Nuclear second-stage electric V-shaped brake valve

An electric and gate valve technology, applied in the direction of sliding valves, valve details, valve devices, etc., can solve the problems of gate prolapse, valve loss of sealing function, and difficult sealing, etc., to prevent sealing surface wear, easy and convenient installation, and prevent internal leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The nuclear two-stage electric V-type gate valve provided by the present invention will be further described in detail below in conjunction with the drawings and embodiments.

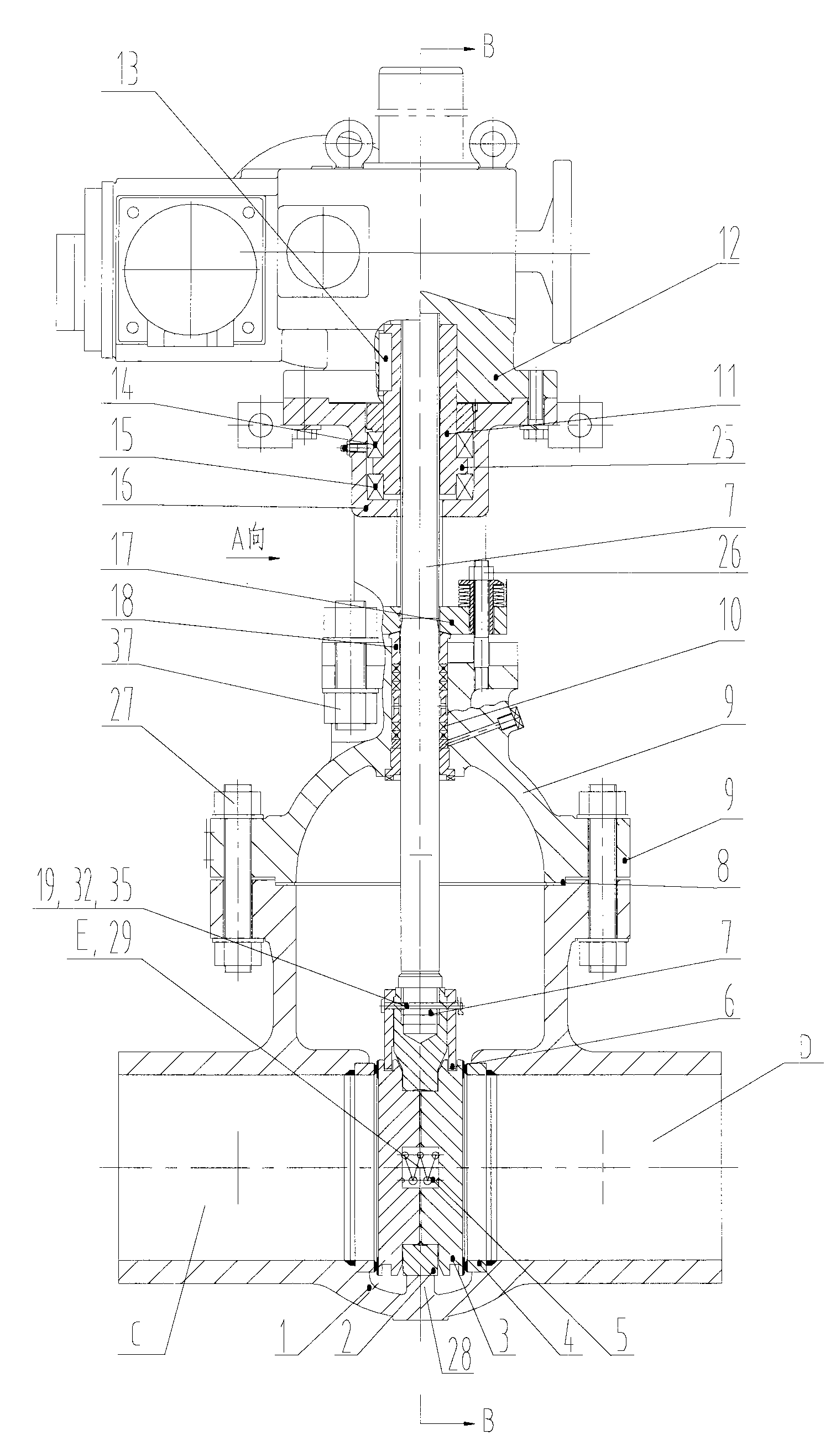

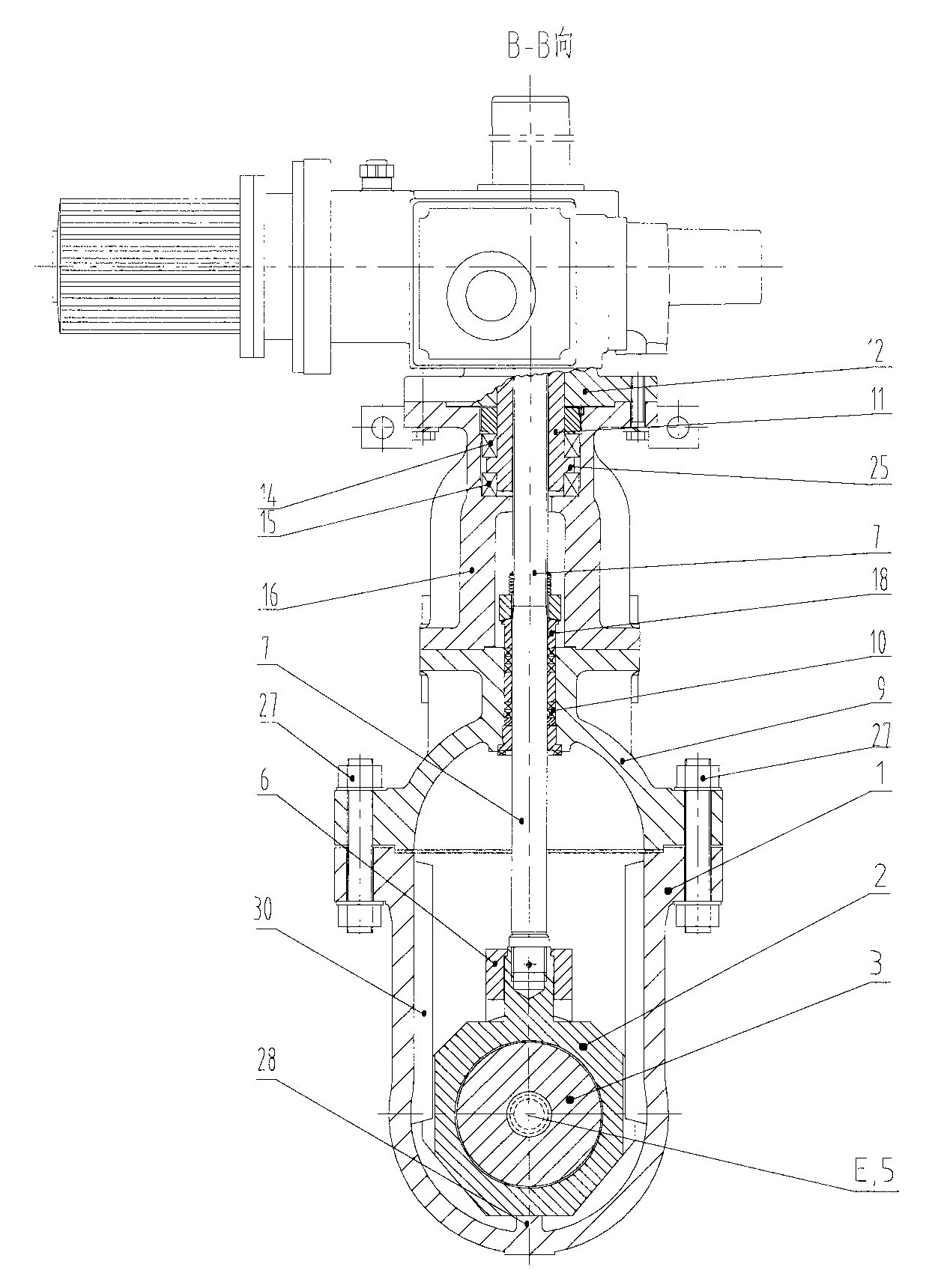

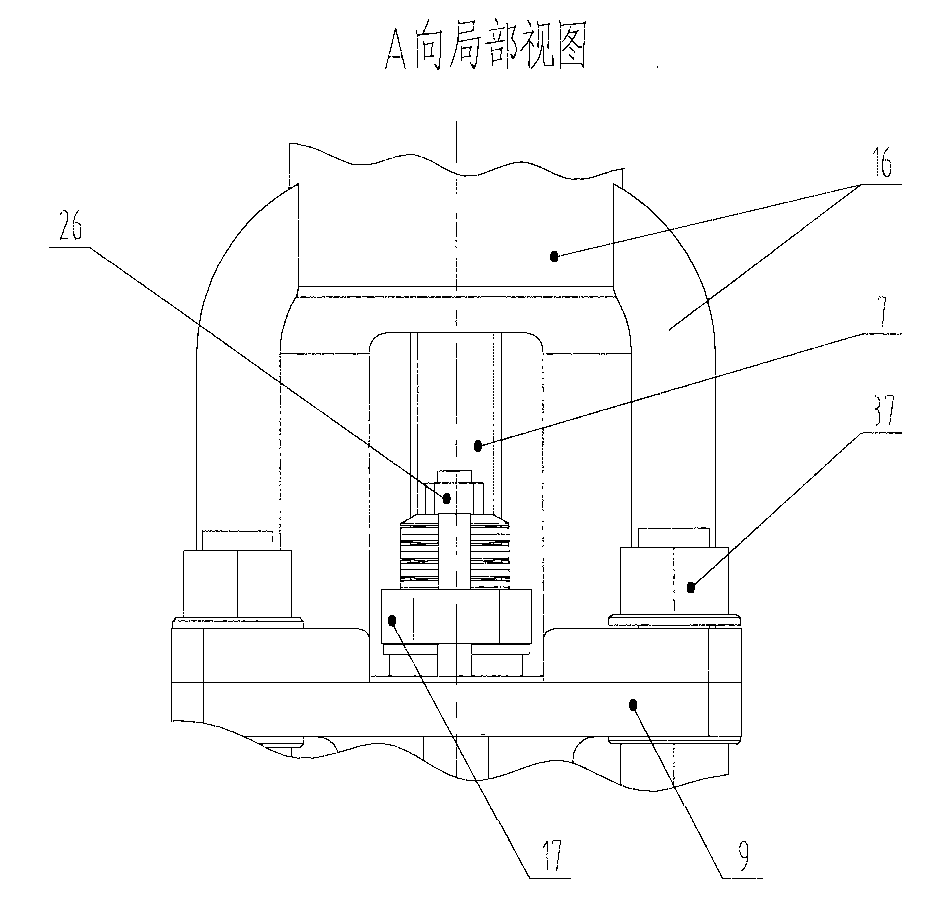

[0024] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a nuclear two-stage electric V-type gate valve includes an electric device 12, a valve stem nut 11 connected to the electric device 12 through a key 13, the valve stem nut 11 is set outside the valve stem 7, and the valve stem 7 is passed between the two. threaded connection. Stem nut 11 is overcoated with support 16, and stem nut 11 bottom is provided with cylinder valve stem nut boss 25, is provided with first bearing 15 between stem nut boss 25 bottoms and support 16, and cylinder boss top is provided with There is a second bearing 14 . The pressure plate 17 in the bottom of the bracket 16 is connected to the valve cover 9 by a stud 26 , and the bottom of the bracket 16 is connected to the valve cover 9 by a stud 37 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com