Automatic bottle cap separation machine for plastic bottles

A technology of automatic separation and plastic bottles, applied in the direction of plastic recycling, recycling technology, etc., can solve the problems of cost increase, low efficiency, production scale expansion, etc., and achieve the effect of good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

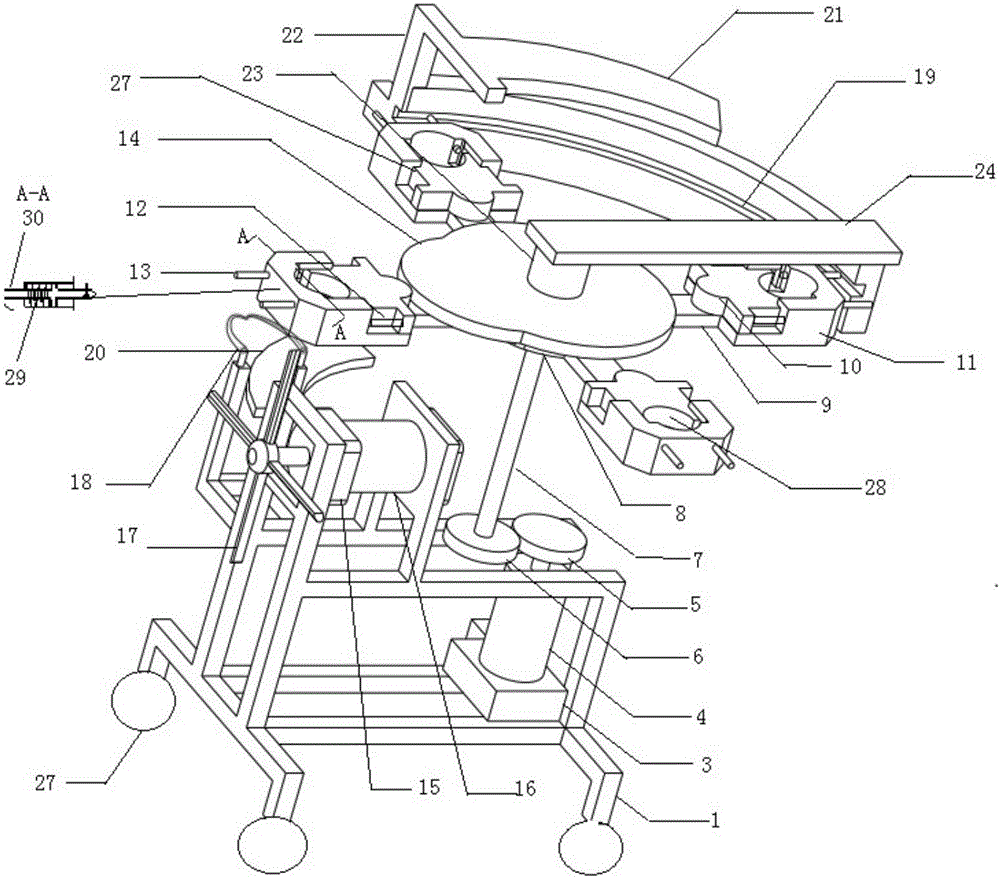

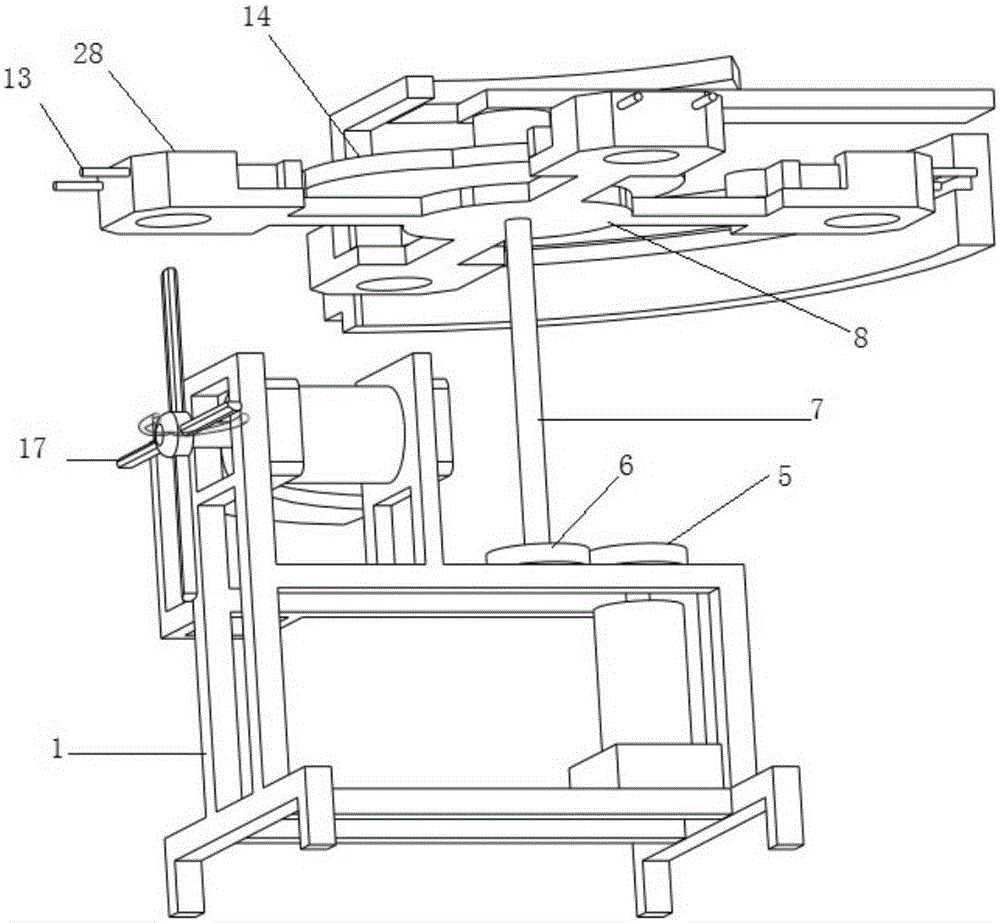

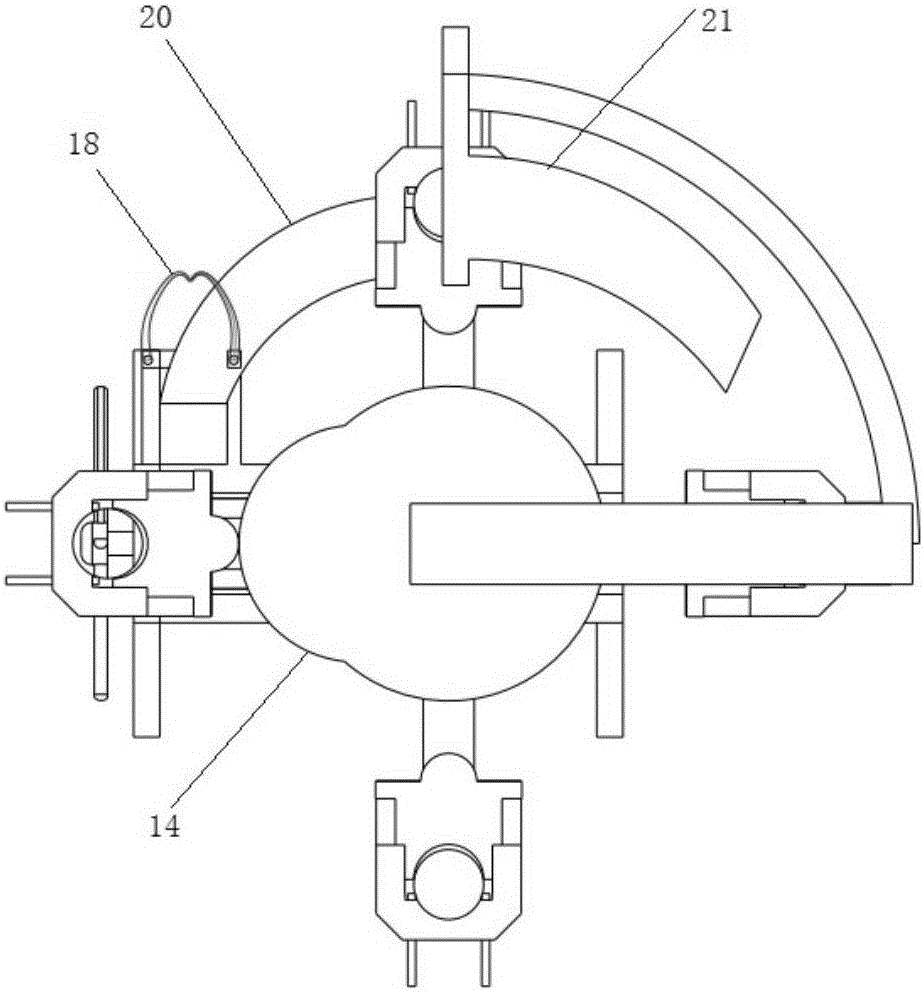

[0019] Specific implementation mode one: combine figure 1Shown, comprise frame 1, cabinet 2, motor seat 3, direct current driving motor 4, central transmission shaft 7, turntable 8, rotating arm 9, locking device 13, cam 14, cutting motor seat 15, speed-regulating motor 16, Spiral cutter 17, claw-shaped hook 18, arc-shaped chute 19, arc-shaped baffle 20, arc-shaped pressure plate 21, baffle bracket 22, rotating shaft 23, cam cantilever 24, universal wheel 27; frame 1 point It is the first layer bracket 101 and the second layer bracket 102, and the material is light stainless steel; the chassis 2 is a box body welded by aluminum alloy plates; the motor base 3 is connected to the first layer bracket 101 of the frame 1 by bolts; The DC drive motor 4 is vertically placed and connected to the motor base 3 by bolts, the output shaft faces upward and extends into the second layer of support 102; the active incomplete gear 5 is connected to the output shaft of the DC drive motor 4 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com