Current guiding device for live operation of distribution network with long-distance real-time monitor

A technology of real-time monitoring and live work, applied in the direction of overhead line/cable equipment, clamping/spring connection, etc., can solve the problems of unfavorable safety production, increase the difficulty of monitoring, and swaying operation direction, so as to achieve the benefit of construction safety , Reduce labor intensity, reduce the effect of operating pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Best practice:

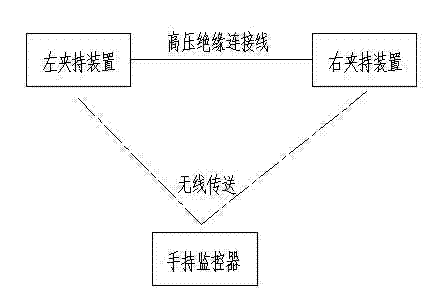

[0058] Refer to attached figure 1 , with long-distance real-time monitoring of the distribution network live work drainage device, including a pair of clamping devices (left clamping device and right clamping device), high-voltage insulated connecting wires and hand-held monitors, the two ends of the high-voltage insulated connecting wires are respectively connected Left clamping device and right clamping device. The hand-held monitor is respectively connected to the remote control of the left and right clamping devices, see the following scheme for details.

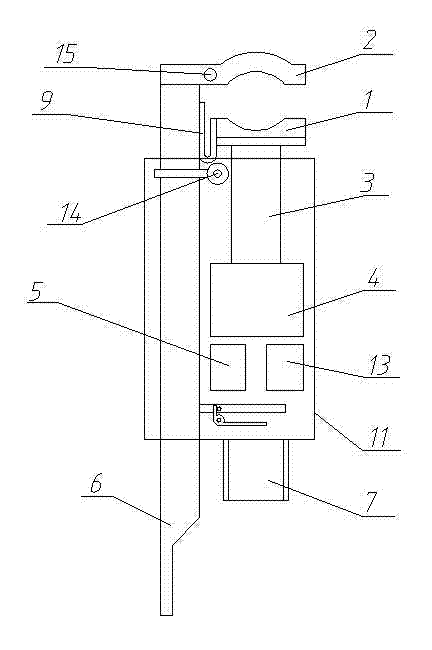

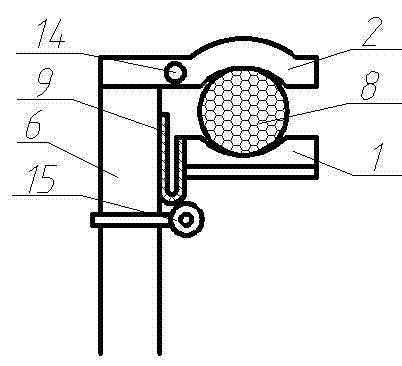

[0059] Refer to attached figure 2, The structure of the left and right clamping devices is the same, specifically as follows, the clamping device includes an outer shell 11, a jaw part, a clamping mechanism 3, a reduction motor 4, a main control board 5, a drainage connection device 6 and an operation rod connection part 7. The drainage connection device is a rod-shaped structure, which passes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com