Patents

Literature

137 results about "Large population" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methods of identifying point mutations in a genome

InactiveUS6994962B1Improve performanceSugar derivativesMicrobiological testing/measurementGeneticsDeleterious mutation

The invention relates to a method for identifying inherited point mutations in a targeted region of the genome in a large population of individuals and determining which inherited point mutations are deleterious, harmful or beneficial. Deleterious mutation are identified directly by a method of recognition using the set of point mutations observed in a large population of juveniles. Harmful mutations are identified by comparison of the set of point mutation observed in a large set of juveniles and a large set of aged individuals of the same population. Beneficial mutations are similarly identified.

Owner:MASSACHUSETTS INST OF TECH

Hydrodynamic capture and release mechanisms for particle manipulation

InactiveUS20060128006A1Bioreactor/fermenter combinationsBiological substance pretreatmentsElectrical resistance and conductanceMicrobubbles

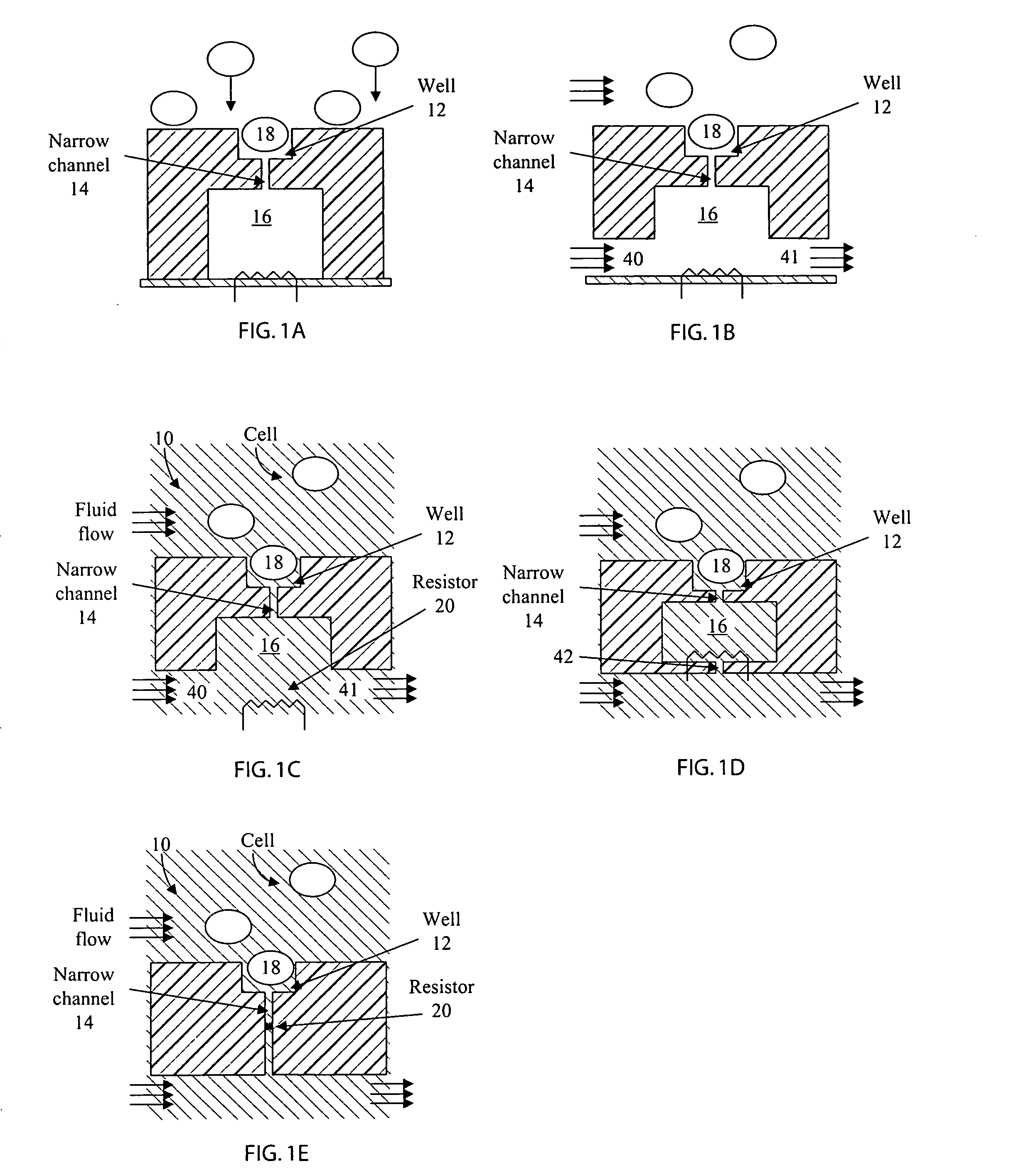

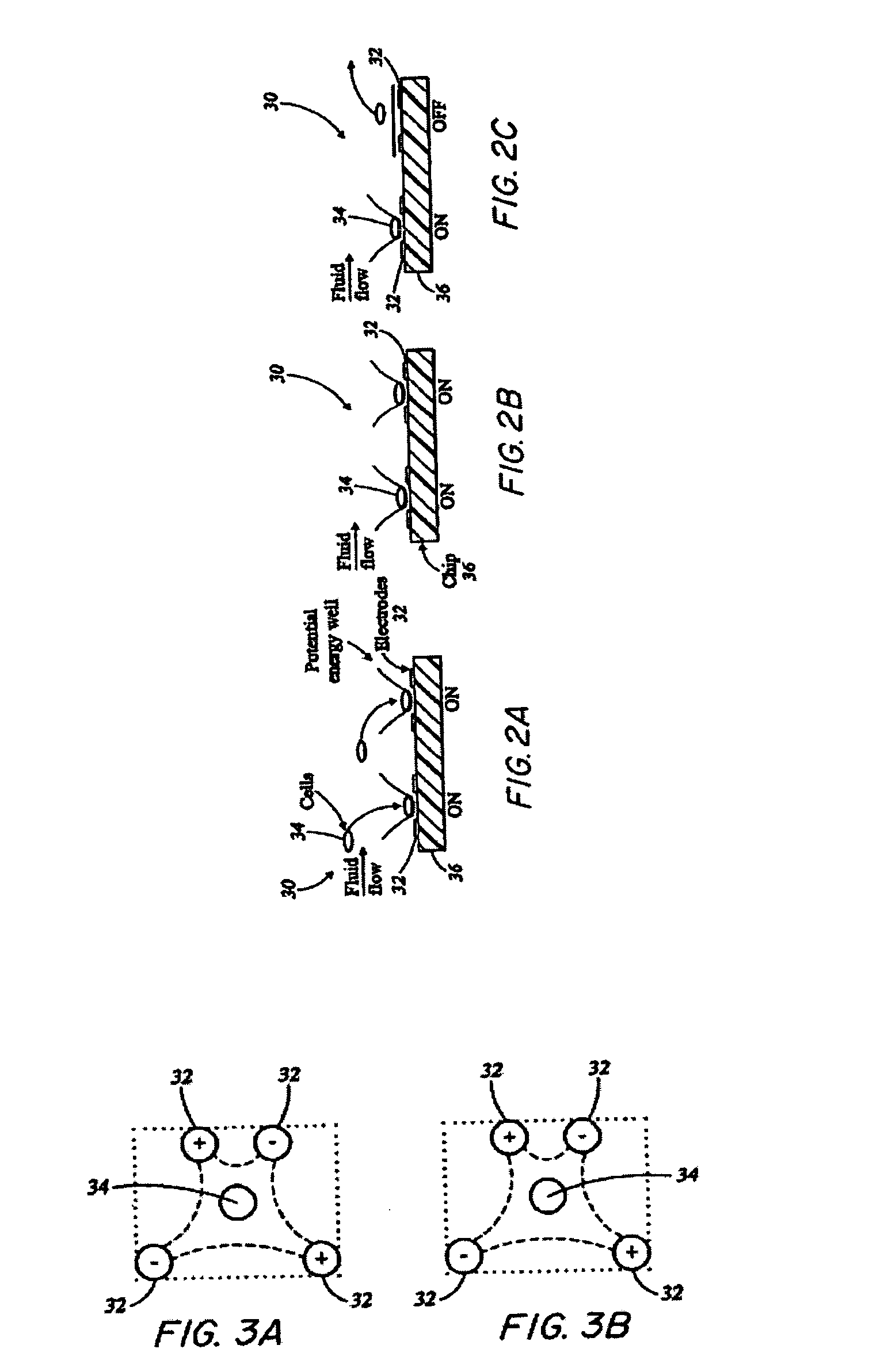

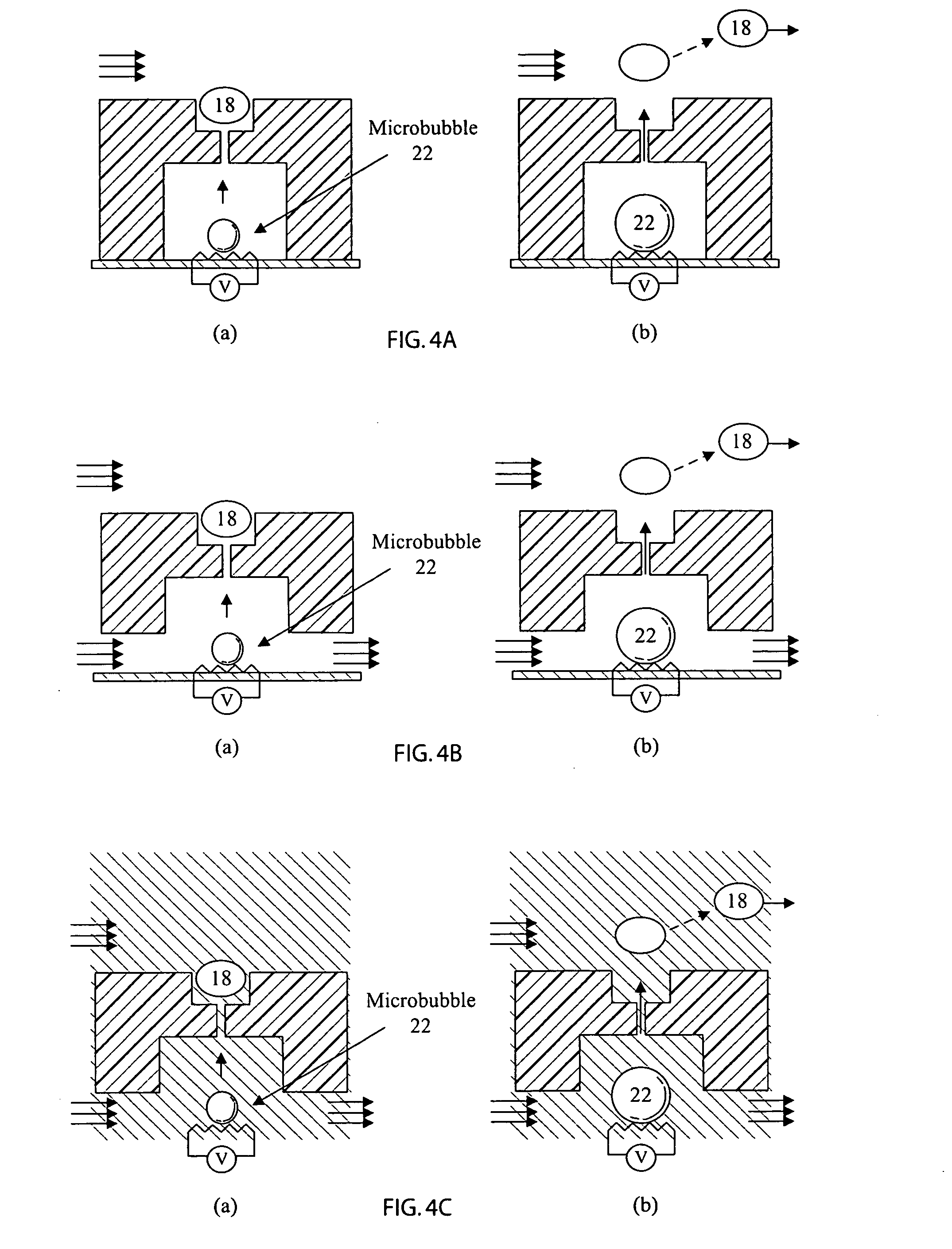

A cell analysis and sorting apparatus is capable of monitoring over time the behavior of each cell in a large population of cells. The cell analysis and sorting apparatus contains individually addressable cell locations. Each location is capable of capturing and holding a specified number of cells, and selectively releasing that specified number of cells from that particular location. In one aspect of the invention, the cells are captured and held in wells, and released using vapor bubbles as a means of cell actuation. Disclosed are: a cell manipulation apparatus design; various resistive heater configurations for nucleating microbubbles; various well designs, each in communication with a nucleation chamber or channel, for capturing a specified number of cells; and methods of fabrication and cell population manipulation.

Owner:GERHARDT ANTIMONY L +6

High throughput multiplex DNA sequence amplifications

InactiveUS20060281105A1Efficient and simultaneous amplificationMinimize formationMicrobiological testing/measurementBiological testingHigh throughput genotypingGenome scale

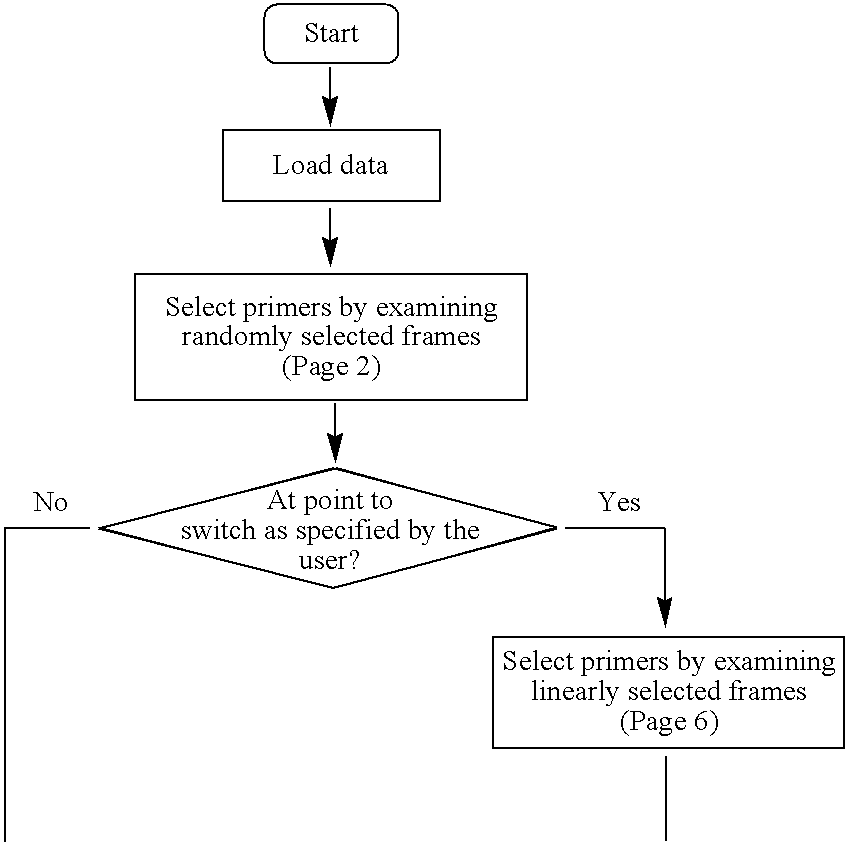

The present invention provides methods of designing PCR primers that allow the efficient and simultaneous amplification of a large number of different desired DNA fragments in a single multiplex PCR and minimize the formation of nonspecific extensions of undesired DNA fragments. The present invention allows a multiplex PCR to use at least 50 pairs of primers and produce at least 50 DNA fragments of interest. The present invention significantly broadens the application of multiplex PCR in the identification of multiple genes related to multifactorial diseases, the genome-scale detection of genetic alterations, the studies in large-scale pharmacogenetic reactions, the genotyping genetic polymorphism in a large population, the gene expression profiling in various samples, and high throughput genotyping technologies.

Owner:LI HONGHUA +1

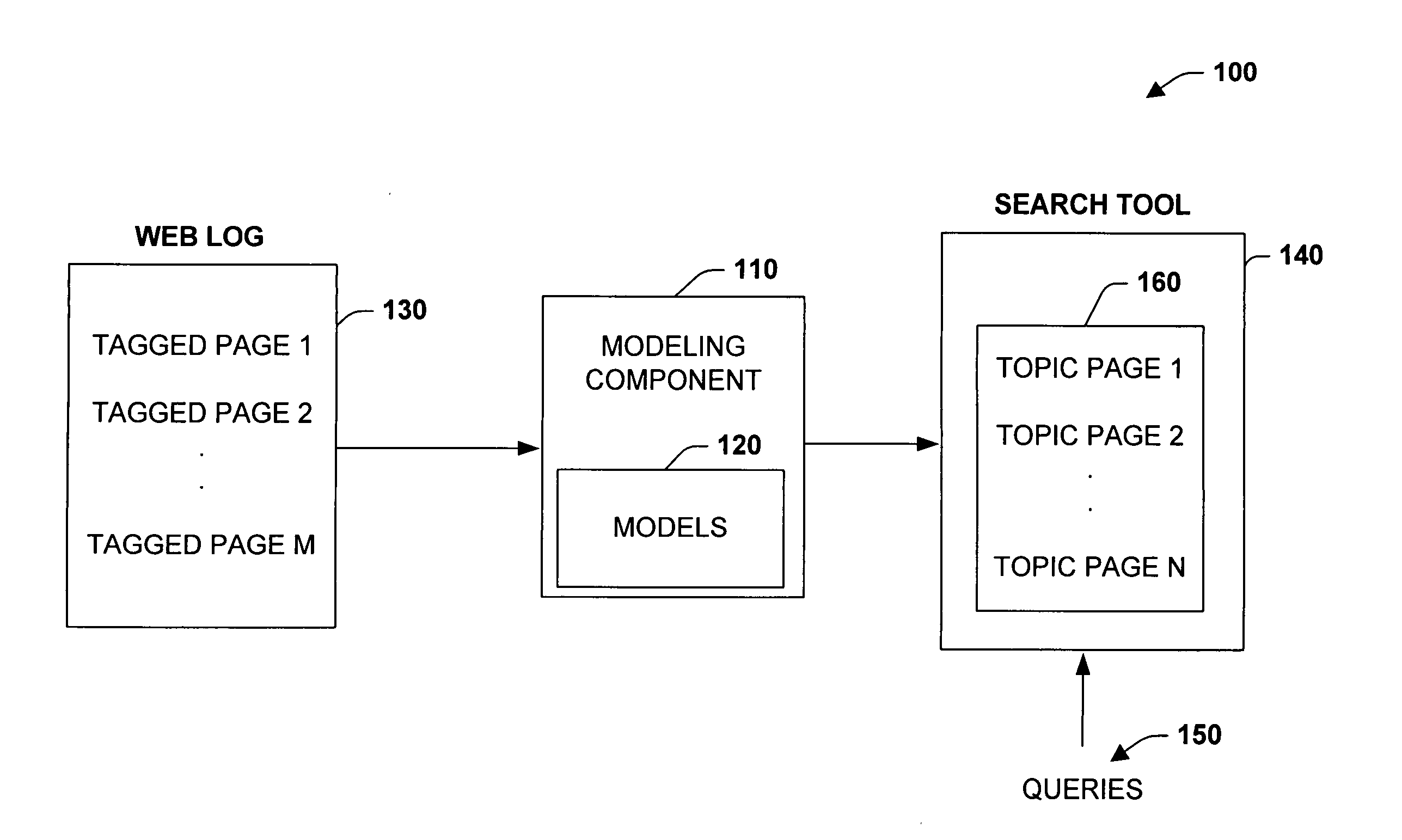

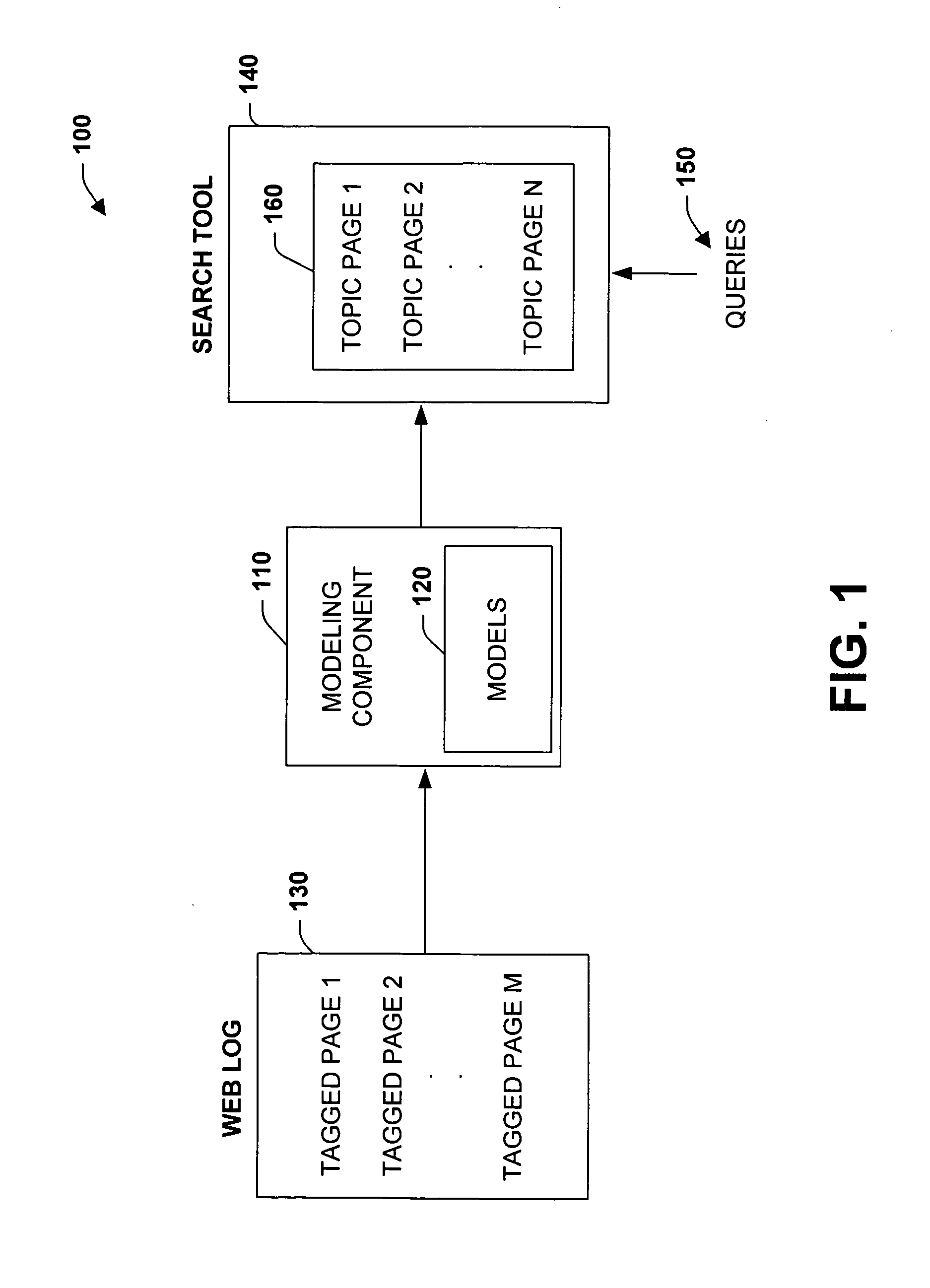

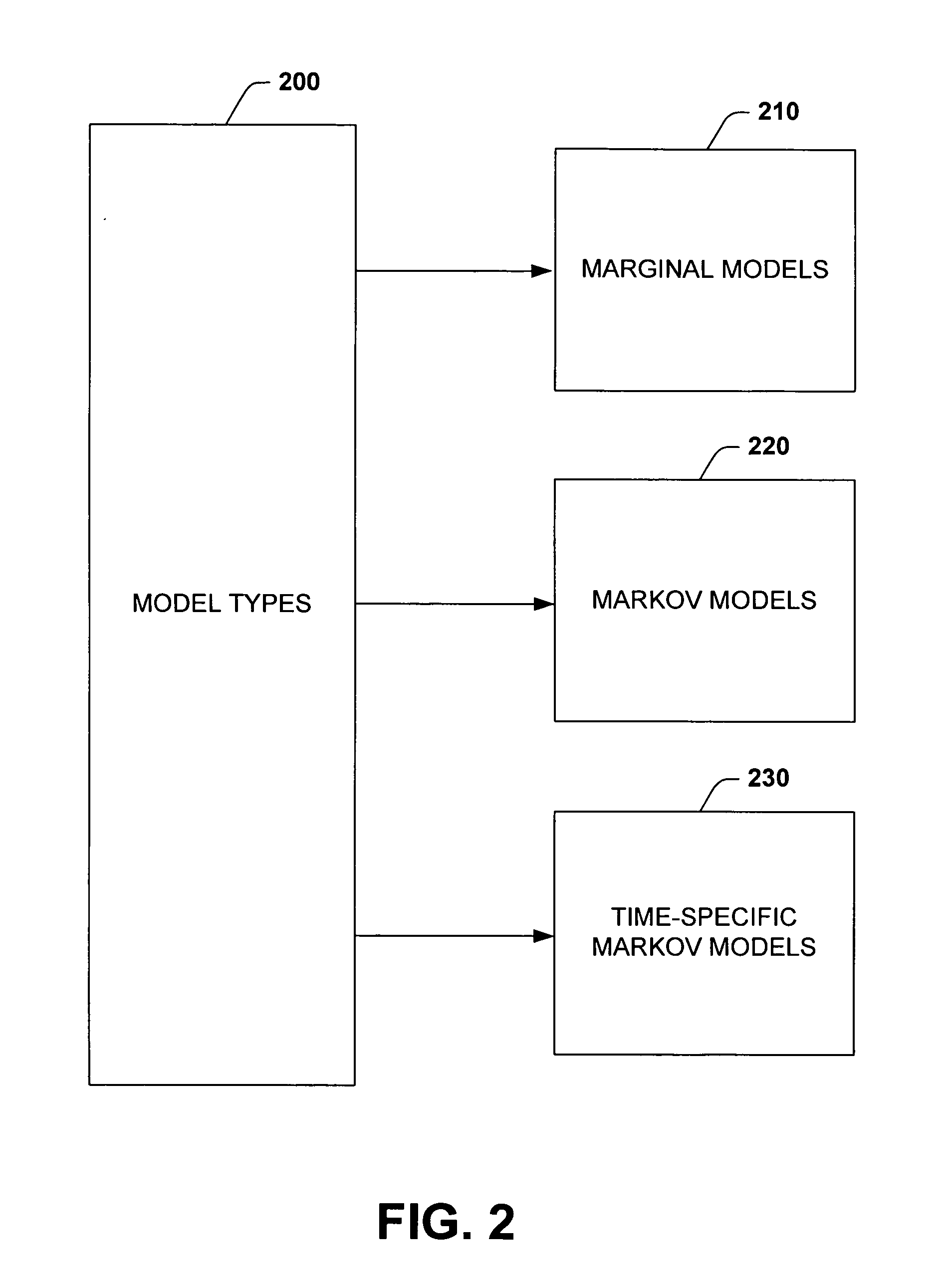

Analysis of topic dynamics of web search

The subject invention relates to probabilistic models that are trained from transitions among various topics of pages visited by a sample population of search users. In one aspect, probabilistic models of topic transitions are learned for individual users and groups of users. Topic transitions for individuals versus larger groups are analyzed, wherein the relative accuracies of personal models of topic dynamics with models constructed from sets of pages drawn from similar groups and from a larger population of users are compared. To exploit temporal dynamics, the accuracy of these models are tested for predicting transitions in topics of visits at increasingly more distant times in the future. The models can be applied to search topic dynamics of tagged pages, and then utilized to predict topics of subsequent pages visited by users.

Owner:MICROSOFT TECH LICENSING LLC

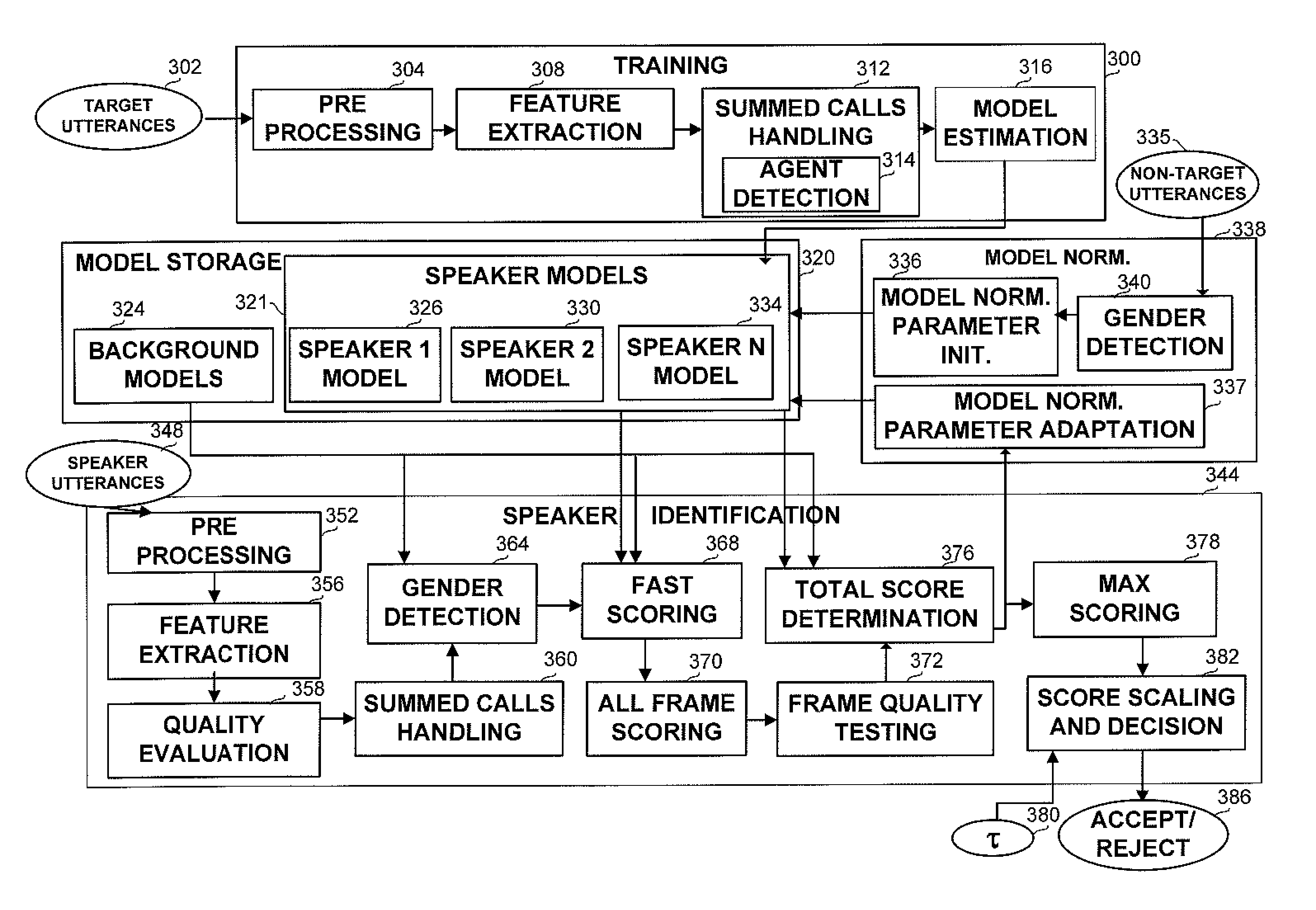

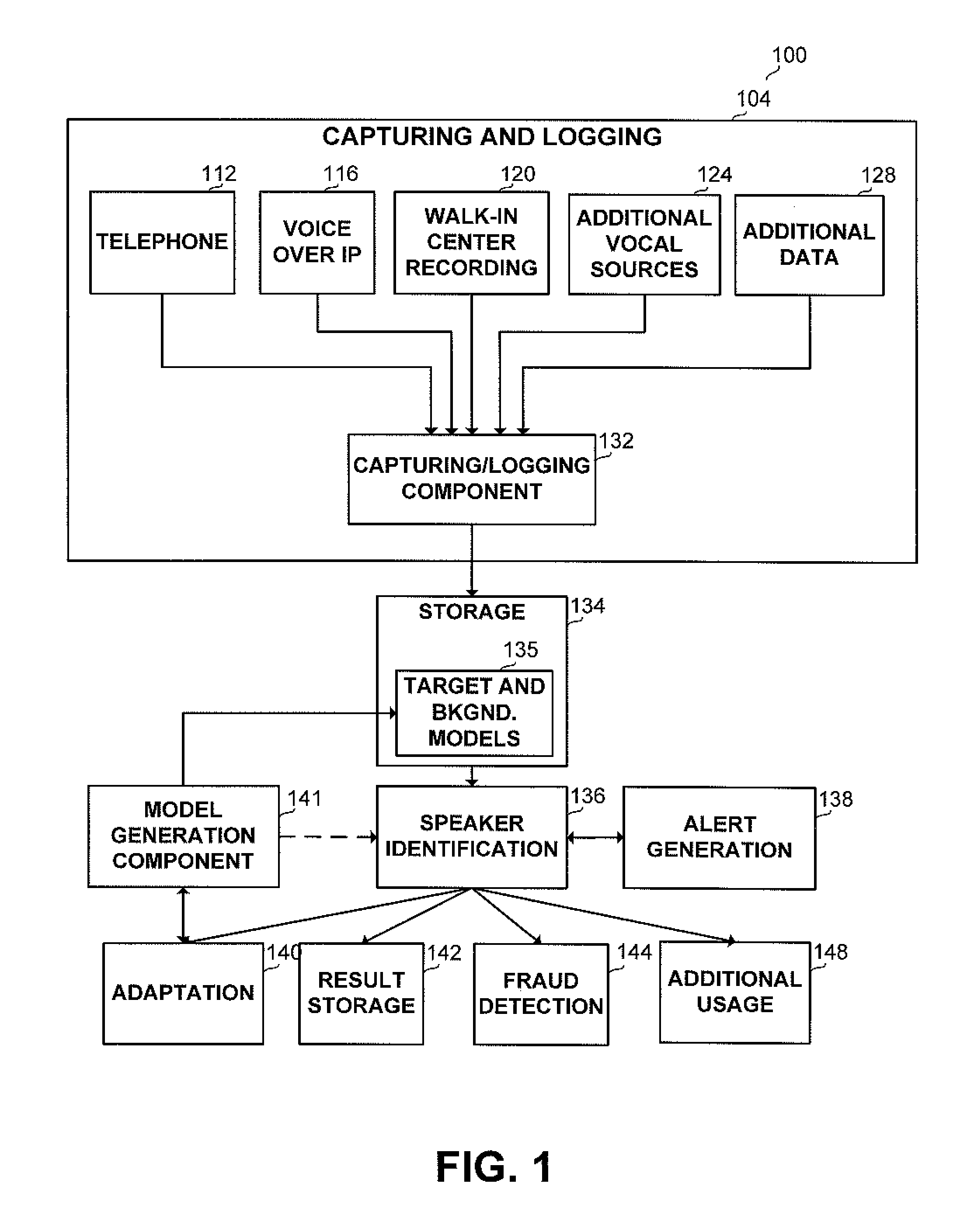

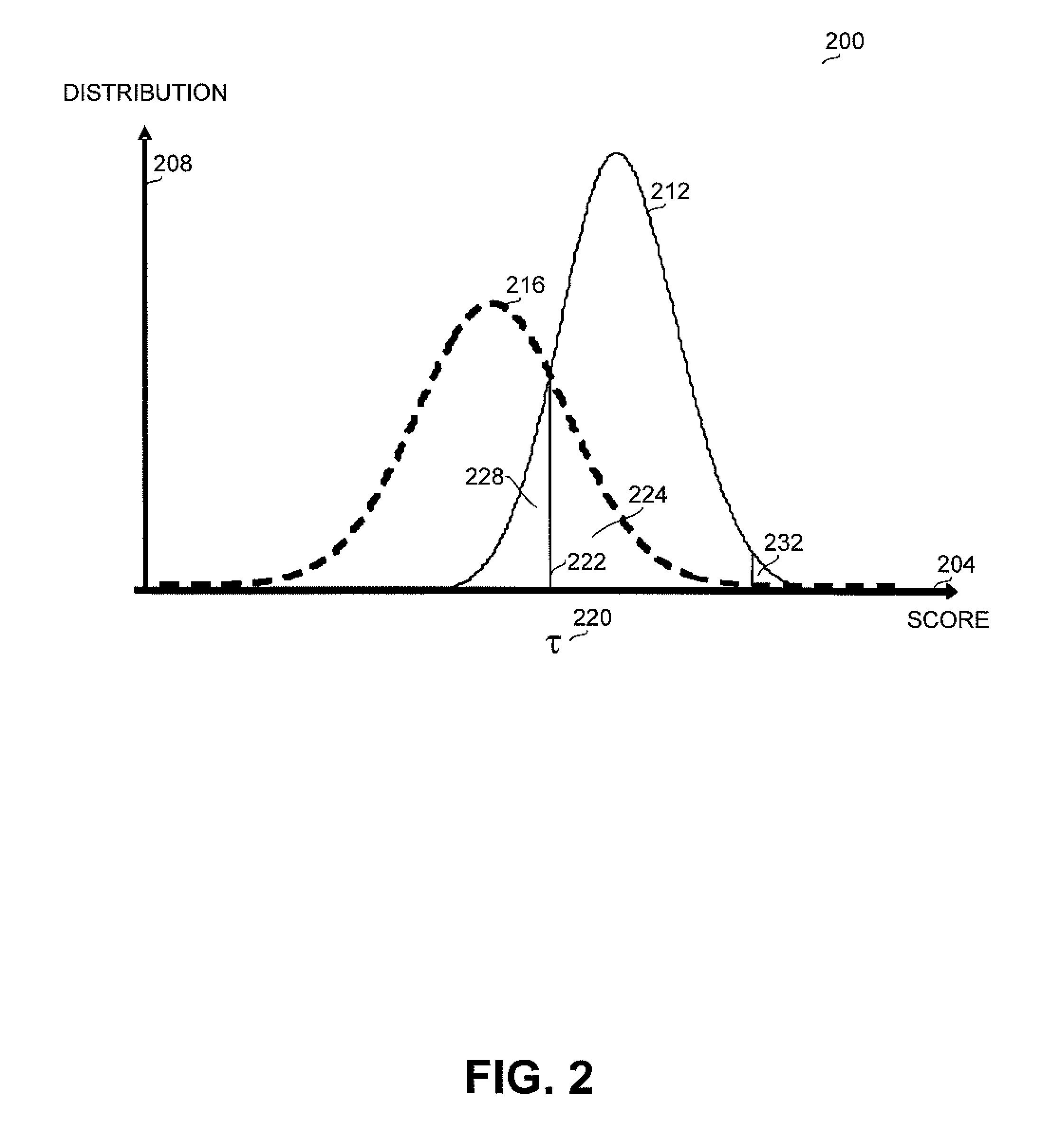

Method and apparatus for large population speaker identification in telephone interactions

A method and apparatus for determining whether a speaker uttering an utterance belongs to a predetermined set comprising known speakers, wherein a training utterance is available for each known speaker. The method and apparatus test whether features extracted from the tested utterance provide a score exceeding a threshold when matched against one or more of models constructed upon voice samples of each known speaker. The method and system further provide optional enhancements such as determining, using, and updating model normalization parameters, a fast scoring algorithm, summed calls handling, or quality evaluation for the tested utterance.

Owner:NICE SYSTEMS

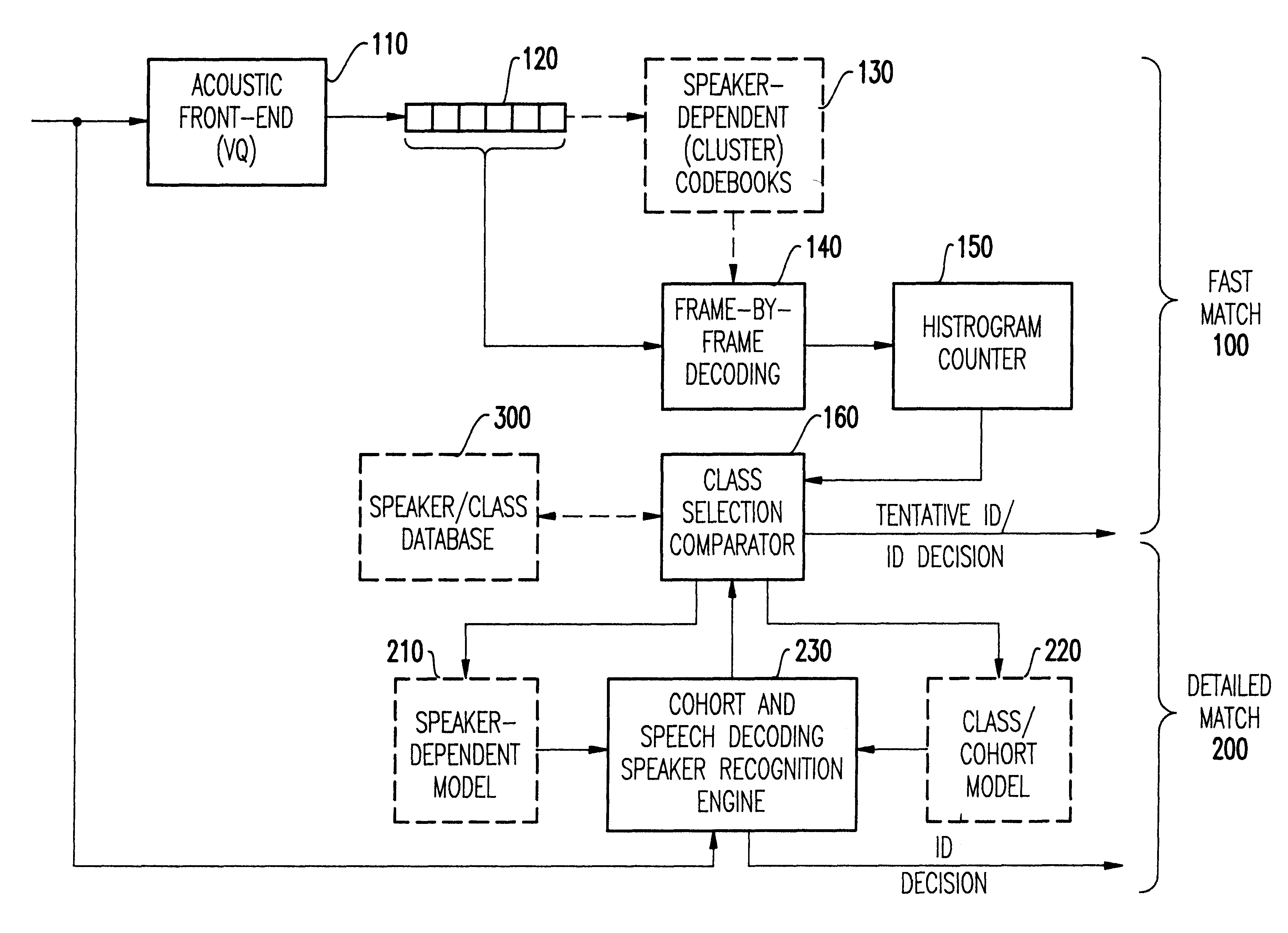

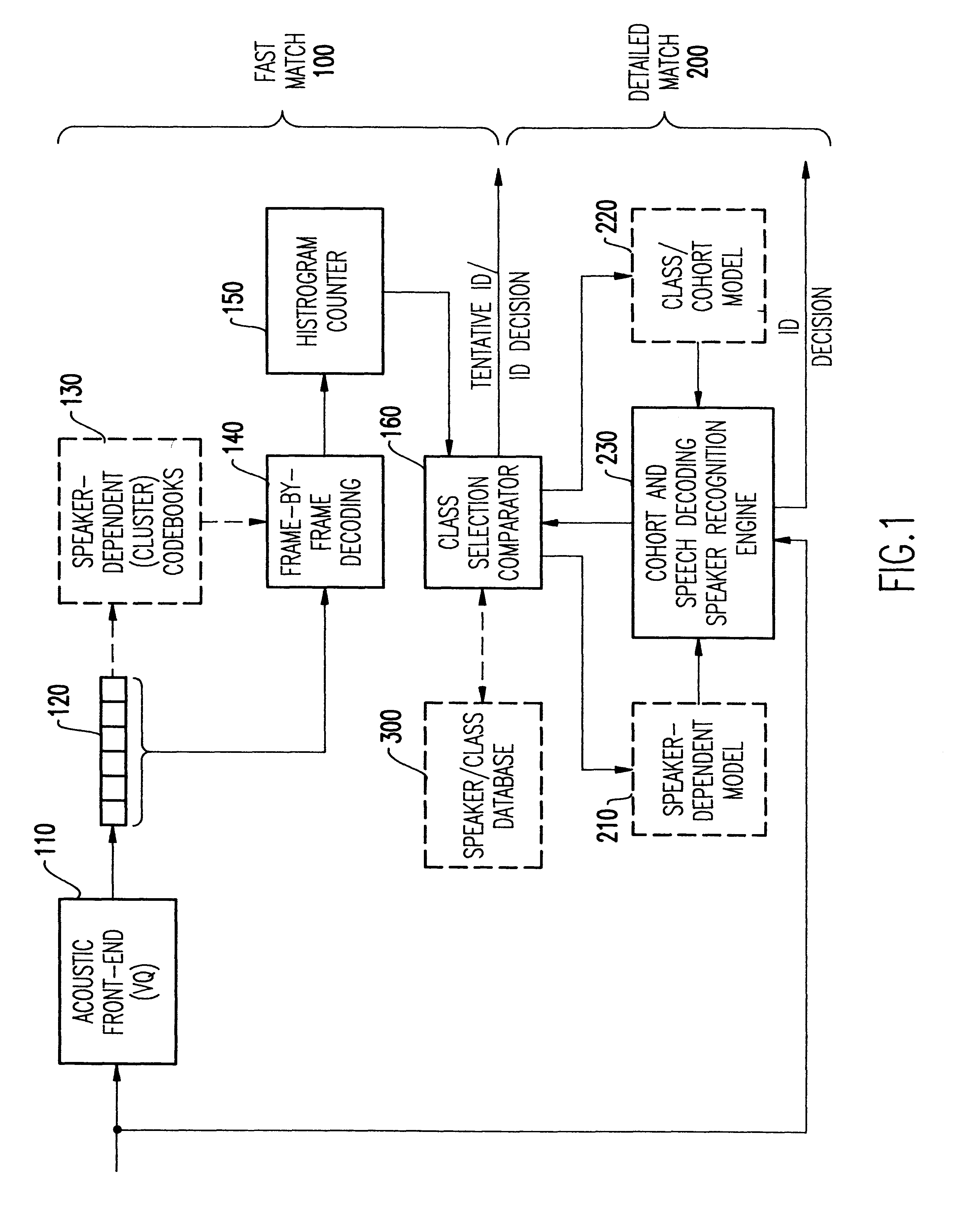

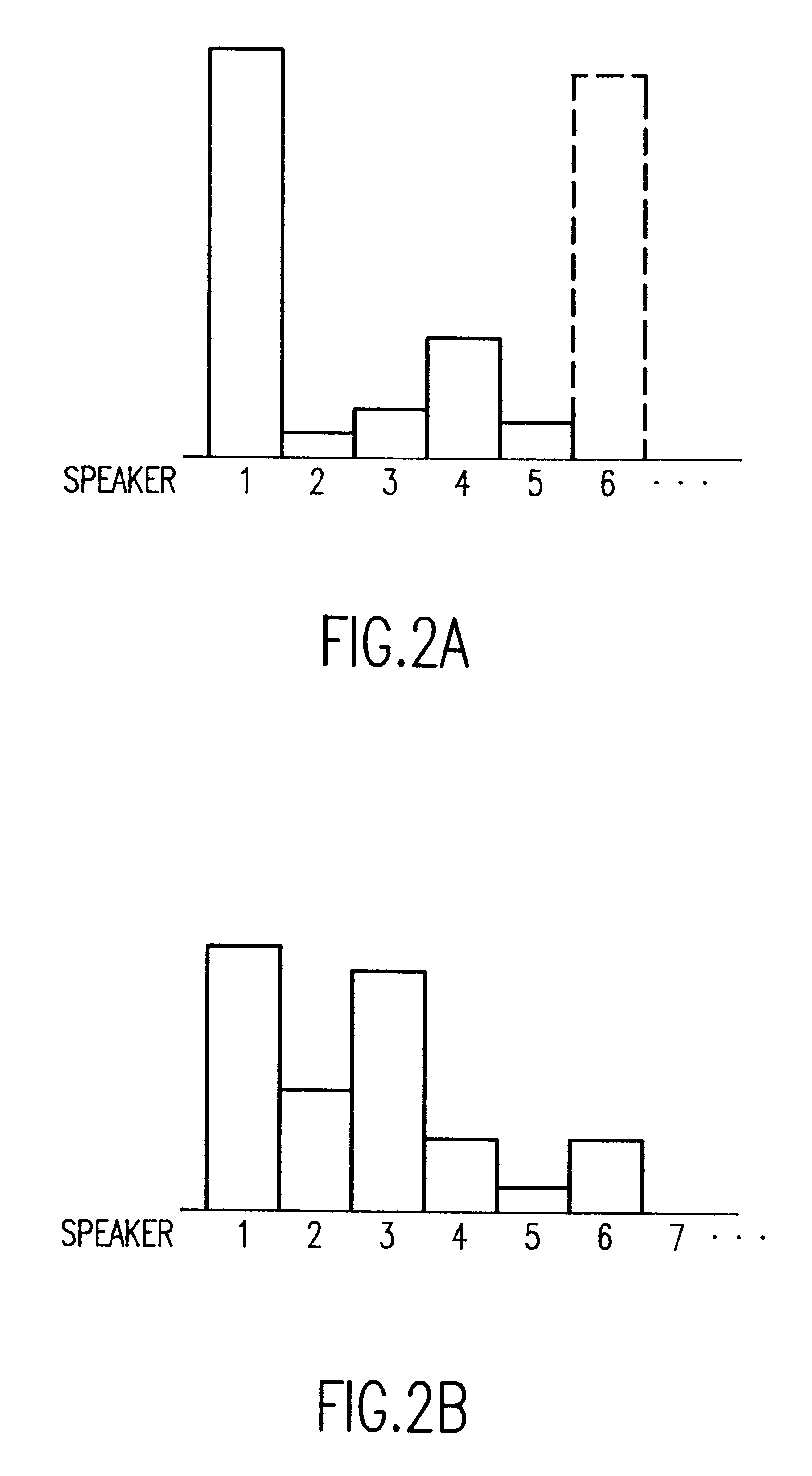

Speaker recognition over large population with fast and detailed matches

InactiveUS6182037B1Simple and rapid and transparent and text-independent enrollment procedureSpeed up the processSpeech recognitionHybrid systemConfusion

Fast and detailed match techniques for speaker recognition are combined into a hybrid system in which speakers are associated in groups when potential confusion is detected between a speaker being enrolled and a previously enrolled speaker. Thus the detailed match techniques are invoked only at the potential onset of saturation of the fast match technique while the detailed match is facilitated by limitation of comparisons to the group and the development of speaker-dependent models which principally function to distinguish between members of a group rather than to more fully characterize each speaker. Thus storage and computational requirements are limited and fast and accurate speaker recognition can be extended over populations of speakers which would degrade or saturate fast match systems and degrade performance of detailed match systems.

Owner:NUANCE COMM INC

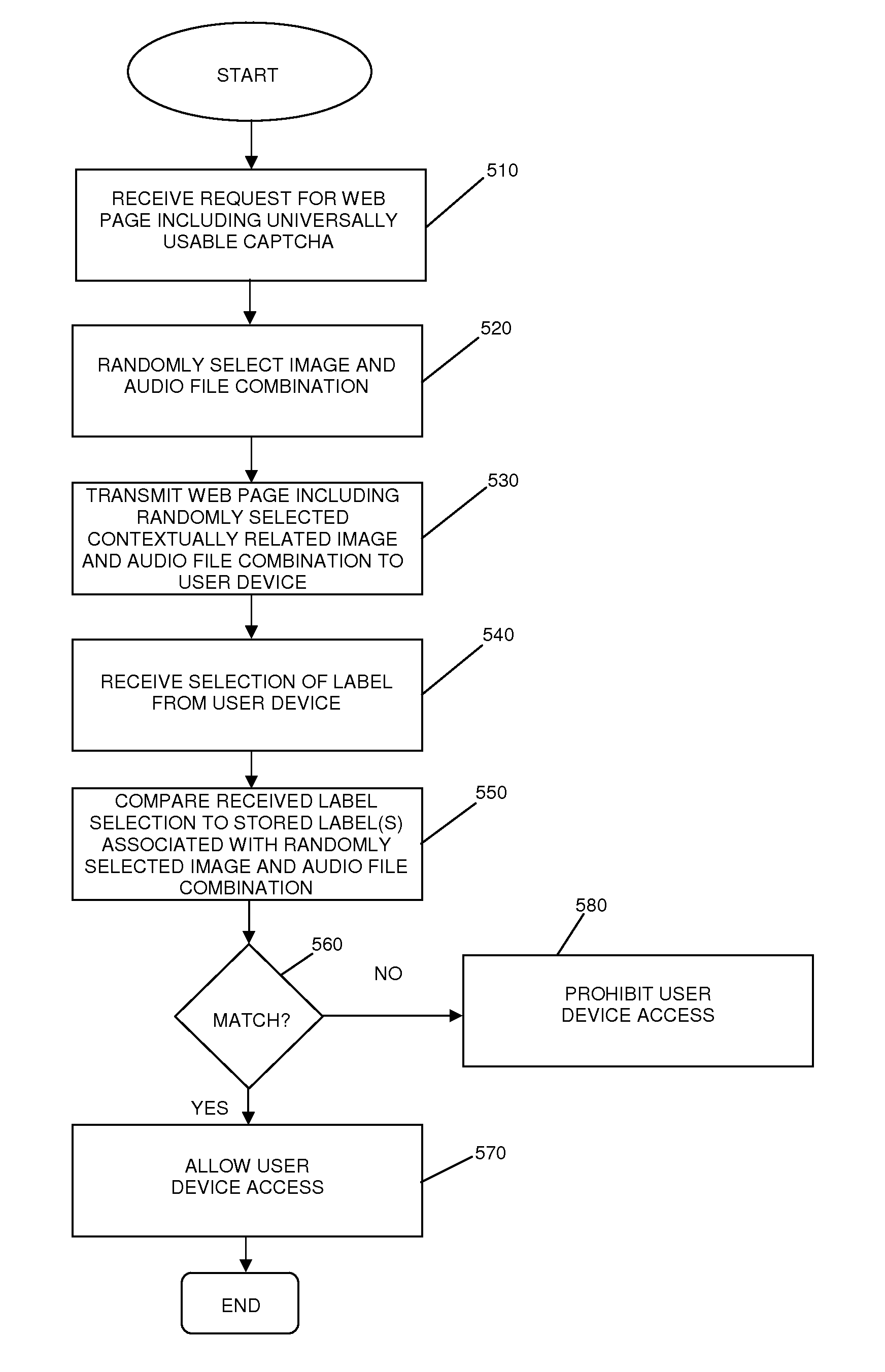

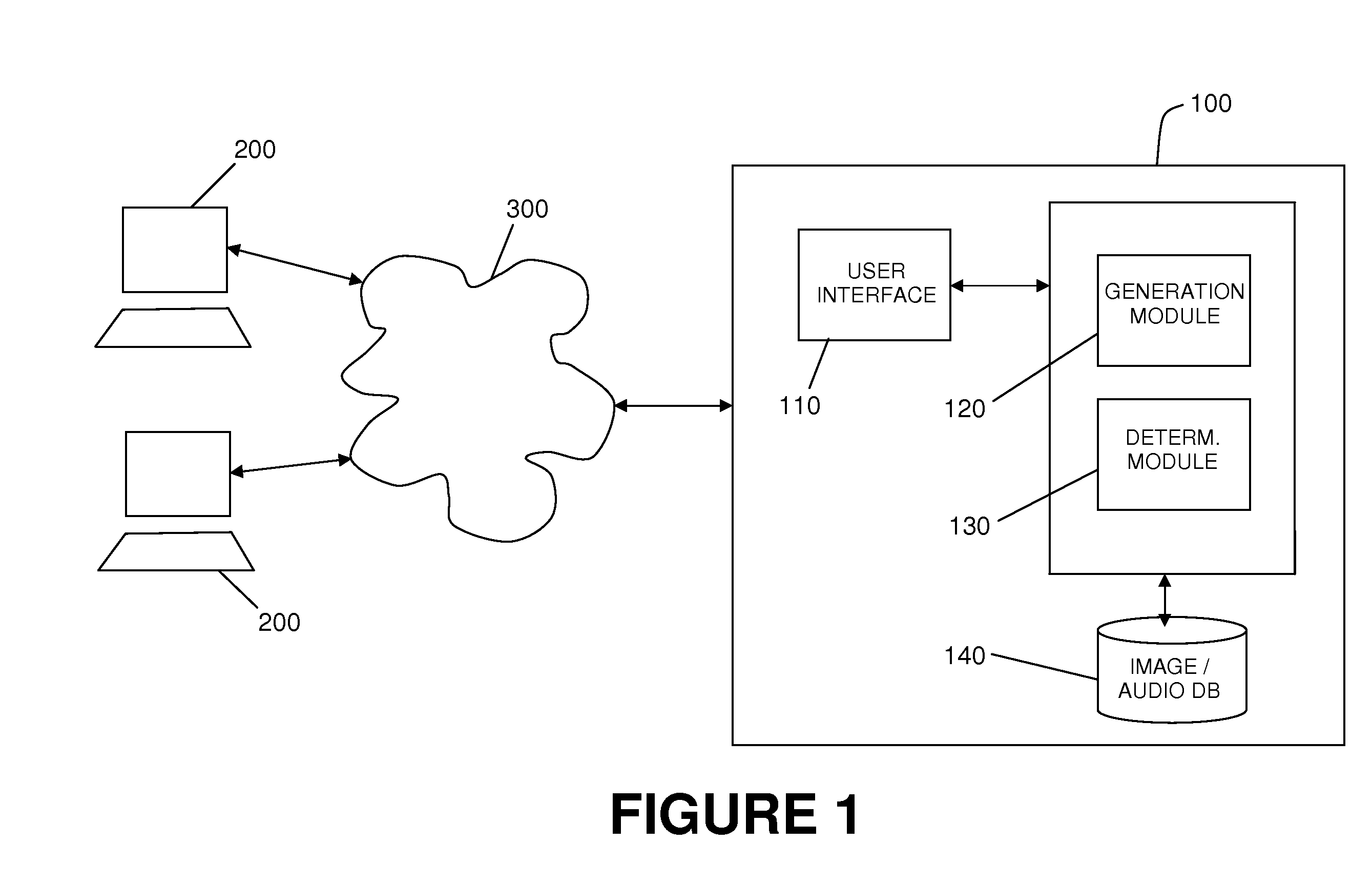

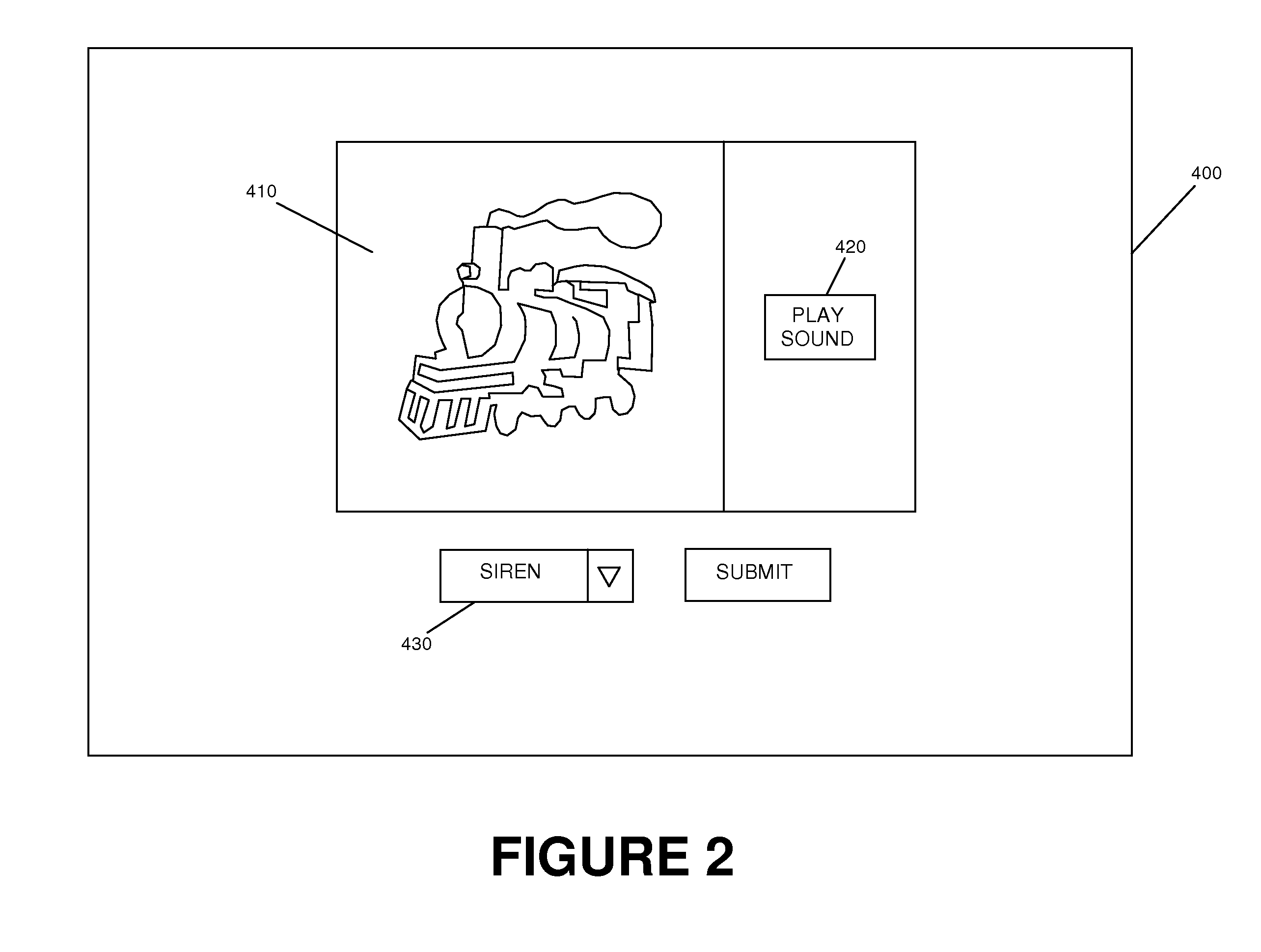

Universally usable human-interaction proof

InactiveUS20100095350A1Easy to adaptEasy to internationalizeDigital data processing detailsMultiple digital computer combinationsHuman interactionInternet privacy

Disclosed is a system and method for generating a universally usable, completely automated public turing test to tell a computer and a human apart (CAPTCHA). The universally usable CAPTCHA uses contextually related pictures and sounds to present concepts to a user. The pictures allow the CAPTCHA to be used by someone who could see, and the audio would allow the CAPTCHA to be used by someone who could not see. This combination of sound and images should make the CAPTCHA more universally usable for a larger population of users than previously known CAPTCHAs.

Owner:TOWSON UNIVERSITY

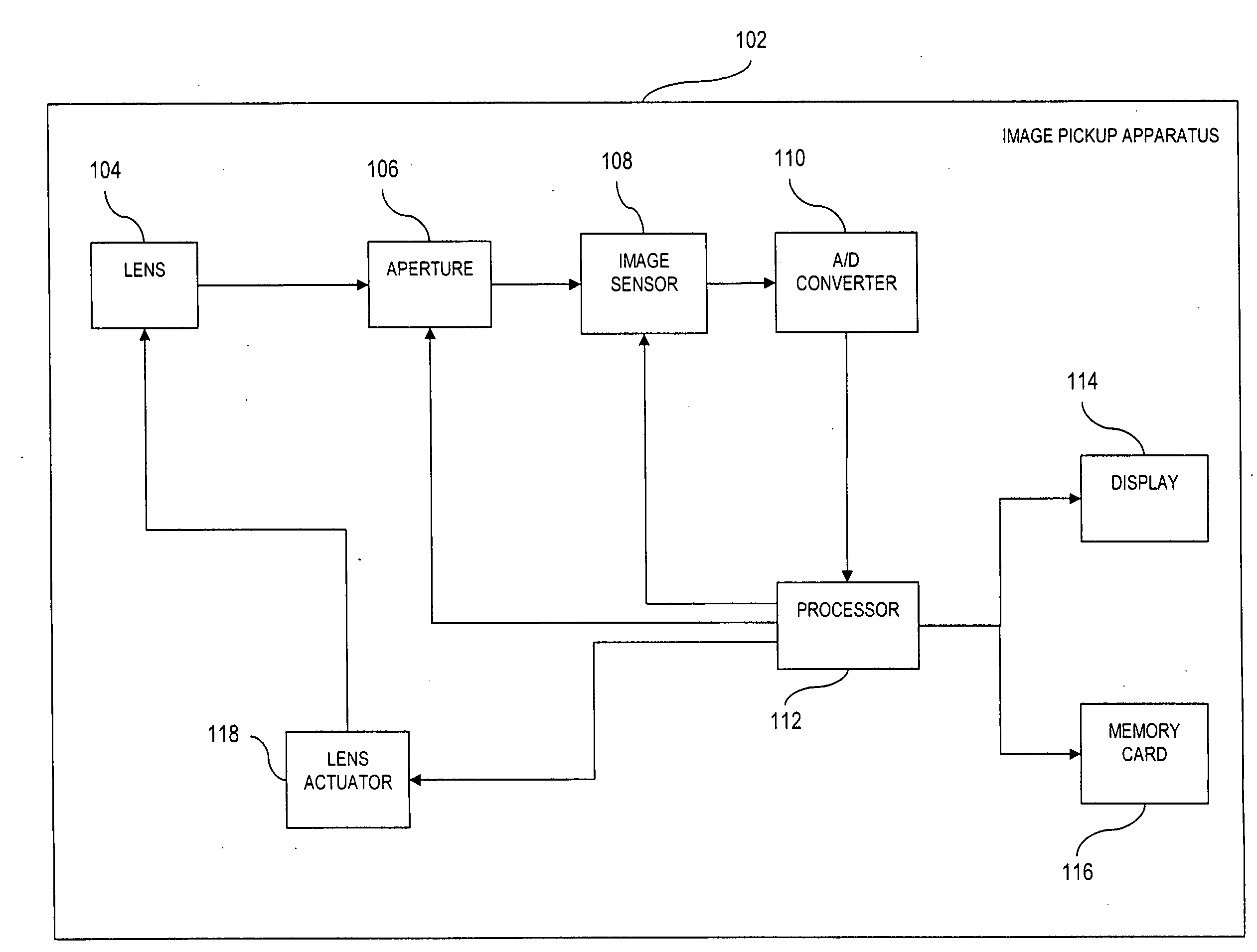

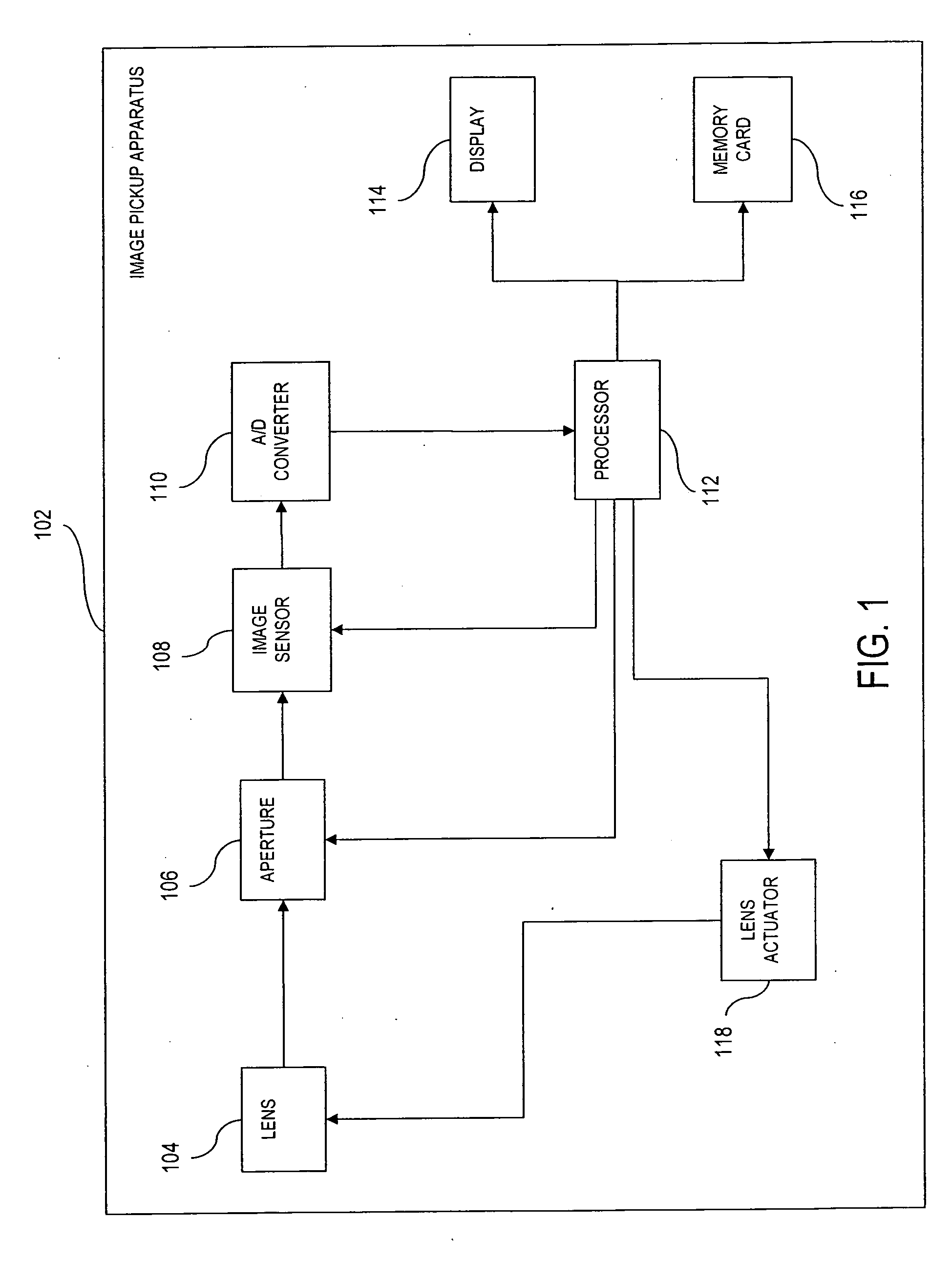

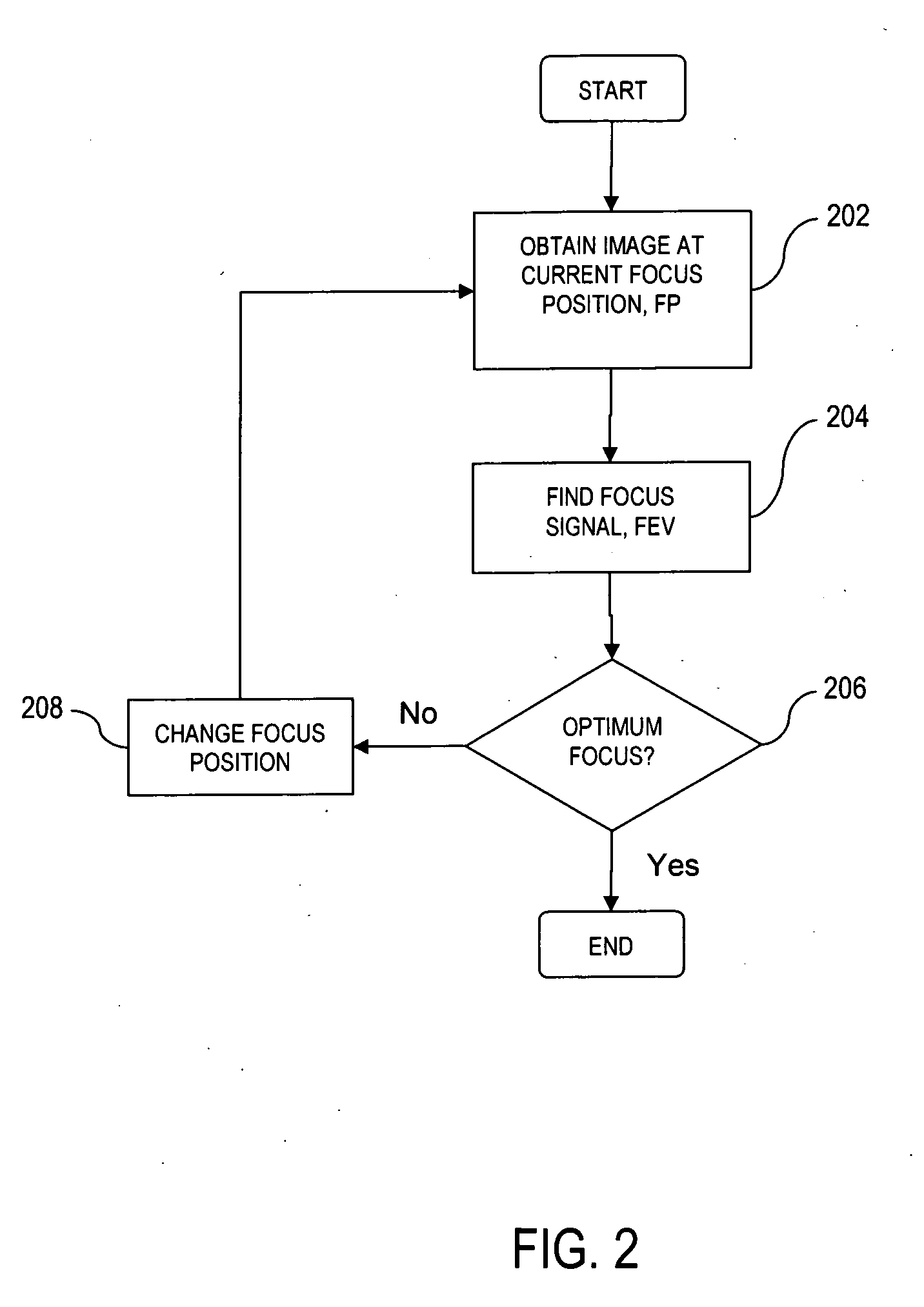

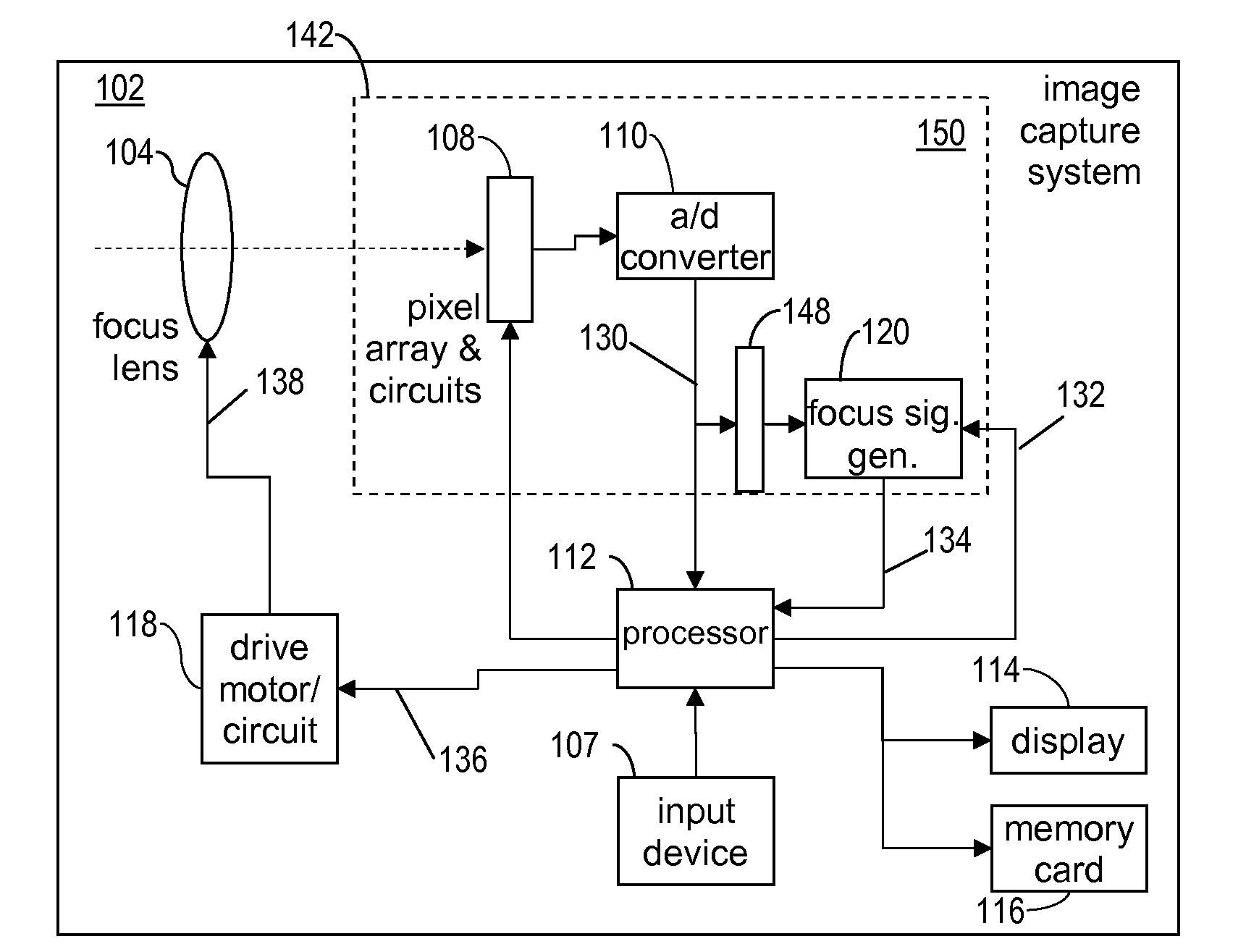

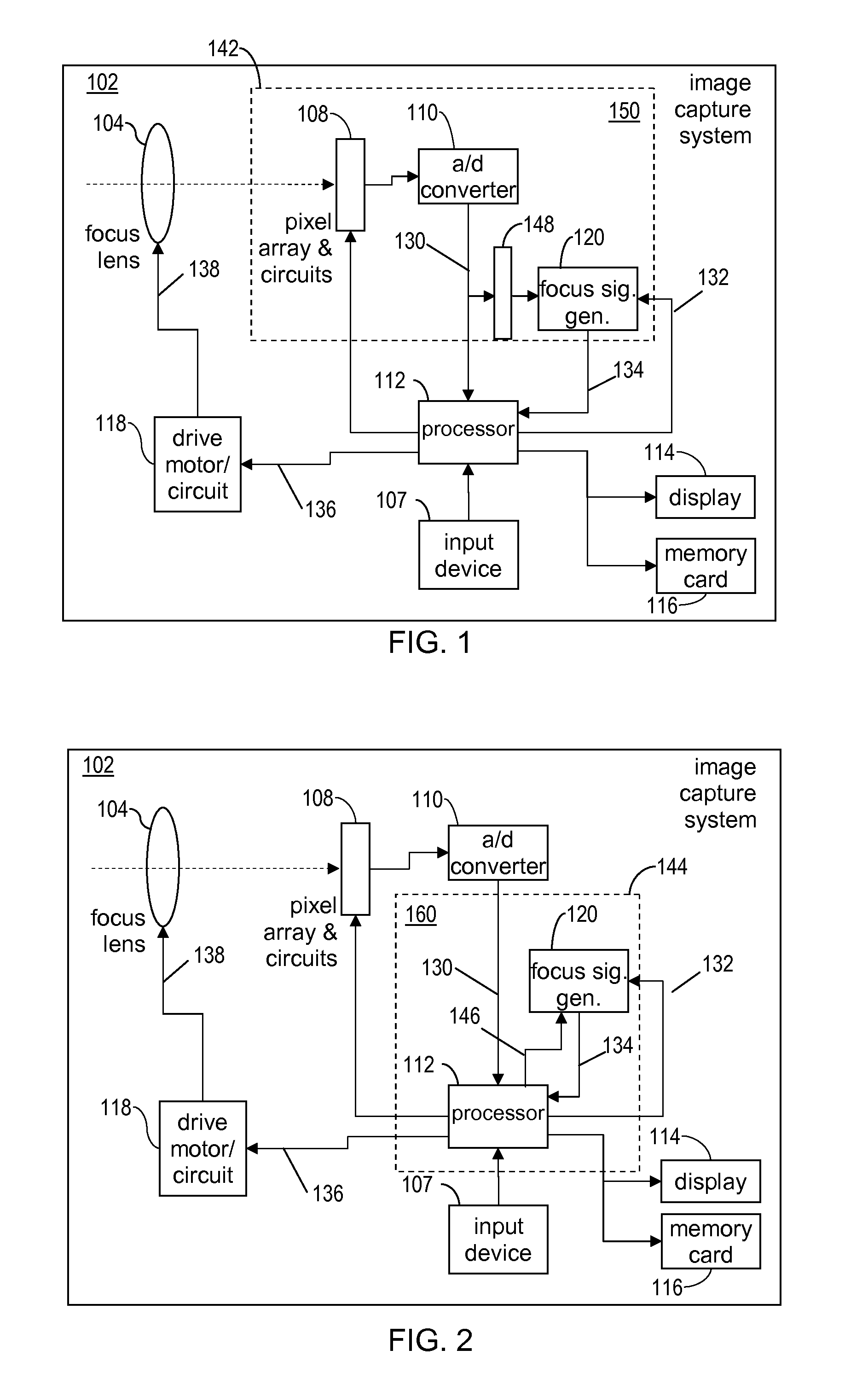

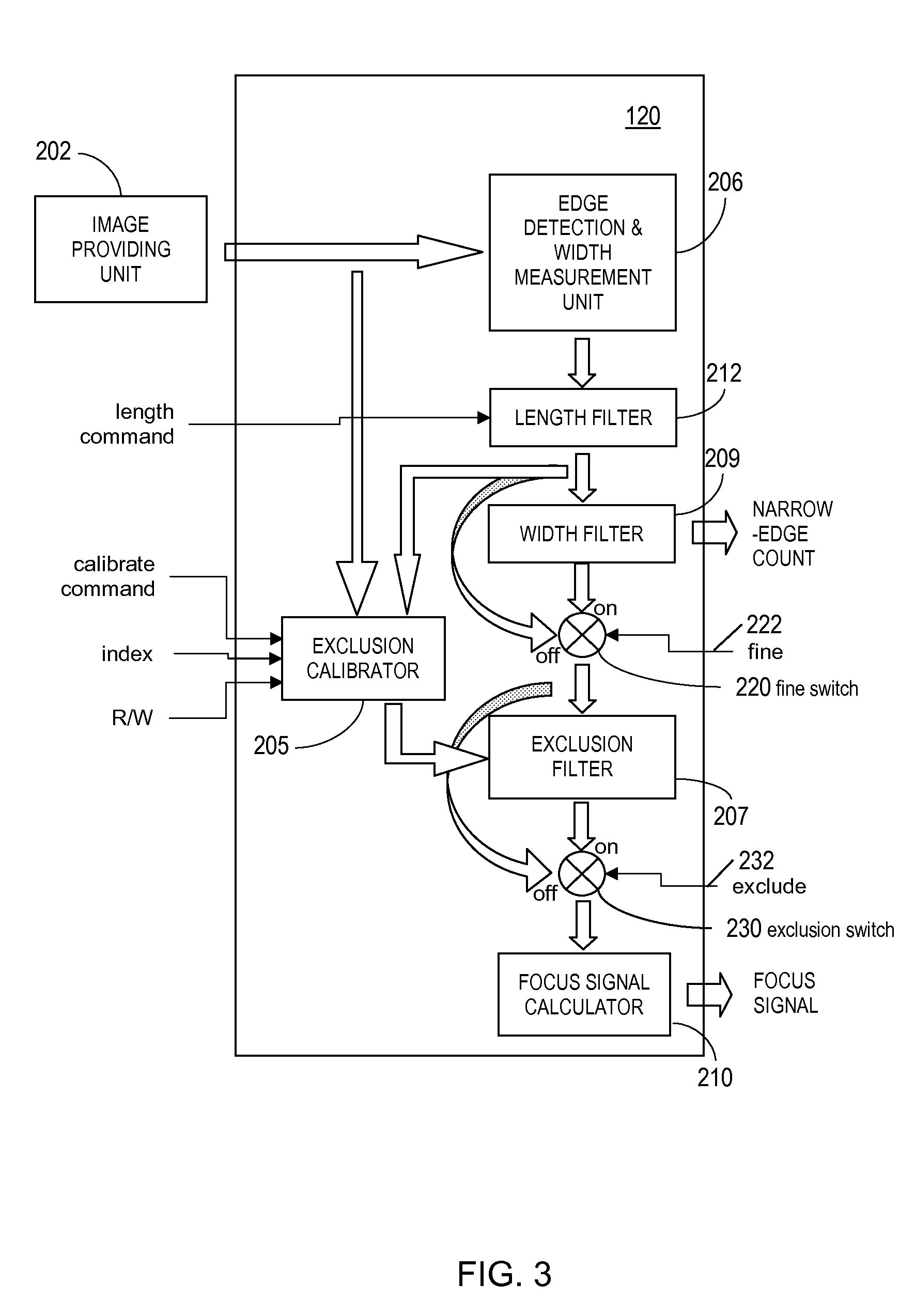

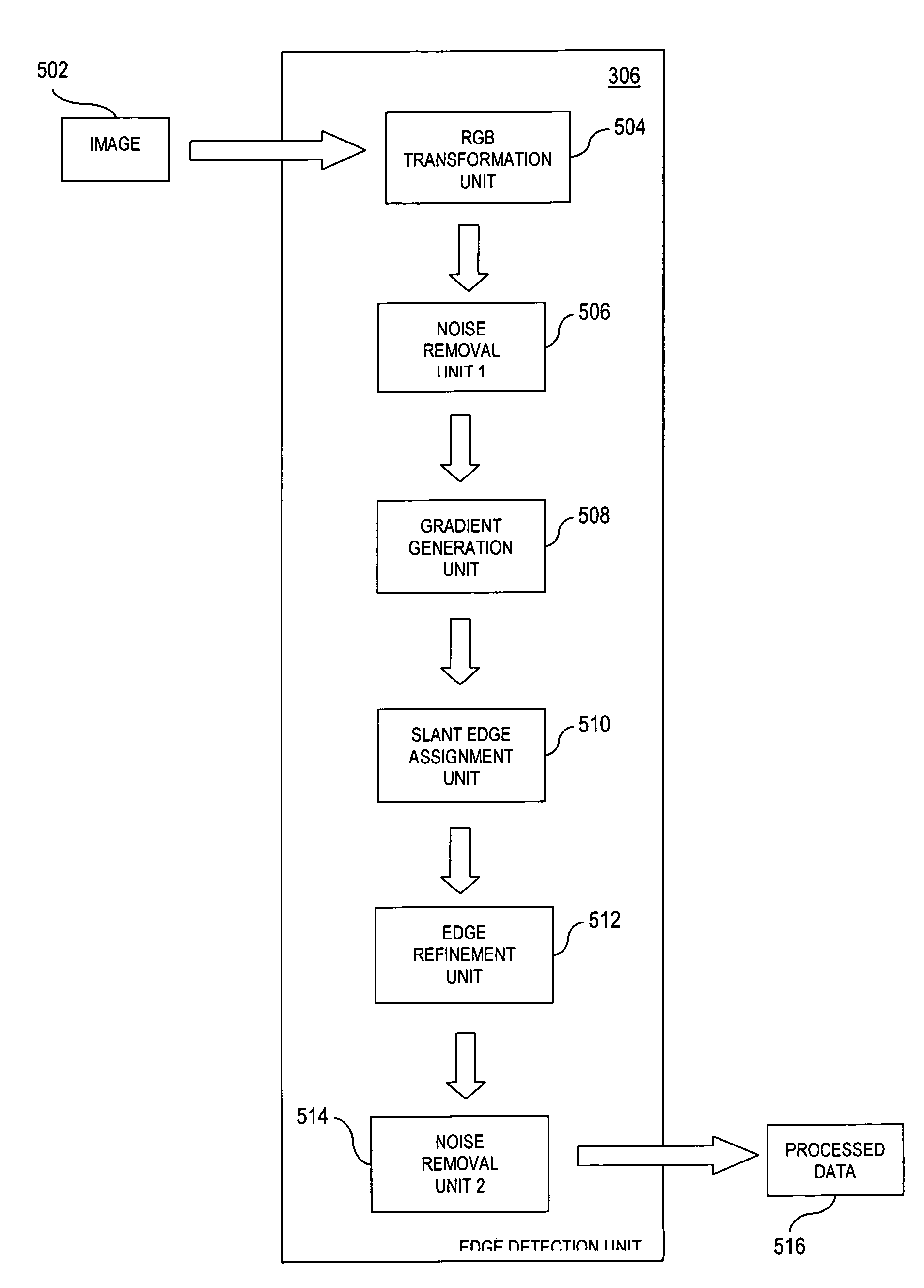

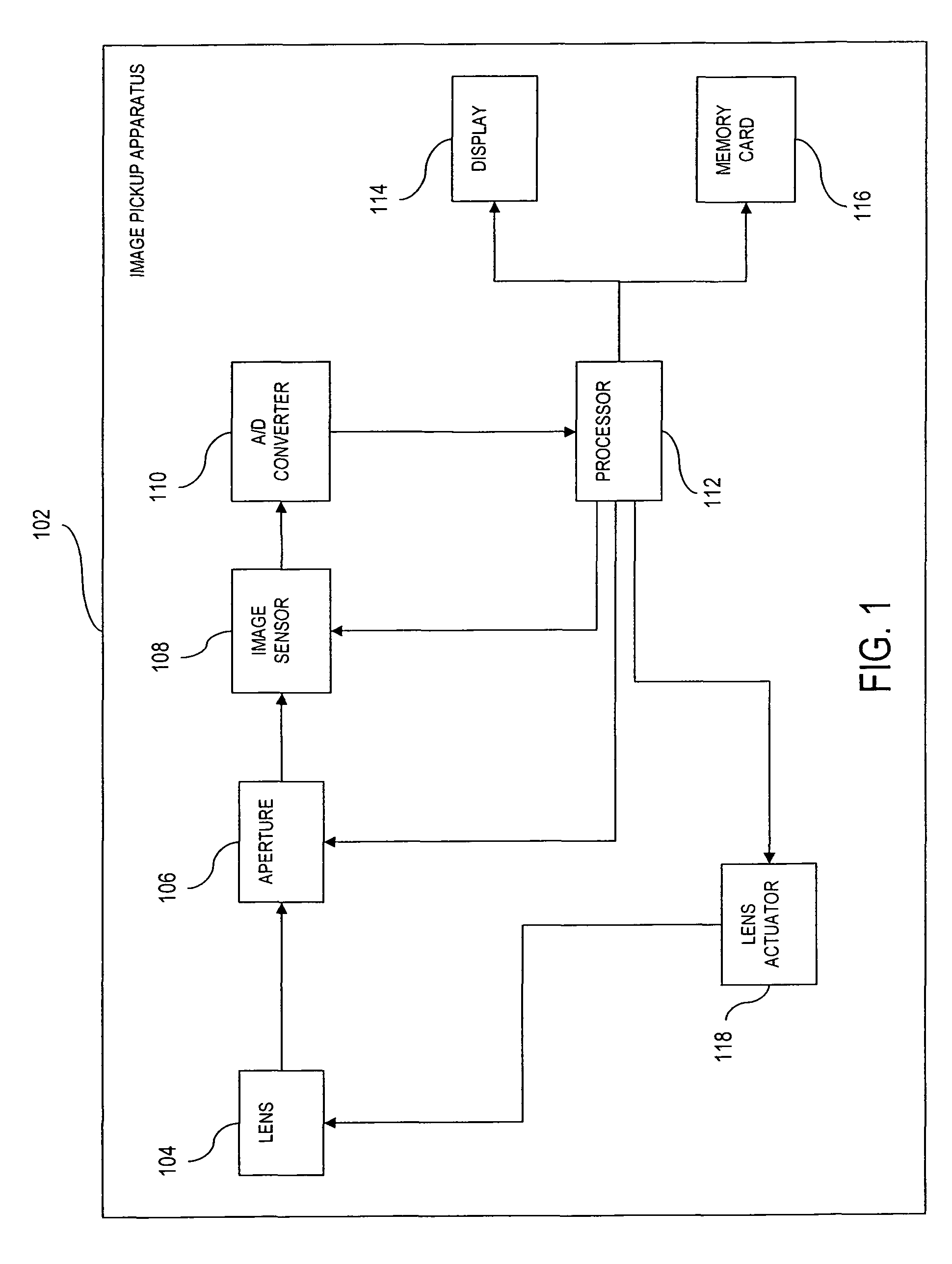

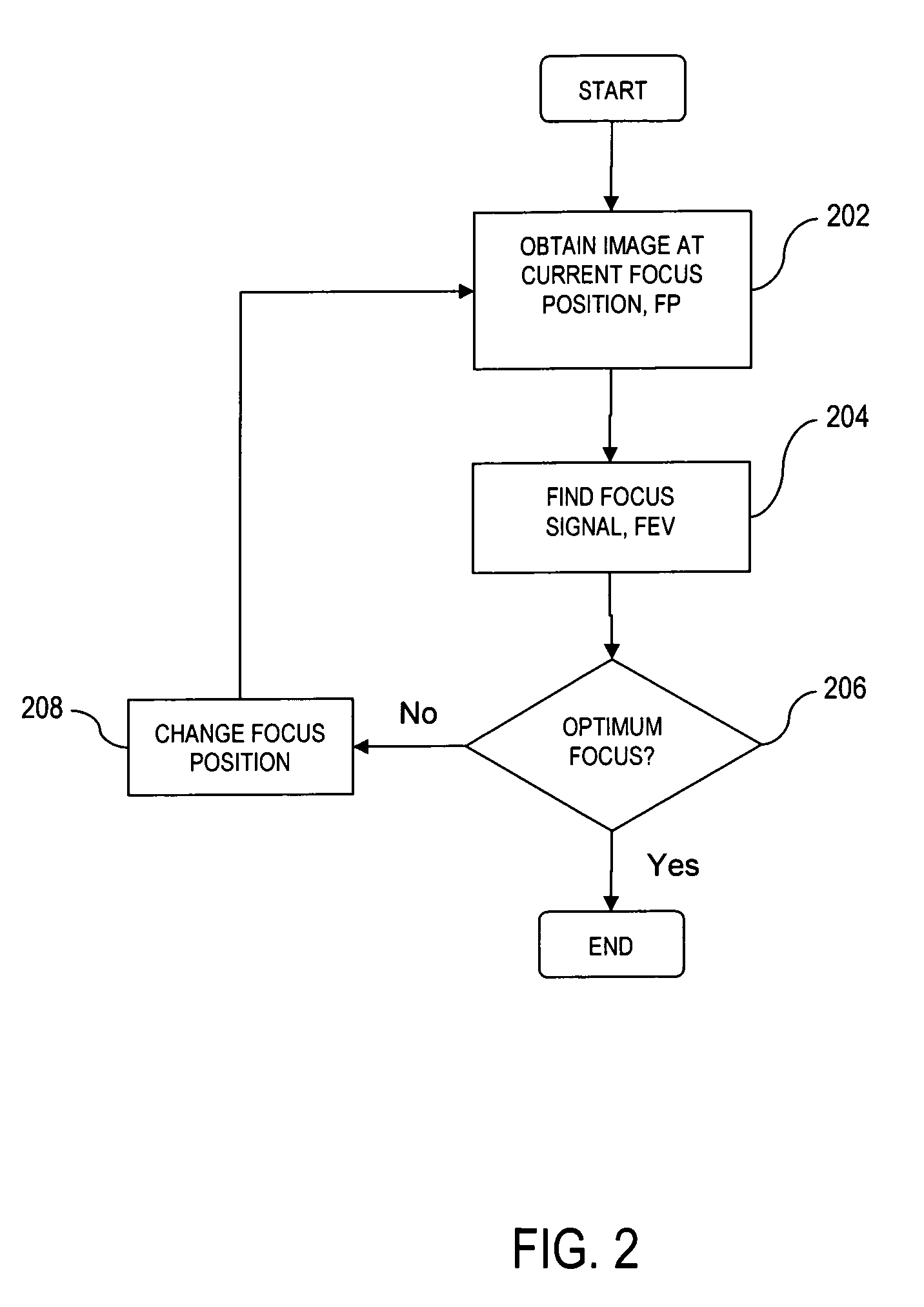

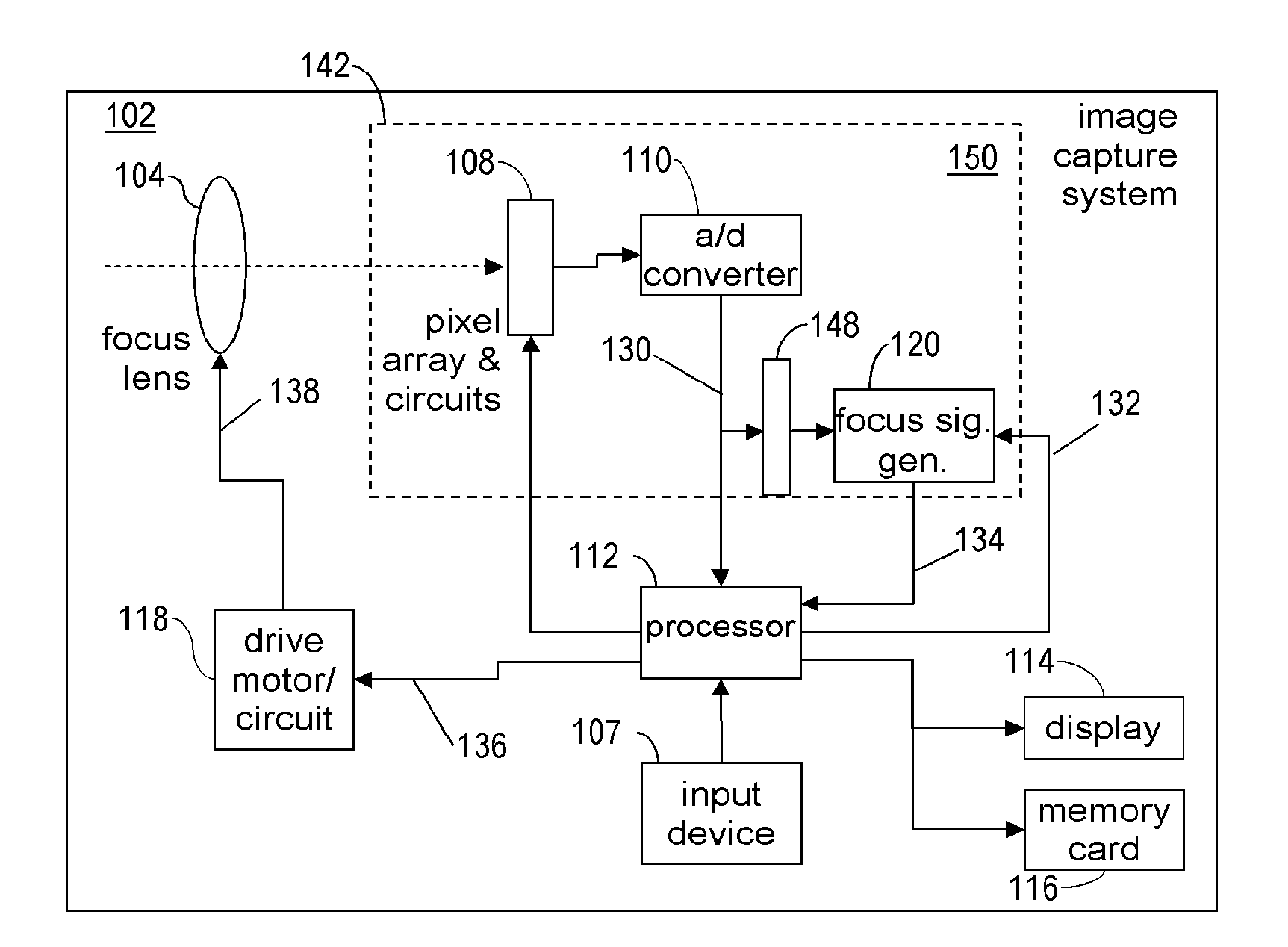

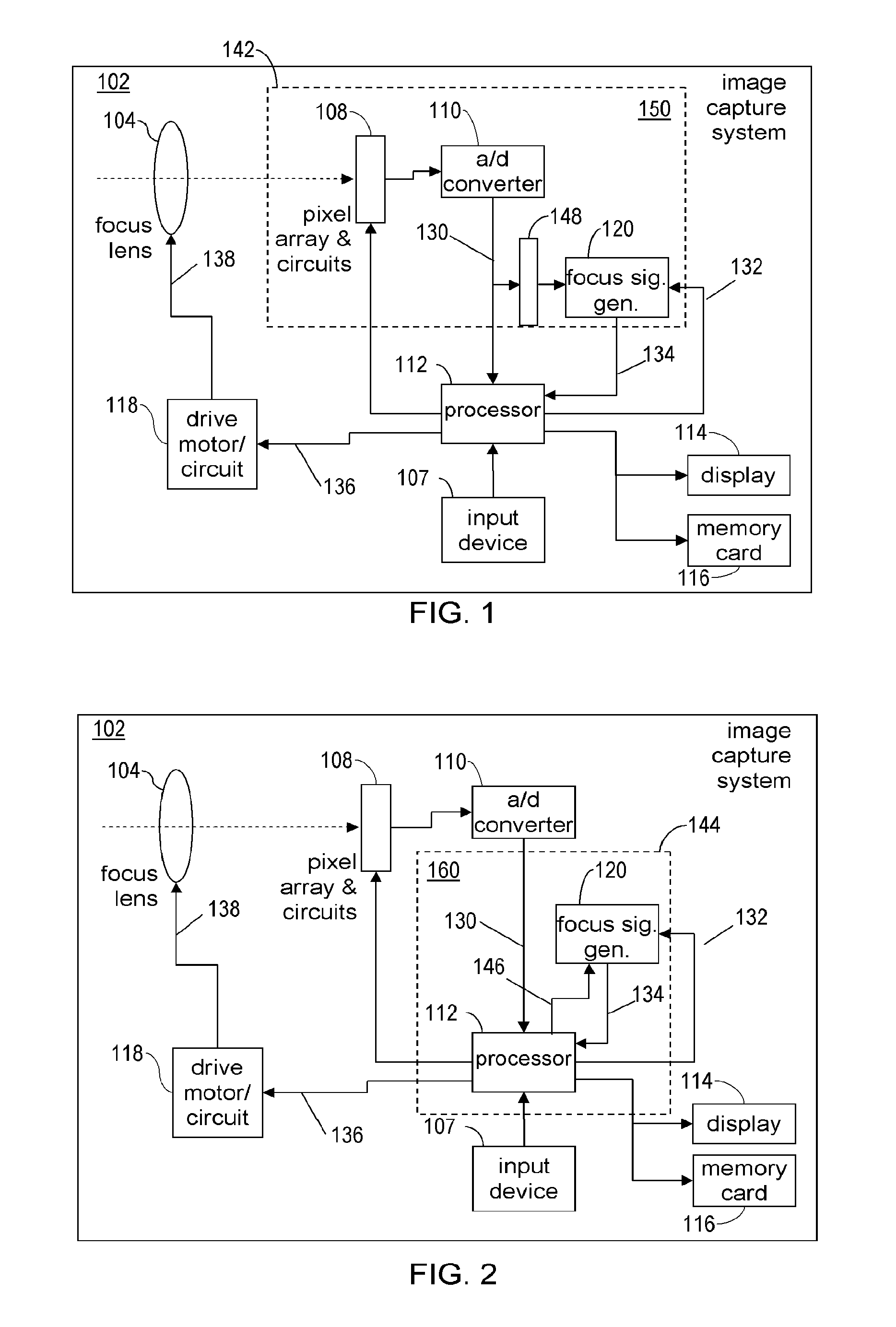

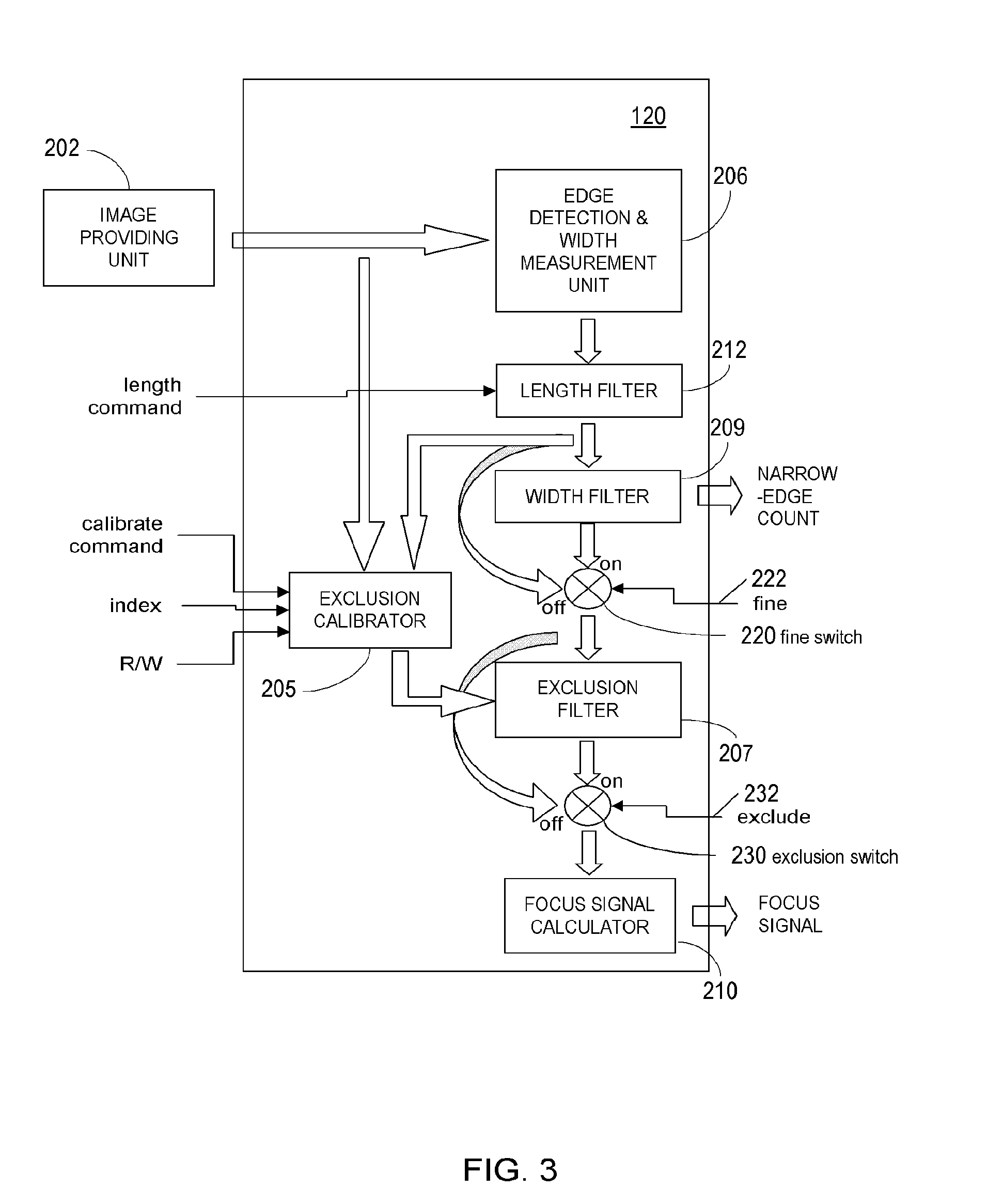

Auto-focus image system

An auto focus image system that includes an image sensor coupled to a controller. The image sensor captures an image that has at least one edge with a width. The controller generates a focus signal that is a function of the edge width. A lens receives the focus signal and adjust a focus. The edge width can be determined by various techniques including the use of gradients. A histogram of edge widths can be used to determine whether a particular image is focused or unfocused. A histogram with a large population of thin edge widths is indicative of a focused image.

Owner:CANDELA MICROSYST S PTE

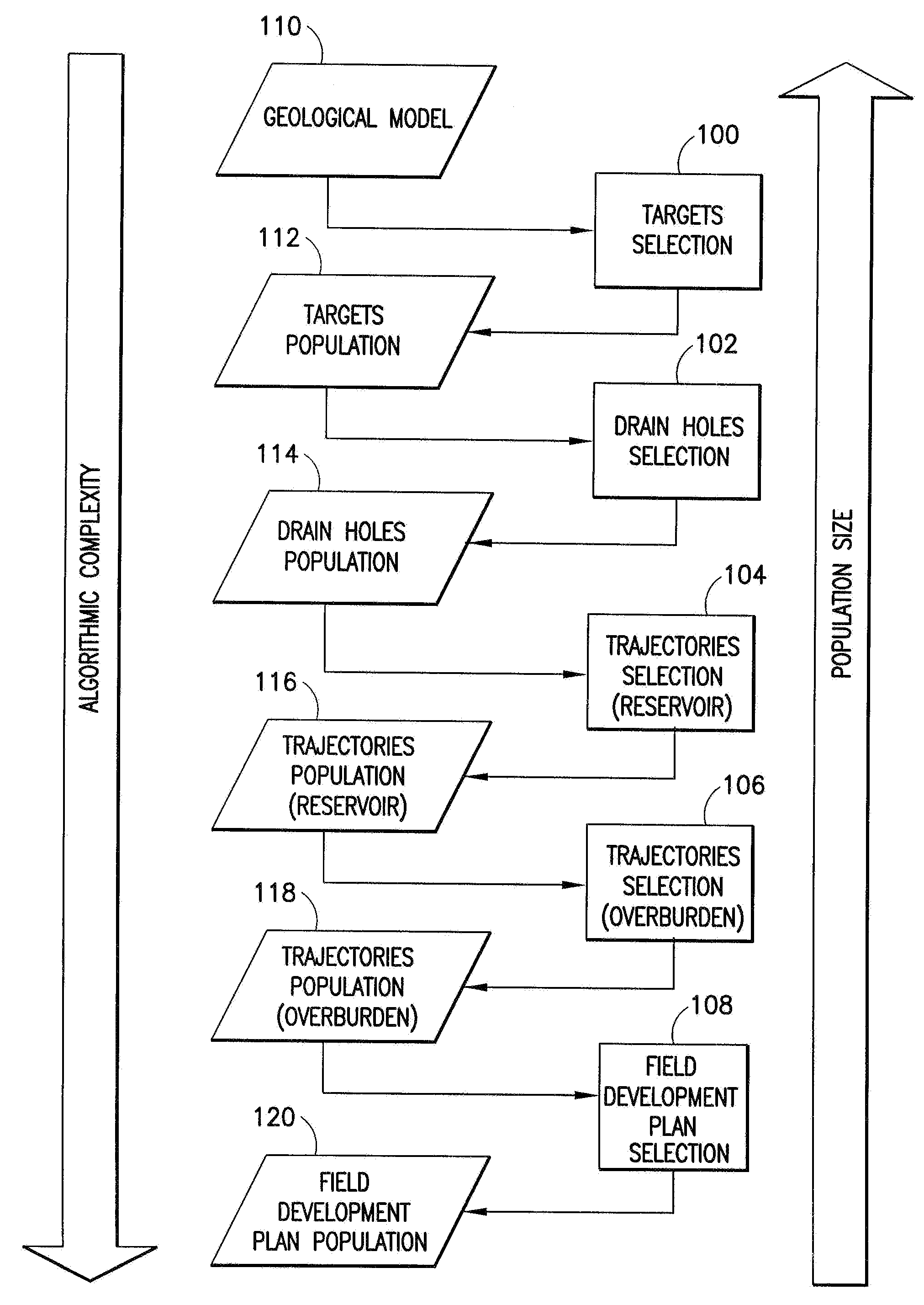

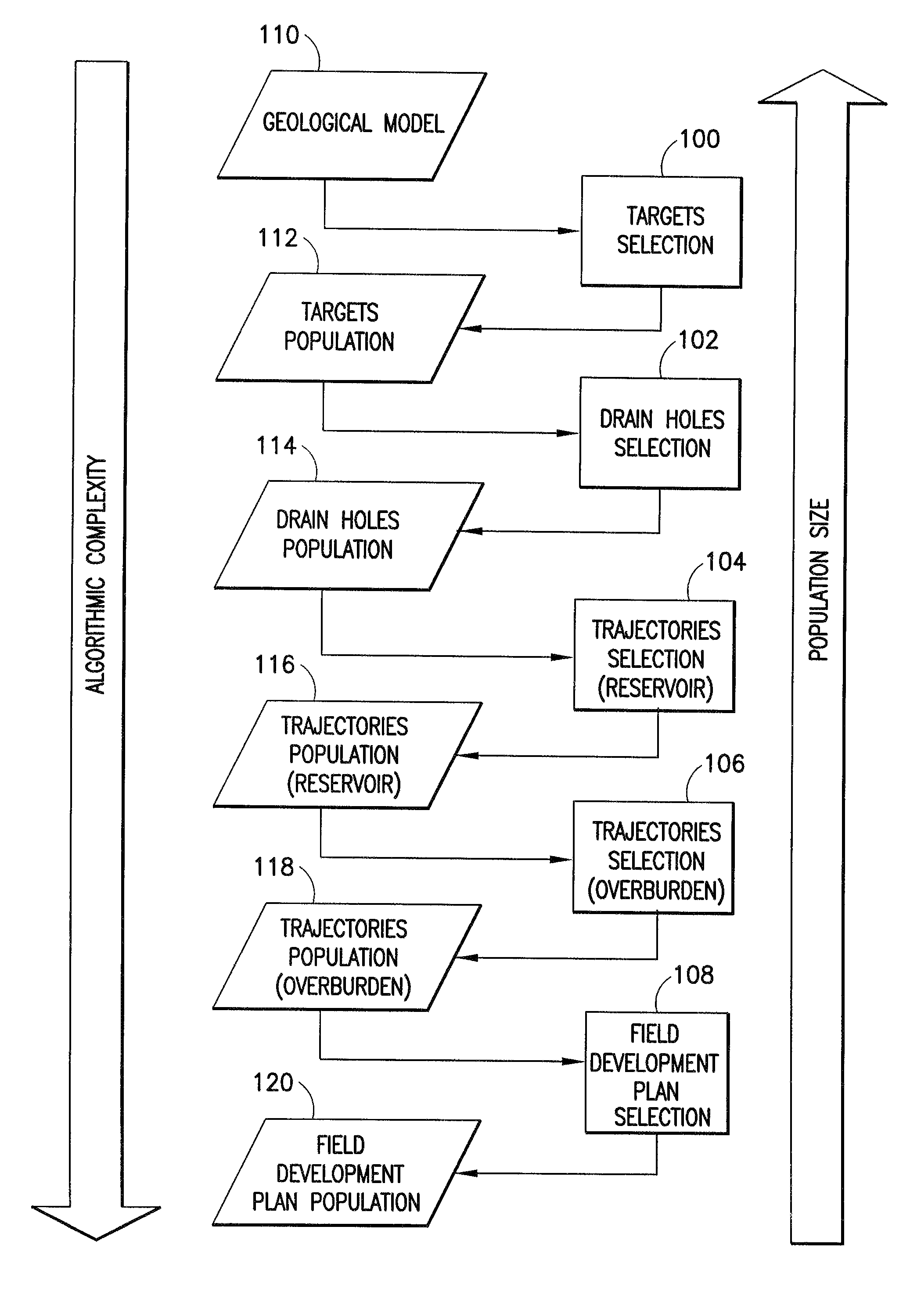

Automated field development planning of well and drainage locations

ActiveUS20080300793A1Reduce in quantityLess timeElectric/magnetic detection for well-loggingFluid removalPopulation sizeTool use by animals

A hybrid evolutionary algorithm (“HEA”) technique is described for automatically calculating well and drainage locations in a field. The technique includes planning a set of wells on a static reservoir model using an automated well planner tool that designs realistic wells that satisfy drilling and construction constraints. A subset of these locations is then selected based on dynamic flow simulation using a cost function that maximizes recovery or economic benefit. In particular, a large population of candidate targets, drain holes and trajectories is initially created using fast calculation analysis tools of cost and value, and as the workflow proceeds, the population size is reduced in each successive operation, thereby facilitating use of increasingly sophisticated calculation analysis tools for economic valuation of the reservoir while reducing overall time required to obtain the result. In the final operation, only a small number of full reservoir simulations are required for the most promising FDPs.

Owner:SCHLUMBERGER TECH CORP

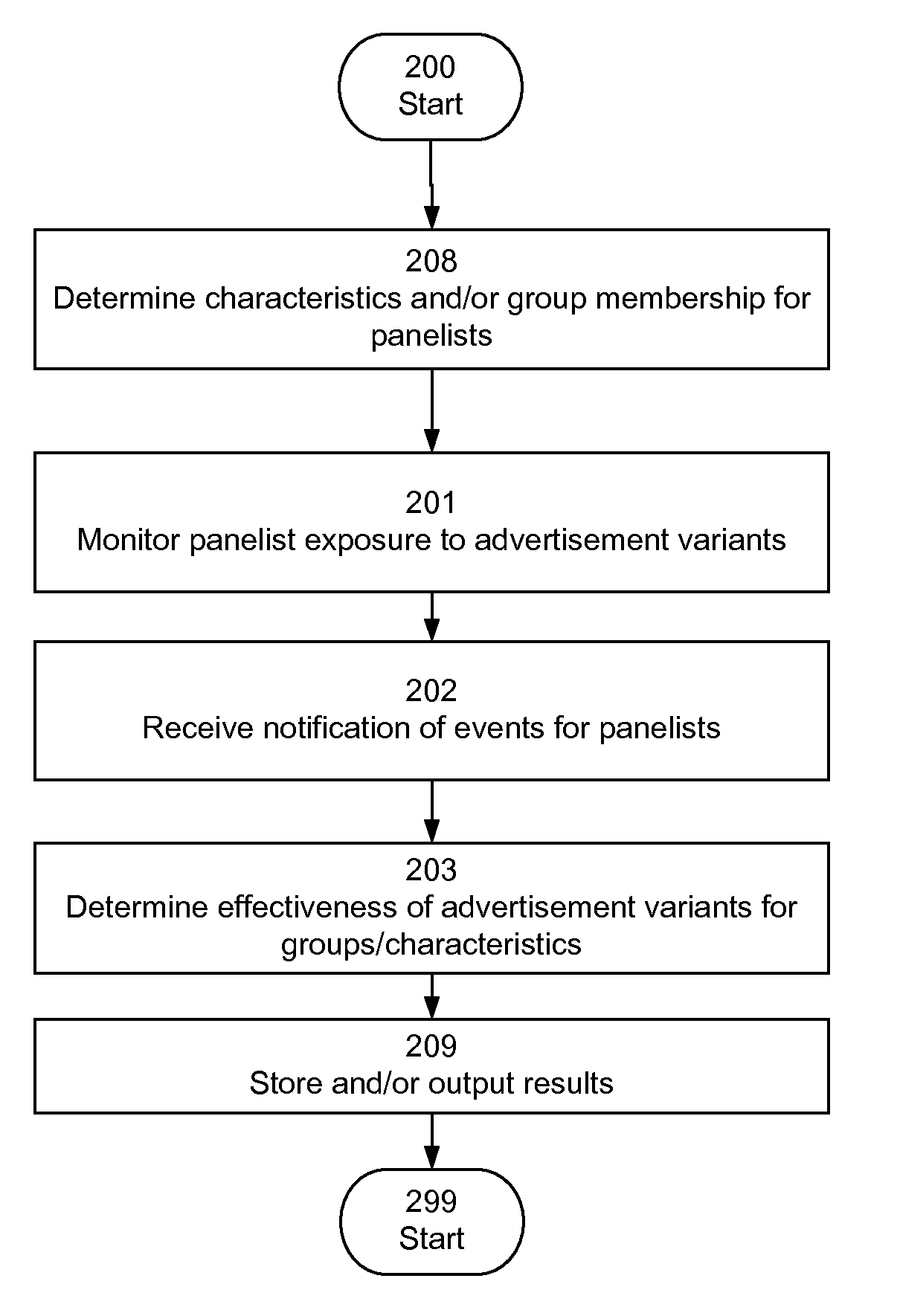

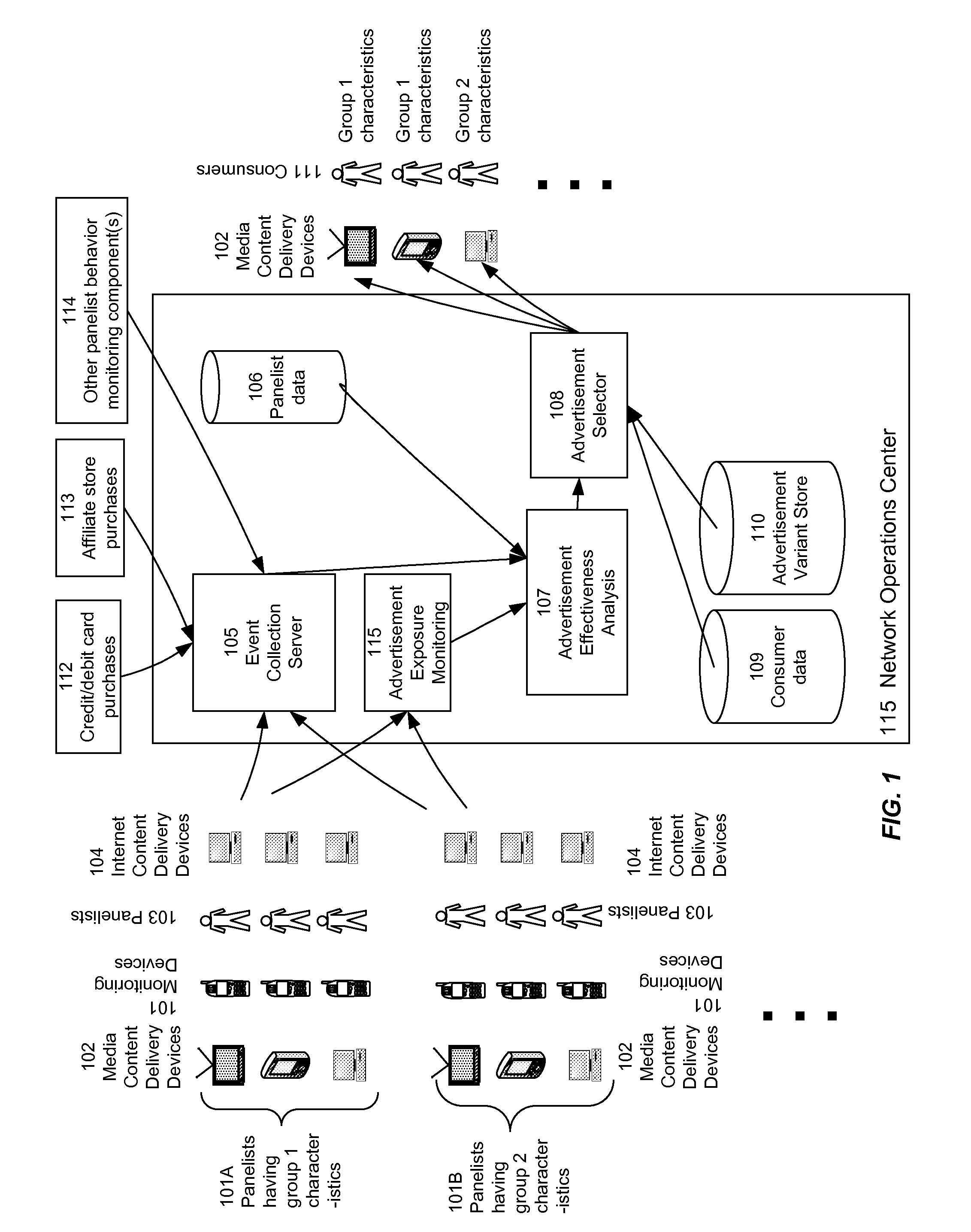

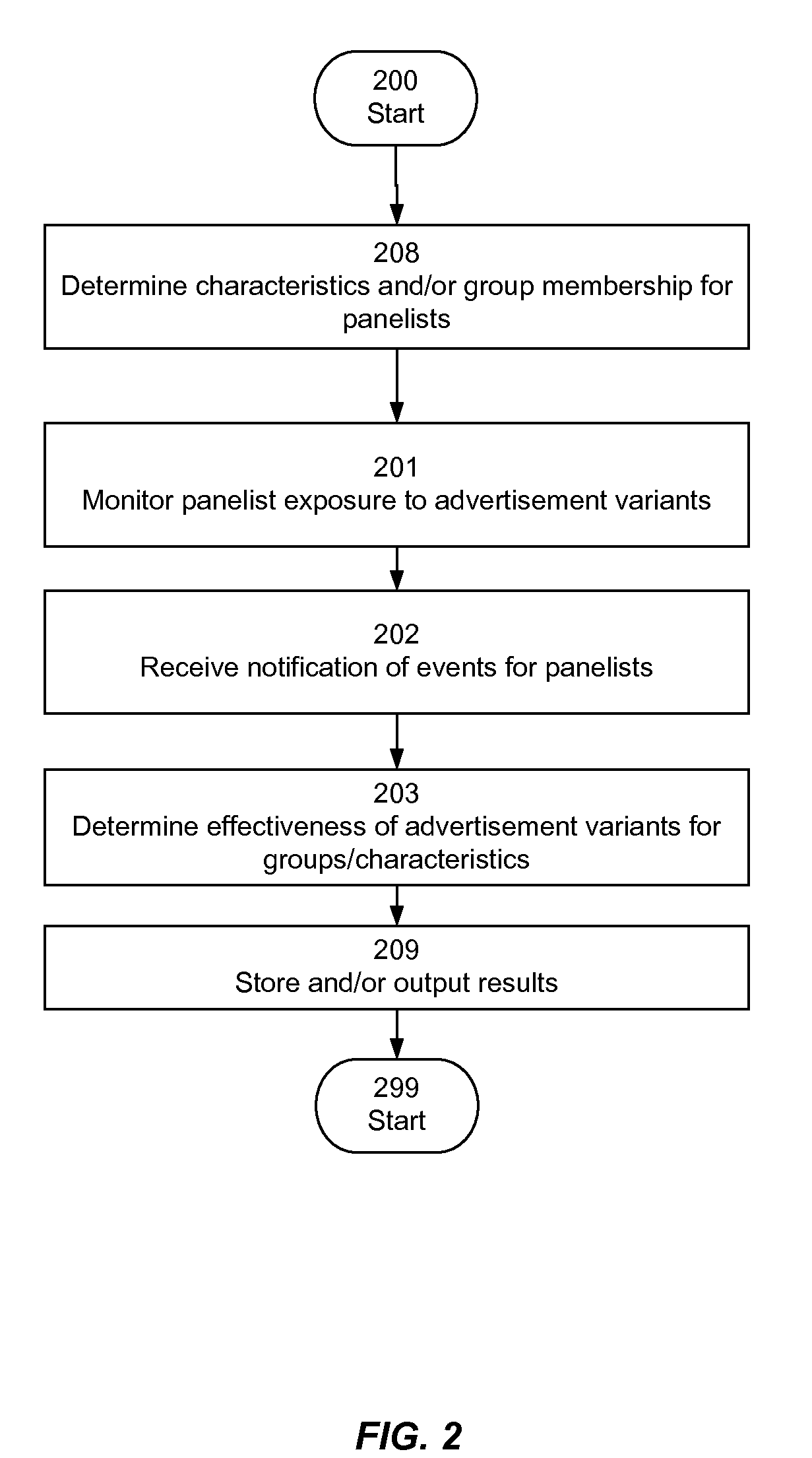

Determining Relative Effectiveness Of Media Content Items

ActiveUS20100114668A1Maximize effectivenessImprove efficiencyMarketingRelative validityComputer science

The effectiveness of advertisements with respect to a group of panelists is measured. Based on the results of such analysis, advertisements and / or variants thereof are selected for presentation to consumers. Effectiveness of advertisements is measured, in one embodiment, by detecting exposure to advertisements, and then monitoring panelist behavior following exposure to an advertisement. In one embodiment, the group of panelists is a representative sample of a larger population, so that observations of panelist behavior can be used as a basis for making decisions regarding presentation of advertisements to a larger audience having characteristics similar to those of the panelists.Once the relative effectiveness for various audiences has been determined, advertisements can be selected for presentation to individual consumers or to groups of consumers, so as to maximize effectiveness. In one embodiment, such analysis and selection is performed substantially in real-time.

Owner:THE NIELSEN CO (US) LLC

Auto-focus image system

An auto focus image system that includes a pixel array coupled to a focus signal generator. The pixel array captures an image that has at least one edge with a width. The focus signal generator may generate a focus signal that is a function of the edge width and / or statistics of edge widths. A processor receives the focus signal and / or the statistics of edge widths and adjust a focus position of a focus lens. The edge width can be determined by various techniques including the use of gradients. A histogram of edge widths may be used to determine whether a particular image is focused or unfocused. A histogram with a large population of thin edge widths is indicative of a focused image.

Owner:TAY HIOK NAM

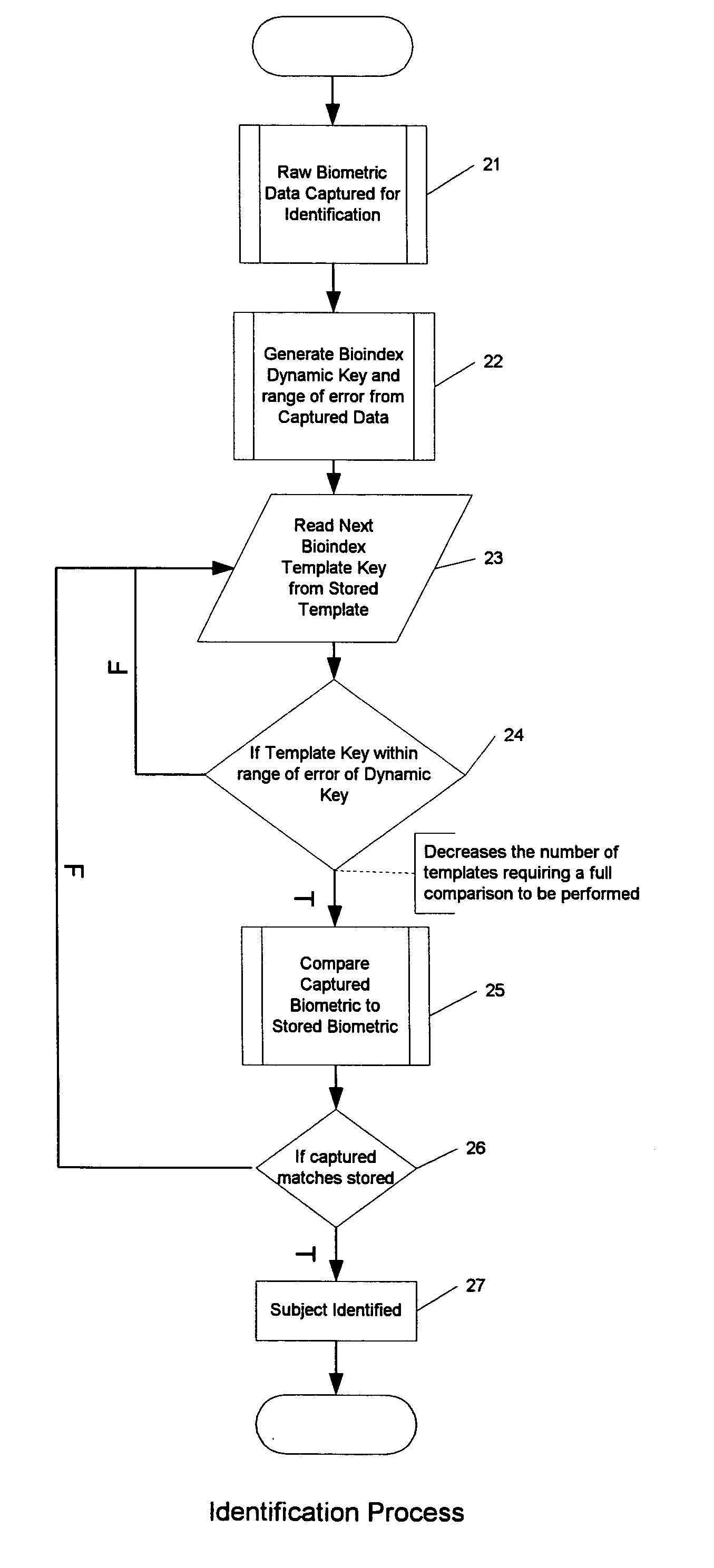

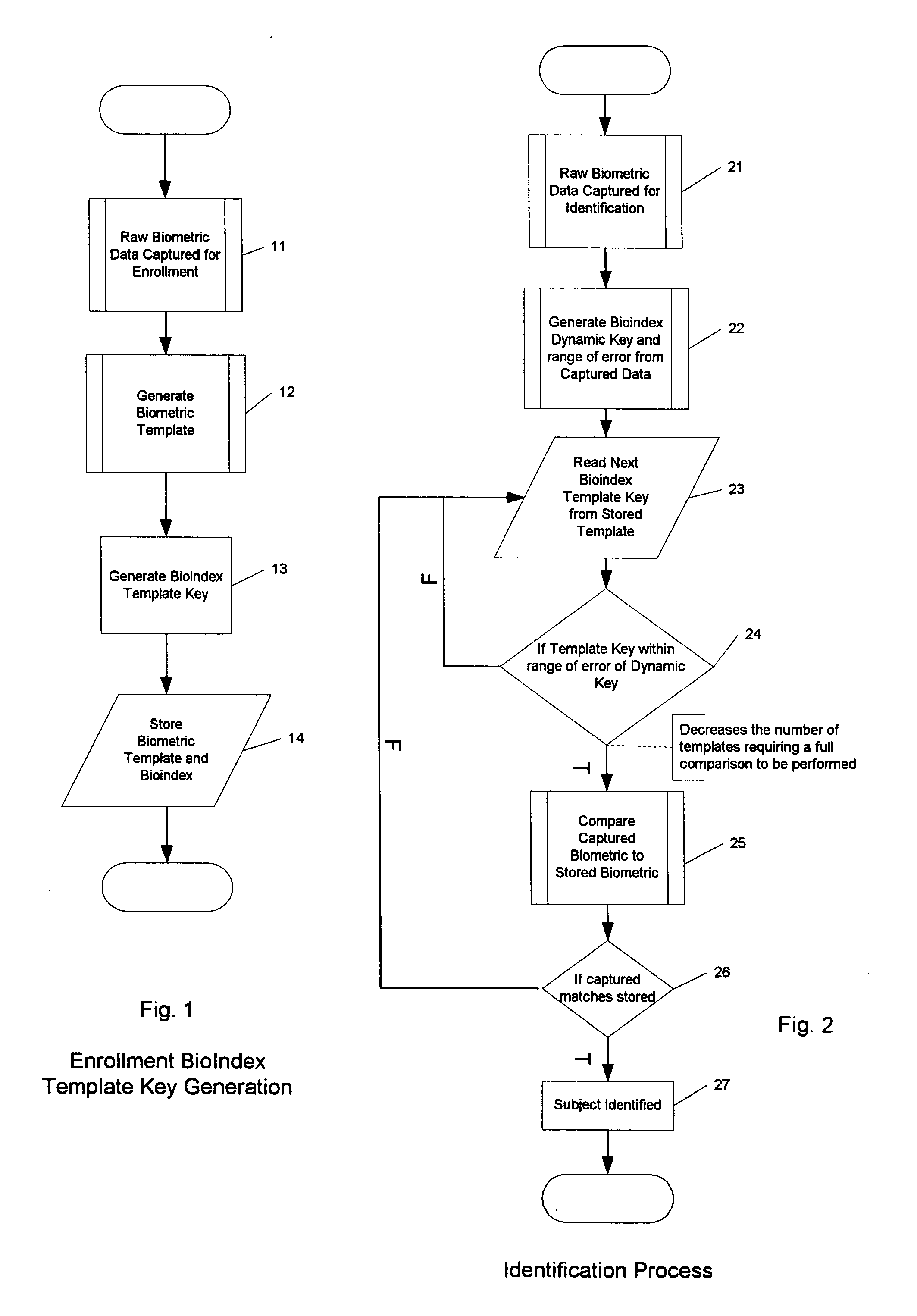

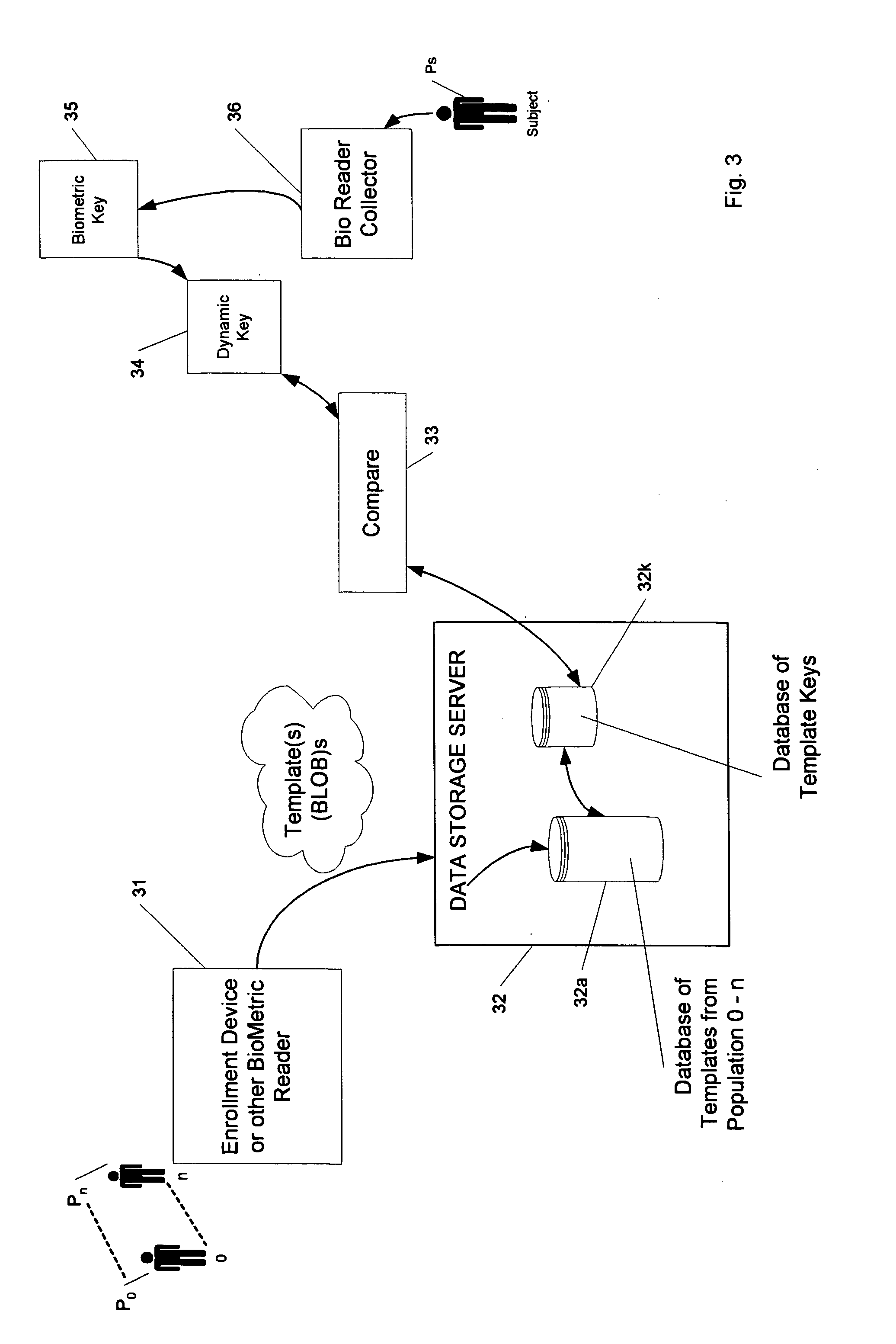

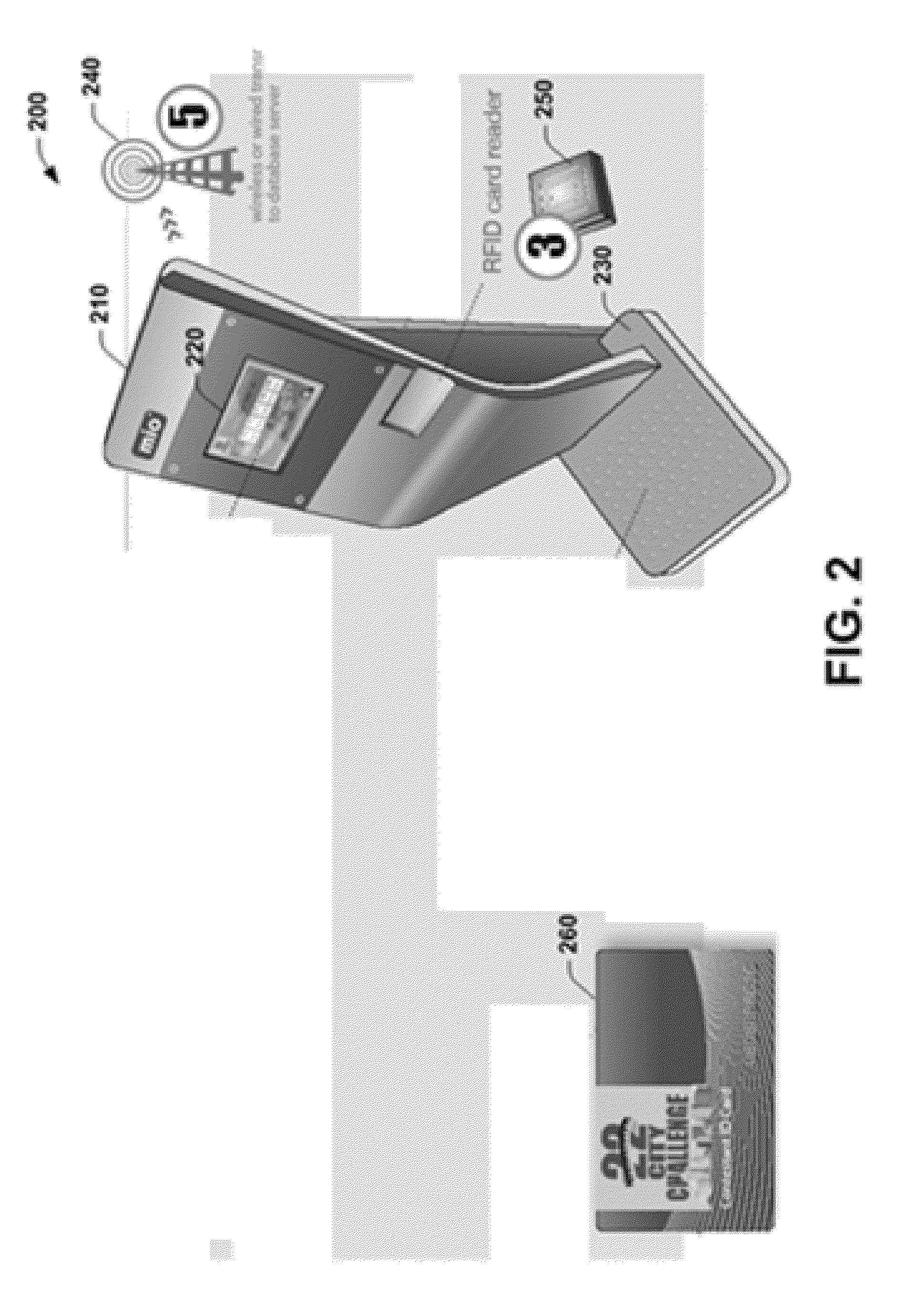

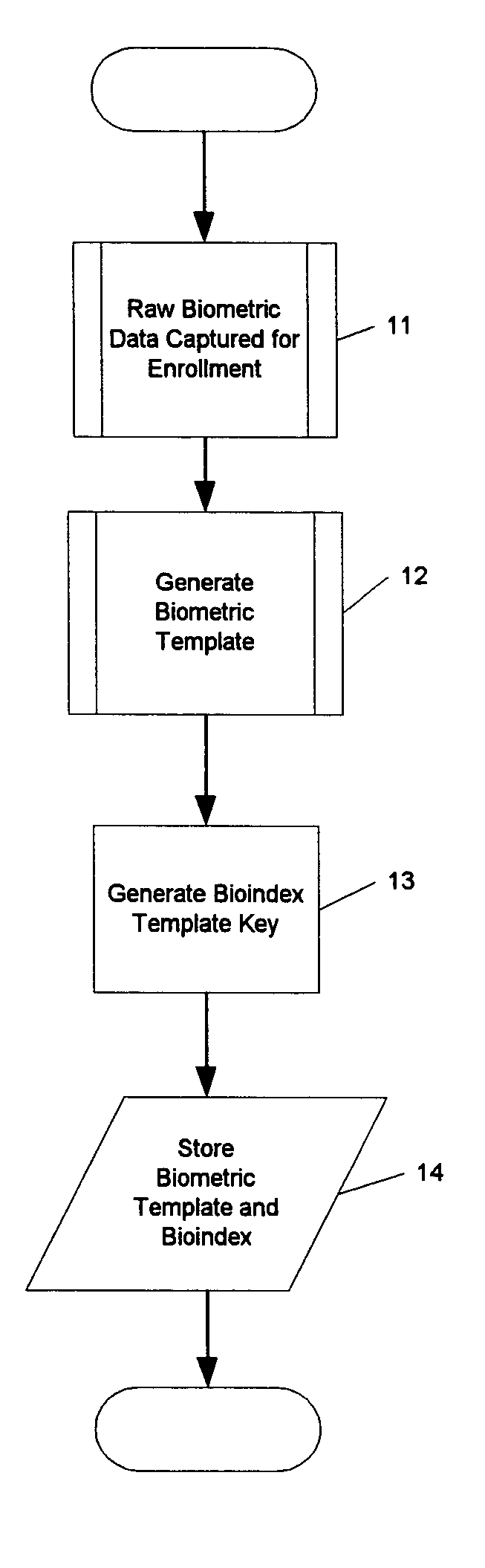

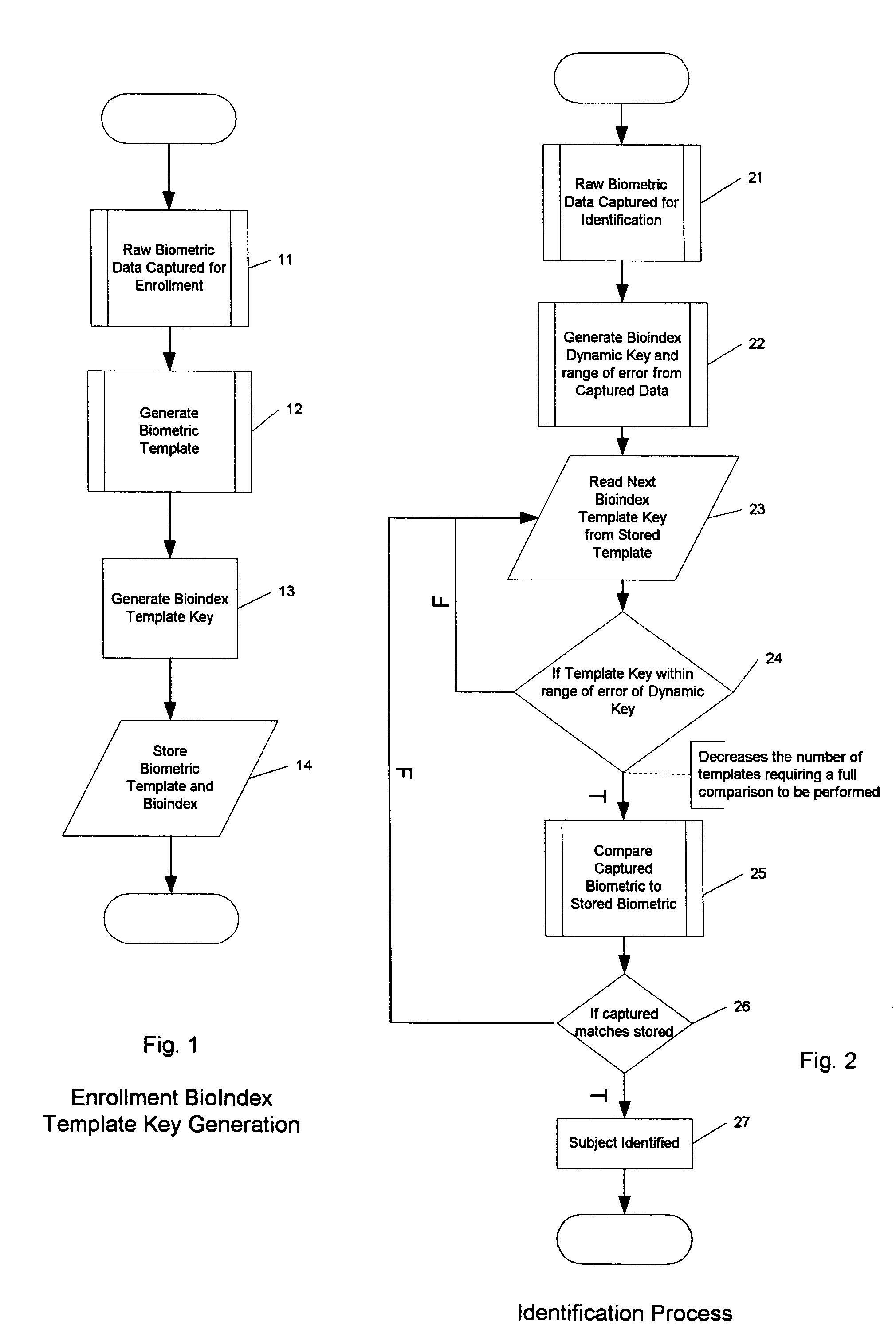

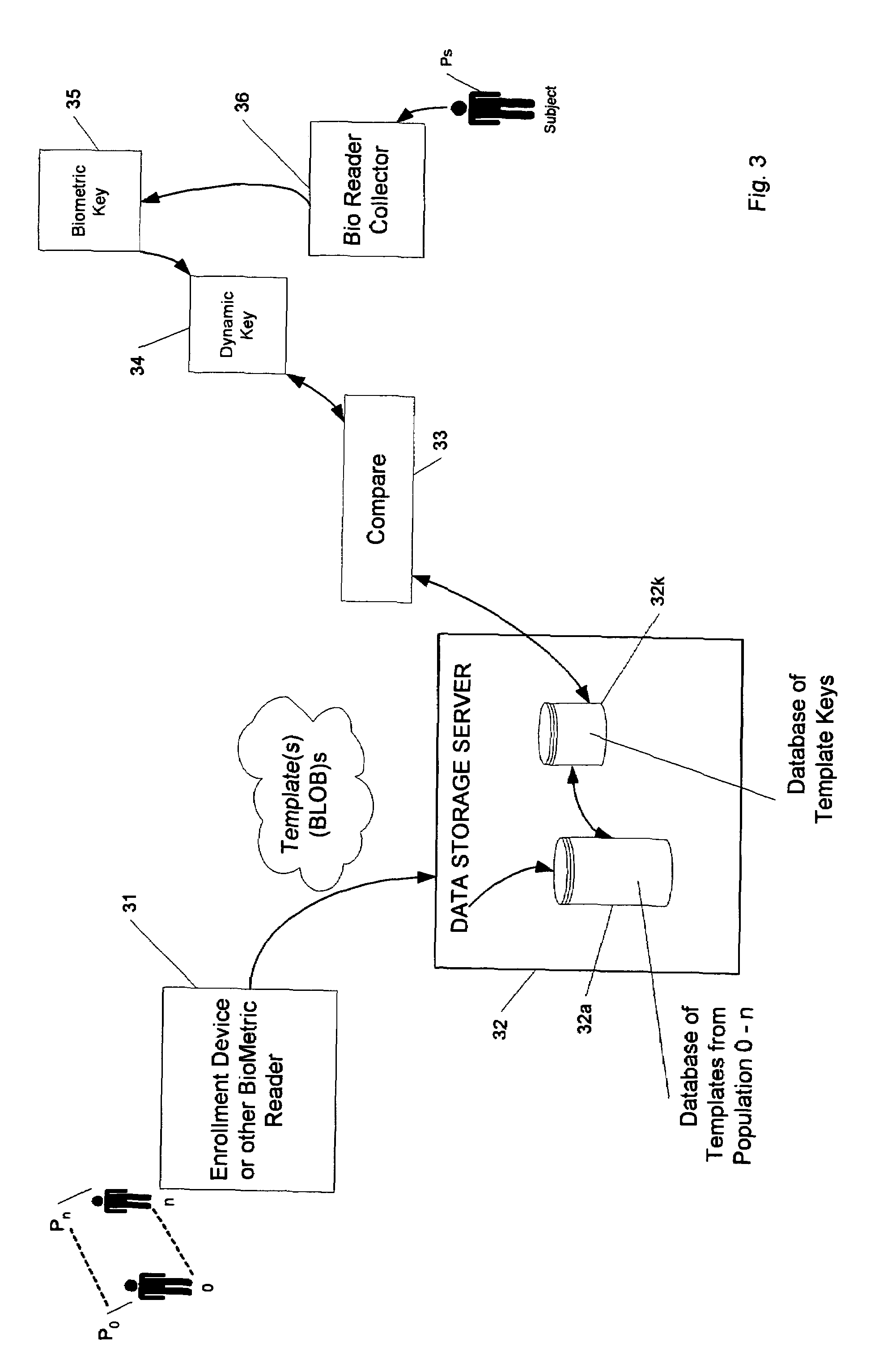

Bioindex mechanism for increasing the relative speed of biometric indentification against large population samples

ActiveUS20090016573A1Reduce the populationIncrease rangeDigital data processing detailsUnauthorized memory use protectionSmall sampleAlgorithm

Owner:UNISYS CORP

Traditional Chinese medicinal bactericidal freshening preparation for sterilizing library

ActiveCN103444801AImprove the bactericidal effectGood volatilization effectBiocideFungicidesSide effectGentiana Lutea Root

The invention relates to a disinfector, and particularly relates to a traditional Chinese medicinal bactericidal freshening preparation for sterilizing a library. The traditional Chinese medicinal extracts of the traditional Chinese medicinal bactericidal freshening preparation are extracted from the following raw materials: astragalus membranaceus, coptis chinensis, cortex phellodendri, honeysuckle, agastache rugosus, folium eucalypti, mother chrysanthemum, liquorice, cordate houttuynia, folium artemisiae argyi, radix angelicae, angelica sinensis, gentiana lutea, rhizoma atractylodis, Eupatorium fortunei, cyrtomium fortune, fructus cnidii, rheum officinale, pepper, schizonepeta, mint and polygala tenuifolia. The traditional Chinese medicinal bactericidal freshening preparation also plays a role of freshening air when sterilizing and disinfecting. The effective components of the traditional Chinese medicinal bactericidal freshening preparation are the traditional Chinese medicinal extracts, so that the traditional Chinese medicinal bactericidal freshening preparation is free of toxic and side effects on a human body, also has the effects of clearing away heat and toxic materials, improving immune capability and the like, and is especially suitable for use in the library with large population flow and long detention time.

Owner:HEBEI INST OF SCI & TECH INFORMATION HEBEI INST OF SCI & TECH INNOVATION STRATEGY

Automated field development planning of well and drainage locations

ActiveUS8005658B2Reduce in quantityWithout significantly compromising the accuracy of the more complex algorithmsElectric/magnetic detection for well-loggingFluid removalEconomic benefitsAnalysis tools

A hybrid evolutionary algorithm (“HEA”) technique is described for automatically calculating well and drainage locations in a field. The technique includes planning a set of wells on a static reservoir model using an automated well planner tool that designs realistic wells that satisfy drilling and construction constraints. A subset of these locations is then selected based on dynamic flow simulation using a cost function that maximizes recovery or economic benefit. In particular, a large population of candidate targets, drain holes and trajectories is initially created using fast calculation analysis tools of cost and value, and as the workflow proceeds, the population size is reduced in each successive operation, thereby facilitating use of increasingly sophisticated calculation analysis tools for economic valuation of the reservoir while reducing overall time required to obtain the result. In the final operation, only a small number of full reservoir simulations are required for the most promising FDPs.

Owner:SCHLUMBERGER TECH CORP

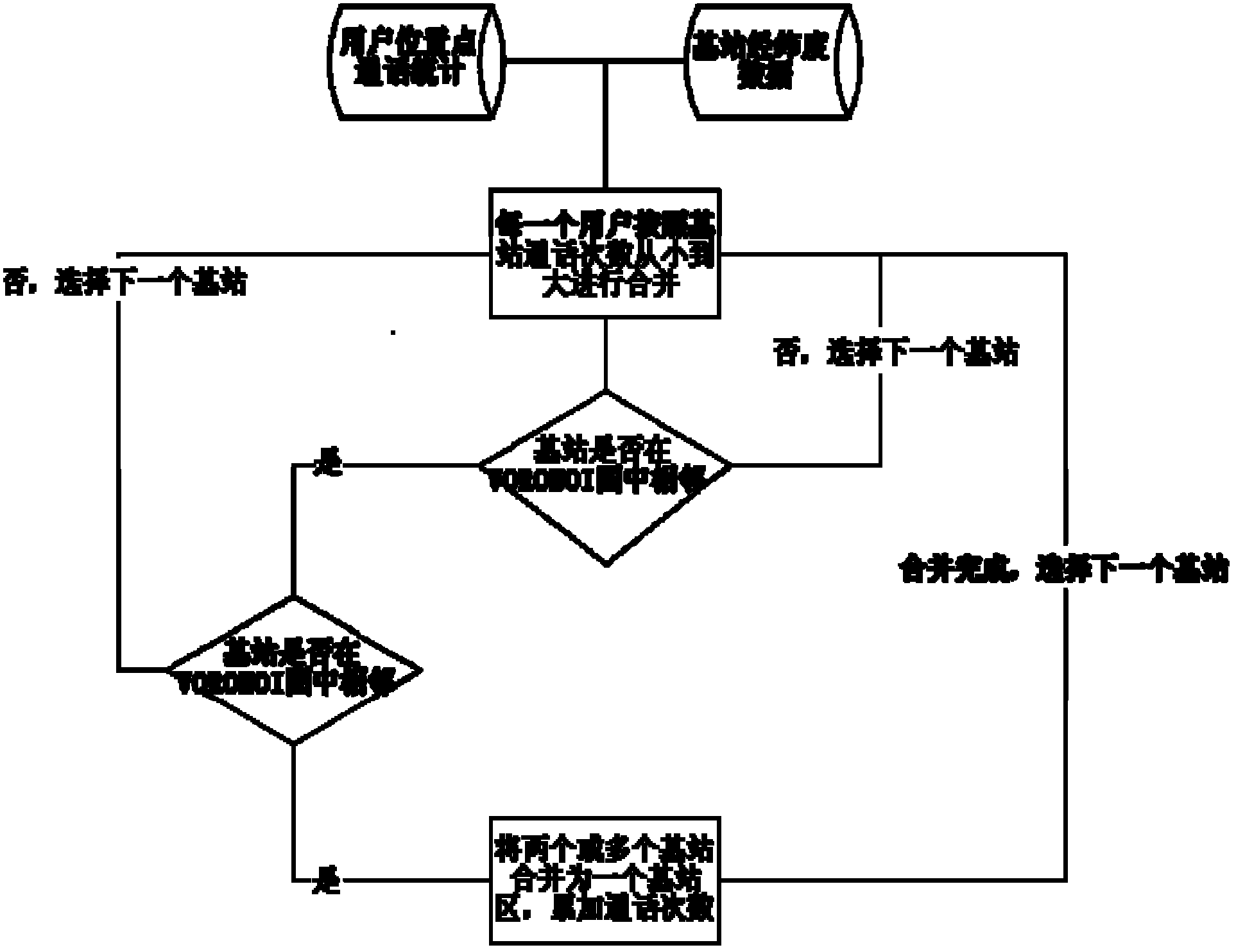

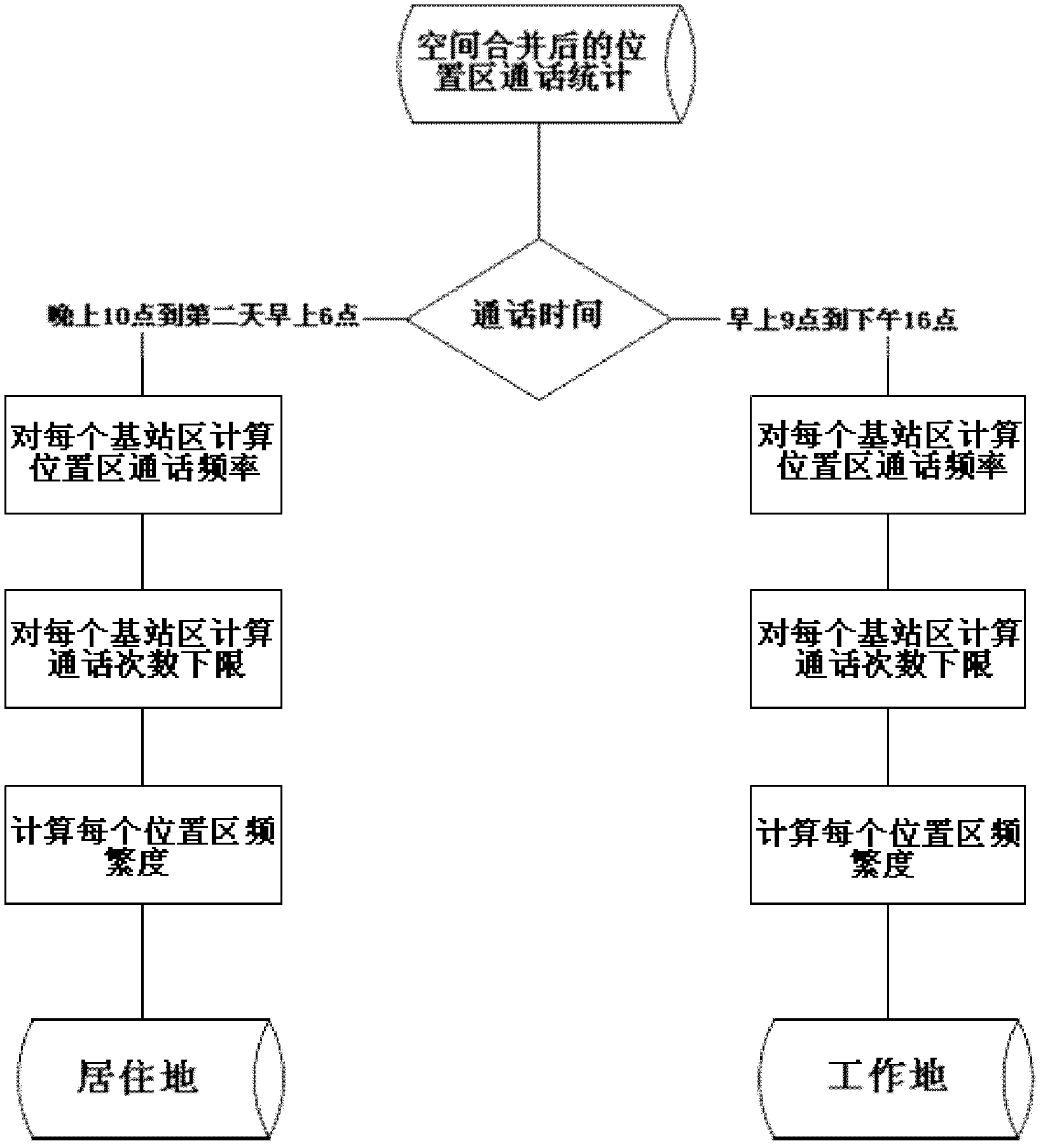

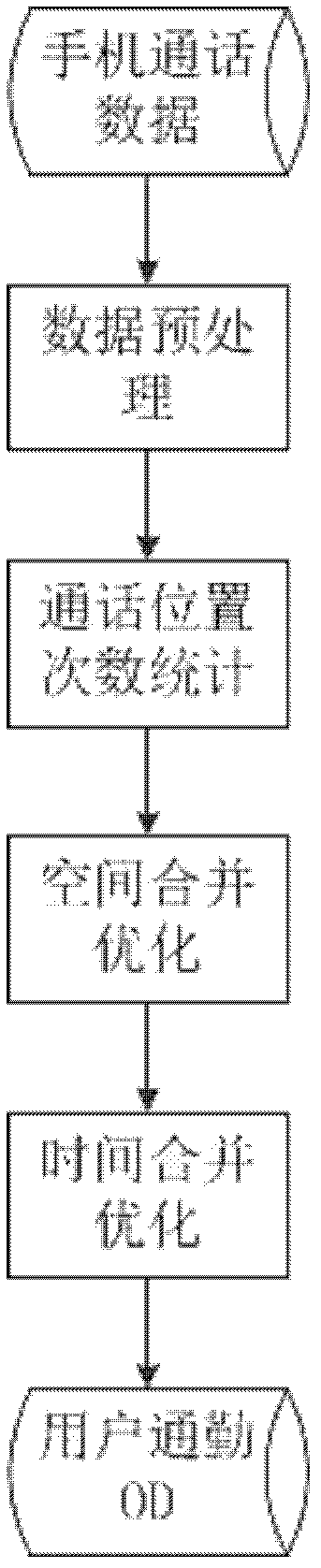

Mining method of user commuting od in mobile phone call data

InactiveCN102281498AWide coverageNo local problemsLocation information based serviceSpecial data processing applicationsResidenceGranularity

The invention discloses a method for mining user commuting OD in mobile phone call data. The number of calls of each mobile phone number in different base station locations; 3) Combine adjacent call base stations with overlapping coverage into one base station area, and count the number of calls of each mobile phone number in the base station area; 4) According to the number of calls of each mobile phone number in the base station area The number of calls determines the residence and work of the user of the mobile phone number, and the base station area with a high number of calls is the residence or work of the user. The method of the invention can obtain the commuting OD information of large-scale people, and has a wide coverage; because the data used is mobile phone call data, the cost is low; because the base station is used as the location unit, and the coverage of the base station is small, the obtained data information The granularity of the information obtained by the method of traditional commuter OD survey is finer.

Owner:PEKING UNIV

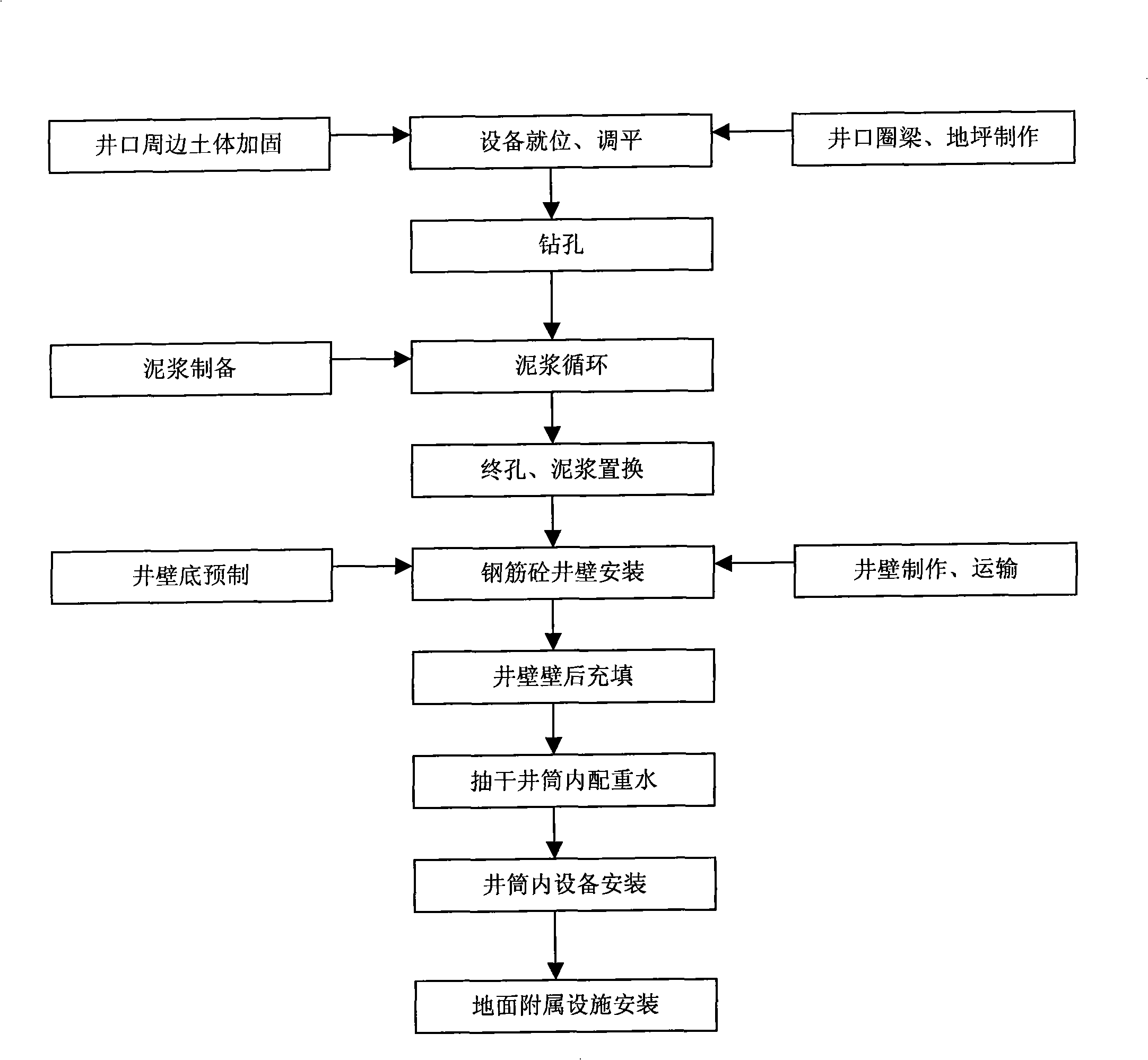

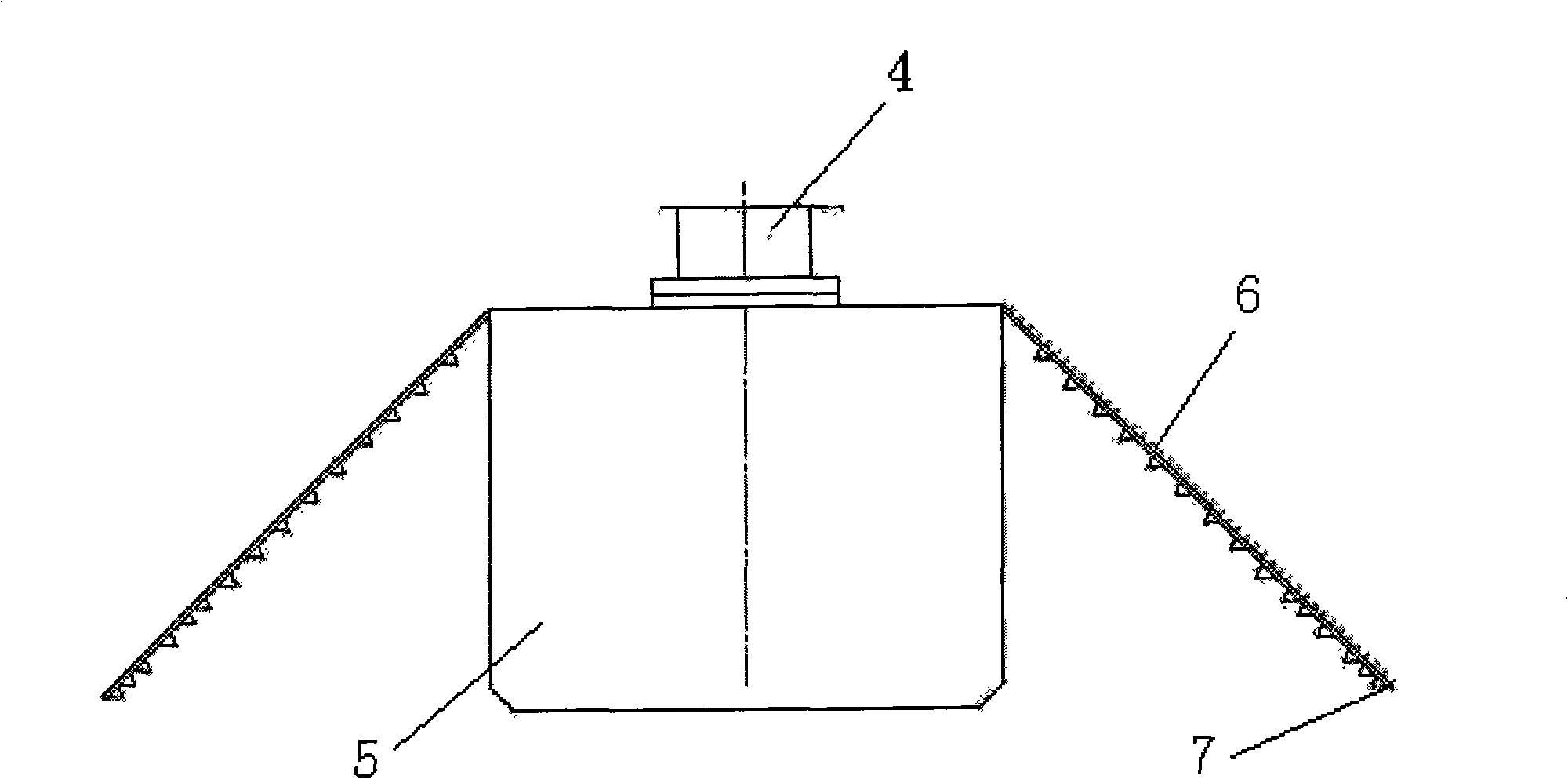

Construction method for barrel type underground garage

ActiveCN101294398ALow costSimple and fast constructionArtificial islandsUnderwater structuresEnvironment effectReinforced concrete

The invention relates to a construction method of a cylindrical underground garage, belongs to the technology field of underground buildings, and aims to solve the technical problems of constructing an underground garage in an area with large population, small space and crowed buildings. The construction method comprises the following steps of: (1) performing preparation work including reinforcing the soil in a certain range around a well mouth, preparing a well mouth ring beam and a well drilling platform, and placing equipment and leveling; (2) drilling an underground vertical well pit; (3) performing slurry replacement when the drilled well reaches a designed depth and diameter; (4) installing a reinforced concrete well wall by sinking according to a suspension method; (5) correcting the verticality of the well wall after the well is sunk to a predetermined position, and backfilling the wall; (6) pumping out the counterweight water in the well pit; and (7) installing the in-well equipment and the ground appurtenant facilities. The inventive construction method has the advantages of low construction cost, short construction period, low construction difficulty, wide application range, and low influence on peripheral environment.

Owner:SHANGHAI GUANGLIAN ENVIRONMENTAL & GEOTECHNICAL ENG CO LTD

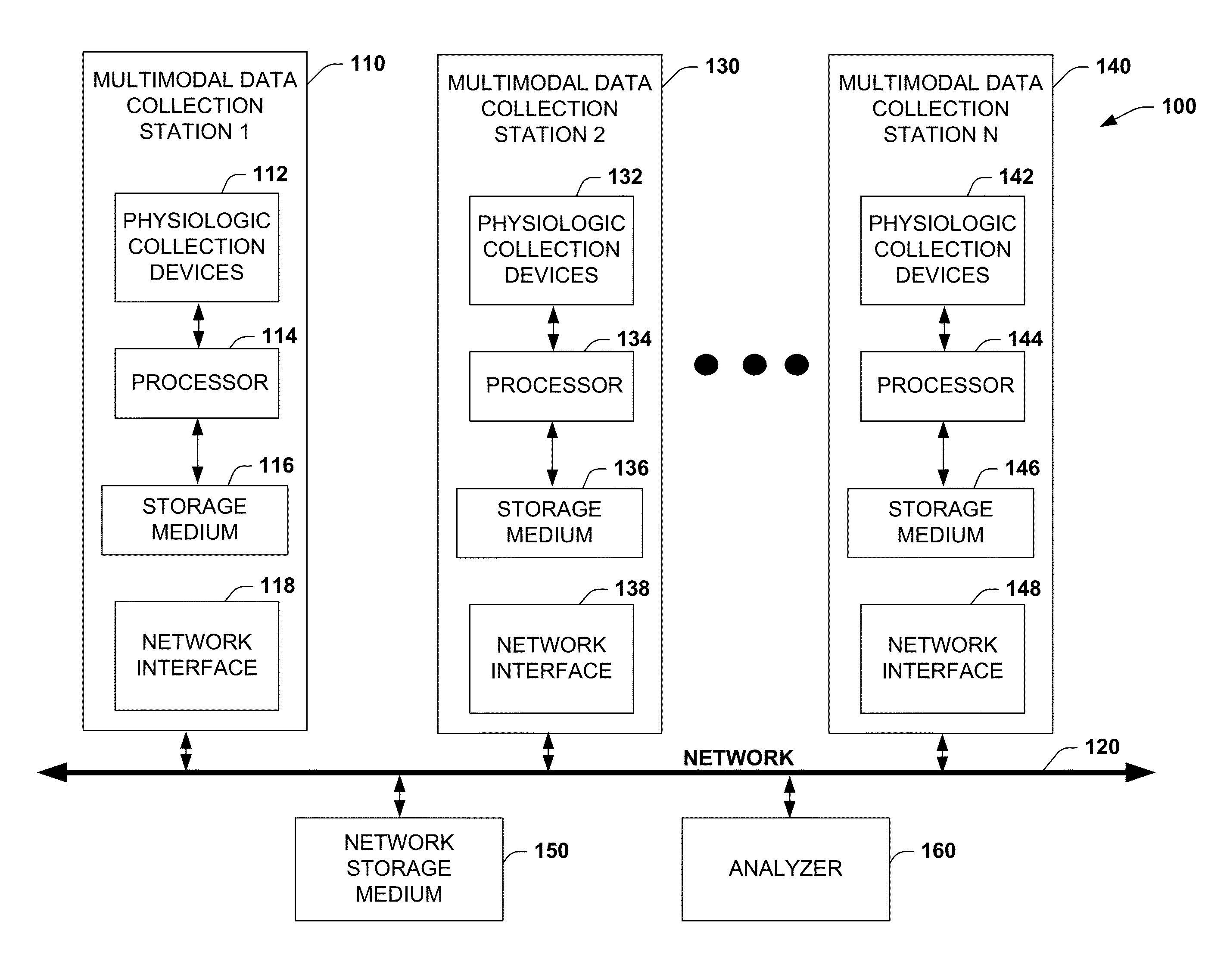

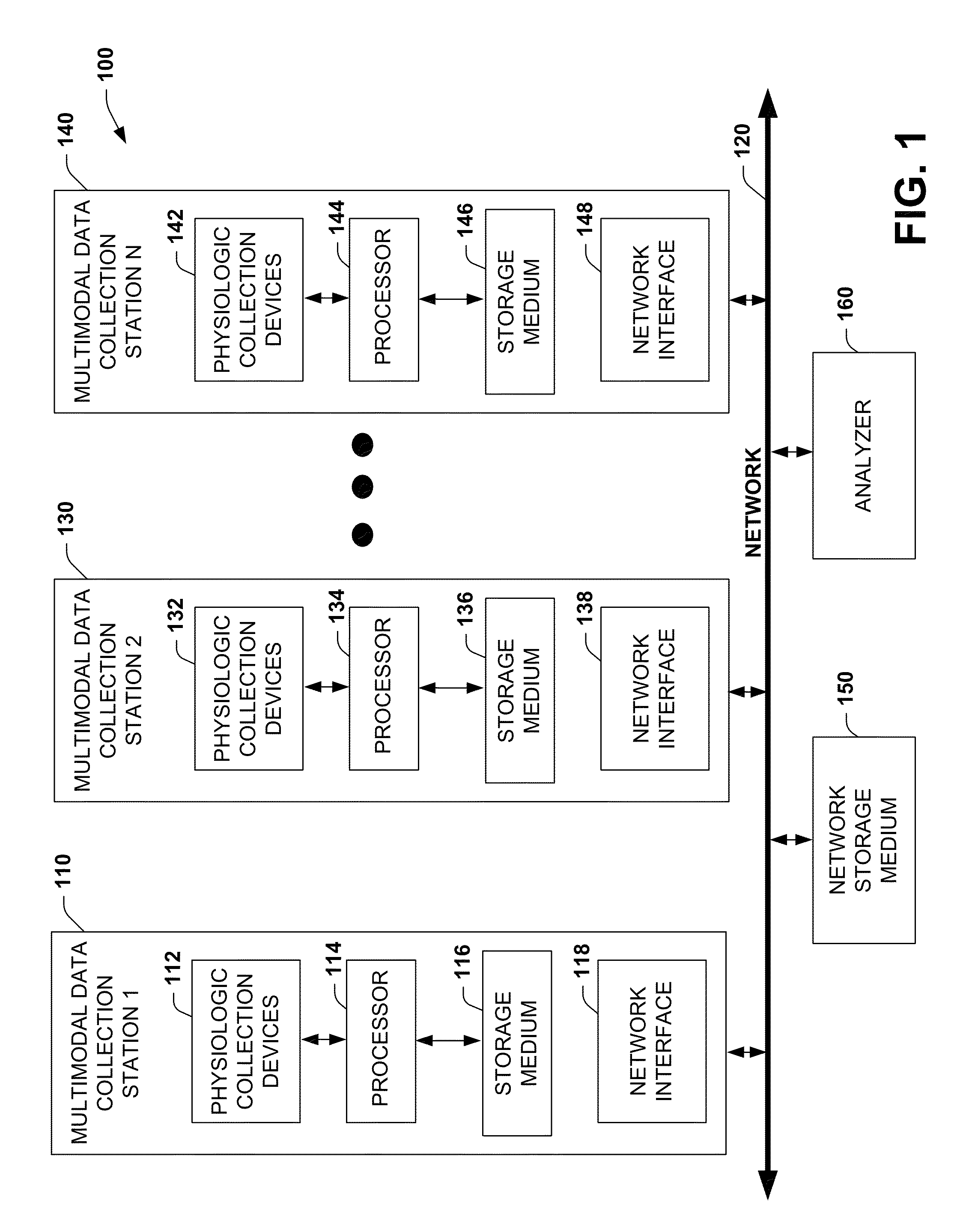

Multimodal physiologic data station and wellness transformation of large populations

InactiveUS20130211852A1Promote resultsPhysical therapies and activitiesMedical data miningComputer scienceLarge population

A method includes determining team participant members for one or more wellness teams. The method includes aggregating participant medical data for each of the one or more wellness teams from one or more networked physiologic stations configured to receive the medical data. The method includes analyzing the medical data to determine wellness information for the one or more wellness teams associated with the aggregated participant medical data. The method can be operated on a system where the system includes at least one physiologic station to generate participant medical information from a plurality of participants. This can include an identification component to facilitate trust in collected data. A storage medium collects the medical information over a network from the plurality of participants and an analyzer determines group wellness information from the collected medical information.

Owner:THE CLEVELAND CLINIC FOUND

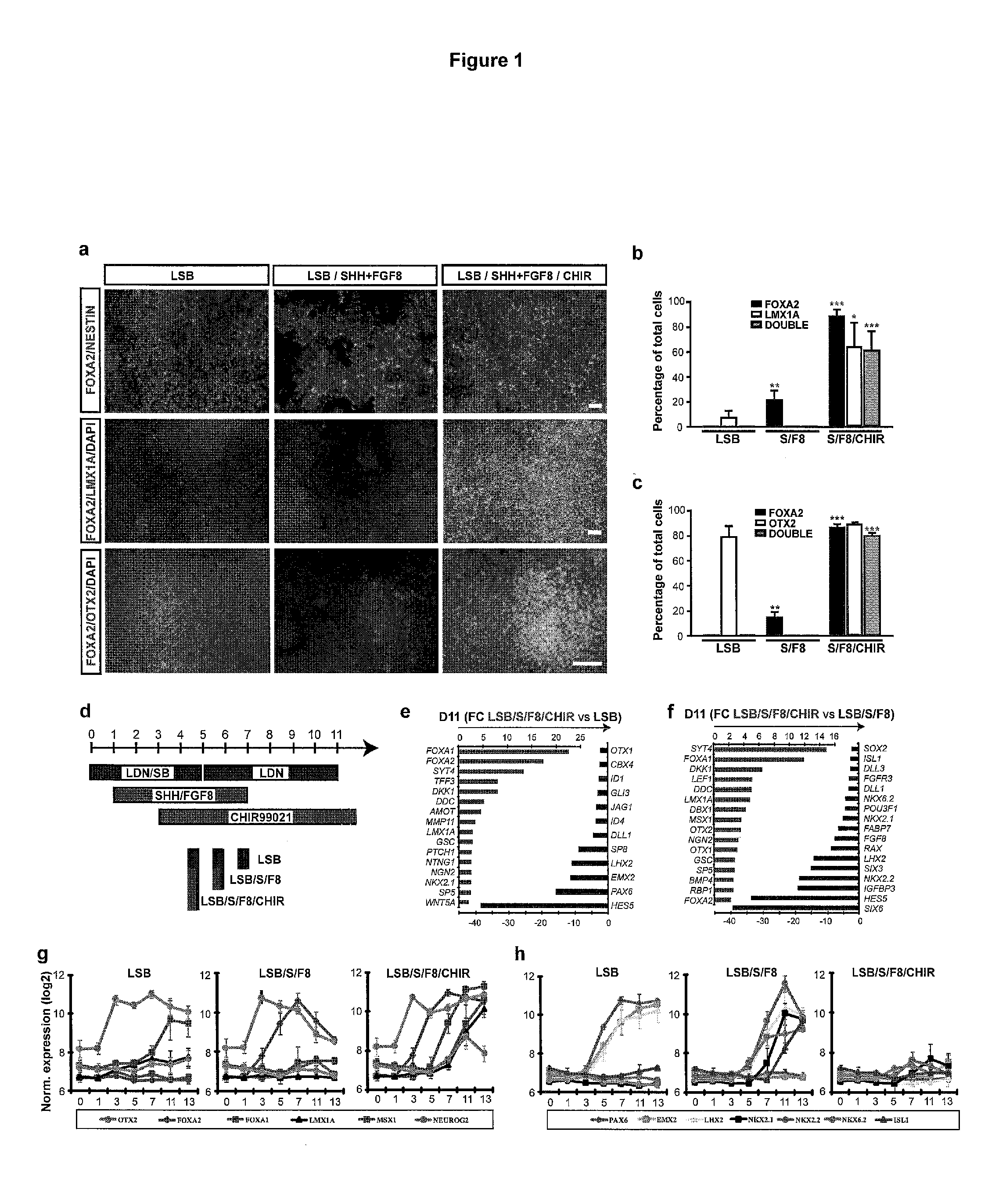

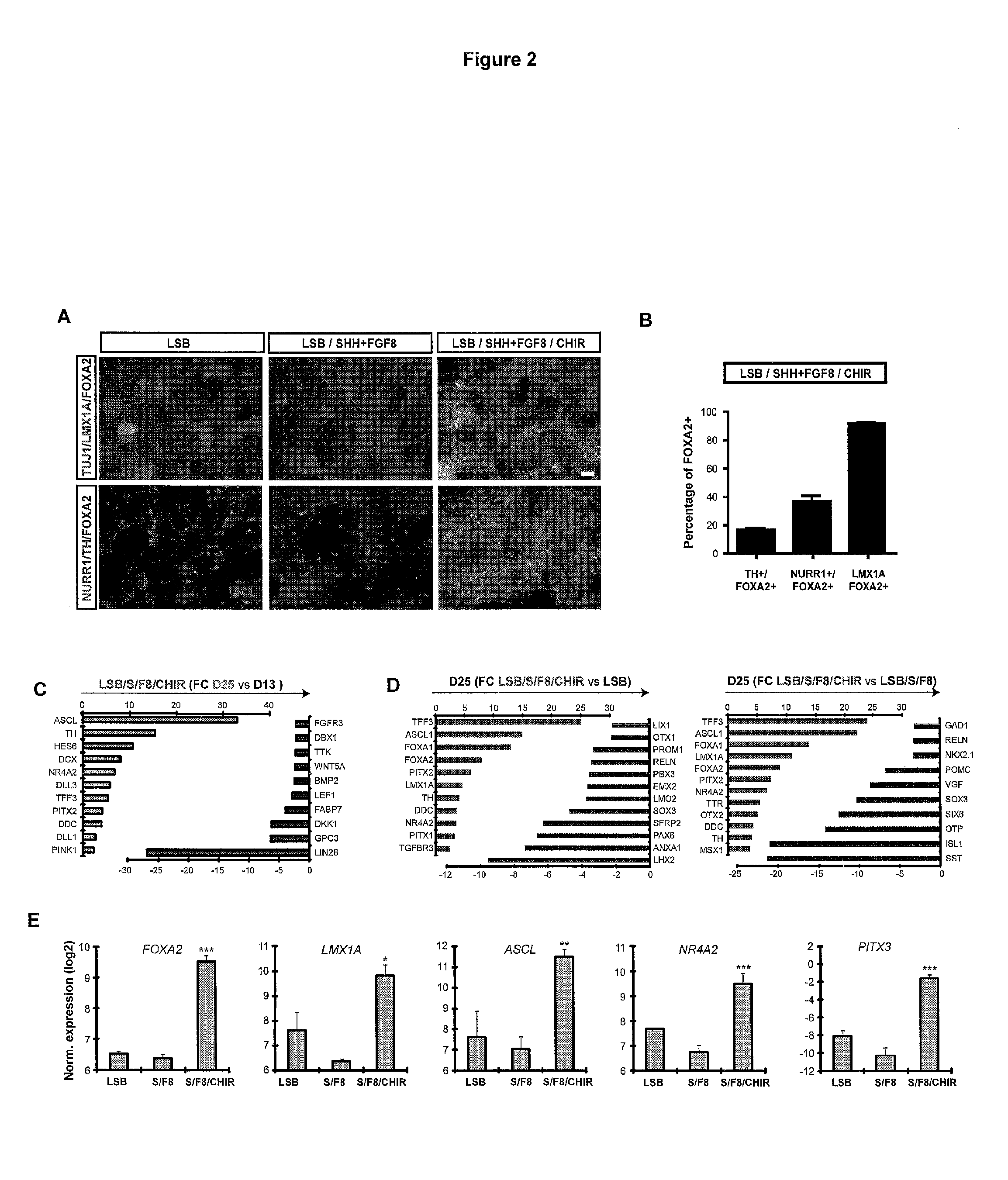

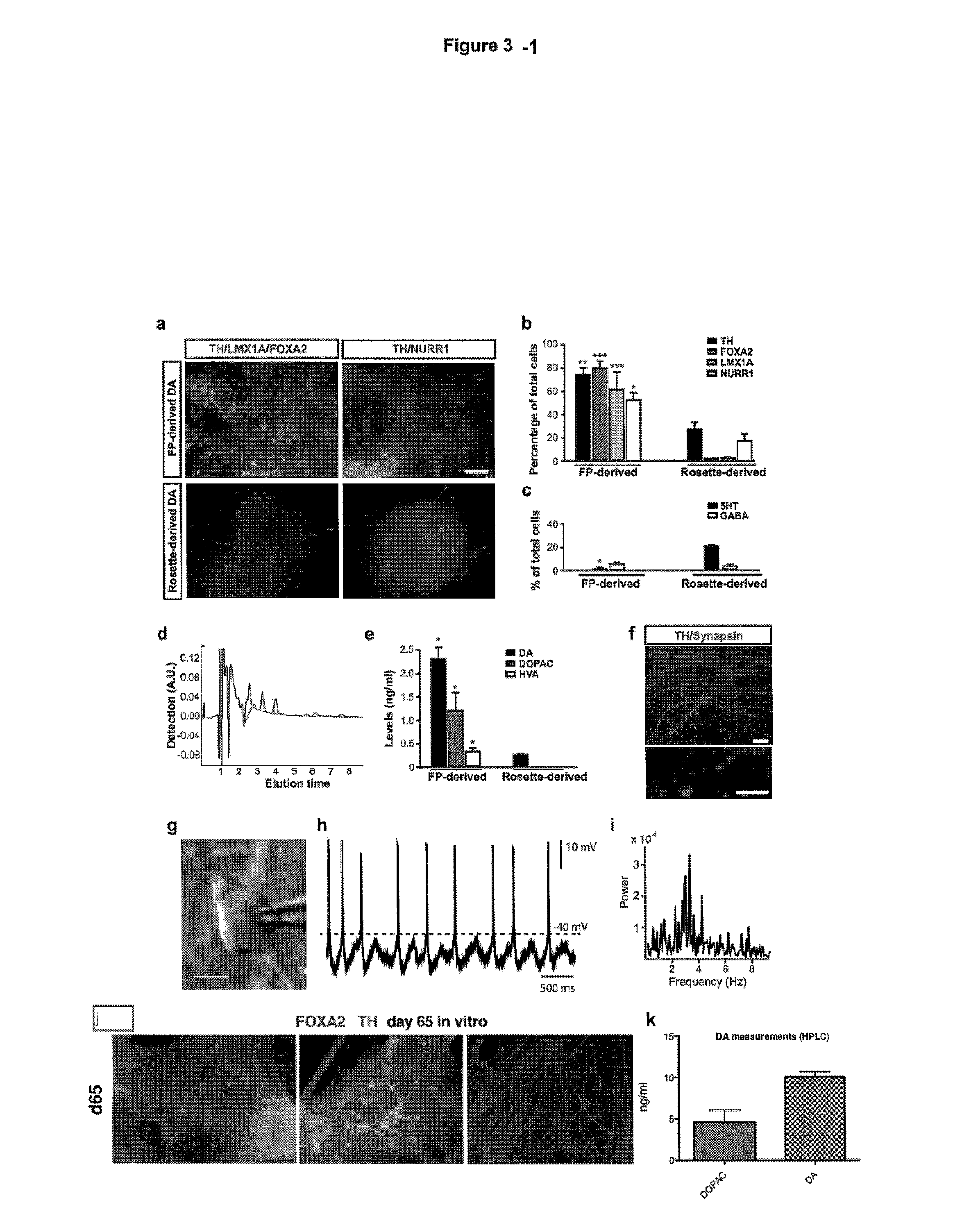

Midbrain dopamine (DA) neurons for engraftment

The present invention relates to the field of stem cell biology, in particular the lineage specific differentiation of pluripotent or multipotent stem cells, which can include, but is not limited to, human embryonic stem cells (hESC) in addition to nonembryonic human induced pluripotent stem cells (hiPSC), somatic stem cells, stem cells from patients with a disease, or any other cell capable of lineage specific differentiation. Specifically described are methods to direct the lineage specific differentiation of hESC and / or hiPSC into floor plate midbrain progenitor cells and then further into large populations of midbrain fate FOXA2+LMX1A+TH+ dopamine (DA) neurons using novel culture conditions. The midbrain fate FOXA2+LMX1A+TH+ dopamine (DA) neurons made using the methods of the present invention are further contemplated for various uses including, but not limited to, use in in vitro drug discovery assays, neurology research, and as a therapeutic to reverse disease of, or damage to, a lack of dopamine neurons in a patient. Further, compositions and methods are provided for differentiating midbrain fate FOXA2+LMX1A+TH+ dopamine (DA) neurons from human pluripotent stem cells for use in disease modeling, in particular Parkinson's disease. Additionally, authentic DA neurons are enriched for markers, such as CD142, and A9 type neuronal cells.

Owner:MEMORIAL SLOAN KETTERING CANCER CENT

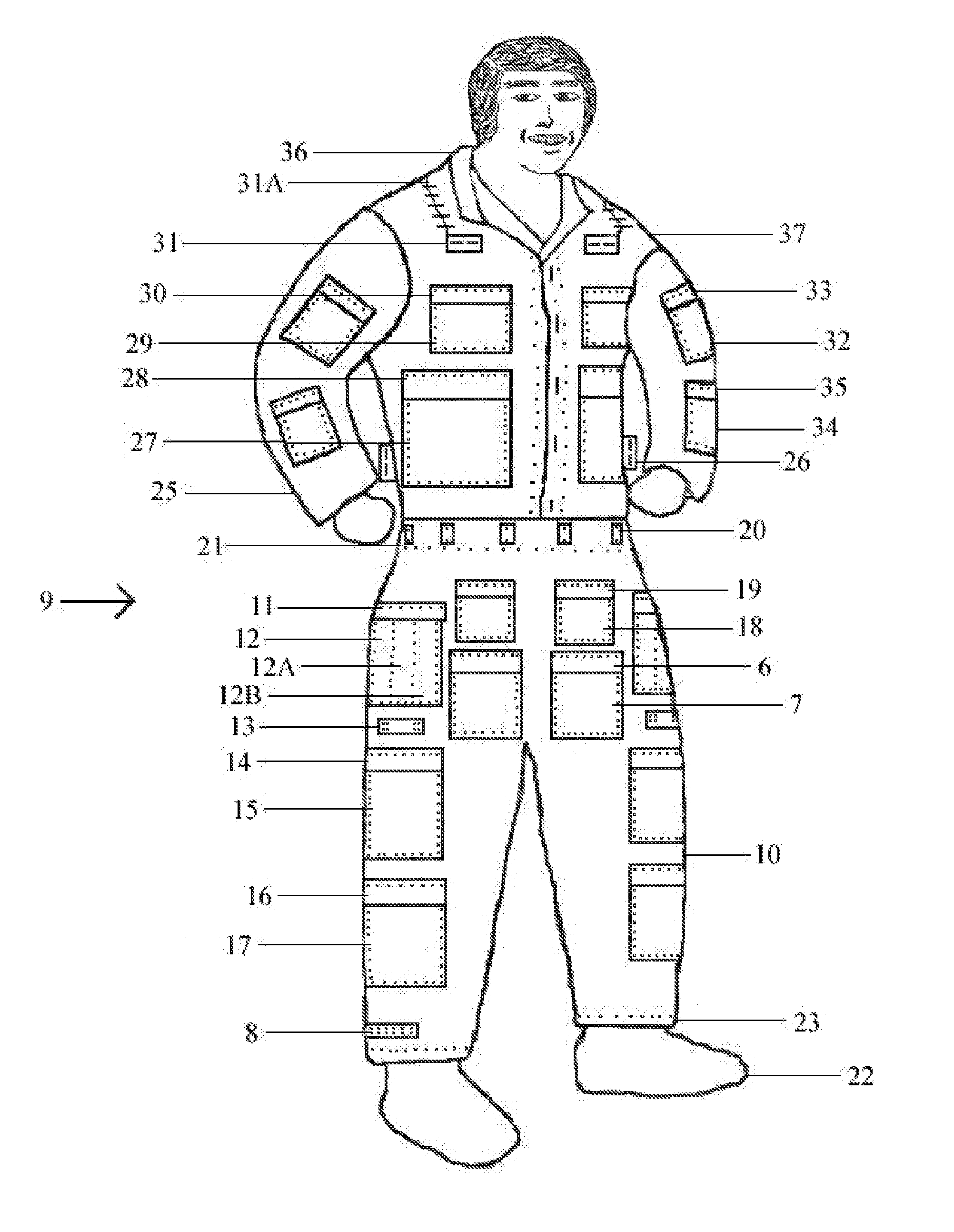

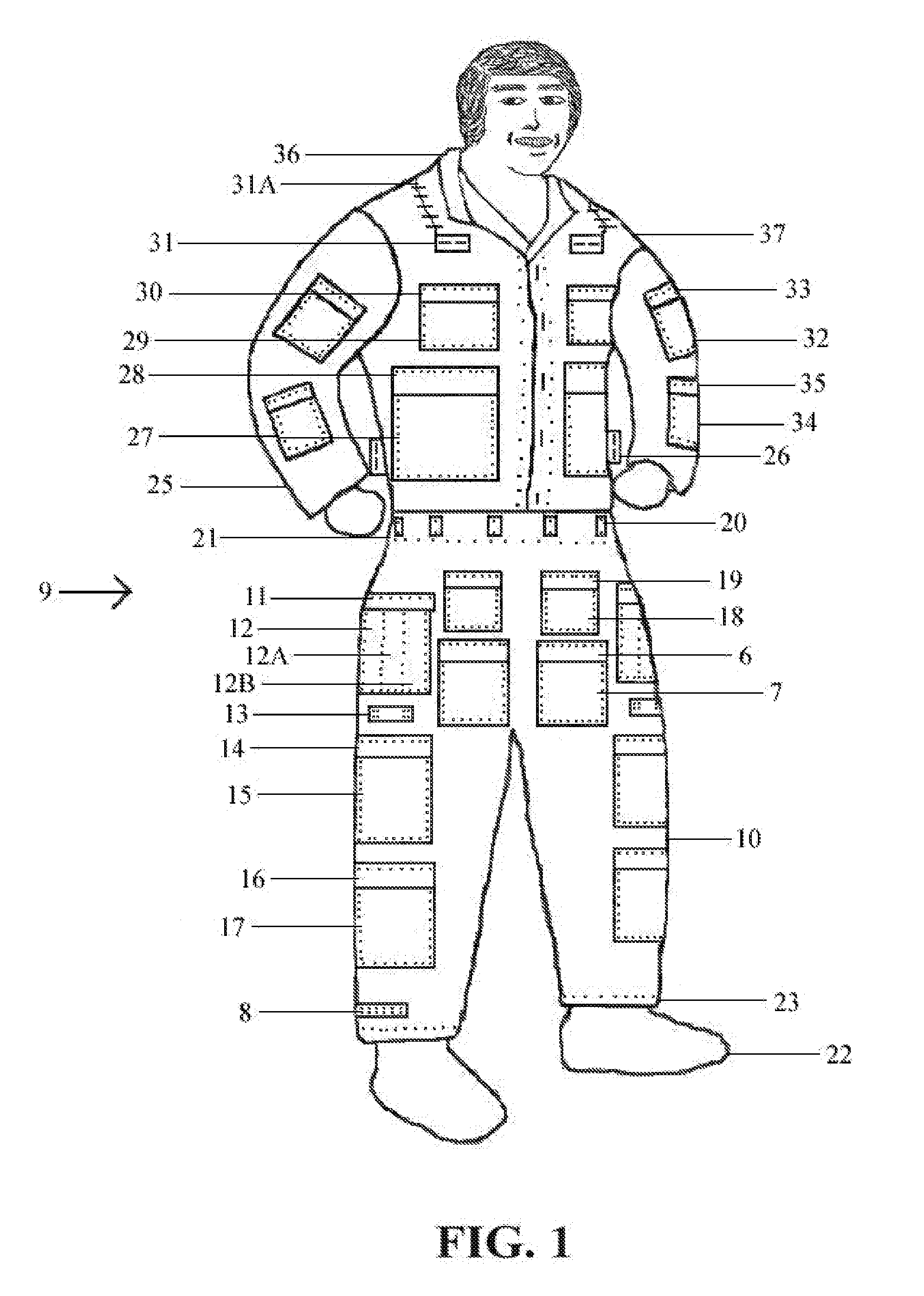

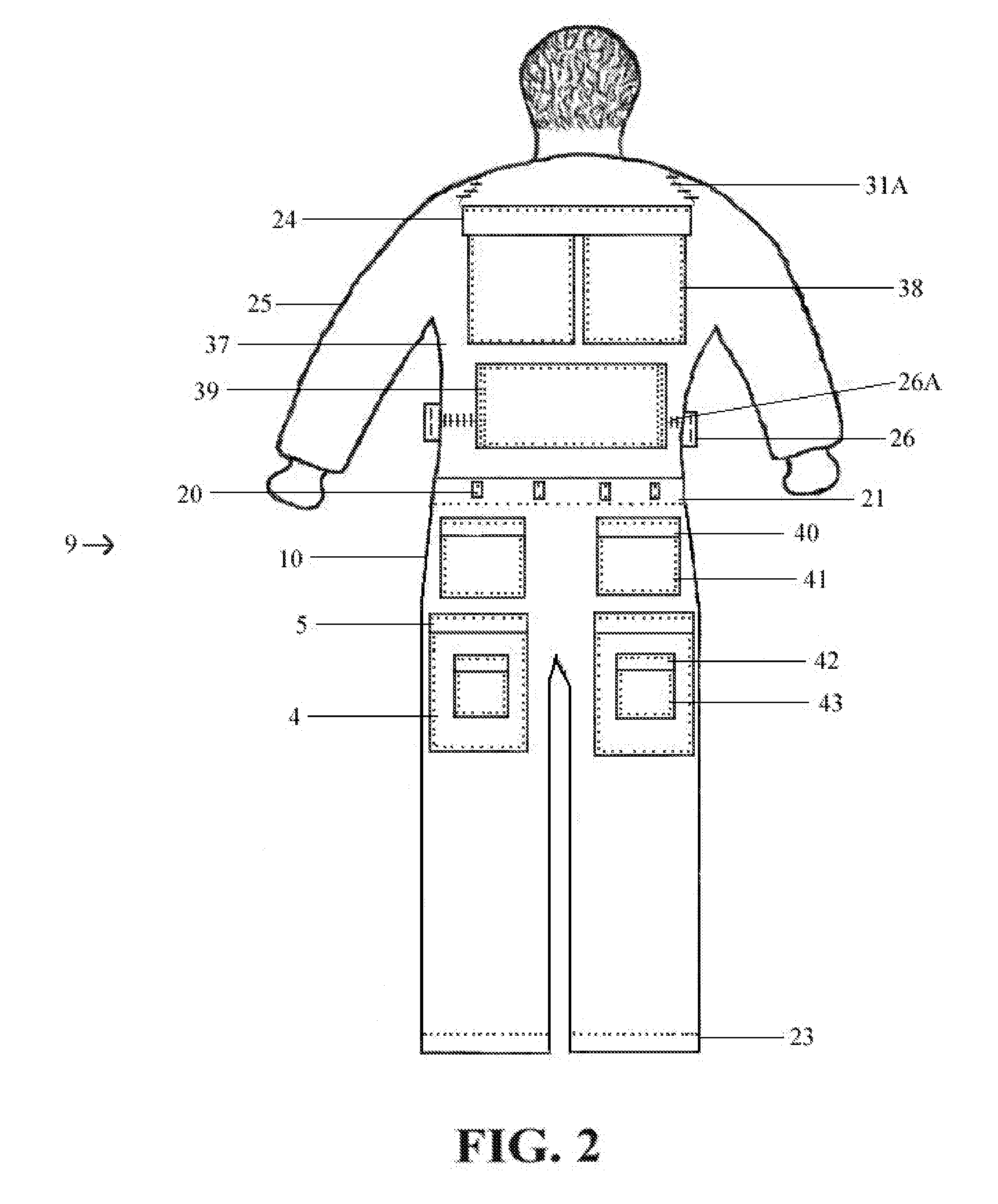

Advanced Combat Uniform for Medics

An advanced combat clothing system for military medics and medical professionals actively involved in the field of combat while providing acute emergency care for wounded soldiers. The Advanced Combat Uniform for Medics also referred to as the ACUM consists of a pair of trousers, a long sleeve shirt and a unique pocket receptacle invention which stabilizes the content within the pockets. The ACUM was invented to replace the use of roll-up bags and back packs used to carry the tools and supplies of the military medics during combat zone engagements.The ACUM invention was strategically designed to disburse the weight of the medical gear over the entire body, therefore, decreasing the entire weight load from exerting pressure over the lumbar and thoracic spinal locations. Additionally, by disbursing the pay-load or weight over the entire body, the military medic will be able to maneuver and combat with more accuracy and precision.The ACUM invention has a unique pull cord system in which the military medic can access lifesaving medicines and triage supplies at the pull of a cord. The ACUM can be made using any fabric including the digital camouflage material used and preferred by military personnel. The ACUM can hold over 100 required medical items while providing extremely fast easy access to the medical supplies carried by the military medics.The ACUM invention was designed to systematically place all of the medical supplies carried by the military medic in strategic areas around the wearer's body. The ACUM can be made to fit any size, male or female. This combat uniform can be produced relatively quick and easy using a line production clothing protocol. Lumbar and spinal injury affects a large population of military personnel at one time or another, by disbursing the weight or load of the military medics gear; this will significantly reduce the risk of developing lumbar spinal disease in general.

Owner:EARLEY BILLY ZACHERY

Method and system for generating focus signal

An auto focus image system that includes an image sensor coupled to a controller. The image sensor captures an image that has at least one edge with a width. The controller generates a focus signal that is a function of the edge width. A lens receives the focus signal and adjust a focus. The edge width can be determined by various techniques including the use of gradients. A histogram of edge widths can be used to determine whether a particular image is focused or unfocused. A histogram with a large population of thin edge widths is indicative of a focused image.

Owner:CANDELA MICROSYST S PTE

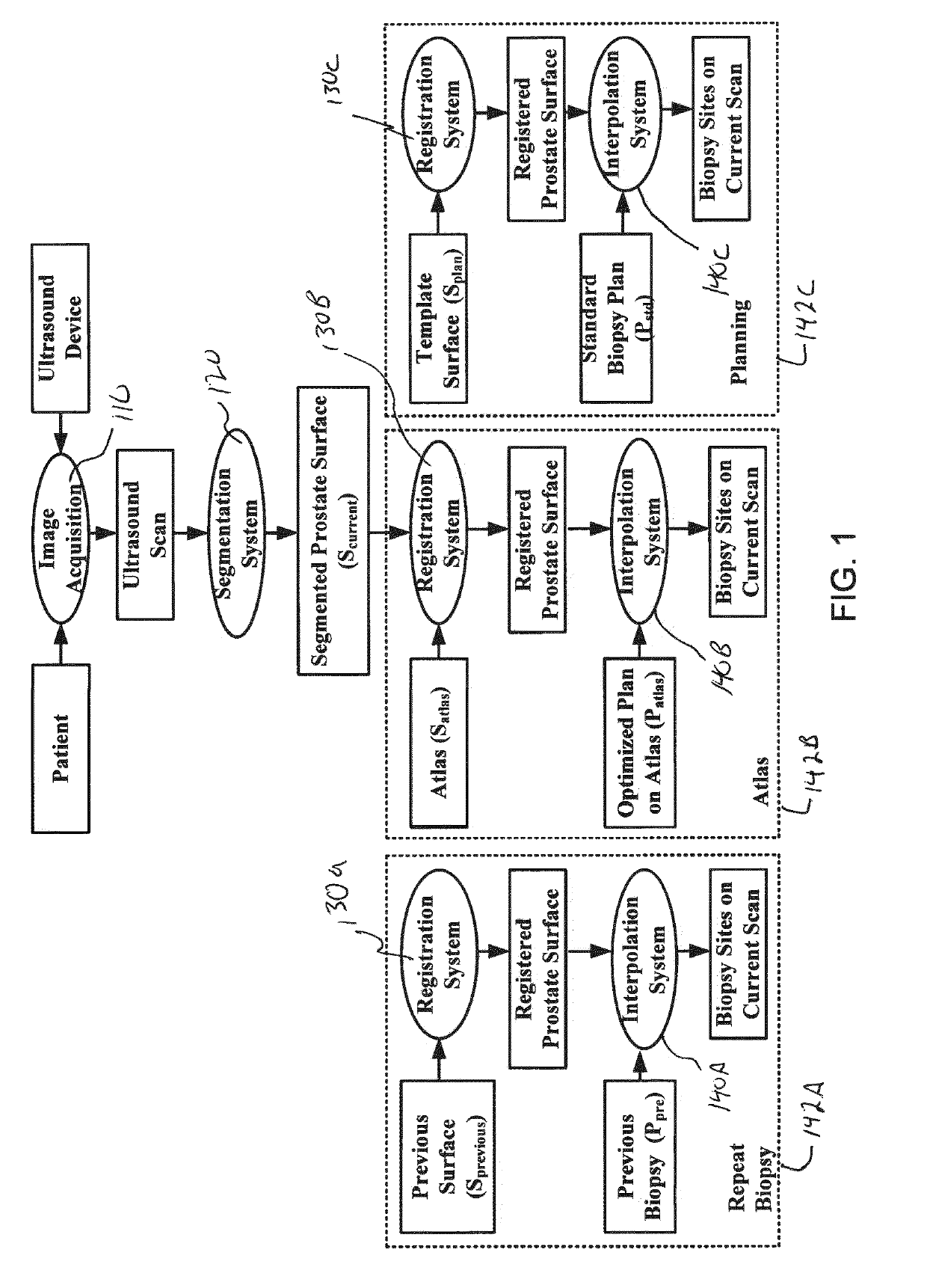

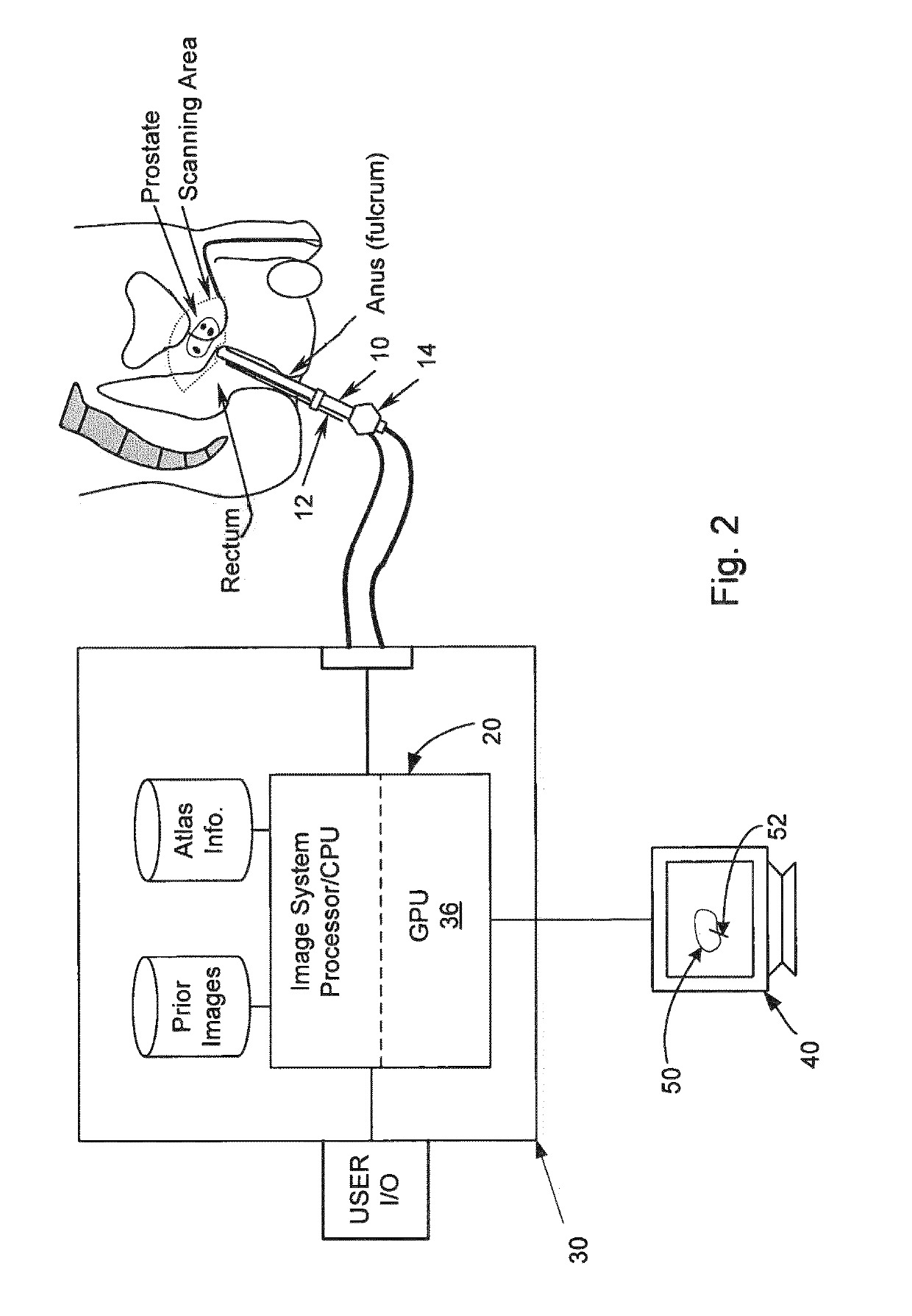

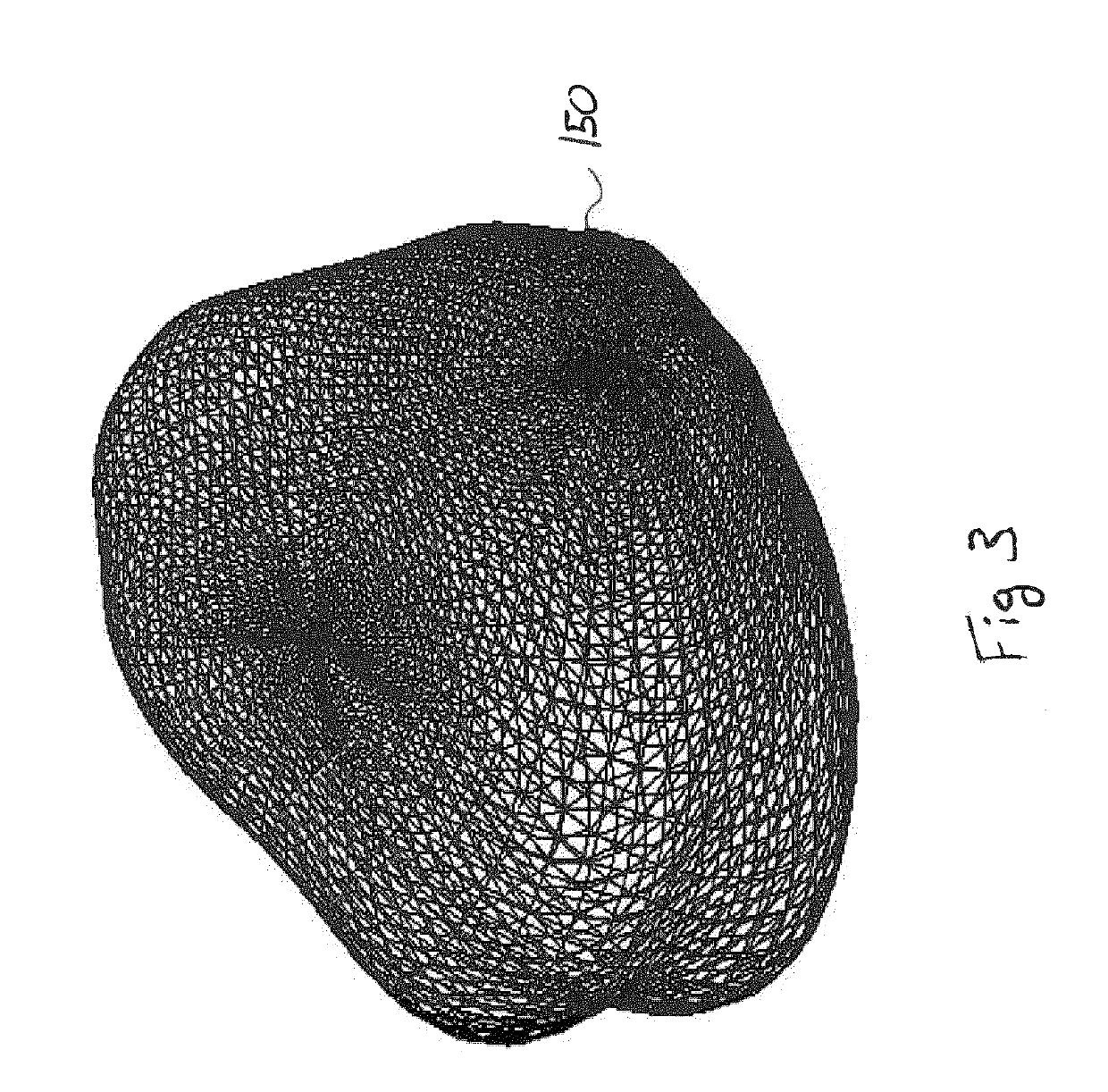

Apparatus for real-time 3D biopsy

InactiveUS20090324041A1Improve visualizationReducing biopsy procedure timeImage enhancementImage analysisGraphicsSonification

A method and apparatus are disclosed for performing software guided prostate biopsy to extract cancerous tissue. The method significantly improves on the current system by accelerating all computations using a graphical processing unit (GPU) keeping the accuracy of biopsy target locations within tolerance. The result is the computation of target locations to guide biopsy using statistical priors of cancers from a large population, as well as based on previous biopsy locations for the same patient, and finally via mapping protocols with predefined needle configurations onto the patient's current ultrasound image.

Owner:EIGEN INC

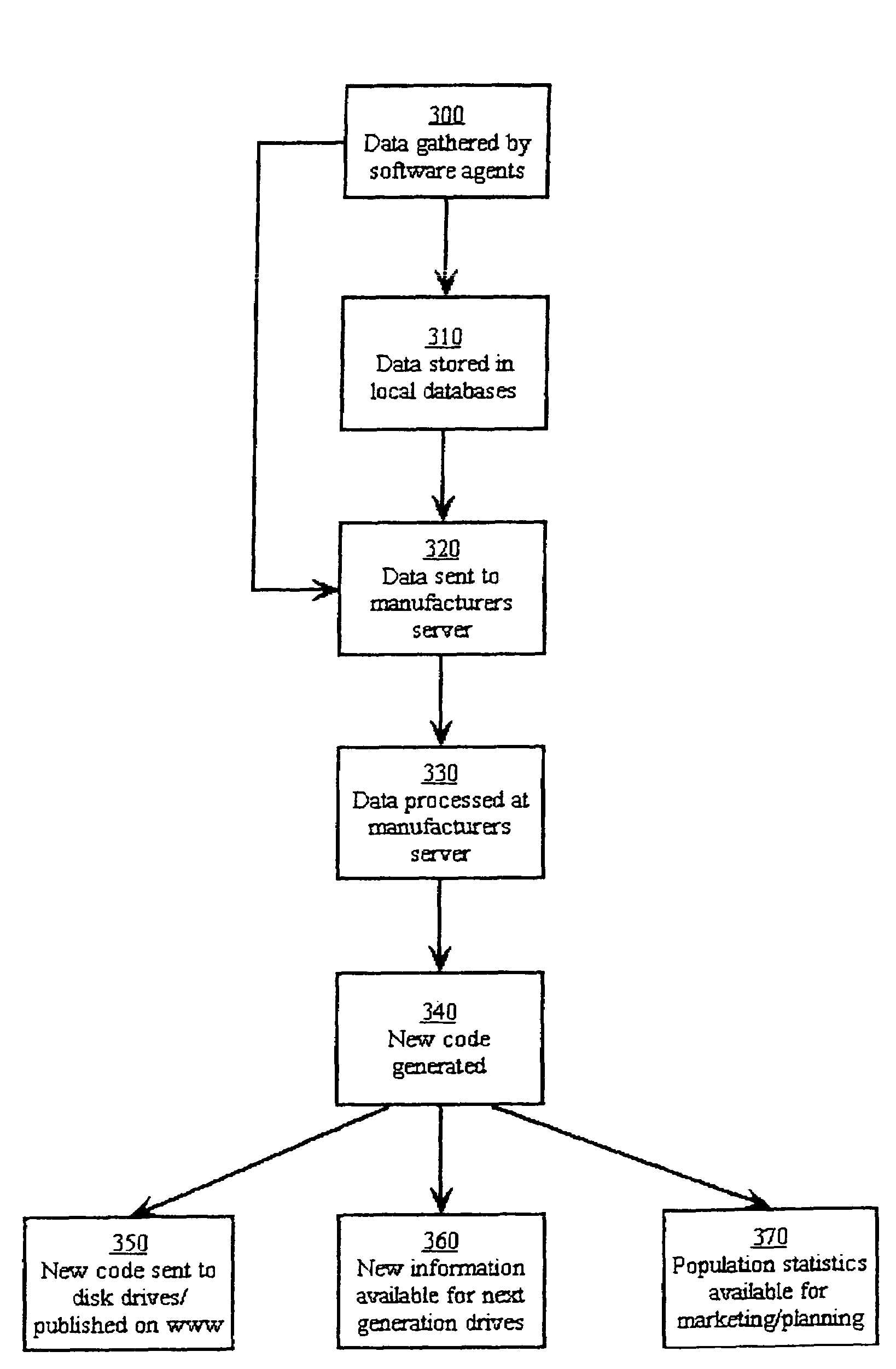

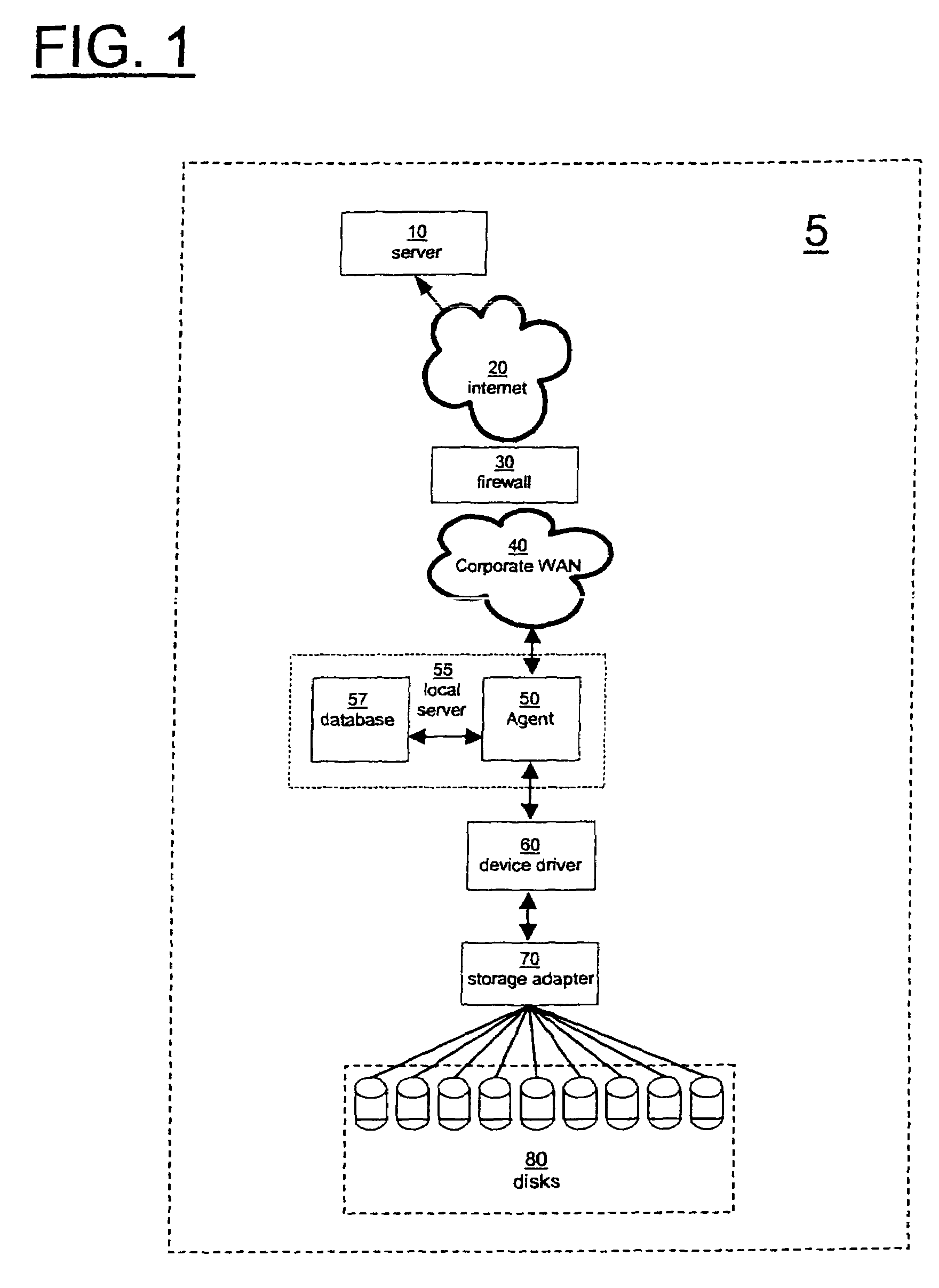

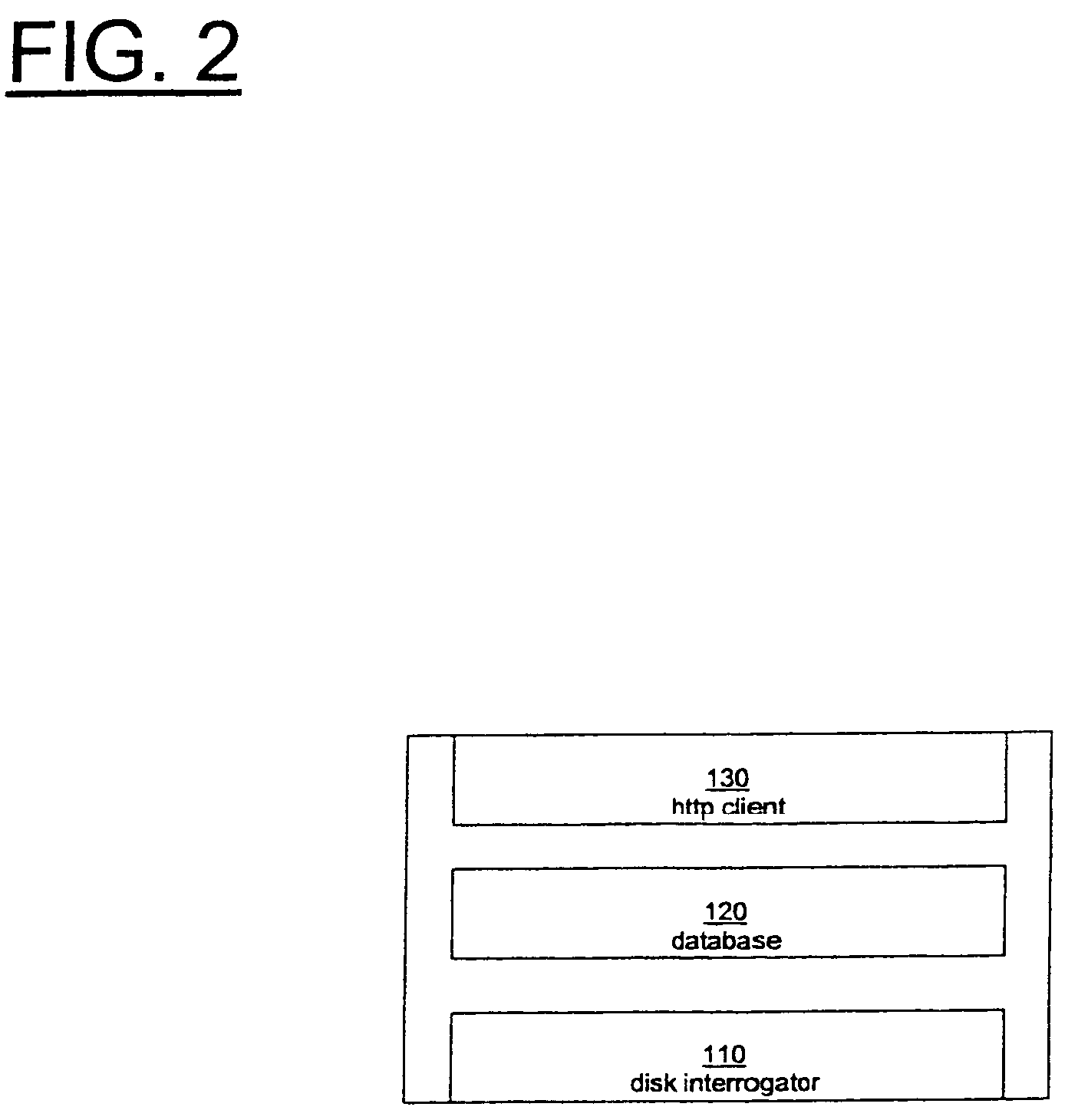

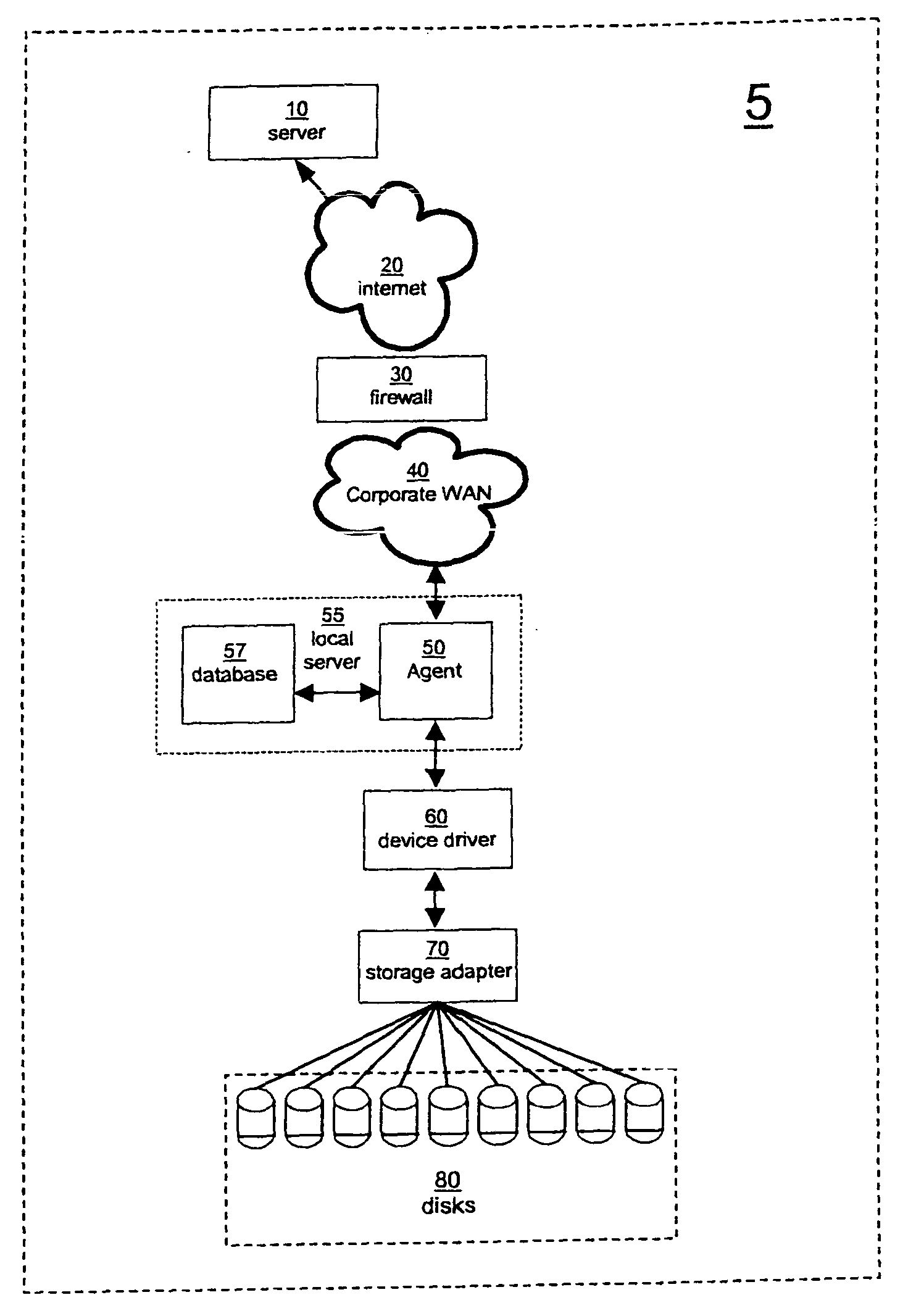

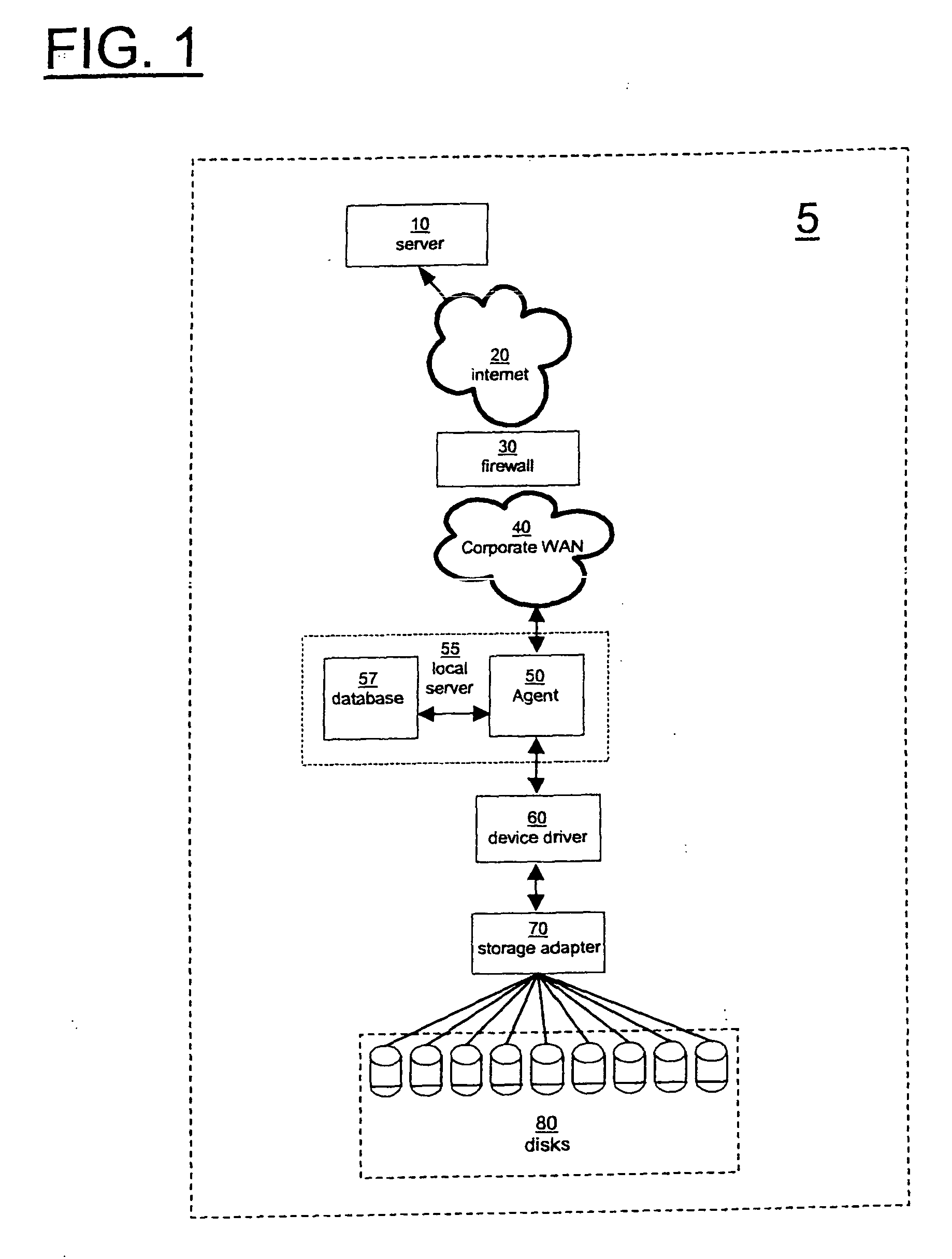

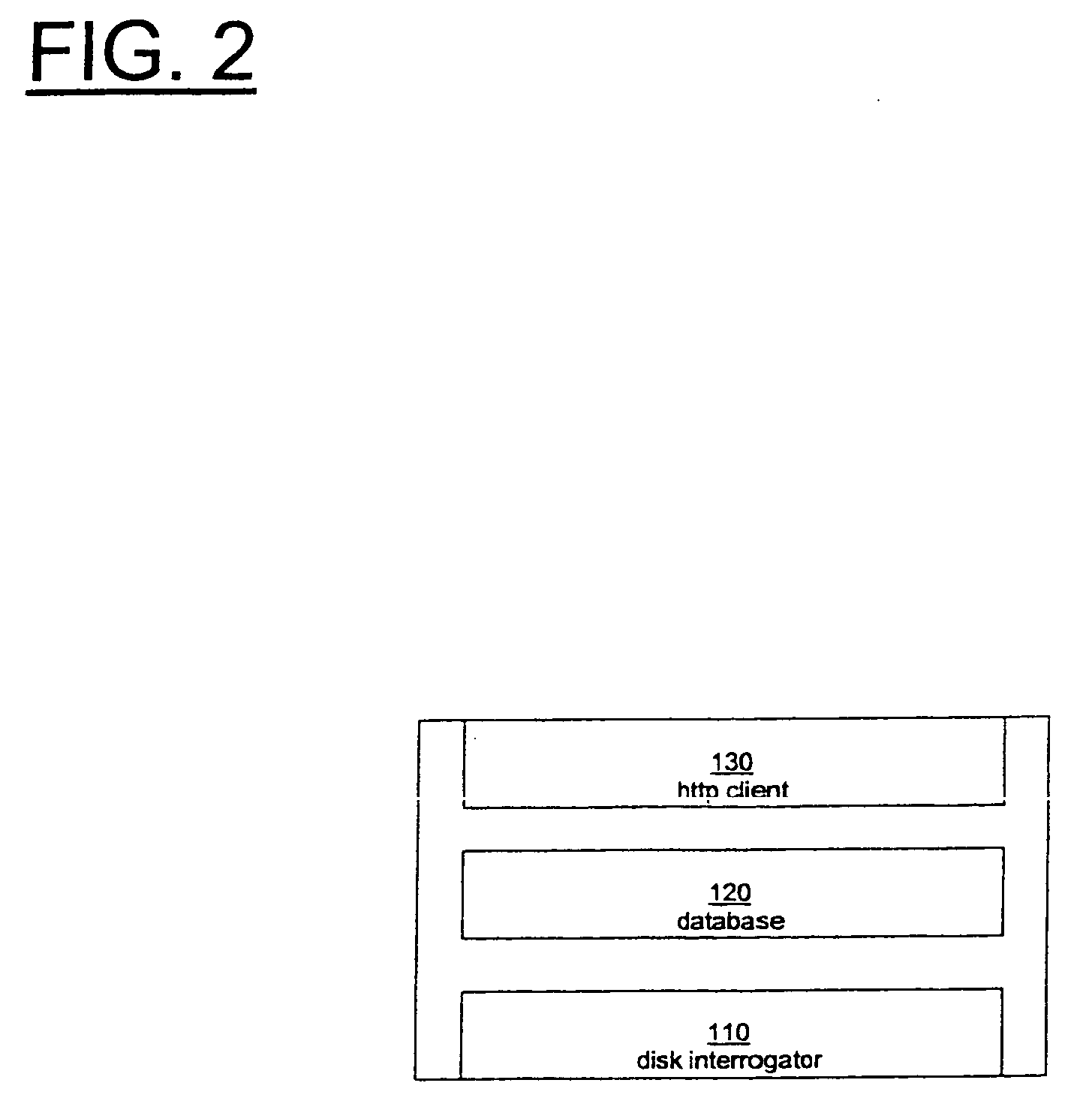

Device, system and method for predictive failure analysis

ActiveUS7370241B2Improving predictive failure attributeEasy to operateDigital computer detailsNuclear monitoringHard disc driveAnalysis data

A large population of mass-produced devices (80) such as a particular model of computer hard disk drive, are distributed around the world. Each device (80) includes an arrangement for collecting failure analysis data of the device (50). Each device (80) is arranged to transmit this data to the device manufacturers server (10) via the internet (20). The server (10) analyses the data in order to determine trends in failure performance of the population of devices in order to improve future designs and to provide updated software for distribution to the devices (80) via the internet (20).

Owner:META PLATFORMS INC

Bioindex mechanism for increasing the relative speed of biometric identification against large population samples

ActiveUS7474769B1Reduce the populationIncrease rangeDigital data processing detailsUnauthorized memory use protectionSmall sampleData mining

A method and system for determining a smaller sample of large data objects to search through for a match to one under test. The data objects are in preferred embodiments biometric templates.

Owner:UNISYS CORP

Auto-focus image system

InactiveUS20110273610A1Remove asymmetryImage enhancementTelevision system detailsAutofocusSignal generator

An auto focus image system that includes a pixel array coupled to a focus signal generator. The pixel array captures an image that has at least one edge with a width. The focus signal generator may generate a focus signal that is a function of the edge width and / or statistics of edge widths. A processor receives the focus signal and / or the statistics of edge widths and adjust a focus position of a focus lens. The edge width can be determined by various techniques including the use of gradients. A histogram of edge widths may be used to determine whether a particular image is focused or unfocused. A histogram with a large population of thin edge widths is indicative of a focused image. Edge corruption / partial corruption may be detected. Partially corrupted edge may have edge width calculated by relying more on the side that is not corrupted and less on the side that is corrupted. Edge or edge side corruption may be detected by detecting a presence of an adjacent edge of the opposite sign.

Owner:TAY HIOK NAM

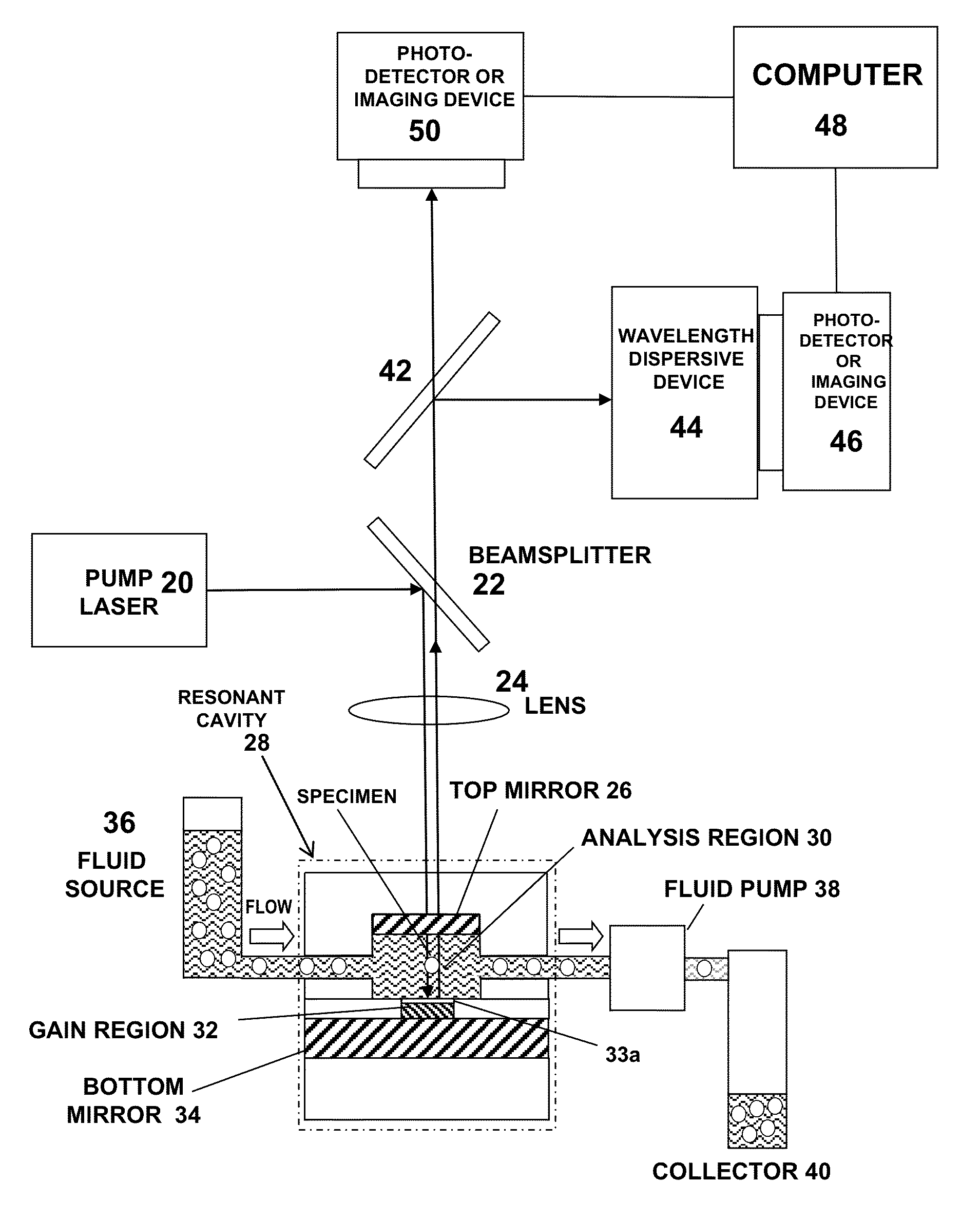

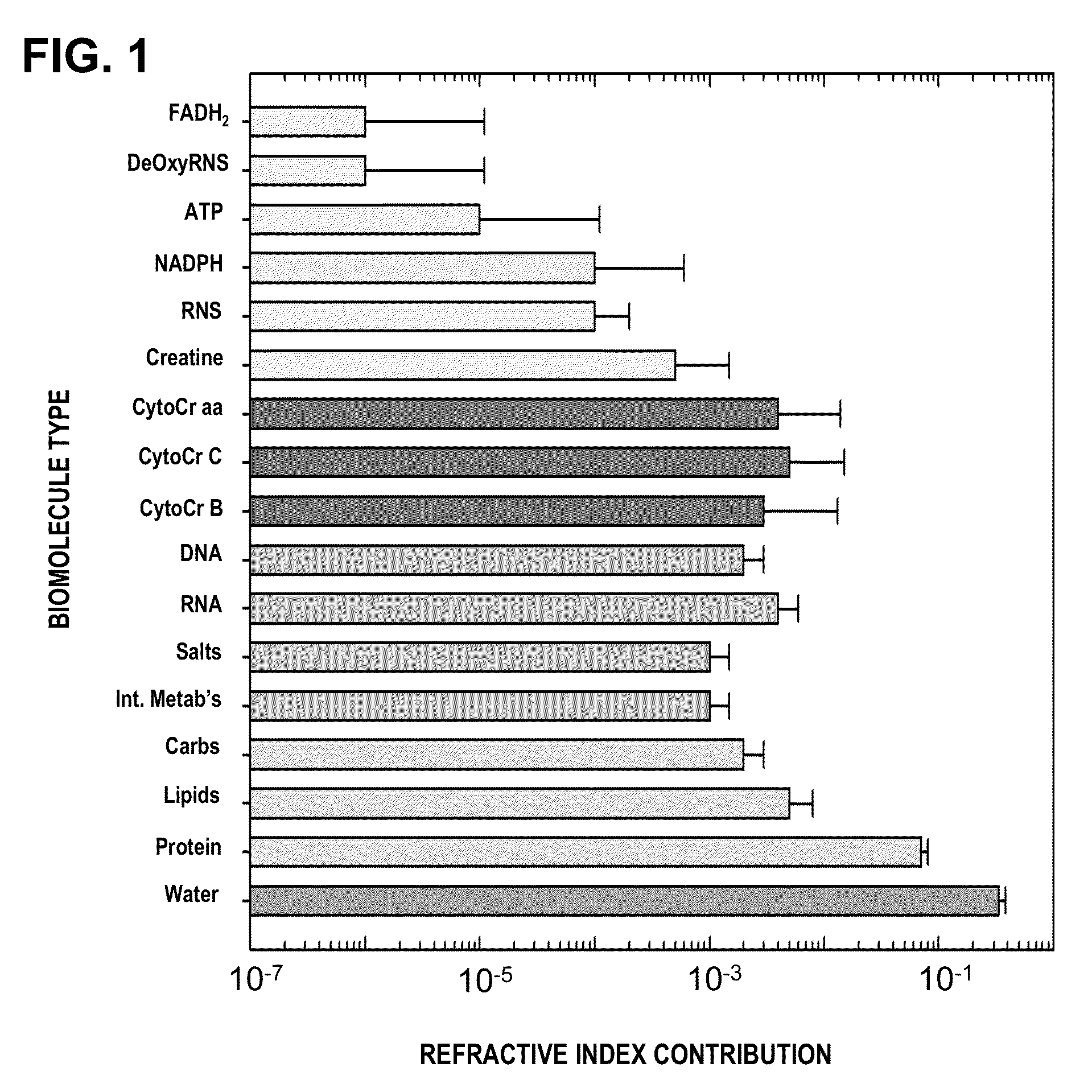

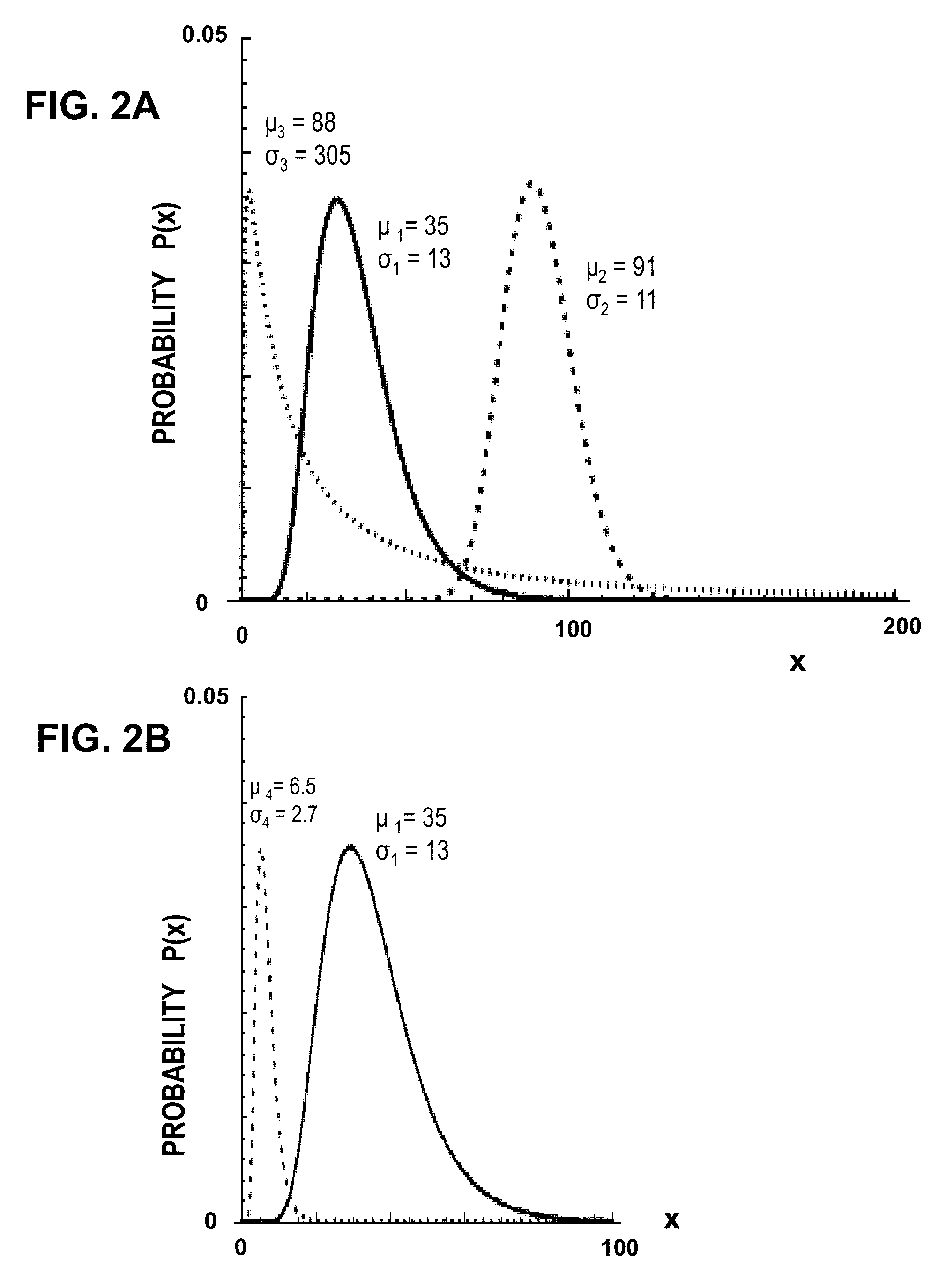

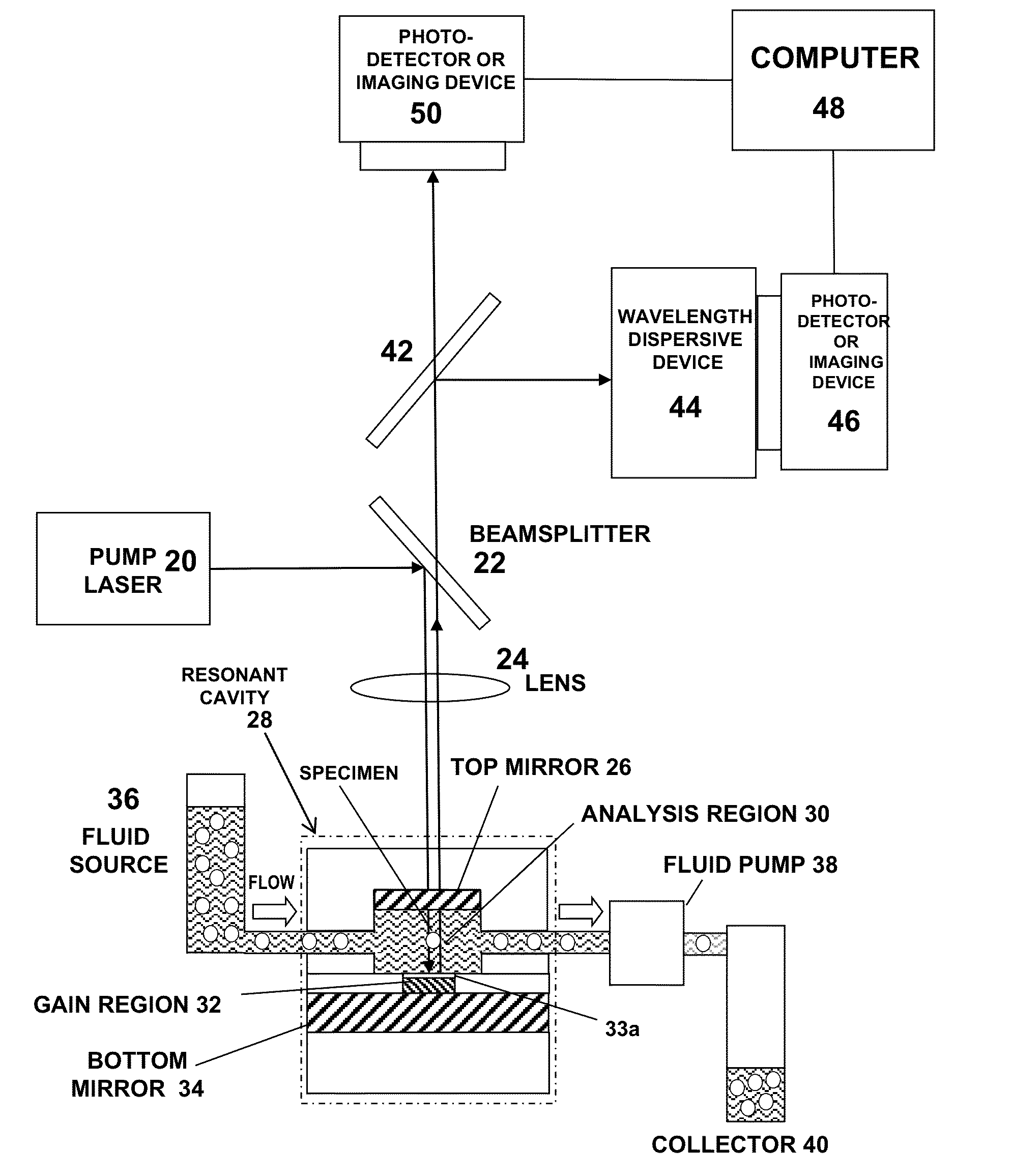

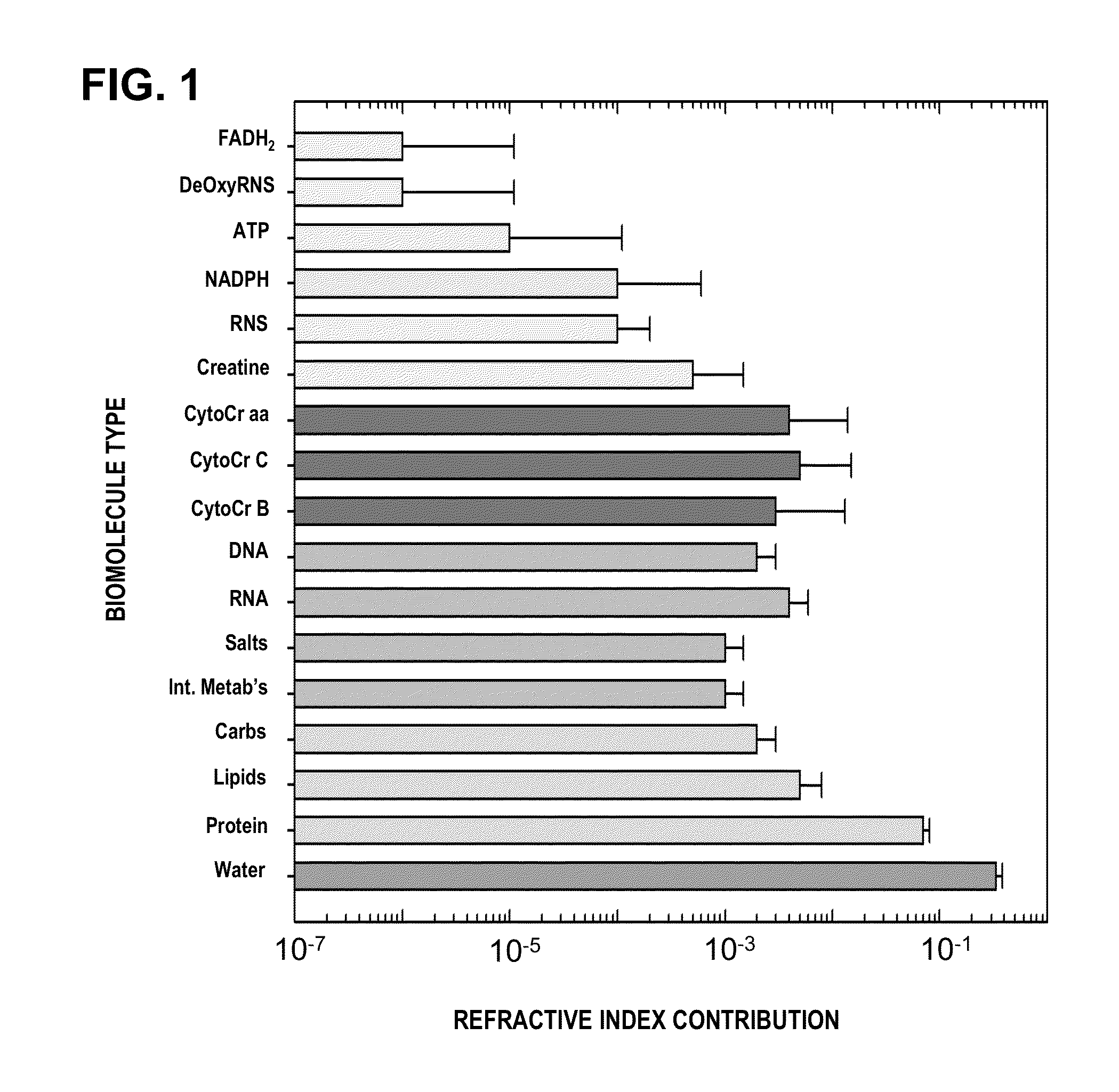

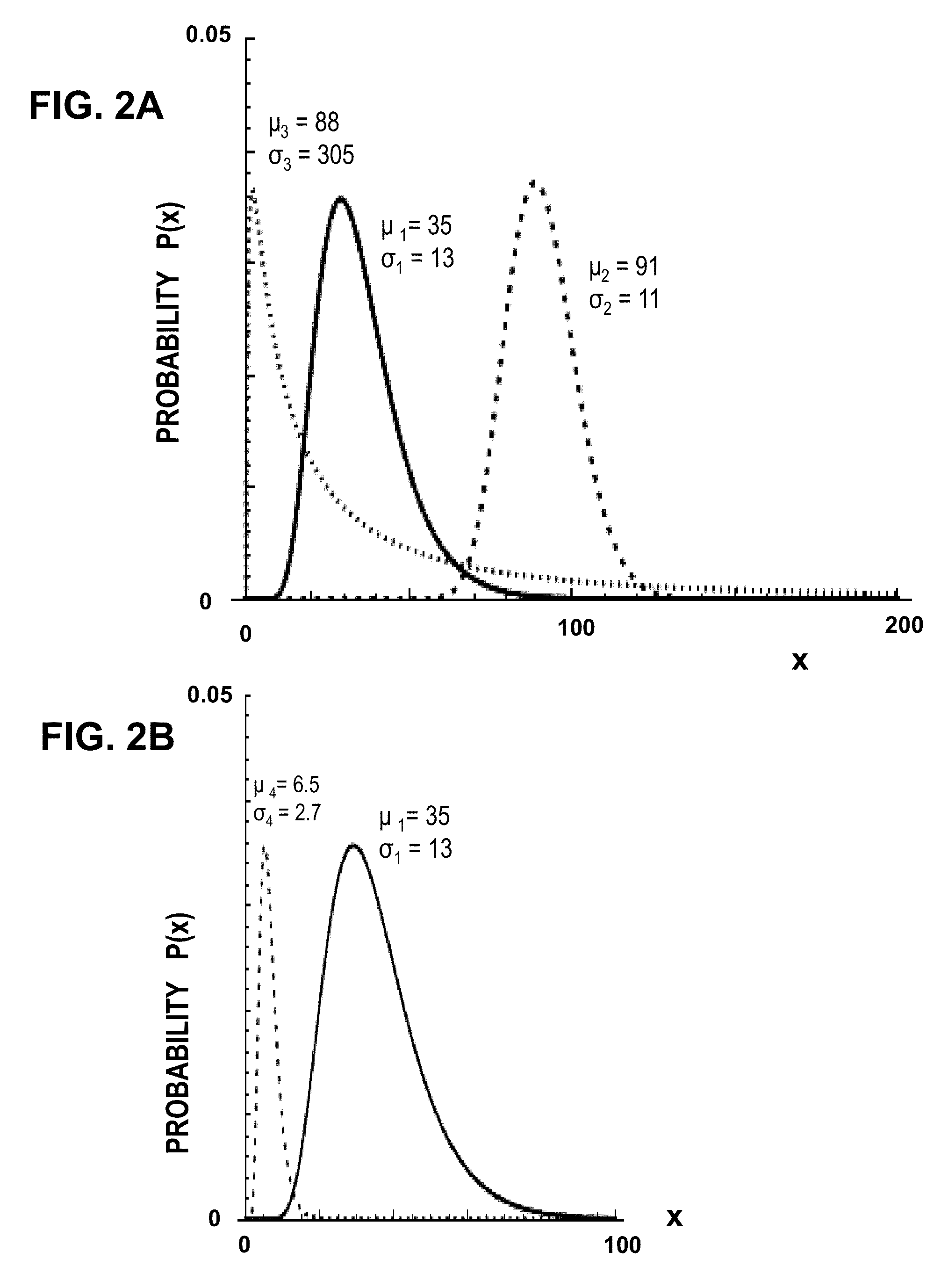

Micro-optical cavity with fluidic transport chip for bioparticle analysis

ActiveUS9063117B2Less-costly to fabricateEasy to measureScattering properties measurementsIndividual particle analysisResonant cavityOptical property

This invention provides new methods and apparatus for rapidly analyzing single bioparticles to assess their material condition and health status. The methods are enabled by a resonant cavity to measure optical properties related to the bioparticle size and refractive index. Refractive index measurements are useful for determining material properties and biomolecular composition of the bioparticle. These properties and composition are dependent on the health state of the bioparticle. Thus, measured optical properties can be used to differentiate normal (healthy) and abnormal (diseased) states of bioparticles derived from cells or tissues. The methods are illustrated with data obtained from a resonator with a gain medium. The invention also provides new methods for multiple measurements in a single device, analyzing and manipulating bioparticles that are much smaller than the wavelength of light, and provides a microfluidic transport chip to enable rapid single bioparticle analysis of large populations of bioparticles.

Owner:GOURLEY PAUL L

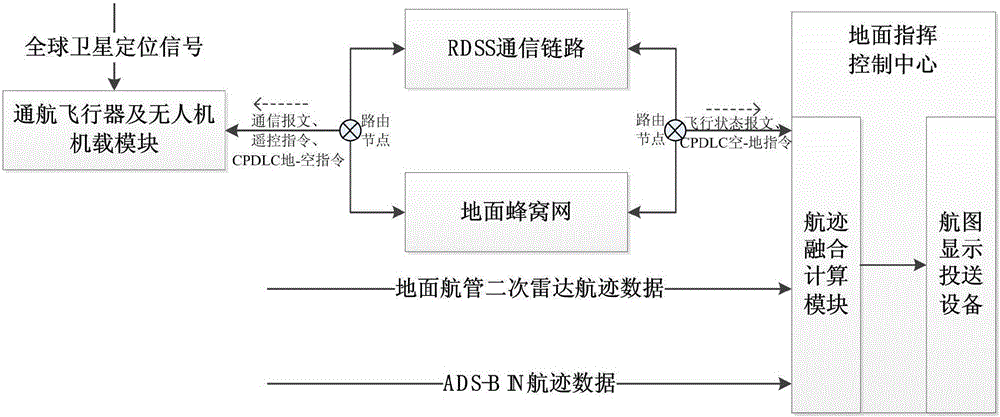

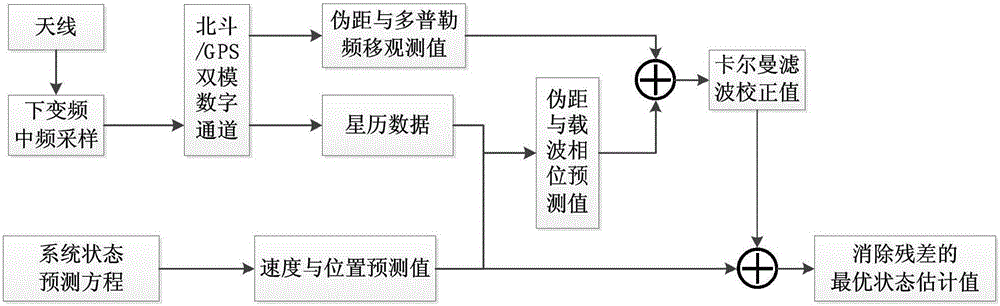

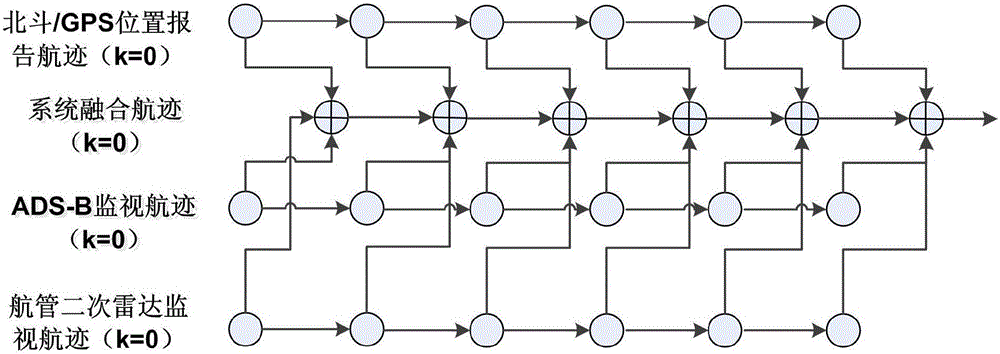

Safety monitoring method for universal aerial vehicle and unmanned aerial vehicle

ActiveCN105867272AEfficient managementEnable seamless monitoringProgramme controlComputer controlSecondary surveillance radarIntellectual property

The invention provides a safety monitoring method for a universal aerial vehicle and an unmanned aerial vehicle. The safety monitoring method aims at problems of single safety monitoring facility and low strength in existing low-altitude flight. Beidou RNSS and GPSL1 combined passive positioning technology, RDSS and ground cellular network communication technology are used for finishing flight state reporting and flight route service pushing of the universal aerial vehicle and the unmanned aerial vehicle. The safety monitoring method is characterized in that in cities and areas with large population density and ground cellular network coverage, comprehensive monitoring is performed through a ground secondary surveillance radar, ADS-B ground station equipment and Beidou / GPS double-mode positioning technology, thereby ensuring high accuracy of an aerial vehicle track; and in undeveloped and remote mountainous regions and areas without secondary surveillance radar or ADS-B ground station coverage, a lowest monitoring performance standard of the aerial vehicle is kept by means of Beidou / GPS double-mode positioning and Beidou RDSS communication. The safety monitoring method according to the invention is the low-altitude space domain safety monitoring method which has advantages of high universality, easy disposition and Chinese proprietary intellectual property right.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

Micro-Optical Cavity with Fluidic Transport Chip for Bioparticle Analysis

ActiveUS20150049333A1Less-costly to fabricateEasy to measureScattering properties measurementsIndividual particle analysisResonant cavityOptical property

This invention provides new methods and apparatus for rapidly analyzing single bioparticles to assess their material condition and health status. The methods are enabled by a resonant cavity to measure optical properties related to the bioparticle size and refractive index. Refractive index measurements are useful for determining material properties and biomolecular composition of the bioparticle. These properties and composition are dependent on the health state of the bioparticle. Thus, measured optical properties can be used to differentiate normal (healthy) and abnormal (diseased) states of bioparticles derived from cells or tissues. The methods are illustrated with data obtained from a resonator with a gain medium. The invention also provides new methods for multiple measurements in a single device, analyzing and manipulating bioparticles that are much smaller than the wavelength of light, and provides a microfluidic transport chip to enable rapid single bioparticle analysis of large populations of bioparticles.

Owner:GOURLEY PAUL L

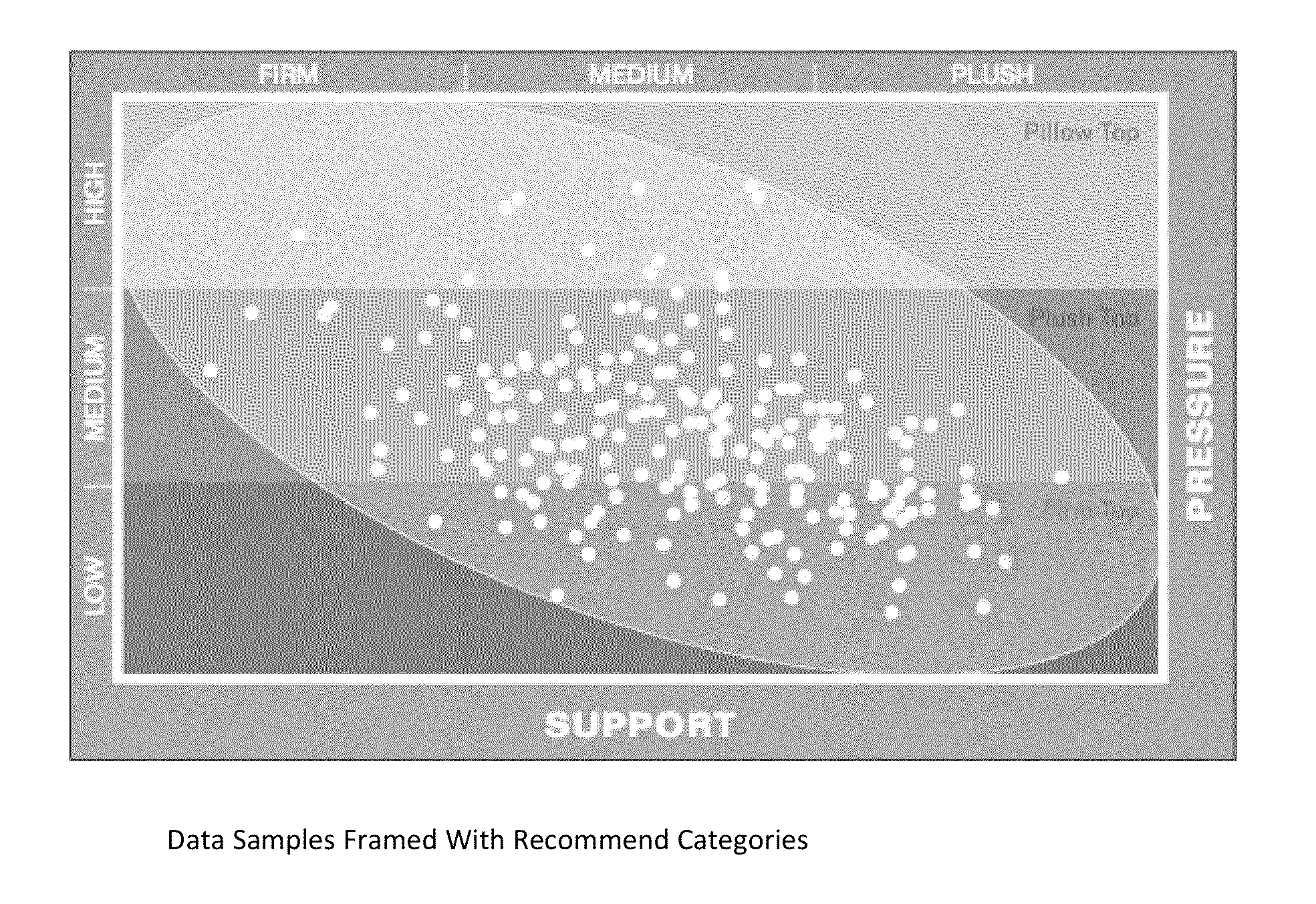

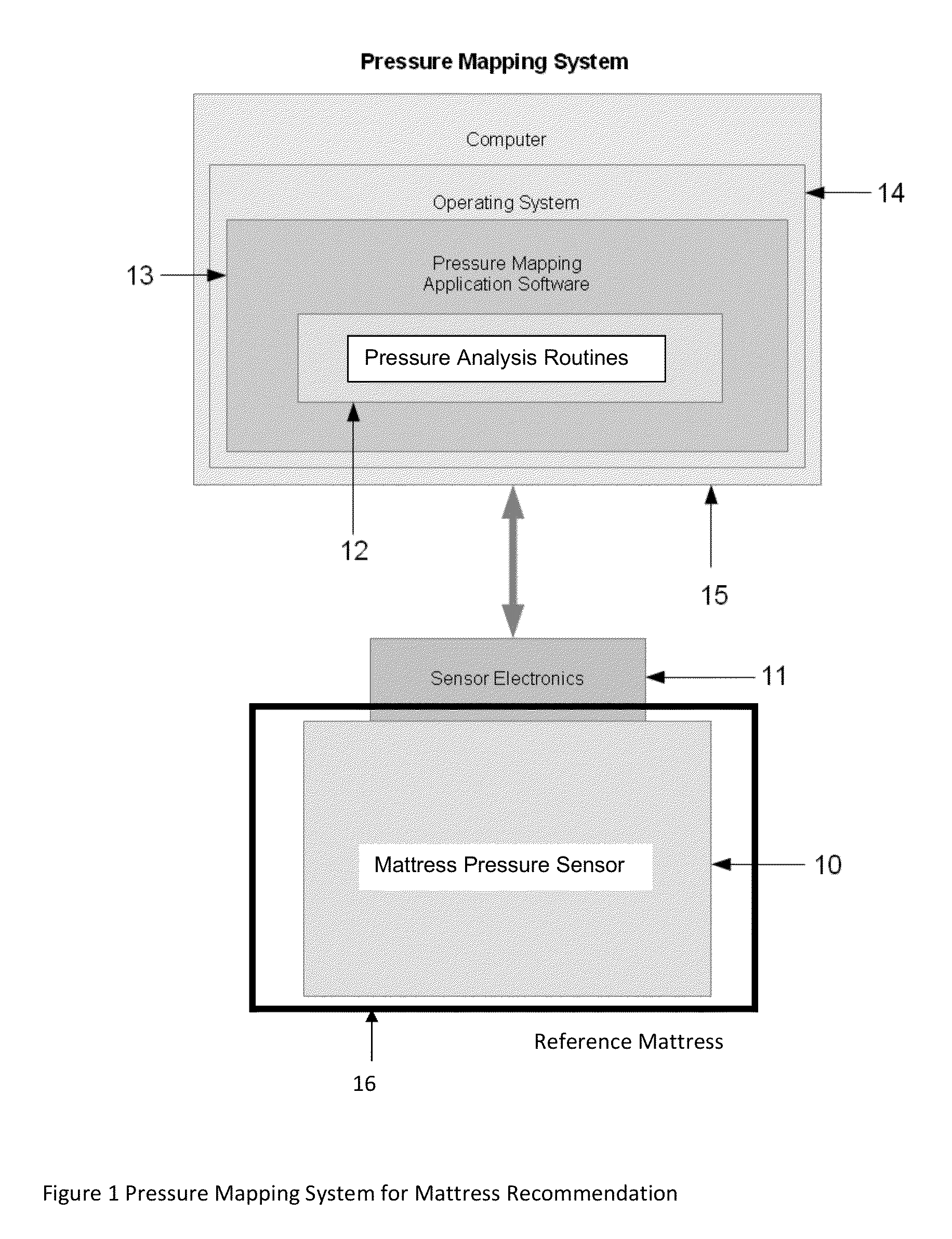

Graphical Display for Recommending Sleep Comfort and Support Systems

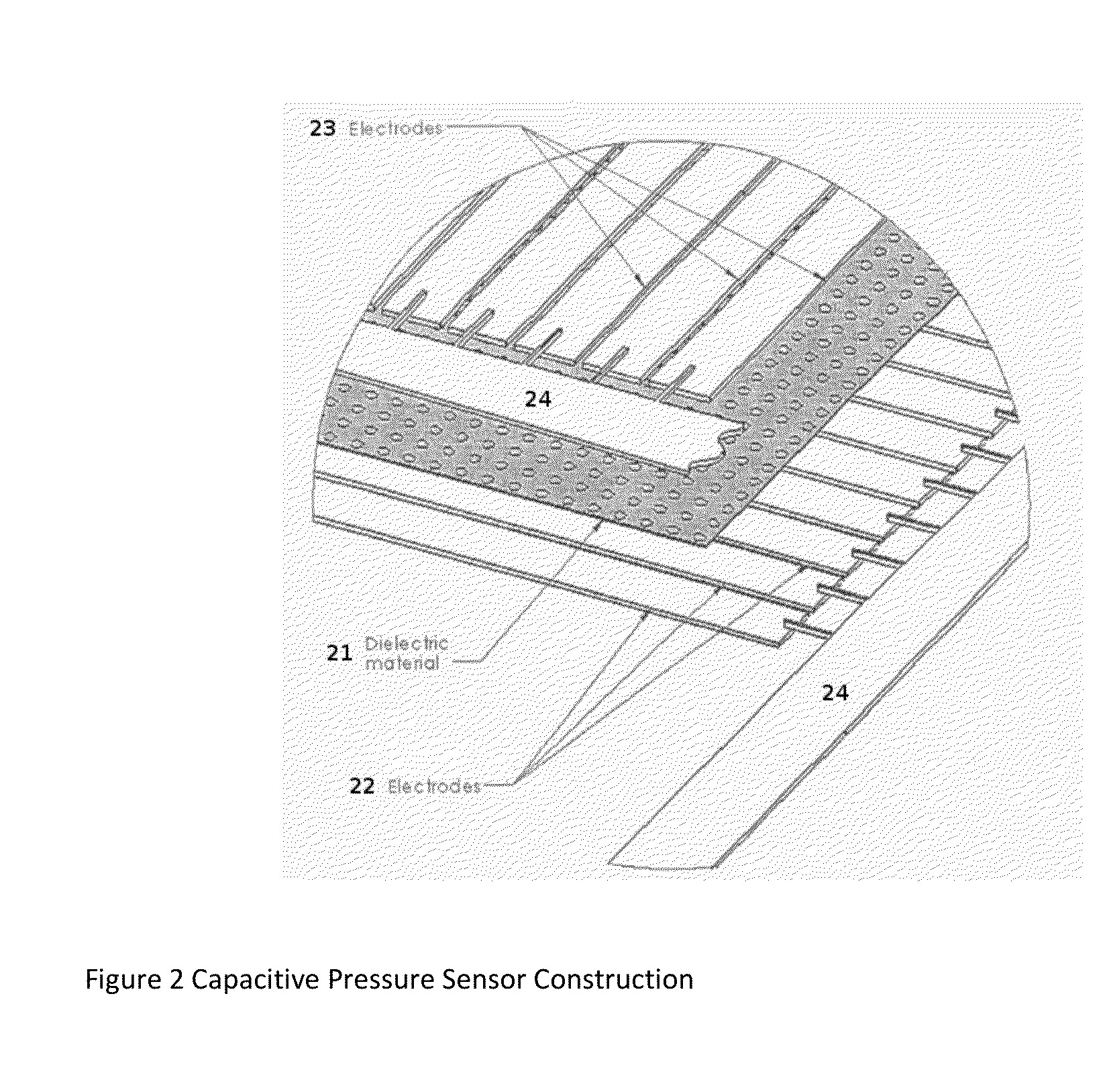

ActiveUS20130144751A1Seating furnitureBuying/selling/leasing transactionsPressure dataFeature parameter

A pressure sensor measures the surface pressure distribution of a body supported by a surface, for example a person lying on a mattress. In one approach, a pressure mapping system acquires a customer's pressure map using a reference mattress and presents this pressure data in the form of a pressure map. The pressure map measurement data is then analyzed to determine body characterizing parameters such as body mass index, contact area and average peak pressure. The pressure map measurements are then located on a mattress category grid that has been referenced and aligned to a large population sample of measurements taken with a reference mattress. Alternatively, the pressure map measurements are matched to a physical profile category within a database. Each category provides ranked mattress recommendations based on selection and ranking criteria derived from pressure map data obtained from a large sample of test subjects. In this way, a customer's pressure map can be translated to a recommendation of specific mattresses or mattress categories that are offered by a mattress retailer or manufacturer.

Owner:XSENSOR TECH CORP

Device, system and method for predictive failure analysis

ActiveUS20050278575A1Reduce disadvantagesImproving predictive failure attributeNuclear monitoringDigital computer detailsHard disc driveAnalysis data

A large population of mass-produced devices (80) such as a particular model of computer hard disk drive, are distributed around the world. Each device (80) includes an arrangement for collecting failure analysis data of the device (50). Each device (80) is arranged to transmit this data to the device manufacturers server (10) via the internet (20). The server (10) analyses the data in order to determine trends in failure performance of the population of devices in order to improve future designs and to provide updated software for distribution to the devices (80) via the internet (20).

Owner:META PLATFORMS INC

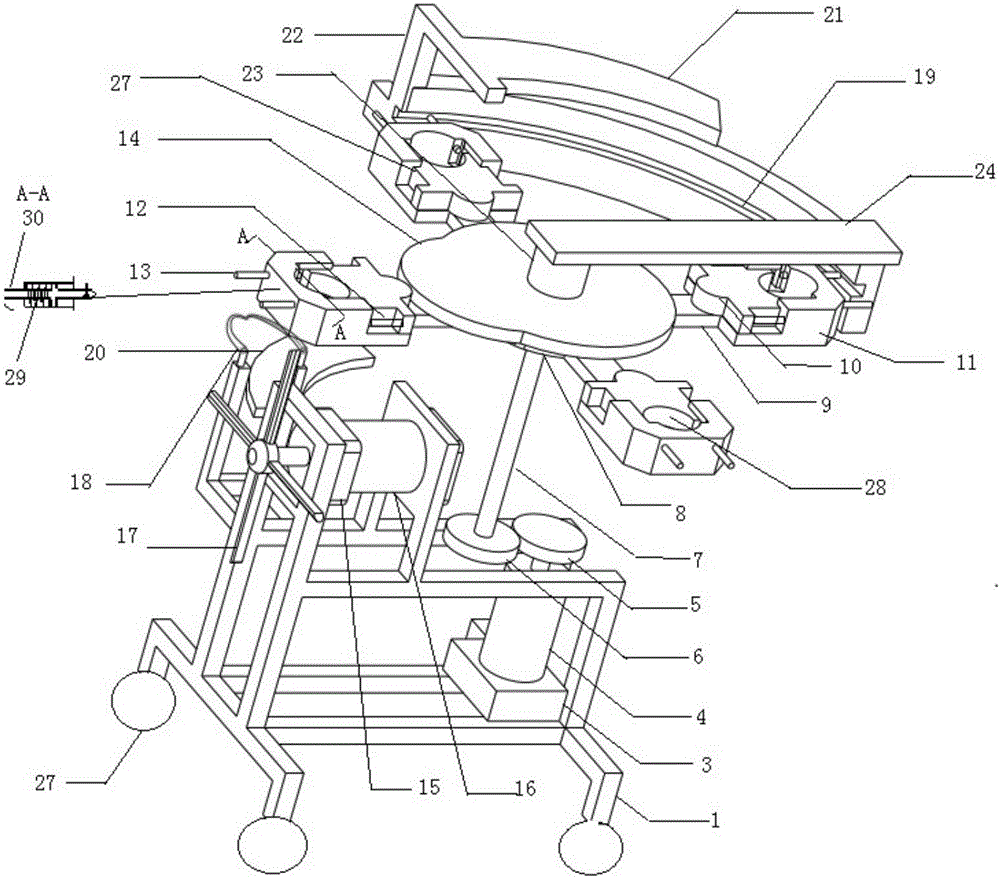

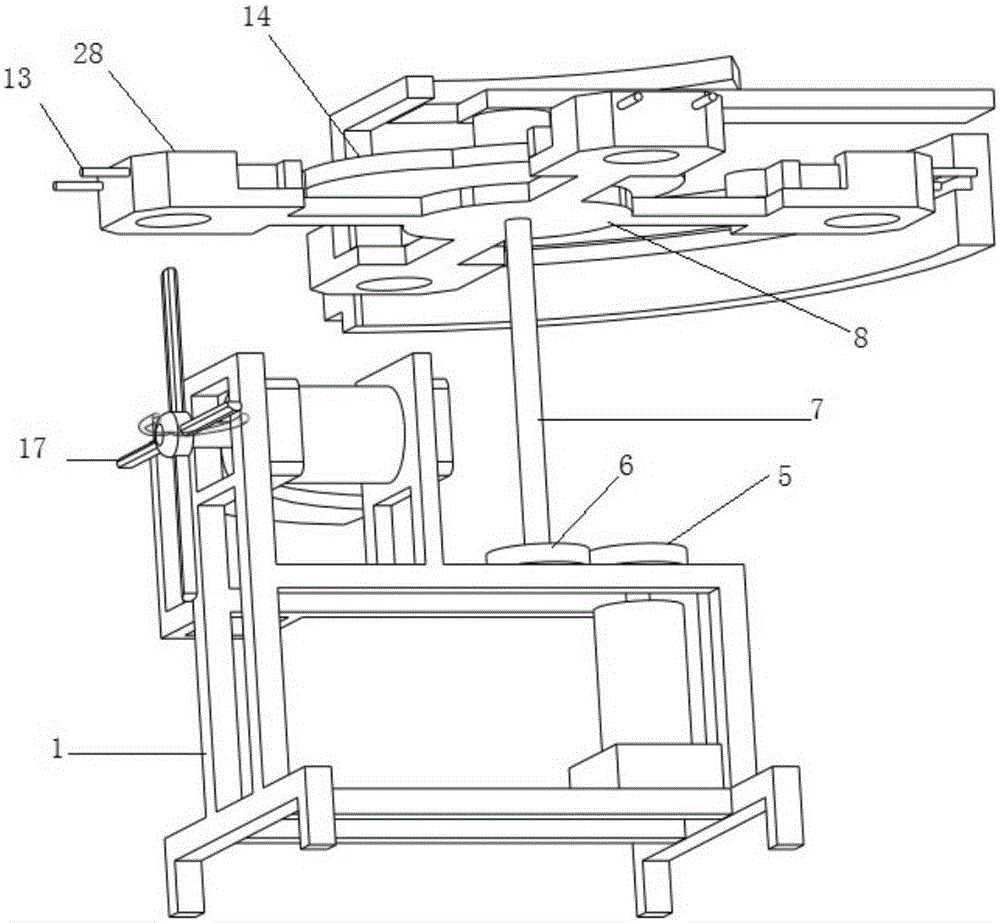

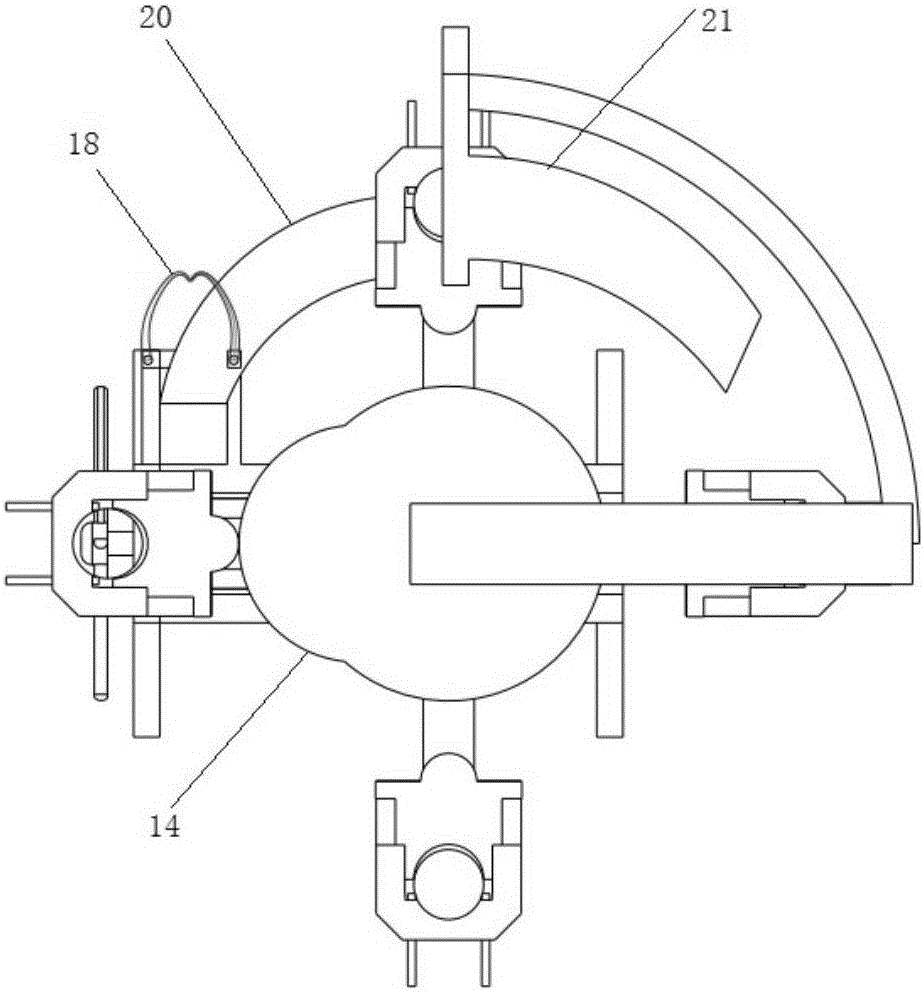

Automatic bottle cap separation machine for plastic bottles

The invention relates to the technical field of classification treatment of plastic bottle materials, in particular to an automatic bottle cap separation machine for plastic bottles. The automatic bottle cap separation machine comprises a rack, a machine box, a direct-current drive motor, a driving intermittent gear, a driven intermittent gear, a center transmission shaft, a rotary disc, rotary arms, locating front concave plates, locating rear concave plates, springs, locking devices, a cam, a variable-speed motor, a spiral cutter, a claw-shaped bent hook, an arc-shaped sliding groove, an arc-shaped baffle, an arc-shaped pressing plate and the like. The combination manner of manual feeding and mechanical automatic machining is adopted for production, so that locating clamping, cutting, bottle cap and bottle mark separation, automatic recycling and a series of actions on the plastic bottles can be completed through the mechanical device. The automatic bottle cap separation machine is mainly used for regions with large population density and mobility such as shopping malls, supermarkets and schools; consumed empty bottles are directly put into the machine, the machine is started and conducts automatic machining, the machined bottle marks, bottle caps and bottle bodies automatically fall into corresponding collection boxes on the lower portion, no specially-assigned person is needed for operation, and manual handling is conducted after the collection boxes are full.

Owner:重庆圆润塑胶制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com