A kind of preparation method of high performance soft magnetic composite material

A soft magnetic composite material, high-performance technology, applied in the fields of magnetic materials, inorganic material magnetism, inductor/transformer/magnet manufacturing, etc., can solve the problem that the thermal expansion coefficient of the inorganic insulating layer and the magnetic powder is greatly different, and the thermal expansion coefficient of the inorganic insulating layer cannot be changed. , Soft magnetic composite materials cannot have magnetic properties and other problems, to achieve the effect of improving density and mechanical strength, improving heat resistance, and preventing oxidation of iron powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

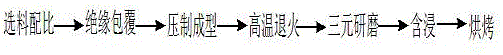

[0019] A method for preparing a high-performance soft magnetic composite material, comprising the following steps:

[0020] (1) Material selection ratio: carbon content 0.008%, silicon content 0.04%, manganese content 0.11%, phosphorus content 0.01%, sulfur content 0.011%, oxygen content 0.13%, bulk density 3.1g / cm 3 For water atomized iron powder, the sieve analysis requirements are: +120 mesh: 3.5%; -120~+150 mesh: 45%; -150~+200 mesh: 30%; -200~+325 mesh: 15%; -325 mesh: 6.5%. The carbon content is 0.018%, the oxygen content is 0.18%, and the bulk density is 2.6g / cm 3 , carbonyl iron powder with a Fischer particle size of 6.8 μm. Water atomized iron powder and carbonyl iron powder are mixed evenly at a mass ratio of 96:4;

[0021] (2) Insulation coating: Use 70nm silicon nitride and aluminum nitride dielectric materials to coat iron powder, lubricant ZF2033 (paraffin wax and zinc stearate compound), silicon nitride, aluminum nitride and mixed iron The mass ratio of the ...

Embodiment 2

[0032] A method for preparing a high-performance soft magnetic composite material, comprising the following steps:

[0033] (1) Material selection ratio: carbon content 0.009%, silicon content 0.03%, manganese content 0.13%, phosphorus content 0.02%, sulfur content 0.013%, oxygen content 0.12%, bulk density 3.1g / cm 3 For water atomized iron powder, the sieve analysis requirements are: +120 mesh: 4.5%; -120~+150 mesh: 48%; -150~+200 mesh: 28%; -200~+325 mesh: 11%; -325 mesh: 8.5%. The carbon content is 0.015%, the oxygen content is 0.15%, and the bulk density is 2.8g / cm 3 , carbonyl iron powder with a Fischer particle size of 6.5 μm. Water atomized iron powder and carbonyl iron powder are mixed evenly at a mass ratio of 95:5;

[0034](2) Insulation coating: use 65nm silicon nitride and aluminum nitride dielectric materials to coat iron powder, lubricant ZF2033 (paraffin wax and zinc stearate compound), silicon nitride, aluminum nitride and mixed iron The mass ratio of the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com