Preparation method of carbon coated Sn-Co/graphene microsphere negative electrode material of lithium ion battery

A technology for lithium ion batteries and negative electrode materials, which is applied in battery electrodes, nanotechnology for materials and surface science, negative electrodes, etc., can solve the problems of lithium storage capacity, coulomb efficiency, large filling density, etc. Volume specific capacity, the effect of improving the filling density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

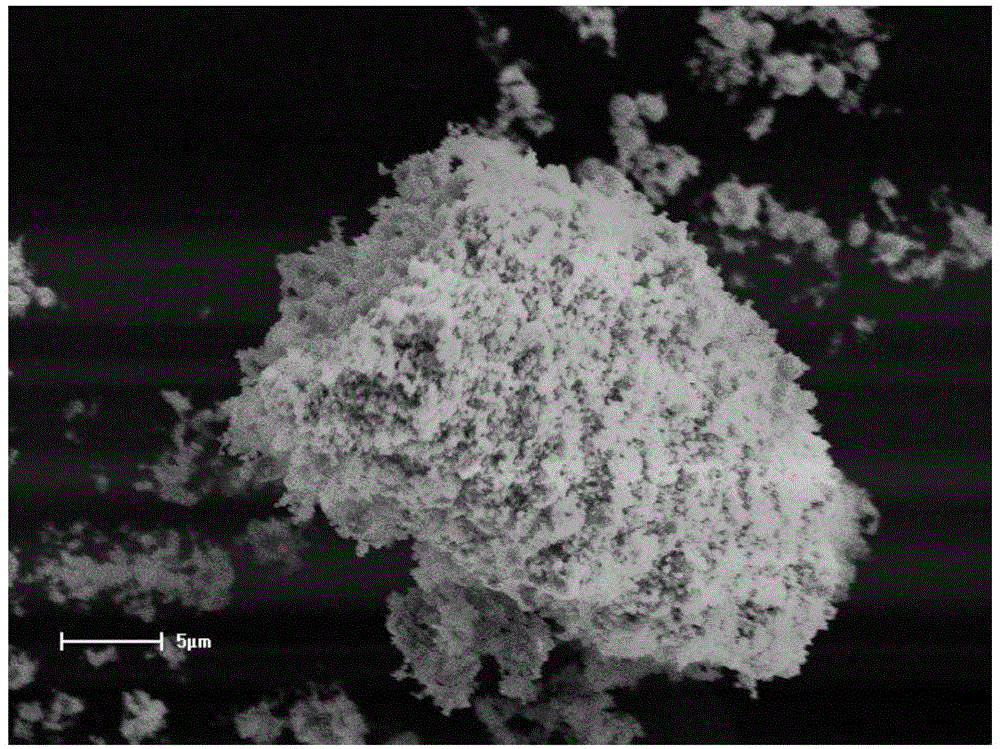

Image

Examples

preparation example Construction

[0027] The preparation method of graphene in the embodiment is: get the concentrated H of 18~25mL98% 2 SO 4 Add 1-1.5 g of natural flake graphite with a particle size of 10-30 μm and 3-4 g of KMnO into a reactor placed in an ice bath 4 Add it into the reactor, stir at 30-80rpm for 30-60min; then move the above-mentioned reactor into a warm water bath at 40±2°C and continue stirring for 30-60min; then raise the temperature of the reaction solution to 98±2°C, add 70 ~100mL deionized water and continue to stir for 30~60min; then add 8~15mL of 5% H 2 o 2 Mix well, filter while hot, wash the filter residue with HCl with a mass fraction of 5%, until there is no SO in the filtrate 4 2- (with BaC1 2 Solution detection), then fully washed with deionized water until neutral, filtered to obtain graphite oxide; then add 400-500mL deionized water to graphite oxide, ultrasonically treat at 60kHz for 60-90min at 80-90°C, and then use 3000 Centrifuge at ~4000rpm for 5~10min; take the su...

Embodiment 1

[0031] 1. Preparation of nano-intermediate: 26.07g of SnCl 4 and 16.79 g of CoSO 4 Add 1286mL deionized water, fully dissolve, then add 92.7mg graphene and 25.7g sodium dodecyl sulfate, ultrasonically disperse for 5min, then add 1mol / L NaBH 4 Ethanol solution 925mL, reacted for 20min, deposited Sn-Co nano-alloy on the surface of graphene, filtered the reaction solution, washed and dried the solid matter, and obtained the nano-intermediate;

[0032] 2. Preparation of composite microsphere intermediate: add 15mL of deionized water to every 10g of the nano-intermediate prepared in step 1, stir evenly, then add 3g of starch to each 10g of nano-intermediate, stir to form a slurry, and use The granulation is carried out by spray drying granulation method, the inlet temperature is 110°C, the outlet temperature is 80°C, the spray pressure is 0.5MPa, and the nozzle diameter is 0.7mm to obtain the composite microsphere intermediate;

[0033] 3. Preparation of carbon-coated composite m...

Embodiment 2

[0037] 1. Preparation of nano-intermediate: 42.94g of SnSO 4 and 33.58 g of CoSO 4 Add 1377mL deionized water, fully dissolve, then add 6.09g graphene and 48.2g sodium dodecyl sulfate, ultrasonically disperse for 10min, then add 0.5mol / L KBH 4 2467mL aqueous solution, react for 10min, deposit Sn-Co nano-alloy on the surface of graphene, filter the reaction solution, wash and dry the solid matter, and obtain the nano-intermediate;

[0038] 2. Preparation of composite microsphere intermediate: add 5mL of deionized water to every 10g of the nano-intermediate prepared in step 1, stir evenly, then add 1g of polyvinyl alcohol to every 10g of nano-intermediate, and stir to form a slurry , using the spray drying granulation method to granulate, the inlet temperature is 140°C, the outlet temperature is 87°C, the spray pressure is 1.5MPa, and the nozzle diameter is 0.5mm, to obtain a composite microsphere intermediate;

[0039] 3. Preparation of carbon-coated composite microspheres: A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com