Construction method for barrel type underground garage

A construction method and technology of underground garages, which are applied in the direction of buildings, buildings, building types, etc. where cars are parked, can solve the problems of failure to meet the accuracy requirements of later equipment installation, easy leakage at the framing joints of underground diaphragm walls, and problems of underground diaphragm walls. Insufficient verticality of the wall and other problems, to achieve the effect of regular hole formation, simple construction process and large torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and all similar methods and similar changes of the present invention should be included in the protection scope of the present invention.

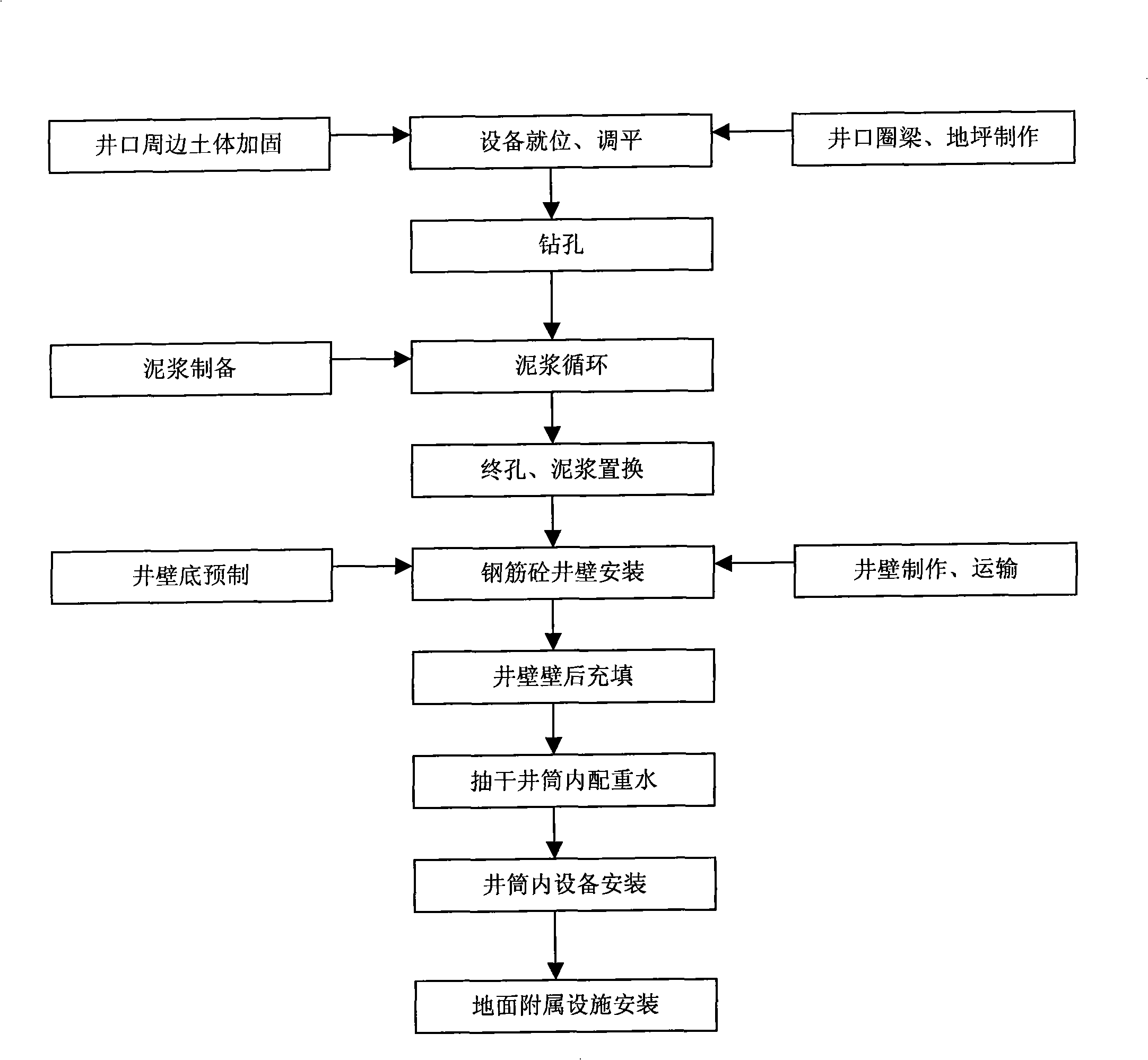

[0059] Depend on figure 1 As shown, the construction method of the tubular underground garage described in the embodiment of the present invention is as follows:

[0060]1) Reinforcement of the soil around the wellhead: The soil around the wellhead is reinforced using the SMW construction method. The reinforcement range is determined according to the stratum conditions around the wellhead and the surrounding environment after calculation, and the lock is made within a certain vertical depth in the wellhead;

[0061] 2) Manufacture of wellhead ring beam and floor: design the size and reinforcement of the wellhead ring beam and dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com