Ditching, layer laying and backfilling combined telecommunication cable mechanical laying equipment

A communication cable and integrated technology, which is applied in the field of laying communication cables, can solve the problems of high labor intensity, tediousness, cumbersome and complicated process, etc., and achieve the effect of reducing labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

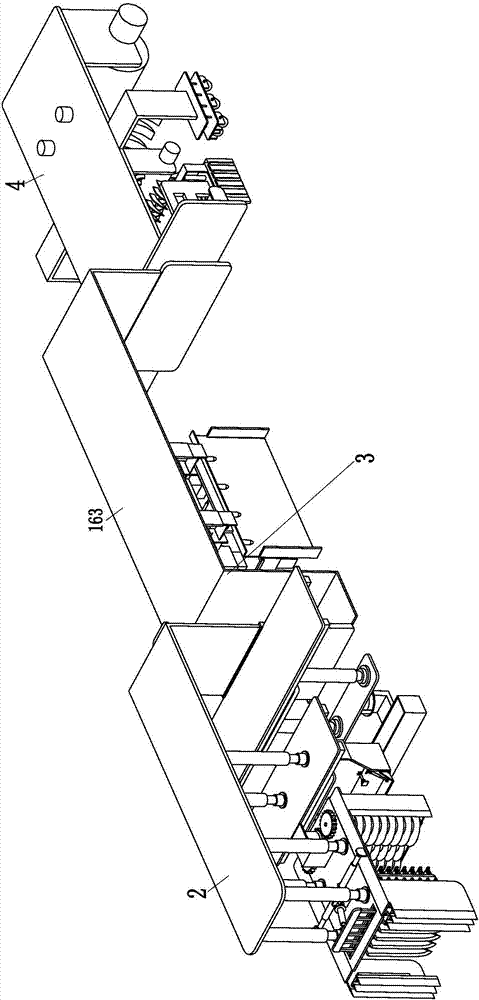

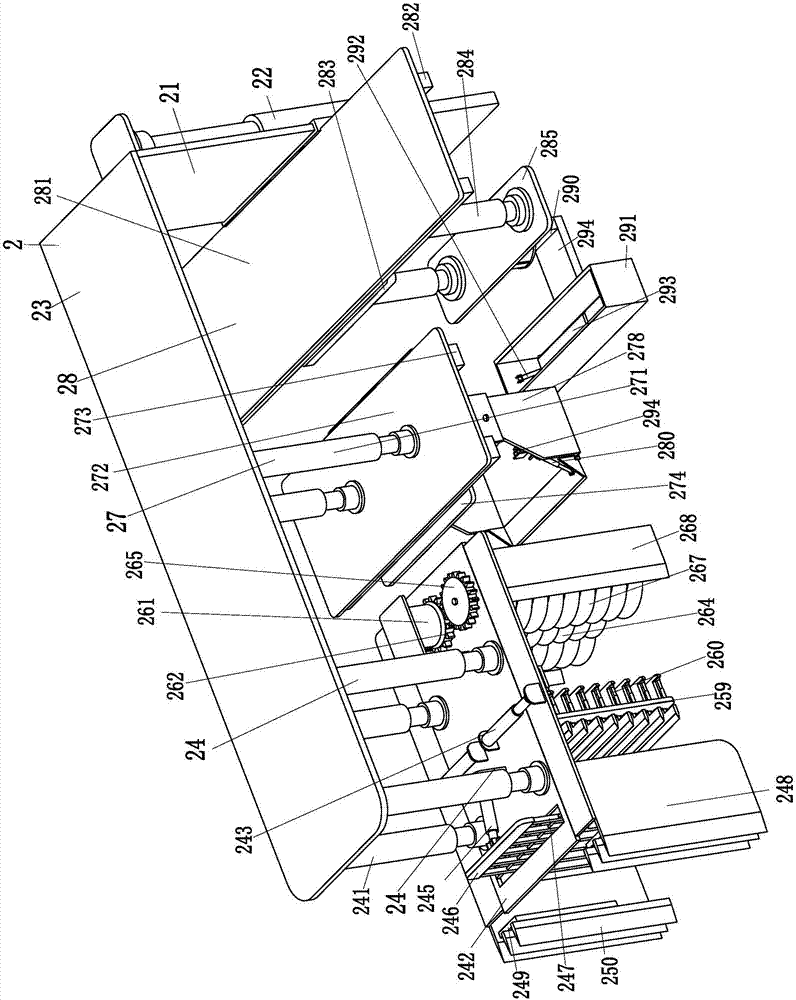

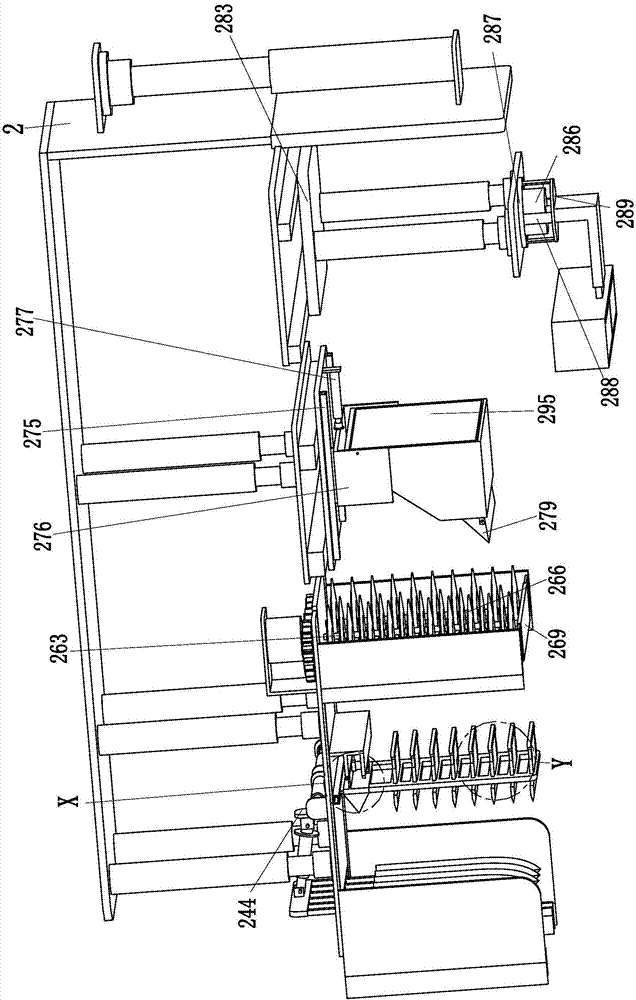

[0039] Such as Figure 1 to Figure 11 As shown, in order to achieve the above object, the present invention adopts the following technical solutions: a kind of mechanized communication cable laying equipment integrating trenching, laying and backfilling, including lifting plate 163, earth digging device 2, grouting device 3 and backfilling device 4. The excavating device 2 plays the role of excavating the soil, the grouting device 3 grouts the excavated soil ditch, and the backfilling device 4 backfills and compacts the excavated soil. The front end of the lifting plate 163 is equipp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com