Patents

Literature

124results about How to "Labor intensity guarantee" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

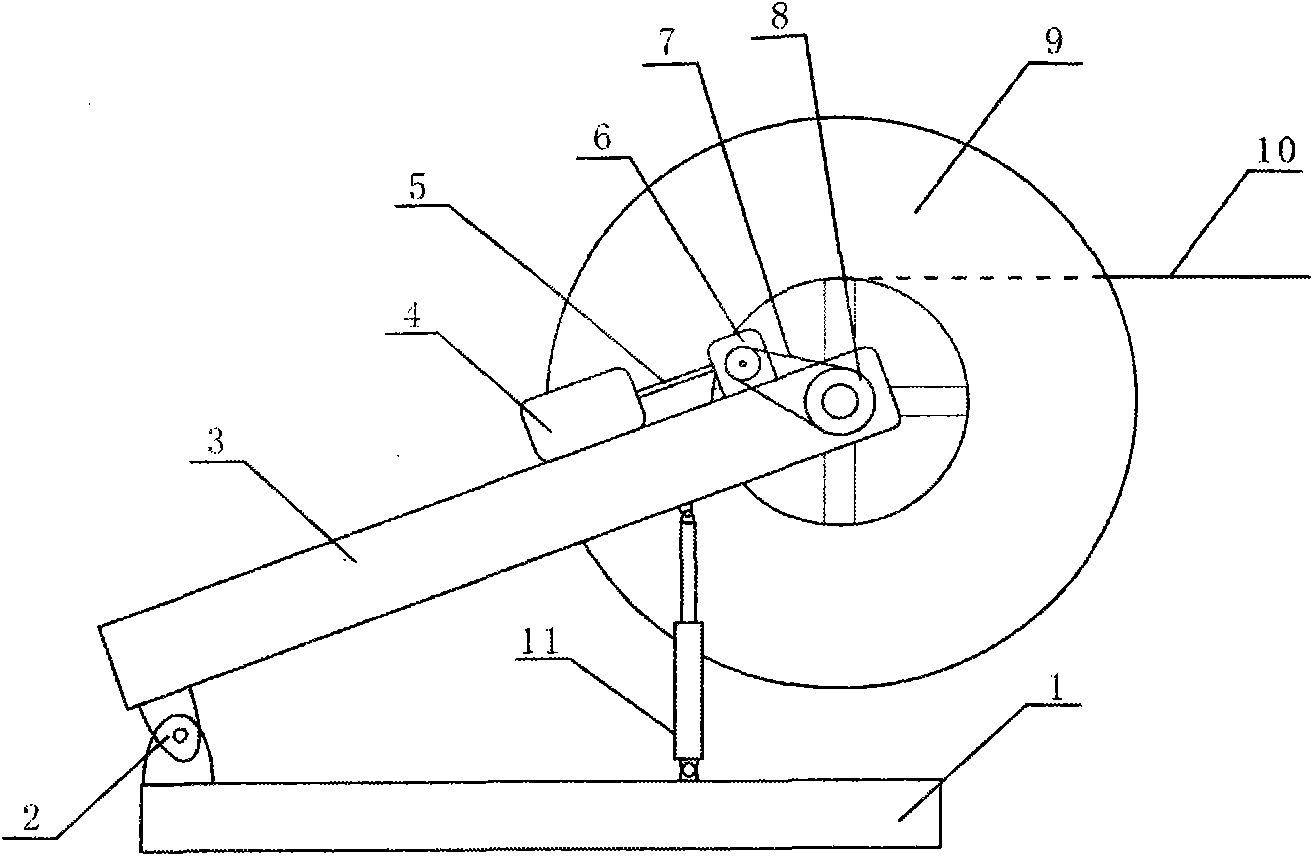

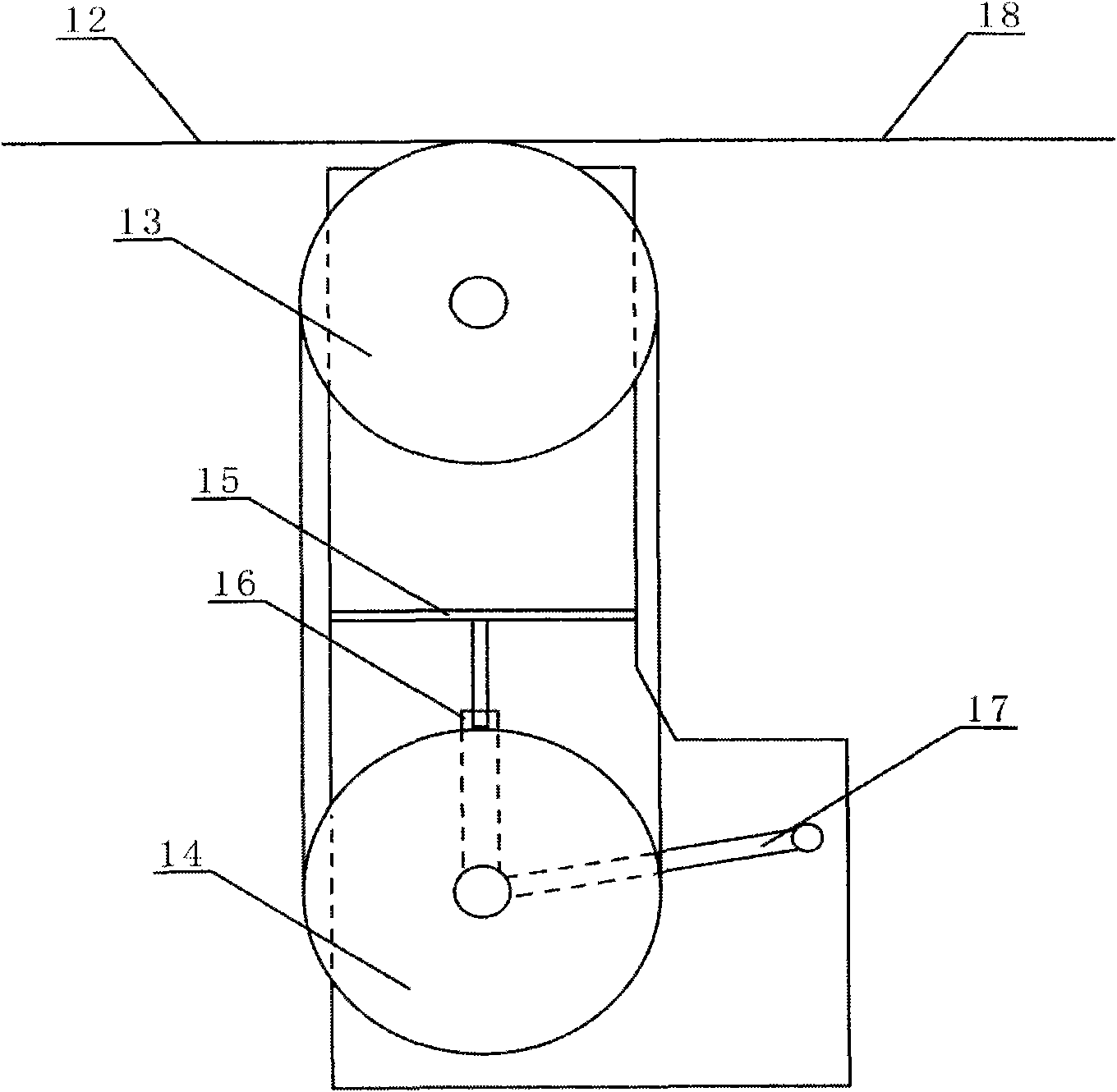

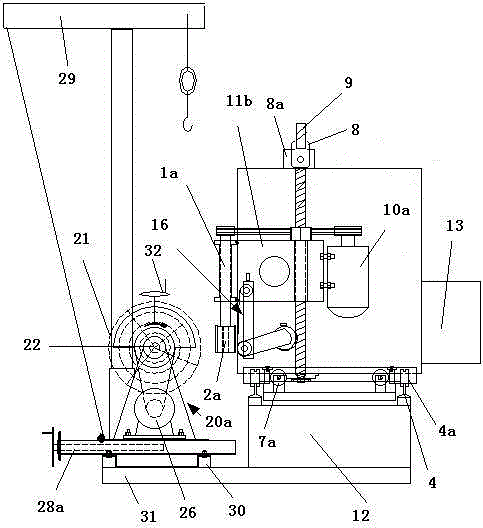

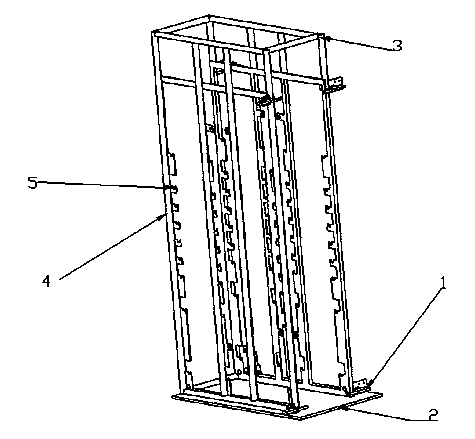

Active wire paying-off rewinder of aluminum clad steel wires

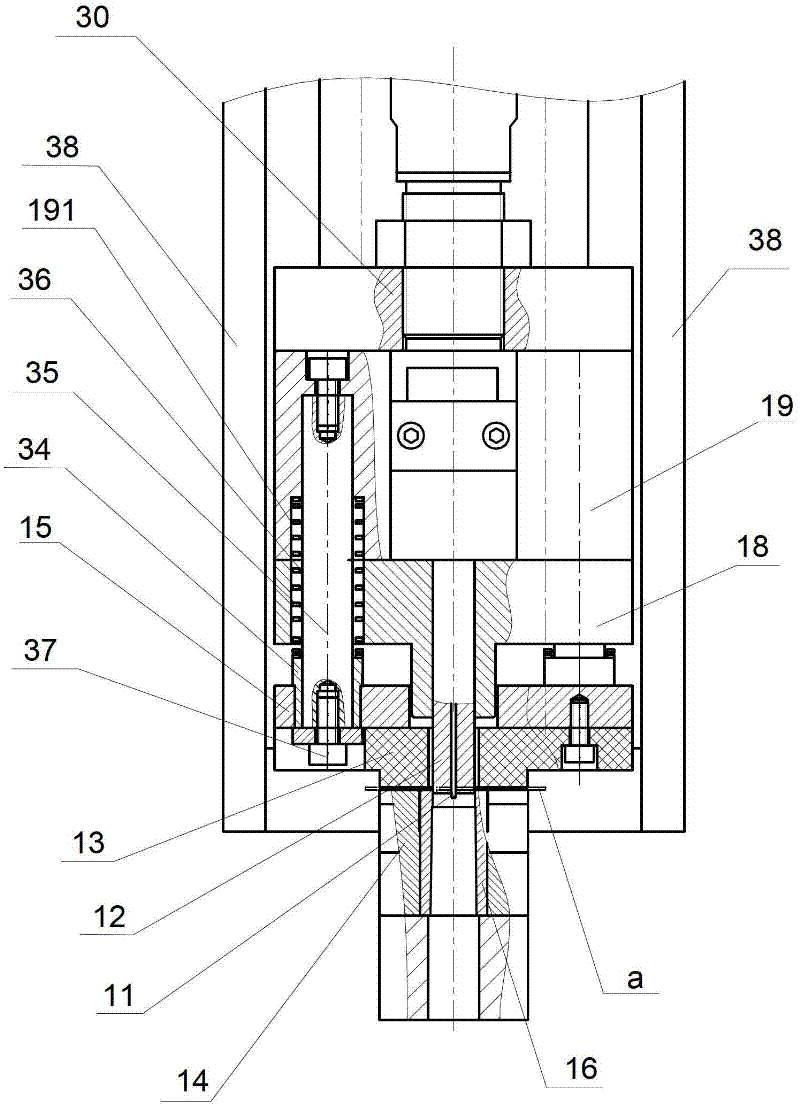

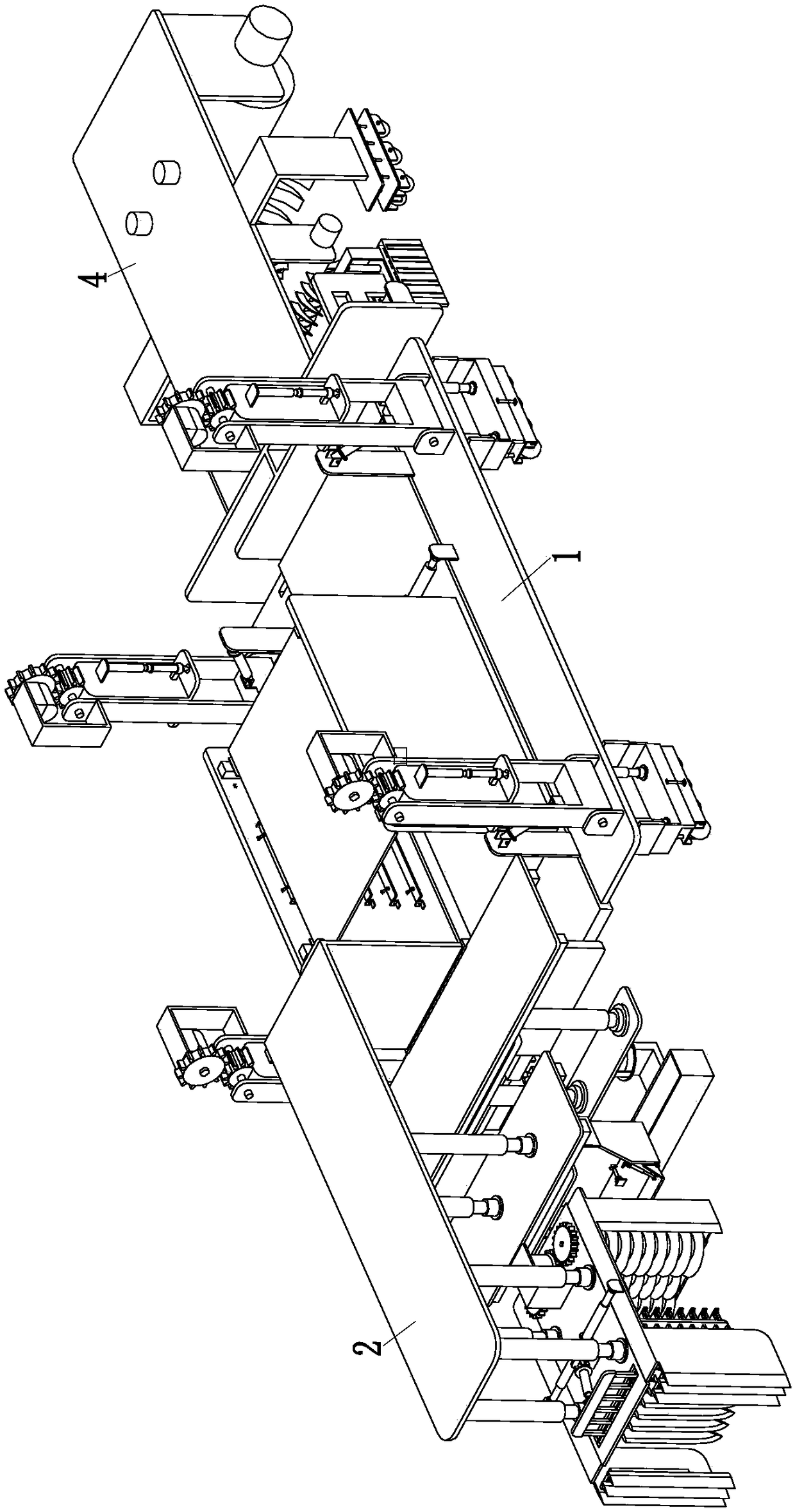

The invention discloses an active paying-off rewinder of aluminum clad steel wires. The rewinder is characterized by comprising an active paying-off mechanism, a tension mechanism and an automatic wire arranging and taking-up mechanism, wherein the aluminum clad steel wire grail tool of the active paying-off mechanism of the rewinder is driven by a motor to realize uniform wire paying-off; an upper tension pulley of the tension mechanism is fixed on a rack, and a lower tension pulley of the tension mechanism is jointly supported by a pneumatic cylinder and a lower tension pulley support; under the action of the pneumatic cylinder and aluminum clad steel wire tension, the tension pulley is used for adjusting the aluminum clad steel wire tension by vertical movement; and the automatic wire arranging and taking-up mechanism is characterized in that a wire arranging seat rotating shaft, a wire arranging seat guide rail, a movable mandril and a fixed mandril are arranged between two fixed supports; the wire arranging seat rotating shaft is provided with a wire arranging seat and a wire arranging seat driving wheel; the wire arranging seat guide rail is provided with two stop pins for playing a limit role; the movable mandril and the fixed mandril are respectively connected with the grail tool in a splicing mode; the fixed mandril is provided with a grail tool driving wheel, a brake pad and a driven wheel; and the driven wheel is connected with the wire arranging driving wheel which is arranged on the wire arranging seat rotating shaft by a driving belt. Therefore, the product quality is ensured, the production efficiency is improved and the labor intensity is reduced.

Owner:HENAN TONG CABLE

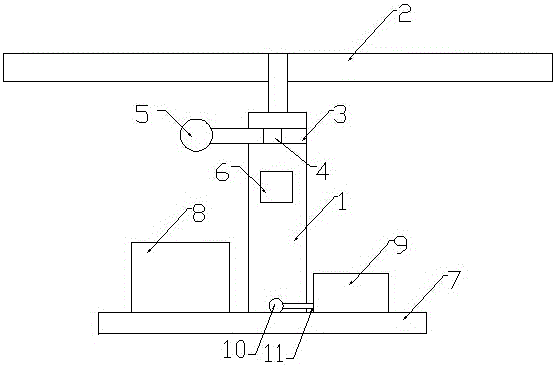

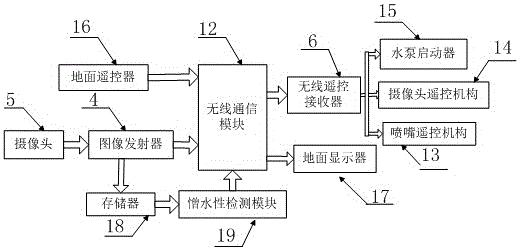

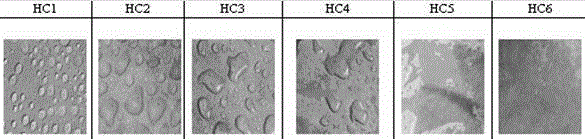

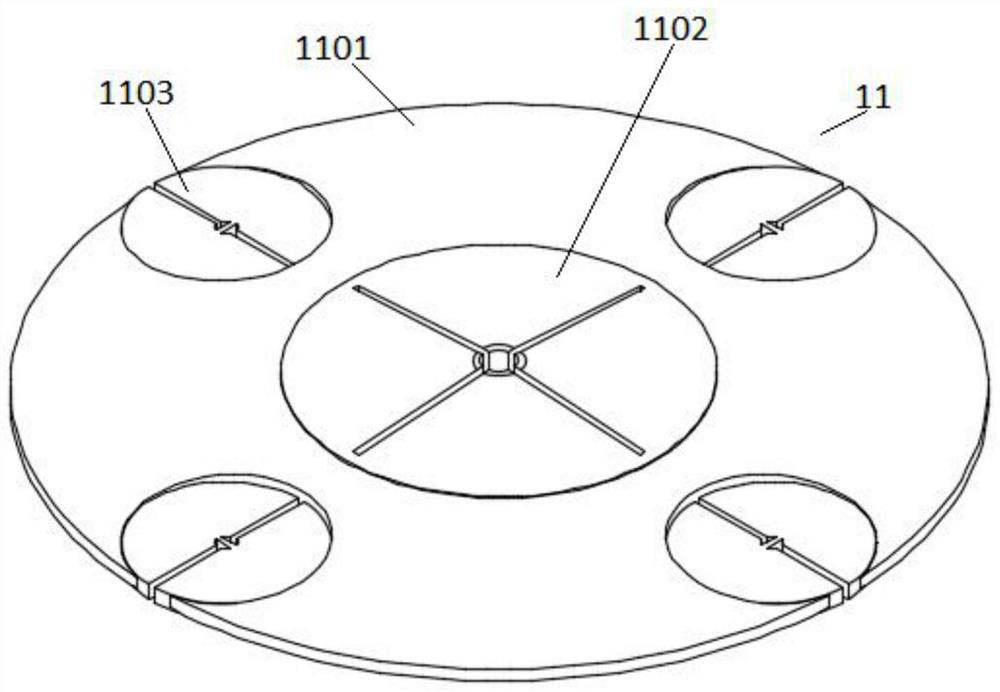

Unmanned plane based live-line test apparatus for hydrophobicity of composite insulator of power transmission line

ActiveCN105067484AReduce labor intensityLabor intensity guaranteeImage analysisSurface/boundary effectComposite insulatorsRemote control

The invention discloses an unmanned plane based live-line test apparatus for hydrophobicity of composite insulator of power transmission line. The Unmanned plane based live-line test apparatus for hydrophobicity of composite insulator of power transmission line comprises an unmanned plane, wherein, the unmanned plane is provided with a wireless remote controller, a water spraying apparatus and an image acquisition and transmission apparatus, the water spraying apparatus comprises a water tank, a water pump and a nozzle, wherein, the water pump and the water tank are connected with each other, and the water pump is connected with the nozzle by a water spraying pipe; the image acquisition and transmission apparatus comprises a pick-up head and an image transmitter, and the pick-up head and the image transmitter are connected with each other; the wireless remote controller comprises a wireless remote control receiver, a wireless communication module, a nozzle remote control mechanism, a pick-up head remote control mechanism and a water pump starter, and the wireless remote control receiver is respectively connected with the nozzle remote control mechanism, the pick-up head remote control mechanism and the water pump starter; the nozzle remote control mechanism is connected with the nozzle, the pick-up head remote control mechanism is connected with the pick-up head, and the water pump starter is connected with the water pump. The apparatus provided by the invention can effectively eliminate hidden troubles and is convenient and easy to operate, thereby reducing labor intensity of personnel to a large degree and guarantying personal safety.

Owner:PUYANG POWER SUPPLY COMPANY STATE GRID HENAN ELECTRIC POWER +1

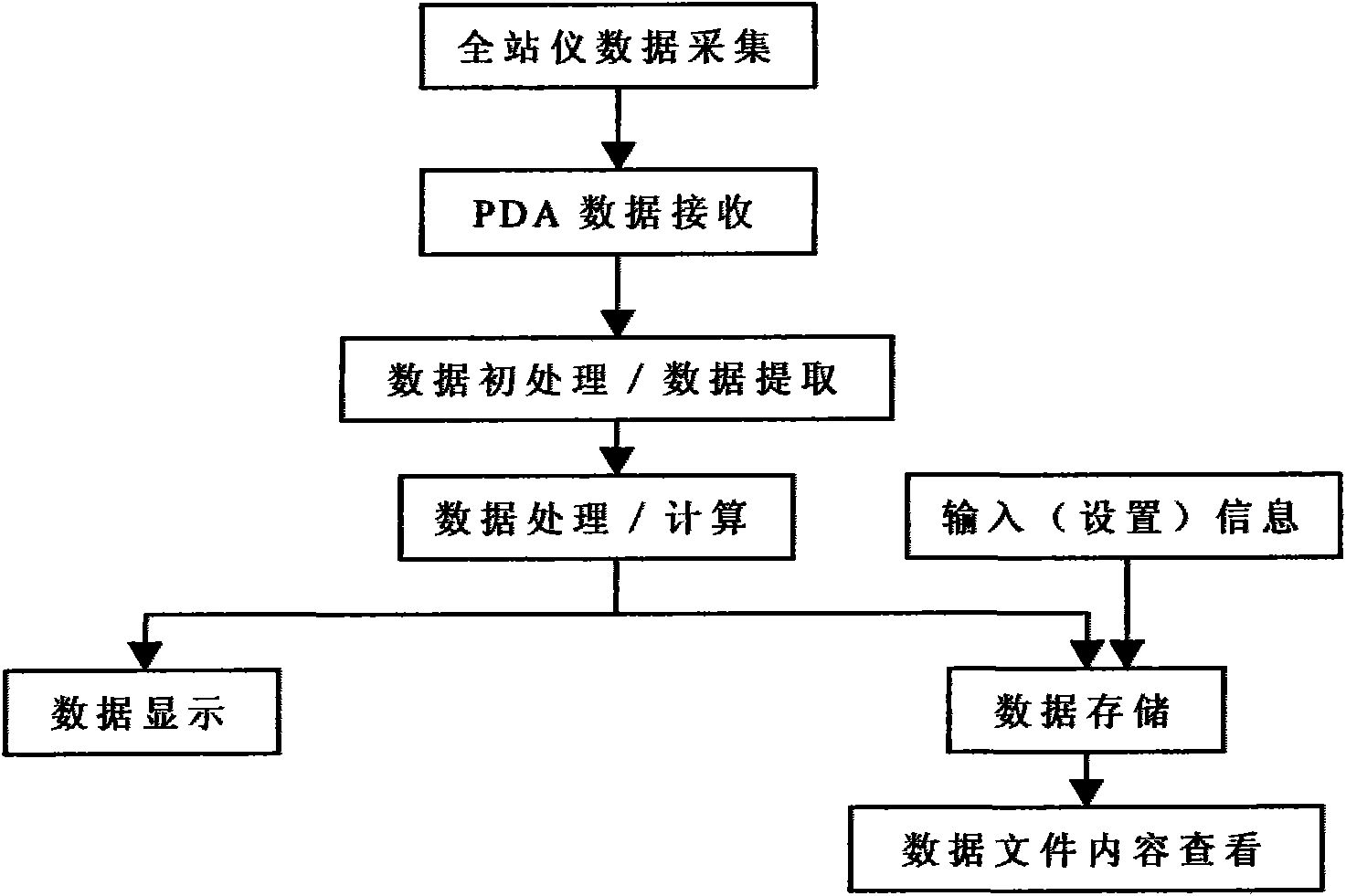

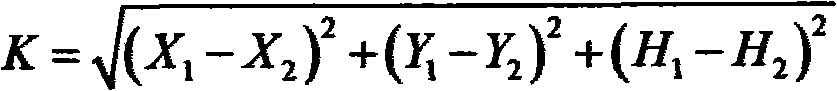

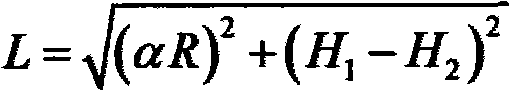

Existing railway survey method based on total station

InactiveCN101539410ARealize measurementAchieving processing powerUsing wave/particle radiation meansHydrologyTotal station

The invention relates to an existing railway survey method based on a total station. In the method, the total station and an electromagnetic wave reflection device are adopted to survey an existing railway. The survey method comprises the following steps: firstly arranging the electromagnetic wave reflection device at the center of the existing railway line to be surveyed by virtue of a traditional measuring square ruler; determining position of the total station, and surveying the line center by the electromagnetic wave reflection device to obtain distance (slant distance), horizontal angle and vertical angle of the surveyed line and 3D coordinates of survey points (X, Y and H) of the measured line (slope distance); and then analyzing and calculating the survey data by a PDA, and performing survey on line mileage, center line, traverse, elevation and other railway equipment. The existing railway survey method based on a total station reduces on-track operation times of operators, guarantees safety of surveyors, instruments and equipment, accuracy and reliability of the surveyed data, improves production efficiency of the existing railways, and alleviates labor intensity of the operators.

Owner:黄远宏 +1

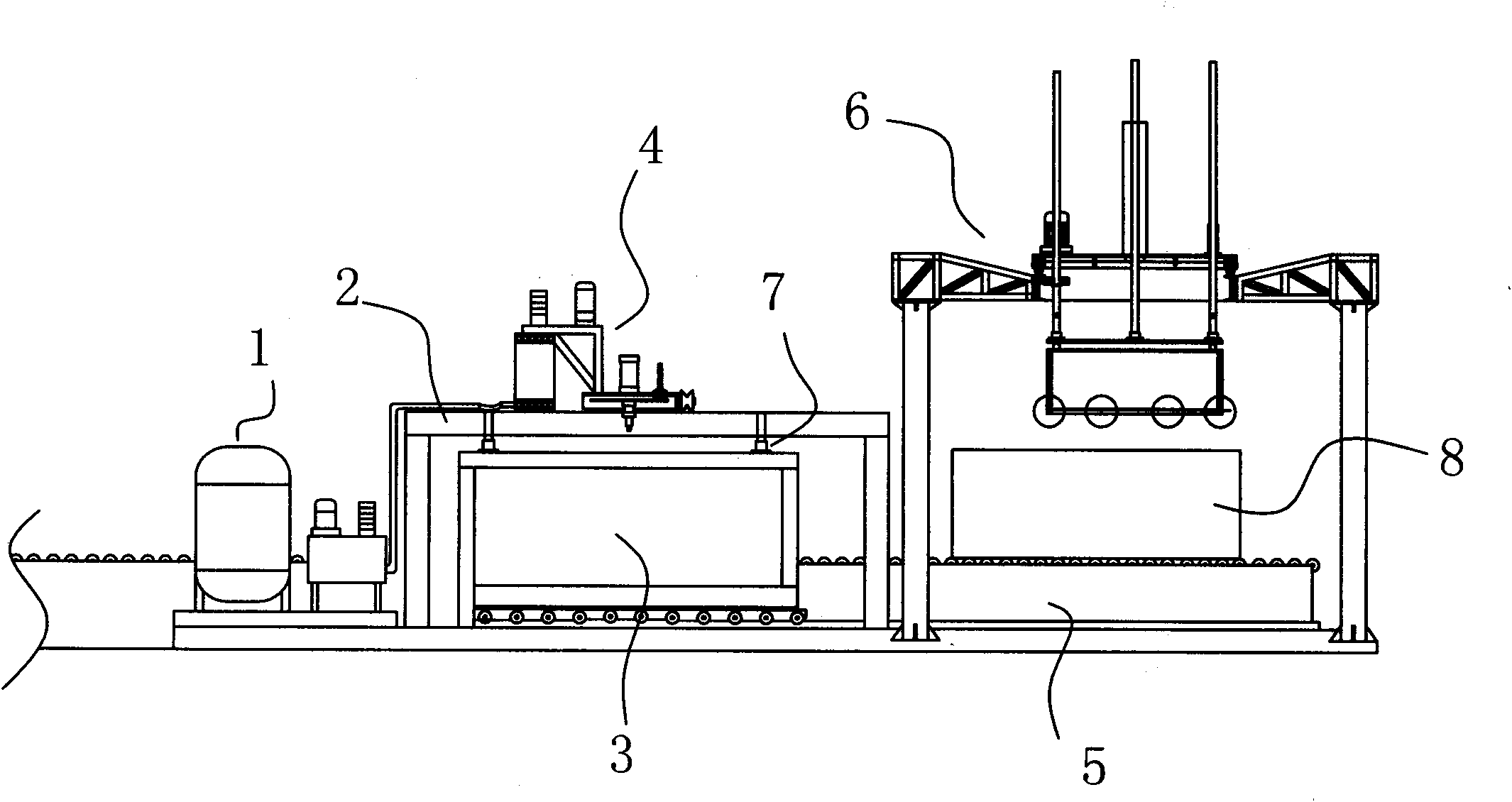

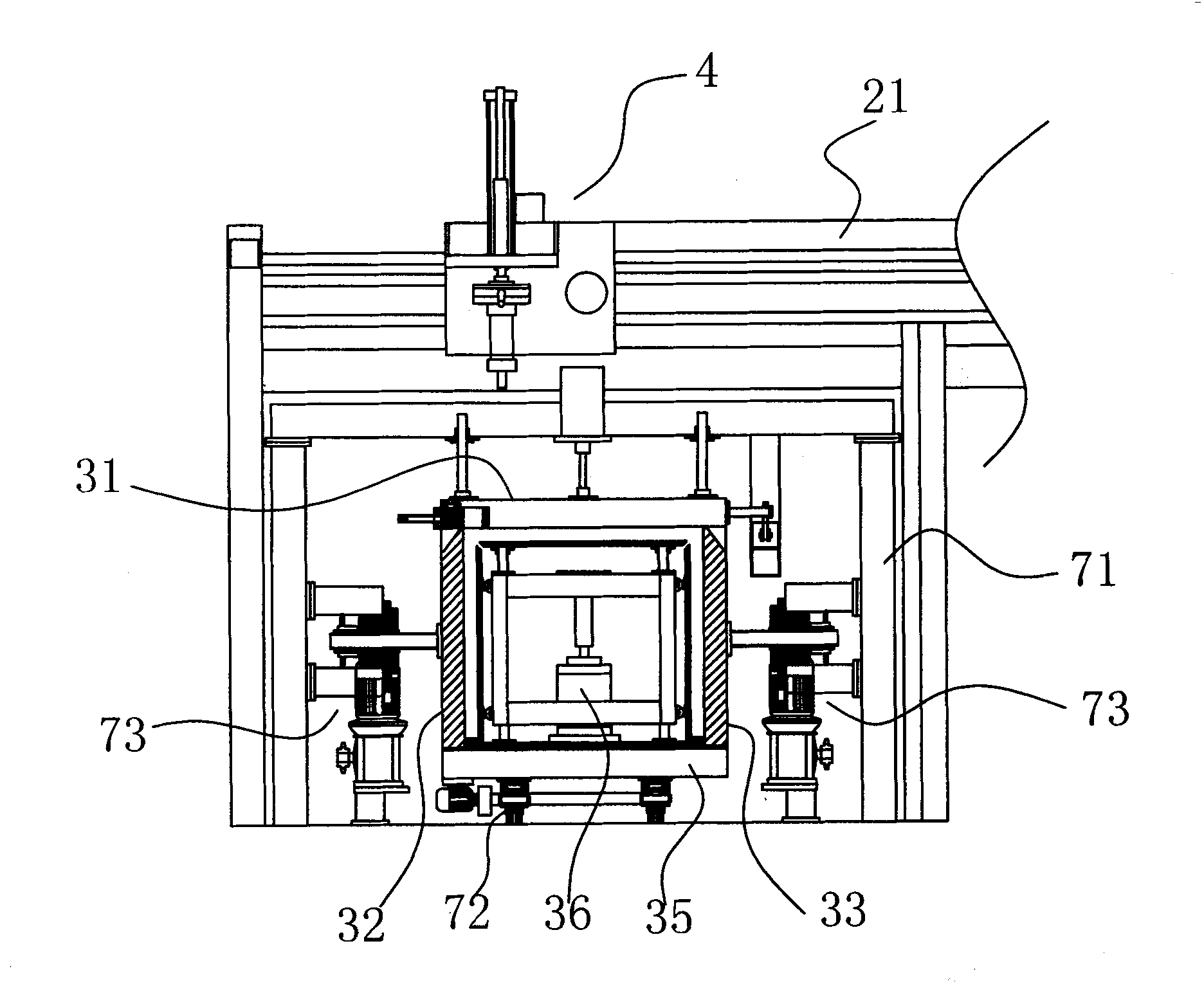

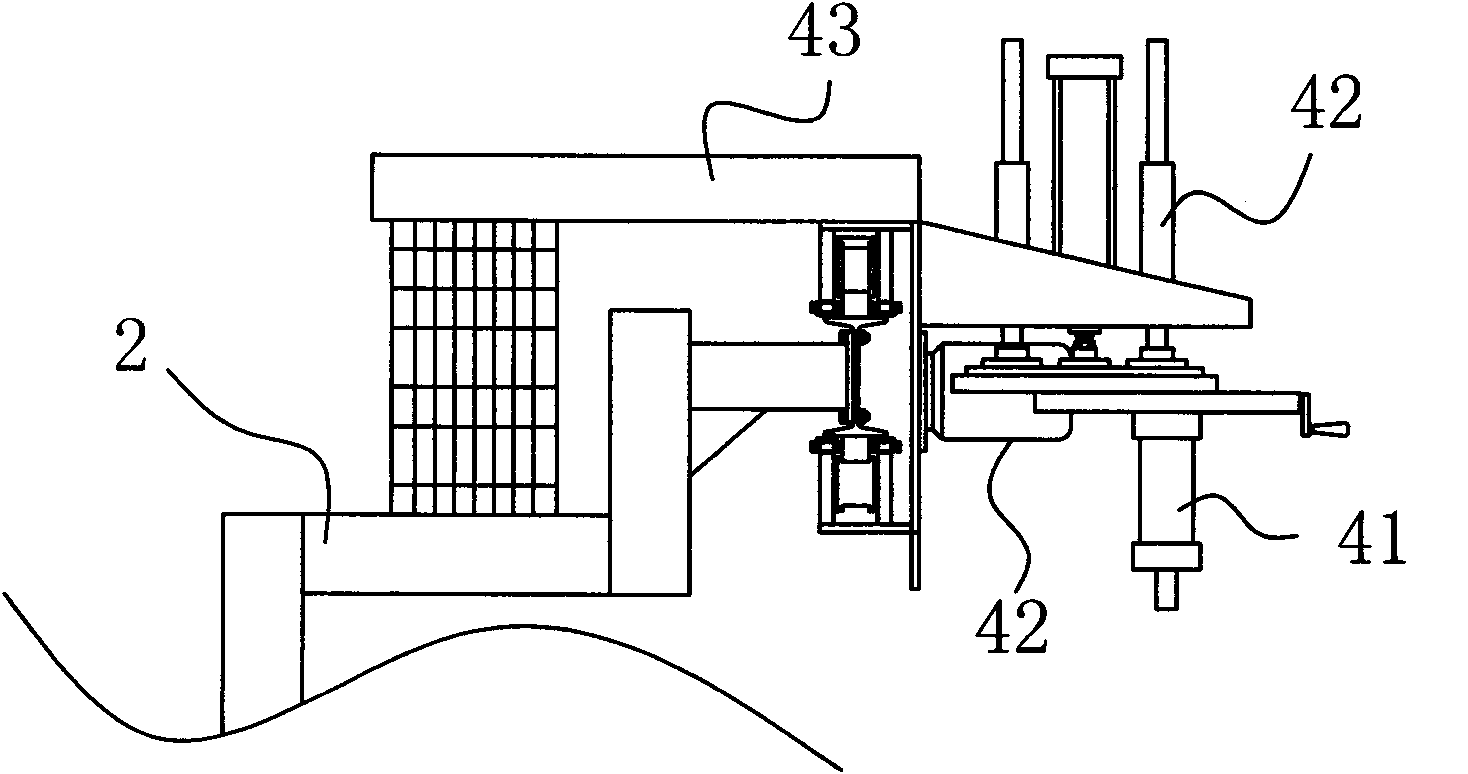

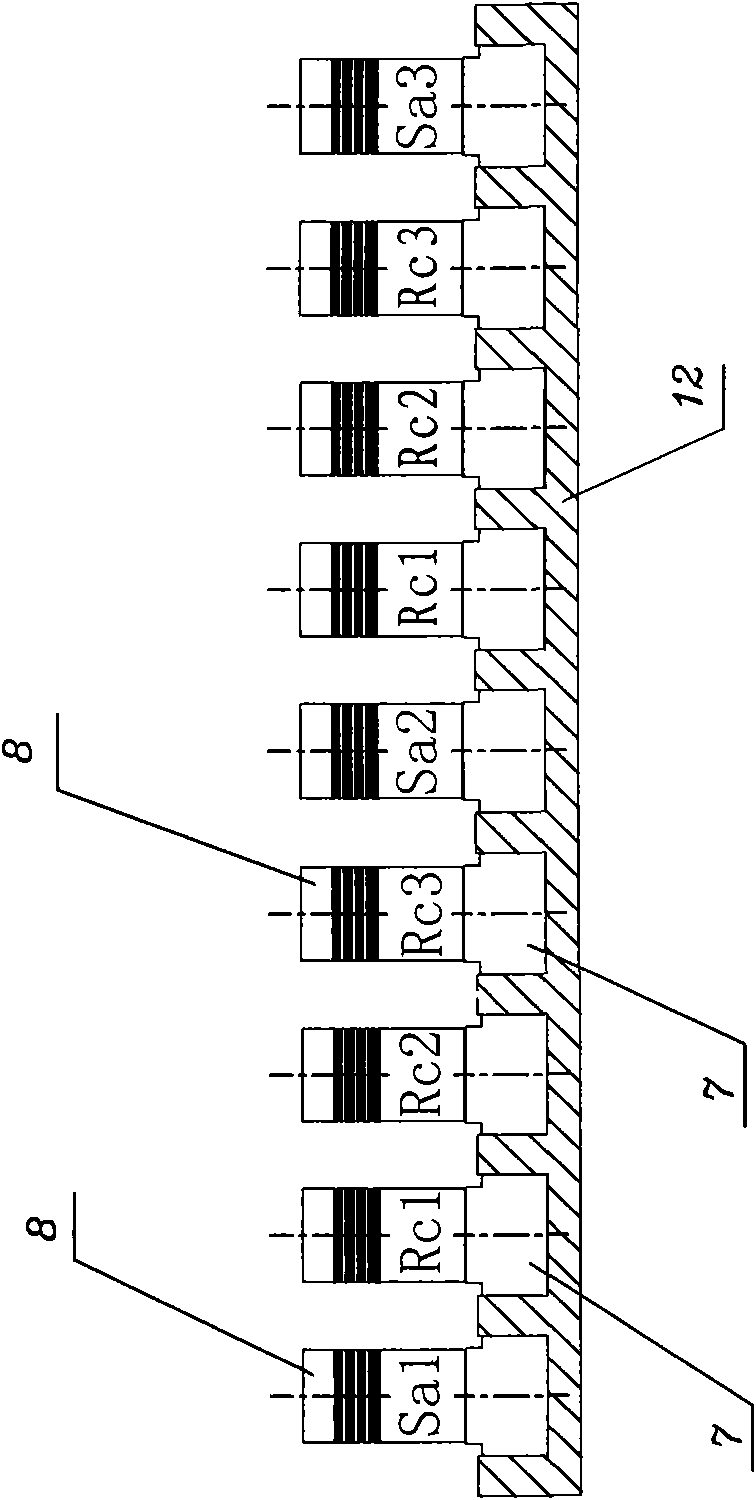

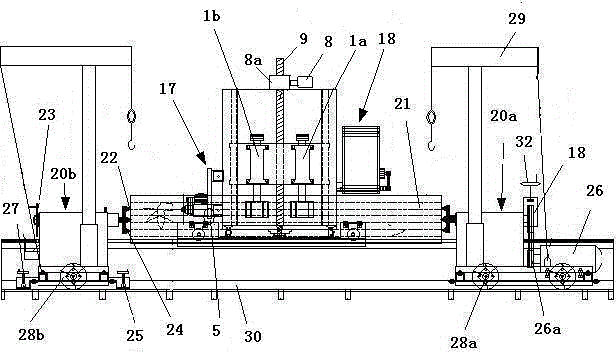

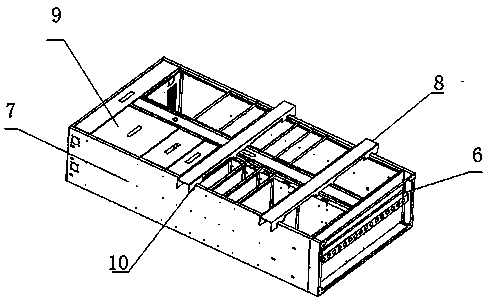

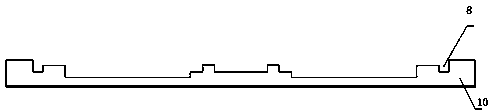

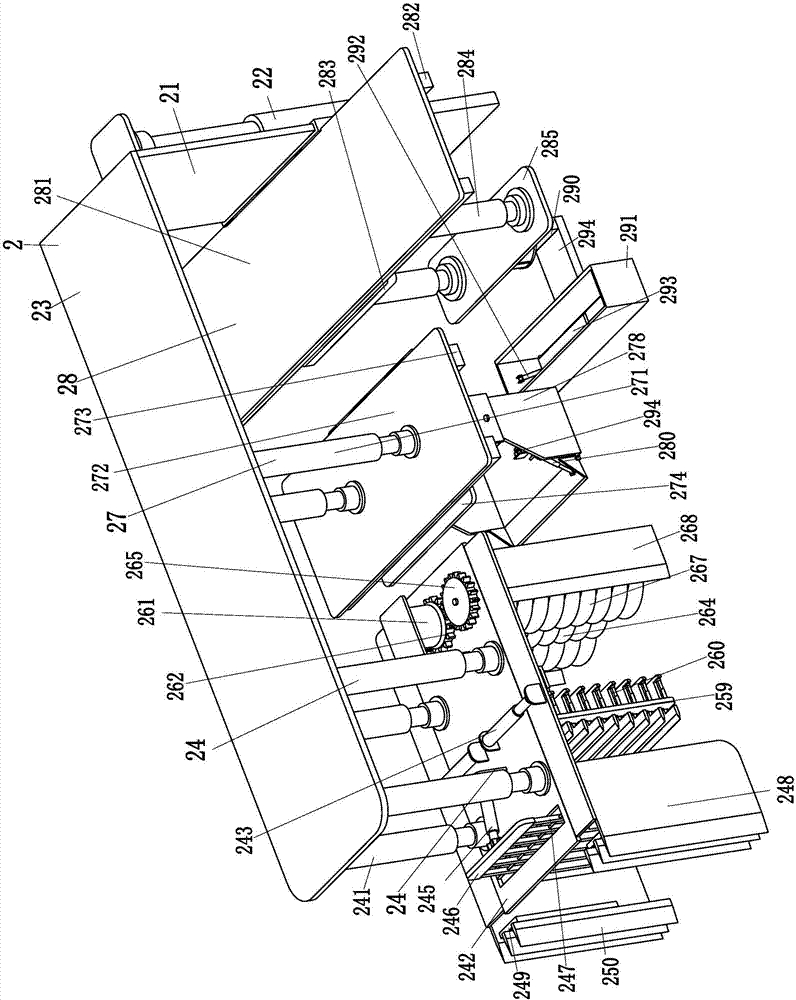

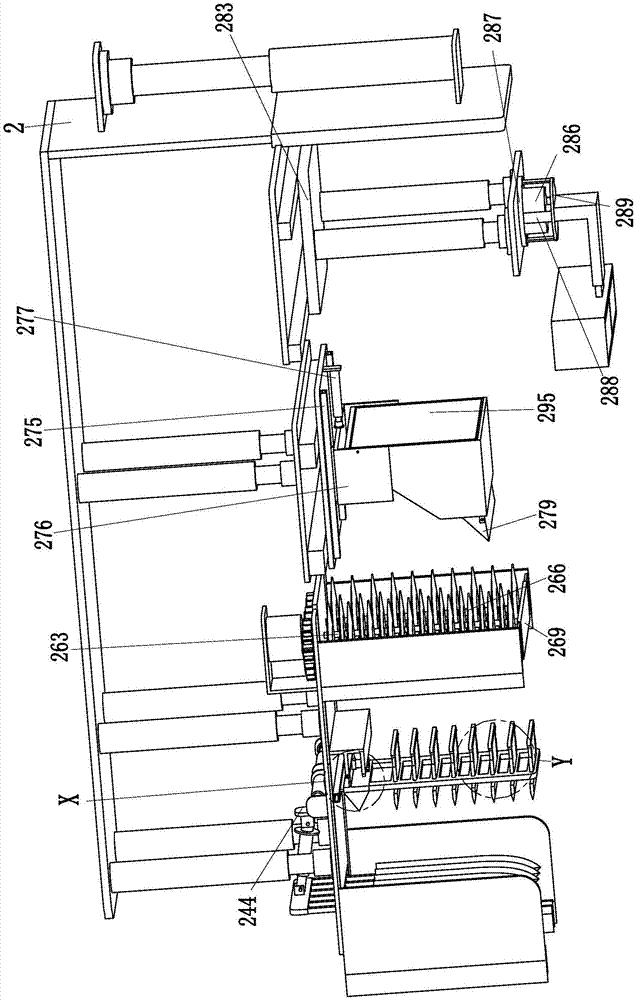

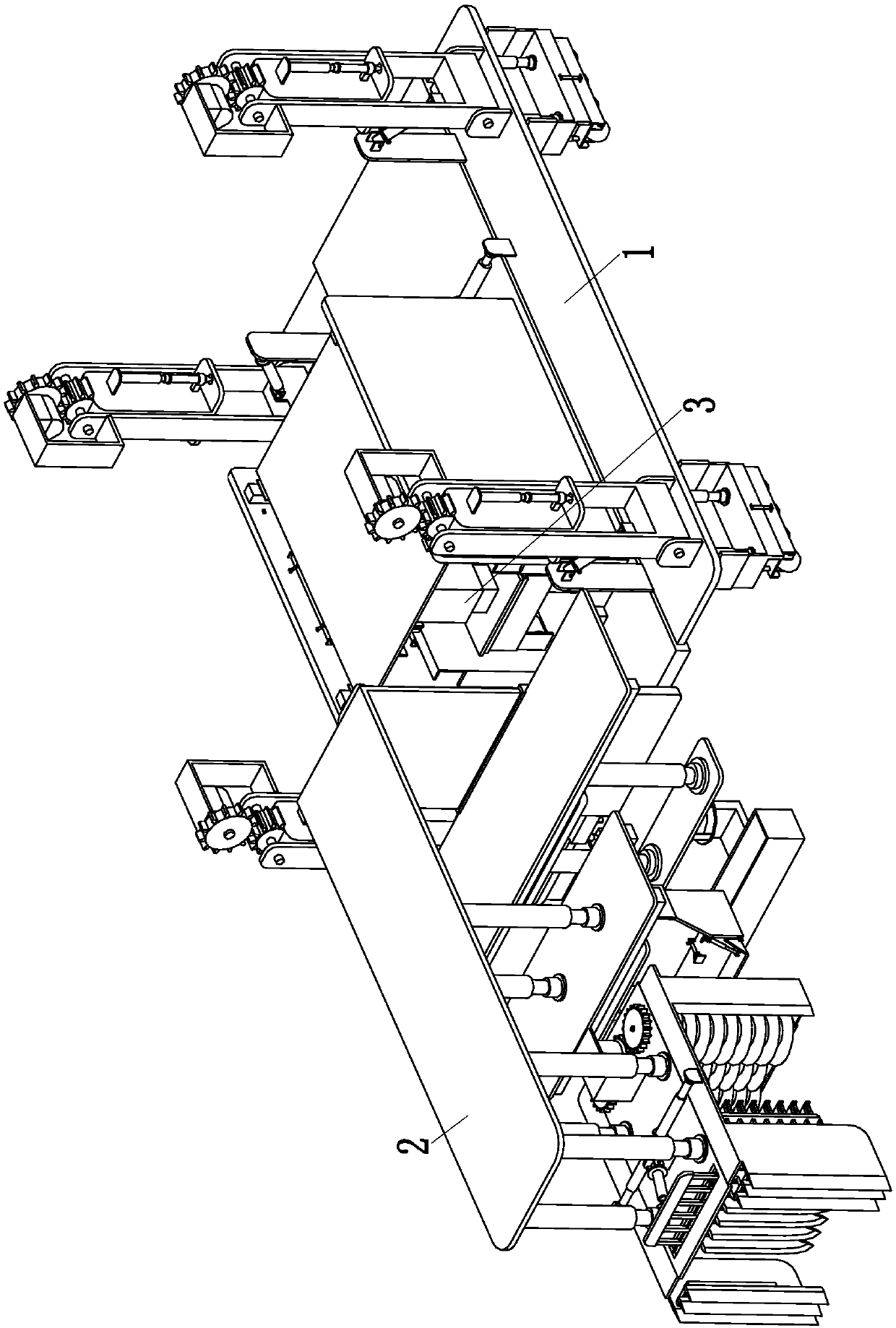

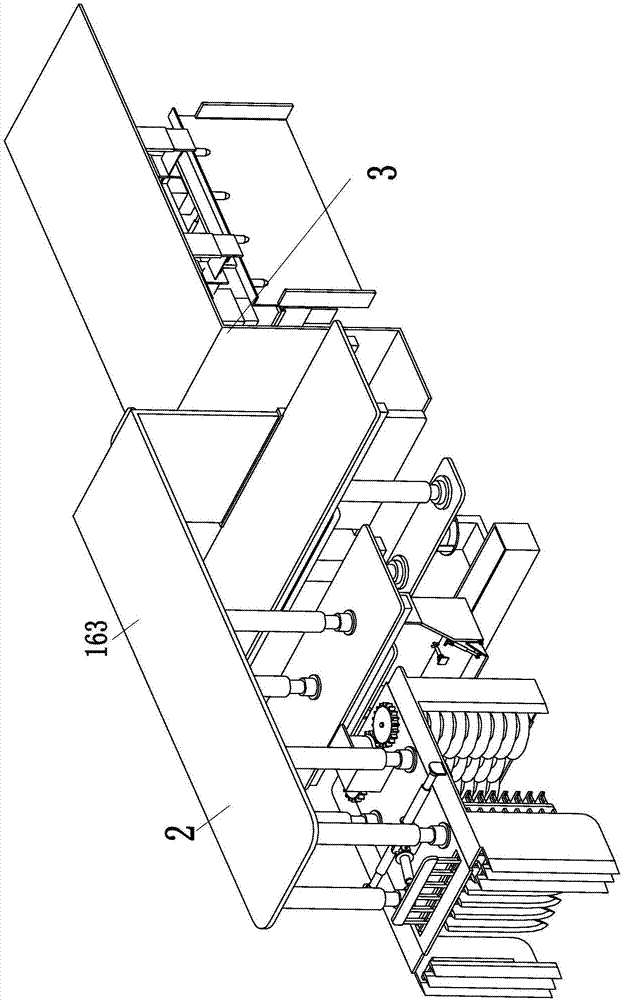

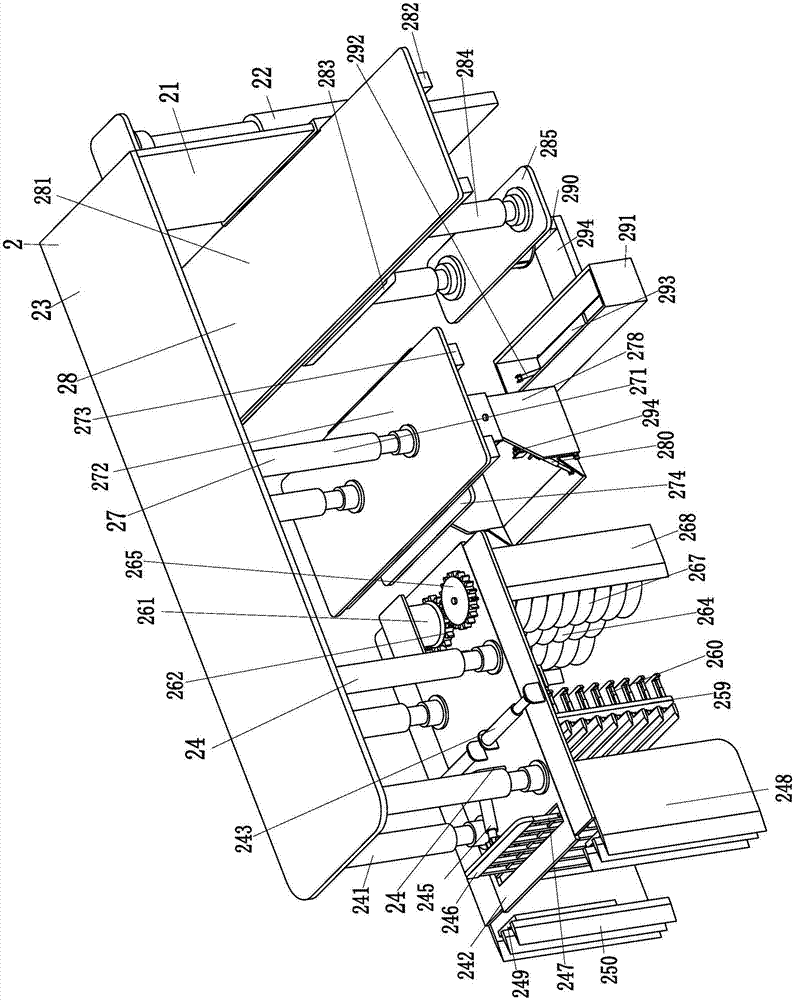

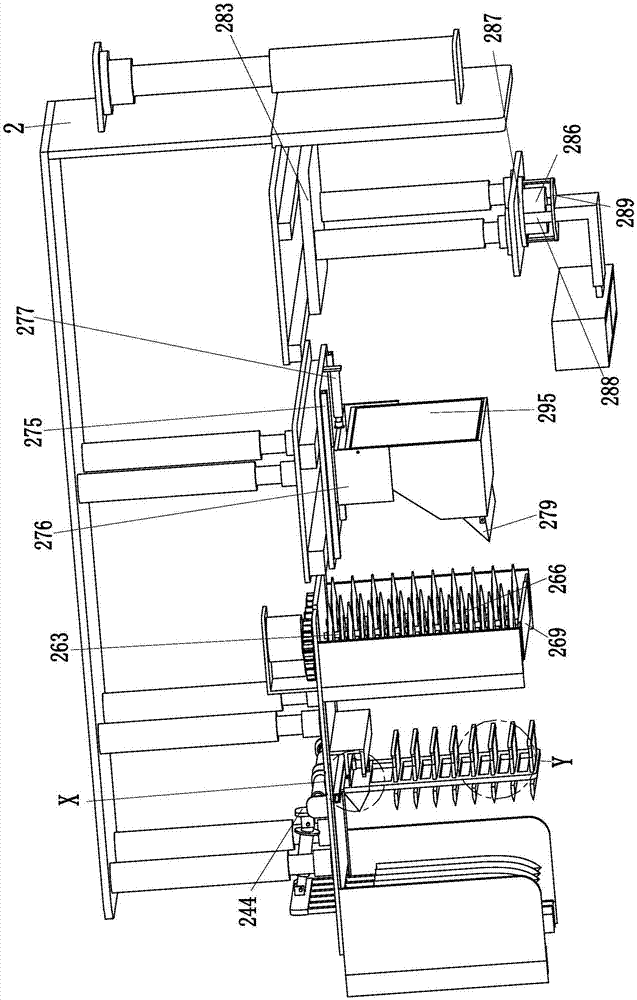

Full-automatic production method of multi-station mobile fixed foaming freezer body and system thereof

InactiveCN101913223AFlexible adjustment of specificationsReduce investmentDomestic articlesAutomatic controlRobot hand

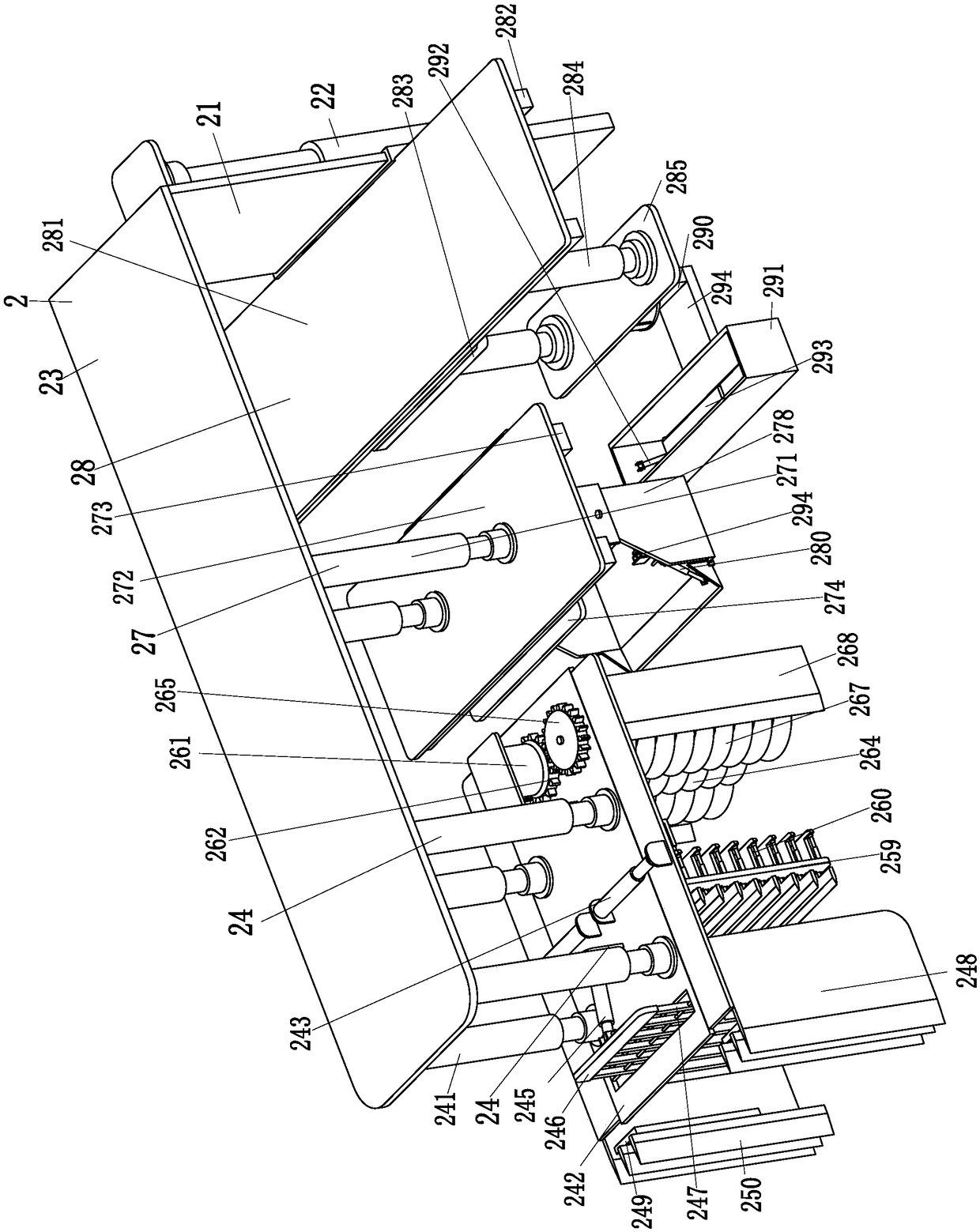

The invention discloses a full-automatic production method of a multi-station mobile fixed foaming freezer body, comprising the following steps of: (1) setting foaming equipment and an automatic foaming control system capable of controlling the work state of the foaming equipment; (2) setting a foaming mould frame with a slide at the top; (3) arranging multiple fixed foaming moulds below the slide juxtaposedly; and (4) setting a pouring manipulator which is controlled by the automatic foaming control system. The invention also discloses a system for implementing the method. The invention employs a mobile fixed foaming technology and an automatic control technology and has simple production process and automated process, thereby effectively decreasing the supervisor, making the operation convenient, greatly reducing the labour intensity, saving the manpower and material resources, and reducing the production cost; furthermore, a multi-station batch production technology with rapid production speed, short period and guaranteed product quality is added, thereby greatly improving the production efficiency and the product qualification rate and strengthening the enterprise competitiveness.

Owner:东莞市百利电器有限公司 +1

Medical equipment for hospital injector treatment

The invention relates to medical equipment for hospital injector treatment. The medical equipment comprises a main frame, a needle cylinder separation device, a needle cylinder crushing device and a syringe needle cutting device, wherein the needle cylinder separation device is arranged at the upper end of the main frame, and the upper end of the main frame is provided with the needle cylinder crushing device; the needle cylinder crushing device is located in the needle cylinder separation device, and the syringe needle cutting device is arranged at the rear end of the main frame. According tothe medical equipment, the problems are solved that when existing injectors are recycled, needle cylinders and syringe needles need to be manually separated, then the syringe needles are broken by pliers and the syringe cylinders are crushed; when the injectors are separated, the injectors need to be manually limited, and then the parts are separated, accordingly the manual separation efficiencyis low, piston parts in the syringe cylinders need to be taken out manually; the size of the syringe cylinders is small, manual separation is not easy, accordingly when the syringe cylinders are crushed, staff need to use tools to crush the cylinders, and part of fragments splash out in the crushing process; when the syringe needles are broken by the pliers, the syringe needles are thin and small,accordingly the syringe needles cannot be broken by the pliers manually.

Owner:绍兴集知汇信息科技有限公司

Ditching, layer laying and backfilling combined telecommunication cable mechanical laying equipment

InactiveCN107989092AReduce labor intensityImprove work efficiencySoil-shifting machines/dredgersFoundation engineeringTelecommunications cableEngineering

The invention relates to ditching, layer laying and backfilling combined telecommunication cable mechanical laying equipment. The equipment comprises a lifting plate, a soil cutting device, a groutingdevice and a backfilling device, wherein the soil cutting device is mounted at the front end of the lifting plate; the grouting device is mounted at the lower end of the lifting plate; and the backfilling device is mounted at the rear end of the lifting plate. By means of the ditching, layer laying and backfilling combined telecommunication cable mechanical laying equipment, the problems can be solved that in the existing cable direct burying processes, workers need to perform ditching, manual grouting and layer laying, and backfilling and soil rolling; during ditching, the workers need to perform ditching with the help of tools, and the later-stage backfilling effect is affected due to different sizes of soil blocks which are manually cut; and during layer laying, the ditch bottoms needsto be subjected to manual grouting and rolling, cement plates need to be subjected to external grouting and solidification and then delivered to the appointed positions to be mounted during groutingof the side surfaces, cut soil needs to be subjected to manual backfilling and then beating and pressing, and the soil is not compact during manual pressing due to different cut soil blocks, and the functions of automatic ditching, layer laying and backfilling of telecommunication cables can be achieved.

Owner:黄正秀

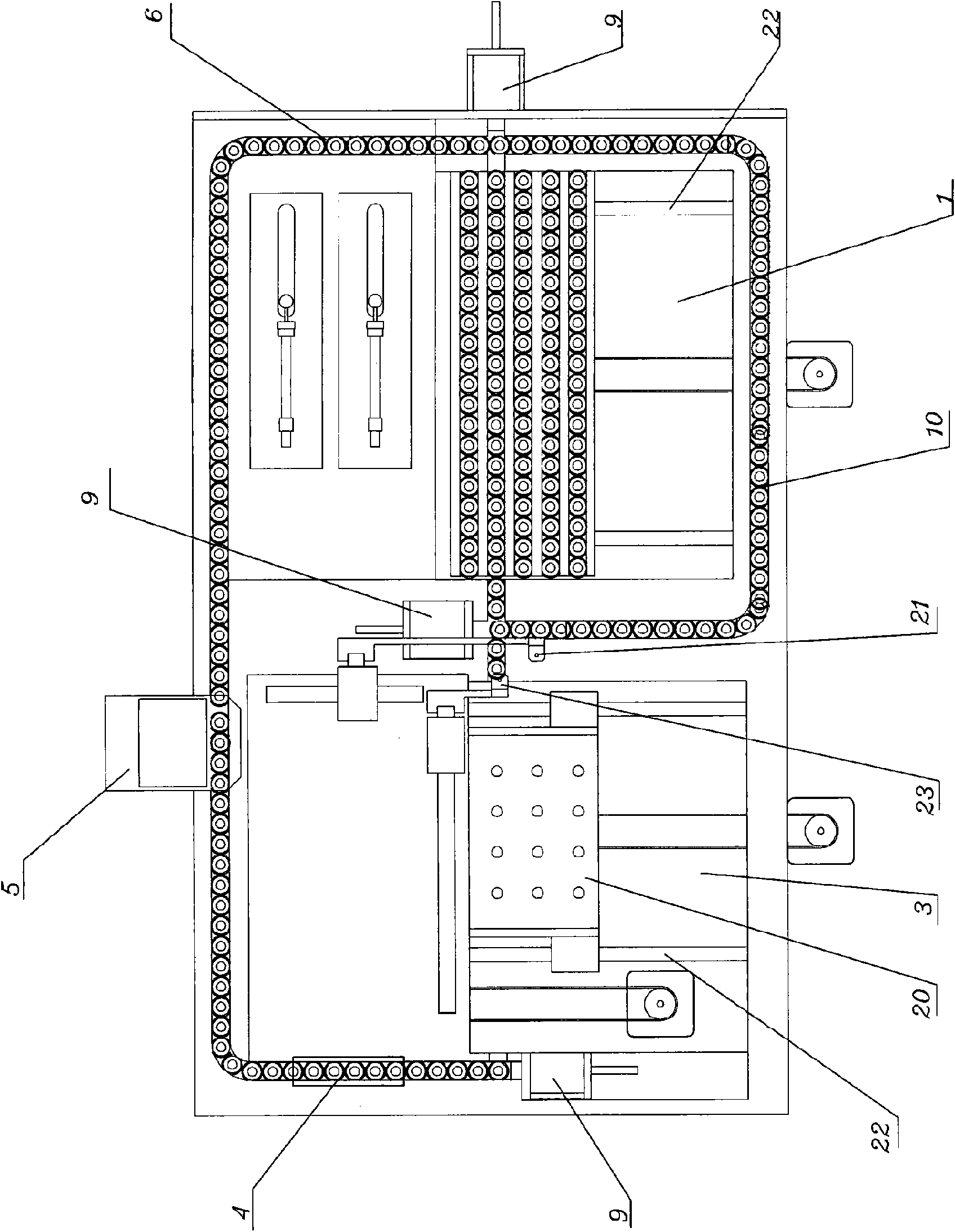

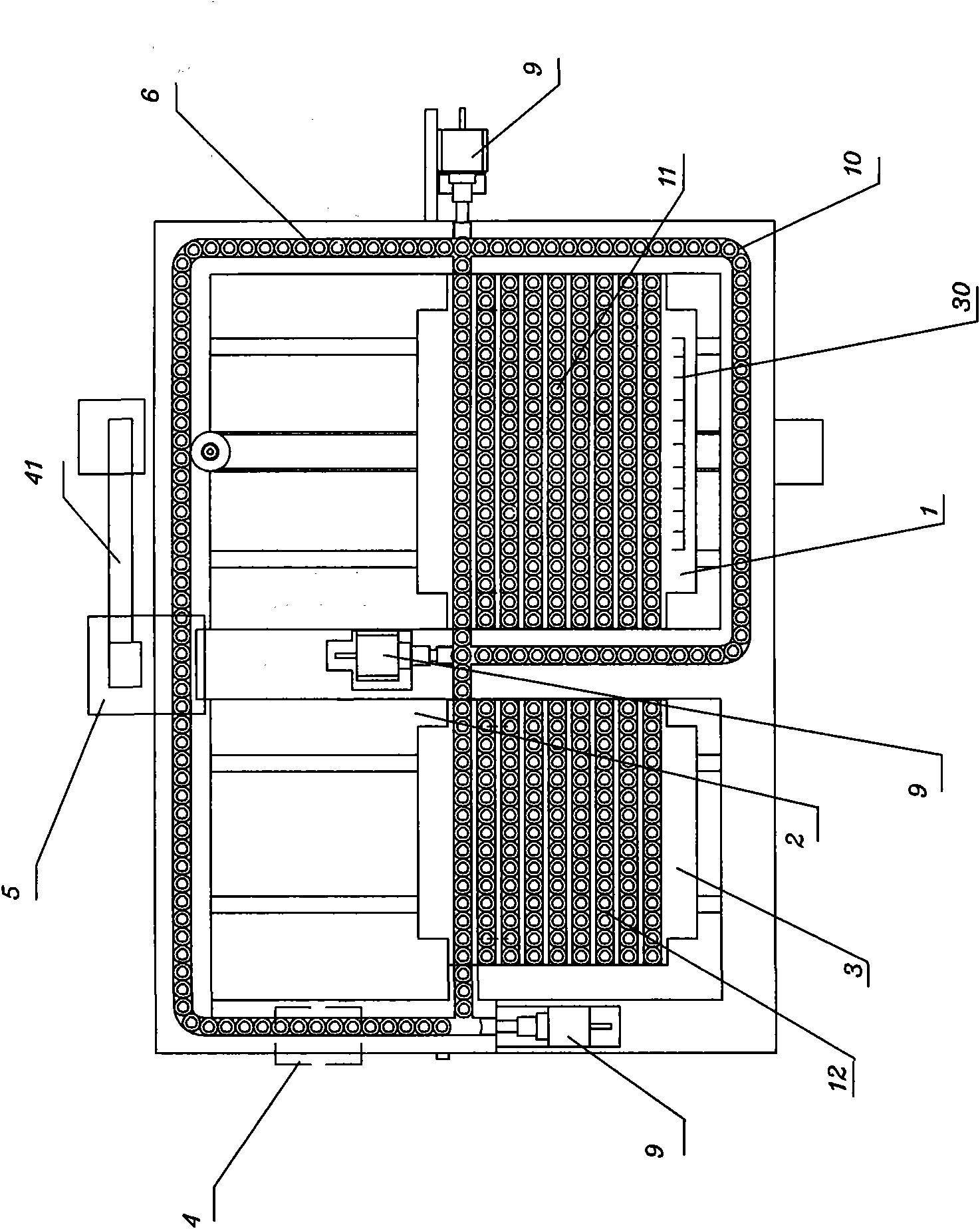

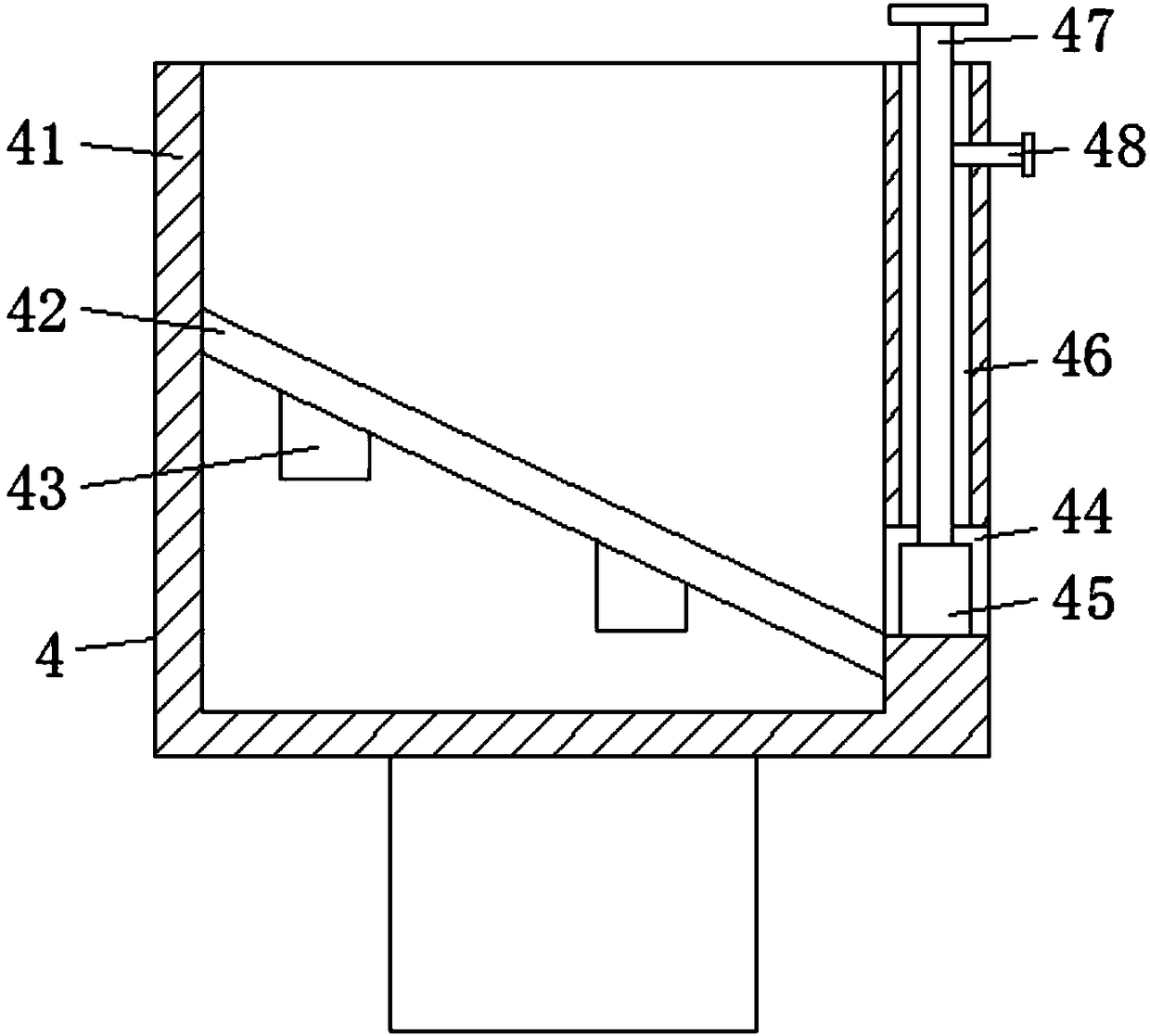

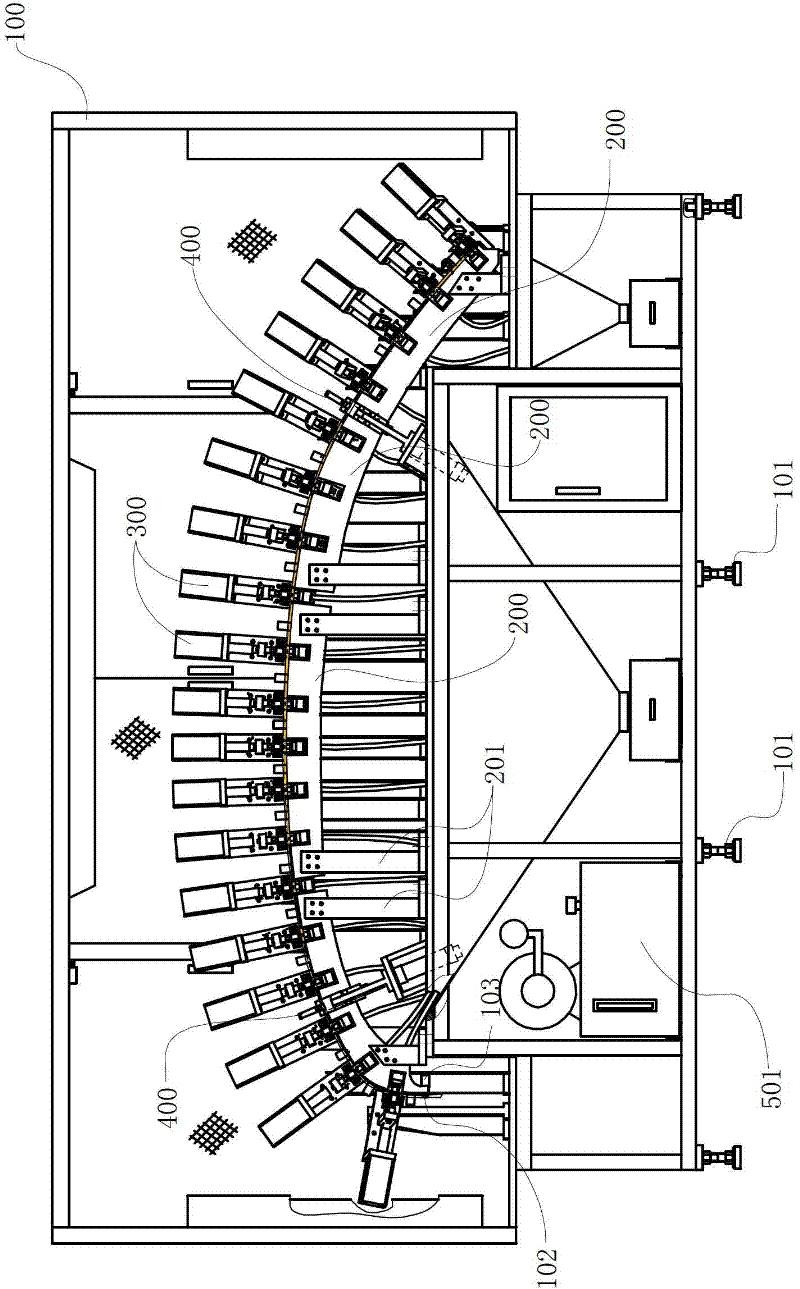

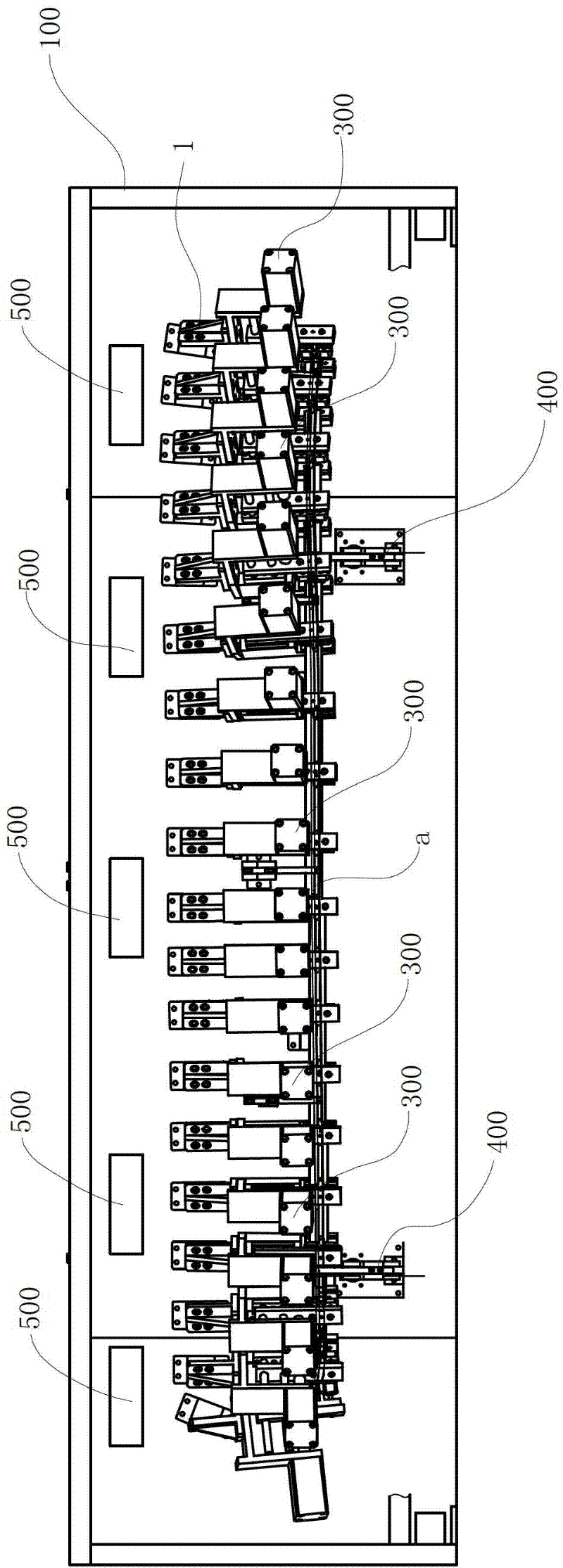

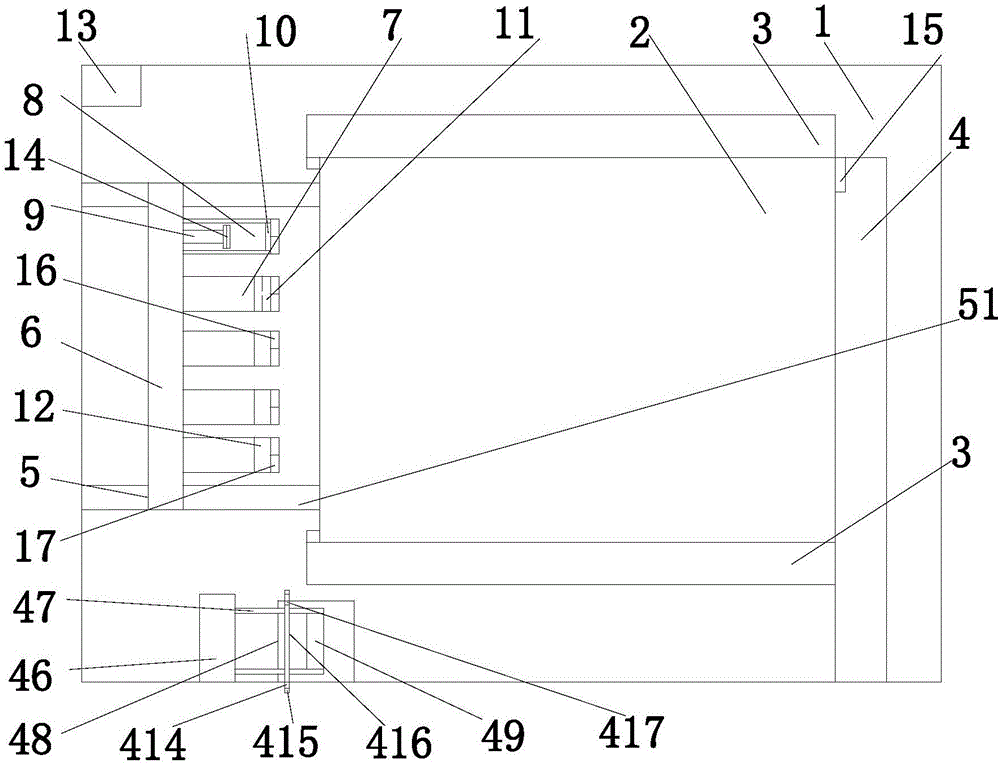

Full-automatic medical inspection and detection system

InactiveCN101566624AFully automated immunoassayIncrease credibilityBiological testingEngineeringUltimate tensile strength

The invention relates to a full-automatic medical inspection and detection system, and belongs to the field of medical detection instruments. The full-automatic medical inspection and detection system comprises a placing area, a reagent injection area, a warm breeding area, a cleaning area and a detection area which are communicated in turn by a closed track; and a reagent injection system is communicated with a reagent refrigerating chamber, and a cup base pushing device pushes a cup base to move along the closed track. By the design of a reaction cup and the cup base which are independent and separable, the cup base is circularly moved on the closed track so as to realize immune detection automation, lighten the labor intensity of an operator and greatly ensure the repeated precision of detection projects so that immune detection has higher reliability. The full-automatic medical inspection and detection system has the advantages of strong processing capability, high efficiency, high precision and low cost, and is not only suitable for chemical luminescent immune detection popularized in large scale at present, but also suitable for other labeling immune detection methods adopting similar detection processes and detection for micro substances in other liquids.

Owner:北京量质科技有限公司

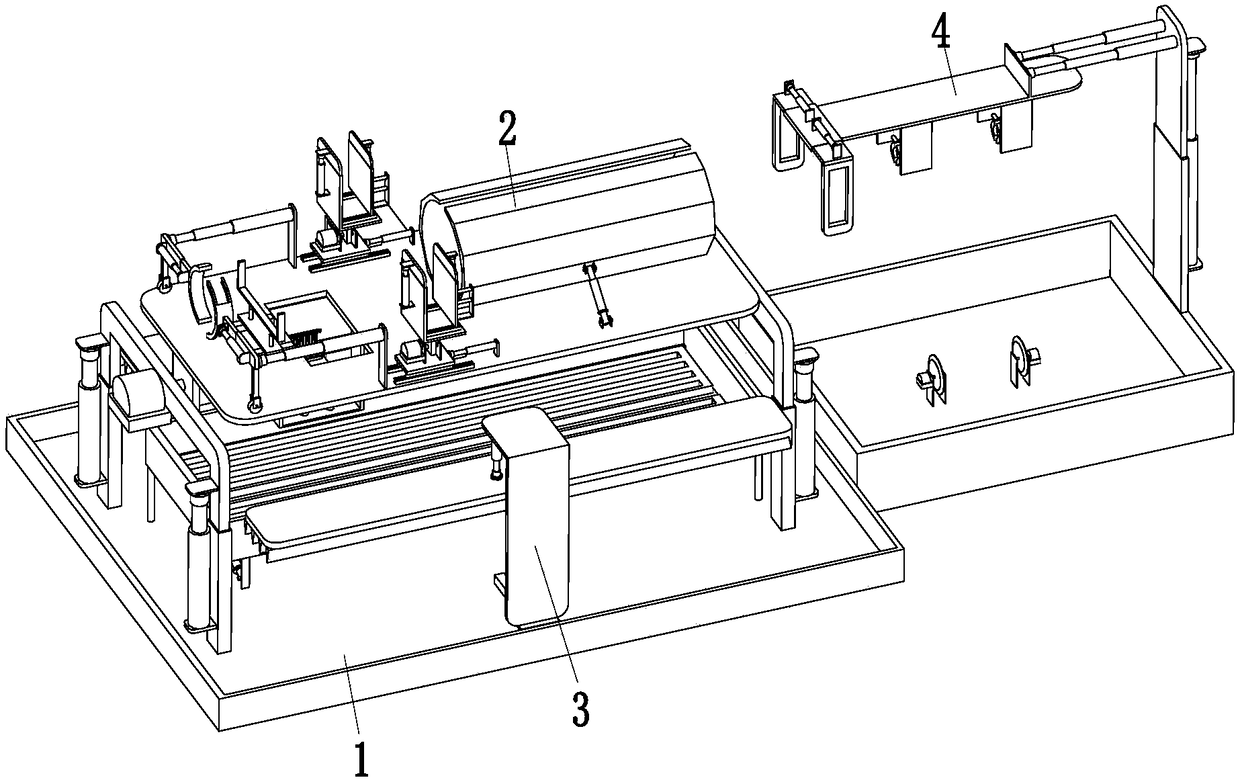

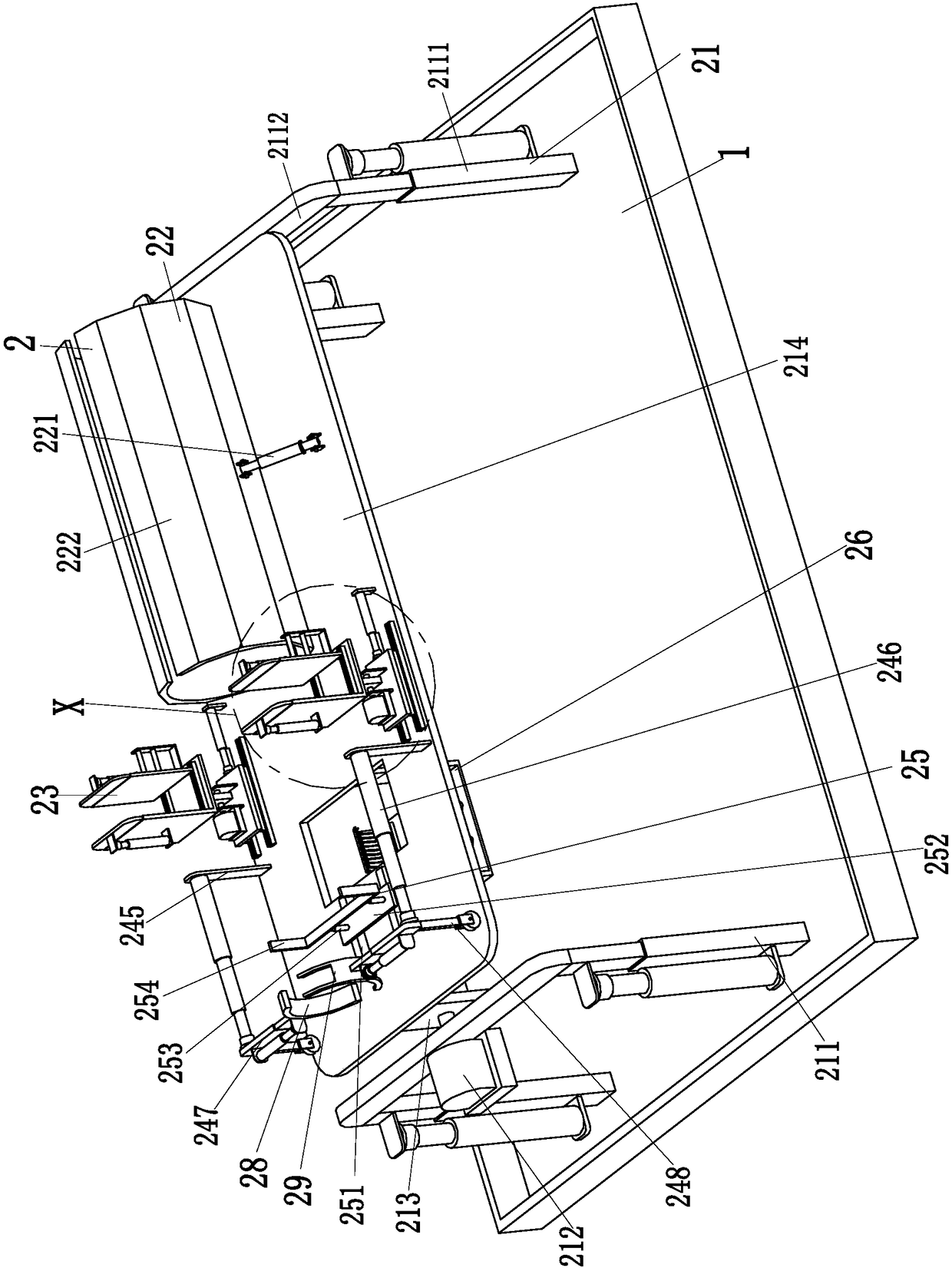

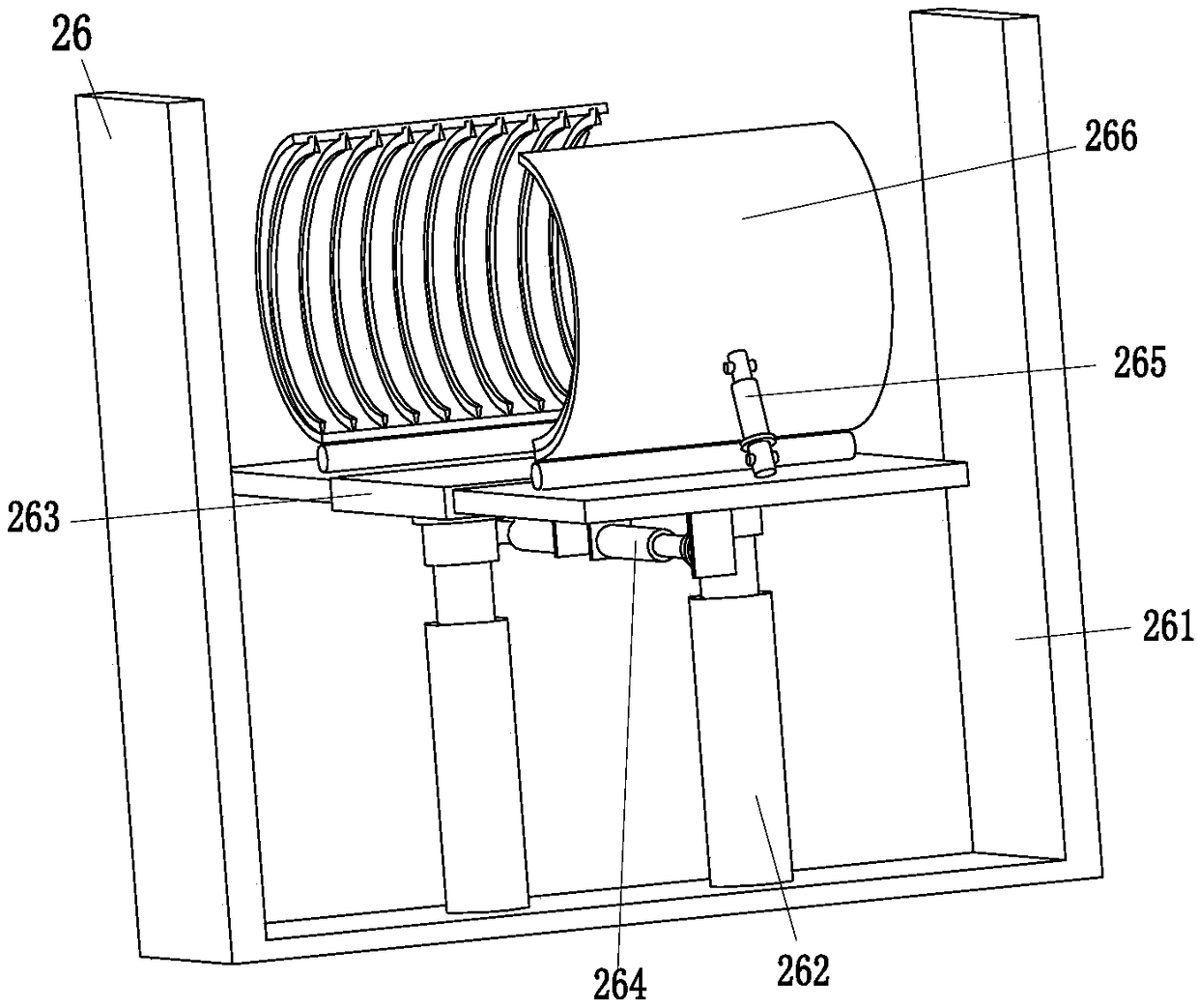

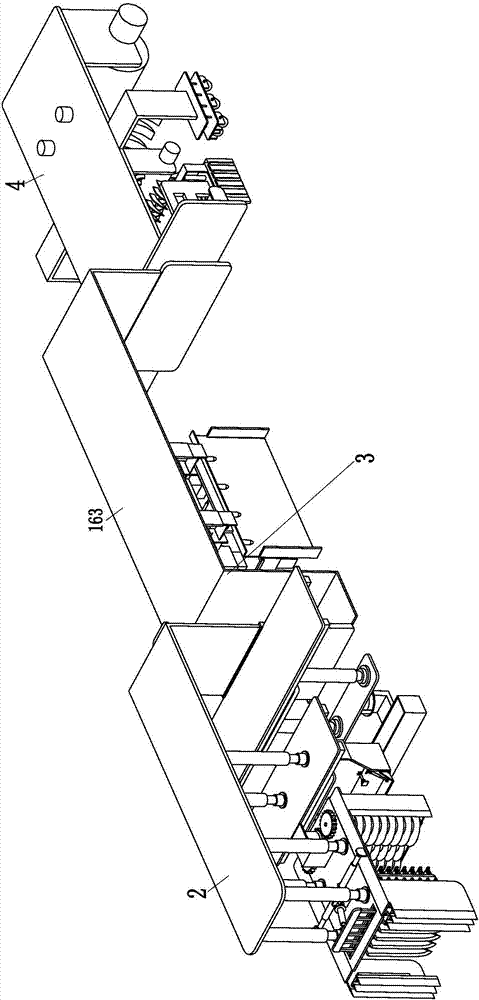

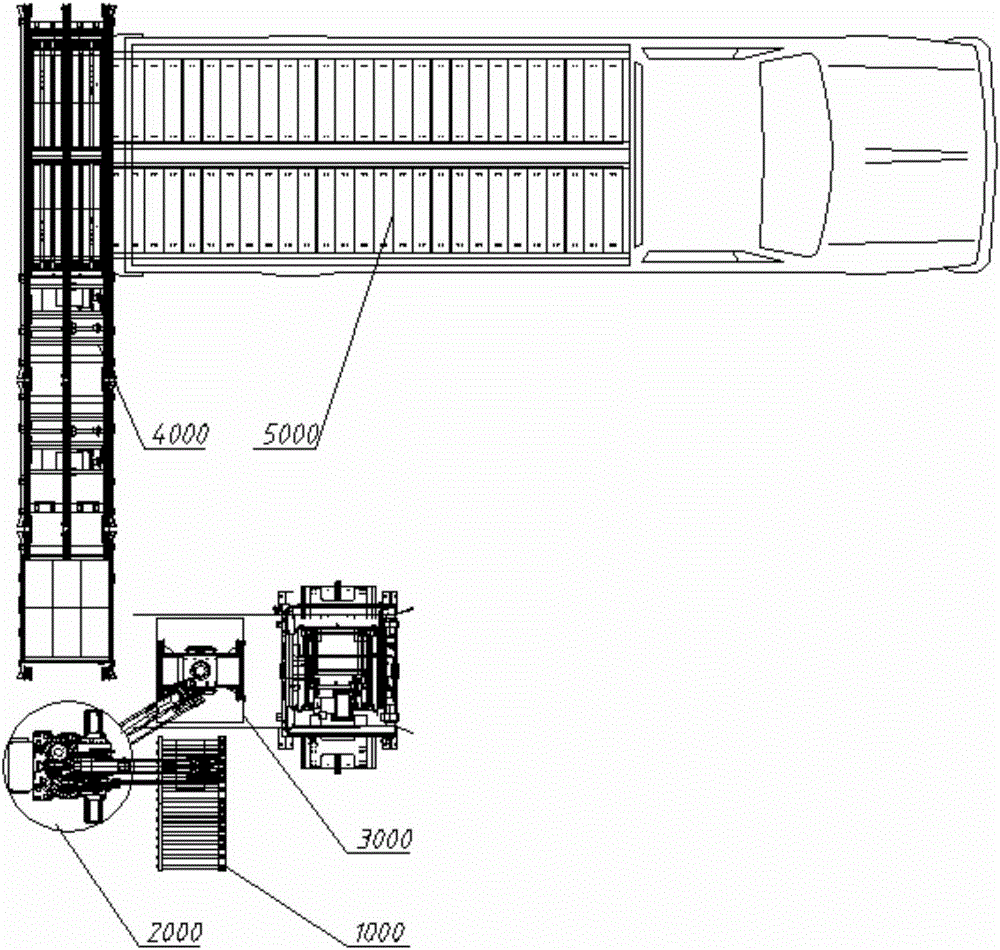

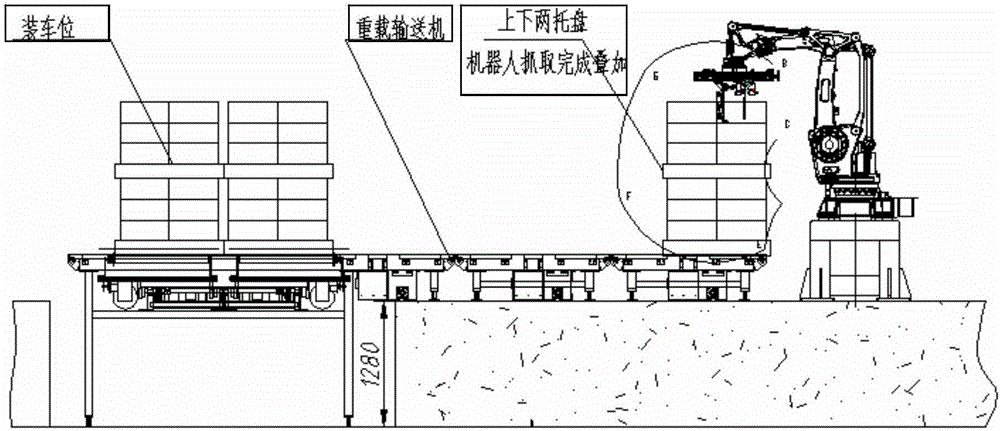

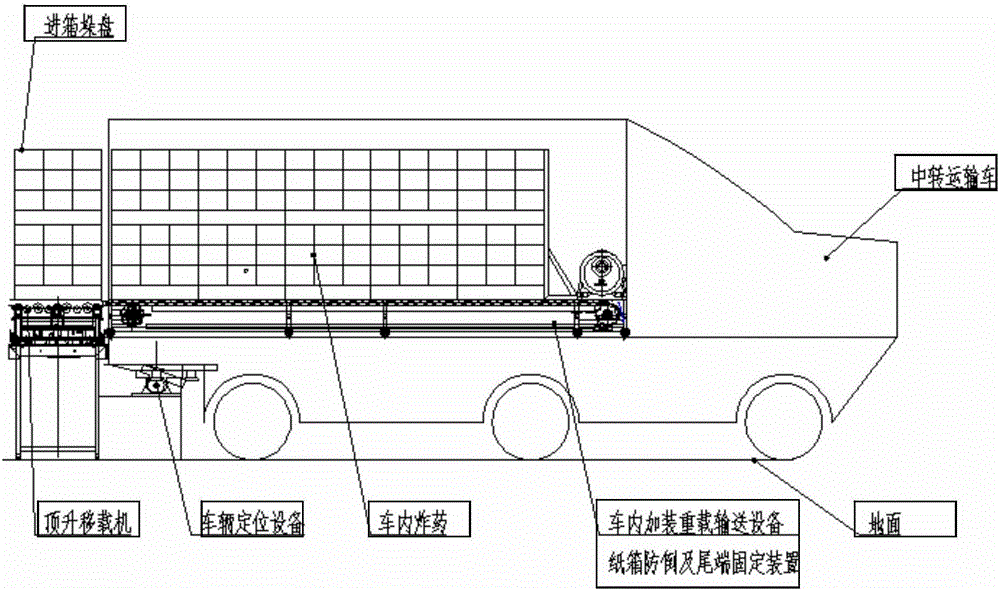

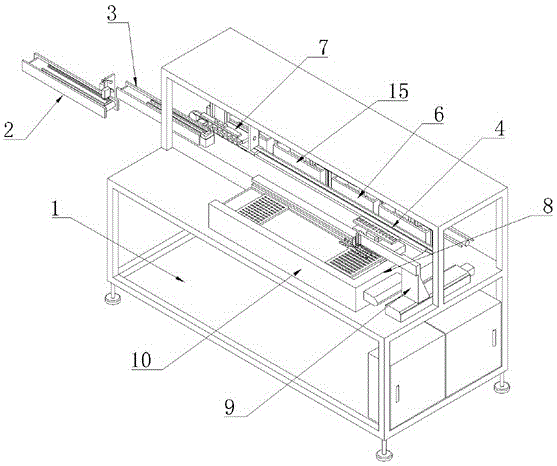

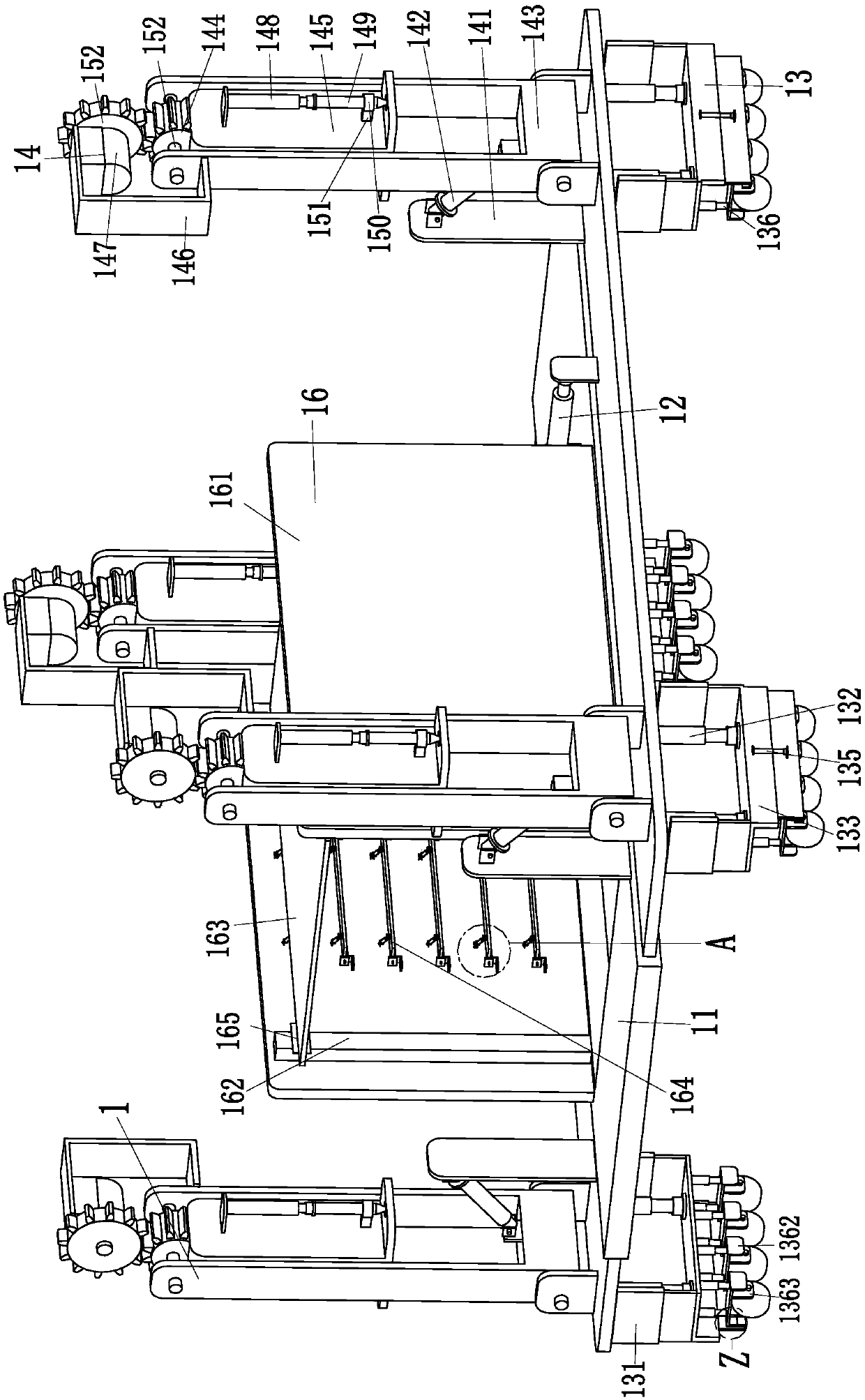

Industrial explosive carton automatic car loading system

ActiveCN105197622AImprove loading and unloading efficiencyHigh degree of intelligenceStacking articlesDe-stacking articlesIntrinsic safetyCarton

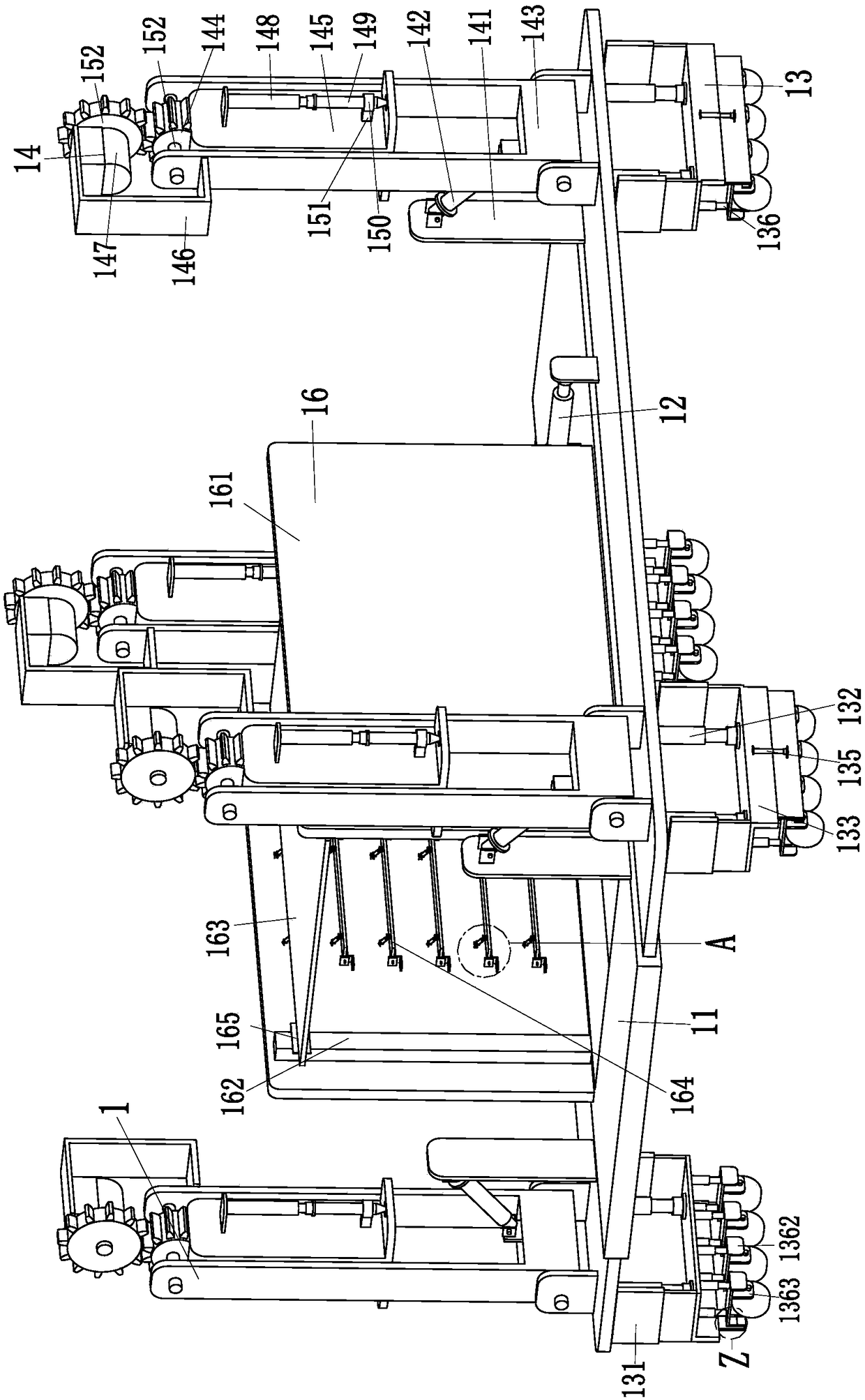

The invention relates to an industrial explosive carton automatic car loading system, which comprises carton conveying equipment, carton stacking equipment, light load tray conveying equipment, heavy load tray conveying equipment, transfer platform automatic loading and unloading equipment and an electric control part, wherein the electric control part controls the coordinated action of the whole set of system for jointly completing the corresponding function; the carton conveying equipment, the carton stacking equipment, the light load tray conveying equipment, the heavy load tray conveying equipment and the transfer platform automatic loading and unloading equipment are respectively and fixedly arranged on the ground; in addition, the carton stacking equipment is respectively connected with the carton conveying equipment and the light load tray conveying equipment; the output end of the light load tray conveying equipment is connected with the input end of the heavy load tray conveying equipment; the output end of the heavy load tray conveying equipment is connected with the transfer platform automatic loading equipment; the electric control part controls the system for jointly completing the industrial explosive carton automatic car loading. The industrial explosive carton automatic car loading system has the characteristics that the structure is simple; the intelligent degree is high; the operation is simple and convenient; the material loading and unloading efficiency can be improved; the work intensity is reduced; the intrinsic safety is ensured.

Owner:WUHAN RENTIAN PACKAGING TECH

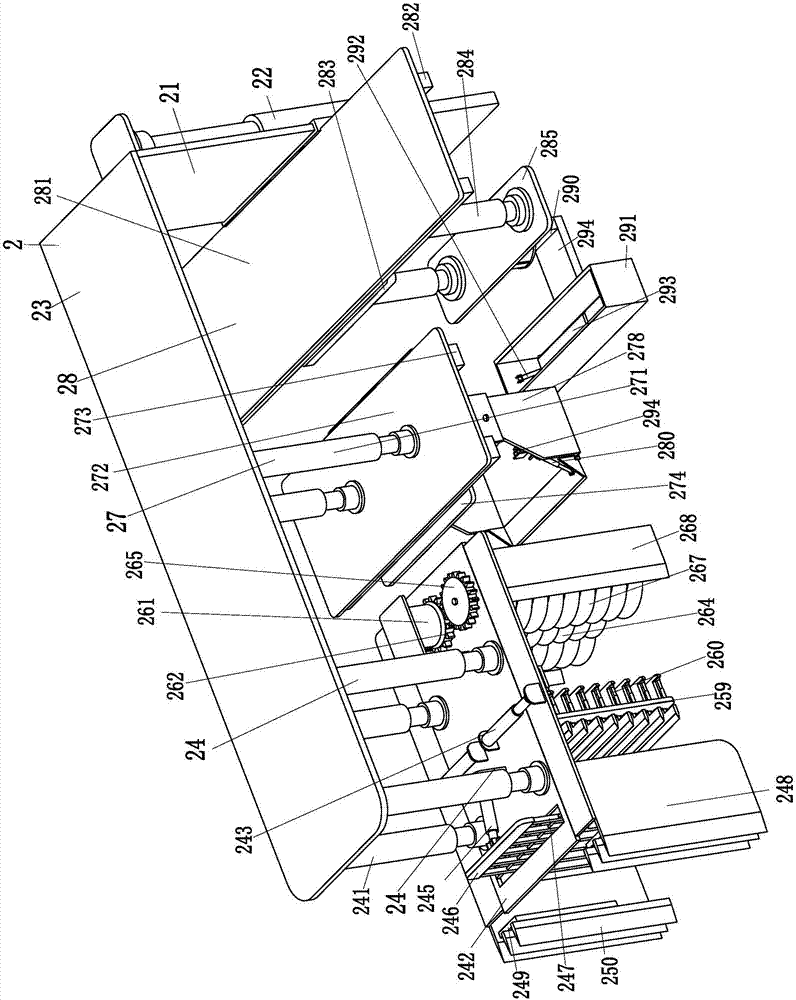

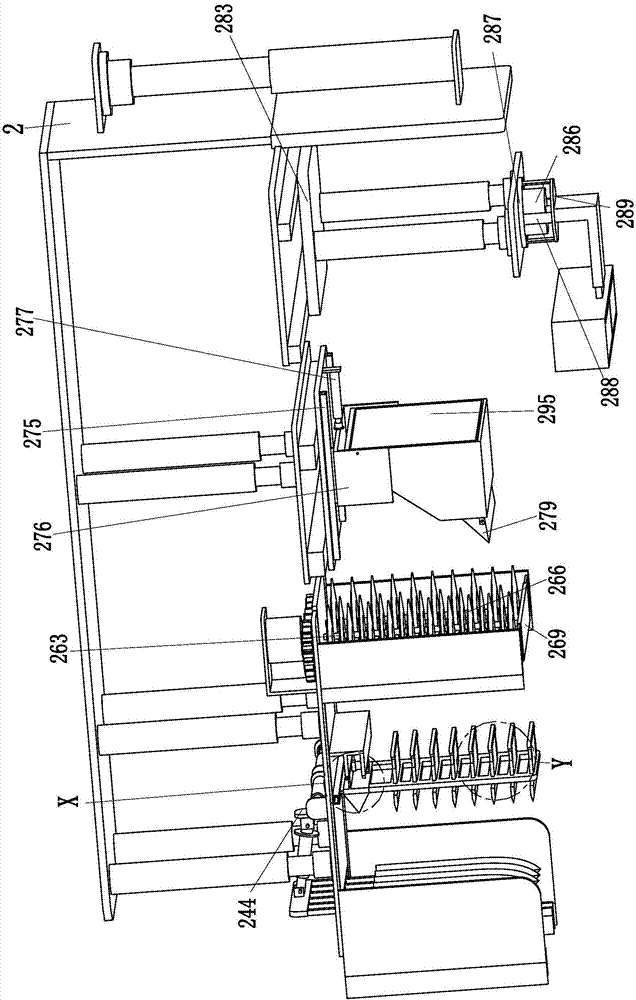

Multifunctional wood machining equipment

ActiveCN104890063AMove fastReduce resistance to movementMulti-purpose machinesBark-zones/chip/dust/waste removalWood machiningEngineering

The invention discloses multifunctional wood machining equipment and belongs to the field of wood machining equipment. A running vehicle comprises a movement and driving devices moving along X-axis direction, Y-axis direction and Z-axis direction, at least two rotating spindles taking vertical direction as axis are arranged at the front end of the movement, a knife is arranged at the lower end of each spindle, and multiple rows of blades are arranged around each knife, distances between the blades on different spindles and cut wood are difference, the spindles are rotatably connected with a motor respectively, multiple top discs different in diameter are arranged on a top tip seat and a top tip of a tail seat, a rolling device along the X-axis direction is arranged on the lower portion of the tail seat, and a control panel is arranged on the multifunctional wood machining equipment. By the multifunctional wood machining equipment, production efficiency can be improved, labor intensity of operating personnel can be lowered, machining diameter can be expanded, machining variety can be increased, and sales market can be expanded.

Owner:安阳市涵缘机械设备有限公司

Work method of novel aluminum alloy section evenly spraying device

ActiveCN108554682AReduce labor intensityImprove spraying effectSpraying apparatusReciprocating motionAluminium alloy

Owner:安徽海福新材料科技有限公司

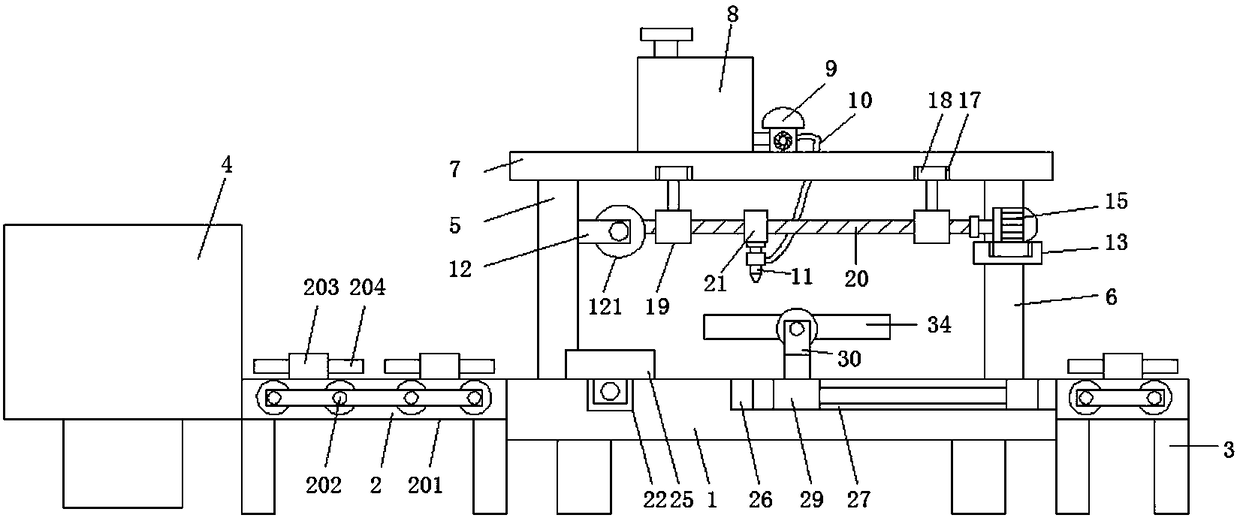

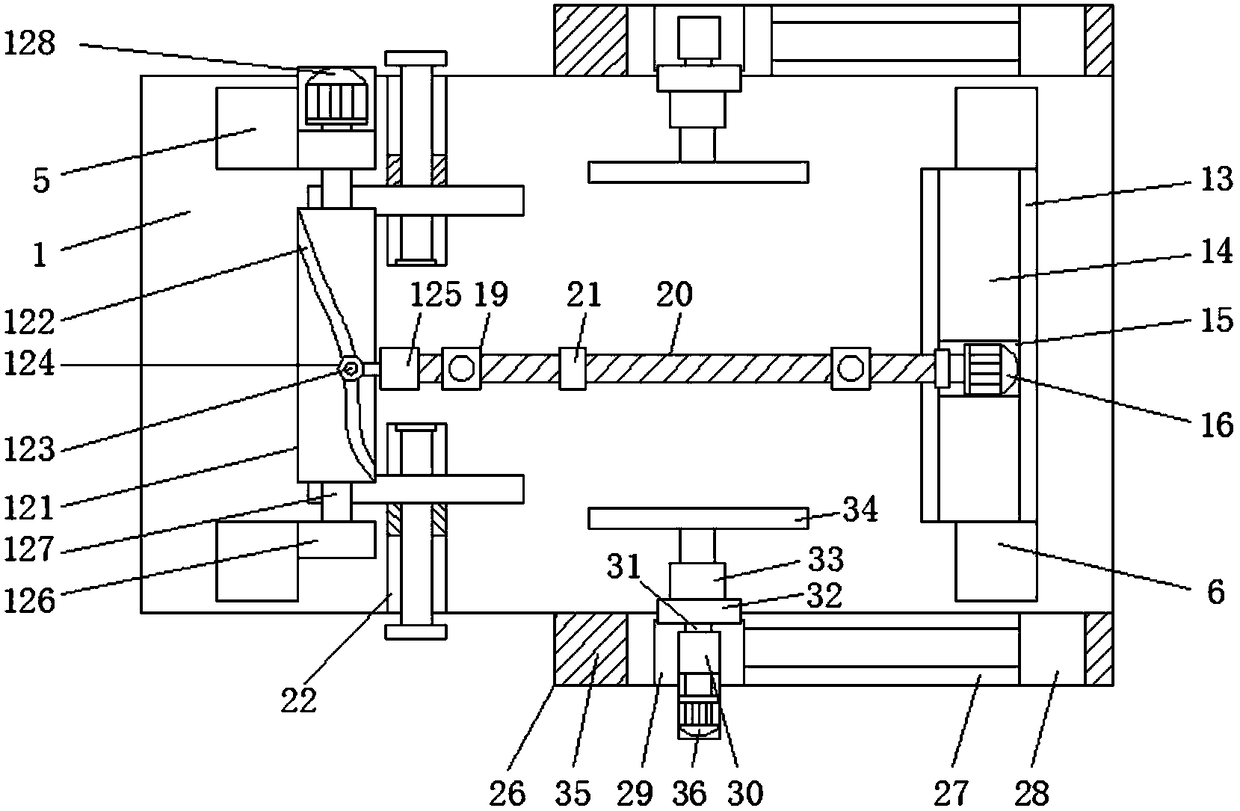

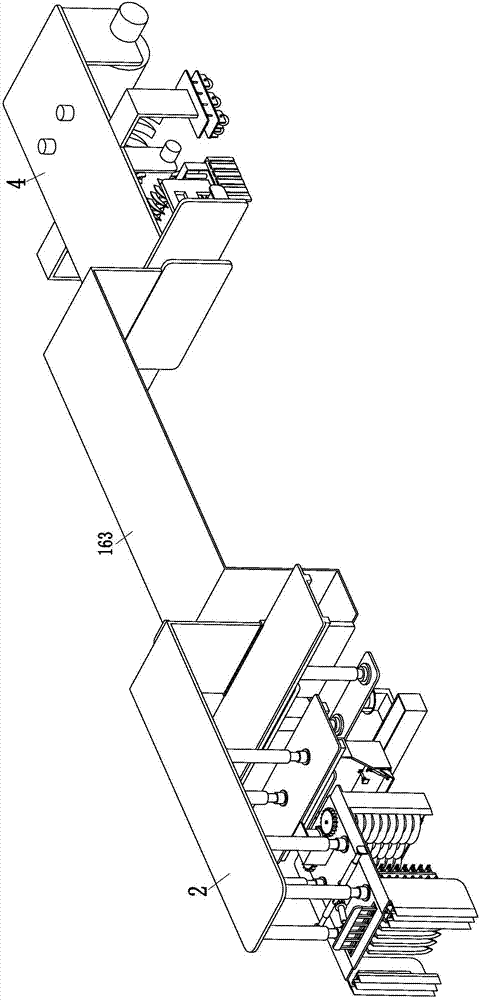

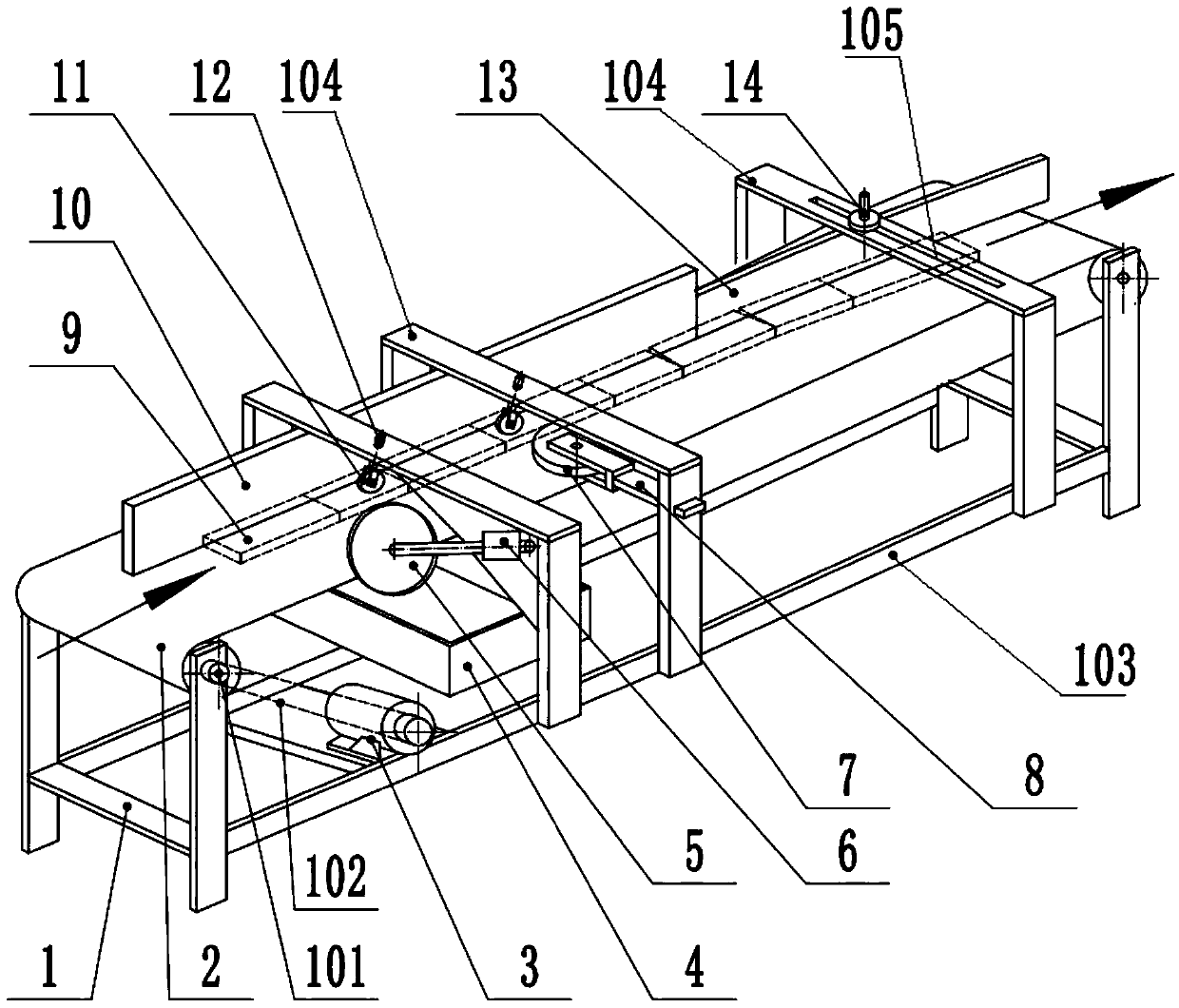

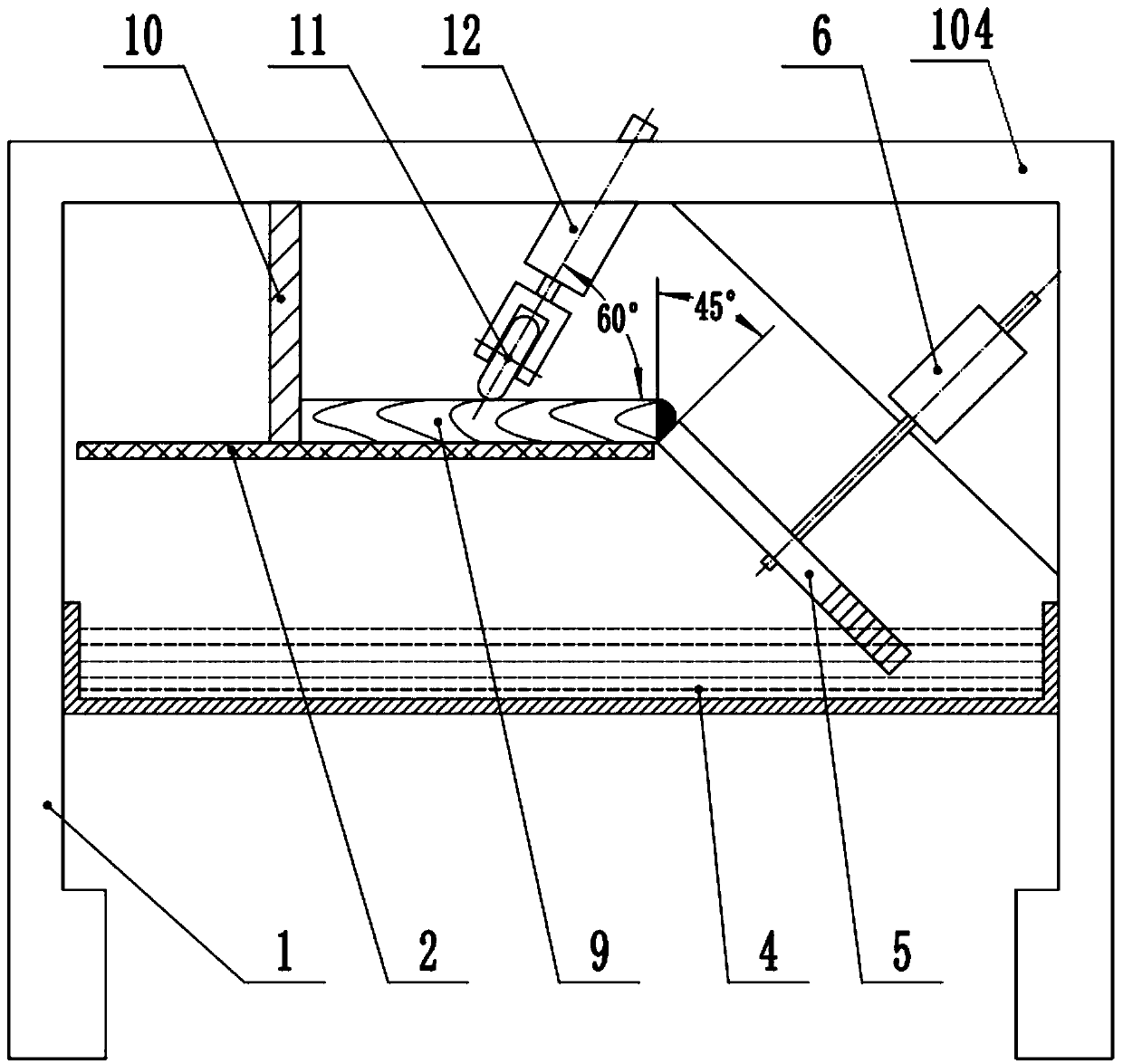

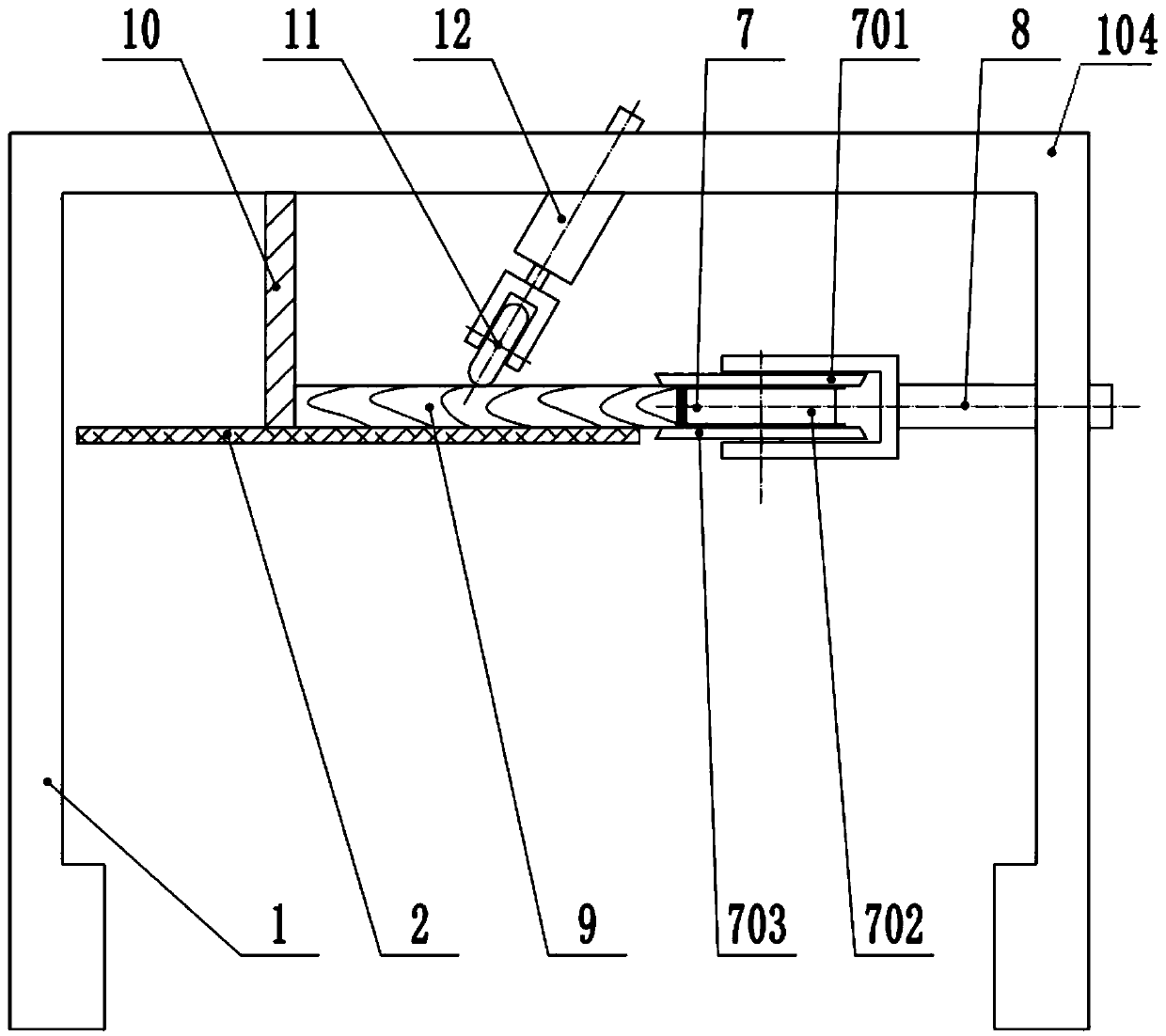

Linear automatic tin soldering device

ActiveCN105127537AImprove securitySave human effortMetal working apparatusSoldering auxillary devicesTransformerHeating furnace

The invention discloses and provides a linear automatic tin soldering device capable of simultaneously completing various motor skills, saving labor and time, relieving labor intensity, improving labor efficiency, guaranteeing the safety of staff and improving the tin soldering quality and yield of products. The linear automatic tin soldering device comprises a rack and a conveying mechanism fixedly arranged on the rack. A feeding mechanism and a linear positioning mechanism are further arranged on the conveying mechanism. A first tin soldering station, a second tin soldering station and a discharging mechanism are further sequentially arranged on the rack. The first tin soldering station and the second tin soldering station each comprise a scaling powder mechanism and a tin furnace which are fixedly arranged on one side of the linear positioning mechanism, the tin furnaces are further provided with high-temperature glue protection devices, a tin soldering mechanism is further arranged on the linear positioning mechanism, the linear positioning mechanism drives the tin soldering mechanism to sequentially pass through the first tin soldering station and the second tin soldering station, and then double-tin-soldering procedures are completed. The linear automatic tin soldering device is suitable for the field of transformer production.

Owner:珠海科德电子有限公司

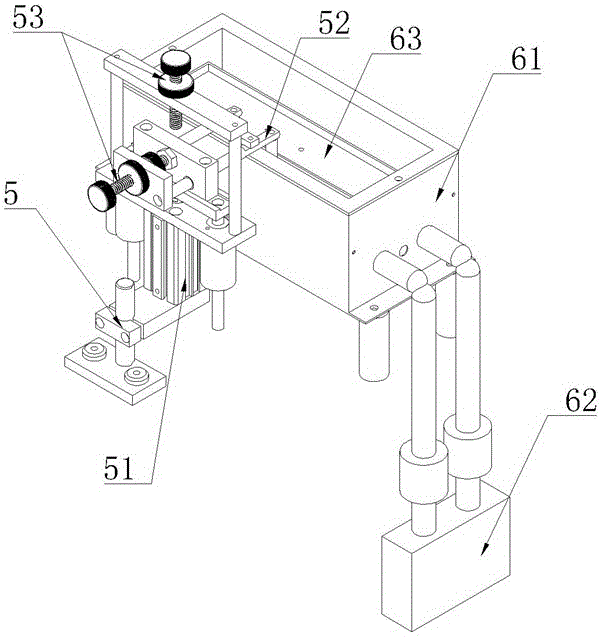

Intelligent connection equipment for reinforcement sleeve for building

The invention relates to intelligent connection equipment for a reinforcement sleeve for a building. The intelligent connection equipment comprises universal wheels, a main plate, a reinforcement sleeve limiting device, two reinforcement bar limiting devices and a cutting device; the universal wheels are uniformly installed at the lower end of the main plate; the main plate is provided with an arc-shaped groove; the reinforcement sleeve limiting device is installed at the middle part of the upper end of the main plate; the two reinforcement bar limiting devices are correspondingly installed atthe front and rear sides of the upper end of the main plate; and the cutting device is installed at the right side of the upper end of the main plate. The intelligent connection equipment provided bythe invention can solve the problems that an existing reinforcement sleeve and a reinforcement bar need manual connection and manual cutting in a connection process and are difficult to fix manuallyin connection because the reinforcement sleeve is small and smooth, meanwhile the reinforcement sleeve and the reinforcement bar cannot be fixed stably manually because the reinforcement bar is long,a person needs to move according to a cutting position in a cutting process, the eyes are easy to injury in a manual cutting process of the reinforcement bar and the like; and the intelligent connection equipment can realize the functions of automatically connecting the reinforcement sleeve with the reinforcement bar and also cutting the reinforcement bar.

Owner:闫西英

Assembling installing method for express cabinet

ActiveCN104384785AHigh welding technology requirementsLabor intensiveWelding/cutting auxillary devicesAuxillary welding devicesEngineeringUltimate tensile strength

The invention discloses an assembling installing method for an express cabinet. According to the method, firstly, express cabinet plates are integrally assembled and spliced together, and then, connecting parts between the plates are welded. The assembling installing method has the advantages that the production and installing mode has low requirements on the welding skill of workers, the work intensity of the workers is reduced, the assembling and welding efficiency is improved under the condition of ensuring the assembling and welding precision, and further, the production efficiency of the finished product of the express cabinet is improved.

Owner:CHENGDU WOLAILA GRID INFORMATION TECH

Excavating and backfilling system for laying underground 450V polyvinyl chloride insulated control cable

InactiveCN107956229AReduce labor intensityImprove work efficiencySoil-shifting machines/dredgersSoil treatmentPolyvinyl chloride

The invention relates to an excavating and backfilling system for laying an underground 450V polyvinyl chloride insulated control cable. The excavating and backfilling system comprises a lifting plate, an excavating device and a backfilling device, wherein the excavating device is arranged at the front end of the lifting plate, and the backfilling device is arranged at the rear end of the liftingplate. The excavating and backfilling system has the advantages that the problems that in the existing cable direct burying process, a worker needs to perform ditching and backfilling rolling on soil,in the ditching process, the worker needs to perform ditching by means of a tool, potential safety hazards occurs due to back injuries caused due to the fact that the worker bends over to work for along term, the later-stage backfilling effect is influenced due to the fact that the sizes of soil blocks excavated manually are not uniform, meanwhile, after manual ditching, the soil treatment is complicated, in the backfilling process, the excavated soil needs to be subjected to manual backfilling and then needs to be beat and pressed manually, the process is tedious, due to the fact that the excavated soil is caked differently, the soil is not compact in the manual pressing process, the time consumed by the laying process is long, the labor intensity is high, and the efficiency is low canbe solved, and the functions of automatically carrying out excavating and backfilling rolling on the soil in the laying process of the underground cable can be achieved.

Owner:黄正秀

Punching device of decoration strip products

ActiveCN102649283AImprove work efficiencyReduce labor intensityMetal working apparatusAutomationPunching

The invention discloses a punching device of decoration strip products. A strip positioning base which is formed by a plurality of positioning blocks sequentially arranged at intervals and used for laying a work piece to be machined during punching is arranged on a frame; a plurality of punching components are sequentially fixed on the frame at intervals along the length direction of the positioning base; a plurality of grooves for female die seats of the punching components to be inserted into are formed on the positioning base; the height of the plane of the positioning base used for laying the work piece to be machined is level with the height of the female die seats; and simultaneously a discharging component which can discharge a machined work piece from one side of the positioning base and a guiding component which is positioned on the other side of the positioning base and used for laying the work piece to be machined before being punched are also arranged on the frame. The punching device can clamp the strip work piece and punch different positions on the work piece in sequence, is not required to perform multiple position adjustment on the strip work piece, also has the automation and manual combined discharging component, not only improves the operating efficiency and reduces the labor intensity, but also guarantees the safety in production and improves the machining accuracy.

Owner:NINGBO XINTAI MACHINERY

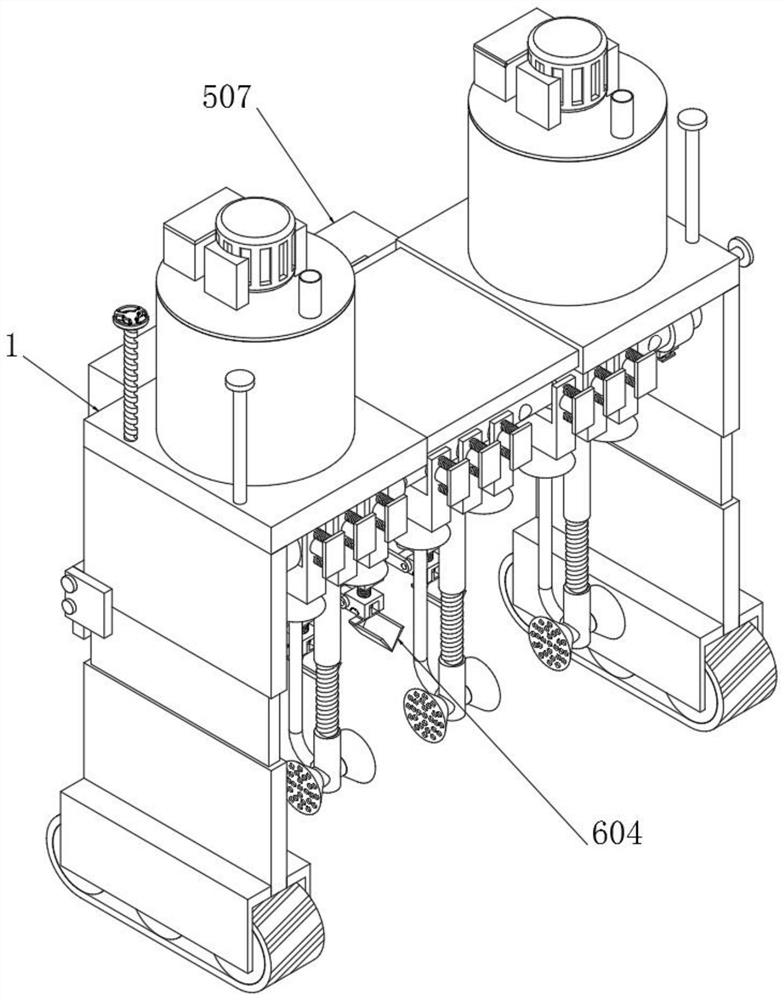

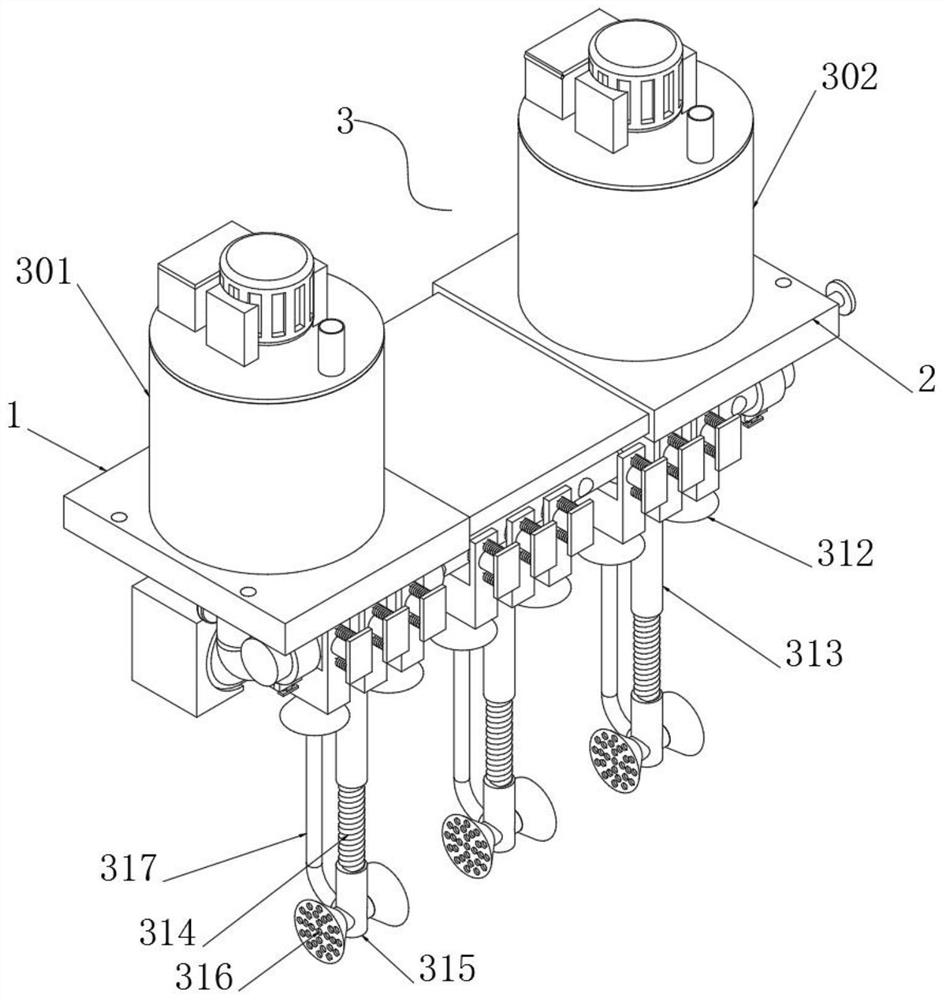

Automatic laying robot for direct-embedded communication cable

InactiveCN108049443AReduce labor intensityImprove work efficiencySoil-shifting machines/dredgersFoundation engineeringDirect-buried cableCement board

The invention relates to an automatic laying robot for direct-embedded communication cable. The automatic laying robot for direct-embedded communication cable comprises a travelling device, an earth cutting device and a grouting device. The earth cutting device is mounted at the front end of the travelling device. The grouting device is mounted on the travelling device. The automatic laying robotcan solve the problems that in the existing direct-embedded cable laying process, operators need to ditch and grout layers manually, during ditching, the operators need to use tools for ditching, later operation is affected due to uneven manual ditching, during laying-up, ditch bottoms need to be manually grouted and rolled, during grouting of side faces, cement boards need to be grouted and solidified by the operators outside and then conveyed to designated spots to be mounted, during advancing, existing equipment vehicles vibrate during travelling due to the steep land surface, the working progress is affected, the existing equipment vehicles is prone to vibrating when standing still in situ for operation due to the fact that no fixing device is arranged, lots of time is taken, the laborintensity is high, and the efficiency is low, and the functions of automatic ditching and laying-up for the direct-embedded cables can be achieved.

Owner:王炯炜

Intelligent robot for direct-buried laying of communication cable

InactiveCN108063416AReduce labor intensityImprove work efficiencyCable installations on groundManipulatorDirect-buried cableEngineering

The invention relates to an intelligent robot for the direct-buried laying of a communication cable. The robot comprises a traveling device, an excavating device and a backfill device. The excavatingdevice is installed at the front end of the traveling device, and the backfill device is installed at the rear end of the traveling device. In an existing direct-buried cable laying process, the trenching and the backfilling and rolling of soil by the staff are needed, the staff need to use tools for trenching in trenching, later work is affected if a trench is not flat in manual trenching, a later backfill effect is affected if the sizes of artificially excavated soil blocks are not consistent, at the same time, the soil processing is cumbersome after the manual trenching, when soil is backfilled, flapping and pressing the soil after the backfilling of the artificially excavated soil are needed, if manual pressing is not compact, an existing vehicle vibrates in walking to affect the process of the work in going forward due to a steep land surface, and the existing vehicle easily shakes without a fixing device when the existing vehicle works at a fixed place, the above problems are solved by the intelligent robot in the invention, and the function of the intelligent laying of the communication cable can be realized.

Owner:倪敏芳

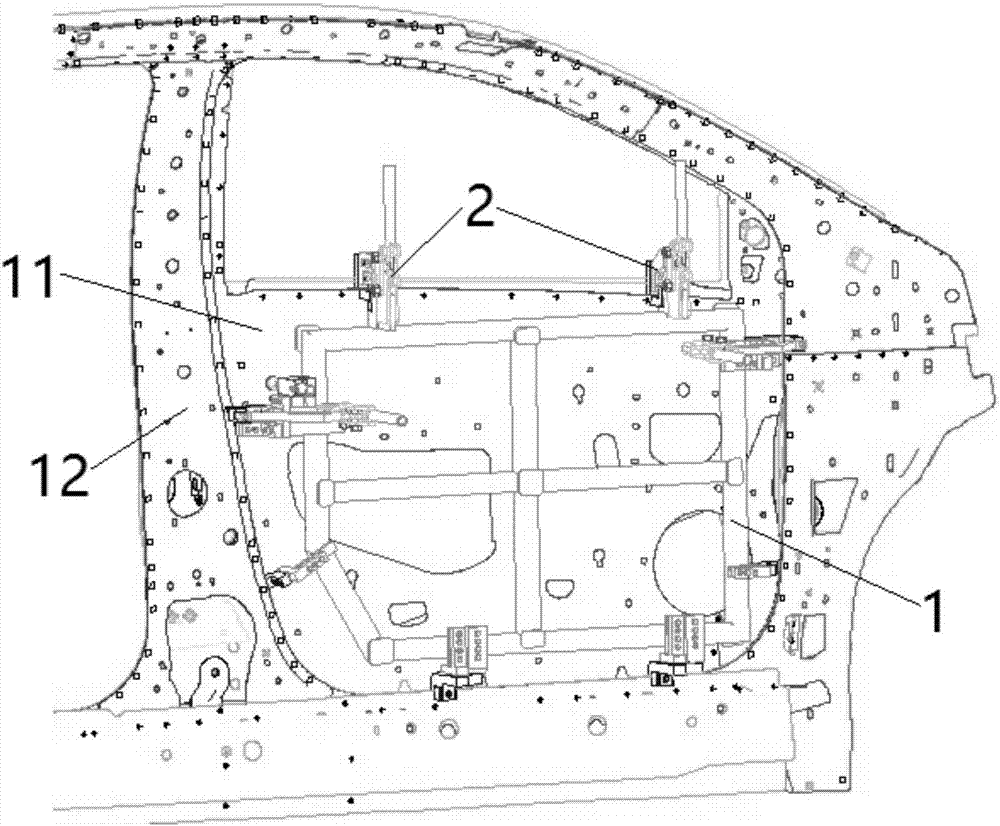

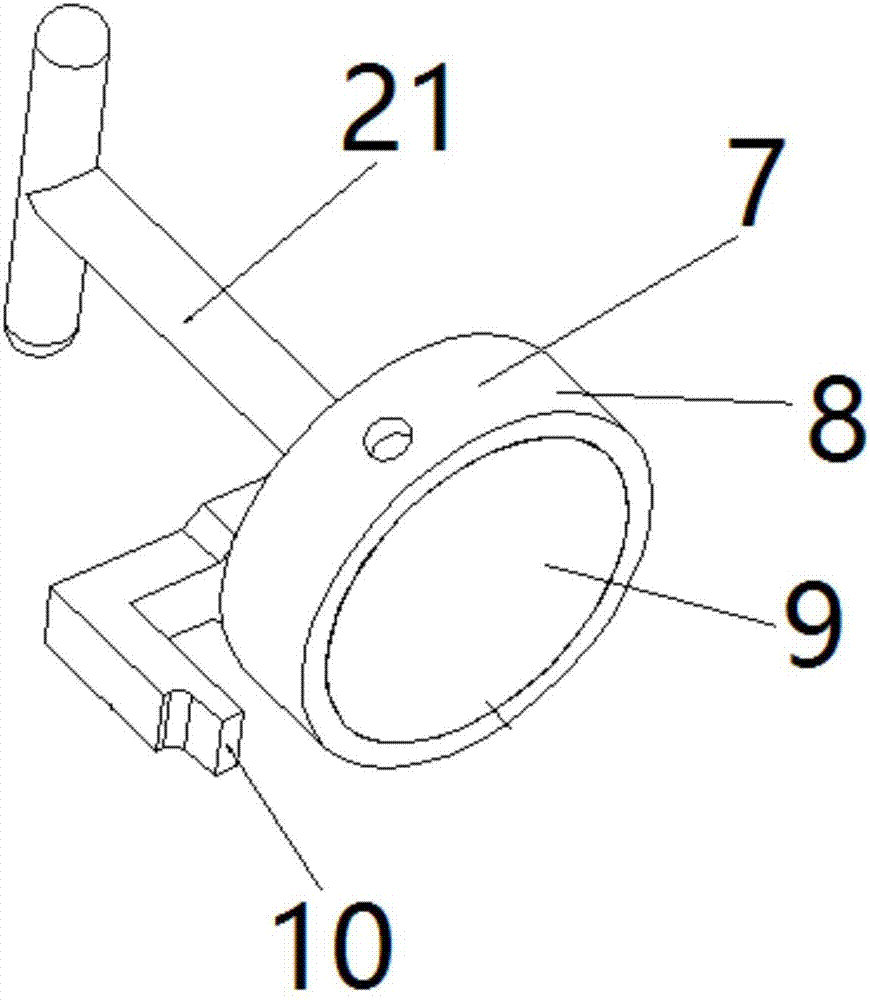

Automobile door positioning installation device

Owner:ANHUI RUIXIANG IND

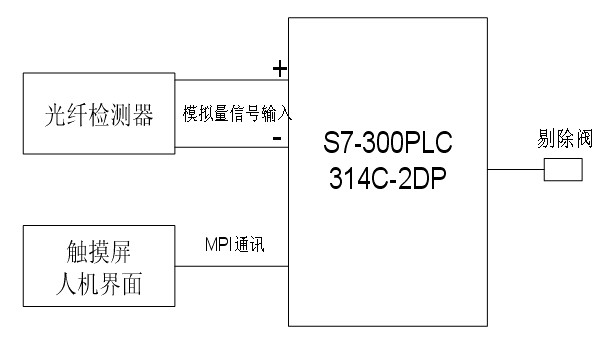

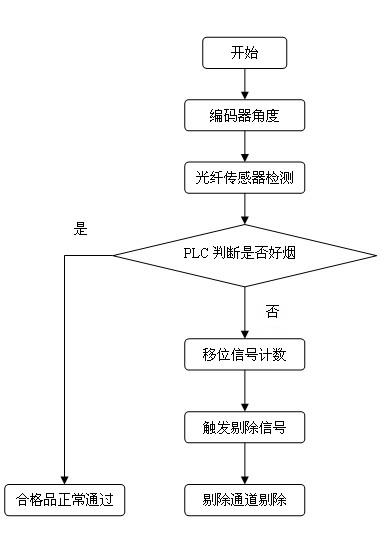

Automatic control device and control method for loose package detection of cigarette box transparent wrapping paper

ActiveCN102275645AImprove packaging accuracyReduce labor intensityPackaging cigarettePackaging cigarsAutomatic controlProgrammable logic controller

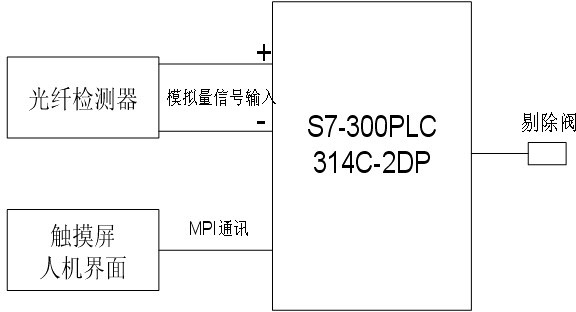

The invention relates to a detection automatic control device and a control method for a loose cigarette packet of a transparent package paper for a cigarette box, an optical fiber probe of an optical fiber detector is fixedly installed at a cigarette packet turret outlet of a cigarette box package set, an optical fiber amplifier of the optical fiber detector is fixedly installed at a main wallboard position of the cigarette box package set, the optical fiber detector is connected with a PLC (Programmable Logic Controller) in a remote terminal of the cigarette box package set via a signal connection line, a loose cigarette packet detecting function module is disposed in the PLC, the PLC is connected with a touch screen via an MPI communication input port, and a removing valve is connectedon a PLC output port, the automatic control device and the control method are advantaged by capability of realizing automatic detection of a loose cigarette packet of a transparent package paper for a cigarette box, improving detection speed and accuracy, reaching beneficial effect of improving package precision of transparent paper for a cigarette box, and replacing original manual examination and detection, reduction of manual labor intensity, improvement of working efficiency, and guarantee of production quality.

Owner:CHINA TOBACCO HENAN IND

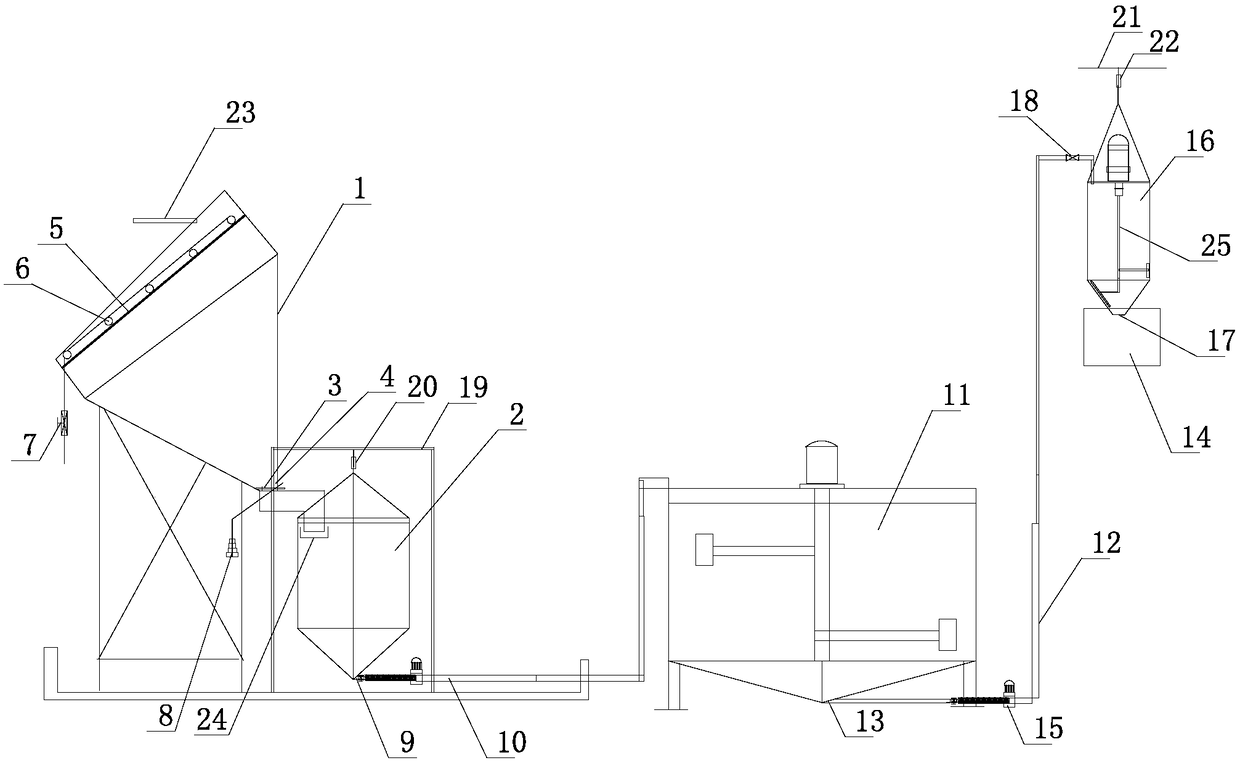

Intelligent recycling device for cement paste

PendingCN108407072ARealize automatic water distributionRealize automatic flushingDischarging apparatusMixing operation control apparatusWater concentrationCement paste

The invention relates to an intelligent recycling device for cement paste. The intelligent recycling device for cement paste is characterized by comprising a paste pouring hopper, wherein a first discharge port is formed in the bottom of the paste pouring hopper, and the first feed inlet of a water distributing cement paste balance hopper is connected to the first discharge port through a heavy punch reversing plate hinged to the interior of the first discharge port; a screen is arranged in an upper opening of the paste pouring hopper, an annular water spray tube is arranged on the inner wallof the upper opening of the paste pouring hopper on the upper side of the screen, the annular water spray tube is connected to a water inlet tube through a water inlet pneumatic butterfly valve, and the heavy punch reversing plate is connected to a stroke switch or a photoelectric switch. The structure is reasonable and novel in design, automatic water distribution, automatic flushing and automatic cleaning on the cement paste are achieved, the stability of the paste water concentration after water distribution is ensured effectively, and the intelligent recycling device for cement paste is low in labor intensity and easy to popularize and use widely.

Owner:李全民

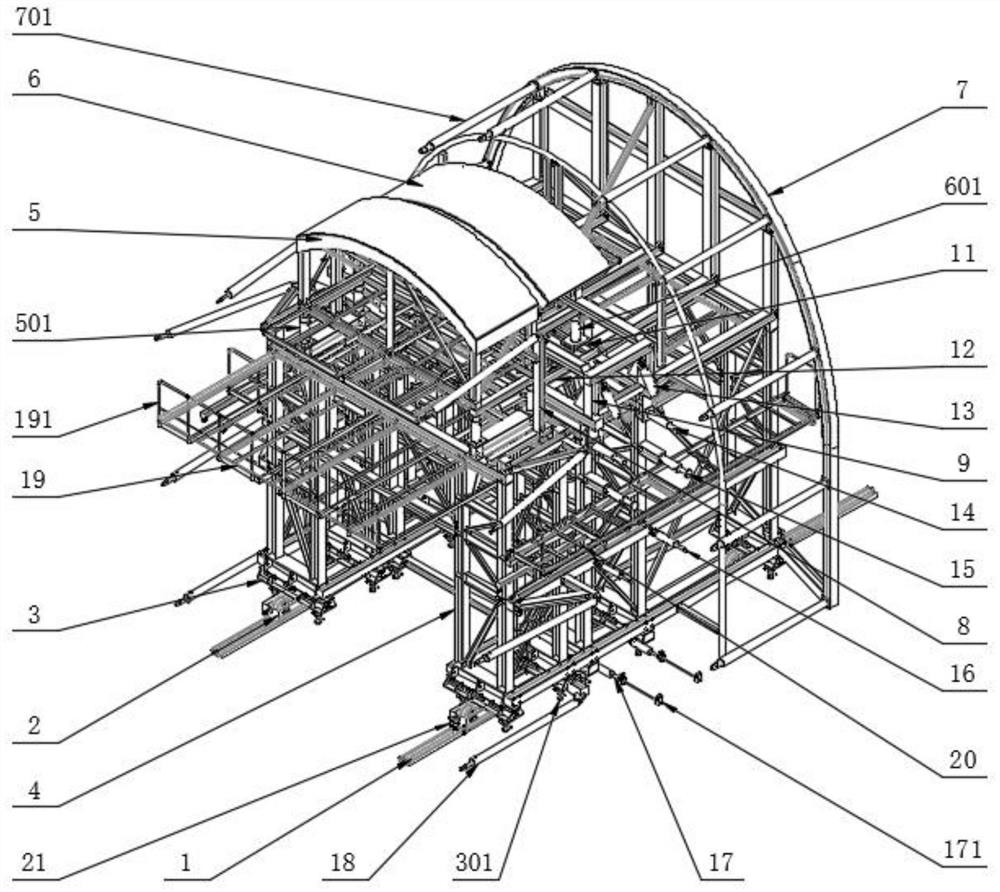

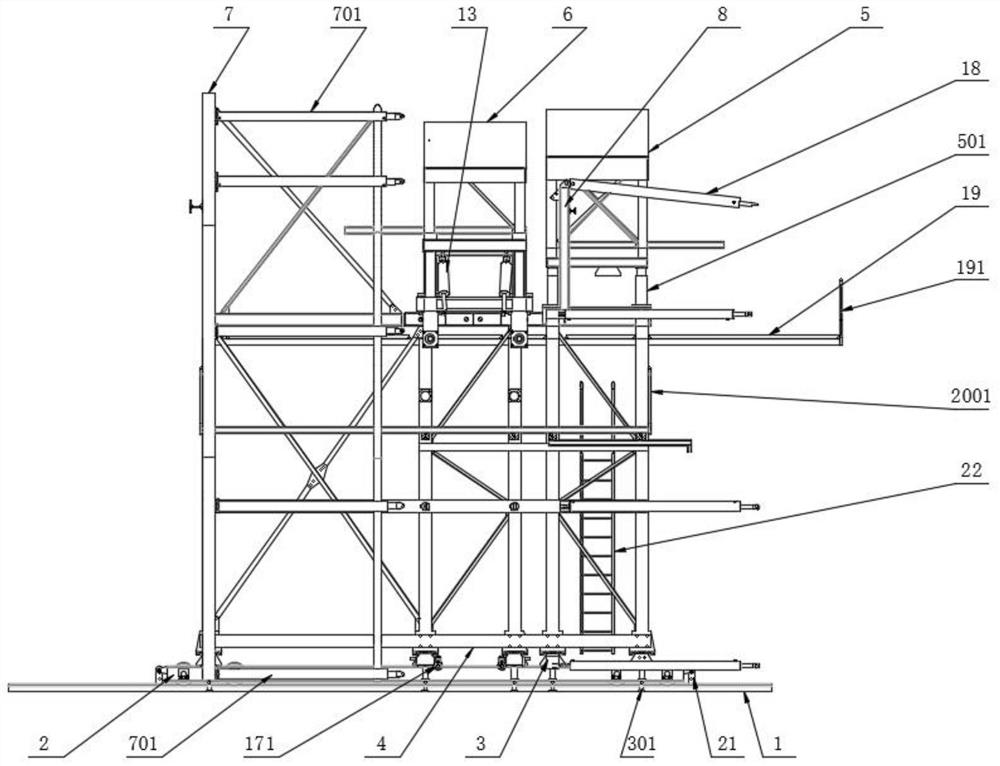

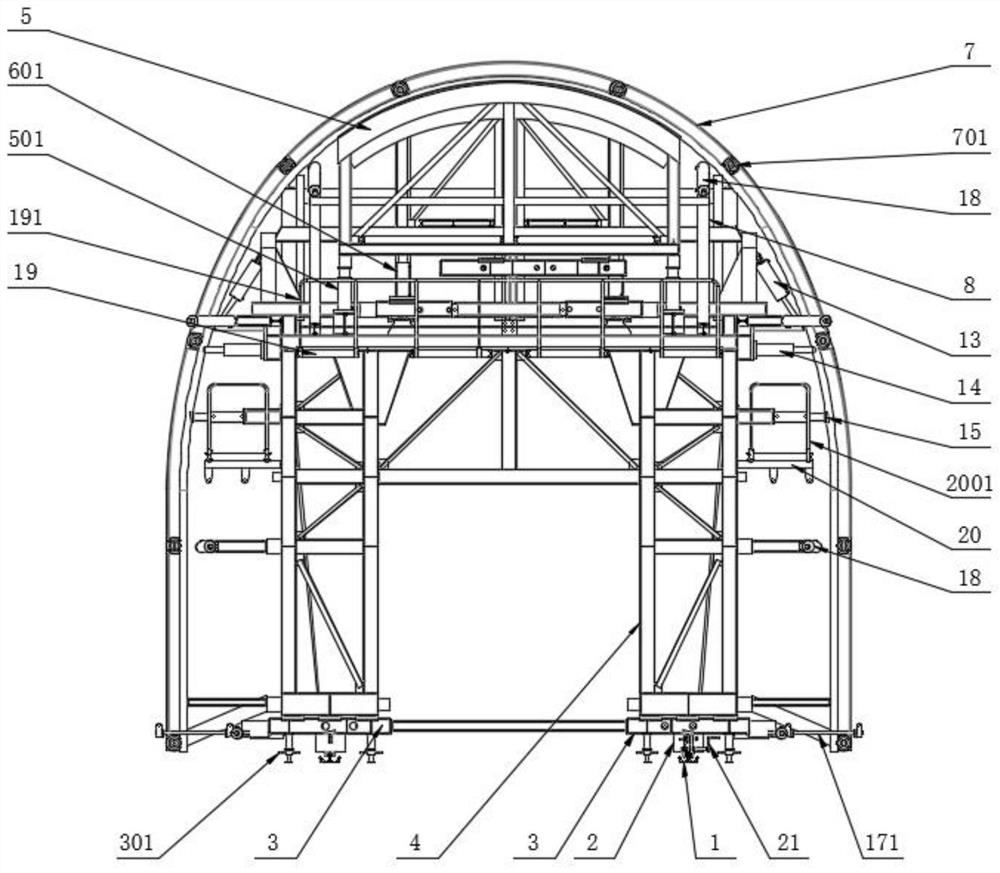

Open cut tunnel segment assembly trolley

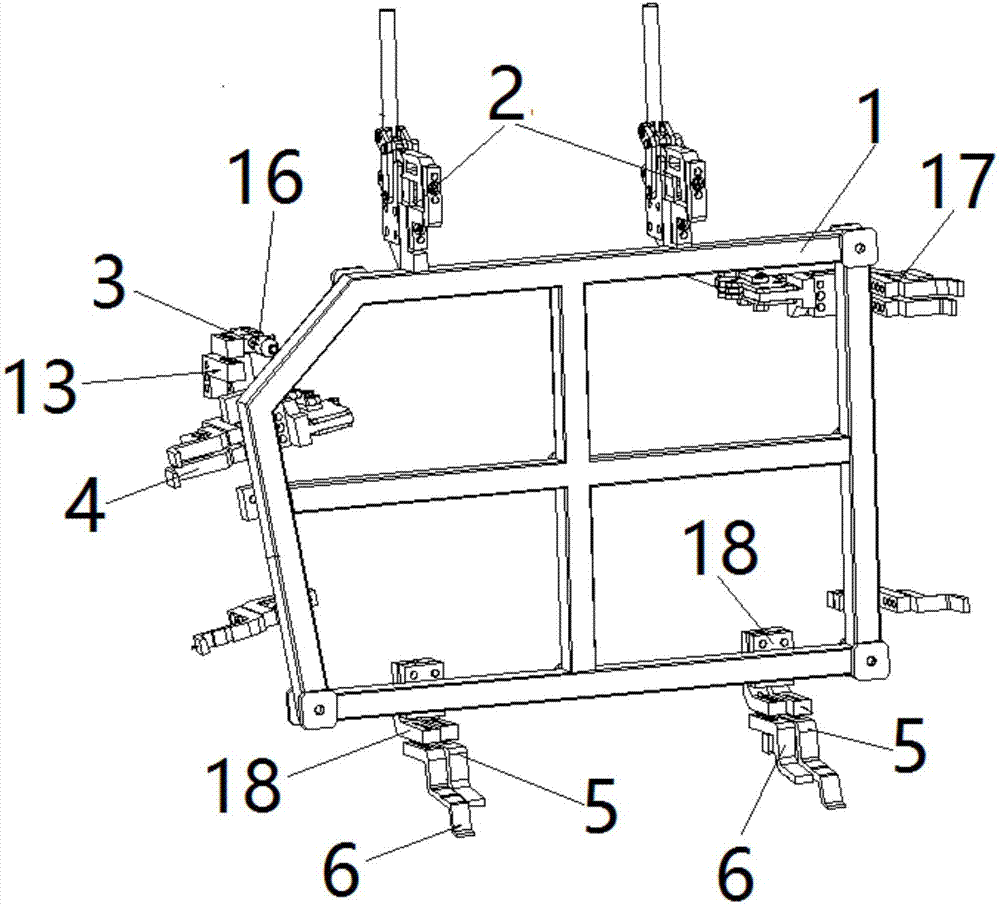

PendingCN111794783AEasy step-by-step installationImprove assembly efficiencyUnderground chambersTunnel liningArchitectural engineeringMechanization

The invention discloses an open cut tunnel segment assembly trolley. The open cut tunnel segment assembly trolley comprises a track, a road wheel assembly, a lower side-slip assembly, a main supporting frame, an alignment formwork frame, an assembly formwork frame, a segment pushing bracket, an adjusting mechanism, an abut wall centralizing mechanism, a side wall centralizing mechanism and a traction mechanism; the bottom of the main supporting frame is connected with the road wheel assembly through the lower side-slip assembly, and the road wheel assembly walks along the track; the alignmentformwork frame is arranged at the middle position of the front part of the upper part of the main supporting frame through a first lifting mechanism, and an arch plate at the top of the alignment formwork frame is positioned; the assembly formwork frame is arranged on the rear part of the alignment formwork frame through the adjusting mechanism, and the assembly formwork frame positions a crown wall prefabricated block; the abut wall centralizing mechanism and the side wall centralizing mechanism are arranged on the two sides of the main supporting frame and used for centralizing and positioning an abut wall prefabricated block and a side wall prefabricated block; the segment pushing bracket tightly pushes the side surfaces of segment rings; and the traction mechanism drives the trolley towalk. According to the open cut tunnel segment assembly trolley, the whole-course mechanization is realized, the labor strength is alleviated, the segment assembly efficiency is improved, and the assembly precision is ensured.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

A method for breed strawberry seedlings save labor

InactiveCN108887103AEasy to operateEasy to masterFertilising methodsHorticulture methodsFragariaCentralized management

A method for breed strawberry seedlings save labor includes such steps as propagating, refrigerate, classifying, transplanting and activating seedlings. The invention improves the breeding coefficientof seedlings, promotes flower bud differentiation, and simultaneously improves the consistency of seedling quality and seedling age. This method is easy to operate, easy to master, repeatable, time-saving, labor-saving, easy to classify and centralized management, perfecting the shortcomings of conventional strawberry seedling.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

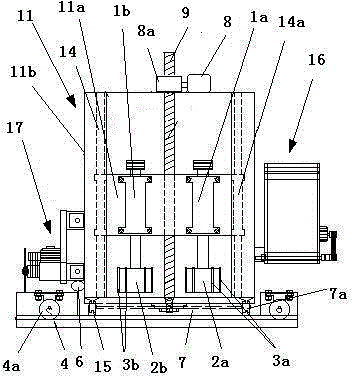

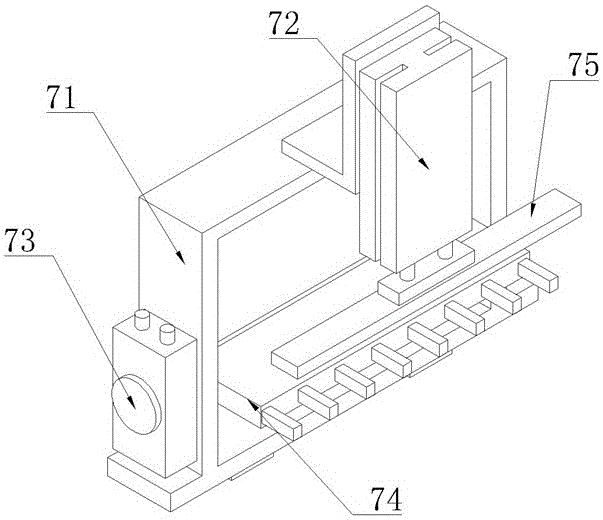

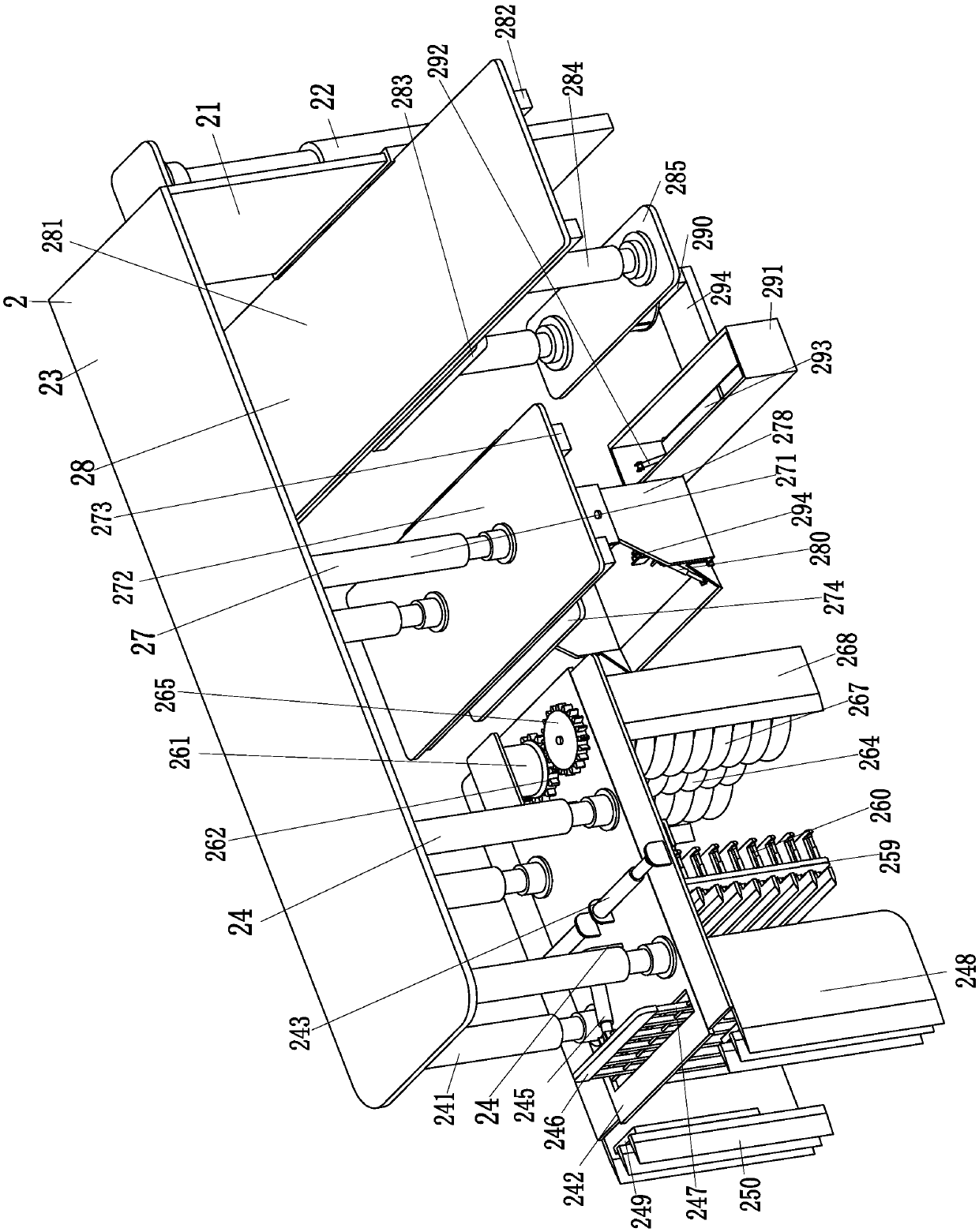

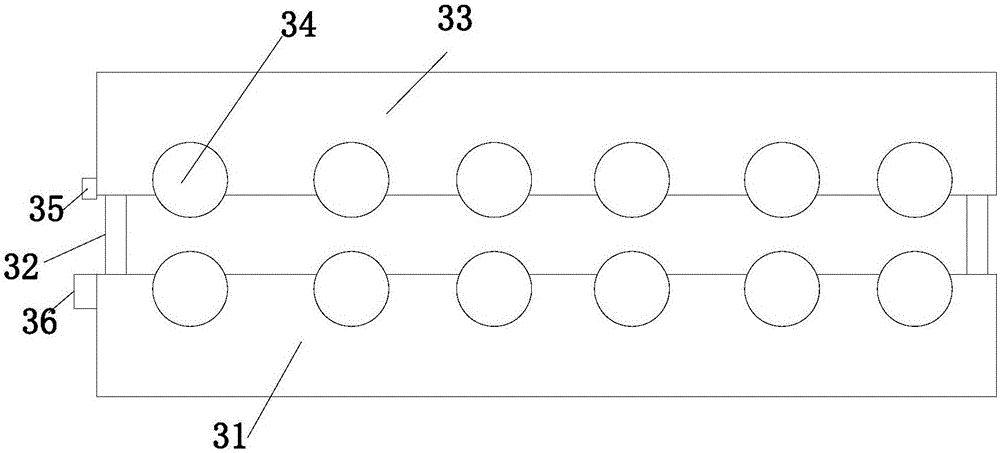

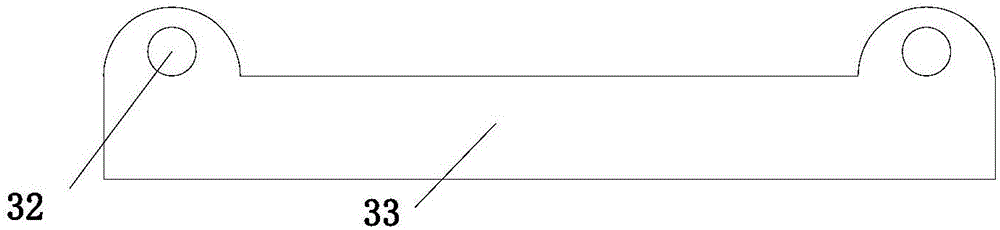

Automatic and quantitative gluing plate jointing device of short and small battens and gluing plate jointing method

ActiveCN109514659ALow degree of automationSimple structureWood veneer joiningSolid woodLayer thickness

The invention discloses an automatic and quantitative gluing plate jointing device of short and small battens and a gluing plate jointing method. The device comprises a side automatic and quantitativegluing device and a fixed-length width jointing, assembling and pre-pressing device. The side automatic and quantitative gluing device comprising a gluing rack, a conveying belt, a glue box, a glue application tooth roller, a glue application tooth roller support, a U-shaped glue scraping roller, a U-shaped glue scraping roller support, a backer, a flexible guide plate and a guide plate transverse adjusting mechanism. The fixed-length width jointing, assembling and pre-pressing device comprises an assembling rack, a workbench plate, a width backer, a length backer, a side press plate and sidepress plate air cylinders. According to the side automatic and quantitative gluing device of the device, the glue application tooth roller can be used for gluing the sides of the short and small battens, and control over quantitative glue layer thickness is achieved through the U-shaped glue scraping roller; the fixed-length width jointing, assembling and pre-pressing device can achieve fixed-length width jointing of the short and small battens; and the process and the device are simple, the automation degree is high, the production cost is low, the production efficiency is high, no glue markcontamination exists on the plate faces, and the device can be widely applied to materials of solid wood furniture, core-boards and the like.

Owner:NANJING FORESTRY UNIV

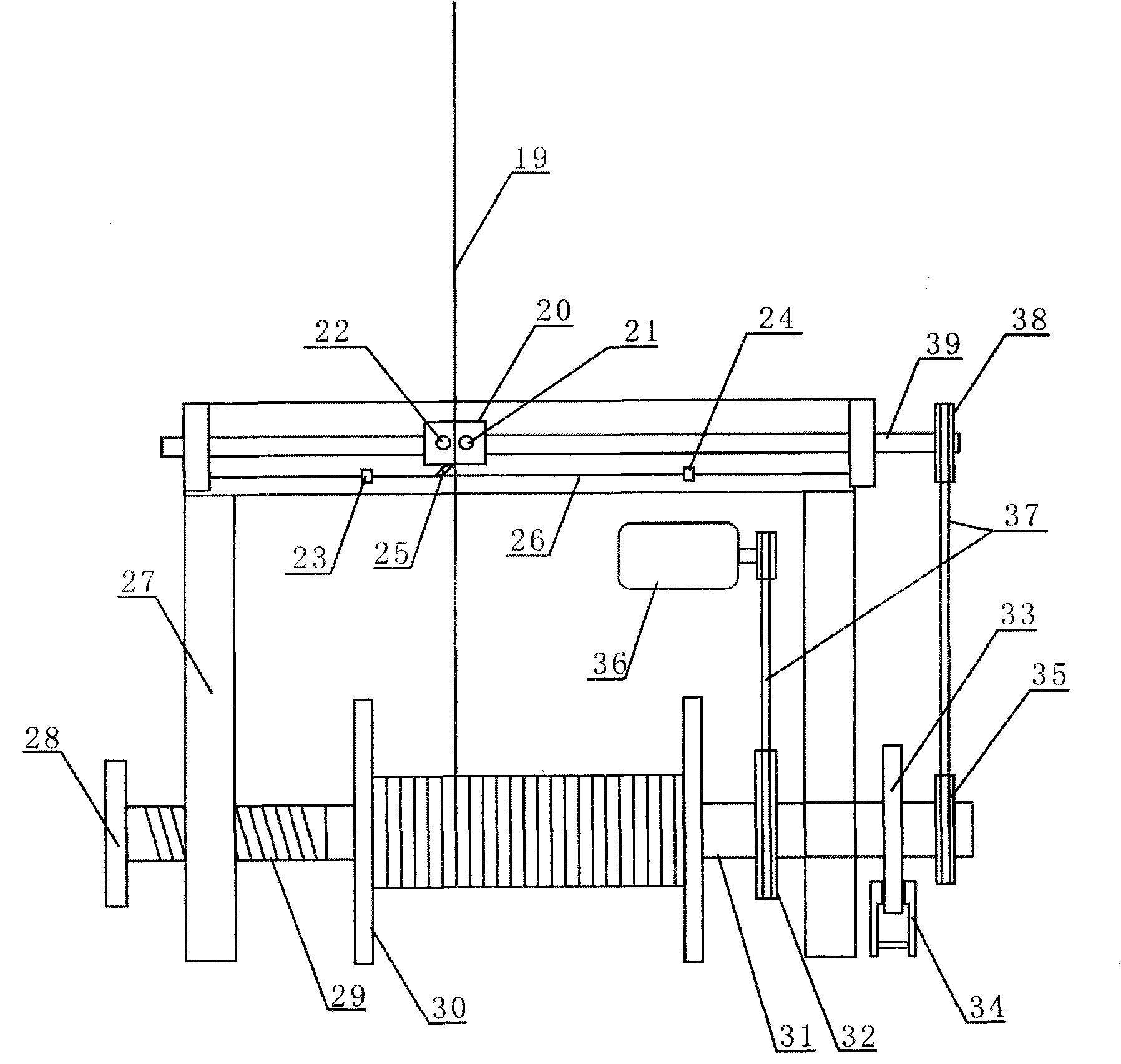

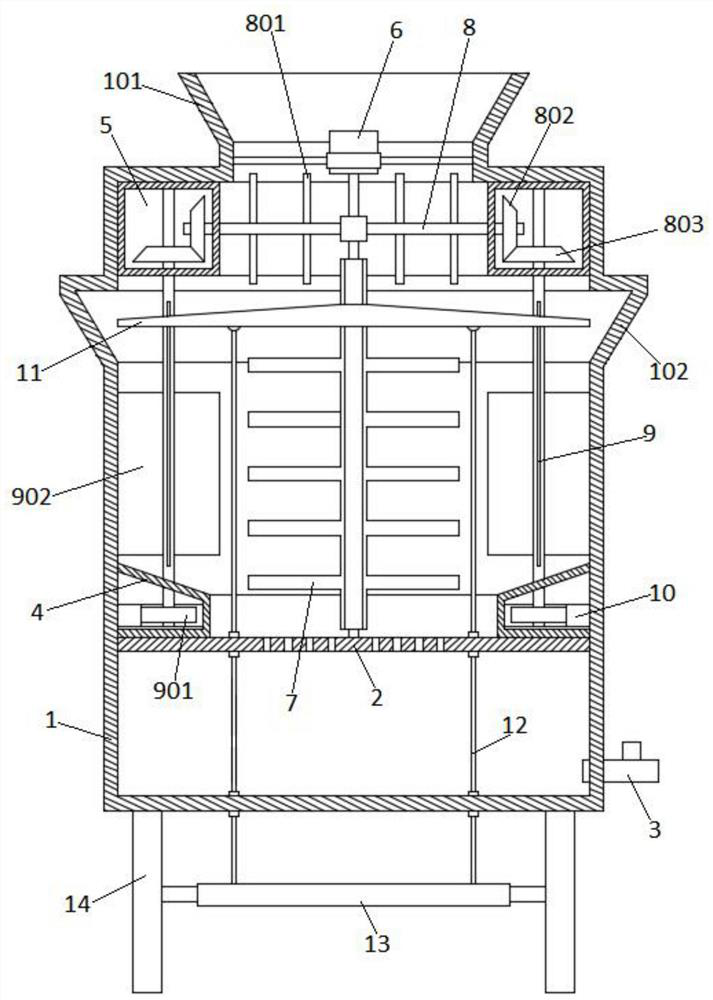

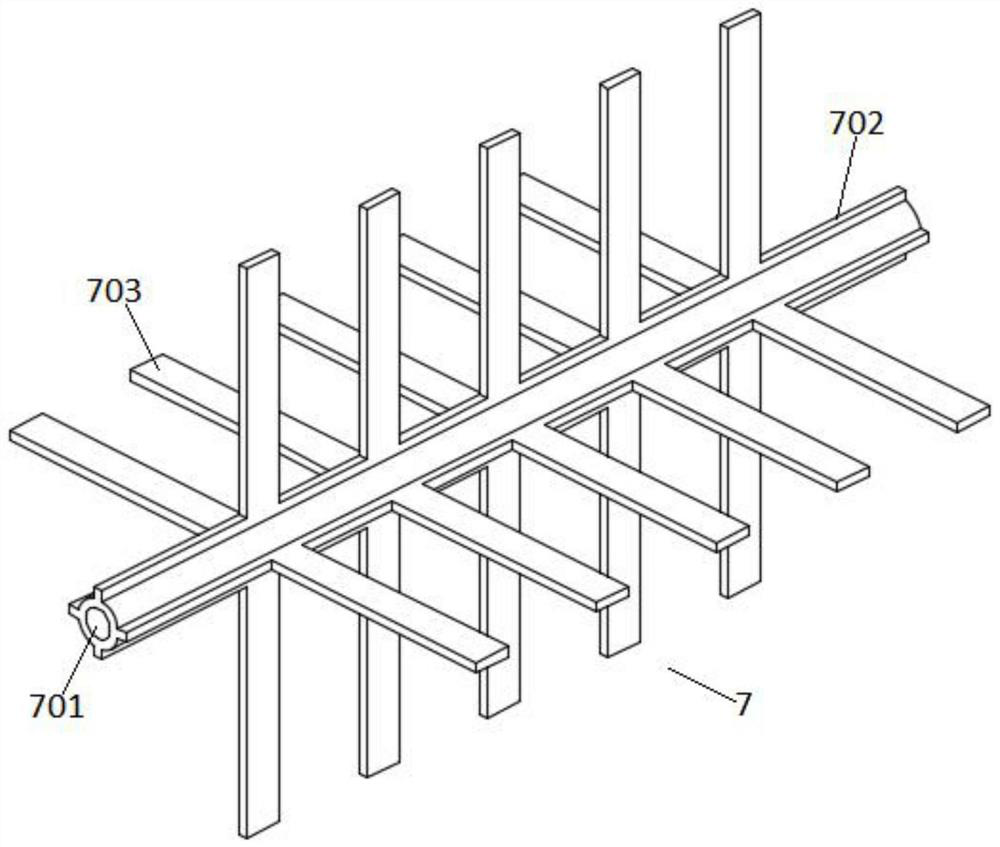

Automatic stirring-frying machine for hotpot condiment

InactiveCN102948653ALabor Intensity GuaranteeQuality assuranceFood preparationEngineeringMechanical engineering

The invention provides an automatic stirring-frying machine for hotpot condiment, and solves the problems of a manual stir-frying technology of the hotpot condiment that the working strength is excessively high and the quality of the hotpot condiment can not be ensured. Machining for stirring-frying the hotpot condiment, provided by the invention, can be used for automatically stirring-frying the hotpot condiment at a constant speed during manufacturing, so that the quality of the hotpot condiment can be effectively ensured, and the working strength of skilled workers can be greatly reduced.

Owner:唐永清

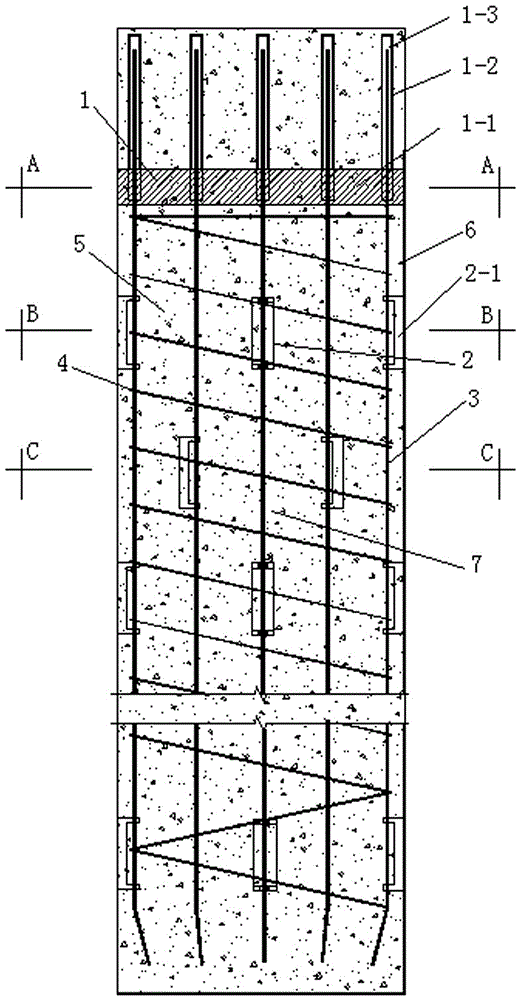

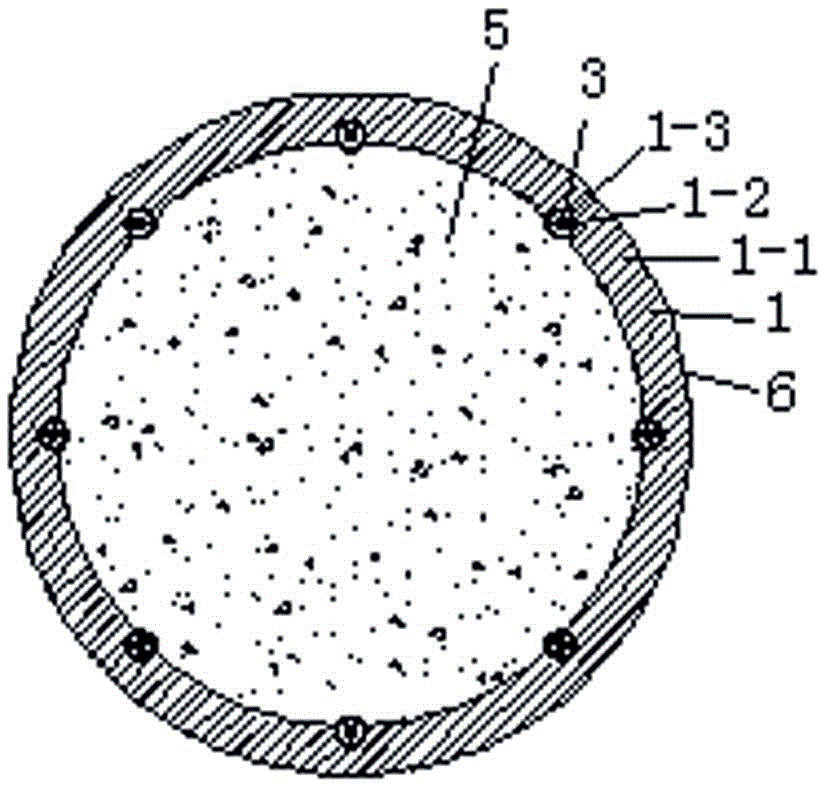

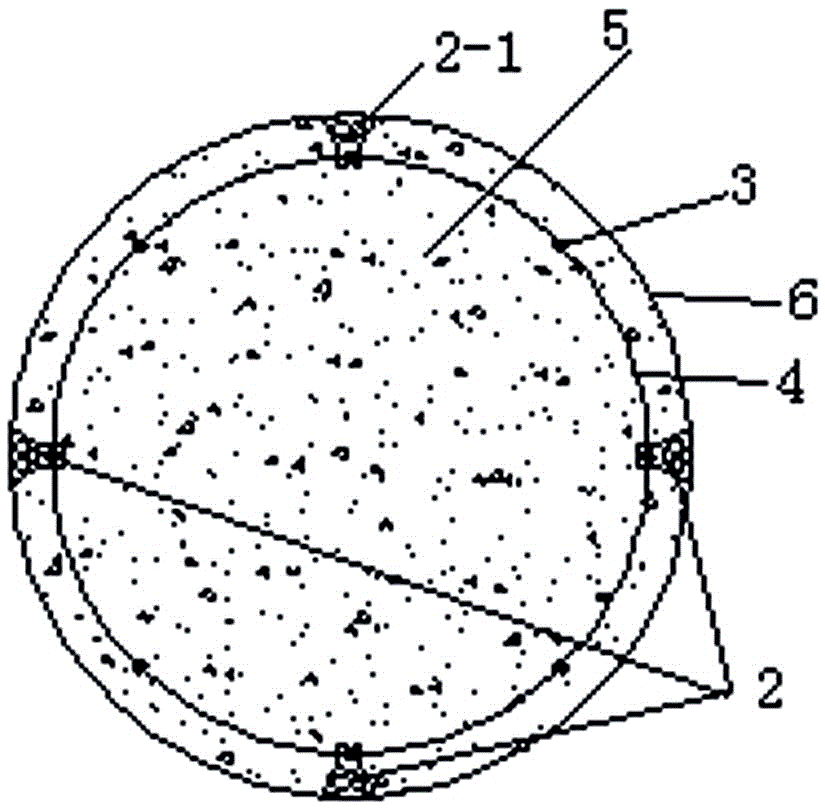

Obstructing pulling method pile digging construction device and method

InactiveCN106400804AGuaranteed to be vertical without deflectionPrecise positioningBulkheads/pilesRebarProtection layer

The invention relates to an obstructing pulling method pile digging construction device and method. The device comprises reinforcement cage main ribs and reinforcement cage stirrups, the reinforcement cage main ribs are equally distributed in a surrounding manner and are annularly, spirally, sequentially and fixedly wound with the reinforcement cage stirrups to form a reinforcement cage, the reinforcement cage is placed into a bored pile formed hole and is provided with reinforcement cage protection layer devices, and a concrete pre-separation device is arranged at the top end of the reinforcement cage; the reinforcement cage protection layer devices are arranged in the length direction of the reinforcement cage every 3 m, and protection layers are arranged on ach reinforcement cage protection layer device every 90 degrees along the circumference; the concrete pre-separation device is composed of vertical reinforcement isolation sleeves, annular protection layer isolation rings and filler, the reinforcement cage main ribs, located at the pile top, of the reinforcement cage are provided with the vertical reinforcement isolation sleeves one by one, and the two ends are closed; and the annular protection layer isolation rings are installed at the bottoms of the vertical reinforcement isolation sleeves. The obstructing pulling method pile digging construction device and method have the beneficial effects of saving labor and being rapid and environment-friendly.

Owner:NINGBO MUNICIPAL ENG CONSTR GROUP

Waste acid recovery device for storage battery production

ActiveCN112820972AEffective filteringReduce labor intensityWaste accumulators reclaimingStationary filtering element filtersProcess engineeringMechanical engineering

The invention discloses a waste acid recovery device for storage battery production, and relates to the technical field of storage battery production. The device comprises a treatment barrel with a feeding hole in the upper part; an expansion part is arranged on the upper side wall of the treatment barrel; the expansion part is arranged below the feeding hole; a filter plate is arranged below the expansion part; the filter plate is horizontally fixed in the treatment barrel; a storage chamber for storing recycled waste acid is formed between the filter plate and the bottom wall of the treatment barrel; a discharge hole is formed in the lower part of the storage chamber; the upper surface of the filter plate is rotationally connected with an annular shell; an annular box is coaxially arranged above the annular shell; and the annular box is rotationally connected to the side wall of the upper part of the treatment barrel and is arranged between the feeding hole and the expansion part. The waste acid recovery device is reasonable in structural design, convenient to operate, good in waste acid recycling effect, high in practicability and high in market application value.

Owner:TIANNENG BATTERY GRP ANHUI

Direct-buried type communication cable laying equipment with capacity of realizing intelligent excavation and laying

InactiveCN107989093AReduce labor intensityImprove work efficiencySoil-shifting machines/dredgersFoundation engineeringSoil treatmentDirect-buried cable

The invention relates to direct-buried type communication cable laying equipment with capacity of realizing intelligent excavation and laying. The equipment comprises a lifting plate, an excavation device and a grouting device, wherein the excavation device is mounted at the front end of the lifting plate; the grouting device is mounted on the lifting plate. With the adoption of the equipment, theproblems that a worker is required to perform ditching and manual grouting and laying in conventional direct-buried cable mounting process and potential safety hazards are produced because of back injury caused by the fact that the worker needs to dig a ditch by a tool during ditching and bends down to work for a long time are solved, and furthermore, the problems that soil treatment is tedious after manual ditching, the bottom of the ditch is required to be subjected to grouting rolling manually during laying, the manual rolling is uneven as well as gaps are easily produced between cement slabs, the cement slabs are mounted unstably, time consumption of the laying process is high, labor intensity is high, efficiency is low and the like due to the fact that the cement slabs are required to be subjected to grouting solidification outside by the worker during grouting on the side surface and then transported to designated positions for mounting are solved, so that the equipment can realize functions of intelligent excavation and laying of communication cables.

Owner:刘静

Stapler convenient for stapling

ActiveCN106079961AAutomate bookbindingImprove binding efficiencySheet bindingBiochemical engineering

Owner:HUZHOU JIANING PRINTING

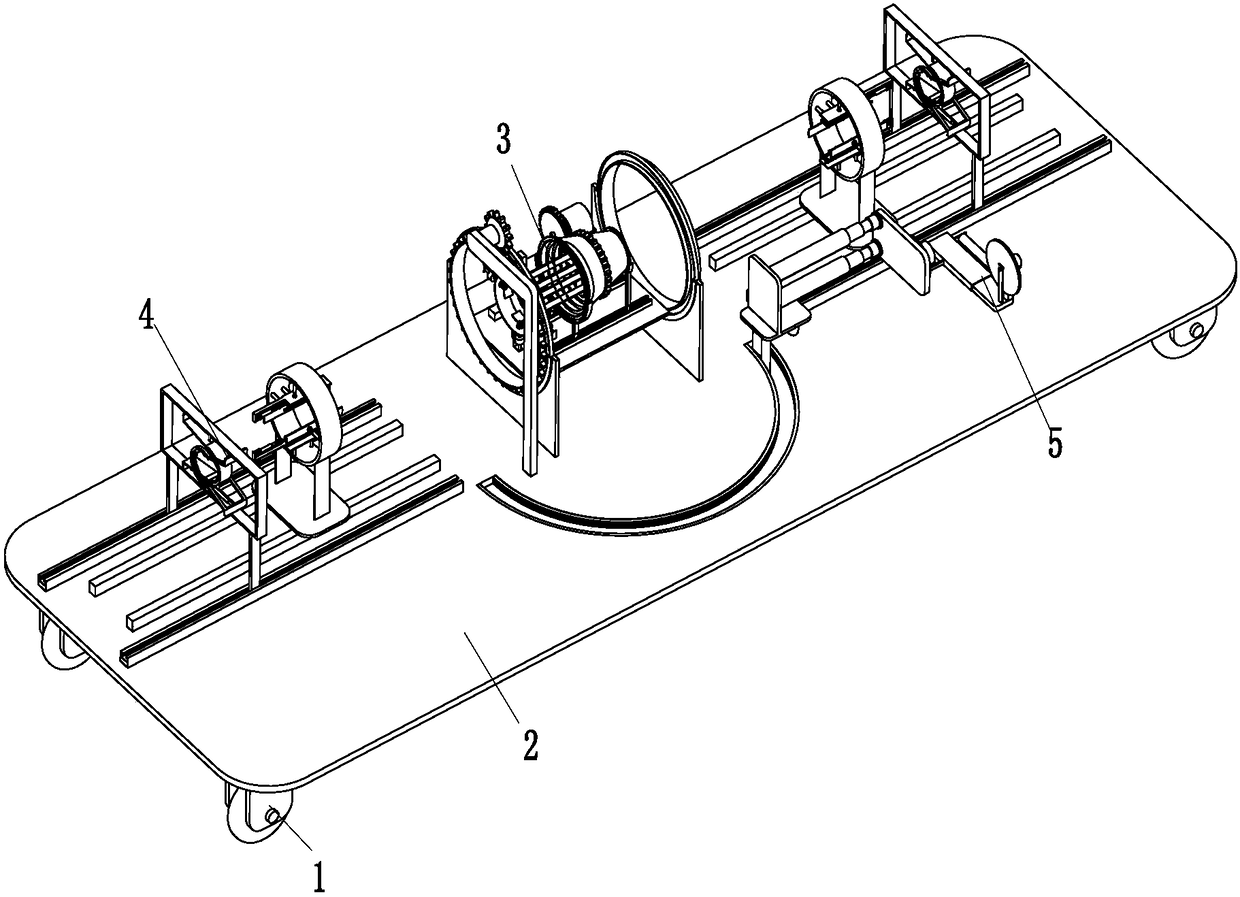

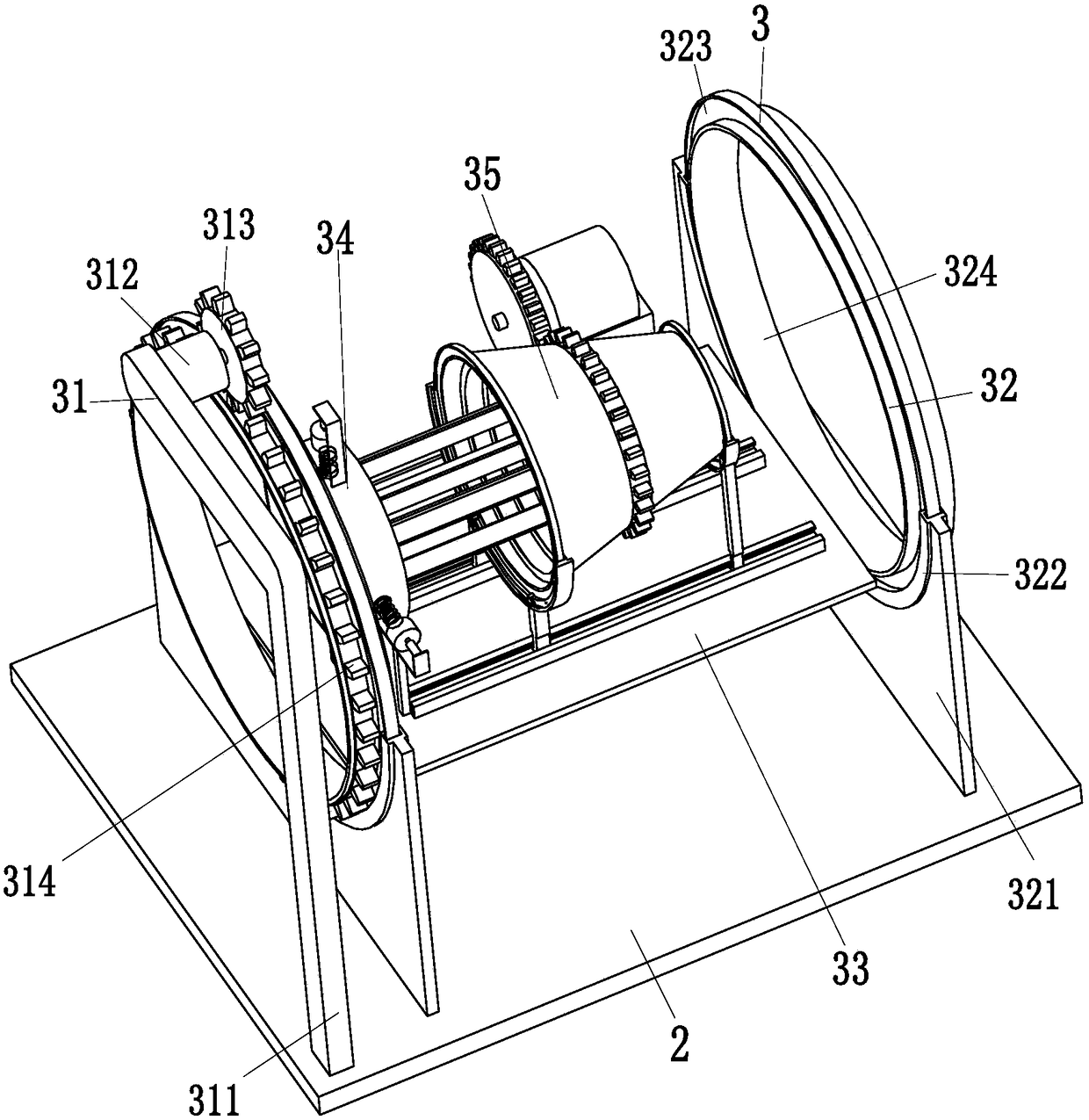

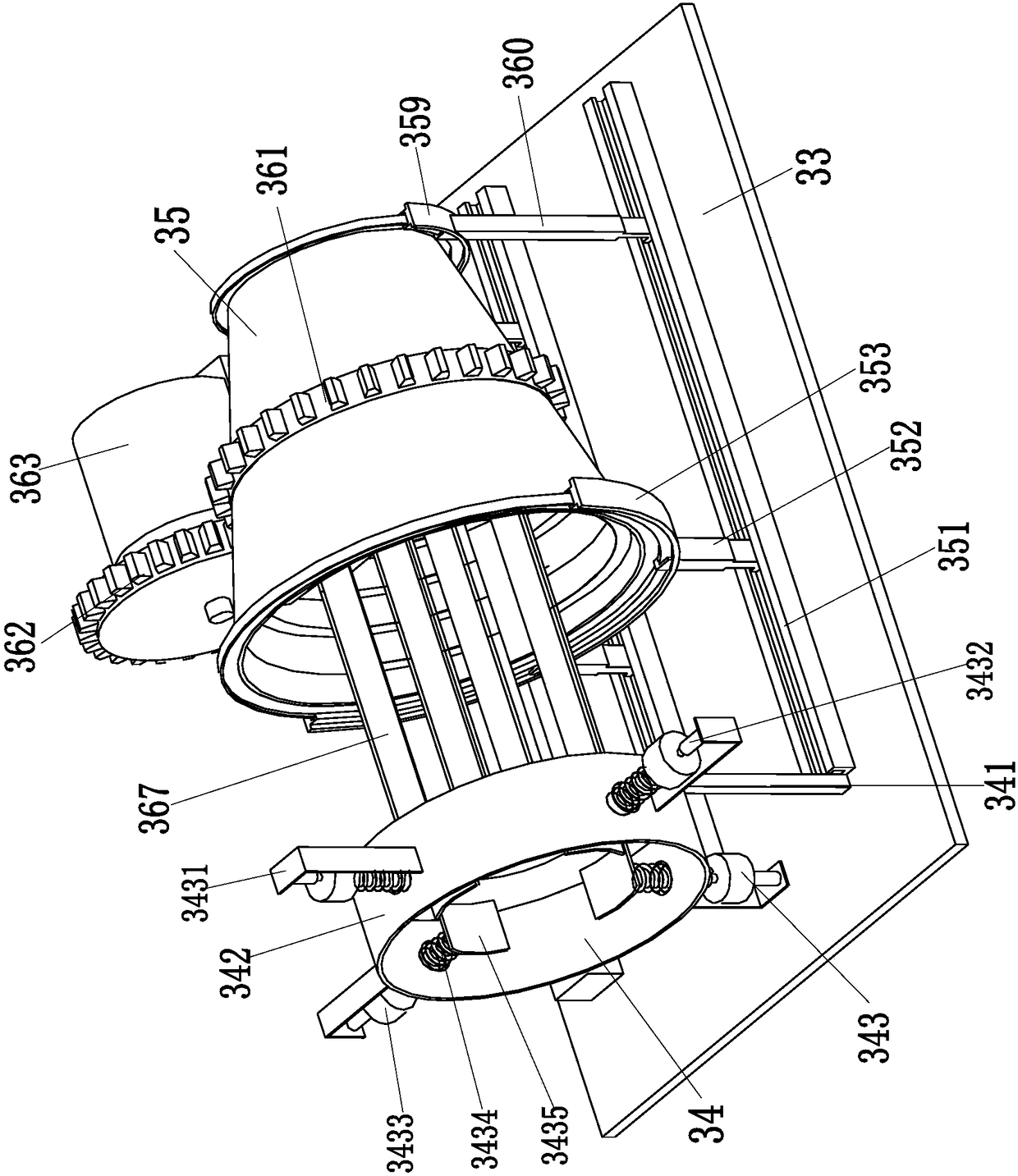

Circular truncated cone-shaped food packaging box fully-automatic rapid processing and forming robot

InactiveCN107498920AAvoid replacementEnsure safetyBox making operationsPaper-makingPunchingBiochemical engineering

The invention relates to a fully automatic and rapid processing and forming robot for a circular table-shaped food packaging box, which includes a bottom plate, four No. 1 universal wheels, a conveying device, a cup body forming device and a bottom punching device. A No. 1 universal wheel, a conveying device is installed on the left side of the front end of the bottom plate, a cup body forming device is installed on the left side of the bottom plate, and a bottom punching device is installed on the bottom plate. The present invention can solve the problem that the existing automatic processing of the frustum-shaped packaging box requires staff to stack the cup body paper neatly and then place it on the existing equipment. At the same time, the cup body is deformed, and at the same time, improper operation will cause safety hazards. People need to replace the mold for cup bodies with different diameters. People arrange the bottom paper of the cup before processing, which is inefficient and difficult to arrange. Unloading, time-consuming, labor-intensive and low-efficiency problems.

Owner:汪成立

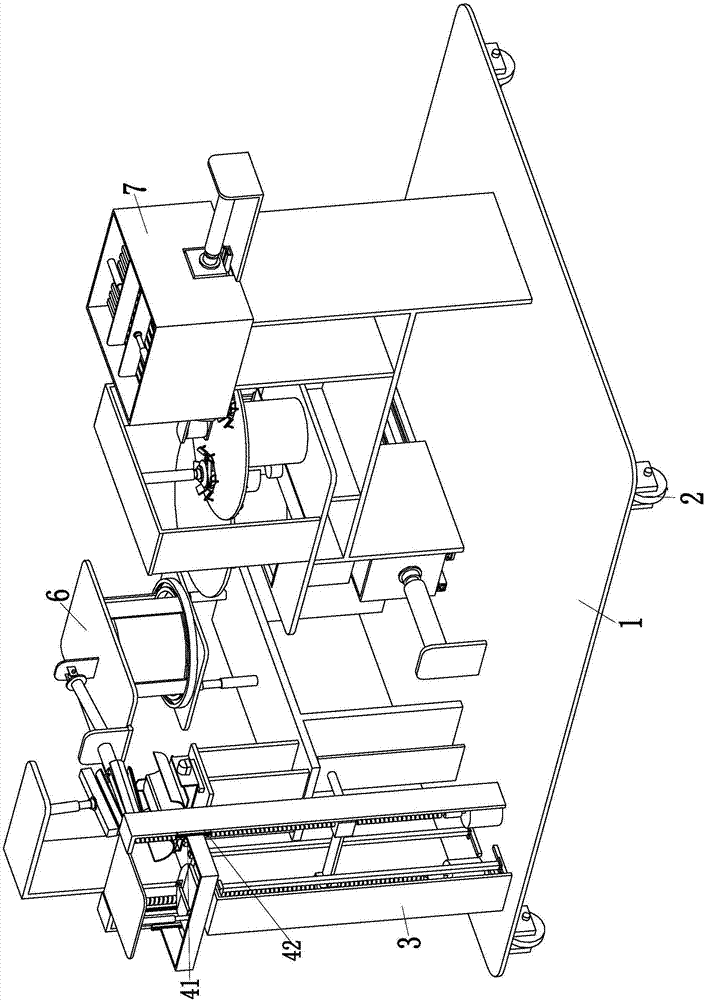

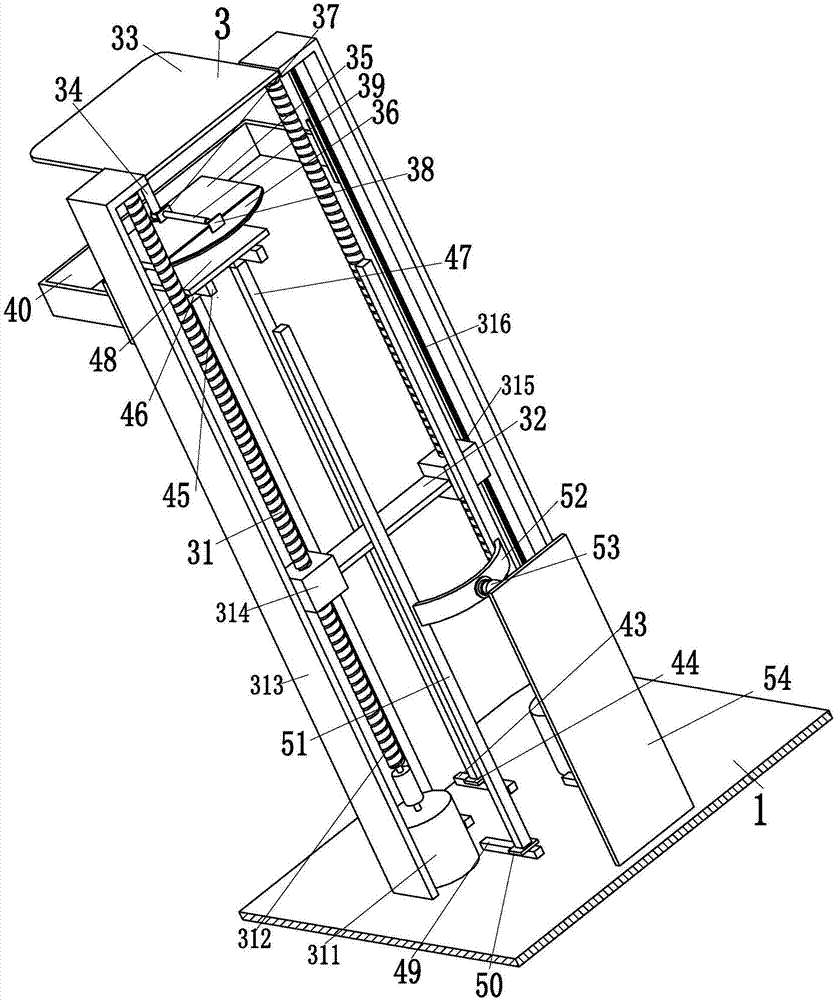

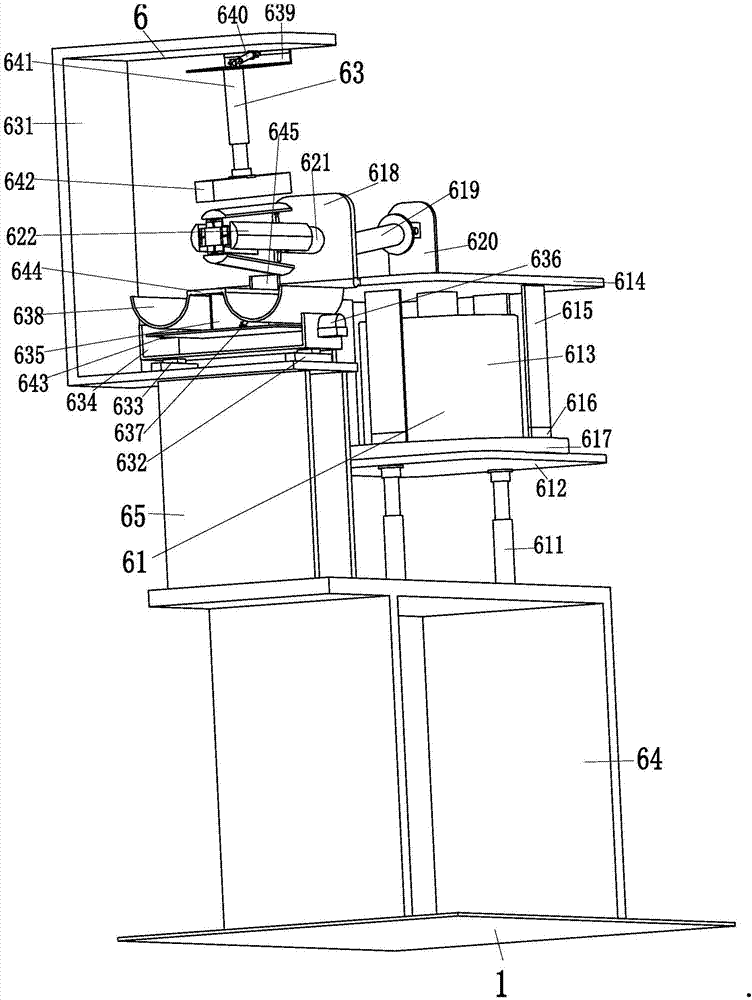

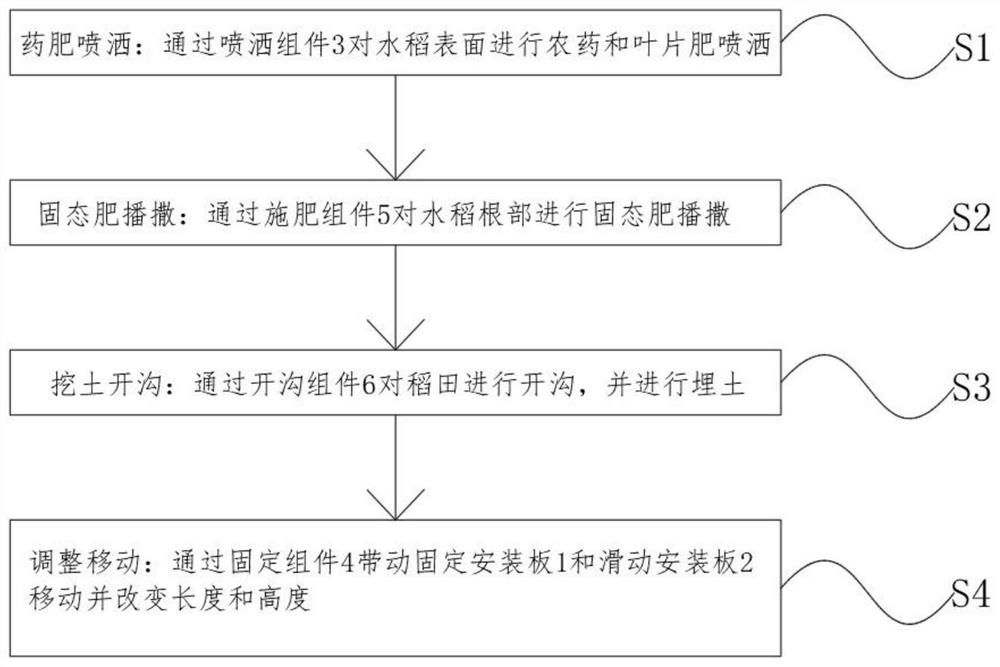

Saline-alkali soil rice planting method

ActiveCN112154880AScientific and reasonable structureSafe to usePlantingFertiliser distributersFertilizerAlkali soil

The invention discloses a saline-alkali soil rice planting method. A pesticide stirring barrel is mounted at the top end of a fixed mounting plate, a water-fertilizer stirring barrel is mounted at thetop end of a sliding mounting plate, a mounting semicircular ring is welded at the bottom end of the fixed mounting plate, and a clamping semicircular ring is hinged at one end of the mounting semicircular ring; and a fixed mounting rod is mounted between the mounting semicircular ring and the clamping semicircular ring in a clamped manner, one end of the fixed mounting rod is sleeved with a first mounting block, one end of the fixed mounting rod is sleeved with a second mounting block, a top end spray head is mounted at the bottom end of the first mounting block, and a bottom spray head is mounted at one end of a connecting fixing cylinder. When rice needs to be subjected to pesticide spraying, spraying is conducted through the top end spray head and the bottom spray head, the height ofthe bottom spray head is adjusted, so that direct pesticide application is effectively conducted on pest and disease damage positions, meanwhile, pesticide and water fertilizer are sprayed at the sametime, synchronous fertilization and pesticide spraying can be conducted on rice, the labor intensity of planters is relieved, and the spraying effect is guaranteed.

Owner:FARMING & CULTIVATION RES INST OF HEILONGJIANG ACADEMY OF AGRI SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com