Patents

Literature

714 results about "Cylinder Valve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

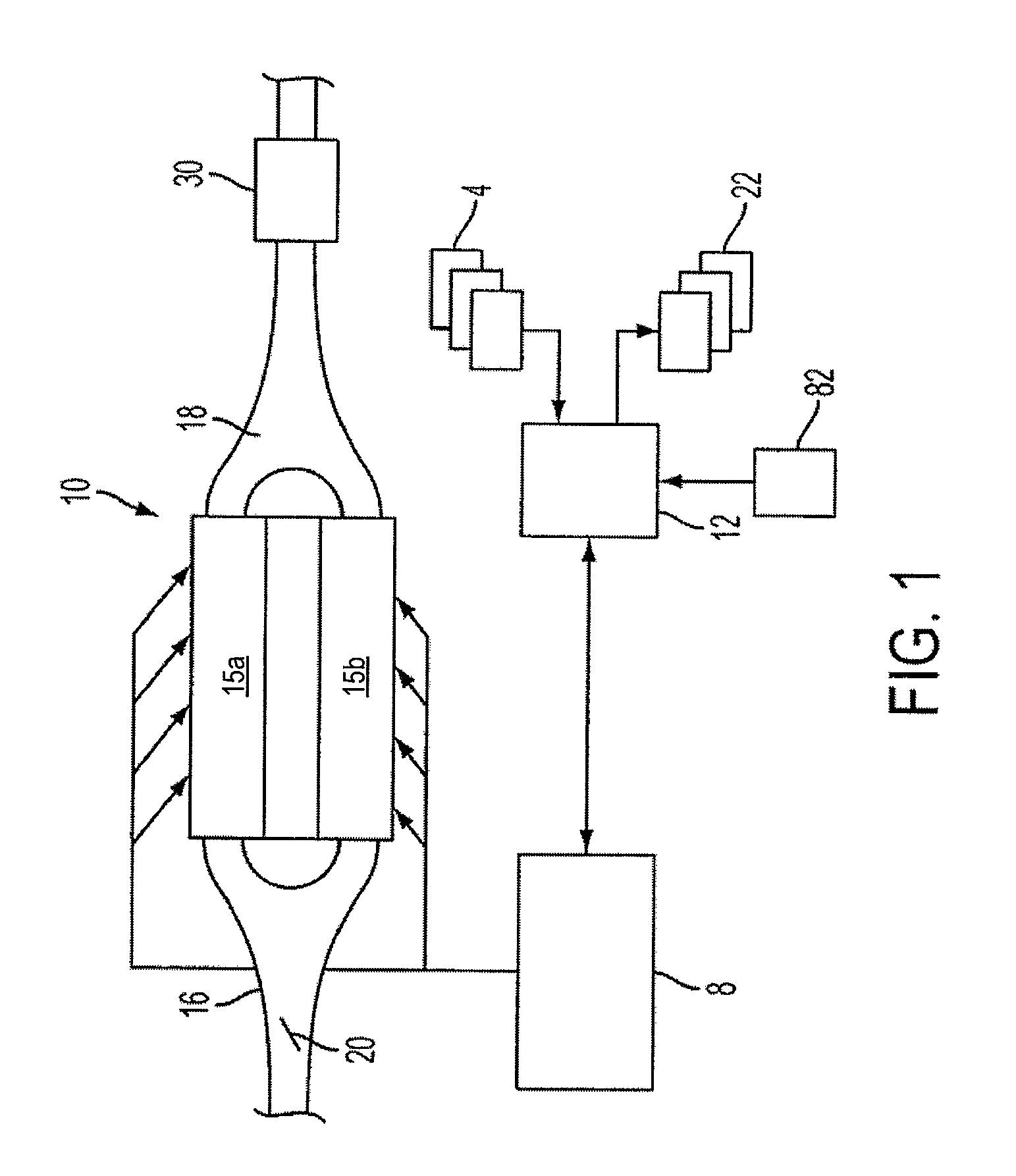

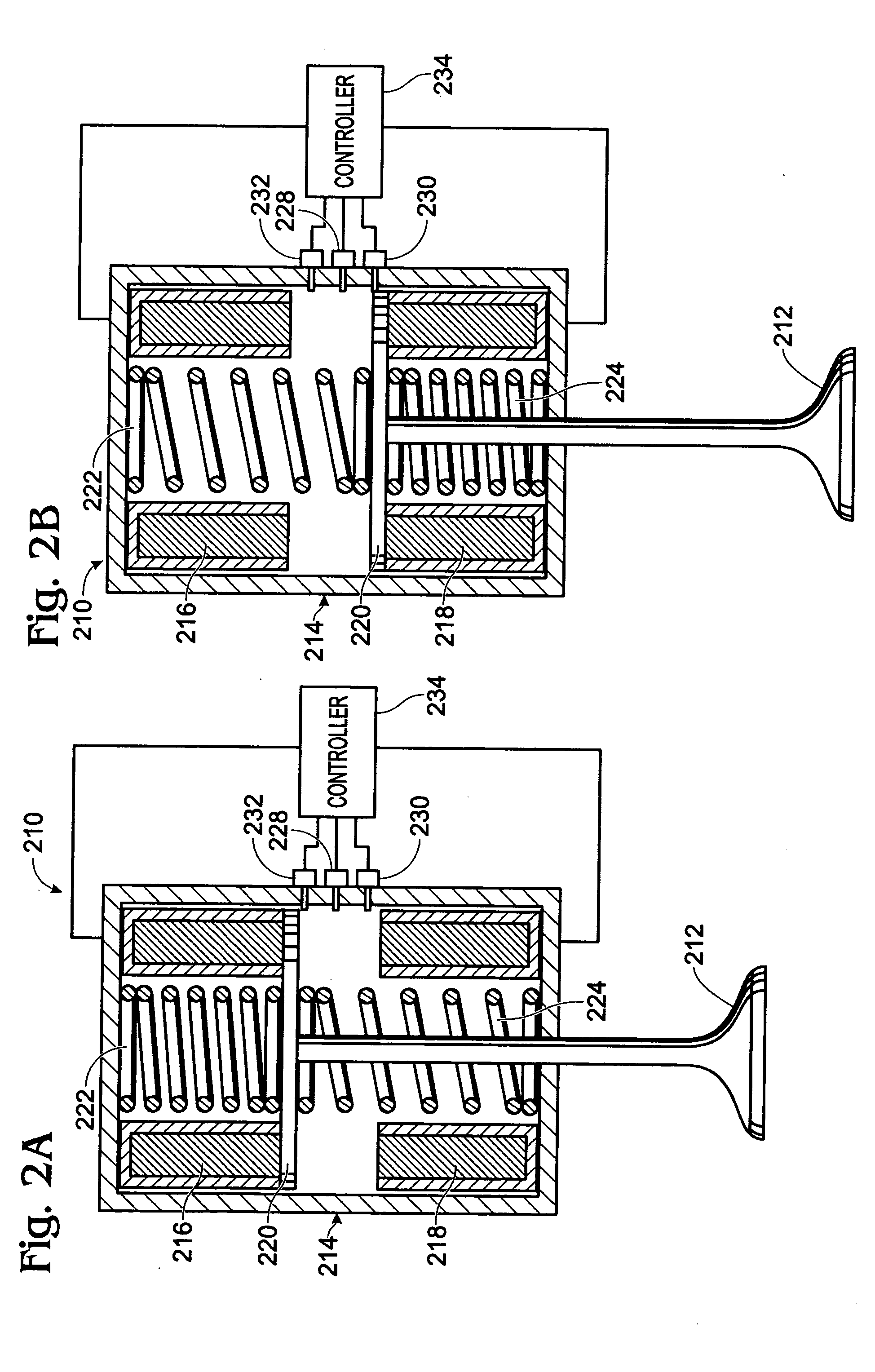

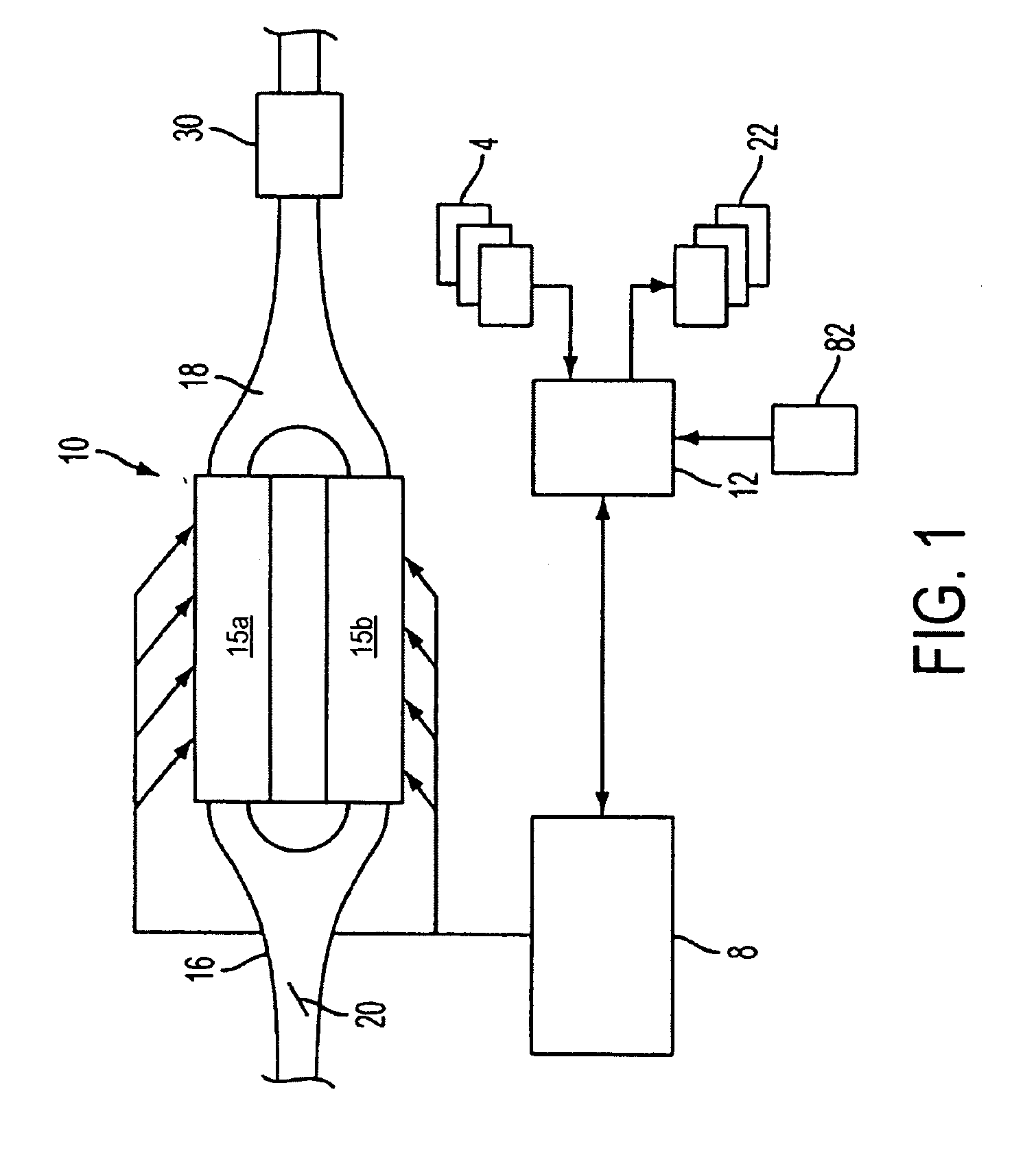

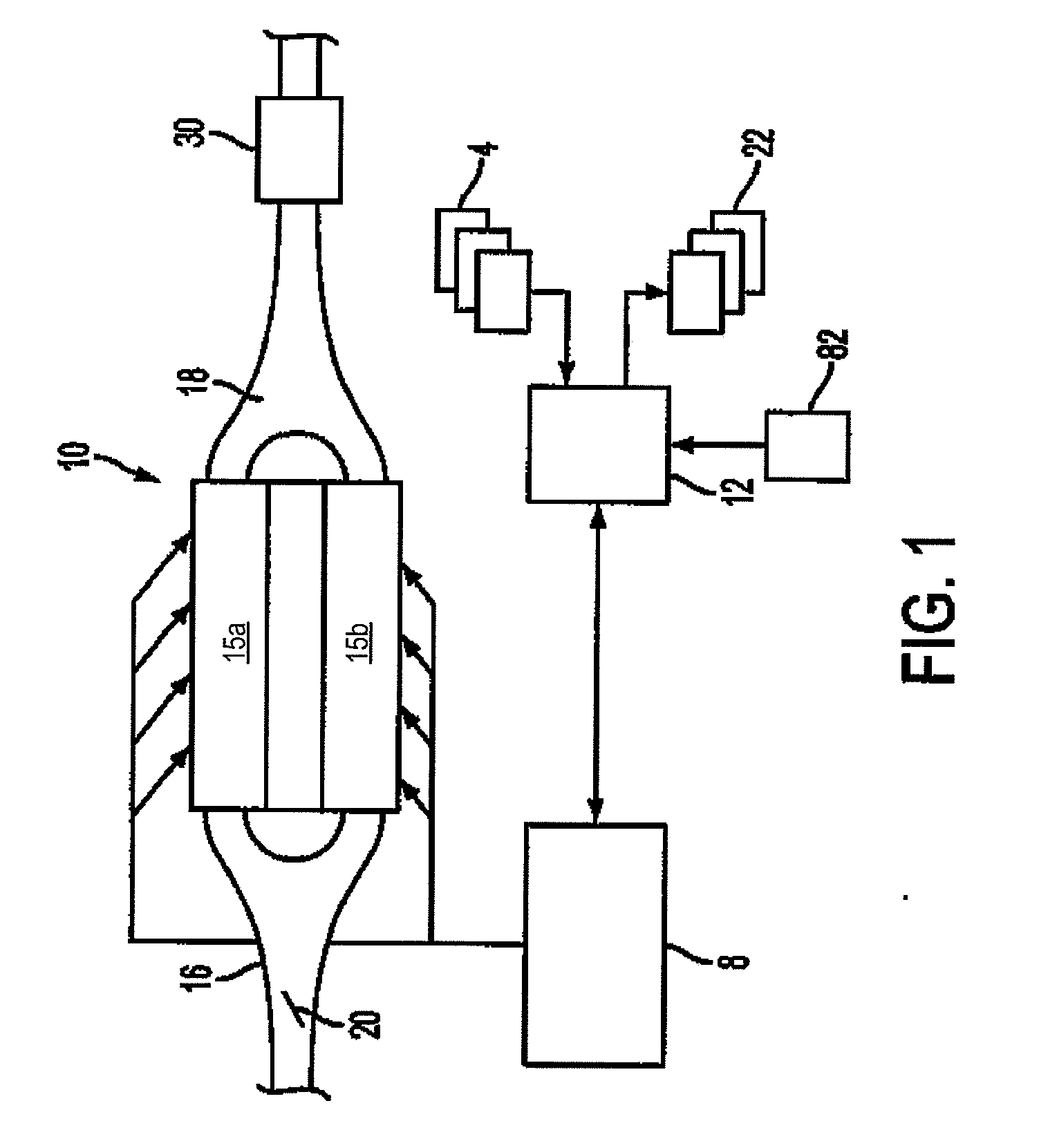

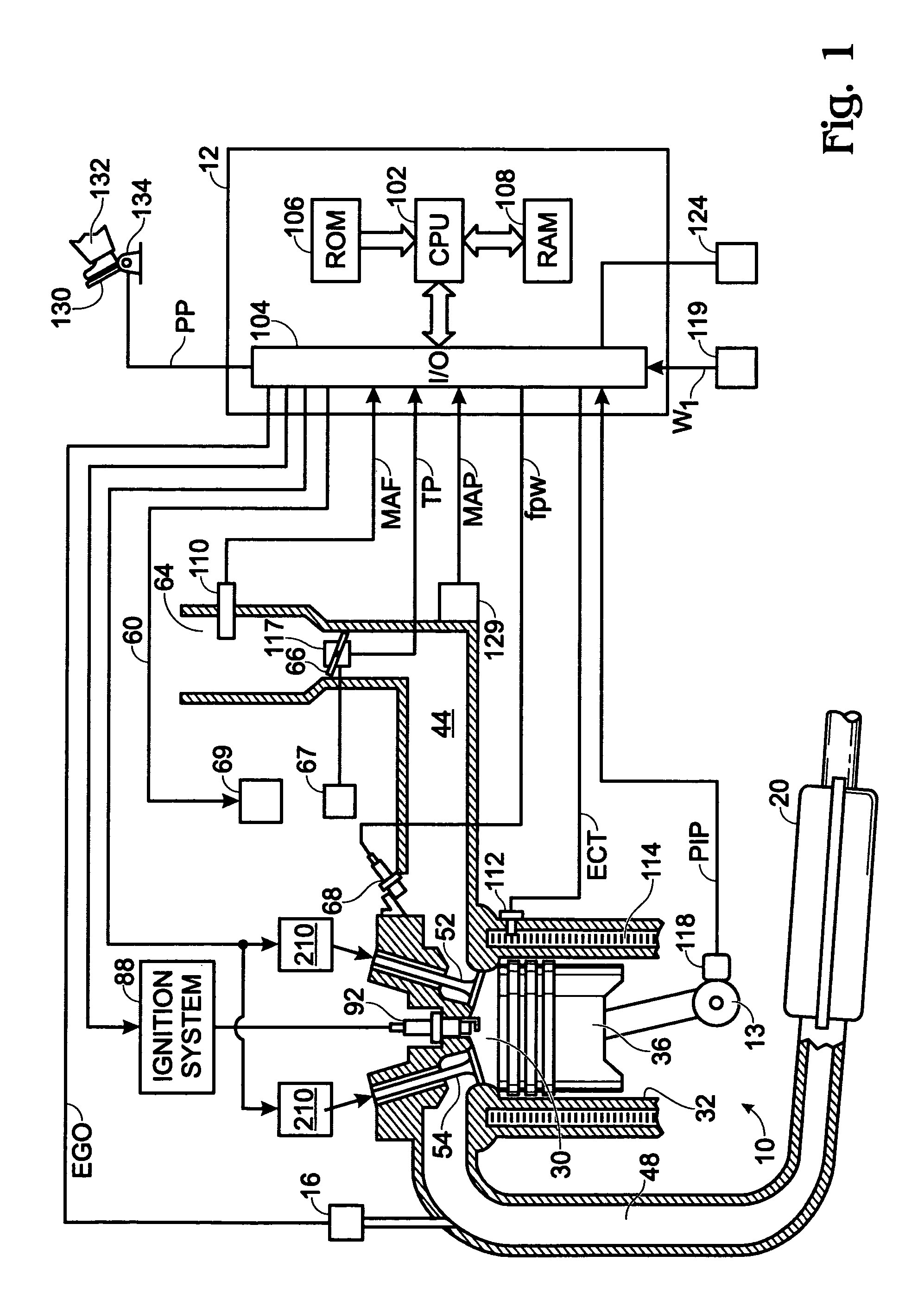

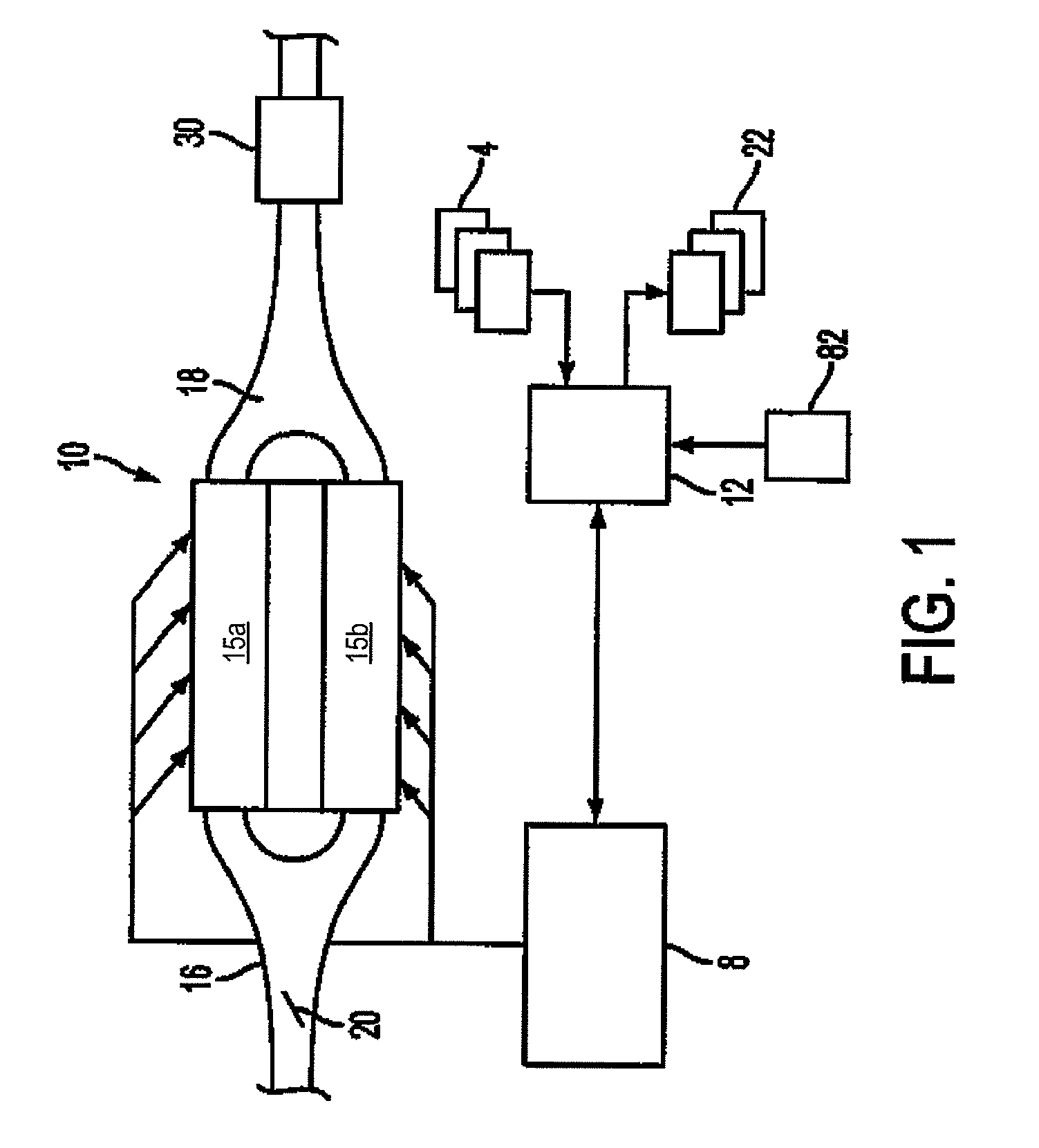

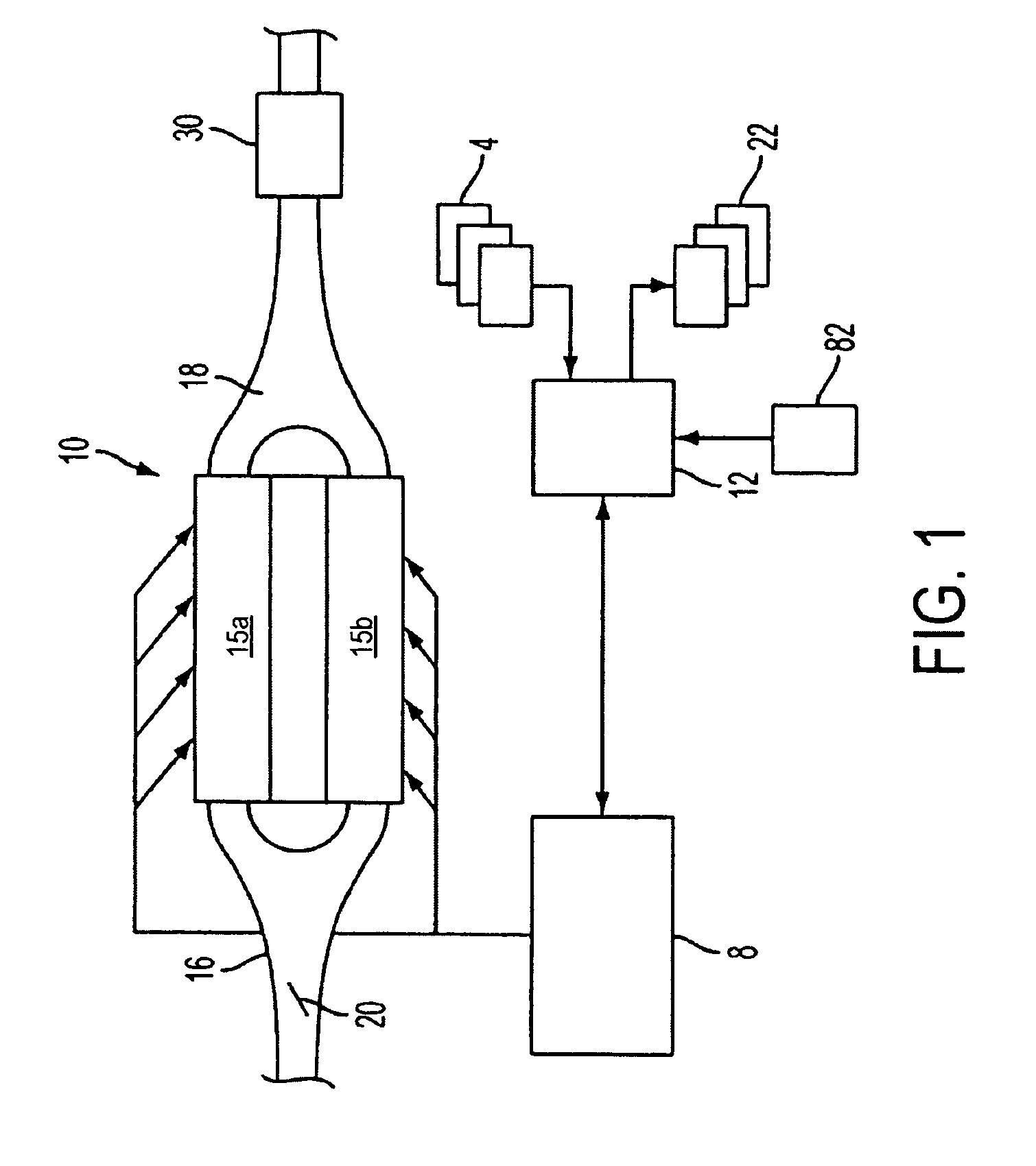

Engine and method of operation with cylinder deactivation

ActiveUS6874463B1Improvement in DOD operationEasy to operateElectrical controlInternal combustion piston enginesExhaust valveCylinder Valve

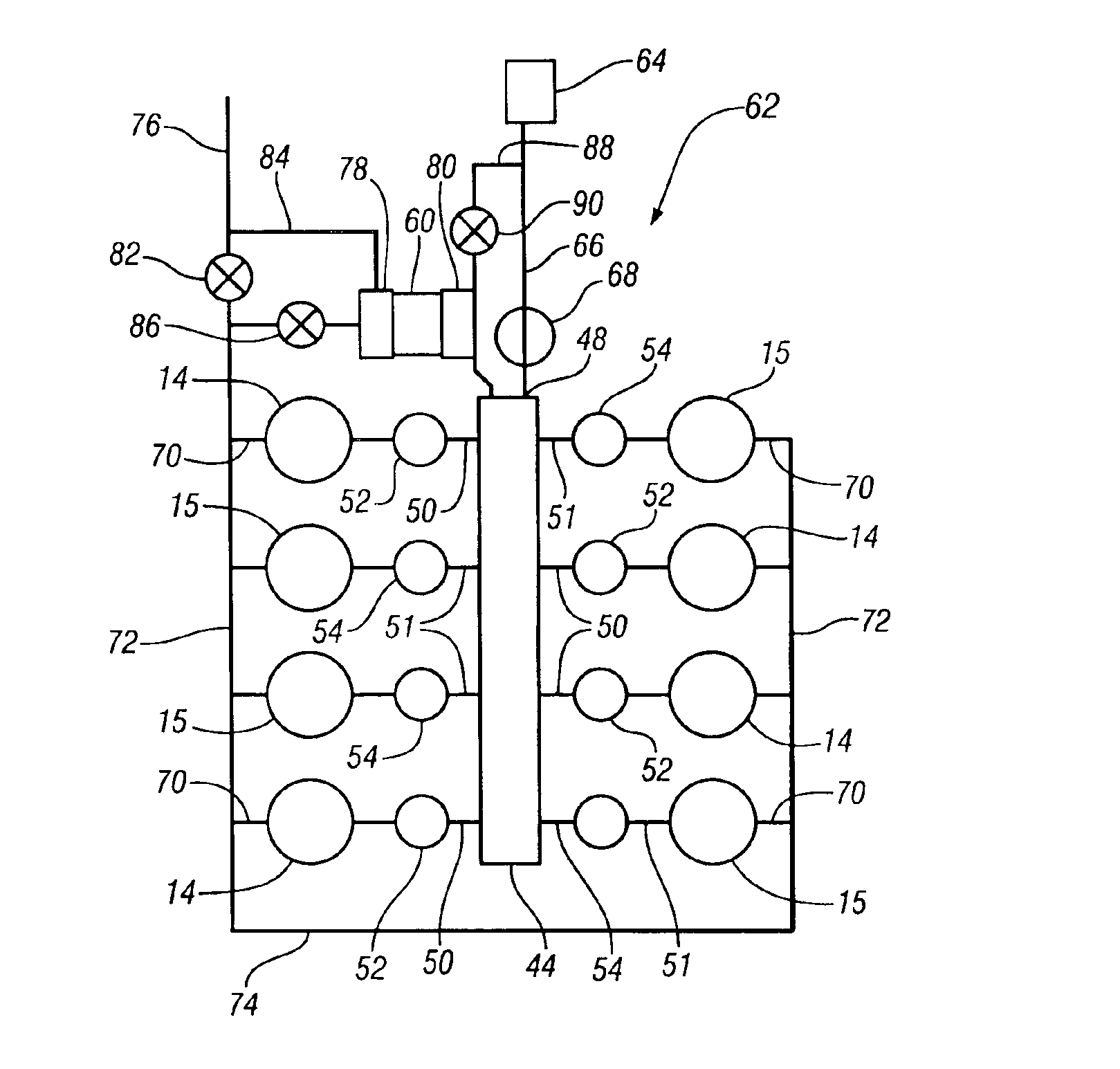

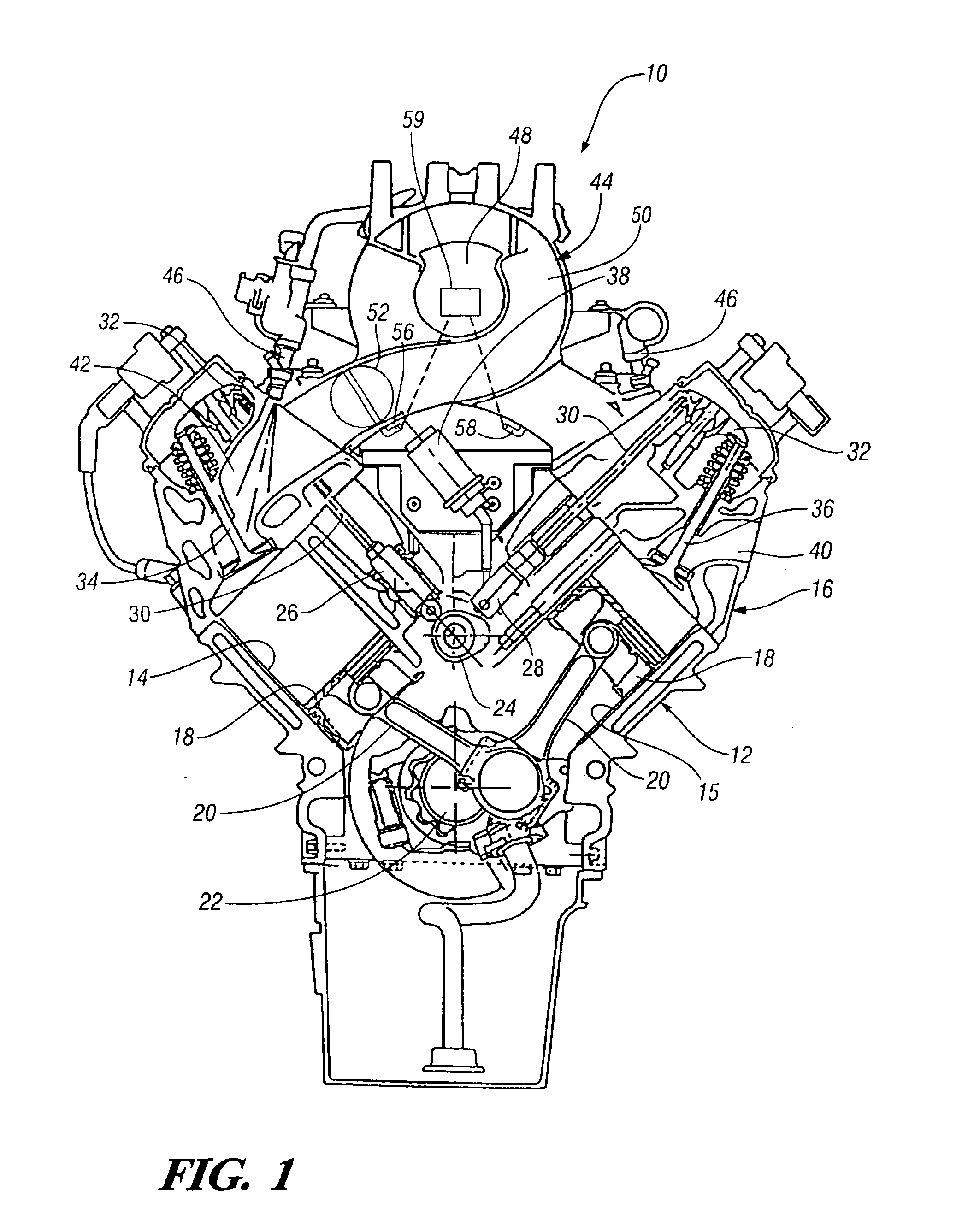

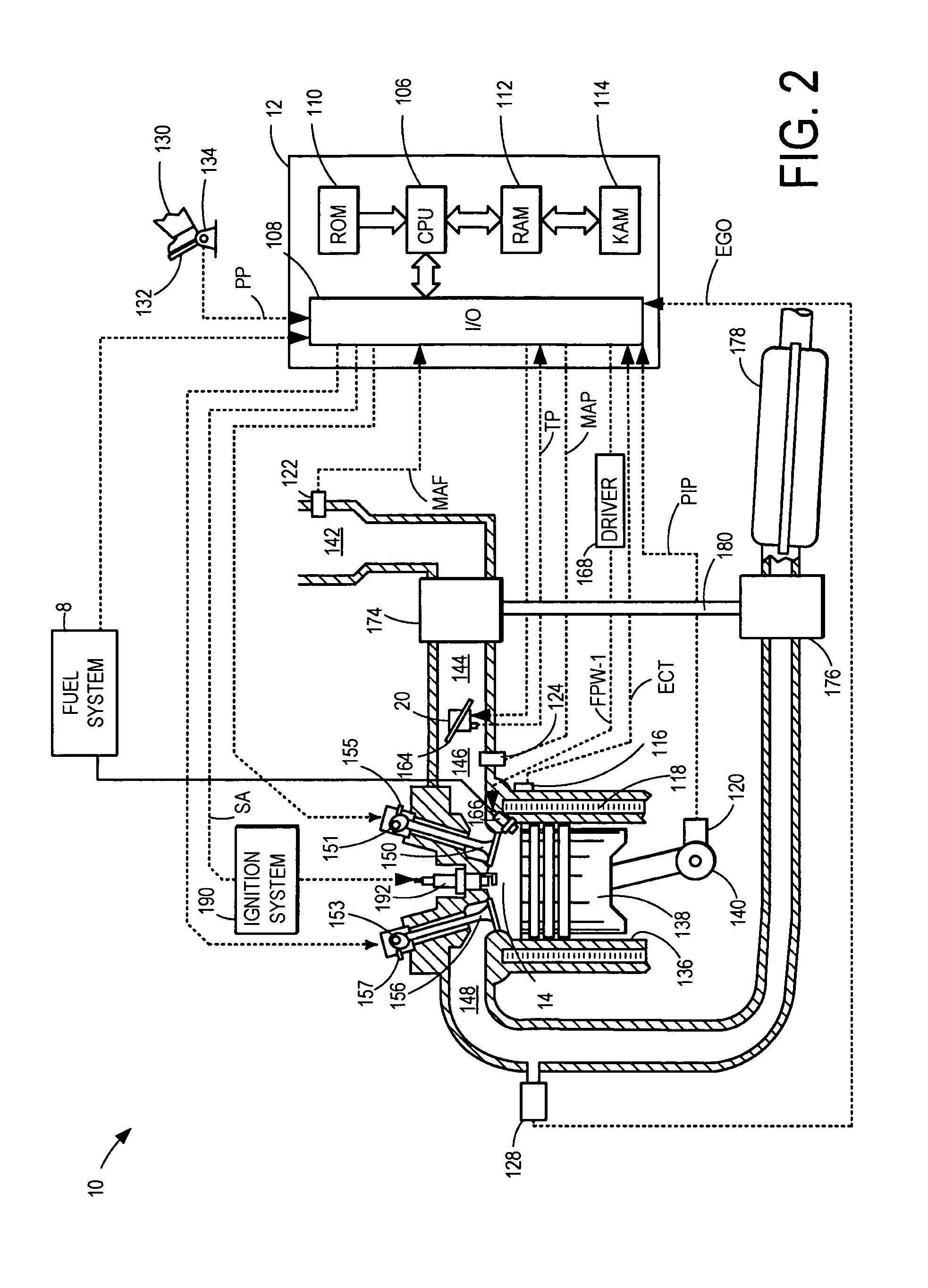

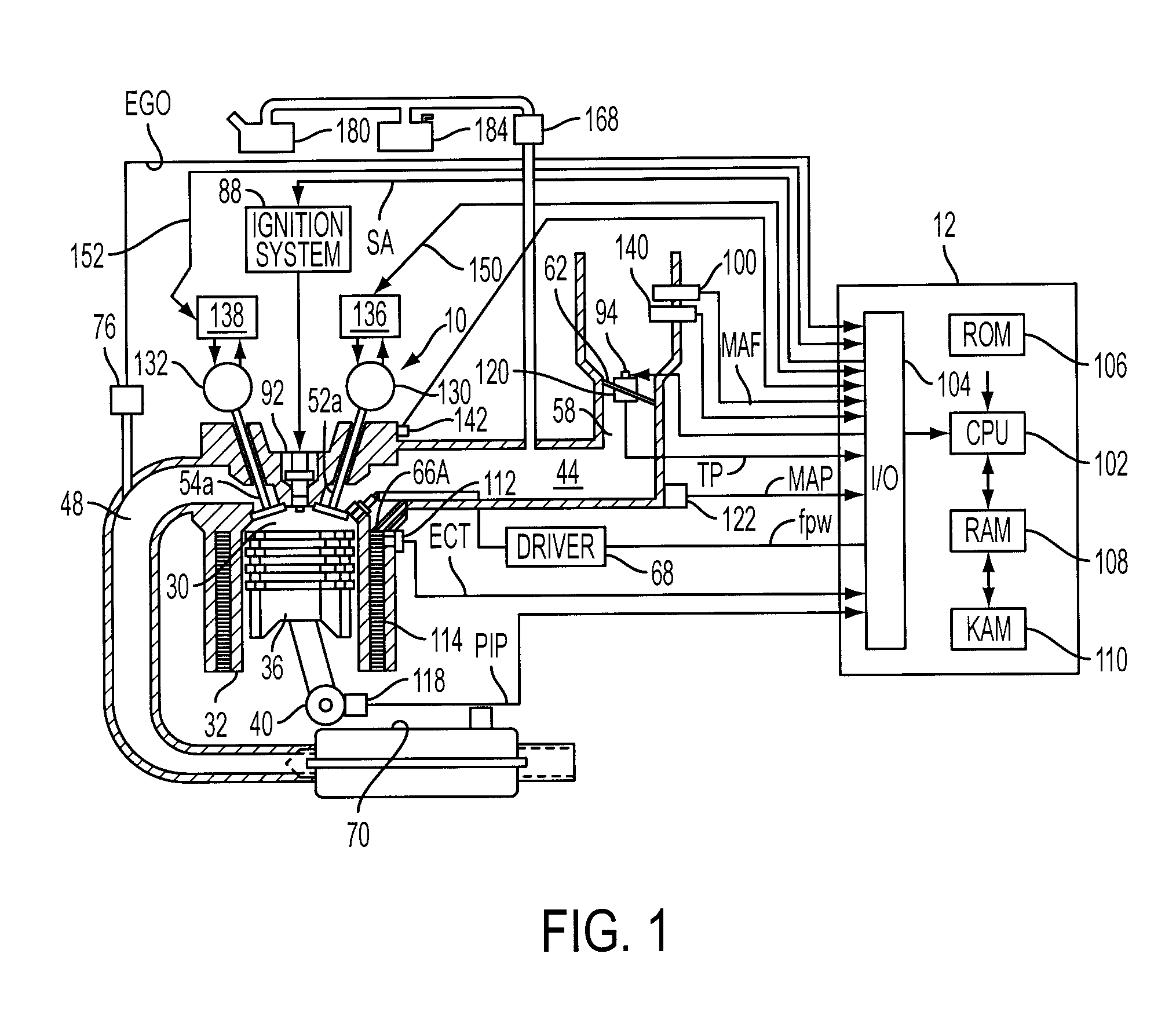

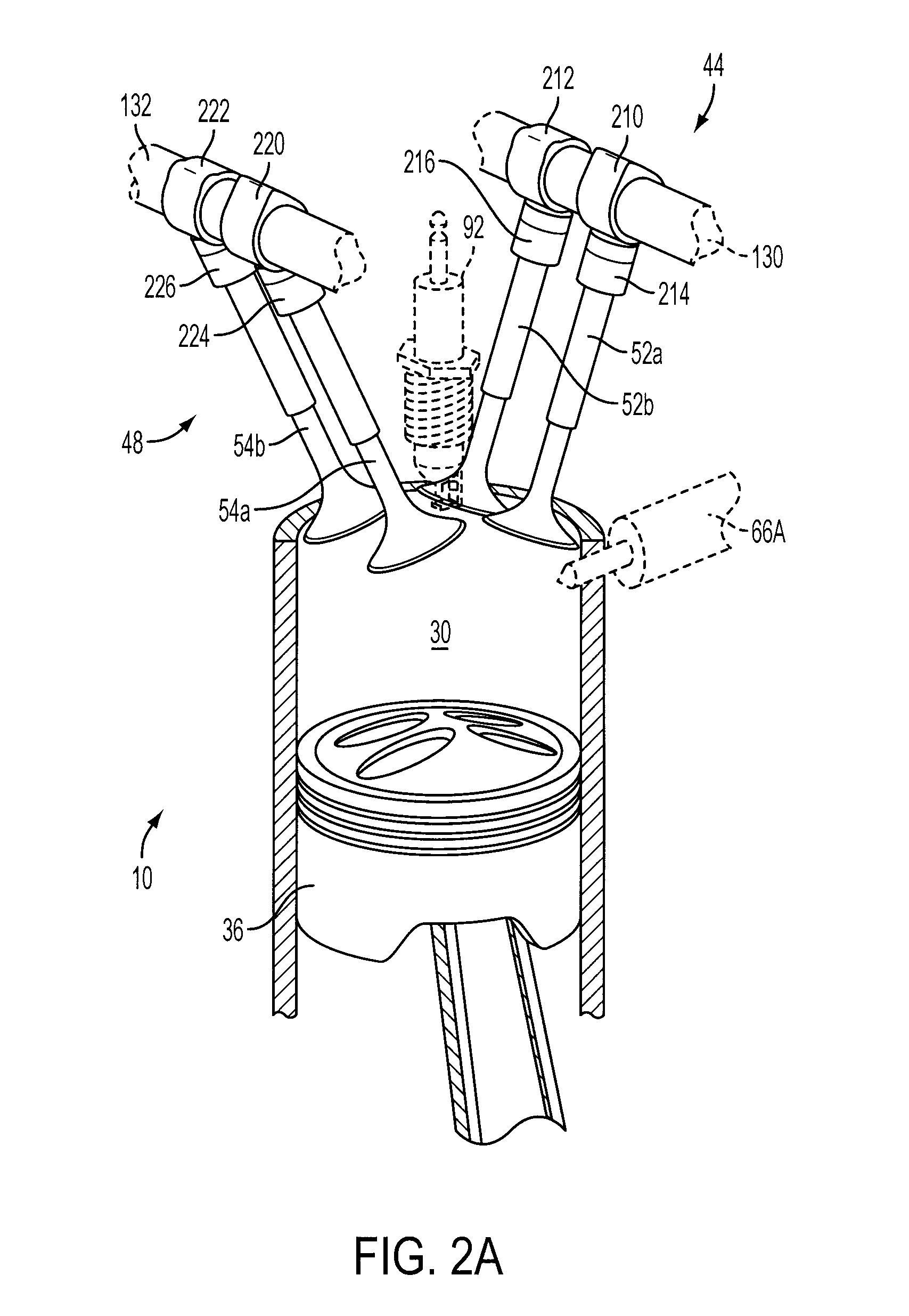

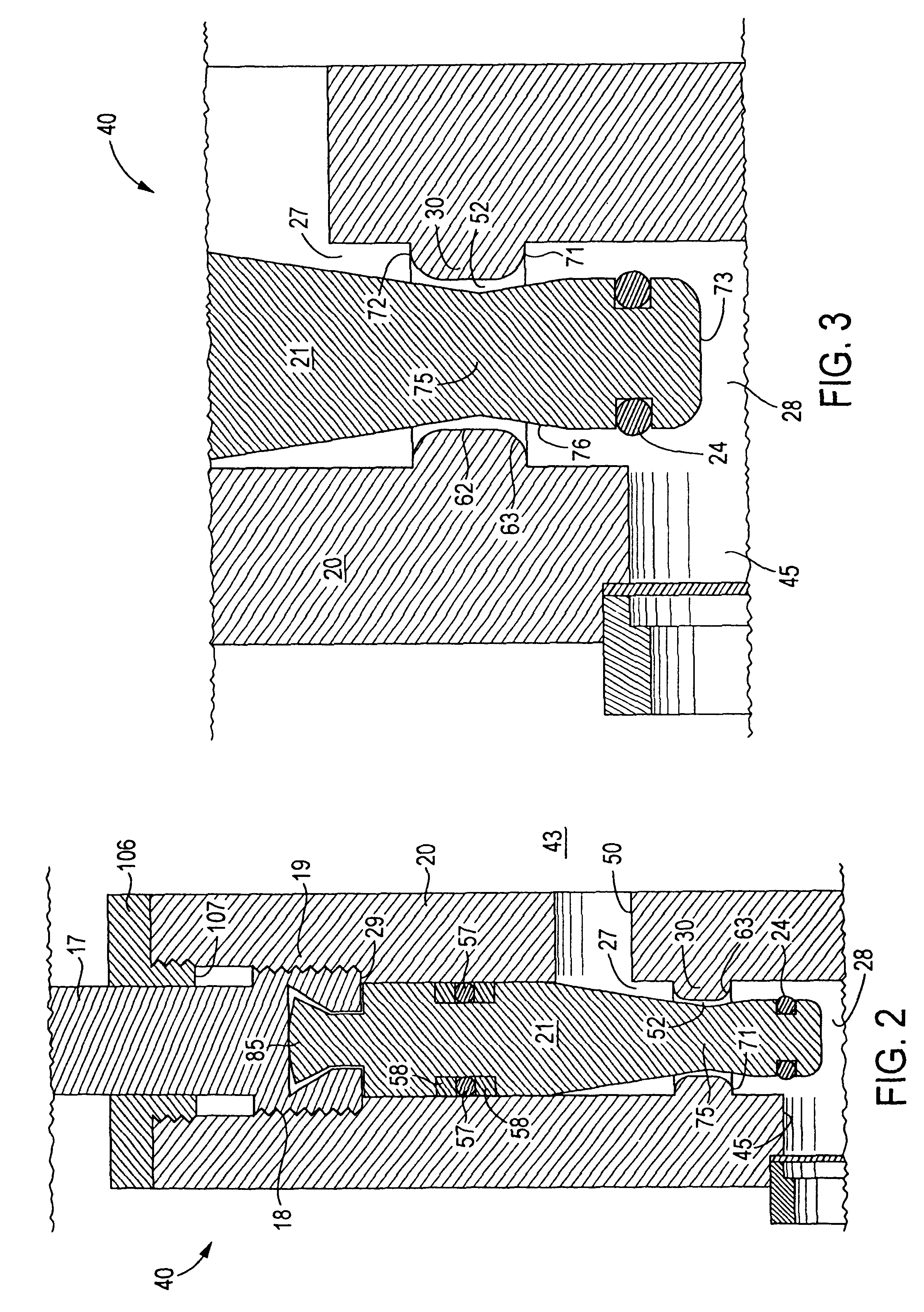

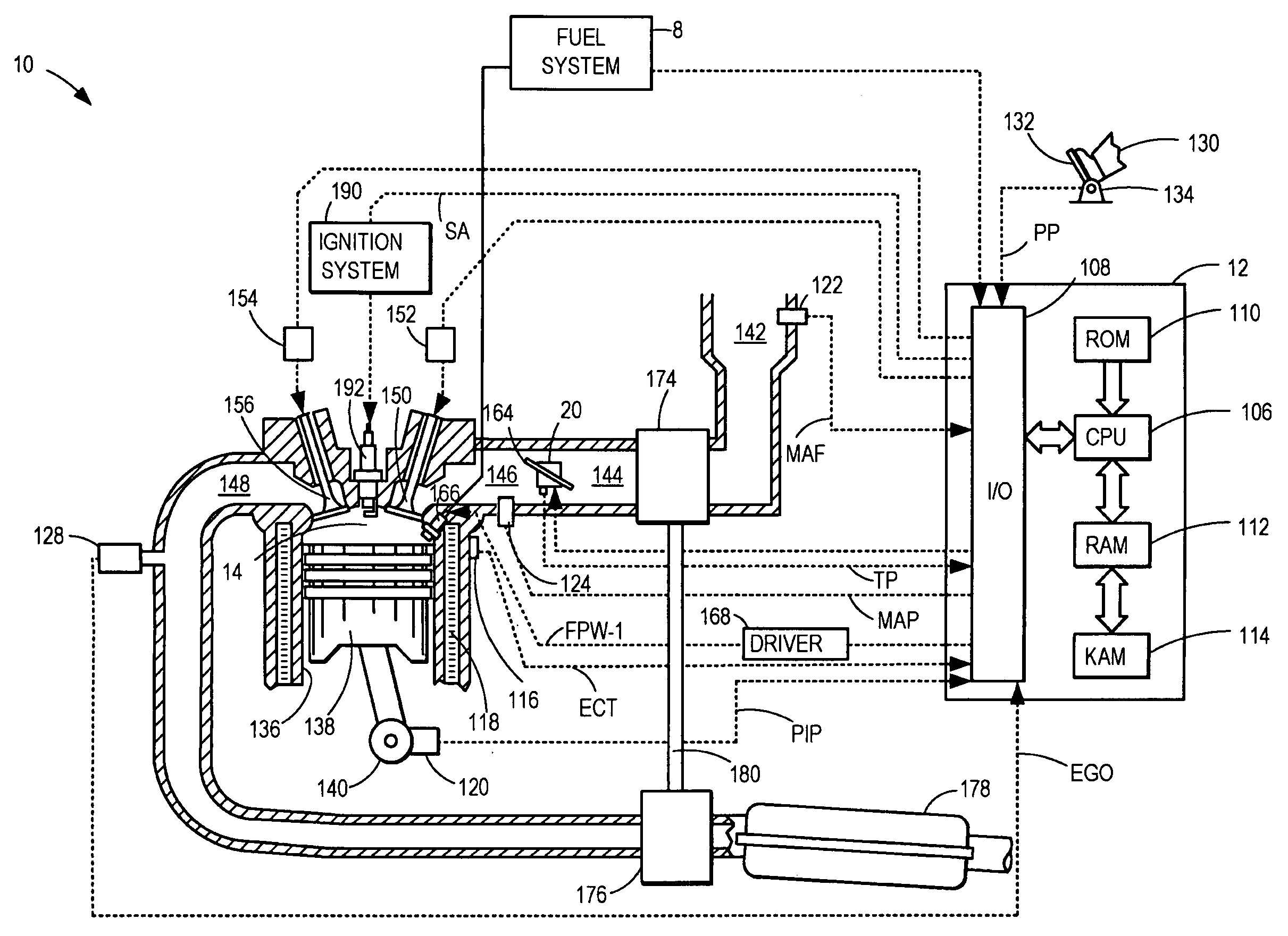

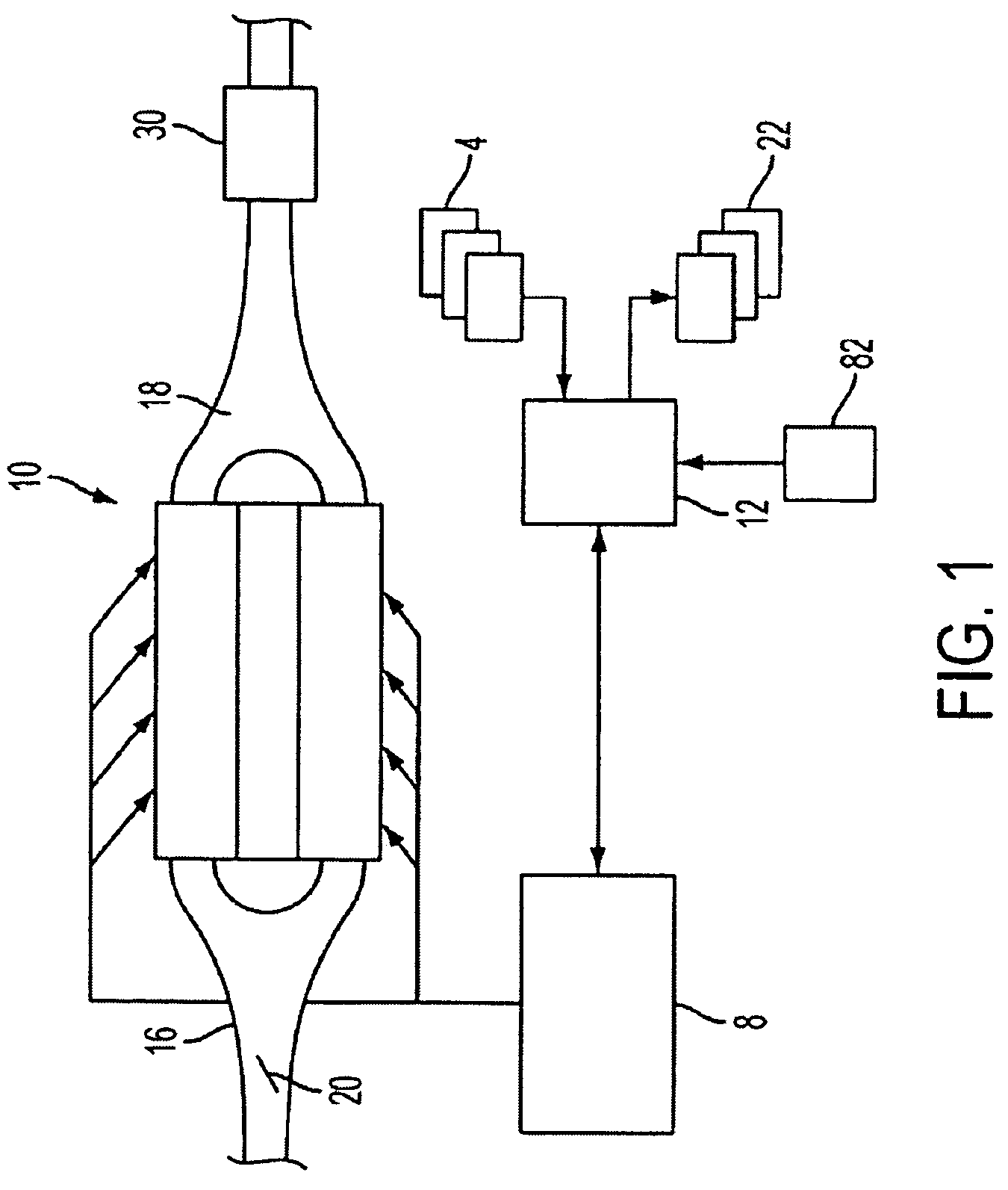

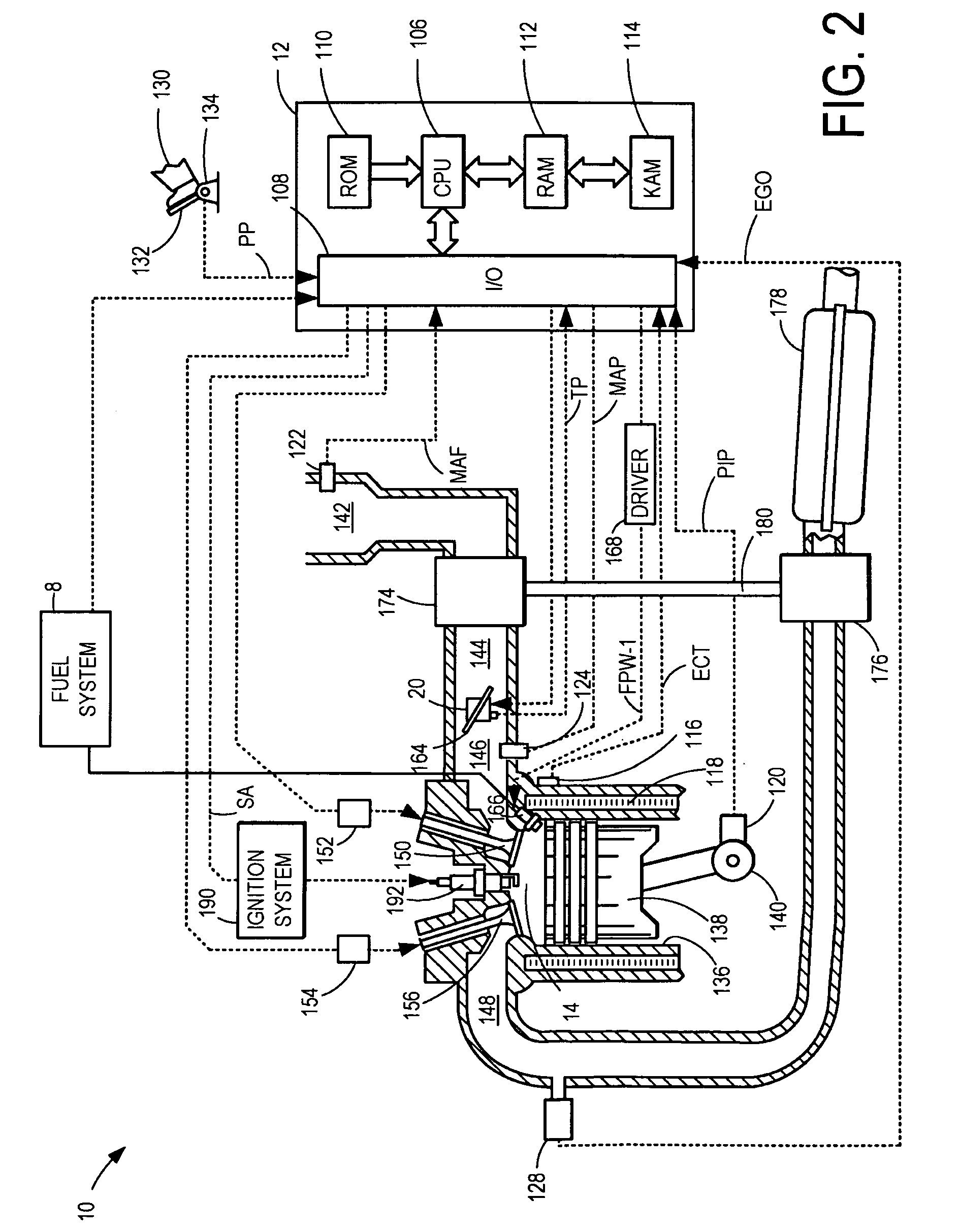

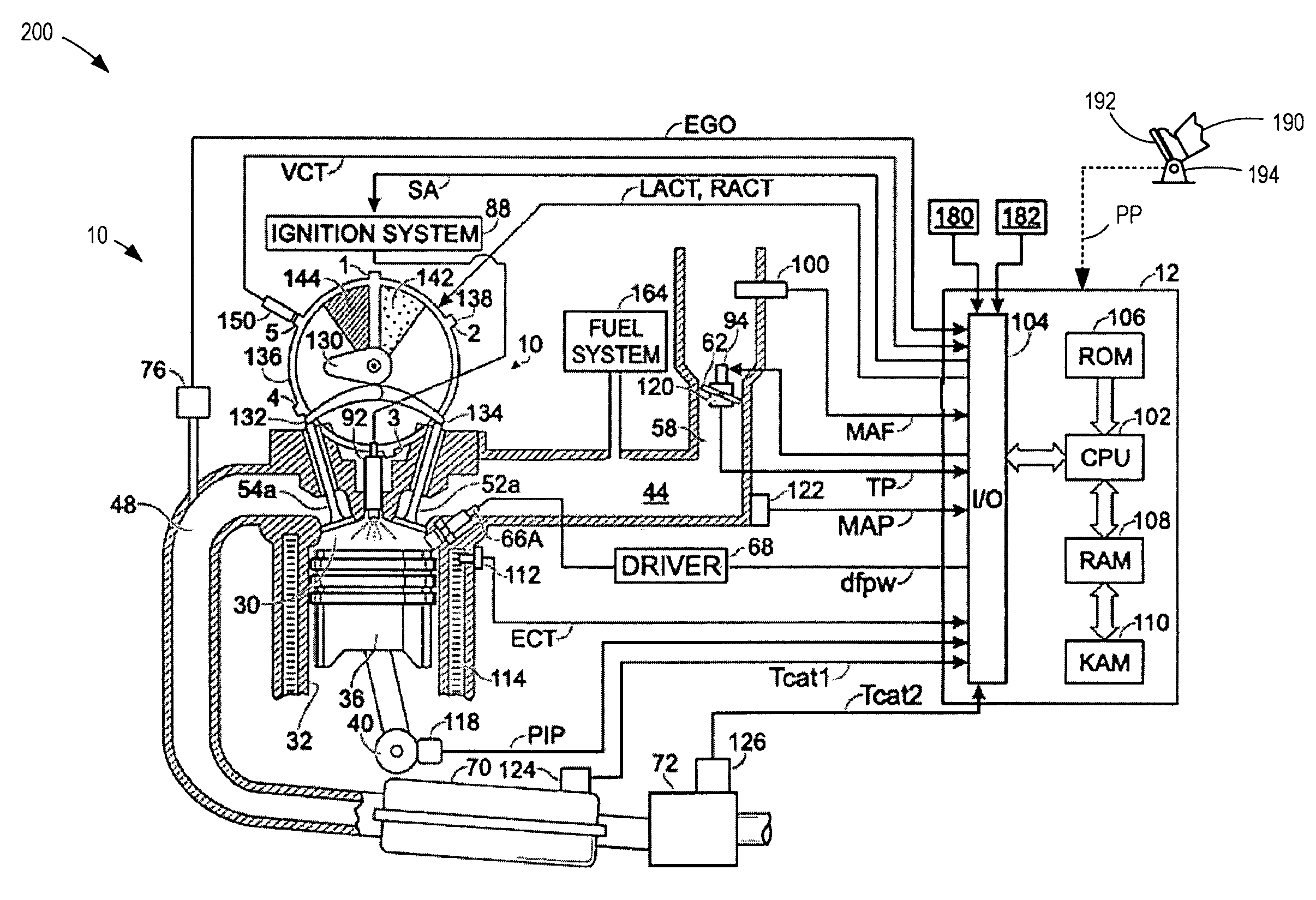

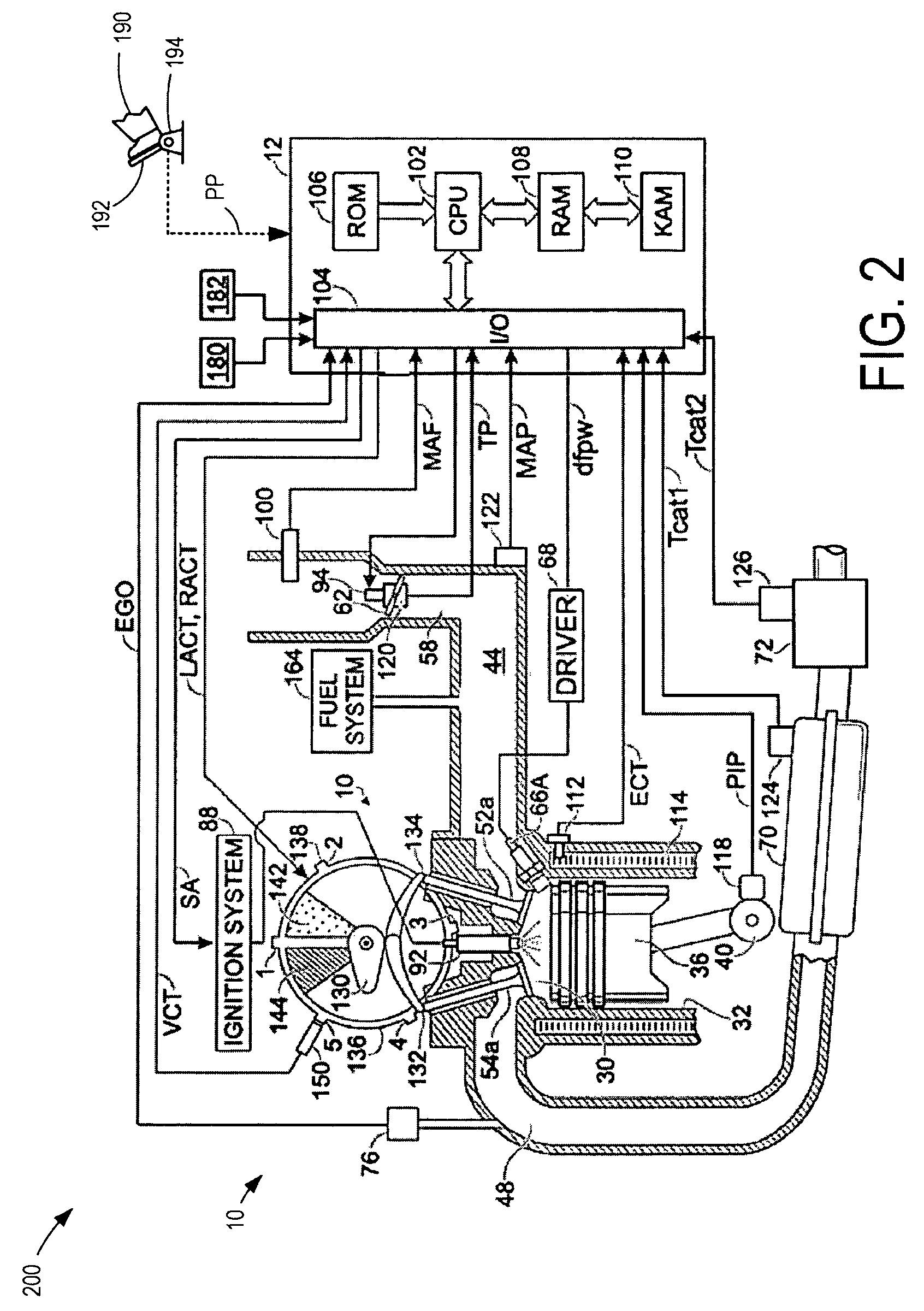

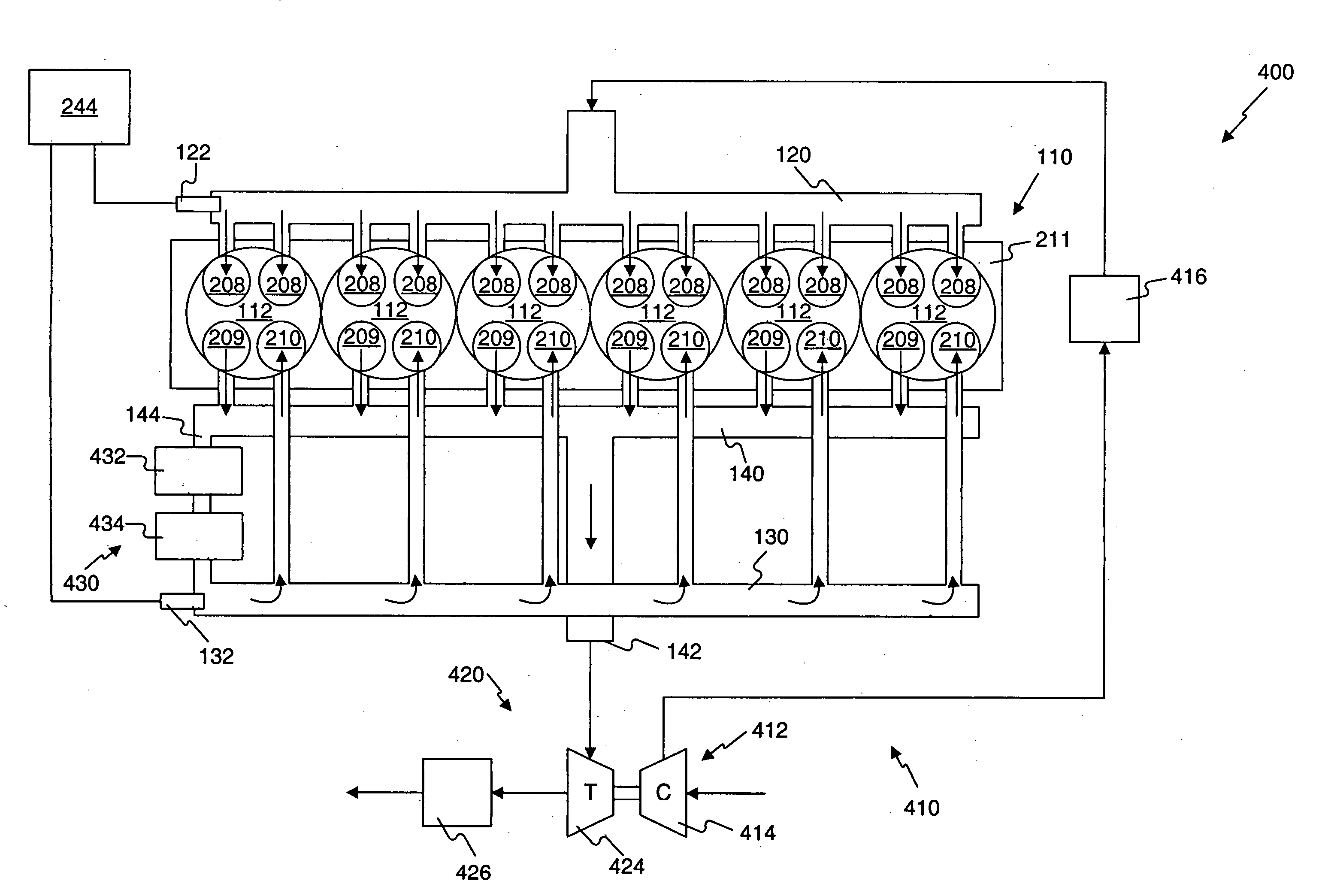

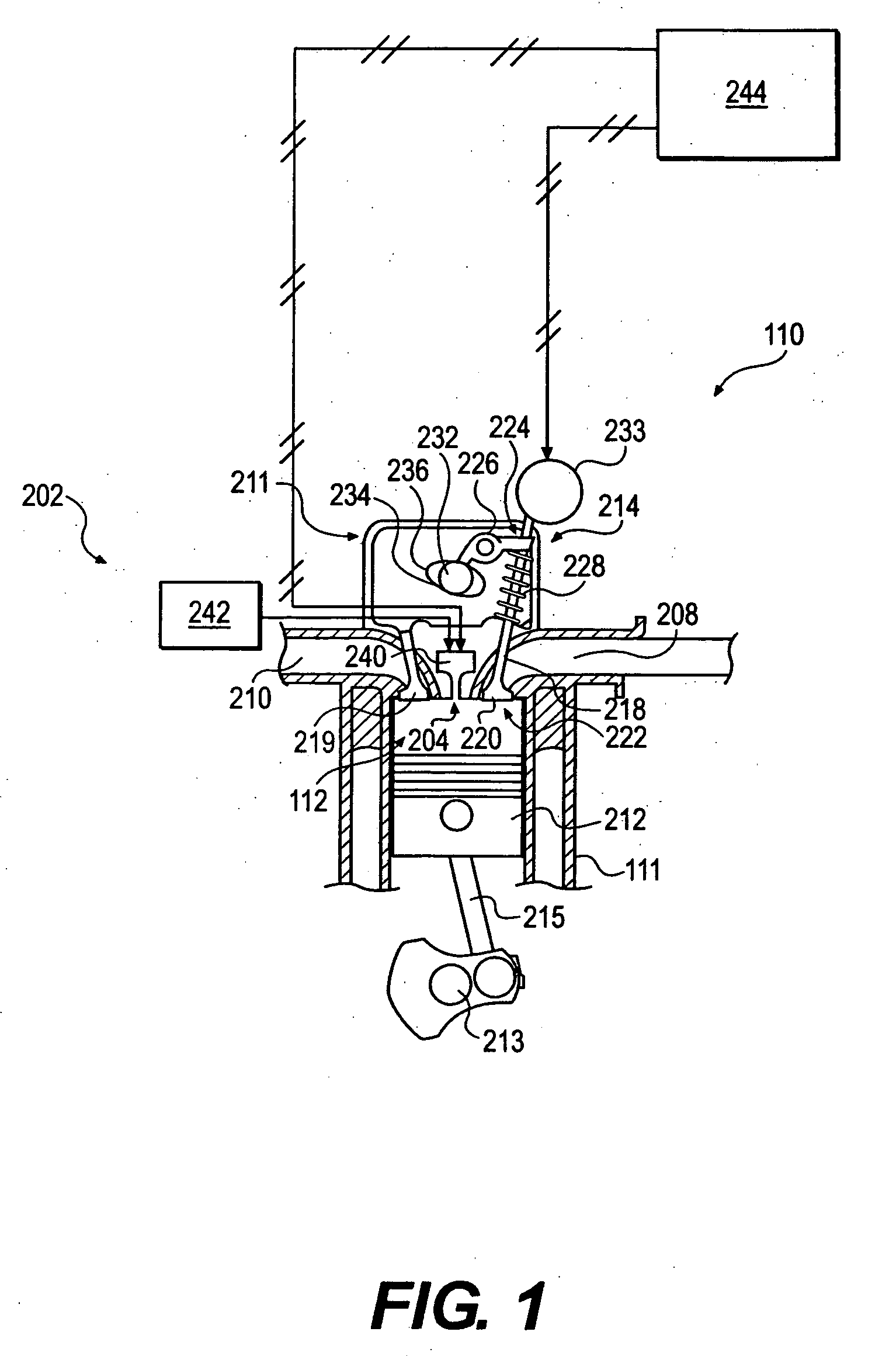

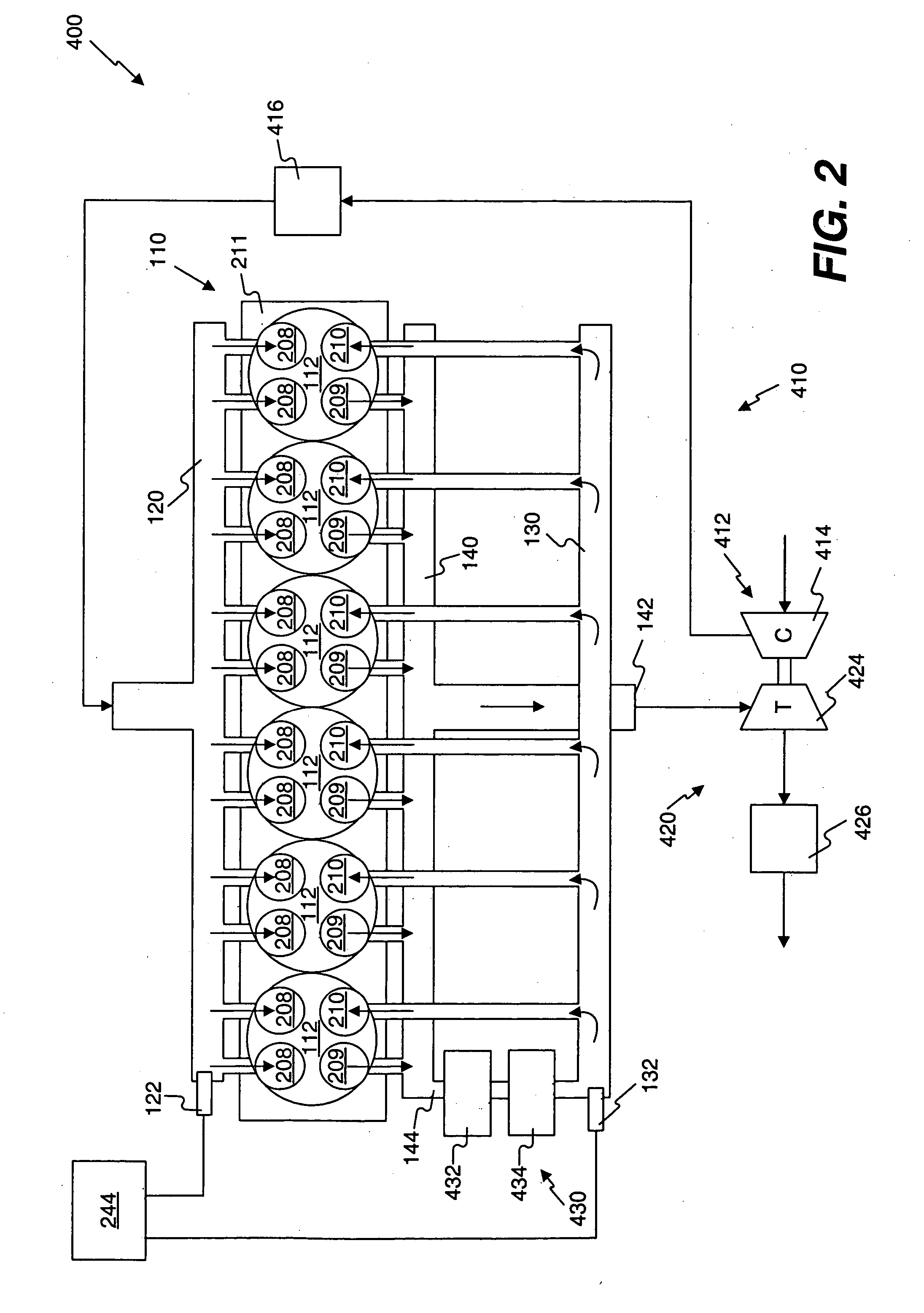

An engine with cylinder deactivation (Displacement on Demand or DOD™) includes standard (STD) cylinders which are not deactivated and DOD cylinders which can be deactivated by closing their intake and exhaust valves and shutting off their fuel supply. To provide smooth transitions, the STD and DOD cylinders form separate groups each supplied with charge air through one or more separate throttles. When switching to DOD operation, the throttles are oppositely actuated to cut out the DOD cylinders and maintain torque in the active cylinders prior to deactivation of the cylinder valves. When returning to STD operation, the valves are reactivated before oppositely actuating the throttles to enable full cylinder operation. In DOD operation, a small supercharger may be operated to boost torque of the operating STD cylinders and thus increase the DOD operating range.

Owner:GM GLOBAL TECH OPERATIONS LLC

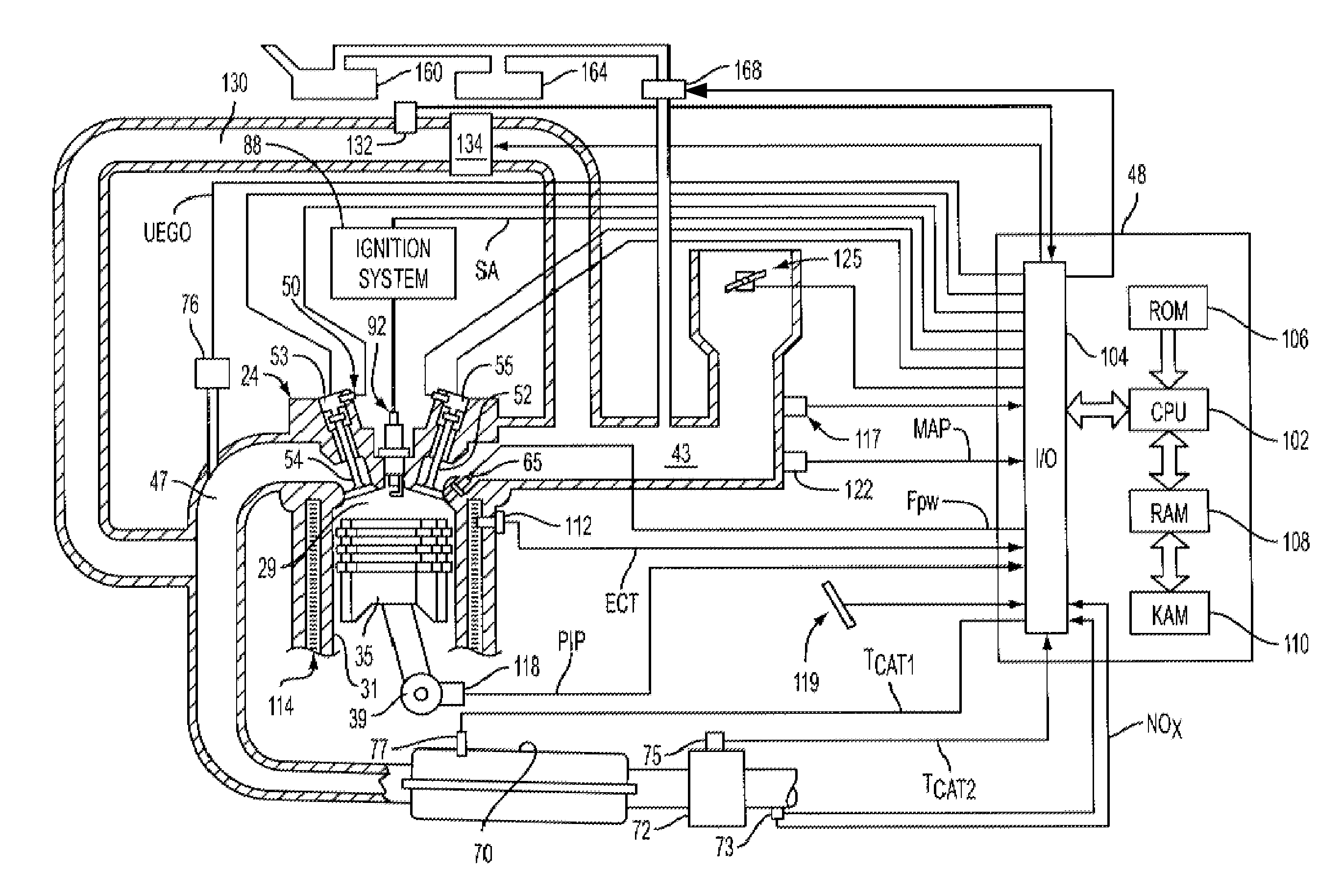

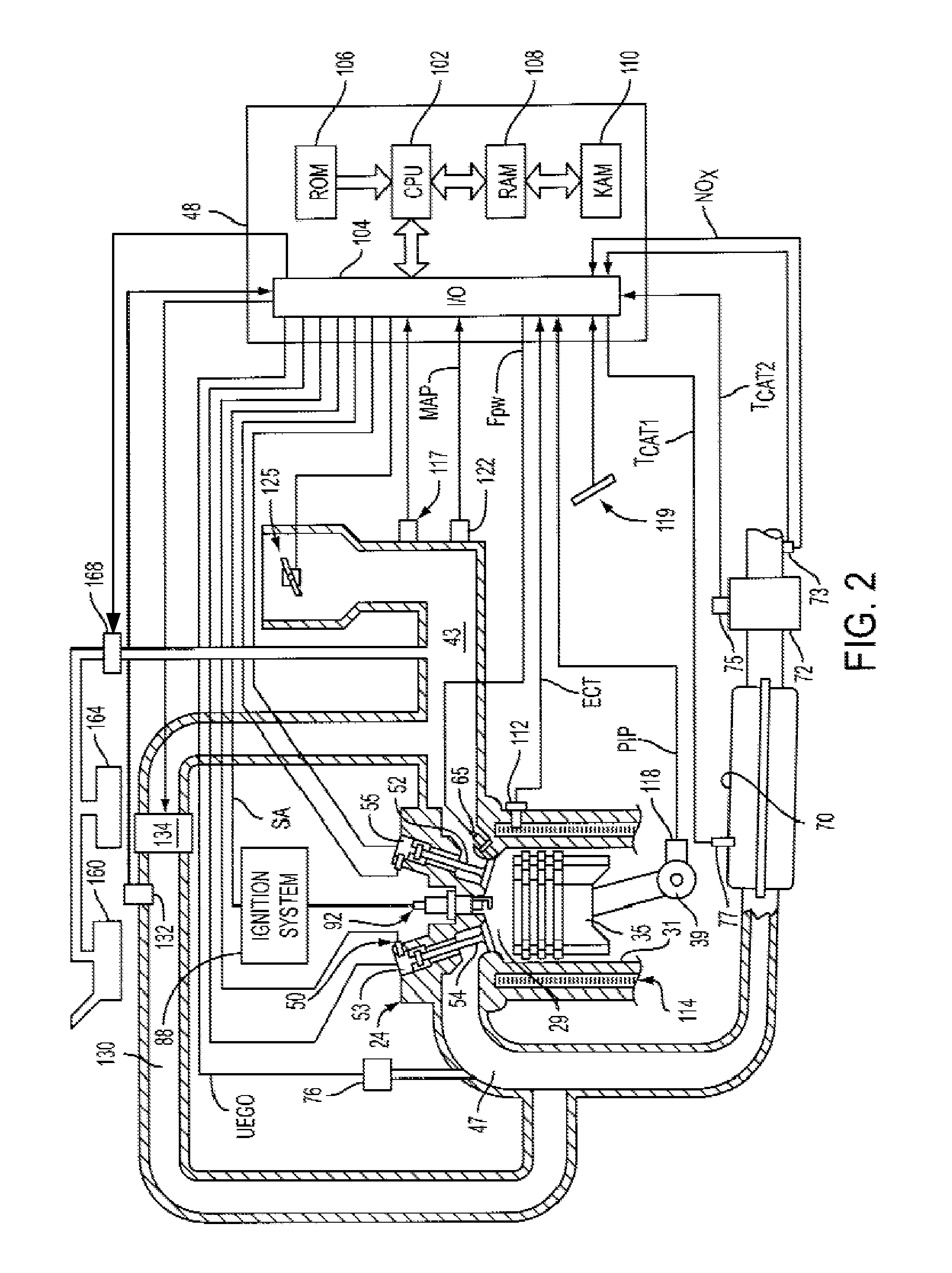

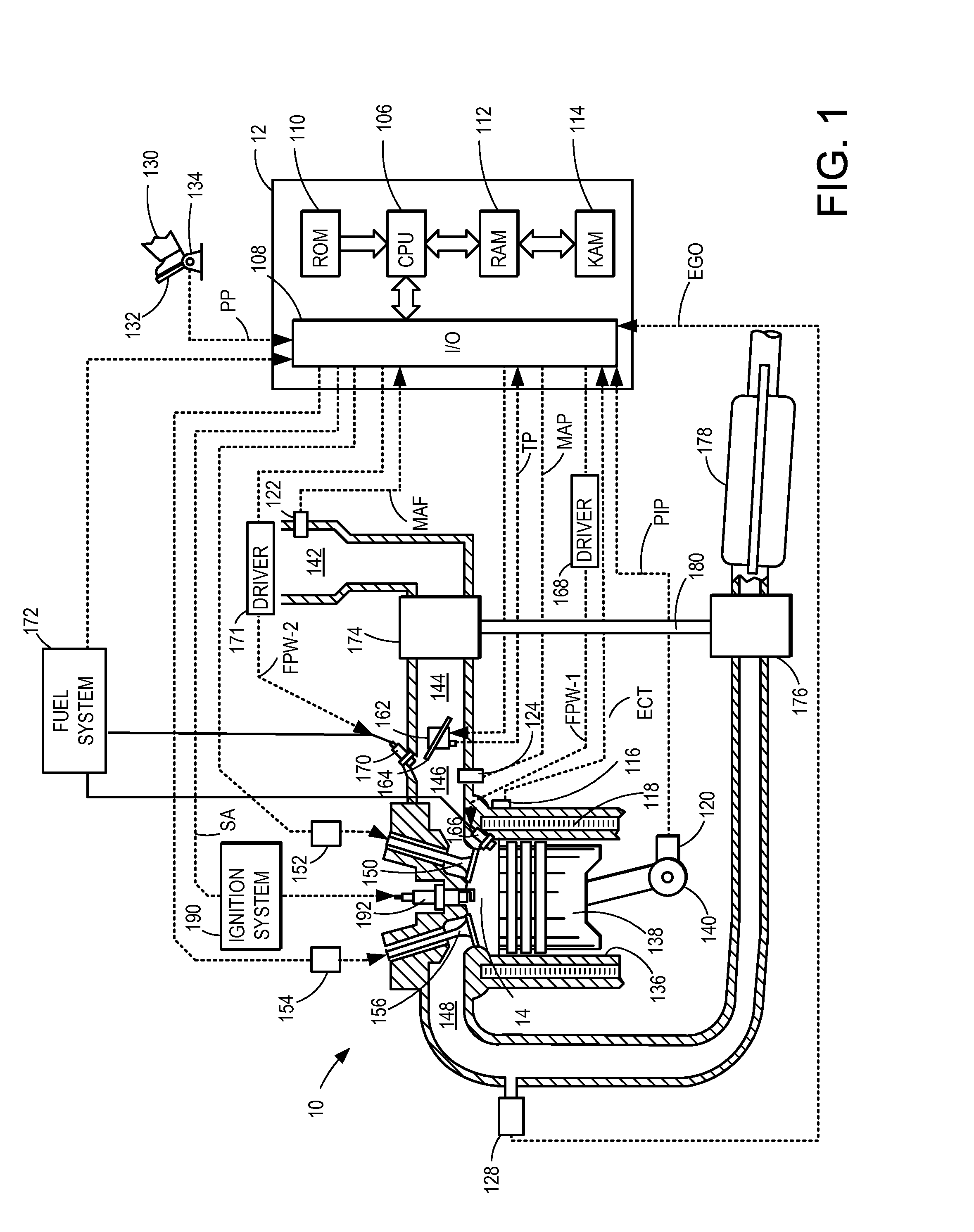

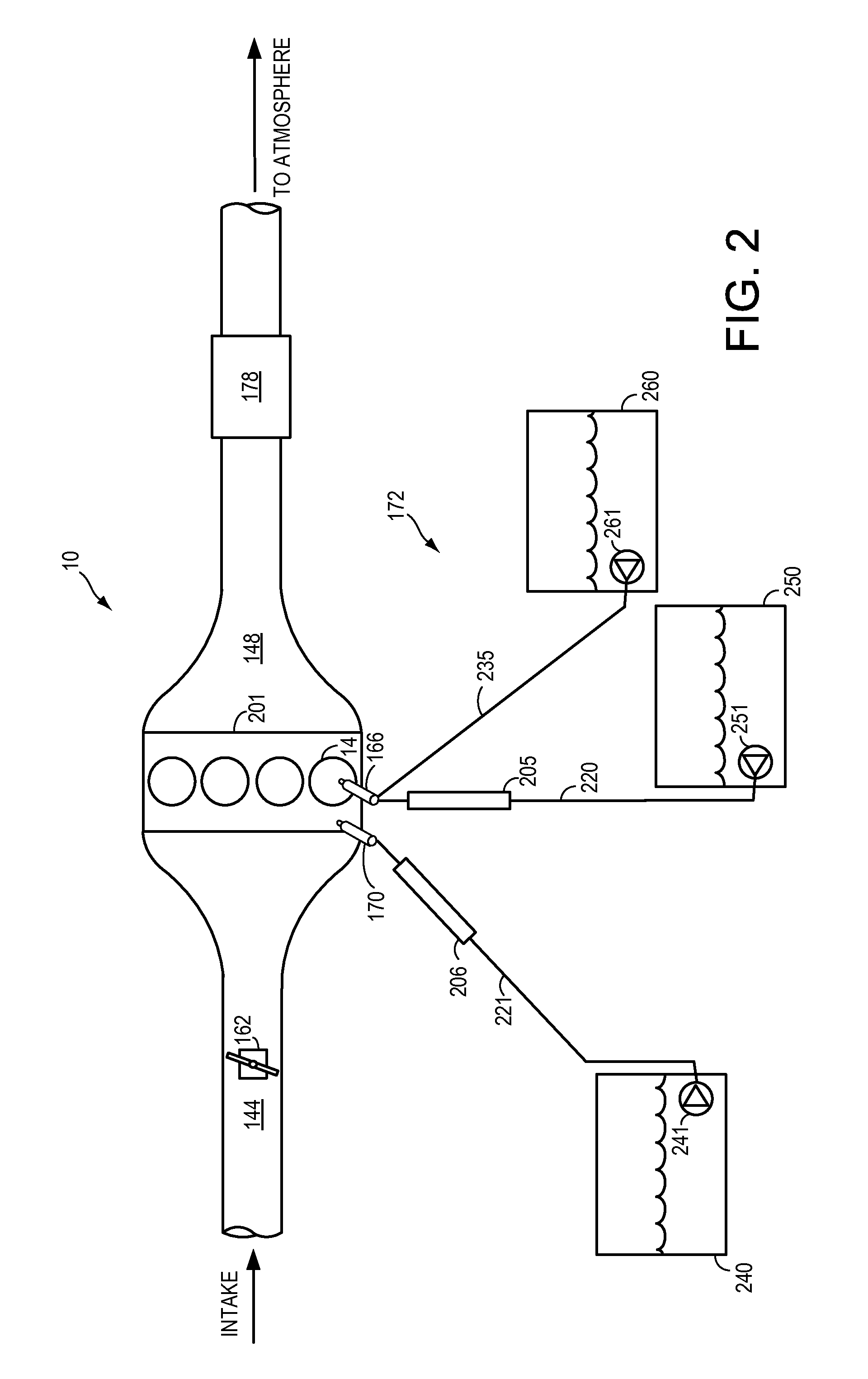

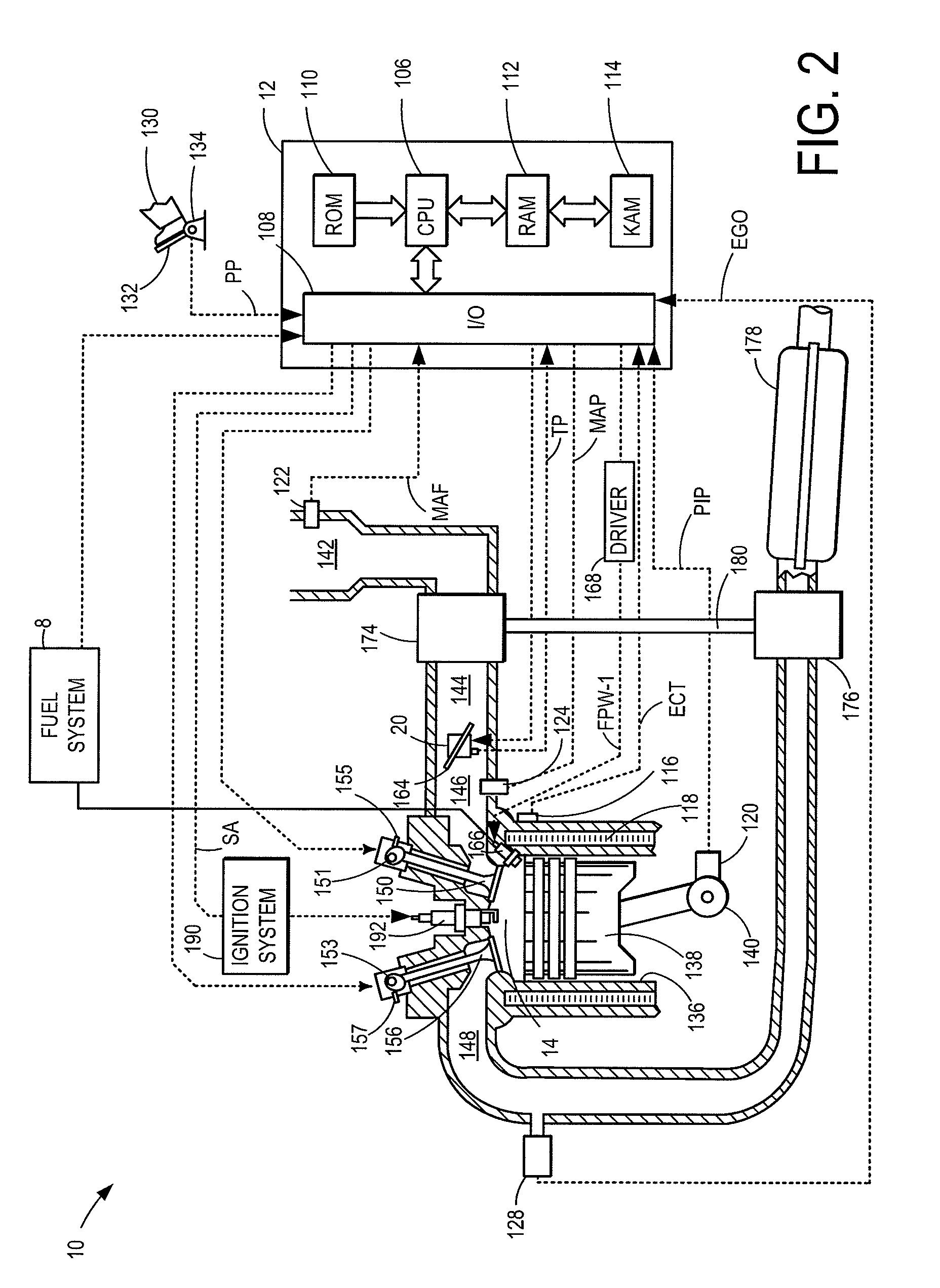

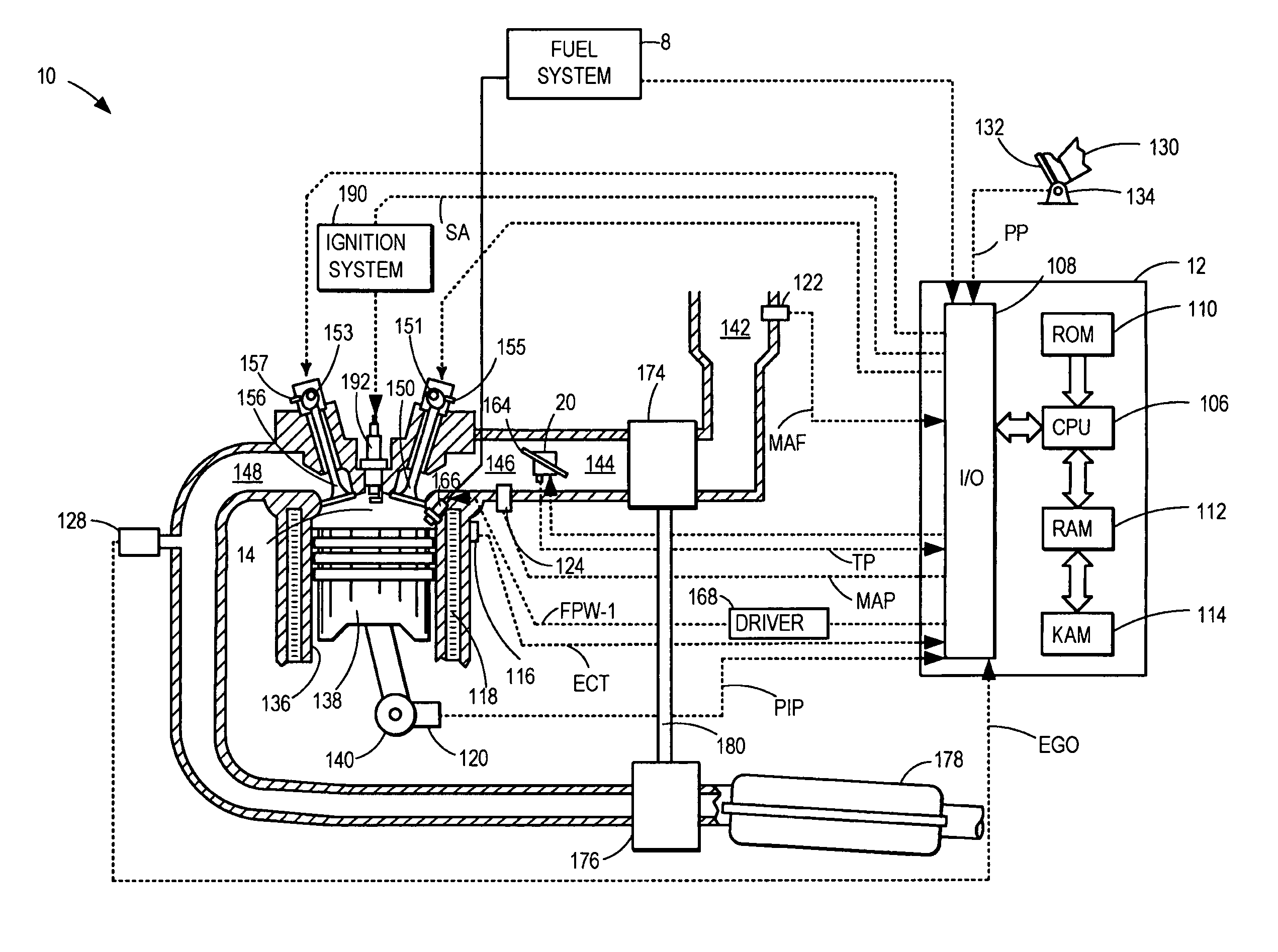

Methods for variable displacement engine diagnostics

InactiveUS7546827B1Improve fuel economyReduce controlValve arrangementsElectrical controlEngineeringCylinder Valve

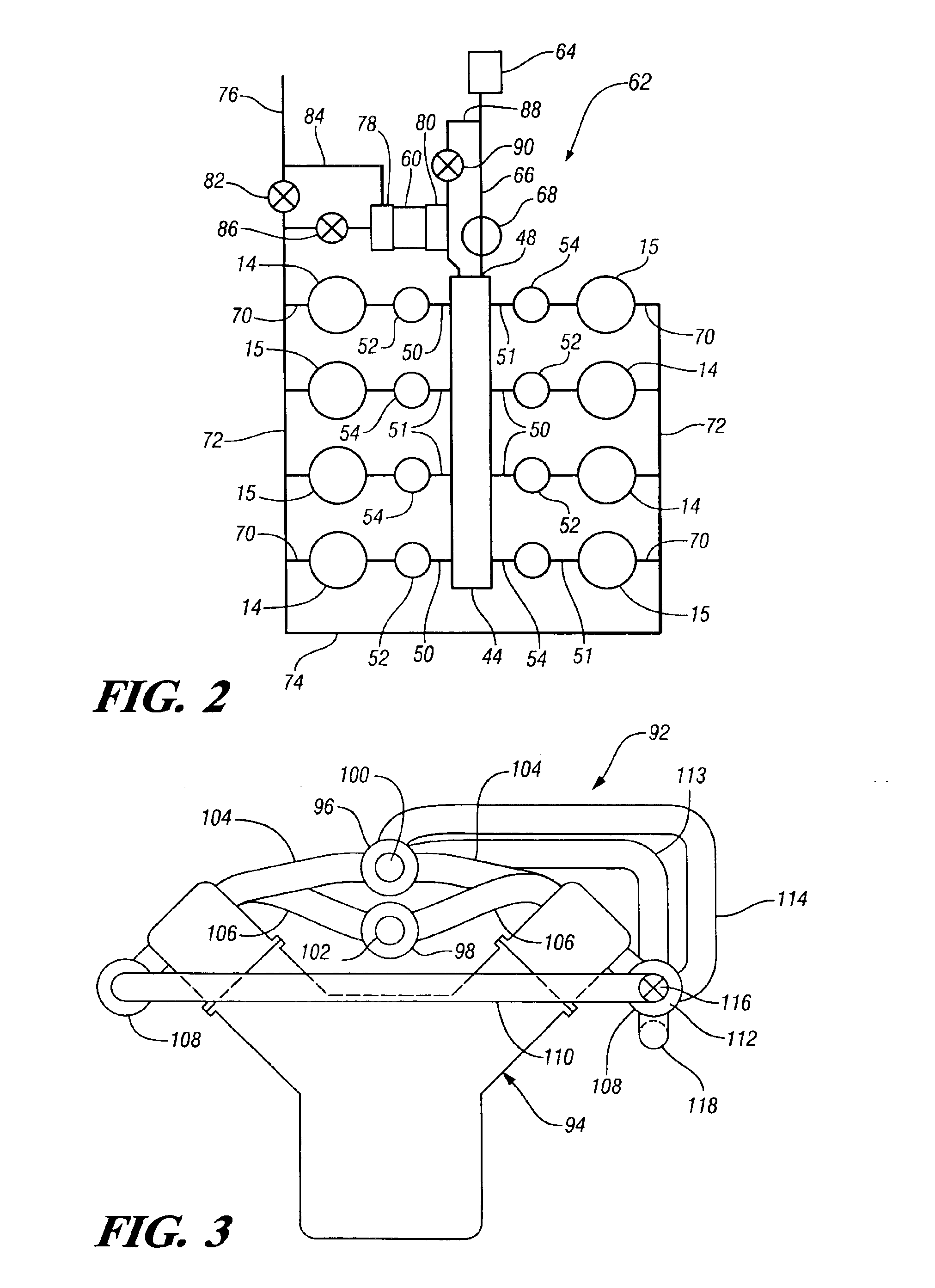

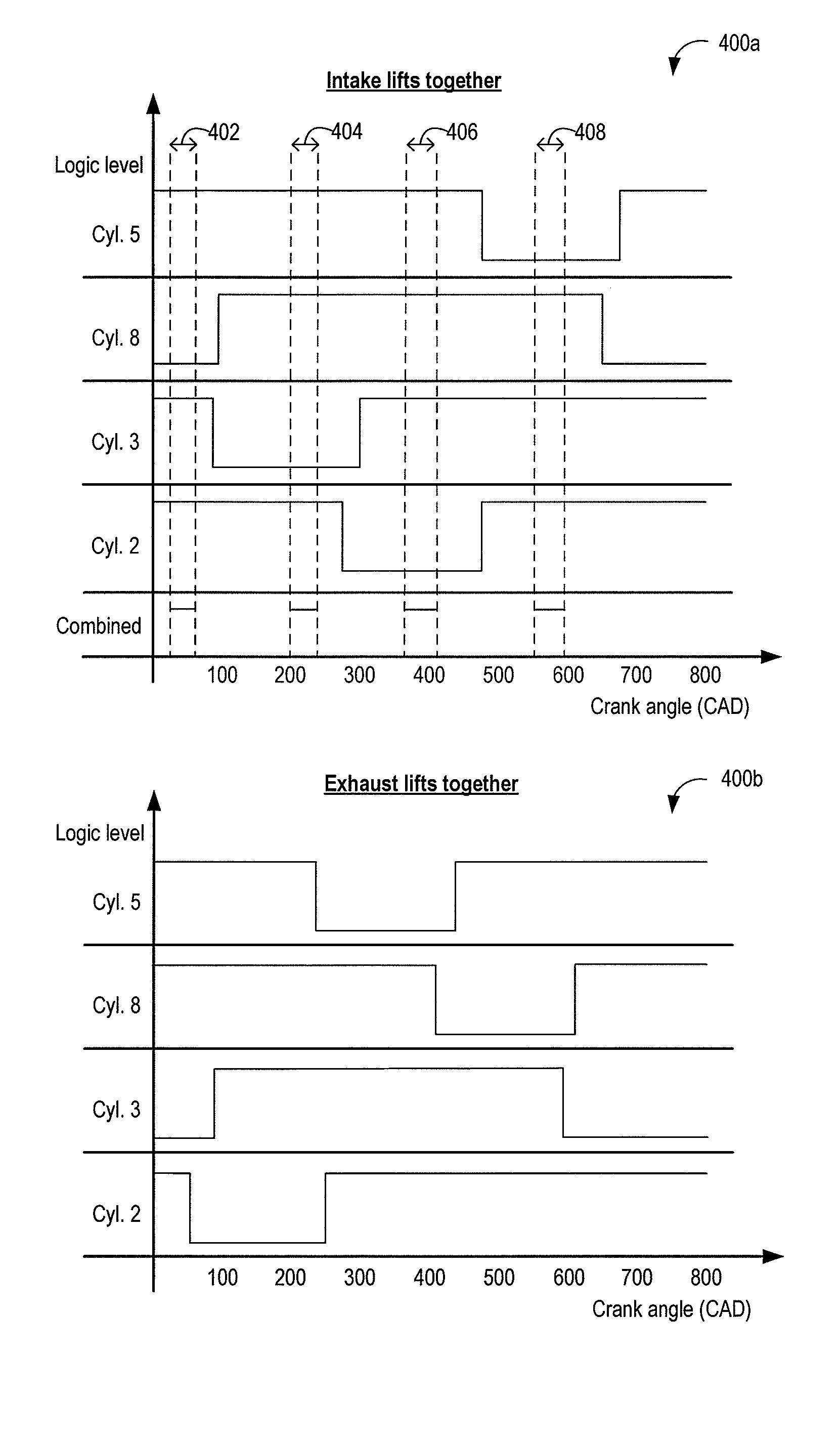

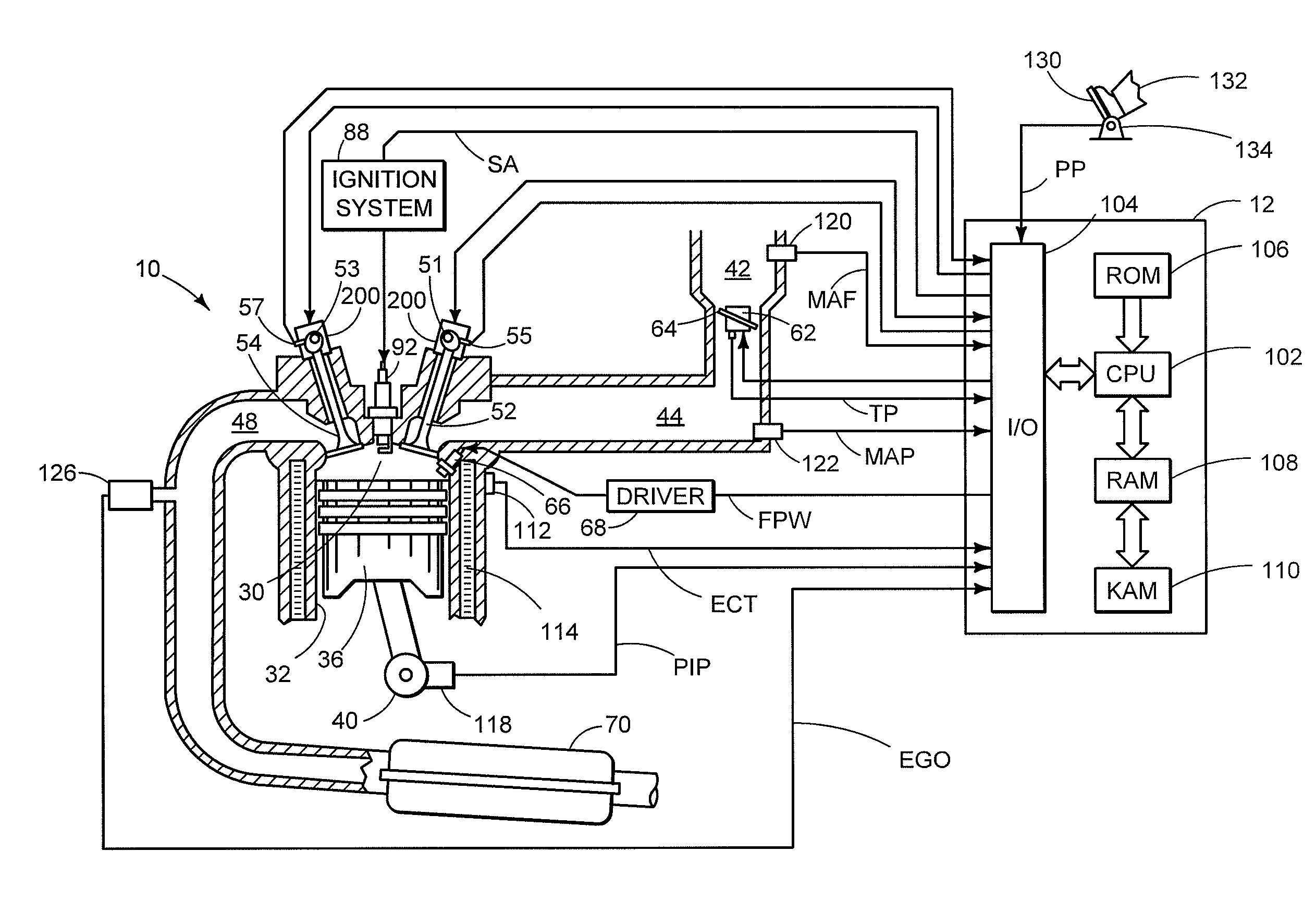

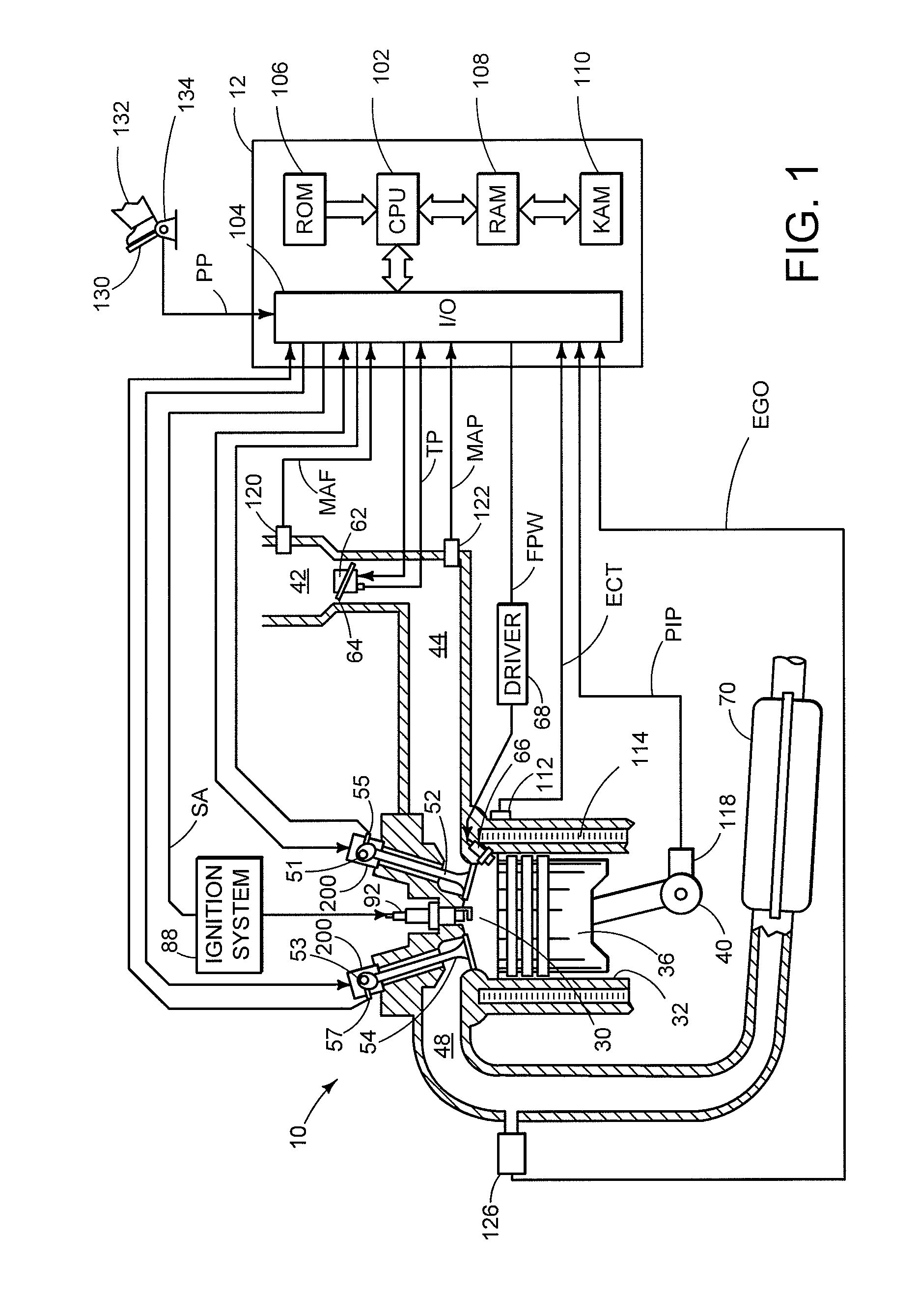

Methods and systems are provided for monitoring cylinder valve deactivation in an engine operating with a plurality of cylinder valves. One example method comprises, sensing a plurality of cylinder valve positions of a plurality of cylinder valves; and combining the plurality of sensed positions to form a combined cylinder valve signal. The method may further include identifying valve degradation and differentiating valve degradation among the plurality of cylinder valves based on the combined cylinder valve signal and an expected value of the signal, and further based on a crank angle at which the expected value differs from the combined signal.

Owner:FORD GLOBAL TECH LLC

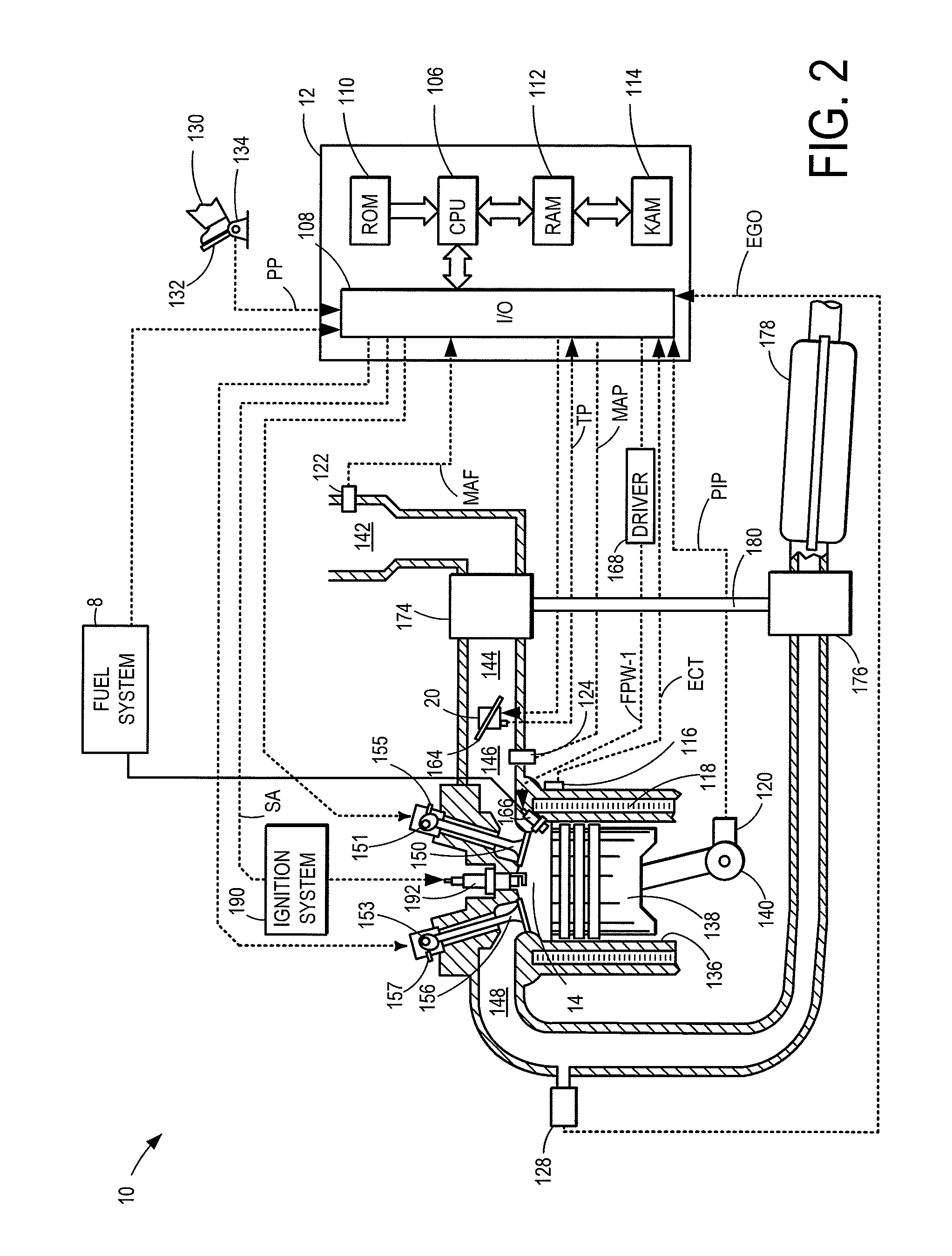

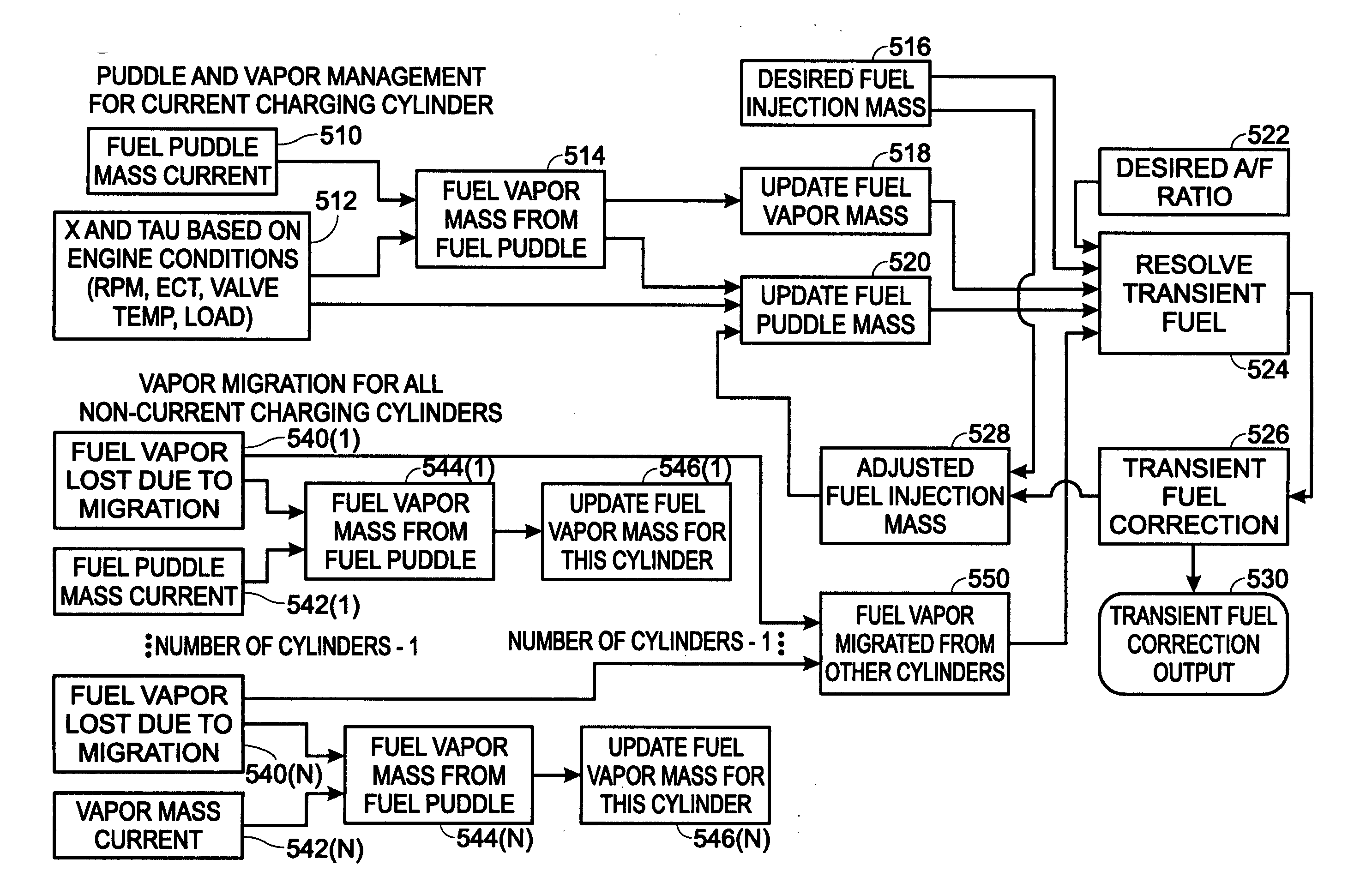

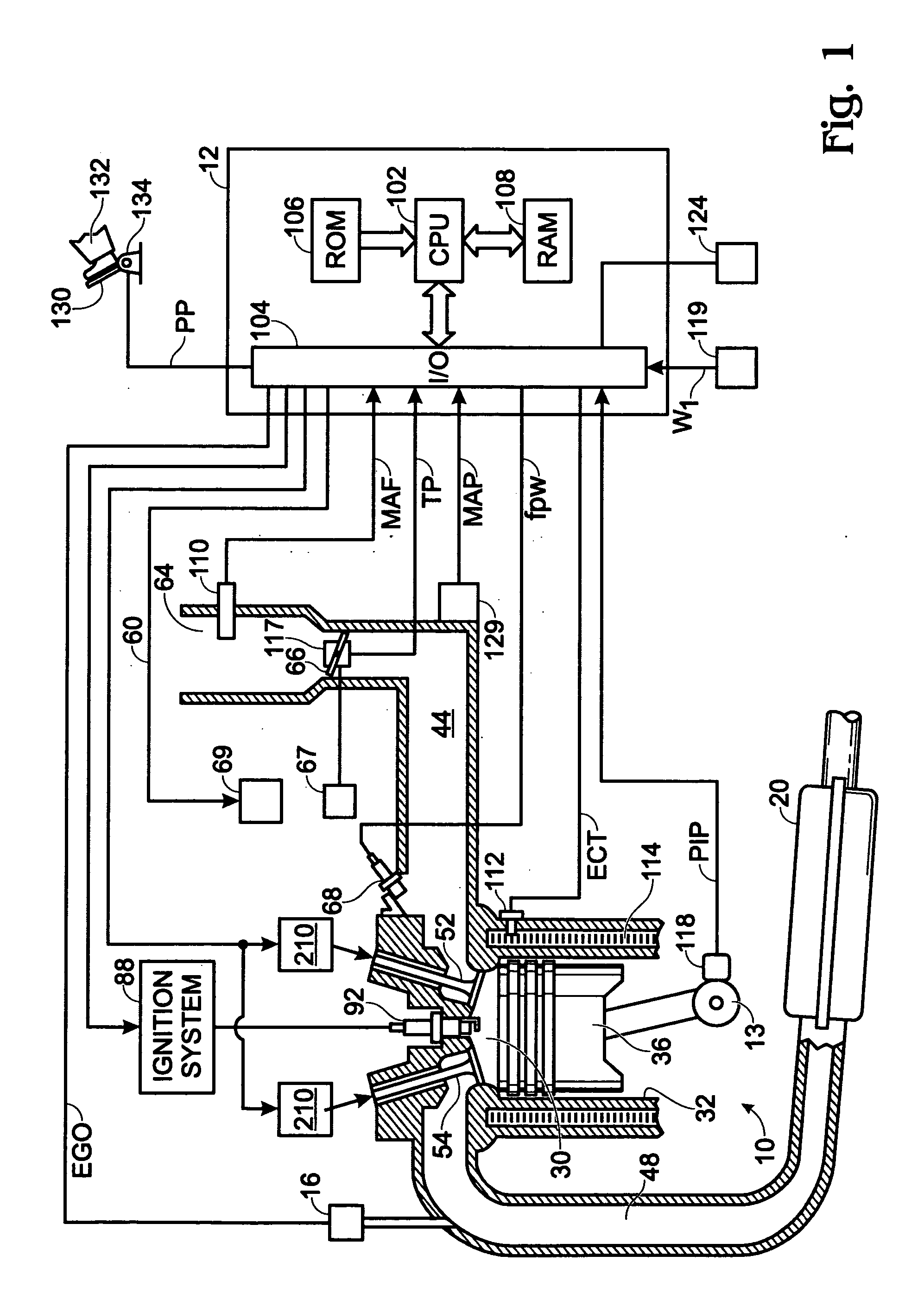

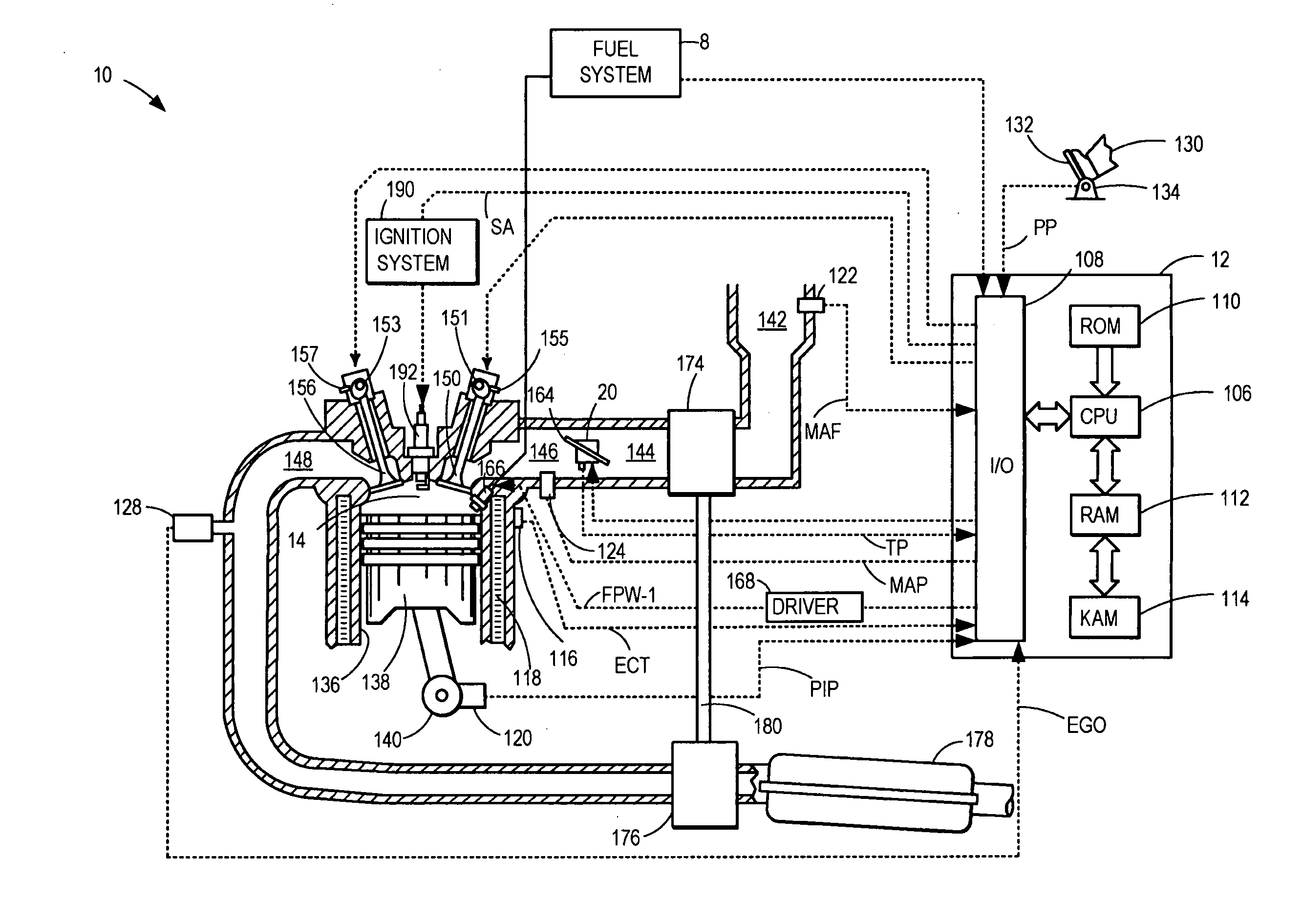

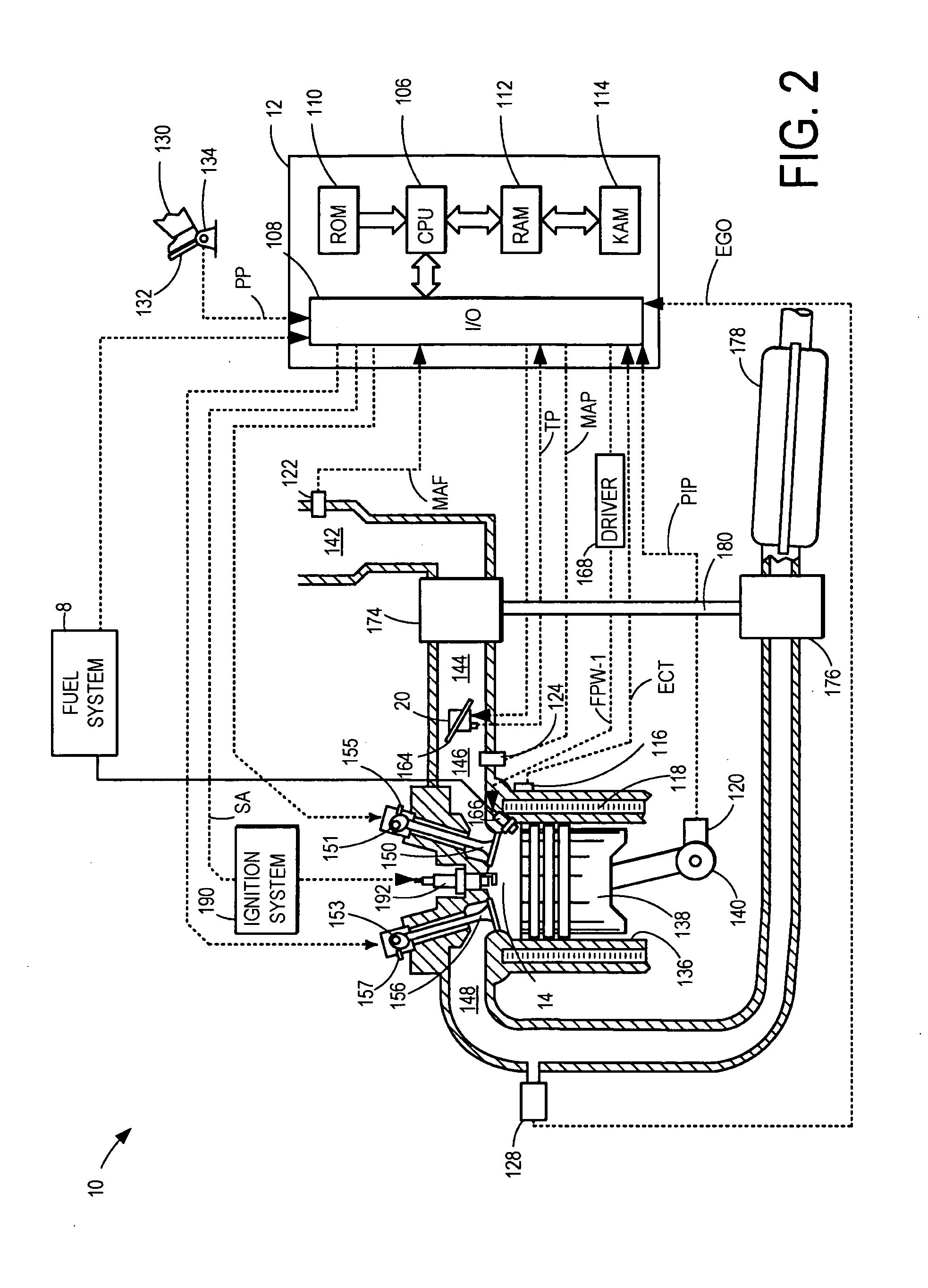

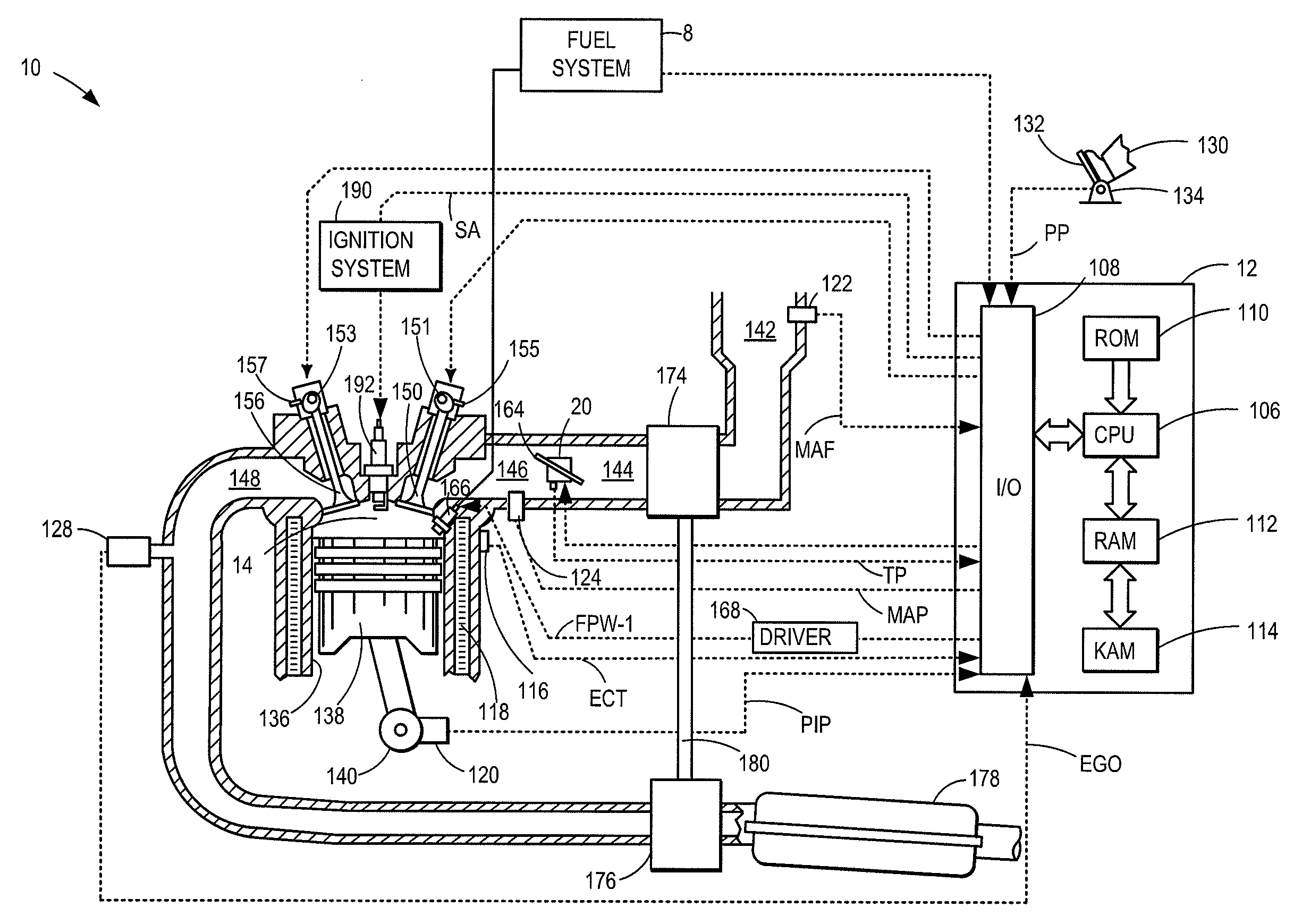

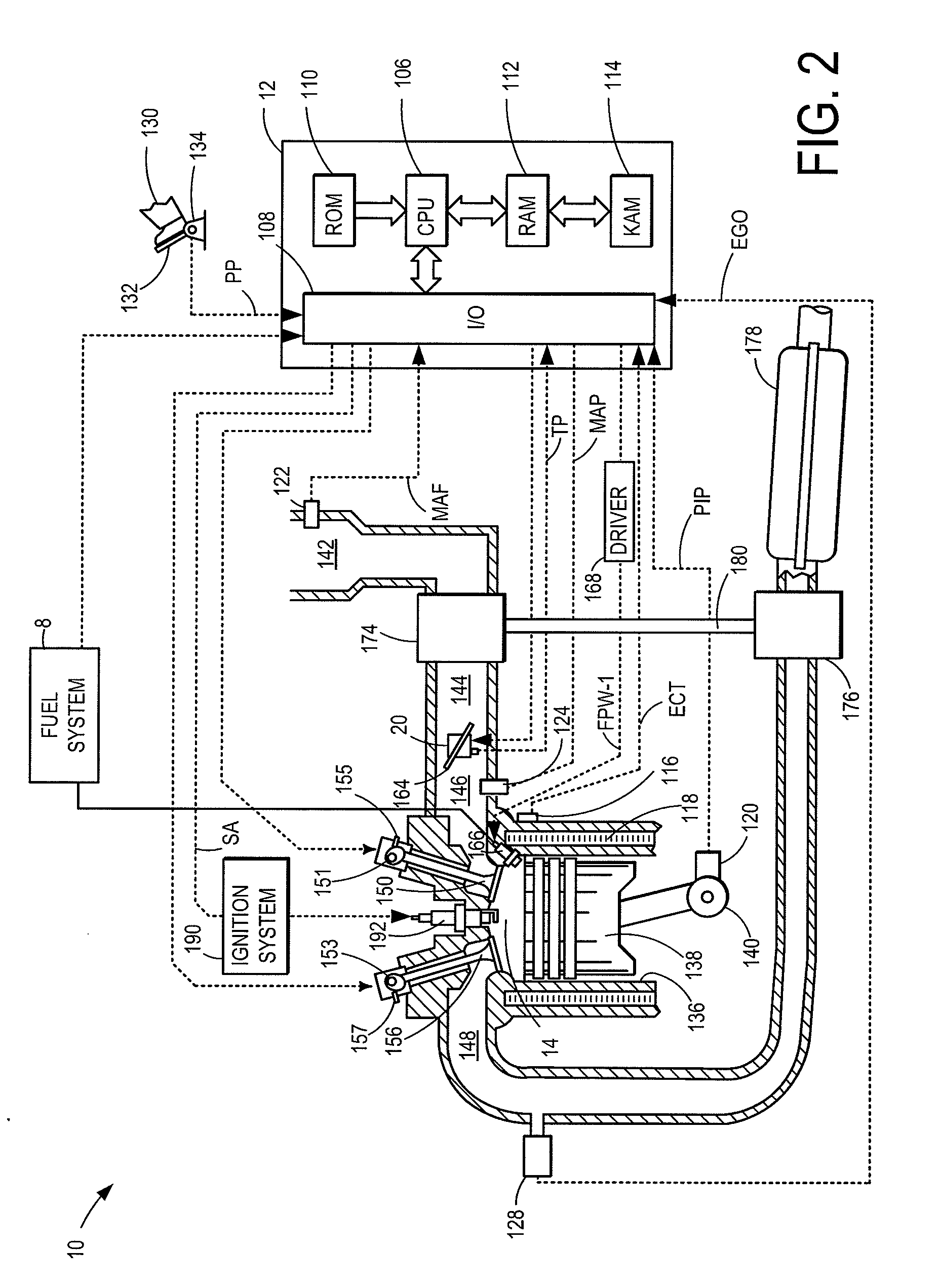

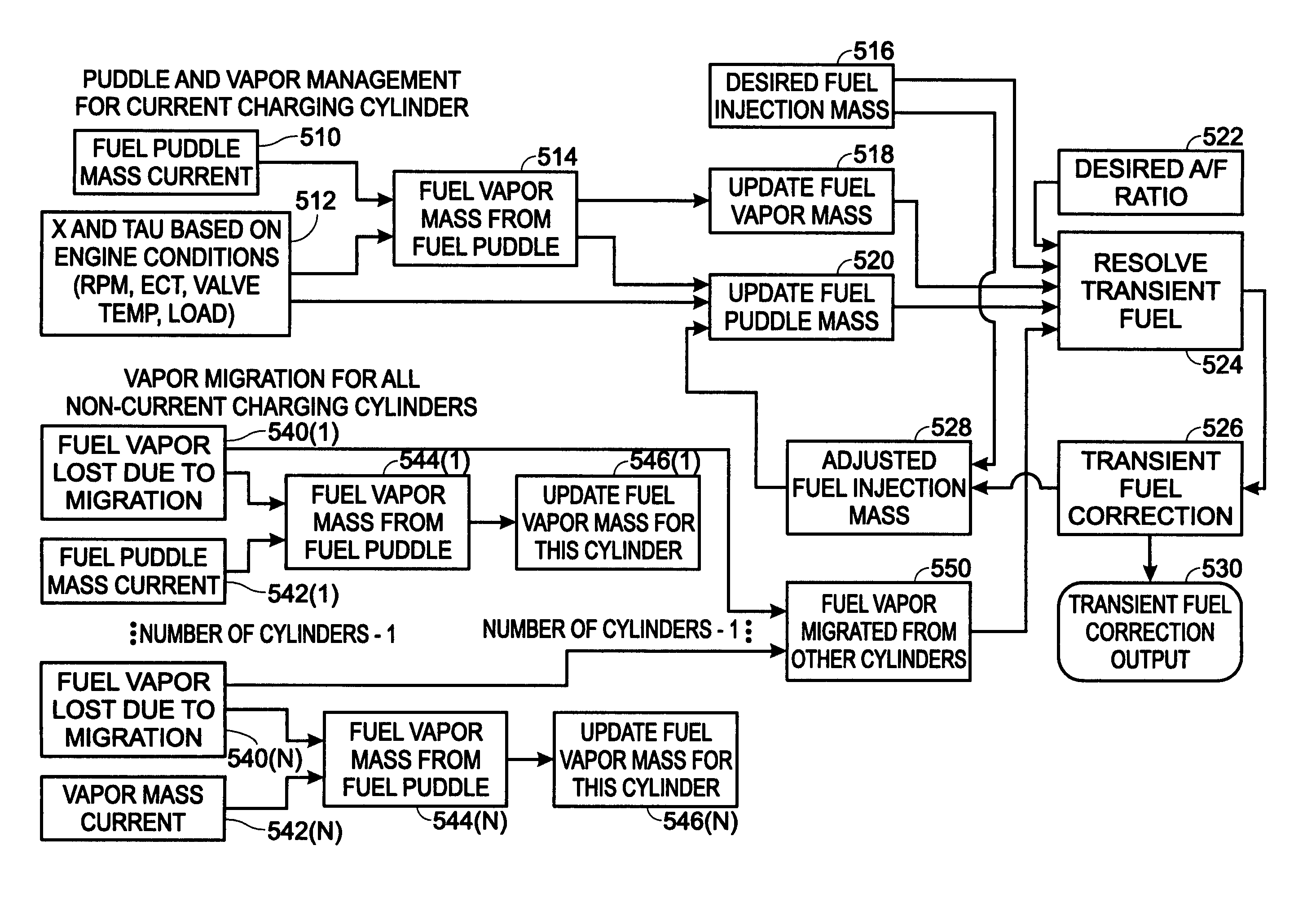

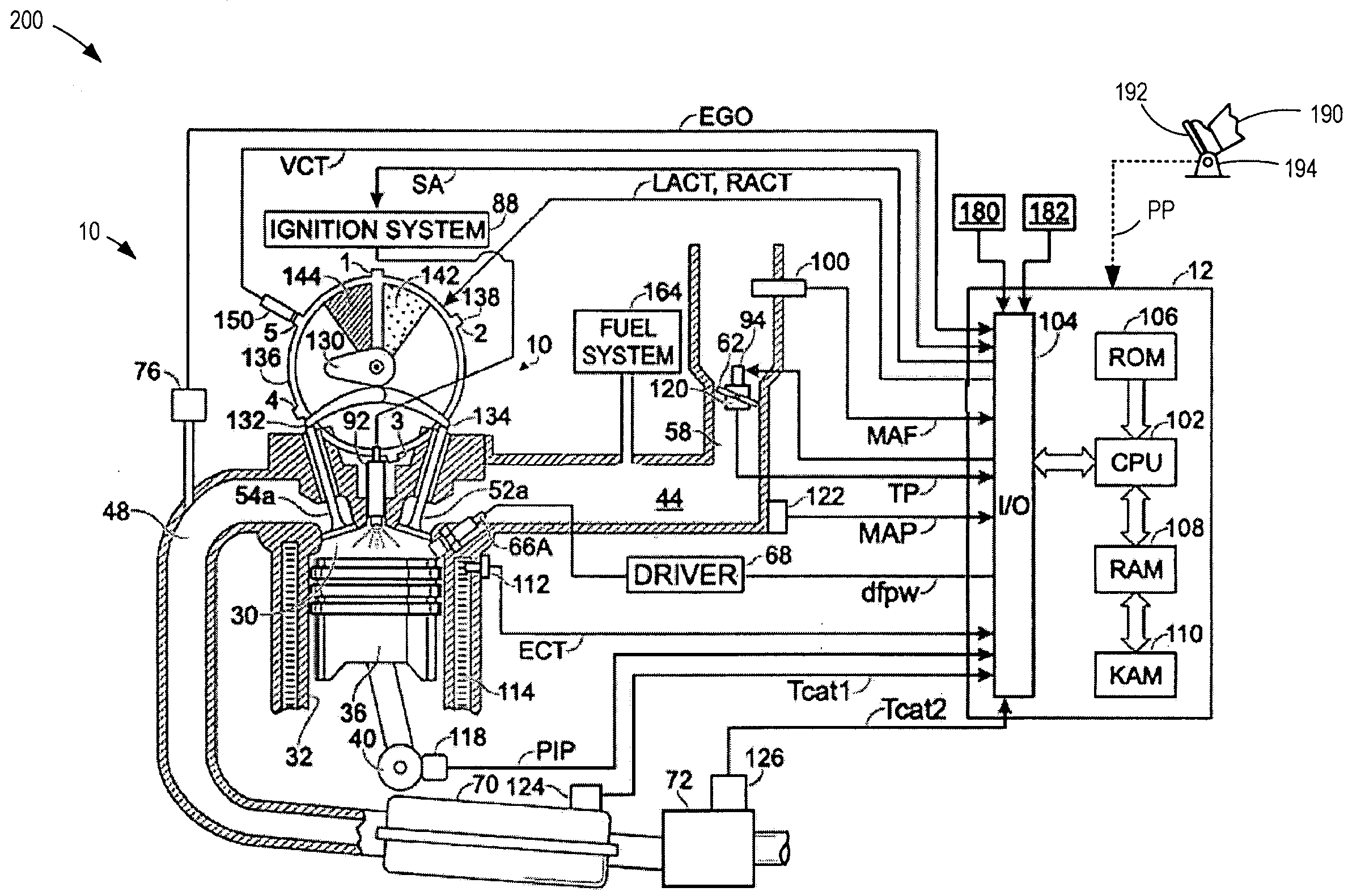

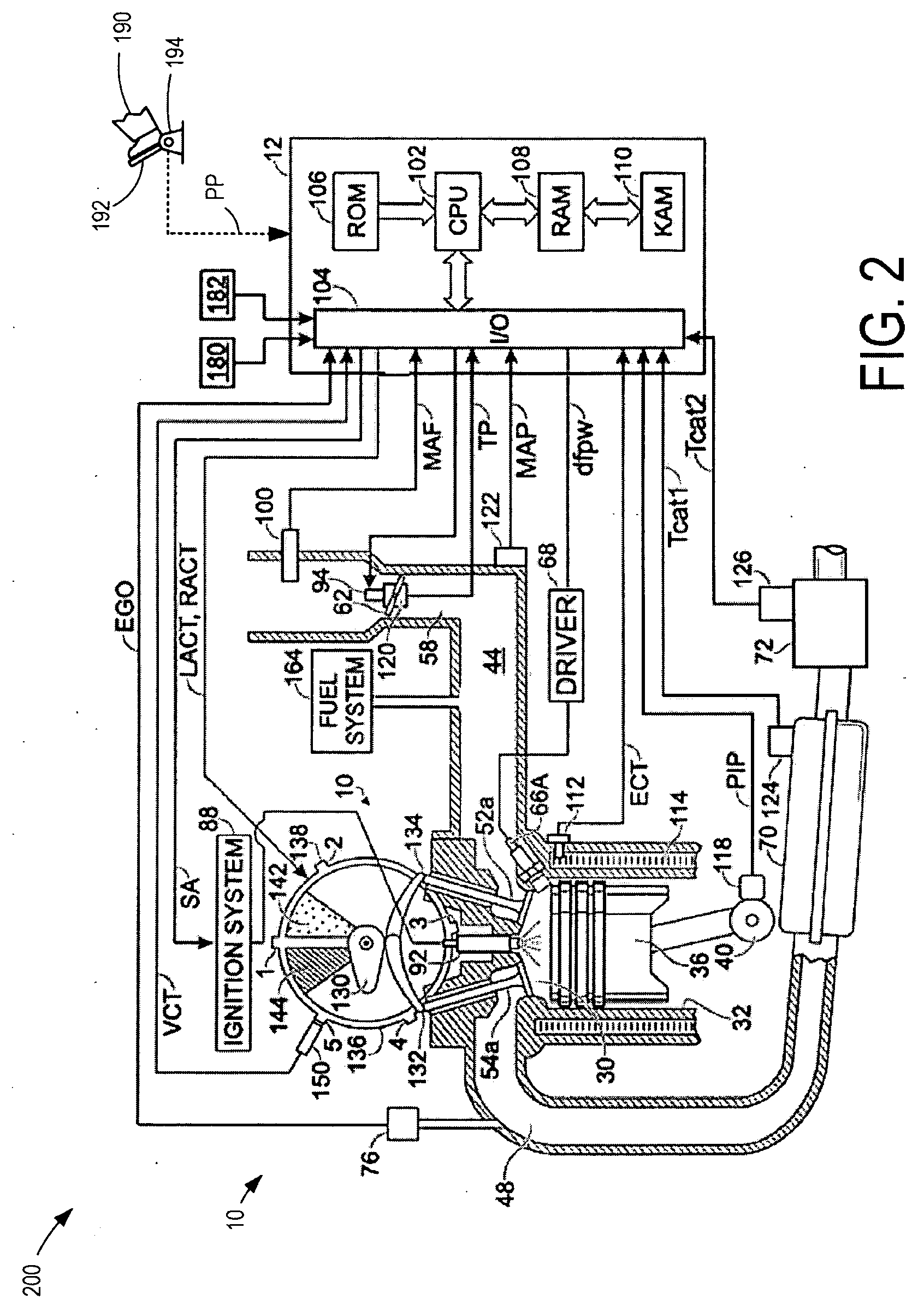

Engine control to compensate for fueling dynamics

ActiveUS20050166900A1Accurate air-fuel ratio controlEasy to controlElectrical controlInternal combustion piston enginesVaporizationCylinder Valve

A method for calculating transient fuel wall wetting characteristics of an operating engine is described. The method accounts for cylinder valve deactivation of cylinders in the engine in calculating the dynamic fueling compensation. In one example, fuel vaporization effects from fuel puddles in deactivated cylinders is considered when calculating the fueling compensation for active cylinders.

Owner:FORD GLOBAL TECH LLC

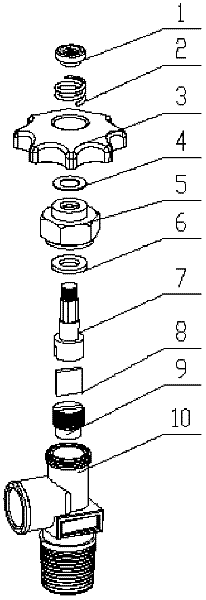

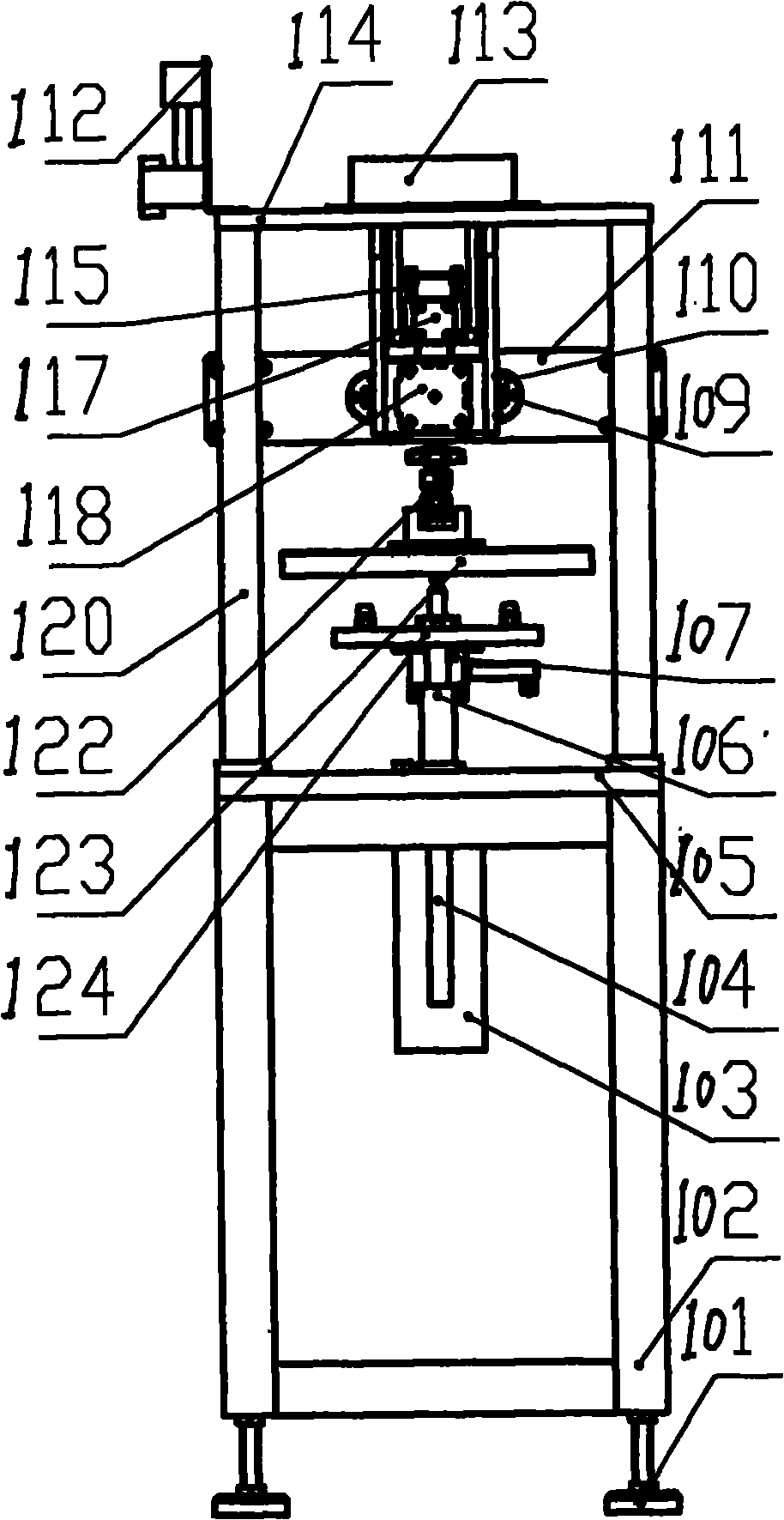

Automatic assembling line of liquefied petroleum gas cylinder valve

InactiveCN102390016AMovement precisionEffective investigationAssembly machinesGas cylinderClosed loop

The invention discloses an automatic assembling line of a liquefied petroleum gas cylinder valve and relates to an improvement on production equipment of a liquefied petroleum gas cylinder valve. The automatic assembling line is characterized by consisting of a loading working platform, a valve core assembling working platform, a connecting piece assembling working platform, a valve rod assembling working platform, a rubber pad assembling working platform, an oil coating working platform, a nut assembling working platform, a nut screwing working platform, a paper pad assembling working platform, a hand wheel assembling working platform, a spring assembling working platform, a round nut assembling working platform, a finished product blanking working platform and a line body. The automatic assembling line has the beneficial effects that a workpiece is clamped and conveyed by adopting a mode of automatic loading of a vibrating disc and stepping transmission so as to be transferred in a reciprocating manner of returning to the original position; and after the assembly of all the working platforms is finished in circulation, the blanking of the workpiece in next circulation is carried out, and the movement of the mechanism is more accurate by utilizing a cylinder and a linear guide rail. A sensor is adopted to sense whether the workpiece exists, a signal is transmitted to a PLC (programmable logic computer) and the PLC sends an instruction to execute the actions of all the working platforms and carry out closed-loop control.

Owner:CHANGCHUN UNIV OF TECH +1

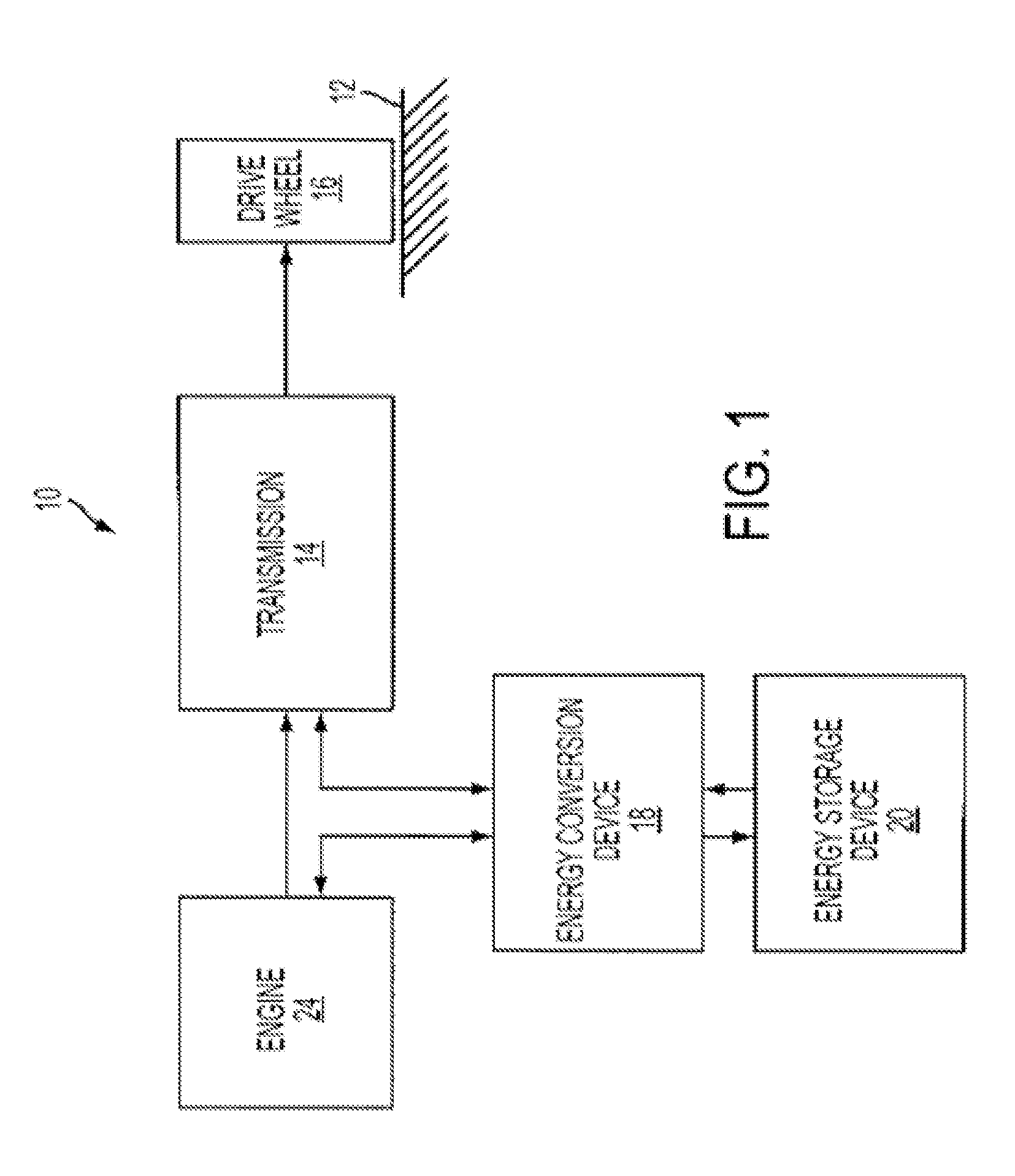

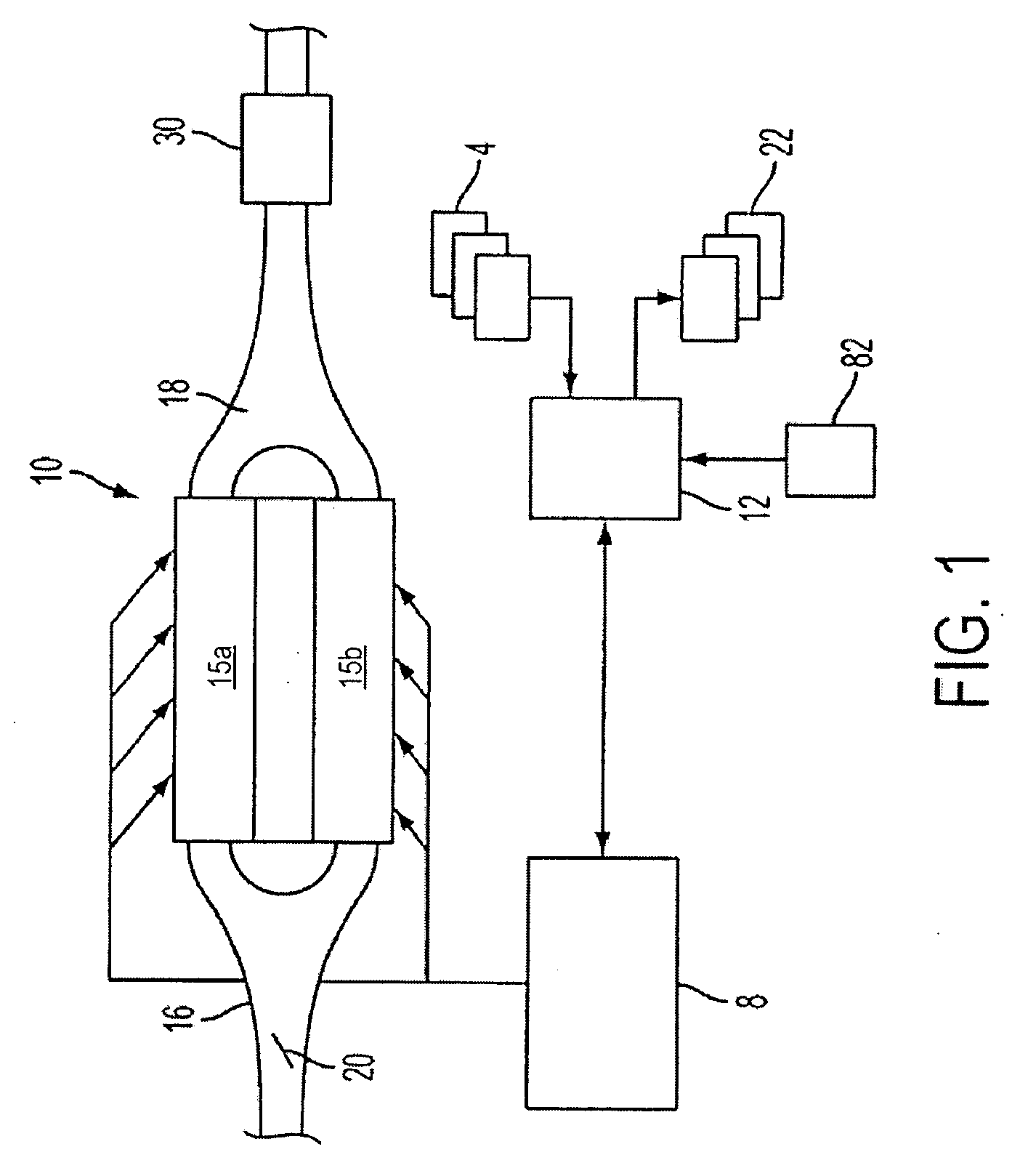

Hybrid Vehicle with Camless Valve Control

InactiveUS20080078593A1Hybrid vehiclesInternal combustion piston enginesExternal combustion engineEngineering

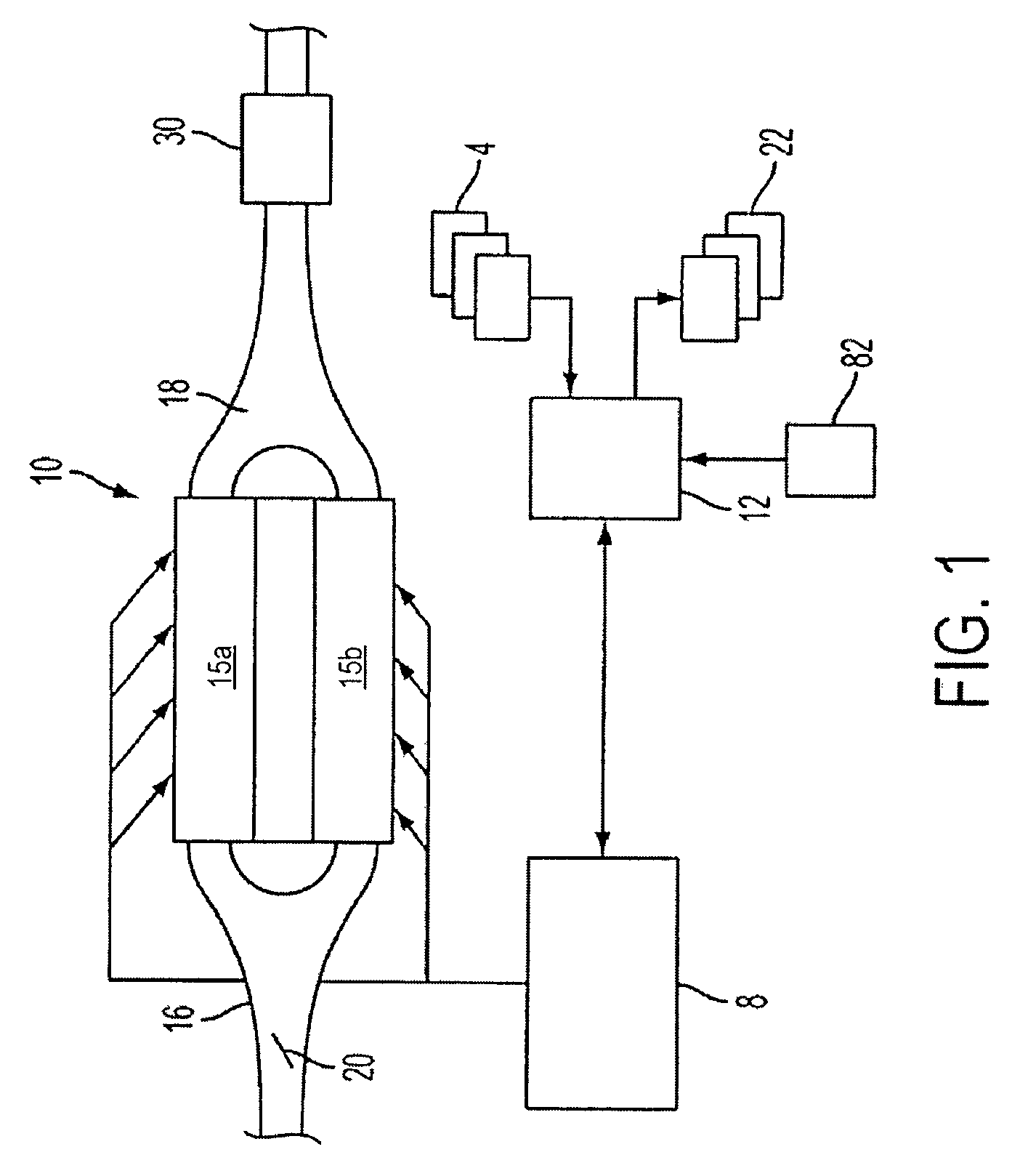

A method of controlling a hybrid propulsion system of a vehicle, where the hybrid propulsion system includes an internal combustion engine and an alternate torque source configured to provide motive power to the vehicle. While the engine is turned off, initial cranking of the engine is performed to initiate an engine start. During initial cranking, a cylinder valve is operated in a startup timing mode so as to reduce pumping work required to move a piston during initial cranking. Subsequent to initial cranking, the valve is operated with a different timing than that employed during the startup timing mode.

Owner:FORD GLOBAL TECH LLC

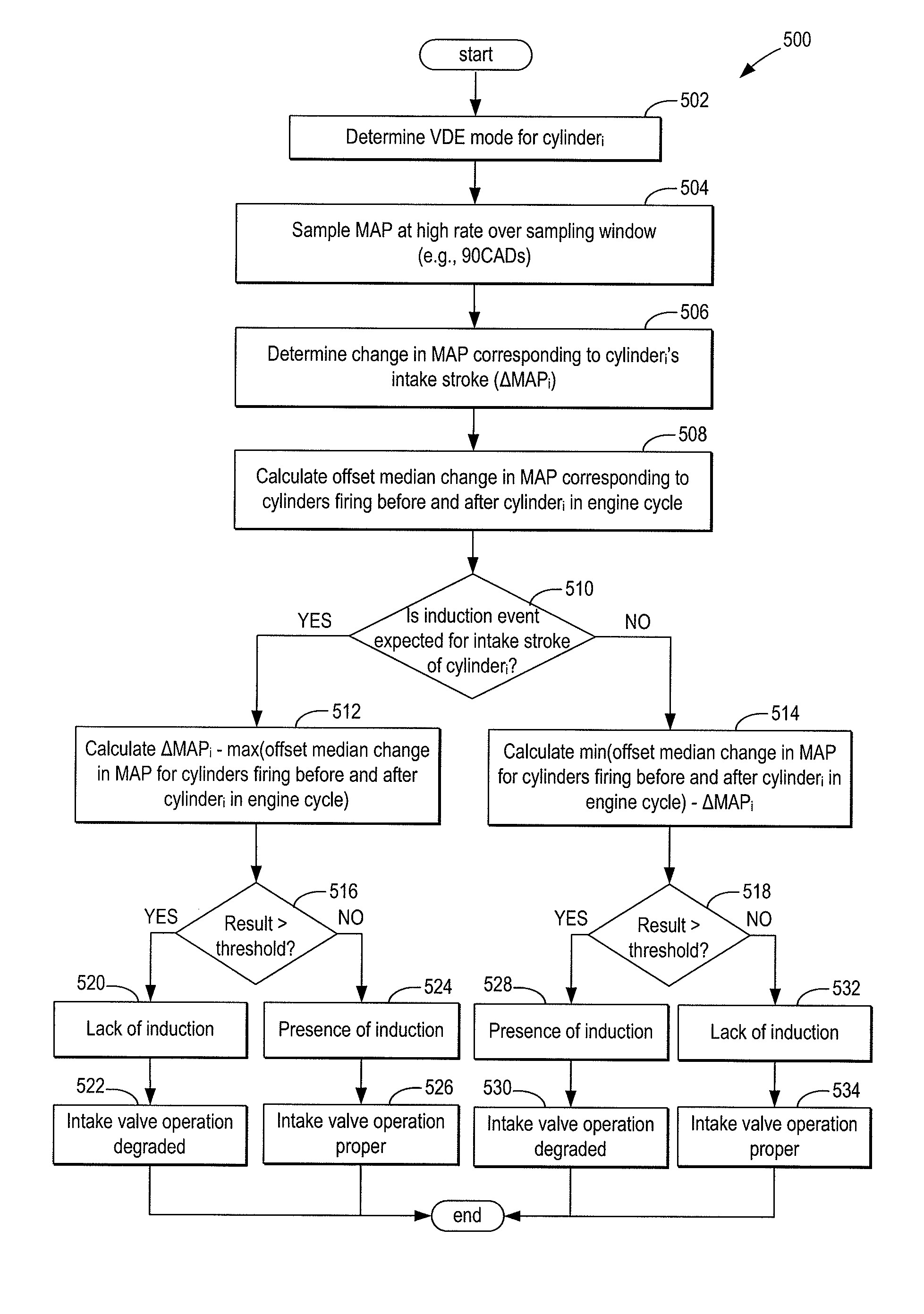

Variable displacement engine diagnostics

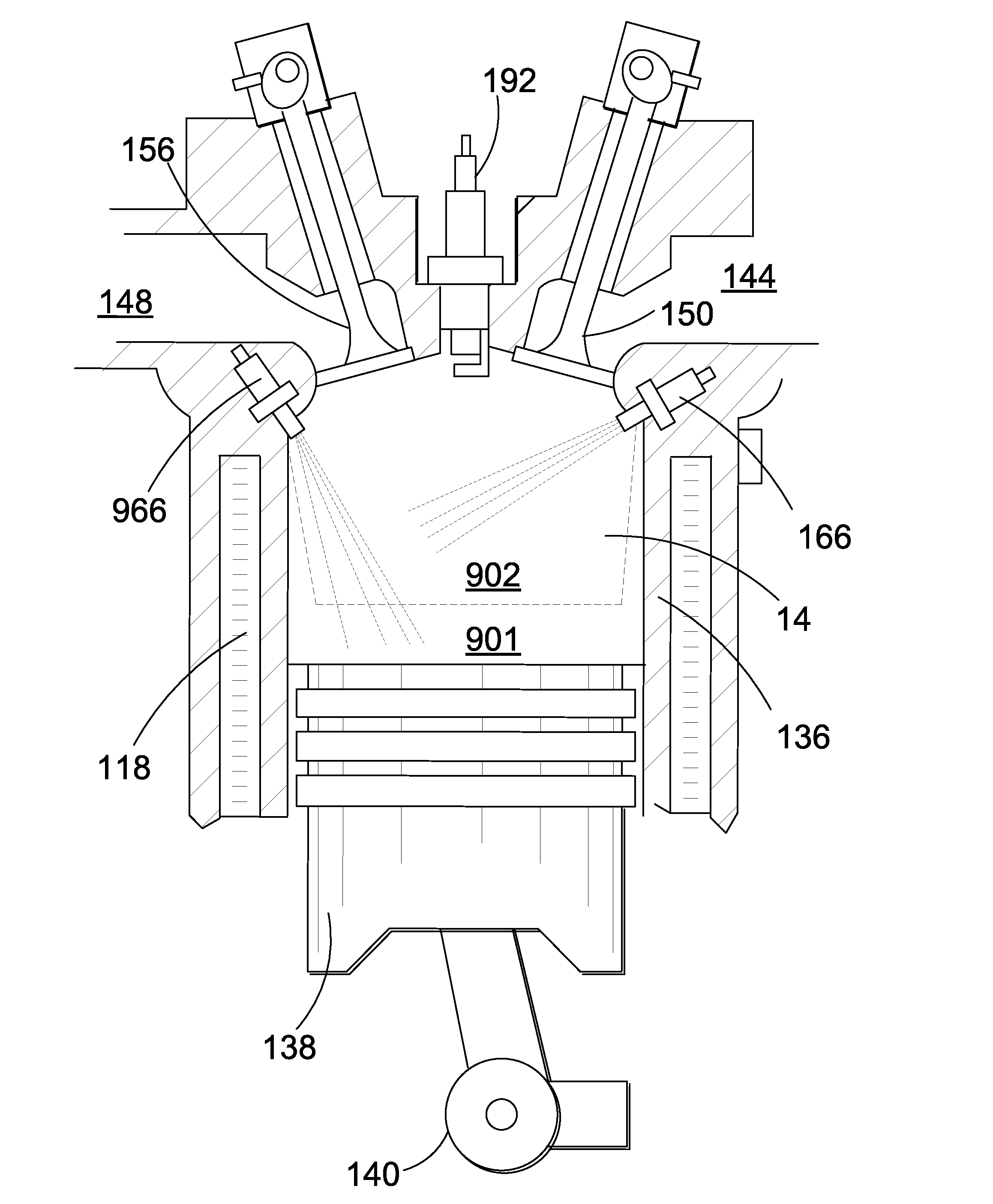

ActiveUS20100175463A1Improve fuel economyInternal-combustion engine testingElectrical controlEngineeringCylinder Valve

Methods and systems are provided for monitoring cylinder valve deactivation of a cylinder valve of an engine. One example method comprises, indicating degradation of cylinder valve deactivation in response to manifold pressure at or around a characteristic frequency.

Owner:FORD GLOBAL TECH LLC

Variable displacement engine diagnostics

ActiveUS20100175462A1Improve fuel economyAnalogue computers for vehiclesInternal-combustion engine testingCylinder ValveMechanical engineering

Methods and systems are provided for monitoring cylinder valve deactivation in an engine operating with a plurality of cylinder valves. One example method comprises indicating valve degradation based on an indication of manifold pressure over a plurality of immediately successive induction events of the engine, said indication responsive to increases and decreases in the indication of manifold pressure correlated to the induction events of engine cylinders and further correlated to whether cylinders are commanded to be activated or deactivated.

Owner:FORD GLOBAL TECH LLC

Engine control to compensate for fueling dynamics

ActiveUS7111593B2Easy to controlCompensation effectElectrical controlInternal combustion piston enginesVaporizationCylinder Valve

A method for calculating transient fuel wall wetting characteristics of an operating engine is described. The method accounts for cylinder valve deactivation of cylinders in the engine in calculating the dynamic fueling compensation. In one example, fuel vaporization effects from fuel puddles in deactivated cylinders is considered when calculating the fueling compensation for active cylinders.

Owner:FORD GLOBAL TECH LLC

Direct injection of diluents or secondary fuels in gaseous fuel engines

ActiveUS20140331970A1Reduce exhaust emissionsHigh priceInternal combustion piston enginesExhaust gas recirculationCombustionDiluent

A method for operating an engine, comprising port injecting a first quantity of a first gaseous fuel in a cylinder cycle and direct injecting a second quantity of a secondary injectant in the cylinder cycle as a function of a desired air-to-fuel ratio (AFR), the desired AFR based on a temperature of an engine cylinder valve. The desired AFR may be outside the AFR range available during natural gas combustion alone and thus allows for cooler engine operation.

Owner:FORD GLOBAL TECH LLC

Variable displacement engine diagnostics

ActiveUS8286471B2Improve fuel economyInternal-combustion engine testingAnalogue computers for vehiclesEngineeringCylinder Valve

Methods and systems are provided for monitoring cylinder valve deactivation in an engine operating with a plurality of cylinder valves. One example method comprises indicating valve degradation based on an indication of manifold pressure over a plurality of immediately successive induction events of the engine, the indication responsive to increases and decreases in the indication of manifold pressure correlated to the induction events of engine cylinders and further correlated to whether cylinders are commanded to be activated or deactivated.

Owner:FORD GLOBAL TECH LLC

Variable displacement engine diagnostics

ActiveUS7921709B2Improve fuel economyInternal-combustion engine testingElectrical controlCylinder ValveMechanical engineering

Methods and systems are provided for monitoring cylinder valve deactivation of a cylinder valve of an engine. One example method comprises, indicating degradation of cylinder valve deactivation in response to manifold pressure at or around a characteristic frequency.

Owner:FORD GLOBAL TECH LLC

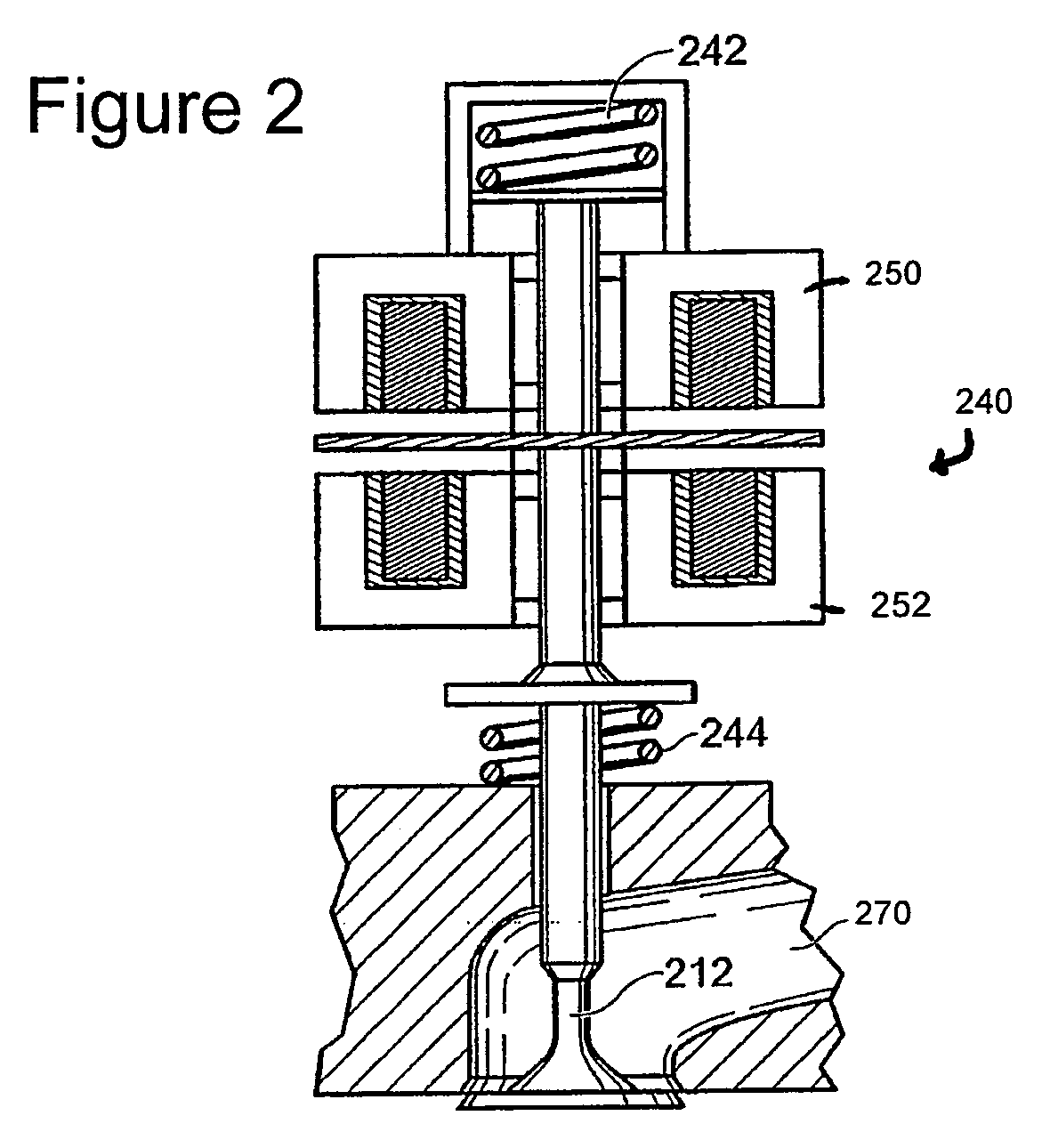

Feed Forward Control for Electric Variable Valve Operation

InactiveUS20120031357A1Easy to operateImprove fuel economyElectrical controlInternal combustion piston enginesCylinder ValveControl theory

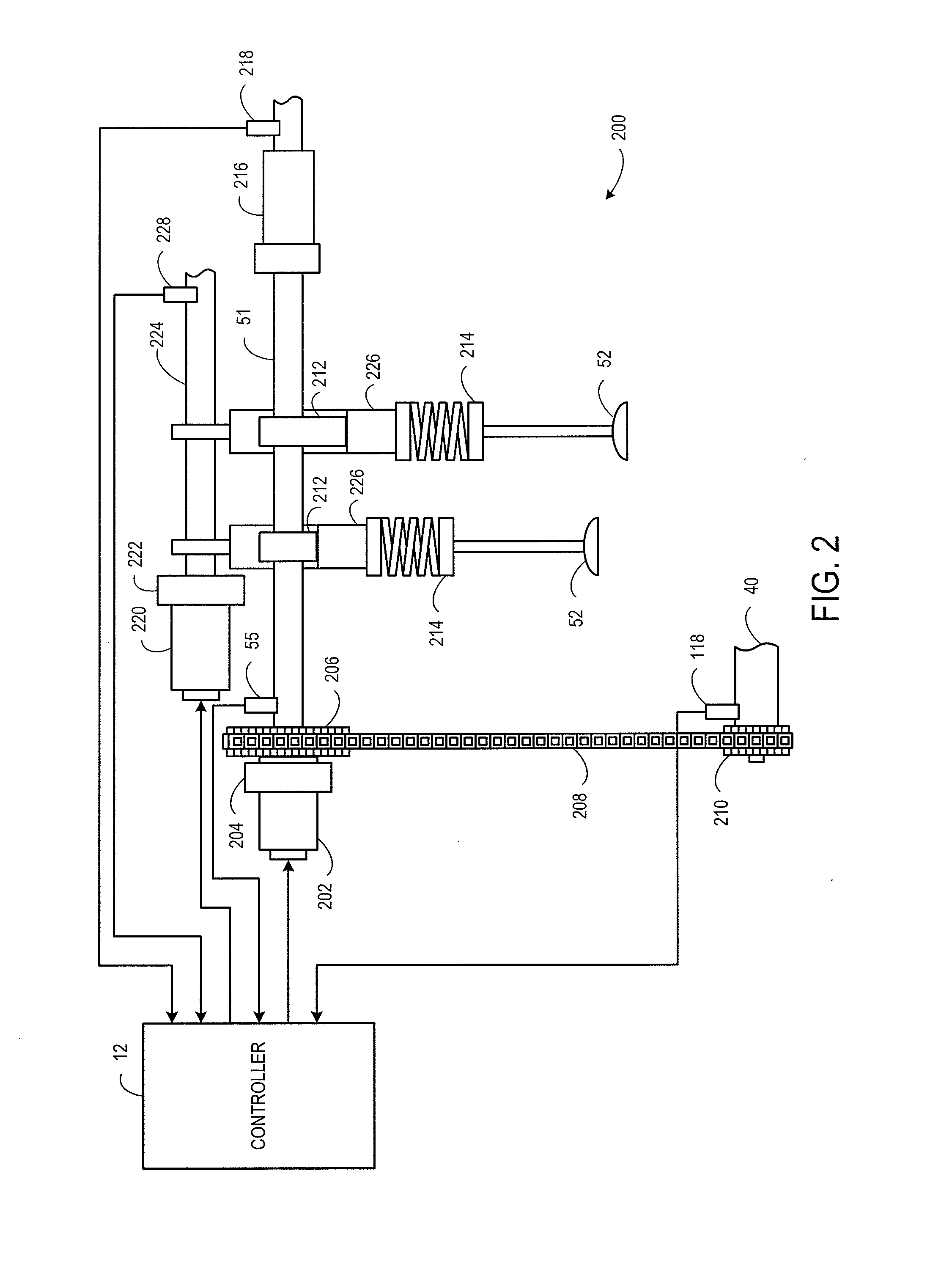

Periodic torque disturbances that affect cylinder valve operation are anticipated, and an appropriate reaction torque is provided by an electric motor to counteract the periodic torque disturbances to position a cylinder valve at a desired position.

Owner:FORD GLOBAL TECH LLC

Coordination of variable cam timing and variable displacement engine systems

ActiveUS20100211297A1Improve fuel economyImprove emission performanceAnalogue computers for vehiclesValve arrangementsVariable valve timingEngineering

Systems and methods are provided for operating an internal combustion engine including a variable cam timing (VCT) mechanism in cooperation with a plurality of deactivatable cylinders, each cylinder with a plurality of cylinder valves. One example method comprises, operating at a first cylinder valve timing before a transition of reactivating deactivated cylinders, and, before the transition, advancing cylinder valve timing from the first valve timing, where after the transition the cylinder valve timing remains at a second valve timing, the second valve timing advanced relative to the first valve timing.

Owner:FORD GLOBAL TECH LLC

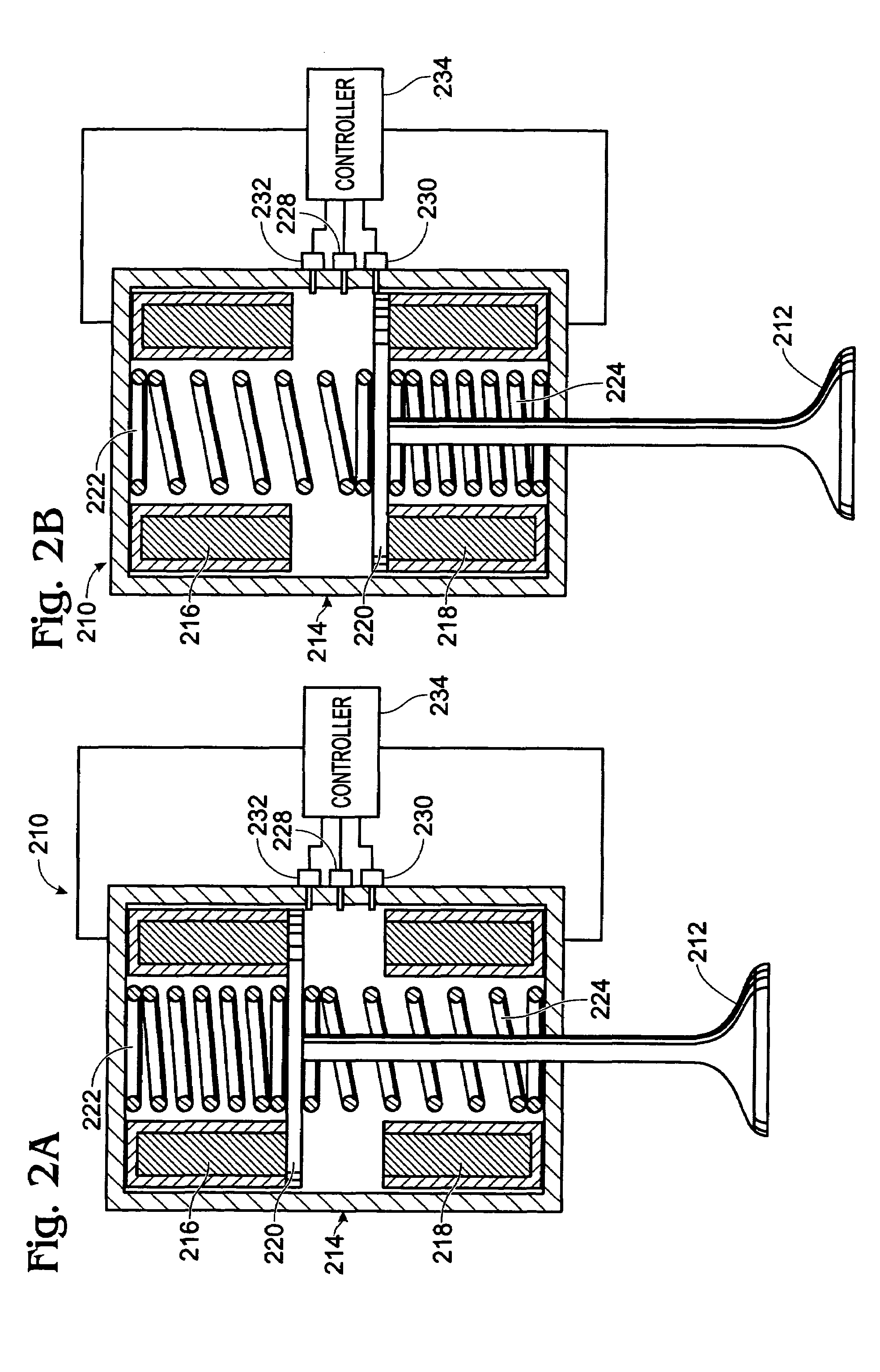

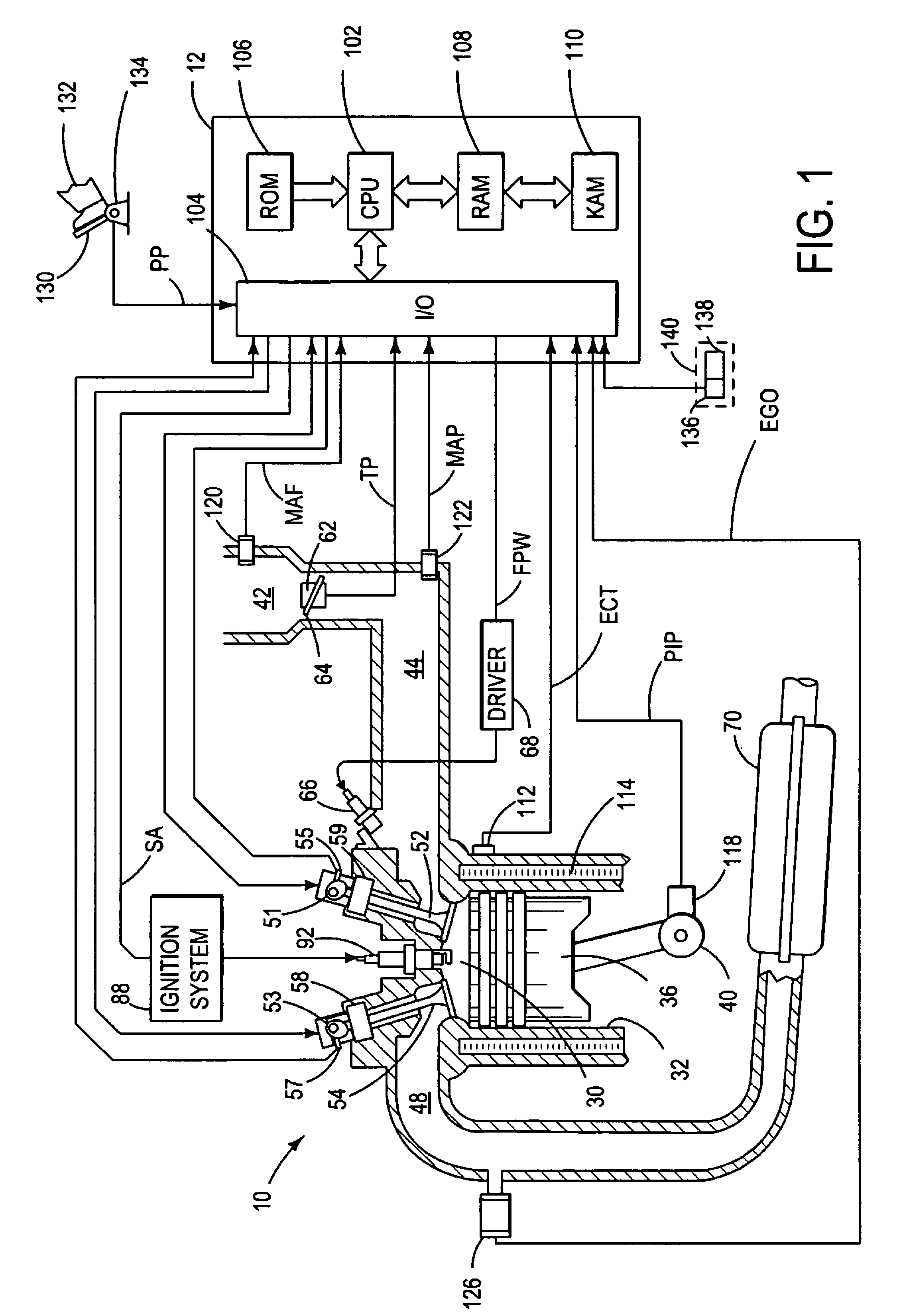

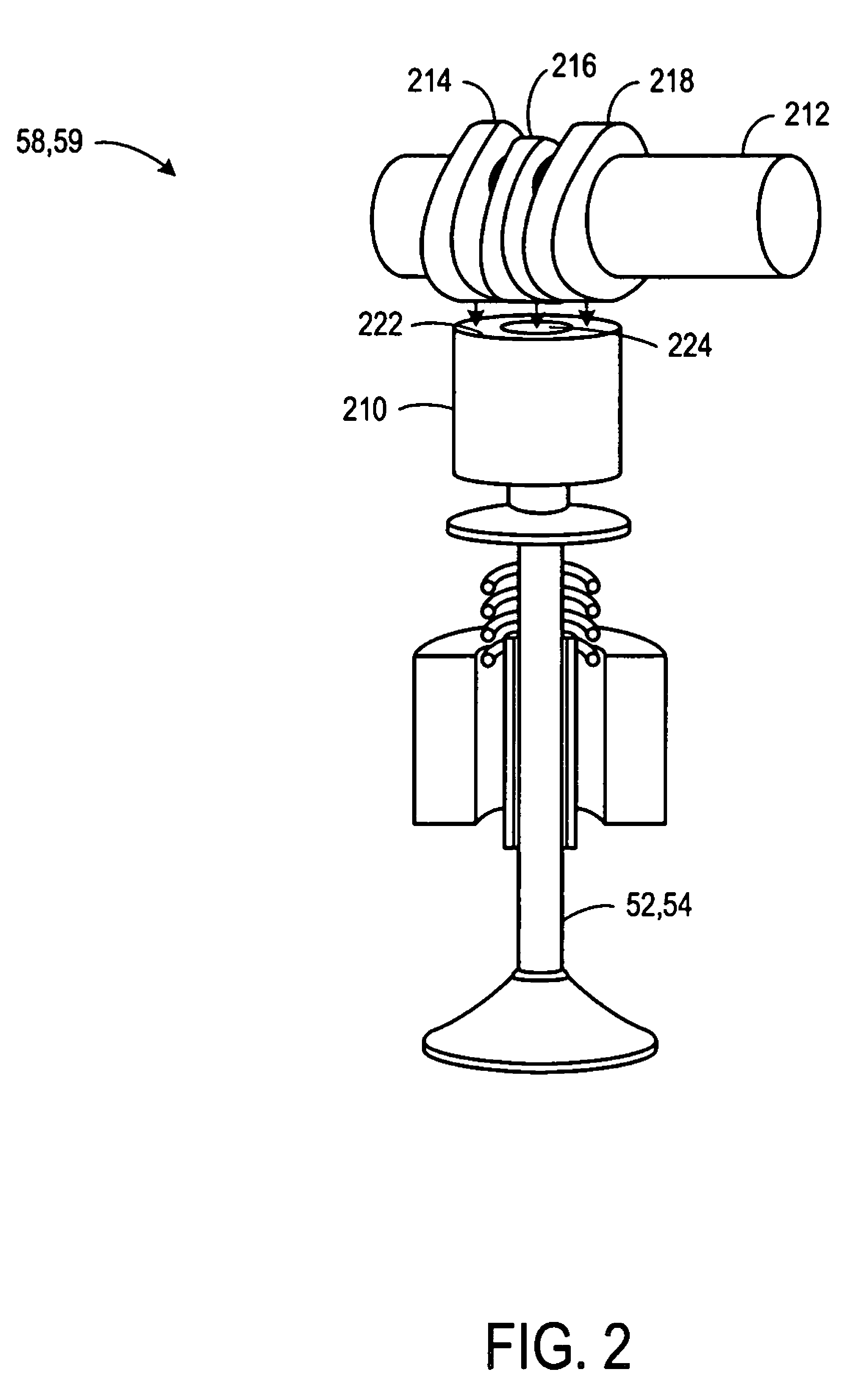

System and method for adaptive control of variable valve lift tappet switching

ActiveUS20070240653A1Reduce torque fluctuationReducing emission spikeValve arrangementsElectrical controlEngineeringCylinder Valve

A method of controlling cylinder valve switching between a first valve condition and a second valve condition for transitioning between combustion modes of an engine comprises adjusting timing of a signal to switch between said valve conditions in response to information from a combustion sensor, wherein said combustion modes include spark ignition and homogeneous compression ignition.

Owner:FORD GLOBAL TECH LLC

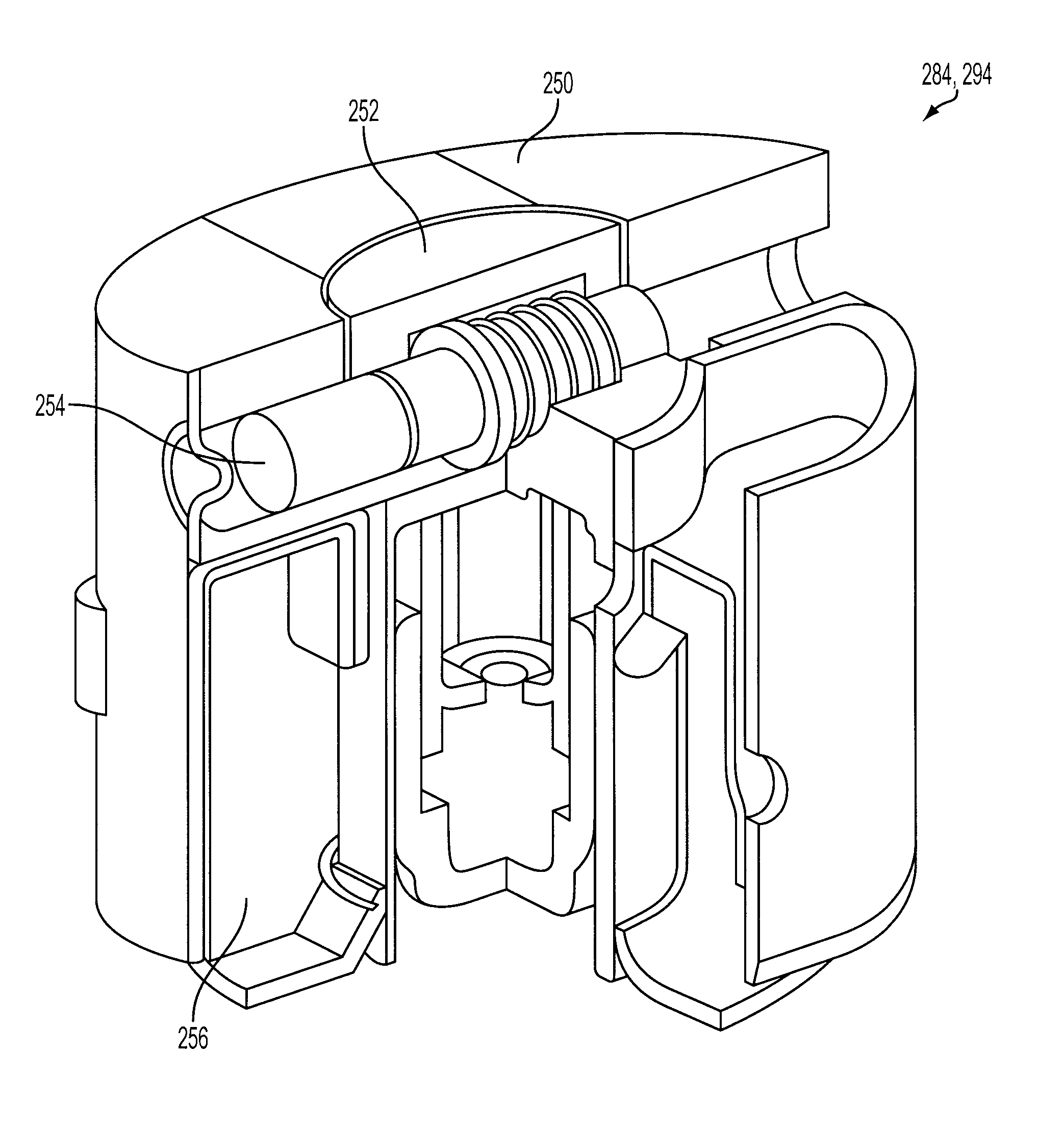

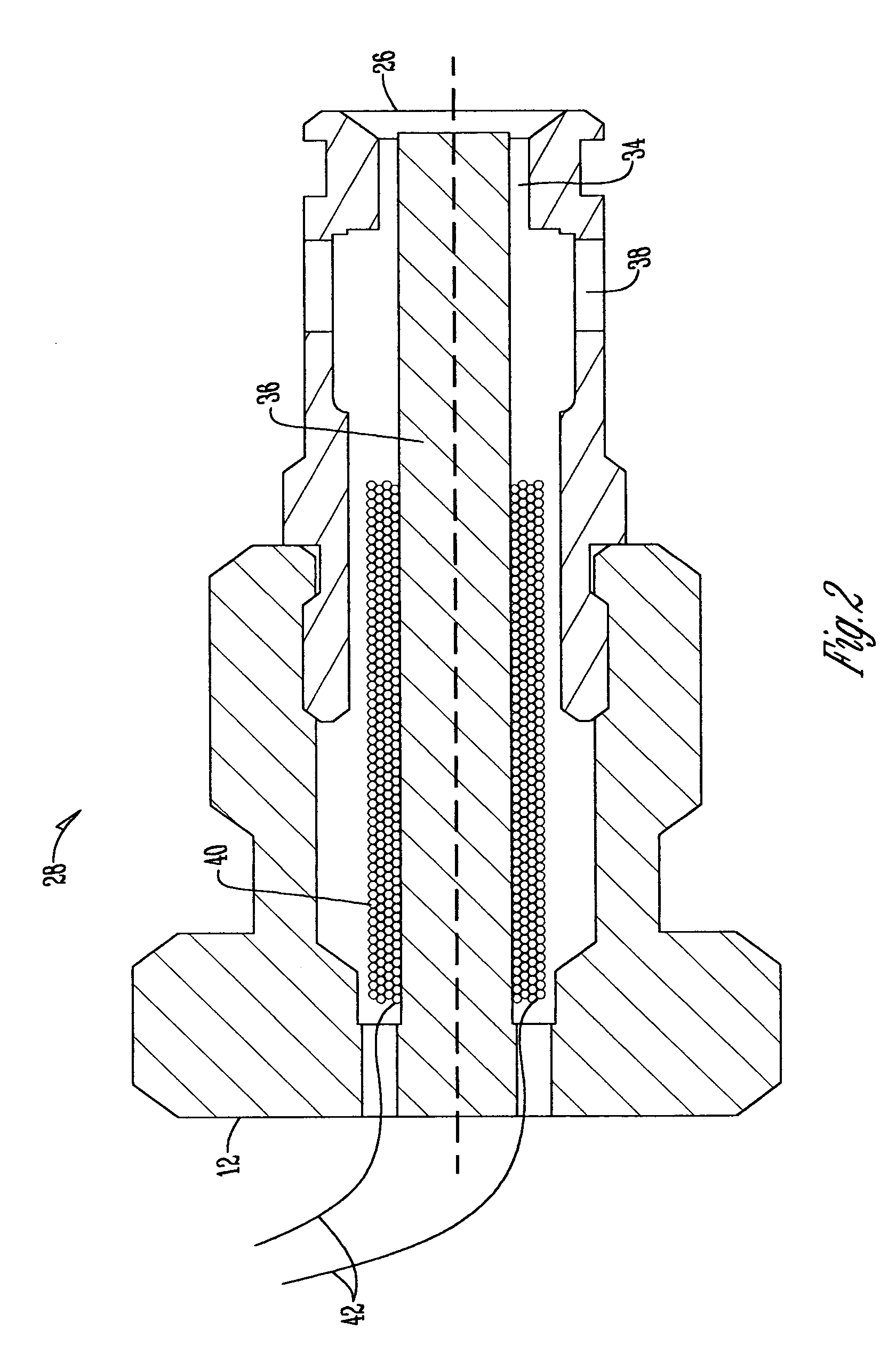

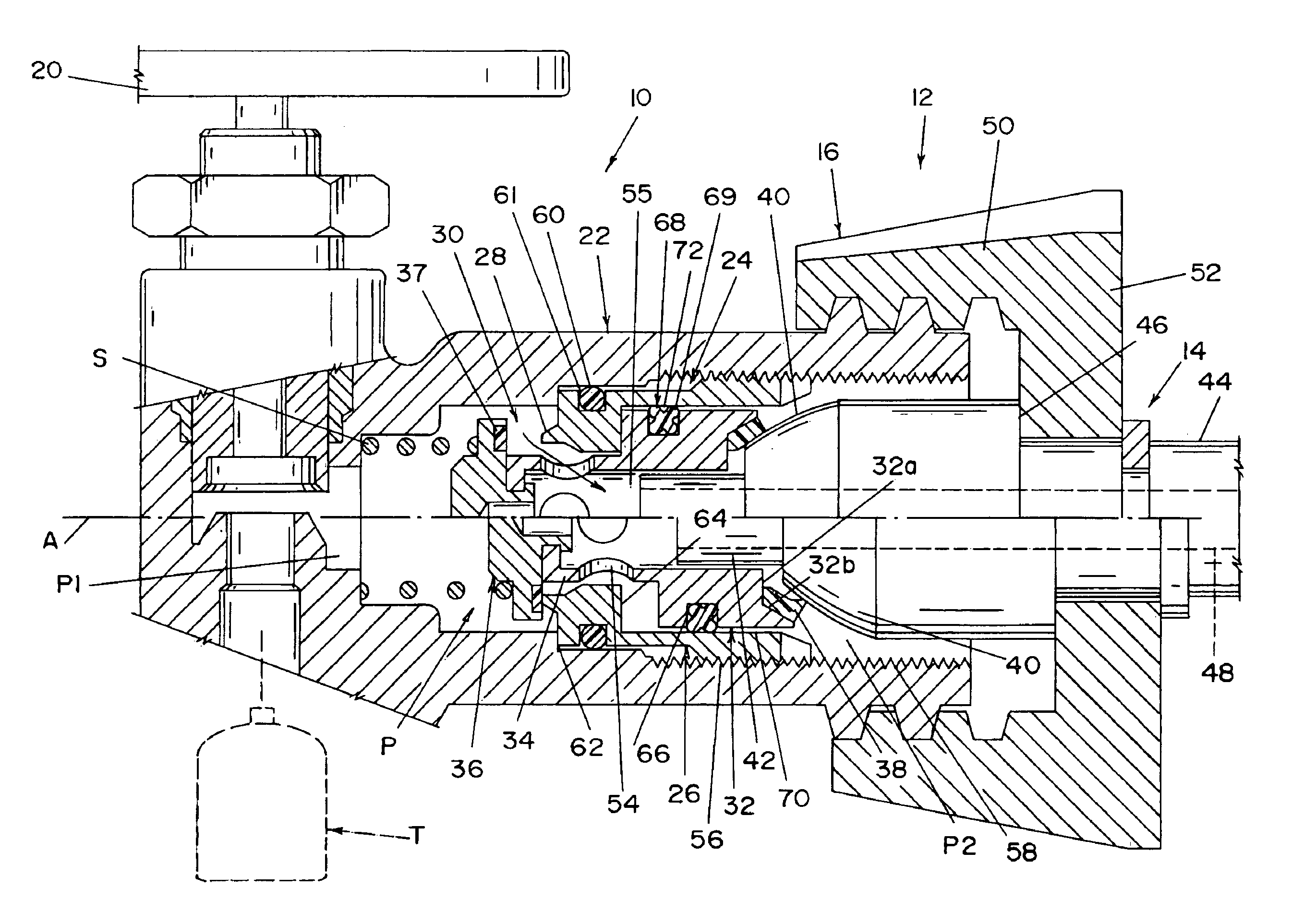

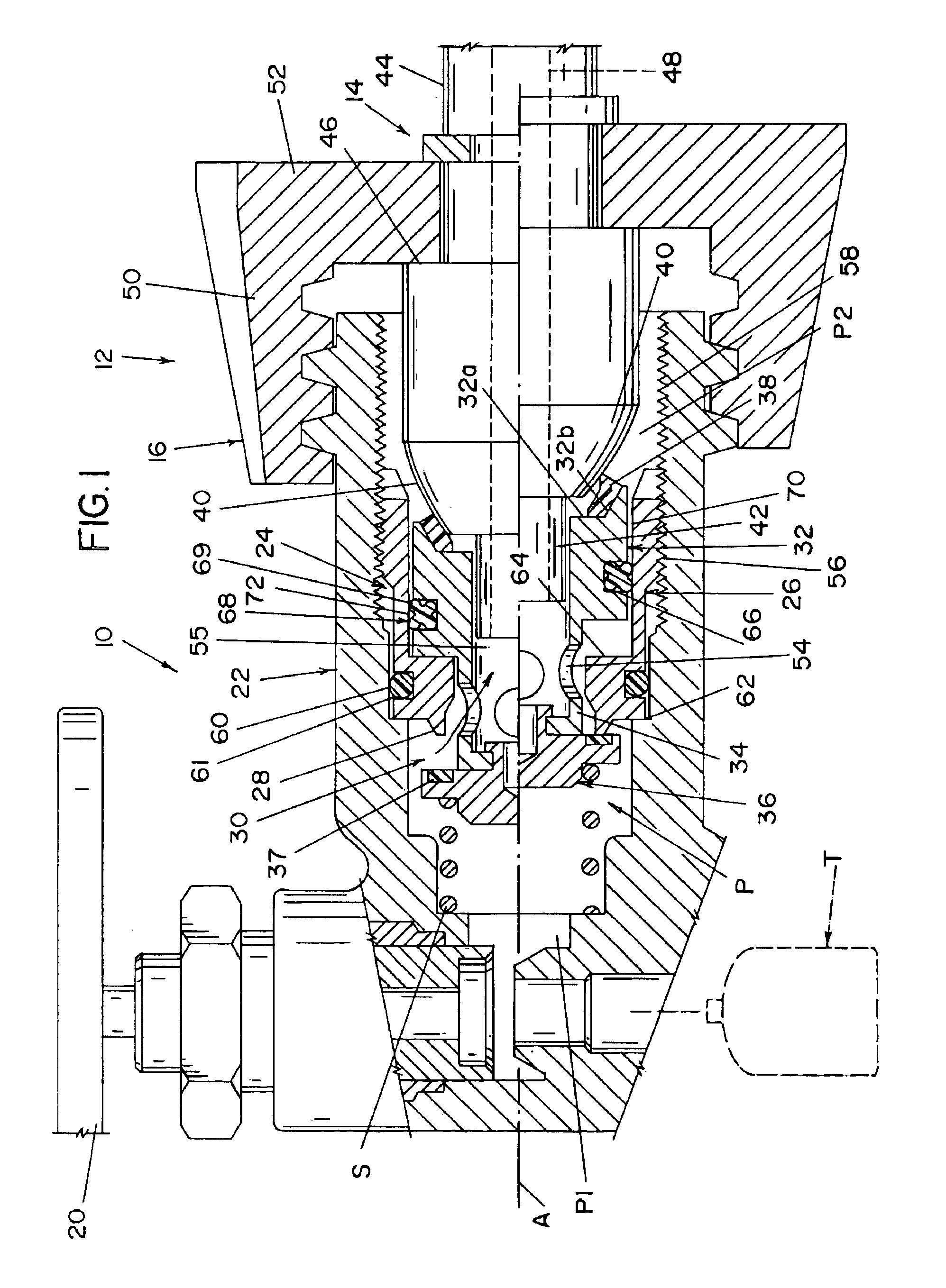

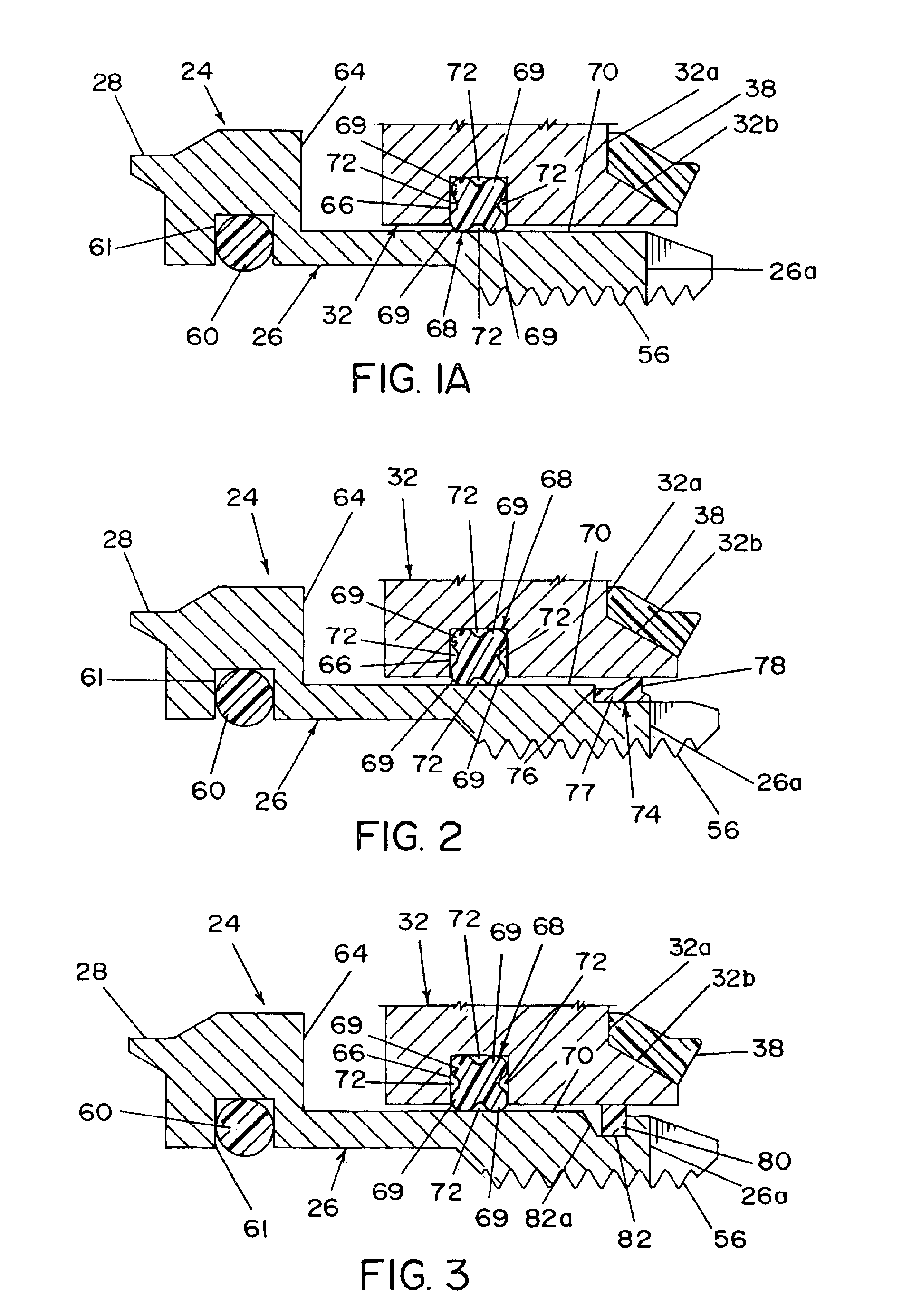

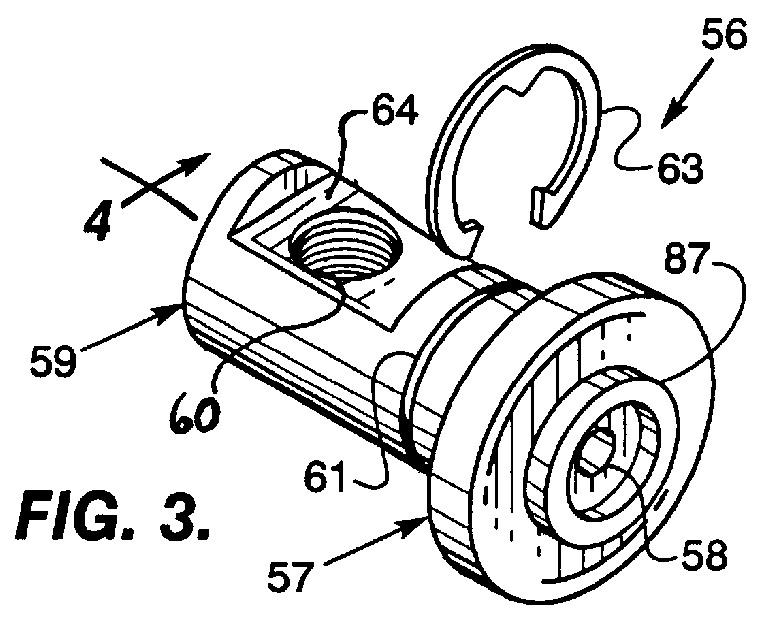

Cylinder valve and bayonet check-filter with excess-flow protection feature

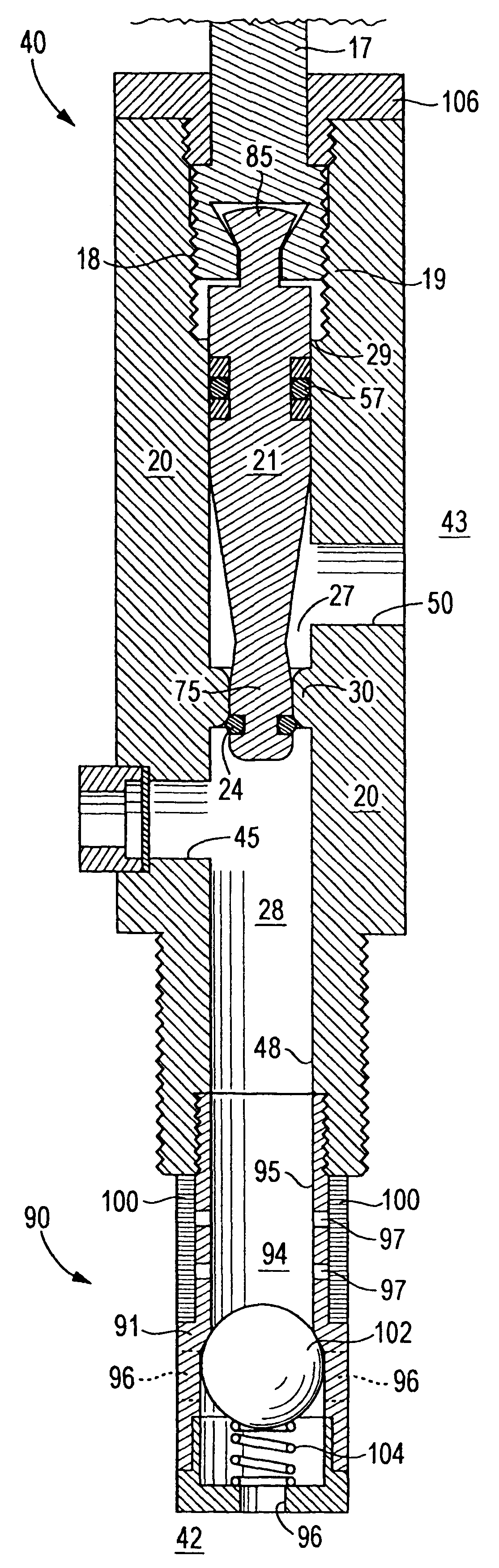

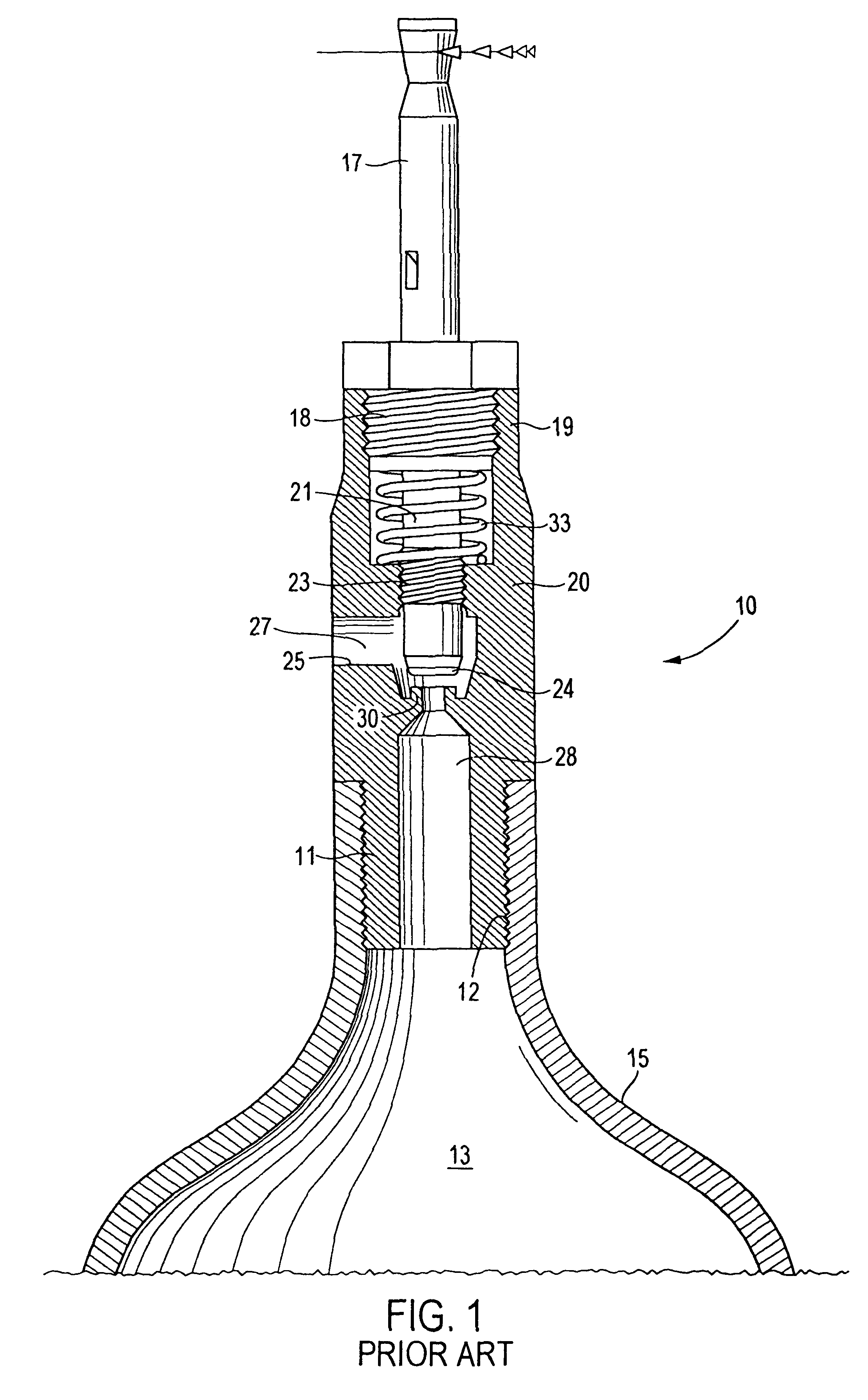

InactiveUS6607007B1Reduce the risk of fireLower potentialFunctional valve typesContainer filling methodsOxygen systemHigh pressure oxygen

A valve apparatus especially well-suited for use in gaseous oxygen delivery systems. A valve apparatus is provided that substantially reduces the risk of fire in high-pressure oxygen systems. The apparatus is particularly well-suited for use as a plug valve on ordinary cylinder containers, but may be beneficially used in any pressurized gas system, particularly oxygen systems such as those encountered in many industrial facilities. The wetted portion of the valve is isolated from threaded portions to prevent particulate contamination of the gas stream. The valve seat is located to protect it from direct impact of high-velocity gas streams. The inventive valve, and its associated inventive check-filter and excess-flow prevention features, reduces the potential for hazardous combustion at valve points within oxygen delivery systems.

Owner:LUXFER INC

Methods for variable displacement engine diagnostics

Various methods are described for monitoring cylinder valve deactivation in an engine, the engine including at least a cylinder valve actuator for deactivating at least a cylinder of the engine. One example method comprises indicating degradation of the valve actuator based on crankshaft acceleration.

Owner:FORD GLOBAL TECH LLC

High-pressure hydrogen storing bottle combined valve

InactiveCN101140051AGuaranteed to workIncrease effective storage spaceVessel mounting detailsContainer filling methodsGas cylinderBottle

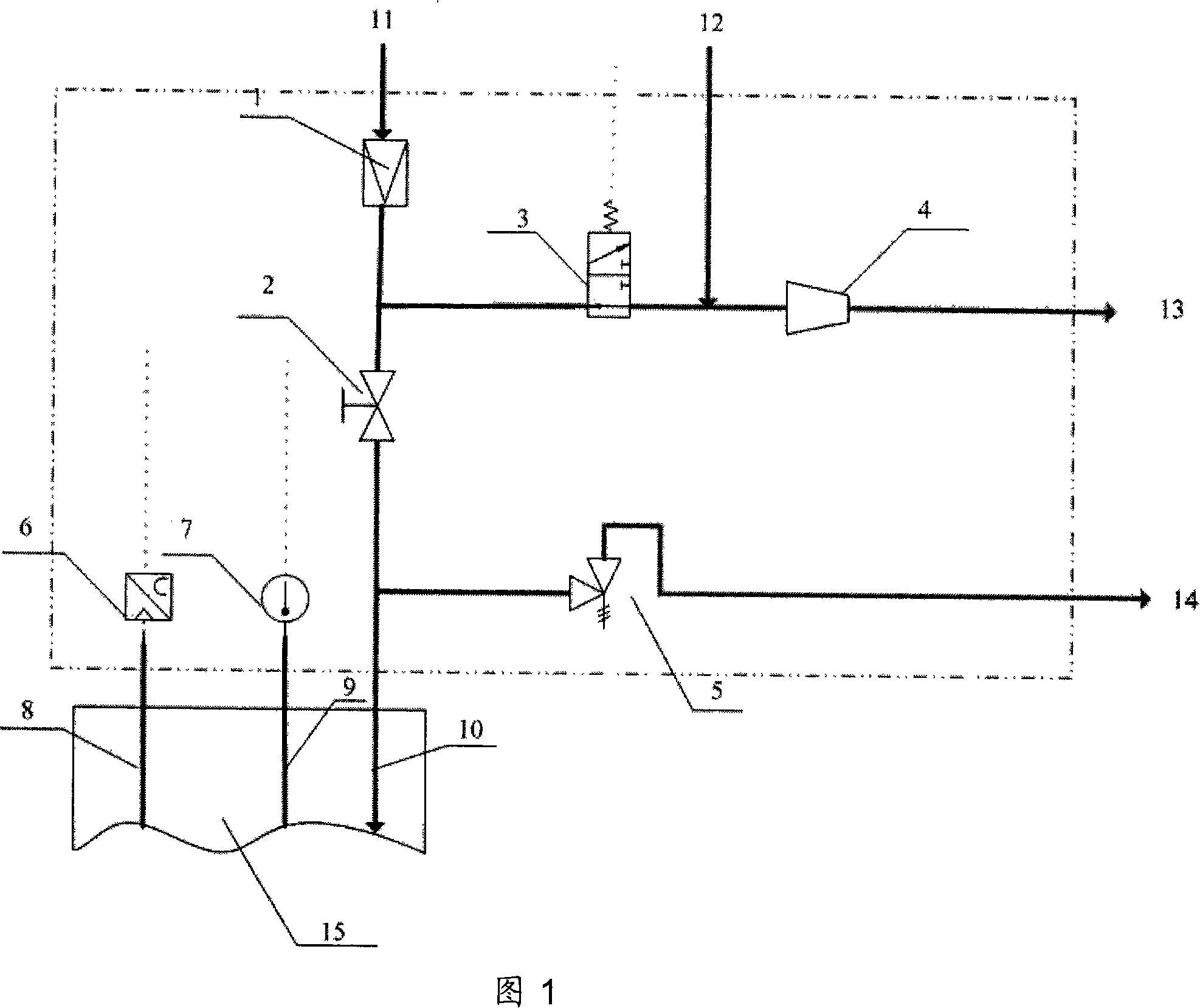

The invention relates to a combination valve for a high-pressure hydrogen storage cylinder, which comprises a charging check valve, a manual stop valve, an electromagnetic valve, a pressure reducing adjusting valve and a safe pressure releasing device; wherein a gas flue of a charging inlet of the hydrogen storage cylinder is provided with the check valve and the manual stop valve, a gas supply flue is educed between the two valves and supplies gas outwards through the electromagnetic valve and the pressure reducing adjusting valve; a pressure releasing gas flue is educed between the manual stop valve and the gas flue connected into the combination and releases pressure outwards through the safe pressure releasing device. As a cylinder valve is provided with the pressure reducing adjusting, considering the integration of the cylinder valve and the mensurability and output controllability of the gas, the invention can implement the low-pressure output; therefore, a gas supply output system has the very high safe reliability and simultaneously can be used as a main valve of a hydrogen storage cylinder group; other gas cylinders of the hydrogen storage cylinder group can supply gas outwards after pressure reduction through the main valve.

Owner:徐焕恩

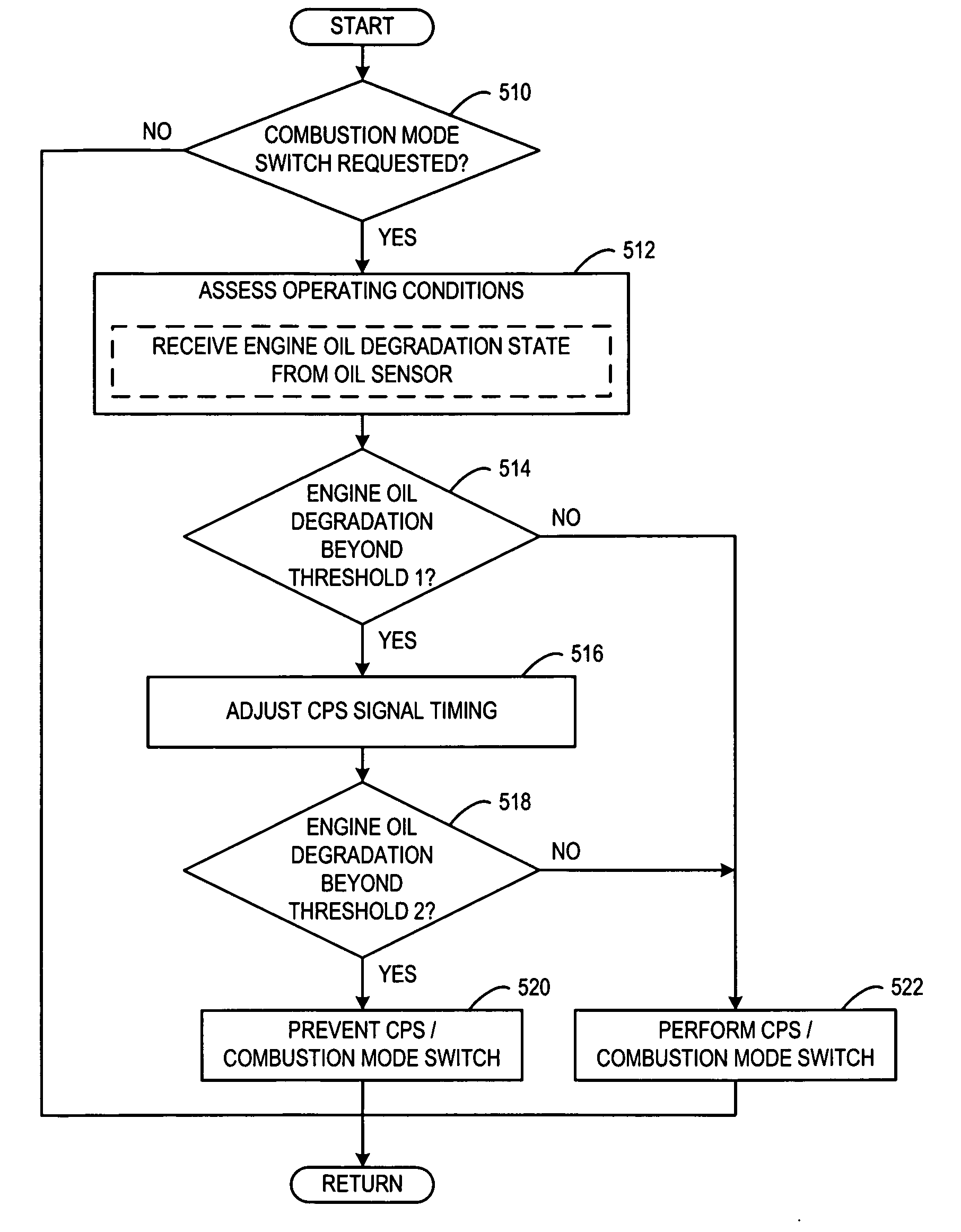

Approach for adaptive control of cam profile switching for combustion mode transitions

InactiveUS7946263B2Easy to operateHigh thermal efficiencyAnalogue computers for vehiclesValve arrangementsHomogeneous charge compression ignitionEngineering

A method is disclosed for controlling cylinder valve switching between a first valve condition and a second valve condition for transitioning between combustion modes of an engine. The method includes adjusting timing of a signal to switch between the valve conditions based on an oil degradation condition from an oil sensor, wherein the combustion modes include spark ignition and homogenous charge compression ignition.

Owner:FORD GLOBAL TECH LLC

Coordination of variable cam timing and variable displacement engine systems

ActiveUS8150605B2Improve fuel economy and emission performanceImprove fuel economyAnalogue computers for vehiclesElectrical controlVariable valve timingCam

Owner:FORD GLOBAL TECH LLC

Exhaust gas recirculation system with in-cylinder valve actuation

InactiveUS20070235011A1Electrical controlNon-fuel substance addition to fuelCombustion chamberExhaust valve

A method for recirculating exhaust gas includes operating an intake valve to open an intake port of a combustion chamber, operating an exhaust valve to open an exhaust port of the combustion chamber, and directing exhaust gas from the exhaust port to an exhaust recirculation port of the combustion chamber. The method also includes operating an exhaust recirculation valve to open the exhaust recirculation port to allow the exhaust gas to enter the combustion chamber and determining at least one valve actuation condition for controlling actuation of each of the intake valve and the exhaust recirculation valve.

Owner:CATERPILLAR INC

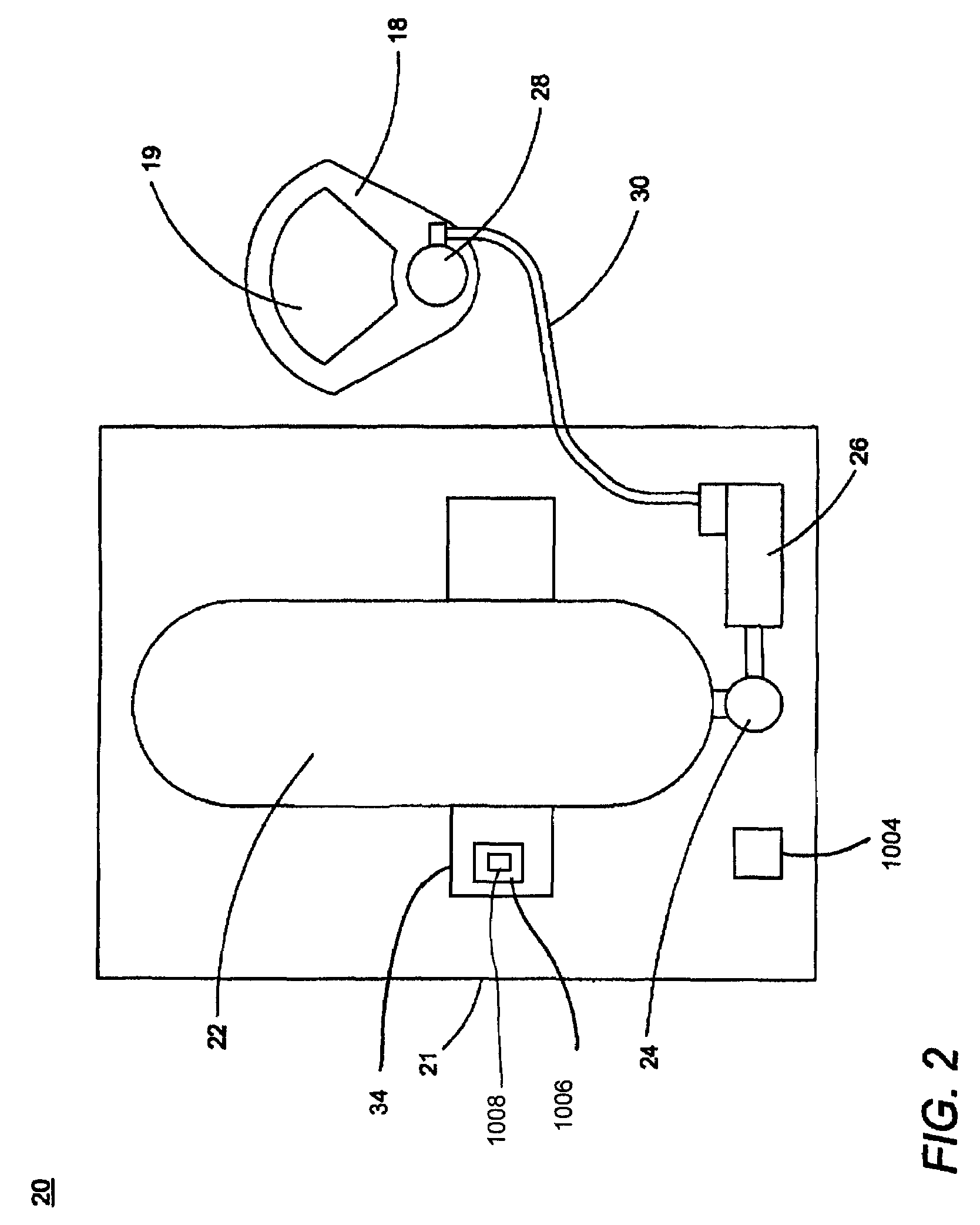

Combined air-supplying/air-purifying system

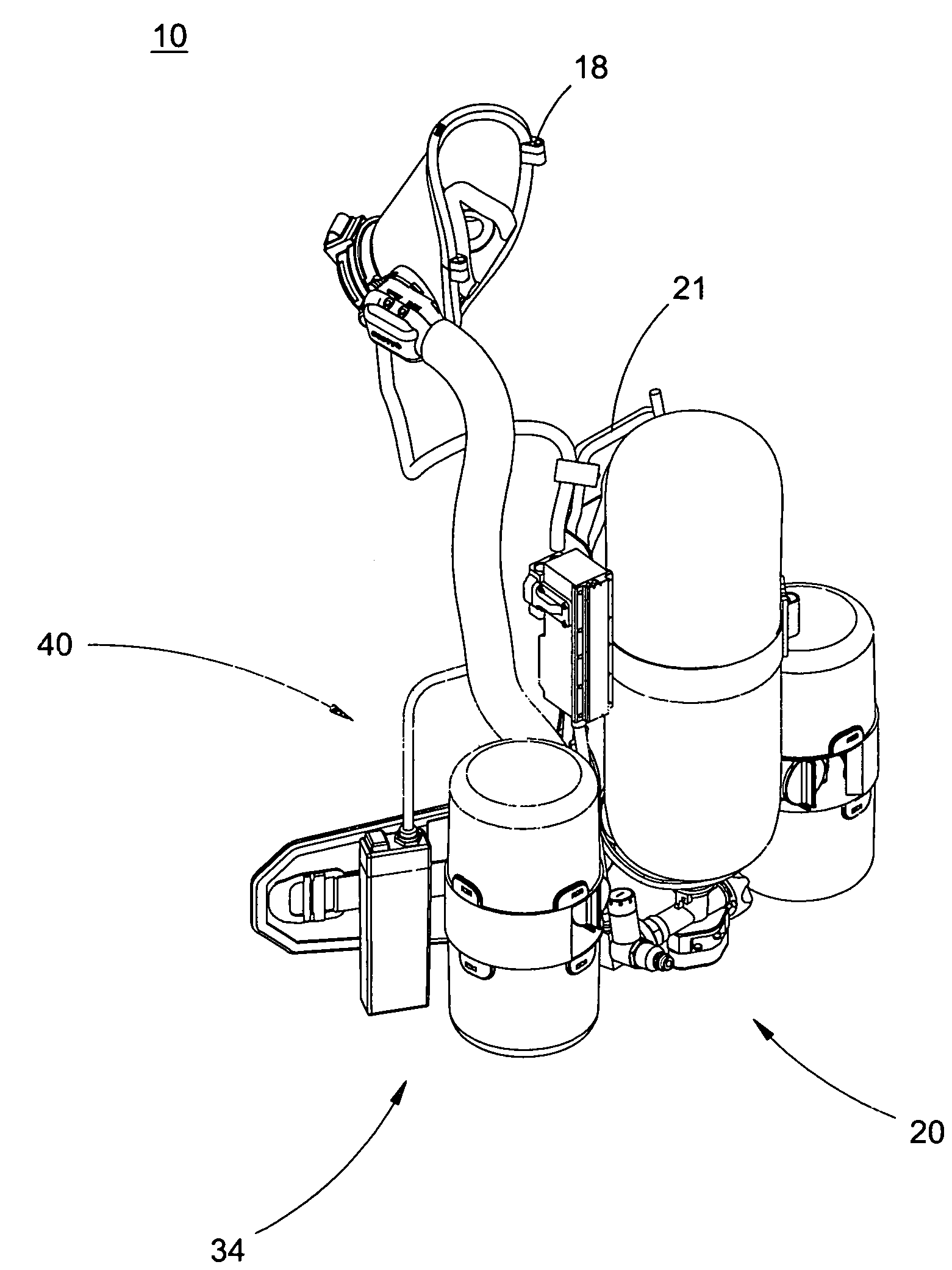

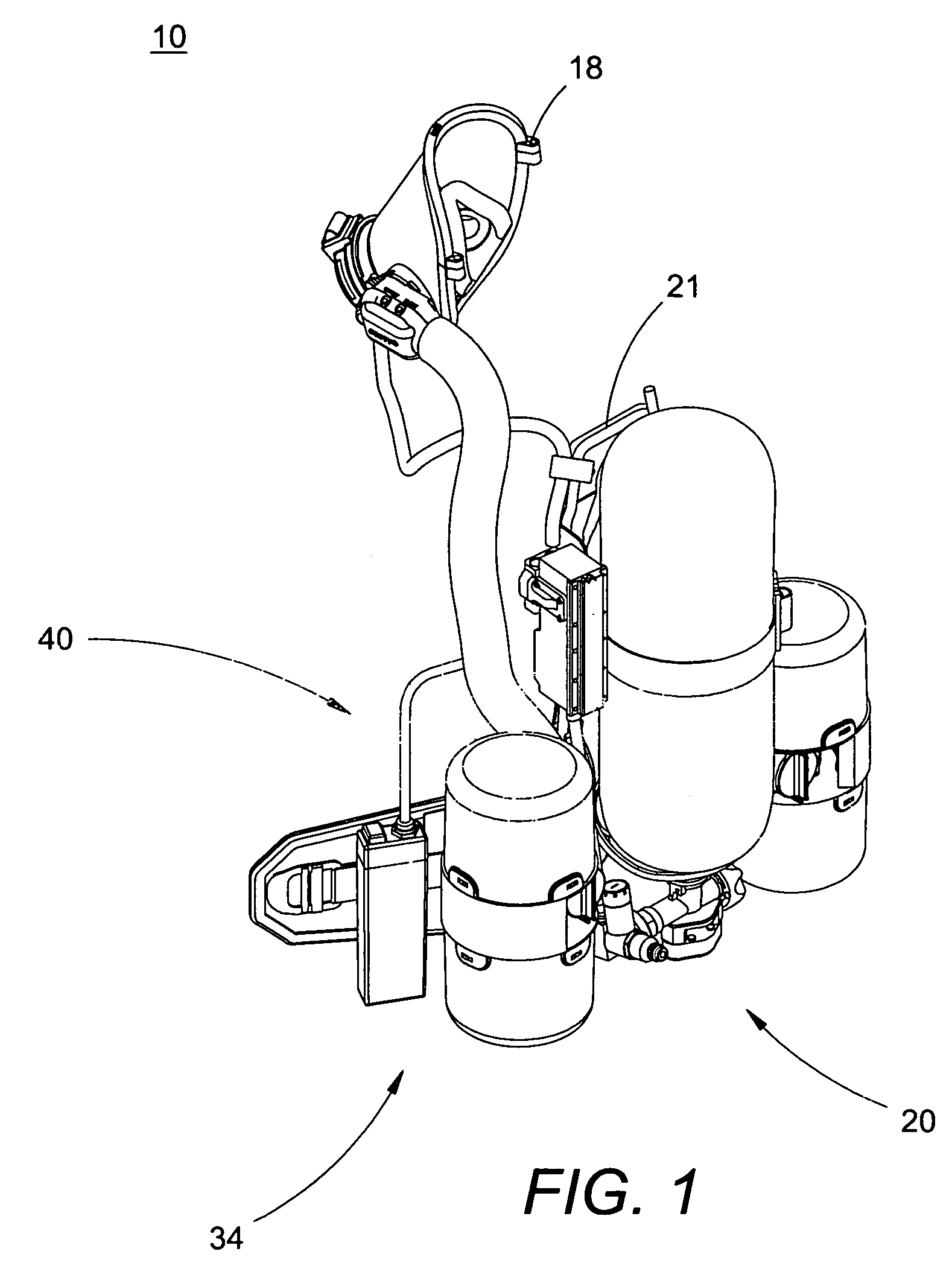

InactiveUS7748380B1Avoid exposureSnag hazardCombination devicesAuxillary pretreatmentPowered air-purifying respiratorAir cleaning

A combined air-supplying / air-purifying breathing system that includes a self-contained breathing apparatus, a facepiece for delivering breathable air from the self-contained breathing apparatus to a user, and a powered air-purifying respirator having at least one filter and a blower and having an output connected by a hose assembly to the facepiece. A control interface operationally connects the self-contained breathing apparatus to the powered air-purifying respirator. The self-contained breathing apparatus includes a pressure vessel, a cylinder valve assembly and a pressure reducer, all carried by a back frame, and the powered air-purifying respirator is adapted to be mounted on, and carried by, the back frame, by coupling the back frame and the respirator together at respective attachment points.

Owner:STI LICENSING CORP

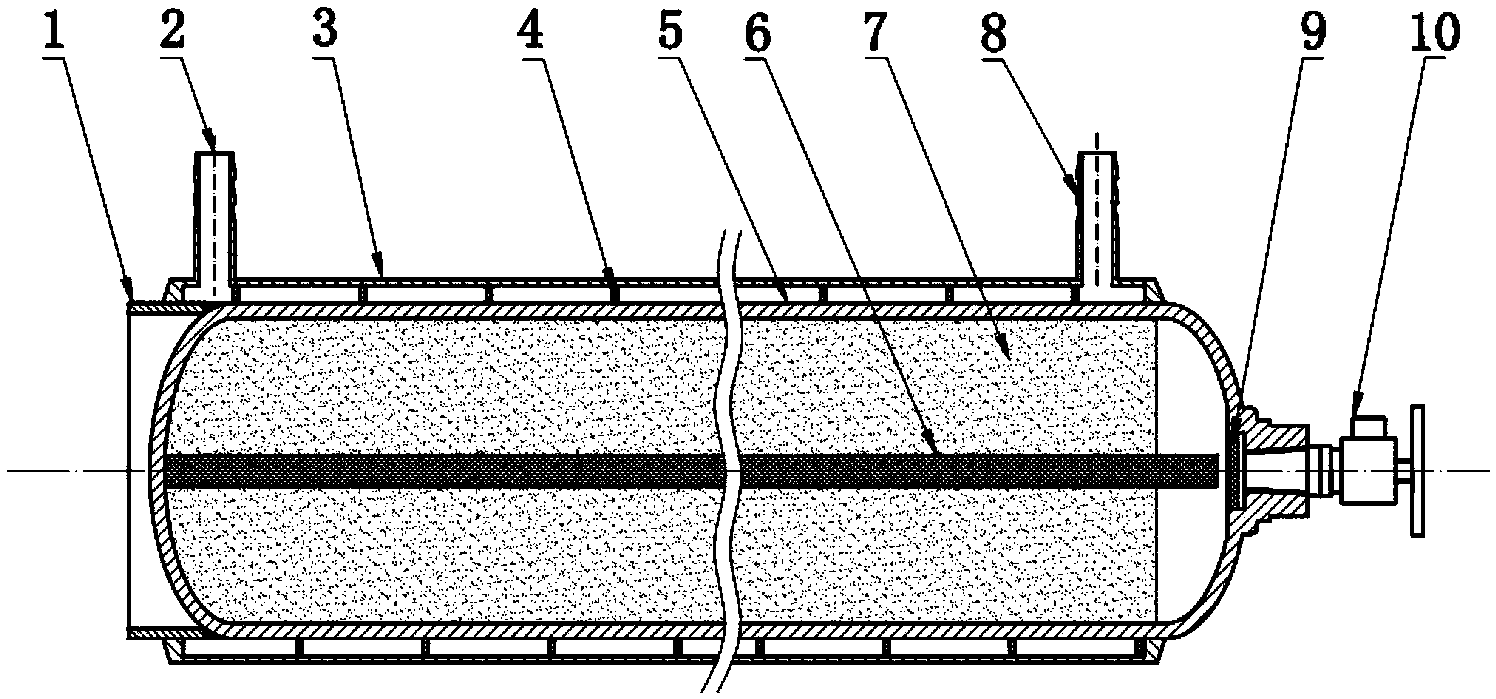

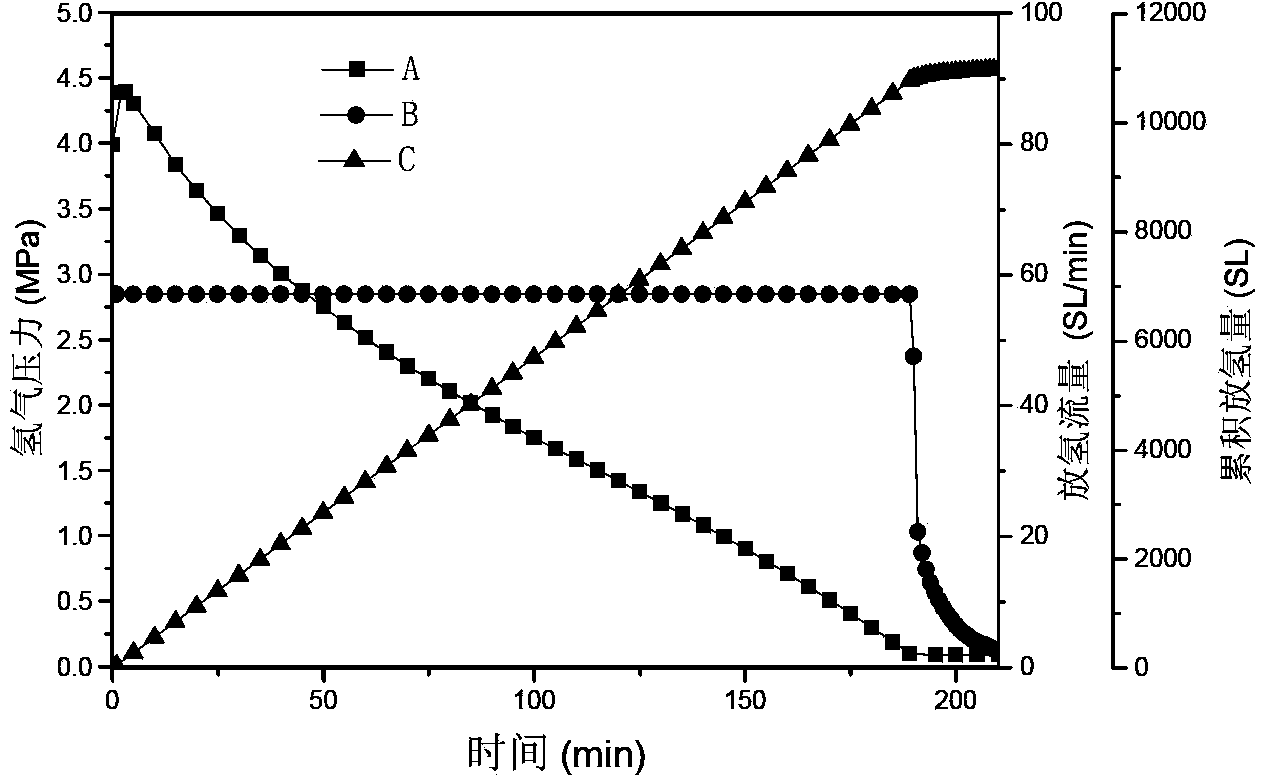

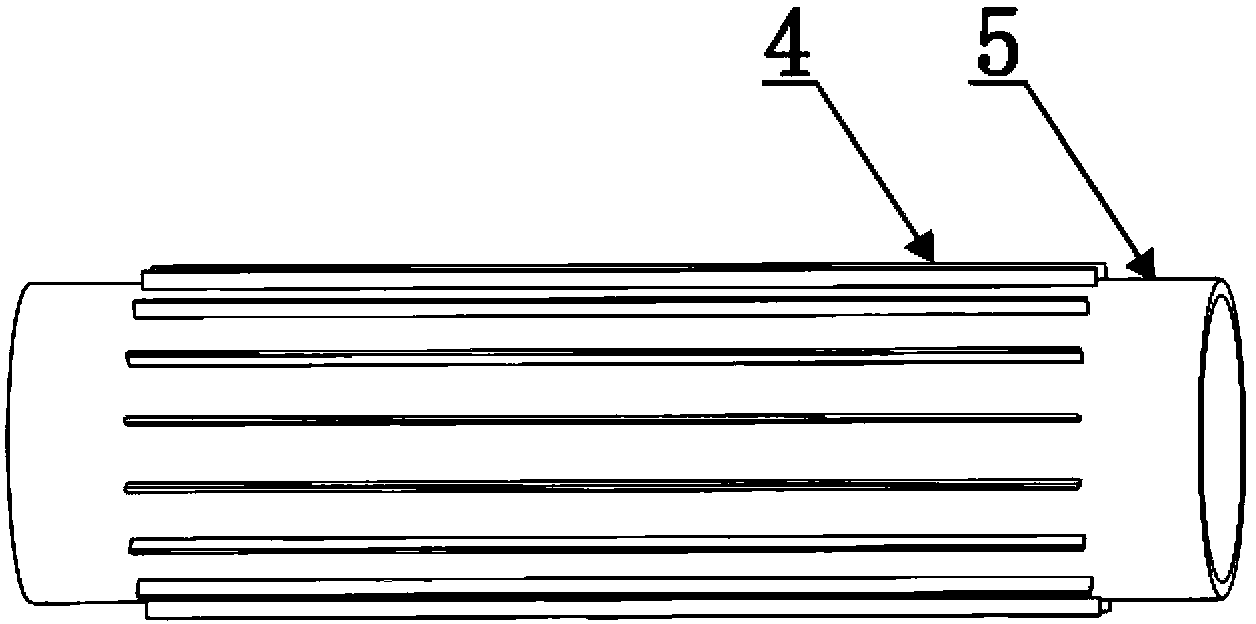

Hydrogen storage tank with external heat exchanging structure

ActiveCN103883874ASimple structureEasy to processPressure vesselsContainer discharging from pressure vesselsCylinder ValveEngineering

The invention discloses a hydrogen storage tank with an external heat exchanging structure, and belongs to the hydrogen storage technical field of the hydrogen energy field. The hydrogen storage tank comprises the following structure: a skirt support is disposed at the bottom of a tank body; a hydrogen storage material bed is disposed in the tank body; a gas guide tube is disposed at the center position in the tank body and pass straight through the tank mouth from the tank bottom; a filter is installed in the tank mouth, and a hydrogen cylinder valve is installed at the external of the tank mouth; a housing is disposed at the external of the tank body, two ends of the housing are respectively provided with a heat conduction liquid inlet and a heat conduction liquid outlet; and a heat exchanging structure is arranged in an annular chamber between the housing and the tank body. The heat exchanging structure is in the shape of a straight flow, a winding flow, a single spiral or multiple spirals, and the hydrogen storage material bed is a uniform mixed body of a hydrogen storage material and heat conduction fiber. The provided hydrogen storage tank is simple in structure, easy for preparation and processing, and low in cost. Compared with conventional hydrogen storage tanks, the hydrogen storage tank provided by the invention has relatively excellent heat exchanging effect and relatively excellent hydrogen desorption performance.

Owner:GRIMAT ENG INST CO LTD

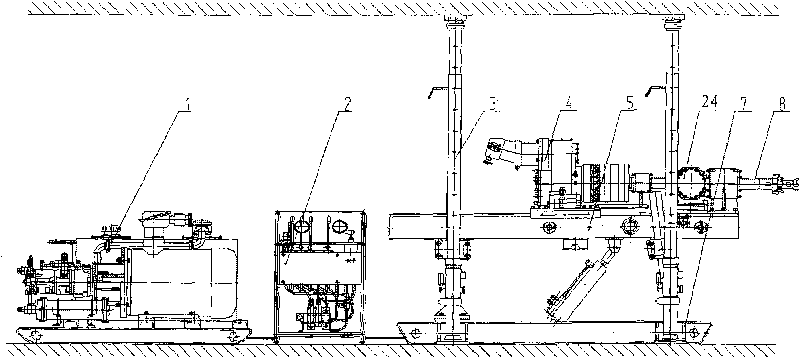

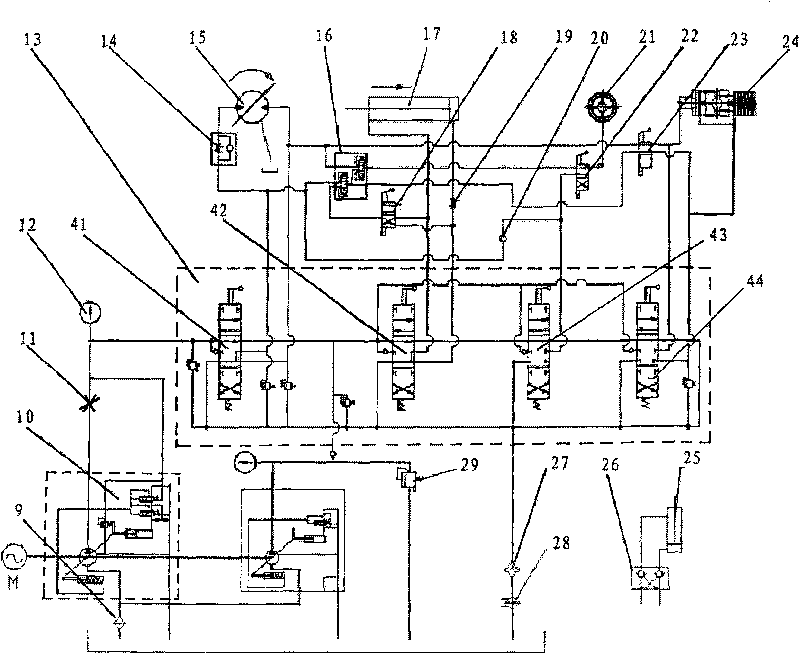

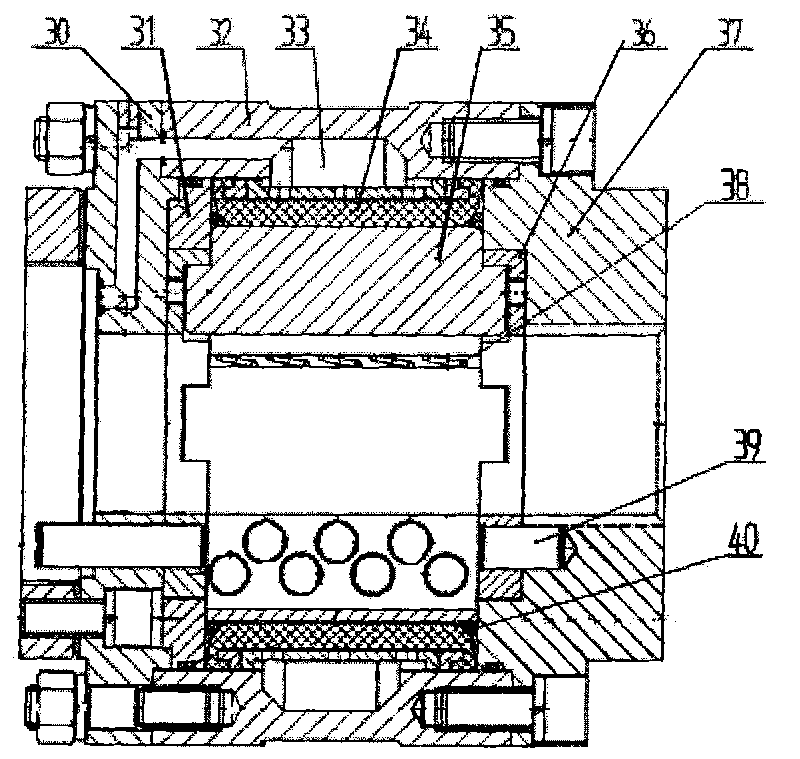

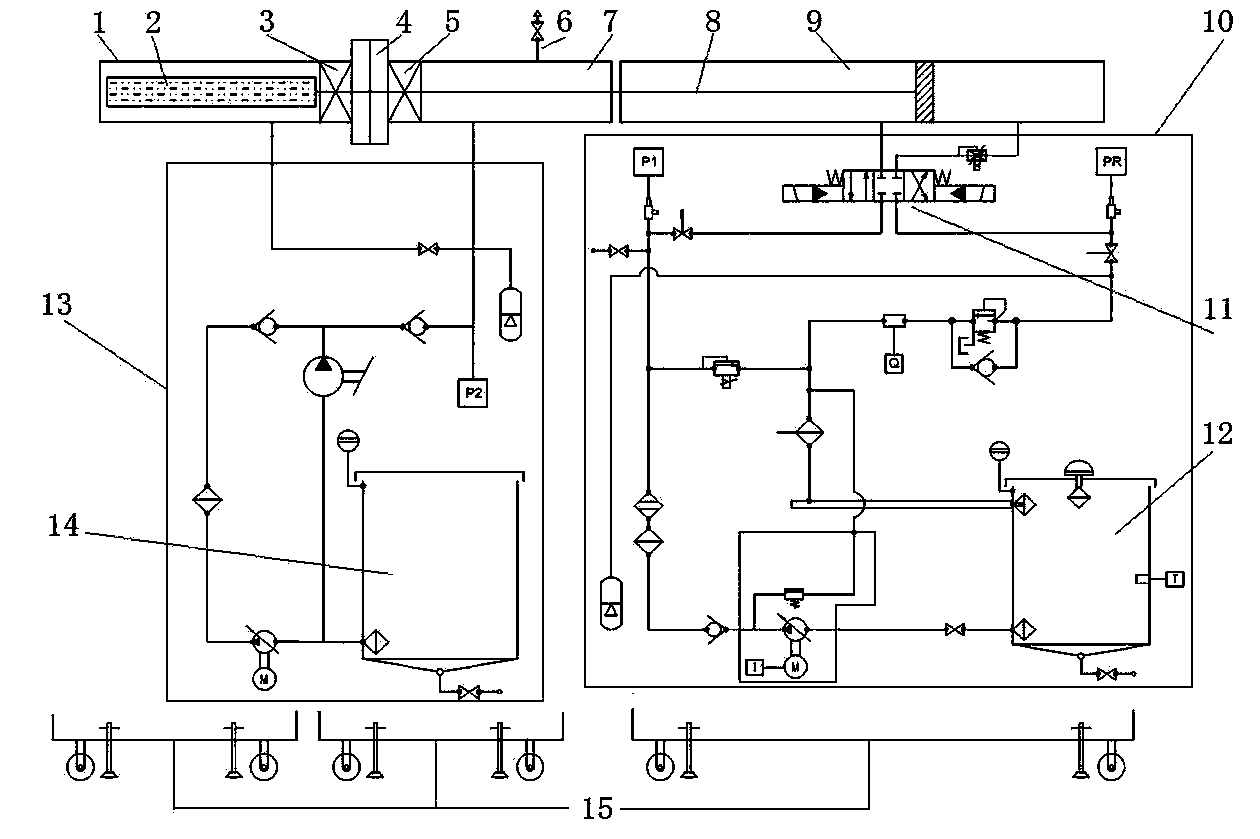

Mining linkage all-hydraulic drilling machine

ActiveCN101705785AReduce auxiliary timeSimple and fast operationDrilling rodsConstructionsHydraulic motorEngineering

The invention discloses a mining linkage all-hydraulic drilling machine which comprises a pump station system, a power head, a base, a machine frame, an upright post, a gripper, a drilling tool, a drilling machine thrust cylinder and a hydraulic linkage system, the hydraulic linkage system comprises a multiway valve unit and a linkage unit, the pump station system is connected with the linkage unit by the multiway valve unit, the linkage unit comprises an advance and retreat pole hand-operated direction valve, a cartridge linkage / single acting hand-operated direction valve and a gripper linkage / single acting hand-operated direction valve, the multiway valve unit comprises thrust cylinder valve leaves, hydraulic cartridge valve leaves, gripper valve leaves and hydraulic motor valve leaves.The invention adopts hydraulic linkage function, thus reducing auxiliary time of drilling machine operation, and leading the drilling machine operation to be more convenient. The drilling machine is compact in structure, light in weight and easy to transport in the pit.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

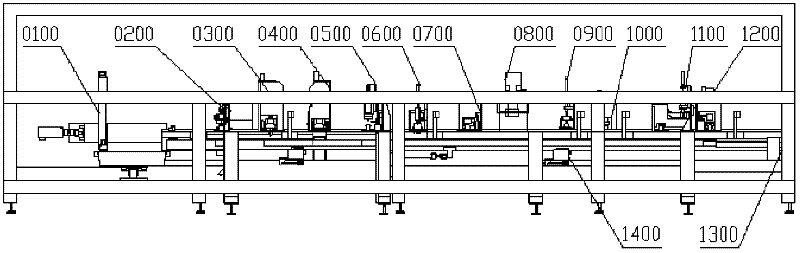

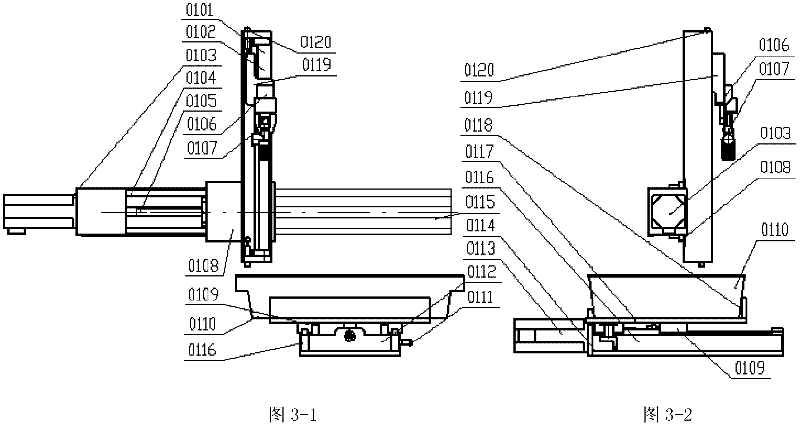

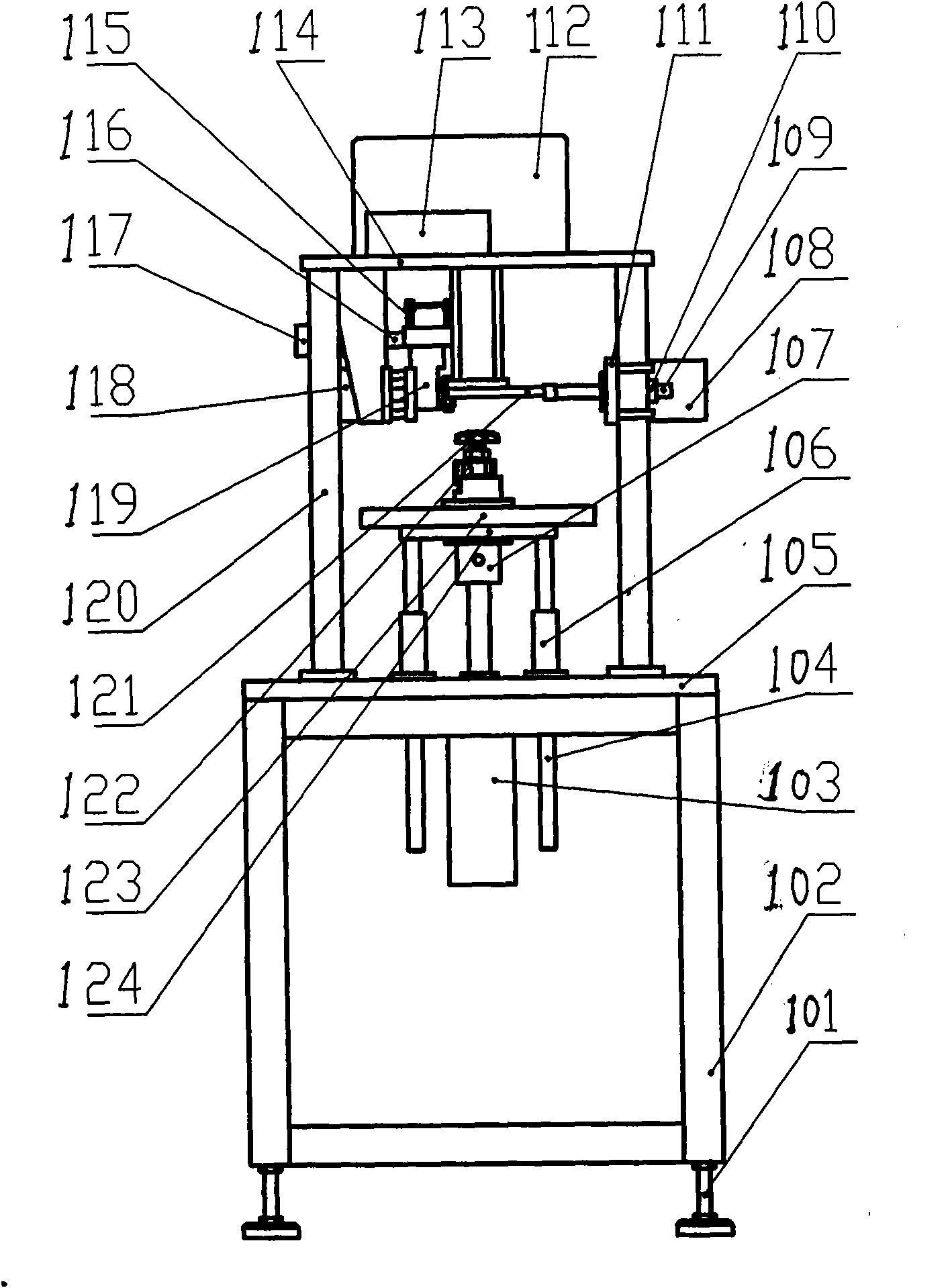

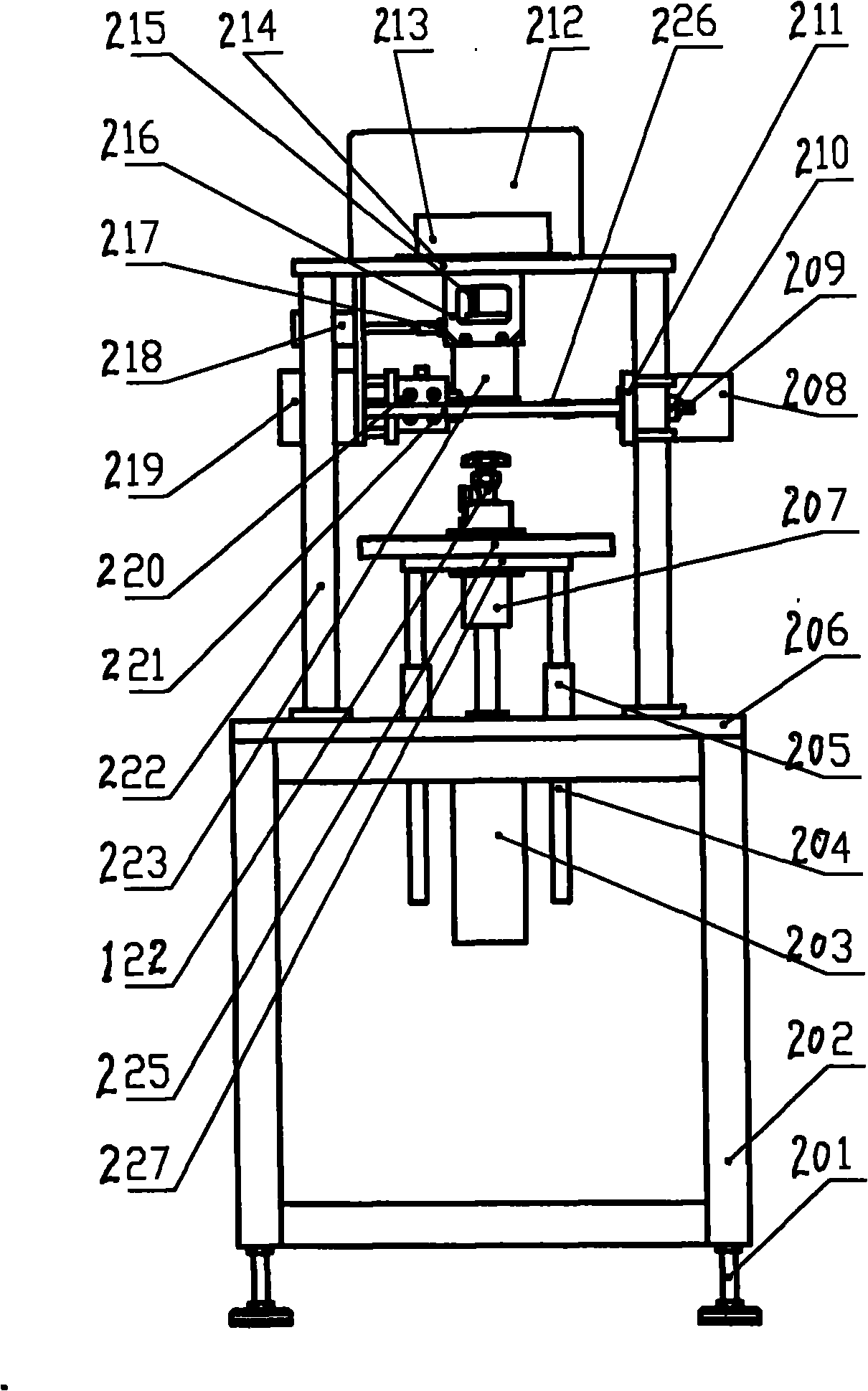

Automatic detection line of liquefied petroleum gas cylinder valve

InactiveCN101865765AShorten detection timeImprove detection efficiencyMachine part testingUsing optical meansPower stationGas detector

The invention relates to an automatic detection line of a liquefied petroleum gas cylinder valve, which belongs to the technical field of detection instruments. The invention is characterized in that the automatic detection line consists of eleven work stations: an upper element work station, a high-pressure closed sealing detection work station, an opening work station, a low-pressure opening sealing detection work station, a high-pressure opening sealing detection work station, an internal thread through gauge detection work station, an internal thread stop gauge detection work station, an external thread detection work station, a flow rate detection work station, a tight screwing work station and an opening reduction work station. The invention has the advantages that the detection line compares the leakage detected by a gas sensor with the leakage detected by a differential pressure sensor, the leakage detection by the gas sensor greatly shortens the detection time and improves the defection efficiency, the efficiency improvement of the leakage detection by the gas sensor is very obvious, particularly for 100 percent detected products, and in addition, the precision is high.

Owner:CHANGCHUN UNIV OF TECH +1

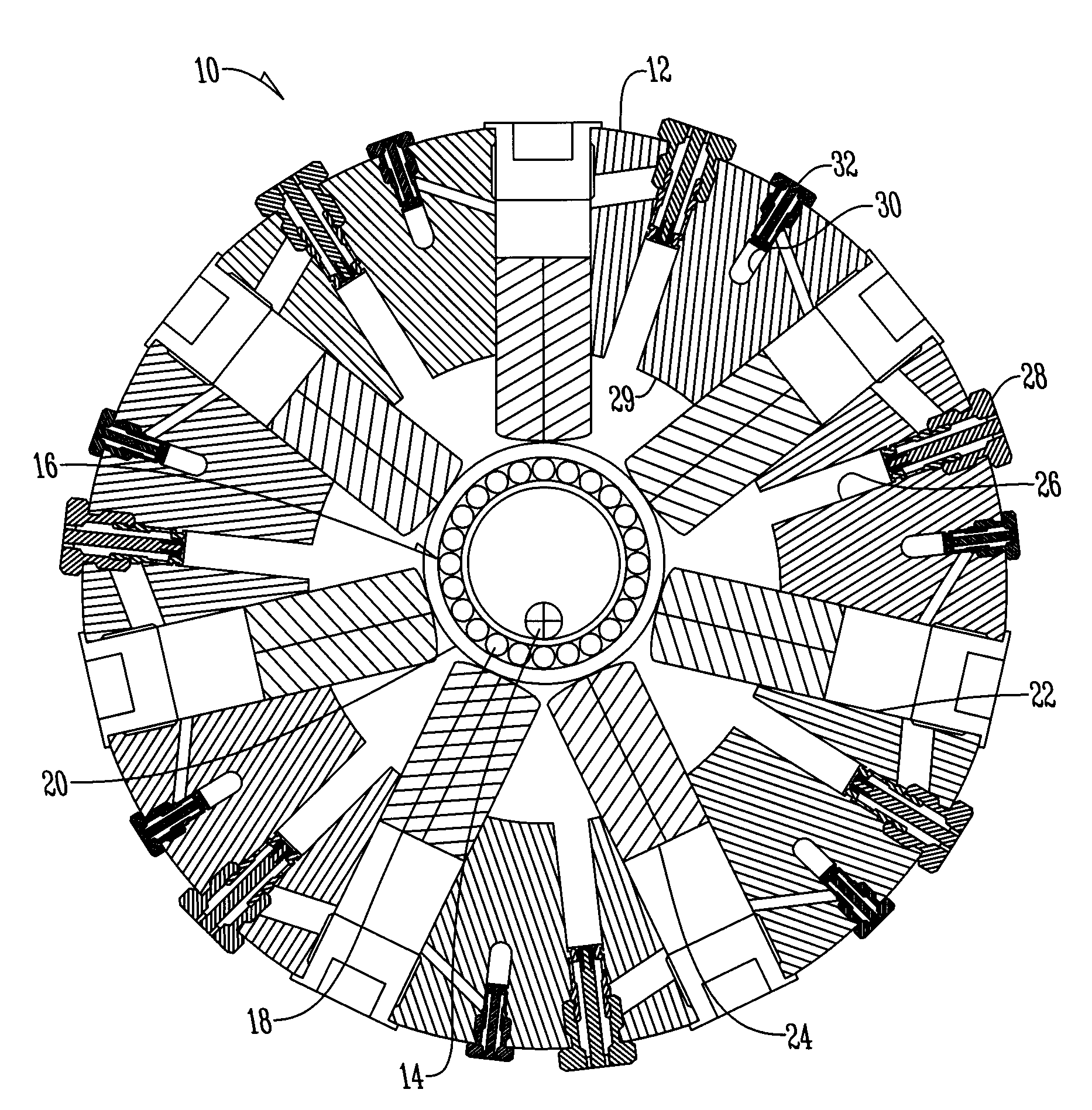

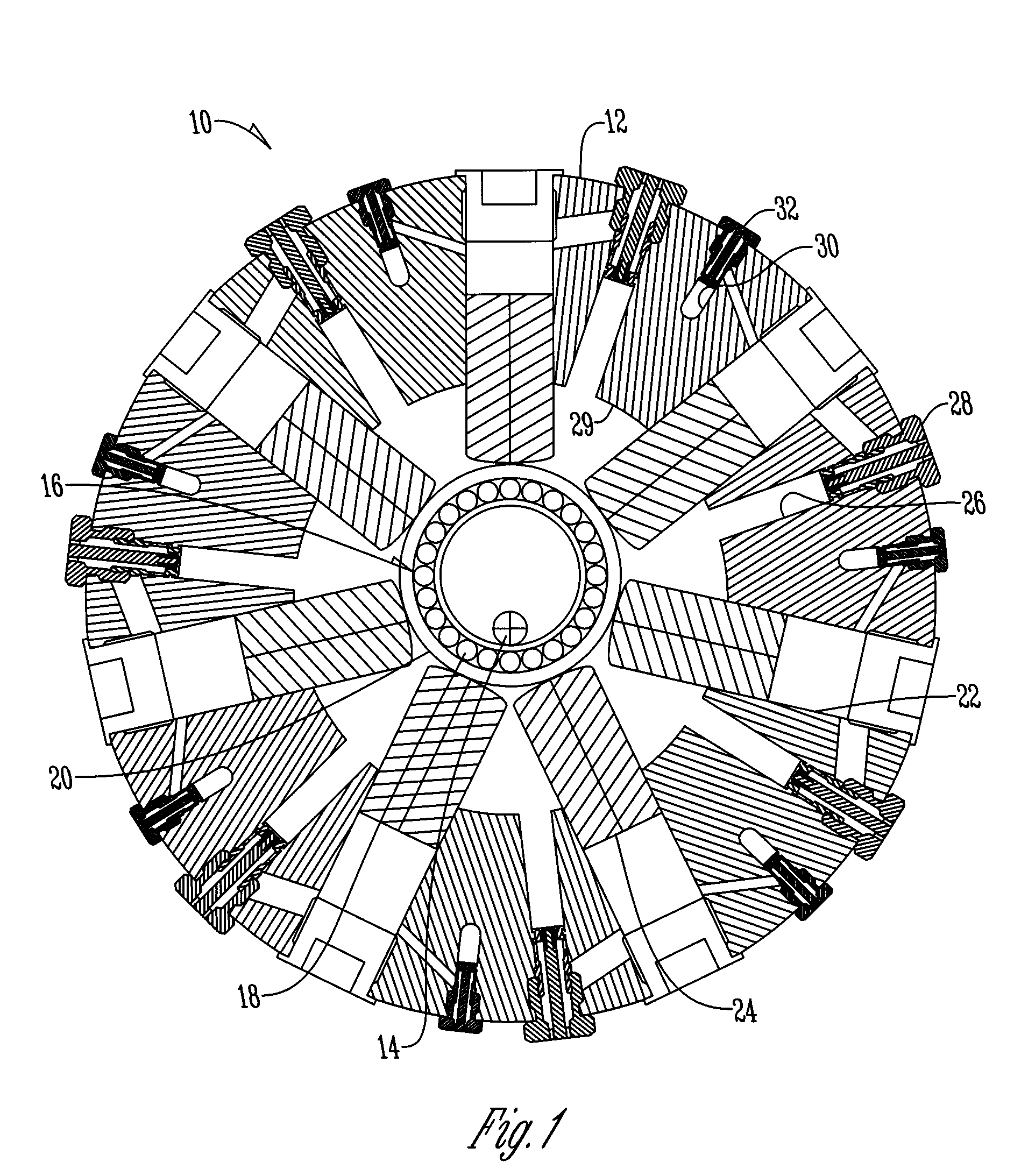

Special fluids for use in a hydrostatic transmission

InactiveUS7300260B1High viscosityControl flowPositive displacement pump componentsPiston pumpsPistonCylinder Valve

A positive displacement piston unit is provided that utilizes a magnetorheological (MR) or electrorheological (ER) fluid as the transmission fluid. Each cylinder of the invention has an intake port connected to the suction port of the hydrostatic pump and an output port connected to the pressure port. Flow of the transmission fluid through the cylinder is controlled by an electromagnet or electrode located in close proximity to the intake and output ports of the cylinder. By energizing the electromagnet or electrode, the viscosity of the transmission fluid can be increased such that the portion of the fluid immediately near the electromagnet or electrode substantially solidifies. The solidified portion of the transmission fluid disables fluid through the particular passage, thereby restricting flow of the transmission fluid to the cylinder. As such, the present invention does not require the use of mechanical cylinder valves to control the flow of the transmission fluid.

Owner:SAUER DANFOSS NORDBERG

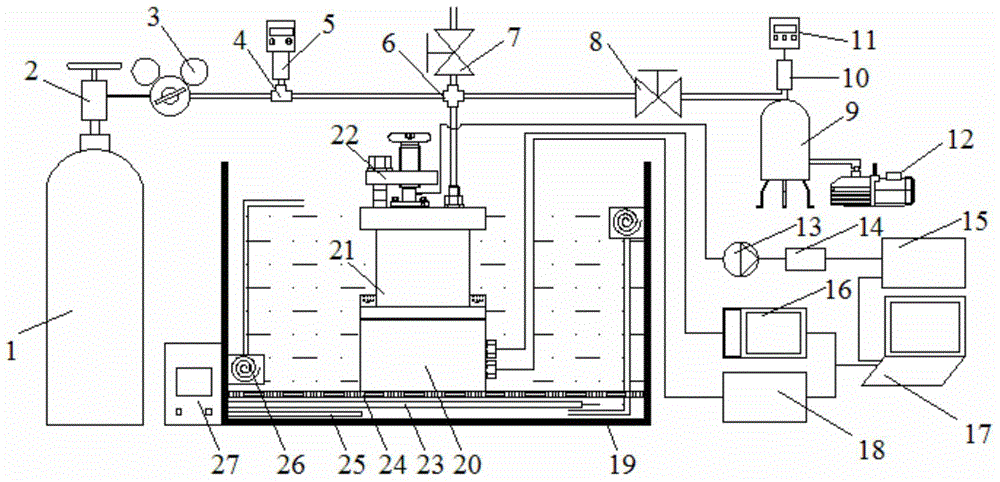

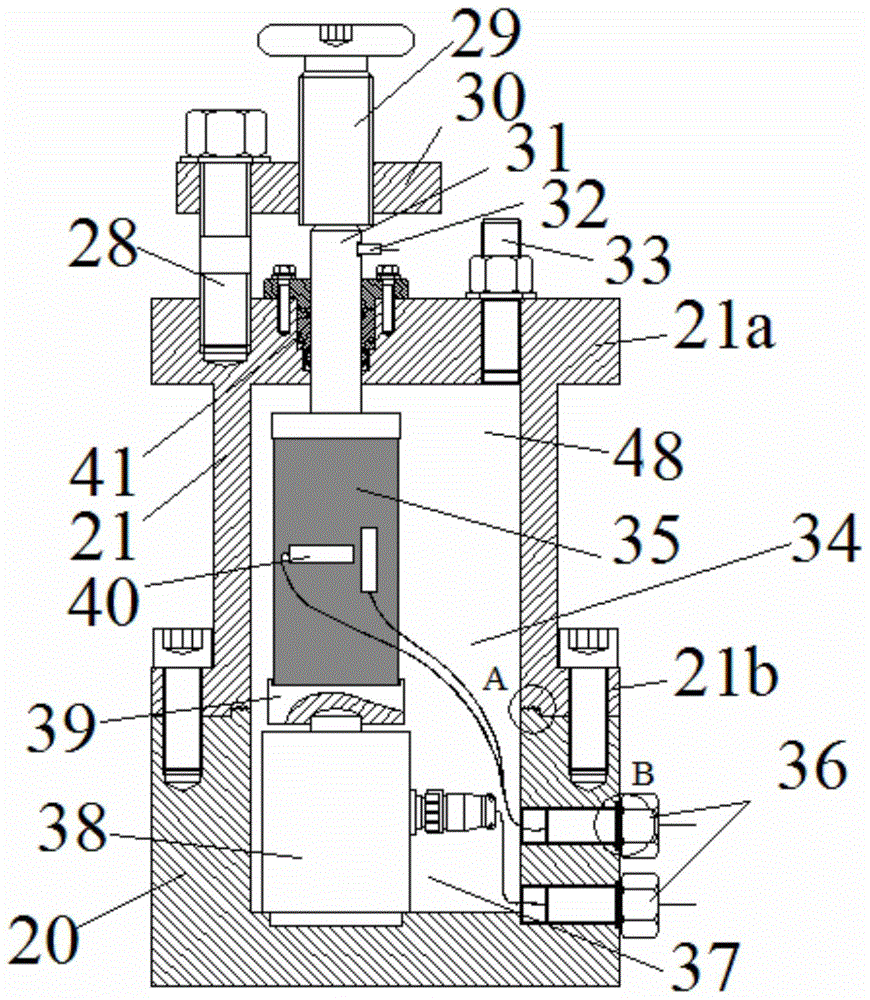

Coal seam gas adsorption and desorption deformation and deformation force dynamic test system

InactiveCN103983302ASolve the deformationEfficient collectionMeasurement devicesDesorptionDirect test

The invention provides a multifunctional test system capable of simultaneously and directly testing deformation and deformation force in coal body gas adsorption and desorption processes. The problem that coal body changes caused by gas adsorption and desorption can not be truly and reliably tested under the condition of a laboratory can be solved. The coal seam gas adsorption and desorption deformation and deformation force dynamic test system comprises a test tank system, a constant temperature system, a pressure system and a measuring system. The test tank system comprises a base, a tank body, a limiting pressing rod, a force transducer and a limiting mechanism. The constant temperature system comprises a tank body with the upper end open. The pressure system comprises a high-pressure gas storage steel cylinder, a cylinder valve, a four-way joint, a vent valve, a vacuum valve and a vacuum pump. The measuring system comprises a resistance strain gauge, a strain collection instrument, an acoustic emission sensor and an acoustic emission collection device. According to the test system, direct reliable tests on deformation and deformation force in the coal body gas adsorption and desorption processes under different gas pressure conditions, different temperature conditions, different strain conditions and / or different initial stress conditions can be achieved.

Owner:CHONGQING UNIV

Cylinder valve insert

InactiveUS6908070B2Inhibits and preventsIncrease displacementPlug valvesVessel mounting detailsCylinder ValveForeign matter

A valve insert for a cylinder valve for connecting an LPG tank to a gas consuming appliance has a body member mounted in the outlet end of the cylinder valve and a valve element slidable in the body member and cooperable therewith to control the flow of gas from the tank to the appliance. A quad sealing ring between the valve body and valve element seals against gas leakage therebetween and provides a lubricant reservoir for lubricating the surfaces thereof, and a wiper ring downstream of the quad sealing ring cleans the surfaces and precludes the ingress of foreign matter to the area of the gas sealing quad ring.

Owner:TAIWAN PAO

Natural gas hydrate core under-pressure transfer method and apparatus

The present invention relates to a natural gas hydrate core under-pressure transfer method, which comprises: establishing end-to-end connection between a pressure keeping cylinder filled with a core tube and a transfer bin having the specification equivalent to the pressure keeping cylinder, conveying the core tube in the pressure keeping cylinder into the transfer bin, sealing the transfer bin, and disconnecting the connection of the pressure keeping cylinder, wherein the pressure of the transfer bin and the initial state pressure of the pressure keeping cylinder are always maintained the same during the steps. The invention further relates to an apparatus applying the method, wherein the opposite connection ends of the pressure keeping cylinder and the transfer bin are respectively connected with a pressure keeping cylinder valve and a transfer bin valve, the valves are sealed and communicated through a flange, and the internals of the pressure keeping cylinder and the transfer bin respectively establish a connection with a pressure balancing control system. According to the present invention, the natural gas hydrate is in the under-pressure state, such that it is ensured that gas, pore water and other components in the core are not changed, and the detected data after the core treatment is close to the in situ situation so as to provide basis for analysis of natural gas hydrate characteristics and determination of reserves.

Owner:CHINA PETROLEUM & CHEM CORP +1

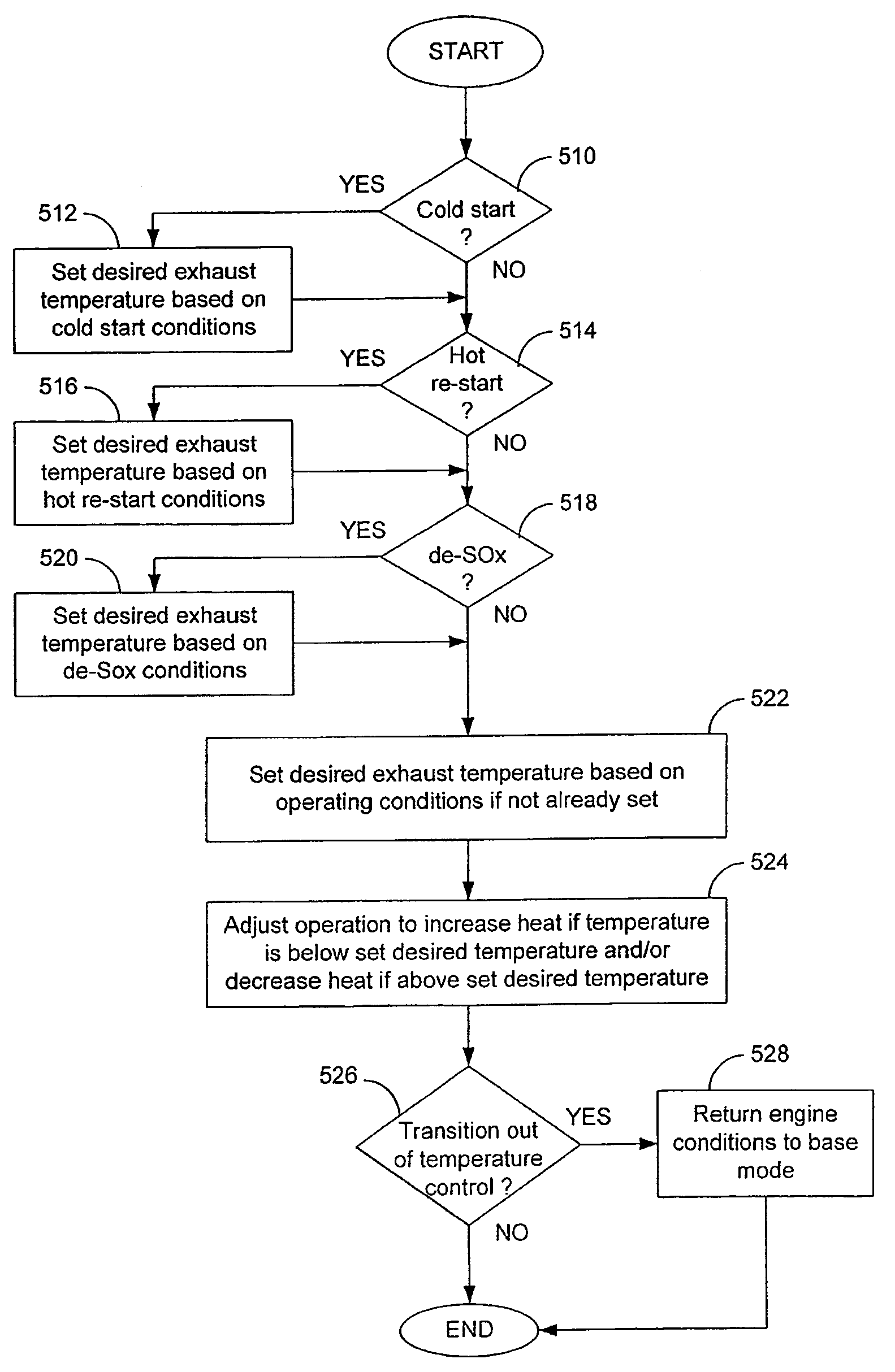

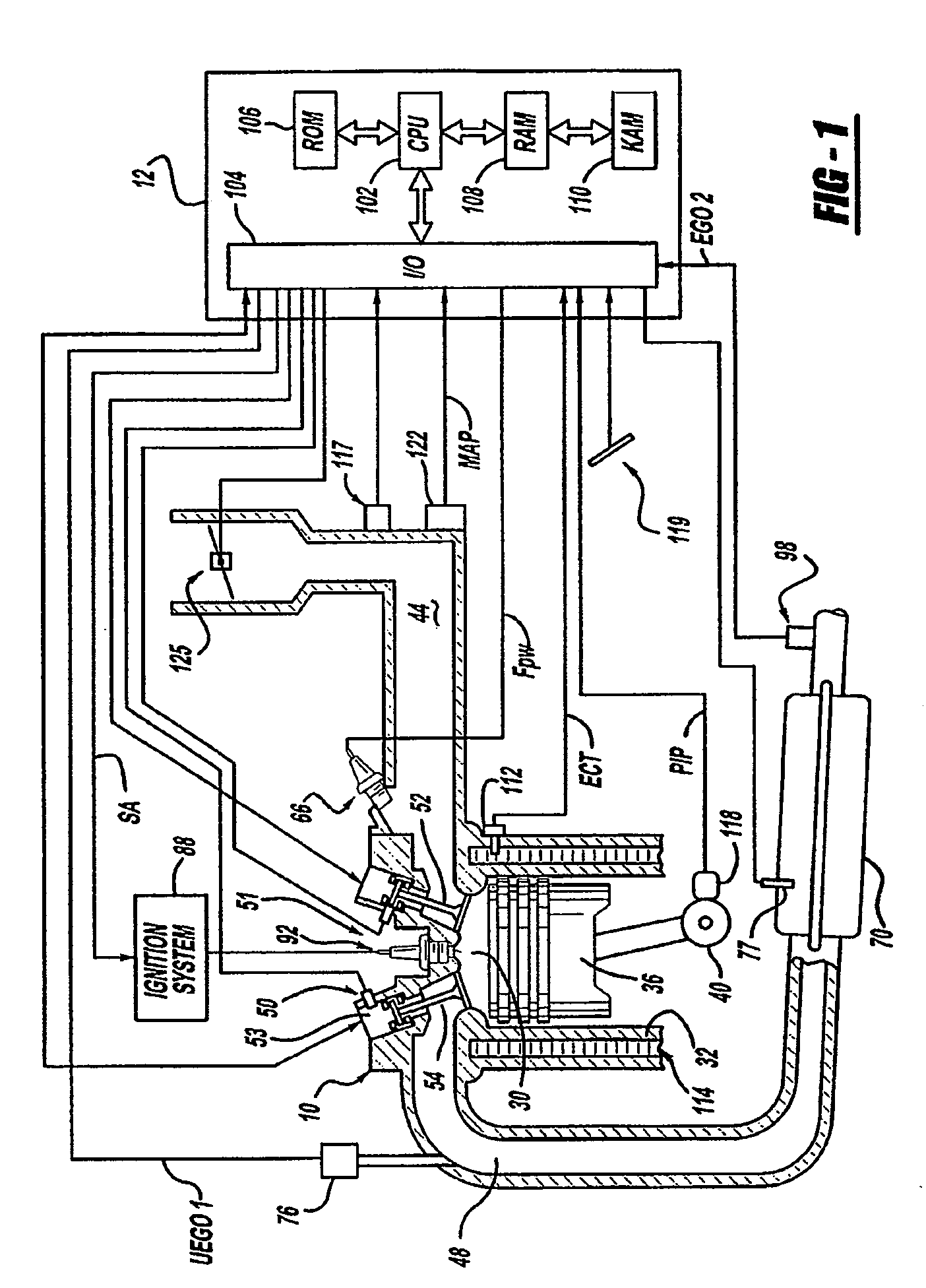

System and method for exhaust heat generation using electrically actuated cylinder valves

InactiveUS7128052B1Easy to operateEmission reductionElectrical controlInternal combustion piston enginesCylinder ValveExhaust heat

Owner:FORD GLOBAL TECH LLC

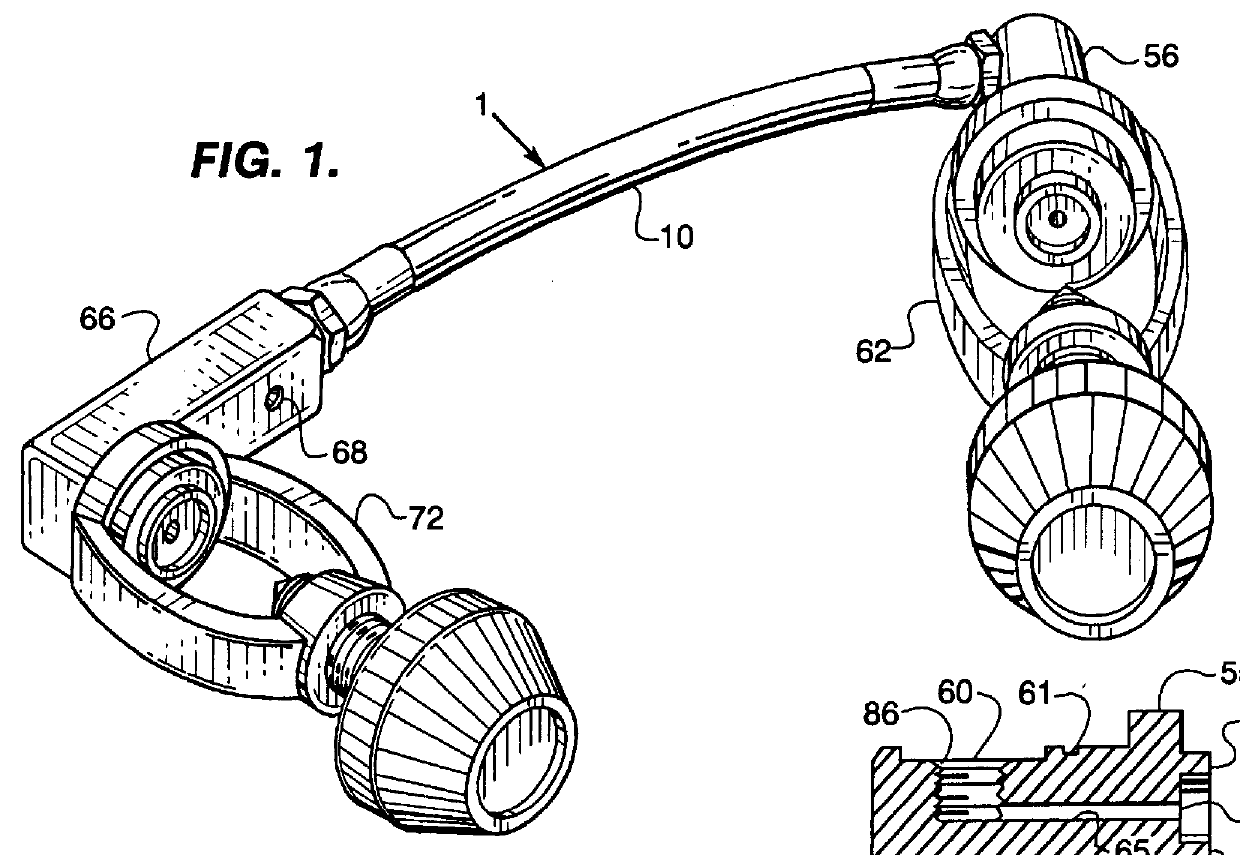

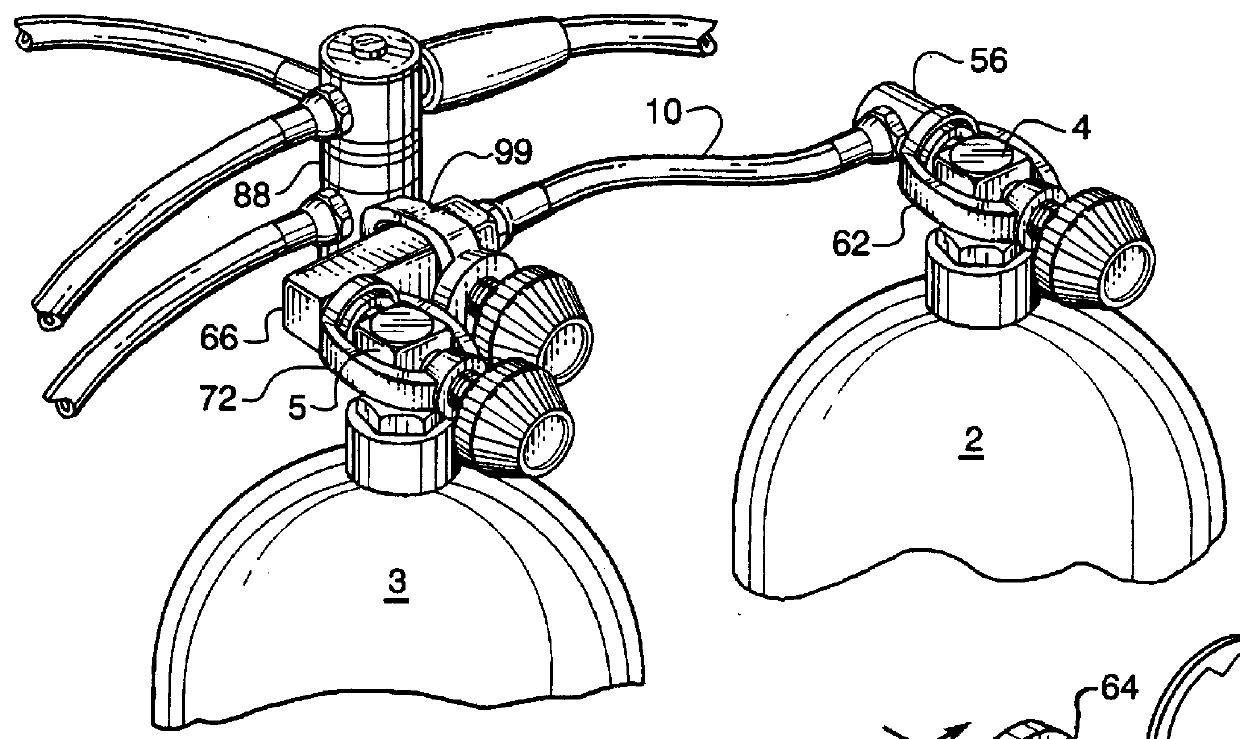

Dual cylinder manifold

InactiveUS6082359AConsiderable movement and distanceConsiderable movementRespiratorsOperating means/releasing devices for valvesInterconnectorHigh pressure

A dual cylinder manifold comprising a flexible, high pressure hose member connected between a first and a second interconnector that funnels pressurized air from two cylinders containing pressurized air to a single regulator. In operation, the first interconnector is attached to a first cylinder valve, the second interconnector to the second cylinder valve, and a regulator attached to the second interconnector. The hose member may be removably connected to the interconnectors so that it can be replaced with another hose member if desired. The manifold may also include valve connectors attached to the interconnectors for connecting to the cylinder valves, a valve adaptor for adapting the second interconnector to receive a regulator of differing connecting design where necessary, a valve connector for making the intended regulator compatible with the second interconnector, or combinations thereof. The manifold may also be provided as a kit having removable or interchangeable components for constructing a several possible manifolds, each connectable to differing dual tank systems.

Owner:PRESTON PAUL CHRISTOPHER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com