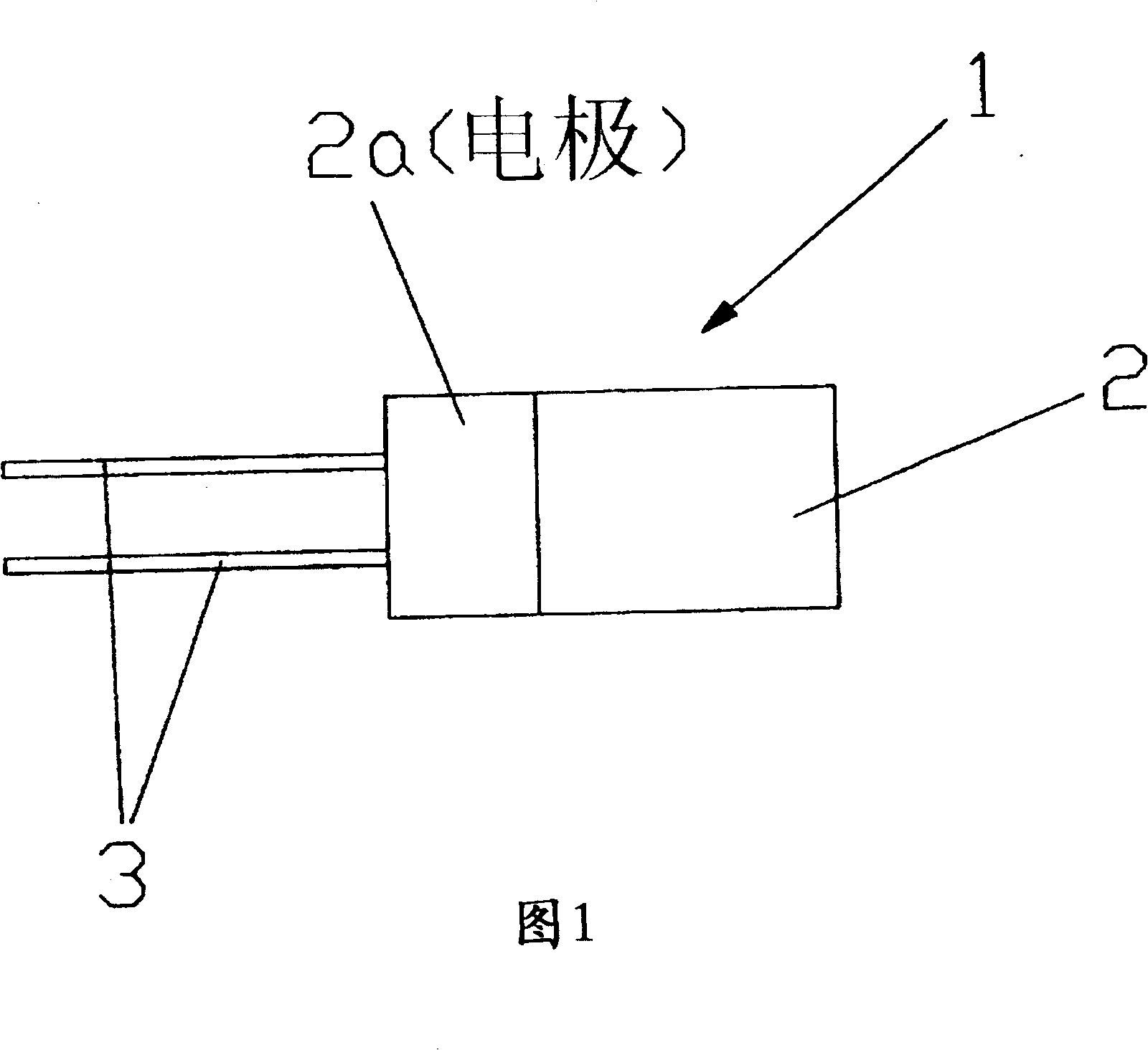

Temperature tester based on film type temperature sensor and its manufacture method

ActiveCN101311691BEasy to fixAvoid mechanical shockThermometer detailsThermometers using electric/magnetic elementsMechanical impactTester device

The invention relates to a temperature tester based on a film type temperature sensor and a manufacturing method, comprising: a cylinder outer protection tube, wherein a first space and a second space are formed by concaving inwards on the upper part and the lower part along the length direction and connected together through a via hole; a film type temperature sensor, arranged in the inner of the outer protection tube through the first space, the second space and the via hole; and fillings, filled in the first space and the second space of the outer protection tube, to fix the film type temperature sensor in the inner of a first protection tube and a second protection tube to become an integer. According to the invention, the film type temperature sensor in the space of the outer protection tube is processed by the filled fillings or ceramic paste based on the temperature tester of the film type temperature sensor, and the pins of the sensor and the wire connecting parts can be fixedstably. Outer connecting metal wires at the lower space are fixed stably through the fillings, therefore, outer mechanical impact is effectively prevented to the film type temperature sensor through the outer connecting metal wires at the lower part.

Owner:DAEYANG ELECTRIC

Spheral anode material for producing lithium battery and preparation method thereof

InactiveCN101626079AGood dispersionSimple filterElectrode manufacturing processesSecondary cellsManganesePhysical chemistry

The invention relates to a spheral anode material for producing a lithium battery and a preparation method thereof. Existing synthesis of spheral lithium manganese (i.e. Ni-Mn) oxide requires numerous control conditions, long reaction time, complex apparatuses and high production cost. In the preparation method, NaHCO3 is utilized as a coprecipitator to prepare spheral Ni-Mn carbonate, and the process is simple and strongly controllable. A spheral intermediate product is burnt to obtain the spheral Ni-Mn oxide. The spheral intermediate product or the spheral Ni-Mn-O is mixed with Li salt, the mixture is burnt, and then the high-performance spheral Li-Ni-Mn-O anode material for the lithium battery can be prepared. The spheral anode material has high stocking density so that the packing density of the anode of the lithium battery can be improved and the aim of improving the discharge capacity of the lithium battery and assembling the high-performance lithium battery can be achieved. The preparation method has a simple and strongly controllable reaction process, can reduce the number of procedures, the energy consumption and the cost, has low cost and wide application range and is favorable for generalization.

Owner:深圳市源源新材料科技有限公司

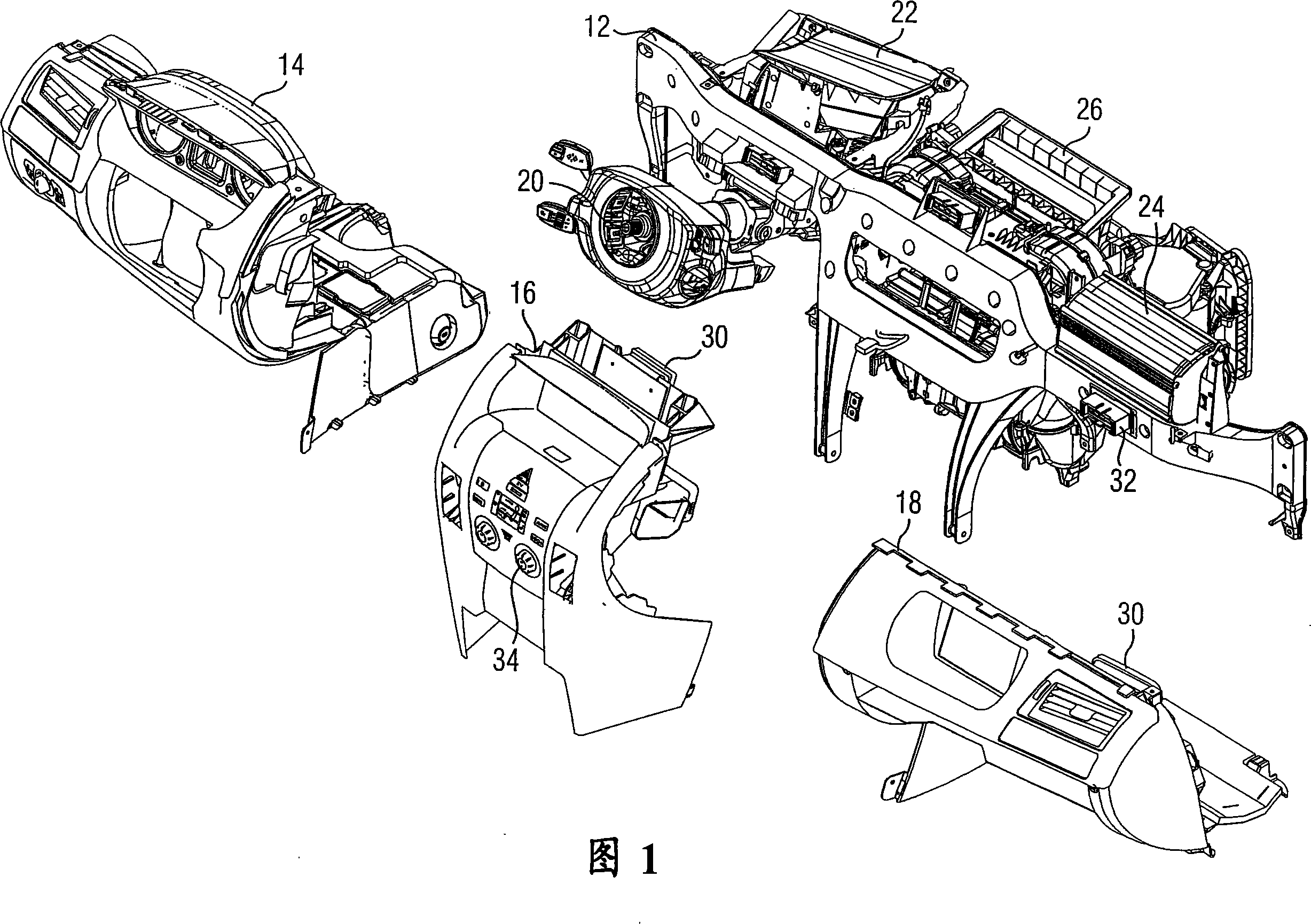

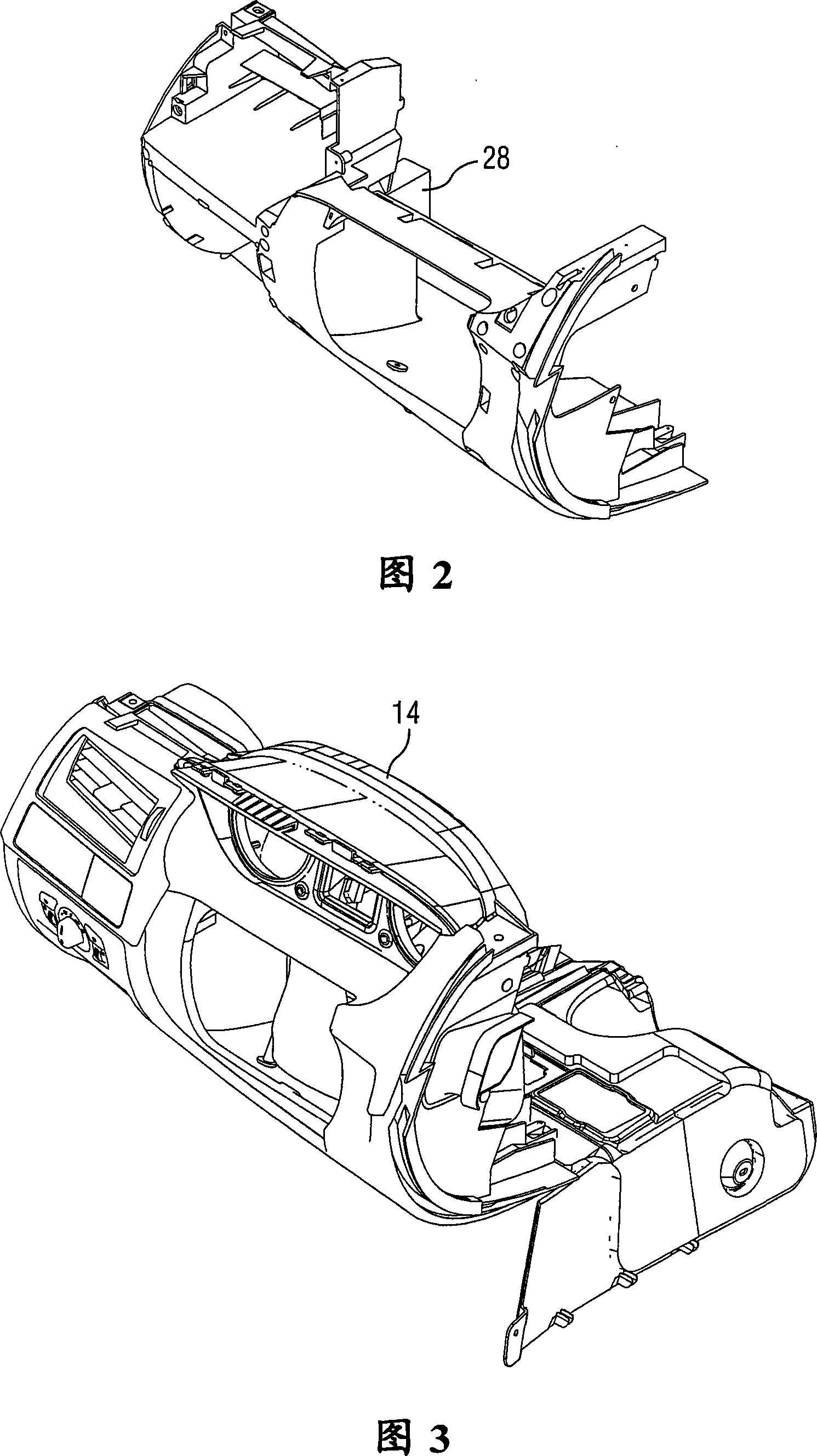

Vehicle cockpit with self supporting submodules

InactiveCN101081597AHigh filling densityImprove reliabilitySuperstructure subunitsDashboardsModularityModular construction

A modular vehicle cockpit has at least a cross bar running over a width of the cockpit and at least two or three sub-modules which holds a plurality of parts and are installed on the beam. The modular vehicle cockpit is provided to simplify the production process. The sub-modules are self-supported to freely manage the pre-mounted components and to transfer its dead weight and outer loads to the cross bar in an integrated condition. The invention also relates to a method for assembling a vehicle cockpit in a modular construction and a method for installing a vehicle cockpit in a vehicle.

Owner:CONTINENTAL AUTOMOTIVE GMBH

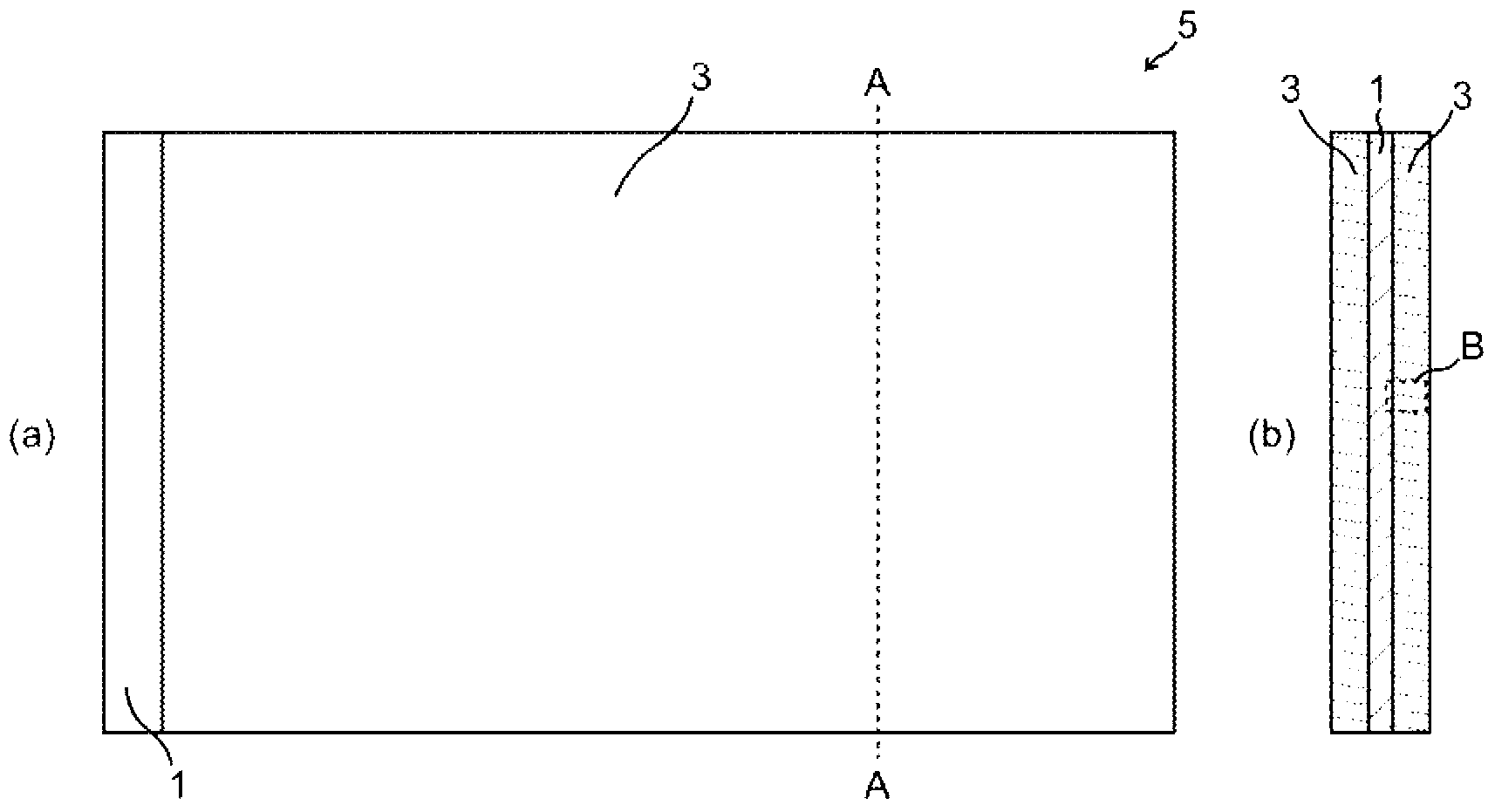

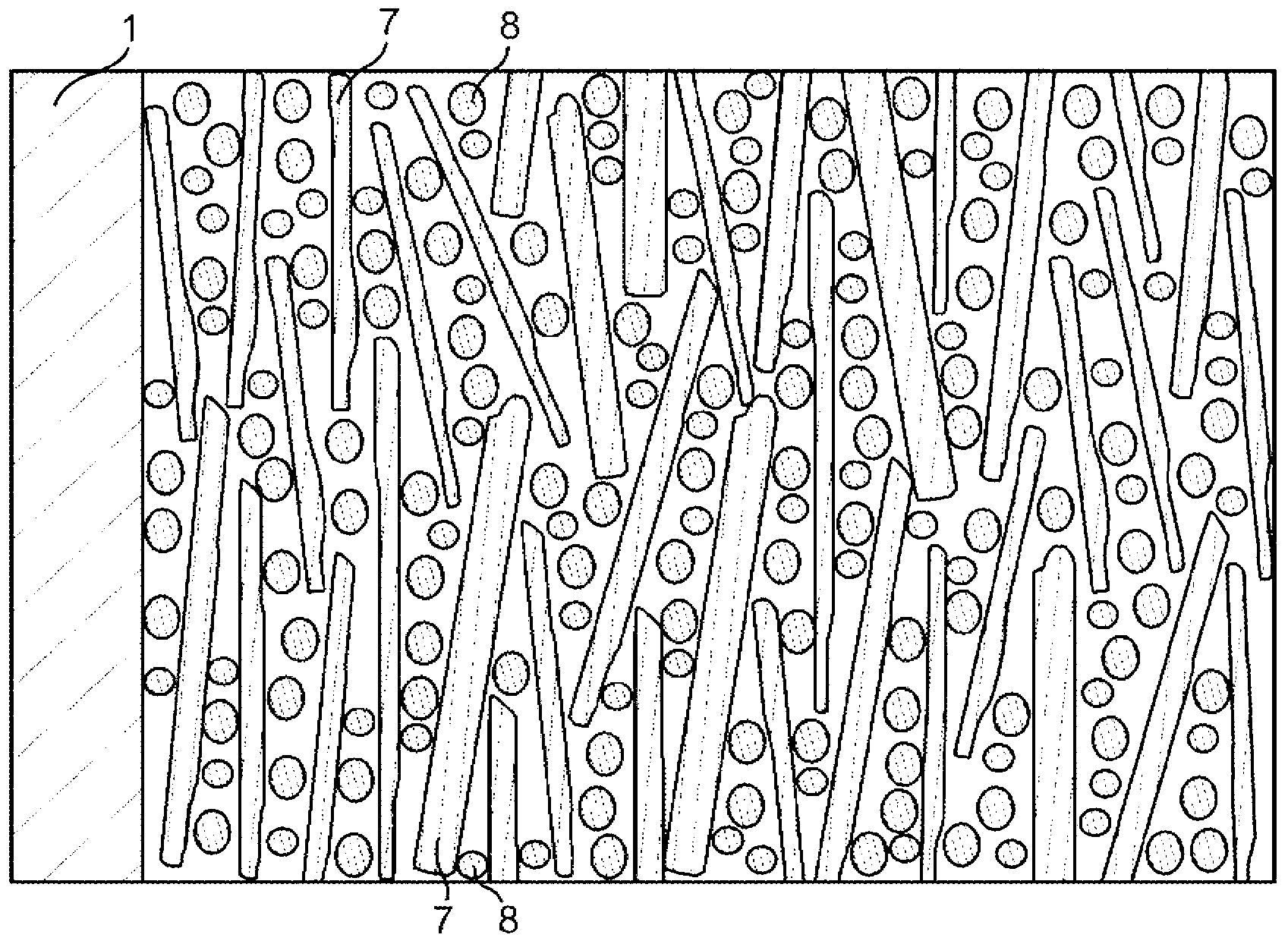

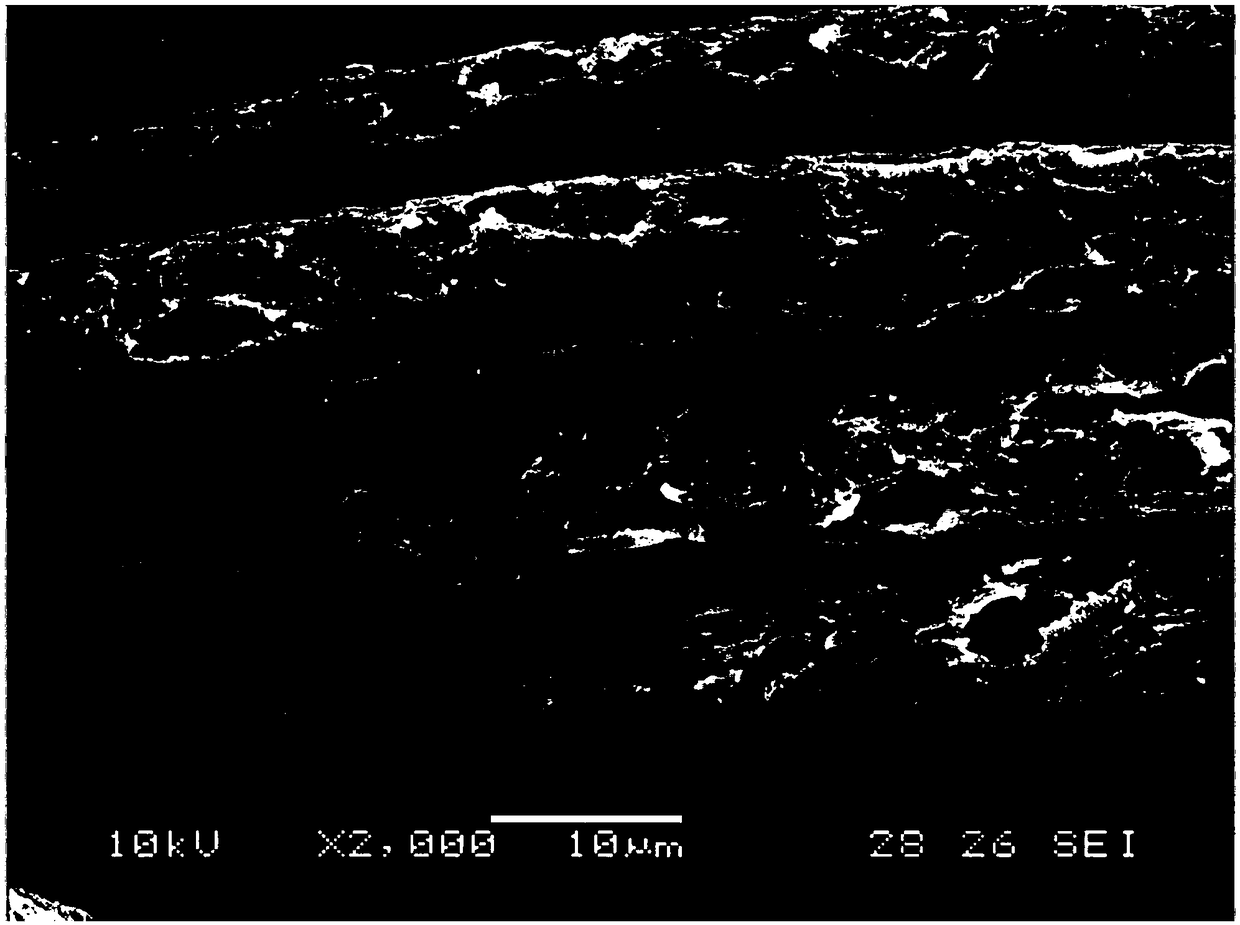

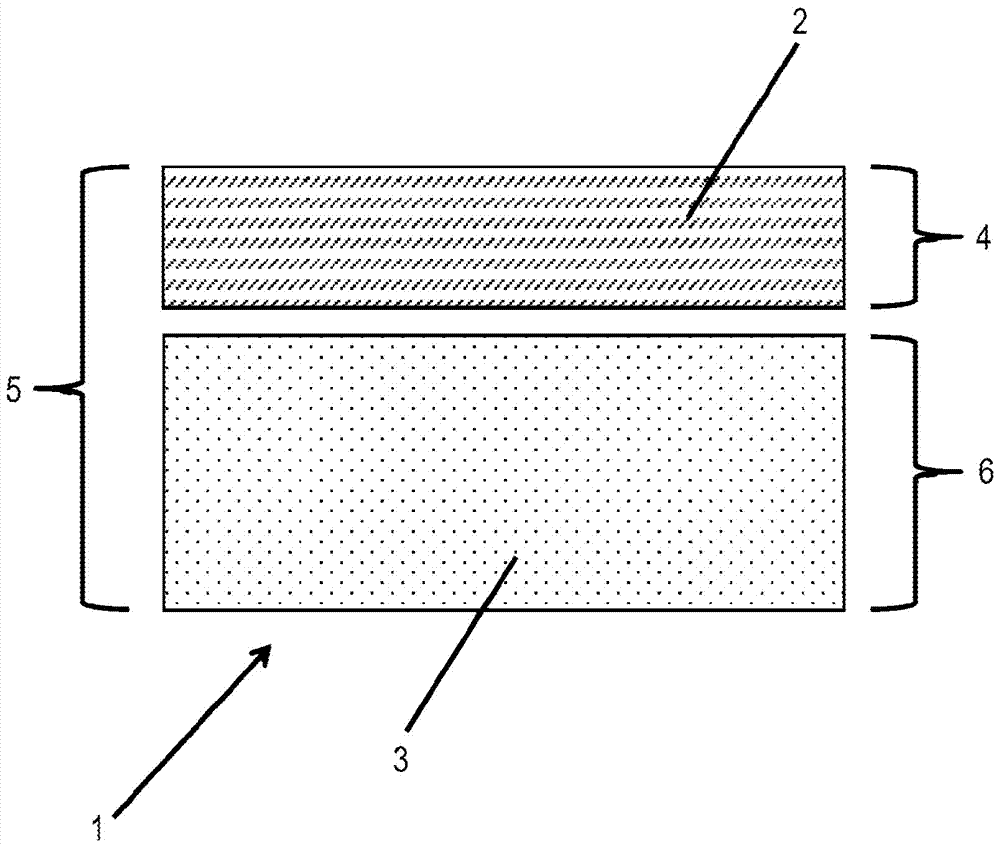

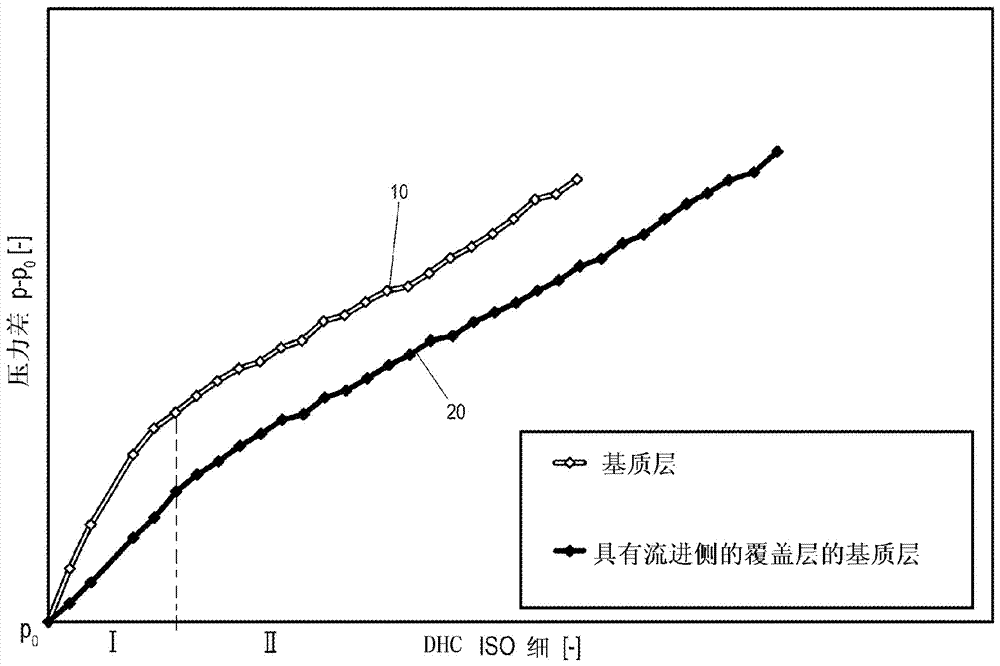

Filter Medium and Use of Filter Medium

InactiveCN107019957AHigh filling densityMulti-foldGas treatmentDispersed particle filtrationPolymer scienceSynthetic materials

The invention relates to a filter medium and a use of the same. Concretely, the filter medium (1) has at least a first filter layer as a substrate layer (2) and a second filter layer as a cover layer (3), wherein the cover layer is arranged at an inflow side relative to the substrate layer. The substrate layer (2)contains a proportion of cellulose fibers of at least 60% relative to a total fiber contents of the substrate layer. The cover layer(3) contains a proportion of polymeric synthetic fibers and / or mineral fibers of at least 20% relative to a total fiber contents of the cover layer. The substrate layer (2)has a maximum thickness of 0.28 mm. The filter medium has a total air permeability according to ISO 9237 that amounts to more than 45 l / m3. The fibers of the cover layer (3)have a packing density of 0.08 to 0.16 and the fibers of the substrate layer (2)have a greater packing density than the fibers of the cover layer(2).

Owner:MANN HUMMEL GMBH

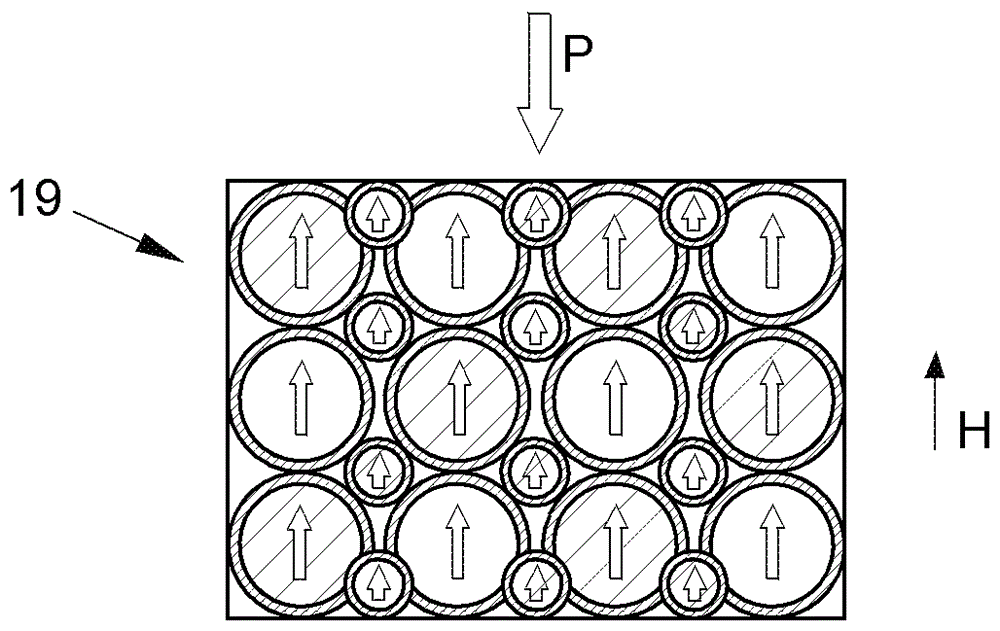

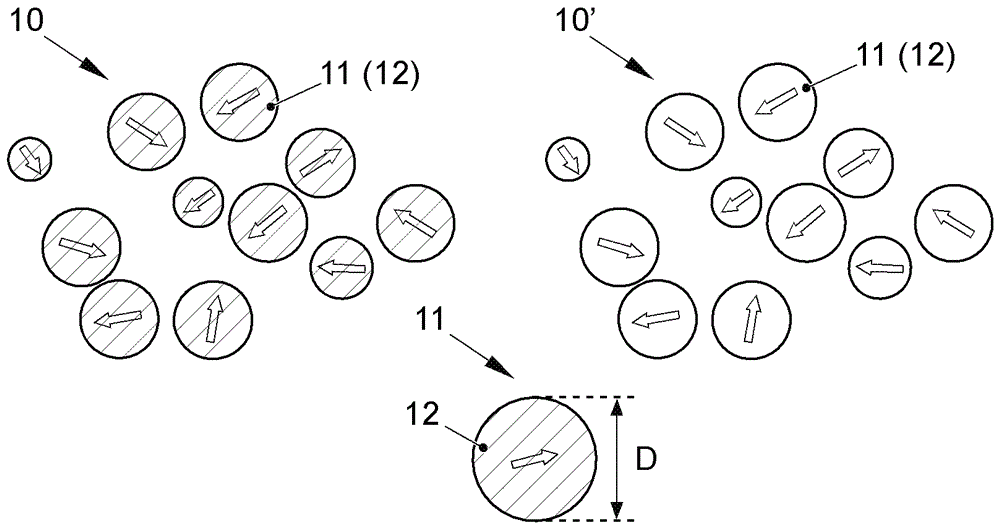

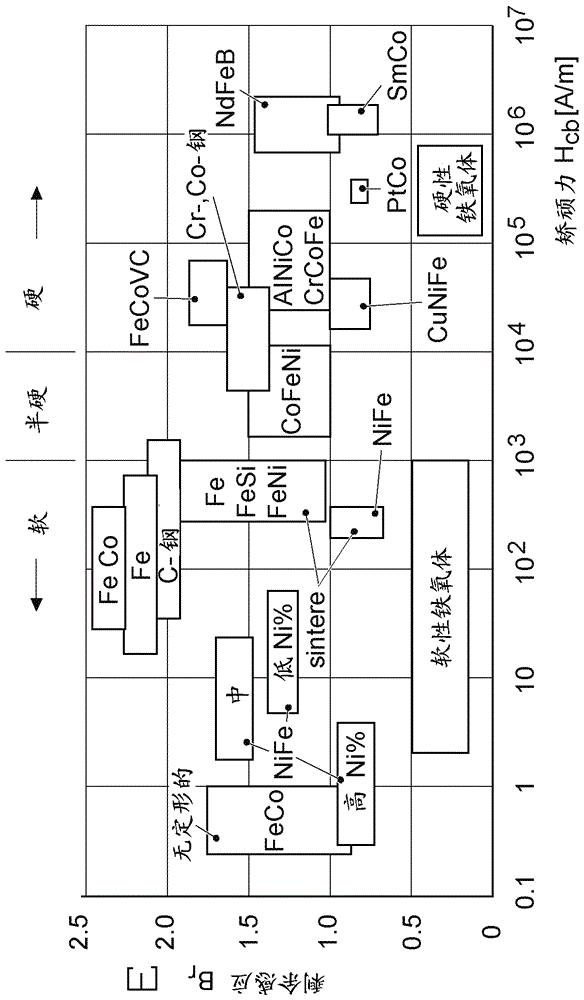

A method for producing a hybrid magnet and the hybrid magnet produced by the method

InactiveCN106373769AImprove featuresImprove coercive forceInductances/transformers/magnets manufactureMagnetic circuit characterised by magnetic materialsMetallurgyAmorphous matrix

The issue of the invention is 'a method for producing a hybrid magnet and the hybrid magnet produced by the method'. The invention relates to a method for producing a hybrid magnet (20) and the hybrid magnet (20) produced by the method. The hybrid magnet comprises nucleons (15, 15') made of at least two different magnetic materials (12, 13') and an amorphous matrix (21) made of an antimagnetic or paramagnetic material (22). The nucleons (15, 15') are embedded into the matrix (21).

Owner:VOLKSWAGEN AG

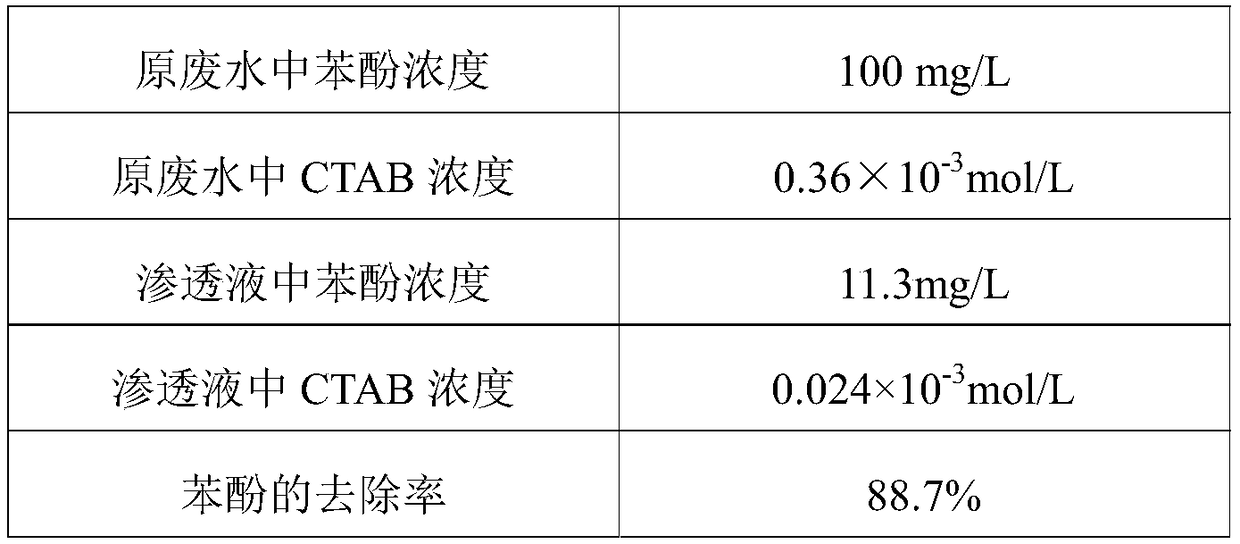

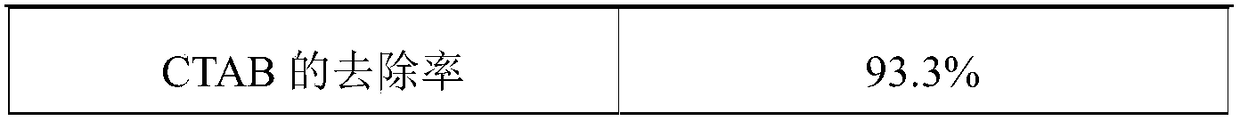

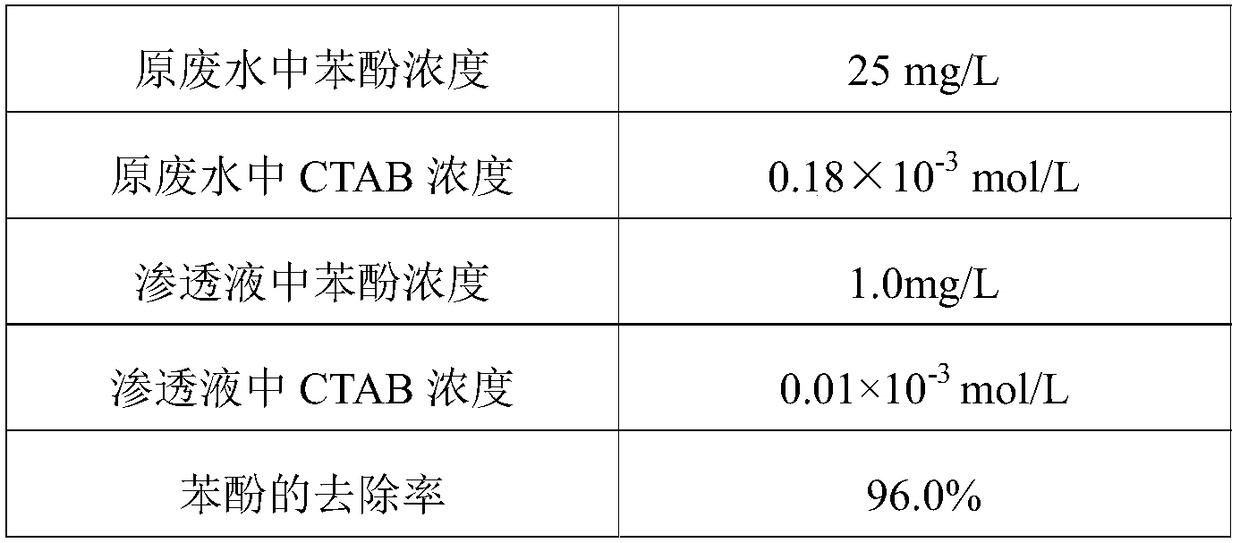

Method for treating phenol-containing wastewater with polyelectrolyte-surfactant

InactiveCN109336210AGood adsorption and solubilization effectHigh removal rateWater contaminantsWater/sewage treatment bu osmosis/dialysisUltrafiltrationPhenol

The invention discloses a method for treating phenol-containing wastewater with a polyelectrolyte-surfactant. The method comprises the following steps: mixing sodium polymethylacrylate, cetyltrimethylammonium bromide and phenol-containing wastewater, stirring, standing, and performing ultrafiltration to complete treatment of phenol in the wastewater. The method for treating phenol-containing wastewater with the polyelectrolyte-surfactant has the advantages of high removal rate, low energy consumption, no phase change, no secondary pollution, easy achievement of pollutant recycling and automatic operation and the like, and also has the advantages of a simple technology, convenience in operation, low cost and the like; by the method, the phenol can be effectively removed from the wastewater;and the method has a good application value and a good application prospect.

Owner:CHANGSHA UNIVERSITY

A kind of open-hole well outside wrapping expansion filling sand control method

The invention relates to an open hole well external inclusion expansion packing sand control method. An external inclusion high-expansion packing sand control screen is tripped into a voided space, afree extension external inclusion continuously stretches outwards under the action of high pushing pressure difference of sand-carrying fluid solid particles until the outer wall of the free extensionexternal inclusion is fitted with an open hole well wall, and packing sand control is realized. According to the sand control method, a high-thickness, high-filling-compactness and high-stability packing strip is formed in immediate vicinity of wellbore of a target sand control layer, and a sand barrier is high in overall sand control strength and long in sand control validity period. The overallsand control strength of the sand barrier is improved, the water content of an oil-gas well can be effectively reduced, and the sand control validity period is prolonged.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +2

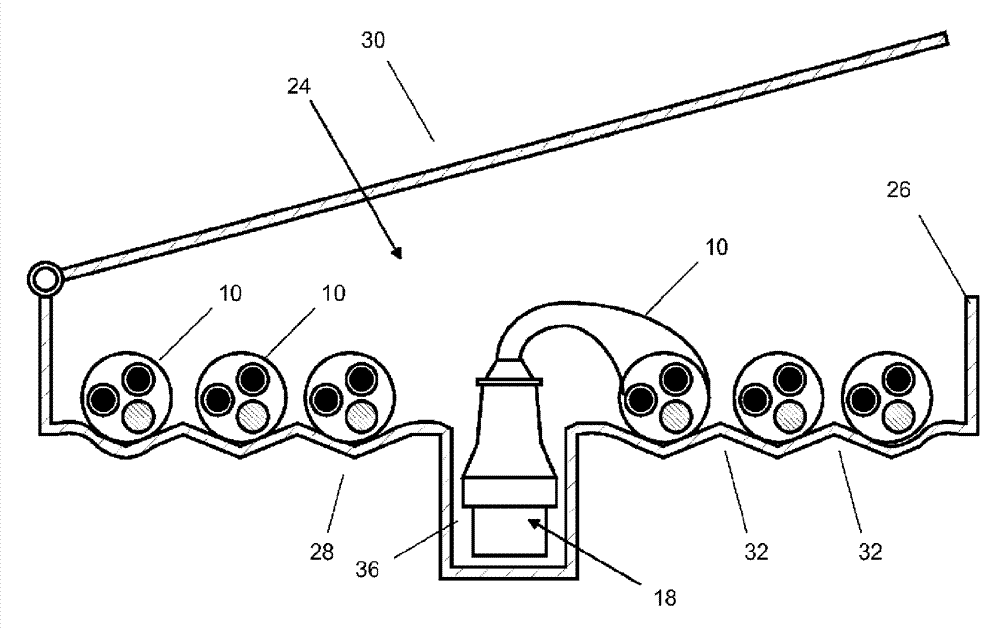

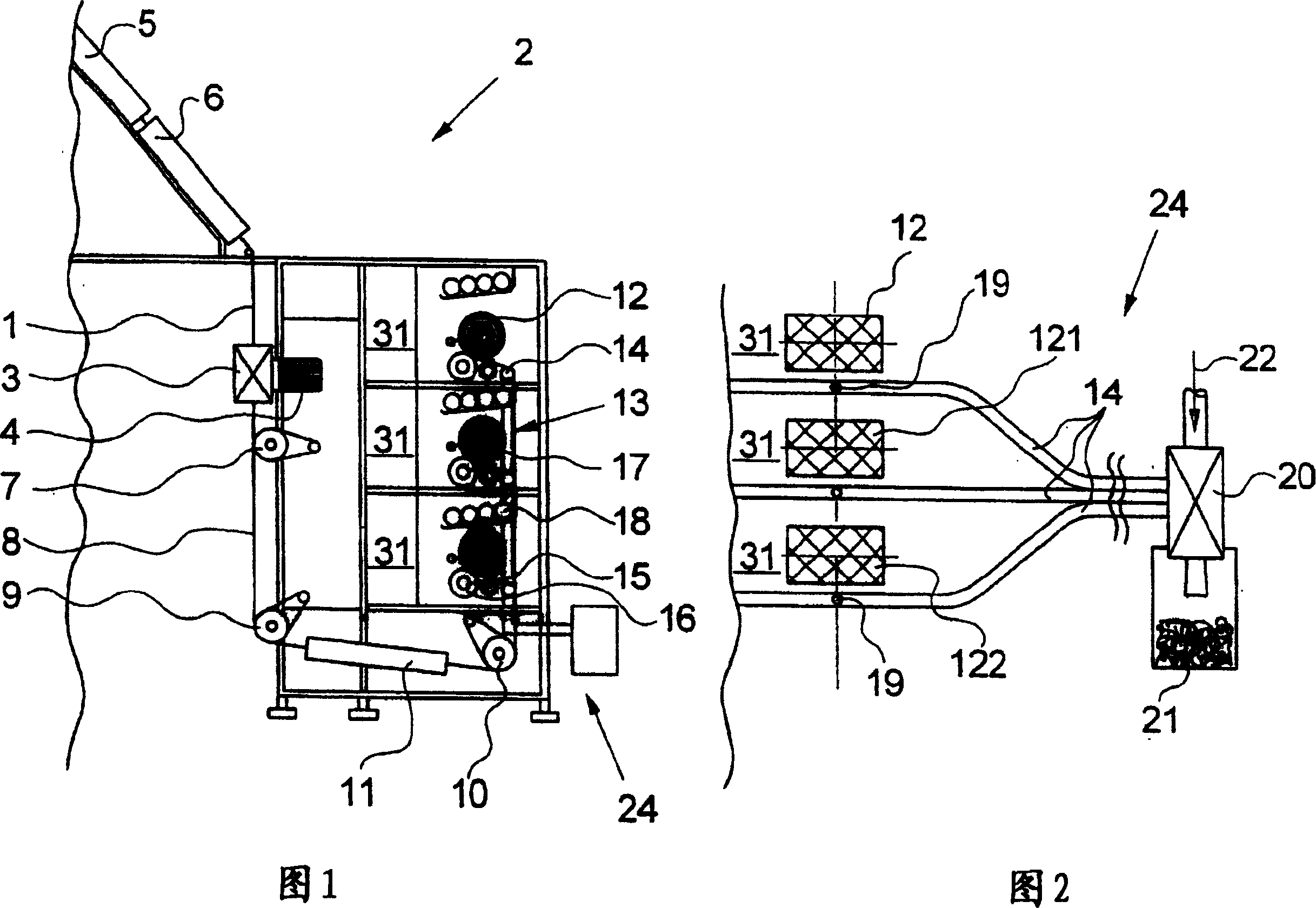

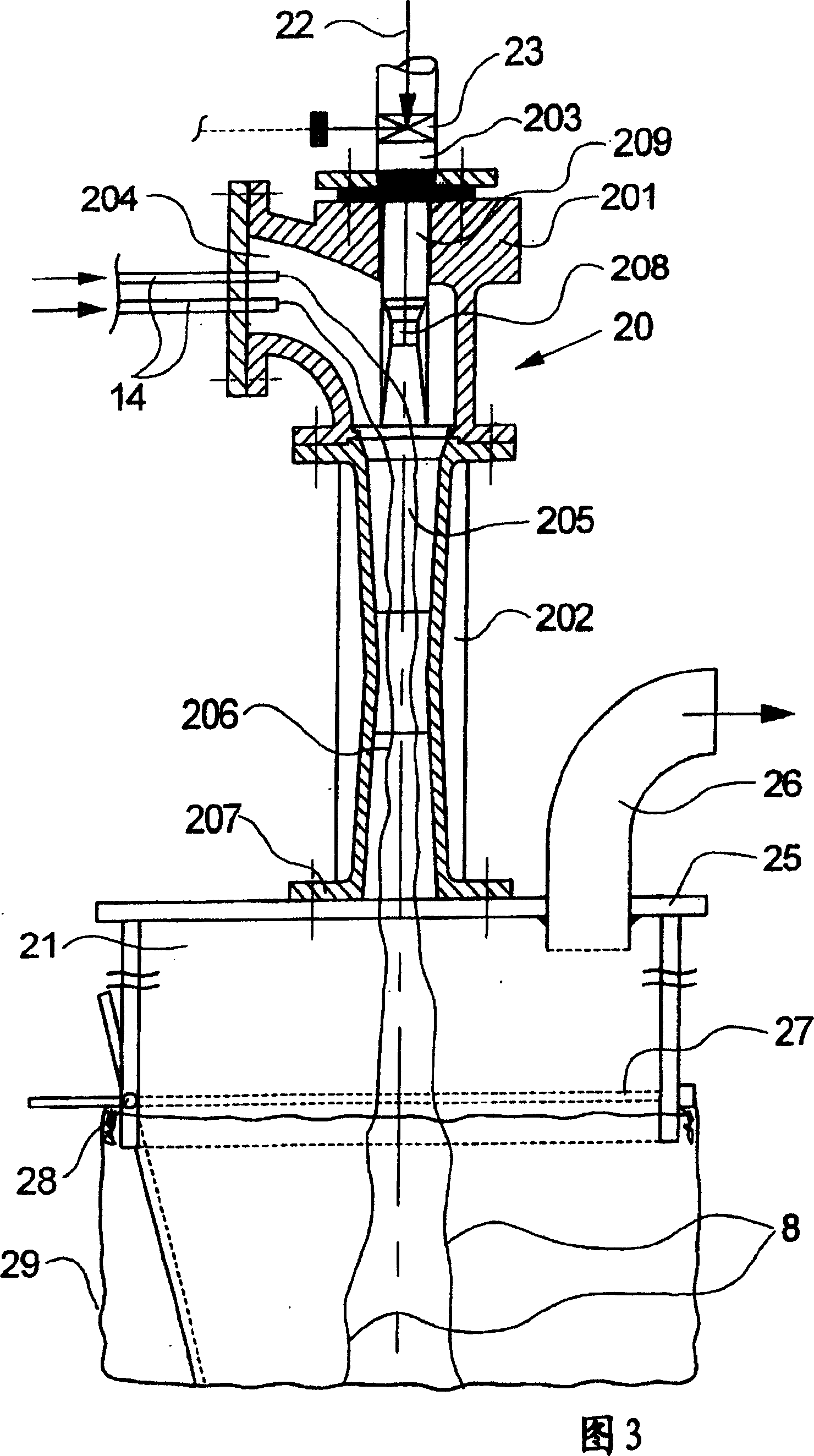

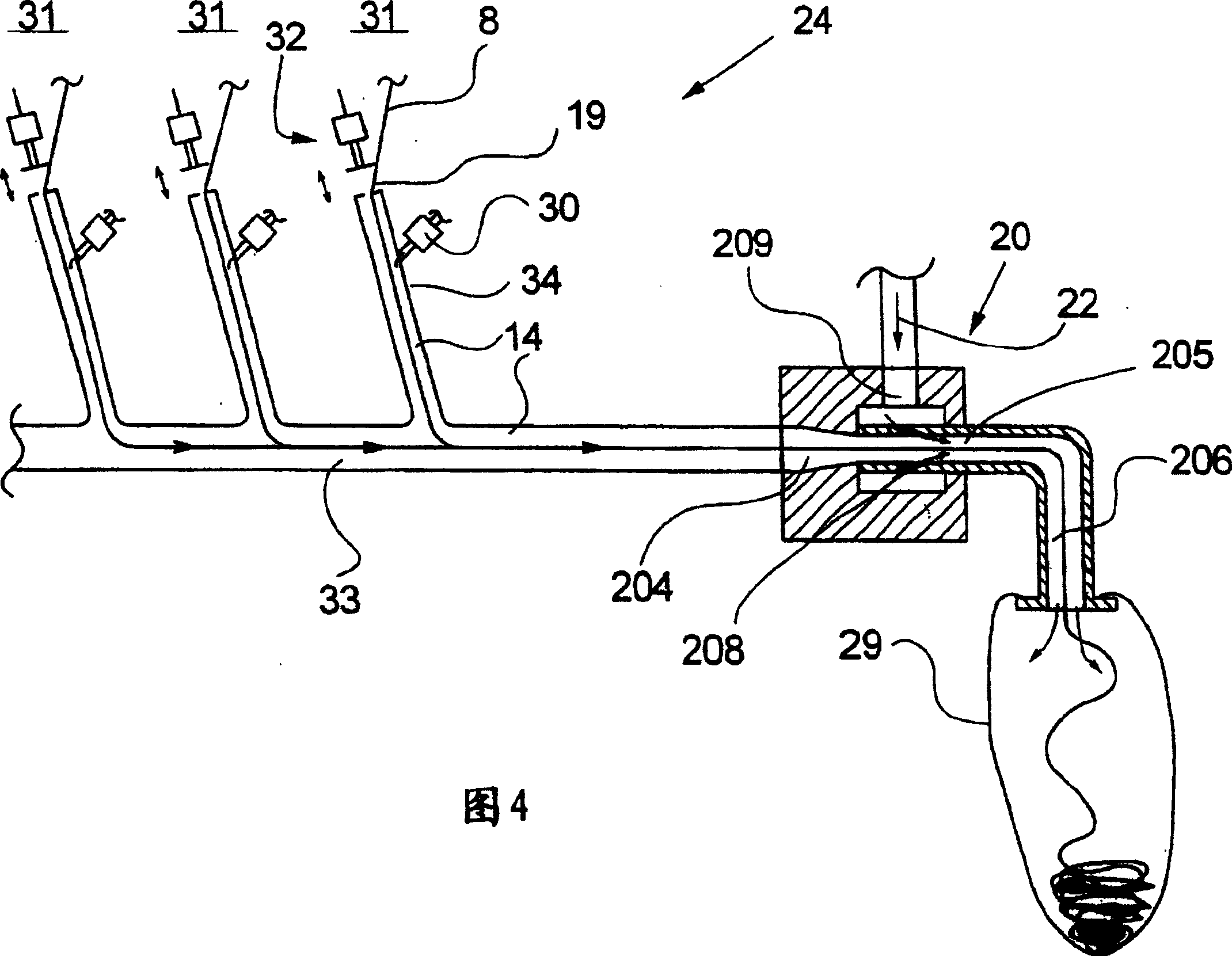

Broken-end collection device

InactiveCN100360389CReliable captureEasy to replaceFilament handlingTextiles and paperBobbinTransport system

The invention relates to a textile machine, particularly a false twist crimping machine equipped with a thread transport system (14) for the threads (8) that continuously accrue in the event of a thread breakage or a bobbin change. The invention provides that the negative pressure in the thread transport system (14) is generated by a jet apparatus (20) supplied with a gaseous working substance. The accumulating thread waste is conveyed by the jet apparatus into a collecting receptacle (21), which also serves as a thread store while being detachably attached as an easily exchangeable thread waste bag that, for improving recycling, is made of the same polymer as the thread remnants collected therein.

Owner:SAURER GMBH & CO KG

A preparation method of carbon-coated sn-co/graphene microsphere negative electrode material for lithium ion battery

ActiveCN104409708BHigh filling densityIncrease volume capacityMaterial nanotechnologyCell electrodesMicrosphereAlloy

In view of the fact that there is no lithium-ion battery negative electrode material based on Sn-Co alloy that can simultaneously have high lithium storage capacity, high Coulombic efficiency, long cycle life and high filling density in the prior art, the present invention provides a lithium-ion battery carbon pack The invention discloses a preparation method of a Sn-Co alloy / graphene composite microsphere negative electrode material, which belongs to the field of lithium ion battery negative electrode materials. In this method, the Sn-Co nano-alloy is deposited on the surface of graphene by a wet method, and then the nano-intermediate is granulated by the spray-drying method, and then the composite microsphere intermediate is coated with pitch, and finally heated and carbonized. Carbon-coated Sn-Co alloy / graphene composite microsphere negative electrode material, the preparation process of this method is simple and suitable for large-scale industrial production; the carbon-coated Sn-Co alloy / graphene microsphere negative electrode material prepared by this method can store lithium High capacity, high coulombic efficiency, long cycle life, high filling density.

Owner:江苏嘉明碳素新材料有限公司

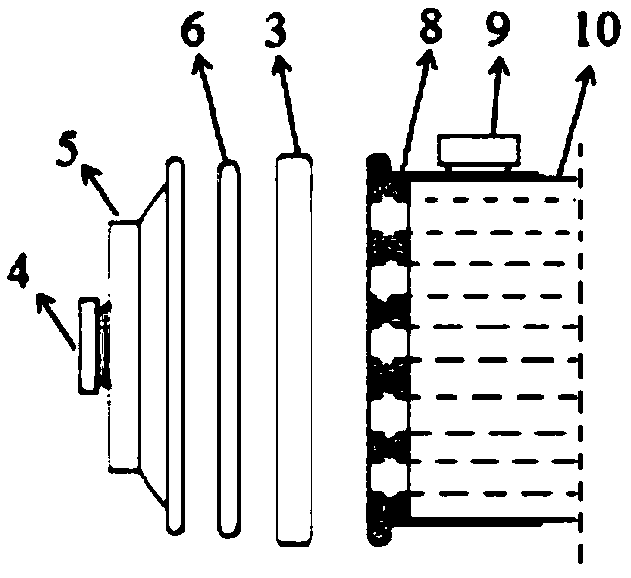

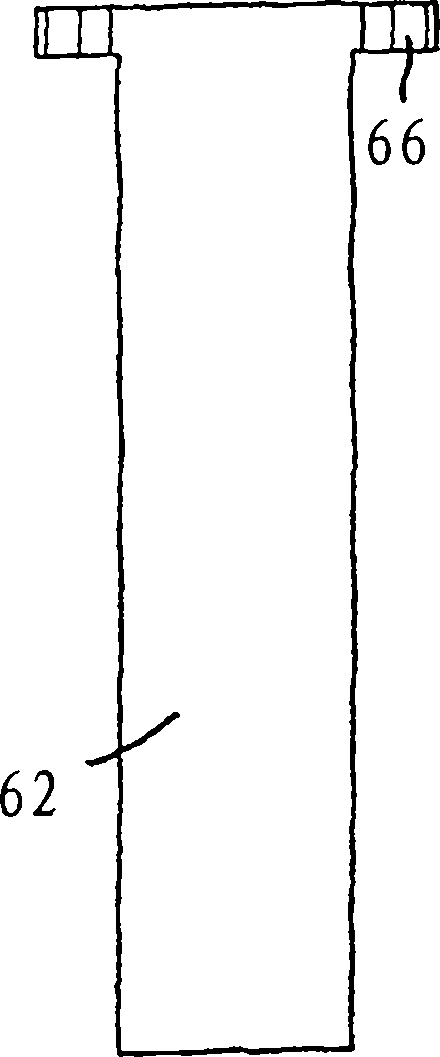

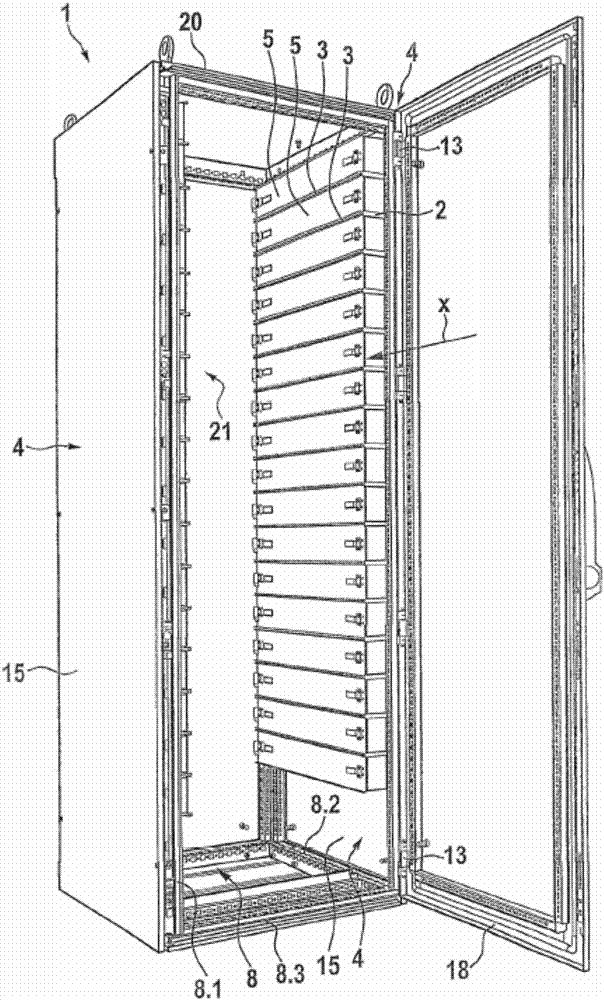

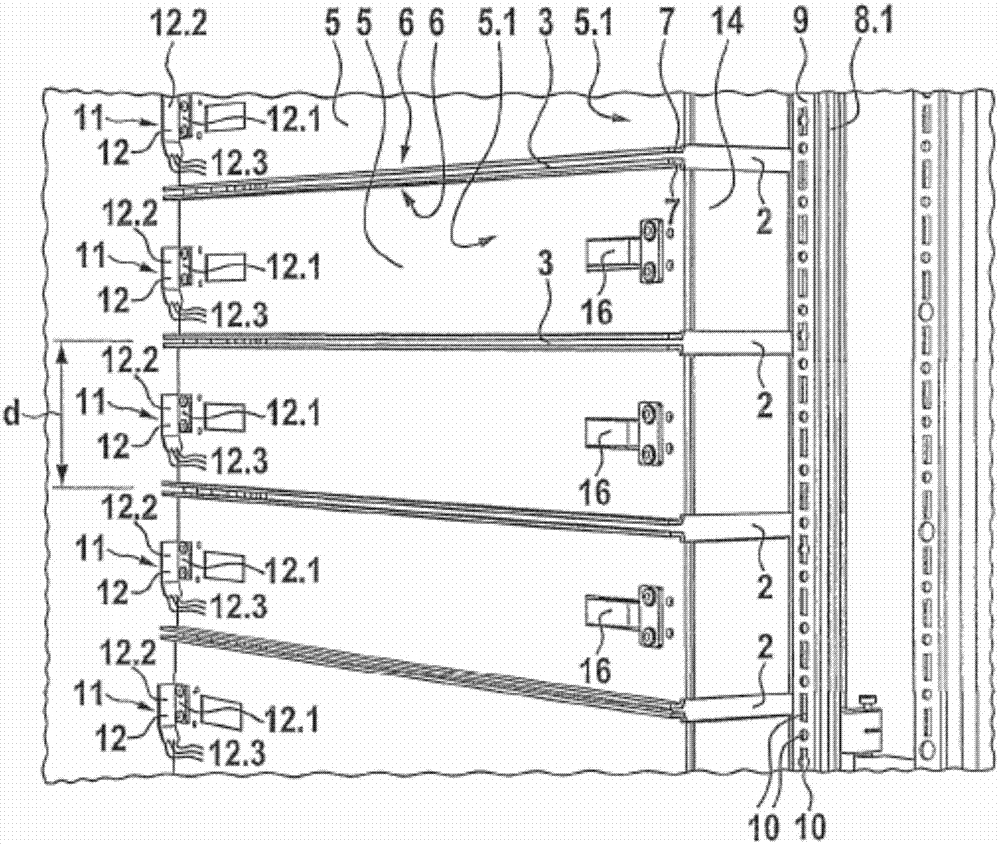

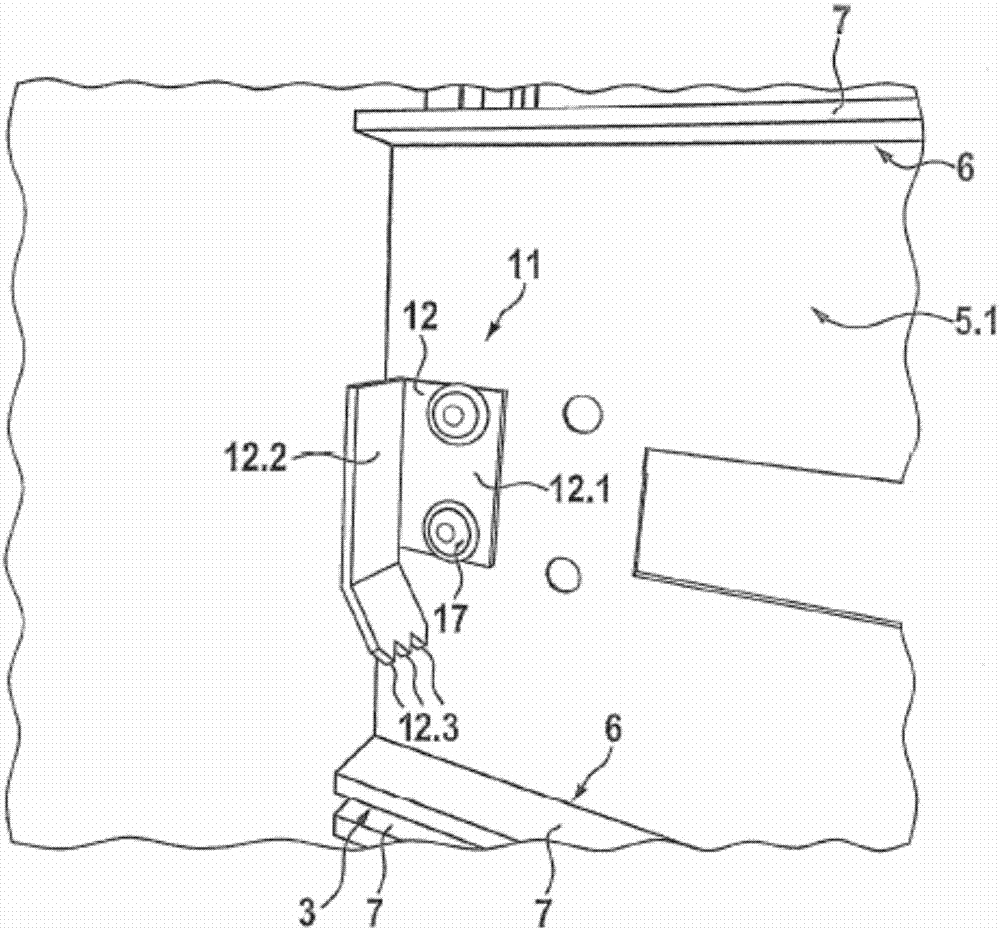

Switchgear cabinet or rack for accommodating electrical energy stores, in particular batteries, and a corresponding switchgear cabinet assembly or rack assembly

InactiveCN107408654AHigh filling densitySubstation/switching arrangement detailsMetal casingsStructural engineeringSwitchgear

The invention relates to a switchgear cabinet or rack for accommodating electrical energy stores, in particular batteries, wherein the switchgear cabinet (1) or the rack comprises a plurality of superimposed energy storage inserts (2), characterized in that the energy storage inserts (2) are formed by a plurality of grooves (3), wherein the longitudinal direction and the direction of insertion (x) thereof extend in a depth direction of the switchgear cabinet (1) or rack, wherein a respective pair of the grooves (3) are directed toward one another on opposite sides (4) of the switchgear cabinet (1) or rack on the same vertical height and with their open longitudinal side. The invention further relates to a corresponding switchgear cabinet assembly or rack assembly.

Owner:RITTALWERK RUDOLF LOH GMBH & CO KG

A kind of method of reclaiming oxytetracycline hydrochloride from oxytetracycline hydrochloride crystallization mother liquor

ActiveCN107011204BAvoid sex changeAvoid lossCarboxylic acid amide separation/purificationInorganic saltsWater methanol

The invention discloses a method for recycling oxytetracycline hydrochloride from oxytetracycline hydrochloride crystallization mother liquid. The method comprises the following steps: (1) adjusting the pH value of oxytetracycline hydrochloride mother liquid, and filtering to remove insoluble impurities; (2) separating treated filtrate by virtue of an ultrafiltration system so as to obtain a concentrated solution rich in oxytetracycline hydrochloride and an alcohol solution containing a small amount of calcium salt, and recycling methanol from the alcohol solution; (3) carrying out alkalization crystallization on the concentrated solution obtained through ultrafiltration, adding an alkalization reagent during alkalization so as to adjust the pH value, and recycling oxytetracycline, wherein the recycling rate of oxytetracycline reaches 93%-96%; and (4) adding recycled oxytetracycline into absolute methanol which is 5 times of volume dose of oxytetracycline, adding a small amount of calcium chloride to aid dissolving, filtering, adding hydrochloric acid methanol, and crystallizing, so as to obtain oxytetracycline hydrochloride. According to the method, inorganic salt, namely calcium salt, is filtered and separated by virtue of a membrane, the concentrated solution is subjected to alkalization crystallization to generate oxytetracycline, oxytetracycline is refined by virtue of hydrochloric acid ethanol so as to generate oxytetracycline hydrochloride, and the content of obtained oxytetracycline hydrochloride reaches 96%.

Owner:扬州联博药业有限公司

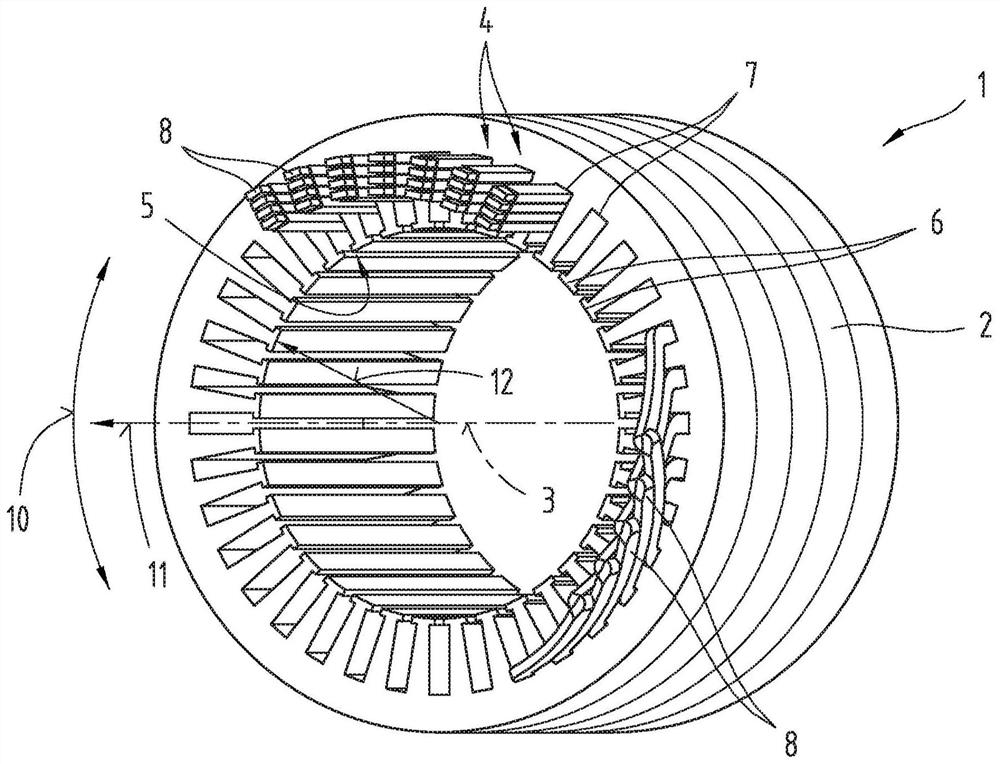

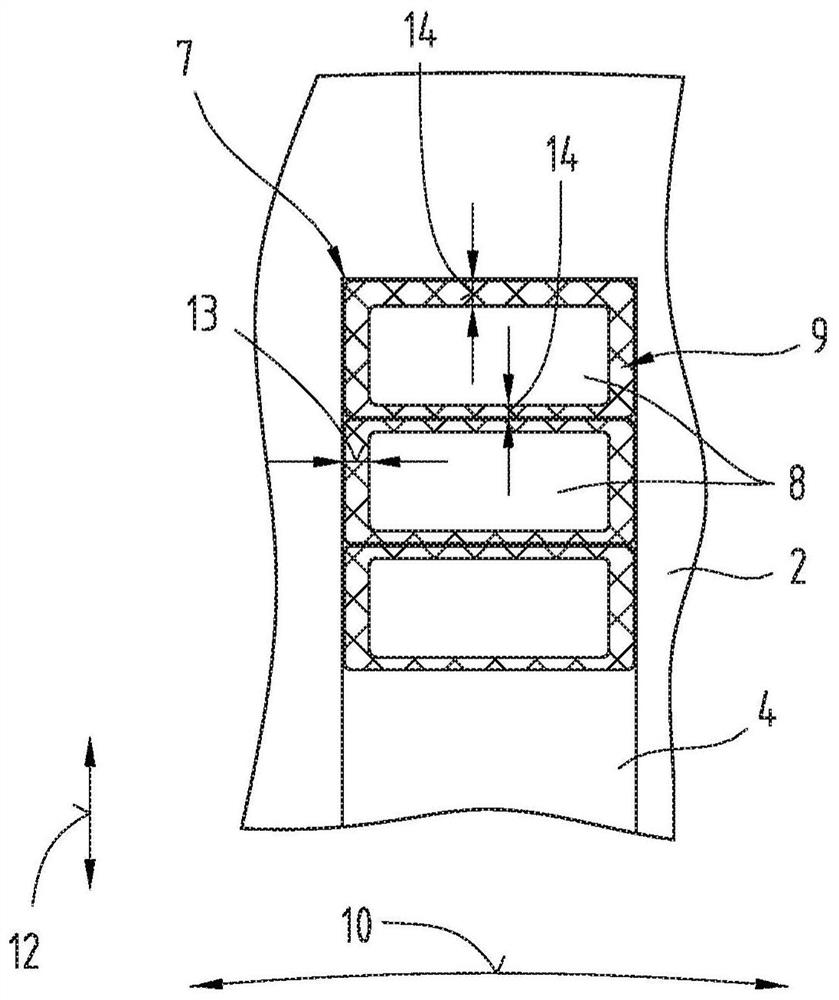

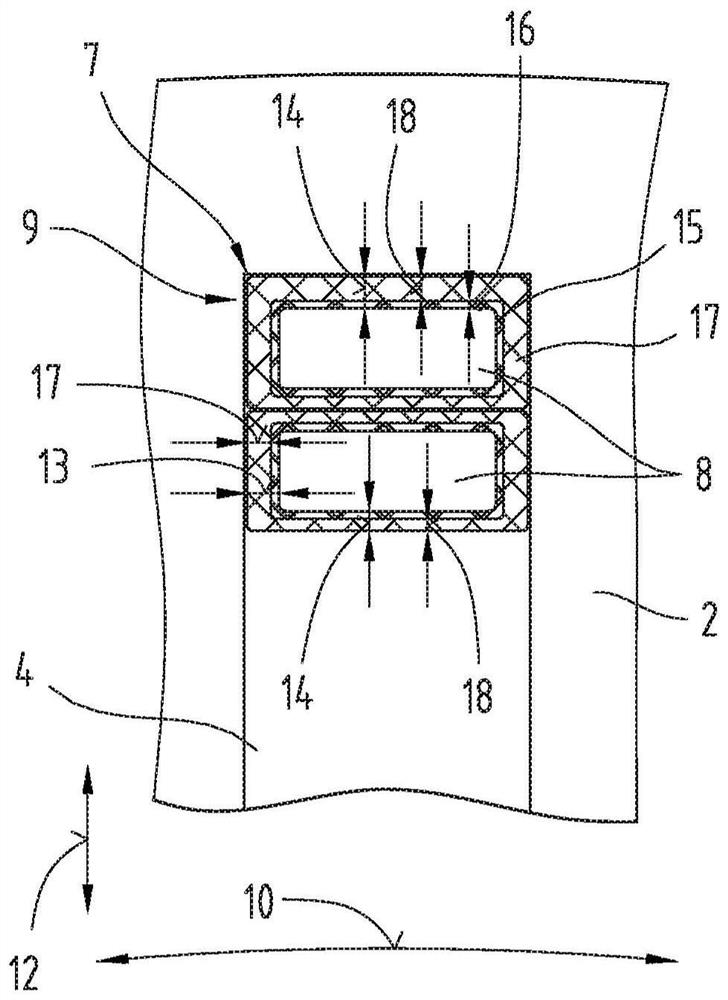

Stator having insulation layer

PendingCN112166541AHigh filling densityImprove efficiencyWindings insulation materialWindings insulation shape/form/constructionInsulation layerElectrical conductor

The invention relates to a stator (1) for an electric machine, comprising a laminated core (2), having a plurality of grooves (4), uniformly distributed in the circumferential direction (10) about a longitudinal axis (3) and extending continuously in a longitudinal direction (11) of the laminated core (2), each for receiving at least two electrical conductors (8) having a substantially rectangularcross-section, said electrical conductors (8) being insulated from each other and in respect of the laminated core (2) by means of at least one insulation layer (9), covering in the radial direction(12) and circumferential direction (10), and at least over a stator height (1) of the stator (1) in the longitudinal direction (11). For defect-free insulation, the at least one insulation layer (9) comprises a thermoplastic high-performance polymer, which is continuously closed in the circumferential direction (10) and in the radial direction (12) and moulded directly on the electrical conductor(8), preferably by means of an extrusion process, wherein the insulation layer (9) has a total circumferential thickness (13), at least in the circumferential direction (10), which is at least 1.5 times to 3 times, preferably 1.8 times to 2.2 times a total radial layer thickness (14) in the radial direction (12) of the respective electrical conductor (8).

Owner:MIBA EMOBILITY GMBH

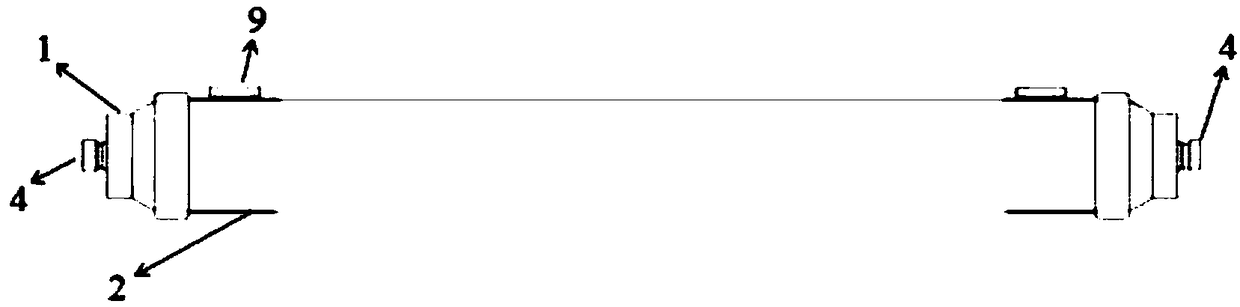

Method for filling coal-steam-free extraction working surface goaf by coal mine waste rock

InactiveCN1936271BRealize no MasuiImprove the environmentUnderground miningSurface miningMining engineeringCoal pillar

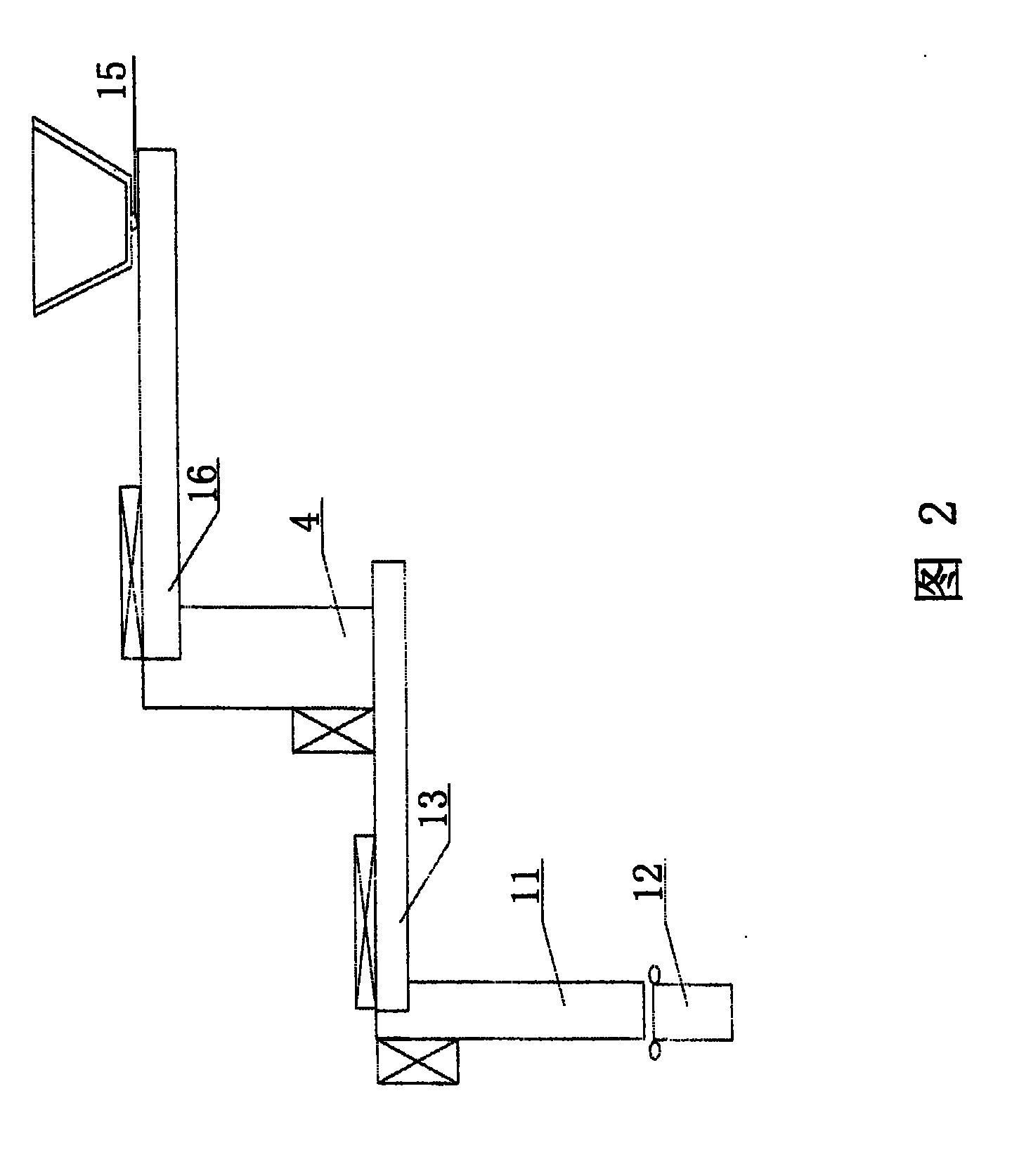

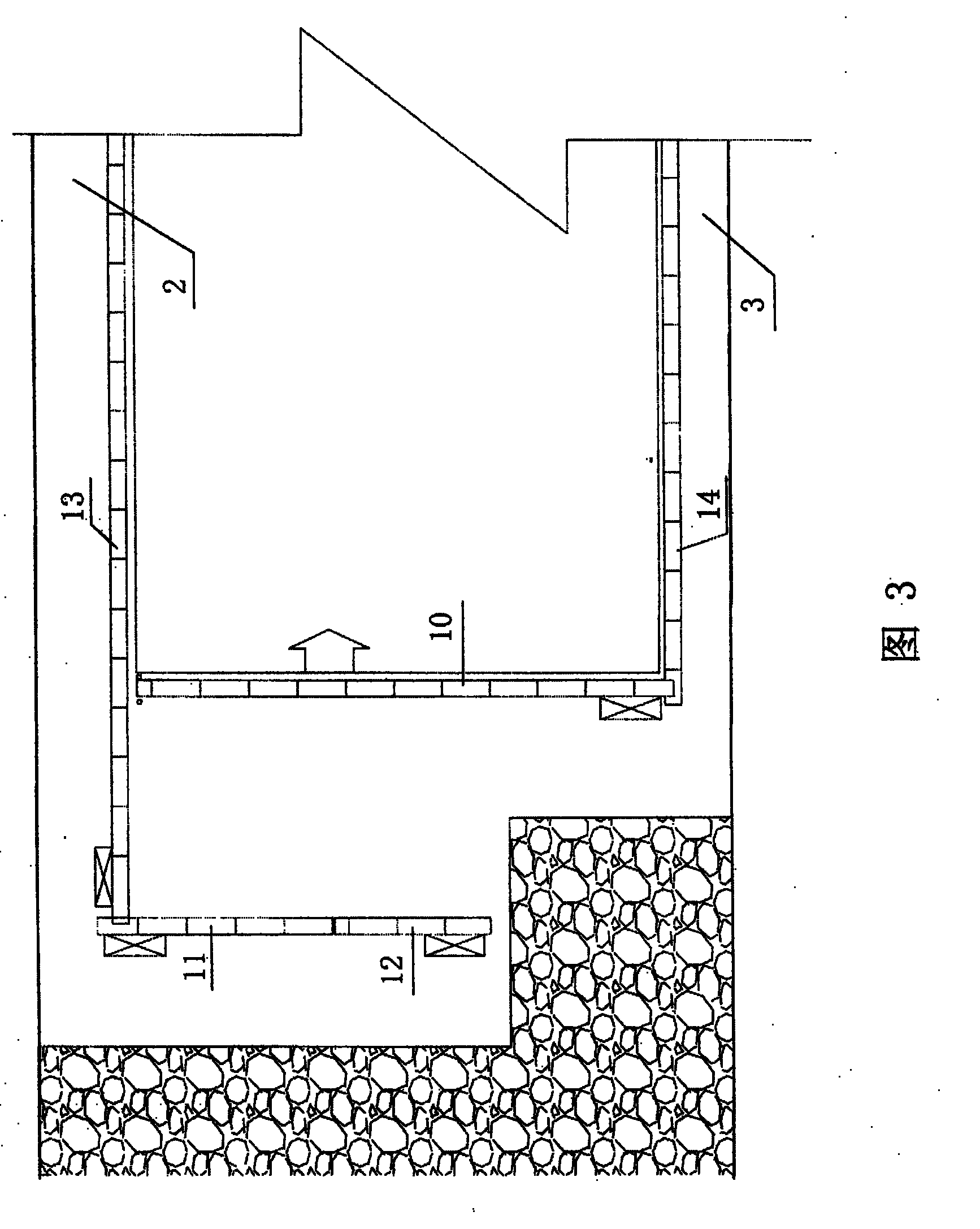

The invention relates to a method for filling non-pillar mining face goaf by using gangue. A face (1) uses roof control of filling every four meters: directly transferring raw gangue to a gangue unloading lane (7) and then a gangue storehouse (9) , unloading to a scrapter conveyer (16) through a hopper gate (15), and transferring the gangue to goaf through a gangue transferring belt (4), a face scrapter conveyer (11) , and a high speed gangue throwing belt (12). According to the invention, raw gangue is directly filled into the non-pillar mining face goaf without being smached or processed, the handling capacity is large; the filling area is large, the space is large, so that gangue does not lift, and the gangue dump can be backfilled, thus finally realizing zero stacking of gangue to improve coal mine environment. The invention supplies a novel coal mining method for realizing environment protecting exploitation and liberating 'three unders' unexploited coal.

Owner:SHANDONG SHENGQUAN MINING

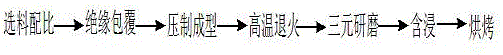

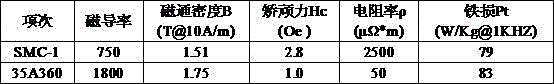

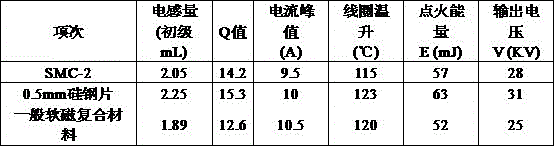

A kind of preparation method of high performance soft magnetic composite material

ActiveCN104157389BEnhanced surface contactHigh filling densityInorganic material magnetismInductances/transformers/magnets manufactureCooking & bakingCore component

Owner:PINGHU GEOR CHI ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com